Metal Sales Pro-Loc II User Manual

PRO-LOC I,II

Table of ConTenTs

Product Page No.

Panel Information

Pro-Loc Panel Proles ..........................................PPL-2

Panel Overview ....................................................PPL-2

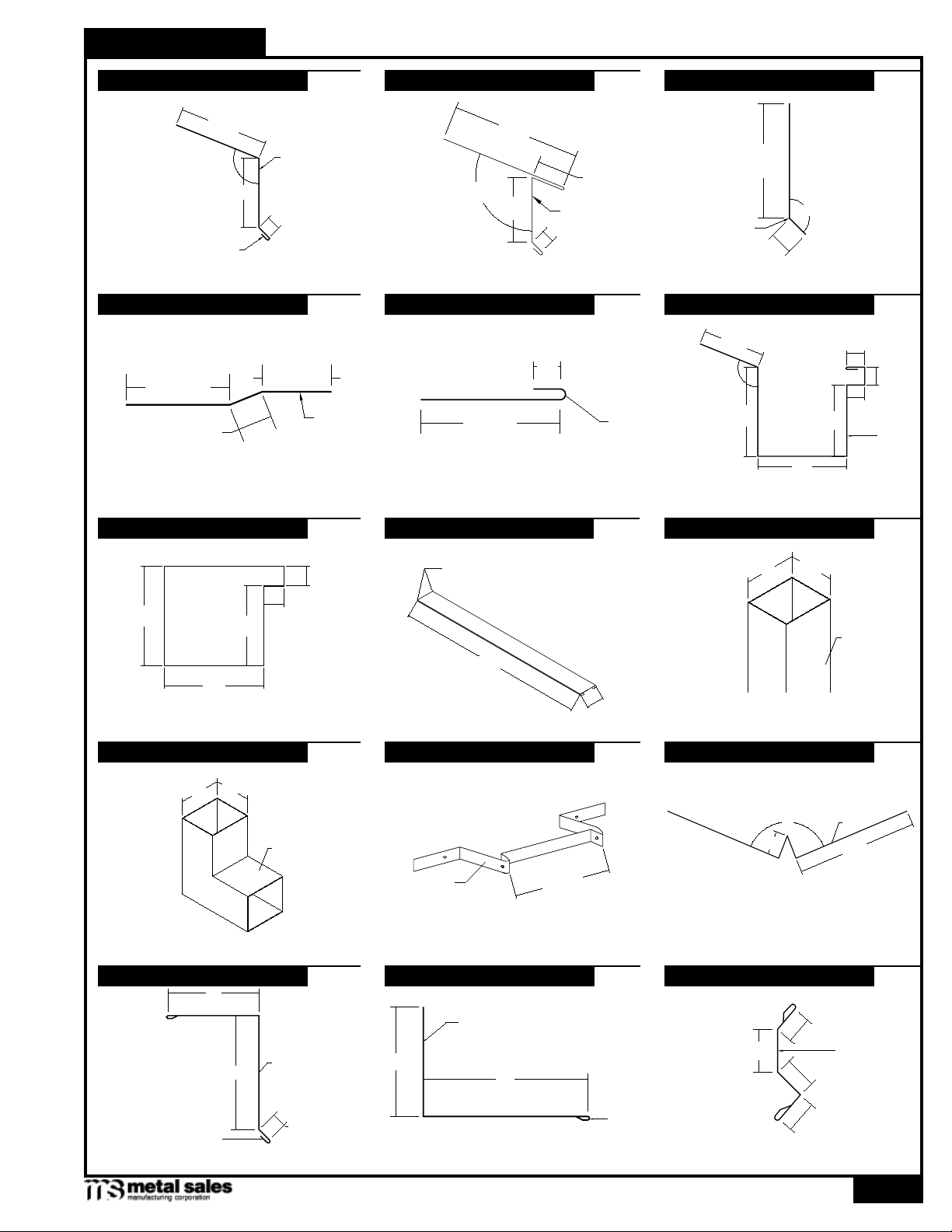

Flashing Proles

Eave .....................................................................PPL-3

Extended Eave .....................................................PPL-3

Cleat .....................................................................PPL-3

Offset Cleat ...........................................................PPL-3

Starter ...................................................................PPL-3

Box Gutter ............................................................PPL-3

Box Gutter End .....................................................PPL-3

Universal Gutter/Downspout Strap .......................PPL-3

1

/2" Downspout .............................................PPL-3

4" x 3

4" x 31/2" 95° Elbow ...............................................PPL-3

Downspout Bracket ..............................................PPL-3

Valley ....................................................................PPL-3

Rake .....................................................................PPL-3

