Metal Sales Image II Installation

Important Information

The application and detail drawings in this manual

are strictly for illustration purposes and may not be

applicable to all building designs or product installations. All projects should conform to applicable building codes for that particular area.

Metal Sales Manufacturing Corporation is not

responsible for the performance of the metal panel

system if it is not installed in accordance with the suggested instructions referenced in this manual. If there

is a conict between this manual and the approved

Metal Sales' erection drawings, the approved erection

drawings are to take precedence.

Prior to ordering and installing materials, all dimen-

sions should be veried by eld measurements.

Oil canning is not a cause for rejection.

Metal Sales reserves the right to modify, without

notice, any details, recommendations or suggestions.

This manual is designed to be utilized as a guide when

installing a Image II Roof System.

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

1

Table of Contents

Important Information ............................................................ 1

Panel Information .................................................................... 3

Handling Material .................................................................... 4

Delivery & Storage ................................................................... 4

Safety Considerations .............................................................. 5

Panel Conditions ...................................................................6-7

Slope Data ................................................................................. 8

Flashings ..............................................................................9-11

Eave ........................................................................................... 9

Extended Eave .......................................................................... 9

Cleat .......................................................................................... 9

Offset Cleat ............................................................................... 9

12" Coil ...................................................................................... 9

Valley ....................................................................................... 10

Image II Rake ......................................................................... 10

Image II Step Rake ................................................................ 10

Rakewall.................................................................................. 10

Image II Step Rakewall ......................................................... 10

Counter Flashing .................................................................... 10

Reglet Flashing ....................................................................... 10

Step Ridge/Hip Cover ............................................................ 10

13" Ridge/Hip Cover .............................................................. 10

Perforated Vent Drip ............................................................. 10

Peak ......................................................................................... 11

Pitch Break ............................................................................. 11

1.5" Sill/Head .......................................................................... 11

1.5" Sill To Soffit ..................................................................... 11

1" Z-Closure ............................................................................ 11

Accessories .............................................................................. 12

Fastener Selection & Installation..........................................13

Fastening Guide ................................................................14-15

Eave Installation..................................................................... 16

Valley Installation .................................................................. 17

Panel Installation (Exposed) ............................................18-19

Panel Installation (Concealed) .........................................20-22

Details .................................................................................23-33

Eave ......................................................................................... 23

Gutter ...................................................................................... 24

Valley ....................................................................................... 25

Rake ......................................................................................... 26

Rakewall with Counter .......................................................... 27

Rakewall with Reglet ............................................................. 28

Endwall with Counter ............................................................29

Endwall with Reglet ............................................................... 30

Slope Change .......................................................................... 31

Peak ......................................................................................... 31

Ridge/Hip ................................................................................ 32

Vented Ridge ........................................................................... 32

1" Z-Closure Installation ....................................................... 33

Final Instructions ................................................................... 34

Section Properties ..................................................................35

Notes ...................................................................................36-39

