Metal Sales Magna-Loc 180 User Manual

MAGNA-LOC

Table of ConTenTs

Product Page No.

Panel Information

Magna-Loc Panel Proles ................................... PML-2

Panel Overview ................................................... PML-2

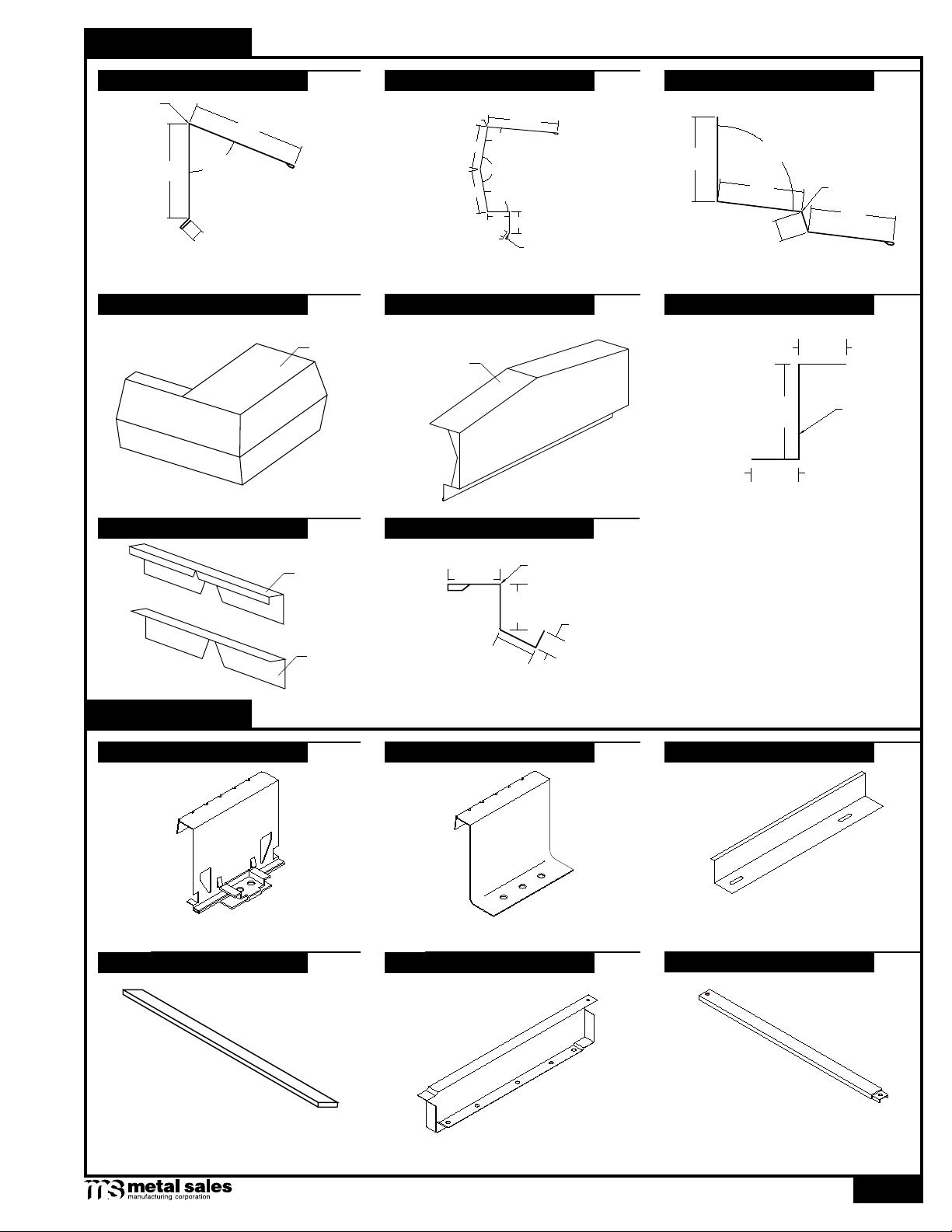

Flashing Proles

Eave .................................................................... PML-3

Magna-Loc Sculptured Eave ............................... PML-3

Cleat .................................................................... PML-3

Offset Cleat ..........................................................PML-3

Box Gutter ........................................................... PML-3

Box Gutter End .................................................... PML-3

Magna-Loc Sculptured Gutter ............................. PML-3

Magna-Loc Sculptured Gutter End ...................... PML-3

Universal Gutter/Downspout Strap ...................... PML-3

6" x 4" Downspout ............................................... PML-3

6" x 4" 95° Elbow ................................................. PML-3

Downspout Bracket ............................................. PML-3

Gutter Drip ........................................................... PML-3

Valley ...................................................................PML-3

SSR 4.5" Drop Valley...........................................PML-3

SSR 9" Drop Valley..............................................PML-4

Rake .................................................................... PML-4

SSR Sculptured Rake (On Module)..................... PML-4

SSR Sculptured Rake (Off Module) .....................PML-4

SSR Sculptured Rake End .................................. PML-4

SSR Rake Cleat .................................................. PML-4

SSR Rake Slide ................................................... PML-4

SSR Rakewall...................................................... PML-4

Counter Flashing ................................................. PML-4

Reglet Flashing.................................................... PML-4

Expansion Joint Flashing..................................... PML-4

20" Ridge/Hip Cover ............................................ PML-4

SSR Ridge ........................................................... PML-4

Vented Ridge Cover ............................................PML-4

Vent Drip ..............................................................PML-4

Peak .................................................................... PML-5

SSR Sculptured High Side Eave ......................... PML-5

SSR High Side Pitch Break ................................. PML-5

SSR Sculptured Corner Box ................................ PML-5

SSR Sculptured Peak Box................................... PML-5

Magna-Loc Z-Closure .......................................... PML-5

Magna-Loc Rib Cover.......................................... PML-5

SSR Gutter Support............................................. PML-5

Product Page No.

