Page 1

www.metabo.com Made in Germany

en Original instructions 5

WA 14-125 Ergo

WA 14-150 Ergo

Page 2

2

E

12

10A

2

2

10B

C

D

1

2

3 4 5

6

7

8

9

11

10

A

B

Page 3

3

WA 14-125 Ergo WA 14-150 Ergo

D

max

mm (in)

125 (5) 150 (6)

t

max1

; t

max2

; t

max3

mm (in)

10; 8; 6

(

3

/8; 5/16; 1/4)

M / l - / mm (in)

M 14 / 20 (25/32)

n min

-1

(rpm)

10000 10000

P

1

W

1400 1400

P

2

W

800 800

m kg (lbs)

2,8 (6.2) 2,8 (6.2)

a

h,SG/Kh,SG

m/s

2

4 / 1,5 5 / 1,5

a

h,DS/Kh,DS

m/s

2

< 2,5 / 1,5 < 2,5/ 1,5

LpA/K

pA

dB(A)

93 / 3 93 / 3

LWA/K

WA

dB(A)

104 / 3 104 / 3

14.

*1) Serial Number: 06252.. *1) Serial Number: 06253..

*2) 2011/65/EU 2006/42/EC 2004/108/EC

*3) EN 60745

2013-10-08, Volker Siegle

Direktor Innovation, Forschung und Entwicklung

(Director Innovation, Research and Development)

*4) Metabowerke GmbH - Metabo-Allee 1 - 72622 Nuertingen, Germany

Page 4

4

G

H

I

J

K

L

M

B

N

O

P

P

EE

D

C

A

(M 14) 6.30706

D

max

= 125 mm (5“) 6.30367

D

max

= 150 mm (6“) 6.30368

(M 14) 6.30800

F

H

(10) (11)

(9)

Page 5

ENGLISH en

5

Original instructions

We declare under our sole responsibility: These

angle grinders, identified by type and serial number

*1), comply with all relevant requirements of the

directives *2) and standards *3). Technical file at *4)

- see page 3.

Machines fitted with original Metabo accessories

are suitable for grinding, sanding, separating and

wire brushing metal, concrete, stone and similar

materials without the use of water.

The user bears sole responsibility for any damage

caused by improper use.

Generally accepted accident prevention

regulations and the enclosed safety information

must be observed.

For your own protection and for the

protection of your electrical tool, pay

attention to all parts of the text that are

marked with this symbol!

WARNING – Reading the operating instructions will reduce the risk of injury.

Pass on your electrical tool only together with these

documents.

General Power Tool Safety Warnings

WARNING – Read all safety warnings and

all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for future

reference! The term "power tool" in the warnings

refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

3.1 Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

3.2 Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3.3 Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your finger on the switch or energising power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

3.4 Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

1. Conformity Declaration

2. Specified Use

3. General Safety Instructions

Page 6

ENGLISHen

6

power tool will do the job better and safer at the rate

for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool's operation. If

damaged, have the power tool repaired before

use. Many accidents are caused by poorly

maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

3.5 Service

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

4.1 Safety Warnings Common for Grinding,

Sanding, Wire Brushing or Abrasive

Cutting-Off Operations:

a) This power tool is intended to function as a

grinder, sander, wire brush or cut-off tool. Read

all safety warnings, instructions, illustrations

and specifications provided with this power

tool. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious

injury.

b) Operations such as polishing are not

recommended to be performed with this power

tool. Operations for which the power tool was not

designed may create a hazard and cause personal

injury.

c) Do not use accessories which are not

specifically designed and recommended by the

tool manufacturer. Just because the accessory

can be attached to your power tool, it does not

assure safe operation.

d) The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their rated speed can break and fly apart.

e) The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories cannot be adequately guarded or

controlled.

f) Threaded mounting of accessories must

match the grinder spindle thread. For accessories mounted by flanges, the arbour hole of the

accessory must fit the locating diameter of the

flange. Accessories that do not match the mounting

hardware of the power tool will run out of balance,

vibrate excessively and may cause loss of control.

g) Do not use a damaged accessory. Before

each use inspect the accessory such as

abrasive wheels for chips and cracks, backing

pad for cracks, tear or excess wear, wire brush

for loose or cracked wires. If a power tool or

accessory is dropped, inspect for damage or

install an undamaged accessory. After

inspecting and installing an accessory,

position yourself and bystanders away from

the plane of the rotating accessory and run the

power tool at maximum no-load speed for one

minute. Damaged accessories will normally break

apart during this test time.

h) Wear personal protective equipment.

