Metal Sales Residential User Manual

TM

Residential Roof Systems

Vertical Seam & Image II

Design Manual

RESIDENTIAL DESIGN GUIDE

The application and detail drawings in this manual are strictly for illustration purposes and may not be applicable to

all building designs or product installations. All projects should conform to applicable building codes for that particular

area. It is recommended to follow all building regulations and standard industry practices.

Metal Sales Manufacturing Corporation is not responsible for the performance of the roof system if it is not installed

in accordance with the suggested instructions referenced in this manual. If there is a conict between this manual

and the actual erection drawings, the erection drawings are to take precedence.

Prior to ordering and installing materials, all dimensions should be veried by eld measurements.

Metal Sales reserves the right to modify, without notice, any details, recommendations or suggestions. Any questions

you may have regarding proper installation of these Residential roong systems should be directed to your local

Metal Sales representative, (see pages 2 and 3).

Oil canning is not a cause for rejection. Oil canning can be described as the amount of waviness found in the at

areas of metal panels. Oil canning is an inherent characteristic of light gauge cold formed metal products, particularly

those with broad at areas. There are many factors which may contribute to oil canning that Metal Sales is not able

to control. These factors include: misalignment of the support system, over driving of fasteners used on the panels,

stress (whether inherent in the panel or induced), thermal expansion and contraction of the panel, improper material

handling, width, gauge, length, color of panels, and improper installation (reference Metal Construction Association

"Oil Canning Position Paper"- Appendix A).

Consult your local Metal Sales Branch for any additional information not outlined in this manual.

Important Information

This manual is designed to be utilized as a guide when installing a Residential roong system. It is the responsibility

of the erector to ensure the safe installation of this product system.

SAFETY

STUDY APPLICABLE OSHA AND OTHER SAFETY REQUIREMENTS BEFORE

FOLLOWING THESE INSTRUCTIONS.

The installation of metal roof systems is a dangerous procedure and should be supervised by

trained knowledgeable erectors. USE EXTREME CARE WHILE INSTALLING ROOF PANELS.

It is not possible for Metal Sales to be aware of all the possible job site situations that could

cause an unsafe condition to exist. The erector of the roof system is responsible for reading

these instructions and determining the safest way to install the roof system.

These instructions are provided only as a guide to show a knowledgeable, trained erector

the correct relationship of parts to one another. If following any of the installation steps would

endanger a worker, the erector should stop work and decide upon a corrective action.

Provide required safety railing, netting, or safety lines for crew members working on

the roof.

Do not use the roof panel as a walking platform. The roof panels will not withstand the weight of

a person standing at the edge of the panel.

Do not stand on any roof panels until the panels have been attached.

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

1

RESIDENTIAL DESIGN GUIDE

Branch Territory Map

14

9

15

16

8

18

6

21

11

1

4

20

13

17

5,10

7

3

12

19

2

NOTE: Shaded areas represent regions served by each location.