Rakewall ...............................................................PPL-3

Counter Flashing ..................................................PPL-3

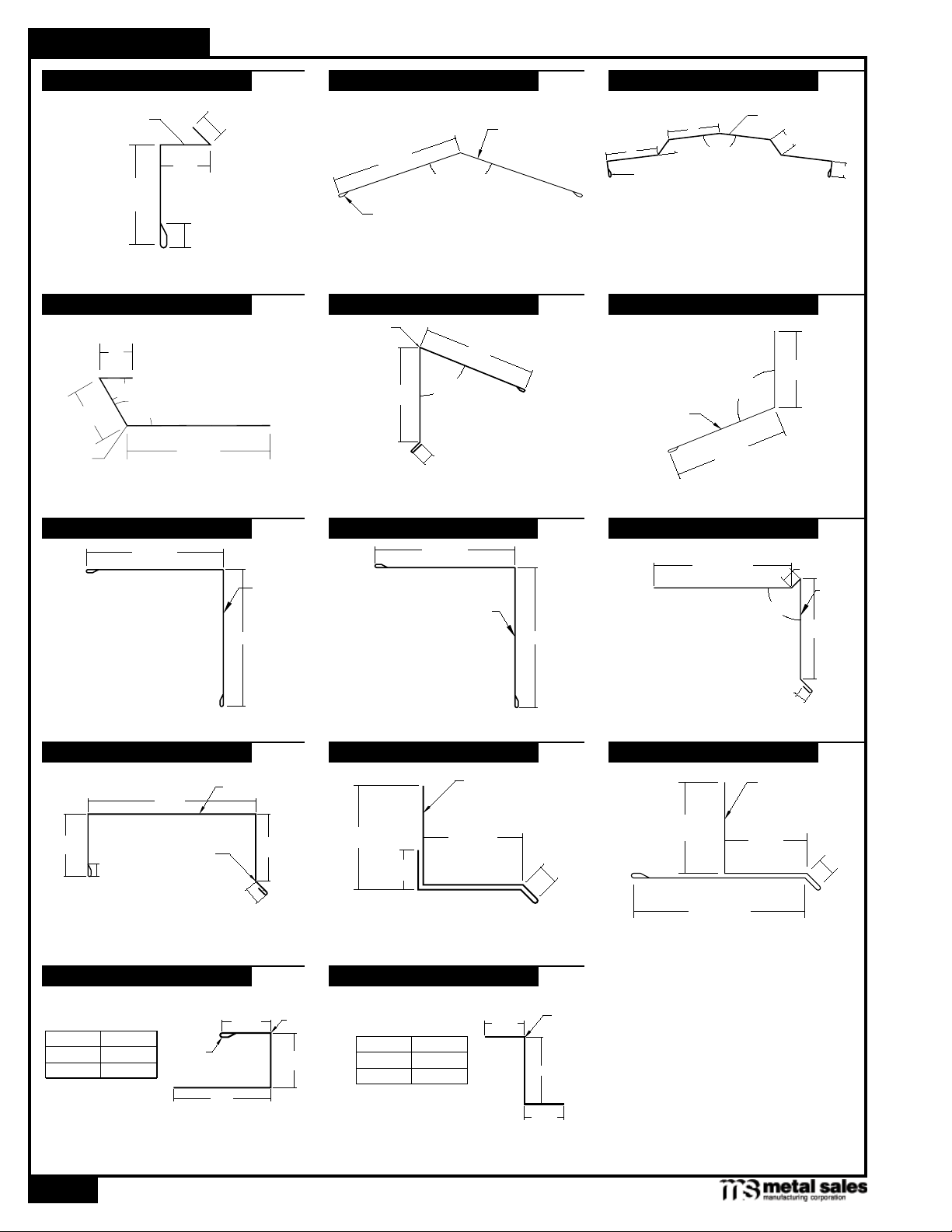

Reglet Flashing.....................................................PPL-4

11" Ridge/Hip Cover .............................................PPL-4

Vented Ridge Cover .............................................PPL-4

Vent Drip ...............................................................PPL-4

Peak .....................................................................PPL-4

Pitch Break ...........................................................PPL-4

Outside Corner .....................................................PPL-4

Inside Corner ........................................................PPL-4

Gravel Stop...........................................................PPL-4

Coping ..................................................................PPL-4

2.25" Sill/Head ......................................................PPL-4

2.25" Sill to Soft ..................................................PPL-4

Pro-Loc Cap .........................................................PPL-4

Pro-Loc Z-Closure ................................................PPL-4

Product Page No.

