Metal Sales Magna-Loc Installation

MAGNA-LOC

The application and detail drawings in this manual are strictly for illustration purposes and may not be applicable to all

building designs or product installations. All projects should conform to applicable building codes for that particular area.

It is recommended to follow all building regulations and standard industry practices.

Metal Sales Manufacturing Corporation is not responsible for the performance of the roof system if it is not installed in

accordance with the suggested instructions referenced in this manual. If there is a conict between this manual and the

approved Metal Sales' erection drawings, the approved erection drawings are to take precedence.

Prior to ordering and installing materials, all dimensions should be veried by eld measurements.

Oil canning is not a cause for rejection. Oil canning can be described as the amount of waviness found in the at

areas of metal panels. Oil canning is an inherent characteristic of light gauge cold formed metal products, particularly

those with broad at areas. There are many factors which may contribute to oil canning that Metal Sales is not able to

control. These factors include: misalignment of the support system, over driving of fasteners used on the panels, stress

(whether inherent in the panel or induced), thermal expansion and contraction of the panel, material handling, width,

gauge, length, color of panels, and installation. (Reference Metal Construction Association "Oil Canning Position Paper"

- Appendix A).

Metal Sales reserves the right to modify, without notice, any details, recommendations or suggestions. Any questions

you may have regarding proper installation of the Magna-Loc roong system should be directed to your Metal Sales

representative, (see pages 2 and 3).

Consult Metal Sales for any additional information not outlined in this manual.

This manual is designed to be utilized as a guide when installing Magna-Loc roong system.

It is the responsibility of the erector to ensure the safe installation of this product system.

IMPORTANT INFORMATION

SAFETY

STUDY APPLICABLE OSHA AND OTHER SAFETY REQUIREMENTS BEFORE

FOLLOWING THESE INSTRUCTIONS.

The installation of metal roof systems is a dangerous procedure and should be supervised

by trained knowledgeable erectors. USE EXTREME CARE WHILE INSTALLING ROOF

PANELS. It is not possible for Metal Sales to be aware of all the possible job site situations

that could cause an unsafe condition to exist. The erector of the roof system is responsible

for reading these instructions and determining the safest way to install the roof system.

These instructions are provided only as a guide to show a knowledgeable, trained erector

the correct parts placement one to another. If following any of the installation steps would

endanger a worker, the erector should stop work and decide upon a corrective action.

Provide required safety railing, netting, or safety lines for crew members working on

the roof.

Do not use the roof panel as a walking platform. The roof panels will not withstand the

weight of a person standing at the edge of the panel.

Do not stand on any part of a roof panel until the panel has been completely attached.

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

1

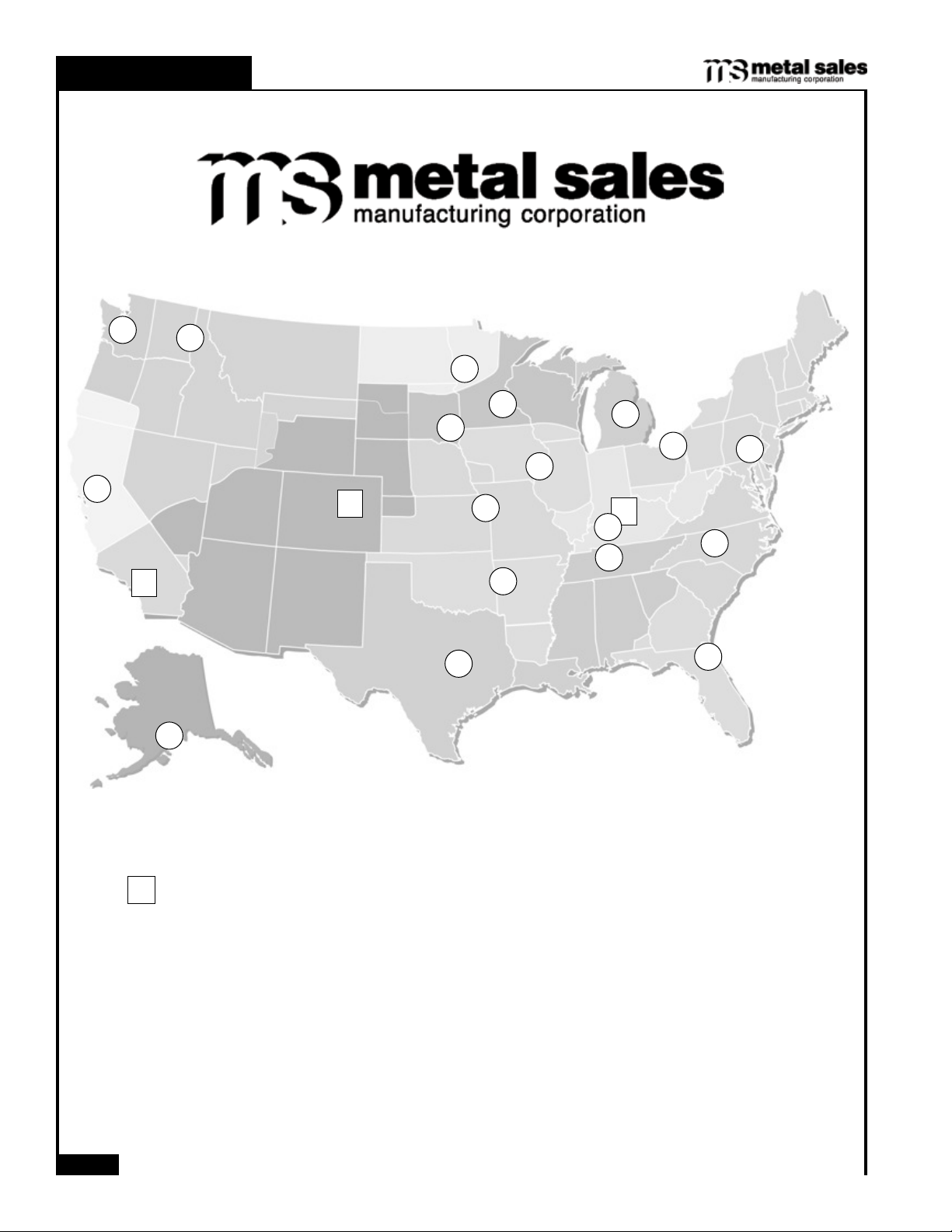

MAGNA-LOC

METAL SALES BRANCHES

14

9

15

16

8

18

6

21

11

1

4

20

13

10

17

3

5

7

12

19

2

NOTE: Shaded areas represent regions served by each location.

*

Indicates Metal Sales branch manufactures Magna-Loc Panels

Metal Sales offers a complete line of metal roof, wall, and fascia panel systems for the commercial,

architectural, industrial, residential, and agricultural markets. Metal Sales offers over 75 profiles with a

wide selection of widths, colors, and gauges - new construction or retrofit.

2

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

MAGNA-LOC

CUSTOMER SERVICE

1.) DENVER BRANCH

7990 E. I-25 Frontage Road

Longmont, CO 80504

303.702.5440 Phone

800.289.7663 Toll Free

800.289.1617 Toll Free Fax

2.) JACKSONVILLE BRANCH

7110 Stuart Avenue

Jacksonville, FL 32254

904.783.3660 Phone

800.394.4419 Toll Free

904.783.9175 Fax

800.413.3292 Toll Free Fax

3.) JEFFERSON BRANCH

352 East Erie Street

Jefferson, OH 44047

440.576.9070 Phone

800.321.5833 Toll Free

440.576.9242 Fax

800.233.5719 Toll Free Fax

4.) INDEPENDENCE BRANCH

1306 S. Powell Road

Independence, MO 64057

816.796.0900 Phone

800.747.0012 Toll Free

816.796.0906 Fax

5.) SELLERSBURG BRANCH

7800 State Road 60

Sellersburg, IN 47172

812.246.1866 Phone

800.999.7777 Toll Free

812.246.0893 Fax

800.477.9318 Toll Free Fax

6.) ROGERS BRANCH

22651 Industrial Blvd.

Rogers, MN 55374

763.428.8080 Phone

800.328.9316 Toll Free

763.428.8525 Fax

800.938.9119 Toll Free Fax

7.) NASHVILLE BRANCH

4314 Hurricane Creek Blvd.

Antioch, TN 37013

615.641.7100 Phone

800.251.8508 Toll Free

615.641.7118 Fax

800.419.4372 Toll Free Fax

8.) SPOKANE BRANCH

East 2727 Trent Avenue

Spokane, WA 99202

509.536.6000 Phone

800.572.6565 Toll Free

509.534.4427 Fax

9.) SEATTLE BRANCH

20213 84th Avenue, South

Kent, WA 98032

253.872.5750 Phone

800.431.3470 Toll Free (Outside WA)

800.742.7900 Toll Free (Inside WA)

253.872.2008 Fax

10.) NEW ALBANY BRANCH

999 Park Place

New Albany, IN 47150

812.944.2733 Phone

812.944.1418 Fax

11.) ROCK ISLAND BRANCH

8111 West 29th Street

Rock Island, IL 61201

309.787.1200 Phone

800.747.1206 Toll Free

309.787.1833 Fax

12.) DEER LAKE BRANCH

29 Pinedale Industrial Road

Orwigsburg, PA 17961

570.366.2020 Phone

800.544.2577 Toll Free

570.366.1648 Fax

800.544.2574 Toll Free Fax

13.) TEMPLE BRANCH

3838 North General Bruce Dr.

Temple, TX 76501

254.791.6650 Phone

800.543.4415 Toll Free

254.791.6655 Fax

800.543.4473 Toll Free Fax

14.) WOODLAND BRANCH

1326 Paddock Place

Woodland, CA 95776

530.668.5690 Phone

800.759.6019 Toll Free

530.668.0901 Fax

15.) FONTANA BRANCH

14213 Whittram Avenue

Fontana, CA 92335

909.829.8618 Phone

800.782.7953 Toll Free

909.829.9083 Fax

16.) ANCHORAGE BRANCH

4637 Old Seward Hwy.

Anchorage, AK 99503

907.646.7663 Phone

866.640.7663 Toll Free

907.646.7664 Fax

17.) BAY CITY BRANCH

5209 Mackinaw Road

Bay City, MI 48706

989.686.5879 Phone

888.777.7640 Toll Free

989.686.5870 Fax

888.777.0112 Toll Free Fax

18.) DETROIT LAKES BRANCH

1435 Egret Avenue

Detroit Lakes, MN 56501

218.847.2988 Phone

888.594.1394 Toll Free

218.847.4835 Fax

888.594.1454 Toll Free Fax

19.) MOCKSVILLE BRANCH

188 Quality Drive

Mocksville, NC 27028

336.751.6381 Phone

800.228.6119 Toll Free

336.751.6301 Fax

800.228.7916 Toll Free Fax

20.) FORT SMITH BRANCH

7510 Ball Road

Fort Smith, AR 72908

479.646.1176 Phone

877.452.3915 Toll Free

479.646.5204 Fax

21.) SIOUX FALLS BRANCH

2700 West 3rd Street, Suite 4

Sioux Falls, SD 57104

605.951.0367 Phone

888.902.8320 Toll Free

TECHNICAL SUPPORT

TECHNICAL SERVICES

545 South 3rd Street

Louisville, KY 40202

502.855.4300 Phone

800.406.7387 Toll Free

502.855.4290 Fax

800.944.6884 Toll Free Fax

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

3

MAGNA-LOC

Important Information ......................................................................................................... 1

Metal Sales' Locations ....................................................................................................... 2

Customer Service ............................................................................................................... 3

Table of Contents .........................................................................................................4 & 5

TABLE OF CONTENTS

Color Codes ..................................................................................................................... 6

Flashing Angle Chart ...................................................................................................... 7

Panel Profiles

90° Panel Profiles ................................................................................................. 8

180° Panel Profiles ............................................................................................... 9

180° Curved Panel Profiles ................................................................................ 10

Accessory Profiles .................................................................................................. 11-14

Flashing Profiles ...................................................................................................... 15-21

Fastener Selection Guide ............................................................................................. 22

Fastener Technical Information

Physical Properties ............................................................................................. 23

Pull Out Strength Values .................................................................................... 24

Pull Over Strength Values .................................................................................. 25

UL 580 Wind Uplift Information ............................................................................... 26-30

UL 263 Fire Resistance Rating ..................................................................................... 30

Section Properties and Load Tables ............................................................................ 31

Handling Material

Receiving Material ............................................................................................................ 32

General Handling ............................................................................................................. 32

Mechanical Handling ........................................................................................................ 32

Manual Handling .............................................................................................................. 33

Storage

General ............................................................................................................................ 34

Storage on Roof ............................................................................................................... 35

Foot Traffic ................................................................................................................... 36

Field Cutting and Touch-up

Field Cutting ..................................................................................................................... 37

Touch-up Paint ................................................................................................................. 37

Design / Installation Considerations

Fastener Installation Technique ........................................................................................38

Condition of Substructure ................................................................................................. 38

Ventilation ........................................................................................................................ 39

Insulation .......................................................................................................................... 39

System Expansion / Contraction ..................................................................................... 40

Selection of System Components ................................................................................... 40

Factory Notching and Prepunching ................................................................................... 41

Installation Procedure Overview ................................................................................. 42

Installation of Panel

Installation of Floating Rake Zee ...................................................................................... 43

Installation of Eave Plate .................................................................................................. 44

Installing First Panel ......................................................................................................... 45

Installing Panel Clips ......................................................................................................... 46

Endlapping of Panel ..................................................................................................... 47-48

Sidelapping of Panel .................................................................................................... 49-50

Termination of Panel ........................................................................................................ 51

Seaming Panels .......................................................................................................... 52-53

Installation of Panel Over Open Framing

Sculptured Eave .............................................................................................................. 54

Sculptured Gutter ............................................................................................................. 55

4.5" Drop Valley ................................................................................................................ 56

9" Drop Valley ................................................................................................................... 57

Endlap .............................................................................................................................. 58

SSR Sculptured Rake (On Module) ................................................................................. 59

SSR Sculptured Rake (Off Module) .................................................................................60

PAGE NO.General Information

4

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

MAGNA-LOC

TABLE OF CONTENTS (cont.)

Installation of Panel Over Open Framing (cont.)

Rakewall (On Module) ......................................................................................................61

Rakewall (Off Module) ......................................................................................................62

Expansion Joint ................................................................................................................ 63

Pitch Break With Wall Panel ............................................................................................64

Sculptured High Side Eave .............................................................................................. 65

SSR Ridge .......................................................................................................................66

20" Ridge / Hip Cover ......................................................................................................67

Vented Ridge ....................................................................................................................68

Installation of Panel Over Decking

Eave Offset ......................................................................................................................69

Box Gutter Offset .............................................................................................................70

Valley Offset ...................................................................................................................... 71

Rake (On Module) ............................................................................................................ 72

Rake (Off Module) ............................................................................................................ 73

Rakewall ...........................................................................................................................74

Peak ................................................................................................................................. 75

20" Ridge / Hip Cover Fixed .............................................................................................76

Vented Ridge ....................................................................................................................77

Installation of End Dam ................................................................................................ 78

Installation of Z-Closures ............................................................................................ 79

Clip Detail ...................................................................................................................... 80

Transition Detail ............................................................................................................ 81

Hemming Detail ............................................................................................................ 82

Roof Penetrations

General Notes ................................................................................................................... 83

Installation Notes............................................................................................................... 83

Care and Maintenance ................................................................................................. 84

Notes ............................................................................................................................ 85

PAGE NO.

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

5

MAGNA-LOC

When placing an order, be sure to include the description of the product being ordered along with its product number.

All product numbers consist of a minimum of seven (7) digits. You will notice throughout our price book that some

parts have a seven (7) digit number and others have ve (5) digits with two blanks. These two blanks are to be lled

in with a designated color code (see below for color codes).

See Metal Sales Color Guides for color and gauge selections.

For example: Magna-Loc Product Number 2835273 means this part is designated to be color code 73 (Patriot Red).

