Page 1

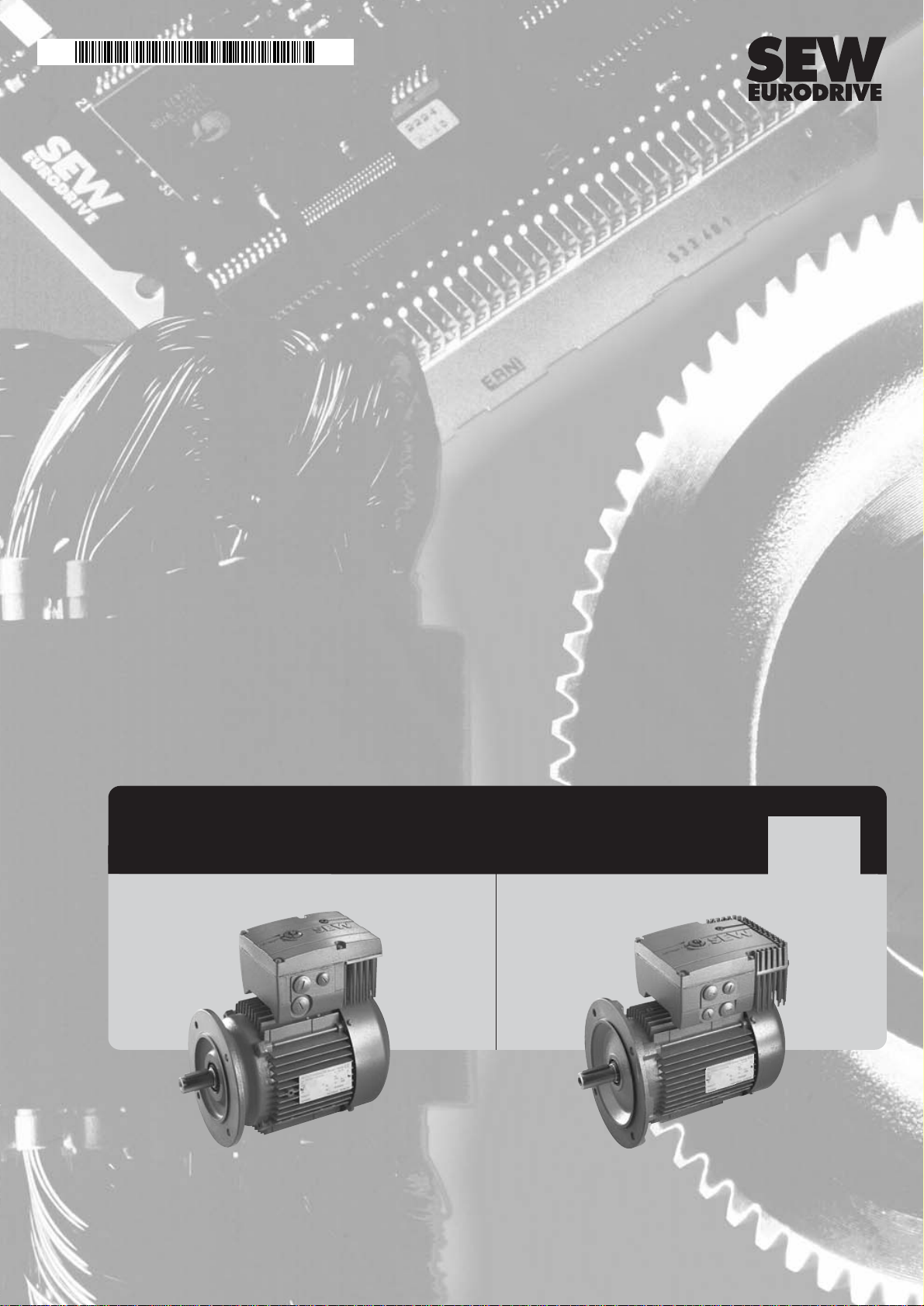

Edition

MOVIMOT® MM..C

08/2003

Operating Instructions

11218126 / EN

Page 2

SEW-EURODRIVE

Page 3

Contents

1 Important Notes................................................................................................. 5

2 Safety Notes ...................................................................................................... 7

3 Unit Design........................................................................................................ 8

3.1 MOVIMOT

3.2 Unit designations (MOVIMOT

3.3 MOVIMOT

3.4 Unit designations (MOVIMOT

4 Mechanical Installation...................................................................................16

4.1 MOVIMOT

4.2 Modular terminal box .............................................................................. 17

4.3 Mounting MOVIMOT

4.4 Option MLU..A / MLG..A / MLK11A ........................................................ 20

4.5 MBG11A option....................................................................................... 21

4.6 MWA21A option...................................................................................... 21

4.7 URM option............................................................................................. 22

5 Electrical Installation of MOVIMOT

5.1 Installation instructions............................................................................ 23

5.2 Connection of MOVIMOT

5.3 MOVIMOT

5.4 Connection MOVIMOT

5.5 Connection RS-485 bus master..............................................................31

5.6 Connection between MOVIMOT

6 Electrical Installation with Integrated AS-Interface ..................................... 37

6.1 Installation instructions............................................................................ 37

6.2 Connection options with integrated AS-Interface....................................39

6.3 Connection of MOVIMOT

6.4 Connection of MOVIMOT

6.5 Connection of MOVIMOT

6.6 Connection of URM option......................................................................45

6.7 Connection between MOVIMOT

7 Startup of Standard Design............................................................................ 51

7.1 Important startup instructions.................................................................. 51

7.2 Description of the controls ...................................................................... 51

7.3 Description of the DIP switches S1.........................................................53

7.4 Description of the DIP switches S2.........................................................55

7.5 Selectable special functions MM..C-503-00............................................ 58

7.6 Startup with binary control (control via terminals)................................... 77

7.7 Startup with options MBG11A or MLG11A ............................................. 79

7.8 Startup with MWA21A option (speed control module)............................ 82

7.9 Startup with external AS-i binary slave MLK11A .................................... 85

7.10 Additional information for mounting close to the motor...........................88

8 Startup with Integrated AS-Interface............................................................. 90

8.1 Important startup instructions.................................................................. 90

8.2 Description of the controls ...................................................................... 90

8.3 Description of the DIP switches S3.........................................................92

8.4 Description of the DIP switches S4.........................................................94

8.5 Selectable special functions MM..C-503-30............................................ 95

8.6 Startup procedure................................................................................. 102

8.7 Advanced startup with MOVITOOLS.................................................... 106

8.8 Additional information for mounting close to the motor.........................115

9 Startup with Communications Interface / Fieldbus ................................... 117

9.1 Startup procedure................................................................................. 117

9.2 Coding of process data......................................................................... 119

9.3 Function with RS-485 master................................................................ 122

®

inverter (standard design)..................................................... 8

®

inverter (with integrated AS-Interface)................................ 12

®

gearmotor ...........................................................................16

®

inverter with option P2.A close to the motor ....... 19

®

plug connectors .................................................................. 26

®

standard design) .....................................9

®

with integrated AS-Interface) ................13

®

Standard Design................................ 23

®

basic unit ..................................................... 25

®

options ............................................................ 27

®

and motor mounting close to motor... 32

®

MM../AVSK (connection option A)............... 42

®

MM../AZSK (connection option B)............... 43

®

MM../AND3/AZSK (connection option C) .... 44

®

and motor mounting close to motor .. 46

Operating Instructions – MOVIMOT® MM03C - MM3XC

3

Page 4

Contents

10 Diagnostics....................................................................................................127

10.1 Diagnostics of MOVIMOT

10.2 Diagnostics of MOVIMOT

®

standard design ........................................ 127

®

with integrated AS-Interface...................... 132

10.3 Important service information................................................................ 140

11 Inspection and Maintenance........................................................................ 141

11.1 Inspection and maintenance periods.................................................... 141

11.2 Inspection and maintenance work on the motor................................... 142

11.3 Inspection and maintenance work on the brake ................................... 144

11.4 Permitted ball bearing types ................................................................. 148

11.5 Working air gap, braking torque, brake.................................................148

12 Technical Data of Standard Design............................................................. 149

12.1 IEC design with connection voltages 380...500 VAC............................149

12.2 UL design with connection voltages 380500 VAC................................ 150

12.3 Technical data of options...................................................................... 151

12.4 Integrated RS-485 interface..................................................................153

12.5 Assignment of internal braking resistors............................................... 153

12.6 Assignment of external braking resistors.............................................. 154

12.7 Resistance and assignment of the brake coil ....................................... 154

13 Technical Data with Integrated AS-Interface.............................................. 155

13.1 IEC design with connection voltages 380...500 VAC............................155

13.2 Assignment of internal braking resistors............................................... 156

13.3 Assignment of external braking resistors.............................................. 156

13.4 Resistance and assignment of the brake coil ....................................... 156

13.5 URM voltage relay ................................................................................ 156

Index of Changes.......................................................................................... 157

Index...............................................................................................................158

4

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 5

1 Important Notes

Important Notes

1

Safety and warning instructions

Always follow the safety and warning instructions contained in this publication!

Electrical hazard

Possible consequences: Severe or fatal injuries.

Hazard

Possible consequences: Severe or fatal injuries.

Hazardous situation

Possible consequences: Slight or minor injuries.

Harmful situation

Possible consequences: Damage to the unit and the environment.

Tips and useful information.

Other applicable documents

Intended usage

• Operating Instructions "DR/DT/DV AC Motors, CT/CV Asynchronous Servomotors"

• If MOVIMOT

"Safe Disconnection for MOVIMOT

nents may be used in safety applications that were explicitly delivered with this

design by SEW-EURODRIVE!

• These MOVIMOT® drives are intended for industrial equipment. They comply with

the applicable standards and regulations and meet the requirements of the Low Voltage Directive 73/23/EEC.

• The use of MOVIMOT

• Technical data and information about the permitted conditions where the unit is used

can be found on the nameplate and in these operating instructions.

• It is essential to observe this specified information!

• Do not start up the unit (take it into operation in the designated fashion) until you have

established that the machine complies with the EMC Directive 89/336/EEC and that

the conformity of the end product has been determined in accordance with the Machinery Directive 89/392/EEC (with reference to EN 60204).

®

is used for emergency stops, the supplemental documentation

®

for hoist applications is limited!

®

" must be observed. Only those compo-

Operating Instructions – MOVIMOT® MM03C - MM3XC

5

Page 6

1

Important Notes

Site of operation

Waste disposal

The following uses are forbidden unless measures are expressly taken to make

them possible:

• Use in explosion-proof areas

• Use in areas exposed to harmful oils, acids, gases, vapors, dust, radiation, etc.

• Use in non-stationary applications which are subject to mechanical vibration and

shock loads in excess of the requirements in EN 50178

• Use in applications in which the MOVIMOT

functions (without master safety systems) for ensuring the safety of machinery and

people

This product consists of:

•Iron

•Aluminum

• Copper

• Plastic

• Electronic components

Dispose of all components in accordance with applicable regulations!

®

inverter undertakes independent safety

6

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 7

2 Safety Notes

• Never install damaged products or take them into operation. Please submit a com-

Safety Notes

plaint to the shipping company immediately in the event of a damage.

2

• Only electrical specialists with the relevant accident prevention training are allowed

to perform installation, startup and service work on the MOVIMOT

®

. They must also

comply with the regulations in force (e.g. EN 60204, VBG 4, DIN-VDE 0100/0113/

0160).

• Preventative measures and protection devices must correspond to the regulations in

force (e.g. EN 60204 or EN 50178).

Necessary protective measures: Grounding of MOVIMOT

®

.

• The unit meets all requirements for reliable isolation of power and electronics connections in accordance with EN 50178. All connected circuits must also satisfy the

requirements for reliable isolation so as to guarantee reliable isolation.

• Before removing the MOVIMOT

®

inverter, it must be disconnected from the supply

system. Dangerous voltages may still be present for up to one minute after disconnection from the power supply source.

• As soon as supply voltage is present at the MOVIMOT

closed, i.e. the MOVIMOT

®

inverter must be screwed on.

®

, the terminal box must be

• The fact that the status LED and other display elements are no longer illuminated

does not indicate that the unit has been disconnected from the power supply and no

longer carries any voltage.

• Mechanical blocking orunit-internal safety functions can cause a motor standstill. Removing the cause of this problem or performing a reset can result in the motor restarting on its own. If, for safety reasons, this is not permissible for the driven machine, MOVIMOT

• Danger of burns: The MOVIMOT

®

must be disconnected from the mains before correcting the fault.

®

surface temperature (especially of the heat sink)

can exceed 60 °C during operation!

• If MOVIMOT

documentation "Safe shutdown for MOVIMOT

®

or field distributors are used for emergency stops, the supplemental

®

" must be observed. Only those components may be used in safety applications that were explicitly delivered with this design by SEW-EURODRIVE!

Operating Instructions – MOVIMOT® MM03C - MM3XC

7

Page 8

3

Unit Design

MOVIMOT® inverter (standard design)

3Unit Design

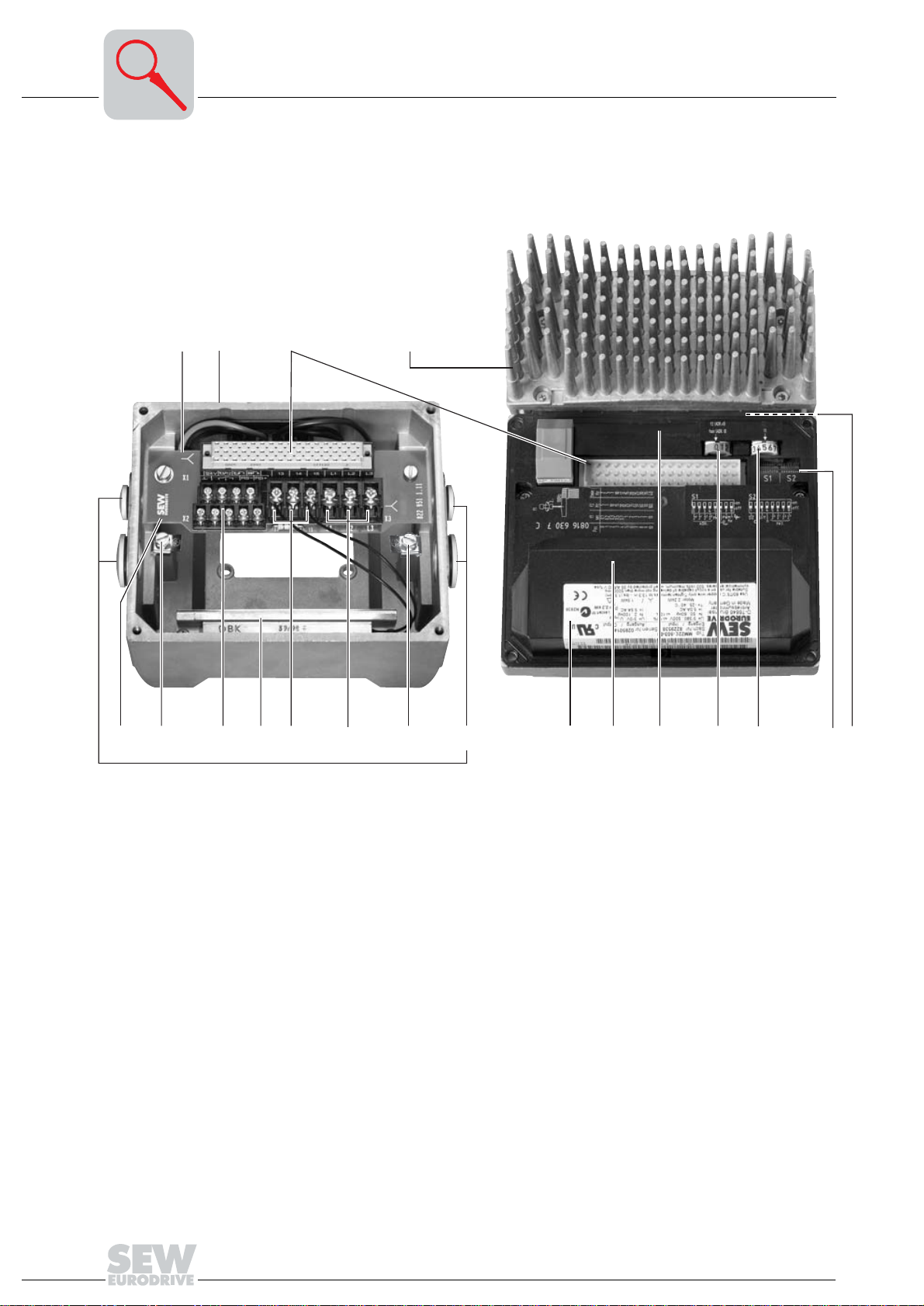

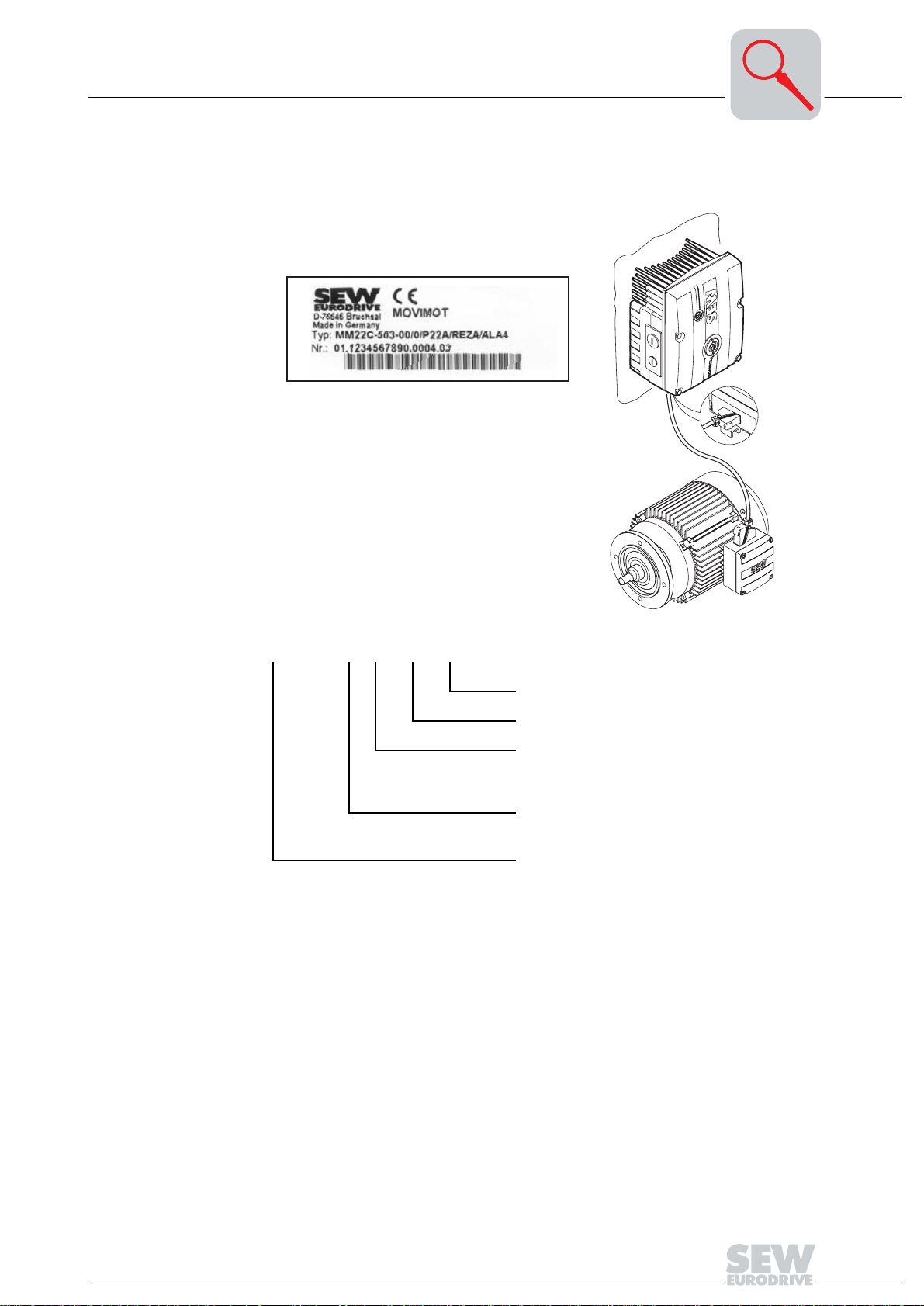

3.1 MOVIMOT® inverter (standard design)

2

1

34

5

6

1. Identification of the circuit type

2. Terminal box (size 2 used as example)

3. Connection plug between connection unit and inverter

4. MOVIMOT

5. Connection unit with terminals

6. Screw for PE connection

7. Electronics terminal strip X2

8. Internal braking resistor BW. (standard for motors without brake)

9. Connection of brake coil (X3). For motors without brake: Connection of internal

braking resistor BW. (standard)

