Page 1

WOOD SANDING MACHINES

SMOOTHING

THE WAY TO

PERFECTION.

Metabo manufacture a wide range of quality sanders for those who require a profes -

sional finish. The wide range allows the user to select exactly the right sander for the

job, be it for sanding flat surfaces, curved surfaces, sanding into corners or along edges.

Backed up with a wide range of accessories Metabo sanders are able to finish a whole

host of materials, be it wood, metal, paints, varnish or filler. Metabo. Work. Don’t play.

150 |

Page 2

WOOD SANDING MACHINES

| 151

Page 3

WOOD SANDING MACHINES

CONSIDERED THE BEST, NOT ONLY ON THE SURFACE.

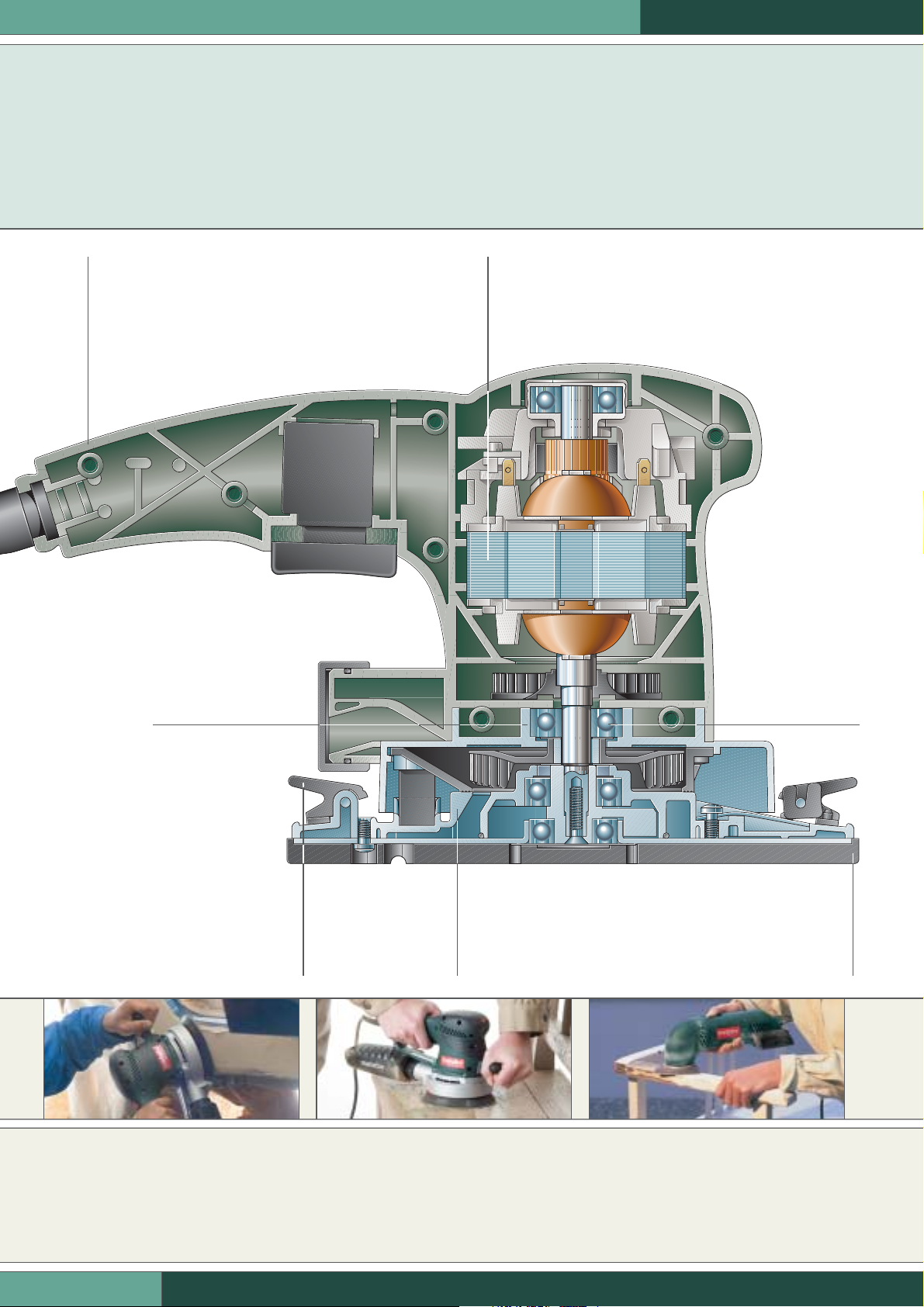

The Metabo range of sanders are considered amongst

the best in the industry. Copied by many and perfected

by none the Metabo sanding range gives you a choice

of machines built to the demands of the profes-

sional. Be it for fine finishing, detail finishing, high

stock removal or surface preparation Metabo has the

sander and accessory to perfect the job in hand time

and time again.

Ergonomic design

Safe and comfortable

work as it fits perfectly

in the hand.

Solid aluminium die

cast bearing flange

Guarantees a longer

service life of the

machine.

Electro-dynamic

balancing system

Fatigue-free work due to

especially low vibrations.

Four quality ball

bearings protected

ideally against dust

Longer service life

due to ideal dust

protection.

External dust extraction

or extraction by Intec

filter system possible

(accessory)

Metabo power control system

A built-in backing pad brake limits

scratches when placing the tool on the

material. This means that no manual postprocessing is needed. This makes the disc

sander particularly suitable for sanding very

thin materials and sensitive surfaces.

152 |

Quick clamping system

For the fast and comfortable change of the

sanding sheet.

Unique Duo oscillating circuit setting

Two adjustment options provide 100% finer

surfaces with the small oscillating circuit

diameter and 70% more material removal

with the large one.

Die-cast aluminium

oscillating plate

More robust material

provides longer service

life.

Sanding up to the outer-

most corner

Oscillating plate

without protruding parts.

DSE 300 Intec – the first triangular base-plate

sander with integrated dust extraction unit

No obstructive suction hose; the dust is

collected in the integrated dust container.

Page 4

WOOD SANDING MACHINES

Which sanding machine for which application?

Application Type and output Page

Delta sander with comfortable one-hand operation and dust extraction unit. FMS 200 Intec 154

Low weight with good material removal. 200 W

Suitable for sanding at places difficult to reach such as corners, edges, intermediate spaces.

Disc sander with comfortable one-hand operation and dust extraction unit. DSE 300 Intec 154

Grinding at places difficult to reach such as corners, profiles, edges, intermediate spaces. 300 W

Suitable for grinding heat-sensitive materials and surfaces.

Removal of carpet or tile adhesive (with scraper, accessory).

Particularly suitable for sanding inner and outer curves. SX E 400 156

Small backing pad diameter and low housing shape 220 W

for sanding at places difficult to reach.

Suitable for sanding heat-sensitive materials and surfaces.

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

Disc sander with comfortable one-hand operation and dust extraction unit. FSX 200 Intec 156

Low weight with good material removal. 200 W

Suitable for sanding wood, plastic and metal on even

and slightly curved surfaces.

Large material removal and finest sanding on even and curved surfaces. SXE 325 Intec 157

Suitable for sanding wood, plastic and metal on even and slightly curved surfaces. 250 W

Intec dust extraction unit.

Substantial material removal and finest grinding finish on even and domed surfaces. SXE 425 TurboTec 157

Suitable for sanding heat-sensitive materials and surfaces. 320 W

Grinding of very thin materials (e.g. veneers).

Universal applications due to Duo-oscillating circuit setting. SXE 450 TurboTec 159

Large material removal and finest grinding on even and curved surfaces. 350 W

Suitable for sanding heat-sensitive materials and surfaces.

Grinding of very thin materials (e.g. veneers).

Sander with comfortable one-hand operation and dust extraction unit. FSR 200 Intec 160

Low weight with good material removal. 200 W

Suitable for sanding wood, plastic and metal on even and slightly curved surfaces.

Robust sander, designed for commercial use. SR 10-23 Intec 160

Sanding of wood, plastic, metal, stone on even or slightly curved surfaces. 200 W

With integrated dust extraction unit for dust-free work without suction hose.

Sanding of wood, plastic, metal, stone on even or slightly curved surfaces. SR 20-23 160

Excellent weight-output ratio for hard and long hours of working, 210 W

as well as working overhead.

NEW

NEW

Fine sanding results when sanding wood, plastic, metal and stone. Sr 356 161

Sanding on even or slightly curved surfaces. 350 W

Clean work with integrated sanding dust extraction.

Like SR 356, however with large sanding disc for quicker material removal. Sr 358 161

350 W

Fine sanding results when sanding wood, plastic, metal and stone. Sr E 357 161

Sanding on even or slightly curved surfaces. 350 W

Suitable for sanding heat-sensitive materials and surfaces.

Clean work with integrated sanding dust extraction.

Like SR E 357, however with large sanding disc for quicker material removal. Sr E 359 161

350 W

For sanding large, even areas. Ba E 1075 163

For sanding notches and for working close to edges. 1.000 W

Suitable for sanding heat-sensitive materials and surfaces.

Can also be used as fixed tool.