Depending on application, use face shield,

safety goggles or safety glasses. As

appropriate, wear dust mask, hearing

protectors, gloves and workshop apron

capable of stopping small abrasive or

workpiece fragments. The eye protection must be

capable of stopping flying debris generated by

various operations. The dust mask or respirator

must be capable of filtering particles generated by

your operation. Prolonged exposure to high

intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from

work area. Anyone entering the work area must

wear personal protective equipment. Fragments

of workpiece or of a broken accessory may fly away

and cause injury beyond immediate area of

operation.

j) Hold power tool by insulated gripping

surfaces only, when performing an operation

where the cutting accessory may contact

hidden wiring or its own cord. A cutting

accessory contacting a "live" wire may make

exposed metal parts of the power tool "live" and

give the operator an electric shock.

k) Position the cord clear of the spinning

accessory. If you lose control, the cord may be cut

or snag ged and your h and or arm ma y be pul led in to

the spinning accessory.

I) Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grab the surface and pull

the power tool out of your control.

m) Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

4. Special Safety Instructions

Page 7

ENGLISH en

7

accessory could snag your clothing, pulling the

accessory into your body.

n) Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

o) Do not operate the power tool near

flammable materials. Sparks could ignite these

materials.

p) Do not use accessories that require liquid

coolants. Using water or other liquid coolants may

result in electrocution or shock.

4.2 Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or any

other accessory. Pinching or snagging causes rapid

stalling of the rotating accessory which in turn

causes the uncontrolled power tool to be forced in

the direction opposite of the accessory’s rotation at

the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into the

surface of the material causing the wheel to climb

out or kick out. The wheel may either jump toward or

away from the operator, depending on direction of

the wheel’s movement at the point of pinching.

Abrasive wheels may also break under these

conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below.

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use the auxiliary

handle, if provided, for maximum control over

kickback or torque reaction during start-up.

The operator can control torque reactions or

kickback forces, if proper precautions are taken.

b) Never place your hand near the rotating

accessory. Accessory may kickback over your

hand.

c) Do not position your body in the area

where power tool will move if kickback occurs.

Kickback will propel

the tool in direction opposite to the wheel’s

movement at the point of snagging.

d) Use special care when working corners,

sharp edges etc. Avoid bouncing and snagging

the accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory and

cause loss of control or kickback.

e) Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades create

frequent kickback and loss of control.

4.3 Safety Warnings Specific for Grinding

and Cutting-Off Operations:

a) Use only wheel types that are recommended

for your power tool and the specific guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot be

adequately guarded and are unsafe.

b) The grinding surface of centre depressed

wheels must be mounted below the plane of

the guard lip. An improperly mounted wheel that

projects through the plane of the guard lip cannot be

adequately protected.

c) The guard must be securely attached to the

power tool and positioned for maximum safety,

so the least amount of wheel is exposed

towards the operator. The guard helps to protect

operator from broken wheel fragments and

accidental contact with wheel.

d) Wheels must be used only for recommended

applications.

For example: do not grind with the side of cutoff wheel. Abrasive cut-off wheels are intended for

peripheral grinding, side forces applied to these

wheels may cause them to shatter.

e) Always use undamaged wheel flanges that

are of correct size and shape for your selected

wheel. Proper wheel flanges support the wheel

thus reducing the possibility of wheel breakage.

Flanges for cut-off wheels may be different from

grinding wheel flanges.

f) Do not use worn down wheels from larger

power tools. Wheels intended for larger power

tools are not suitable for the higher speed of a

smaller tool and may burst.