10.Mains connection L1, L2, L3 (X3) (suitable for 2 x 4 mm

11. Screw for PE connection

12.Cable glands

13.Electronics nameplate

14.Safety hood for inverter electronics

15.Setpoint potentiometer f1 (not visible), accessible from top of MOVIMOT

via screw fitting

16.Setpoint switch f2 (green)

17.Switch t1 for generator ramp (white)

18.DIP switches S1 and S2 (for settings see the section "Startup")

19.Status LED (visible from top of MOVIMOT

®

inverter with heat sink (size 2 used as example)

8

7

910

댷

댷

11 12

2

)

®

inverter, see the section "Diagnostics")

13

®

inverter

14 15 16

17

06496AXX

18

19

8

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 9

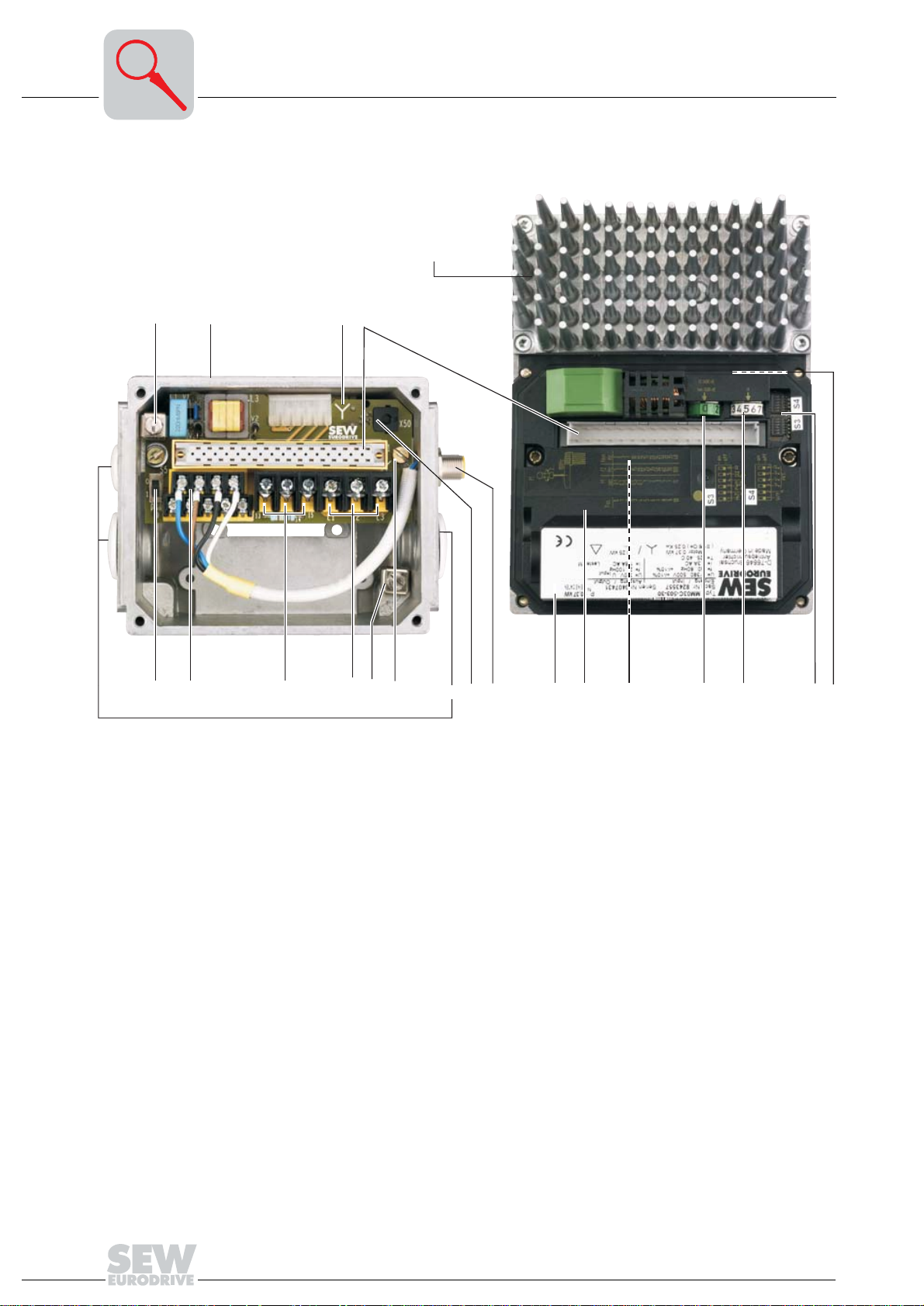

Unit designations (MOVIMOT® standard design)

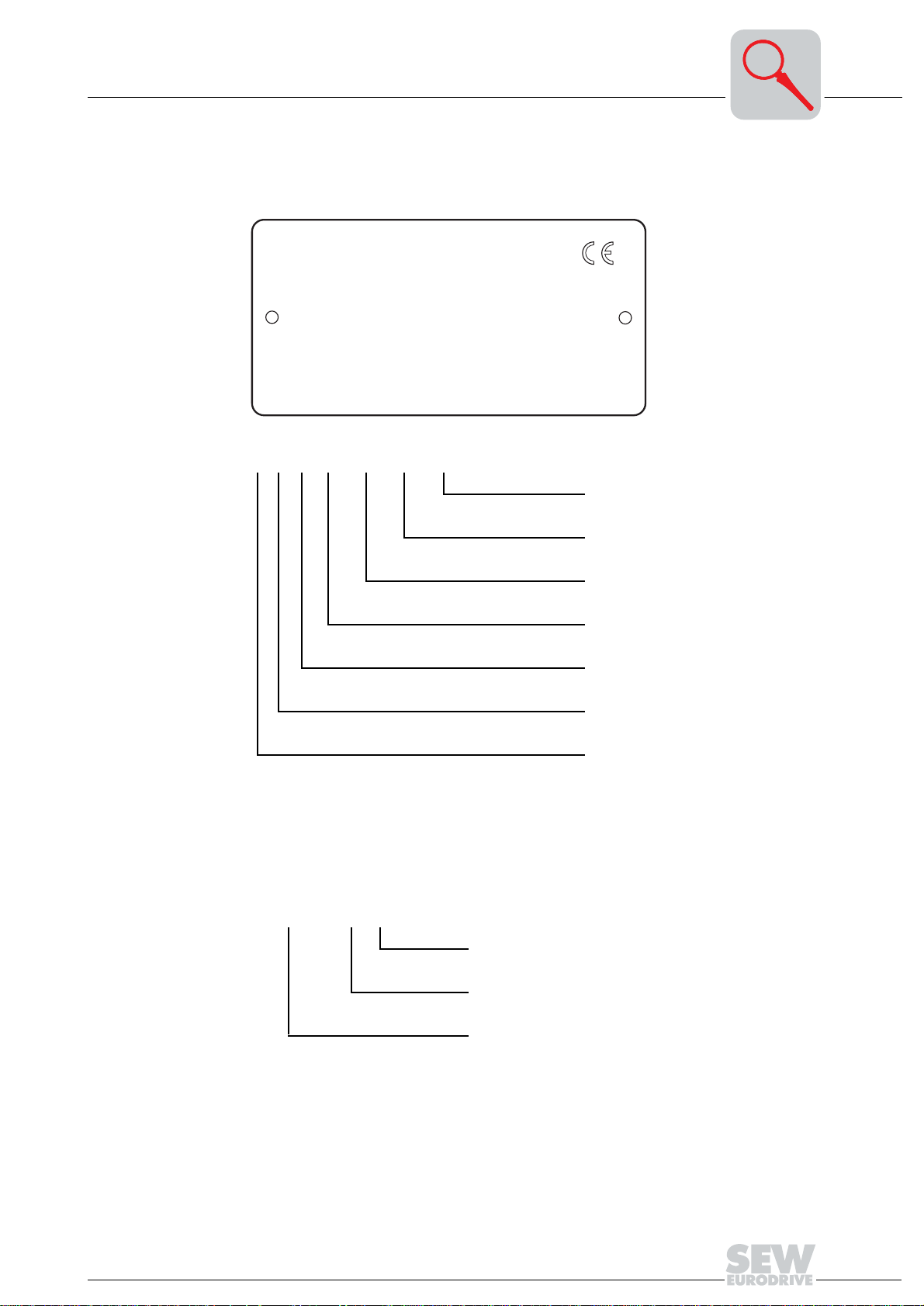

3.2 Unit designations (MOVIMOT® standard design)

Sample motor nameplate

Unit Design

3

SEW-EURODRIVE

Typ

KA77 DT90L4/BMG/MM15/MLU

Nr.

3009818304. 0001. 99

KW

1,5/50HZ

50Hz

60Hz

r/min

Bremse

kg 73

Schmierstoff

KA 77 DT 90L4 BMG/MM15/MLU

V 380-500

V 380-500

22/1400

V 230

Ma 665

Nm 20

Nm

Bruchsal / Germany

IEC 34

3~

IM

B3

0,99

cos

j

3,50

A

A

3,50

IP

Gleichrichter

i

Made in Germany 184103 3.14

Kl

54 F

:1

64,75

06491AXX

Additional feature Inverter

MOVIMOT® frequency inverter

Additional feature motor (brake)

Size, motor pole count

Motor series

1)

Gear unit size

Gear unit series

1) Only factory-installed options are listed on the nameplate.

2) Detailed information about geared motor combinations can be found in the catalog "MOVIMOT® Geared

Motors."

2)

2)

Structure of sample fabrication number:

3009818304. 0001. 99

Final two digits of the year of manufacture

Running unit number (4 digits)

Order number (10 digits)

Operating Instructions – MOVIMOT® MM03C - MM3XC

9

Page 10

3

Unit Design

Unit designations (MOVIMOT® standard design)

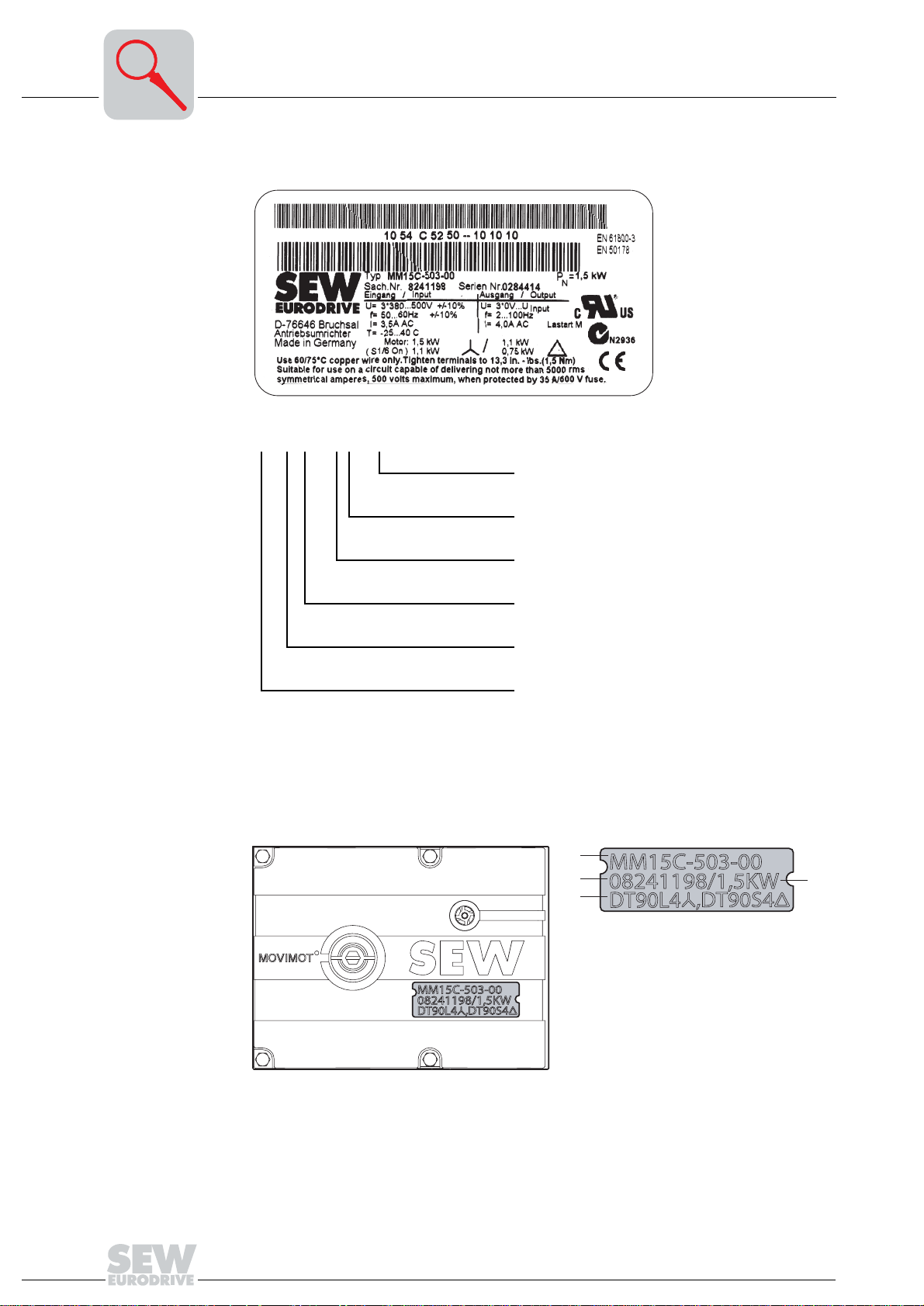

Sample inverter nameplate

MM 15 C – 503 – 00

Design (00 = Standard)

Connection type (3 = 3-phase)

Supply voltage

(50 = 380...500 V

Version C

AC

)

05605AXX

Device identification

Motor power (15 = 1.5 kW)

®

MOVIMOT

series

The device identification [1] at the top of the MOVIMOT® inverter contains information

about inverter type [2], inverter part number [3], equipment power [4] and adapted (associated) motors [5].

[2]

[3]

[5]

[1]

[4]

50862AXX

10

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 11

Unit Design

Unit designations (MOVIMOT® standard design)

3

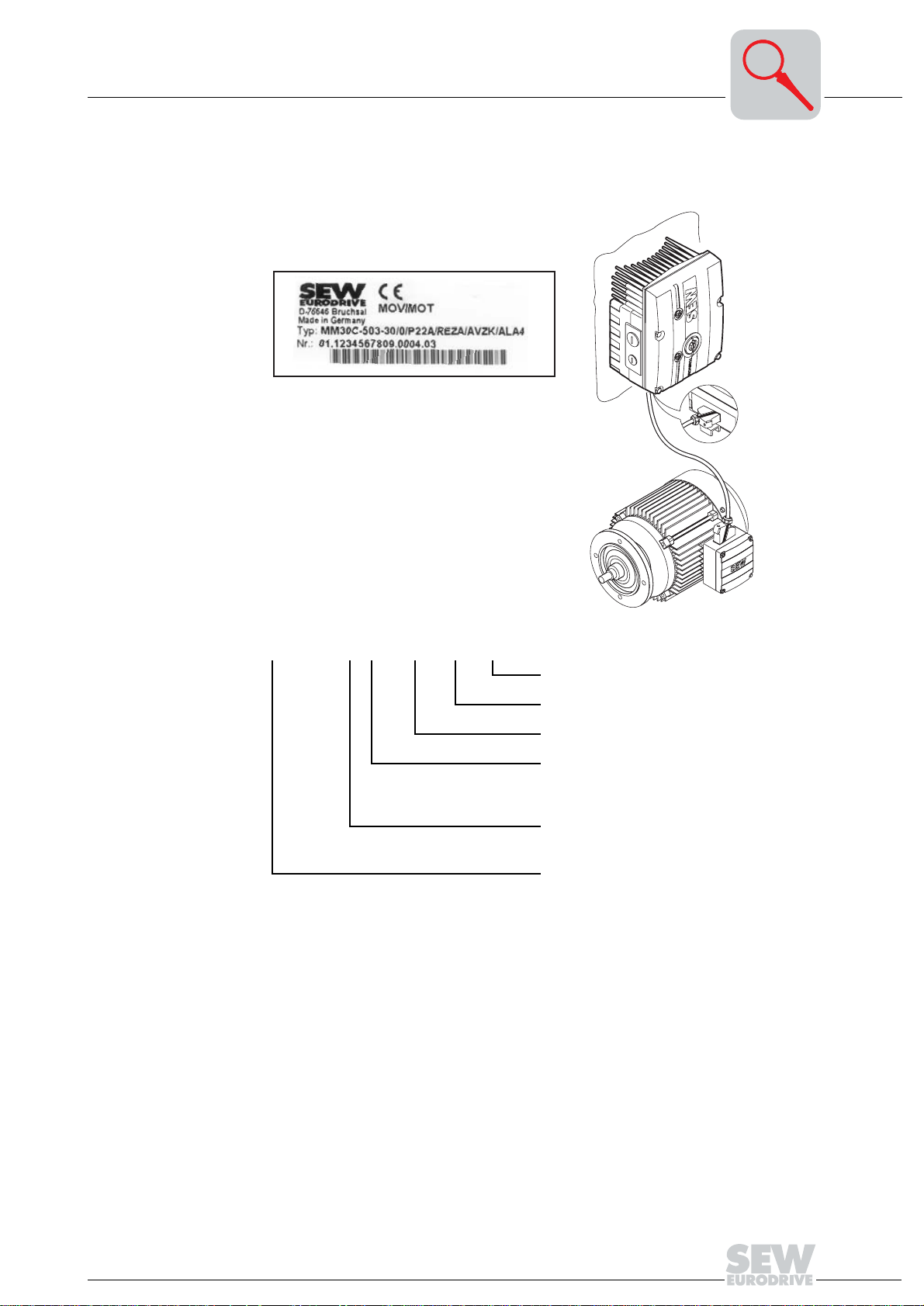

"Mounting close

to motor" design

with option P2.A

The following illustration shows an example of the MOVIMOT® inverter with option P2.A

mounted close to the motor with corresponding nameplate and unit designation:

MM22C-503-00/0/P22A/REZA/ALA4

52232AXX

Plug connector for the connection to the motor

Terminal box design

Adapter for mounting close to the motor

21 = Size 1

22 = Size 2

Circuit type

0 =

댴

1 =

쑶

MOVIMOT

®

Operating Instructions – MOVIMOT® MM03C - MM3XC

11

Page 12

3

Unit Design

MOVIMOT® inverter (with integrated AS-Interface)

3.3 MOVIMOT® inverter (with integrated AS-Interface)

5

1

6

7

89

324

10

11

12

13

14

15 16 17 18

1. Screw for PE connection 댷

2. Terminal box (size 1 used as example)

3. Identification of the circuit type

4. Connection plug between connection unit and inverter

5. MOVIMOT

®

inverter with heat sink (size 1 used as example)

6. Switch S5 (AUX/24 V supply, for settings see the section "Startup")

7. Electronics terminal strip X2

8. Connection of brake coil (X3). For motors without brake: Connection of internal

braking resistor BW. (standard)

9. Mains connection L1, L2, L3 (X3) (suitable for 2 x 4 mm

10.Screw for PE connection

댷

2

)

11. Connection unit with terminals

12.Cable glands

13.Diagnostic interface (see the section "Diagnostics")

14.AS-i connection

15.Electronics nameplate

16.Safety hood for inverter electronics

17.Setpoint potentiometer f1 (not visible), accessible from top of MOVIMOT

®

inverter

via screw fitting

18.Setpoint switch f2 (green)

19.Switch t1 for generator ramp (white)

20.DIP switches S3 and S4 (for settings see the section "Startup")

21.Status LEDs (visible from top of MOVIMOT

®

inverter, see the section "Diagnostics")

19

20

06413AXX

21

12

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 13

Unit Design

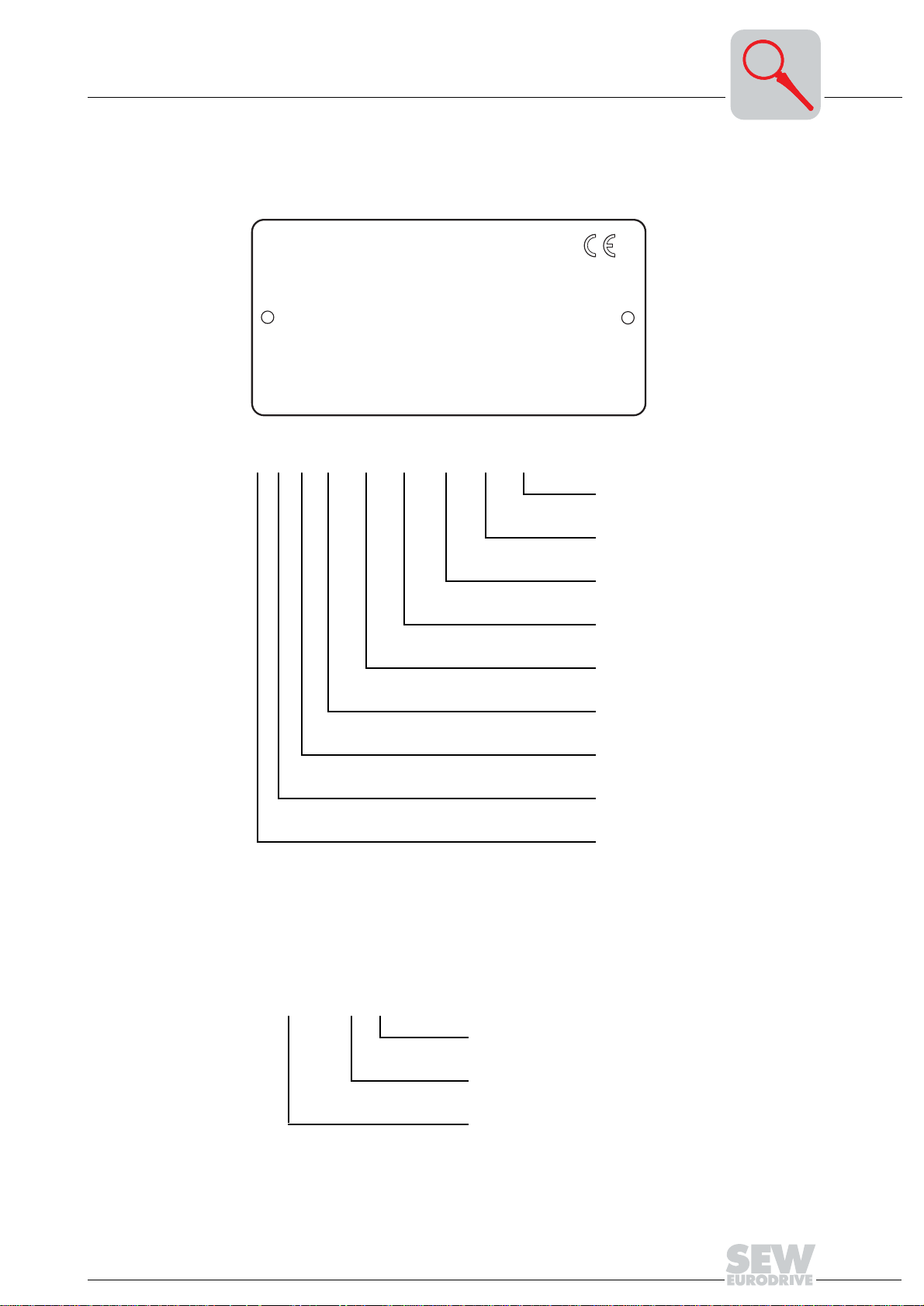

Unit designations (MOVIMOT® with integrated AS-Interface)

3.4 Unit designations (MOVIMOT® with integrated AS-Interface)

Sample motor nameplate

3

SEW-EURODRIVE

KA77 DT90L4/BMG/MM15/RJ1A/AND3/AZSK

Typ

Nr.

3009818304. 0001. 99

KW

1,5/50HZ

50Hz

60Hz

r/min

Bremse

kg 73

Schmierstoff

KA 77 DT 90L4 BMG/MM15/RJ1A/AND3/AZSK

V 380-500

V 380-500

22/1400

V 230

Ma 665

Bruchsal / Germany

Nm 20

Nm

Made in Germany 184103 3.14

IEC 34

3~

IM

B3

0,99

cos

j

3,50

A

A

3,50

IP

Gleichrichter

i

Kl

54 F

64,75

:1

06488AXX

Plug connector for AS-i and sensor

connection

Plug connector for power

Terminal box design

MOVIMOT

Additional feature motor (brake)

®

frequency inverter

Size, motor pole count

Motor series

Gear unit size

Gear unit series

1) Detailed information about geared motor combinations can be found in the catalog "MOVIMOT® Geared

Motors."

1)

2)

Structure of sample fabrication number:

3009818304. 0001. 99

Final two digits of the year of manufacture

Running unit number (4 digits)

Order number (10 digits)

Operating Instructions – MOVIMOT® MM03C - MM3XC

13

Page 14

3

Unit Design

Unit designations (MOVIMOT® with integrated AS-Interface)

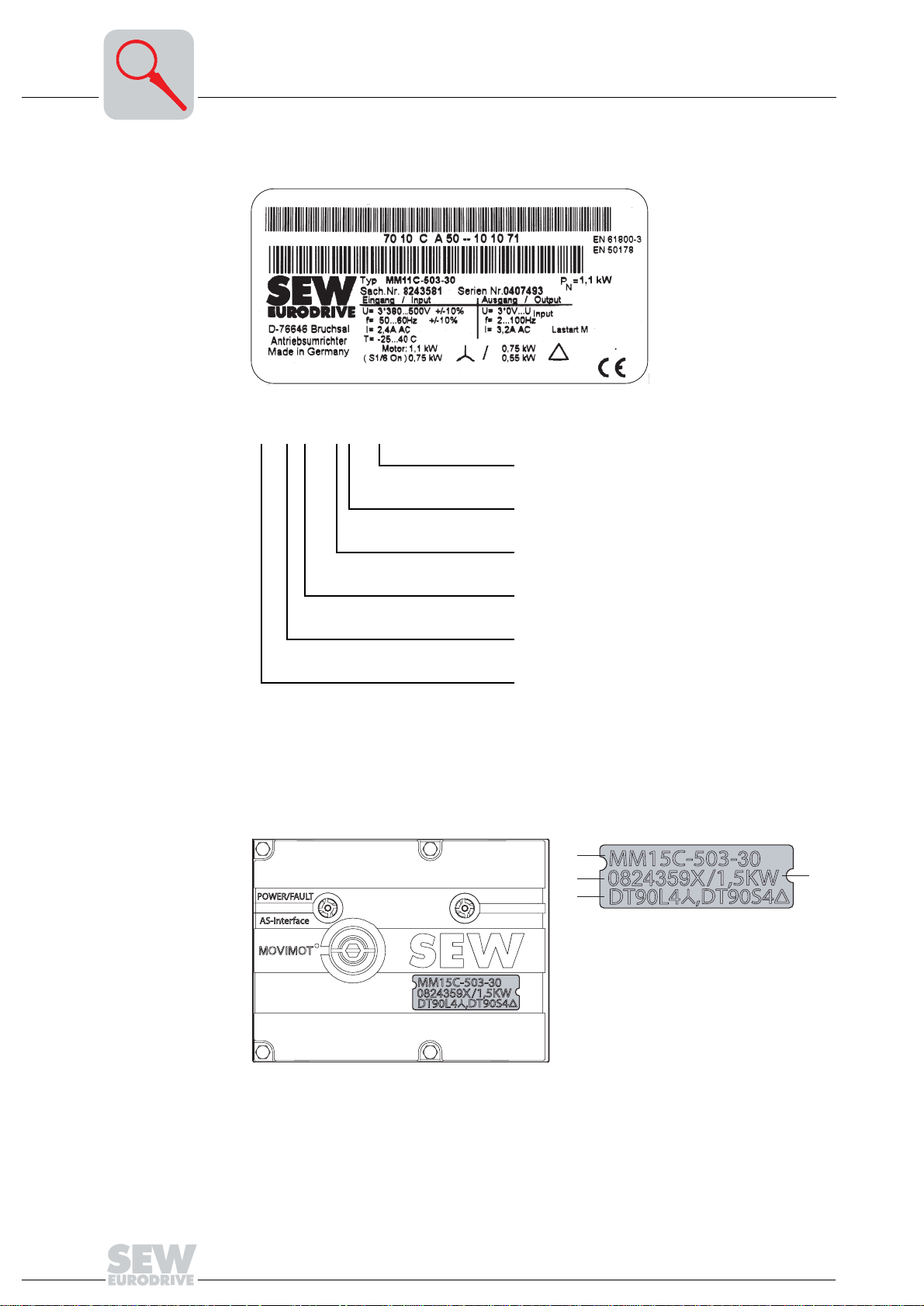

Sample inverter nameplate

MM 15 C – 503 – 30

52118AXX

Design

(30 = with integrated AS-Interface)

Connection type (3 = 3-phase)

Supply voltage

(50 = 380...500 V

Version C

AC

)

Device identification

Motor power (15 = 1.5 kW)

MOVIMOT

®

series

The device identification [1] at the top of the MOVIMOT® inverter contains information

about inverter type [2], inverter part number [3], equipment power [4] and adapted (associated) motors [5].

[2]

[3]

[5]

[1]

[4]

51967AXX

14

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 15

Unit Design

Unit designations (MOVIMOT® with integrated AS-Interface)

3

"Mounting close to the motor" design with option P2.A

The following illustration shows an example of the MOVIMOT® inverter with option P2.A

mounted close to the motor with corresponding nameplate and unit designation:

MM30C-503-30/0/P22A/REZA/A VSK/ALA4

52233AXX

Plug connector for connection to the motor

Plug connector option

Terminal box design

Adapter for mounting close to the motor

21 = Size 1

22 = Size 2

Circuit type

0 =

댴

1 = 쑶

MOVIMOT

®

Operating Instructions – MOVIMOT® MM03C - MM3XC

15

Page 16

4

Mechanical Installation

MOVIMOT® gearmotor

4 Mechanical Installation

4.1 MOVIMOT® gearmotor

Before you begin

Installation tolerances

Mounting

MOVIMOT

®

Install MOVIMOT® only if

• the entries on the nameplate of the drive match the voltage supply system,

• the drive is undamaged (no damage caused by transport or storage).

• it is certain that the following requirements have been fulfilled:

– Ambient temperature between –25 °C and +40 °C (remember that the tempera-

ture range of the gear unit may be restricted → operating instructions for the gear

unit)

– No oil, acid, gas, vapors, radiation, etc.

Shaft end Flanges

Diametric tolerance in accordance with DIN 748

• ISO k6 at ∅ ≤ 50 mm

•ISO m6 at ∅ > 50 mm

(Center bore in accordance with DIN 332, shape

DR)

Centering shoulder tolerance in accordance with

DIN 42948

•ISO j6 at ∅ ≤ 230 mm

• ISO h6 at ∅ > 230 mm

• The MOVIMOT® may only be mounted or installed in the specified mounting position

on a level, vibration-proof and torsionally rigid support structure.

• Thoroughly remove anti-corrosion agents from the shaft extensions (use a commercially available solvent). Do not allow the solvent to penetrate the bearings and shaft

seals – this could cause material damage!

• Carefully align MOVIMOT

®

and the driven machine, to avoid placing any unacceptable strain on the motor shafts (observe permissible overhung load and axial thrust

data!).

• Do not butt or hammer the shaft end.

• Use an appropriate cover to protect motors in vertical mounting positions from objects or fluids entering!

• Ensure an unobstructed cooling air supply and that air heated by other apparatus

cannot be drawn in or reused.

• Balance components for subsequent mounting on the shaft with a half key (output

shafts are balanced with a half key).

• Any condensation drain holes are closed with plastic plugs and must not be opened

unless needed.

• Do not leave any condensation drain holes open, since this defeats higher enclosure

ratings.

Installation in damp areas or in the open

16

• Use suitable screwed cable glands for the supply leads (use reducing adapters if

necessary).

• Coat the threads of cable glands and pocket caps with sealant and tighten them well

– then coat them again.

• Seal the cable entry well.

®

• Clean the sealing faces of the MOVIMOT

inverter well before re-assembly.

• Restore the anticorrosive coating if necessary.

• Check the type of enclosure is authorized (refer to the nameplate).

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 17

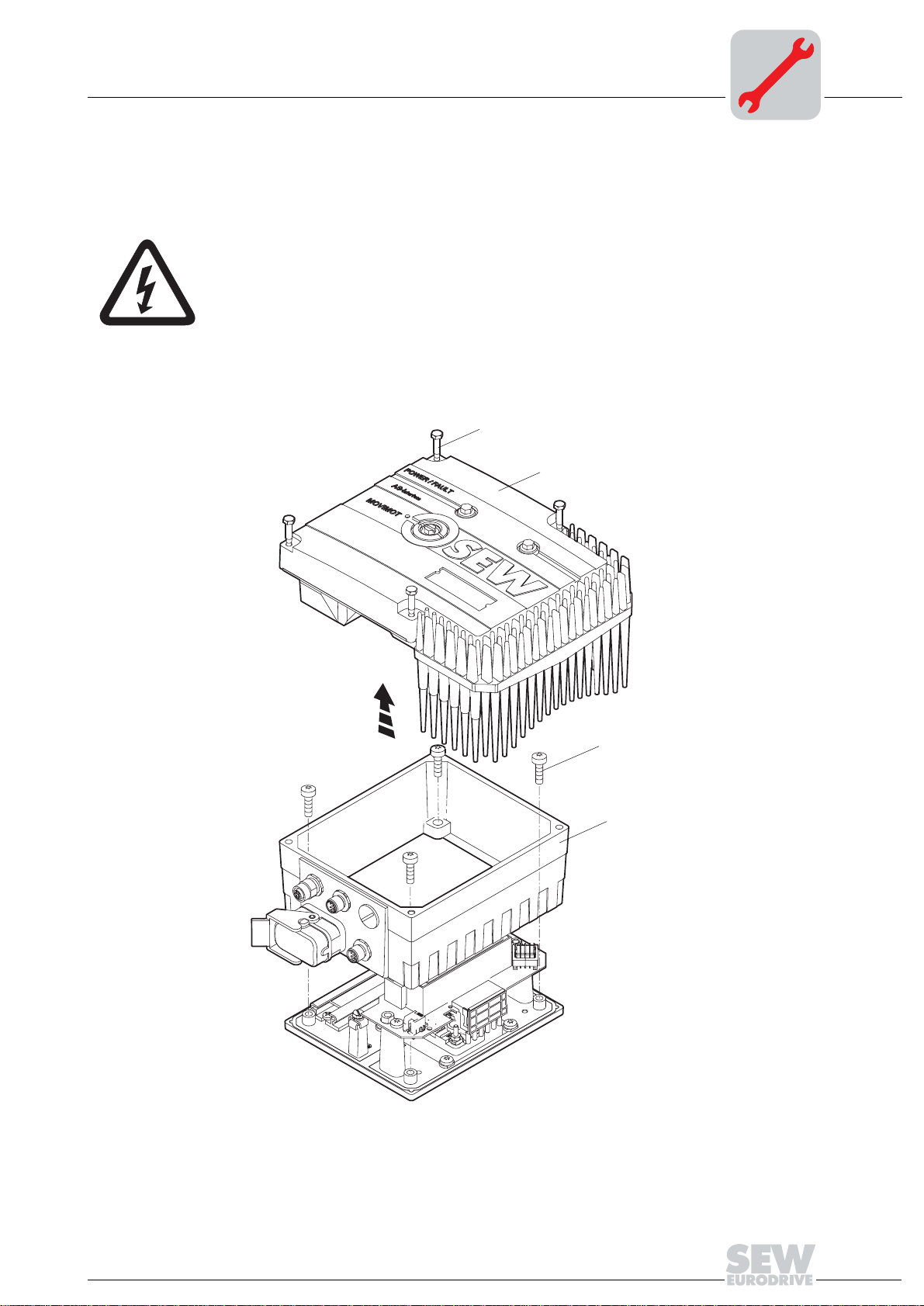

4.2 Modular terminal box

Mechanical Installation

Modular terminal box

4

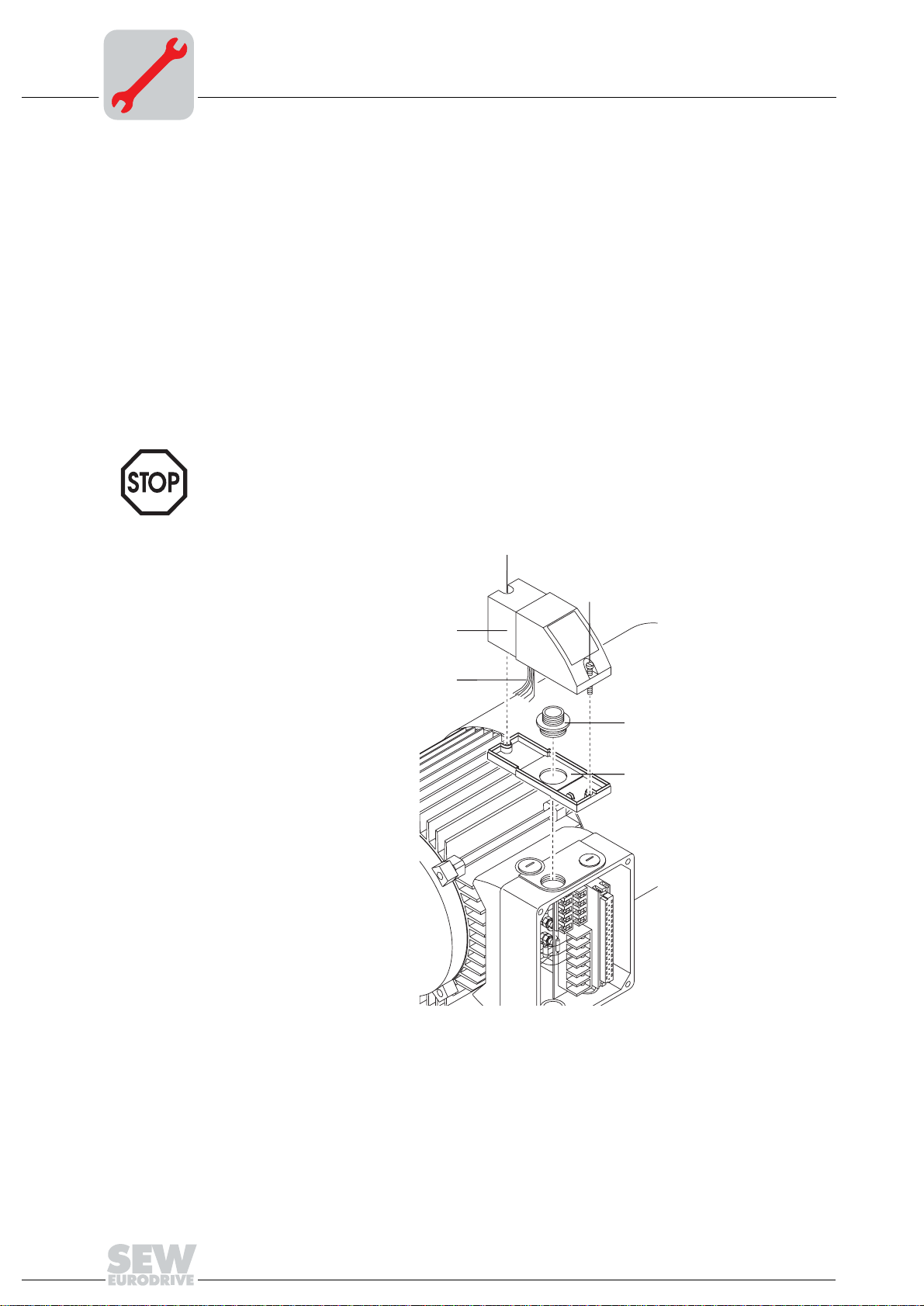

Turning the terminal box

In principle it is recommended to purchase factory pre-fabricated MOVIMOT® systems

with the correct position of cable entries. In exceptional cases, the position of the cable

entries can be turned to the opposite side (only for designs with modular terminal box).

