Page 1

®

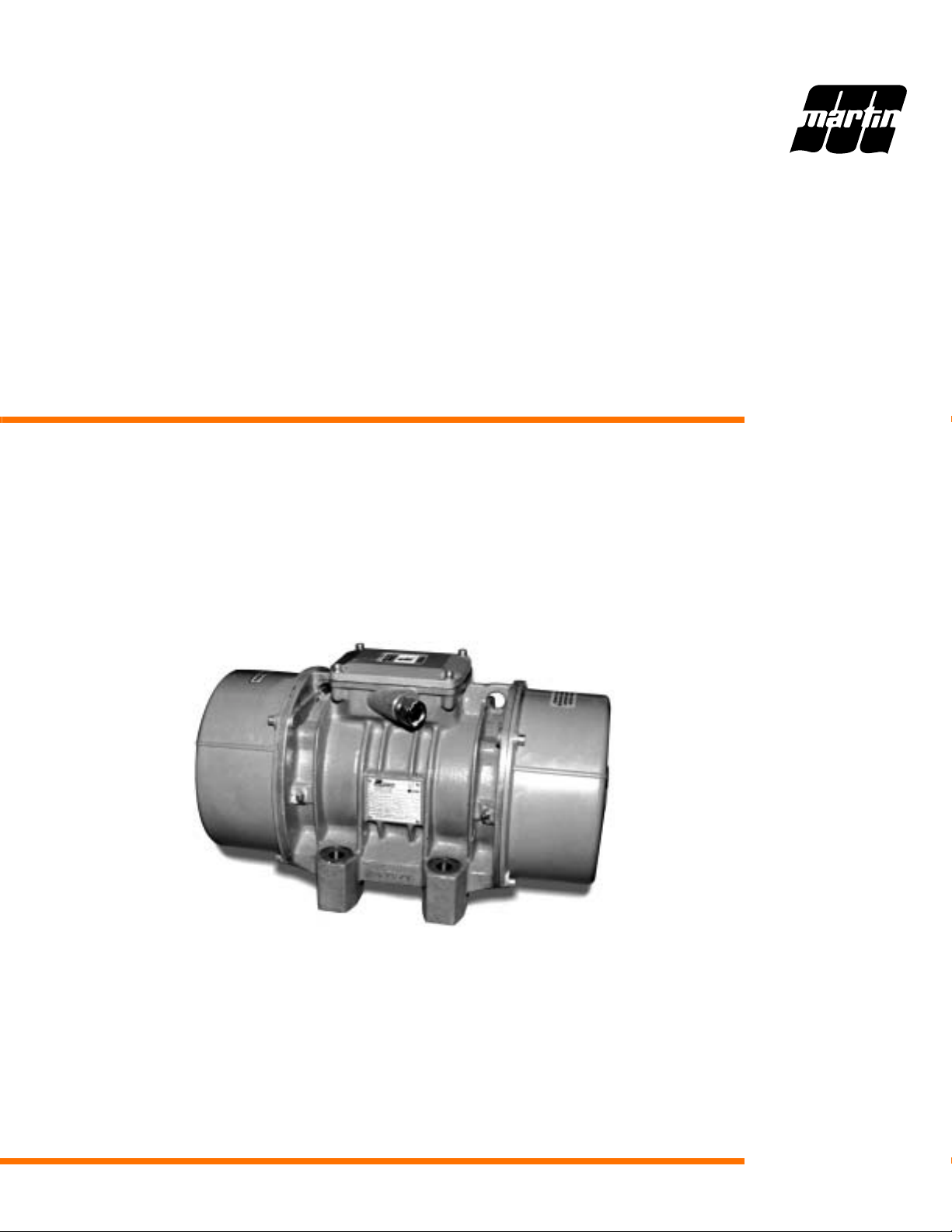

MARTIN®

MOTOMAGNETIC

Electric Vibrators

OPERATOR’S MANUAL

®

Page 2

Important

Martin Engineering hereby disclaims any liability for injuries or damage resulting from use or application

of this product contrary to instructions and specifications contained herein. Martin Engineering’s liability

shall be limited to repair or replacement of product shown to be defective.

Observe all safety rules given herein along with owner and Government standards and regulations. Know

and understand lockout/tagout procedures as defined by American National Standards Institute (ANSI)

z244.1-1982, American National Standard for Personnel Protection - Lockout/Tagout of Energy Sources -

Minimum Safety Requirements and Occupational Safety and Health Administration (OSHA) Federal

Register, Part IV, 29 CFR Part 1910, Control of Hazardous Energy Source (Lockout/Tagout); Final Rule.

The following symbols may be used in this manual:

!

DANGER

Danger: Immediate hazards that will result in severe personal injury or death.

!

WARNING

Warning: Hazards or unsafe practices that could result in personal injury.

!

CAUTION

Caution: Hazards or unsafe practices that could result in product or property damages.

IMPORTANT

Important: Instructions that must be followed to ensure proper installation/operation of equipment.

NOTE

Note: General statements to assist the reader.

Page 3

Table of Contents

Section Page

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Materials required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Before Installing Vibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing Vibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting vibrator onto structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Nut and cap screw torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting power to vibrator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Thermistors and thermostats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installing overload, short-circuit, and ground-fault protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

After Installing Vibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Checking shaft rotation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting eccentric weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Initial start up/checking line current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Variable frequency inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Lubricating vibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Repairing motor and replacing bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Inspecting vibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Part Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Appendix. MOTOMAGNETIC® Electric Vibrator Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Table of Contents

Martin Engineering M3286-8/01 i MOTOMAGNETIC

®

Electric Vibrators

Page 4

List of Figures

Figure Title Page

1 Locating Vibrator on Hoppers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 W-Beam, ECF Bracket, and Locking Wedge Mounts. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Mounting Bolt Tightening Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Installing Restraining Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Installing Wire Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

List of Figures/Tables

7 Thermistor Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Manual Reset Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9 Adjusting Eccentric Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

10 Adjustable Weights Set at 50% (fixed weight shaded) . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

11 Setting Sets of Eccentric Weights to Mirror Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

List of Tables

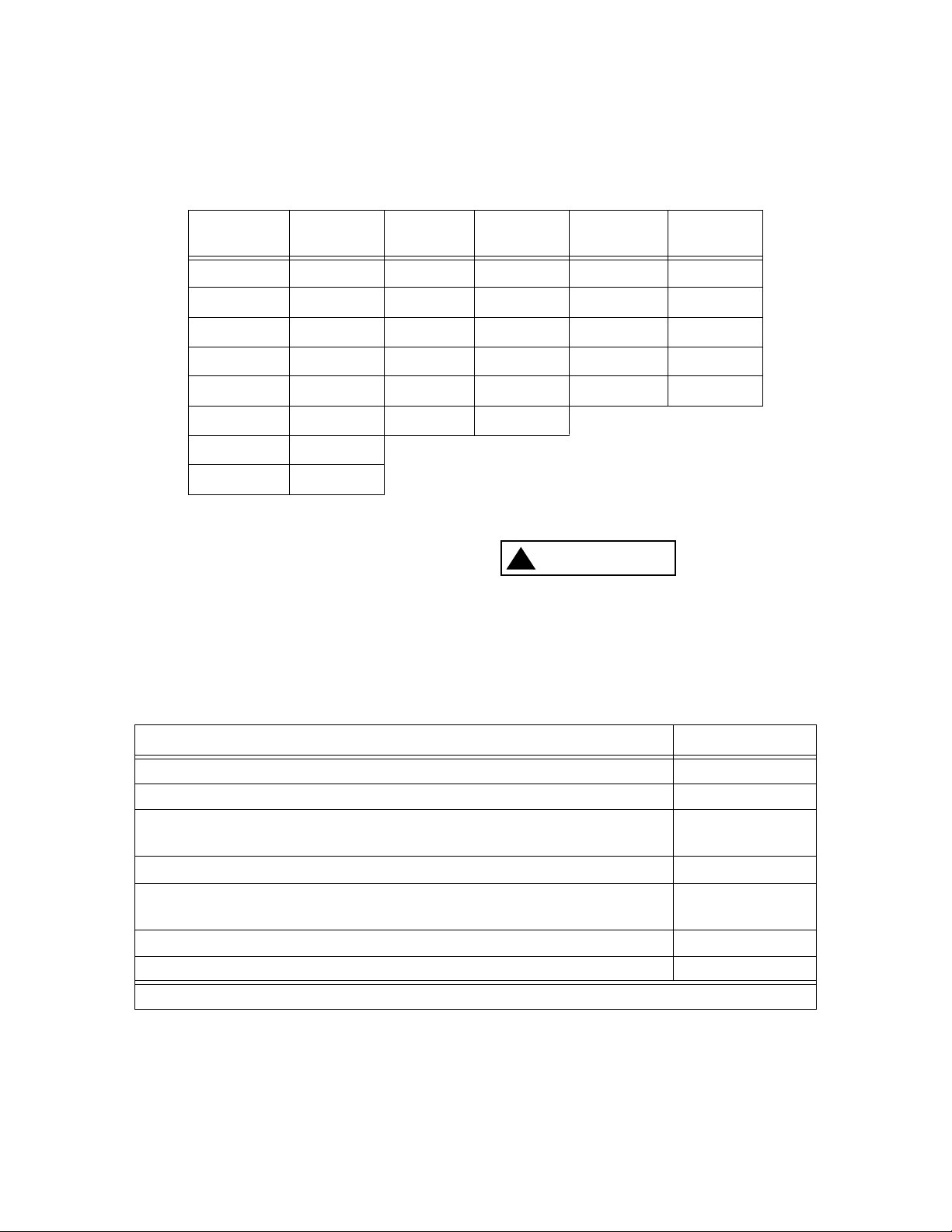

Table Title Page

I Mounting Bolts and Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

II Vibrator Nut and Cap Screw Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

III Vibrators and Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IV Wire Diameter Range for Cord Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

V Lubrication Schedule For Each Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

VI MOTOMAGNETIC® Electric Vibrator Model Numbers and Part Numbers. . . . . . . . . . 22

Martin Engineering M3286-8/01 ii MOTOMAGNETIC

®

Electric Vibrators

Page 5

Introduction

General MARTIN

and manufactured to ensure the best performance and reliability in severeduty applications. The vibrator motor has a recommended operational

ambient temperature and mounting surface temperature range of -22 to 104° F

(-30 to 40° C). If operating the motor in environments beyond these

temperatures, call Martin Engineering, as the vibrator may require rating

reduction, more frequent lubrication, or lubrication substitution.

The explosion-proof MOTOMAGNETIC® Electric Vibrators (CDX models)

have been tested and approved by Underwriters Laboratories Incorporated

(UL) and the Canadian Standards Association (CSA) for use in Class I, Groups

C and D, and Class II, Groups E, F , and G hazardous locations. CDX V ibrators

have been approved by KEMA for Gas Group IIB and have the flame-proof

rating of EEx d IIB T4. CDX vibrators are rated for a maximum ambient

temperature of 104°F (40°C).

This manual provides instructions for installation onto steel bins and hoppers

only. For installation onto other structures, call Martin Engineering or a

representative.

The vibrators in this manual may be referred to by their model numbers or

part numbers. T able V in the “P art Numbers” section provides model numbers

and part numbers together with frame size. The following letter designations

are used throughout this manual:

®

MOTOMA GNETIC® Electric Vibrators (CD models) are designed

Introduction

®

• CD (continuous-duty three-phase).

• CDS (continuous-duty single-phase).

• CDX (continuous-duty explosion-proof).