*

TABLE OF CONTENTS

Important Information .........................................1

Branch Territory Map ..........................................2

Branch Locations ................................................3

Vertical Seam Panel Options ..............................4

Vertical Seam Design Information .......................5

Image II Panel Options .......................................6

Image II Design Information ................................7

Flashing Profiles ............................................8-12

Accessories .......................................................13

Tools .................................................................14

Fasteners ..........................................................15

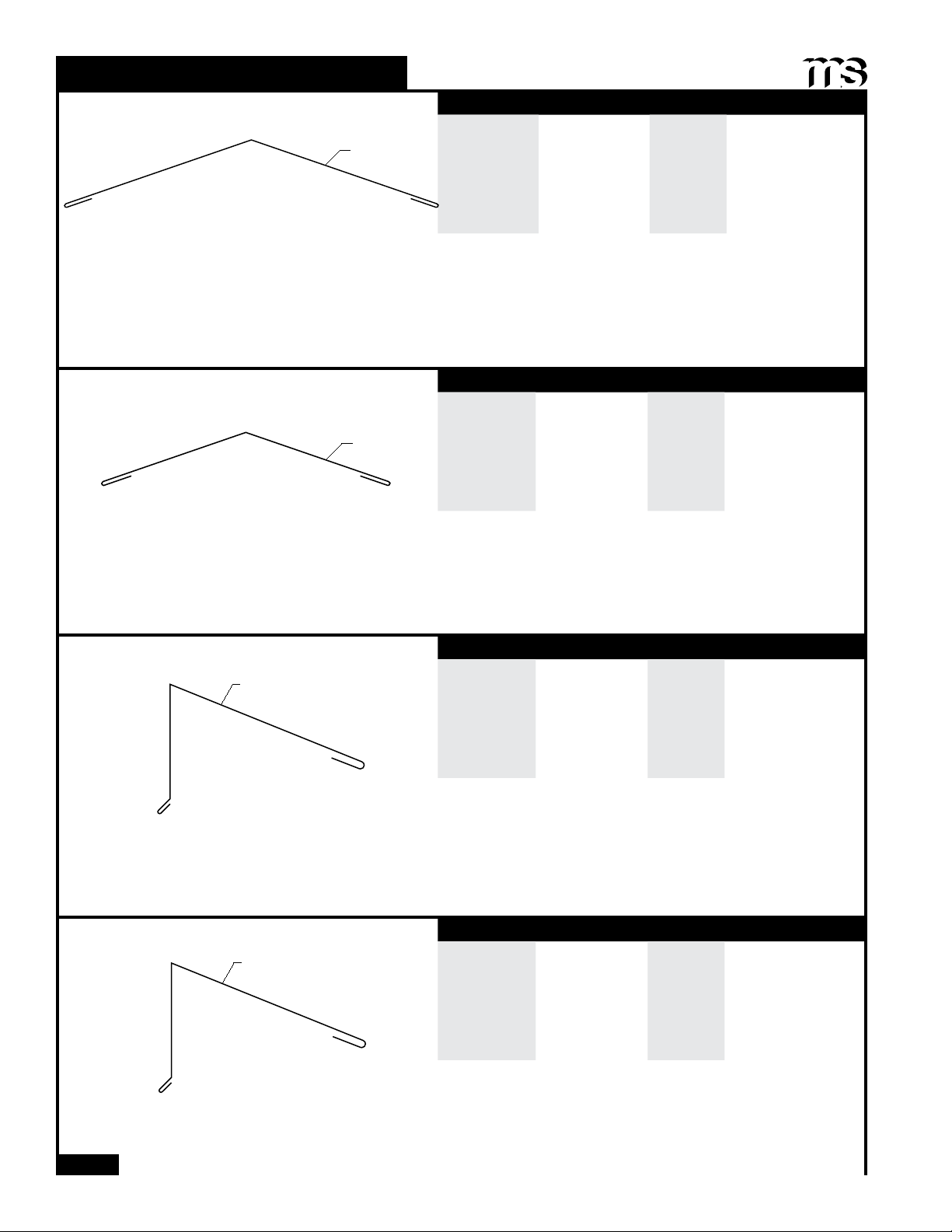

VERTICAL SEAM DETAILS

Eave ..................................................................16

Extended Eave ..................................................17

W-Valley ...........................................................18

Residential Rake ...............................................19

Rakewall with Counter .......................................20

Rakewall with Counter and Receiver.................21

Rakewall ............................................................22

Ridge/Hip ...........................................................23

Ridge/Hip Notch Detail ......................................24

Hip End Cap Detail ............................................25

Pitch Break ........................................................26

Vented Peak .....................................................27

Peak ..................................................................28

Peak Flashing Lap Details ................................29

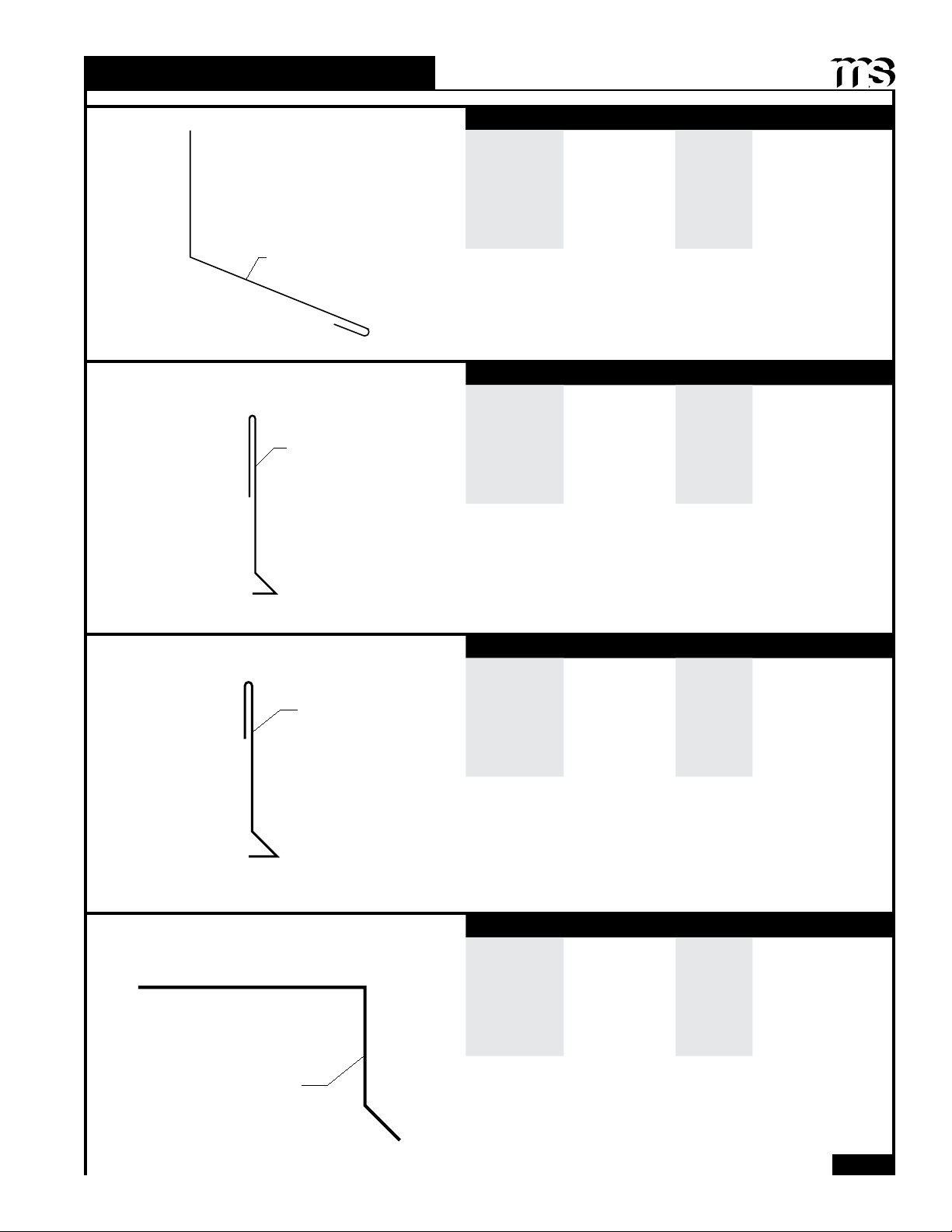

IMAGE II DETAILS

Eave ..................................................................30

Extended Eave ..................................................31

W-Valley ...........................................................32

Residential Rake ...............................................33

Rakewall with Counter .......................................34

Rakewall with Counter and Receiver.................35

Rakewall ............................................................36

Ridge/Hip ...........................................................37

Ridge/Hip Notch Detail ......................................38

Hip End Cap Detail ............................................39

Pitch Break ........................................................40

Vented Peak .....................................................41

Peak ..................................................................42

Peak Flashing Lap Details ................................43

Skylight/Chimney Details ..............................44-45

Care and Maintenance ......................................46

Notes .........................................................47-48

2

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

RESIDENTIAL DESIGN GUIDE

Branch Locations

1.) DENVER BRANCH

7990 E. I-25 Frontage Road

Longmont, CO 80504

303.702.5440 Phone

800.289.7663 Toll Free

800.289.1617 Toll Free Fax

2.) JACKSONVILLE BRANCH

7110 Stuart Avenue

Jacksonville, FL 32254

904.783.3660 Phone

800.394.4419 Toll Free

904.783.9175 Fax

800.413.3292 Toll Free Fax

3.) JEFFERSON BRANCH

352 East Erie Street

Jefferson, OH 44047

440.576.9070 Phone

800.321.5833 Toll Free

440.576.9242 Fax

800.233.5719 Toll Free Fax