4.4 Additional Safety Warnings Specific for

Abrasive Cutting-Off Operations:

a) Do not “jam” the cut-off wheel or apply

excessive pressure. Do not attempt to make an

excessive depth of cut. Overstressing the wheel

increases the loading and susceptibility to twisting

or binding of the wheel in the cut and the possibility

of kickback or wheel breakage.

b) Do not position your body in line with and

behind the rotating wheel. When the wheel, at the

point of operation, is moving away from your body,

the possible kickback may propel the spinning

wheel and the power tool directly at you.

c) When wheel is binding or when interrupting

a cut for any reason, switch off the power tool

and hold the power tool motionless until the

wheel comes to a complete stop. Never attempt

to remove the cut-off wheel from the cut while

the wheel is in motion otherwise kickback may

occur. Investigate and take corrective action to

eliminate the cause of wheel binding.

d) Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully reenter the cut. The wheel may bind,

walk up or kickback if the power tool is restarted in

the workpiece.

e) Support panels or any oversized workpiece

to minimize the risk of wheel pinching and

kickback. Large workpieces tend to sag under their

own weight. Supports must be placed under the

workpiece near the line of cut and near the edge of

the workpiece on both sides of the wheel.

Page 8

ENGLISHen

8

f) Use extra caution when making a "pocket

cut" into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes,

electrical wiring or objects that can cause kickback.

4.5 Safety Warnings Specific for Sanding

Operations:

a) Do not use excessively oversized sanding

disc paper. Follow manufacturer's

recommendations when selecting sanding

paper. Larger sanding paper extending beyond the

sanding pad presents a laceration hazard and may

cause snagging, tearing of the disc or kickback.

4.6 Safety Warnings Specific for Wire

Brushing Operations:

a) Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive

load to the brush. The wire bristles can easily

penetrate light clothing and/or skin.

b) If the use of a guard is recommended for wire

brushing, do not allow any interference of the

wire wheel or brush with the guard. Wire wheel

or brush may expand in diameter due to work load

and centrifugal forces.

4.7 Additional Safety Instructions

WARNING – Always wear protective

goggles.

Use elastic cushioning layers if they have been

supplied with the abrasive and if required.

Observe the specifications of the tool or accessory

manufacturer! Protect the discs from grease or

impacts!

Grinding discs must be stored and handled with

care in accordance with the manufacturer's

instructions.

Never use parting grinder discs for roughing work!

Do not apply pressure to the side of parting grinder

discs.

The workpiece must lay flat and be secured against

slipping, e.g. using clamps. Large workpieces must

be sufficiently supported.

If accessories with threaded inserts are used, the

end of the spindle may not touch the base of the

hole on the grinding tool. Make sure that the thread

in the accessory is long enough to accommodate

the full length of the spindle. The thread in the

accessory must match the thread on the spindle.

See page 2 and chapter 14. Technical

Specifications for more information on the spindle

length and thread.

During machining, of metals in

particular, conductive dust can form

deposits inside the machine. This can lead to the

transfer of electrical energy onto the machine

housing. This can mean a temporary danger of

electric shocks. This is why it is necessary when the

machine is running to blow compressed air through

the rear ventilation slots of the machine regularly,

frequently and thoroughly. Here, the machine must

be held firmly.

It is recommended to use a stationary extraction

system and to place a ground fault circuit interrupter

(GFCI) downstream. When the angle grinder is shut

down via the FI circuit breaker, it must be checked

and cleaned. See chapter

9. Cleaning for more information on cleaning the

motor.

Dust from material such as paint containing lead,

some wood species, minerals and metal may be

harmful. Contact with or inhalation of the dust may

cause allergic reactions and/or respiratory diseases

to the operator or bystanders.

Certain kinds of dust are classified as carcinogenic

such as oak and beech dust especially in

conjunction with additives for wood conditioning

(chromate, wood preservative). Material containing

asbestos must only be treated by specialists.

- Where the use of a dust extraction device is

possible it shall be used.

- The work place must be well ventilated.

- The use of a dust mask of filter class P2 is

recommended.

Follow national requirements for the materials you

want to work with.

Materials that generate dusts or vapours that may

be harmful to health (e.g. asbestos) must not be

processed.

When working in dusty conditions, ensure that

ventilation openings are not blocked. If it becomes

necessary to remove dust, first disconnect the

power tool from the mains supply (use non-metallic

objects) and avoid damaging internal components.

Damaged, eccentric or vibrating tools must not be

used.

Avoid damage to gas or water pipes, electrical

cables and loadbearing walls (static).

Connect a FI circuit-breaker with max.

release current (30 mA) upstream when using the

machine outdoors!

Pull the plug out of the socket before making any

adjustments, converting or servicing the machine.

A damaged or cracked additional handle must be

replaced. Never operate a machine with a defective

additional handle.