References The following documents are referenced in this manual:

• The National Electrical Code (NEC), National Fire Protection Association,

1 Batterymarch Park, P.O. Box 9101, Quincy MA 02269-9101.

• American National Standards Institute (ANSI) z244.1-1982, American

National Standard for Personnel Protection - Lockout/Tagout of Energy

Sources - Minimum Safety Requirements, American National Standards

Institute, Inc., 1430 Broadway, New York, NY 10018.

• Code of Federal Regulation (CFR) 29, Part 1910, Control of Hazardous

Energy Source (Lockout/Tagout); Final Rule, Department of Labor,

Occupational Safety and Health Administration (OSHA), 32nd Floor, Room

3244, 230 South Dearborn Street, Chicago, IL 60604.

• CFR 29, Part 1910.15, Occupational Noise Exposur e, Department of Labor ,

OSHA, 32nd Floor, Room 3244, 230 South Dearborn Street,

Chicago, IL 60604.

Safety All safety rules defined in the above documents and all owner/emplo yer safety

rules must be strictly followed when working on the vibrator.

Martin Engineering M3286-8/01 1 MOTOMAGNETIC

®

Electric Vibrators

Page 6

Materials required In addition to metric hand tools, the following materials are required to install

this equipment:

• Rigid beam or mounting plate.

• BBAC Cable Kit, P/N 32271, or equivalent.

Introduction

Storage Store vibrator in an ambient temperature not less than 41°F (5°C) with a

(Mount Kit for Electric Vibrators, P/N 32401-XX includes W-Beam Mount,

mounting hardware, and BBAC Safety Cable Kit.)

relative humidity not more than 60%. If the vibrator has been stored for 2 or

more years, remove bearings, wash them, and repack them with new grease

(see “Lubricating vibrator”).

Martin Engineering M3286-8/01 2 MOTOMAGNETIC

®

Electric Vibrators

Page 7

Before Installing Vibrator

The delivery service is responsible for damage occurring in

transit. Martin Engineering CANNOT enter claims for

damages. Contact your transportation agent for more

information.

1. Inspect shipping container/pallet for damage. Report damage to deliv ery

service immediately and fill out delivery service’s claim form. Keep any

damaged goods subject to examination.

2. Remove vibrator from shipping container/pallet.

3. If anything is missing contact Martin Engineering or a representative.

Turn off and lock out/tag out all energy sources to conveyor/

loading systems to mounting structure.

4. Before installing vibrator, turn off and lock out/tag out all ener gy sources

to conveyor/loading systems to mounting structure according to ANSI

standards (see “References”).

IMPORTANT

!

WARNING

Before Installation

!

WARNING

If equipment will be installed in an enclosed area, gas level or

dust content must be tested before using a cutting torch or

welding. Using a cutting torch or welding in an area with gas

or dust may cause an explosion.

5. If using a cutting torch or welding, test atmosphere for gas level or dust

content.

6. Mounting surface must be strong and flat, 0.01 in. (0.25 mm) across

vibrator feet. (This will minimize internal stress to vibrator casting when

tightening mount bolts. W elding in the area of the mounting surface could

affect its flatness.)

7. Make sure mounting surface is free of paint and debris, and foot of

vibrator is clean.

Martin Engineering M3286-8/01 3 MOTOMAGNETIC

®

Electric Vibrators

Page 8

Installing Vibrator

Installation

IMPORTANT

Read entire section before beginning work. This manual

provides instructions for installations onto steel bins and

hoppers only . For other in stallations, call Martin Engineering

or a representative.

!

CAUTION

If installation instructions are not followed, structure and

vibrator can be damaged. Abusing or handling vibrator

carelessly will accelerate wear and shorten bearing life.

Mounting vibrator

onto structure

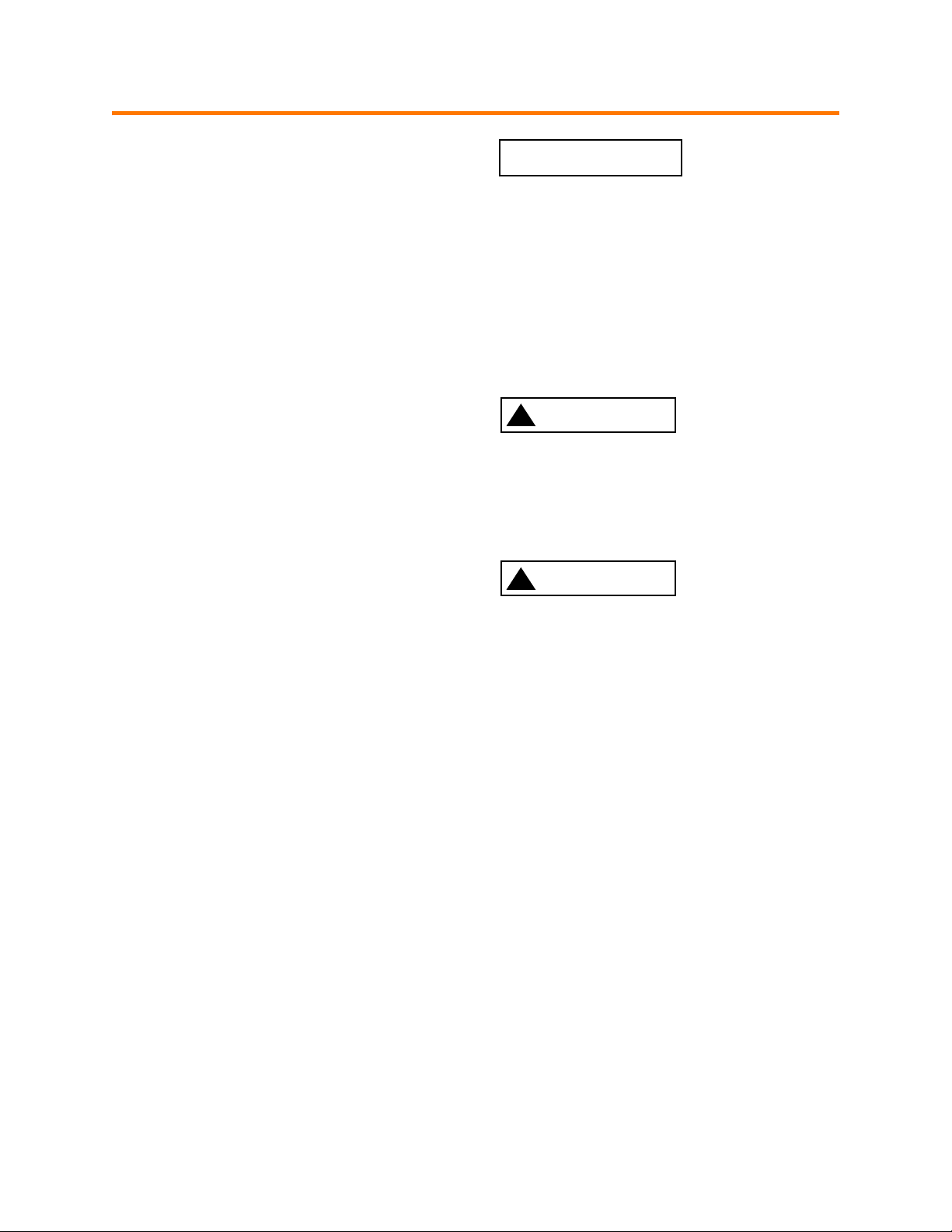

1. See Figure 1. Locate vibrator in lower 1/4 to 1 /3 of structure slope length.

If second vibrator is required, mount 180° from first vibrator and halfway

up slope.

Figure 1. Locating Vibrator on Hoppers

!

CAUTION

Never weld structure with vibrator mounted and wired.

Welding may cause damage to motor windings and bearings.

IMPORTANT

The object of rotary vibration on bins, hoppers, and chutes is

to transmit vibration through the wall into the product

contained inside. If structure is not made rigid, vibrator may

draw high amperage and move material less efficiently.

Make sure structure is fr ee of paint before mounting vibrator.

2. If using customer-supplied mounting plate to mount vibrator onto

structure, do the following:

a. Make sure plate is at least the size of vibrator base.

b. Locate plate so that vibrator can be positioned as shown in Figure 1.

c. Weld mounting plate onto structure.

Martin Engineering M3286-8/01 4 MOTOMAGNETIC

®

Electric Vibrators

Page 9

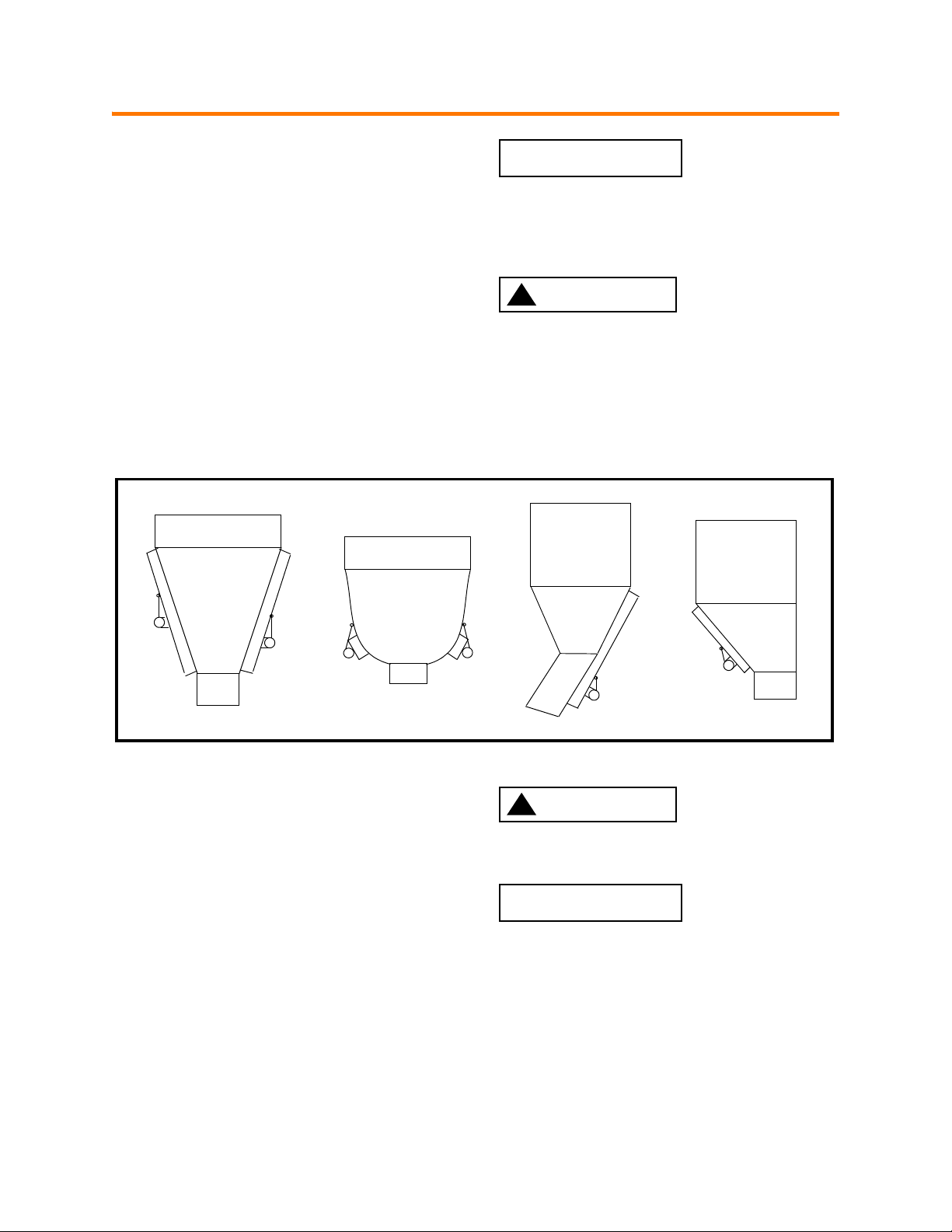

3. If using MARTIN W -Beam Mount (or equi valent) or T-beam to mount

vibrator onto structure (see Figure 2), do the following:

a. Locate beam so that vibrator can be positioned as shown in Figure 1.

b. Extend beam at least 3/4 the length of sloped wall. Cut off end(s) of

beam if necessary to fit on structure.

c. Skip-weld beam in place: W eld 3 in. (76 mm), then skip 2 in. (51 mm).