Detail Conditions

Eave with Offset Cleat Detail ..............................PPL-11

Extended Eave Detail ......................................... PPL-11

Gutter with Offset Cleat Detail ............................PPL-12

Valley with Offset Cleat Detail ............................PPL-12

Slope Change Detail...........................................PPL-13

Rake (On Module) Detail ....................................PPL-13

Rake (Off Module) Detail ....................................PPL-14

Rakewall with Counter Flashing Detail ...............PPL-14

Rakewall with Reglet Flashing Detail .................PPL-15

Endwall with Counter Flashing Detail .................PPL-15

Endwall with Reglet Flashing Detail ...................PPL-16

Peak Detail .........................................................PPL-16

Vented Ridge Detail ............................................PPL-17

11" Ridge/Hip Detail............................................PPL-17

Gravel Stop Detail ..............................................PPL-18

Coping Detail ......................................................PPL-18

Sill/Head Detail ...................................................PPL-19

Sill to Soft Detail ...............................................PPL-19

Outside Corner Detail .........................................PPL-20

Inside Corner Detail ............................................PPL-20

Accessory Proles

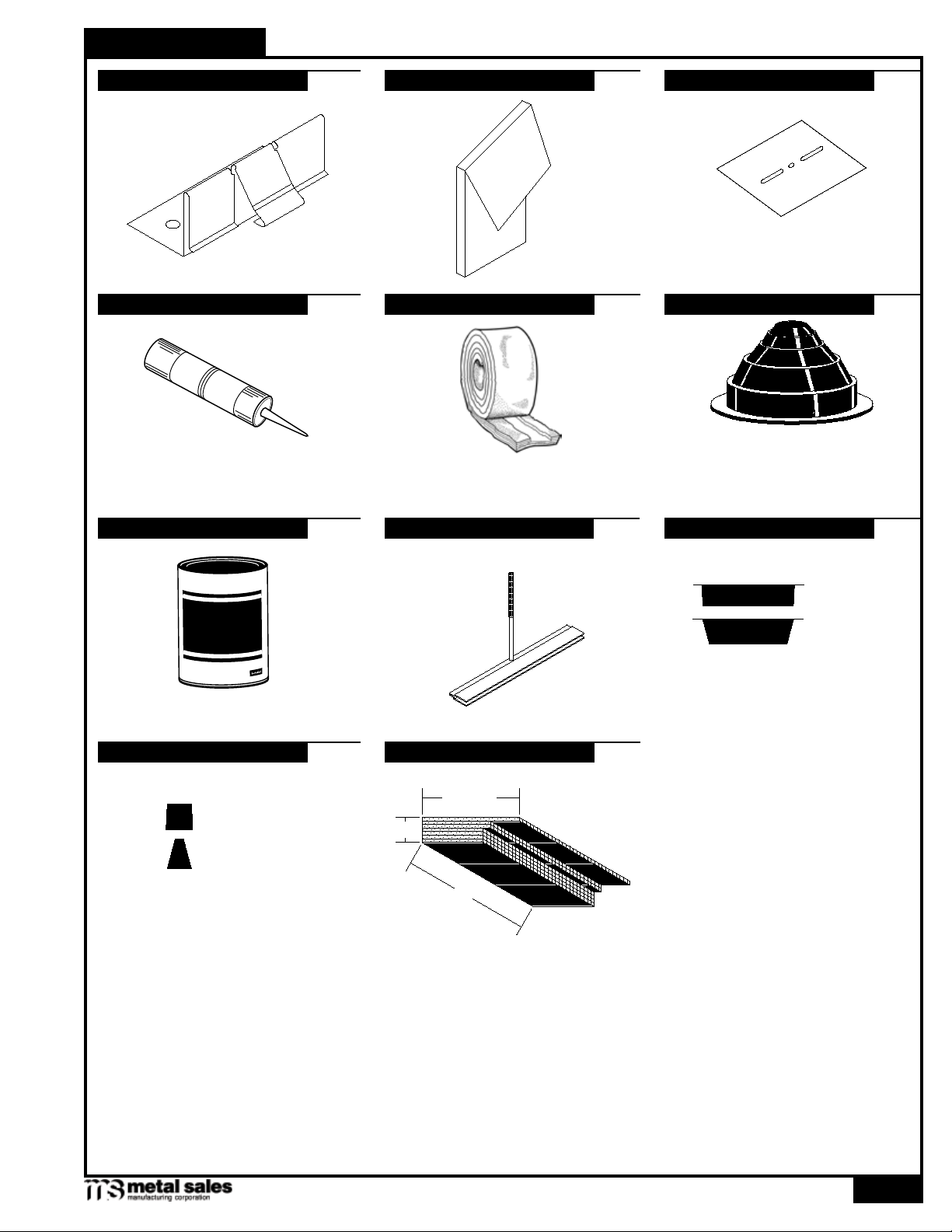

Pro-Loc Clip ..........................................................PPL-5

Pro-Loc Rib Cover ................................................PPL-5

Bearing Plate ........................................................PPL-5

Tube Sealant ........................................................PPL-5

Tape Sealant.........................................................PPL-5

Rubber Roof Jack .................................................PPL-5

Touch-Up Paint .....................................................PPL-5

Metal Panel Hemming Tool ...................................PPL-5

Pro-Loc Outside Closures ....................................PPL-5

Pro-Loc Inside Closures .......................................PPL-5

Vent Material.........................................................PPL-5

Testing Information

UL 580 Wind Uplift Information ......................... PPL-6-7

UL 263 Fire Resistance Ratings ...........................PPL-8

Design/Installation Considerations

Fastener Installation Technique ............................PPL-9

Condition of Substructure .....................................PPL-9

Ventilation ...........................................................PPL-10