1. Isolate MOVIMOT

restarting! Dangerous voltages may still be present for up to 1 minute after

shutdown!

2. Label the connections before disconnecting them for later reassembly.

3. Disconnect the supply system, control and sensor connections.

4. Remove screws [A] and detach MOVIMOT

5. Loosen screws [C] and remove terminal box [D].

®

drive from the supply, safeguarding it against unintentional

®

inverter [B].

[A]

[B]

[C]

[D]

51819AXX

Operating Instructions – MOVIMOT® MM03C - MM3XC

17

Page 18

4

Mechanical Installation

Modular terminal box

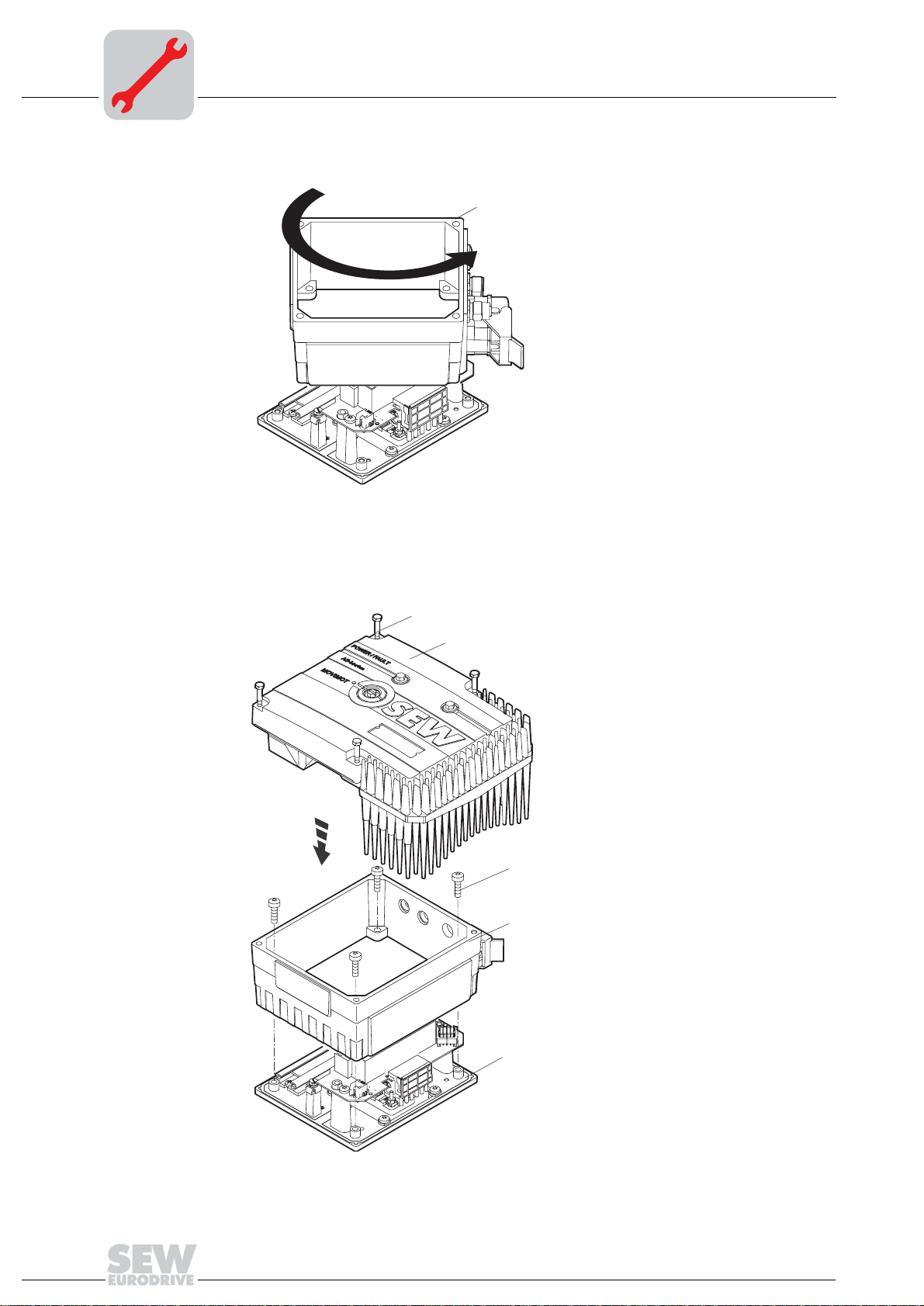

6. Turn terminal box [D] by 180°.

180˚

[D]

51820AXX

7. Place terminal box [D] on mounting plate [E] and fasten it with screws [C].

8. Reestablish cable connections.

9. Reattach MOVIMOT

®

inverter [B] and secure with screws [A].

[A]

[B]

18

[C]

[D]

[E]

51821AXX

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 19

Mechanical Installation

Mounting MOVIMOT® inverter with option P2.A close to the motor

4.3 Mounting MOVIMOT® inverter with option P2.A close to the motor

4

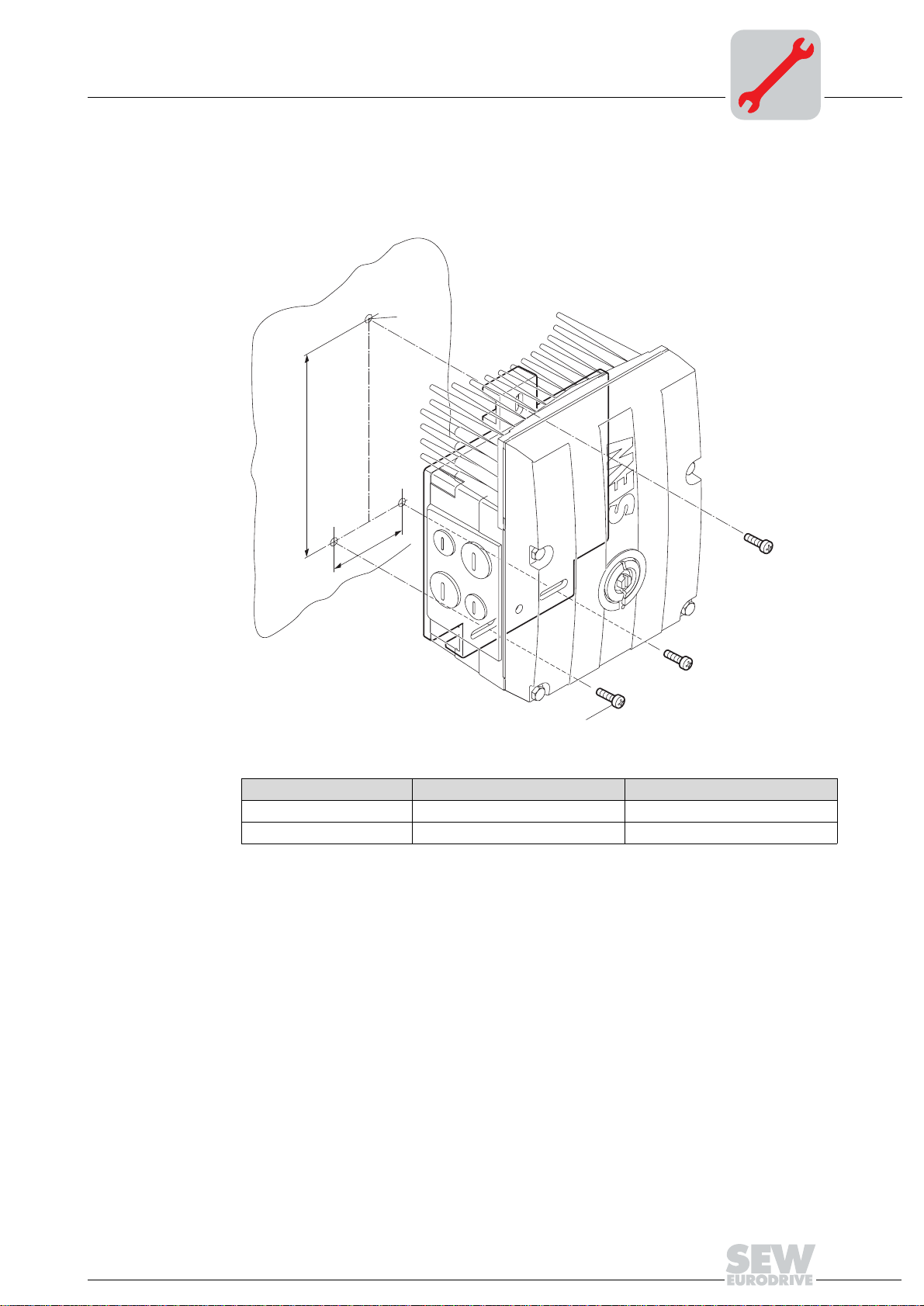

The following illustration shows the mounting dimensions when mounting the

MOVIMOT

®

inverter with option P2.A close to the motor:

6

M

A

B

M6

Size A B

MM03 to MM15 65 mm 140 mm

MM22 to MM3X 65 mm 170 mm

51772AXX

Operating Instructions – MOVIMOT® MM03C - MM3XC

19

Page 20

4

Mechanical Installation

Option MLU..A / MLG..A / MLK11A

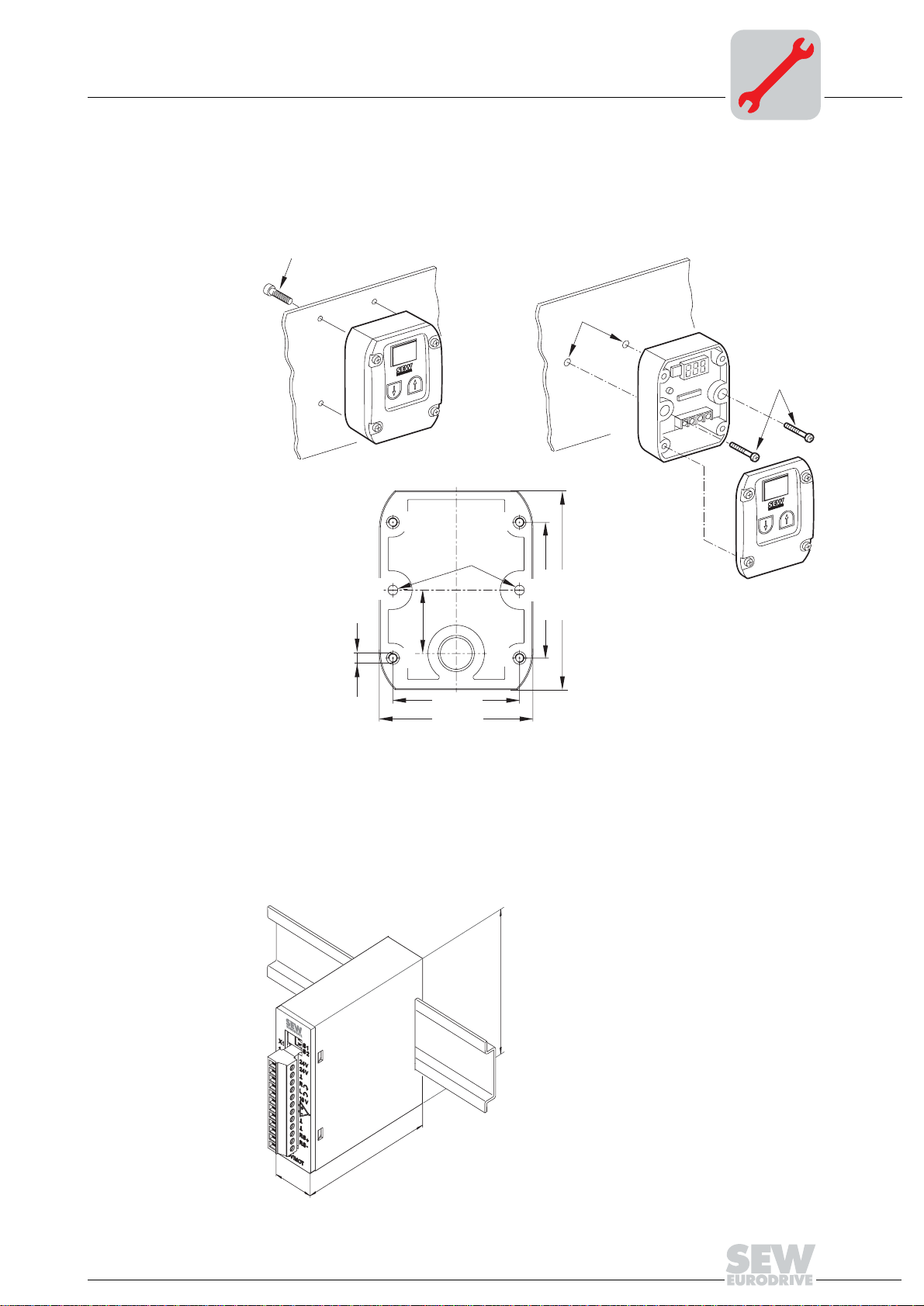

4.4 Option MLU..A / MLG..A / MLK11A

Scope of delivery

Installation

• MLU..A / MLG..A / MLK11A top [2]

•2 screws [1]

• Cable entry screw [4]

• MLU..A / MLG..A / MLK11A lower section [5]

1. Remove a screw plug from the MOVIMOT® terminal box.

2. Attach lower section [E] to MOVIMOT

®

terminal box and fasten it with cable entry

screw [4].

®

3. Guide connection cable [3] through cable entry screw [4] into the MOVIMOT

termi-

nal box.

4. Place top [2] on bottom [5] and fasten it with 2 screws [1].

Important: Option may be assembled only in the position shown in the following

figure!

[1]

[1]

[2]

[3]

[4]

[5]

05625AXX

20

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 21

4.5 MBG11A option

• A: Assembly from the rear via 4 tapped holes

• B: Assembly from the front via 2 mounting holes

Mechanical Installation

MBG11A option

4

M4 x 5 + a

!!!!!A!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!B

M4

A

Ø 4,3 mm

A

B

m

m

60

m

m

88

M4

B

A

A

mm

8

2

56 mm

68 mm

M4 x 25

50520AXX

a = wall thickness

Screws are not included in the delivery!

4.6 MWA21A option

• MWA21A is installed in the switch cabinet on the DIN rail (DIN EN 50022):

75

74

22,5

50519AXX

Operating Instructions – MOVIMOT® MM03C - MM3XC

21

Page 22

4

4.7 URM option

Mechanical Installation

URM option

Mount the URM option with two screws according to the following illustration. Connection according to section "Electrical Installation."

The installation is only allowed in conjunction with modular terminal box!

52207AXX

22

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 23

Electrical Installation of MOVIMOT® Standard Design

Installation instructions

5 Electrical Installation of MOVIMOT® Standard Design

5.1 Installation instructions

5

Connecting supply system leads

• The rated voltage and frequency of MOVIMOT® must correspond to the data for the

power supply system (mains).

• Cable cross section: according to input current I

for rated power (see Technical

mains

Data).

• Permitted cable cross section of MOVIMOT

®

terminals (does not apply to field dis-

tributor)

Power terminals Control terminals

2

1.0 mm

AWG17 – AWG10 (2 x AWG10) AWG22 – AWG17 (2 x AWG18)

– 4.0 mm2 (2 x 4.0 mm2) 0.25 mm2 – 1.0 mm2 (2 x 0.75 mm2)

• Use conductor end sleeves without insulating shrouds (DIN 46228 part 1, material

E-CU).

• Install line safety at the beginning of the power cable behind supply bus junction (see

the section "Connection of MOVIMOT

®

basic unit," F11/F12/F13). Use D, DO, NH or

circuit breakers. The fusible rating should be selected in accordance with the cable

cross section.

• Do not use a conventional earth-leakage circuit breaker as a protective device. Universal current-sensitive earth leakage circuit-breakers (tripping current 300 mA) are

permitted as a protective device. During normal operation of MOVIMOT

®

, earth-leak-

age currents of > 3.5 mA can occur.

• Use contactor switch contacts to switch MOVIMOT

®

from utilization category AC-3

according to IEC 158.

• SEW recommends using earth-leakage monitors with pulse-code measurement for

voltage supply systems with non-grounded star point (IT nets). The use of such devices avoids mis-tripping of the earth-leakage monitor due to the earth capacitance

of the inverter.

Installation at 1000 meters above sea level (msl)

MOVIMOT® drives with supply voltages of 380 to 500 V can be used at altitudes above

2000 m MSL up to 4000 m MSL under the following peripheral conditions.

1)

• The rated continuous power is reduced based on the reduced cooling above 1000 m

(see the section "Technical Data and Dimension Drawings").

• Above 2000 msl, the air and creeping distances are only sufficient for overvoltage

class 2. If the installation requires overvoltage class 3, an additional external overvoltage protection must be used to ensure that overvoltage surges are limited to

2.5 kV phase-to-phase and phase-to-ground.