Repeat for entire perimeter of beam. Do not weld last 1 in. (25 mm) of

either end of beam or any corner.

d. Install vibrator onto W-beam mount or ECF bracket.

Installation

Skip weld

W-Beam

P/N 29757-XX

Locking wedge

P/N 28309-XX

ECF bracket

P/N 29383-XX

Vibrator

mounting

holes

Figure 2. W-Beam, ECF Bracket, and Locking Wedge Mounts

4. If installing vibrator onto hopper with female wedge mount already in

place, use MARTIN

vibrator.

Never weld structure with vibrator mounted and wired.

Welding may cause damage to motor windings and bearings.

®

Locking Wedge (Figure 2) or equivalent to mount

!

CAUTION

T- be am

Use only new Grade 5 bolts and lock nuts to install vibrator.

Old fasteners can break and cause damage to vibrator or

structure.

Do not use split lock washers to install vibrator onto mount.

Damage to vibrator could result.

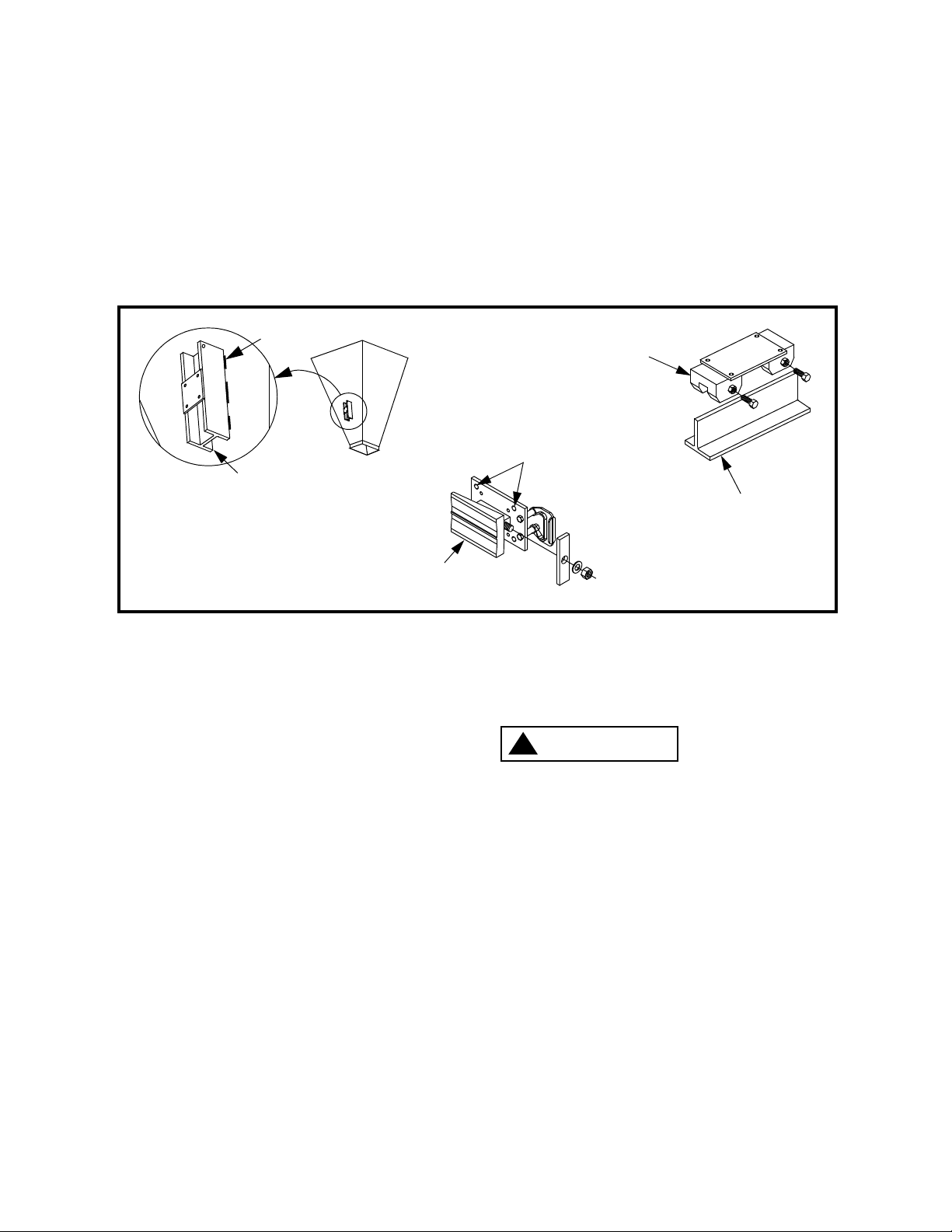

Tighten mounting bolts in sequence shown in Figure 3. If not

tightened in order, vibrator casting could be damaged.

5. Before installing vibrator onto mount, apply thread sealing compound to

all bolts.

6. Install vibrator onto mount with new lock nuts, compression washers, and

bolts according to T able I. Tighten bolts in order gi ven in Figure 3 to avoid

damaging vibrator casting. (Contact fastener manufacturer for specific

information regarding bolt torque.)

Martin Engineering M3286-8/01 5 MOTOMAGNETIC

®

Electric Vibrators

Page 10

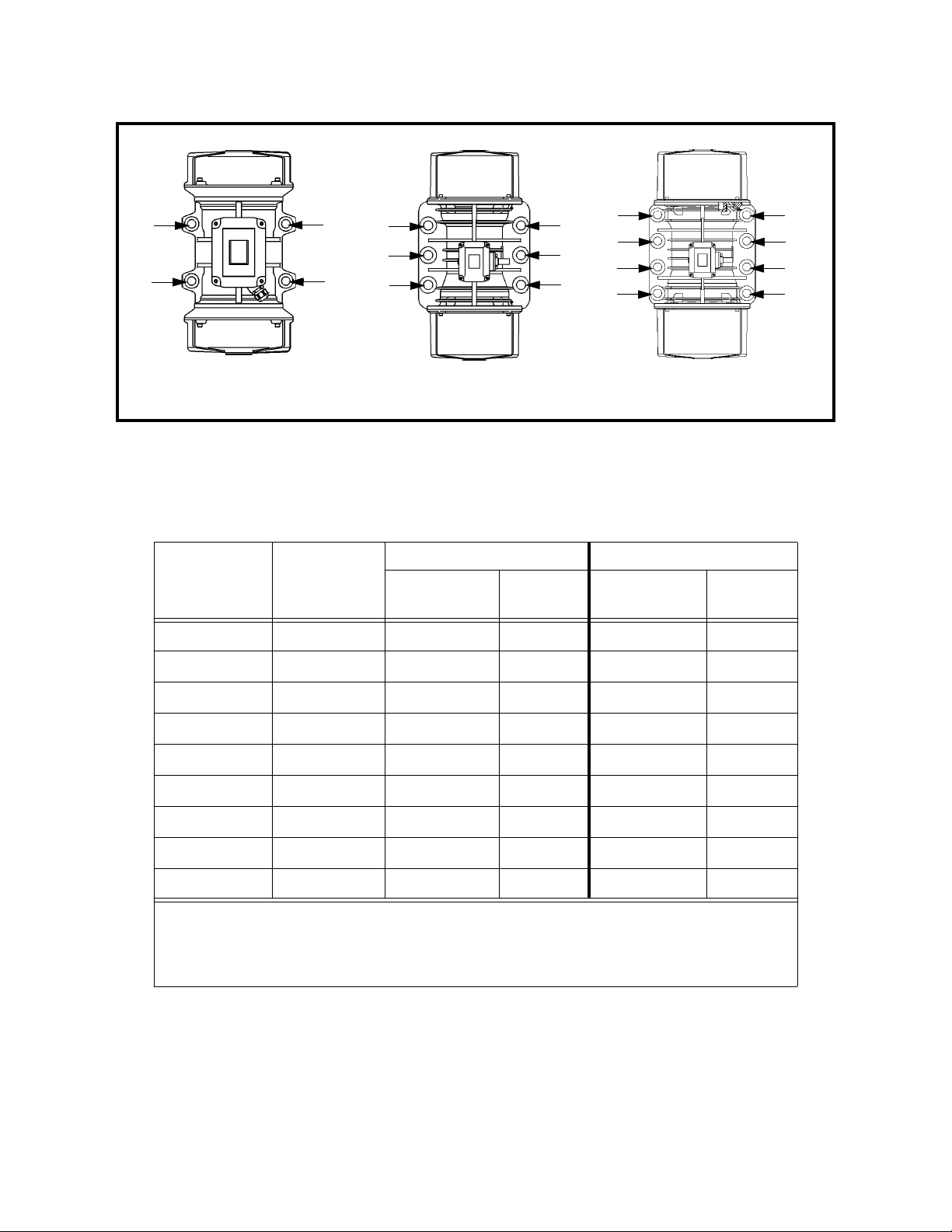

Installation

1

3

Vibrator Type Frame Size*

CD, CDS 00, 01 5/16 in. -18NC 17 M8 2

CD, CDS 10, 20 1/2 in. -13NC 76 M12 8

5

4

3

6

3

1

2

5

2

1

4

7

4 Bolts 6 Bolts 8 Bolts

Figure 3. Mounting Bolt Tightening Sequence

7. After the vibrator has been operated for 10 to 20 minutes, check bolt

torque. Tighten if necessary.

Table I. Mounting Bolts and Torque Requirements*

English Metric

Bolt Size

(Gr 5)

Dry Torque

(ft-lb)

Bolt Size

Dry Torque

8

2

4

6

(kgm)

CD, CDS, CDX 30, 35, 40, 50†5/8 in. -11NC 137 M16 19

CD, CDX 50††, 60 3/4 in. -10NC 288 M20 38

CD, CDX 70 7/8 in. -9NC 430 M22 56

CD 80 1 in. -8NC 644 M24 71

CD 90, 95 1 in. -8NC 644 M25 89

CD 97 1-1/2 in. -8NC 1950 M36 190

CD 100, 105, 110 1-3/4 in. -8NC N/A M42 **290

*See “Part Numbers” section for specific model numbers.

**Plated bolt with antiseize.

†

Frame size for CD model only.

††

Frame size for CDX model only.

*Torque specifications are for reference only. Contact fastener manufacturer for specific information

regarding bolt torque.

Martin Engineering M3286-8/01 6 MOTOMAGNETIC

®

Electric Vibrators

Page 11

!

WARNING

If vibrator is mounted more than 6 in. (152 mm) above

ground, install cable securing vibrator to structure. Without

cable, vibrator could fall and cause injury.

