Page 1

W 650-100

W 650-125

en Original instructions 5

ru Оригинальное руководство по

эксплуатации 11

PRC 使用说明 25

www.metabo.com

uk Оригінальна інструкція з експлуатації 18

KOR 지침 원본 31

Page 2

345

2

1

6

7

1

7

10

11

8

9

1

8X

8Y

8Z

A

W 650-100

B

C

2

Page 3

13.

Ø mm (in)

t

max1

t

max3

mm (in)

mm (in)

M / l - / mm (in)

n min

P

1

P

2

m kg (lbs)

a

/

h,SG

K

h,SG

a

h,DS

K

h,DS

LpA/K

LWA/K

pA

WA

m/s

/

m/s

dB(A)

dB(A)

-1

W

W

(rpm)

2

2

W 650-100

9

7,1 (

9

7,1 (

M 10 / 19 (

*1) 03600..

/

32

/

32

3

/

)M 14 / 19 (

4

*1) 03602..

W 650-125

)5( 521)4( 001

9

/

( 1,7)

)

32

9

/

( 1,7)

)

32

3

/

)

4

0001100011

056056

083083

)7.3( 7,1)5.3( 6,1

5,1/5,95,1/5,9

5,1 / 55,1 / 5

3 / 983 / 98

3 / 893 / 89

3

Page 4

(7)

(1)

(8) (9)

B

630327000

A

CLICK

D

= 100 mm (4“) 630346000

max

D

= 125 mm (5“) 630352000

max

C

4

(M 14) 630706000

(M 10) 34110205

Page 5

Original instructions

1. Specified Conditions of Use

The angle grinders, when fitted with original Metabo

accessories, are suitable for grinding, sanding,

separating and wire brushing metal, concrete,

stone and similar materials without the use of water.

The user bears sole responsibility for any damage

caused by inappropriate use.

Generally accepted accident prevention

regulations and the enclosed safety information

must be observed.

2. General Safety Information

For your own protection and for the

protection of your power tool, pay

attention to all parts of the text that are

marked with this symbol!

WARNING – Read the operating

instructions to reduce the risk of injury.

WARNING Read all safety warnings and

instructions. Failure to follow all safety

warnings and instructions may result in electric

shock, fire and/or serious injury.

Keep all safety instructions and information for

future reference.

Always include these documents when passing on

your power tool.

3. Special Safety Instructions

3.1General Safety Recommendations for

Grinding, Sanding, Wire Brushing or

Abrasive Cutting:

Use

a) This power tool is intended to function as a

grinder, sander, wire brush or cut-off tool. Read

all safety warnings, instructions, illustrations

and specifications provided with this power

tool. Failure to follow all instructions listed below

may result in electric shock, fire and/or serious

injury.

b) Operations such as polishing are not

recommended to be performed with this power

tool. Operations for which the power tool was not

designed may create a hazard and cause personal

injury.

c) Do not use accessories which are not

specifically designed and recommended by the

tool manufacturer. Even if an accessory can be

attached to your power tool, this does not ensure

safe operation.

d) The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their rated speed can break and fly apart.

e) The external diameter and thickness of your

accessory must be within the capacity rating of

ENGLISH en

your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

f) The threaded mounting of accessories must

match the grinder spindle thread. For

accessories mounted by flanges, the arbour

hole of the accessory must fit the locating

diameter of the flange. Accessories that do not

match the mounting hardware of the power tool will

run out of balance, vibrate excessively and may

result in a loss of control.

g) Do not use damaged accessories. Inspect

accessories such as grinding discs before

each use for chips and cracks and inspect

backing pads for cracks, tear or excess wear

and wire brushes for loose or cracked wires. If

a power tool or accessory is dropped, inspect

for damage or install an undamaged

accessory. After inspecting and installing an

accessory, position yourself and bystanders

away from the plane of the rotating accessory

and run the power tool at the maximum no-load

speed for one minute. Damaged accessories will

normally break apart during this test time.

h) Wear personal protective equipment. Use a

face shield, safety goggles or safety goggles

depending on the application. If necessary,

wear a dust mask, hearing protectors, gloves

and a workshop apron capable of stopping

small abrasive or workpiece fragments. Eye

protection must be capable of stopping flying debris

generated by various operations. A dust mask or

respirator must be capable of filtering particles

generated by your operation. Prolonged exposure

to high intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from

the work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of a workpiece or broken accessory may

fly off and result in injury beyond the immediate area

of operation.

j) Only hold the cordless tool by its insulated

grip areas while completing work where the

tool may come into contact with hidden power

lines or its own power cable. Cutting accessory

contacting a "live" wire may make exposed metal

parts of the power tool "live" and could give the

operator an electric shock.

k) Position the cord clear of the rotating

accessory. If you lose control, the cord may be cut

or snagged and your hand or arm may be pulled into

the rotating accessory.