4.) INDEPENDENCE BRANCH

1306 South Powell Road

Independence, MO 64057

816.796.0900 Phone

800.747.0012 Toll Free

816.796.0906 Fax

5.) SELLERSBURG BRANCH

7800 State Road 60

Sellersburg, IN 47172

812.246.1866 Phone

800.999.7777 Toll Free

812.246.0893 Fax

800.477.9318 Toll Free Fax

6.) ROGERS BRANCH

22651 Industrial Boulevard

Rogers, MN 55374

763.428.8080 Phone

800.328.9316 Toll Free

763.428.8525 Fax

800.938.9119 Toll Free Fax

7.) NASHVILLE BRANCH

4314 Hurricane Creek Boulevard

Antioch, TN 37013

615.641.7100 Phone

800.251.8508 Toll Free

615.641.7118 Fax

800.419.4372 Toll Free Fax

8.) SPOKANE BRANCH

East 2727 Trent Avenue

Spokane, WA 99202

509.536.6000 Phone

800.572.6565 Toll Free

509.534.4427 Fax

9.) SEATTLE BRANCH

20213 84th Avenue, South

Kent, WA 98032

253.872.5750 Phone

800.431.3470 Toll Free (Outside WA)

800.742.7900 Toll Free (Inside WA)

253.872.2008 Fax

10.) NEW ALBANY BRANCH

999 Park Place

New Albany, IN 47150

812.944.2733 Phone

812.944.1418 Fax

11.) ROCK ISLAND BRANCH

8111 West 29th Street

Rock Island, IL 61201

309.787.1200 Phone

800.747.1206 Toll Free

309.787.1833 Fax

12.) DEER LAKE BRANCH

29 Pinedale Industrial Road

Orwigsburg, PA 17961

570.366.2020 Phone

800.544.2577 Toll Free

570.366.1648 Fax

800.544.2574 Toll Free Fax

13.) TEMPLE BRANCH

3838 North General Bruce Drive

Temple, TX 76501

254.791.6650 Phone

800.543.4415 Toll Free

254.791.6655 Fax

800.543.4473 Toll Free Fax

14.) WOODLAND BRANCH

1326 Paddock Place

Woodland, CA 95776

530.668.5690 Phone

800.759.6019 Toll Free

530.668.0901 Fax

15.) FONTANA BRANCH

14213 Whittram Avenue

Fontana, CA 92335

909.829.8618 Phone

800.782.7953 Toll Free

909.829.9083 Fax

16.) ANCHORAGE BRANCH

4637 Old Seward Highway

Anchorage, AK 99503

907.646.7663 Phone

866.640.7663 Toll Free

907.646.7664 Fax

17.) BAY CITY BRANCH

5209 Mackinaw Road

Bay City, MI 48706

989.686.5879 Phone

888.777.7640 Toll Free

989.686.5870 Fax

888.777.0112 Toll Free Fax

18.) DETROIT LAKES BRANCH

1435 Egret Avenue

Detroit Lakes, MN 56501

218.847.2988 Phone

888.594.1394 Toll Free

218.847.4835 Fax

888.594.1454 Toll Free Fax

19.) MOCKSVILLE BRANCH

188 Quality Drive

Mocksville, NC 27028

336.751.6381 Phone

800.228.6119 Toll Free

336.751.6301 Fax

800.228.7916 Toll Free Fax

20.) FORT SMITH BRANCH

7510 Ball Road

Fort Smith, AR 72908

479.646.1176 Phone

877.452.3915 Toll Free

479.646.5204 Fax

21.) SIOUX FALLS BRANCH

2700 West 3rd Street, Suite 4

Sioux Falls, SD 57104

605.335.2745 Phone

888.299.0024 Toll Free

TECHNICAL SUPPORT

TECHNICAL SERVICES

545 South 3rd Street, Suite 200

Louisville, KY 40202

502.855.4300 Phone

800.406.7387 Toll Free

502.855.4290 Fax

800.944.6884 Toll Free Fax

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

3

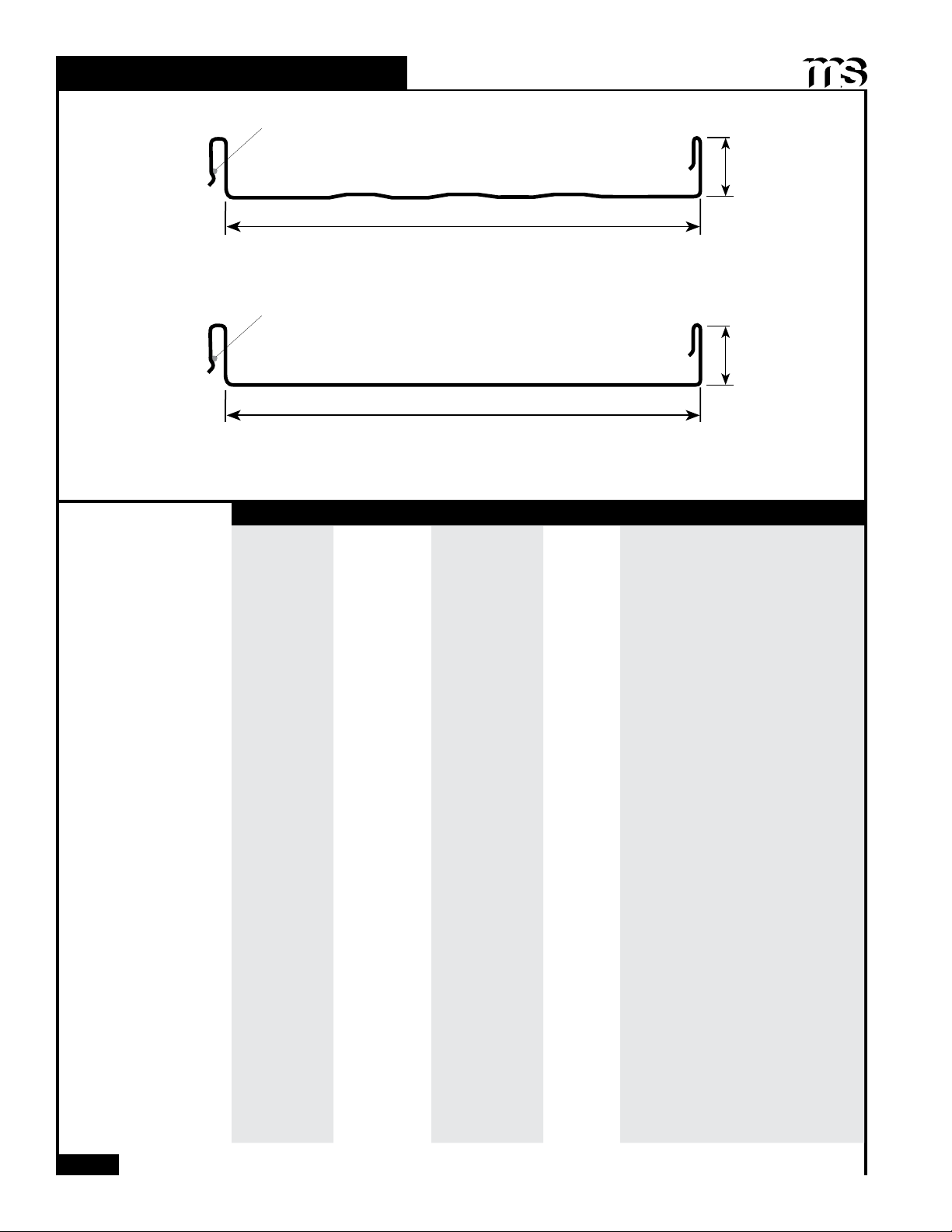

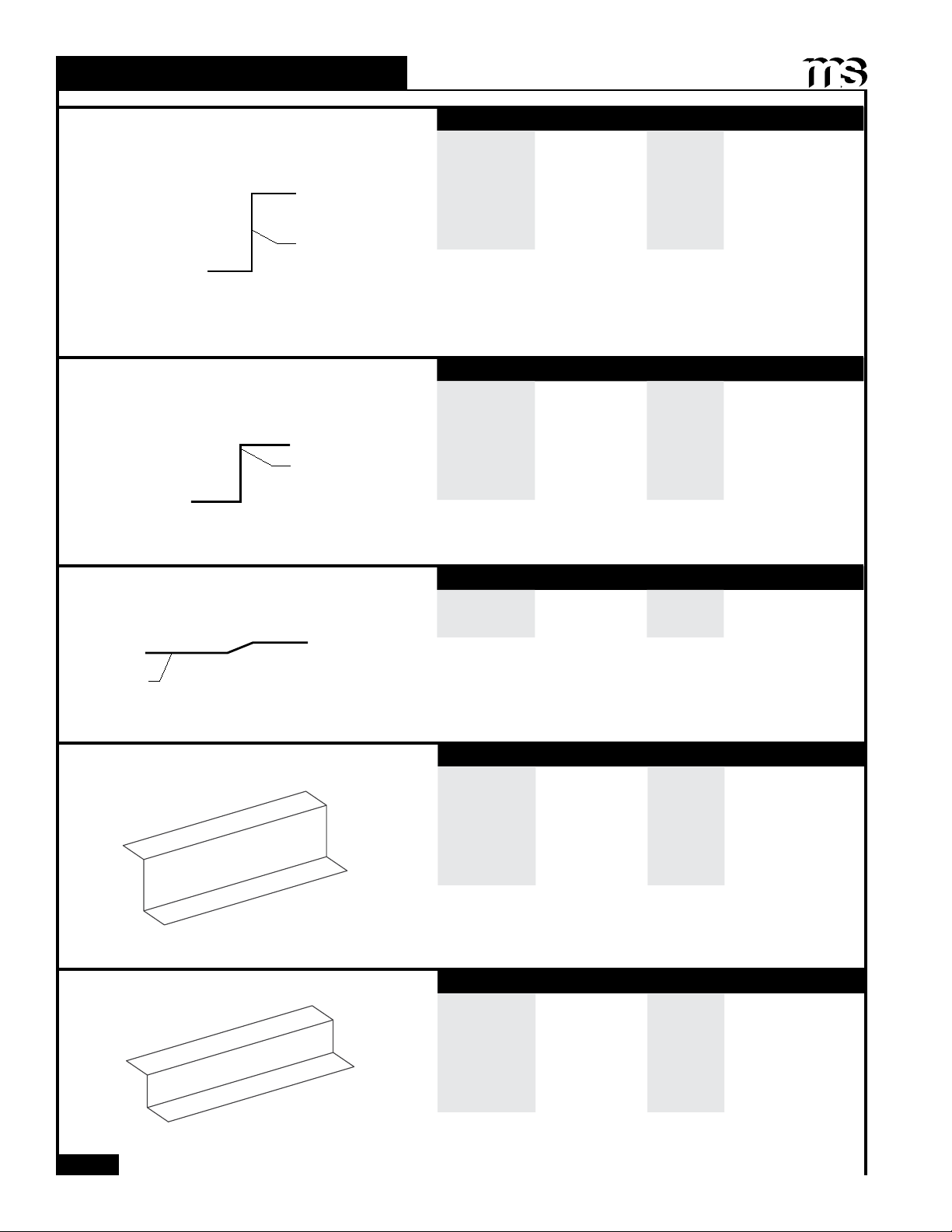

RESIDENTIAL DESIGN GUIDE

1-3/4"

1-3/4"

Factory-Applied Sealant

Vertical Seam Panels

with Striations

12",16" or 18" Coverage

12", 16", or 18" Coverage

1-3/4"

Factory-Applied Sealant

Flat Pan

1-3/4"

12", 16", or 18" Coverage

Product No. Coverage Description Gauge Finish

2543941 12" Striated 26 Galvalume® (ACG)

®

25439XX 12" Striated 26 MS Colorfast45

26439XX 12" Striated 26 PVDF (Kynar 500

Painted (CF45)

®

) Painted

2743841 12" Flat 24 Galvalume

2743941 12" Striated 24 Galvalume

®

®

28438XX 12" Flat 24 PVDF (Kynar 500

28439XX 12" Striated 24 PVDF (Kynar 500

2545941 16" Striated 26 Galvalume

25459XX 16" Striated 26 MS Colorfast45

®

®

Painted (CF45)