| 153

MACHINES

WOOD SANDING

ROUTERS

AND PLANERS

Page 5

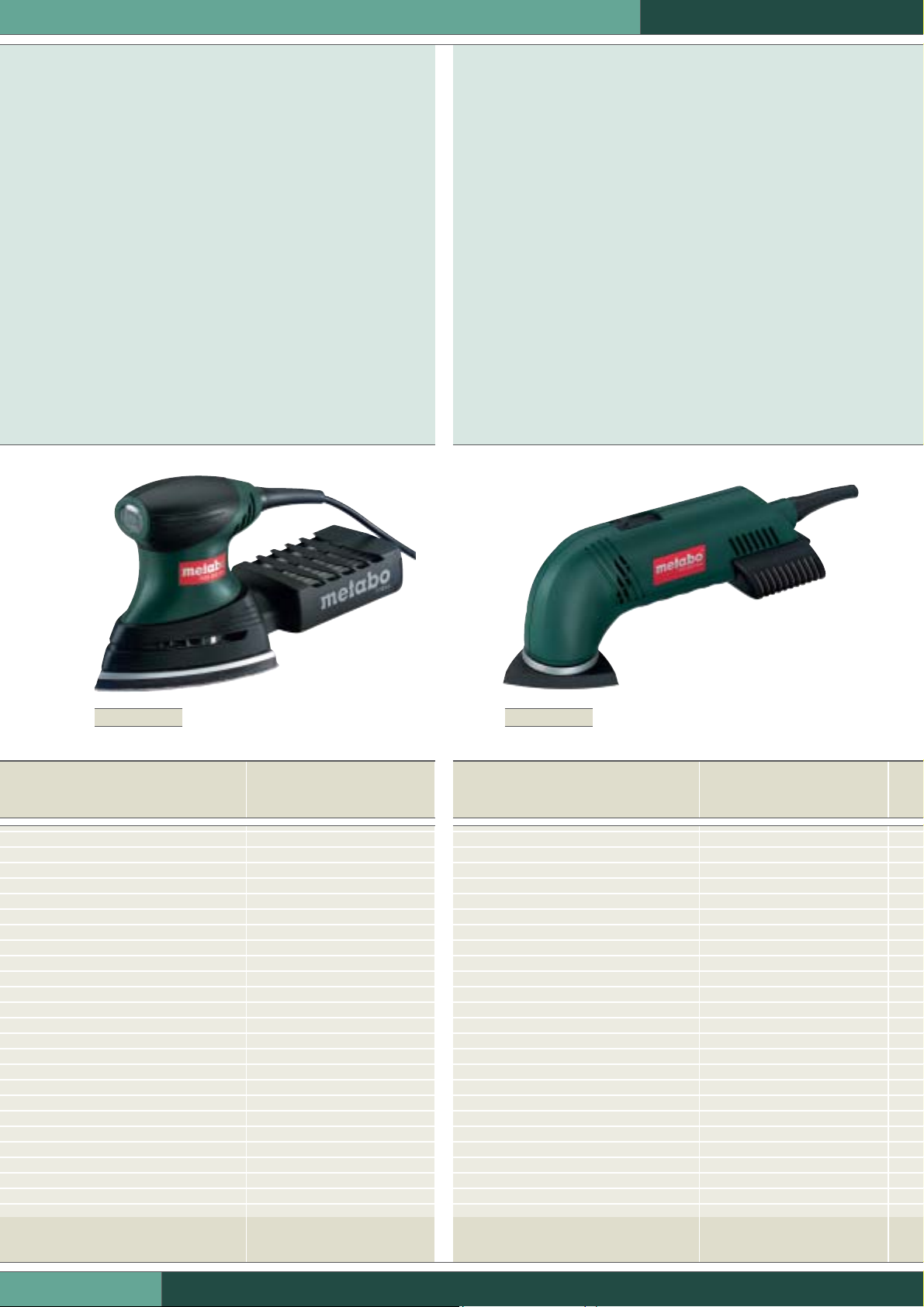

TRIANGULAR BASE-PLATE SANDERS

EQUIPMENT FEATURES

Triangular base plate for sanding edges,

corners and surfaces

Light and handy machine for convenient

one-hand operation

Very good weight-performance ratio

Vibration-damping, non-slip rubber

coated handle

Dust-proof ball bearing

Velcro-faced base plate

Dust extraction unit with Intec filter system,

with washable filter cartridge

EQUIPMENT FEATURES

Universal use for sanding wood, plastics, metals and stone

Also suitable for louvre sanding and for sanding

varnished surfaces

Robust gear design for severe applications

Spindle with dustproof triple ball bearing design

Base plate holder and base body in sturdy aluminum

High stock removal

Variospeed (V) electronics

Thumbwheel for preselection of orbital frequency

PU-foamed base plate enables flexible adjustment

to the workpiece surface

Velcro-faced base-plate

High extraction output

Dust extraction unit

Ideal handling by slim handle and handy recessed grips

Low housing

Rotatable base plate without tools (360°)

External dust extraction outlet

FMS 200 Intec DSE 300 Intec

200 Watt

Multisander

FMS 200 Intec

Comparative device characteristics

Base plate 100 x 147 mm

Orbital frequency at no-load 26.000 /min

Rated input power 200 W

Output power 80 W

Orbital frequency at rated load 22.000 /min

Oscillating circuit 1,4 mm

Weight (without mains cable) 1,25 kg

Standard equipment 3 cling-fit sanding sheets

(perforated), dust collector

cartridge, 1 pleated filter,

carry case

300 Watt

Electronic

Triangular Base-Plate Sander

DSE 300 Intec

Comparative device characteristics

Base plate size (corner to corner) 93 mm

Orbital frequency at no-load 14.000 - 22.000 /min

Orbital frequency at rated load 18.000 /min

Rated input power 300 W

Oscillating circuit 1,8 mm

Weight (without mains cable) 1,3 kg

Standard equipment 3 perforated sanding sheets

(P 60, P 100, P 240), carry case

Type FMS 200 Intec

Order no. 6.00065

154 |

154 |

Type DSE 300 Intec

Order no. 6.00311

Page 6

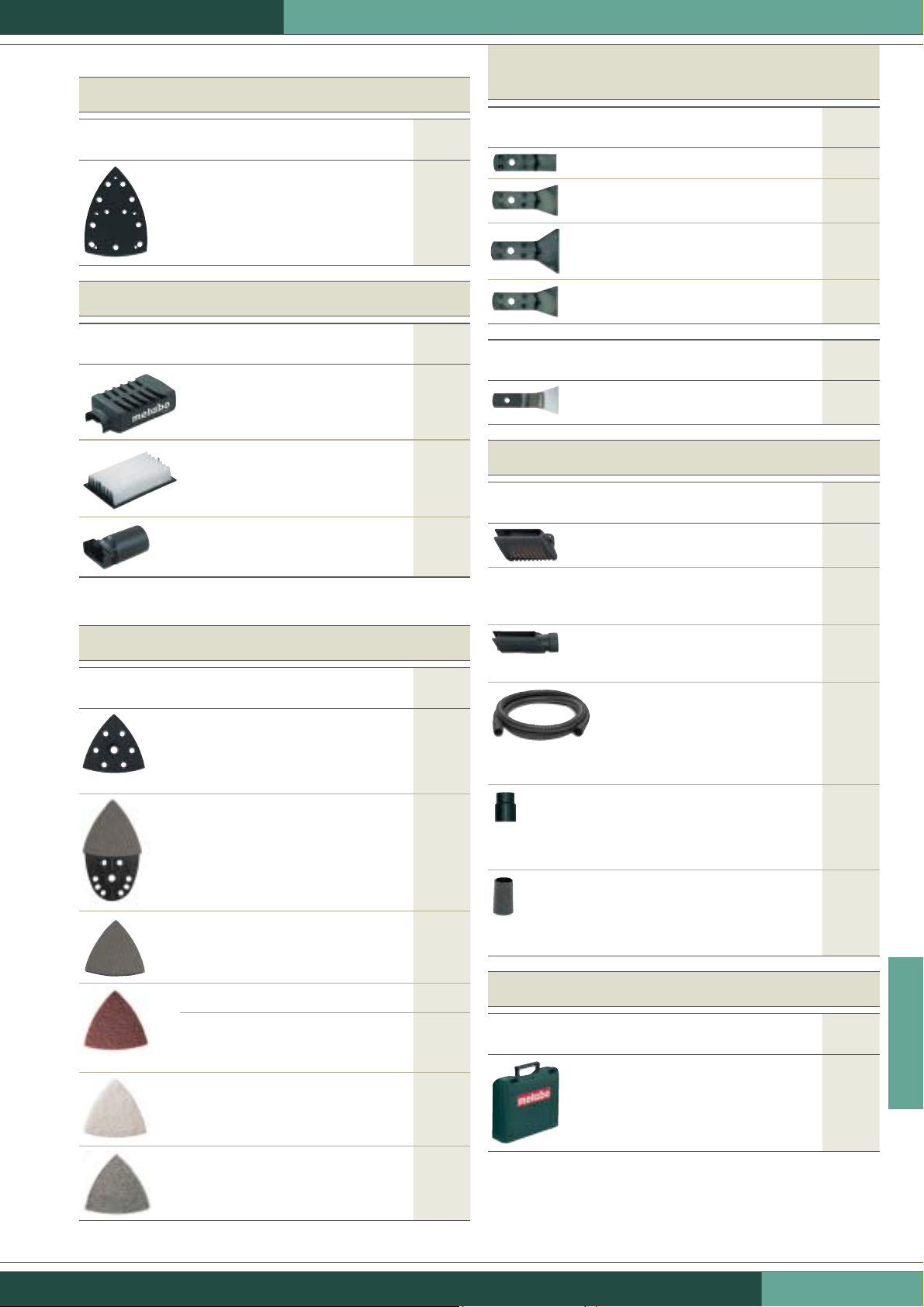

ACCESSORIES

FOR THE FMS 200 INTEC

Velcro-faced base-plates

Sanding plate, perforated

Sanding plate for FSR 200 Intec

(as spare)

Dimensions: 147 x 100 mm

Dust collection box

Dust collector cartridge

Dust collector cartridge

including dust filter 6.25602

Pleated filter

Pleated filter, polyester,

for dust collector

cartridge (6.25601)

Connector

Connector Ø 35 mm for

connecting to a normal

vacuum cleaner

FOR FOR DSE 300 INTEC

Velcro-faced base-plates

Perforated velcro-faced base-plate

For the triangular base-plate

sanders DSE 300 and DSE 300 Intec

(as spare)

Dimension from corner

to corner: 90 mm

special louvre base-plate

Velcro-faced at the bottom side.

The self-adhesive velcro-faced

liner supplied can be fitted to

the top of this base-plate so

that cling-fit sanding sheets

can be fitted for top and bottom

sanding of louvres.

Self-adhesive liner

Self-adhesive velcro-faced liner

(as spare for special louvre

base-plate 6.24971)

Cling-fit abrasive nylon web,

corundum abrasive

Grit: P 100 6.24958

Grit: P 280 6.24959

Cling-fit cleaning nylon web

Order

no.

6.25600

Order

no.

6.25601

6.25602

6.26996

Order

no.

6.24992

6.24971

6.24972

6.24957

Scraper blade

For easy removal of old paint, glue,

and other residues

Blade width

mm

30 6.31662

50 6.31663

70 6.31664

50 Carbide-tipped 6.31661

Spatula

Made of spring sheet-steel

Blade width: 60 mm

Dust extraction accessories

Dust collector cartridge

For dust extraction unit with

DSE 300 Intec

10 dust filters

For the dust collector

cartridge 6.24993 of the

DSE 300 Intec

Extraction nozzle

For external extraction for

DSE 300/ DSE 300 Intec

Suction hose

Connector with

internal Ø 30 mm and

connector with

outer Ø 35 mm

Hose length: 5 m

Suction hose Ø: 19 mm

Adapter

For connecting the

suction hose with

connector Ø 35 mm

to an extraction

nozzle Ø 30 mm

Connector

For connecting

suction hose 6.31592

(Ø 30/35 mm connection)

to a household vacuum

cleaner

Other accessories

Carry case

Order

no.

Order

no.

6.31659

Order

no.

6.24993

6.24995

6.24994

6.31592

6.24996

6.31593

Order

no.