I) Never lay the power tool down until the

accessory has come to a complete stop. The

rotating accessory may grab the surface and pull

the power tool out of your control.

m) Do not run the power tool while carrying it at

your side. Accidental contact with a rotating

accessory could snag your clothing, pulling the

accessory into your body.

n) Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the housing

5

Page 6

ENGLISHen

and an excessive accumulation of powdered metal

may cause electrical hazards.

o) Do not operate the power tool near

flammable materials. Sparks could ignite these

materials.

p) Do not use accessories that require liquid

coolants. Using water or other liquid coolants may

result in electrocution or shock.

3.2Kickback and related warnings

Kickback is a sudden reaction to a pinched or

snagged sanding wheel, backing pad, brush or any

other accessory. Pinching or snagging causes the

rotating accessory to stall rapidly, This in turn

causes the uncontrolled power tool to be forced in

the opposite direction from which the accessory is

rotating at the pinched or snagged point.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

entering the pinch point can dig into the surface of

the material causing the wheel to climb out or kick

out. The abrasive wheel may either jump toward or

away from the operator, depending on direction the

disc is moving at the pinch point. Abrasive wheels

may also break under these conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and

can be avoided if suitable precautionary measures

are taken as described below.

a) Maintain a firm grip on the power tool and

position your body and arm so that you can

resist kickback forces. Always use the

additional handle, if provided, for maximum

control over kickback or a torque reaction

during start-up. The operator can control torque

reactions or kickback forces if proper precautions

are taken.

b) Never place your hand near a rotating

accessory. The accessory may kickback over your

hand.

c) Do not position your body in the area

where the power tool will move if kickback

occurs. Kickback

will propel the tool in the direction opposite to the

grinding wheel’s movement at the pinch or snag

point.

d) Use special care when working corners,

sharp edges etc. Avoid bouncing and snagging

the accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory and

cause loss of control or kickback.

e) Do not attach a saw chain, woodcarving

blade or toothed saw blade. Such blades create

frequent kickback and can cause you to lose

control.

3.3Safety Warnings Specific for Grinding

and Cut-Off Grinding:

a) Use only wheel types that are recommended

for your power tool and the specific guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot be

adequately guarded and are unsafe.

6

b) The grinding surface of the centre depressed

wheels must be mounted below the plane of

the guard lip. An improperly mounted grinding

wheel that projects through the plane of the guard

lip cannot be adequately guarded.

c) The guard must be securely attached to the

power tool and positioned for maximum safety

so that the least amount of wheel is exposed

towards the operator. The guard helps to protect

operator from broken wheel fragments and

accidental contact with the wheel and sparks which

could ignite clothing.

d) Grinding media must be used only for

recommended applications.

For example: do not grind with the side of the

cutting disc. Cutting discs are intended for

grinding using the edge of the disc. Applying force

to the sides of these discs may cause them to

shatter.

e) Always use undamaged wheel flanges that

are the correct size and shape for your selected

grinding wheel. Proper wheel flanges support the

grinding wheel, reducing the possibility of

breakage. Flanges for cutting discs may be different

from grinding wheel flanges.

f) Do not use worn down grinding wheels from

larger power tools. Grinding wheels intended for

larger power tools are not suitable for the higher

speed of a smaller tool and may break.

3.4Additional Safety Warnings Specific for

Cut-Off Grinding:

a) Do not “jam” the cutting disc or apply

excessive pressure. Do not attempt to make an

excessively deep cut. Overstressing the cutting

disc increases the load and makes the disc more

susceptible to twisting or bending in the cut and

more likely to kick back and break.

b) Do not position your body in line with or

behind the rotating cutting disc. When the

cutting disc is moving away from your body at the

point of operation, any kickback can propel the

spinning disc and the power tool directly towards

you.

c) If the cutting disc is stuck or when

interrupting a cut for any reason, switch off the

power tool and hold the power tool motionless

until the disc comes to a complete stop. Never

attempt to remove the cutting disc from the cut

while the disc is in motion; otherwise kickback

may occur. Investigate and take corrective action

to eliminate the cause if a disc becomes stuck.

d) Do not restart the cutting operation in the

workpiece. Let the cutting disc reach full speed

and carefully re-enter the cut. The wheel may

bind, walk up or kickback if the power tool is

restarted in the workpiece.

e) Support panels or any oversized workpiece

to minimize the risk of cutting disc pinching

and kickback.Large workpieces tend to sag under

their own weight. Supports must be placed under

the workpiece near the line of the cut and near the

edge of the workpiece on both sides of the wheel.

Page 7

f) Use extra caution when making "pocket cuts"

into existing walls or other blind areas. The

protruding cutting disc may cause kickback when

cutting gas or water pipes, electrical wiring or other

objects.

3.5Safety Warnings Specific for Sanding

Operations:

a) Do not use excessively large sanding disc

paper. Follow the manufacturers

recommendations when selecting sandpaper.

Larger sandpaper that extends beyond the sanding

pad presents a laceration hazard and may cause

snagging or kickback, or may cause the disc to tear

off.