Testing Information

UL 580 Wind Uplift Information (506) ..................PML-7

UL 580 Wind Uplift Information (506A) .............PML-8-9

UL 580 Wind Uplift Information (506B) ......... PML-10-11

UL 263 Fire Resistance Information .................. PML-11

Section Properties & General Information ....PML-12-13

Design/Installation Considerations

Ventilation ..........................................................PML-14

Insulation .......................................................... PML-14

System Expansion/Contraction ......................... PML-15

Selection of System Components ..................... PML-15

Factory Prepunch and Notching ........................ PML-16

Seaming Panels ...........................................PML-17-18

Detail Conditions

Sculptured Eave Detail ...................................... PML-19

Sculptured Gutter Detail .................................... PML-20

4.5" Drop Valley Detail .......................................PML-20

9" Drop Valley Detail ..........................................PML-21

Endlap Detail ..................................................... PML-22

SSR Sculptured Rake (On Module) Detail ........ PML-22

SSR Sculptured Rake (Off Module) Detail ........PML-23

Rakewall (On Module) Detail ............................. PML-24

Rakewall (Off Module) Detail ............................. PML-24

Expansion Joint Detail ....................................... PML-25

Endwall with Wall Panel Detail ..........................PML-25

Sculptured High Side Eave Detail ..................... PML-26

Vented Ridge Detail ...........................................PML-26

SSR Ridge Detail............................................... PML-27

20" Ridge/Hip Detail .......................................... PML-28

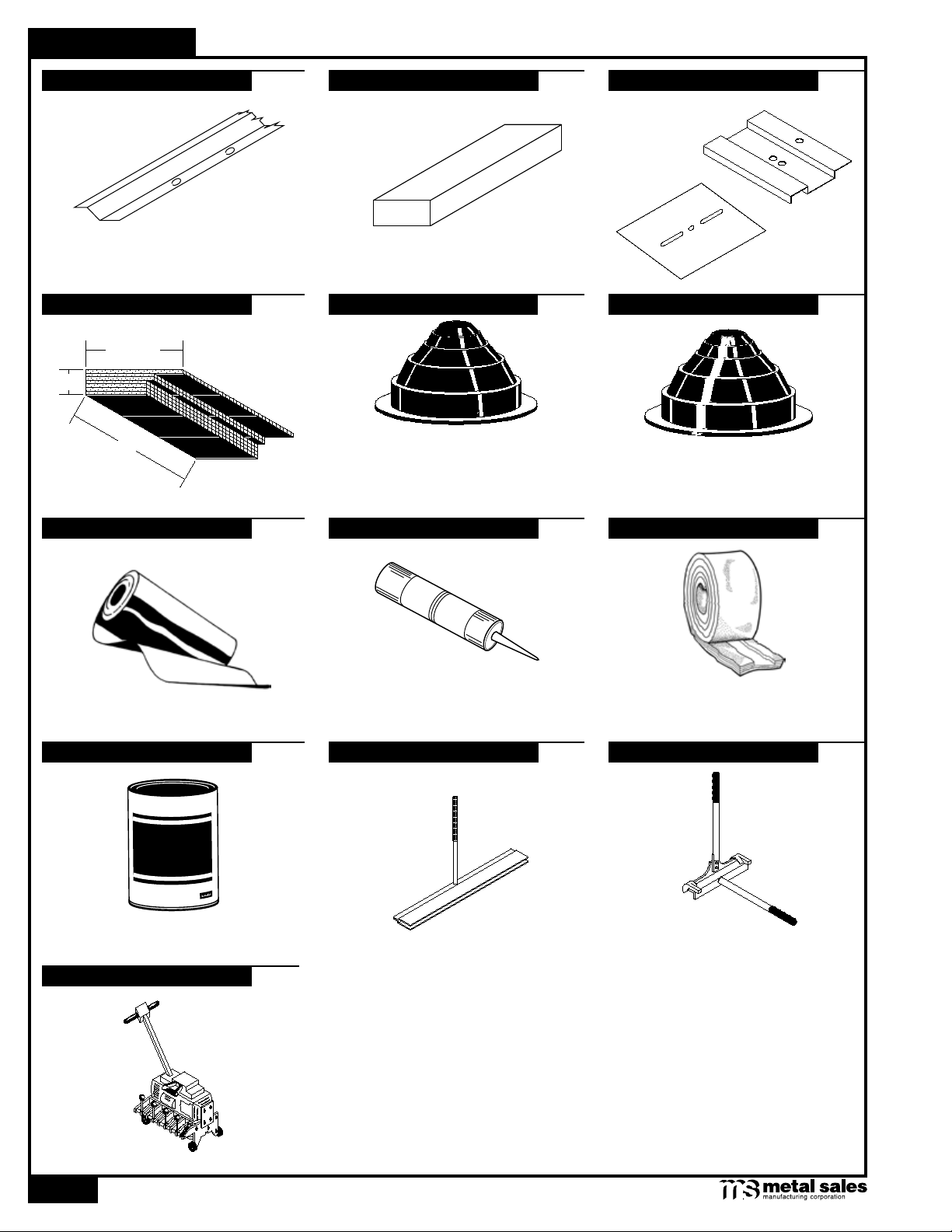

Accessory Proles

Magna-Loc Clip (Floating) ................................... PML-5

Magna-Loc Clip (Fixed) ....................................... PML-5

Floating Rake Zee ............................................... PML-5

Endlap Pad .......................................................... PML-5

End Dam.............................................................. PML-5

Back-Up Channel ................................................ PML-5

Eave Plate ........................................................... PML-6

Thermal Block...................................................... PML-6

Bearing Plates ..................................................... PML-6

Vent Material........................................................PML-6

Rubber Roof Jack ................................................ PML-6