6.25447

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

MACHINES

WOOD SANDING

Cling-fit polishing felt

Hard

6.24949

| 155

| 155

ROUTERS

AND PLANERS

Page 7

DISC SANDERS

EQUIPMENT FEATURES

Very suitable for sanding inner and outer curves

Light and handy machine for convenient one-hand operation

Rotating and additional oscillating movement of backing

pad for optimum finish

Variospeed (V) electronics

Thumbwheel for preselection of speed

Limit scratches while placing the running machine

on the material (Power Control System)

Clean sanding result in narrow rails

Excellent result even for polishing smaller surfaces

Low housing

Especially quiet through electro dynamic fine balancing

Optimum power transmission through reduced

crown wheel gear

Long service life through spindle with dustproof

triple ball bearing design

Velcro-faced backing pad

External dust extraction outlet

EQUIPMENT FEATURES

Multi-purpose machine for sanding even

and cambered surfaces, wood, plastics,

non-ferrous metals, sheet steel

Light and handy machine for convenient one-hand

operation

Very good weight-performance ratio

Dust-proof ball bearing

Velcro-faced backing pad

Vibration-damping, non-slip rubber coated handle

Dust extraction unit with Intec filter system,

with washable filter cartridge

SX E 400 FSX 200 Intec

220 Watt

Electronic

Disc Sander

SX E 400

Comparative device characteristics

Diameter of backing pad 80 mm

No load speed 5.000 - 10.000 /min

Rated input power 220 W

Output power 100 W

Rated load speed 6.000 /min

Oscillating circuit 3 mm

Weight (without mains cable) 1,2 kg

Standard equipment 5 perforated cling-fit sanding

sheets, cling-fit intermediate

disc, allen key

240 Watt

Palm Grip

Random Orbital Sander

FSX 200 Intec

Comparative device characteristics

Diameter of backing pad 125 mm

No load speed 11.000 /min

Rated input power 240 W

Output power 90 W

Rated load speed 9.500 /min

Oscillating circuit 2,7 mm

Weight (without mains cable) 1,3 kg

Standard equipment 3 perforated cling-fit sanding

sheets, dust collector cartridge,

1 pleated filter, carry case

Type SX E 400

Order no. 6.00405

156 |

Order no. 6.09225

Type FSX 200 Intec

Page 8

DISC SANDERS

EQUIPMENT FEATURES

Multi-purpose machine for sanding even

and cambered surfaces, wood, plastics,

non-ferrous metals, sheet steel

Variospeed (V) electronics

Thumbwheel for preselection of speed

Limit scratches while placing the running machine

on the material (Power Control System)

Dust-proof ball bearing

Velcro-faced backing pad

Dust extraction unit with Intec filter system,

with washable filter cartridge

EQUIPMENT FEATURES

TurboBoost switch: allows additional power reserves

to be employed for achieving maximum removal

Multi-purpose machine for sanding even

and cambered surfaces, wood, plastics,

non-ferrous metals, sheet steel

Rotating and additional oscillating movement

of backing pad for optimum finish

Variospeed (V) electronics

Thumbwheel for preselection of speed

Limit scratches while placing the running machine

on the material (Power Control System)

Removable front handle

Dust-proof ball bearing

Sturdy aluminum die cast bearing housing

Velcro-faced backing pad

Vibration damping, non-slip rubber support

on the machine housing and the handle

Dust extraction unit with Intec filter system,

with washable filter cartridge

External dust extraction outlet

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

SXE 325 Intec SXE 425

250-Watt

Electronic

Disc Sander

SXE 325 Intec

Comparative device characteristics

Diameter of backing pad 125 mm

No load speed 5.000 - 11.000 /min

Rated input power 250 W

Output power 100 W

Rated load speed 7.500 /min

Oscillating circuit 5 mm

Weight (without mains cable) 1,7 kg

Standard equipment 3 perforated cling-fit sanding

sheets, allen key, dust collector

cartridge, 1 pleated filter,

carry case

TurboTec

NEW

320 Watt

Electronic

Disc Sander

SXE 425 TurboTec

Comparative device characteristics

Diameter of backing pad 125 mm

No load speed 12600 /min

Rated input power 320 W

Output power 160 W

Rated load speed 9.000 /min

Oscillating circuit 5 mm

Weight (without mains cable) 2 kg

Standard equipment Velcro-faced backing

pad, 3 perforated

cling-fit sanding sheets,

allen key, removable

side handle, dust

collector cartridge,

1 pleated filter

MACHINES

WOOD SANDING

Type SXE 325 Intec

Order no. 6.00325

Type SXE 425 TurboTec

Order no. 6.00131

ROUTERS

AND PLANERS

| 157

Page 9

ACCESSORIES FOR DISC SANDERS

FOR SX E 400

Order

no.

Velcro-faced backing pad

6.24064

Diameter: 80 mm

Hardness: Medium-hard

Version: Perforated

Backing pad, for self-adhesive

6.24062

sanding discs

Diameter: 80 mm

Hardness: Medium

Version: Perforated

Velcro-faced

6.24061

intermediate disc

For sanding curved surfaces

Diameter: 80 mm

Hardness: Soft

Version: Perforated

Cling-fit polishing sponge

6.24092

Diameter: 80 mm

Thickness: 20 mm

Packing unit: 1

Cling-fit lambswool

6.24063

polishing disc

Diameter: 85 mm

Packing unit: 1

Cling-fit abrasive nylon web

6.24067

Diameter: 80 mm

Grit: P 100

Packing unit: 2

Cling-fit abrasive nylon web

6.24068

Diameter: 80 mm

Grit: P 280

Packing unit: 2

FOR FSX 200 INTEC, SXE 325 INTEC AND

SXE 425 TURBOTEC

Velcro-faced backing pad

Diameter

Hardness Version Suitable for

machine

mm

122 Medium Perforated FSX 200 Intec 6.25658

125 Soft Perforated Backing pad,

diameter

125 mm

125 Medium-hard Perforated Backing pad,

diameter

125 mm

Velcro-faced intermediate disc

Diameter: 125 mm

Hardness: Soft

Version: Not perforated

Cling-fit polishing sponge

Diameter: Ø 130 mm

Order

no.

6.31220

6.31219

Order

no.

6.31216

6.31222

Cling-fit abrasive nylon web

Diameter: 125 mm

Grit: P 100

Cling-fit abrasive nylon web

Diameter: 125 mm

Grit: P 280

3 cling-fit abrasive meshes

For sanding/grinding

gypsum boards

Diameter: 125 mm

Grit: P 100

Packing unit: 3

FOR FSX 200 INTEC

Dust extraction

Dust collector cartridge

Dust collector cartridge

including dust filter 6.25602

Pleated filter

Pleated filter,

polyester,

for dust collector

cartridge (6.25601)

Connector

Connector Ø 35 mm

for connecting to a

normal vacuum cleaner

FOR SXE 325, SXE 425 TURBOTEC AND

SXE 450 TURBOTEC

Dust collector cartridge

Can be cleaned several times with

pleated filter 6.31980

For SXE 325 (as spare)

Dust collector cartridge

Can be cleaned several times

with pleated filter 6.31980

For SXE 425 TurboTec and

SXE 450 TurboTec (as spare)

NEW

Pleated filter

Polyester (as spare),

for the dust collection box

(6.31981 and 6.25599)

Dust bag holder, complete

As spare,

with 1 dust bag

Dust bag

Without dust bag holder 6.31289,

as space, pack of 5

Order

no.

6.31238

6.31239

6.31215

Order

no.

6.25601

6.25602

6.26996

Order

no.

6.31981

6.25599

6.31980

6.31289

6.31288

158 | 158 |

Cling-fit lambswool

polishing disc

Diameter: 130 mm

Cling-fit polishing felt, hard

Diameter: 130 mm

Thickness: 5 mm

6.31223

6.31242

Dust bag

Can be used in the dust

bag holder (6.31289) instead

of the paper dust bag

provided (6.31288)

Carry case

For SXE 425, SXE 425 XL,

SXE 450 Duo

6.31758

6.23894

Page 10

EQUIPMENT FEATURES

TurboBoost switch: allows additional power reserves

to be employed for achieving maximum removal

Multi-purpose machine for sanding even and cambered surfaces,

wood, plastics, non-ferrous metals, sheet steel

Rotating and additional oscillating movement

of backing pad for optimum finish

Variospeed (V) electronics

Thumbwheel for preselection of speed

Limit scratches while placing the running machine

on the material (Power Control System)

"Duo" Oscillating circuit setting for finishing or more cut

Removable front handle

Dust-proof ball bearing

Sturdy aluminum die cast bearing housing

Velcro-faced backing pad

Vibration damping, non-slip rubber support

on the machine housing and the handle

Dust extraction unit with Intec filter system,

with washable filter cartridge

External dust extraction outlet

SXE 450

TurboTec

NEW

350 Watt

Electronic

Disc Sander

SXE 450 TurboTec

Comparative device characteristics

Diameter of backing pad 150 mm

No load speed 13100 /min

Rated input power 350 W

Output power 180 W

Rated load speed 8.500 /min

Oscillating circuit 2,8/6,2 mm

Weight (without mains cable) 2,2 kg

Standard equipment Velcro-faced backing pad,

3 perforated cling-fit sanding

sheets, allen key, removable side

handle, dust collector cartridge,

1 pleated filter

DISC SANDERS

ACCESSORIES FOR SXE 450 TURBOTEC

Velcro-faced backing pad

Diameter

mm

150 Medium-hard Perforated (6 holes) 6.31158

150 Soft Perforated (6 holes) 6.31156

150 Medium-hard Perforated

Backing pad, for self-adhesive sanding discs

Diameter

mm

150 Medium Perforated (6 holes) 6.31169

Velcro-faced intermediate disc

Additional accessories for SXE 450 TurboTec

Hardness Version Order

(6 or 8 holes)

Hardness Version Order

Velcro-faced intermediate disc

For sanding curved surfaces

Velcro-faced intermediate disc,

for machining curved areas

Diameter: 150 mm

Hardness: Soft

Version: Not perforated

Cling-fit polishing sponge

Diameter: 160 mm

Packing unit: 1

Suitable for machine:

Backing pad,

diameter 150 mm

Cling-fit lambswool polishing disc

For high-gloss polishing

Suitable for: System 150 mm

Diameter: 160 mm

Packing unit: 1

Cling-fit polishing felt

Diameter: 150 mm

Thickness: 5 mm

Cling-fit abrasive nylon web

Diameter: 150 mm

Grit: P 100

Diameter: 150 mm

Grit: P 280

Carry case

For SXE 425, SXE 425 XL,

SXE 450 Duo

no.

6.31150

no.

Order

no.

6.24037

Order

no.

6.31233

6.31217

6.31168

6.24038

6.24039

Order

no.