A damaged or cracked safety guard must be

replaced. Never operate a machine with a defective

safety guard.

Do not switch on the machine if tool parts or guard

devices are missing or defective.

This power tool is not suitable for polishing work.

Improper use of the machine will void the warranty!

The motor may overheat and damage the electric

power tool. We recommend using our angle

polisher for polishing work.

Page 9

ENGLISH en

9

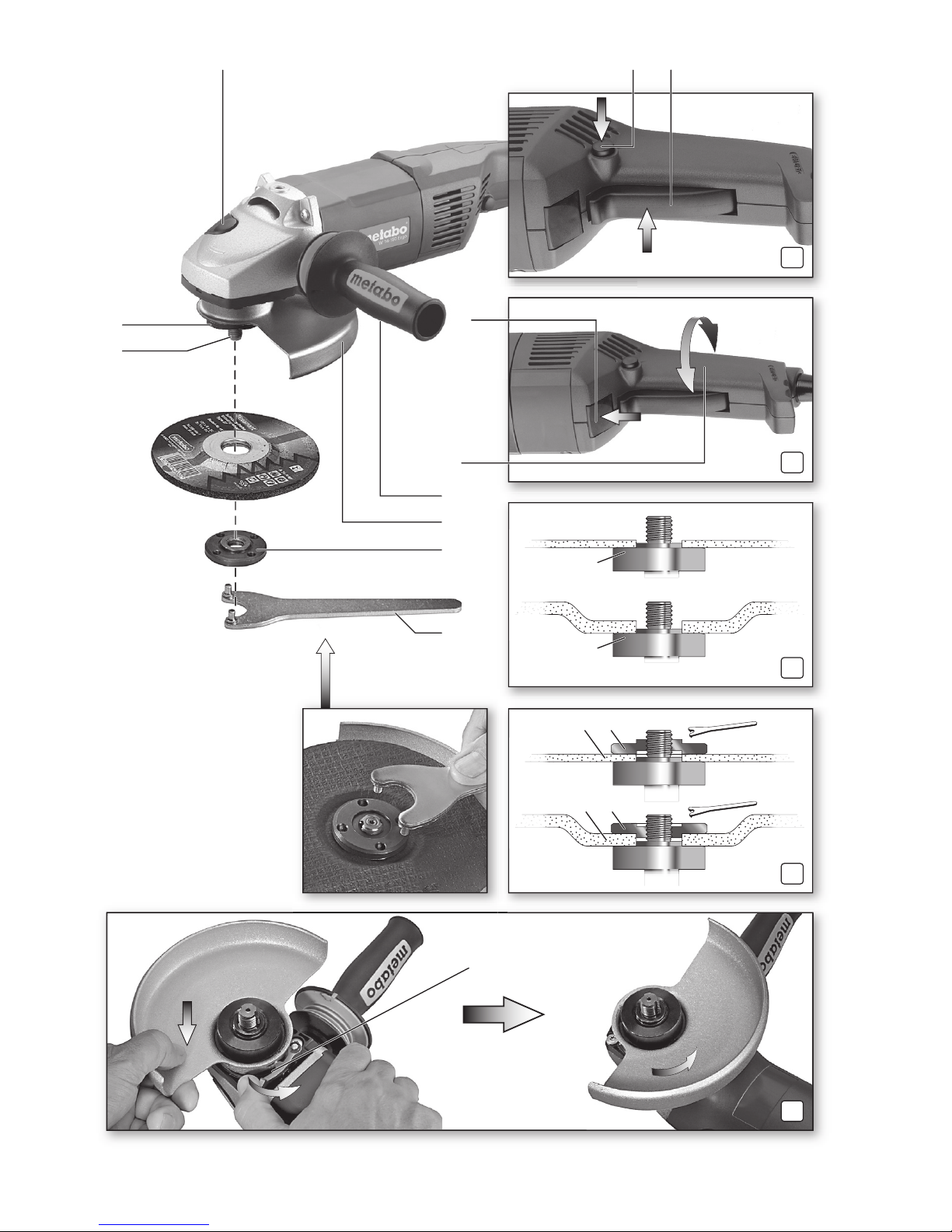

See page 2.