Retro Roof Jack ................................................... PML-6

Rubber Roof Flashing Kit .................................... PML-6

Tube Sealant .......................................................PML-6

Tape Sealant........................................................ PML-6

Touch-Up Paint .................................................... PML-6

Metal Panel Hemming Tool ..................................PML-6

Hand Crimper ...................................................... PML-6

Mechanical Seamer ............................................. PML-6

Specications

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

PML-1

MAGNA-LOC

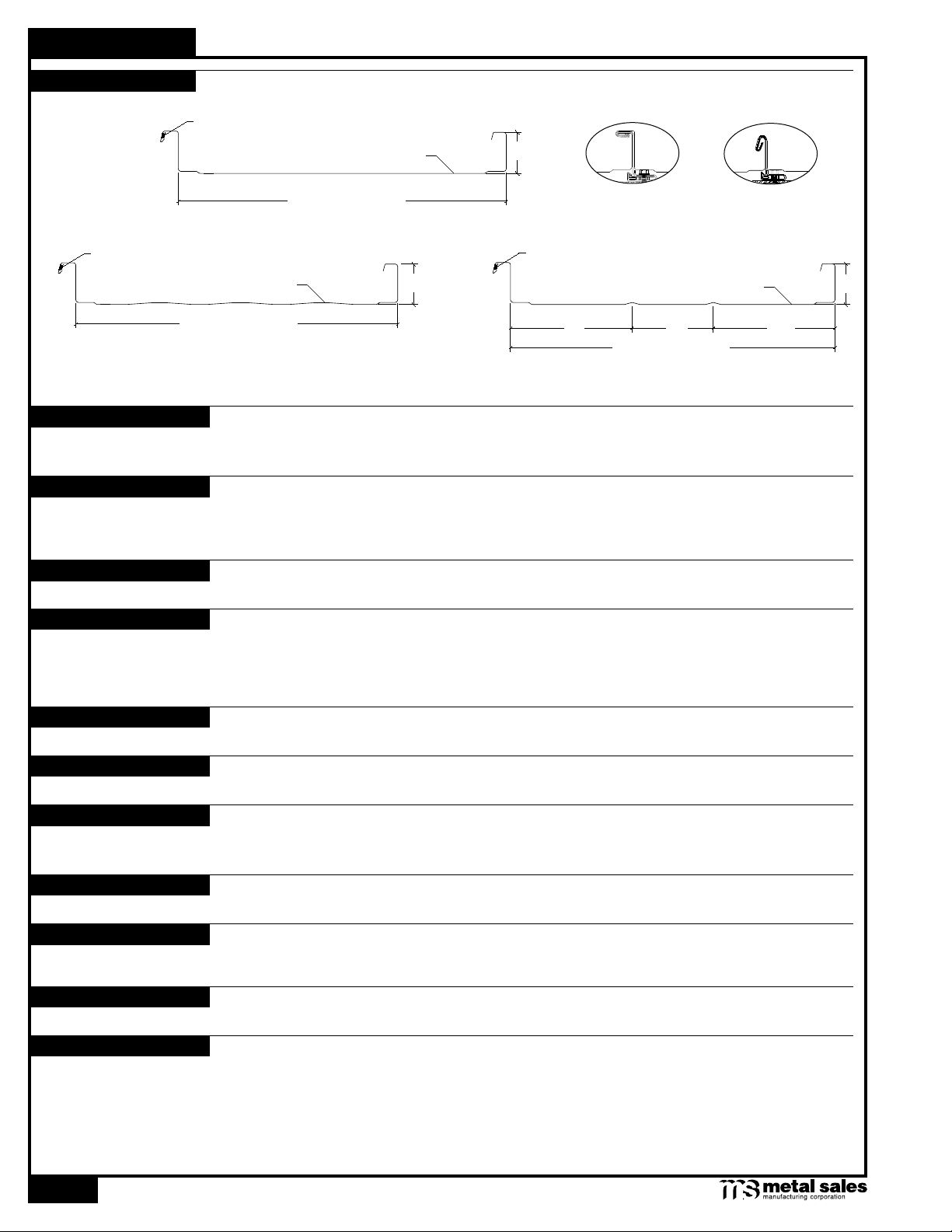

PANEL PROFILES

Panel overview

Factory Applied Sealant

Factory Applied Sealant

SLOPE

SUBSTRATE

COVERAGE

2"

90° Seam 180° Seam

Factory Applied Sealant

6"

16" or 18" Coverage

C

4"

(Pencil Ribs)

16" or 18" Coverage

(Striated)

16" or 18" Coverage

(Flat)

C

C

2"

The minimum recommended slope for any Magna-Loc roong panel is 1/2:12, where valley conditions exist the

recommended minimum slope is 3:12.

Magna-Loc is designed to be utilized over open structural framing, but can easily be used with a solid substrate.

The recommended solid substrate is

5

/8" plywood with a 30 pound felt moisture barrier. To avoid panel distor-

tion, use a properly aligned and uniform substructure.

Magna-Loc panels are available in 16" and 18" coverage with a 2" rib height.

2"

6"

LENGTH

AVAILABILITY

APPLICATION

PERFORMANCE TEST

FASTENING SYSTEM

FASTENERS

MATERIALS

FINISH

Lengths under 5'-0" on panels with striations and lengths under 7'-0" for at or pencil ribbed panels are available with some cutting restrictions. Maximum recommended panel length is 45'-0". Longer panels require

additional consideration in packaging, shipping, and erection. Please consult your Metal Sales branch for

recommendations (see PGI-2 and 3 for locations).

Magna-Loc panels are available in 24 and 22 gauge. Minimum quantities may apply.

Commercial, Industrial, and Architectural panel.

FM 1-90, UL 580, ASTM E 1592, ASTM E 1646, ASTM E 1680, UL 790, UL 2218,

and Florida Building Code (FBC).

Concealed Clip System (oating or xed).

The fastener selection guide should be consulted for choosing proper fasteners for specic applications. Quan-

tity and type of fastener must meet necessary loading and code requirements (see PGI-12-14).

Steel grade 50, per ASTM A-792

*

Acrylic Coated Galvalume® (ACG) / ASTM A-792 - AZ55

Pre-painted Galvalume / ASTM A-792 - AZ50

**Fluorocarbon (PVDF)

* Differential appearance of Acrylic Coated Galvalume roong materials is not a cause for rejection.