6.23894

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

MACHINES

WOOD SANDING

Type SXE 450 TurboTec

Order no. 6.00129

Metabox III

6.24619

For SX E 425 Turbo Tec,

SX E 450 Turbo Tec

For SX E 450 Duo, SX E 425 XL

Accessories for the dust intake action are to be found on page 158.

| 159| 159

ROUTERS

AND PLANERS

Page 11

SANDERS

EQUIPMENT FEATURES

Universal use for sanding wood, plastics, metals,

stone and varnished surfaces

Light and handy machine for convenient one-hand operation

Very good weight-performance ratio

Vibration-damping, non-slip rubber coated handle

Dust-proof ball bearing

Velcro-faced base plate and clamp fixture

Dust extraction unit with Intec filter system,

with washable filter cartridge

COMMON FEATURES

Universal use for sanding wood, plastics, metals,

stone and varnished surfaces

Robust sander with long service life even under

tough conditions

Very good weight-performance ratio

High material removal

Even sanding pattern with high class base plate made

of microcellular polyurethane elastomere

Especially vibration-free by electrodynamic fine balancing

4 high quality oscillating buffers and dust-proof quality

ball bearing for long service life with continuous use

Sturdy aluminum die cast oscillating plate

Unique clamping system enables quick and comfortable

change of sanding sheet

Sanding possible up to the outermost corner

External dust extraction outlet

Auto-stop carbon brushes

FSR 200 Intec SR 10-23 Intec SR 20-23

200 Watt

Palm Grip Sander

FSR 200 Intec

Comparative device characteristics

Base plate 114 x 102 mm

Orbital frequency at no-load 26.000 /min

Rated input power 200 W

Output power 80 W

Orbital frequency at rated load 22.000 /min

Oscillating circuit 1,4 mm

Weight (without mains cable) 1,25 kg

Standard equipment 3 cling-fit sanding sheets

(perforated), dust collector

cartridge, 1 pleated filter,

carry case

200 Watt

Sander

SR 10-23 Intec

210 Watt

Sander

SR 20-23

Special advantages

Designed for continuous

commercial use

Solid aluminium die cast

bearing flange

Dust extraction unit with

Intec filter system, multiple

cleaning

Dust extraction unit with

Intec filter system, can be

retrofitted as accessory

Comparative

device characteristics

Base plate 92 x 183 mm 92 x 183 mm

Orbital frequency at no-load 21.700 /min 21.700 /min

Rated input power 200 W 210 W

Output power 90 W 95 W

Orbital frequency at rated

18.000 /min 16.000 /min

load

Oscillating circuit 2,5 mm 2,5 mm

Weight (without mains cable) 1,75 kg 1,8 kg

Type FSR 200 Intec

Order no. 6.00066

160 |

Standard equipment 2 sanding sheets

(perforated),

2 sanding sheets

(perforated)

dust collector

cartridge,

1 pleated filter

Type SR 10-23 Intec SR 20-23

Order no. 6.01024 6.02026

Page 12

COMMON FEATURES

Universal use for sanding wood, plastics, metals,

stone and varnished surfaces

Powerful motor with high capacity reserve

Even sanding pattern with high class base plate made

of microcellular polyurethane elastomere

Especially vibration-free by electrodynamic fine balancing

4 high quality oscillating buffers and dust-proof quality

ball bearing for long service life with continuous use

Solid aluminium die cast bearing housing

Sturdy aluminum die cast oscillating plate

SANDERS

Quick-grip clamping with rubber-coated pressure pad

Sanding possible up to the outermost corner

Dust extraction unit

Dust bag holder with dust retaining flap

External dust extraction outlet

Auto-stop carbon brushes

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

Sr 356 Sr 358 Sr E 357 Sr E 359

350 Watt

Sander

Sr 356

350 Watt

Sander

Sr 358

350 Watt

Electronic Sander

Sr E 357

350 Watt

Electronic Sander

Sr E 359

Special advantages

Variospeed (V) electronics

Thumbwheel for preselection

of orbital frequency

Comparative device characteristics

Base plate 92 x 190 mm 112 x 230 mm 92 x 190 mm 112 x 236 mm

Orbital frequency at no-load 22.000 /min 22.000 /min 12.000 - 22.000 /min 12.000 - 22.000 /min

Rated input power 350 W 350 W 350 W 350 W

Output power 190 W 190 W 190 W 190 W

Orbital frequency at rated load 15.000 /min 15.000 /min 15.000 /min 15.000 /min

Oscillating circuit 2,5 mm 2,5 mm 2,5 mm 2,5 mm

Weight (without mains cable) 2,5 kg 2,7 kg 2,6 kg 2,8 kg

Standard equipment 3 sanding sheets

(perforated), removable

side handle, dust bags

(paper), dust bag holder

3 sanding sheets

(perforated), removable

side handle, dust bags

(paper), dust bag holder

3 sanding sheets

(perforated), removable

side handle, dust bags

(paper), dust bag holder

3 sanding sheets

(perforated), removable

side handle, dust bags

(paper), dust bag holder

MACHINES

WOOD SANDING

Type Sr 356 Sr 358 Sr E 357 Sr E 359

Order no. 6.00356

6.00358

6.00357

6.00359

ROUTERS

AND PLANERS

| 161

Page 13

ACCESSORIES FOR SANDERS

PERFORATED VELCRO-FACED BASE-PLATES

For the palm grip sander FSR 200 Intec

Perforated, velcro-faced

sanding plate FSR 200 Intec

(as spare)

Length: 114 mm

Width: 112 mm

For the Sr 356 and Sr E 357 sanders

The base-plate of sanders

Sr 356/Sr E 357 can be

replaced by the velcro-faced

base-plate

Length: 185 mm

Width: 92 mm

For the Sr 358 and Sr E 359 sanders

The base-plate of sanders

Sr 358/Sr E 359 can be

replaced by the velcro-faced

base-plate

Length: 230 mm

Width: 112 mm

Order

no.

6.25657

Order

no.

6.24736

Order

no.

6.24749

For the sanders SR 10-23, SR 10-23 Intec and SR 20-23

Dust collector cartridge

Can be cleaned several times

with pleated filter 6.31980

Included in delivery with

SR 10-23 Intec

Pleated filter

Polyester (as spare),

for the dust collection

box (6.31981)

For the sanders Sr 356, Sr E 357, Sr 358 and Sr E 359

Dust bag holder, complete

As spare, with 1 dust bag

Dust bag

Without dust bag holder 6.31289,

as space, pack of 5

Dust bag

Can be used in the dust

bag holder (6.31289) instead

of the paper dust bag

provided (6.31288)

Paper dust bag, complete

Sawdust bag (paper)

with connector

(as spare)

Order

no.

6.31981

6.31980

Order

no.

6.31289

6.31288

6.31758

6.31385

Self-adhesive velcro-faced liner for the

Sr 356 and Sr E 357 sanders

The perforated liner is stuck

onto the sanding plate of sanders.

The sanding plate should be free

of dust and grease before applying

the adhesive liner.

Length: 191 mm

Width: 93 mm

DUST EXTRACTION ACCESSORIES

For the palm grip sander FSR 200 Intec

Dust collector cartridge

Dust collector cartridge

including dust filter 6.25602

Pleated filter

Pleated filter, polyester,

for dust collector

cartridge (6.25601)

Connector

Connector Ø 35 mm for

connecting to a normal

vacuum cleaner

Order

no.

6.24709

Order

no.

6.25601

6.25602

6.26996

Hoses

Carry cases

Dust bag

Without dust bag

holder 6.31385,

as space, pack of 5

Suction hose

With connector Ø 58 mm

for bayonet fitting and

rubber connector

(internal Ø 30 mm,

outside Ø 35 mm)

Hose length: 3,5 m

Sheet steel carry case

For Sr 226, Sr E 227, Sr 356,

Sr E 357, Sr 358, Sr E 359

Carry case

For SR 10-23, SR 10-23 Intec,

SR 20-23

6.31286

Order

no.

6.31938

Order

no.

6.31396

6.25448

162 |

162 |

Page 14

BELT SANDERS

EQUIPMENT FEATURES

Powerful and loadable motor with high reserve capacity

Fast and easy sanding belt change

Very good polished section by extremely precise belt path

Excellent sanding results and comfortable operation

by favourable centre of gravity position of the motor

Metabo S-automatic torque limiting clutch

Variospeed (V) electronics

Thumbwheel for preselection of belt speed

Auto-stop carbon brushes

Side handle for ideal machine guidance

Dust extraction unit

External dust extraction outlet

Suitable for stationary use

Accessories

Sanding frame

For accurate sanding

of flat surfaces with the

belt sander Ba E 1075

Length guide

For stationary use

of the sander, can be

tilted up to 45° for

sanding bevels

Bases for sanding belt

Made from

graphite-coated fabric

Packing unit: 2

Base for sanding belt

Comprising: spring sheetsteel with cork lining for

rough grinding work with

rapid material removal

Packing unit: 1

Order

no.

6.31033

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

6.31032

6.31034

6.31037

Ba E 1075

1000 Watt

Electronic

Belt Sander

Ba E 1075

Comparative device characteristics

Torque 7 Nm

Sanding/grinding width 75 mm

Sanding belt supporting surface 75 x 125 mm

No-load belt speed 200 - 380 m/min

Rated input power 1.000 W

Rated load belt speed 320 m/min

Weight (without mains cable) 3,8 kg

Standard equipment Dust bag, 1 sanding belt P 100,

side handle, suction adapter,

base for fixed use

MACHINES

WOOD SANDING

Type Ba E 1075

Order no. 6.01075

| 163

| 163

ROUTERS

AND PLANERS

Page 15

SANDING MEDIUM

SOUND ARGUMENTS.

A quality machine also needs a quality accessory. For

sanders a wide range of accessories are required to give

the best finish for a wide range of materials. Be it for

wood, metal, stone, paint, varnish or filler Metabo has the

Structure and purpose of Metabo abrasive mediums

right accessory for the machine and the material.

At Metabo we do not just make accessories for our own

machines but for other manufactures as well.

The sanding compound

carries the grains and transfers the chip removal forces. Besides high

strength and small expansion, the sanding compound has to render

a sanding process matching flexibility .

Carriers are

– Highly compressed papers of various thicknesses.

– Fabric based on polyester and cotton wool of various strengths.

– Vulcanized fibre as a strong and tear-proof base is the base

material for the (Vulcan) fibre disc.

The abrasive grain

is the actual sanding tool. It penetrates the material to be worked on

and removes the surface. The abrasive grain is anchored on the grainholding medium. High hardness, toughness and a sharp edged

geometry are the most important attributes of the abrasive grain.

For top quality sanding medium only synthetic abrasive grain materials

are used.

Abrasive grain types are

– Corundum (Aluminiumoxide) as a hard, slightly brittle grain

for the processing of metal, wood, lacquers.... of rough- and

fine ground finishes.

– Silicon carbide as a hard, sharp-edged abrasive grain for

processing of lacquer, wood, ceramic, glass, rubber... for rough

and fine ground finish.

– Aluminous zircon as a tough and fine crystalline combination

of Aluminiumoxide and aluminous zircon for the processing

of metal and non-rusting materials.

The bonding agent

anchors the abrasive grain in the sanding compound carrier and

supports it against the forces generated by the removal of the

surface material.

Bonding agents are

– Phenolic resins and partially synthetic resins for sufficient

support with a certain elasticity.

164 |

Abrasive grain

(Corundum,

silicone

carbide)

Sanding compound carrier: Paper, fabric, fibre or a

P-G-combination

Covering

bonding

material

(Phenolic resin)

More

grindactive

Coat

Basic

bond

(Phenolic

resin)

Page 16

The quality of Metabo sanding mediums

SANDING MEDIUM

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

for example for orbital sander:

Wood + metal / wood + metal "professional"

E-paper, pink aluminium oxide, resin bonded

– High quality grinding paper with dense dispersion and high

material removal rate

– For the best results when sanding wood and metal in

professional application

Application:

– For veneers, solid wood, steel- and special steel sheeting, NE-special

steels, light metals. e.g. for sanding veneered and foil covered furniture

parts with hot-melt glue edging, decor sanding on special steel

sheeting, refurbishment sanding and deburring of sheet edges

for example for disc sander:

Wood / wood „classic“

A-/B-Paper, normal corundum, resin-/glue bond

– High quality sanding paper with half-open grain distribution

– Best suited for sanding of wood with an outstanding

price-performance ratio.