2

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

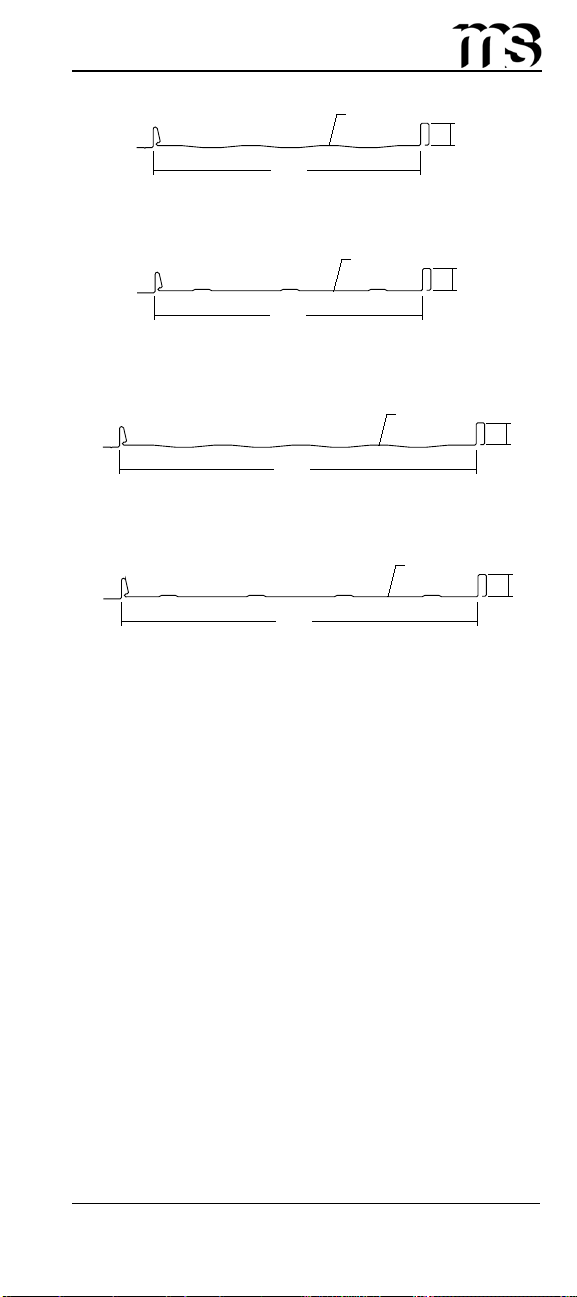

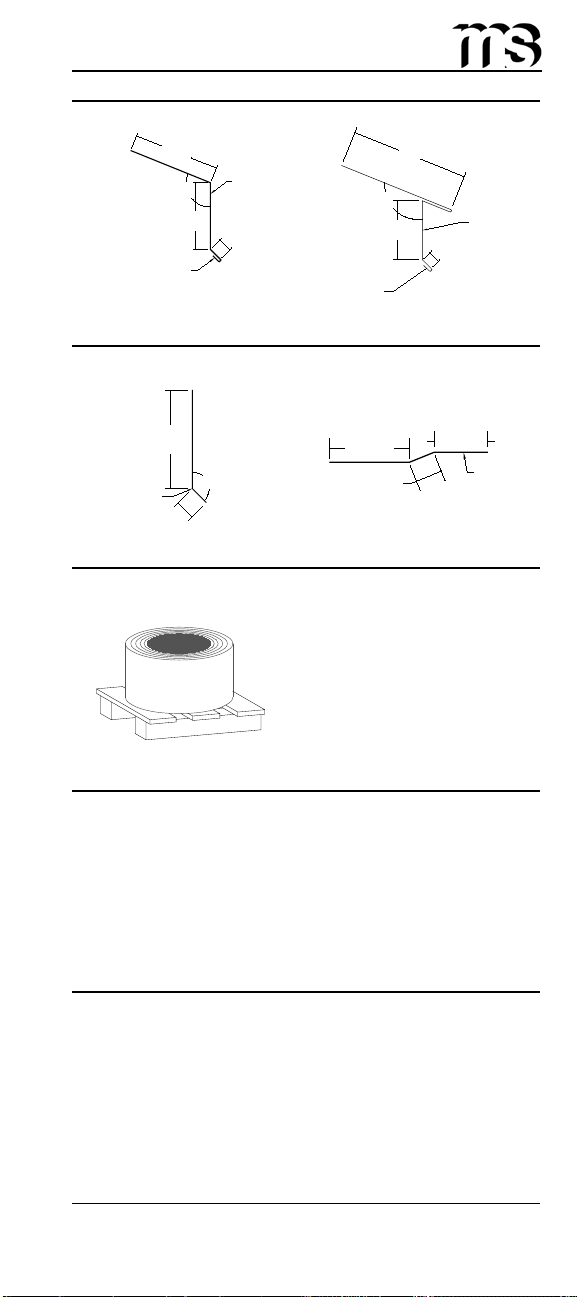

Panel Information

12"

Panel Coverage

Striated

12"

Panel Coverage

With Minor Ribs

(West Coast Only*)

16"

Panel Coverage

Striated

16"

Panel Coverage

With Minor Ribs

(West Coast Only*)

C

1"

C

1"

C

1"

C

1"

• Minimum recommended slope for Image II is 3:12

• Recommended substrate is 5/8" plywood with 30#

felt moisture barrier

• Available in 12" and 16" widths with 1" rib height

• Minimum panel length is 5'

• Maximum panel length is 30'

Call a Metal Sales representative for more information.

*West Coast refers to Image II panels manufactured at the

Woodland, California and Anchorage, Alaska branches

C - Indicates colored side of panel

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

3

Handling Material

General Handling

Each bundle should be handled carefully to avoid

being damaged. Care should be taken to prevent

bending of the panel or scratching the nish. Whenever possible, the bundle should remain crated until

it is located in its place of storage. If bundles must

be opened, we recommend you recrate them before

lifting. To avoid damage please lift the bundle at its

center of gravity.