1Spindle

2 Autobalancer support flange (non-detachable)

3 Spindle locking button

4 Lock (to prevent the machine from being switched

on unintentionally, or for continuous operation)*

5 Trigger (

for switching on and off)

6 Button (to turn the main handle)*

7 Main handle

8 Additional handle / Additional handle with vibration

damping *

9 Safety guard

10 Clamping nut *

11 2-hole spanner *

12 Lever (to adjust safety guard without the use of

tools)

* depending on equipment/not in scope of delivery

Before plugging in, check to see that the rated

mains voltage and mains frequency, as

specified on the rating label, match your power

supply.

6.1 Attaching the additional handle

Always work with the additional handle

attached (8)! Manually screw in the additional

handle securely in the left, centre or right threaded

hole (depending on requirements).

6.2 Attaching the safety guard

(for work involving grinding wheels)

For reasons of safety, the safety guard (9)

should always be attached when roughing

work is performed.

For reasons of safety, the special parting

guard should always be attached before

parting work is performed (see chapter 11.

Accessories).

See illustration E on page 2.

- Push and hold the lever (12). Place the safety

guard (9) in the position indicated.

- Release the lever and turn the safety guard until

the lever engages.

- Push the lever and turn the safety guard until the

closed section is facing the operator.

- Make sure that the guard is seated securely: the

lever must engage and you should not be able to

turn the safety guard.

6.3 Rotatable main handle

Only work with the main handle (7) engaged.

See illustration B on page 2.

- Push in the button (6).

- The main handle (7) can now be turned 90° to both

sides and can be engaged.

- Make sure that it is securely positioned: the main

handle (7) must be engaged and it should not be

possible to move it.

6.4 Power supply

The mains sockets must be protected using timedelay fuses or circuit breakers.

Disconnect the mains plug before changing

any accessories. The machine must be

switched off and the spindle at a standstill.

For reasons of safety, attach the parting guard

before performing parting work (see chapter

11. Accessories).

7.1 Locking the spindle

Press in the spindle locking button (3) only

when the spindle is stationary!

- Press in the spindle locking button (3) and turn the

spindle

(1) by hand until you feel the spindle locking

button engage.

7.2 Placing the grinding wheel in position

See illustration C on page 2.

The Autobalancer support flange (2) is

permanently fitted on the spindle. As is the

case with most other angle grinders, a detachable

support flange is not necessary.

The contact surfaces of the Autobalancer

support flange (2), grinding wheel and the

adjusting nut (10) must be clean. Clean if

necessary.

- Place the grinding wheel on the Autobalancer

support flange (2) (see illustrations above).

The grinding wheel must lie flat on the

Autobalancer supporting flange. The metal flange

on the parting grinder discs must lie flat on the

Autobalancer support flange.

7.3 Securing/Releasing the clamping nut

Securing the clamping nut (10):

The 2 sides of the clamping nut are different. Screw

the clamping nut onto the spindle as follows:

See illustration D on page 2.

- A) For thin grinding wheels:

The edge of the clamping nut (10) faces upwards

so that the thin grinding wheel can be attached

securely.

B) For thick grinding wheels:

The edge of the clamping nut (10) faces

downwards so that the clamping nut can be

attached securely to the spindle.

- Lock the spindle. Turn the clamping nut (10)

clockwise using the 2-hole spanner (11) to

secure.

5. Overview

6. Commissioning

7. Attaching the grinding wheel

Page 10

ENGLISHen

10

Releasing the clamping nut:

- Lock the spindle (see chapter 7.1). Turn the

clamping nut (10) anticlockwise using the 2-hole

spanner (11) to unscrew.

8.1 Switching On and Off

Always guide the machine with both hands.

Switch on first, then guide the

accessory

towards the workpiece.

The machine must not be allowed to draw in

additional dust and shavings. When switching

the machine on and off, keep it away from dust

deposits. After switching off the machine, only place

it down when the motor has come to a standstill.

Avoid inadvertent starts: always switch the

tool off when the plug is removed from the

mains socket or if there has been a power cut.

In continuous operation, the machine

continues running if it is forced out of your

hands. Therefore, always hold the machine with

both hands at the intended handles, take a secure

stance and concentrate on the work.

See illustration A on page 2.

Switching the angle grinder ON just for a

moment:

Switching on:

Press in the lock (4) and then press

the trigger switch (5). Let go of the lock (4).

Switching off:

Release the trigger switch (5).