Application:

– For wood generally, solid wood, veneers, plastic, acrylic glass, lacquer,

spatula, fillers, e.g. for deburring, cleaning of plywood, veneer-, solid

wood, lacquered surfaces, deburring of veneered furniture edges

for triangular base-plate sanders:

Paint / paint „professional“

B-/C-Paper, pink grade corundum, stearate-coated, resin bonded

– High quality sanding paper with medium-dense grain dispersion

and a high material removal rate

– The special stearate coating ensures a long service life by not clogging

the sanding medium

– For best results when sanding off paint, lacquer, body-filler on wood or

metal on professional application

Application:

– To deburr and clean veneer, solid wood, ply-wood and lacquered sur-

faces, deburring of veneered furniture edges

Special / special „expert“

C-paper/ latex, silicone carbide, synthetic resin bonded, waterproof

– High quality sanding paper with dense grain distribution

– For best results in a professional as well as in a domestic environment.

Ideal for wet-sanding of primed surfaces in body-workshops and on

motorcar repairs

Application:

– Especially for extremely hard surfaces, filler coat, filler, lacquers

of all types e.g. when wet-sanding of primed surfaces and roughing

up of all lacquered surfaces

MACHINES

WOOD SANDING

ROUTERS

AND PLANERS

| 165

Page 17

SANDING MEDIUM

Which sanding medium for which machine and for which manufacturer?

SANDING SHEETS FOR TRIANGULAR

BASE-PLATE SANDERS

93 mm, 6 holes,

velcro

Metabo DSE 130

DSE 170

DSE 300 / Intec

Bosch GDA 280 E

PDA 100

PDA 120E

PDE 180 / E

PDA 240E

PSM 160

Casals BLD 180

VLD 230

Makita BO 4561

95 mm, 6 holes,

velcro

Festo DX 93E/E Plus

100 x 150 mm, 7 holes,

velcro

Festo DS 400/E/EQ

100 x 150 mm, 11 holes,

velcro

Metabo FMS 200 Intec

Bosch PSM 160 A

PSM 80 A

PRIO

105 mm, 6 holes,

velcro

AEG DSE 220

DSE 260

120 mm, 6 holes,

velcro

Kress CDS 280 DSXL

CDS 6425 EXL

SANDING SHEETS

FOR DISC SANDERS

115 mm, 8 holes,

velcro

Bosch PEX11A/AE

PEX 115

Einhell EX 115

Kress CPS 6115-1/E

Peugeot PAE 115

Skil 7415

Stayer LRT 115

Metabo FSX 200 Intec

SXE 125

SXE 425

AEG EX 400

EX 450

EXE 400

Atlas Copco TXE 150

125 mm, 8 holes,

velcro

150 mm, 6 holes,

velcro

150 mm, 8 holes,

velcro

150 mm, 9 holes,

velcro

150 mm, 16 holes,

velcro

Bosch GEX 125A / AC

PEX 12A / AE

PEX 125A - 1

PEX 125 AE

PEX 400AE

De Walt DW 423

Elu ES 55E

Fein MSF 636-1

Festo ES 125 / E

Hitachi TSV 13Y

Kress CPS 6125-1 / E

HEX 6385E

HEX 1385E

Skil 7400

7425

7430

7435

Wegoma LRE 84H

Metabo SXE 425 XL

SXE 450 DUO

Bosch GEX 150AC/ACE

PEX 15AE

PEX 420 AE

DeWalt DW 443

Elu ES 56E/EK

Felisatti TP 521AS/EAS

TP 522 AS

Hilti WFE 380

WFE 450E

Hitachi SAY 150A

Kress 900 HEX

Milwaukee ROS 150 E

Peugeot PRX 150E

Stayer LRT 150

RO 150

Wegoma RX 91 C

AEG EXE 450

Casals VEX 150 E

Fein MSF 636-1

MSF 649-2A/-2B

Makita BO 6030

BO 6040

Festo ET 2E

RO 150E

ES 150/3 EQ/C

ES 150/5 EQ/C

ProTool ESP 150 E

AEG EX 450

EXE 450

Atlas Copco TXE 150

Fein MSF 649-2A /-2B

Holz Her 2445

SANDING SHEETS

FOR SANDERS

80 x 133 mm, 8 holes,

velcro

Atlas Copco VS 11

Black&Decker P 63-01

Bosch GSS 16 A

Felisatti TP 31 E

Festo RS 4 / E / STF

Hitachi SV 8 SA

80 x 166 mm, 8 holes,

tightened

Atlas Copco VS 11

Black&Decker P 63-01

Bosch GSS 16A

Hitachi SV 8 SA

Wegoma LRE 84H

93 x 178 mm, 8 holes,

velcro

Festo LRS 93G

LRS 93M

RS 3/E

RS 4/E/STF

93 x 185 mm, 8 holes,

velcro

Metabo SR 356

SR 357

SR4350

Atlas Copco VS 230/E

VSS 22/E

VSS 260/E

Bosch GSS 23 AE

GSS 230 A/AE

PSS / A/AE

PSS 180A

PSS 240A/AE

Casals KLR 210

Einhell EST 170

Festo RS 3 SFE/E

Hitachi FS 10 SB

Makita 9036

Peugeot PV 240 A

TV 4102

Skil 7300/S

7390

7395

Black&Decker KA 175

KA 186/E

166 |

Page 18

SANDING MEDIUM

93 x 230 mm, 8 holes,

tightened

Metabo SR 10-23

SR 10-23 Intec

SR 20-23

SR 226

SR 356

SR 4350

SRE 227

SRE 357

Atlas Copco VS 230

VSE 230

VSS 260

VSSE 260

Black&Decker BD 175

BD 180 E

CD 400

DN 41 AE

DN 180E

KA 196

Bosch GSS 23/AE

GSS 230A/AE

PSS 23/A/AE

PSS 230

PSS 240A/AE

Festo RS 3 SFE

RS 3E SFE

Makita 9036

3700

Peugeot PV 240 A

TV 4102

Ryobi NS 401

NS 801

S 35

Skil 7300

7330 S

7385

7390

7395

93 x 230 mm, 8 holes,

tightened

AEG VS 230

VSS 260/E

Black&Decker KA 185

KA 185E

93 x 280 mm, 8 holes, tightened

Velcro for extended

grinding disc

Bosch GSS 23AE

GSS 230 A/AE

115 x 103 mm, 6 holes,

velcro

Metabo FSR 200 Intec

Makita BO 4553 / 4554

Hitachi SV 12 SF

115 x 107 mm, 6 holes,

velcro

Bosch GSS 140 A

115 x 115 mm, 8 holes,

velcro

Metabo SRA 60

SRE 217

Hitachi SV 12 SF

Makita 4554

115 x 140 mm, 6 holes,

tightened

Metabo FSR 200 Intec

Makita BO 4553/4554

Hitachi SV 12 SF

115 x 140 mm, 8 holes,

tightened

Black&Decker SR 400

Bosch GSS 9,6V

GSS 140 A

DeWalt DW 411

Makita BO 4553

BO 4554

BO 4556

Ryobi S 605 D

Skil 7576U

115 x 230 mm, 14 holes,

velcro

Metabo SR 358

SR 4351

SRE 359

Atlas Copco VS 280/E

VS 280/SE

VSE 230

VSS 20 E

Black&Decker KA 273

Bosch GSS 28/A/AE

GSS 280A/AE

PSS 28 AE

PSS 280AE

Casals BLR 250

VLR 300

Einhell ERU 270

Elu VS 41

VS 71

Festo RS 1 STF

RS 2 STF/E

Hitachi SV 12SD/V

Kress CRS 6165A

CRS 6175EA

Makita 9045B/N

9046

Peugeot TV 4003

TV 4103

Ryobi NS 6200

NS 6300 A

Skil 666

115 x 280 mm, 14 holes,

tightened

Metabo SR 328

SR 4321

SRE 329

Atlas Copco VS 280/E

VS 280/SE

VSE 230

VSS 20/E

Black&Decker BD 273

DN 41 AE

KA 273

P 63-03/-04/-05

SR 410E

Bosch GSS 28 A

GSS 280A/AE

PSS 28AE

PSS 280AE

115 x 280 mm, 14 holes,

tightened

Casals BLR 250

LN 216

LR 228

Elu VS 41 / 71

Hitachi SV 12 SD/V

Kress CRS 6165A

CRS 6175ES

Makita BO 4900 V

9046

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

MACHINES

WOOD SANDING

ROUTERS

AND PLANERS

| 167

Page 19

ABRASIVE ACCESSORIES

CLING-FIT SANDING SHEETS

FOR MULTISANDERS

Cling-fit sanding sheets for wood and metal,

"professional" series

DimensionsmmGrit Packing

Cling-fit sanding sheets 100 x 150 mm,

7 holes

100 x 150 P 40 25 6.25671

100 x 150 P 60 25 6.25672

100 x 150 P 80 25 6.25673

100 x 150 P 100 25 6.25674

100 x 150 P 120 25 6.25675

100 x 150 P 180 25 6.25676

100 x 150 P 240 25 6.25677

100 x 150 P 320 25 6.25678

Cling-fit sanding sheets for wood,

"classic" series

DimensionsmmGrit Packing

Cling-fit sanding sheets 100 x 150 mm,

11 holes,

2-piece

100 x 150 P 40 10 6.25603

100 x 150 P 60 10 6.25604

100 x 150 P 80 10 6.25605

100 x 150 P 100 10 6.25606

100 x 150 P 120 10 6.25607

100 x 150 P 180 10 6.25608

100 x 150 P 240 10 6.25609

10 cling-fit sanding sheets

Assortment (2 each of P 60, P 80, P 120, P 180, P 240)

Dimensions: 100 x 150 mm

Version: Perforated (11 holes, 2-piece)

Cling-fit sanding sheets for paints and lacquers,

"professional" series

DimensionsmmGrit Packing

Cling-fit sanding sheets 100 x 150 mm,

7 holes

100 x 150 P 40 25 6.25701

100 x 150 P 60 25 6.25702

100 x 150 P 80 25 6.25703

100 x 150 P 100 25 6.25704

100 x 150 P 120 25 6.25705

100 x 150 P 180 25 6.25706

100 x 150 P 240 25 6.25707

100 x 150 P 320 25 6.25708

Cling-fit sanding sheets 100 x 150 mm,

11 holes, 2-piece

100 x 150 P 40 10 6.25611

100 x 150 P 60 10 6.25612

100 x 150 P 80 10 6.25613

100 x 150 P 100 10 6.25614

100 x 150 P 120 10 6.25615

100 x 150 P 180 10 6.25616

100 x 150 P 240 10 6.25617

10 cling-fit sanding sheets

Dimensions: 100 x 150 mm

Version: Perforated (11 holes, 2-piece)

unit

unit

unit

Order

no.

Order

no.

Order

no.

6.25610

Order

no.

Order

no.