CAUTION

Improper loading and unloading of bundles and

crates may result in bodily harm and/or

material damage. Metal Sales is not responsible for

bodily injuries and/or material

damages resulting from improper

loading and unloading.

Delivery & Storage

• Always check the shipment upon delivery. Check

for damage and check material quantities against

the shipping list. Note any damaged material or

shortages at the time of delivery and notify your

supplier within 24 hours.

• Store the panels and other materials in a dry, well-

ventilated area away from traffic. Elevate one end

of the bundle, maximum 2', so that any moisture

that may have accumulated during shipping can

run off. Be sure that air will be able to circulate

freely around the bundles to avoid the build-up of

moisture. Never store materials in direct contact

with the ground.

• Some products may have a peel off plastic film

over the painted surface. This film was factory

applied to prevent damage to the finish that

may occur during manufacturing or shipping. If

this film is present, avoid exposure of the “peelcoated” parts to sunlight and remove the “peelcoat” prior to installation.

• Do not slide panels or accessories across one

another.

4

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

Safety Considerations

STUDY APPLICABLE OSHA AND OTHER STATE

AND FEDERAL SAFETY REQUIREMENTS BEFORE

FOLLOWING THESE INSTRUCTIONS.

The installation of metal roofing systems is a

dangerous procedure and should be supervised by

trained, knowledgeable installers. USE EXTREME

CARE WHILE INSTALLING ROOFING PANELS.

The installer of the roofing system is responsible

for reading these instructions and determining the

safest way to install the roofing system.

Proper personal protective equipment may

include, but is not limited to:

• Hand Protection: Kevlar coated gloves to

reduce risk of abrasion and laceration while

handling product

• Eye Protection: Approved safety glasses to

protect against flying debris when handling or

cutting product

• Fall Protection: Never step on unsecured panels.

Never work on a roof without protection from

falls

Note: Other personal protective equipment may be

required, including: hard hats, protective clothing,

or a harness.