Continuous operation (depends on machine

features):

Switching on:

Press in the lock (4) and hold in place.

Press and hold the trigger switch (5). The

machine is now switched on. Now press in

the lock (4) a second time to lock the trigger

switch (5) in position (continuous operation).

Switching off:

Press and release the trigger switch

(5).

8.2 Working instructions

Grinding:

Press down the machine evenly on the surface and

move back and forth so that the surface of the

workpiece does not become too hot.

Roughing: position the machine at an angle of 30° 40° for the best working results.

Separating:

Always work against the run of the disc

(see illustration). Otherwise there is

the danger of the machine kicking

back from the cut out of control. Guide

the machine evenly at a speed

suitable for the material being processed. Do not tilt,

apply excessive force or sway from side to side.

Sanding:

Press down the machine evenly on the surface and

move back and forth so that the surface of the

workpiece does not become too hot.

Wire brushing:

Press down the machine evenly.

Motor cleaning: blow compressed air through the

rear ventilation slots of the machine regularly,

frequently and thoroughly. Here, the machine must

be held firmly.

Button (6) for adjustment of the handle:

Occasionally blow compressed air through the

button (when pressed, in all 3 main handle

positions).

Switching on procedures produce brief reductions

in voltage. Unfavourable power conditions can be

detrimental to other devices. Power impedances

smaller than 0.4 ohm should not cause any

malfunction.

Use only genuine Metabo accessories.

If you need any accessories, check with your

dealer.

The dealer needs to know the exact model

designation of your power tool in order to select the

correct accessory.