6.25618

CLING-FIT SANDING SHEETS

FOR TRIANGULAR BASE-PLATE SANDERS

Cling-fit sanding sheets for wood and metal,

"professional" series

DimensionsmmGrit Packing

Cling-fit sanding sheets 93 x 93 mm,

6 holes

93 x 93 P 40 5 6.24940

93 x 93 P 60 5 6.24941

93 x 93 P 80 5 6.24942

93 x 93 P 100 5 6.24943

93 x 93 P 120 5 6.24944

93 x 93 P 180 5 6.24945

93 x 93 P 240 5 6.24946

93 x 93 P 320 5 6.24947

93 x 93 P 40 25 6.24980

93 x 93 P 60 25 6.24981

93 x 93 P 80 25 6.24982

93 x 93 P 100 25 6.24983

93 x 93 P 120 25 6.24984

93 x 93 P 180 25 6.24985

93 x 93 P 240 25 6.24986

93 x 93 P 320 25 6.24987

Cling-fit sanding sheets 95 x 95 mm,

6 holes

95 x 95 P 40 25 6.25661

95 x 95 P 60 25 6.25662

95 x 95 P 80 25 6.25663

95 x 95 P 80 25 6.25664

95 x 95 P 120 25 6.25665

95 x 95 P 180 25 6.25666

95 x 95 P 240 25 6.25667

95 x 95 P 320 25 6.25668

25 cling-fit sanding sheets

Assortment (10 x P 60, 10 x P 80, 5 x P 120)

Dimensions: 93 x 93 mm

Version: Perforated (6 holes)

Cling-fit sanding sheets for paints and lacquers,

"professional" series

DimensionsmmGrit Packing

Cling-fit sanding sheets 93 x 93 mm,

6 holes

93 x 93 P 40 25 6.25681

93 x 93 P 60 25 6.25682

93 x 93 P 80 25 6.25683

93 x 93 P 100 25 6.25684

93 x 93 P 120 25 6.25685

93 x 93 P 180 25 6.25686

93 x 93 P 240 25 6.25687

93 x 93 P 320 25 6.25688

Cling-fit sanding sheets 95 x 95 mm,

6 holes

95 x 95 P 40 25 6.25691

95 x 95 P 60 25 6.25692

95 x 95 P 80 25 6.25693

95 x 95 P 100 25 6.25694

95 x 95 P 120 25 6.25695

95 x 95 P 180 25 6.25696

95 x 95 P 240 25 6.25697

95 x 95 P 320 25 6.25698

unit

unit

Order

no.

Order

no.

6.24988

Order

no.

168 |

Page 20

ABRASIVE ACCESSORIES

CLING-FIT SANDING SHEETS

FOR DISC SANDERS

Cling-fit sanding sheets for wood and metal,

"professional" series

Diameter

mm

Cling-fit sanding sheets Ø 80 mm,

6 holes

80 P 40 10 6.24041

80 P 60 10 6.24042

80 P 80 10 6.24043

80 P 100 10 6.24044

80 P 120 10 6.24045

80 P 180 10 6.24046

80 P 240 10 6.24047

80 P 320 10 6.24048

80 P 400 10 6.24049

80 P 40 25 6.24051

80 P 60 25 6.24052

80 P 80 25 6.24053

80 P 100 25 6.24054

80 P 120 25 6.24055

80 P 180 25 6.24056

80 P 240 25 6.24057

80 P 320 25 6.24058

80 P 400 25 6.24059

Cling-fit sanding sheets Ø 115 mm,

8 holes

115 P 40 5 6.26097

115 P 60 5 6.26098

115 P 80 5 6.26099

115 P 100 5 6.26100

115 P 120 5 6.26101

115 P 180 5 6.26102

115 P 240 5 6.26103

115 P 320 5 6.26104

115 P 400 5 6.26105

Cling-fit sanding sheets Ø 125 mm,

8 holes

125 P 40 5 6.31226

125 P 60 5 6.31227

125 P 80 5 6.31228

125 P 120 5 6.31229

125 P 180 5 6.31230

125 P 240 5 6.31231

125 P 320 5 6.31236

125 P 400 5 6.31237

125 P 40 25 6.31584

125 P 60 25 6.31585

125 P 80 25 6.31586

125 P 120 25 6.31587

125 P 180 25 6.31588

125 P 240 25 6.31589

125 P 320 25 6.31596

125 P 400 25 6.31597

Grit Packing

unit

Order

no.

Diameter

Grit Packing

mm

Cling-fit sanding sheets Ø 150 mm,

6 holes

150 P 40 5 6.24001

150 P 60 5 6.24002

150 P 80 5 6.24003

150 P 100 5 6.24004

150 P 120 5 6.24005

150 P 180 5 6.24006

150 P 240 5 6.24007

150 P 320 5 6.24008

150 P 400 5 6.24009

150 P 40 25 6.24019

150 P 60 25 6.24020

150 P 80 25 6.24021

150 P 100 25 6.24022

150 P 120 25 6.24023

150 P 180 25 6.24024

150 P 240 25 6.24025

150 P 320 25 6.24026

150 P 400 25 6.24027

Cling-fit sanding sheets Ø 150 mm,

9 holes

150 P 40 25 6.25715

150 P 60 25 6.25716

150 P 80 25 6.25717

150 P 100 25 6.25718

150 P 120 25 6.25719

150 P 180 25 6.25720

150 P 240 25 6.25721

150 P 320 25 6.25722

150 P 400 25 6.25723

25 cling-fit sanding sheets

Assortment (10 x P 60, 10 x P 80, 5 x P 120)

Diameter: 80 mm

Version: Perforated (6 holes)

6 cling-fit sanding sheets

Assortment (2 x P 60, 2 x P 120, 2 x P 240)

Diameter: 115 mm

Version: Perforated (8 holes)

6 cling-fit sanding sheets

Assortment (2 x P 60, 2 x P 120, 2 x P 240)

Diameter: 125 mm

Version: Perforated (8 holes)

25 cling-fit sanding sheets

Assortment (10 x P 60, 10 x P 80, 5 x P 120)

Diameter: 125 mm

Version: Perforated (8 holes)

25 cling-fit sanding sheets

Assortment (10 x P 60, 10 x P 80, 5 x P 120)

Diameter: 150 mm

Version: Perforated (6 holes)

Cling-fit sanding sheets for paints and lacquers,

"professional" series

Diameter

Grit Packing

mm

Cling-fit sanding sheets Ø 80 mm,

6 holes

80 P 40 25 6.24081

80 P 60 25 6.24082

80 P 80 25 6.24083

80 P 100 25 6.24084

80 P 120 25 6.24085

80 P 180 25 6.24086

80 P 240 25 6.24087

80 P 320 25 6.24088

80 P 400 25 6.24089

unit

unit

Order

no.

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

Order

no.

6.24060

6.26106

6.31232

6.31583

6.24066

Order

no.

MACHINES

WOOD SANDING

ROUTERS

AND PLANERS

| 169

Page 21

ABRASIVE ACCESSORIES

Diameter

Grit Packing

mm

Cling-fit sanding sheets Ø 115 mm,

8 holes

115 P 40 5 6.26107

115 P 60 5 6.26108

115 P 80 5 6.26109

115 P 100 5 6.26110

115 P 120 5 6.26111

115 P 180 5 6.26112

115 P 240 5 6.26113

115 P 320 5 6.26114

115 P 400 5 6.26115

Cling-fit sanding sheets Ø 125 mm,

8 holes

125 P 40 25 6.25726

125 P 60 25 6.25727

125 P 80 25 6.25728

125 P 100 25 6.25729

125 P 120 25 6.25730

125 P 180 25 6.25731

125 P 240 25 6.25732

125 P 320 25 6.25733

125 P 400 25 6.25734

Cling-fit sanding sheets Ø 150 mm,

6 holes

150 P 40 25 6.24028

150 P 60 25 6.24029

150 P 80 25 6.24030

150 P 100 25 6.24031

150 P 120 25 6.24032

150 P 180 25 6.24033

150 P 240 25 6.24034

150 P 320 25 6.24035

150 P 400 25 6.24036

Cling-fit sanding sheets Ø 150 mm,

9 holes

150 P 40 25 6.25738

150 P 60 25 6.25739

150 P 80 25 6.25740

150 P 100 25 6.25741

150 P 120 25 6.25742

150 P 180 25 6.25743

150 P 240 25 6.25744

150 P 320 25 6.25745

150 P 400 25 6.25746

25 cling-fit sanding sheets

Assortment (10 x P 60, 10 x P 80, 5 x P 120)

Diameter: 80 mm

Version: Perforated (6 holes)

25 cling-fit sanding sheets

Assortment (10 x P 60, 10 x P 80, 5 x P 120)

Diameter: 115 mm

Version: Perforated (8 holes)

25 cling-fit sanding sheets

Assortment (10 x P 60, 10 x P 80, 5 x P 120)

Diameter: 125 mm

Version: Perforated (8 holes)

25 cling-fit sanding sheets

Assortment (10 x P 60, 10 x P 80, 5 x P 120)

Diameter: 150 mm

Version: Perforated (6 holes)

unit

Order

no.

Order

no.

6.24090

6.26116

6.25735

6.24069

SANDING SHEETS FOR SANDERS /

ORBITAL SANDERS

Sanding sheets wood and metal,

"professional" series

DimensionsmmGrit Packing

Cling-fit sanding sheets 80 x 133 mm,

8 holes,

with velcro

80 x 133 P 40 10 6.25749

80 x 133 P 60 10 6.25750

80 x 133 P 80 10 6.25751

80 x 133 P 100 10 6.25752

80 x 133 P 120 10 6.25753

80 x 133 P 180 10 6.25754

80 x 133 P 240 10 6.25755

80 x 133 P 320 10 6.25756

80 x 133 P 400 10 6.25757

80 x 133 P 40 25 6.26052

80 x 133 P 60 25 6.26053

80 x 133 P 80 25 6.26054

80 x 133 P 100 25 6.26055

80 x 133 P 120 25 6.26056

80 x 133 P 180 25 6.26057

80 x 133 P 240 25 6.26058

80 x 133 P 320 25 6.26059

80 x 133 P 400 25 6.26060

Cling-fit sanding sheets 93 x 185 mm,

8 holes,

with velcro

93 x 185 P 40 10 6.25765

93 x 185 P 60 10 6.25766

93 x 185 P 80 10 6.25767

93 x 185 P 100 10 6.25768

93 x 185 P 120 10 6.25769

93 x 185 P 180 10 6.25770

93 x 185 P 240 10 6.25771

93 x 185 P 320 10 6.25772

93 x 185 P 400 10 6.25773

93 x 185 P 40 25 6.25775

93 x 185 P 60 25 6.25776

93 x 185 P 80 25 6.25777

93 x 185 P 100 25 6.25778

93 x 185 P 120 25 6.25779

93 x 185 P 180 25 6.25780

93 x 185 P 240 25 6.25781

93 x 185 P 320 25 6.25782

93 x 185 P 400 25 6.25783

Sanding sheets 93 x 230 mm,

8 holes,

for clamping

93 x 230 P 40 10 6.24480

93 x 230 P 60 10 6.24481

93 x 230 P 80 10 6.24482

93 x 230 P 100 10 6.24483

93 x 230 P 120 10 6.24484

93 x 230 P 180 10 6.24485

93 x 230 P 240 10 6.24486

93 x 230 P 320 10 6.25761

93 x 230 P 400 10 6.25762

Cling-fit sanding sheets 103 x 115 mm,

6 holes,

with velcro

103 x 115 P 40 10 6.25619

103 x 115 P 60 10 6.25620

103 x 115 P 80 10 6.25621

103 x 115 P 100 10 6.25622

103 x 115 P 120 10 6.25623

103 x 115 P 180 10 6.25624

103 x 115 P 240 10 6.25625

103 x 115 P 320 10 6.25626

103 x 115 P 400 10 6.25627

unit

Order

no.