3.6Safety Warnings Specific for Wire

Brushing Operations:

a) Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive

load to the brush. Wire bristles can easily

penetrate light clothing and/or skin.

b) If a guard is recommended for wire brushing,

do not allow the wire wheel or brush to come

into contact with the guard. The wire wheel or

brush may expand in diameter due to the work load

and centrifugal forces.

3.7Additional Safety Instructions:

WARNING – Always wear protective

goggles.

Use elastic cushioning layers if they have been

supplied with the grinding media and if required.

Observe the specifications of the tool or accessory

manufacturer! Protect discs from grease or impact!

Grinding wheels must be stored and handled with

care in accordance with the manufacturer's

instructions.

Never use cut-off wheels for roughing work! Do not

apply pressure to the side of cut-off wheels.

The workpiece must lay flat and be secured against

slipping, e.g. using clamps. Large workpieces must

be sufficiently supported.

If accessories with threaded inserts are used, the

end of the spindle may not touch the base of the

hole on the sanding tool. Make sure that the thread

in the accessory is long enough to accommodate

the full length of the spindle. The thread in the

accessory must match the thread on the spindle.

See page 3 and the 12. Technical Specifications

chapter for more information on the spindle length

and thread.

It is recommended to use a stationary extraction

system and to place a ground fault circuit interrupter

(GFCI) downstream. If the angle grinder is shut

down via the GFCI, it must be checked and cleaned.

See the 8. Cleaning chapter for more information on

cleaning the motor.

Damaged, eccentric or vibrating tools must not be

used.

ENGLISH en

Avoid damage to gas or water pipes, electrical

cables and load-bearing walls (building structure).

Pull the plug out of the socket before making any

adjustments, converting or servicing the machine.

A damaged or cracked additional handle must be

replaced. Never operate the machine with a

defective additional handle.

A damaged or cracked safety guard must be

replaced. Never operate a machine with a defective

safety guard.

This power tool is not suitable for polishing work.

Improper use of the machine will void the warranty!

The motor may overheat and damage the electric

power tool. We recommend using our angle

polisher for polishing work.

Secure small workpieces, for example by clamping

them in a vice.

Reducing dust exposure:

WARNING

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to

cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

-Lead from lead-based paints,

-Crystalline silica from bricks and cement and

other masonry products, and

-Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a wellventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic

particles.

This also applies to dust from other materials such

as some timber types (like oak or beech dust),

metals, asbestos. Other known diseases are e.g.

allergic reactions, respiratory diseases. Do not let

dust enter the body.

Observe the relevant guidelines and national

regulations for your material, staff, application and

place of application (e.g. occupational health and

safety regulations, disposal).

Collect the particles generated at the source, avoid

deposits in the surrounding area.

Use suitable accessories for special work. In this

way, fewer particles enter the environment in an

uncontrolled manner.

Use a suitable extraction unit.

Reduce dust exposure with the following measures:

-do not direct the escaping particles and the

exhaust air stream towards yourself or nearby

persons or towards dust deposits,

-use an extraction unit and/or air purifiers,

-ensure good ventilation of the workplace and keep

it clean using a vacuum cleaner. Sweeping or

blowing stirs up dust.

-Vacuum or wash protective clothing. Do not blow,

beat or brush protective gear.

- Some dust created by power

7

Page 8

ENGLISHen

4. Overview

See page 2.

1Support flange

2Spindle

3Spindle locking button

4Sliding on/off switch

5Handle

6Side handle

7Safety cover

8Two-hole nut

9two-hole spanner

10 Clamp screw

11 Clamping ring

* depending on model / not in scope of delivery

5. Initial Operation

Before commissioning, check that the rated

mains voltage and mains frequency stated on

the type plate match your power supply.

Always install an RCD with a maximum trip

current of 30 mA upstream.

5.1Attaching the additional handle

Always work with the additional handle (6)

attached! Attach the additional handle on the

left or right of the machine and secure.

5.2Attach the safety guard

For safety reasons, always use the safety

guard provided for the respective wheel! See

also chapter 9. Accessories!

Safety guard for grinding

Designed for work with roughing wheels, flap

sanding pads, diamond cutting discs.

See illustration C on page 2.

-Loosen the clamping screw (10) until the clamping

ring (11) on the safety guard expands sufficiently.

-Place the safety guard (7) in the position

indicated.

-Turn the safety guard until the closed section is

facing the operator.

-Tighten the clamping screw (10) firmly. Make sure

that the guard is seated securely - you should not

be able to turn the safety guard (7).

Use only accessories that

are covered by at least 3.4

mm by the safety guard.

6. Attaching the grinding wheel

Prior to any conversion work: pull the mains

plug out of the socket. The machine must be

switched off and the spindle at a standstill.

For reasons of safety, attach the cut-off

grinding guard before performing cut-off

grinding work (see Chapter 9. Accessories).

8

6.1Locking the spindle

-Press in the spindle locking button (3) and

turn the spindle (2) by hand until the spindle

locking button engages.

6.2Placing the grinding wheel in position

See illustration A on page 2.