• If safe electrical separation is required, it must be implemented outside the device at

altitudes above 2000 m MSL (Safe Electrical Separation in accordance with

EN 50178).

• The permitted rated supply voltage of 3 x 500 V up to 2000 msl is reduced by 6 V for

every 100 m to a maximum of 3 x 380 V at 4000 msl.

1) The maximum altitude is limited by creeping distances and flameproof components such as electrolytic

capacitors.

Operating Instructions – MOVIMOT® MM03C - MM3XC

23

Page 24

5

Electrical Installation of MOVIMOT® Standard Design

Installation instructions

Connecting

24V

supply

DC

Conventional

control (via

binary commands)

Control via

RS-485 interface

Protection devices

UL compliant installation

• Supply MOVIMOT® either via external 24 VDC or via the MLU..A or MLG..A options.

• Connect the required control leads (e.g. CW/Stop, CCW/Stop, f1/f2 setpoint change)

• Use shielded cables as control leads and route them separately from power supply

cables.

with bus master PLC, MLG..A, MBG11A, MWA21A option or MF../MQ.. fieldbus interfaces

• Important: Connect only one bus master.

• Use twisted pair shielded cables as control leads and route them separately from

power supply cables.

•MOVIMOT® drives are equipped with integrated protective overload devices that are

making external overload devices obsolete.

• Only use copper cables with the temperature range 60/75 °C as connection lead:

• The permitted tightening torques for MOVIMOT

– 1.5 Nm (13.3 lb.in).

•MOVIMOT

(TN and TT systems) supplying a maximum supply current of 5000 A

a maximum rated voltage of 500 V

mance data of the fuses must not exceed 35 A/600 V.

• Only use tested units with a limited output voltage (V

current (I ≤ 8 A) as an external 24 V

• UL certification applies only to operation in voltage supply systems with voltages to

ground up to 300 V.

®

are suited for operation on voltage supply systems with grounded star

(MM03C-503 to MM3XC-503). The perfor-

AC

voltage source.

DC

®

power terminals are:

= 30 VDC) and limited output

max

and having

AC

24

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 25

Electrical Installation of MOVIMOT® Standard Design

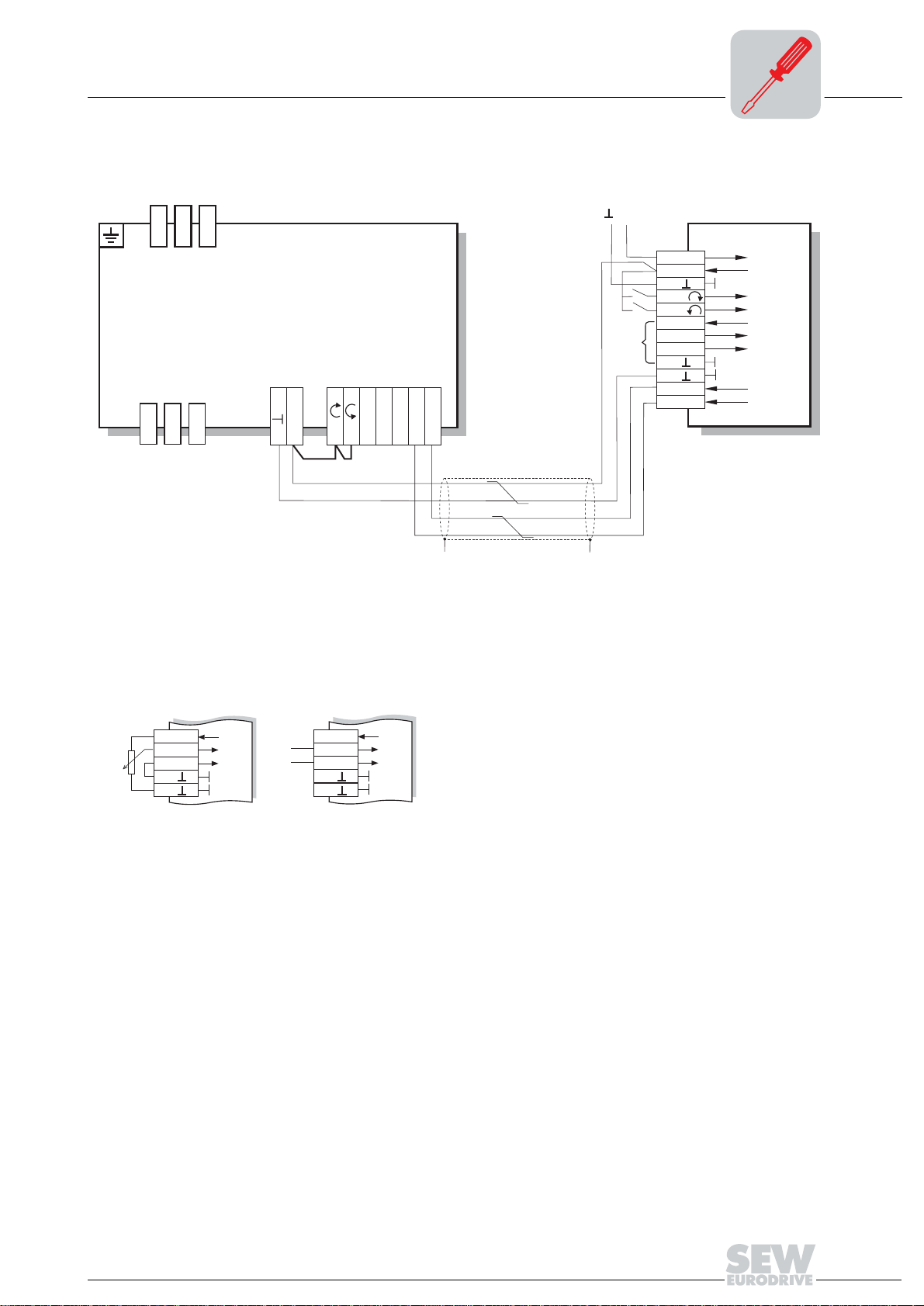

Connection of MOVIMOT® basic unit

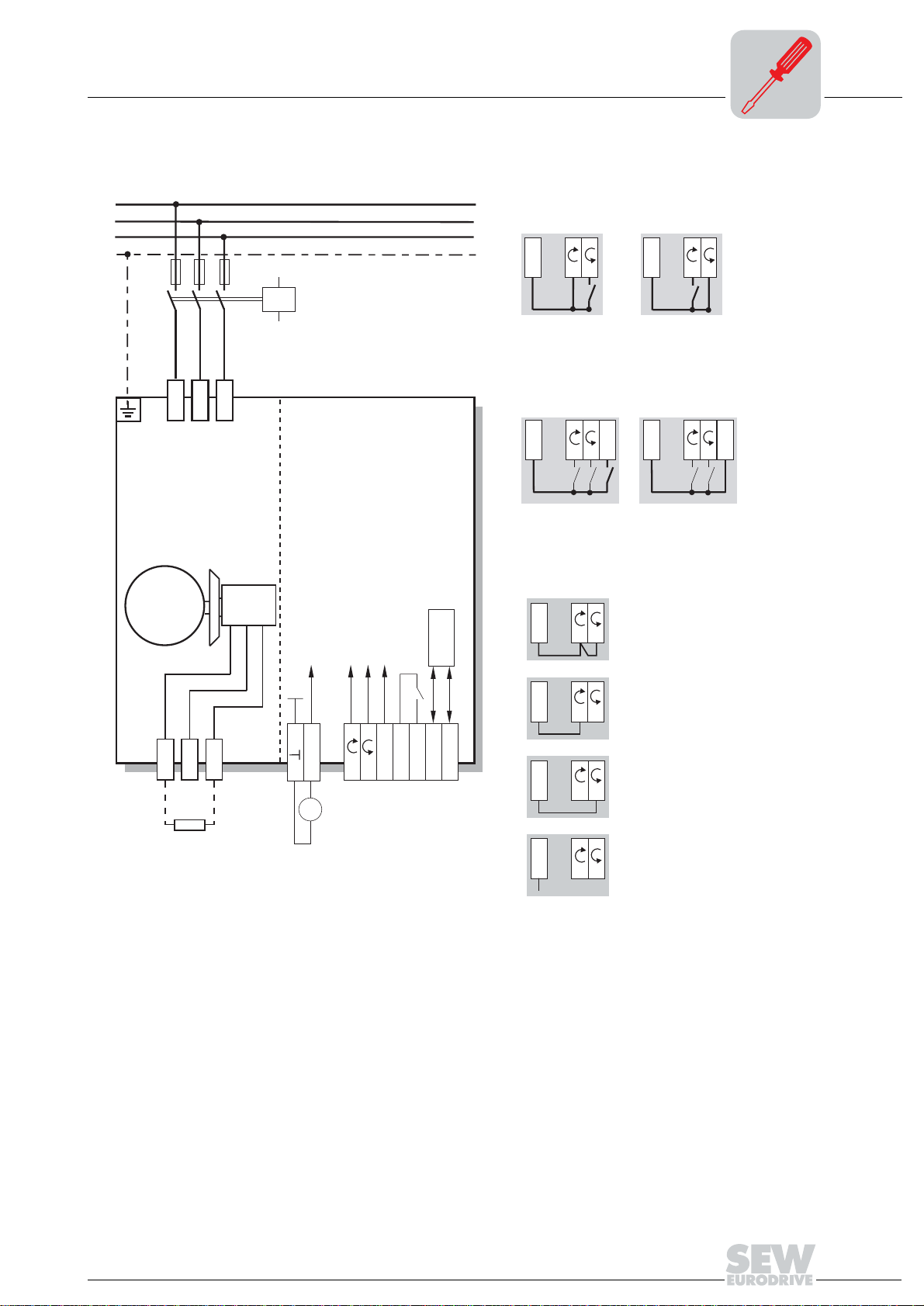

5.2 Connection of MOVIMOT® basic unit

5

L1

L2

L3

PE

M

3~

L1

F11/F12/F13

L2

L3

BMG

BMG

K11

[1]

MOVIMOT

MOVIMOT

[4]

[2]

[3]

[5]

®

®

RS-485

Function of terminals CW/Stop and CCW/Stop

with binary control:

24V

R

L

Rotation

CW active

Functions of terminals f1/f2:

24V

R

L

Setpoint f1 active Setpoint f2 active

Function of terminals CW/Stop and CCW/Stop

with control via RS-485 interface/fieldbus:

24V

R

L

24V

R

L

Rotation

CCW active

24V

R

f1/f2

Both directions of rotation

are enabled

L

f1/f2

K1

WH

14

13

BW.[6]

BL

15

=

24V

+

-

24 V

DC

L

R

f1/f2

K1a

K1b

RD

[1] 24 VDC supply (external or MLU../MLG.. option)

[2] CW/Stop

[3] CCW/Stop

[4] Setpoint toggle f1/f2

[5] Ready message (contact closed = ready for operation)

[6] BW.. braking resistor (in MOVIMOT

®

without mechanical brake only)

RS-

RS+

05614AXX

24V

24V

24V

Only CW rotation

R

R

R

is enabled,

L

Setpoint selections for CCW rotation

result in standstill of drive

Only CCW rotation

is enabled,

Setpoint selections for CW rotation

L

result in standstill

of drive

Drive is blocked or

L

brought to standstill

Operating Instructions – MOVIMOT® MM03C - MM3XC

25

Page 26

5

Electrical Installation of MOVIMOT® Standard Design

MOVIMOT® plug connectors

5.3 MOVIMOT® plug connectors

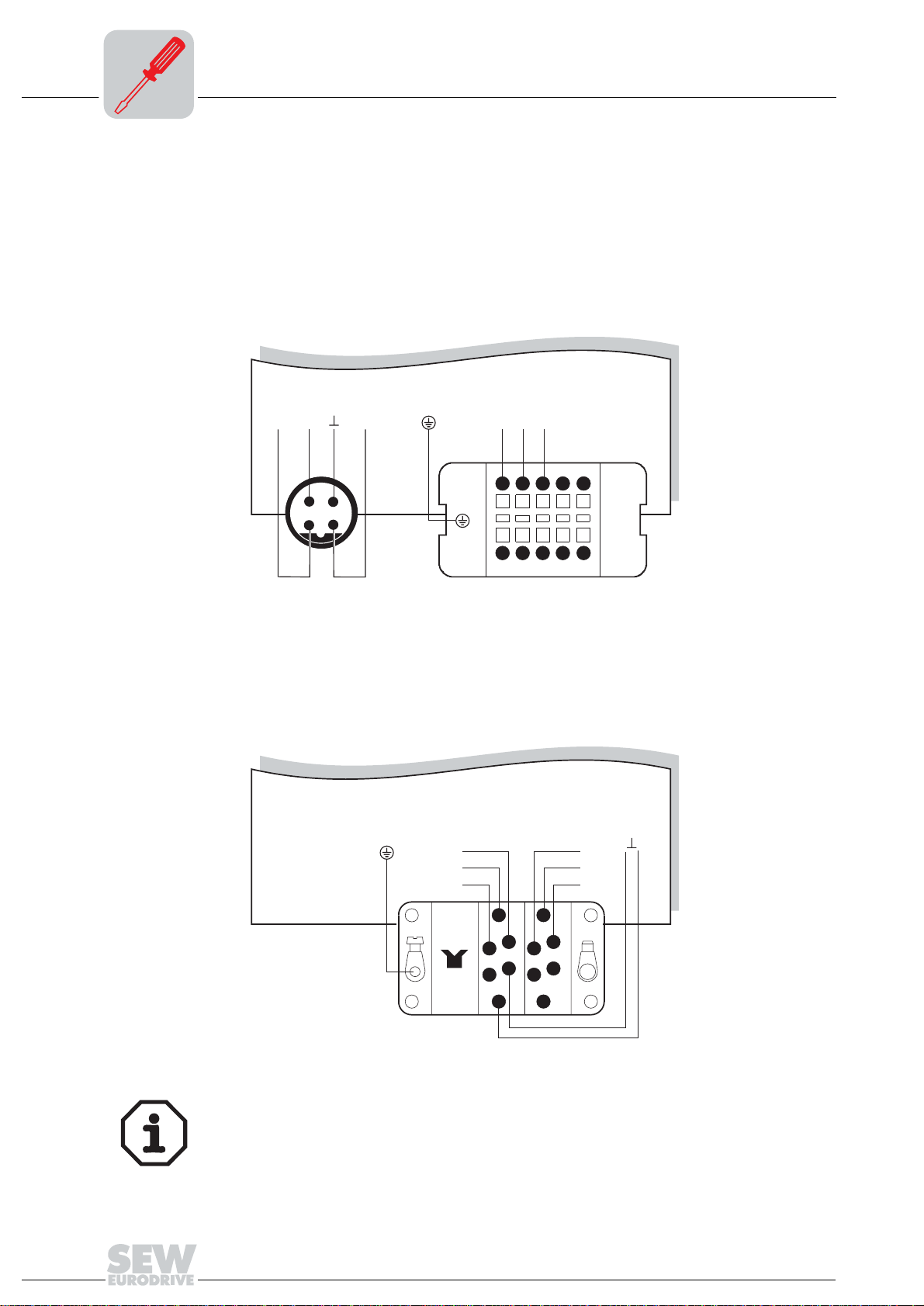

AVT1, ASA3 plug connectors

The following illustration shows the assignment of the optional AVT1 and ASA3 plug

connectors.

Available designs:

• MM.../ASA3

• MM.../AVT1

• MM.../ASA3/AVT1

®

52113AXX

24V RS+ RS-

4

3

12

AVT1

MOVIMOT

L1 L2 L3

12345

6789

ASA3

10

Plug connector AMA6

The following illustration shows the assignment of the optional AMA6 plug connector.

Available design:

• MM.../AMA6

MOVIMOT

RSRS+

24 V

C

1

3

5

6

AMA6

1

2

3

4

5

L3

L1

L2

A

2

4

6

®

52114AXX

For designs with plug connectors, both directions of rotation are enabled at the

factory. If only one direction of rotation is desired, please observe the section

"Connection of MOVIMOT

®

Basic Unit, Functions of the CW/STOP, CCW/STOP

terminals in control via RS-485 interface."

26

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 27

Electrical Installation of MOVIMOT® Standard Design

5.4 Connection MOVIMOT® options

Connection MOVIMOT® options

5

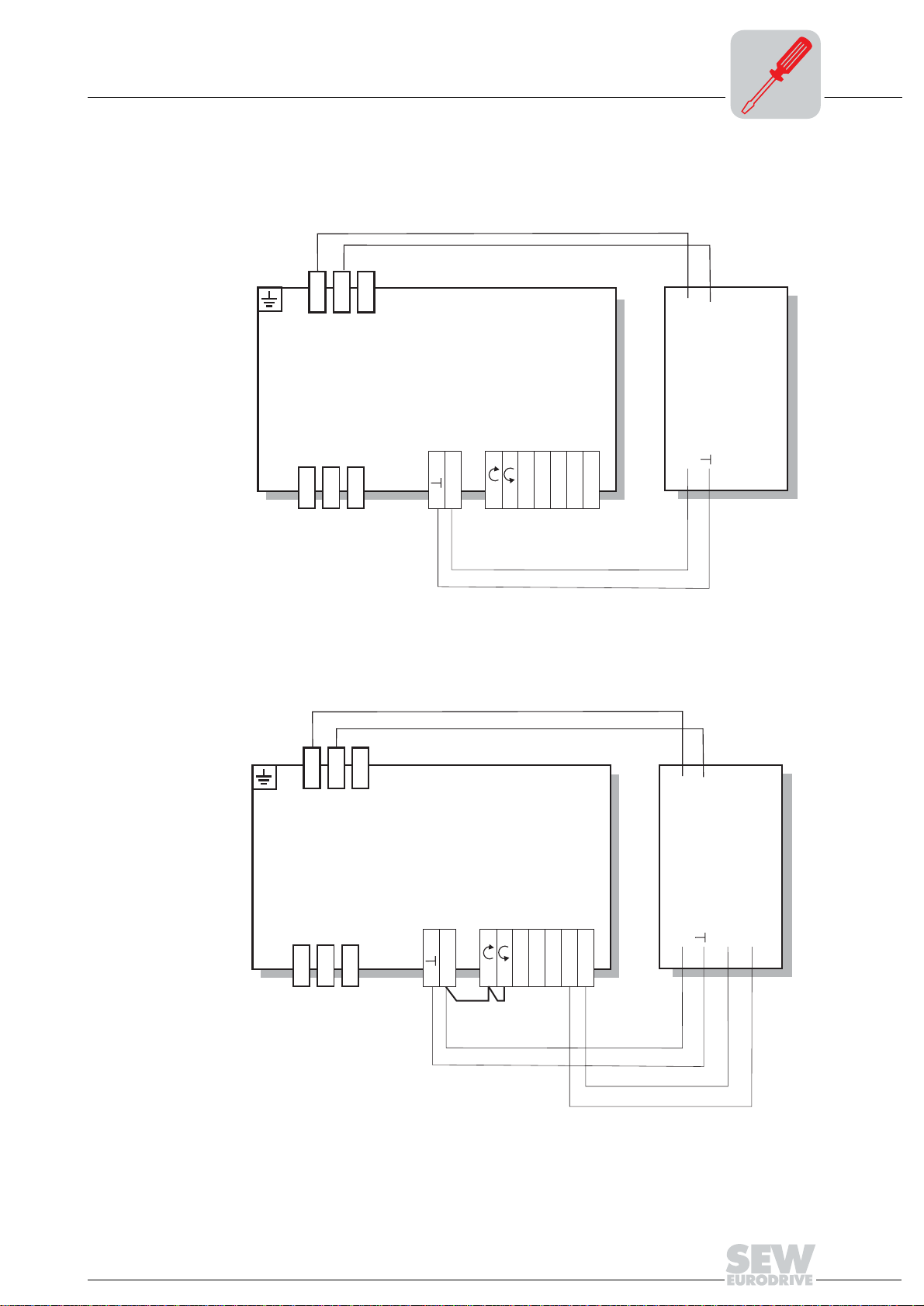

Connection of MLU11A option

The following figure shows the connection of the MLU11A option.

