Page 1

MMetalfab, Inc.

Dry Solids Processing Equipment

P.O. BOX 9, PRICES SWITCH ROAD, VERNON, NEW JERSEY 07462 ♦ 973-764-2000 ♦ FAX # 973-764-0272

INSTRUCTIONS FOR OPERATION & MAINTENANCE

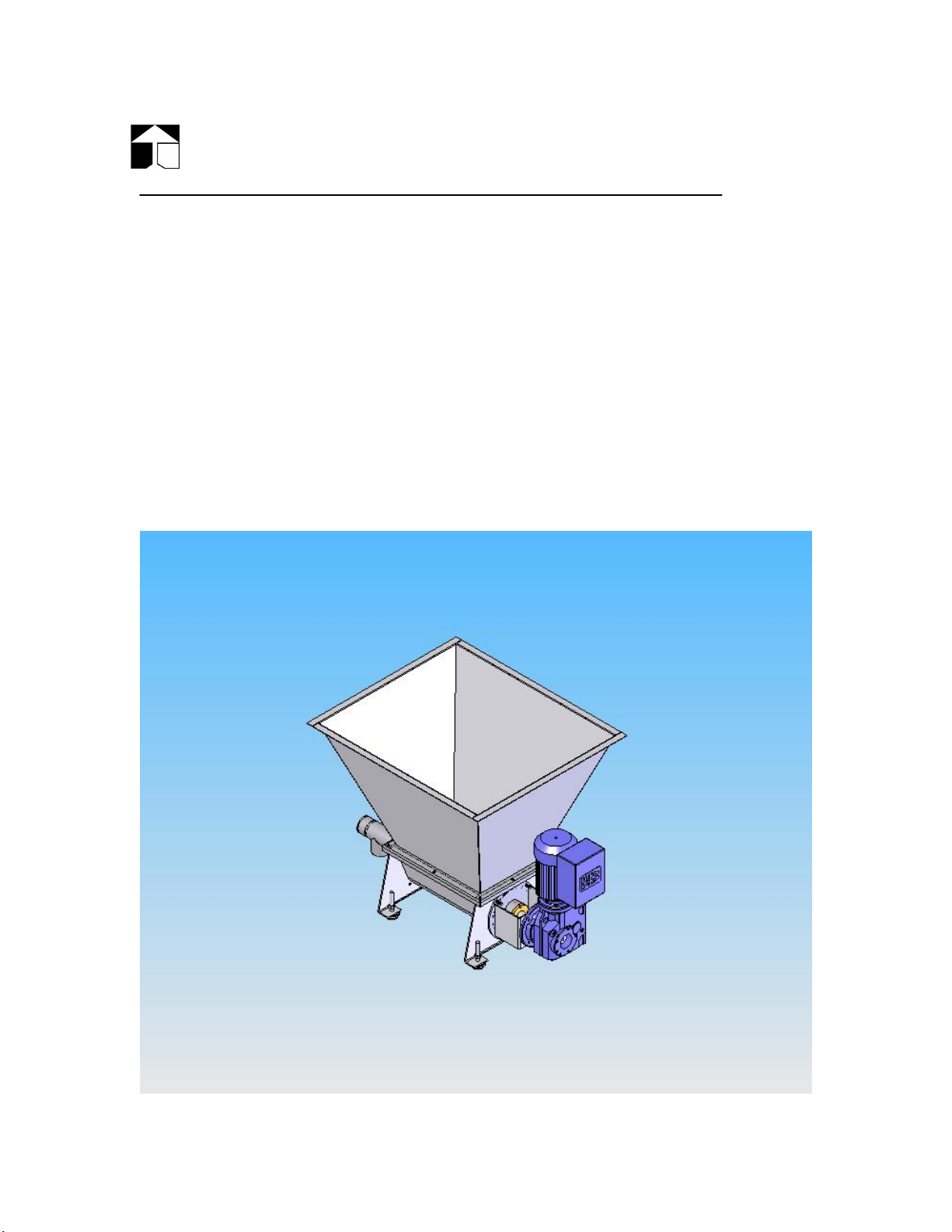

MetaTech MT-X-XXX Series

VOLUMETRIC SCREW FEEDER

Fig A.

Page 2

The MetaTech Feeder is a simple, rugged and accurate Volumetric Feeder used

for the dependable metering of dry solid materials into a variety of

manufacturing processes. It consists of a trough assembly. a hopper in various

capacities, a GearMotor Drive (which is available in many input power

configurations and ratios), a Metering Screw and Tube in sizes and styles to fit

the application. The metering screw is coupled to the variable speed drive,

either AC with a VFD or DC with an SCR; all mounted on the trough assembly

with isolation feet mounts or mounted to a custom frame.