** Meets both Kynar 500 and Hylar 5000 specications.

PML-2

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

MAGNA-LOC

flashing Profiles

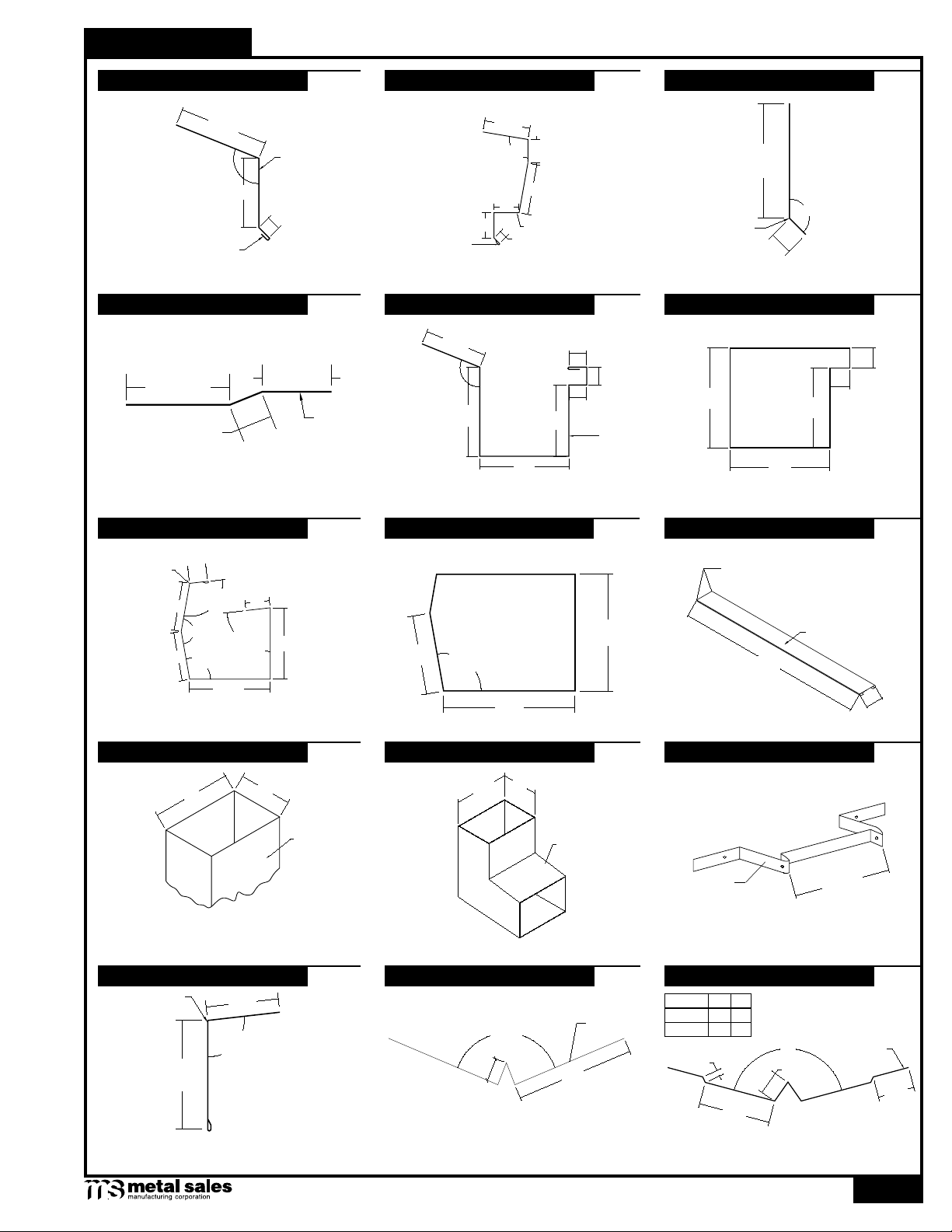

EAVE

MAGNA-LOC CLEAT

SCULPTURED EAVE

7

3

/8"

C

X*

3"

5

/8"

Hem

Length 10'-2" - *Specify Slope Angle

Hem

Length 10'-2", 20'-3" - *Specify Slope Angle

2"

35/8"

2"

X*

17/8"

1

/2"

2

4"

135°

C

5

/8"

C

1

/2"

Length 10'-2"

OFFSET CLEAT BOX GUTTER BOX GUTTER END

1

/2"

3

1

/2"

1

1

/2"

Length 10'-2"

1"

C

Length 10'-2", 20'-3" - *Specify Slope Angle

X*

5"

MAGNA-LOC MAGNA-LOC

SCULPTURED GUTTER

1

1

C

/2"

SCULPTURED GUTTER END

5"

4"

Hem

1"

1"

5"

C

5"

UNIVERSAL GUTTER/

DOWNSPOUT STRAP

Hem

1"

1"

4"

2"

A*

4"

4"

160°

100°

B*

D*

4"

100°

65/8"

5

6

*Specify Slope Angle For A and B, and Length for D.

Length 10'-2", 20'-3"

/8"

DOWNSPOUT 6" x 4" 950 ELBOW 6" x 4"

6"

Length 10'-2", 20'-3"

(Also available 4" x 31/2")

4"

C

(Also available 4" x 31/2")

6"

4"

VALLEYGUTTER DRIP SSR 4.5" DROP VALLEY

C

41/2"

X*

3"

X*

2"

C

10"

7

5

/8"

C

16"

11/2"

DOWNSPOUT BRACKET

C

(Also available 4")

SYSTEM

C

LOW

HIGH

A B

3

/8" 41/2"

13/8" 31/2"

X*

A

1

/2"

4

1

1

6"

C

/2"

B

Length 10'-2", 20'-3" - *Specify Slope Angle

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

Length 10'-2", 20'-3" - *Specify Slope AngleLength 10'-2" - *Specify Slope Angle

PML-3

MAGNA-LOC

flashing Profiles (ConT.)