Panel Applications ..............................................PPL-10

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

PPL-1

PRO-LOC I,II

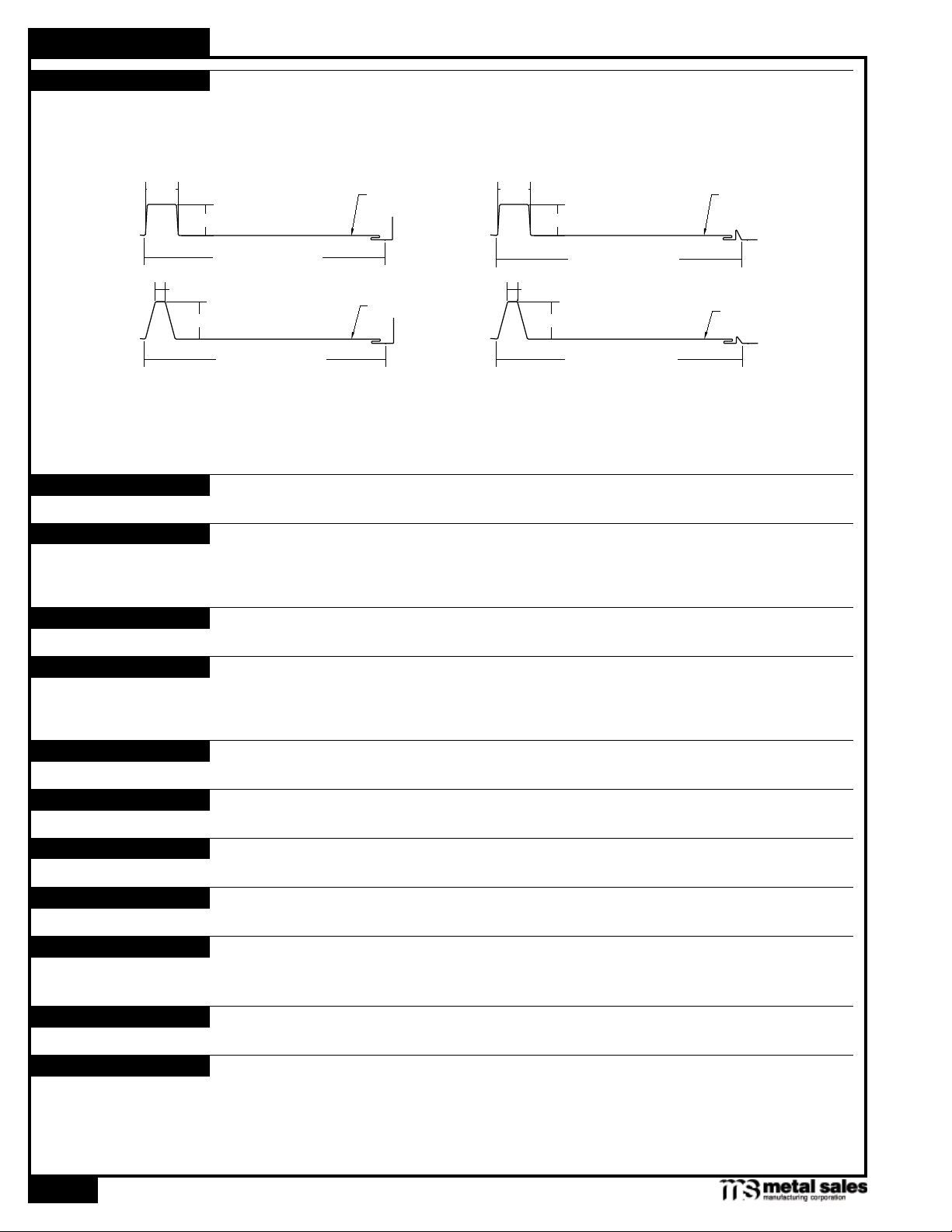

Panel overview

PANEL PROFILES

11/2"

SLOPE

1

/2"

115/16"

Pro-Loc is available in a (CCS) Concealed Clip System, or as a (CDF) Concealed Direct Fasten.

C

9

1

/16"

Pro-Loc I (CCS) Pro-Loc I (CDF)

12" Coverage

C

Pro-Loc II (CCS)

12" Coverage

The minimum recommended slope for any Pro-Loc roong panel is 3:12.

11/2"

1

/2"

115/16"

C

19/16"

12" Coverage

C

Pro-Loc II (CDF)

12" Coverage

SUBSTRATE

COVERAGE

LENGTH

AVAILABILITY

APPLICATION

PERFORMANCE TEST

FASTENING SYSTEM

FASTENERS

The recommended substrate is

use a properly aligned and uniform substructure. Please note that Pro-Loc panels are not recommended

for use over open framing.

Pro-Loc panels have a coverage of 12".

Lengths under 5'-0" are available with some cutting restrictions. Maximum recommended panel length is 45'-0".

Longer panels require additional consideration in packaging, shipping, and erection. Please consult your Metal

Sales branch for recommendations (see PGI-2 and 3 for locations).

Pro-Loc panels are available in 26, 24, and 22 gauge. Minimum quantity may apply.

Architectural and Residential panel.