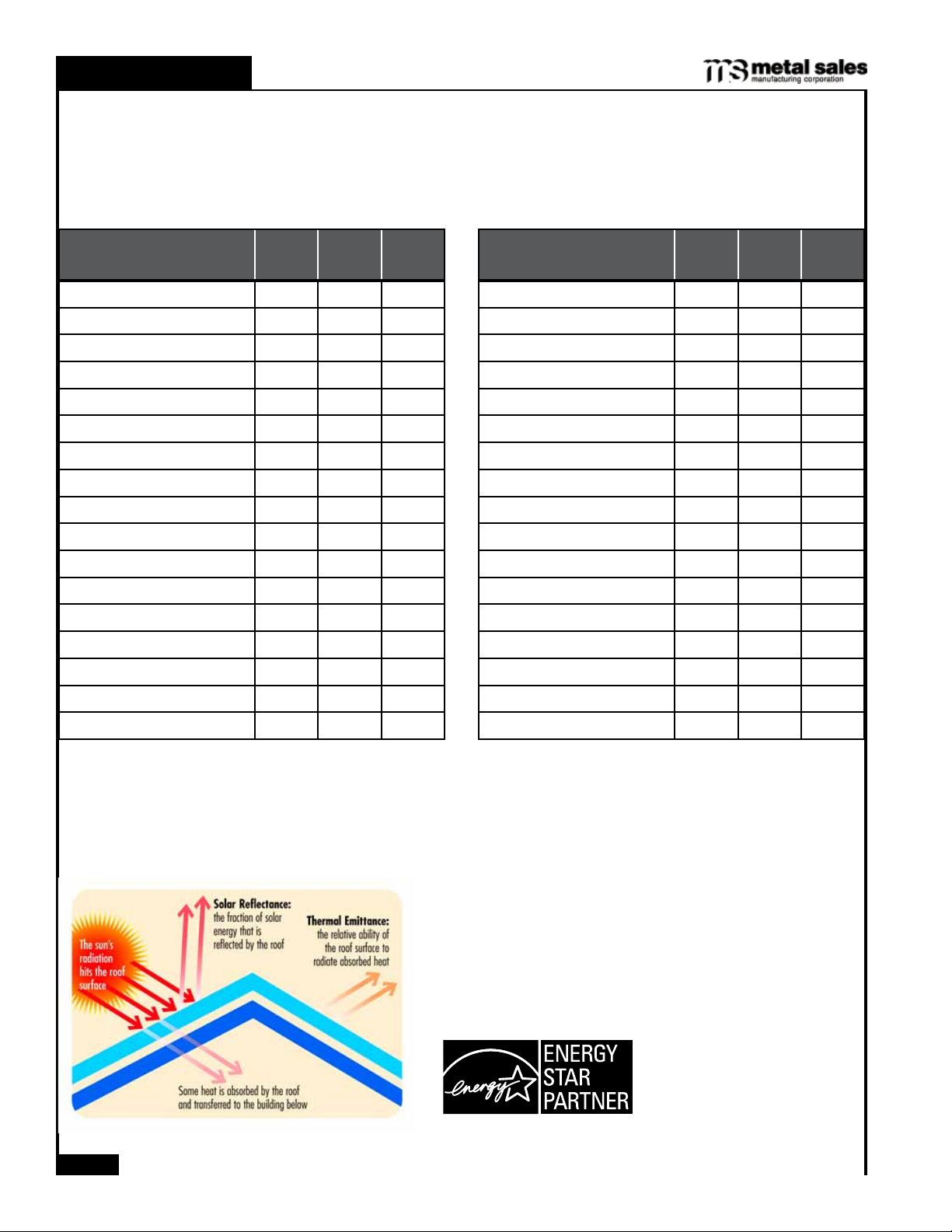

COLOR CODES

PVDF

(Kynar 500®) Color

Aged Copper (65) 0.32 0.85 32

Antique Patina (M1) 0.38 0.85 40

Ash Grey (25) 0.38 0.86 41

Brandywine (P8) 0.26 0.85 24

Champagne Metallic (168) 0.47 0.85 53

Classic Green (66) 0.32 0.86 33

Colonial Red (W75) 0.35 0.86 37

Copper Penny (W92) 0.45 0.85 50

Dark Bronze (50) 0.30 0.86 30

Felt Green (W66) 0.31 0.84 31

Galvalume (41) 0.67 0.14 56

Hemlock Green (M7) 0.36 0.85 38

Khaki (88) 0.35 0.87 37

Linen White (81) 0.73 0.86 89

Mansard Brown (133) 0.30 0.87 31

SR TE SRI

PVDF

(Kynar 500®) Color

Metallic Silver (K7) 0.60 0.77 68

Mistique Plus (W31) 0.34 0.82 34

Ocean Blue (35) 0.29 0.86 29

Old Town Grey (W25) 0.40 0.85 43

Old Zinc Grey (W29) 0.42 0.85 46

Parchment (W74) 0.41 0.86 45

Patina Green (W58) 0.46 0.85 51

Patriot Red (73) 0.46 0.86 52

Regal Blue (W35) 0.27 0.86 26

River Teal (59) 0.29 0.86 29

Sandstone (W51) 0.54 0.86 63

Slate Grey (W38) 0.30 0.85 30

Snowdrift White (W81) 0.65 0.85 78

Tahoe Blue (W71) 0.30 0.86 30

Taupe (74) 0.29 0.84 28

SR TE SRI

Matte Black (106) 0.27 0.86 26

Medium Bronze (H4) 0.30 0.87 31

SR = Solar Reectance

TE = Thermal Emittance

SRI = Solar Reectance Index

Terra Cotta (W72) 0.39 0.85 42

Weathered Copper (W50) 0.32 0.84 32

All Colors meet or exceed

Steep Slope ENERGY STAR

Requirements

6

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

MAGNA-LOC

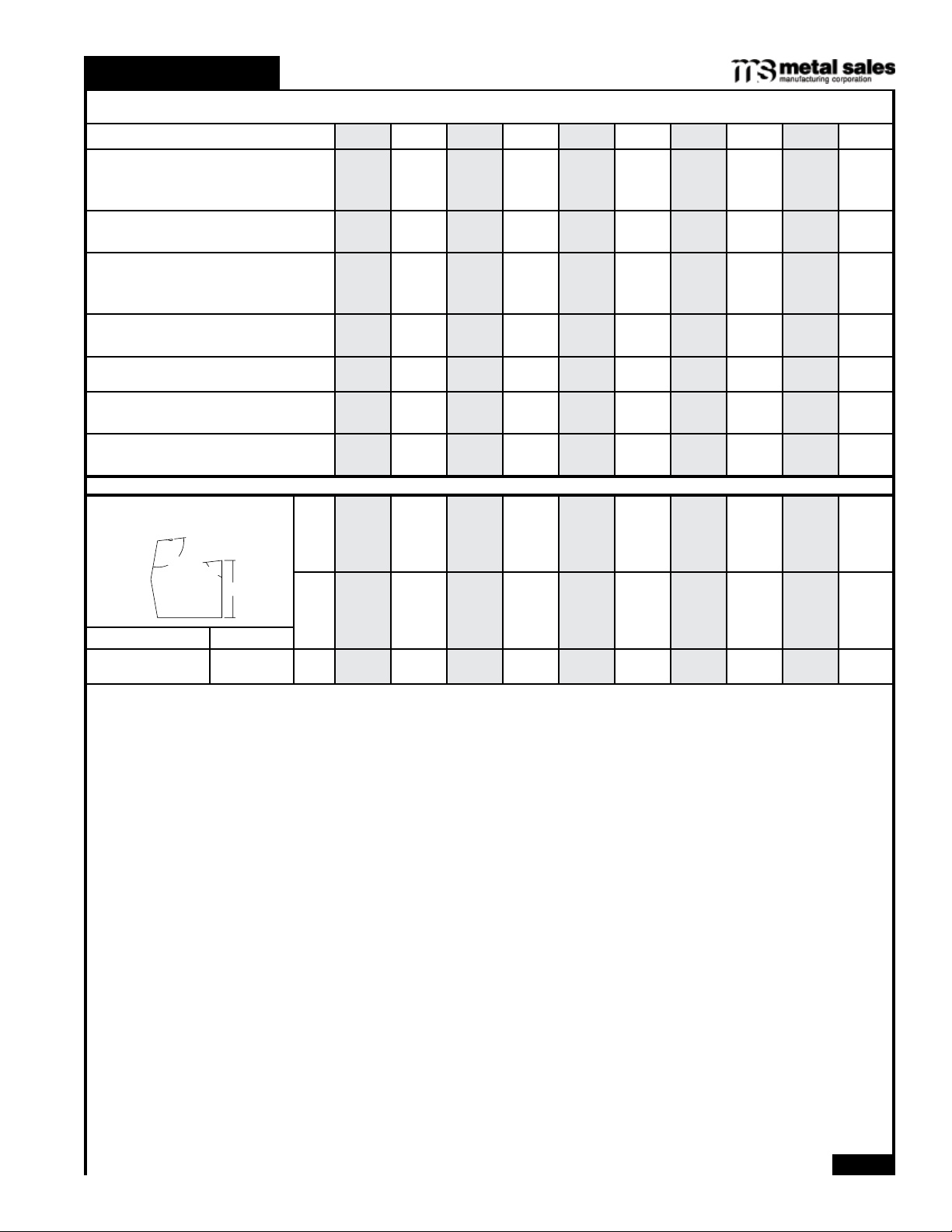

FLASHING ANGLE CHART

This chart should be used to determine the specied angle.

1

PROFILE/FLASHING

/4":121/2":12 1:12 2:12 3:12 4:12 5:12 6:12 7:12 8:12

RIDGE

SSR RIDGE

178° 175° 170° 161° 152° 143° *135° *127° *120° *113°

VENTED RIDGE COVER

HIP

VALLEY

178° 177° 173° 167° 160° 154° 148° 143° 138° 134°

EAVE

EXTENDED EAVE

91° 92° 95° 99° 104° 108° 113° 117° 120° 124°

SCULPTURED EAVE

SSR SCULPTURED

HIGH SIDE EAVE

99° 98° 95° 91° 86° 82° *77° *73° *70° *66°

PEAK 89° 88° 85° 81° 76° 72° 67° 63° 60° 56°

PITCH BREAK

HIGH SIDE PITCH BREAK

GUTTER DRIP

BOX GUTTER

91° 92° 95° 99° 104° 108° 113° 117° 120° 124°

91° 92° 95° 99° 104° 108° 113° 117° 120° 124°

SSR SCULPTURED

GUTTER

4"

A

4"

PROFILE RIB HT.

B

C

A 101° 102° 105° 109° 114° 118° 123° 127° 130° 134°

B 89° 88° 85° 81° 76° 72° 67° 63° 60° 56°

MAGNA-LOC 2" C 55/8" 53/4" 6" 61/2" 7" 71/2" 8" 81/2" 9" 91/2"

*Note: Metal Sales standard flashing dimensions may not accomodate all situations, please inquire about custom flashings with slopes 6:12 or greater.

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

7

MAGNA-LOC

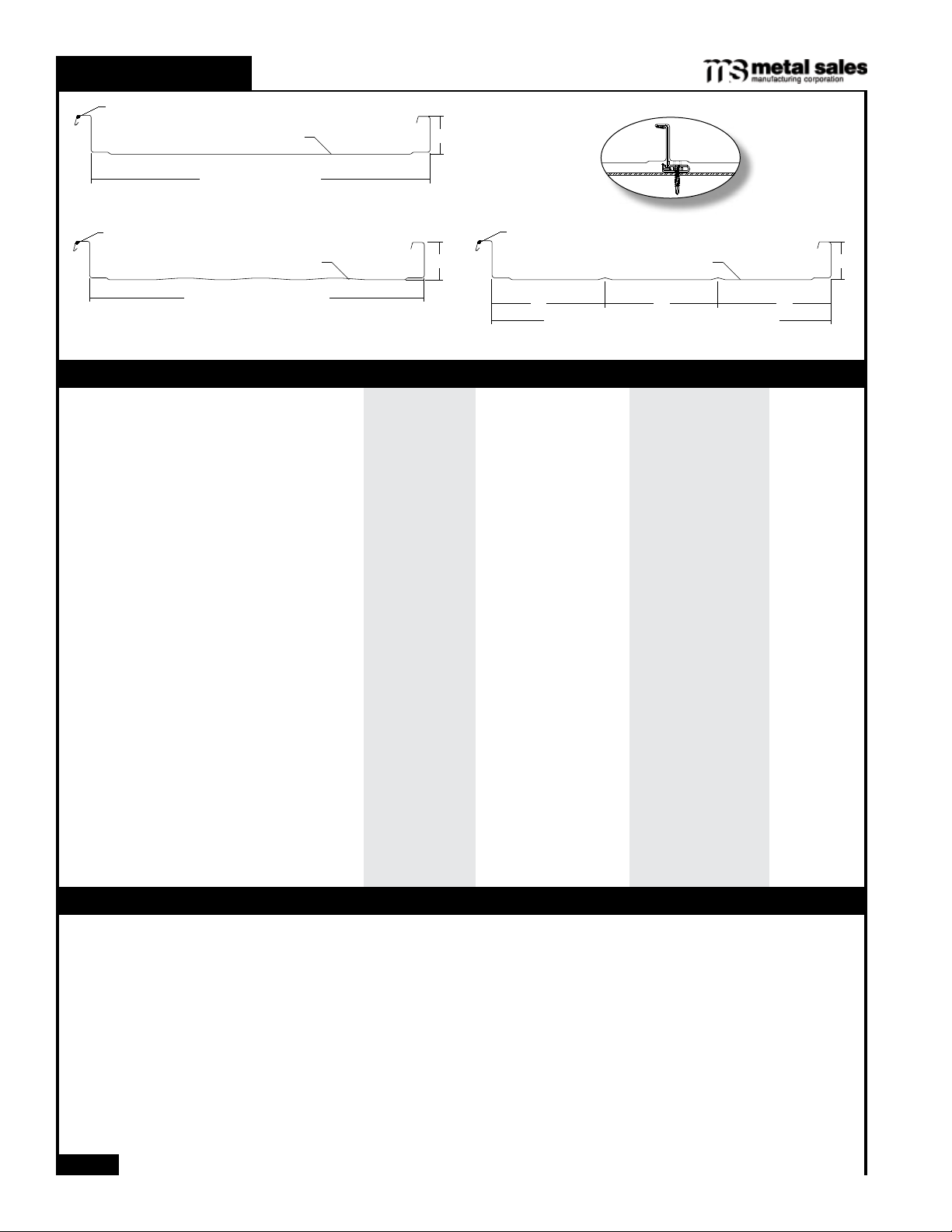

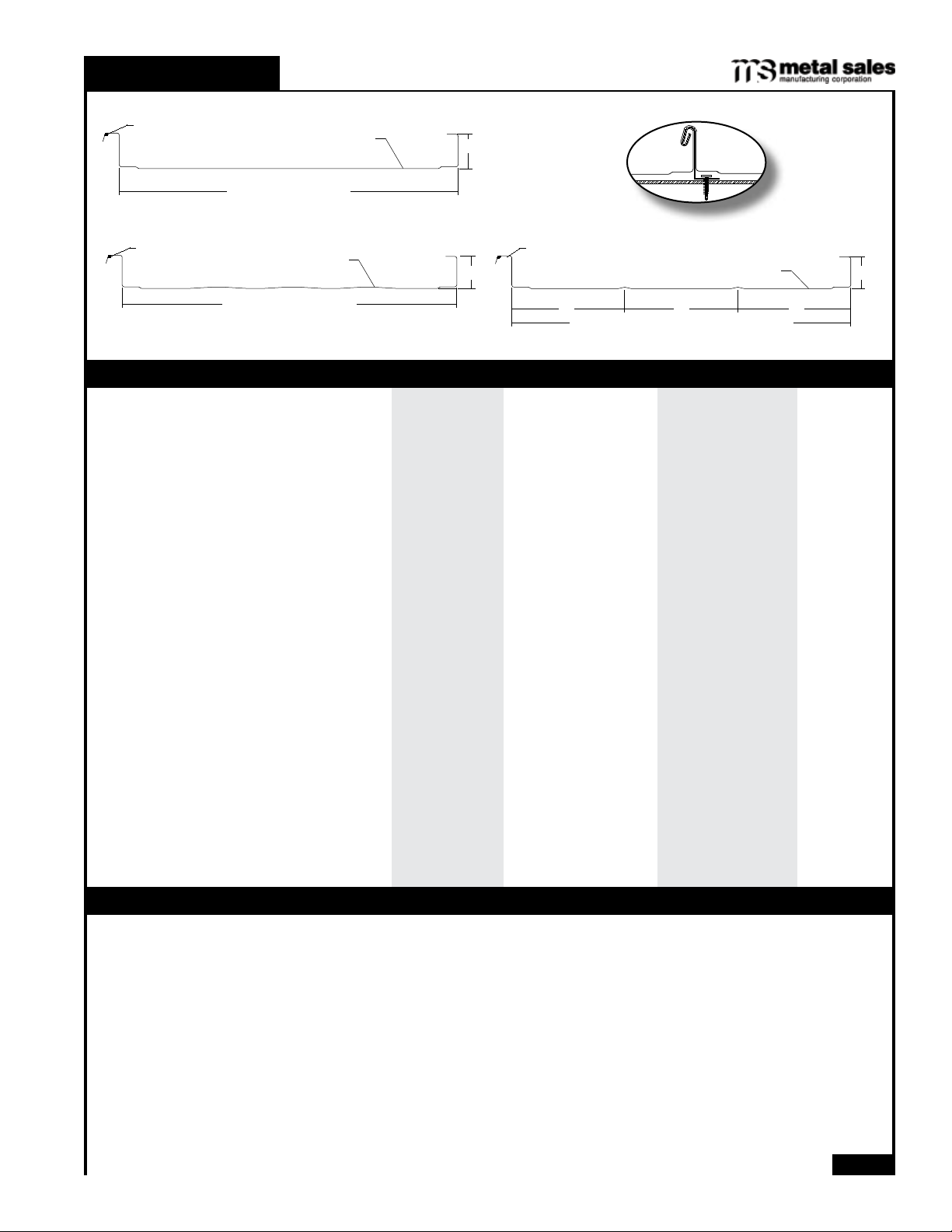

90° PANEL PROFILE

Factory Applied Sealant

Panel Coverage (Flat)