-Fit the support flange (1) on the spindle. The

flange should not turn on the spindle when

properly attached.

Only W 650-100: Screw support flange with twohole spanner onto spindle so that the small collar

(with diameter 16 mm) is facing upwards.

-Place the grinding wheel on the support flange (1).

The grinding wheel must lay flat on the supporting

flange.

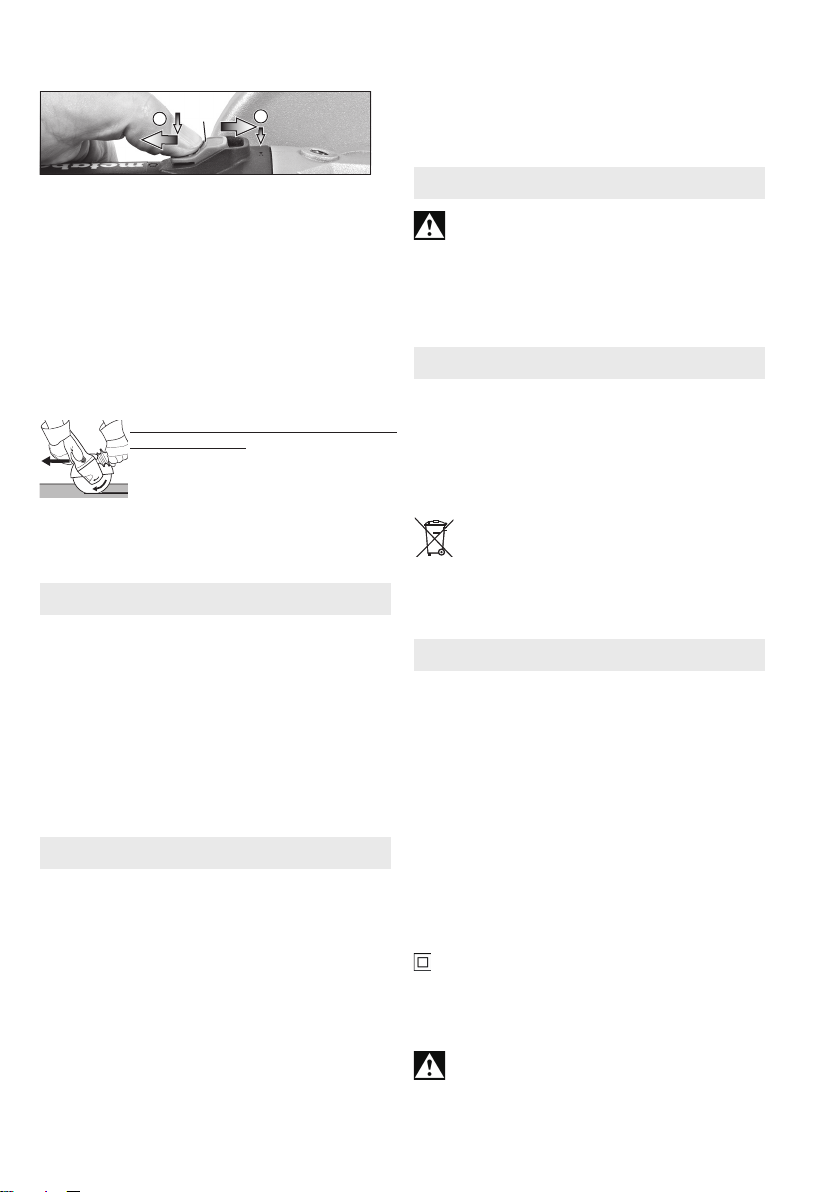

6.3Secure / loosen two hole nut

Securing the 2-hole nut (8):

The 2 sides of the two-hole nut are different.

Screw the two-hole nut onto the spindle as follows:

See illustration B on page 2.

- X) For thin grinding discs:

The edge of the 2-hole nut (8) faces upwards so

that the thin grinding disc can be attached

securely.

Y) For thick grinding discs:

The edge of the two-hole nut (8) faces downwards

so that the two-hole nut can be attached securely

to the spindle.

Z) Only for W 650-100:

The collar of the two-hole nut faces downwards

and/or the flat surface faces upwards.

-Lock the spindle. Turn the two-hole nut (8)

clockwise using the two-hole spanner (9) to

secure.

Releasing the 2-hole nut:

-Lock the spindle (see chapter 6.1). Turn the twohole nut (8) anticlockwise using the two-hole

spanner (9) to unscrew.

7. Use

7.1Switching on and off

Always guide the machine with both hands.

Switch on first, then guide the accessory

towards the workpiece.

The machine must not be allowed to draw in

additional dust and shavings. When switching

the machine on and off and keep it away from dust

deposits. After switching off the machine, only set it

down when the motor has come to a standstill.

Avoid inadvertent starts: always switch the

tool off when the plug is removed from the

mains socket or if there has been a power cut.

In continuous operation, the machine

continues running if it is forced out of your

hands. Therefore, always hold the machine with

both hands using the handles provided, stand

securely and concentrate.