The steep, sloped hopper, with its large rectangular outlet, allows for material

flow to the metering screw. The metering screw consists of three spiral wraps,

the largest being the agitator which assists the motion of produce within the

trough, the mid sized The function of this screw is to keep the material in motion

and also "condition" the material to a constant density while insuring complete

filling of the metering screw flights. Hence, accuracy is maintained while rates

are varied by screw speed changes.

Installation

The MetaTech Feeder is shipped complete and ready for operation. For

enhanced safety, the unit should be bolted in place, absent this there are four

(4) levelers positioned under the base which are equipped with rubber pads.

Room should be provided at the discharge end to allow for screw removal.

Normally, 20" clearance is sufficient.

Electrical Requirements

Standard units are provided with AC Inverter Duty Drives which can have their

own VFD controllers mounted integral to the motor housing or stand alone

VFDÅfs of the Customer specification. Typical VFDÅfs capable of varying output

frequency from 0 to 100 Hz, minimum operation at 5 hz is recommended for

adequate cooling. The controller may be mounted at the Feeder location or

remotely. SEW Eurodrive Inverter Manual and DC SCR Control Manuals are

attached at the end of this manual. All standard motors are TEFC (totally

enclosed, fan cooled), severe heat applications may require TEBC (blower

cooled) models which will require a separate power input for the blower.

Inverter Duty Motors are dual voltage 230/460 three phase. Inverter Drives

(VFDÅfs) are 230 vac OR 460 vac models special applications for single phase

input power can be accommodated as can 380vac, 575vac and 50Hz models;

contact Metalfab Inc. for these special applications and consult Inverter Drive

Manuals and for specifications. For amperage considerations 460/3 motors will

draw 1 amp per Hp and should be equipped with supply capacity 2X this nominal

Page 3

amperage for inrush consideration. 230/3 models will draw exactly double the

460/3 ratings.

DC Motors are available with field windings (shunt wound) or permanent

magnet, both are available in 90vdc (std _ Hp) and 180vdc (std 1Hp) armatures.

DC motor speed is modulated by varying the armature voltage from 0 to max,

15% speed should be considered the min speed for motor cooling considerations

Operation

After the Feeder is in place and wired, it is ready for operation. Units equipped

with electrically variable speed drives can have their speed adjusted at anytime,

i.e., with the unit stopped or in motion. The dial provides for setting screw

speeds to 1 part in 100. Speed is increased by turning the potentiometer in

clockwise rotation. Optional digital keypads for Local/Remote operation are

available, again consult the feeder specification and pricing sheets for options.

The hopper should be filled with the feed material and the potentiometer should

be set to 50%. The unit should be allowed to run for 5 minutes before a 1

minute sample is collected and weighed. It is suggested that 5 or more samples

be taken to assure the Feeder is operating properly. Once the feed rate is

known at 50%, the required rate may then be obtained by proper speed change.

The drive and, therefore, the feed rates are linear, hence, at setting of 50% the

Feeder will be operating at approximately half capacity. As an example, if at a

50% setting a 20#/minute rate is achieved and a 10#/minute rate is desired,

change the setting to 25% and a 10#/minute rate will be delivered. Take

samples at 3 or 4 settings and plot a graph, setting versus rate. From this

graph, any feed rate may be selected. This calibration should be done at the

end user application as material bulk density and condition due to prior steps in

the process will have an impact on the ÅgActual Discharge RatesÅh, approximate

rates are listed on the drawing on the final pages in the spare parts section of

this manual.

Warning: Keep hands clear of all moving parts. Serious injury can occur.

Page 4

Standard Inverter Duty Gearmotor fig B.

The hopper may be equipped with a pneumatically or electrically operated

vibrator if the feed product requires an assist to promote flow. The hopper is

also equipped with a baffle when a vibrator is used. The amount of vibration

should be minimal, just enough to promote flow. The vibrations of the

pneumatic vibrator may be adjusted by changing the P.S.I. setting (pressure

regulator, filter, gauge, etc., by customer), but should not exceed a maximum

pressure of 80 P.S.I. For electric vibrators, the vibrations may be adjusted by

changing the alignment of the centerlines of the eccentric weights, consult the

vibrator manual for proper instructions. In all applications, the vibrator should

be controlled such that it only operates while the feeder is operating. Operation

of the vibrator without an established discharge from the feeder may cause the

material to pack in the trough and/or hopper.

The closer you align the centerlines of the two (2) OUTER weights with the

centerlines of the two (2) INNER weights, you are INCREASING the force. The

further you misalign the referenced centerlines, the more your DECREASE the

force. If the centerlines of all four (4) weights are completely aligned, you will

Page 5

develop the maximum force available. Under all conditions, the OUTER weights

should be a mirror image of each other and the INNER weights should be a

mirror image of each other so that the imbalance of the vibrator is uniform on

both ends of the vibrator motor shaft.