UL-580 (CCS Only), ASTM E-1592 (15" Only), UL-790, UL-2218, UL-263 & Texas Department of Insurance.

Concealed Clip System (CCS) or Concealed Direct Fasten (CDF).

The fastener selection guide should be consulted for choosing proper fasteners for specic applications.

Quantity and type of fastener must meet necessary loading and code requirements (see PGI-12-14).

5

/8" plywood with a 30 pound felt moisture barrier. To avoid panel distortion,

MATERIALS

FINISH

PPL-2

Steel grade 50, per ASTM A-792

*

Acrylic Coated Galvalume® (ACG) / ASTM A-792 - AZ55

Prepainted Galvalume / ASTM A-792 - AZ50

**Fluorocarbon (PVDF)

* Differential appearance of Acrylic Coated Galvalume roong materials is not a cause for rejection.

** Meets both Kynar 500 and Hylar 5000 specications.

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

PRO-LOC I,II

flashing Profiles

EAVE

7

/8"

3

C

X*

3"

5

/8"

Hem

Length 10'-2" - *Specify Slope Angle

EXTENDED EAVE CLEAT

6"

1

/2"

1

X*

3"

Length 10'-2" - *Specify Slope Angle

C

5

/8"

1

/2"

2

C

1

/2"

Length 10'-2"

OFFSET CLEAT STARTER BOX GUTTER

1

/2"

3

1

/2"

X*

C

Length 10'-2", 20'-3" - *Specify Slope Angle

5"

DOWNSPOUT 4" x 31/2"

1

/2"

1

1

/2"

Length 10'-2"

BOX GUTTER END

1"

C

21/2"

Length 10'-2"

UNIVERSAL GUTTER/

DOWNSPOUT STRAP

1"

Hem

4"

135°

Hem

1"

1"

4"

C

5"

31/2"

5"

4"

5"

950 ELBOW 4" x 31/2"

31/2"

4"

(Also available 6" x 4")

RAKE

4"

5"

1"

C

16"

11/2"

DOWNSPOUT BRACKET

VALLEY

C

C

(Also available 4")

6"

Length 10'-2", 20'-3" - *Specify Slope Angle

Length 10'-2", 20'-3"

(Also available 6" x 4")

X*

2"

C

10"

RAKEWALL COUNTER FLASHING

C

C

31/2"

4"

1"

5

/8"

C

3

/4"

Hem

Length 10'-2", 20'-3"

5

/8"

Length 10'-2"

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

Hem

3

/4"

Length 10'-2"

PPL-3

PRO-LOC I,II

flashing Profiles (ConT.)

REGLET FLASHING

C

1"

1

/2"

11" RIDGE/HIP COVER

1

5

/2"

X*

2"

Hem

Hem

Length 10'-2"

VENT DRIP

Length 10'-2", 20'-3" - *Specify Slope Angle

PEAK

C

3

/4"

60°

120°

1

/4"

1

C

Length 10'-2"

31/4"

Length 10'-2", 20'-3" - *Specify Slope Angle

5"

X*

3

/8"

OUTSIDE CORNER INSIDE CORNER

1

5

/2"

C

51/2"

51/2"

6"

VENTED RIDGE COVER

C

1

1

/8"

7

/8"

1"

3"

X*

C

3"

Hem

Length 10'-2", 20'-3" - *Specify Slope Angle

PITCH BREAK

4"

X*

C

6"

Length 10'-2"

GRAVEL STOP

1

/2"

5

C

1

/2"

5

X*

1

/2"

C

4"

Length 10'-2", 20'-3" Length 10'-2", 20'-3"

Length 10'-2", 20'-3" - *Specify Slope Angle

COPING 2.25" SILL/HEAD 2.25" SILL TO SOFFIT

19/16"

15

1

A

/16"

C

1

/2"

1

2

/4"

1

/2"

1"

C

C- Indicates color side of flashing.

