Metal Fab 4CGSWHVK, 4CGVSWHVK Installation Manual

CORR/GUARD ADDENDUM

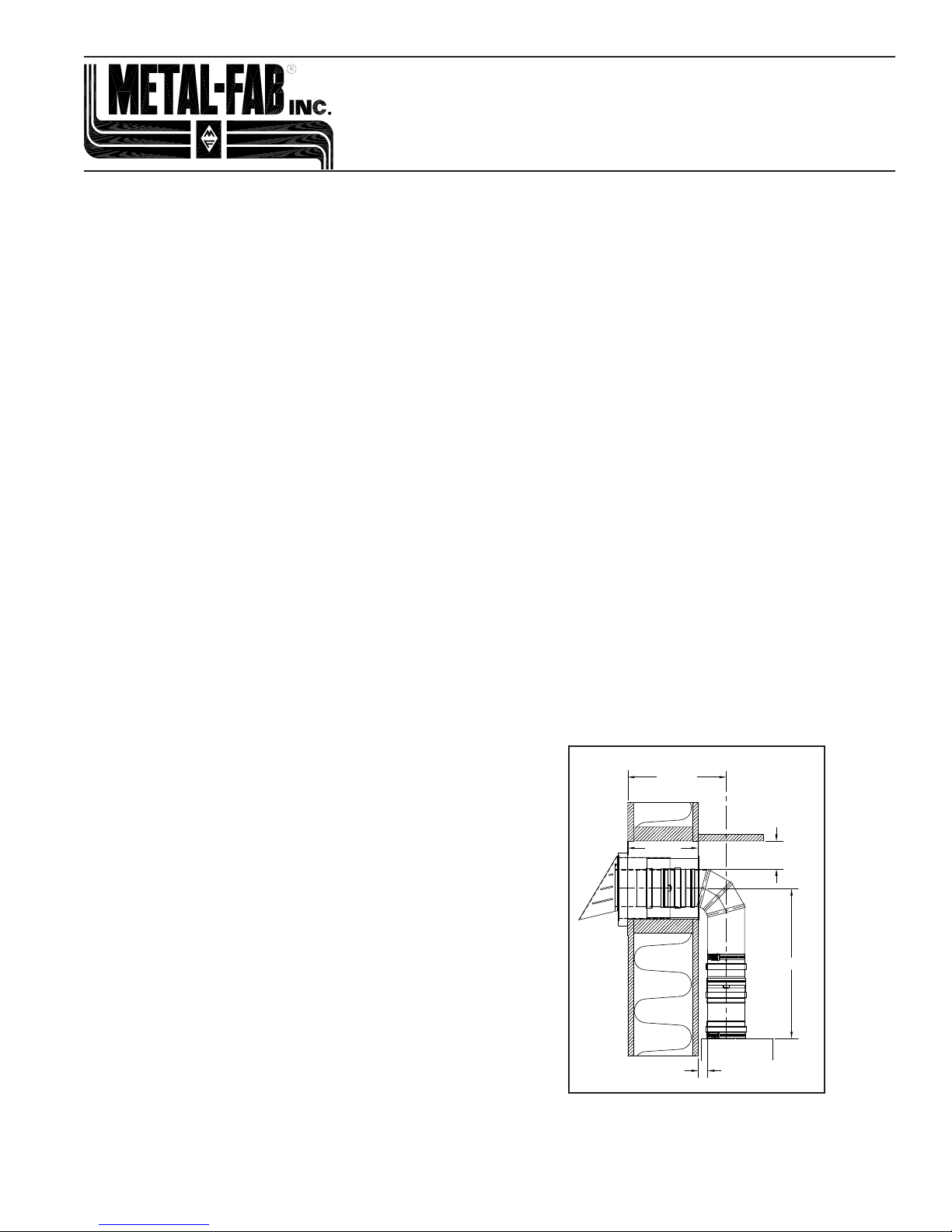

3.00"

MIN.

1.00"

MIN.

APPLIANCE

WALL

ROOF

12.5"-16.0"

4.5"-9.0"

8.5"-12.0"

4CGSWHVK & 4CGVSWHVK

INSTALLATION INSTRUCTIONS

IMPORTANT: DO NOT INSTALL WITHOUT FIRST READING

THESE INSTRUCTIONS VERY CAREFULLY.

These instructions pertain to the installation of the 4CGSWHVK

& 4CGVSWHVK vent kits.

The Corr/Guard 4CGSWHVK & 4CGVSWHVK vent kits are

designed for sidewall venting of instantaneous tankless water

heaters and wall hung boilers. Each kit contains the parts

necessary to vent through any combustible wall. The vent kit is

compatible with standard Corr/Guard products.

Be sure to read these instructions completely, and those of the

appliance itself, before proceeding with the installation of this

kit. Additional information and requirements regarding the use

and installation of Corr/Guard products can be found in the

installation instructions (L2153 and L2154). Installation is to be in

accordance with local and national building codes.