Factory Applied Sealant

Panel Coverage (Striated)

C

C

2"

Factory Applied Sealant

2"

6"

Panel Coverage (Pencil Ribs)

Sellersburg and Fontana Branches Only

90o Seam

C

6" 6"

FINISH GAUGE COVERAGE PRODUCT NO. WT/SQ

ACG (Flat) 24 16" 2735141 130

ACG

ACG

PVDF

PVDF

PVDF

ACG

ACG

ACG

(Striated) 24 16" 2735241 130

(Pencil Rib) 24 16" 2785041 130

Standard(Flat) 24 16" 28351_ _ 130

Standard(Striated) 24 16" 28352_ _ 130

Standard(Pencil Rib) 24 16" 28850_ _ 130

(Flat) 22 16" 2935141 161

(Striated) 22 16" 2935241 161

(Pencil Rib) 22 16" 2985041 161

2"

PVDF

PVDF

PVDF

ACG

ACG

ACG

(Flat) 22 16" 30351_ _ 161

(Striated) 22 16" 30352_ _ 161

(Pencil Rib) 22 16" 30850_ _ 161

(Flat) 24 18" 2735341 126

(Striated)

(Pencil Ribs) 24 18" 2785241 126

24

18"

2735441 126

PVDF

PVDF

PVDF

Standard(Flat)

Standard(Striated)

Standard(Pencil Ribs) 24 18" 28852_ _ 126

24

24

18"

18"

28353_ _ 126

28354_ _ 126

ACG

ACG

ACG

PVDF

PVDF

PVDF

(Flat) 22 18" 2935341 156

(Striated)

(Pencil Ribs) 22 18" 2985241 156

(Flat)

(Striated)

(Pencil Ribs) 22 18" 30852_ _ 156

22

22

22

18"

18"

18"

2935441 156

30353_ _ 156

30354_ _ 156

PANEL NOTES

1. For panel lengths over 45'-0", please inquire.

2. Minimum recommended roof slope:

1

/2:12.

3. All panels have factory applied sealant.

4. Oil canning is not a cause for rejection. Heavier gauges help minimize oil canning.

5. The Magna-Loc panel system requires the use of a mechanical seamer for proper installation. Contact Metal Sales for rental

information.

6. If requested, panels are factory notched and/or pre-punched for endlap conditions.

7. Finish: PVDF (Meets Kynar 500/Hylar 5000 Specs).

8. For additional information on product applications, loadings and flashing details, consult the Product or Installation

Manuals.

_ _ Represents color code designation.

See page 6 in this manual or Metal Sales color guides for color selection.

Requires additional lead time.

8

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

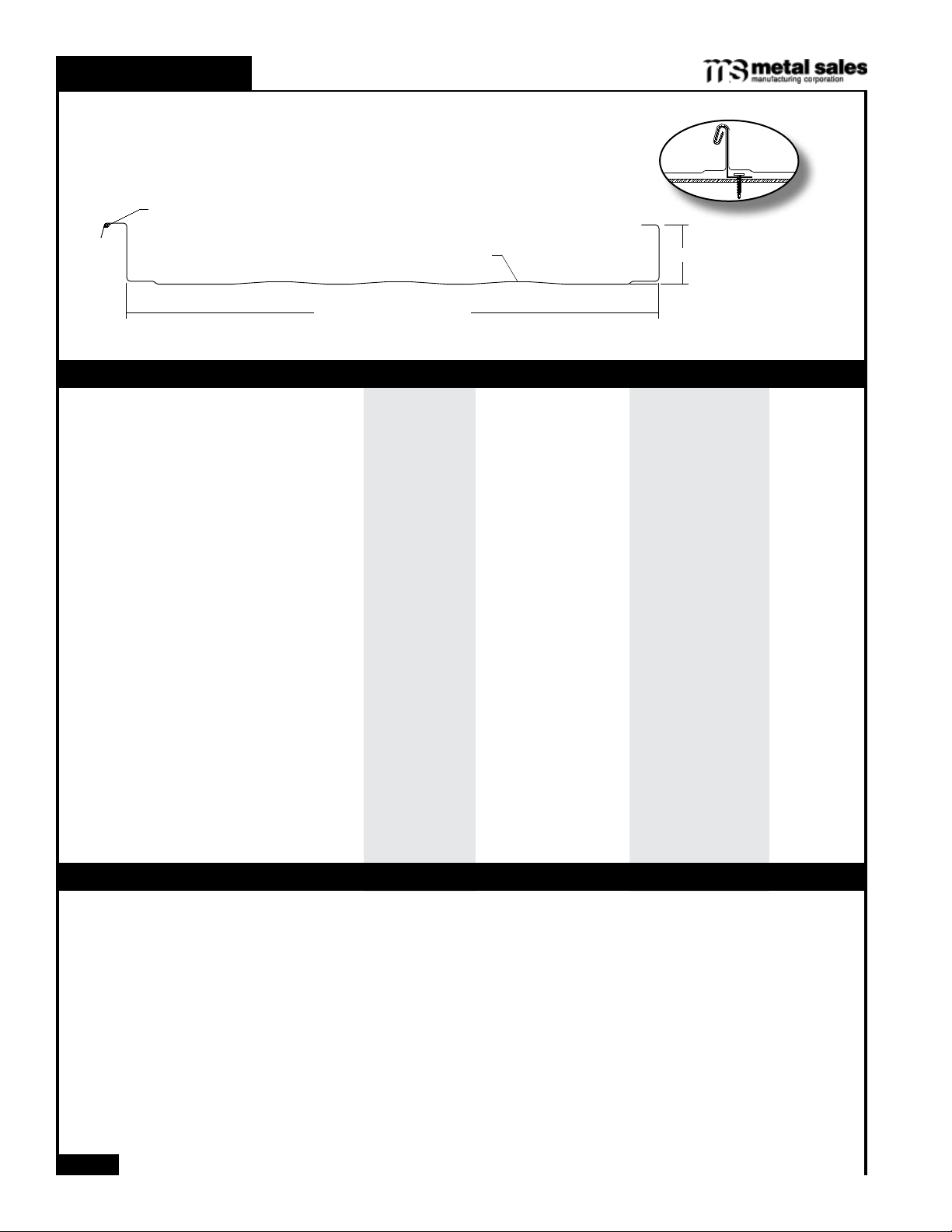

MAGNA-LOC

Factory Applied Sealant

16" Coverage (Flat)

180° PANEL PROFILE

C

2"

180

o

Seam

Factory Applied Sealant

16" Coverage (Striated)

C

2"

Factory Applied Sealant

6"

16" Coverage (Pencil Ribs)

Sellersburg and Fontana Branches Only

4"

C

6"

FINISH GAUGE COVERAGE PRODUCT NO. WT/SQ

ACG (Flat) 24 16" 2735741 130

ACG

ACG

PVDF

PVDF

PVDF

ACG

ACG

ACG

PVDF

PVDF

PVDF

ACG

ACG

ACG

PVDF

PVDF

PVDF

ACG

ACG

ACG

(Striated) 24 16" 2735841 130

(Pencil Rib) 24 16" 2735541 130

Standard(Flat) 24 16" 28357_ _ 130

Standard(Striated) 24 16" 28358_ _ 130

Standard(Pencil Rib) 24 16" 28355_ _ 130

(Flat) 22 16" 2935741 161

(Striated) 22 16" 2935841 161

(Pencil Rib) 22 16" 2935541 161

(Flat) 22 16" 30357_ _ 161

(Striated) 22 16" 30358_ _ 161

(Pencil Rib) 22 16" 30355_ _ 161

(Flat) 24 18" 2735941 126

(Striated) 24 18" 2736041 126

(Pencil Rib) 24 18" 2735641 126

Standard(Flat) 24 18" 28359_ _ 126

Standard(Striated) 24 18" 28360_ _ 126

Standard(Pencil Rib) 24 18" 28356_ _ 126

(Flat) 22 18" 2935941 156

(Striated) 22 18" 2936041 156

(Pencil Rib) 22 18" 2935641 156

2"

PVDF

PVDF

PVDF

(Flat) 22 18" 30359_ _ 156

(Striated) 22 18" 30360_ _ 156

(Pencil Rib) 22 18" 30356_ _ 156

PANEL NOTES

1. For panel lengths over 45'-0", please inquire.

2. Minimum recommended roof slope:

1

/2:12.

3. All panels have factory applied sealant.

4. Oil canning is not a cause for rejection. Heavier gauges help minimize oil canning.

5. The Magna-Loc panel system requires the use of a mechanical seamer for proper installation. Contact Metal Sales for rental

information.

6. If requested, panels are factory notched and/or pre-punched for endlap conditions.

7. Finish: PVDF (Meets Kynar 500/Hylar 5000 Specs).

8. For additional information on product applications, loadings and flashing details, consult the Product or Installation

Manuals.

_ _ Represents color code designation.

See page 6 in this manual or Metal Sales color guides for color selection.

Requires additional lead time.

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

9

MAGNA-LOC

Factory Applied Sealant

180° cURVED PAnEL PRoFILE

180o Seam

C

Panel Coverage (Striated)

2"

FINISH GAUGE COVERAGE PRODUCT NO. WT/SQ

ACG (Striated) 24 16" 3135841 130

PVDF

ACG

PVDF

ACG

PVDF

ACG

PVDF

Standard(Striated) 24 16" 32358_ _ 130

(Striated) 24 16" 3335841 161

(Striated) 22 16" 34358_ _ 161

(Striated)

(Striated)

Standard(Striated)

(Striated)

24

24

22

22

18"

18"

18"

18"

3536041 126

37360_ _ 126

3836041 156

39360_ _ 156

PANEL NOTES

1. For panel lengths over 45'-0", please inquire.

2. Minimum recommended roof slope:

1

/2:12.

3. All panels have factory applied sealant. The sealant is applied as part of the curving operation.

4. Oil canning is not a cause for rejection. Heavier gauges help minimize oil canning.

5. The Magna-Loc panel system requires the use of a mechanical seamer for proper installation. Contact Metal Sales for rental

information.

6. If requested, panels are factory notched and/or pre-punched for endlap conditions.

7. Finish: PVDF (Meets Kynar 500/Hylar 5000 Specs).

8. For additional information on product applications, loadings and flashing details, consult the Product or Installation

Manuals.

9. Add 30 feet of extra sheets for fine tuning curving machine per radius, per job.

_ _ Represents color code designation.

See page 6 in this manual or Metal Sales color guides for color selection.

Requires additional lead time.

10

* Additional charges for Field Bending and for Factory Bending

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

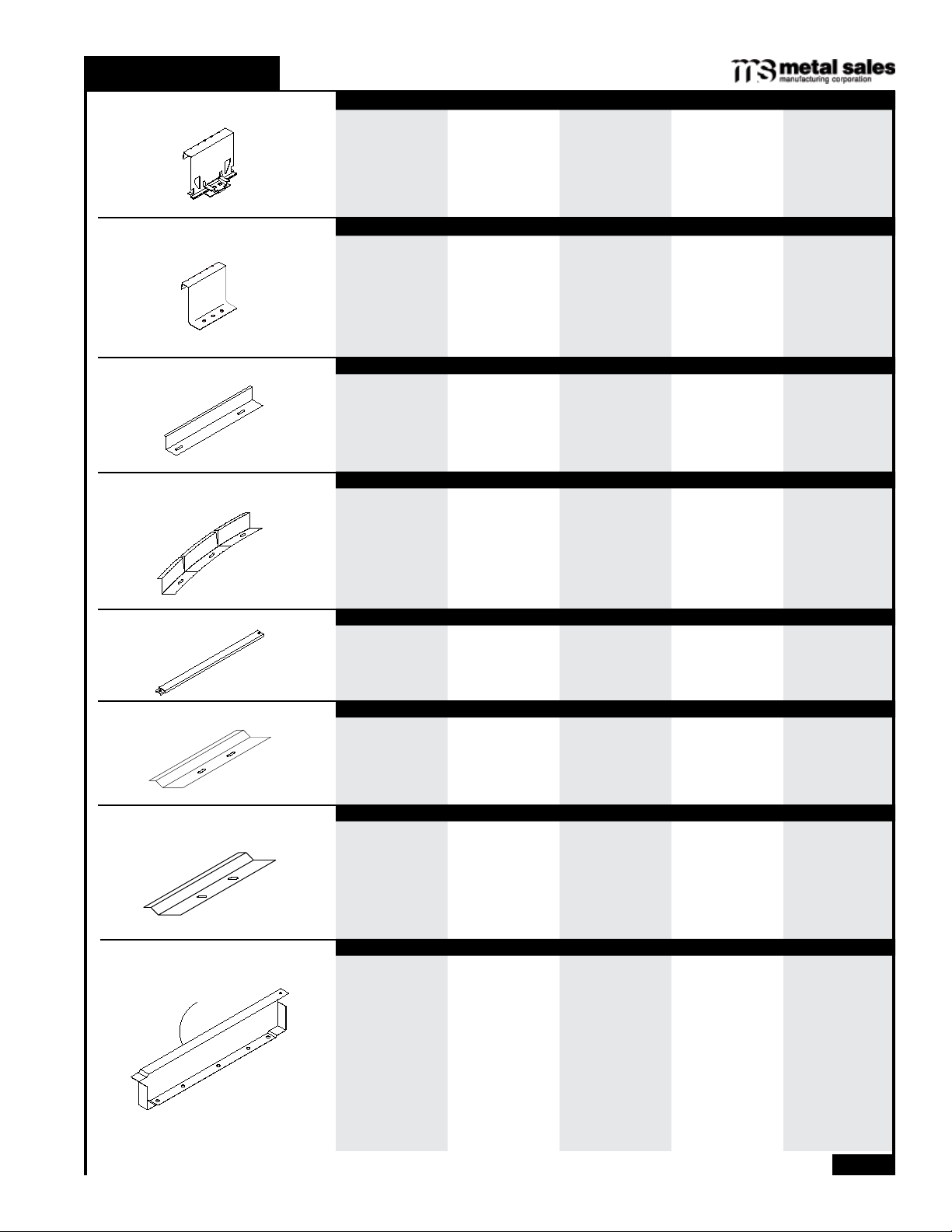

MAGNA-LOC

MAGNA-LOC CLIP

(FLOATING)

ACCESSORY PROFILES

SIZE TYPE PRODUCT NO.

23/8" Low (Floating) 4923302 50 pieces 12.50 lbs

CARTON

QUANTITY

WT/ CARTON

MAGNA-LOC CLIP

(FIXED)

MAGNA-LOC RAKE ZEE

MAGNA-LOC RAKE ZEE

(CURVED APPLICATION)

3

3

/8" High (Floating) 4923303 50 pieces 15.50 lbs

SIZE TYPE PRODUCT NO.