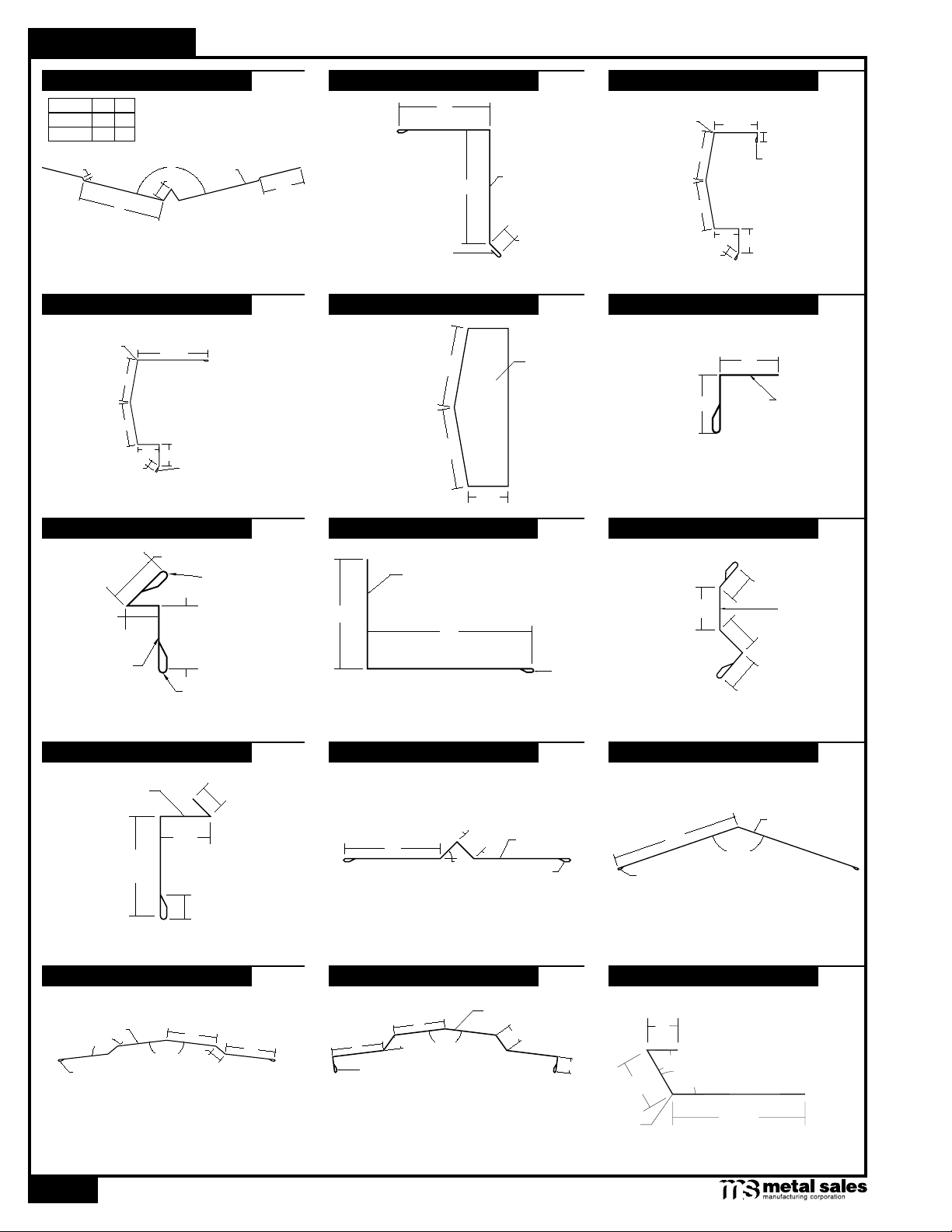

SSR 9" DROP VALLEY RAKE SSR SCULPTURED RAKE

SYSTEM

LOW

HIGH

A

A B

3

/8" 10"

13/8" 9"

X*

1

/2"

C

B

1

9"

Length 10'-2", 20'-3" - *Specify Slope Angle

4"

C

5"

Hem

Length 10'-2", 20'-3"

5

/8"

(ON MODULE)

C

100°

4"

160°

4"

100°

5

/8"

Length 10'-2", 20'-3"

31/2"

2"

3

Hem

2"

/4"

SSR SCULPTURED RAKE SSR SCULPTURED

(OFF MODULE) RAKE END

C

61/2"

100°

100°

4"

C

SSR RAKE CLEAT

1"

4"

160°

4"

100°

2"

2"

5

/8"

Length 10'-2", 20'-3"

Hem

4"

160°

100°

2"

1"

Length 10'-2"

C

SSR RAKE SLIDE SSR RAKEWALL COUNTER FLASHING

3

/4"

C

5

1"

6"

Hem

Length 10'-2"

/8"

3

/4"

3

/4"

20" RIDGE /HIP COVER

1

/2"

1"

C

Hem

Length 10'-2" Length 10'-2"

REGLET FLASHING

C

Hem

1

/2"

4"

EXPANSION JOINT

FLASHING

C

1"

2"

Hem

Length 10'-2"

SSR RIDGE

C

135°

Hem

Length 10'-2", 20'-3" - *Specify Slope Angle

PML-4

4"

1"

X*

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

4"

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

4"

Length 10'-2"

1"

45°

C

Hem

VENTED RIDGE COVER

3"

1"

3"

X*

Hem

Length 10'-2", 20'-3" - *Specify Slope Angle

C

1

1

/8"

7

C

10"

X*

Hem

Length 10'-2", 20'-3" - *Specify Slope Angle

VENT DRIP

3

/4"

/8"

60°

120°

1

/4"

1

C

31/4"

Length 10'-2"

MAGNA-LOC

flashing and aCCessory Profiles (ConT.)

PEAK

C

6"

X*

5"

3

/8"

Length 10'-2", 20'-3" - *Specify Slope Angle Length 10'-2", 20'-3" - *Specify Slope Angle

SSR SCULPTURED

HIGH SIDE EAVE

C

61/2"

X*

4"

160°

4"

100°

2"

2"

5

/8"

Hem

Length 10'-2", 20'-3" - *Specify Slope Angle

SSR SCULPTURED SSR SCULPTURED

CORNER BOX

C

PEAK BOX

SSR HIGH SIDE

PITCH BREAK

4"

X*

C

4"

1"

4"

MAGNA-LOC Z-CLOSURE

1"

C

2"

C

1"

Length 10'-2"

MAGNA-LOC RIB-COVER

SSR GUTTER SUPPORT

Magna-loC

MAGNA-LOC CLIP

Height 2

ENDLAP PAD

3

/8", 33/8"

C

C

a

CCessory Profiles

MAGNA-LOC CLIP FLOATING RAKE ZEE

(FIXED)(FLOATING)

END DAM BACK-UP CHANNEL

1"

Height 21/8", 23/8"

C

7

/8"

3

/4"

Length 10"

3

/8"

C- Indicates color side of flashing.

Length 10'-0"

Height 2", 23/8", 33/8"

Galvanized

1

/2" x 3/32" x 20" - (16" Panel)

1

11/2" x 3/32" x 261/4" - (18" Panel)

Butyl - Gray

16" or 18"

Galvanized or Painted

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

Length 48" and 72"

Galvanized

PML-5

MAGNA-LOC

aCCessory Profiles (ConT.)

EAVE PLATE THERMAL BLOCK

Length 10'-0"

3

/8", 13/8"

Height

Galvanized

1" x 3" x 24" - (18" Panel)

1" x 3" x 16" - (16" Panel)

Polystyrene Foam

VENT MATERIAL RUBBER ROOF JACK

33/8"

7

/8"

1

/4" to 11/8" O.D. Pipe)

4"

MINI (

#2 (13/4" to 3" O.D. Pipe)

#4 (3" to 6" O.D. Pipe)

#6 (6" to 9" O.D. Pipe)

#8 (7" to 13" O.D. Pipe)

BEARING PLATES

Magna-Loc

Low Bearing Plate

RETRO ROOF JACK

RETRO

#801

#802

#803

(3/4" to 23/4" O.D. Pipe)

RETRO

(2" to 71/4" O.D. Pipe)

RETRO

(31/4" to 10" O.D. Pipe)

RUBBER ROOF TUBE SEALANT TAPE SEALANT

FLASH KIT

Bearing Plate

4" X 5"

12" x 50'-0" Flash Kit

18" x 50'-0" Flash Kit

TOUCH-UP PAINT

Available in Pints or 2 oz Bottles

PVDF / MS Colorfast45

MECHANICAL SEAMER

7

10.3 oz. Cartridge

Urethane

/8" X 3/16" X 25'