26459XX 16" Striated 26 PVDF (Kynar 500

2745641 16" Flat 24 Galvalume

2745941 16" Striated 24 Galvalume

®

®

28456XX 16" Flat 24 PVDF (Kynar 500

28456XX 16" Striated 24 PVDF (Kynar 500

2546241 18" Striated 26 Galvalume

25462XX 18" Striated 26 MS Colorfast45

®

®

Painted (CF45)

26462XX 18" Striated 26 PVDF (Kynar 500

2746041 18" Flat 24 Galvalume

2746241 18" Striated 24 Galvalume

®

®

28460XX 18" Flat 24 PVDF (Kynar 500

28462XX 18" Striated 24 PVDF (Kynar 500

(ACG)

(ACG)

®

) Painted

®

) Painted

(ACG)

®

) Painted

(ACG)

(ACG)

®

) Painted

®

) Painted

(ACG)

®

) Painted

(ACG)

(ACG)

®

) Painted

®

) Painted

4

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

RESIDENTIAL DESIGN GUIDE

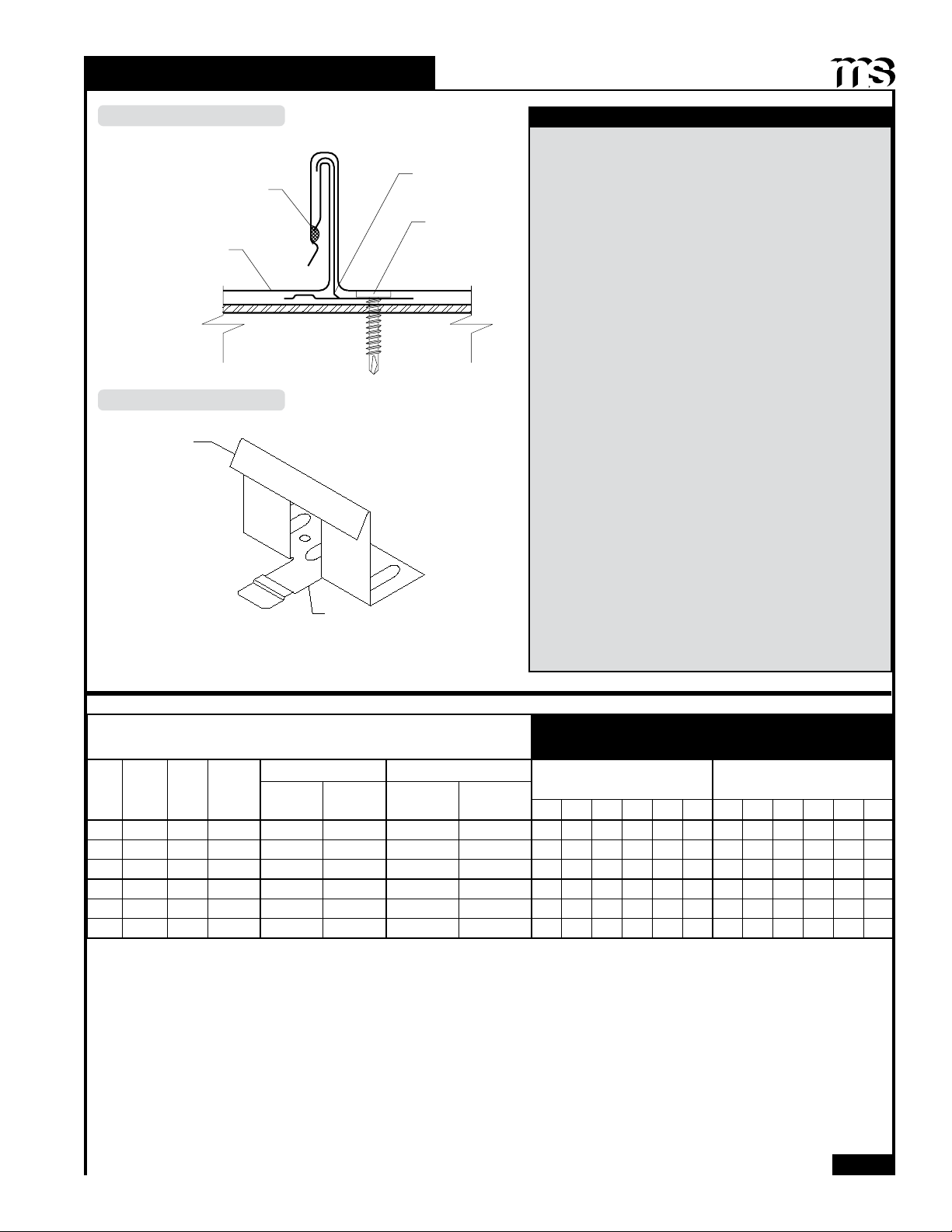

Vertical Seam Design Information

ATTACHMENT DETAIL

Factory Applied Sealant

Vertical Seam Panel

PANEL CLIPS

Vertical

Tab

Clip

Pancake Head

Fastener

GENERAL INFORMATION

Slope

The minimum recommended slope for the Vertical Seam

roof panel is 3:12 over open framing and 1:12 over solid

substrate.

Clips

Clip spacing is based upon the spacing of structural

framing members and loading requirements.

Coverage

Vertical Seam panels are available in a 13/4" seam height

with a 12", 16", or 18" width coverage.

Lengths

Minimum factory cut length is 5'-0". Maximum

recommended panel length is 45'-0". Longer panels

require additional consideration in packaging,

shipping, and erection. Please consult Metal Sales for

recommendations.

Fasteners

The fastener selection guide should be consulted for

choosing the proper fastener for specic applications.

Quantity and type of fastener must meet necessary

loading and code requirements.

NOTE: All panels are subject to surface distortion due to

improperly applied fasteners. Overdriven fasteners will

cause stress and induce oil canning across the face of

the panel at or near the point of attachment.

Availability

Base

UL90 Clip - 2 Fasteners

SECTION PROPERTIES

WidthinYield

Ga.

26 12 50 1.06 0.0781 0.0530 0.0377 0.0408 148 104 77 59 - - 55 49 42 36 - -

26 16 50 0.97 0.0614 0.0402 0.0283 0.0306 114 79 58 45 - - 114 79 58 45 - -

26 18 50 0.94 0.0553 0.0358 0.0253 0.0273 - - - - - - - - - - - -

24 12 50 1.38 0.1118 0.0774 0.0533 0.0557 204 143 105 81 64 52 44 43 42 41 40 39

24 16 50 1.26 0.0885 0.0589 0.0398 0.0419 153 107 79 61 48 39 42 38 34 30 27 24

24 18 50 1.22 0.0800 0.0526 0.0353 0.0372 136 95 70 54 43 35 33 30 27 24 20 19

Weight

ksi

Top In Compression Bottom In Compression

psf

Ixx

in4/ft

Sxx

in3/ft

Ixx

in4/ft

Sxx

in3/ft

Finishes: in PVDF (Kynar 500®), MS Colorfast45®, and

Acrylic Coated Galvalume®.

Gauges: 24 gauge or 26 gauge

ALLOWABLE UNIFORM LOADS, psf

For various fastener spacings

Inward

Load

2.5' 3' 3.5' 4' 4.5' 5' 2.5' 3' 3.5' 4' 4.5' 5'

Outward

Load

1. Theoretical section properties have been calculated per AISI 2007 'North American Specication for the Design of ColdFormed Steel Structural Members'. Ixx and Sxx are effective section properties for deection and bending.

2. Allowable loads are calculated in accordance with AISI 2007 specications considering bending, shear, combined bending

and shear, deection and ASTM E 1592 uplift testing for 24 ga and 22 ga and UL 580 uplift testing for 26 ga. Allowable

loads consider the 3 or more equal spans condition. Allowable loads do not address web crippling, fasteners or support

material. Panel weight is not considered.