CARTON

QUANTITY

WT/ CARTON

*21/8" Utility (Fixed) 4923321 50 pieces 6.00 lbs

2

*Pancake Head fasteners to be used with fixed clips.

3

/8" Low (Fixed) 4923322 50 pieces 7.00 lbs

SIZE FINISH TYPE PRODUCT NO. WT

2" x 16 Ga. Galvanized Utility 10'-0" 4923850 9.80 lbs

23/8" x 16 Ga. Galvanized Low 10'-0" 4923855 10.60 lbs

33/8" x 16 Ga. Galvanized High 10'-0" 4923865 12.80 lbs

SIZE FINISH TYPE PRODUCT NO. WT

2" x 16 Ga. Galvanized Utility 10'-0" 4924850 9.80 lbs

23/8" x 16 Ga. Galvanized Low 10'-0" 4924855 10.60 lbs

33/8" x 16 Ga. Galvanized High 10'-0" 4924865 12.80 lbs

BACK-UP CHANNEL

MAGNA-LOC EAVE PLATE

MAGNA-LOC EAVE PLATE

(CURVED APPLICATION)

MAGNA-LOC END DAM

(LEFT TO RIGHT)

C

SIZE FINISH LENGTH PRODUCT NO. WT

3" x 3/8" Galvanized 48" 4923640 2.00 lbs

3" x 3/8" Galvanized 72" 4923645 4.00 lbs

SIZE FINISH TYPE PRODUCT NO. WT

3

/8" x 16 Ga. Galvanized Low 10'-0" 4923835 7.80 lbs

13/8" x 16 Ga. Galvanized High 10'-0" 4923845 10.30 lbs

SIZE FINISH TYPE PRODUCT NO. WT

3/8" x 16 Ga. Galvanized Low 10'-0" 4933800 7.80 lbs

13/8" x 16 Ga. Galvanized High 10'-0" 4934800 10.30 lbs

SIZE FINISH PRODUCT NO. WT

16" x 24 Ga. Galvanized 4925010 .60 lbs

16" x 24 Ga. Painted 49255_ _ .60 lbs

18" x 24 Ga. Galvanized 4925020 .80 lbs

18" x 24 Ga. Painted 49256_ _ .80 lbs

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

11

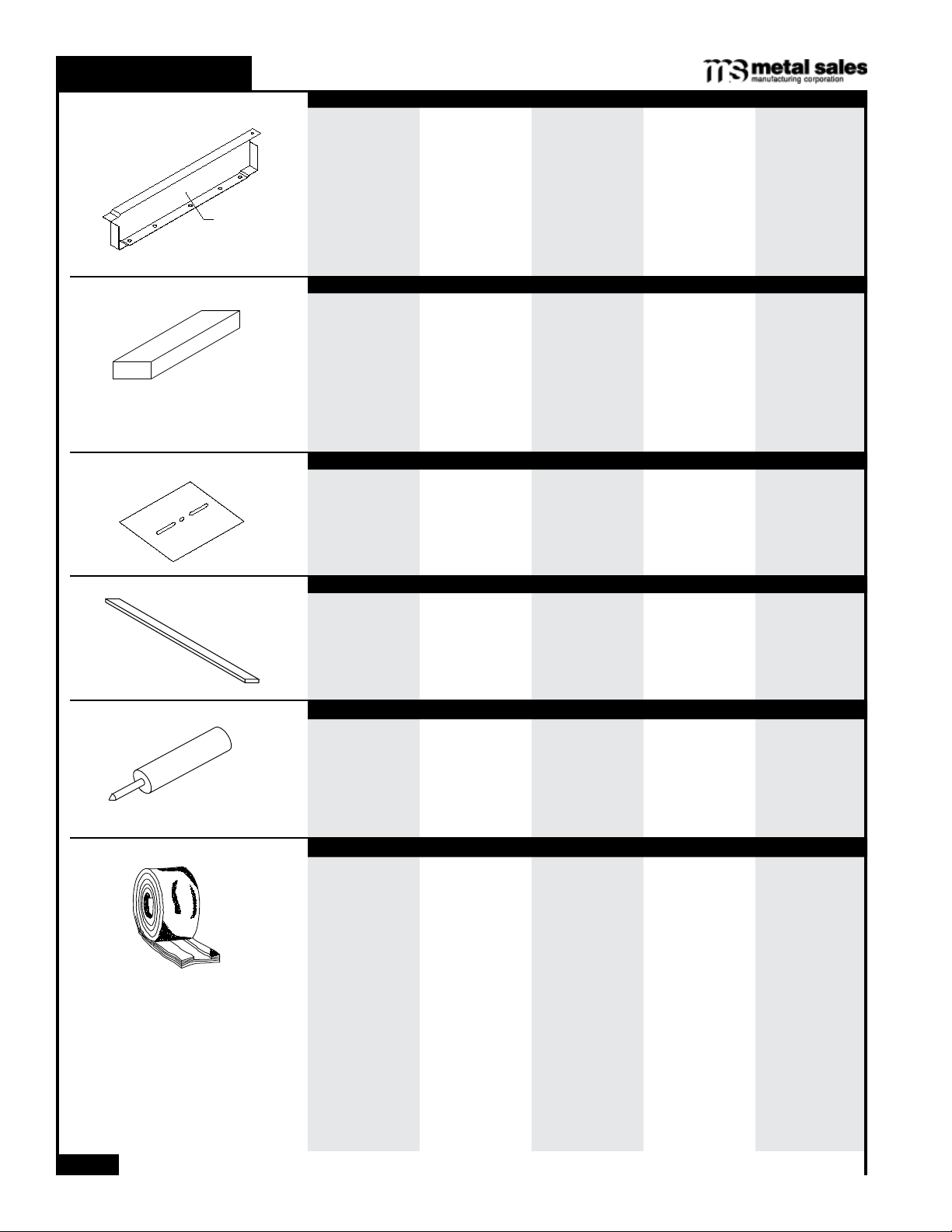

MAGNA-LOC

MAGNA-LOC END DAM

(RIGHT TO LEFT)

C

ACCESSORY PROFILES (CONT.)

SIZE FINISH PRODUCT NO. WT

16" x 24 Ga. Painted 49257_ _ .60 lbs

18" x 24 Ga. Painted 49258_ _ .80 lbs

THERMAL BLOCK

BEARING PLATE

ENDLAP PAD

TUBE SEALANT

SIZE FINISH PRODUCT NO. WT/100

3/8" x 3" x 16" Polystyrene 4923787 1.50 lbs

Foam

3/8" x 3" x 18" Polystyrene 4923775 1.75 lbs

Foam

1" x 3" x 16" Polystyrene 4923760 3.00 lbs

Foam

1" x 3" x 18" Polystyrene 4923770 3.50 lbs

Foam

SIZE FINISH PRODUCT NO. WT/100

4" x 5" x 20 Ga. Galvanized 4923886 30 lbs

PANEL SIZE PRODUCT NO. TYPE WT/CARTON

Seam-Loc 24

Magna-Loc

11/2" x 3/32" x 27"

6411998 Butyl 27 lbs

Snap-Loc 24

Note: 51 pieces per box

SIZE COLOR PRODUCT NO.

10.3 oz

Urethane White

6402830 30 cartridges 19.31 lbs

CARTON

QUANTITY

WT/ CARTON

12

TAPE SEALANT

Double Bead

10.3 oz

10.3 oz

10.3 oz

Urethane Bronze

Urethane Gray

Acrylic Clear

6402829 30 cartridges 19.31 lbs

6402800 30 cartidges 19.31 lbs

6402999 30 cartridges 19.31 lbs

SIZE TYPE PRODUCT NO.

7/8" x 3/16" x 25' Butyl 6403899 20 rolls 40.00 lbs

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

(Double Bead)

CARTON

QUANTITY

WT/ CARTON

MAGNA-LOC

VENT MATERIAL

33/8"

7

/8"

ACCESSORY PROFILES (CONT.)

SIZE TYPE PRODUCT NO.

35/16" x 7/8" x 4' Black 6852406 24 pieces 30.00 lbs

CARTON

QUANTITY

WT/ CARTON

4'

TOUCH-UP PAINT

ms-HT UNDERLAYMENT

UNDERLAYMENT

PRIMER

For use on roof with a 3:12 or greater slope

TYPE SIZE PRODUCT NO. WT

For CF45 nish Pint 66004_ _ 1.60 lbs

For PVDF nish Pint 66010_ _ 1.60 lbs

_ _ Represents color code designation

TYPE SIZE PRODUCT NO. WT/ ROLL

Peel-and-Stick 36" x 66.67’ 4121200 44.00 lbs

(2 Sq Roll)

SIZE PRODUCT NO. WT/ ROLL

5 Gallon* 6600000 42.00 lbs

*100-125 ft2 per gallon depending on substrate.

ALSAN

POLY FLEECE ROLL

HEMMING TOOL

20"

TYPE SIZE PRODUCT NO. WT

5 Gallon* 4130200 47.00 lbs

1 Gallon* 4130300 10.00 lbs

Kit* 5 Gallon 4130100 9.20 lbs

*50 lf per gallon depending on weather tempature

Kit includes 1 gallon Alsan, tools, instuctional video, and roll of Poly Fleece

SIZE TYPE PRODUCT NO. QUANTITY WT

4" x 50' Poly 4130500 1 rolls .30 lbs

Fleece

6" x 50' Poly 4130400 1 rolls .50 lbs

Fleece

TYPE SIZE PRODUCT NO. WT/100

Zinc Plated 20" 6560102 4.00 lbs

Used for bending lower end of the metal panel to accept

Offset Cleat flashing for concealed fastener application.

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

13

MAGNA-LOC

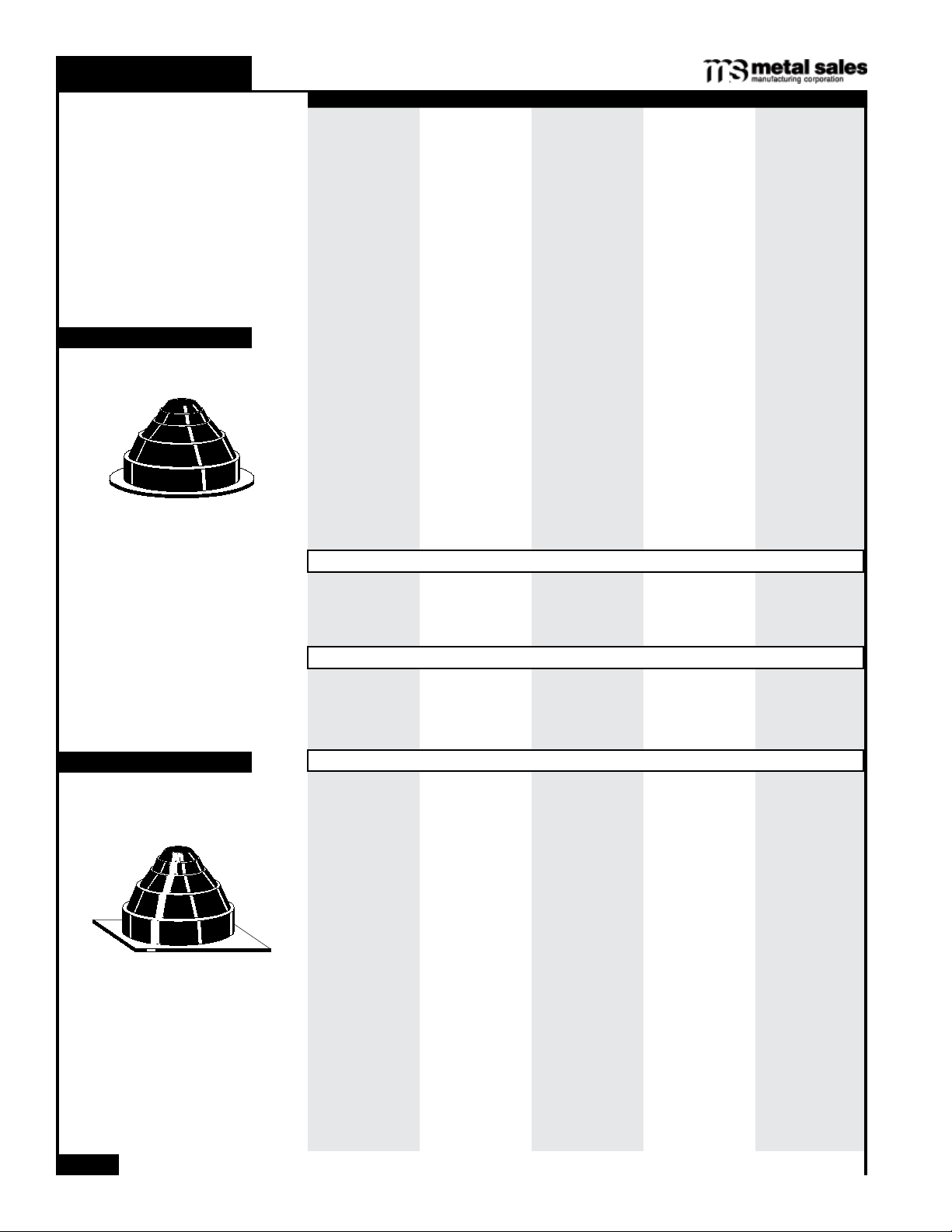

RUBBER ROOF DECK

FLASHINGS

ACCESSORY PROFILES (CONT.)

TYPE SIZE BASE DIAM. PRODUCT NO. WT

Rubber #1 Flasher

Rubber #2 Flasher 13/4" - 31/4" 68502_ _* 3.00 lbs

Rubber #3 Flasher

Rubber #4 Flasher 3" - 6

Rubber #5 Flasher 41/4" - 71/2" 68505_ _* 5.00 lbs

Rubber #6 Flasher 5" - 9" 68506_ _* 9.00 lbs

Rubber #7 Flasher 6" - 11" 68507_ _* 11.00 lbs

Rubber #8 Flasher 7" - 13" 68508_ _* 13.00 lbs

Rubber #9 Flasher 10" - 19" 68509_ _* 13.00 lbs

*Special order colors: 93=Brown; 94=Green; 95=Red; 96=Blue; 97=White; 98=Grey; 99=Black

1

/4" - 2" 68501_ _* 3.00 lbs

1

/4" - 5" 68503_ _* 3.00 lbs

1

/4" 68504_ _* 3.00 lbs

ROUND

SQUARE

Rubber Roof Jack

Round Base

Retro Roof Jack

Square Base

HT Silicone #1 Flasher

HT Silicone #2 Flasher 13/4" - 31/4" 6850012 3.00 lbs

HT Silicone #3 Flasher

1

/4" - 2" 6850011 3.00 lbs

1

/4" - 5" 6850013 3.00 lbs

HT Silicone #4 Flasher 3" - 61/4" 6850014 3.00 lbs

HT Silicone #5 Flasher 41/4" - 71/2" 6850015 5.00 lbs

HT Silicone #6 Flasher 5" - 9" 6850016 9.00 lbs

HT Silicone #7 Flasher 6" - 11" 6850017 11.00 lbs

HT Silicone #8 Flasher 7" - 13" 6850018 13.00 lbs

HT Silicone #9 Flasher 10" - 19" 6850019 13.00 lbs

Retrot HT #1 Masterash

Retrot HT #2 Masterash 11/4" - 3" 6850061 4.00 lbs

Retrot HT #3 Masterash

1

/4" - 2" 6850060 4.00 lbs

1

/4" - 4" 6850062 4.00 lbs

GRAY ROUND RETRO ROOF JACK

Retrot E.P.D.M. #1 Masterash

Retrot E.P.D.M. #2 Masterash 11/4" - 3" 6850071 4.00 lbs

Retrot E.P.D.M. #3 Masterash

1

/4" - 2" 6850070 4.00 lbs

1

/4" - 4" 6850072 4.00 lbs

BLACK ROUND RETRO ROOF JACK

Retrot E.P.D.M. #1 Masterash

Retrot E.P.D.M. #2 Masterash 11/4" - 3" 6850074 4.00 lbs

Retrot E.P.D.M. #3 Masterash

1

/4" - 2" 6850073 4.00 lbs

1

/4" - 4" 6850075 4.00 lbs

BLACK SQUARE RETRO ROOF JACK

Retrot E.P.D.M. #1 Masterash

Retrot E.P.D.M. #2 Masterash 11/4" - 3" 6850047 4.00 lbs

Retrot E.P.D.M. #3 Masterash

1

/4" - 2" 6850046 4.00 lbs

1

/4" - 4" 6850048 4.00 lbs

14

*Kit includes: membrane fasteners, termination strips, splice material and

sealant. (Deck Flashing temperature range is -65o to +250o: HT Deck Flashing

temperature range is -100o to +450o)