Double Bead

Butyl - Gray

METAL PANEL HAND CRIMPER

HEMMING TOOL

PML-6

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

MAGNA-LOC

Ul 580 wind UPlifT inforMaTion

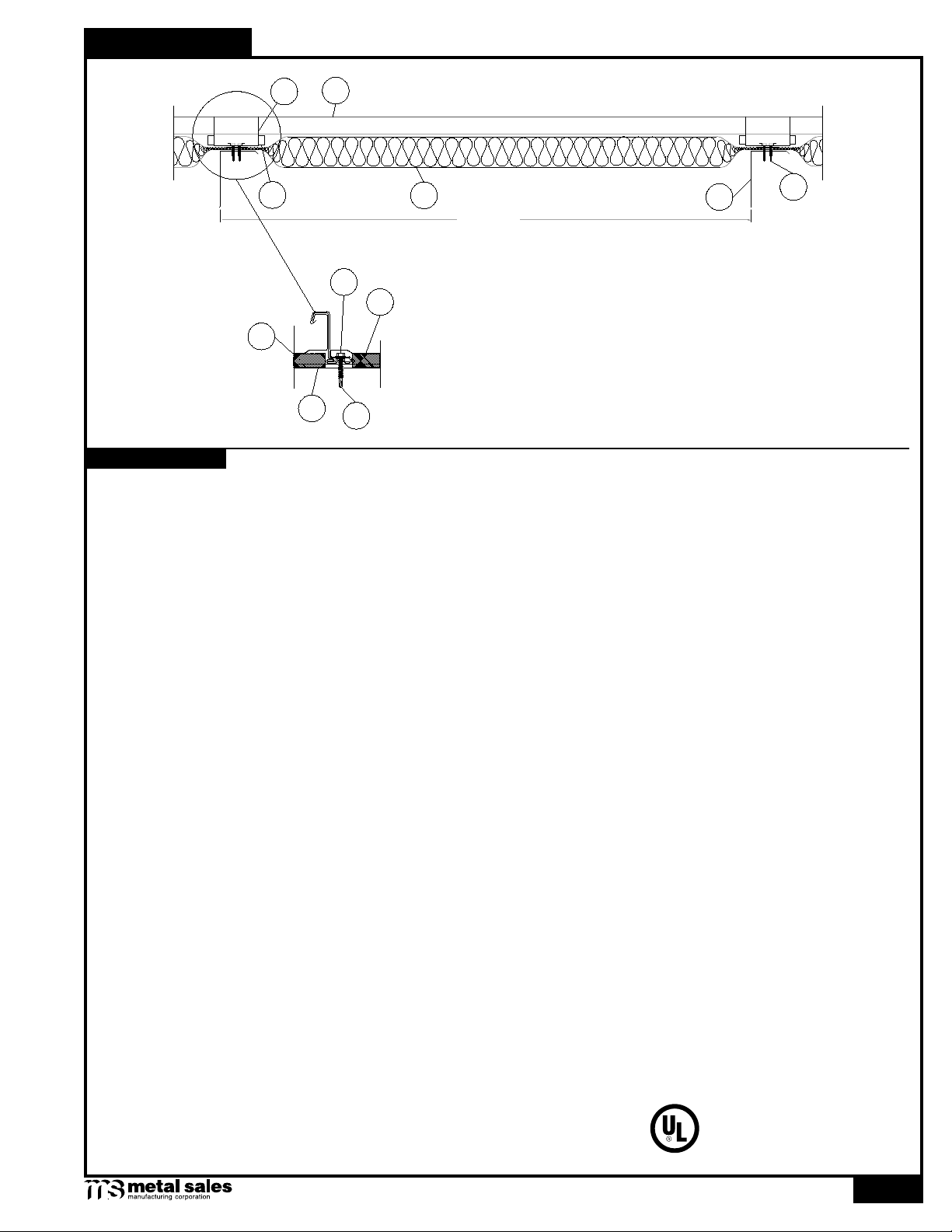

MAGNA-LOC

Construction No. 506

October 16, 2001

Uplift - Class 90

Fire Not Investigated

2

4

4

1. Metal Roof Deck Panels* No. 24 MSG min thick coated steel. Panel width, max 18 in., min 12 in.; rib height 2 in. Panels continuous over two or more spans. The panel flat area may have optional striations or minor corrugations placed at various locations in the

panel flat area beginning min of 2 in. from side ribs. The upper flange of the panel rib may be horizontal, or optionally formed down

to form an angle of 0 degree to 90 degree between the vertical segment and the top flange of the rib. End lap to occur adjacent to and

within 12 in. of purlin (Item 6) with panels overlapped 2 in. min. An end lap back-up-plate (Item 2A) to be used. A bead of sealant

may be used at panel end laps and side ribs. Ribs to be seamed with an electric or hand seaming tool to form a flange with a tight hem.

Seaming process to include the upper portion of the Panel Clips (Item 2).

METAL SALES MANUFACTURING CORPORATION - “Magna-Loc 18”, “Magna-Loc 16”

1

5

60" MAX

2

1

5

6

6

3

2. Roof Deck Fasteners* (Panel Clips) Located at side of panels over purlins (Item 6). (Max spacing 60 in. OC). When wood thermal

block (Item 4A) is used, clips to be located on top. Either of the following:

Fixed Clip (Not Shown) - One piece assembly fabricated from No. 22 MSG min thick steel, 3-1/2 in. wide.

Floating Clip - Two piece assembly with a base fabricated from No. 16 MSG min thick steel, 2 in. wide and a top fabricated

from No. 22 MSG min thick steel, 4-5/16 in. wide.

2A. End Lap Back-Up-Plate (Not shown) - No. 16 MSG min thick coated steel channel, 3 in. wide with two 3/8 in. deep legs. Max

length 74 in. Located under the panel end lap (50 ksi min yield strength).

2B. Roof Deck Fasteners*(Cinch Plate) (Optional) - (Not Shown) - width 1-5/16 in., length 18 in. max. Fabricated from No. 20 MSG

min thick stainless steel. Located over end lap.

2C. End Lap Back-Up-Plate (Optional) - (Not shown) - No. 16 MSG min thick coated steel. Width 11, 13 or 19 in., length 7 in. Two

3/4 in. by 3/4 in. tabs and a 1 in. deep vertical leg located at upslope edge of panel. Used with Item 2A when Item

*2B is not used (50 ksi min yield strength).

3. Fasteners (Screws) For panel clip-to-purlin attachment to be No. 1/4-14 by min 1 in. long self drilling, self-tapping hex-washer head plated steel screws. Two fasteners used per clip. Fasteners used at end lap to be one of the following: No. 1/4-14 by 1 in. long

Type AB point, self-drilling, self-tapping hex-washer-head plated or stainless steel screws or No. 12-14 by 1-1/4 in. long self-drilling

self-tapping hex-washer-head plated steel screws. Spacing for 16 in. wide panels to be a 1, 3, 4, 4, 3 in. pattern; spacing for 18

in. wide panels to be a 1-1/2, 3-1/2, 4, 4, 3-1/2, 1-1/2 in. pattern. When optional cinch plate (Item 2B) is used, four fasteners to be

required, inserted into factory punched guide holes.

4. Thermal Spacer (Optional) - Polyisocyanurate - 3/8 in. min, 2-3/8 in. max thick, 4 in. min width, length sized to fit between

panel clips (Item 2).