170 |

Page 22

ABRASIVE ACCESSORIES

DimensionsmmGrit Packing

unit

Sanding sheets 115 x 140 mm,

6 holes,

for clamping

115 x 140 P 40 10 6.25629

115 x 140 P 60 10 6.25630

115 x 140 P 80 10 6.25631

115 x 140 P 100 10 6.25632

115 x 140 P 120 10 6.25633

115 x 140 P 180 10 6.25634

115 x 140 P 240 10 6.25635

115 x 140 P 320 10 6.25636

115 x 140 P 400 10 6.25637

Cling-fit sanding sheets 115 x 230 mm,

14 holes,

with velcro

115 x 230 P 40 10 6.25786

115 x 230 P 60 10 6.25787

115 x 230 P 80 10 6.25788

115 x 230 P 100 10 6.25789

115 x 230 P 120 10 6.25790

115 x 230 P 180 10 6.25791

115 x 230 P 240 10 6.25792

115 x 230 P 320 10 6.25793

115 x 230 P 400 10 6.25794

115 x 230 P 40 25 6.25796

115 x 230 P 60 25 6.25797

115 x 230 P 80 25 6.25798

115 x 230 P 100 25 6.25799

115 x 230 P 120 25 6.25800

115 x 230 P 180 25 6.25801

115 x 230 P 240 25 6.25802

115 x 230 P 320 25 6.25803

115 x 230 P 400 25 6.25804

Sanding sheets 115 x 280 mm,

14 holes,

for clamping

115 x 280 P 40 10 6.24491

115 x 280 P 60 10 6.24492

115 x 280 P 80 10 6.24493

115 x 280 P 100 10 6.24494

115 x 280 P 120 10 6.24495

115 x 280 P 180 10 6.24496

115 x 280 P 240 10 6.24497

10 cling-fit sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 80 x 133 mm

Version: Perforated (8 holes)

10 cling-fit sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 93 x 185 mm

Version: Perforated (8 holes)

10 sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 93 x 230 mm

Version: Perforated (8 holes)

10 sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 103 x 115 mm

Version: Perforated (6 holes)

10 sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 115 x 140 mm

Version: Perforated (6 holes)

10 cling-fit sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 115 x 230 mm

Version: Perforated (14 holes)

10 sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 115 x 280 mm

Version: Perforated (14 holes)

Order

no.

Order

no.

6.25758

6.25774

6.24490

6.25628

6.25638

6.25765

6.24499

Sanding sheets for wood,

"classic" series

DimensionsmmGrit Packing

Cling-fit sanding sheets 93 x 185 mm,

8 holes,

with velcro

93 x 185 P 40 10 6.25813

93 x 185 P 40 10 6.25814

93 x 185 P 80 10 6.25815

93 x 185 P 100 10 6.25816

93 x 185 P 120 10 6.25817

93 x 185 P 180 10 6.25818

93 x 185 P 240 10 6.25819

93 x 185 P 320 10 6.25820

93 x 185 P 40 25 6.25822

93 x 185 P 60 25 6.25823

93 x 185 P 80 25 6.25824

93 x 185 P 100 25 6.25825

93 x 185 P 120 25 6.25826

93 x 185 P 180 25 6.25827

93 x 185 P 240 25 6.25828

93 x 185 P 30 25 6.25829

Sanding sheets 93 x 230 mm,

non-perforated,

for clamping

93 x 230 P 40 10 6.24808

93 x 230 P 60 10 6.24809

93 x 230 P 80 10 6.24810

93 x 230 P 100 10 6.24811

93 x 230 P 120 10 6.24812

93 x 230 P 180 10 6.24813

93 x 230 P 240 10 6.24814

93 x 230 P 320 10 6.25808

Sanding sheets 93 x 230 mm,

8 holes,

for clamping

93 x 230 P 40 10 6.24826

93 x 230 P 60 10 6.24827

93 x 230 P 80 10 6.24828

93 x 230 P 100 10 6.24829

93 x 230 P 120 10 6.24830

93 x 230 P 180 10 6.24831

93 x 230 P 240 10 6.24832

93 x 230 P 320 10 6.25807

Cling-fit sanding sheets 115 x 115 mm,

8 holes,

with velcro

115 x 115 P 40 5 6.24710

115 x 115 P 60 5 6.24711

115 x 115 P 80 5 6.24712

115 x 115 P 100 5 6.24713

115 x 115 P 120 5 6.24714

115 x 115 P 240 5 6.24715

Sanding sheets 115 x 140 mm,

8 holes,

for clamping

115 x 140 P 40 10 6.24700

115 x 140 P 60 10 6.24701

115 x 140 P 80 10 6.24702

115 x 140 P 100 10 6.24703

115 x 140 P 120 10 6.24704

115 x 140 P 240 10 6.24705

unit

Order

no.

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

MACHINES

WOOD SANDING

ROUTERS

AND PLANERS

| 171

Page 23

ABRASIVE ACCESSORIES

DimensionsmmGrit Packing

unit

Cling-fit sanding sheets 115 x 230 mm,

14 holes,

with velcro

115 x 230 P 40 10 6.25832

115 x 230 P 60 10 6.25833

115 x 230 P 80 10 6.25834

115 x 230 P 100 10 6.25835

115 x 230 P 120 10 6.25836

115 x 230 P 180 10 6.25837

115 x 230 P 240 10 6.25838

115 x 230 P 320 10 6.25839

115 x 230 P 40 25 6.25841

115 x 230 P 60 25 6.25842

115 x 230 P 80 25 6.25843

115 x 230 P 100 25 6.25844

115 x 230 P 120 25 6.25845

115 x 230 P 180 25 6.25846

115 x 230 P 240 25 6.25847

115 x 230 P 320 25 6.25848

Sanding sheets 115 x 280 mm,

non-perforated,

for clamping

115 x 280 P 40 10 6.24816

115 x 280 P 60 10 6.24817

115 x 280 P 80 10 6.24818

115 x 280 P 100 10 6.24819

115 x 280 P 120 10 6.24820

115 x 280 P 180 10 6.24821

115 x 280 P 240 10 6.24822

115 x 280 P 320 10 6.25810

Sanding sheets 115 x 280 mm,

14 holes,

for clamping

115 x 280 P 40 10 6.24800

115 x 280 P 60 10 6.24801

115 x 280 P 80 10 6.24802

115 x 280 P 100 10 6.24803

115 x 280 P 120 10 6.24804

115 x 280 P 180 10 6.24805

115 x 280 P 240 10 6.24806

115 x 280 P 320 10 6.25809

10 cling-fit sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 93 x 185 mm

Version: Perforated (8 holes)

10 sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 93 x 230 mm

Version: Perforated (8 holes)

Sanding sheet assortment

Comprising 2 sanding sheets in each of the following grits:

P 40, P 80, P 120, P 180, and P 240

Dimensions: 93 x 230 mm

Version: Not perforated

10 cling-fit sanding sheets

Comprising 2 sanding sheets in each of the following grits:

P 40, P 80, P 120, P 180, and P 240

Dimensions: 115 x 230 mm

Version: Perforated (14 holes)

10 sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 115 x 280 mm

Version: Perforated (14 holes)

10 sanding sheets

Assortment (2 each of P 40, P 80, P 120, P 180 and P 240)

Dimensions: 115 x 280 mm

Version: Not perforated

Order

no.

Order

no.

6.25821

6.24833

6.24815

6.25840

6.24807

6.24823

Sanding sheets for paints and lacquers,

"professional" series

DimensionsmmGrit Packing

Cling-fit sanding sheets 80 x 133 mm,

8 holes,

with velcro

80 x 133 P 40 25 6.25851

80 x 133 P 60 25 6.25852

80 x 133 P 80 25 6.25853

80 x 133 P 100 25 6.25854

80 x 133 P 120 25 6.25855

80 x 133 P 180 25 6.25856

80 x 133 P 240 25 6.25857

80 x 133 P 320 25 6.25858

Cling-fit sanding sheets 93 x 185 mm,

8 holes,

with velcro

93 x 185 P 40 25 6.25881

93 x 185 P 60 25 6.25882

93 x 185 P 80 25 6.25883

93 x 185 P 100 25 6.25884

93 x 185 P 120 25 6.25885

93 x 185 P 180 25 6.25886

93 x 185 P 240 25 6.25887

93 x 185 P 320 25 6.25888

Sanding sheets 93 x 230 mm,

8 holes,

for clamping

93 x 230 P 40 25 6.25861

93 x 230 P 60 25 6.25862

93 x 230 P 80 25 6.25863

93 x 230 P 100 25 6.25864

93 x 230 P 120 25 6.25865

93 x 230 P 180 25 6.25866

93 x 230 P 240 25 6.25867

93 x 230 P 320 25 6.25868

Cling-fit sanding sheets 103 x 115 mm,

6 holes,

with velcro

103 x 115 P 40 10 6.25639

103 x 115 P 60 10 6.25640

103 x 115 P 80 10 6.25641

103 x 115 P 100 10 6.25642

103 x 115 P 120 10 6.25643

103 x 115 P 180 10 6.25644

103 x 115 P 240 10 6.25645

103 x 115 P 320 10 6.25646

Sanding sheets 115 x 140 mm,

6 holes,

for clamping

115 x 140 P 40 10 6.25648

115 x 140 P 60 10 6.25649

115 x 140 P 80 10 6.25650

115 x 140 P 100 10 6.25651

115 x 140 P 120 10 6.25652

115 x 140 P 180 10 6.25653

115 x 140 P 240 10 6.25654

115 x 140 P 320 10 6.25655

unit

Order

no.

172 |

Page 24

ABRASIVE ACCESSORIES

DimensionsmmGrit Packing

Cling-fit sanding sheets 115 x 230 mm,

14 holes,

with velcro

115 x 230 P 40 25 6.25891

115 x 230 P 60 25 6.25892

115 x 230 P 80 25 6.25893

115 x 230 P 100 25 6.25894

115 x 230 P 120 25 6.25895

115 x 230 P 180 25 6.25896

115 x 230 P 240 25 6.25897

115 x 230 P 320 25 6.25898

Sanding sheets 115 x 280 mm,

14 holes,

for clamping

115 x 280 P 40 25 6.25871

115 x 280 P 60 25 6.25872

115 x 280 P 80 25 6.25873

115 x 280 P 100 25 6.25874

115 x 280 P 120 25 6.25875

115 x 280 P 180 25 6.25876

115 x 280 P 240 25 6.25877

115 x 280 P 320 25 6.25878

10 cling-fit sanding sheets

Assortment (2 each of P40, P80, P120, P180, P240)

Dimensions: 103 x 115 mm

Version: Perforated (6 holes)

10 sanding sheets

Assortment (2 each of P40, P80, P120, P180, P240)

Dimensions: 115 x 140 mm

Version: Perforated (6 holes)

unit

Order

no.