Page 9

Machines with a slide switch:

4

0

ENGLISH en

Install the hand guard under the additional sidemounted handle.

I

CTwo hole nut (8)

For a complete range of accessories, see

www.metabo.com or the accessories catalogue.

Switching on: push the slide switch (4) forwards.

For continuous operation, tilt it downwards until it

engages.

Switching off: press the rear end of the slide switch

(4) and release it.

7.2Working directions

Grinding and sanding operations:

Press down the machine evenly on the surface and

move it back and forth so that the surface of the

workpiece does not become too hot.

Rough grinding: position the machine at an angle of

30° - 40° for the best working results.

Cut-off grinding:

the material being processed. Do not tilt, apply

excessive force or sway from side to side.

Wire brushing:

Press down the machine evenly.

Always work against the run of the disc

(see illustration). Otherwise the

machine may kick back from the cut in

an out of control manner. Guide the

machine evenly at a speed suitable for

8. Cleaning

Particles may become deposited inside the power

tool during operation. This impairs the cooling of the

power tool. Conductive build-up can impair the

protective insulation of the power tool and create an

electrical hazard.

The power tool should be cleaned regularly, often

and thoroughly through all front and rear air vents

using a vacuum cleaner or by blowing in dry air.

Prior to this operation, separate the power tool from

the power source and wear protective glasses and

dust mask. Ensure appropriate suction is available

when blowing out vents.

9. Accessories

Use only genuine Metabo accessories.

See page 4.

Use only accessories that fulfil the requirements

and specifications listed in these operating

instructions.

ACutting guard clip / guard for cut-off

grinding

Designed for work with cutting disc and diamond

cutting discs. Once the cutting guard clip is fitted,

the safety guard becomes a cutting guard.

BHand protection

Intended for work with backing pads, sanding

plates, wire brushes and support plates, sanding

pads, wire brushes and diamond drill bits for tiles.

10. Repairs

Repairs to electrical tools must ONLY be

carried out by qualified electricians!

Contact your local Metabo representative if you

have Metabo power tools requiring repairs. See

www.metabo.com for addresses.

You can download a list of spare parts from

www.metabo.com.

11. Environmental Protection

The sanding dust generated may contain

hazardous materials: do not dispose of dust with

household waste, but at a special collection point

for hazardous waste.

Observe national regulations on environmentally

compatible disposal and on the recycling of disused

machines, packaging and accessories.

Only for EU countries: never dispose of

power tools in your household waste!

According to European Directive 2012/19/EU

on Waste from Electric and Electronic Equipment

and implementation in national law, used power

tools must be collected separately and recycled in

an environmentally-friendly manner.

12. Technical Specifications

Explanatory notes on the specifications on page 3.

Changes due to technological progress reserved.

Ø=max. diameter of the accessory

=max. permitted thickness of the clamping

t

max,1

t

max,3

M=Spindle thread

l=Length of the sanding spindle

n=No-load speed (maximum speed)

P

P

m=Weight without mains cable

Measured values determined in conformity with

EN 60745.

shank on accessory when using two-hole

nut (8)

=roughing disc/cutting disc:

max. permitted thickness of accessory

=Rated input power

1

=Power output

2

Machine in protection class II

~ AC power

The technical specifications quoted are subject to

tolerances (in compliance with relevant valid

standards).

Emission values

These values make it possible to assess the

emissions from the power tool and to compare

different power tools. The actual load may be higher

or lower depending on operating conditions, the

condition of the power tool or the accessories used.

9

Page 10

ENGLISHen

Please allow for breaks and periods when the load

is lower for assessment purposes. Arrange

protective measures for the user, such as

organisational measures based on the adjusted

estimates.

Total vibration value

determined in accordance with EN 60745:

a

h, SG

a

h, DS

K

h,SG/DS

Typical A-effective perceived sound levels

L

pa

L

WA

K

pA

=Vibration emission value

=Vibration emission value

=Uncertainty (vibration)

=Sound-pressure level

=Acoustic power level

, KWA=Uncertainty

Wear ear protectors!

(vector sum of three directions)

(surface grinding)

(sanding with sanding plate)

:

10

Page 11

РУССКИЙ ru

Оригинальное руководство по эксплуатации

1. Использование по

назначению

Угловые шлифмашины, оснащенные

оригинальными принадлежностями Metabo,

предназначены для шлифования, шлифования

наждачной бумагой, обработки кардощетками

и абразивной резки металла, бетона, камня и

схожих с ними материалов без использования

воды.

За ущерб, возникший в результате

использования не по назначению,

ответственность несет только пользователь.

Необходимо с облюдать общепринятые правила

предотвращения несчастных случаев, а также

указания по технике безопасности,

приведенные в данном руководстве.

2. Общие указания по технике

безопасности

Для вашей собственной безопасности

и защиты электроинструмента от

повреждений необходимо соблюдать

данным символом!