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

5

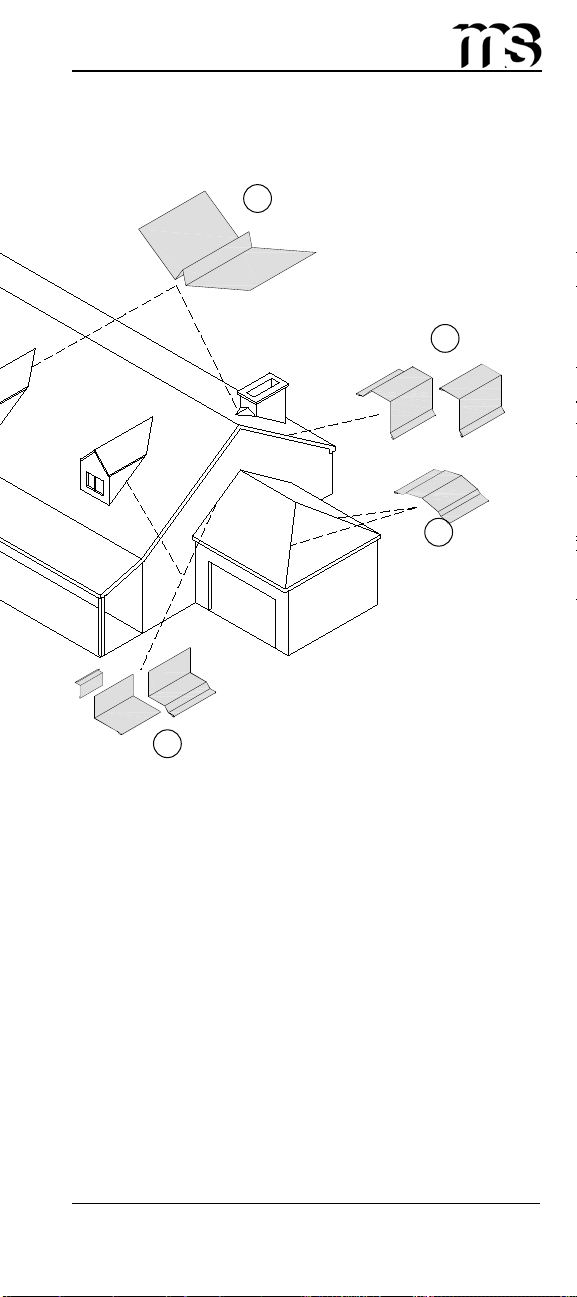

Panel Conditions

5

1

4

2

3

Map of Typical Conditions

1. Gutter (See Page 24)

2. Peak (See Page 31)

3. Endwall (See Pages 29-30)

4. Ridge/Vented Ridge (See Page 32)

5. Eave (See Pages 16, 23)

6. Hip (See Page 32)

7. Valley (See Pages 17, 25)

8. Rakewall (See Pages 27-28)

9. Rake (See Page 26)

10. Slope Change (See Page 31)

6

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

10

7

9

6

8

The application and detail drawings that follow are

strictly for illustration purposes and may not be applicable to all building designs or product installations.

All projects should conform to applicable building

codes for that particular area. It is recommended to

follow all building regulations and standard industry

practices.

Metal Sales is not responsible for the performance of

the metal panel system if it is not installed in accordance with the suggested instructions referenced in

this manual. If there is a conict between this manual

and the approved Metal Sales erection drawings, the

approved erection drawings are to take precedence.

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

7

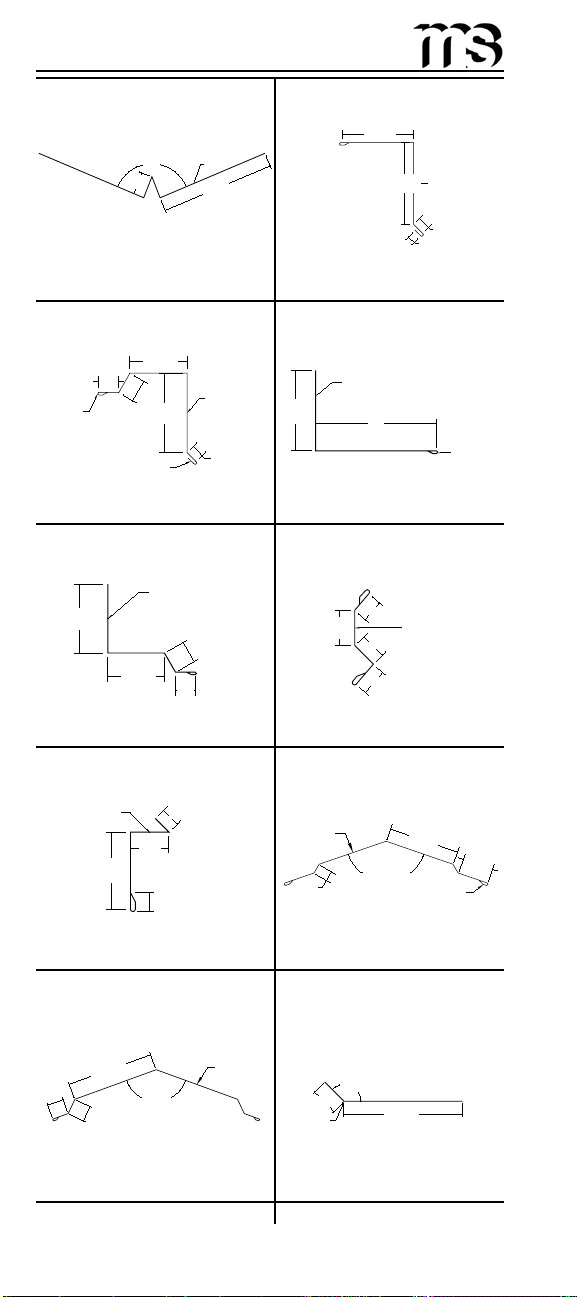

Slope Data

This chart should be used when specifying and ordering

panels and ashings. It will help you determine overall

required length of material on sloped applications.