8. Secure vibrator to structure by installing MARTIN® BBAC Cable Kit,

P/N 32271, or equiv alent as follows (cable is included with Mount Kit for

Electric V ib r ators, P/N 32 401 -XX):

a. Weld D-ring (A, Figure 4) onto structure wall (B) above vibrator.

Installation

D-ring

A.

Structure wall

B.

Wire cable

C.

Vibrator lifting eye

D.

D-ring on W-Beam

E.

Cable clamp (6)

F.

C

E

F

D

A

B

B

Figure 4. Installing Restraining Cable

b. Loop 1/4-in. (6 mm) wire cable (C) through vibrator lifting eye (D)

and D-ring on structure wall.

c. If using a MARTIN® W -Beam Mount, also loop cable through D-ring

on W-Beam (E) as shown. Take up slack so cable is taut.

d. Apply thread-sealing compound to nuts on cable clamps (F). Install six

cable clamps (two on each end and two on loop around D-ring on

W-beam) to secure cable to vibrator eye and D-rings. Torque nuts on

cable clamps according to drawing B-32401-XX supplied with Mount

Kit for Electric Vibrators.

e. Trim loose ends of wire cable.

Martin Engineering M3286-8/01 7 MOTOMAGNETIC

®

Electric Vibrators

Page 12

Nut and cap screw

torque

Installation

Connecting power

to vibrator

After removing any nuts or cap screws from vibrator assembly, re-install to

the torque values specified in Table II.

Table II. Vibrator Nut and Cap Screw

Torque Requirements

Cap Screws ft/lb (kgm) Shaft Nuts ft/lb (kgm)

M6 7 (1) M13x1 22 (3) M4 0.87 (0.12)

M8 16.5 (2.3) M15x1 36 (5) M5 1.45 (0.20)

M10 35 (4.8) M20x1 72 (10) M6 2.17 (0.30)

M12 58 (8) M25x1.5 123 (17) M8 4.70 (0.65)

M14 94 (13) M30x1.5 246 (34) M10 9.80 (1.35)

M16 137 (19) M45x1.5 360 (50)

M18 195 (27)

M20 275 (38)

!

WARNING

Wire vibrator in accordance with National Electrical Code

Article 430. Have wiring installed by a qualified electrician

only.

Terminal

Block Nuts

ft/lb (kgm)

1. Find wiring diagram number for your vibrator on vibrator nameplate, or

see Table III.

Table III. Vibrators and Wiring Diagrams

Frame Size* Wiring Diagrams

00 through 01, single-phase, 3600 rpm Diagram 1A

10 through 30, singe-phase, 3600 rpm Diagram 1E

00 through 70, three-phase, 1200, 1800, and 3600 rpm; CD9-570;

and 575-volt 900 rpm

40 through 70, three-phase, 900 rpm except 575V Diagram 2C

80 through 110, three-phase, 1200, 1800, and 3600 rpm; and 575V

900 rpm

80 through 110, three-phase, 900 rpm except 575V Diagram 5B

CDX models CDX 6- or 9-Lead

*See “Part Numbers” section for specific model numbers.

Diagram 2A

Diagram 5A

Martin Engineering M3286-8/01 8 MOTOMAGNETIC

®

Electric Vibrators

Page 13

!

CAUTION

Before running cord to vibrator , mak e sure cord voltage rating

equals or exceeds the voltage at which you will be operating

the vibrator. It must have a minimum temperature rating of

221°F (105°C) and a minimum diameter as shown in Table IV.

If wire is not proper diameter, cord grip will not tighten

properly and vibrator could be damaged by moisture or

material getting inside wiring compartment. If cord is

damaged, it could short power supply or short to ground

causing damage to vibrator.

2. See Table IV. Make sure wire diameter is within the range for your

vibrator’s frame size and cord grip.

Table IV. Wire Diameter Range for Cord Grips

Installation

Vibrator

Frame Size

00 to 01 511546

10 to 60 511530

70 to 95 511513

97 to 110 504012

When wiring vibrator, leave slack in electrical cable so that

cable does not become taut during vibration cycle and cause

stress on wire connections. On applications wher e moistur e is

present, leave enough slack in power cable to pr event moisture

from running down cable into vibrator.

Cord Grip

Part Number

Wire Diameter

Range mm (in.)

9 to 11.5

(0.35 to 0.45)

12.5 to 15

(0.49 to 0.59)

16 to 19

(0.63 to 0.75)

19 to 21

(0.75 to 0.83)

IMPORTANT

3. Wire vibrator according to appropriate wiring diagram inside terminal

box, or see Figure 5. Use closed loop wire connectors only.

Martin Engineering M3286-8/01 9 MOTOMAGNETIC

®

Electric Vibrators

Page 14

Rotation in one direction Rotation in opposite direction

Installation

box

switch

W2 U 2 V2

U1 V1 W1

Diagram 1A

switch

box

cord

4-wire

W2 U 2 V2

U1 V1 W1

cord

4-wire

Rotation in one direction

W2 U2

V1 W1

U1

box

switch

Diagram 1E

V2

cord

4-wire

Rotation in opposite direction

U2

box

switch

W2

U1 V1 W1

V2

cord

4-wire

G L1 L2 T1 T2 T3

Neutral

Hot

power supply

115V, 60Hz

3-wire cord

Diagram 2A

Low Voltage High Voltage

W2 U2 V2

U1 V1 W1

Ground Ground

3-phase

power supply

Diagram 5A

Low Voltage

W2 U2 V2

U1 V1 W1

3-phase

power supply

To control

module

Ground

Thermistor

G L1 L2 T1 T2 T3

Neutral

Hot

3-wire cord

W2

U1 V1 W1

High Voltage

W2 U2 V2

U1 V1 W1

3-phase

power supply

To control

module

Ground

power supply

115V, 60Hz

DIAGRAM 2A

V2

U2

3-phase

power supply

DIAGRAM 5A

Thermistor

G L1 L2 T1 T2 T3

Neutral

Hot

power supply

115V, 60Hz

3-wire cord

230 V

45 6

789

123

Ground

3-phase

power supply

6

5

4

7

8

9

3

1

2

3-phase

power supply

To control

Ground

module

Diagram 2C

460 V

Ground

Diagram 5B

60 HZ

230 V

Thermistor

456

789

123

Ground

G L1 L2 T1 T2 T3

Neutral

Hot

power supply

115V, 60Hz

3-wire cord

DIAGRAM 2C60 HZ

456

789

123

3-phase

power supply

DIAGRAM 5B

460 V

Thermistor

3-phase

power supply

To control

module

CDX Model, 6-lead, 3-phase

Thermostat Connection Di agram to Terminal Board

P1P2

W2 U2 V2

W1

U1 V1

G

Y - High Voltage s - Low Voltage

Cable Entry

G

P1P2

W2 U2 V2

U1 V1

W1

CDX Model, 9-lead, 3-phase

9700 K Thermostat Connection Diagram to Terminal Board

P1P2

75 8 69123

4

W

UV

GG

Y (S) - High Voltage YY - Low Voltage

Cable Entry

U

Figure 5. Wiring Diagrams

Martin Engineering M3286-8/01 10 MOTOMAGNETIC

P1P2

47586912 3

V

W

®

Electric Vibrators

Page 15

Wire

connector

Flat

washers

Figure 6. Installing Wire Connector

4. Install wire connector between the two flat washers. See Figure 6.

!

WARNING

Vibrator must be grounded using the power supply ground

wire (or other if specified in the NEC). Failure to properly

ground vibrator can cause sever e injury or death.

5. Connect power supply ground wire (or other if specified in the NEC) to

ground vibrator terminal. Use closed loop wire connector only.

6. Reassemble wiring cover, o-ring, and rubber compression block(s),

taking care not to pinch the o-ring. Tighten cord grip around supply

line(s).

Installation

!

WARNING

Thermistors and

thermostats

Martin Engineering M3286-8/01 11 MOTOMAGNETIC

Thermistors and thermostats are intended for motor winding

protection or to limit external motor surface temperatures.

They do not replace overload protection. Always install

overload protection. Failure to do so could result in severe

injury or death.

!

CAUTION

If installing low-voltage line to vibrator’s thermistor circuit

(frame size 70 and larger), make sure you install cord grip,

P/N 511546, on opening in wiring compartment. Without a

cord grip, moisture or material could enter terminal block

and damage vibrator . If cord is damaged, it could short power

supply or short to ground causing damage to vibrator.

1. If applicable wiring codes specify that low and high voltage circuits are

to be separated from each other, remove plug on back of wiring

compartment and install cord grip, P/N 511546.

2. Run low-voltage line to thermistor circuit and tighten cord grip. Ensure

wire is of proper voltage rating and size (see Table IV).

®

Electric Vibrators

Page 16

Installation

3. For diagrams 5A and 5B, wire thermistor to control module in accordance

with Figure 7. (Martin Engineering recommends using the control

module shown in Figure 7, but other suitable control modules may be

used.)

Figure 7. Thermistor Wiring Diagram

NOTE

The thermostat terminals on CDX units are identified as P1

and P2. The thermostat circuit is rated 60 0 V ac maximum and

720 VA. A manual momentary start switch must be used.

4. For CDX vibrators, wire thermostats to control circuit. See Figure 8.

W

V

Line

U

Motor Starter

Start

Starter

Coil

Motor

Windings

Stop

Starter

Overload

Contacts

Motor

1

2

3

P1

P2

Figure 8. Manual Reset Connections

Martin Engineering M3286-8/01 12 MOTOMAGNETIC

®

Electric Vibrators

Page 17

!

CAUTION

Installing

overload, shortcircuit, and

ground-fault

protection

Install overload protection fo r vibrator. If vibrator is not

protected from overload, vibrator can be destroyed and

warranty will be void. Determine size of overload protection

according to NEC Article 430, and have it installed by a

qualified electrician only.

1. Determine overload, short-circuit, and ground-fault protection acco rding

to NEC Article 430.

NOTE

All single-phase vibrators are supplied with overload

protection.

2. Have qualified electrician install ov erload, short-circuit, and ground-fault

protection.

3. If overload trips during operation, fix problem before resetting.

!

CAUTION

For equipment using two vibrators, the two motors must be

electrically interlocked. If using a single contactor , each motor

must be provided with separate overload protection. The

motor control circuit must be arranged so that if one motor

becomes de-energized, the other motor will automatically and

immediately become de-energized. Failure to properly

interlock motors could result in severe damage to equipment

if one vibrator fails.

Installation

4. If using two vibrators, interlock the two vibrator motors and install

separate overload protection for each.

Martin Engineering M3286-8/01 13 MOTOMAGNETIC

®

Electric Vibrators

Page 18

After Installing Vibrator

IMPORTANT

Read entire section before beginning work.

Checking shaft

rotation

After Installation

1. Remove cap screws and washers, and remove vibrator end cap.

!

CAUTION

DO NOT run vibrator with eccentric weights removed.

Running vibrator with eccentric weights removed will damage

bearings.

!

WARNING

When checking shaft rotation with end cap removed, keep

hands away from swinging weights. W eights can crush fingers.

2. Start vibrator for one second, then stop.

3. Observe direction of motor rotation. If motor is not rotating in correct

direction, lock out/tag out energy source and reve rse rotation. To reverse

rotation of three-phase vibrator, re verse any two of the three po wer supply

wires. To reverse rotation of single-phase vibrator, see Figure 5, diagram

1A or 1E.

4. Replace end cap, taking care not to pinch o-ring.

NOTE

Adjusting

eccentric weights

All MOTOMAGNETIC Electric Vibrators have one set of

eccentric weights on each end of shaft. Eccentric weights are

set at 50% at factory (model CD18-3850 is set at 70%, and

models CD36-11000 and CD36-20000 are set at 100%). See

Figure 10.