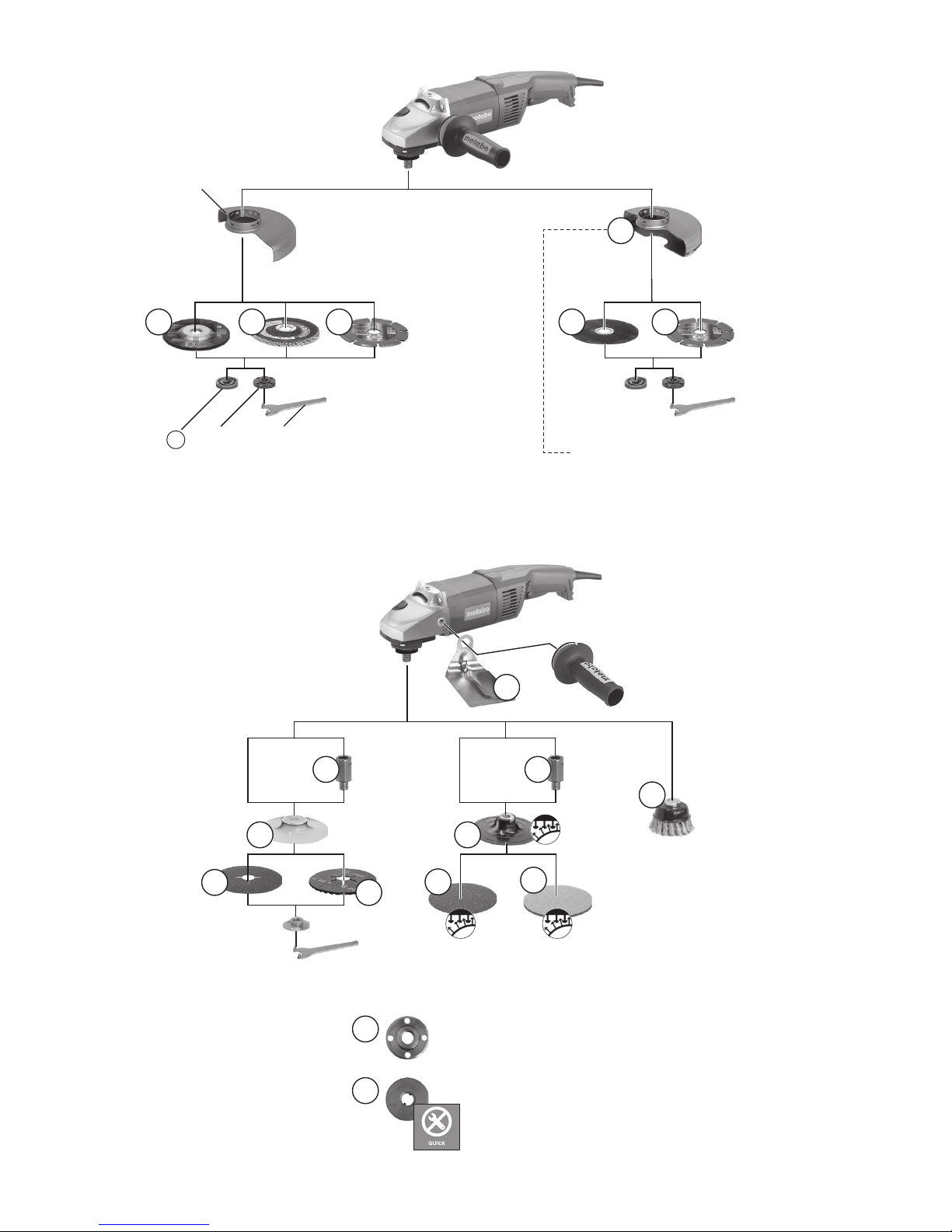

See page 4.

A Roughing disc (always use with safety guard

attached)

B Louver disc (always use with safety guard

attached)

C Parting safety guard.

D Parting disc (always use with parting safety

guard attached)

E Diamond discs (always use with parting safety

guard attached)

F Hand guard (for attaching under the additional

side-mounted handle.)

G Extension piece (for working with supporting

discs. Increases the distance between the

spindle and the supporting disc by approx.

35 mm)

H Supporting disc for fibre discs (always attach

using the supporting disc clamping nut

supplied.) (always use with the hand guard

attached.)

I Fibre discs (always use with the hand guard

attached.)

J Semi-flexible sanding discs (for use with elastic

supporting disc 6.23279) (always use with hand

guard attached.)

K Sanding pad with Velcro (always use with the

hand guard attached.)

L Adhesive sanding disc (always use with the

hand guard attached.)

M Adhesive fleece (always use with the hand

guard attached.)

N

Steel wire brushes

(always use with the hand

guard attached.)

8. Use

9. Cleaning

10. Troubleshooting

11. Accessories

Page 11

ENGLISH en

11

O Adjusting nut (10)

P "Quick" clamping nut

For complete range of accessories, see

www.metabo.com or refer to the main catalogue.

Repairs to electrical tools must be carried out

by qualified electricians ONLY!

Any Metabo power tool in need of repair can be sent

to one of the addresses listed in the spare parts list.

Please enclose a description of the fault to the

power tool.

The sanding dust generated may contain

hazardous materials: do not dispose of with the

household waste, but at a special collection point

for hazardous waste.

Metabo packaging is 100% recycled. Scrap power

tools and accessories contain large amounts of

valuable resources and plastics that can be

recycled.

Only for EU countries: Never dispose of

power tools in your household waste! In

accordance with European Guideline 2002/

96/EC on used electronic and electric equipment

and its implementation in national legal systems,

used power tools must be collected separately and

handed in for environmentally compatible recycling.

These instructions are printed on chlorine-free

bleached paper.