SLOPE

SLOPE

1:12

2:12

3:12

4:12

5:12

6:12

FACTOR

1.0035

1.0138

1.0308

1.0541

1.0833

1.1180

EXAMPLE:

HIP / VALLEY

MULTIPLIER

S

1.4167

1.4240

1.4362

1.4530

1.4743

1.5000

SLOPE

10:12

11:12

12:12

Peak

7:12

8:12

9:12

SLOPE

FACTOR

1.1577

1.2019

1.2500

1.3017

1.3566

1.4142

HIP / VALLEY

MULTIPLIER

1.5298

1.5635

1.6008

1.6415

1.6853

1.7320

Eave

L

H

L

Hip or Valley

Rake

Eave or Gutter

28'-0''

14'-0''

Ridge

14'-0''

28'-0''

Your building is 28

'-0'' wide with a 4:12 pitch

To determine the panel lengths for each side:

(L) X (SLOPE FACTOR) = S

Slope

12

4

14'-0'' x 1.0541(from chart above) = 14.7573' OR 14'-9''

8

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

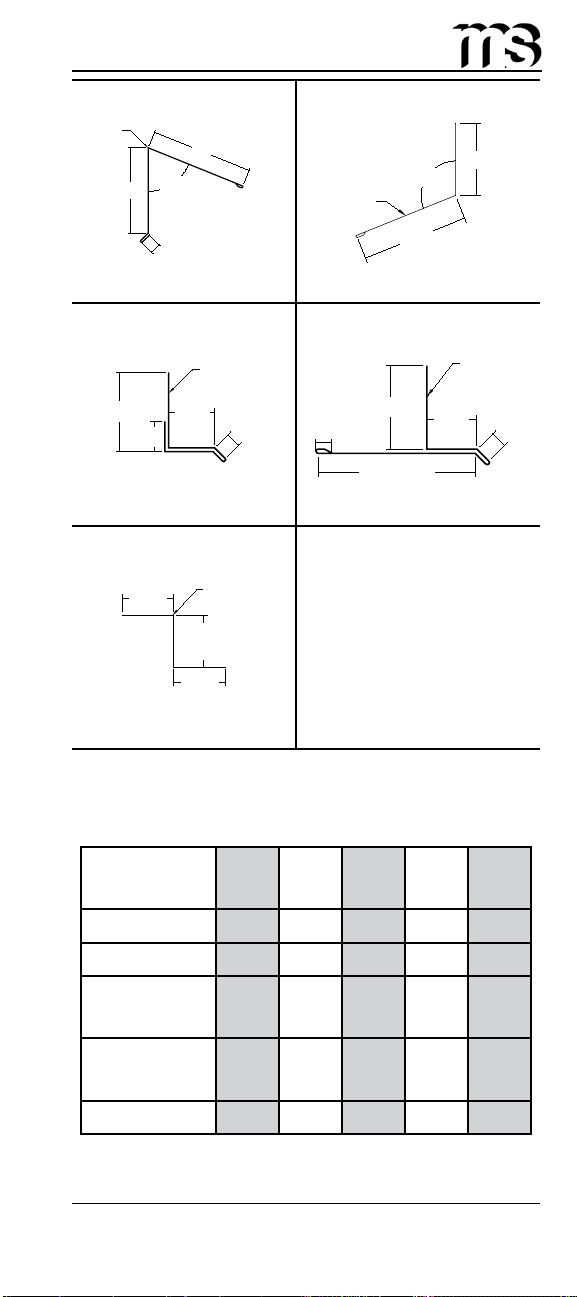

Standard Flashings

C - Indicates colored side of panel

Eave

37/8"

X*

3"

Open Hem

10'-2'' Length

* Specify Slope Angle

C

5

/8"

Extended Eave

Open Hem

6"

X*

3"

5

/8"

10'-2'' Length

* Specify Slope Angle

C

Cleat

1

/2"

2

135°

C

1

/2"

10'-2'' Length

12'' Coil

(For continuous gutters)

16'' Inside Diameter

Offset Cleat

11/2"

1

/2"

10'-2'' Length

1"

C

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

9

Standard Flashings (Cont.)

Valley

X*

2"

10'-2'' Length

* Specify Slope Angle

C

10"

Image II Step Rake

27/8"

1"

Hem

11/8"

Open Hem

10'-2'' or 20'-3'' Length

4"

C

5

/8"

Image II Step Rakewall

C

4"

11/8"

27/8"

1"

Image II Rake

31/2"

4"

10'-2'' or 20'-3'' Length

Rakewall

C

31/2"

4"

10'-2'' Length

Counter Flashing

5

/8"

1"

3

/4"

3

/4"

C

5

/8"

3

/8"

Hem

C

10'-2'' Length

Reglet Flashing

1

C

/2"

Step Ridge/Hip Cover

1"

2"

Hem

10'-2'' Length

13” Ridge/Hip Cover

51/2"

1

/2"

1

10

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

X*

1

/2"

10'-2'' Length

* Specify Slope Angle

C

Perforated Vent Drip

10'-2'' Length

C

1

/2"

10'-2'' Length

* Specify Slope Angle

135°

3

/4"

C

10'-2'' Length

X*

31/4"

1

3

/2"

Hem

11/2"

Standard Flashings (Cont.)