The percentage incr ements on the weight adjustment disks ar e

percentages of the total f orce pounds listed on the nameplate.

For example, if the nameplate shows 8340 lb, setting the

weights to 50% would produce 4170 pounds of force.

IMPORTANT

For the most efficient operation, vibrator eccentric weights

should be adjusted to the lowest force setting r equired to move

the material. This will increase vibrator life and reduce energy

costs.

Martin Engineering M3286-8/01 14 MOTOMAGNETIC

®

Electric Vibrators

Page 19

!

WARNING

Before adjusting eccentric weights, turn off and lock out/tag

out energy source to vibrator.

1. Turn off and lock out/tag out energy source to vibrator according to ANSI

standards (see “References”).

2. Remove end cap.

3. Loosen nut or screw (A, Figure 9) so adjustable weight (B) will rotate

around shaft (C).

After Installation

A

C

A.B.Nut or screw

Adjustable weight

Shaft

C.

Fixed weight

D.

B

D

D

A

C

B

Figure 9. Adjusting Eccentric Weights

NOTE

The fixed weight is attached to the shaft. The adjustable

weight rotates around the shaft. The weight adjustment disk

will be attached to either the fixed or the adjustable weight.

4. See Figure 10. Rotate adjustable eccentric weight to proper setting. T o

produce more force, move weight to higher setting (i.e., hi gher number).

When set, tighten cap screw or nut according to Table II.

Martin Engineering M3286-8/01 15 MOTOMAGNETIC

®

Electric Vibrators

Page 20

.

After Installation

Weight adjustment disk attached to adjustable weight

Arrow shows

0

0

5

direction to turn

5

0

0

adjustable weight

to increase

0

0

1

unbalance

RightLeft

Weight adjustment disk attached to fixed weight

Arrow shows

0

direction to turn

adjustable weight

to increase

unbalance

0

1

0

0

RightLeft

Figure 10. Adjustable Weights Set at 50% (fixed weight shaded)

5. Check o-rings for damage. Replace if damaged.

!

CAUTION

Do not operate vibrator with end caps removed. Dust

accumulating around vibrator shaft could cause unit to fail.

6. Replace end caps.

!

CAUTION

Adjust both sets of eccentric weights to same setting number

(mirror images), or force output will be uneven and damage

vibrator.

7. Repeat steps 2 through 5 for second set of weights. Set both sets of

weights to same setting number so they are mirror images, as shown in

Figure 11.

Martin Engineering M3286-8/01 16 MOTOMAGNETIC

®

Electric Vibrators

Page 21

Figure 11. Setting Sets of Eccentric Weights to Mirror Images

After Installation

Initial start up/

checking line

current

1. Close power supply disconnect switch and allow motor(s) to operate for

10 to 20 minutes.

2. If vibrator makes unusual or excessive noise, make sure mounting bolts

are tight and mount welds are not damaged.

!

WARNING

Vibrator may produce loud noise during operation when

mounted on structure. See OSHA 1910.95 for guidelines. If

required, wear ear protection to avoid impairment or loss of

hearing.

3. Check decibel level of vibrator noise during operation. See OSHA

1910.95 to determine whether noise exceeds safe limits. If required, wear

ear protection to avoid impairment or loss of hearing.

!

CAUTION

Do not allow motor current to exceed nameplate rating. If

vibrator is operated continuously with line current above

nameplate rating, vibrator can be damaged.

4. After a few hours of operation, check each line current. If reading is

higher than nameplate rating, reduce eccentric weight setting, stiffen

vibrator mount, or move vibrator to more rigid location. After making

adjustments, check line current again to ensure line current does not

exceed nameplate rating.

5. After first 8 hours of use and periodically thereafter , check mounting bolts

and tighten if necessary.

Martin Engineering M3286-8/01 17 MOTOMAGNETIC

®

Electric Vibrators

Page 22

!

CAUTION

Variable

frequency inverter

After Installation

All motors can be supplied with a pulse-width modulated

variable frequency inverter. NEVER operate the motor at a

frequency higher than that specified on the nameplate.

Damage to vibrator can result.

Do not operate vibrator motor at frequency higher than specified on

nameplate. Throughout frequency range, verify that each line current does not

exceed current rating on nameplate. If reading is higher than nameplate,

consult inverter manual. If necessary, adjust inverter, reduce eccentric weight

setting, stiffen vibrator mount location, or move vibrator to more rigid

location. After making adjustment, check line current again to ensure line

current does not exceed nameplate rating.

Martin Engineering M3286-8/01 18 MOTOMAGNETIC

®

Electric Vibrators

Page 23

Maintenance

IMPORTANT

Read entire section befor e beginni ng work. Allow vibrator to

cool to ambient temperature before working on it.

NOTE

All vibrators are lubricated at the factory.

!

CAUTION

Use only prescribed grease in vibrator. If a different grea se is

used, vibrator can be damaged and warranty will be void.

Use only prescribed amount of grease to lubricate vibrator.

Too much grease will cause bearings to overheat and result in

premature bearing failure.

Maintenance

Lubricating

vibrator

1. See Table V for lubrication schedule and amount of grease required for

your vibrator . Unless specified otherwise, lubricate the vibrator after each

2000 hours of operation.

!

CAUTION

For 3600 rpm machines operating continuously or for long

periods of time, reduce lubrication time and amount as sho wn

in step 2. Failure to do so could run bearings dry and destroy

unit.

2. If motor housing temperatures exceed 194° F (90° C), cut lubrication time

and amount in half for every 18° F (10° C) increment that meets or

exceeds 194° F (90° C). For example, if CD9-1410 motor housing

temperature is 204° F (96° C), use 4.5 grams of grease per bearing e v ery

1000 hours. (Maximum bearing temperature allowed is 248° F [120° C].)

For motor housing temperatures above 212° F (100° C), consult Martin

Engineering or a representative.

NOTE

Kluber grease may be purchased from Martin Engineering by

calling 800-544-2947 or from Kluber Lubrication by calling

603-434-7704.

3. For CD9, CD12, and CD18 model vibrators, lubricate frame size 35

and larger vibrators with Kluber Isoflex NB U 8EP grease only . For CD36

model vibrators, lubricate with Kluber Isoflex NBU15 grease only.

Lubricate as follows:

a. Clean vibrator case around grease fitting with clean shop towel.

b. Insert grease gun into grease fitting. Add grease.

Martin Engineering M3286-8/01 19 MOTOMAGNETIC

®

Electric Vibrators

Page 24

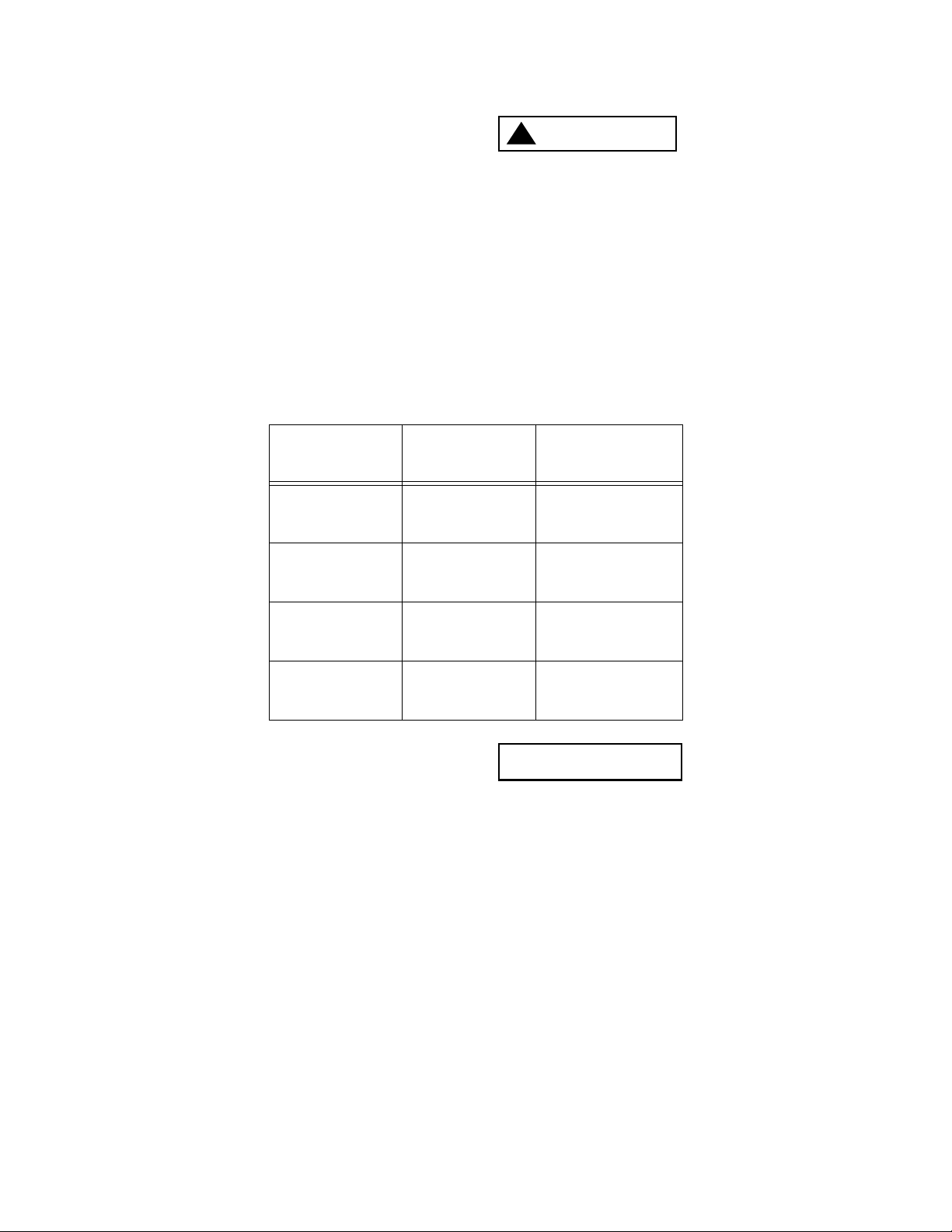

Table V. Lubrication Schedule For Each Bearing*

00 Frame 01 Frame 10 Frame 20 Frame 30 Frame 33 Frame

Model

CD18-80 Life CD18-170 Life CD12-90 Life CD9-330 Life CD9-570 Life CD36-2900 9

CD36-210 Life CD36-390 Life CD12-220 Life CD12-575 Life CD12-750 Life

CDS36-210 Life CDS18-170 Life CD18-470 Life CD18-910 Life CD18-1670 Life

Lube

g

Model

CDS36-390 Life CD36-650 Life CD18-1300 Life CD36-1660 Life

MaintenanceMaintenance

35 Frame 40 Frame 50 Frame 60 Frame 70 Frame 80 Frame

Model

CD9-910 7 CD9-1440 9 CD9-2020 16 CD9-2920 14 CD9-4640 18 CD9-6830 30

CD12-1630 7 CD12-1990 9 CD12-2530 16 CD12-3410 14 CD12-6050 18 CD12-8450 30

CD18-2150 7 CD18-2160 9 CD18-3870 16 CD18-5380 19 CD18-8300 26 CD18-10900 40

Lube

g

Model

CD18-3190 9 CD36-3280 9 CDX9-2880 14 CD36-6860 26

CDX9-1600 12 CD36-4100 16 CDX12-3400 14 CD36-8240 26

CDX12-2300 12 CD36-4910 16 CDX18-5950 19 CD36-11000 30†

CDX18-3500 12 CDX9-2300 16 CDX36-5070 19 CDX9-4610 18

CDX36-3500 12 CDX12-3000 16 CDX12-5740 18

Lube

g

Lube

Model

CDS18-470 Life CD36-1040 Life CDS36-1660 Life

CDS36-650 Life CDS18-910 Life CDX9-700 Life

g

Model

CDX18-4600 16 CDX18-8340 26

CDX18-5140 16 CDX36-7060 26

CDX36-4400 16

Lube

g

Lube

Model

CDS36-1040 Life CDX12-1200 Life

g

Model

Lube

g

CDX18-2100 Life

CDX36-2000 Life

Lube

g

Model

Model

Lube

g

Lube

g

Model

Model

Lube

g

Lube

g

90 Frame 95 Frame 97 Frame** 100 Frame** 105 Frame** 110 Frame**

Model

CD9-9310 50 CD9-14400 80 CD9-21900 90 CD9-24800 130 CD9-31000 150 CD9-49000 220

CD9-11700 60 CD9-15500 80 CD12-14200 90 CD12-26500 130 CD9-38000 180 CD12-44000 220

CD12-11700 50 CD12-17600 80 CD12-20100 90 CD18-25300 130 CD12-31000 150

CD12-14400 60 CD12-19100 80 CD18-19700 90 CD12-37000 180

CD18-14500 60** CD18-17600 80**

*Unless otherwise noted, lubricate every 2000 hours.