The UL Listing for this product is void if components other than

those supplied as Listed Components by Metal-Fab, Inc. are

used. All warranties, stated or implied, are void if this product

and the appliance to which it is connected are not installed in

accordance with their respective instructions and jurisdictional

code requirements.

Proper joint assembly is essential for a safe installation. Failure

to follow these instructions and sound installation practices can

lead to risk of damage, re and carbon monoxide poisoning.

KIT COMPONENTS:

The following items are included in the box for this kit:

• Wall thimble termination.

• 2 each male adjustable collars.

• Telescoping 90-degree elbow.

• Appliance adapter.

• Installation instructions.

GENERAL REQUIREMENTS:

WARNING: Failure to conform to any of these requirements. May

violate local, state, or national codes and create conditions that

may cause catastrophic property damage or personal injury.

• Proper operation of the vent system and appliance depends

on the use and correct assembly of all parts specied by

Metal-Fab, Inc. for a particular installation.

• If required by the appliance manufacturer, a drain tting

must be located as close as possible to the appliance ue

outlet.

• More than one appliance may not be connected to the same

• Vent system must avoid any contact with plumbing or

• Proper clearances to combustibles must be maintained over

vent kit termination.

electrical systems.

the entire length of the system (FIG. 1). Maximum appliance

outlet temperature must not exceed 480 degrees Fahrenheit

and a rating for positive pressure of 10” W.C..

• Refer to the appliances instructions to determine limitations

with respect to the installation and use such as maximum

horizontal length from the appliance, maximum height,

joining of two or more parts to constitute the intended

assembly, maximum number of joints or sections of pipe for

use in the assembly, and required installation clearances.

• Do not place any type of insulation in the required clearance

spaces surrounding the vent system.

• Never install Corr/Guard on an appliance that is not listed for

use with a Special Gas Vent or Type BH Vent.

• Additional Corr/Guard vent lengths can be installed

for extended runs. The overall equivalent length of the

system shall not exceed the specications of the appliance

manufacturer’s instructions.

• Horizontal vent runs shall have a slope of no less than 1/4

inch (6.4mm) every 12 inches (305mm) to prevent collection

of condensate.

• The termination should be away from trees, shrubs, or

decorative items as ue gases could cause damage.

• The venting system must be free to expand and contract.

• Check for unrestricted vent movement through walls,

ceilings, and roof penetrations.

• Manufacturers have different joint systems and adhesives.

Do not mix pipe, ttings, or joining methods from different

manufacturers.

FIG. 1

GENERAL TERMINATION GUIDELINES:

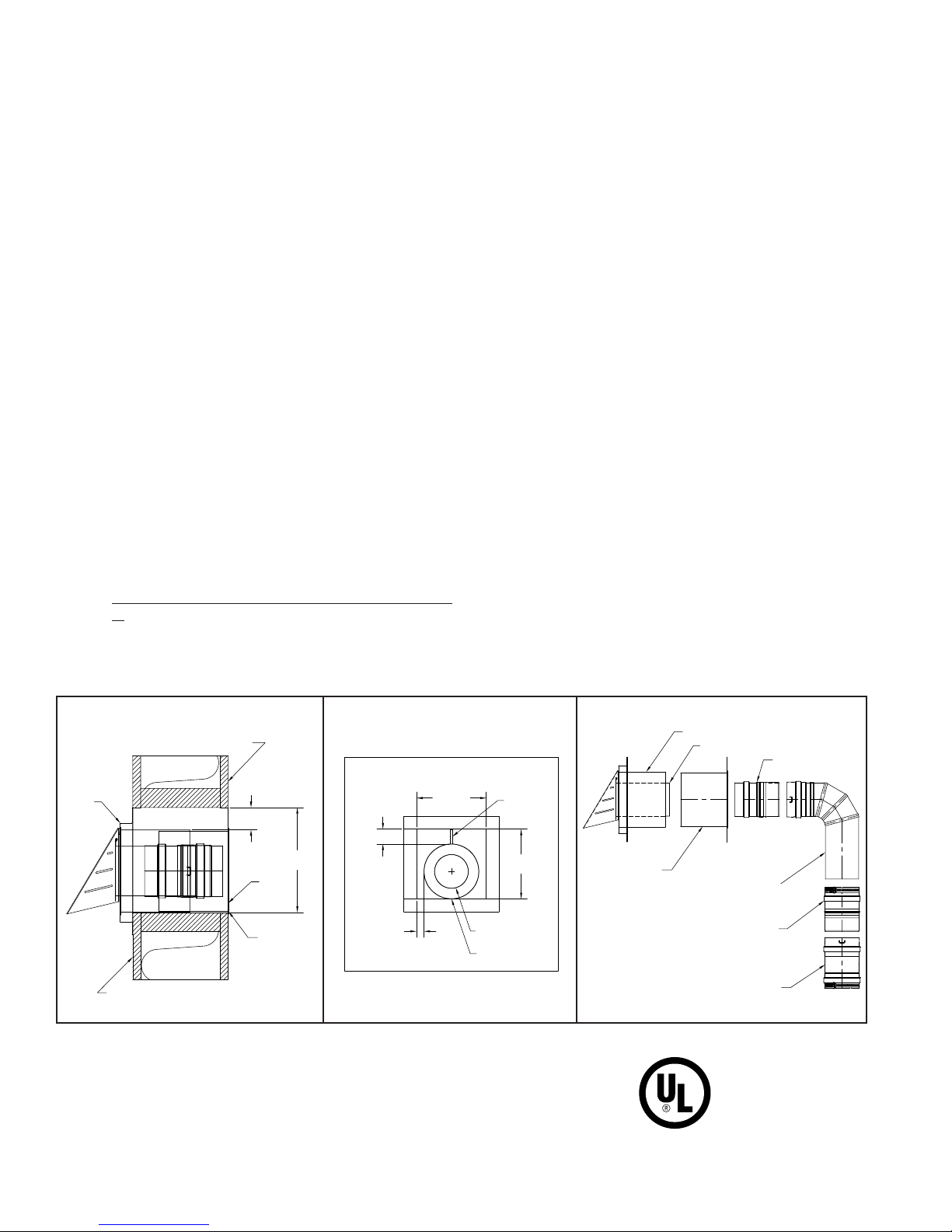

THIMBLE

HOOD

INNER

THIMBLE

0" BOTTOM

CLEARANCE

1.75" TOP

CLEARANCE

WALL

OUTSIDE SURFACE

INSIDE SURFACE

8.25"

SQUARE

8.250

OPENING

8.250

OPENING

1.750

0.875

HOOD REMOVED FOR CLARITY

6.50" DIA. THIMBLE

0" CLEARANCE

VENT

4.00" DIA.

SPACER

CLIP

HOOD THIMBLE

INNER THIMBLE

SLIP COLLAR

ELBOW

ADJUSTABLE COLLAR

APPLIANCE ADAPTER

VENT SLEEVE

NOTICE: The following is to be used as a guideline only. Check

with the code enforcement ofce in your area for specic

termination requirements.

A mechanical draft vent system, excluding direct-vent appliances,

shall terminate at least 4 feet (1219 mm) below, 4 feet (1219

mm) horizontally from, or 12 inches (305 mm) above any door,

window, or gravity air inlet into any building. The bottom of the

vent terminal shall be located at least 12 inches (305 mm)

above grade. In geographical areas where snow accumulates,

terminate the system at least 12 inches (305 mm) above the

snow line. The termination must be kept clear of snow and ice

at all times.

NOTE: The State of Massachusetts requires additional

restrictions for vent terminations located less than 7 feet

above grade. Consult your local code.

The termination of the venting system shall not be located in

trafc areas, such as walkways, unless the venting system is at

least 7 feet (2.13m) above the ground.

INSTALLATION INSTRUCTIONS:

• Examine all components for possible shipping damage prior

to installation.

• Do not penetrate or puncture any part of the system with

fasteners.

• Determine the location and cut a 8.25” x 8.25” (210mm x

210mm) opening for the wall thimble (FIG. 2).

o Position thimble hood into the opening so that the

angled hood is located on the outside of the structure.

The thimble hood is not centered in the opening (FIG.

3). Clearance to combustibles at top of thimble is

1.75” (44 mm), bottom of thimble is 0” (0 mm), and

centered from side to side. The clip attached to the

top of the thimble will maintain the necessary clearance

to combustibles.

o Apply a bead of silicone between the structure and

mounting plate before nailing or screwing thimble hood

to the outside surface of the building.

o From the inside, slide the inner thimble sleeve into the

thimble hood sleeve until the surface is ush to the wall.

Fasten with screws or nails.

• Slide the adjustable collar over the thimble hood vent sleeve.

Insert female end of 90° elbow onto adjustable collar until it

locks. Slide adjustable collar onto male end of 90° elbow.

Insert female end of appliance adapter onto adjustable

collar until it locks. Attach appliance adapter to appliance

collar.

• Adjust collars until the desired pitch is achieved.

• Tighten clamps at the adjustable collar and appliance

adapter until snug.

• When installing the adjustable collars, it is important to make

sure that each end is inserted past the silicone gasket. To

ensure the collars are fully engaged, at least two inches of

sleeve must be inserted.

• If you are unable to insert the sleeves at least two inches

into the adjustable collars, additional vent lengths must be

installed.

• Prior to initial start up, check the entire system to ensure

all joints are secured and sealed correctly. The seams and

joints must be checked for gas tightness when using the

venting system with Category III or IV appliances and for

free movement of the outlet ap. Metal-Fab recommends

that a qualied inspector check the entire system at least

once annually following the initial installation.

• The installation must conform to the requirements of the

appliance manufacturer’s instructions, the National Fuel

Gas Code, and local codes and regulations.

FIG. 2

FIG. 3

FIG. 4

C US

LISTED

©2010 Metal-Fab, Inc. Form No. L2376 - 04/10

8624

Loading...

Loading...