безопасности. Несоблюдение инструкций и

указаний по технике безопасности может

привести к поражению электрическим током,

возникновению пожара и/или к получению

тяжелых травм.

Необходимо сохранять все инструкции и

указания по технике безопасности для

использования в будущем.

Передавать электроинструмент следующему

владельцу можно только вместе с этими

документами.

указания, отмеченные в тексте

ПРЕДУПРЕЖДЕНИЕ! В ц елях снижения

риска травмы следует прочесть данное

руководство по эксплуатации.

ПРЕДУПРЕЖДЕНИЕ! Следует прочесть

все инструкции и указания по технике

3. Особые указания по технике

безопасности

3.1Общие указания по технике

безопасности при шлифовании,

шлифовании наждачной бумагой,

обработке кардощетками и

абразивной резке:

Применение

а) Данный электроинструмент следует

использовать в качестве шлифмашины,

шлифователя с наждачной бумагой,

проволочной щетки и шлифовальноотрезной машины. Необходимо соблюдать

все указания по технике безопасности,

инструкции, изображения и данные,

полученные вместе с прибором.

Несоблюдение следующих инструкций может

привести к поражению электрическим током,

пожару и/или серьезным травмам.

б) Данный электроинструмент не

предназначен для полирования.

Использование электроинструмента не по

назначению может привести к возникновению

опасной ситуации и получению травм.

в) Не использовать принадлежности, не

предусмотренные и не рекомендованные

производителем для данного

электроинструмента. Одно лишь надежное

крепление принадлежности в

электроинструменте не гарантирует его

надежной эксплуатации.

г) Допустимая частота вращения рабочего

инструмента не должна превышать

максимальную частоту вращения,

указанную на электроинструменте.

Принадлежности, скорость вращения которых

превышает допустимое значение, могут

сломаться и отлететь в сторону.

д) Наружный диаметр и толщина рабочего

инструмента должны соответствовать

размерным данным электроинструмента.

Невозможно обеспечить экранирование и

контроль рабочих инструментов с неверно

рассчитанными параметрами.

е) Рабочие инструменты с резьбовой

вставкой должны точно подходить к

шлифовальному шпинделю

электроинструмента. У рабочих

инструментов, закрепленных с помощью

фланцев, крепежное отверстие должно

точно подходить к форме фланца. Рабочие

инструменты, размеры которых не

соответствуют зажимному приспособлению,

вращаются неравномерно, очень сильно

вибрируют и могут привести к потере контроля

над электроинструментом.

ж) Не использовать поврежденные рабочие

инструменты. Перед каждым

использованием осматривать рабочие

инструменты: шлифовальные круги не

должны иметь сколов и трещин,

шлифовальные тарелки — трещин, следов

износа или сильного истирания, в

проволочных щетках не должно быть

выпавших или обломившихся проволочных

прядей. В случае падения

электроинструмента или рабочего

инструмента проверить его исправность и

использовать только неповрежденный

рабочий инструмент. После проверки и

установки рабочего инструмента

убедиться, что никто не находится в зоне

вращающегося рабочего инструмента, и на

одну минуту запустить инструмент с

максимальной частотой вращения.

Поврежденные рабочие инструменты обычно

ломаются в ходе такой проверки.

11

Page 12

РУССКИЙru

з) Использовать средства индивидуальной

защиты. В зависимости от вида

выполняемой работы использовать маску

для полной защиты лица, средства для

защиты глаз или защитные очки. Для

защиты от мелких частиц шлифовального

инструмента и материала надевать

респиратор, защитные наушники,

защитные перчатки или специальный

фартук. Защищать глаза от отлетающих

посторонних предметов при выполнении

различных работ. Респираторы и защитные

маски должны отфильтровывать пыль,

возникающую во время работы. Длительное

воздействие громкого шума может привести к

потере слуха.

и) Следить за тем, чтобы другие люди

находились на безопасном расстоянии от

вашего рабочего места. Каждый человек,

входящий в рабочую зону, обязан надевать

средства индивидуальной защиты.

Отлетающие осколки заготовки или обломки

рабочих инструментов могут нанести травму

даже за пределами рабочей зоны.

й) При выполнении работ вблизи скрытой

электропроводки или сетевого кабеля

самого инструмента держать

электроинструмент только за

изолированные поверхности. При контакте с

находящимися под напряжением проводами

возможна передача напряжения на

металлические части прибора и удар

электрическим током.

к) Сетевой кабель должен находиться

вдали от вращающихся рабочих

инструментов. В случае потери контроля над

инструментом он может перерезать или

затянуть сетевой кабель, при этом руки могут

попасть в зону вращения рабочего

инструмента.

л) Никогда не класть электроинструмент до

полной остановки рабочего инструмента.

Вращающийся рабочий инструмент может

коснуться поверхности, в результате чего

возможна потеря контроля над

электроинструментом.

м) Не включать электроинструмент во

время его переноски. Возможно попадание

одежды во вращающийся рабочий инструмент,

в результате чего можно получить травму.