YE

YE

L1

L1

L2

L3

L2

13

13

14

14

15

15

L3

24V

24V

MOVIMOT

MOVIMOT

L

L

R

R

f1/f2

f1/f2

K1a

K1a

RD

BU

K1b

K1b

RS-

RS-

®

®

RS+

RS+

L1

L1

L2

L2

MLU11A

24V

24V

05651AXX

Connection of MLG11A option

The following figure shows the connection of the MLG11A option.

YE

YE

L1

L2

13

14

15

L3

24V

[1]

L

R

MOVIMOT

K1a

f1/f2

K1b

RS-

®

RS+

RD

L1

L2

MLG11A

24V

BU

RS+

OG

RS-

GN

[1] Observe the enabled direction of rotation (see the section "Connection of MOVIMOT®

basic unit, Functions of CW/Stop, CCW/Stop terminals with control via RS-485 interface.")

Operating Instructions – MOVIMOT® MM03C - MM3XC

05652AXX

27

Page 28

5

Electrical Installation of MOVIMOT® Standard Design

Connection MOVIMOT® options

Connection of MBG11A option

The following figure shows the connection of the MBG11A option.

L1

L2

13

14

15

L3

24V

L

R

MOVIMOT

K1a

f1/f2

[1]

24 V

DC

[1] Observe the enabled direction of rotation (see the section "Connection of MOVIMOT®

basic unit, Functions of CW/Stop, CCW/Stop terminals with control via RS-485 interface.")

[2] EMC metal cable gland

K1b

[2]

RS-

®

RS+

댷

MBG11A

24V

RS+

RS-

03183CXX

Connection of MLK11A option

L1

14

13

L2

The following illustration shows the connection of the MLK11A option (external AS-i binary slave).

15

L3

24V

L

R

MOVIMOT

K1a

f1/f2

K1b

RS-

®

RS+

AS-i -

AS-i +

WH

BK/BU

BK/RD

BK/WH

RD

BU

N.C.

N.C.

[1]

(DI0)

(DO2)

(DO1)

(DO0)

(DO3)

()

MLK11A

[2]

0V

DI2

4

3

2

1

3

4

5

21

N.C.

24V

DI3

05118CXX

28

[1] AS-i connection

[2] Connection for two external sensors

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 29

Electrical Installation of MOVIMOT® Standard Design

Connection MOVIMOT® options

5

Connection of

The following figure shows the connection of the MWA21A option.

MWA21A option

L1

L2

13

14

15

L3

24V

L

R

MOVIMOT

K1a

f1/f2

[1]

[1] Note the released direction of rotation

(see the section "Connection of MOVIMOT® Basic Unit" Functions of CW/Stop,

CCW/Stop terminals with control via RS-485 interface)

[2] EMC metal cable gland

[3] Potentiometer with integration of 10 V reference voltage [A]

or potential-free analog signal [B]

K1b

RS-

®

RS+

댷

24V

DC

MWA21A

1 24V

2 24V

3

4 R

5 L

6 10V

[3]

댷

[2][2]

7 +

-

8

9

10

11 RS+

12 RS-

03184DXX

[A]

6 10V

7 +

8

9

10

6 10V

-

[B]

MWA21A

7 +

8

9

10

-

MWA21A

05622BXX

Operating Instructions – MOVIMOT® MM03C - MM3XC

29

Page 30

5

Electrical Installation of MOVIMOT® Standard Design

Connection MOVIMOT® options

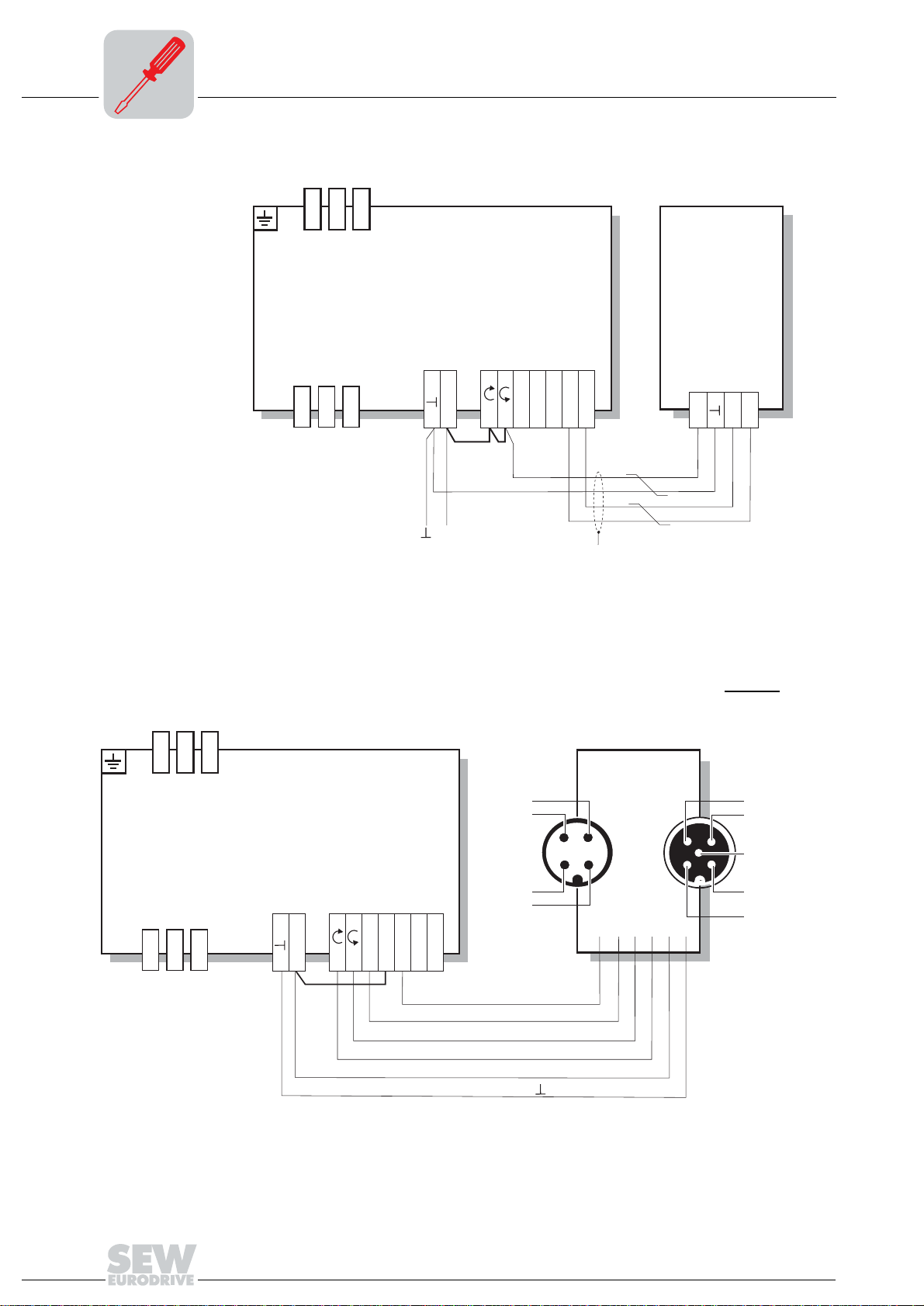

Connection of URM option

Connection of MDG11A option

The following figure shows the connection of the URM option.

URM

13

14

15

M

3~

RD

WH

13

14

L3

BMG

15

BU

24V

MOVIMOT

R

L

f1/f2

K1a

K1b

RS-

52203AXX

®

RS+

L1

L2

The following figure shows the connection of the MDG11A option.

• The diagnostic unit must be connected prior to the possible occurrence of a fault, as

MOVIMOT

®

error messages are not saved and the information is lost when the 24 V

supply is disconnected.

• Connecting the MDG11A to an RS-485 bus with several MOVIMOT

®

is not al-

lowed.

• The diagnostic unit can be used if the MOVIMOT

®

is controlled via terminals

(= address 0 [S1/1-S1/4 = OFF]).

• Do nut use the diagnostic unit if setpoint setting takes place via the RS-485 interface.

30

L1

L2

L3

R

14

13

[1] EMC metal cable gland

For operation see the section "Diagnostics"

15

[1]

24V

댷

Operating Instructions – MOVIMOT® MM03C - MM3XC

MOVIMOT

L

K1a

f1/f2

K1b

RS-

®

RS+

MDG11A

24V

RS+

RS-

03404CXX

Page 31

Electrical Installation of MOVIMOT® Standard Design

5.5 Connection RS-485 bus master

The following figure shows the connection of the RS-485 bus master.

L1

L2

L3

Connection RS-485 bus master

MOVIMOT

®

Busmaster

(SPS / PLC)

5

RS-485

14

13

[1] Observe enabled direction of rotation (see section "Connection of MOVIMOT® basic unit,

Functions of CW/Stop, CCW/Stop terminals with control via RS-485 interface.")

[2] EMC metal cable gland

[3] Potential compensation MOVIMOT

24 V

15

DC

24V

[1]

[3]

f1/f2

®

/RS-485 master

L

R

K1a

K1b

RS-

RS+

댷

RS-485

댷

[2][2]

03177BXX

Operating Instructions – MOVIMOT® MM03C - MM3XC

31

Page 32

5

Electrical Installation of MOVIMOT® Standard Design

Connection between MOVIMOT® and motor mounting close to the motor

5.6 Connection between MOVIMOT® and motor mounting close to the motor

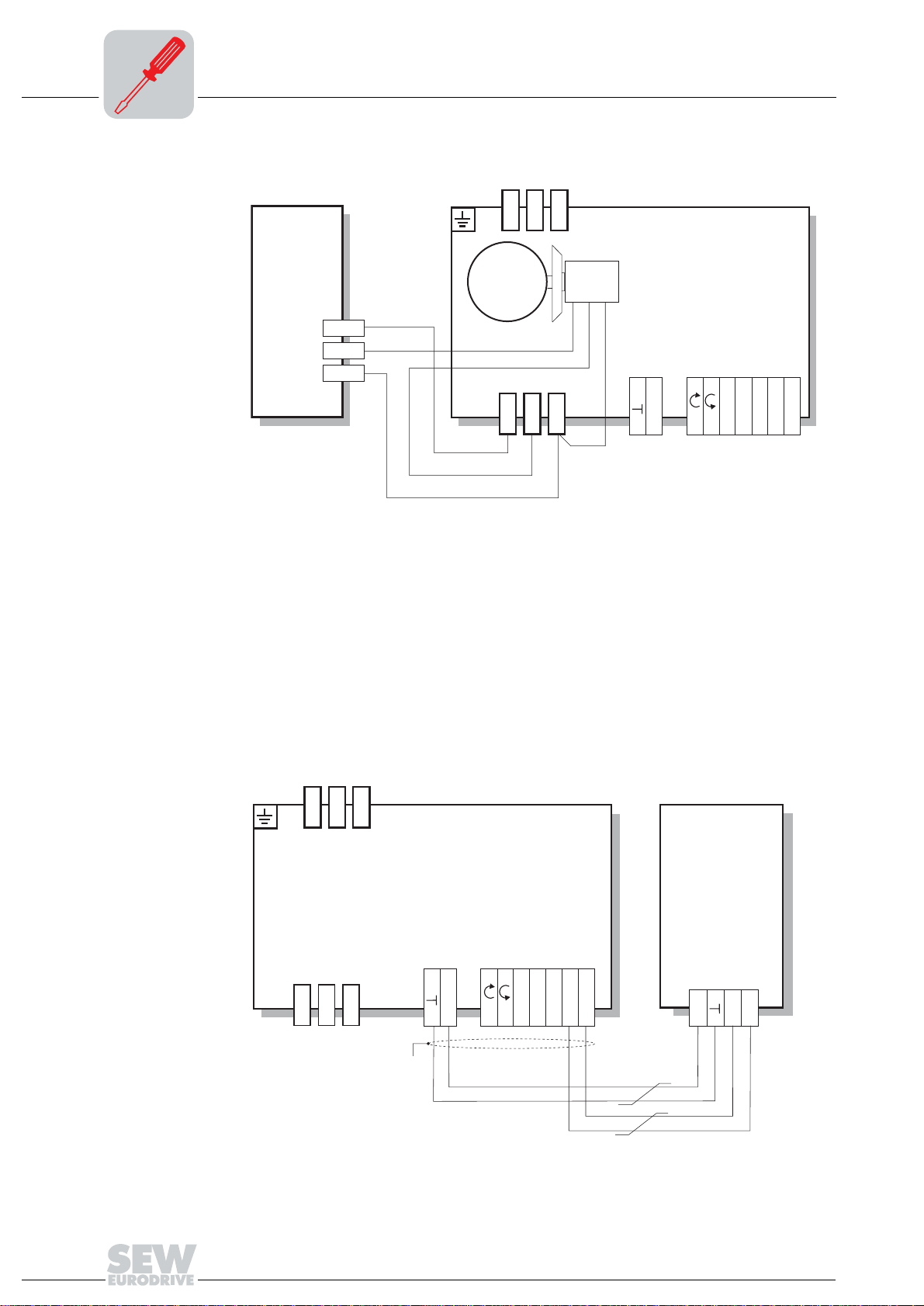

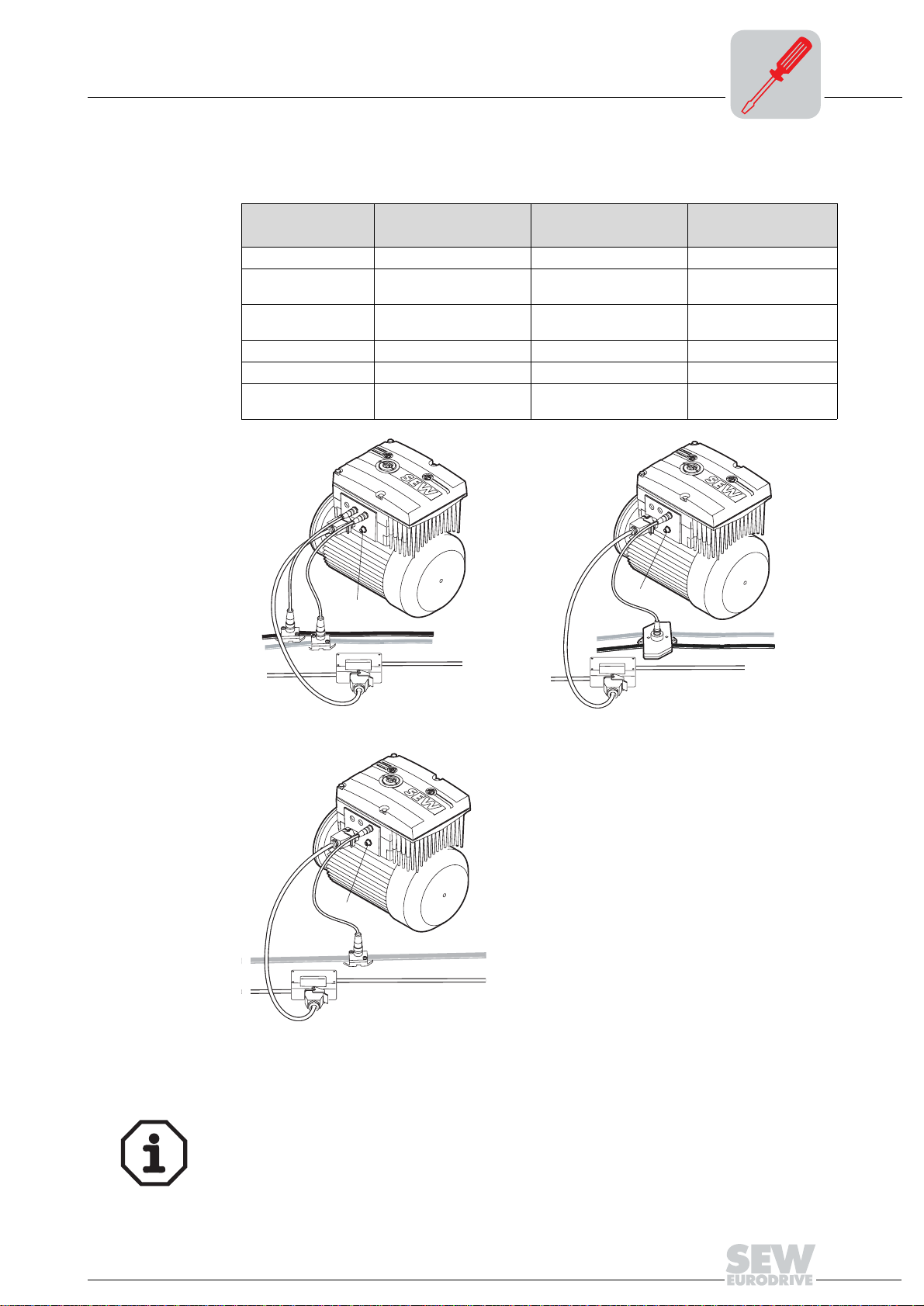

If the MOVIMOT® inverter with option P2.A is mounted close to the motor, the connection to the motor uses a pre-fabricated cable. The following designs are possible on the

MOVIMOT

• A: MM../P2.A/RO.A/APG4

• B: MM../P2.A/RE.A/ALA4

The APG 4 design results in the following connection options to the motor, dependent

upon the hybrid cable used:

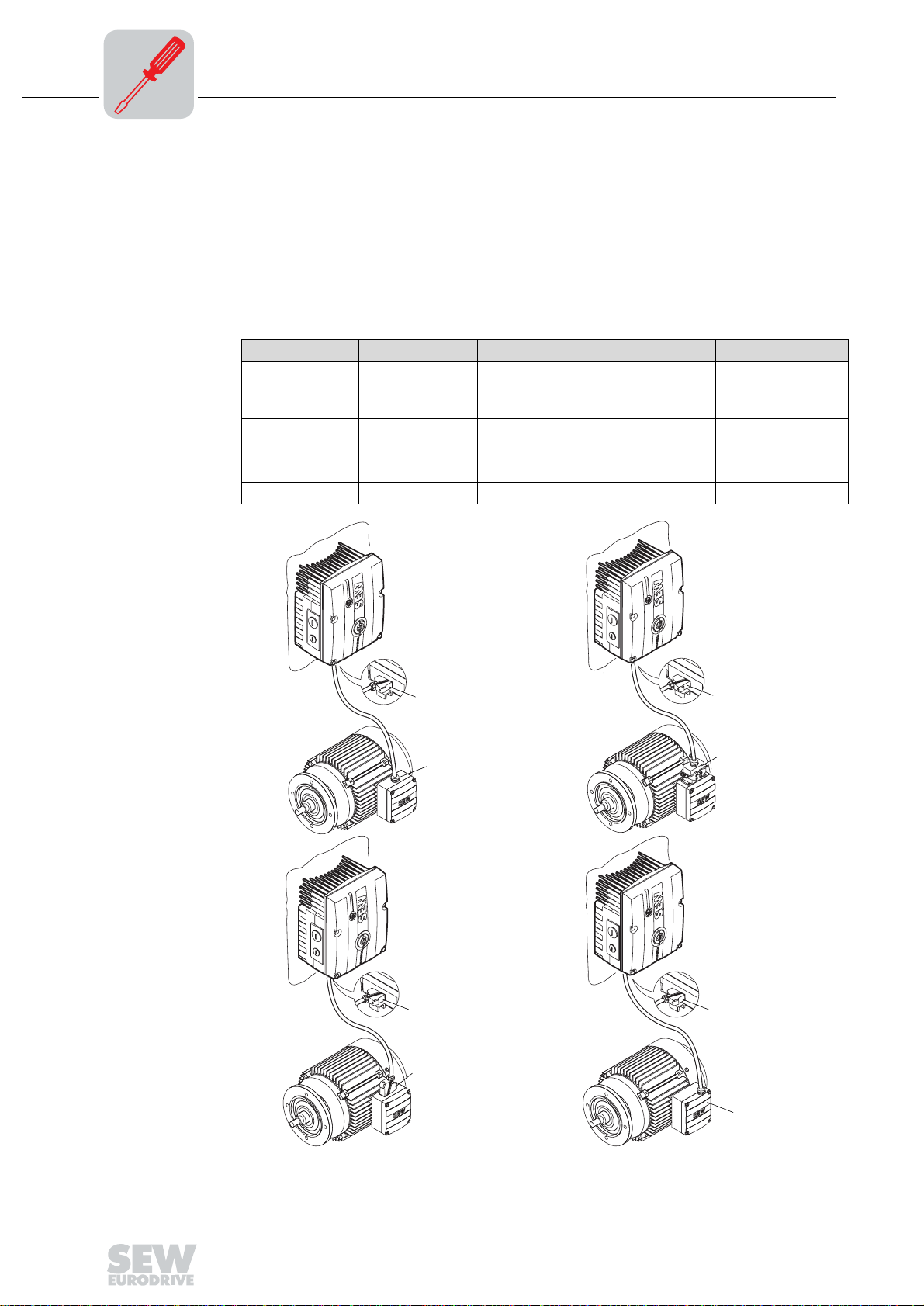

Design A1 A2 A3 A4

MOVIMOT

Motor Cable gland/termi-

Hybrid cables 0 593 231 9 0 593 076 6 0 186 741 5 0816 325 1

See also... page 34 page 34 page 35 page 35

®

®

side:

APG4APG4APG4APG4

ASB4 APG4 IS

nals

0816 326 X 쑶

쑶

0593 278 5 댴

0593 755 8 댴

A1

A3

APG4

[1]

APG4

A2

APG4

ASB4

A4

APG4

32

APG4

IS

52198AXX

[1] Connection via terminals

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 33

Electrical Installation of MOVIMOT® Standard Design

Connection between MOVIMOT® and motor mounting close to the motor

The ALA 4 design results in the following connection options to the motor, dependent

upon the hybrid cable used:

Design B1 B2

MOVIMOT

Motor Cable gland/terminals ASB4

Hybrid cables 0 817 948 4 0 816 208 5

Additional

Information

®

ALA4 ALA4

page 36 page 36

5

B1

[1] Connection via terminals

[1]

ALA4

B2

ALA4

ASB4

52199AXX

Operating Instructions – MOVIMOT® MM03C - MM3XC

33

Page 34

5

Electrical Installation of MOVIMOT® Standard Design

Connection between MOVIMOT® and motor mounting close to the motor

Hybrid cable design A

• Design A1

Part number 0 593 231 9

52073AXX

The overall shield of the cable must be attached to the housing of the motor terminal box

using an EMC metal cable gland.

Cable assignment

Motor terminal Core color / designation

U1 Black / U1

V1 Black / V1

W1 Black / W1

13 Red / 13

14 White / 14

15 Blue / 15

TH Black / 1

TH Black / 2

PE terminal Green-yellow + shield end (inside shield)

• Design A2

Part number 0 593 076 6

52074AXX

34

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 35

Electrical Installation of MOVIMOT® Standard Design

Auftragsnummer:

R 01/00

Laenge (m):

593 278 5

Connection between MOVIMOT® and motor mounting close to the motor

• Design A3

Part number 0 186 741 5

• Design A4

52075AXX

R 01/00

Auftragsnummer:

593 278 5

Laenge (m):

52076AXX

5

Motor with IS lower part

Size DT71 – DT90

Motor with IS lower part

Size DV100

MOVIMOT® in star connection MOVIMOT® in delta connection

Hybrid cable part number

0593 278 5

Hybrid cable part number

0593 755 8

Hybrid cable part number

0816 325 1

Hybrid cable part number

0816 326 X

Operating Instructions – MOVIMOT® MM03C - MM3XC

35

Page 36

5

Electrical Installation of MOVIMOT® Standard Design

Connection between MOVIMOT® and motor mounting close to the motor

Hybrid cable design B

• B1 version

Part number 0 817 948 4

52077AXX

The overall shield of the cable must be attached to the housing of the motor terminal box

using an EMC metal cable gland.

Cable assignment

Motor terminal Core color / designation

U1 Black / U1

V1 Black / V1

W1 Black / W1

13 Red / 13

14 White / 14

15 Blue / 15

TH Black / 1

TH Black / 2

PE terminal Green-yellow + shield end (inside shield)

• B2 version

Part number 0 816 208 5

52078AXX

36

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 37

Electrical Installation with Integrated AS-Interface

Installation instructions

6 Electrical Installation with Integrated AS-Interface

6.1 Installation instructions

6

Connecting supply system leads

• The rated voltage and frequency of MOVIMOT® must correspond to the data for the

power supply system (mains).

• Cable cross section: according to input current I

for rated power (see Technical

mains

Data).

• Permitted cable cross section of MOVIMOT

®

terminals (does not apply to field dis-

tributor)

Power terminals Control terminals

2

1.0 mm

AWG17 – AWG10 (2 x AWG10) AWG22 – AWG17 (2 x AWG18)

– 4.0 mm2 (2 x 4.0 mm2) 0.25 mm2 – 1.0 mm2 (2 x 0.75 mm2)

• Use conductor end sleeves without insulating shrouds (DIN 46228 part 1, material

E-CU).

• Install line safety at the beginning of the power cable behind supply bus junction (see

the section "Connection of MOVIMOT

®

Basic Unit," F11/F12/F13). Use D, DO, NH

or circuit breakers. The fusible rating should be selected in accordance with the cable

cross section.

• Do not use a conventional earth-leakage circuit breaker as a protective device. Universal current-sensitive earth leakage circuit-breakers (tripping current 300 mA) are

permitted as a protective device. During normal operation of MOVIMOT

®

, earth-leak-

age currents of > 3.5 mA can occur.

• Use contactor switch contacts to switch MOVIMOT

®

from utilization category AC-3

according to IEC 158.

• SEW recommends using earth-leakage monitors with pulse-code measurement for

voltage supply systems with non-grounded star point (IT nets). The use of such devices avoids mis-tripping of the earth-leakage monitor due to the earth capacitance

of the inverter.

Installation at 1000 meters above sea level (msl)

MOVIMOT® drives with supply voltages of 380 to 500 V can be used at altitudes above

2000 m MSL up to 4000 m MSL under the following peripheral conditions.

1)

• The rated continuous power is reduced based on the reduced cooling above 1000 m

(see the section "Technical Data and Dimension Drawings").

• Above 2000 msl, the air and creeping distances are only sufficient for overvoltage

class 2. If the installation requires overvoltage class 3, an additional external overvoltage protection must be used to ensure that overvoltage surges are limited to

2.5 kV phase-to-phase and phase-to-ground.

• If safe electrical separation is required, it must be implemented outside the device at

altitudes above 2000 m MSL (Safe Electrical Separation in accordance with

EN 50178).

• The permitted rated supply voltage of 3 x 500 V up to 2000 msl is reduced by 6 V for

every 100 m to a maximum of 3 x 380 V at 4000 msl.

1) The maximum altitude is limited by creeping distances and flameproof components such as electrolytic

capacitors.

Operating Instructions – MOVIMOT® MM03C - MM3XC

37

Page 38

6

Electrical Installation with Integrated AS-Interface

Installation instructions

Protection devices

UL compliant installation

•MOVIMOT® drives are equipped with integrated protective overload devices that are

making external overload devices obsolete.

• Use only copper cables with the temperature range 60 / 75 °C.

• The permitted tightening torques for MOVIMOT

– 1.5 Nm (13.3 lb.in).

•MOVIMOT

(TN and TT systems) supplying a maximum supply current of 5000 A

a maximum rated voltage of 500 V

mance data of the fuses must not exceed 35 A/600 V.

• Only use tested units with a limited output voltage (V

current (I ≤ 8 A) as an external 24 V

• UL certification applies only to operation in voltage supply systems with voltages to

ground up to 300 V.

®

are suited for operation on voltage supply systems with grounded star

(MM03C-503 to MM3XC-503). The perfor-

AC

voltage source.

DC

®

power terminals are:

= 30 VDC) and limited output

max

and having

AC

38

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 39

Electrical Installation with Integrated AS-Interface

Connection options with integrated AS-Interface

6.2 Connection options with integrated AS-Interface

6

Mains and control

A Design with AVSK plug (1 x M12 connector):

Design A1 A2

Type designation MM../AVSK MM../AVSK

Switch S5 01

24 V supply Yellow AS-i cable Black AUX-PWR cable

AS-i connection Yellow AS-i cable Yellow AS-i cable (double tap)

Mains connection Terminals Terminals

Sensor connection Terminals Terminals

Additional

information

A1

[1]

page 42 page 42

A2

[1]

AS-i (YE)

(double tap)

AS-i (YE)

AUX-PWR

(BK)

52001AXX

[1] Mains

• The designs listed above are also valid for mounting the MOVIMOT® inverter with

option P2.A close to the motor.

Operating Instructions – MOVIMOT® MM03C - MM3XC

39

Page 40

6

Electrical Installation with Integrated AS-Interface

Connection options with integrated AS-Interface

B Design with AZSK plug (3 x M12 connector):

Design B1 B2 B3

Type designation MM../RC.A/AZSK MM../RC.A/AZSK MM../RC.A/AZSK

Switch S5 110

24 V supply Black AUX-PWR cable Black AUX-PWR cable

AS-i connection Yellow AS-i cable Yellow AS-i cable (double

Mains connection Terminals Terminals Terminals

Sensor connection M12 plug connector M12 plug connector M12 plug connector

Additional

information

page 43 page 43 page 43

(double tap)

tap)

Yellow AS-i cable

Yellow AS-i cable

B1

[1]

B3

[1]

2 x DI

2 x DI

AUX-PWR (BK)

AS-i (YE)

B2

[1]

2 x DI

AS-i (YE)

AUX-PWR

(BK)

40

AS-i (YE)

52002AXX

[1] Mains

• The designs listed above are also valid for mounting the MOVIMOT® inverter with

option P2.A close to the motor.

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 41

Electrical Installation with Integrated AS-Interface

Connection options with integrated AS-Interface

C Design with AND3/AZSK plug connector

(3 x M12 plug, 1 x Han Q8/0):

Design C1 C2 C3

Type designation MM../RJ.A/AND3/AZSK MM../RJ.A/AND3/AZSK MM../RJ.A/AND3/AZSK

Switch S5 110

24 V supply AUX-PWR cable AUX-PWR cable (double

AS-i connection Yellow AS-i cable Yellow AS-i cable (double

Mains connection AND3 plug connector AND3 plug connector AND3 plug connector

Sensor connection M12 plug connector M12 plug connector M12 plug connector

Additional

Information

page 44 page 44 page 44

tap)

tap)

Yellow AS-i cable

Yellow AS-i cable

6

C1

C3

2 x DI

AUX-PWR (BK)

AS-i (YE)

[1]

C2

2 x DI

[1]

AS-i (YE)

AUX-PW

(BK)

2 x DI

[1] Mains

• The designs listed above are also valid for mounting the MOVIMOT® inverter with

option P2.A close to the motor.

Operating Instructions – MOVIMOT® MM03C - MM3XC

AS-i (YE)

[1]

51761AXX

41

Page 42

6

Electrical Installation with Integrated AS-Interface

Connection of MOVIMOT® MM../AVSK (connection option A)

6.3 Connection of MOVIMOT® MM../AVSK (connection option A)

The following figure shows the connection of the MM../AVSK design.

L1

L2

L3

PE

L1

F11/F12/F13

L2

L3

K11

MM../AVSK

M

3~

WH

RD

13

BW.[7]

[1] 24 VDC supply

[2] AS-i data cable [3] AS-i data cable +

[4] Voltage supply for sensors

[5] Sensor DI2

[6] Sensor DI3

[7] BW.. braking resistor (in MOVIMOT

[8] M12 plug (yellow)

14

BL

15

BMG

BMG

[1]

[2]

[3]

[4]

[5]

VO

DI2

VO24

AS-I-

3

2

[8]

24V

AS-i -

AS-i +

4

3

2

1

®

without mechanical brake only)

[6]

DI3

24 V

4

1

AS-I+

51823AXX

42

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 43

Electrical Installation with Integrated AS-Interface

Connection of MOVIMOT® MM../AZSK (connection option B)

6.4 Connection of MOVIMOT® MM../AZSK (connection option B)

The following figure shows the connection of the MM../AZSK design.

L1

L2

L3

PE

L1

F11/F12/F13

L2

L3

K11

MM../AZSK

6

M

3~

WH

13

BW

BL

14

.

RD

AZSK plug connector

[1] M12 plug connector

(plug, black)

[2] M12 plug connector

(plug, yellow)

[3] M12 plug connector

(socket, black)

BMG

BMG

[1]

BK

4

3

2

15

1 24 V 24 V supply (AUX-PWR)

2 N.C. Not assigned

3 0 V AUX-PWR reference potential

4 N.C. Not assigned

1 AS-i + AS-i data cable +

2 0 V AUX-PWR reference potential

3 AS-i - AS-i data cable 4 24 V 24 V supply (AUX-PWR)

1 VO24 24 V voltage supply for sensors

2 DI3 Sensor input DI3

3VO⊥ 0 V reference potential for sensors

4 DI2 Sensor input DI2

1

3

4

2

24V

[2]

YE

4

1

AS-I -

3

2

1

3

2

24 V

4

1

AS-I+

BK

3

2

DI2

4

VO24

[3]

1

4

1

VO

3

2

DI3

52061AXX

Operating Instructions – MOVIMOT® MM03C - MM3XC

43

Page 44

6

V

Electrical Installation with Integrated AS-Interface

Connection of MOVIMOT® MM../AND3/AZSK (connection option C)

6.5 Connection of MOVIMOT® MM../AND3/AZSK (connection option C)

The following figure shows the connection of the MM../AND3/AZSK design.

24V 0

ASI+24V ASI-0V

4

4

3

3

2

2

1

1

3

3

4

4

1

1

2

2

[4]

PE

L1

N.C.

N.C.

L2

N.C.

[3]

PE

N.C.

N.C.

L3

[1]

4

4

3

3

[2]

2

2

1

1

0V

DI3 DI224V

AZSK plug connector

[1] M12 plug connector

(plug, black)

[2] M12 plug connector

(plug, yellow)

[4] M12 plug connector

(socket, black)

AND3 plug connector

[3] AND3 plug connector

(plug)

51940AXX

1 24 V 24 V supply (AUX-PWR)

2 N.C. Not assigned

3 0 V AUX-PWR reference potential

4 N.C. Not assigned

1 AS-i + AS-i data cable +

2 0 V AUX-PWR reference potential

3 AS-i - AS-i data cable 4 24 V 24 V supply (AUX-PWR)

1 VO24 24 V voltage supply for sensors

2 DI3 Sensor input DI3

3VO⊥ 0 V reference potential for sensors

4 DI2 Sensor input DI2

1 N.C. Not assigned (reserved for N)

2 L2 Mains connection L2

3 N.C. Not assigned

4 N.C. Not assigned

5 N.C. Not assigned

6 L3 Mains connection L3

7 N.C. Not assigned

8 L1 Mains connection L1

댷 PE PE

44

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 45

Electrical Installation with Integrated AS-Interface

6.6 Connection of URM option

The following figure shows the connection of the URM option.

URM

Connection of URM option

L1

L2

L3

MOVIMOT

6

®

13

14

15

M

3~

RD

WH

13

14

BMG

15

BU

24V

AS-i -

AS-i +

VO

DI2

VO24

DI3

52208AXX

Operating Instructions – MOVIMOT® MM03C - MM3XC

45

Page 46

6

Electrical Installation with Integrated AS-Interface

Connection between MOVIMOT® and motor mounting close to the motor

6.7 Connection between MOVIMOT® and motor mounting close to the motor

If the MOVIMOT® inverter with option P2.A is mounted close to the motor (only in conjunction with modular terminal box), the connection to the motor uses a pre-fabricated

cable. The following designs are possible on the MOVIMOT

• A: MM../P2.A/RO.A/APG4

• B: MM../P2.A/RE.A/ALA4

The APG4 design results in the following connection options to the motor, dependent

upon the hybrid cable used:

Design A1 A2 A3 A4

MOVIMOT

Motor Cable gland/termi-

Hybrid cables 0 593 231 9 0 593 076 6 0 186 741 5 0816 325 1

See also... page 48 page 48 page 49 page 49

®

APG4APG4APG4APG4

ASB4 APG4 IS

nals

®

side:

0816 326 X 쑶

쑶

0593 278 5 댴

0593 755 8 댴

A1

A3

APG4

[1]

APG4

A2

APG4

ASB4

A4

APG4

46

APG4

IS

51771AXX

[1] Connection via terminals

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 47

Electrical Installation with Integrated AS-Interface

Connection between MOVIMOT® and motor mounting close to the motor

The ALA4 design results in the following connection options to the motor, dependent

upon the hybrid cable used:

Design B1 B2

MOVIMOT

Motor Cable gland/terminals ASB4

Hybrid cables 0 817 948 4 0 816 208 5

Additional

Information

®

ALA4 ALA4

page 50 page 50

6

B1

[1] Connection via terminals

[1]

ALA4

B2

ALA4

ASB4

51853AXX

Operating Instructions – MOVIMOT® MM03C - MM3XC

47

Page 48

6

Electrical Installation with Integrated AS-Interface

Connection between MOVIMOT® and motor mounting close to the motor

Hybrid cable design A

• Design A1

Part number 0 593 231 9

52073AXX

The overall shield of the cable must be attached to the housing of the motor terminal box

using an EMC metal cable gland.

Cable assignment

Motor terminal Core color / designation

U1 Black / U1

V1 Black / V1

W1 Black / W1

13 Red / 13

14 White / 14

15 Blue / 15

TH Black / 1

TH Black / 2

PE terminal Green-yellow + shield end (inside shield)

• Design A2

Part number 0 593 076 6

52074AXX

48

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 49

Electrical Installation with Integrated AS-Interface

Auftragsnummer:

R 01/00

Laenge (m):

593 278 5

Connection between MOVIMOT® and motor mounting close to the motor

• Design A3

Part number 0 186 741 5

• Design A4

52075AXX

R 01/00

Auftragsnummer:

593 278 5

Laenge (m):

52076AXX

6

Motor with IS lower part

Size DT71 – DT90

Motor with IS lower part

Size DV100

MOVIMOT® in star connection MOVIMOT® in delta connection

Hybrid cable part number

0593 278 5

Hybrid cable part number

0593 755 8

Hybrid cable part number

0816 325 1

Hybrid cable part number

0816 326 X

Operating Instructions – MOVIMOT® MM03C - MM3XC

49

Page 50

6

Electrical Installation with Integrated AS-Interface

Connection between MOVIMOT® and motor mounting close to the motor

Hybrid cable design B

• B1 version

Part number 0 817 948 4

52077AXX

The overall shield of the cable must be attached to the housing of the motor terminal box

using an EMC metal cable gland.