2

21/4"

3

4

/4"

A

1"

5

3

/8"

3

/8"

Length 10'-2", 20'-3"

PRO-LOC CAP

PRO-LOC I

PRO-LOC II

A

111/16"

2"

10"

Hem

Hem

3"

C

1

/2"

4"

2

1"

5

/8"

Length 10'-2" Length 10'-2"

PRO-LOC Z-CLOSURE

1

1

/2"

C

A

PRO-LOC I

PRO-LOC II

3

/8"

C

1

/2"

PPL-4

Length 10'-2"Length 10'-2"

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

PRO-LOC I,II

aCCessory Profiles

PRO-LOC CLIP

TUBE SEALANT

10.3 oz. Cartridge

Urethane

TOUCH-UP PAINT

PRO-LOC RIB COVER BEARING PLATE

4" X 5"

TAPE SEALANT

7

/8" X 3/16" X 25'

Double Bead

Butyl - Gray

METAL PANEL

HEMMING TOOL

RUBBER ROOF JACK

MINI (1/4" to 11/8" O.D. Pipe)

#2 (13/4" to 3" O.D. Pipe)

#4 (3" to 6" O.D. Pipe)

#6 (6" to 9" O.D. Pipe)

#8 (7" to 13" O.D. Pipe)

PRO-LOC OUTSIDE

CLOSURES

Available in pints

PVDF / MS Colorfast45

PRO-LOC INSIDE

CLOSURES

Pro-Loc I

Pro-Loc II

VENT MATERIAL

33/8"

7

/8"

4"

Pro-Loc I

Pro-Loc II

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

PPL-5

PRO-LOC I,II

Ul 580 wind UPlifT informaTion

6

24" Maximum

3

2

1

PRO-LOC I

Construction No. 393

November 20, 1993

Uplift - Class 90

Fire Not Investigated

5

1.593" Nom.