5. Insulation (Optional) - Any compressible blanket insulation 8 in. max thick before compression, or 6 in. max thick when

located between Thermal Spacer (Item 4) or Thermal Block (Item 4A) and purlin (Item 6).

6. Purlins No. 16 MSG min thick steel ( 50 ksi min yield strength ). Max spacing 60 in. OC.

Refer to General Information, Roof Deck Constructions for items not evaluated.

*Bearing the UL Classification Mark

Underwriters Laboratories Inc. ®

LISTED

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

PML-7

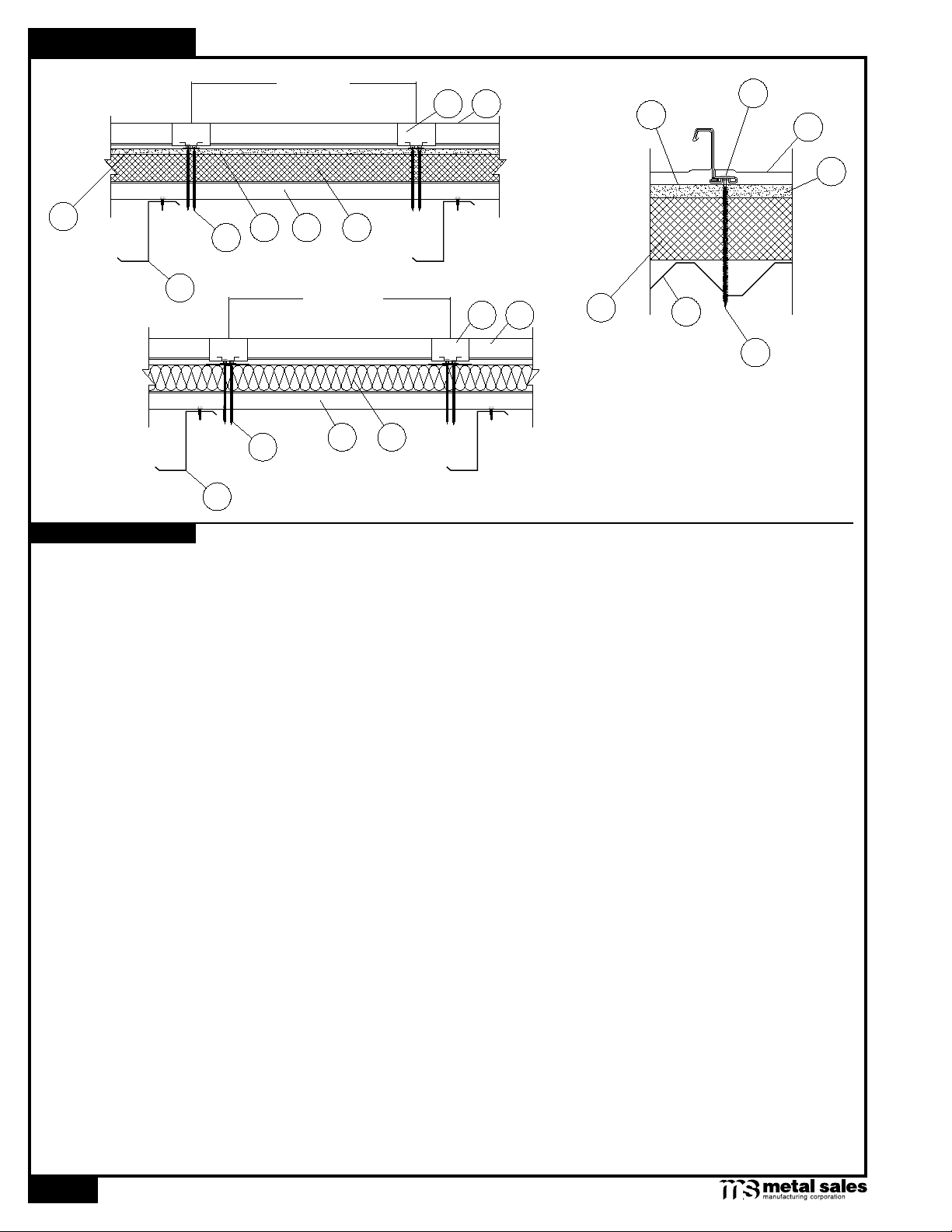

MAGNA-LOC

Ul 580 wind UPlifT inforMaTion (ConT.)

4

MAGNA-LOC

Construction No. 506A

October 16, 2001

Uplift - Class 90

Fire Not Investigated

See Item 2

1

2

3

6a

9

6a

9

1. Metal Roof Deck Panels* No. 24 MSG min coated steel. Max panel width 18 in.; min 12 in. Rib height 2 in. Panels

continuous over three or more clips (Item 2). The panel flat area may have optional striated or minor ribs placed at various

locations in the panel flat area beginning min of 2 in. from side ribs. The upper flange of the panel rib may be horizontal, or

optionally formed down to produce an angle of 0 to 90° between the vertical segment and the top flange of the rib. Panel end

lap 2 in. min. An end lap back-up plate (Item 2A) to be used at panel end lap. A bead of sealant may be used at panel end lap

and side ribs. Ribs to be seamed with an electric or hand seaming tool to form a flange with a tight hem. Seaming process to

include the upper portion of the panel clips (Item 2) .

METAL SALES MANUFACTURING CORPORATION - “Magna-Loc 16”, “Magna-Loc 18”

8

5

See Item 2

8

5a

1

2

5

4

8

2

6a

1

3

2. Roof Deck Fasteners* - (Panel Clips) Located at side of panels (Item 1) over substructure (Item 3, 3A, 3B or 3C) and

fastened through substructure to liner panel (Item 8) with max spacing of 48 in. OC or over sub-purlins (Item 7) with max spacing of 48 in. OC; or when panel clips are fastened directly to plywood (Item 3B) as described in Item 6B, max spacing to be

36 in. OC.

Fixed Clip (Not Shown) - One piece assembly fabricated from No. 22 MSG min thick steel, 3-1/2 in. wide.

Floating Clip Two piece assembly with a base fabricated from No. 16 MSG min thick steel, 2 in. wide and a tab fabricated

from No. 22 MSG min thick steel, 4-1/4 in. wide.

2A.End Lap Back-Up Plate (Not Shown) - No. 16 MSG min thick coated steel channel, 3 in. wide with two 3/8 in. deep legs.

Max length 74 in. Located under the panel (Item 1) end lap (50 ksi min yeild strength).

2B.End Lap Back-Up-Plate (Optional) (Not Shown) - No. 16 MSG min thick coated steel. Width 11, 13 or 19 in., length 7 in.

Two 3/4 in. by 3/4 in. tabs and a 1 in. deep vertical leg located at upslope edge of panel (50 ksi min yield strength).