н) Регулярно очищать вентиляционные

щели электроинструмента. Вентилятор

двигателя затягивает пыль в корпус, а большое

скопление металлической пыли сопряжено с

опасностью поражения электрическим током.

o) Не использовать электроинструмент

вблизи легковоспламеняющихся

материалов. Искры могут вызвать

воспламенение этих материалов.

п) Не использовать рабочие инструменты,

для которых требуется использование

охлаждающей жидкости. Использование

воды или иной охлаждающей жидкости может

привести к поражению электрическим током.

12

3.2Отдача и соответствующие указания

по технике безопасности

Отдача представляет собой внезапную

реакцию в результате зацепления или

заклинивания вращающегося рабочего

инструмента, например, шлифовального круга,

шлифовальной тарелки, проволочной щетки и

т. д. Зацепление или заклинивание ведет к

внезапной остановке вращающегося рабочего

инструмента. В результате происходит

неконтролируемое движение

электроинструмента в направлении,

противоположном направлению вращения

рабочего инструмента в месте блокировки.

Если, например, шлифовальный круг цепляется

или заедает в заготовке, кромка круга

застревает, в результате чего круг может

обломиться или вызвать отдачу. Вследствие

этого шлифовальный круг движется на

оператора или в противоположном

направлении, в зависимости от направления

вращения круга в месте заклинивания. При

этом шлифовальный круг может разломиться.

Отдача является следствием неправильной и ли

неумелой эксплуатации электроинструмента.

Ее можно избежать при с облюдении описанных

ниже мер предосторожности.

a) Крепко держать электроинструмент в

руках и занимать такую позицию, чтобы

суметь противодействовать силе отдачи.

При наличии дополнительной рукоятки

всегда использовать ее, чтобы

максимально контролировать силу отдачи

и реактивный момент при запуске. При

соблюдении мер предосторожности можно

управлять отдачей и реактивными силами.

б) Никогда не держать руку вблизи

вращающихся рабочих инструментов. При

отдаче возможен контакт рабочего

инструмента с рукой.

в) Избегать нахождения в зоне,

в которую электроинструмент смещается

во время отдачи. При отдаче

электроинструмент смещается в направлении,

обратном направлению движения

шлифовального круга в месте блокировки.

г) Особенно осторожно работать в области

углов, острых кромок и т.п. Не допускать

отскакивания или заклинивания рабочих

инструментов в заготовке. Вращающийся

рабочий инструмент склонен к заклиниванию

при работе в области углов, острых кромок или

при отскакивании. Это вызывает потерю

контроля или отдачу.

д) Не использовать цепное или зубчатое

пильное полотно. Подобные рабочие

инструменты часто вызывают отдачу или

потерю контроля над электроинструментом.

3.3Особые указания по технике

безопасности при шлифовании и

абразивной резке:

а) Использовать только подходящий для

соответствующего электроинструмента

Page 13

шлифовальный инструмент и

предназначенный для него защитный

кожух. Шлифовальные инструменты, не

предназначенные для данного

электроинструмента, в достаточной степени не

защищены экраном и не являются

безопасными.

б) Выпуклые шлифовальные круги должны

быть размещены таким образом, чтобы их

рабочая поверхность находилась ниже

кромки защитного кожуха. Неправильно

размещенный шлифовальный круг,

выступающий за кромку защитного кожуха, не

может быть защищен должным образом.

в) Защитный кожух должен быть надежно

закреплен на э лектроинструменте и в целях

максимальной безопасности

отрегулирован таким образом, чтобы

открытой оставалась лишь самая малая

часть шлифовального инструмента.

Защитный кожух с лужит для защиты оператора

от осколков и случайного соприкосновения с

шлифовальным инструментом, а также от искр,

от которых может воспламениться одежда.

г) Шлифовальные инструменты должны

использоваться строго по назначению.

Например, нельзя проводить шлифование

боковой поверхностью отрезного круга.

Отрезные круги предназначены для снятия

материала кромкой круга. Боковое силовое

воздействие на отрезной круг может

разрушить его.

д) Всегда использовать исправный

зажимной фланец, его размер и форма

должны соответствовать выбранному

шлифовальному кругу. Подходящие фланцы

представляют собой опору для шлифовального

круга и тем самым снижают опасность его

разлома. Фланцы для отрезных кругов могут

отличаться от фланцев для других

шлифовальных кругов.

е) Не использовать изношенные

шлифовальные круги от

электроинструментов большего размера.

Шлифовальные круги для

электроинструментов большего размера не

рассчитаны на повышенную частоту вращения

электроинструментов меньшего размера и

могут разломиться.

3.4 Дополнительные особые указания по

технике безопасности п ри абразивной

резке:

а) Избегать заклинивания отрезного круга

или слишком большого давления прижима.

Не выполнять слишком глубокие пропилы.

Перегрузка отрезного круга приводит к его

перенапряжению и перекосам или

заклиниванию, что увеличивает вероятность

отдачи или поломки шлифовального

инструмента.