3. Deection consideration is limited by a maximum deection ratio of L/180 of span.

4. Allowable loads do not include a 1/3 stress increase for wind.

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

5

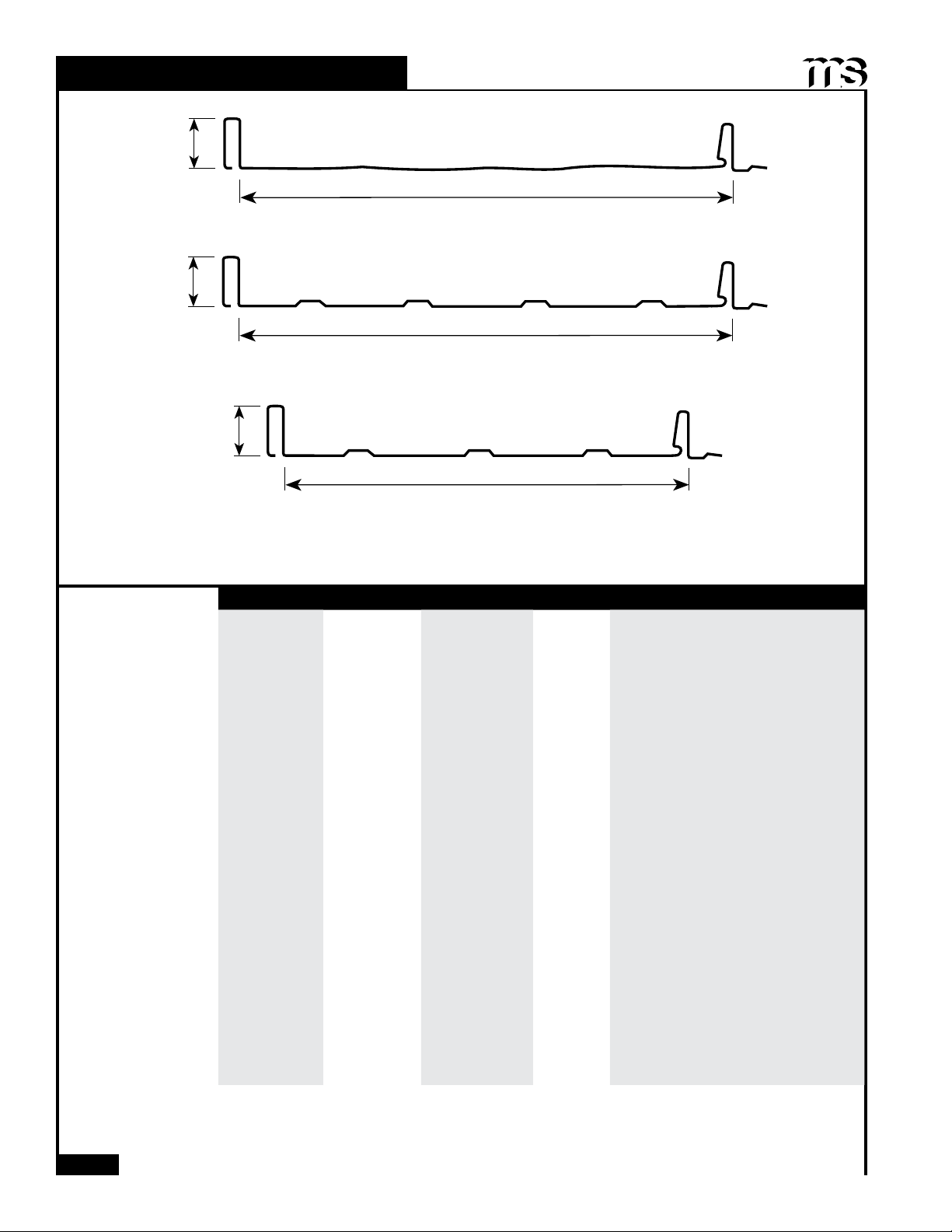

RESIDENTIAL DESIGN GUIDE

12" or 16" Coverage

with Striations

Flat Pan

12" or 16" Coverage

Image II Panels

1"

1"

1"

1"

with Striations

16" Coverage

with Minor Ribs

16" Coverage

16" Coverage

with Minor Ribs

12" Coverage

Product No. Coverage Description Gauge Finish

2544141 12" Striated 26 Galvalume® (ACG)

2514641 12" Minor Rib 26 Galvalume

25441XX 12" Striated 26 MS Colorfast45

25146XX 12" Minor Rib 26 MS Colorfast45

26441XX 12" Striated 26 PVDF (Kynar 500

2718841 12" Striated 24 Galvalume

2718641 12" Minor Rib 24 Galvalume

27188XX 12" Striated 24 PVDF (Kynar 500

27186XX 12" Minor Rib 24 PVDF (Kynar 500

2534641 16" Minor Rib 26 Galvalume

25444XX 16" Striated 26 MS Colorfast45

25346XX 16" Minor Rib 26 MS Colorfast45

26444XX 16" Striated 26 PVDF (Kynar 500) Painted

2718741 16" Striated 24 Galvalume

2718941 16" Minor Rib 24 Galvalume

27187XX 16" Striated 24 PVDF (Kynar 500

27189XX 16" Minor Rib 24 PVDF (Kynar 500

®

(ACG)

®

Painted (CF45)

®

Painted (CF45)

®

) Painted

®

(ACG)

®

(ACG)

®

) Painted

®

) Painted

®

(ACG)

®

Painted (CF45)

®

Painted (CF45)

®

(ACG)

®

(ACG)

®

) Painted

®

) Painted

6

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

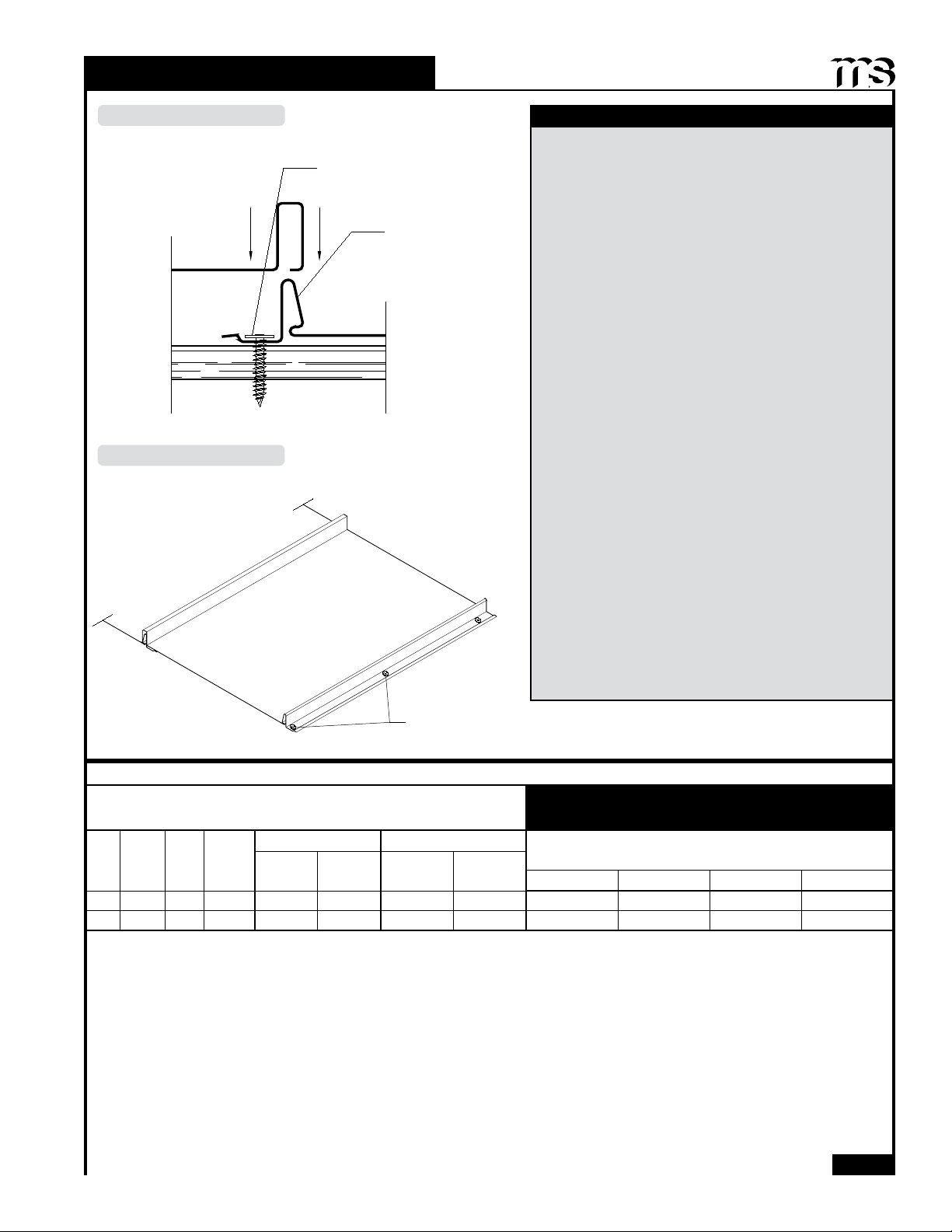

RESIDENTIAL DESIGN GUIDE

Image II Design Information

ATTACHMENT DETAIL

FASTENING PATTERN

Woodscrew

Image II Panel

GENERAL INFORMATION

Slope

The minimum recommended slope for the Image II roof

panel is 3:12.