Order

no.

6.25647

6.25656

Rolls for wood,

"classic" series

Single sheets

DimensionsmmGrit Packing

unit

Order

no.

Rolls 93 mm x 5 m

93 x 5 P 40 1 6.26003

93 x 5 P 60 1 6.26004

93 x 5 P 80 1 6.26005

93 x 5 P 100 1 6.26006

93 x 5 P 120 1 6.26007

93 x 5 P 180 1 6.26008

93 x 5 P 240 1 6.26009

93 x 5 P 320 1 6.26010

Rolls 115 mm x 5 m

115 x 5 P 40 1 6.26013

115 x 5 P 60 1 6.26014

115 x 5 P 80 1 6.26015

115 x 5 P 100 1 6.26016

115 x 5 P 120 1 6.26017

115 x 5 P 180 1 6.26018

115 x 5 P 240 1 6.26019

115 x 5 P 320 1 6.26020

DimensionsmmGrit Packing

unit

Order

no.

Single sheet (230 x 280 mm)

for wood,

"classic" series

230 x 280 P 40 50 6.26023

230 x 280 P 60 50 6.26024

230 x 280 P 80 50 6.26025

230 x 280 P 100 50 6.26026

230 x 280 P 120 50 6.26027

230 x 280 P 180 50 6.26028

230 x 280 P 240 50 6.26029

230 x 280 P 320 50 6.26030

Single sheets (230x280 mm)

for paints and lacquers,

"professional" series

230 x 280 P 40 50 6.26033

230 x 280 P 60 50 6.26034

230 x 280 P 80 50 6.26035

230 x 280 P 100 50 6.26036

230 x 280 P 120 50 6.26037

230 x 280 P 180 50 6.26038

230 x 280 P 240 50 6.26039

230 x 280 P 320 50 6.26040

Single sheets (230 x 280 mm)

for extremely hard materials,

"expert" series

230 x 280 P 80 50 6.26043

230 x 280 P 100 50 6.26044

230 x 280 P 120 50 6.26045

230 x 280 P 180 50 6.26046

230 x 280 P 240 50 6.26047

230 x 280 P 320 50 6.26048

230 x 280 P 400 50 6.26049

230 x 280 P 600 50 6.26050

230 x 280 P 1200 50 6.26051

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

MACHINES

WOOD SANDING

| 173

ROUTERS

AND PLANERS

Page 25

SANDING MEDIUMS

Which sanding medium for which machine and for which manufacturer?

SANDING BELTS

FOR BELT-SANDERS

60 x 400 mm

63 x 406 mm

65 x 410 mm

75 x 457 mm

75 x 480 mm

75 x 508 mm

Bosch PBS 60

PBS 60E

Skil 5903

593U

Metabo BA 0665

BAE 0666

AEG HBS 65

HBSE 65

Black&Decker BD 83/E

BS 650

DN 83/E

KA 83/E

Holz Her 2405

2406

Kress CBS 6800 /E

Bosch PBS 7

Makita 9910

9911

Peugeot PB 600

TPB 7500

Skil 1100

1200 / H

1205 / H

7600 A

7675 S

Stayer 2 N 75

Elu MHB 157 / E

MHB 158 / E

Black&Decker BD 85

DN 85/E

KA 83

SR 500 E

75 x 533 mm

75 x 575 mm

75 x 610 mm

100 x 533 mm

100 x 560 mm

Metabo BAE 0775

BAE 0875

BAE 1075/0876

AEG HBSE 600

RBSE 75 AE

Atlas Copco HBSE 75

MBSE 705

Black&Decker KA 75/E

Bosch GBS 75A/AE

PBS 75A/AE

Casals LC 75

DeWalt DW 430

DW 431

Felisatti TP 411

Festo BS 75

BS 75 E

BS 75 E-Set

Hitachi SB 75

Holz Her 2410

2411

2420

Makita 9900B

9901

9902

9903

Peugeot PAB 75

Ryobi B 850F / K7

BE 321SF

Skil 594 U

595 U

Stayer LEN 75

Metabo BAE 4350

Hitachi 9924DB

Makita 9920

9924

Ryobi B 7100

Makita M 99

AEG BBS 1100

BBSE 1100

HBS 100 / E

Atlas Copco BBS 100/E

De Walt DW 650

DW 650 E

Elu MHB 90/E/K

Festo BU 25

Ryobi B 422

BE 422 K 5

HB 422/E

100 x 610 mm

Bosch GBS 100A/AE

Hitachi SB10T/V

Makita 9402

9403

9404

9924 DB

Ryobi B 7200 A

BE 424

Wegoma LB 31 EA

100 x 620 mm

Metabo BA 6100

AEG HBS 10 /E

Atlas Copco BBS 100/E

Bosch GBS 100A/AE

Hitachi SB 110

Makita 9402

9924DB

102 x 552 mm

Peugeot RP 102

Skil 1400 / H

1405 / H

105 x 620 mm

Metabo BA 6100

Festo BS 105

BS 105 E

BS105 E-Set

Hitachi SB 110

Holz Her 2422

2423

2424

110 x 620 mm

Casals LC 110

Hitachi SB 110

40 x 303 mm

Bosch GVS 350 AE

PVS 300 AE

6/13 x 451 mm

Black&Decker

Powerfile KA 290

Powerfile KA 292 E

174 |

Page 26

ABRASIVE ACCESSORIES

SANDING BELTS

FOR BELT SANDERS

Sanding belts for wood and metal,

"professional" series

DimensionsmmGrit Packing

Sanding belts 65 x 410 mm

65 x 410 P 40 3 6.31410

65 x 410 P 60 3 6.31411

65 x 410 P 80 3 6.31412

65 x 410 P 100 3 6.31413

65 x 410 P 120 3 6.25901

65 x 410 P 150 3 6.31414

65 x 410 P 180 3 6.25902

65 x 410 P 240 3 6.31415

Sanding belts 75 x 457 mm

75 x 457 P 40 3 6.25905

75 x 457 P 60 3 6.25906

75 x 457 P 80 3 6.25907

75 x 457 P 100 3 6.25908

75 x 457 P 120 3 6.25909

75 x 457 P 150 3 6.25910

75 x 457 P 180 3 6.25911

75 x 457 P 240 3 6.25912

Sanding belts 75 x 480 mm

75 x 480 P 80 3 6.25916

75 x 480 P 60 3 6.25917

75 x 480 P 80 3 6.25918

75 x 480 P 100 3 6.25919

75 x 480 P 120 3 6.25920

75 x 480 P 150 3 6.25921

75 x 480 P 180 3 6.25922

75 x 480 P 240 3 6.25923

Sanding belts 75 x 533 mm

75 x 533 P 40 3 6.31001

75 x 533 P 60 3 6.31002

75 x 533 P 80 3 6.31003

75 x 533 P 100 3 6.31004

75 x 533 P 120 3 6.31005

75 x 533 P 150 3 6.25927

75 x 533 P 180 3 6.31006

75 x 533 P 240 3 6.31007

75 x 533 P 320 3 6.31008

75 x 533 P 40 10 6.25929

75 x 533 P 60 10 6.25930

75 x 533 P 80 10 6.25931

75 x 533 P 100 10 6.25932

75 x 533 P 120 10 6.25933

75 x 533 P 150 10 6.25934

75 x 533 P 180 10 6.25935

75 x 533 P 240 10 6.25936

75 x 533 P 320 10 6.25937

Sanding belts 75 x 575 mm

75 x 575 P 40 3 6.25940

75 x 575 P 60 3 6.25941

75 x 575 P 80 3 6.25942

75 x 575 P 100 3 6.25943

75 x 575 P 120 3 6.25944

75 x 575 P 150 3 6.25945

75 x 575 P 180 3 6.25946

75 x 575 P 240 3 6.25947

Sanding belts 75 x 610 mm

75 x 610 P 40 3 6.25951

75 x 610 P 60 3 6.25952

75 x 610 P 80 3 6.25953

75 x 610 P 100 3 6.25954

75 x 610 P 120 3 6.25955

75 x 610 P 150 3 6.25956

75 x 610 P 180 3 6.25957

75 x 610 P 240 3 6.25958

unit

Order

no.

DimensionsmmGrit Packing

Sanding belts 100 x 560 mm

100 x 560 P 40 3 6.25962

100 x 560 P 60 3 6.25963

100 x 560 P 80 3 6.25964

100 x 560 P 100 3 6.25965

100 x 560 P 120 3 6.25966

100 x 560 P 150 3 6.25967

100 x 560 P 180 3 6.25968

100 x 560 P 240 3 6.25969

Sanding belts 100 x 610 mm

100 x 610 P 40 3 6.25973

100 x 610 P 60 3 6.25974

100 x 610 P 80 3 6.25975

100 x 610 P 100 3 6.25976

100 x 610 P 120 3 6.25977

100 x 610 P 150 3 6.25978

100 x 610 P 180 3 6.25979

100 x 610 P 240 3 6.25980

Sanding belts 100 x 620 mm

100 x 620 P 40 3 6.25984

100 x 620 P 60 3 6.25985

100 x 620 P 80 3 6.25986

100 x 620 P 100 3 6.25987

100 x 620 P 120 3 6.25988

100 x 620 P 150 3 6.25989

100 x 620 P 180 3 6.25990

100 x 620 P 240 3 6.25991

100 x 620 P 40 10 6.25993

100 x 620 P 60 10 6.25994

100 x 620 P 80 10 6.25995

100 x 620 P 100 10 6.25996

100 x 620 P 120 10 6.25997

100 x 620 P 150 10 6.25998

100 x 620 P 180 10 6.25999

100 x 620 P 240 10 6.26000

3 sanding belts

Assortment ( 1 each of P60, P80, P100)

Dimensions: 65 x 410 mm

3 sanding belts

Assortment ( 1 each of P60, P80, P100)

Dimensions: 75 x 457 mm

3 sanding belts

Assortment ( 1 each of P60, P80, P100)

Dimensions: 75 x 480 mm

3 sanding belts

Assortment ( 1 each of P60, P80, P100)

Dimensions: 75 x 533 mm

3 sanding belts

Assortment ( 1 each of P60, P80, P100)

Dimensions: 75 x 575 mm

3 sanding belts

Assortment ( 1 each of P60, P80, P100)

Dimensions: 75 x 610 mm

3 sanding belts

Assortment ( 1 each of P60, P80, P100)

Dimensions: 100 x 560 mm

3 sanding belts

Assortment ( 1 each of P60, P80, P100)

Dimensions: 100 x 610 mm

3 sanding belts

Assortment ( 1 each of P60, P80, P100)

Dimensions: 100 x 620 mm

unit

Order

no.

Order

no.

6.25903

6.25913

6.25924

6.25928

6.25948

6.25959

6.25970

6.25981

6.25992

ANGLE GRINDERSMETAL PROCESORSHAMMERSIMPACT DRILLSDRILLSSCREWDRIVERS

MACHINES

WOOD SANDING

ROUTERS

AND PLANERS

| 175

Loading...

Loading...