Any other arrangement could cause damage to the hopper, welds and

the feeder in general.

Maintenance Fig C.

The MT Series Feeders are reasonably maintenance free. Listed below are

suggested maintenance schedules:

1. The Front Bushing supports the discharge end of the metering screw and

is retained by a bolt at the extreme end of the discharge tube. This

bushing is sealed to the Tube with an O-Ring, the bushing has a blind

hole so that zero leakage from the discharge bushing can be expected.

The bushing will wear over time and should be replaced as required.

Page 6

Wear rate is dependent on material being discharged and other factors,

including bulk density, particle size, hardness and discharge rate. Sealed

flange bearings are available as an option, these bearings typically have a

zerk style grease fitting and should be lubricated every 6 months.

2. The rear of the metering screw is supported by the bearings in the

gearbox assembly and lubricated via the gearbox oil (see #4 below). The

hollow shaft gearbox aligns and supports the shaft and retains it via a

7/16 bolt. .

3. Rear seal packing is a standard Teflon Braided Packing Rope. If any

leakage is observed, the packing pusher (bronze unit under motor mount)

should be tightened. Periodically the Teflon Rope will require

replacement, again the actual schedule being determined by type of

material and amount of use.

4. The standard speed reducer is oil lubricated and should not be re

lubricated for up to (5) years of service.

5. The Drive Motors have lifetime-lubed bearings, which give years of

service. If bearings fail, a competent motor repair shop must replace

them. Brushes on DC Drives should be checked for wear every (6)

months of continuous service.

6. When handling highly abrasive materials, the screw should be checked

periodically for wear.

7. When units are equipped with a vibrator assembly it is important that the

unit is not operated with an empty hopper as this may cause cracks

around or near the vibrator mounts or at the welded corners of the

hopper. Check welds near the vibrator periodically (6 months) for

evidence of cracks, should cracks be found, corrective action is to

determine how to prevent the vibrator from operating with an empty

hopper.

8. The trough end plates are secured with (4) nuts on studs, they are sealed

to the trough with a captured o-ring seal, ensure the o-ring cord stock is

in the groove before tightening the nuts. O-ring face seals ensure zero

leakage of dry materials at the trough ends.

9. Trough and Hopper covers are available with dust sock and vent ports for

the capture of fugitive dust and to prevent air lock while refilling the

hopper.

Page 7

Fig D.

Disassembly

Warning: Motor must be electrically Locked-out before any work is

performed.

The MT-X-XXX Series Feeder is easily disassembled for cleaning, changing of

screws, or maintenance purposes. To remove the discharge tube:

1. Remove the four (4) nuts and pull the discharge tube forward until it

disengages the screw.

To remove the screw the tube must be removed as indicated above then:

Page 8

1. Remove plastic end cap on gearbox shaft center, under the cap is a 7/16 bolt

which retains the screw to the gearbox, remove this bolt and the screw will

easily slide forward and out of the trough section.

2. Loosen the bronze pusher and remove it from the packing box to remove

and replace the packing rope with three rings of Teflon braid.

The hopper may be removed by undoing the bolts and lifting vertically off the

trough assembly. The low level switch (if provided) is threaded into the pipe

coupling on the top of the Hopper assembly, please see the Babbit LS-2000 Level

Sensor Literature for specific wiring information.

Re-assemble by reversing the above procedures.

When inquiring about any feeder, always refer to the Serial Number

stamped on the Metalfab nameplate J-XXXXXXX

Fig E.

Page 9

MT-X-XXXX

FEEDER SPARE PARTS LIST

Fig F.

ITEM DESCRIPTION P/N

1. FRONT END BUSHING S/N-BUSH

2. REAR SEAL PUSHER S/N-PUSH

3. REAR SEAL (TEFLON BRAID) TEFLON PACKING

4. DUST SOCK (OPTIONAL) DUST-DIA

Page 10

5. LEVEL SENSOR (OPTIONAL) LS-2000

6. FEED SCREW * MT-X-SCREW

7. FEED TUBE* MT-X-TUBE

8. MOTOR* SPECIFY TYPE

9. GEARBOX* KAZ37AM6

*ITEMS MARKED WITH ASTERISK ARE PROVIDED FOR

REFERENCE ONLY. THESE ITEMS WILL REQUIRE

REFERENCE TO SERIAL NUMBER, MODEL, SIZE, RATIO,

INPUT POWER AS REQUIRED.

Metalfab Service

Metalfab, Inc.

Prices Switch Road

P.O. Box 9

Vernon, NJ 07462

Phone (973) 764-2000 * Fax (973) 764-0272

Email: metalfab@metalfabinc.com

Loading...

Loading...