4

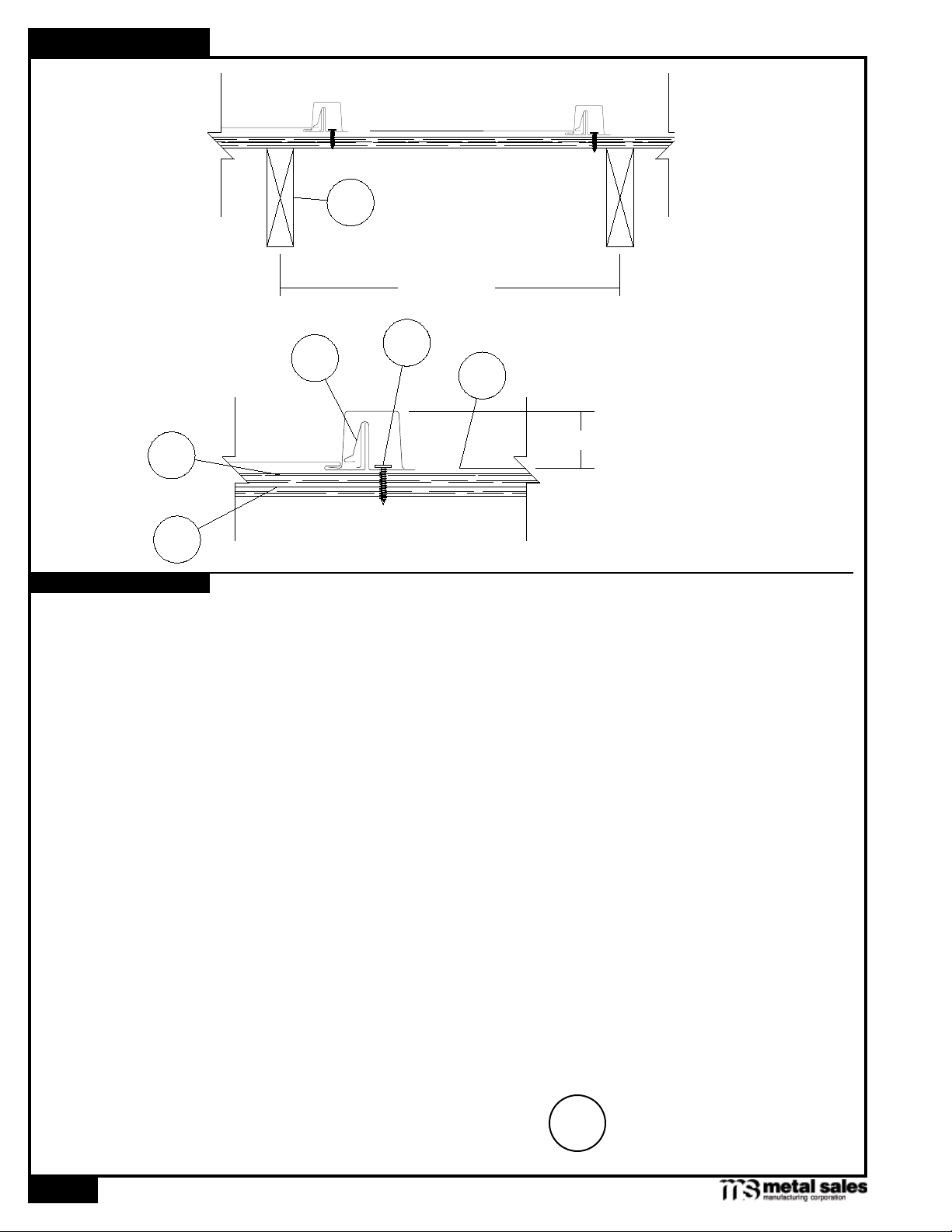

1. Metal Roof Deck Panels* No. 24 MSG min coated steel. Width 18 in. max, 19/16 in. high at female rib. Panels continuous

over three or more clips with no endlaps.

METAL SALES MANUFACTURING CORPORATION - “ProLoc I”

2. Roof Deck Fasteners (Panel Clips)* One piece assembly, 3 in. wide, 1-1/4 in. high with 1-1/4 in. horizontal leg. Min thickness No.

24 MSG coated steel. Clips spaced 18 in. OC, located at panel side ribs and fastened to plywood deck.

METAL SALES MANUFACTURING CORPORATION - “ProLoc Clip”

3. Fasteners (Screws) Screws used to attach panel clips to plywood deck (item 4) to be No. 10-12 by 1 in. long, pancake head, No. 2

Phillips drive, coated steel wood screws. As an alternate fastener, No. 10-12 by 1 in. long hex-head plated steel wood screws may be

used. For both fastener types, one screw per clip to be used. Inserted into clip guide hole.

Screws used to attach plywood substructure (Item 4) to wood trusses or joists (Item 6) to be No. 8 by 2 in. bugle head screws. An

an optional fastener, 2-1/2 in. long 8d common deformed shank nails may be used. When light gauge structural steel joists are used

as supports, screws to be No. 10-24 by 1-7/16 in. long self-drilling, self-tapping, No. 2 Phillips drive wafer head steel.

Spacing of screws to be 6 in. OC at plywood butt ends and 12 in. OC in the interior.

4. Plywood Decking Plywood decking to be graded per PS83 specifications, nom 5/8 in. (18/32) thick, APA rated exposure sheathing,

square edged. Butt ends not blocked.

5. Felt Paper One ply Type 30. Side and end laps to be per manufacturer’s recommendations. Attached to plywood deck with staples

in a random spacing.

PPL-6

6. Supports (Joists) Joists spaced max 2 ft, 0 in. OC. Any of the following types may be used to support the plywood decking:

A. Nom 2 by 6 in. wood joists No. 2 grade S-P-F, Hemlock Fir, Douglas Fir, Southern Pine or equivalent.

B. Wood trusses with a nom 2 by 4 in. upper chord of the same grade as Item A.

C. No. 22 MSG min cold formed steel (min yield strength to be 33,000 psi.)

Refer to General Information Roof Deck Construction, (Roofing Materials and Systems Directory) for items not evaluated.

*Bearing the UL Classification Marking

U

®

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

Underwriters Laboratories Inc. ®

L

LISTED

Loading...

Loading...