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

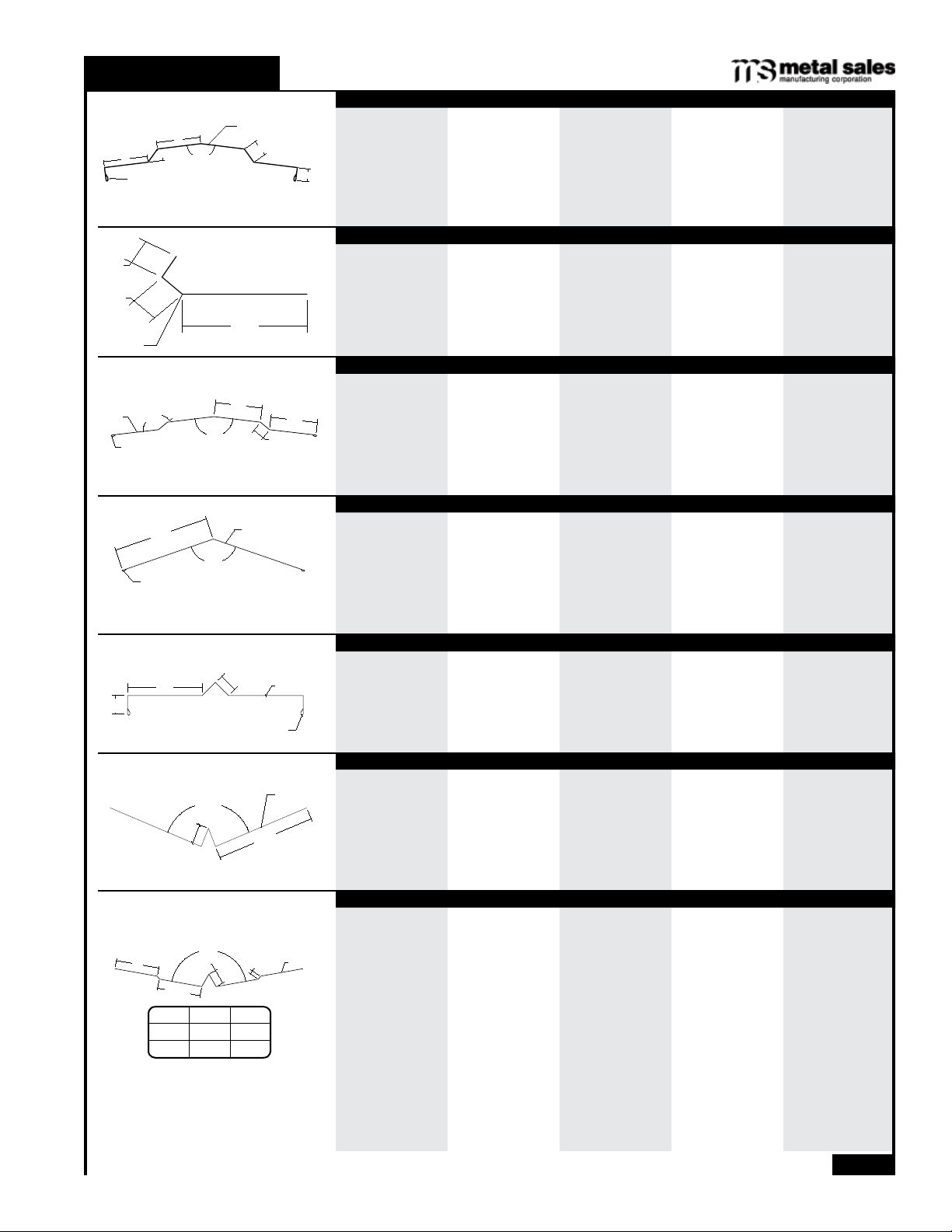

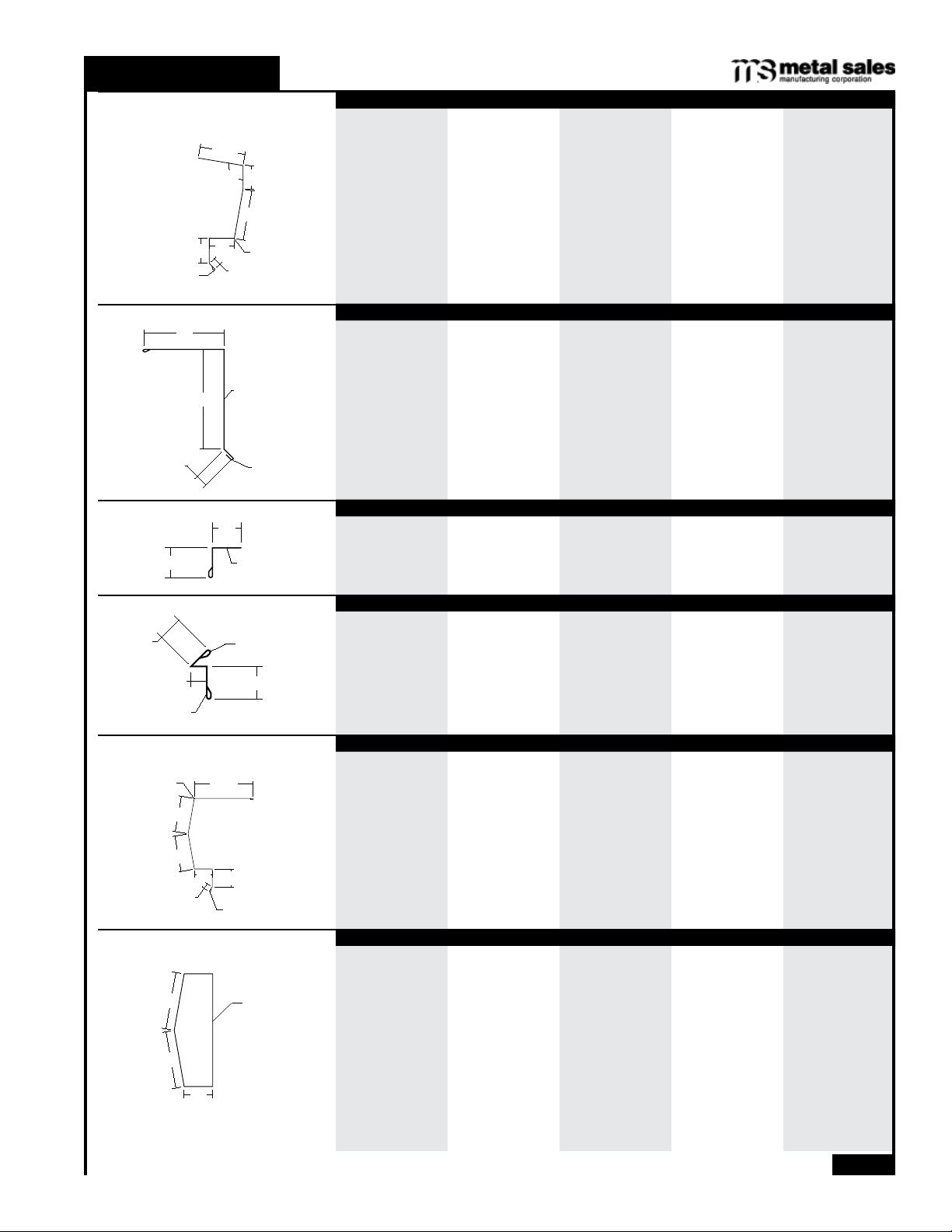

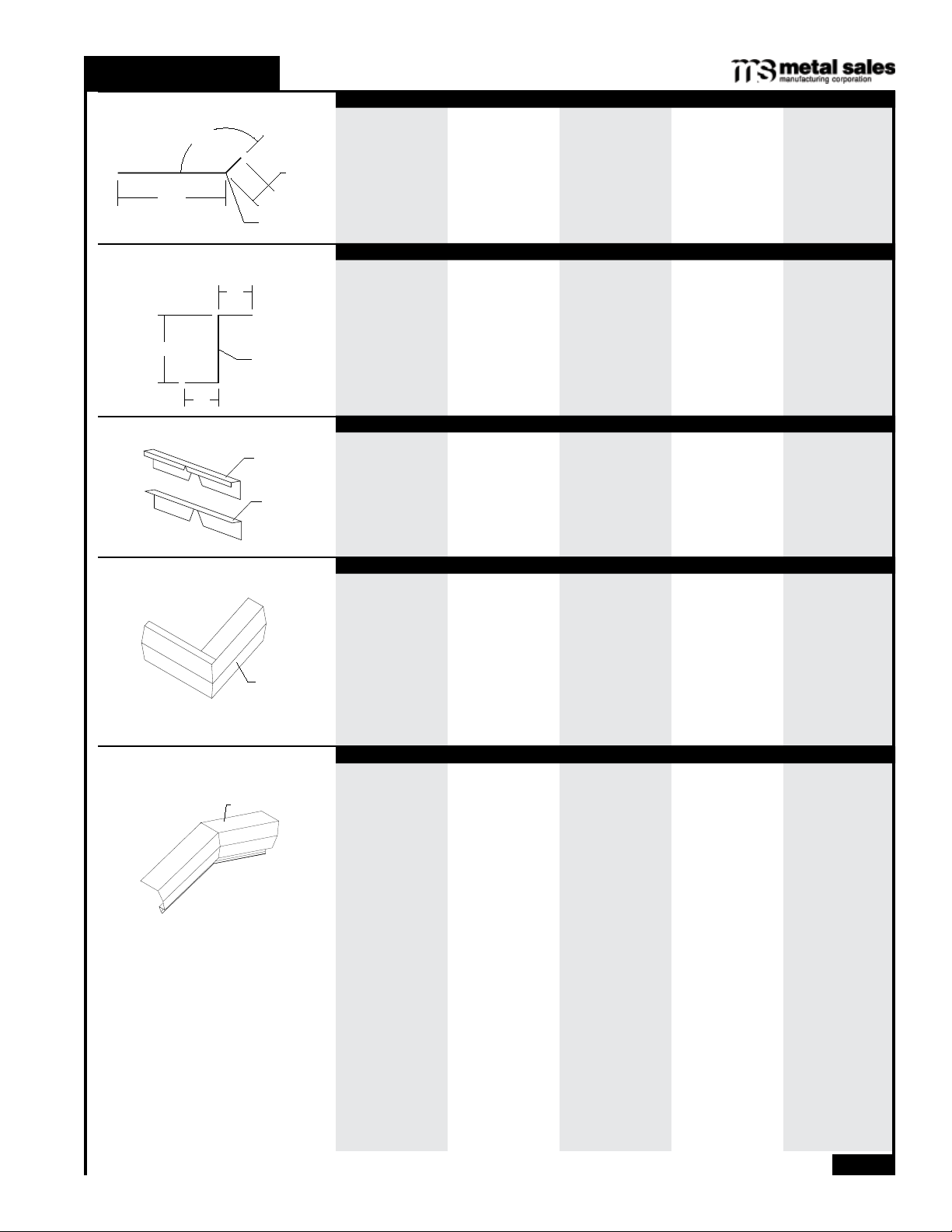

MAGNA-LOC

VENTED RIDGE COVER

C

X*

3"

Hem

3"

1"

FLASHING PROFILES

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5701341 13.40 lbs 10'-2"

1

/8"

1

24 ACG 5701541 26.80 lbs 20'-3"

24 PVDF 58013_ _ 13.40 lbs 10'-2"

7

/8"

24 PVDF 58015_ _ 26.80 lbs 20'-3"

* See chart on page 7

VENT DRIP

3

/4"

3

/4"

105°

C

SSR RIDGE

C

135°

Hem

20" HIP COVER

10"

Hem

EXPANSION JOINT

6"

1"

135°

X*

X*

31/4"

4"

1"

C

1"

HEM

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5701741 3.30 lbs 10'-2"

24 PVDF 58017_ _ 3.30 lbs 10'-2"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5775141 15.20 lbs 10'-2"

24 ACG 5775341 30.40 lbs 20'-3"

4"

24 PVDF 58751_ _ 15.20 lbs 10'-2"

24 PVDF 58753_ _ 30.40 lbs 20'-3"

* See chart on page 7

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5700641 15.90 lbs 10'-2"

24 ACG 5700841 31.80 lbs 20'-3"

24 PVDF 58006_ _ 15.90 lbs 10'-2"

24 PVDF 58008_ _ 31.80 lbs 20'-3"

* See chart on page 7

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 6372241 10.60 lbs 10'-2"

C

24 ACG 6372341 21.20 lbs 20'-3"

24 PVDF 64722_ _ 10.60 lbs 10'-2"

24 PVDF 64723_ _ 21.20 lbs 20'-3"

VALLEY

X*

2"

C

10"

MAGNA-LOC

SRR 4.5" DROP VALLEY

X*

B

1

/2"

1

A

41/2"

SYSTEM

LOW

HIGH

A B

3

/8"

3

/8"

1

1

/2"

4

1

/2"

3

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5701841 16.85 lbs 10'-2"

24 ACG 5702041 33.70 lbs 20'-3"

24 PVDF 58018_ _ 16.85 lbs 10'-2"

24 PVDF 58020_ _ 33.70 lbs 20'-3"

* See chart on page 7

GAUGE FINISH PRODUCT NO. WT LENGTH

Low 4.5"

Drop Valley

24 ACG 5781741 18.20 lbs 10'-2"

C

24 ACG 5781941 36.40 lbs 20'-3"

24 PVDF 58817_ _ 18.20 lbs 10'-2"

24 PVDF 58819_ _ 36.40 lbs 20'-3"

High 4.5"

Drop Valley

24 ACG 5782341 18.20 lbs 10'-2"

24 ACG 5782541 36.40 lbs 20'-3"

24 PVDF 58823_ _ 18.20 lbs 10'-2"

24 PVDF 58825_ _ 36.40 lbs 20'-3"

* See chart on page 7

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

15

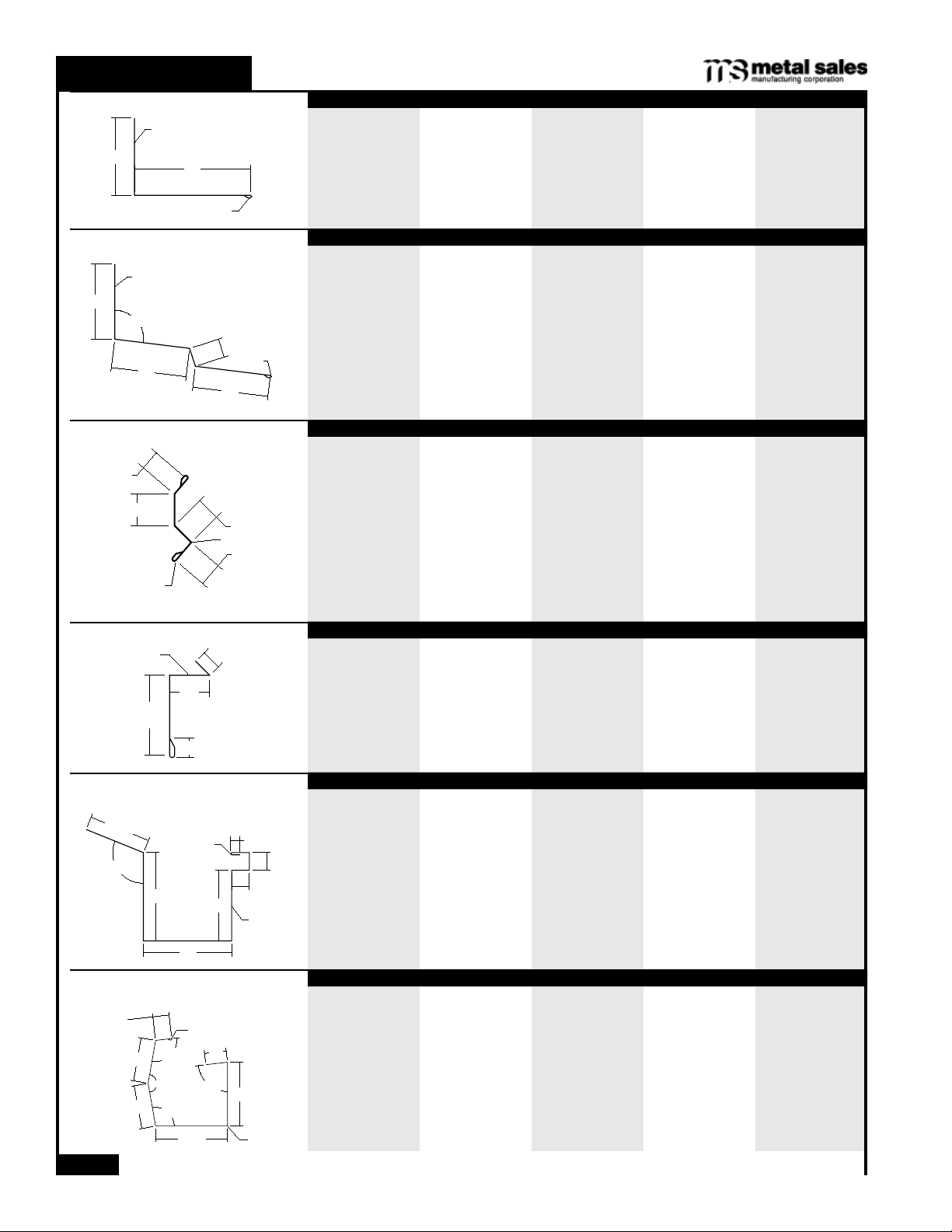

MAGNA-LOC

MAGNA-LOC

SSR 9" DROP VALLEY

LOW

HIGH

9"

1

1

X*

/2"

A B

3

/8"

3

/8"

1

A

10"

9"

B C

SYSTEM

FLASHING PROFILES (CONT.)