Substructure

Image II is designed to be utilized over a solid substrate.

To avoid panel distortion use a properly aligned and

uniform substructure.

NOTE: Image II roof panels are not recommended for use

over open structural framing.

Coverage

Image II panels are available in a 1" seam height with a 12"

or 16" width coverage.

Length

Minimum factory cut length is 5'-0". Maximum

recommended panel length is 30'-0". Longer panels require

additional consideration in packaging, shipping, and

erection. Please consult Metal Sales for recommendations.

Fasteners

The fastener selection guide should be consulted for

choosing the proper fastener for specic applications.

Quantity and type of fastener must meet necessary loading

and code requirements.

NOTE: All panels are subject to surface distortion due to

improperly applied fasteners. Overdriven fasteners will

cause stress and induce oil canning across the face of the

panel at or near the point of attachment.

Availability

Finishes: Acrylic Coated Galvalume

or various PVDF (Kynar 500

®

, MS Colorfast45®,

®

) colors.

Gauges: 26 gauge or 24 gauge

Panel Fasteners

SECTION PROPERTIES

WidthinYield

Ga.

26 16 50 0.90 0.0165 0.0174 0.0165 0.0177

24 16 50 1.19 0.0210 0.0226 0.0210 0.0226 103 96 90 84

Weight

ksi

Top In Compression Bottom In Compression

psf

Ixx

in4/ft

Sxx

in3/ft

Ixx

in4/ft

Sxx

in3/ft

ALLOWABLE UNIFORM LOADS, psf

For various fastener spacings

Outward

Load

0'-6" 1'-0" 1'-6" 2'-0"

103 96 90 84

1. Theoretical section properties have been calculated per AISI 2007 'North American Specication for the Design of ColdFormed Steel Structural Members'. Ixx and Sxx are effective section properties for deection and bending.

2. Allowable loads are calculated in accordance with AISI 2007 specications considering bending, shear, combined bending

and shear, deection and ASTM E 1592 uplift testing for 24 ga and 22 ga and UL 580 uplift testing for 26 ga. Allowable

loads consider the 3 or more equal spans condition. Allowable loads do not address web crippling, fasteners or support

material. Panel weight is not considered.

3. Deection consideration is limited by a maximum deection ratio of L/180 of span.

4. Allowable loads do not include a 1/3 stress increase for wind.

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

7

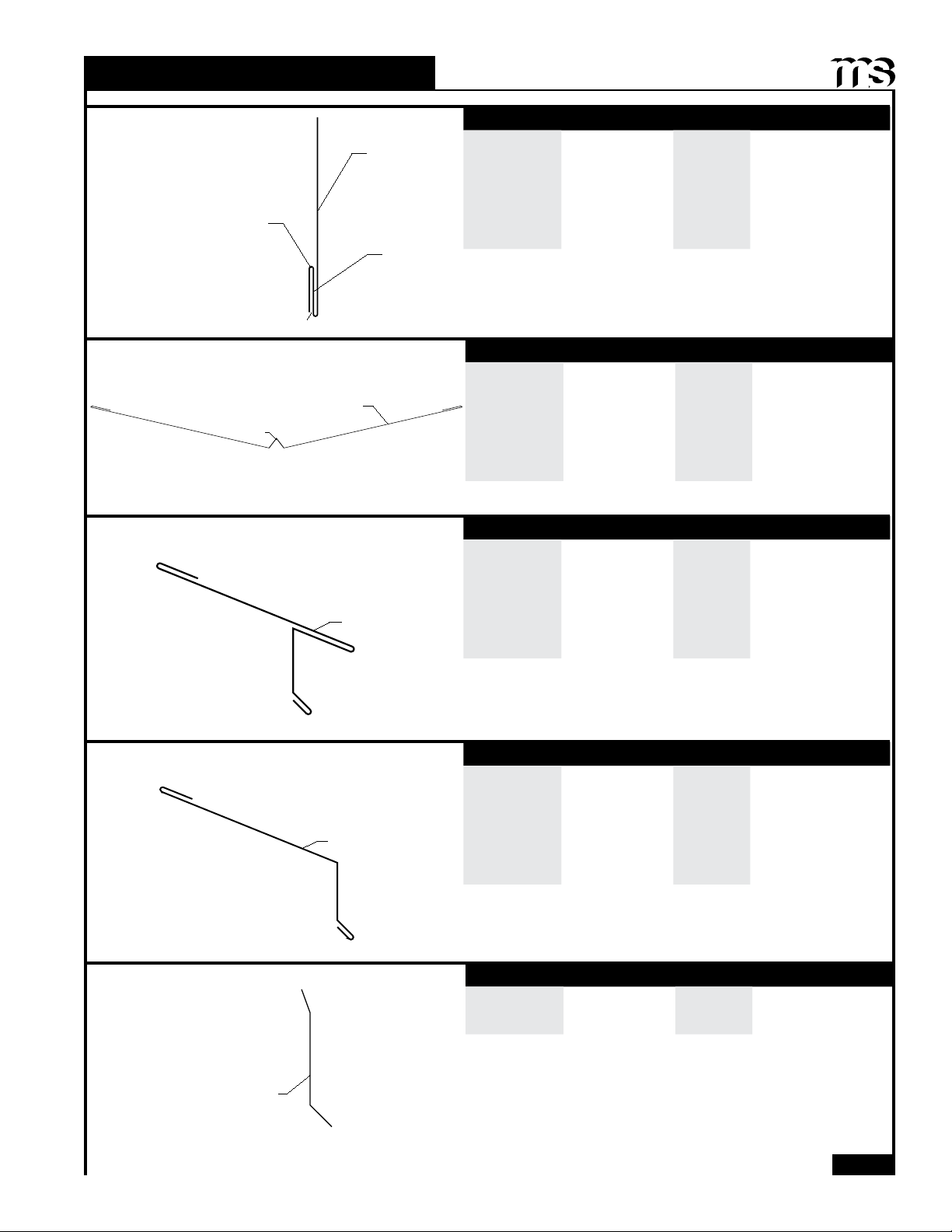

RESIDENTIAL DESIGN GUIDE

7" RIDGE/HIP COVER

C

7"

Open Hem

Flashing Proles

Specify Pitch

Product No. Length

5013141 10'-2" 26 Galvalume (ACG)

50131XX 10'-2" 26 CF45 Painted

51131XX 10'-2" 26 PVDF Painted

1"

5213141 10'-2" 24 Galvalume (ACG)

52131XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 16"

Gauge

Finish

5" RIDGE/HIP COVER

5"

Open Hem

VERTICAL SEAM RESIDENTIAL PEAK

C

7"

7

3

/8"

1"

º

135

5

/8"

1

Open Hem

/2"

Specify Pitch

C

1"

Specify Pitch

Open Hem

Product No. Length

Gauge

Finish

5013041 10'-2" 26 Galvalume (ACG)

50130XX 10'-2" 26 CF45 Painted

51130XX 10'-2" 26 PVDF Painted

5213041 10'-2" 24 Galvalume (ACG)

52130XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 12"

Product No. Length

Gauge

Finish

5013341 10'-2" 26 Galvalume (ACG)

50133XX 10'-2" 26 CF45 Painted

51133XX 10'-2" 26 PVDF Painted

5213341 10'-2" 24 Galvalume (ACG)

52133XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 13"

IMAGE II RESIDENTIAL PEAK

C

7"

3"

º

135

5

/8"

1

Open Hem

8

/2"

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

1"

Specify Pitch

Open Hem

Product No. Length

Gauge

Finish

5013441 10'-2" 26 Galvalume (ACG)

50134XX 10'-2" 26 CF45 Painted

51134XX 10'-2" 26 PVDF Painted

5213441 10'-2" 24 Galvalume (ACG)