Cable assignment

Motor terminal Core color / designation

U1 Black / U1

V1 Black / V1

W1 Black / W1

13 Red / 13

14 White / 14

15 Blue / 15

TH Black / 1

TH Black / 2

PE terminal Green-yellow + shield end (inside shield)

• B2 version

Part number 0 816 208 5

52078AXX

50

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 51

7 Startup of Standard Design

7.1 Important startup instructions

• It is essential to comply with the safety notes during installation!

• Before removing/attaching the MOVIMOT

from the power supply system (mains). Dangerous voltages may still be

present for up to 1 minute after shutdown.

• Ensure before startup that the drive has not been damaged.

• Check that all protective covers are installed correctly.

• Use "CW/Stop" or "CCW/Stop" for jog mode.

• A minimum switch-off time of 2 seconds must be maintained for the mains contactor

K11.

7.2 Description of the controls

Startup of Standard Design

Important startup instructions

®

inverter, it must be disconnected

I

7

00

Setpoint potentiometer f1

Setpoint switch f2

3

4

5

6

7

8

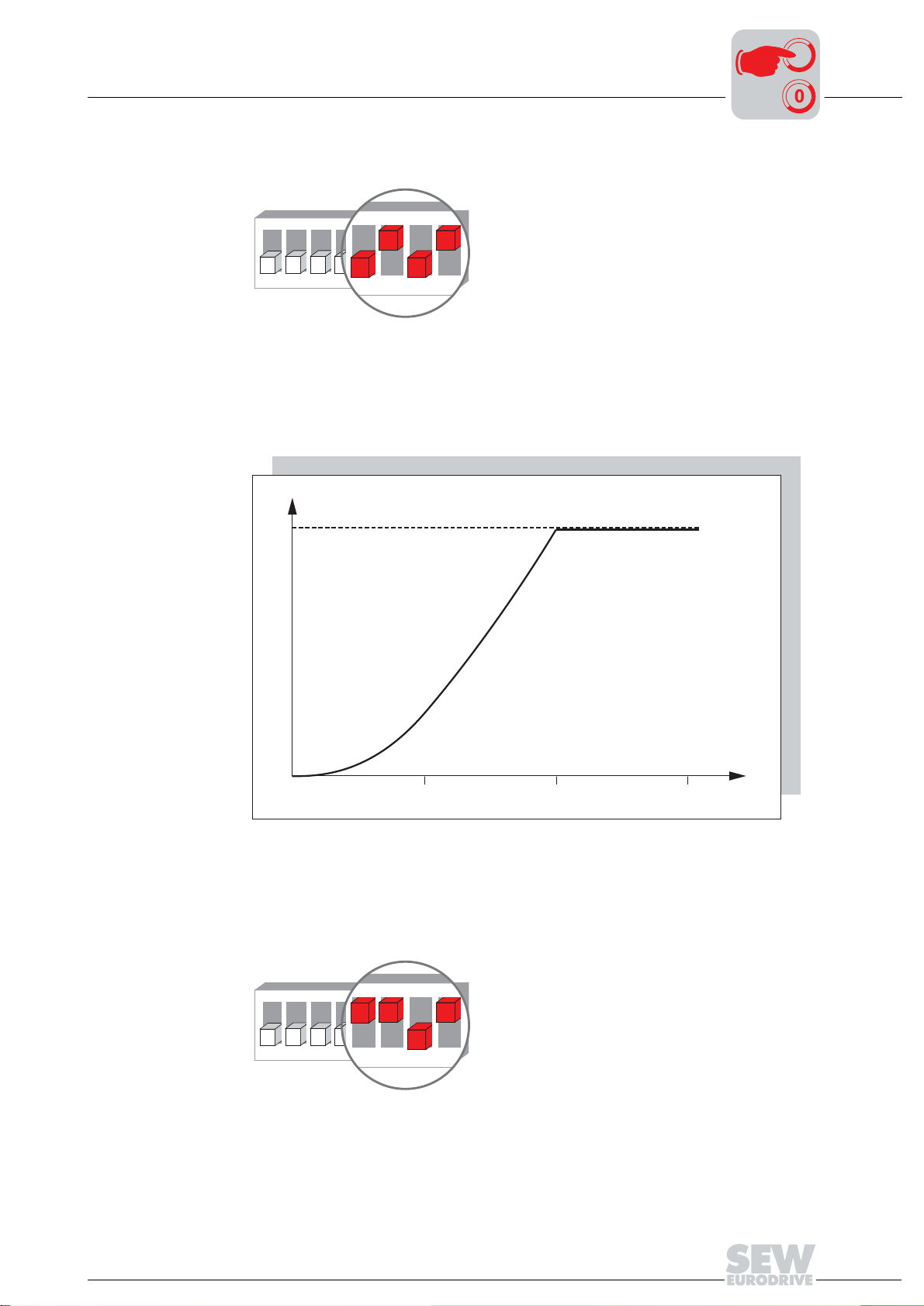

The potentiometer has a different function, depending on the unit operating mode:

• Control via terminals: Setpoint f1 (selected by tl. f1/f2 = "0")

• Control via RS-485: Maximum frequency f

100

f [Hz

]

75

50

25

2

123456789100

[1] Pot. position

6

5

max

[1]

f

1

05066BXX

The function of the switch changes depending on the unit operating mode:

• Control via terminals: Setpoint f2 (selected by tl. f1/f2 = "1")

• Control via RS-485: Minimum frequency f

Switch f2

Detent position 0 12345678910

Setpoint f2 [Hz] 5 7 1015202535506070100

Mini. frequency [Hz] 2 5 7 10 12 15 20 25 30 35 40

min

Switch t1

3

4

5

6

7

8

Operating Instructions – MOVIMOT® MM03C - MM3XC

For integrator ramp (ramp times based on a setpoint jump of 50 Hz)

Switch t1

Detent position 012345 678910

Ramp time t1 [s] 0.1 0.2 0.3 0.5 0.7 1 235710

51

Page 52

7

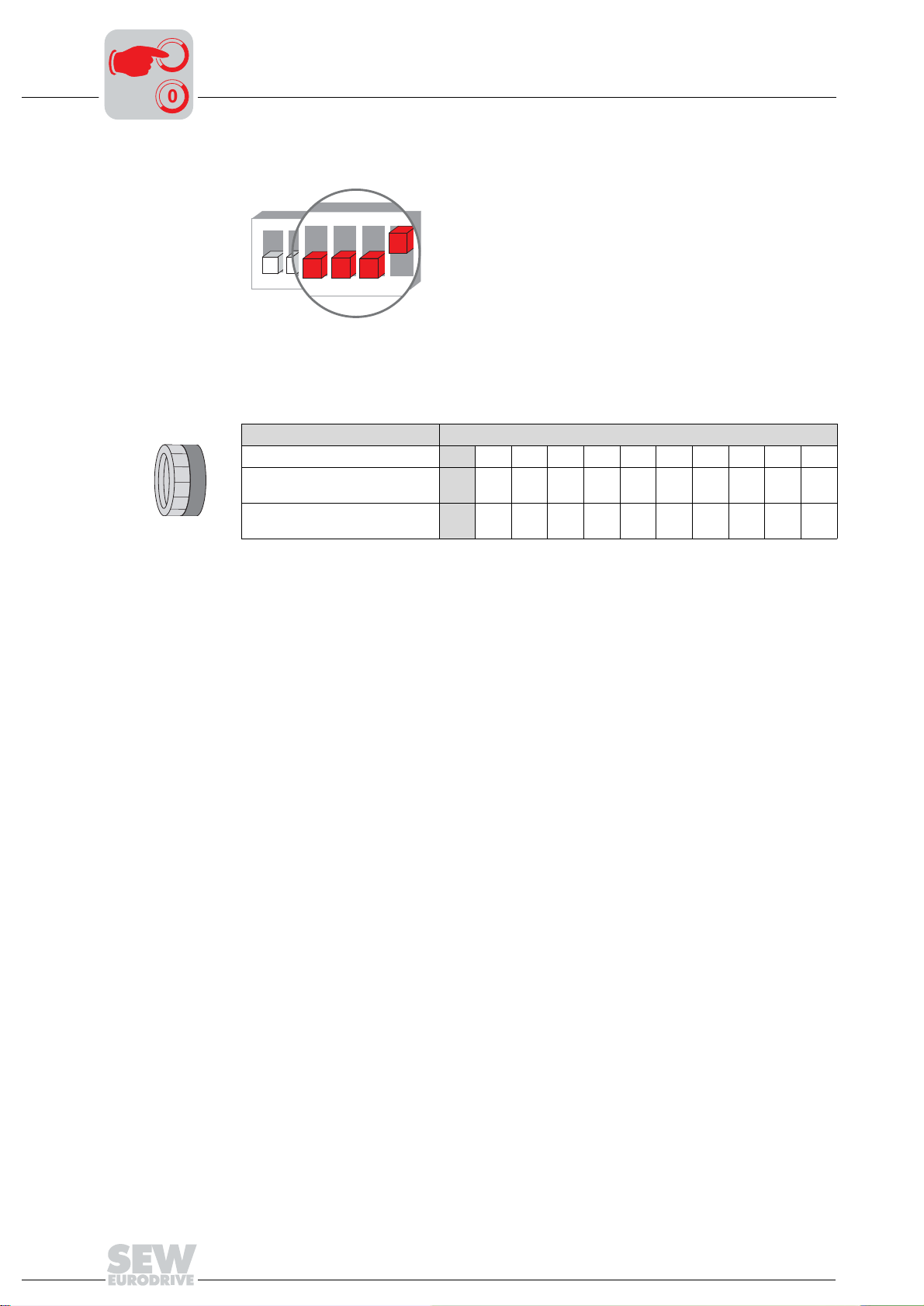

DIP switches S1 and S2

I

Startup of Standard Design

Description of the controls

00

50522AXX

DIP switch S1:

S1 1 2 3 4 5

Message RS-485 address

2021222

ON 1111 Off

OFF 0 0 0 0 On adapted 4 kHz Off

Motor

3

protec-

tion

6

Motor

rating class

Motor one

size smaller

7

PWM

frequency

Variable

(16, 8, 4 kHz)

8

No-load

damping

On

DIP switch S2:

S2 1 2 3 4 5 6 7 8

Message Motor

ON

OFF IEC motor Off VFC Off 0 0 0 0

1) only available in Brazil

type

SEW DZ

motor:

1)

Brake release

without

Enable

On V/f On

Control pro-

cess

Speed

monitoring

Selection of options

2021222

1111

3

52

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 53

Description of the DIP switches S1

7.3 Description of the DIP switches S1

Startup of Standard Design

I

7

00

DIP switches

S1/1-S1/4

Selection of RS-485 address of MOVIMOT® via binary coding

Decimal

Address

S1/1 – X – X – X – X – X – X – X – X

S1/2 ––

S1/3 ––––

S1/4 ––––––––

X = ON

–= OFF

Depending on the control of MOVIMOT

Control RS-485 address

Binary control (terminal operation) 0

Via external AS-i binary slave (MLK11A) 0

Via keypad (MLG.., MBG..) 1

Via fieldbus interface (MF..) 1

Via fieldbus interface with integrated small control system (MQ..) 1 to 15

Via RS-485 master 1 to 15

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

X X ––X X ––X X ––X X

X X X X ––––X X X X

X X X X X X X X

®

, different addresses must be set:

DIP switches

S1/5

Motor protection activated or deactivated

• If the MOVIMOT

®

inverter is mounted close to the motor (with option P2.A or in the

field distributor), the motor protection must be deactivated.

• To ensure motor protection after all, a TH (bimetallic thermostat) must be used. In

this case, the TH opens the sensor circuit after reaching the nominal response temperature (see the "Startup with field distributor" section in the "Drive System for Decentralized Installation" system manual).

Operating Instructions – MOVIMOT® MM03C - MM3XC

53

Page 54

7

I

Startup of Standard Design

Description of the DIP switches S1

00

DIP switches

S1/6

Motor rating class smaller

• If it is activated, the DIP switch enables the assignment of MOVIMOT

®

to a motor

with a smaller rating class. The rated power of the unit remains unchanged.

• If a motor with less power is used, the overload capacity of the drive may increase

since the motor considers the MOVIMOT

®

to be one power increment too high. A

larger current may be impressed for a short period of time, which results in higher

torques.

• The purpose of switch S1/6 is the short-term utilization of the motor peak torque. The

current limit of the respective unit is always the same, independent of the switch setting. The motor protection function is adapted in reference to the switch setting.

• In this operating mode with S1/6 = "ON", a pull-out protection of the motor is

not possible.

MOVIMOT®

inverter

S1/6 = OFF S1/6 = ON

Assigned motor

댴 쑶 댴 쑶

MM03 DT71D4 DR63L4

MM05 DT80K4 DT71D4 DT71D4 DFR63L4

MM07 DT80N4 DT80K4 DT80K4 DT71D4

MM11 DT90S4 DT80N4 DT80N4 DT80K4

MM15 DT90L4 DT90S4 DT90S4 DT80N4

MM22 DV100M4 DT90L4 DT90L4 DT90S4

MM30 DV100L4 DV100M4 DV100M4 DT90L4

MM3X – DV100L4 DV100L4 DV100M4

1) Only possible with offset assembly

1)

DR63L4

1)

–

1)

DIP switches

S1/7

DIP switches

S1/8

Setting the maximum PWM frequency

• With setting DIP SWITCH S1/7 = OFF, MOVIMOT

®

operates with 4 kHz PWM fre-

quency.

• With setting DIP SWITCH S1/7 = ON, MOVIMOT

®

operates with a 16 kHz PWM frequency (low noise) and switches back in steps to lower switching frequencies depending on the heat sink temperature.

No-load damping function (S1/8 = ON)

Upon activation, the function prevents resonant oscillations in no-load operation.

54

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 55

Description of the DIP switches S2

7.4 Description of the DIP switches S2

Startup of Standard Design

I

7

00

DIP switches

S2/1

DIP switches

S2/2

Operation with

braking resistor

Function with terminal control

(address = 0)

Motor type

• With IEC and NEMA motors, DIP switch S2/1 must always be set to OFF!

• With DZ motor with rated voltages of 220/380 V, 60 Hz (only available in Brazil), the

DIP switch must always be set to ON.

Releasing the brake without enable

With activated switch S2/2 = "ON", the brake can also be released if no drive enable is

present.

The special function is not in effect if operated with braking resistor.

With terminal control, the brake can be released by setting terminal f1/f2 if the following

requirements exist:

Terminal condition

R L f1/f2

"1"

"0"

"0"

"1"

"1"

"0"

"0"

"1"

"1"

"1"

"0"

"0"

"1" "1" "1" Unit not

"0" "0" "1" Unit not

All conditions possible

Enable condition Fault condi-

"0" Unit enabled No

"1" Unit enabled No

"0" Unit not

enabled

enabled

enabled

Unit not

enabled

tion

Unit fault

Unit fault

No

Unit fault

No

Unit fault

No

Unit fault

Unit fault Brake closed

Brake function

Brake is controlled by MOVIMOT

setpoint f1

Brake is controlled by MOVIMOT

setpoint f2

Brake closed

Brake closed

Brake released for manual procedure

®

,

®

,

Functions in bus

In bus operation, the brake is released through control in the control word.

operation

Master

PO1

PI1

PO = Process output data PI = Process input data

PO1 = Control word PI1 = Status word 1

PO2 = Speed (%) PI2 = Output current

PO3 = Ramp PI3 = Status word 2

DO = Digital outputs DI = Digital inputs

Operating Instructions – MOVIMOT® MM03C - MM3XC

PO2

PI2

PO

PI

PO3

PI3

DO

DI

MOVIMOT

+

-

®

52117AXX

55

Page 56

7

I

Startup of Standard Design

Description of the DIP switches S2

00

Setting bit 8 in the control word allows the brake to be released under the following conditions:

Basic control block

15 14 13 12 11 10 9

Control word

Not assigned

Enable

condition

Unit

enabled

Unit

enabled

Unit not

enabled

Unit not

enabled

Unit not

enabled

Fault condition Status of bit 8 in con-

No unit fault /

no communications timeout

No unit fault /

no communications timeout

No unit fault /

no communications timeout

No unit fault /

no communications timeout

Unit fault /

communications timeout

876543210

Bit

"8"

trol word

"0" Brake is controlled by

"1" Brake is controlled by

"0" Brake closed

"1" Brake released for man-

"1" or "0" Brake closed

"1" =

Reset

Virtual terminals for releasing the brake without

drive enable

Not assigned

Brake function

MOVIMOT

MOVIMOT

ual procedure

"1 1 0" = Release

otherwise stop

®

®

In case of a unit fault / communications timeout, the brake cannot be released via

special function.

Setpoint selection

in terminal operation

Behavior with a

non-operating unit

LED display

Setpoint selection in terminal operation depends on status of terminal f1/f2:

Enable condition Terminal f1/f2 Active setpoint

Unit enabled Terminal f1/f2 = "0" Setpoint potentiometer f1 active

Unit enabled Terminal f1/f2 = "1" Setpoint potentiometer f2 active

In case of a non-operating unit, the brake is always applied independent of the setting

of terminal f1/f2 or bit 8 in the control word.

The yellow LED display flashes periodically and quickly (ton : t

= 100 ms : 300 ms) if

off

the brake was released for manual procedure. This applies to terminal operation as well

as bus operation.

56

Operating Instructions – MOVIMOT® MM03C - MM3XC

Page 57

Startup of Standard Design

Description of the DIP switches S2

I

7

00

DIP switches

S2/3

DIP switches

S2/4

DIP switches

S2/5 to S2/8

Control process

• DIP switches S2/3 = OFF: VFC operation for 4-pole motors

• DIP switches S2/3 = ON: U/f operation reserved for special cases

Speed monitoring

• Speed monitoring (S2/4 = "ON" is used for the protection of the drive during blocking.

• If the drive is operated at the current limit for more than 1 second with active speed

monitoring (S2/4 = "ON"), the speed monitoring trips. MOVIMOT

®

signals a fault via

status LED (red, flashing slowly, fault code 08). The current limit must be attained uninterruptedly for the duration of the delay time before the monitoring function responds.

Selection of options

• Special functions can be selected using the binary coding of the DIP switches.

• The possible values can be set as follows:

Decimal

Value

S2/5 –

S2/6 ––

S2/7 ––––

S2/8 ––––––––

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

X – X – X – X – X – X – X – X

X X ––X X ––X X ––X X

X X X X ––––X X X X

X X X X X X X X

X = ON

–= OFF

• An overview of the selectable special functions can be found on page 58.

Operating Instructions – MOVIMOT® MM03C - MM3XC

57

Page 58

I

7

Startup of Standard Design

Selectable special functions MM..C-503-00

00

7.5 Selectable special functions MM..C-503-00

Overview of

selectable special

functions

Decimal

Value

0 Basic functionality, no special function selected X X – –

1 MOVIMOT

2 MOVIMOT

3 MOVIMOT

4 MOVIMOT

5 MOVIMOT