GAUGE FINISH PRODUCT NO. WT LENGTH

Low 9"

Drop Valley

24 ACG 5786341 35.60 lbs 10'-2"

24 ACG 5786441 70.80 lbs 20'-3"

24 PVDF 58863_ _ 35.60 lbs 10'-2"

24 PVDF 58864_ _ 70.80 lbs 20'-3"

High 9"

Drop Valley

24 ACG 5786741 35.60 lbs 10'-2"

24 ACG 5786841 70.80 lbs 20'-3"

24 PVDF 58867_ _ 35.60 lbs 10'-2"

24 PVDF 58868_ _ 70.80 lbs 20'-3"

* See chart on page 7

PEAK

C

6"

5"

X*

Hem

3

/8"

SSR SCULPTURED

HIGH SIDE EAVE

C

4"

61/2"

X*

160°

4"

100°

2"

2"

3

/8"

Hem

EAVE

37/8"

X*

3"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5702241 9.95 lbs 10'-2"

24 ACG 5702441 19.90 lbs 20'-3"

24 PVDF 58022_ _ 9.95 lbs 10'-2"

24 PVDF 58024_ _ 19.90 lbs 20'-3"

* See chart on page 7

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5776941 16.75 lbs 10'-2"

24 ACG 5777141 33.50 lbs 20'-3"

24 PVDF 58769_ _ 16.75 lbs 10'-2"

24 PVDF 58771_ _ 33.50 lbs 20'-3"

* See chart on page 7

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5706541 6.35 lbs 10'-2"

C

24 PVDF 58065_ _ 6.35 lbs 10'-2"

* See chart on page 7

EXTENDED EAVE

16

3

X*

3

/8"

Hem

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5707341 9.55 lbs 10'-2"

6"

24 PVDF 58073_ _ 9.55 lbs 10'-2"

11/2"

3"

/8"

C

Hem

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

* See chart on page 7

MAGNA-LOC

MAGNA-LOC

SCULPTURED EAVE

35/8"

X*

17/8"

4"

2"

2"

Hem

C

5

/8"

FLASHING PROFILES (CONT.)

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5783541 11.50 lbs 10'-2"

24 ACG 5783741 23.00 lbs 20'-3"

24 PVDF 58835_ _ 11.50 lbs 10'-2"

24 PVDF 58837_ _ 23.00 lbs 20'-3"

* See chart on page 7

RAKE

4"

C

5"

5

/8"

Hem

SSR RAKE CLEAT

1"

1"

C

SSR RAKE SLIDE

3

/4"

1

/2"

Hem

1"

C

SSR SCULPTURED RAKE

(OFF MODULE)

C

61/2"

100°

4"

160°

4"

100°

2"

/8"

2"

Hem

5

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5703441 9.95 lbs 10'-2"

24 ACG 5703641 19.90 lbs 20'-3"

24 PVDF 58034_ _ 9.95 lbs 10'-2"

24 PVDF 58036_ _ 19.90 lbs 20'-3"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5776741 2.00 lbs 10'-2"

24 PVDF 58767_ _ 2.00 lbs 10'-2"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5776541 2.60 lbs 10'-2"

24 PVDF 58765_ _ 2.60 lbs 10'-2"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5775941 16.75 lbs 10'-2"

24 ACG 5776141 33.50 lbs 20'-3"

24 PVDF 58759_ _ 16.75 lbs 10'-2"

24 PVDF 58761_ _ 33.50 lbs 20'-3"

SSR SCULPTURED

RAKE END

4"

C

160°

4"

2"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5776341 .18 lbs

24 PVDF 58763_ _ .18 lbs

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

17

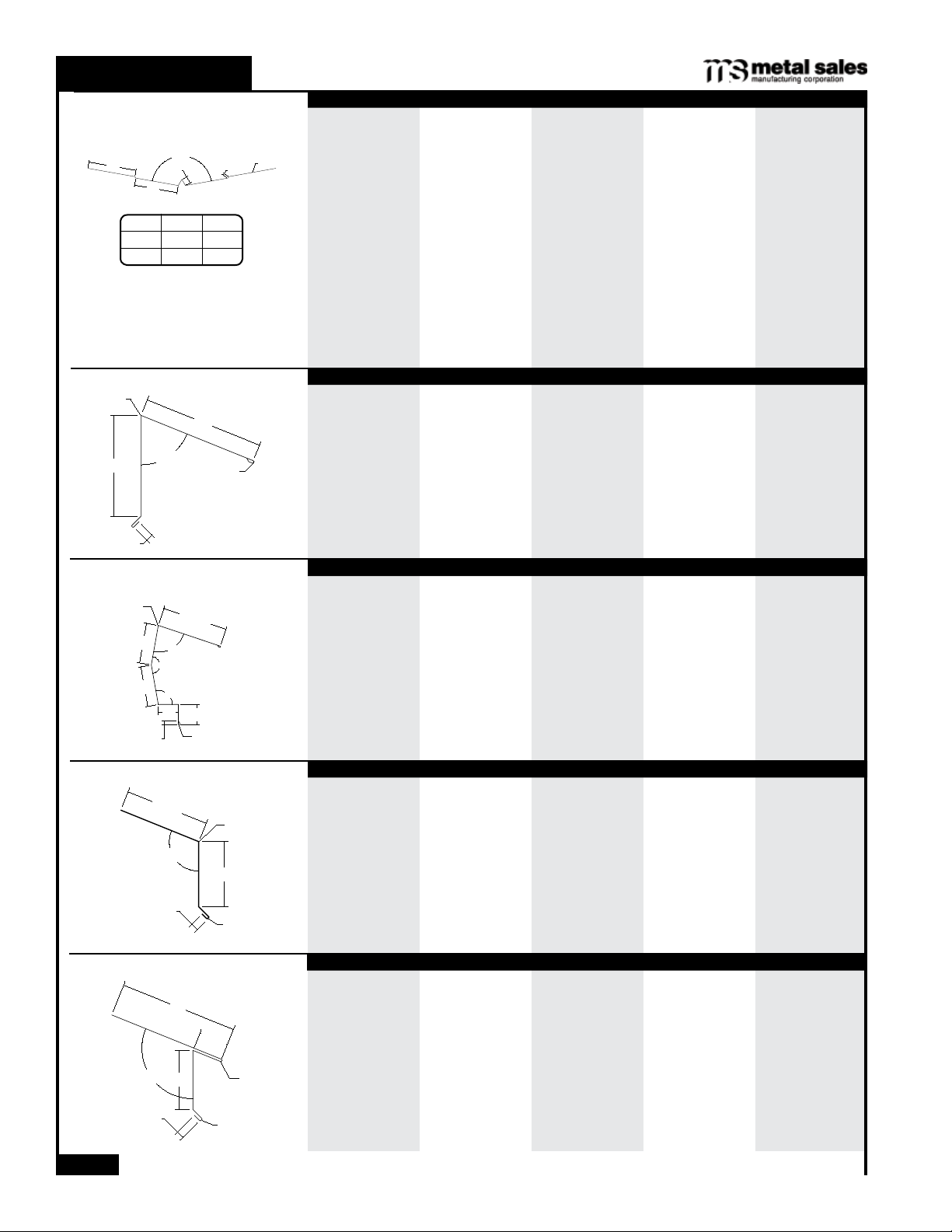

MAGNA-LOC

SSR RAKEWALL

C

FLASHING PROFILES (CONT.)

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5777741 8.80 lbs 10'-2"

4"

6"

SSR PITCH BREAK

C

4"

X*

4"

COUNTER FLASHING

5

/8"

1"

Hem

Hem

1"

C

4"

Hem

3

/4"

3

/4"

24 PVDF 58777_ _ 8.80 lbs 10'-2"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5777341 10.80 lbs 10'-2"

24 ACG 5777541 21.60 lbs 20'-3"

24 PVDF 58773_ _ 10.80 lbs 10'-2"

24 PVDF 58775_ _ 21.60 lbs 20'-3"

* See chart on page 7

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5705241 3.35 lbs 10'-2"

24 PVDF 58052_ _ 3.35 lbs 10'-2"

REGLET FLASHING

C

1"

2"

5

/8"

BOX GUTTER

31/2"

Hem

X*

5"

5"

SCULPTURED GUTTER

11/2"

4"

Hem

A*

160°

4"

100°

65/8"

18

B*

1

2"

GAUGE FINISH PRODUCT NO. WT LENGTH

/2"

24 ACG 5705441 3.20 lbs 10'-2"

24 PVDF 58054_ _ 3.20 lbs 10'-2"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5707741 16.95 lbs 10'-2"

24 ACG 5707941 33.90 lbs 20'-3"

1

/2"

24 PVDF 58077_ _ 16.95 lbs 10'-2"

1"

24 PVDF 58079_ _ 33.90 lbs 20'-3"

1"

4"

* See chart on page 7

C

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5780841 18.90 lbs 10'-2"

24 ACG 5781041 37.80 lbs 20'-3"

24 PVDF 58808_ _ 18.90 lbs 10'-2"

24 PVDF 58810_ _ 37.80 lbs 20'-3"

D*

* See chart on page 7

C

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

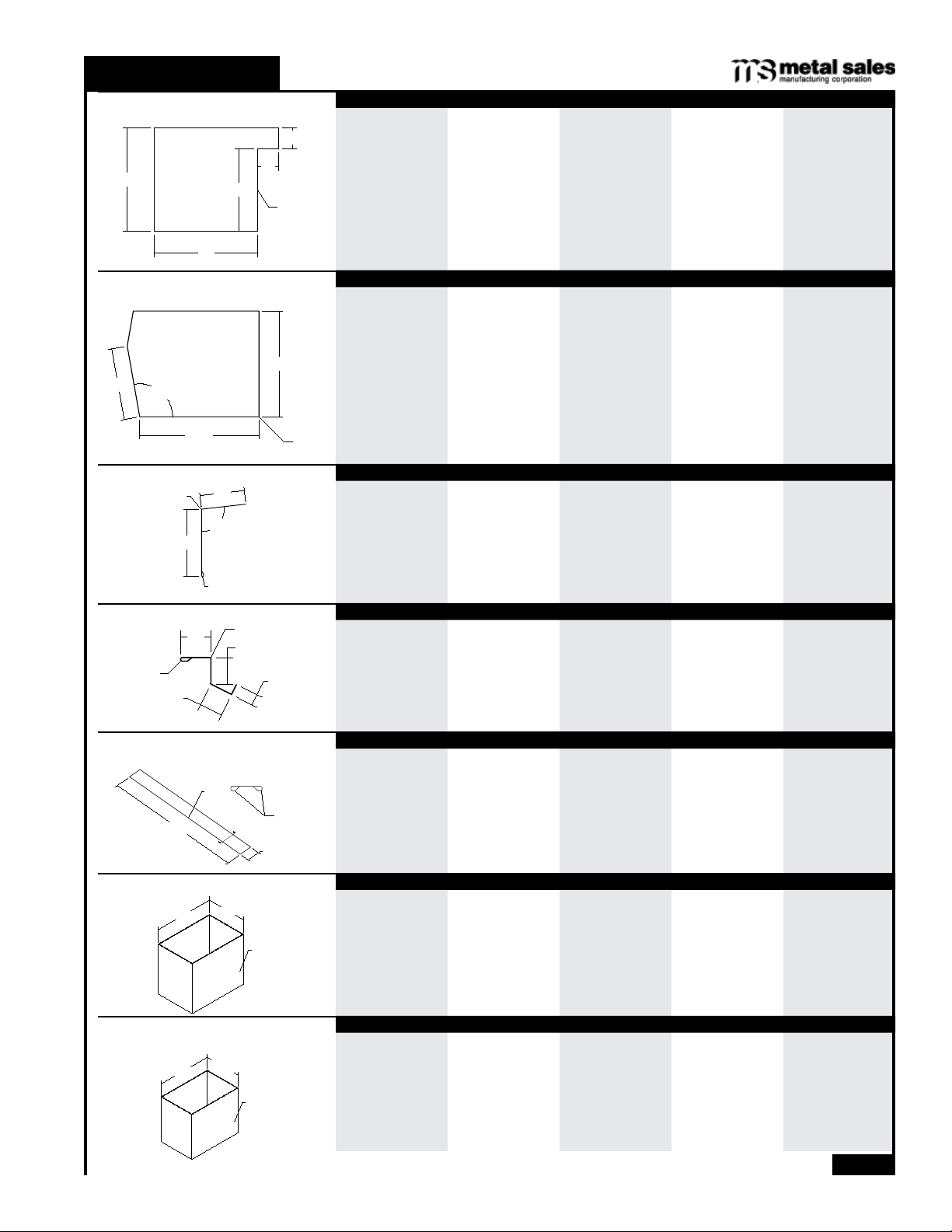

MAGNA-LOC

BOX GUTTER END

FLASHING PROFILES (CONT.)

GAUGE FINISH PRODUCT NO. WT

1"

24 ACG 5708141(Left) .24 lbs

5708241

(Right)

5"

SCULPTURED

GUTTER END

4"

100°

SSR GUTTER DRIP

C

41/2"

SSR GUTTER SUPPORT

Hem

3

/4"

5"

65/8"

1"

3"

X*

Hem

4"

C

7

/8"

1"

51/2"

3

/8"

24 PVDF 58081_ _(Left) .24 lbs

58082_ _(Right)

C

GAUGE FINISH PRODUCT NO. WT

24 ACG 5781241

5781341(Right)

24 PVDF 58812_ _(Left) .24 lbs

58813_ _

C

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5778141 8.70 lbs 10'-2"

24 PVDF 58781_ _ 8.70 lbs 10'-2"

* See chart on page 7

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5781441 .25 lbs 0'-10"

24 PVDF 58814_ _ .25 lbs 0'-10"

(Left) .24 lbs

(Right)

UNIVERSAL GUTTER/

DOWNSPOUT STRAP

A-A

C

16"

A

4” x 6” DOWNSPOUT

4"

6"

3 1/2” x 4” DOWNSPOUT

1

3

/

4"

2

Hems

A

11/2"

C

"

C

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5709241 .36 lbs 1'-4"

24 PVDF 58092_ _ .36 lbs 1'-4"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5709841 16.95 lbs 10'-2"

24 ACG 5710141 33.90 lbs 20'-3"

24 PVDF 58098_ _ 16.95 lbs 10'-2"

24 PVDF 58101_ _ 33.90 lbs 20'-3"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5709441 12.90 lbs 10'-2"

24 ACG 5709741 25.80 lbs 20'-3"

24 PVDF 58094_ _ 12.90 lbs 10'-2"

24 PVDF 58097_ _ 25.80 lbs 20'-3"

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

19

MAGNA-LOC

4” DOWNSPOUT BRACKET

FLASHING PROFILES (CONT.)