52134XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 12-1/8"

RESIDENTIAL DESIGN GUIDE

Flashing Proles

RESIDENTIAL PITCH BREAK

4"

C

6"

NOTE: 6" dimension will not work

in all applications. Provide slopes

of adjoining planes

1"

VERTICAL SEAM RESIDENTIAL RAKE

3

/4"

1

135

1

C

3

3

/8"

º

5

/8"

/2"

Specify Pitch

Open Hem

Product No. Length

Gauge

Finish

5394341 10'-2" 26 Galvalume (ACG)

53943XX 10'-2" 26 CF45 Painted

51143XX 10'-2" 26 PVDF Painted

5294341 10'-2" 24 Galvalume (ACG)

52943XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 11"

Product No. Length

Gauge

Finish

5012741 10'-2" 26 Galvalume (ACG)

50127XX 10'-2" 26 CF45 Painted

51127XX 10'-2" 26 PVDF Painted

5212741 10'-2" 24 Galvalume (ACG)

52127XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 6-1/4"

IMAGE II RESIDENTIAL RAKE

1"

2

135

1

/2"

C

5

/8"

º

5

/8"

RESIDENTIAL RAKE CLEAT

7

/8"

2

C

5

1

135

/8"

Product No. Length

Gauge

Finish

5012641 10'-2" 26 Galvalume (ACG)

50126XX 10'-2" 26 CF45 Painted

51126XX 10'-2" 26 PVDF Painted

5212641 10'-2" 24 Galvalume (ACG)

52126XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 4-3/4"

Product No. Length

Gauge

Finish

5013241 10'-2" 26 Galvalume (ACG)

50132XX 10'-2" 26 CF45 Painted

51132XX 10'-2" 26 PVDF Painted

5213241 10'-2" 24 Galvalume (ACG)

1

/2"

º

52132XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 5"

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

9

RESIDENTIAL DESIGN GUIDE

Flashing Proles

FLAT CLEAT (Field Cut to 1" Pieces)

3/4"

2-3/4"

1"

REGLET FLASHING

1

/2"

1"

82°

3"

Open Hem

5

/8"

1

/2"

COUNTER FLASHING

5

/8"

3

/4"

2"

5

/8"

1

/2"

Open Hem

1"

1

/2"

Open Hem

135°

135°

135°

118°

135°

COUNTER FLASHING FLAT

1"

3

/4"

2"

5

/8"

Open Hem

1

/2"

137°

118°

135°

45°

Product No. Length

Gauge

Finish

5506199 10'-2" 26 Varies

5806199 10'-2" 24 Varies

Flashing Stretch Out = 3-1/2"

Product No. Length

Gauge

Finish

5552641 10'-2" 26 Galvalume (ACG)

55526XX 10'-2" 26 CF45 Painted

56526XX 10'-2" 26 PVDF Painted

5852641 10'-2" 24 Galvalume (ACG)

58526XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 5-5/8"

Product No. Length

Gauge

Finish

5552741 10'-2" 26 Galvalume (ACG)

55527XX 10'-2" 26 CF45 Painted

56527XX 10'-2" 26 PVDF Painted

5852741 10'-2" 24 Galvalume (ACG)

58527XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 6"

Product No. Length

Gauge

Finish

5552841 10'-2" 26 Galvalume (ACG)

55528XX 10'-2" 26 CF45 Painted

56528XX 10'-2" 26 PVDF Painted

5852841 10'-2" 24 Galvalume (ACG)

58528XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 4-7/8"

COUNTER FLASHING RECEIVER

1

/2"

2-1/2"

5

/8"

1-3/4"

10

1-1/2"

Open Pocket

2-1/2"

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

95°

165°

95°

Product No. Length

Gauge

Finish

5552941 10'-2" 26 Galvalume (ACG)

55529XX 10'-2" 26 CF45 Painted

56529XX 10'-2" 26 PVDF Painted

5852941 10'-2" 24 Galvalume (ACG)

58529XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 9-3/8"

RESIDENTIAL DESIGN GUIDE

Flashing Proles

RESIDENTIAL RAKEWALL

6"

Open Hem

13/8"

Open Hem

RESIDENTIAL W-VALLEY

Open Hem

10"

º

70

1"

RESIDENTIAL EXTENDED EAVE

7

Open Hem

/8"

5"

º

135

1

/2"

1

5

/8"

Open Hem

1

/2"

Product No. Length

C

5012941 10'-2" 26 Galvalume (ACG)

Gauge

Finish

50129XX 10'-2" 26 CF45 Painted

51129XX 10'-2" 26 PVDF Painted

5212941 10'-2" 24 Galvalume (ACG)

1

1

/2"

Specify Pitch

52129XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 8-7/8"

Product No. Length

Gauge

Finish

5013541 10'-2" 26 Galvalume (ACG)

7

50136XX 10'-2" 26 CF45 Painted

C

/8"

51136XX 10'-2" 26 PVDF Painted

5213641 10'-2" 24 Galvalume (ACG)

52136XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 23-3/4"

Specify Pitch

Product No. Length

Gauge

Finish

5013441 10'-2" 26 Galvalume (ACG)

50134XX 10'-2" 26 CF45 Painted

51134XX 10'-2" 26 PVDF Painted

C

1

1

/2"

5212441 10'-2" 24 Galvalume (ACG)

52124XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 10"

RESIDENTIAL EAVE

7

Open Hem

/8"

RESIDENTIAL CLEAT

Specify Pitch

Product No. Length

5002241 10'-2" 26 Galvalume (ACG)

50022XX 10'-2" 26 CF45 Painted

5"

C

º

135

11/2"

5

/8"

1

Open Hem

/2"

51122XX 10'-2" 26 PVDF Painted

5202241 10'-2" 24 Galvalume (ACG)

52022XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 8-1/2"

Product No. Length

1

/2"

º

160

7

1

/8"

C

º

135

5

/8"

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

5013599 10'-2" 26 Varies

5213599 10'-2" 24 Varies

Flashing Stretch Out = 3"