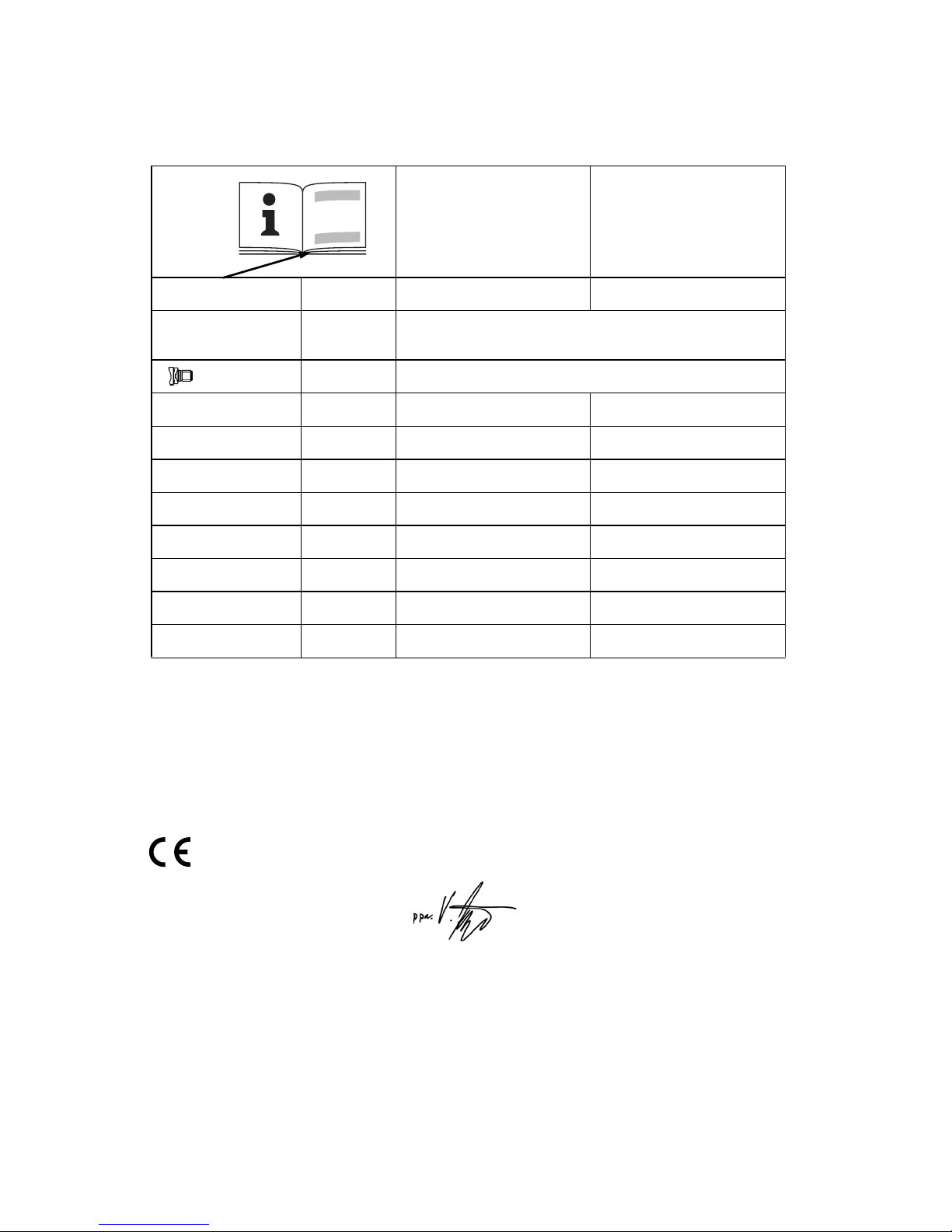

Explanation of details on page 3. Subject to

changes serving technical progress.

D

max

=Maximum sanding disc diameter

t

max,1

= max. permitted thickness of clamping

shank on accessory when using clamping

nut (10)

t

max,2

= max. permitted thickness of clamping

shank on accessory when using

"Quick"clamping nut

t

max,3

=Roughing disc/Parting disc:

max. permitted thickness of accessory

M=Spindle thread

l =Length of the grinding spindle

n =No-load speed (maximum speed)

P

1

= Nominal power input

P

2

=Power output

m = Weight without mains cable

Measured values determined in conformity with

EN 60745.

Machine in protection class II

~ Alternating current

The technical specifications quoted are subject to

tolerances (in compliance with the relevant valid

standards).

Emission values

These values make it possible to assess the emissions from the power tool and to compare different

power tools. Depending on the operating conditions, the condition of the power tool or the accessories, the actual load may be higher or lower. For

assessment purposes, please allow for breaks and

periods when the load is lower. Based on the

adjusted estimates, arrange protective measures

for the user e.g. organisational measures.

Vibration total value

(vector sum of three directions)

determined in accordance with EN 60745:

a

h, SG

= Vibration emission value

(surface grinding)

a

h, DS

= Vibration emission value

(disc sanding)

K

h,SG/DS

= Uncertainty (vibration)

Typical A-effective perceived sound levels

:

L

pA

=Sound pressure level

L

WA

=Acoustic power level

KpA, KWA= Uncertainty

During operation the noise level can exceed

80 dB(A).

Wear ear protectors!

12. Repairs

13. Environmental Protection

14. Technical Specifications

Page 12

Metabowerke GmbH,

72622 Nuertingen, Germany

www.metabo.com

170 27 2570 - 1013 (incl.SHW)

Loading...

Loading...