GAUGE FINISH PRODUCT NO. WT

24 ACG 5711041 .12 lbs

24 PVDF 58110_ _ .12 lbs

C

6” DOWNSPOUT BRACKET

C

ELBOWS

D

W

W

TYPE A ELBOWS

4"

6"

C

D

C

GAUGE FINISH PRODUCT NO. WT

24 ACG 5711241 .15 lbs

24 PVDF 58112_ _ .15 lbs

GAUGE FINISH PRODUCT NO. WT

31/2" x 4" ELBOWS (D x W)

95 DEGREE

24 ACG 5710241 2.30 lbs

24 PVDF 58102_ _ 2.30 lbs

45 DEGREE

24 ACG 5710641 2.30 lbs

24 PVDF 58106_ _ 2.30 lbs

4"x 6" ELBOWS (D x W)

95 DEGREE

24 ACG 5710441 3.00 lbs

24 PVDF 58104_ _ 3.00 lbs

20

D

C

TYPE B ELBOW

OFFSET CLEAT

11/2"

C

W

1"

1

/2"

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

45 DEGREE

24 ACG 5710841 3.00 lbs

24 PVDF 58108_ _ 3.00 lbs

Notes:

1) Type “A” & “B” has seam on heel. Specify otherwise at time of order.

2) Specify left or right at time of order for Type “B” elbows.

GAUGE FINISH PRODUCT NO. WT LENGTH

24 Supplied in 5806499 2.40 lbs 10'-2"

Various Colors

MAGNA-LOC

CLEAT

135°

21/2"

FLASHING PROFILES (CONT.)

GAUGE FINISH PRODUCT NO. WT LENGTH

24 Supplied in 5806099 2.40 lbs 10'-2"

Various Colors

1

/2"

C

MAGNA-LOC

Z-CLOSURE

1"

2"

1"

MAGNA-LOC

RIB COVER

SSR SCULPTURED

GUTTER CORNER BOX

Looking from Eave to Ridge (Right Shown)

C

C

C

C

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5782641 3.32 lbs 10'-2"

24 PVDF 58826_ _ 3.32 lbs 10'-2"

GAUGE FINISH PRODUCT NO. WT LENGTH

24 ACG 5785441 .57 lbs 8"

24 PVDF 58854_ _ .57 lbs 8"

Sold as a 2-piece unit.

GAUGE FINISH PRODUCT NO. WT

24 ACG 5778441 6.00 lbs

24 PVDF 58784_ _ 6.00 lbs

Specify Roof Slope

Specify Right or Left

SSR SCULPTURED

PEAK BOX

C

GAUGE FINISH PRODUCT NO. WT

24 ACG 5778541 6.00 lbs

24 PVDF 58785_ _ 6.00 lbs

* See chart on page 7

Specify Roof Slope

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

21

MAGNA-LOC

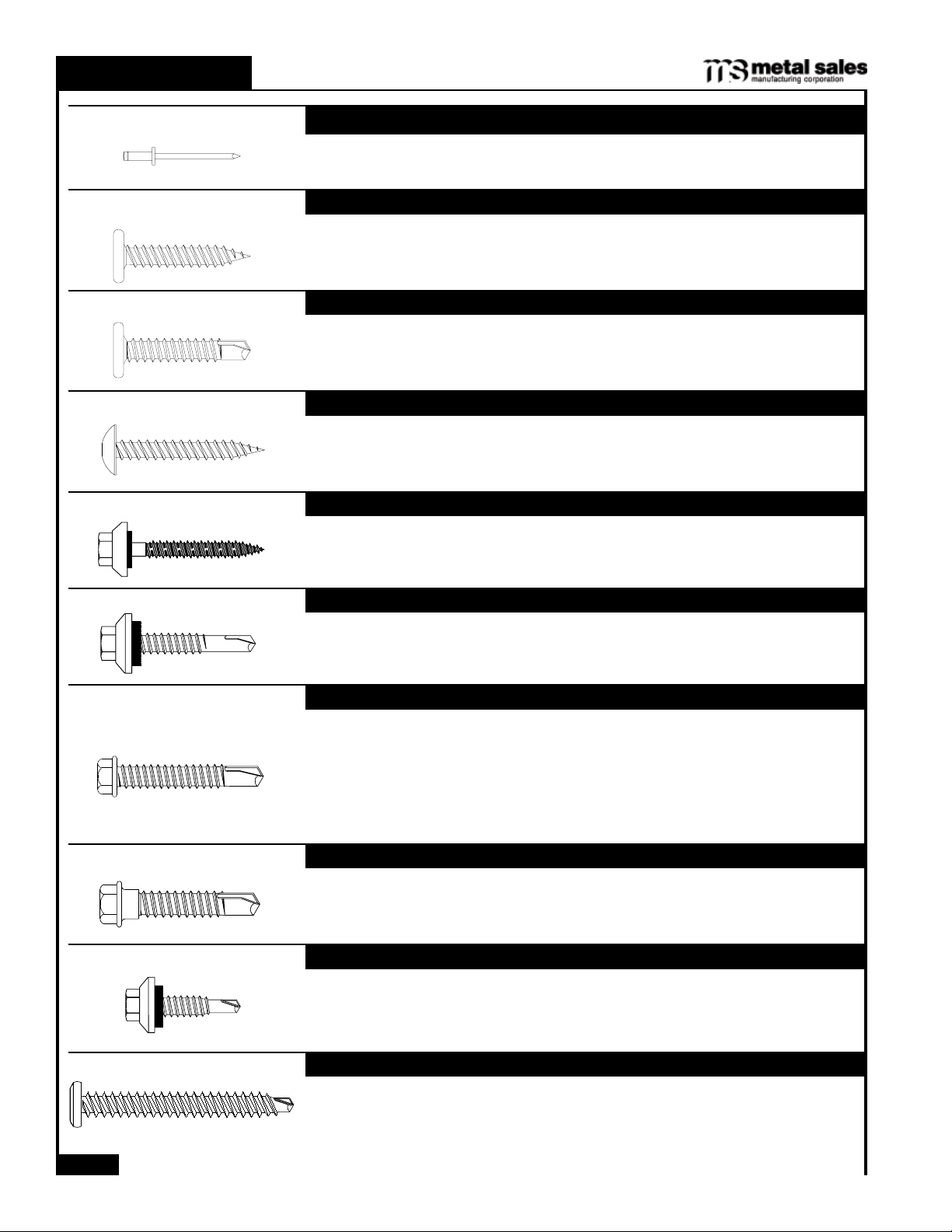

FASTENER SELECTION GUIDE

POP RIVET

PANCAKE HEAD

SIZE TYPE FINISH APPLICATION

1

/8"x 3/16" A Unpainted Flashing to Panel or Flashing

1

/8"x 3/16" A Painted Flashing to Panel or Flashing

SIZE TYPE FINISH APPLICATION

WOODSCREW

#10-12x1" A Plated Flashing to wood decking

PANCAKE HEAD DRILLER SIZE TYPE FINISH APPLICATION

#10-16x1" Driller Plated

Flashing to metal

substructure

LOW PROFILE WOODSCREW SIZE TYPE FINISH APPLICATION

#12-11x11/2" A Plated Clips to wood decking

WOODSCREW XL SIZE TYPE FINISH APPLICATION

#9-16x11/4"-11/2"

1

#9-16x1

/4"-11/2" A Painted

A

Unpainted

Panel or Flashing to wood

substructure

Panel or Flashing to wood

substructure

SELF DRILLER XL SIZE TYPE FINISH APPLICATION

#12-14x11/4"-11/2" Driller Unpainted

#12-14x1

1

/4"-11/2" Driller Painted

Panel or Flashing to metal

substructure

Panel or Flashing to metal

substructure

SELF DRILLER NO WASHER SIZE TYPE FINISH APPLICATION

1

/4"-14x11/2" Driller (#2 point) Plated

Panel clipst to metal

substructure

#12-24x11/4" Driller (#4 point) Plated

#12-14x1" Driller Plated

Panel clipss to bar joists up

to 3/8" thick

Accessories to meta

substructure and used with

framing on retrofit

SHOULDER SELF DRILLER SIZE TYPE FINISH APPLICATION

1

/4"-14x11/4" Driller Plated

For use with Floating Rake

Zee to substructure

STITCH SCREW XL SIZE TYPE FINISH APPLICATION

1

/4"-14x7/8" Stitch Unpainted Flashing to Panel or Flashing

1

/4"-14x7/8" Stitch Painted Flashing to Panel or Flashing

DECK SCREW SIZE TYPE FINISH APPLICATION

Panel Clip to metal deck

and rigid board insulation

assembly or wood

substructure

22

#14-14x2"-8" Driller Black

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

MAGNA-LOC

FASTENER TECHNICAL INFORMATION

PHYSICAL PROPERTIES

FASTENER

TRUSS HEAD WOODSCREW

#8-15x

PANCAKE HEAD WOODSCREW

#10-12x1"

WOODSCREW

#9-16x1",11/2"

LOW PROFILE WOODSCREW

12-11 x11/2"

PANCAKE HEAD DRILLER

#10-16x1" SELF DRILLING

SELF DRILLER

NO WASHER

3

/4"

HEAD

DIA/TYPE

Truss Hd.

#2 Philips

.447 IN.

#2 Philips

THREAD

DIA. O.D.

THREAD

DIA. I.D.

MIN

TENSILE

MIN.

TORSIONAL

.162-.168 .105-.110 1672 lbs 61 In lbs 1087 lbs

.188-.194 .126-.133 1673 lbs 79 In lbs 1311 lbs

1/4" HWH .175-.181 .127-133 2429 lbs 80 In lbs 1355 lbs

#3 Square

Drive

.201-.208 .125-.131 2050 lbs 81 In lbs 1369 lbs

#2 Philips .183-.189 .135-.141 1984 lbs 80 In lbs 1442 lbs

NOM.

SHEAR

SELF DRILLER

SELF DRILLER

#12-14x1",1

STITCH

DECK SCREW

1

/4"-14x11/2" SELF DRILLING

NO WASHER

#12-14x1",11/2" SELF DRILLING

1

/4",11/2" SELF DRILLING

1

/4"-14x7/8" SELF DRILLING

#14-14x2",4",5",6",8"

3/8" HWH .240-.246 .185-.192

5/16"

HWH

5/16"

HWH

5/16"

HWH

#3 Philips

.448 Max

.209-.215 .157-.165

.209-.215 .157-.165

.240-.246 .185-.192

.235-.242 .155

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

23

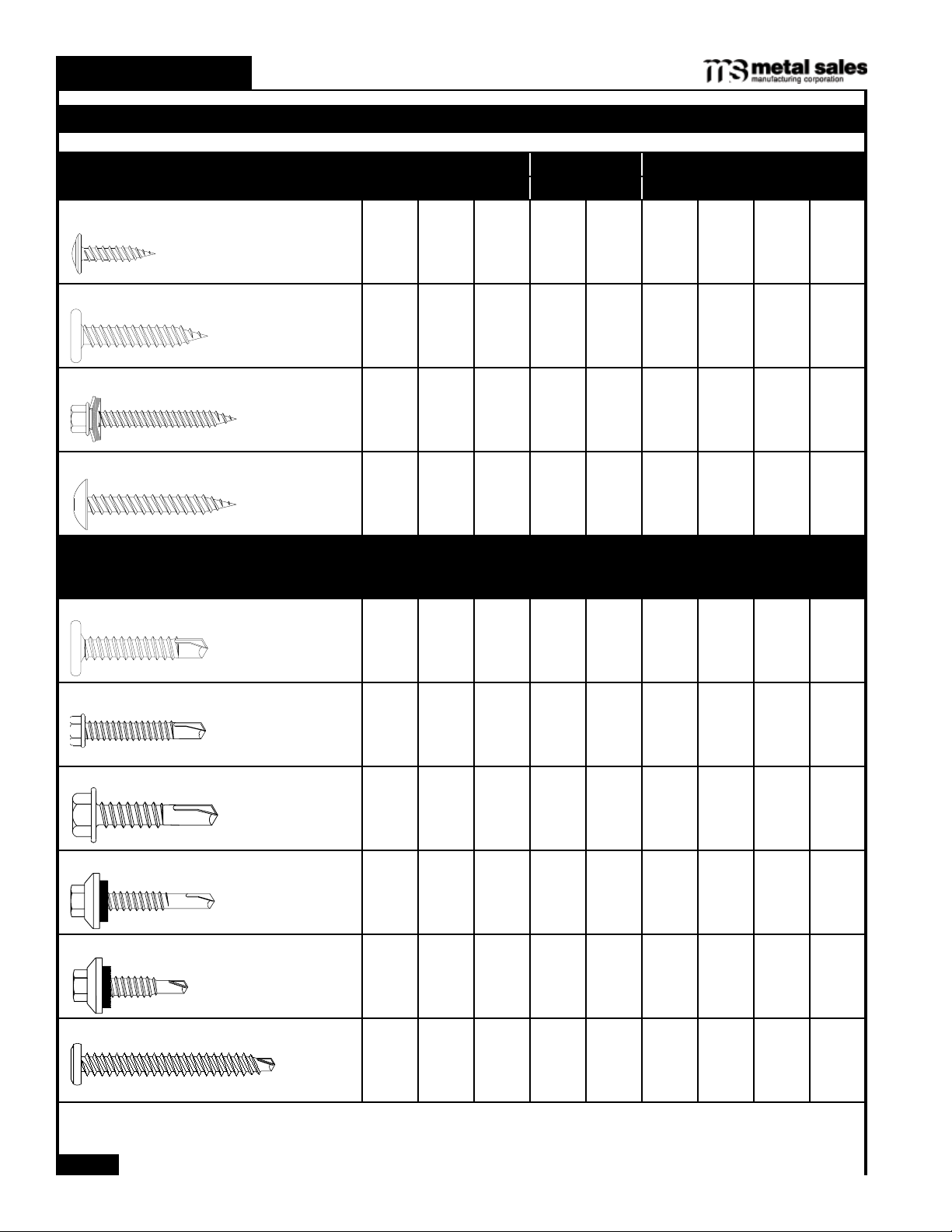

MAGNA-LOC

FASTENER TECHNICAL INFORMATION (CONT.)