2C. Roof Deck Fasteners*(Cinch Plate)-(Optional)-(Not Shown) width 1-15/16 in., length 18 in. max. Fabricated from No. 20

MSG min thick stainless steel. Located over end lap.

3. Substructure - (Gypsum Board) (Optional) - Min thick 1/2 in. To be placed on top of either the liner panel (Item 8) or rigid

insulation (Item 5). Combined thickness of the gypsum board and rigid insulation not to exceed 4 in. All joints to be taped

with 2.5 in. wide joint tape.

3A. Substructure - (Plywood) (Optional) - (Not Shown) - Plywood decking, used in lieu of gypsum board (Item 3), to be nom

1/2 in. thick, exposure 1 sheathing, 40/20, CD. Located over rigid insulation (Item 5). Combined thickness of the plywood and

rigid insulation not to exceed 4 in.

3B. Substructure - (OSB) (Optional) - (Not Shown) - OSB decking, used in lieu of gypsum board (Item 3), to be nom 1/2 in.

thick. Located over rigid insulation (Item 5). Combined thickness of the OSB and rigid insulation not to exceed 4 in.

3C. Substructure - (Bearing Plate) (Optional) - Bearing plate to be used in lieu of gypsum board (Item 3) to be 4 by 4 in. by

No. 18 MSG min thick coated steel (33 ksi min yield strength). Used under each clip (Item 2) over rigid insulation (Item 5)

only when rigid insulation is located directly under panel (Item 1).

PML-8

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

MAGNA-LOC

MAGNA-LOC

Construction No. 506A (cont.)

October 16, 2001

Uplift - Class 90

Fire Not Investigated

Ul 580 wind UPlifT inforMaTion (ConT.)

4. Vapor Barrier (Optional) - Single ply, used between the substructure (Items 3, 3A or 3B) and panel (Item 1). To be min 30 lb

roofing felt.

5. Foamed Plastic - (Rigid Insulation) (Optional) Max thickness 3-1/2 in. when gypsum board (Item 3), plywood (Item 3A)

or OSB (Item 3B) is used and 6 in. when bearing plates (Item 3C) are used. Min bearing strength to be 20 psi. 1.8 pcf min

density.

5A. Insulation (Optional) - Compressible blanket insulation 8 in. max thickness before compression. Used with sub-purlins

(Item 7) only.

6. Fasteners - (Screws) Fasteners used to attach panel clips (Item 2) to sub-purlins (Item 7) to be No. 1/4-14 by 1 in. long selfdrilling, self-tapping, hex-washer-head, plated steel screws. Two fasteners per clip.

Fasteners used at end lap of panel (Item 1) to be one of the following: No. 1/4-14 by 1 in. long, Type AB point self-drilling,

self-tapping, hex-washer-head, plated or stainless steel screws or No. 12-14 by 1-14 in. long self-drilling, self-tapping, hexwasher-head, plated steel screws. Spacing for 12 in. wide panel to be 1, 3, 4, 4, 3, 1 in. pattern. Spacing for 16 in. wide panels

to be 1, 3, 4, 4, 3, 1 in. pattern; spacing for 18 in. wide panels to be 1-1/2, 3-1/2, 4, 4, 3-1/2, 1-1/2 in. pattern.

6A. Fasteners - (Screws) Fasteners used to attach panel clips (Item 2) through gypsum board, plywood, OSB, or bearing plate

(Item 3, 3A, 3B, or 3C, respectively) and foamed plastic (Item 5) into liner panel (Item 8) to be No. 12-13, No. 3 Phillips drive,

truss head, coated steel screws. Fastener length to penetrate liner panel min 1/2 in. Two fasteners per clip.

Note: The panel clips may be fastened directly to the bearing plate using two No. 10-16 by 1 in. long self-drilling, self-tapping, pancake head No. 2 Phillips drive coated steel screws. The panel clip/bearing plate combination is to be fastened to the

liner panel using two No. 12-13 truss head screws described above, inserted through guide holes in the bearing plates and into

the liner panel. Min penetration 1/2 in.

6B. Fasteners - (Screws) (Not Shown) - Fasteners used to attach plywood Substructure (Item 3A) through rigid insulation (Item

5) to liner panel (Item 8) to be No. 14-13, No. 3 Phillips drive truss head screws. Fastener length to penetrate liner panel min

1/2 in. Total of 33 fasteners per 4 by 8 ft plywood sheet to be used. Fasteners located in five rows along the 4 ft length in

a 3-9-12-12-9-3 in. pattern. The two outer rows are in a 3-9-12-12-12-12-12-12-9-3 in. pattern and the three center rows are

in a 2-21-24-24-21-3 in. pattern. All spacing from board edges. Fasteners used to attach panel clips (Item 2) to plywood (when

plywood is fastened to liner panel as indicated above) to be No. 10-12 by 1 in. long pancake head wood screw with No. 2 Phillips drive, or No. 10-12 by 1 in. long hex-head wood screw. Two fasteners per clip.

7. Sub-Purlin No. 16 MSG min thick coated steel (50 ksi min yield strength). Hat section, min 3/4 in. deep, 2 in. wide or Zee

section, 2 in. wide, flanges 2 in. deep. Max spacing between sub-purlins to be 48 in. OC.

Note: Screws used to attach sub-purlin to liner panel to be No. 12-13, No. 3 Phillips drive, truss head, coated steel. Max

fastener spacing to be 12 in. OC for Zee section with fasteners located in center of lower flange. For hat section, two screws,

spaced 24 in. OC, located at each side of channel to be used.

8. Liner Panel - (Steel Deck) No. 22 MSG min thick coated steel. Fabricated to various profiles (33 ksi min yield strength).

Steel deck depth and profile, support spacing (max 6 ft), method of positioning (end and side laps), and fastening of deck to

supports to be per deck manufacturer’s and local code requirements for uplift loading.

9. Liner Panel Supports - Purlins No. 16 MSG min thick steel (50 ksi min yield strength). Spacing to depend on design

considerations for uplift loading: max 6 ft, 0 in. OC.

Joists (Optional) - (Not Shown) - Open web steel joist having a min No. 16 MSG upper flange (50 ksi min yield strength) or

a min 1/8 in. thick upper flange ( 33 ksi min yield strength). Max spacing 6 ft, 0 in. OC. Refer to general information, Roof

Deck Construction, (Roofing Materials and System Directory) for items not evaluated.

*Bearing the UL Classification Mark

Underwriters Laboratories Inc. ®

LISTED

© Metal Sales Manufacturing Corporation/ Subject to change without notice/ Effective Date 9/11

800.406.7387 (Corporate Ofce) • www.metalsales.us.com

PML-9

Loading...

Loading...