Gauge

Gauge

Finish

Finish

11

RESIDENTIAL DESIGN GUIDE

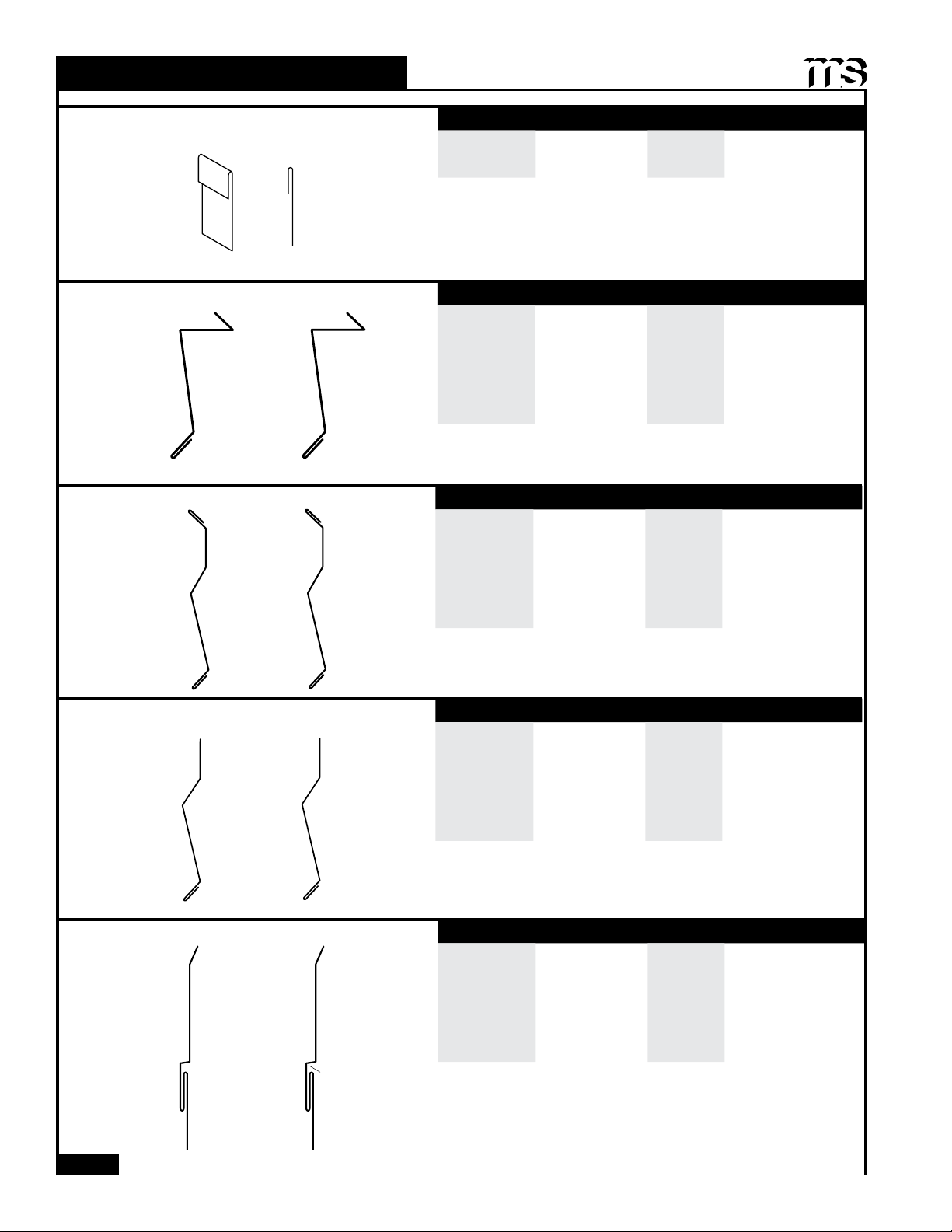

Flashing Proles

VERTICAL SEAM Z-CLOSURE

1"

3

1

/4"

1"

IMAGE II Z-CLOSURE

1"

1"

1"

Product No. Length

Gauge

Finish

5570241 10'-2" 26 Galvalume (ACG)

55702XX 10'-2" 26 CF45 Painted

56702XX 10'-2" 26 PVDF Painted

5830241 10'-2" 24 Galvalume (ACG)

C

58702XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 3-3/4"

Product No. Length

Gauge

Finish

5560341 10'-2" 26 Galvalume (ACG)

55603XX 10'-2" 26 CF45 Painted

56603XX 10'-2" 26 PVDF Painted

C

5860341 10'-2" 24 Galvalume (ACG)

58603XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 3"

OFFSET CLEAT

11/2"

C

1

/2"

VERTICAL SEAM END CAP

2"

1"

IMAGE II END CAP

1-1/4"

1"

Product No. Length

Gauge

Finish

5506499 10'-2" 26 Varies

1"

1"

5806499 10'-2" 24 Varies

Flashing Stretch Out = 3"

Product No. Length

Gauge

Finish

5011041 10'-2" 26 Galvalume (ACG)

50110XX 10'-2" 26 CF45 Painted

51110XX 10'-2" 26 PVDF Painted

5211041 10'-2" 24 Galvalume (ACG)

52110XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 4"

Product No. Length

1"

5011141 10'-2" 26 Galvalume (ACG)

Gauge

Finish

50111XX 10'-2" 26 CF45 Painted

51111XX 10'-2" 26 PVDF Painted

5211141 10'-2" 24 Galvalume (ACG)

52111XX 10'-2" 24 PVDF Painted

Flashing Stretch Out = 3-1/4"

12

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

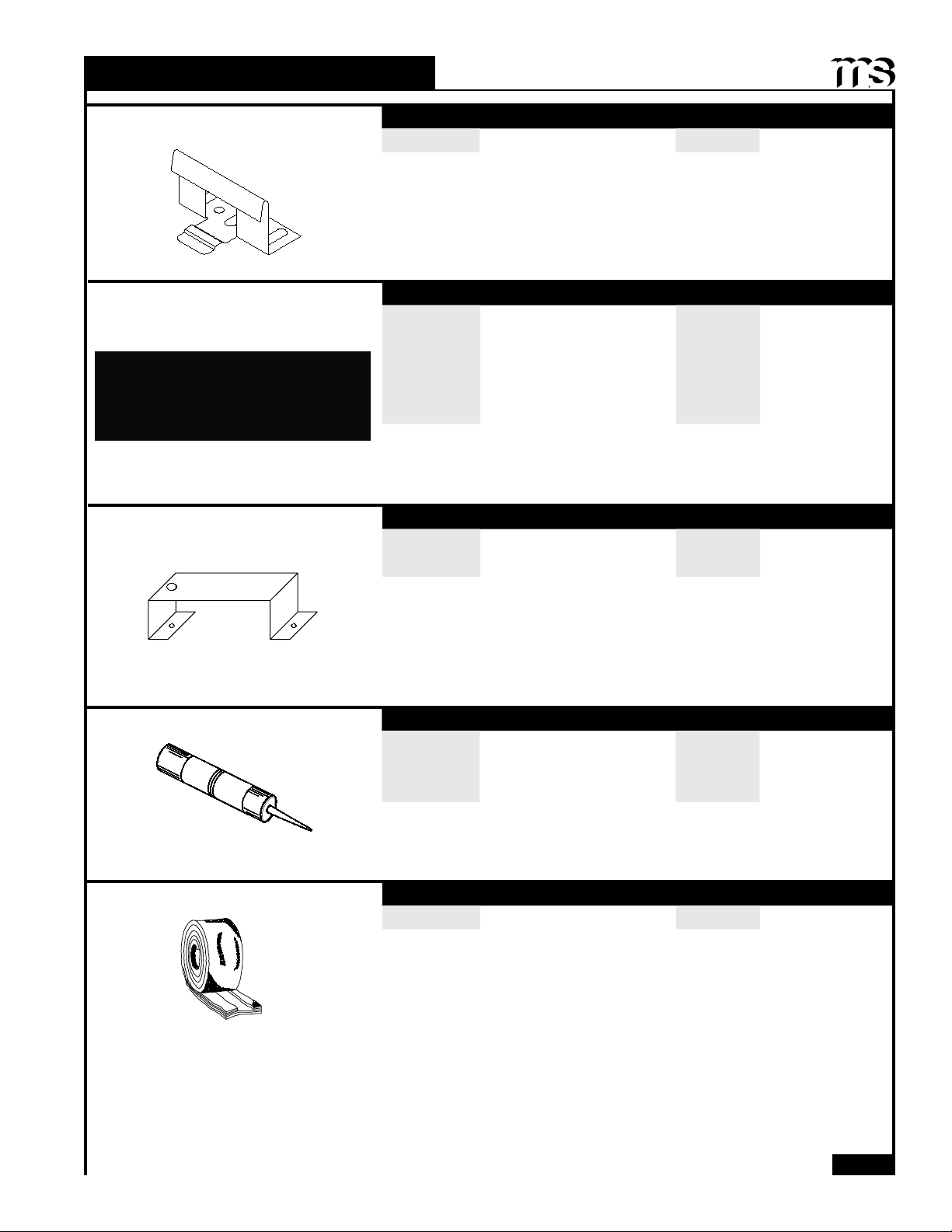

RESIDENTIAL DESIGN GUIDE

Accessories

VERTICAL SEAM CLIP

PROFILE VENT

PROFILE VENT CLIPS

Product No. Height Weight/Ea Finish

4923565 1-3/4" 0.15 lbs Galvanized

Product No. Panel Prole

6462118 16" Vertical Seam 100' Notched

6462119 18" Vertical Seam 100' Notched

6441799 12" Image II 100' Notched

6441898 16" Image II 50' Notched

6441899 16" Image II 100' Notched

Product No. Length

6541000 Vertical Seam 1.75" Black

6540000 Image II 1" Black

Length

Height

Type

Finish

TUBE SEALANT

DOUBLE BEAD TAPE SEALANT

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

Product No. Length

6403200 Acrylic Tube Sealant 3.31 lbs Clear

64032XX Tube Sealant 3.31 lbs Color Match

Product No. Length Weight Color

6403899 25'-0" 1.75 lbs Gray

Weight

Finish

13

RESIDENTIAL DESIGN GUIDE

Tools

20" DUAL BAR FOLDER/HEMMER

TURBO SHEARS

Product No.

6534599

VERSA HEMMER

Product No.

6531299

Product No.

6531499

VERSA BENDER SINGLE

14

Product No.

6531599

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/14

VERSA BENDER DOUBLE STATION

Product No.

6531699

Loading...

Loading...