PULL OUT VALUES - POUNDS (RECOMMENDED SAFETY FACTOR)

FASTENER

TRUSS HEAD WOODSCREW

PANCAKE HEAD WOODSCREW

WOODSCREW

#9-16x1",11/2"

LOW PROFILE WOODSCREW

FASTENER

PANCAKE HEAD DRILLER

#10-16x1" SELF DRILLING

SELF DRILLER

SELF DRILLER

SELF DRILLER

NO WASHER

1

/4"-14x11/2" SELF DRILLING

NO WASHER

#12-14x1",11/2" SELF DRILLING

#8-15x3/4"

#10-12x1"

12-11 x11/2"

Plywood OSB Hard/Soft Wood

3/4" 5/8" 1/2" 19/32" 7/16"

461

340

(3.26

377

(

Spruce Fir Oak Pine

98 375 405 593 464

615 521 339 290 257

565 498 326 223 1537

Steel

3/8" 1/4" 3/16" 10 GA 12 GA

(55)

1514

(2.59)

2031

(2.55)

1788

(2.54)

14 GA

(55)

953

(2.54)

1172

(2.54)

1056

(2.54)

16 GA

825

(2.54)

1043

(2.55)

850

(3.10)

(55)

18 GA

(50)

951

(2.62)

790

(2.60)

22 GA

(50)

167

(2.69)

209

(2.68)

180

(2.76)

#12-14x1",1

STITCH

DECK SCREW

24

1

/4",11/2" SELF DRILLING

1

/4"-14x7/8" SELF DRILLING

#14-14x2",4",5",6",8"

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

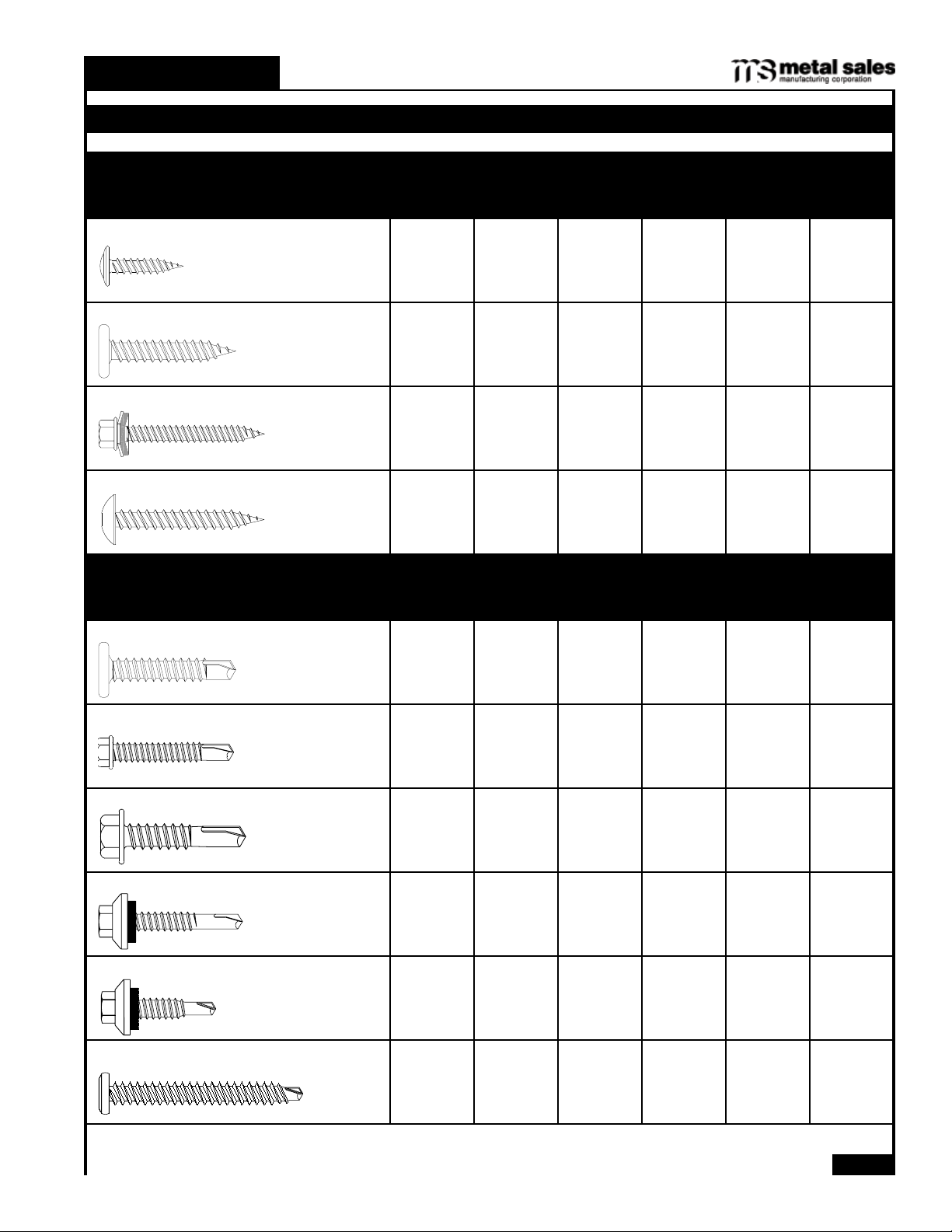

MAGNA-LOC

FASTENER TECHNICAL INFORMATION (CONT.)

PULL OVER STRENGTH VALUES (POUNDS ULTIMATE)

FASTENER

TRUSS HEAD WOODSCREW

#8-15x

PANCAKE HEAD WOODSCREW

#10-12x1"

WOODSCREW

#9-16x1",11/2"

LOW PROFILE WOODSCREW

20 GA 22 GA

3

/4"

(50)

N/A

1129

(2.56)

901

(2.59)

24 GA

(50)

852

(2.57)

843

(2.55)

728

(2.73)

STEEL

26 GA

(80)

693

(2.64)

658

(2.60)

563

(2.63)

26 GA

(50)

619

(2.60)

661

(2.55)

492

(2.67)

29 GA

(80)

546

(2.83)

500

(3.08)

426

(2.77)

FASTENER

PANCAKE HEAD DRILLER

#10-16x1"

SELF DRILLER

SELF DRILLER NO WASHER

SELF DRILLER

STITCH

NO WASHER

1

/4"-14x11/2" SELF DRILLING

#12-14x1",11/2" SELF DRILLING

#12-14x1",1

1

/4",11/2" SELF DRILLING

12-11 x11/2"

SELF DRILLING

20 GA 22 GA

(50)

751

(2.74)

24 GA

(50)

1263

(2.55)

1357

(2.61)

STEEL

26 GA

(80)

870

(2.63)

918

(2.60)

26 GA

(50)

654

(2.71)

667

(2.63)

29 GA

(80)

524

(2.95)

DECK SCREW

1

/4"-14x7/8" SELF DRILLING

#14-14x2",4",5",6",8"

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

25

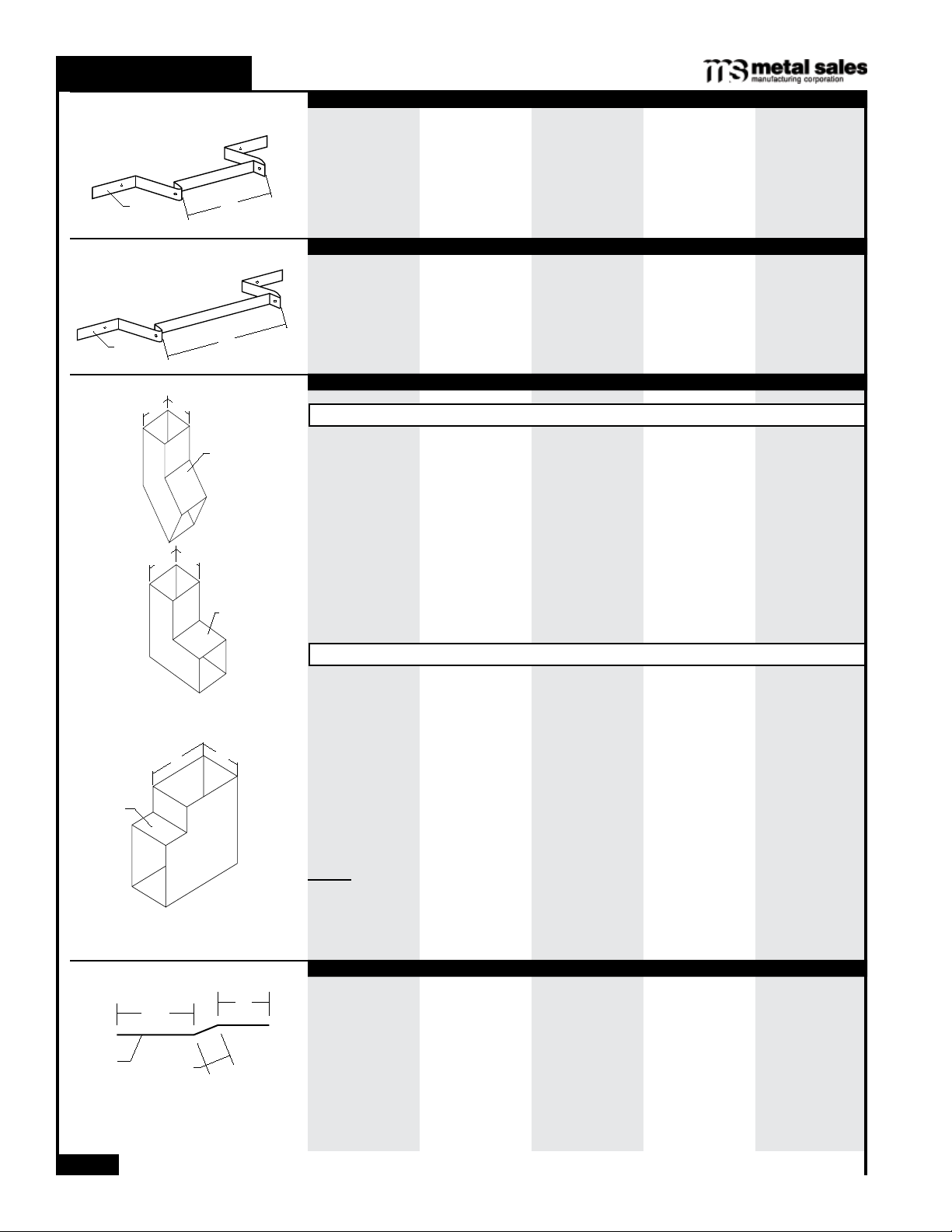

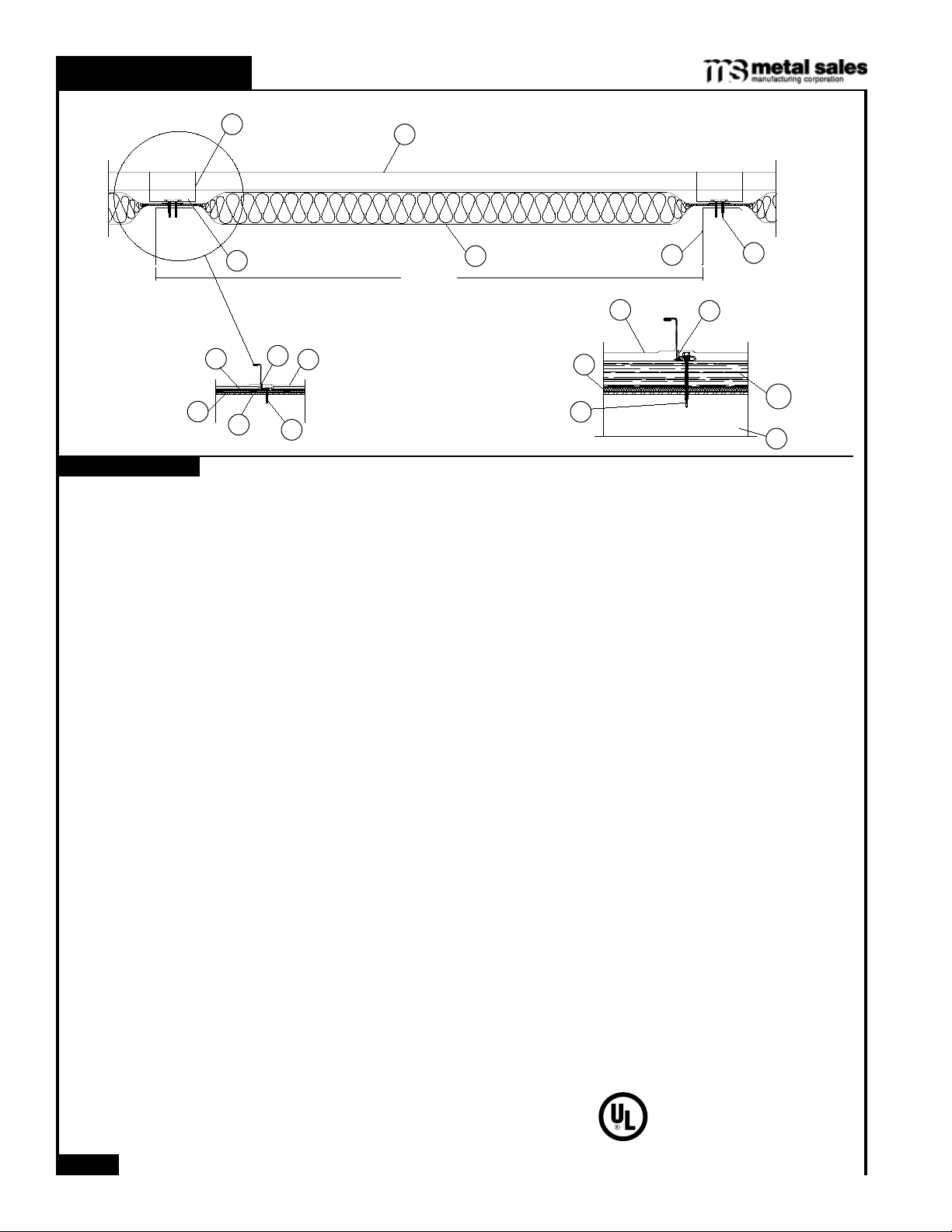

MAGNA-LOC

UL 580 WIND UPLIFT INFORMATION

MAGNA-LOC

Construction No. 506

October 16, 2001

Uplift - Class 90

Fire Not Investigated

2

4

4

6

1. Metal Roof Deck Panels* No. 24 MSG min thick coated steel. Panel width, max 18 in., min 12 in.; rib height 2 in.

Panels continuous over two or more spans. The panel flat area may have optional striations or minor corrugations

placed at various locations in the panel flat area beginning min of 2 in. from side ribs. The upper flange of the panel

rib may be horizontal, or optionally formed down to form an angle of 0 degree to 90 degree between the vertical

segment and the top flange of the rib. End lap to occur adjacent to and within 12 in. of purlin (Item 6) with panels

overlapped 2 in. min. An end lap back-up-plate (Item 2A) to be used. A bead of sealant may be used at panel

end laps and side ribs. Ribs to be seamed with an electric or hand seaming tool to form a flange with a tight hem.

Seaming process to include the upper portion of the Panel Clips (Item 2).

METAL SALES MFG CORP - “Magna-Loc 18”, “Magna-Loc 16”

2. Roof Deck Fasteners* (Panel Clips) Located at side of panels over purlins (Item 6). (Max spacing 60 in. OC).

When wood thermal block (Item 4A) is used, clips to be located on top. Either of the following:

Fixed Clip (Not Shown) - One piece assembly fabricated from No. 22 MSG min thick steel, 3-1/2 in. wide.

Floating Clip - Two piece assembly with a base fabricated from No. 16 MSG min thick steel, 2 in. wide and a

top fabricated from No. 22 MSG min thick steel, 4-5/16 in. wide.

2A. End Lap Back-Up-Plate (Not shown) - No. 16 MSG min thick coated steel channel, 3 in. wide with two 3/8 in. deep

legs. Max length 74 in. Located under the panel end lap (50 ksi min yield strength).

2B. Roof Deck Fasteners*(Cinch Plate) (Optional) - (Not Shown) - width 1-5/16 in., length 18 in. max. Fabricated from

No. 20 MSG min thick stainless steel. Located over end lap.

2C. End Lap Back-Up-Plate (Optional) - (Not shown) - No. 16 MSG min thick coated steel. Width 11, 13 or 19 in.,

length 7 in. Two 3/4 in. by 3/4 in. tabs and a 1 in. deep vertical leg located at up-slope edge of panel. Used with

Item 2A when Item

*2B is not used (50 ksi min yield strength).

3. Fasteners (Screws) For panel clip-to-purlin attachment to be 1/4"-14 by min 1 in. long self drilling, self-tapping

hex-washer-head plated steel screws. Two fasteners used per clip. Fasteners used at end lap to be one of the

following: No. 1/4-14 by 1 in. long Type AB point, self-drilling, self-tapping hex-washer-head plated or stainless steel

screws or No. 12-14 by 1-1/4 in. long self-drilling self-tapping hex-washer-head plated steel screws. Spacing for 16

in. wide panels to be a 1, 3, 4, 4, 3 in. pattern; spacing for 18 in. wide panels to be a 1-1/2, 3-1/2, 4, 4, 3-1/2, 1-1/2

in. pattern. When optional cinch plate (Item 2B) is used, four fasteners to be required, inserted into factory punched

guide holes.

4. Thermal Spacer (Optional) - Polyisocyanurate - 3/8 in. min, 2-3/8 in. max thick, 4 in. min width, length sized to fit

between panel clips (Item 2).

5. Insulation (Optional) - Any compressible blanket insulation 8 in. max thick before compression, or 6 in. max thick

when located between Thermal Spacer (Item 4) or Thermal Block (Item 4A) and purlin (Item 6).

6. Purlins No. 16 MSG min thick steel ( 50 ksi min yield strength ). Max spacing 60 in. OC.

Refer to General Information, Roof Deck Constructions for items not evaluated.

*Bearing the UL Classification Mark

2

1

5

3

1

60" MAX

5

1

5

3

6

3

2

4A

6

26

Underwriters Laboratories Inc. ®

LISTED

© Metal Sales Manufacturing Corporation / Subject to change without notice 6/12

Loading...

Loading...