**Lubricate every 1000 hours.

†Lubricate every 750 hours.

††Lubricate every 100 hours.

Lube

g

CD36-20000 30††

Model

Lube

g

Model

Lube

g

Model

Lube

g

Model

Lube

g

Model

Lube

4. For explosion-proof CDX model vibrators, lubricate frame size 40 and

larger with Kluber Isoflex Topas NB52 grease only, as follows:

a. For frame size 40 and 50 CDX models, remove each weight cover, all

eccentric weights, and each pipe plug in flange. Insert grease fitting.

Add grease. Remove grease fitting, and replace pipe plugs, eccentric

weights, and weight covers, taking care not to pinch o-rings.

b. For frame size 60 and 70 CDX models, remove pipe plug in each

flange. Insert grease fitting. Add grease. Remove grease fitting,

replace pipe plugs.

g

Martin Engineering M3286-8/01 20 MOTOMAGNETIC

®

Electric Vibrators

Page 25

!

CAUTION

Repairing motor

and replacing

bearings

Inspecting

vibrator

Do not attempt to repair vibrator motor or replace bearings

yourself. If you attempt to do so during the warranty period,

the warranty may be void.

If vibrator motor needs repair or if bearings need to be replaced, call Martin

Engineering at 800-544-2947 for instructions.

At least quarterly, inspect vibrator, cable and connections as follows:

!

WARNING

Before inspecting vibrator, turn off and lock out/tag out

energy source to vibrator.

1. Turn off and lock out/tag out energy source to vibrator according to ANSI

standards (see “References”).

2. Inspect end caps for cracks and check cap screws for tightness.

3. Inspect cable for damage including cuts and abrasions. Replace if

damaged.

4. Inspect ground connection. Make sure ground connection to motor

enclosure does not exceed 0.1 ohm. Ensure screw on ground terminal is

tightened to proper torque (see Table II).

5. Make sure all nuts on connections on terminal block are tightened to

proper torque. Do not overtighten (see Table II).

Maintenance

Martin Engineering M3286-8/01 21 MOTOMAGNETIC

®

Electric Vibrators

Page 26

Part Numbers

This section provides part numbers for the S90 Series MOTOMAGNETIC®

Electric Vibrators and related equipment. Please reference part numbers when

ordering parts.

Table VI. MOTOMAGNETIC® Electric Vibrator

Part Numbers

00 Frame 01 Frame 10 Frame 20 Frame 30 Frame 33 Frame

Model Part No. Model Part No. Model Part No. Model Part No. Model Part No. Model Part No.

CD18-80 601144 CD18-170 601145 CD12-90 602169 CD9-330 602883 CD9-570 602816 CD36-2900 600243

CD36-210 600177 CD36-390 600178 CD12-220 602170 CD12-575 602098 CD12-750 602082

CDS36-210 600177 CDS18-170 601145 CD18-470 601146 CD18-910 601147 CD18-1670 601148

CDS36-390 600178 CD36-650 600179 CD18-1300 601198 CD36-1660 600181

35 Frame 40 Frame 50 Frame 60 Frame 70 Frame

Model Part No. Model Par t No. Model Part No. Model Part No. Model Part No.

CD9-910 602865 CD9-1440 602888 CD9-2020 602889 CD9-2920 602890 CD9-4640 602891

CD12-1630 602150 CD12-1990 602161 CD12-2530 602162 CD12-3410 602165 CD12-6050 602167

CD18-2150 601201 CD18-2160 601227 CD18-3870 601219 CD18-5380 601220 CD18-8300 601221

CD18-3190 601217 CD36-3280 600254 CDX9-2880 602853 CD36-6860 600199

CDX9-1600 602818 CD36-4100 600256 CDX12-3400 602122 CD36-8240 600219

CDX12-2300 602084 CD36-4910 600257 CDX18-5950 601187 CD36-11000* 600200*

CDX18-3500 601150 CDX9-2300 602819 CDX36-5070 600215 CD36-11000* 600212*

CDX36-3500 600183 CDX12-3000 602085 CDX9-4610 602854

Model Numbers and Part Numbers

CDS36-470 601146 CD36-1040 600180 CDS36-1660 600181

CDS36-650 600179 CDS18-910 601147 CDX9-700 602817

CDS36-1040 600180 CDX12-1200 602083

CDX18-2100 601149

CDX36-2000 600182

CDX18-4600 601151 CDX12-5740 602123

CDX18-5140 601196 CDX18-8340 601188

CDX36-4400 600184 CDX36-7060 600216

80 Frame 90 Frame 95 Frame 97 Frame

Model Part No. Model Part No. Model Part No. Model Part No.

CD9-6830 602884 CD9-9310 602862 CD9-14400 602827 CD9-21900 602870

CD12-8450 602154 CD9-11700 602826 CD9-15500 602828 CD12-14200 602136

CD18-10900 601211 CD12-11700 602138 CD12-17600 602092 CD12-20100 602137

CD12-14400 602091 CD12-19100 602093 CD18-19700 601204

CD18-14500 601165 CD18-17600 601166

CD36-20000 600201

100 Frame 105 Frame 110 Frame

Model Part No. Model Part No. Model Part No.

CD9-24800 602863 CD9-31000 602871 CD9-49000 602873

CD12-26500 602134 CD9-38000 602872 CD12-44000 602144

CD18-25300 601205 CD12-31000 602142

CD12-37000 602143

*Use Part Number 600200 for 50 Hz CD36-11000 and Part Number 600212 for 60 Hz CD36-11000.

Martin Engineering M3286-8/01 22 MOTOMAGNETIC

®

Electric Vibrators

Page 27

Vibrator mounts Cradle Lug Bracket: P/N 28732.

Locking Wedge Bracket for CD36-210, CD36-390, CD36-1040,

CDS36-210, CDS36-390, and CDS36-1040: P/N 28309-01.

Locking Wedge Bracket for CD36-650, CD36-1660, CDS36-650, and

CDS36-1660: P/N 28309-02.

ECF Bracket for CD36-210, CD36-390, CD36-1040, CDS36-210,

CDS36-390, and CDS36-1040: P/N 29383-01.

ECF Bracket for CD36-650, CD36-1660, CDS36-650, and CDS36-1660:

P/N 29383-02.

W-Beam Mount: P/N 29757-XX. XX indicates vibrator frame size (see chart

below).

Mount Kit for Electric Vibrators: P/N 32401-XX. (Kit includes W-Beam

Mount, mounting hardware, and BBAC Cable Kit.) XX indicates vibrator

frame size (see chart below).

Frame Size Part No.

00 32401-00

01 32401-01

10 32401-10

20 32401-20

30 32401-30

40 32401-40

Part Numbers

50 32401-50

Miscellaneous BBAC Cable Kit: P/N 32271. (Kit includes D-ring, cable, cable clamps, and

clamp hardware.)

The following reducers and adapters can be used to adjust the size of the cord

grip opening to ensure the grip seals tightly around the power supply cord.

Reducer, PG16M to PG13.5F: P/N 34526.

Reducer, PG21M to PG16F: P/N 34092.

Adapter, PG21M to 3/4 NPTF: P/N 35059.

Adapter, PG16M to 1/2 NPTF: P/N 35058.

Adapter, PG13.5M to 1/2 NPTF: P/N 35 057.

Adapter, PG13.5M to PG16F: P/N 511543.

Martin Engineering M3286-8/01 23 MOTOMAGNETIC

®

Electric Vibrators

Page 28

Martin Engineering M3286-8/01 24 MOTOMAGNETIC

Part Numbers

Frame sizes: 00 & 01

CD and CDS part numbers:

600177

600178

601144

601145

13

3

22

14

19

15

21

13

10

35

36

34

33

32

27

28

26

39

29

30

31

1

6

7

32

37

22

10

24

25

23

21

3

6

2

15

19

14

®

Electric Vibrators

23

24

25

Page 29

Martin Engineering M3286-8/01 25 MOTOMAGNETIC

Frame sizes: 10 & 20

CD and CDS part numbers:

600179

600180

601146

601147

601198

602098

602169

602170

602883

14

19

15

21

16

17

13

13

7

13

13

22

12

10

11

35

36

34

33

32

27

28

26

39

37

9

7

32

29

30

31

12

11

21

15

19

14

22

9

6

1

16

17

15

19

3

10

6

2

24

25

23

20

14

16

17

®

Electric Vibrators

25

23

24

3

16

17

14

19

15

20

Part Numbers

Page 30

Frame sizes: 30, 33, & 50

Martin Engineering M3286-8/01 26 MOTOMAGNETIC

CD and CDS

part numbers:

Part Numbers

23

45

600181

600243

600254

600256

600257

601148

602082

602816

CDX part

numbers:

600182

601149

602083

602817

23

21

41

14

19

15

42

14

15

13

13

13

24

25

33

32

35

36

34

28

26

29

44

8

10

12

38

30

31

39

1

6

2

7

9

11

32

27

37

22

3

38

12

10

11

9

6

21

41

15

19

14

1

23

®

Electric Vibrators

3

22

24

25

Page 31

Martin Engineering M3286-8/01 27 MOTOMAGNETIC

Frame sizes: 35, 40, 50, & 60

CD part numbers:

602161

602162

602165

602865

602888

602889

602890

5

4

16

17

19

15

20

23

25

24

®

Electric Vibrators

600216

601201

601217

601219

601220

601227

602150

14

19

15

41

21

13

13

33

32

32

27

18

29

30

31

37

21

41

15

19

14

38

12

10

11

40

6

9

22

4

5

3

16

17

15

19

24

25

23

20

14

16

17

35

36

34

50

49

51

7

10

12

38

3

22

14

16

17

13

13

40

11

28

26

39

6

2

1

7

9

Part Numbers

Page 32

Martin Engineering M3286-8/01 28 MOTOMAGNETIC

Frame sizes: 70, 80, 90, 95, 97, 100, 105, & 110

CD part numbers:

Part Numbers

®

Electric Vibrators

600199

600200

600201

600212

600219

601165

601166

601204

601205

601211

601221

602091

602092

602093

602134

602136

602137

602138

602142

602143

602144

602154

602167

602826

5

4

14

15

22

20

25

24

23

602827

602828

602862

602863

602870

602871

602872

602873

602884

602891

66

38

19

46

13

47

48

50

49

51

7

10

16

17

46

48

47

17

16

14

22

3

5

4

2

6

Frame sizes: 40, 50, 60, & 70

19

CDX part numbers:

600183

600184

600215

601150

601151

601187

601188

601196

602084

602085

602122

602123

602818

602819

602853

602854

23

25

24

20

15

27

28

26

29

30

31

37

39

6

13

1

52

40

59

54

53

3

56

55

35

36

34

33

32

32

38

10

18

65

58

57

62

Page 33

Martin Engineering M3286-8/01 29 MOTOMAGNETIC

®

Electric Vibrators

S90 Vibrator (CD, CDS)

Description Item 600177 601144 600178 601145 600179 601146 602169 602170 600180 601147 601198 602098 602883 600181 601148 602082 602816 600243

Case 1 * * * * * * * * * * * * * * * * * *

Flange 3 301140 301140 301141 301141 301142 301142 301142 301142 301143 301143 301143 301143 301143 301144 301144 301144 301144 301207

O-Ring 6 508630 508630 508615 508615 508555 508555 508555 508555 508566 508566 508566 508566 508566 508618 508618 508618 508618

Shaft 7 400201 400201 400202 400202 400203 400204 400203 400204 400205

Bushing, Shaft 9 513528 513528 513528 513528 513528 508052

Bearing 10 507002 507002 507029 507029 507026 507026 507026 507026 507025 507025 506533 507025 507025 506533 506533 506533 506533 506531

Seal, Grease 11 502078 502057 502057 502057 502057

Seal, Shaft 12 502079 502065 502065 502065 502065

Key 13 506000 506000 506000 506000 506000 506024 506000 506024 506024 506028 506028 506028 506028 506024 506002 506002 506002 506029

Weight, Fixed 50 Hz 14 517500 517500 517580 517580 517503 517627 517503 517627 517581 304286 304317 304286 304286 517505 304288 304288 304288 517603

Weight, Fixed 60 Hz 14 517500 517500 517580 517580 517503 517627 517503 517627 517581 304287 304286 304287 304286 517505 304289 304289 304288 517603

Weight, Adj 50 Hz 15 517500 517500 517580 517580 517503 517628 517503 517629 517581 305210 305242 305210 305210 517505 305212 305212 305212 517603

Weight, Adj 60 Hz 15 517500 517500 517580 517580 517503 517629 517503 517629 517581 305211 305210 305211 305211 517505 305213 305213 305212 517603

Screw 16 515613 515613 515509 515509 515509 515509 515514 515514 515514

Washer, Schnorr 17 513004 513004 513004 513004 513004 513005 513005 513005

Disc, Weight Adj 50 Hz 19 518119/20 518129/30 518121/2 518131/2 518123/4 518205/6 518123/4 518205/6 518125/6 518154/5 518154/5 518154/5 518154/5 518127/8 518156/7 518156/7 518156/7 518150/1

Disc, Weight Adj 60 Hz 19 518119/20 518129/30 518121/2 518131/2 518123/4 518205/6 518123/4 518205/6 518125/6 518154/5 518154/5 518154/5 518154/5 518127/8 518156/7 518156/7 518156/7 518150/1

Ring, Snap 20 500049 500049 500056 500056 500056 500056 500059 500059 500059 500078

Nut, Shaft 21 509011 509011 509011 509011 509009 509005 509005 509051

O-Ring 22 508615 508615 508616 508616 508562 508562 508562 508562 508617 508617 508617 508617 508617 508548 508548 508548 508548 508548

Cover, Weight 50 Hz 23 517042 517042 517043 517043 517044 517045 517044 517045 517046 517047 517069 517047 517047 517048 517049 517049 517049 517084

Cover, Weight 60 Hz 23 517042 517042 517043 517043 517044 517045 517044 517045 517046 517047 517069 517047 517047 517048 517049 517049 517049 517050

Screw 24 515554 515554 515554 515554 515509 515509 515509 515509 515510 515510 515510 515510 515510 515511 515511 515511 515511 515508

Washer, Schnorr 25 513003 513003 513003 513003 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004

Terminal Block 26 510503 510503 510503 510503 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501

Terminal Block U.S. 26 510503 510503 510503 510503 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501

Screw 27 M5x12 M5x12 M5x12 M5x12 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502

Screw, U.S. 27 M5x12 M5x12 M5x12 M5x12 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502

Washer, Schnorr 28 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002

Screw, Ground 29 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533

Washer, Schnorr 30 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002

Tag, Ground 31 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025

Cushion, Foam 32 514014 514014 514014 514014 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015

O-Ring 33 508555 508555 508555 508555 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612

Cover, Wiring Box 34 502501 502501 502501 502501 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500

Screw 35 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611

Washer, Schnorr 36 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003

Fitting, Cord 37 511546 511546 511546 511546 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530

Fitting, Grease 38 510000

Protector, Lead 39 514016 514016 514016 514016 514016 514016 514016 514016 514016 514016 514016 514016 514016 514016 514016 514016 514016 514016

Washer, Schnorr 41 513012

Cover, Bearing 46 502805

*Encapsulated stator and case. Contact Martin Engineering for Part Number specific to electrical rating.

**Use part number 400256 with single-phase models.

Frame Size and Part Number

00 01 10 20 30 33

400256**

400206 400263 400239 400239 400257 400208 400209 400209 400310

Part Numbers

Page 34

Part Numbers

Martin Engineering M3286-8/01 30 MOTOMAGNETIC

®

Electric Vibrators

S90 Vibrator (CD, CDS)

Description Item 601201 602150 602865 601217 601227 602161 602888 600254 600256 600257 601219 602162 602889 601220 602165 602890

Case 1 * * * * * * * * * * * * * 300238 300238 300238

Flange 3 301195 301195 301195 301196 301196 301196 301196 301196 301197 301197 301197 301197 301197 301198 301198 301198

Screw 4 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515538 515538 515538

Washer, Schnorr 5 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513005 513005 513005

O-Ring 6

Shaft 7 400285 400285 400285 400286 400286 400286 400286 400311 400312 400312 400287 400287 400287 400295 400295 400295

Bushing, Shaft 9 508048 508048 508048 508049 508049 508049 508049 508049 508049 508049 508049 508049 508049 508050 508050 508050

Bearing 10 506561 506561 506561 506535 506535 506535 506535 506535 506538 506538 506538 506547 506547 506553 506552 506552

Key 13 506029 506029 506029 506044 506044 506044 506044 506029 506029 506029 506044 506044 506044 506044 506044 506044

Weight, Fixed 50 Hz 14 304347 304349 304349 304351 304354 304351 304351 517609 517609 517609 304357 304357 304357 304363 304363 304363

Weight, Fixed 60 Hz 14 304348 304349 304349 304354 304362 304351 304351 517609 517609 517609 304358 304357 304357 304364 304363 304363

Weight, Adj 50 Hz 15 305375 305377 305377 305380 305385 305386 305386 517609 517609 517609 305387 305389 305389 305392 305394 305394

Weight, Adj 60 Hz 15 305376 305377 305377 305385 305391 305380 305386 517609 517609 517609 305388 305387 305389 305393 305392 305394

Screw 16 515539 515539 515539 515559 515559 515559 515559 515559 515559 515559 515612 515612 515612

Washer, Schnorr 17 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513006 513006 513006

Disc, Weight Adj 50 Hz 19 518156/7 518156/7 518156/7 518174/5 518174/5 518191/2 518191/2 518135/6 518135/6 518137/8 518174/5 518193/4 518193/4 518174/5 518174/5 518241/2

Disc, Weight Adj 60 Hz 19 518156/7 518156/7 518156/7 518174/5 518174/5 518174/5 518191/2 518135/6 518137/8 518135/6 518174/5 518174/5 518194/5 518174/5 518174/5 518241/2

Ring, Snap 20 500041 500041 500041 500055 500055 500055 500055 500055 500055 500055 500058 500058 500058

Nut, Shaft 21 509053 509053 509053

O-Ring 22 508556 508556 508556 508621 508621 508621 508621 508556 508556 508556 508621 508621 508621 508619 508619 508619

Cover, Weight 50 Hz 23 517075 517075 517075 517076 517076 517055 517055 517085 517086 517086 517055 517077 517077 517078 517079 517079

Cover, Weight 60 Hz 23 517075 517075 517075 517076 517076 517076 517055 517085 517086 517086 517055 517055 517077 517078 517078 517079

Screw 24 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508

Washer, Schnorr 25 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004

Terminal Block 26 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510501 510508

Terminal Block U.S. 26 510501 510501 510501 510501 510501 510501 510508 510501 510501 510501 510501 510501 510508 510501 510501 510508

Screw 27 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502 515502

Screw, U.S. 27 515502 515502 515502 515502 515502 515502 515534 515502 515502 515502 515502 515502 515534 515502 515502 515534

Washer, Schnorr 28 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002

Screw, Ground 29 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533 515533

Washer, Schnorr 30 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002 513002

Tag, Ground 31 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025 518025

Cushion, Foam 32 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015 514015

O-Ring 33 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612 508612

Cover, Wiring Box 34 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500 502500

Screw 35 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611 515611

Washer, Schnorr 36 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003

Fitting, Cord 37 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530 511530

Fitting, Grease 38 510000 510000 510000 510000 510000 510000 510000 510000 510000 510000 510000 510000 510000 510007 510007 510007

Protector, Lead 39 514023 514023 514023 514023 514023 514023 514023 514023 514026 514026 514026

Ring, Snap 40 500073 500073 500073 500015 500015 500015 500015 500015 500015 500015 500015 500015 500015 500076 500076 500076

Washer, Schnorr 41 513010 513010 513010

Cover, Bearing 46 502800 502800 502800 502801 502801 502801 502801 502801 502801 502801 502801 502801 502801 502802 502802 502802

35 40 50 60

Frame Size and Part number

*Encapsulated stator and case. Contact Martin Engineering for Part Number specific to electrical rating.