Peak

C

5"

10'-2'' or 20'-3'' Length

* Specify Slope Angle

6"

X*

3

/8"

1.5” Sill/Head

C

21/2"

11/2"

1"

10'-2'' Length

1” Z-Closure

1"

1"

Pitch Break

4"

X*

C

6"

10'-2'' Length

* Specify Slope Angle

1.5” Sill To Soft

C

21/2"

1

/2"

C

3

/8"

11/2"

43/4"

10'-2'' Length

1

/2"

1"

10'-2'' Length

PROFILE/

FLASHING

EAVE

PEAK

PITCH

BREAK

VALLEY,

HIP

RIDGE

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

3:12 4:12 5:12 6:12 7:12

104° 108° 113° 117° 120°

76° 72° 67° 63° 60°

104° 108° 113° 117° 120°

160° 154° 148° 143° 138°

152° 143° 135° 127° 120°

11

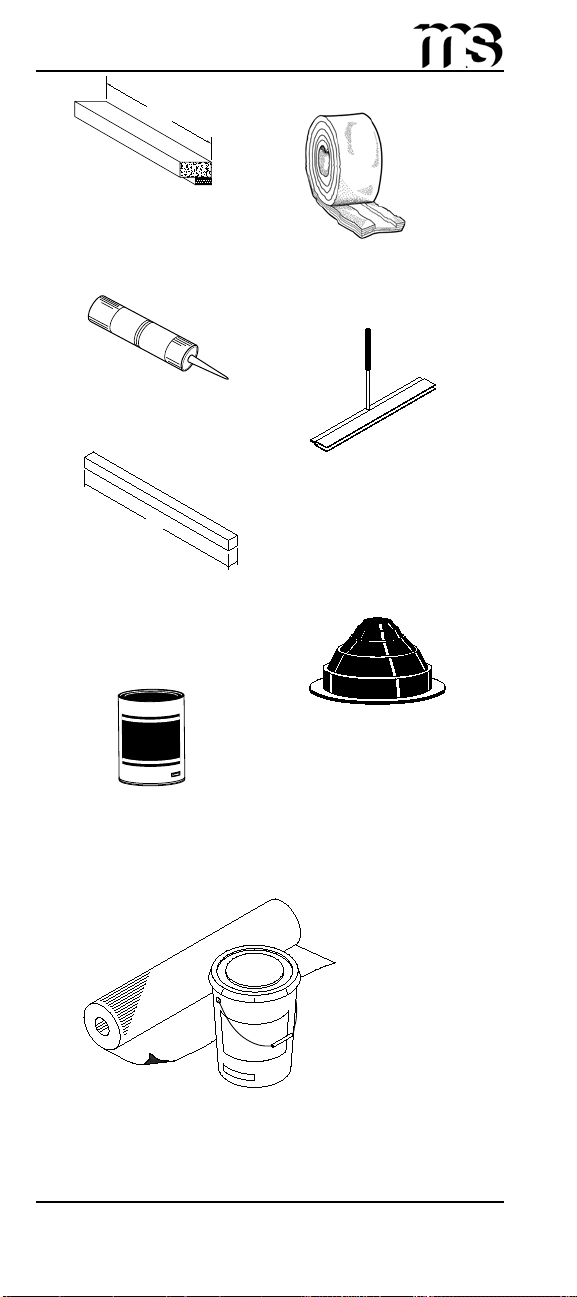

Accessories

36"

Cobra Vented Closure

Double Bead Tape Sealant

Tube Sealant

Metal Panel Hemming Tool

36"

1"

Image II Outside Closure

Touch-Up Paint

Available in pints

PVDF and CF45

7

/8" x 3/16" x 25'-0''

Butyl-Gray

Rubber Roof Jack

MINI (1/4" to 11/8" O.D. Pipe)

#2 (13/4" to 3" O.D. Pipe)

#4 (3" to 6" O.D. Pipe)

#6 (6" to 9" O.D. Pipe)

#8 (7" to 13" O.D. Pipe)

Underlayment

Primer

ms-HT

Peel-and-Stick

Underlayment

12

© Metal Sales Manufacturing Corporation / Subject to change without notice, effective 6/2011

Loading...

Loading...