Page 35

Martin Engineering M3286-8/01 31 MOTOMAGNETIC

®

Electric Vibrators

S90 Vibrator (CD, CDS)

Description Item 600199 600219 600200 600212 601221 6021 67 602891 601211 602154 602884 601165 602138 602091 602862 602826

Case 1 300194 300194 300194 300194 300239 300239 300239 300220 300220 300220 300215 300215 300215 300215 300215

Flange 3 301168 301168 301165 301165 301199 301199 301199 301188 301188 301188 301173 301180 301173 301180 301173

Screw 4 515514 515514 515514 515514 515558 515558 515558 515517 515517 515517 515518 515518 515518 515518 515518

Washer, Schnorr 5 513005 513005 513005 513005 513006 513006 513006 513006 513006 513006 513007 513007 513007 513007 513007

O-Ring 6 508603 508603 508603 508603

Shaft 7 400247 400247 400242 400242 400296 400296 400296 400273 400274 400274 400261 400267 400259 400267 400259

Bushing, Shaft 9 513516 513516 513525 513525 508051 508051 508051

Bearing 10 506536 506536 506518 506518 506536 506555 506555 506551 50 6557 506557 506556 506539 506556 506539 506556

Seal, Grease 11 502055 502055 502052 502052

Seal, Shaft 12 502043 502043 502069 502069

Key 13 506045 506045 5060 45 506045 506046 506046 506046 506046 506046 506046 506032 506032 506032 506032 506032

Weight, Fixed 50 Hz 14 517630 517630 517630 304292 304292 304292 304265 304267 304267 304315 304327 304309 304327 304309

Weight, Fixed 60 Hz 14 517630 517630 517630 304293 304292 304292 304266 304268 304267 304316 30 4328 304314 304327 304309

Weight, Adj 50 Hz 15 517630 517630 517630 305217 305395 305395 305190 305192 305192 305240 305252 305232 305252 305232

Weight, Adj 60 Hz 15 517630 517630 517630 305218 305396 305395 305191 305193 305192 305241 305253 305239 305252 305232

Screw 16 515588 515588 515588 515602 515602 515602 515614 515621 515614 515614 515614

Washer, Schnorr 17 513007 513008 513007 513007 513007

Washer, Brass 18 513514 513514

Disc, Weight Adj 50 Hz 19 518211/2 518211/2 518211/2 518203/4 518241/2 518241/2 518203/4 518203/4 518203/4 518207/8 518207/8 518207/8 518207/8 518207/8

Disc, Weight Adj 60 Hz 19 518211/2 518211/2 518211/2 518203/4 518241/2 518241/2 518203/4 518203/4 518203/4 518207/8 518207/8 518207/8 518207/8 518207/8

Ring, Snap 20 500063 500063 500063 500061 500061 500061 500022 500022 500022 500022 500022

Nut, Shaft 21 509057 509057 509057 509057

O-Ring 22 508619 508619 508619 508619 508629 508629 508629 508628 508628 508628 508632 508632 508632 508632 508632

Cover, Weight 50 Hz 23 517057 517057 517057 517062 517080 517080 517060 517070 517070 517063 517073 517064 517073 517064

Cover, Weight 60 Hz 23 517057 517057 517057 517062 517080 517080 517060 517070 517070 517063 517073 517064 517073 517064

Screw 24 515508 515508 515508 515508 515508 515508 515508 515538 515538 515538 515514 515514 515514 515514 515514

Washer, Schnorr 25 513004 513004 5130 04 513004 513004 513004 513004 513005 513005 513005 513005 513005 513005 513005 513005

Te r min al Bl o ck 26 510502 510502 510502 510502 510502 510502 510502 510502 510502 510507 510502 510502 510502 510502 510502

Te r min al Bl o ck U. S. 26 510502 510502 510507 510502 510502 510502 510507 510502 510502 510502 510502 510502 510502 502507 502507

Screw 27 515504 515504 515504 515504 515504 515504 515505 515504 515504 515505 515504 515504 515504 515504 515504

Screw, U.S. 27 515504 515504 5155 04 515504 515504 515504 515505 515504 515504 515505 515504 515504 515504 515554 515554

Washer, Schnorr 28 513003 513003 5130 03 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003

Screw, Ground 29 515601 515601 515601 515601 515601 515601 515601 515601 515601 515601 515601 515601 515601 515601 515601

Washer, Schnorr 30 513003 513003 5130 03 513003 513003 513003 513003 513003 513003 513003 513003 513003

Tag, Ground 31 518026 518026 518026 518026 518026 518026 518026 518026 518026 518026 518026 518026 518026 518026 518026

Cushion, Foam 32 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025

O-Ring 33 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588

Cover, Wiring Box 34 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503

Screw 35 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508

Washer, Schnorr 36 513004 513004 5130 04 513004 513004 513004 513004 513004 513004 513004 513004 513004

Fitting, Cord 37 511513 511513 511513 511513 511513 511513 511513 511513 511513 511513 511513 511513 511513 511513 511513

Fitting, Grease 38 509029 509029 5090 29 509029 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007

Protector, Lead 39 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026

Ring, Snap 40 500008 500008 500008 500009 500009 500009 500064 500064 500064 500064 500064

Washer, Schnorr 41 513533 513533 5135 33 513533

Cover, Bearing 46 502803 5028 03 502803 303063 303063 303063 303053 303059 303053 303059 303053

Thermistor Term. Block 49 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510

Screw, Terminal Block 50 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609

Screw Insert 51 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056

Plug 52 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515

Screw 53 515566 515566 515566

Washer, Schnorr 54 513002 513002 513002

70 80 90

Frame Size and Part Number

Part Numbers

Page 36

Part Numbers

Martin Engineering M3286-8/01 32 MOTOMAGNETIC

®

Electric Vibrators

S90 Vibrator (CD, CDS)

Description Item 600201 601166 60 2092 602093 602827 602828 601204 602136 602137 602870 601205 602134 602863 602142 602143 602871 602872 602144 602873

Case 1 300210 300210 300210 300210 300210 300210 300219 300219 300219 300219 300216 300216 300216 300222 300222 300222 300222 300234 300234

Flange 3 301192 301192 301192 301192 301192 301192 301179 301178 301179 301179 301175 301175 301175 301193 301194 301193 301194 301191 301191

Screw 4 515518 515518 515518 515518 515518 515518 515610 515610 515610 515610 515610 515610 515610 515608 515608 515608 515608 516559 516559

Washer, Schnorr 5 513007 513007 513007 513007 513007 513007 513008 513008 513008 513008 513008 513008 513008 513014 513014 513014 513014 513012 513012

Shaft 7 400297 400299 400300 400300 400300 400300 400265 400266 400265 400269 400264 400264 400268 400281 400280 400282 400280 400290 400289

Shaft, 60 Hz 7 400264

Bearing 10 506554 506537 506537 506537 506537 506537 506558 506556 506558 506558 506544 506544 506544 506559 506560 506559 506560 506550 506550

Key 13 506032 506032 506032 506032 506032 506032 506032 506032 506032 506032 506048 506048 506048 506048 506048 506048 506048 506048 506048

Weight, Fixed 50 Hz 14 304296 304297 304299 304301 304299 304299 304332 304324 304323 304334 304318 304320 304320 304339 304342 304342 304342 304352 304352

Weight, Fixed 60 Hz 14 304273 304298 304300 304302 304299 304299 304333 304324 304325 304335 304319 304321 304320 304340 304341 304342 304342 304353 304352

Weight, Adj 50 Hz 15 305221 305222 305224 305226 305224 305224 305358 305249 305248 305360 305243 305245 305357 305367 305372 305369 305373 305381 305383

Weight, Adj 60 Hz 15 305197 305223 305225 305227 305224 305224 305359 305249 305250 305361 305244 305246 305356 305368 305372 305370 305374 305382 305384

Screw 16 515600 515600 515600 515600 515600 515600 515619 515619 515619 515619 515619 515619 515619 515623 515623 515623 515623 515623 515623

Washer, Schnorr 17 513007 513007 513007 513007 513007 513007 513008 513008 513008 513008 513008 513008 513008 513014 513014 513014 513014 513014 513014

Washer, Brass 18 513514 513514 513514 513514 513514 513514

Disc, Weight Adj 50 Hz 19 518207/8 518207/8 518207/8 518207/8 518207/8 518207/8 518220/1 518220/1 518220/1 518220/1 518220/1 518220/1 518220/1 518220/1 518220/1 518228/9 518228/9 518220/1 518232/3

Disc, Weight Adj 60 Hz 19 518207/8 518207/8 518207/8 518207/8 518207/8 518207/8 518220/1 518220/1 518220/1 518220/1 518220/1 518220/1 518220/1 518220/1 518220/1 518220/1 518228/9 518220/1 518232/3

Ring, Snap 20 500062 500062 500062 500062 500062 500062 500017 500022 500017 500017 500065 500065 500065 500069 500069 500069 500069 500060 500060

O-Ring 22 508631 508631 508631 508631 508631 508631 508559 508559 508559 508559 508635 508635 508635 508636 508636 508636 508636 508641 508641

Cover, Weight 50 Hz 23 517067 517067 517068 517068 517068 517068 306089 306090 306089 306093 306087 306087 306092 306094 306096 306096 306098 306101 306101

Cover, Weight 60 Hz 23 517067 517067 517068 517068 517068 517068 306089 306090 306089 306093 306087 306087 306092 306094 306096 306096 306098 306101 306101

Screw 24 515514 515514 515514 515514 515514 515514 515514 515514 515514 515514 515514 515514 515514 515514 515514 515514 515514 515612 515612

Washer, Schnorr 25 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513006 513006

Ter mi na l Bl oc k 26 510502 510502 510502 510502 510502 510502 510515 510515 510515 510515 510515 510515 510515 510515 510515 510515 510515 510512 510512

Ter mi na l Bl oc k U. S. 26 510502 510502 510502 510502 510507 510507 510515 510515 510515 510507 510515 510515 510507 510515 510515 510507 510507 510512 510512

Screw 27 515504 515504 515504 515504 515504 515505 515504 515504 515504 515504 515504 515504 515504 515504 515504 515504 515504 515508 515508

Screw, U.S. 27 515504 515504 515504 515504 515554 515505 515504 515504 515504 515554 515504 515504 515554 515504 515504 515505 515505 515508 515508

Washer, Schnorr 28 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513003 513004 513004

Screw, Ground 29 515601 515601 515601 515601 515601 515601 515618 515618 515618 515618 515618 515618 515618 515618 515618 515618 515618 516558 516558

Washer, Schnorr 30 513003 513003 513003 513003 513003 513003 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513005 513005

Tag, Ground 31 518026 518026 518026 518026 518026 518026 518223 518223 518223 518223 518223 518223 518223 518223 518223 518223 518223 518181 518181

Cushion, Foam 32 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514025 514024 514024

O-Ring 33 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508588 508619 508619

Cover, Wiring Box 34 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 502503 309033 309033

Screw 35 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515508 515538 515538

Washer, Schnorr 36 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513004 513005 513005

Fitting, Cord 37 511513 511513 511513 511513 511513 511513

Fitting, Grease 38 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007 510007

Protector, Lead 39 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026 514026

Ring, Snap 40 500034 500034 500034 500034 500034 500034 500068 500013 500068 500068 500067 500067 500067 500070 500072 500070 500072

Shaft Spacer 42 508646 508046 508046 508046 508047 508047

Cover, Bearing 46 303068 303068 303068 303068 303068 303068 303057 303058 303057 303057 303056 303056 303056 303060 303064 303060 303064 303065 303065

Screw 47 515538 515538

Washer, Schnorr 48 513005 513005

Thermistor Term. Block 49 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510 510510

Screw, Terminal Block 50 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515609 515605 515605

Screw Insert 51 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056 509056

Plug 52 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515 514515

Screw 53 515566 515566 515566 515566 515566 515566

Washer, Schnorr 54 513002 513002 513002 513002 513002 513002

Washer, Schnorr 55 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005 513005

Screw 56 509061 515620 509061 509061 509061 509061 509061 515620 515620 515620 515620 515620 515620

Tub e, C or d 57 504012 504012 504012 504012 504012 504012 504012 504012 504012 504012 504012 504012 504012

Cord Cover 58 309035 309035 309035 309035 309035 309035 309035 309035 309035 309035 309035 309035 309035

Shaft Bushing 59 308520 308520 308520 308521 308522 308521 308522

O-Ring 62 508639 508639 508639 508639 508639 508639 508639 508639 508639 508639 508639 508639 508639

Screw, Special 64 509062 509062 509062 509062 509064 509064

Plug, Plastic 65 514516 514516 514516 514516 514516 514516 514516 514516 514516 514516 514516 514516 514516

Grease Seal Ring 66 502080 502080 502080 502080 502081 502081

95 97 100 105 110

Frame Size and Part Number

Page 37