б) Не стоять в зоне перед вращающимся

отрезным кругом и за ним. Если начать

двигать отрезной к руг с заготовкой о т себя, то в

случае отдачи электроинструмент с

РУССКИЙ ru

вращающимся кругом будет отброшен прямо на

пользователя.

в) В случае зажима отрезного круга или при

перерыве в работе отключить инструмент и

подержать его в руке до полной остановки

вращающегося круга. Никогда не пытаться

извлечь движущийся отрезной круг из

пропила, так как это может вызвать отдачу.

Определить и устранить причину

заклинивания.

г) Не включать электроинструмент, если он

находится в заготовке. Сначала дать

отрезному кругу набрать полную частоту

вращения, только после этого осторожно

продолжить резку. В противном случае круг

может заклинить, отскочить из заготовки или

вызвать отдачу.

д) Для снижения риска отдачи в результате

заклинивания отрезного круга при

обработке плит и заготовок большого

размера использовать опору. Заготовки

большого размера могут прогнуться под

собственным весом. Под заготовку следует

подвести опоры с двух сторон, а именно вблизи

реза и кромки.

е) Следует проявить особую осторожность

при выполнении погружных пропилов в

имеющихся стенах или других

непросматриваемых зонах. Погружаемый

отрезной круг может вызвать отдачу при

разрезании газо- и водопроводов,

электрических проводов или иных объектов.

3.5Особые указания по технике

безопасности при шлифовании

наждачной бумагой:

a) Не использовать шлифовальные листы

слишком большого размера, соблюдать

указанные производителем размеры.

Шлифовальные листы, выступающие за края

шлифовальных тарелок, могут стать причиной

травм, разорваться, а также привести к

заклиниванию или к отдаче.

3.6Особые указания по технике

безопасности при обработке

проволочными щетками:

а) Помнить о том, что из щетки выпадают

кусочки проволоки даже при обычной

эксплуатации. Не перегружать проволоку

слишком высоким давлением прижима.

Отлетающие кусочки проволоки могут легко

проникнуть сквозь тонкую одежду и/или кожу.

б) Если рекомендовано применение

защитного кожуха, не допускать

соприкосновения кожуха и проволочной

щетки. Диаметр тарельчатых и чашечных

щеток может увеличиваться под воздействием

давления прижима и центробежных сил.

3.7Дополнительные указания по технике

безопасности:

ПРЕДУПРЕЖДЕНИЕ! Всегда носить

защитные очки.

13

Page 14

РУССКИЙru

При необходимости использовать эластичные

прокладки, если они поставляются вместе с

инструментом.

Соблюдать указания производителей рабочих

инструментов или принадлежностей! Беречь

круги от ударов и контакта с жирами и

смазками!

Бережно хранить шлифовальные круги и

применять их в соответствии с предписаниями

производителя.

Никогда не использовать круги для

абразивного отрезания для обдирочных работ!

Отрезные круги нельзя подвергать боковому

давлению.

Заготовку нужно прочно закрепить и

зафиксировать о т сдвига, например, с помощью

зажимных приспособлений. К рупные заготовки

должны иметь достаточную опору.

При использовании рабочих инструментов с

резьбовой вставкой конец шпинделя не должен

касаться основания отверстия шлифовального

инструмента. Следить за тем, чтобы резьба

рабочего инструмента имела достаточную

длину для шпинделя. Резьба рабочего

инструмента должна совпадать с резьбой

шпинделя. Длина шпинделя и резьба шпинделя

указаны на стр.3 и в главе 12. «Технические

характеристики».

Компания рекомендует использовать

стационарную установку для удаления пыли и

предварительно включать автомат защиты от

тока утечки (FI). В случае отключения угловой

шлифмашины автоматом з ащиты от т ока утечки

инструмент следует проверить и очистить.

Очистка двигателя описана в главе 8.

«Очистка».

Использование поврежденных,

деформированных или вибрирующих

инструментов запрещено.

Не допускать повреждений газо- или

водопроводов, линий электропитания и

несущих стен (статика).

Перед проведением каких-либо настроек,

переоснащения или работ по техобслуживанию

извлекайте сетевую вилку из розетки.

Поврежденная или потрескавшаяся

дополнительная рукоятка подлежит замене. Не

использовать электроинструмент с дефектной

дополнительной рукояткой.

Поврежденный или потрескавшийся защитный

кожух подлежит замене. Не использовать

инструмент с дефектным защитным кожухом.

Данный электроинструмент не предназначен

для полирования. Претензии по гарантии не

принимаются при использовании не по

назначению! Возможен перегрев двигателя и

повреждение электроинструмента. Для

проведения полировальных работ мы

рекомендуем угловую полировальную машину.

Небольшие заготовки следует закреплять,

например, зажимать их в тисках.

14

Снижение пылевой нагрузки:

ПРЕДУПРЕЖДЕНИЕ — Пыль,

образовавшаяся в результате шлифовки

наждачной бумагой, распиливания, шлифовки,

сверления и других видов работ, может

содержать химические вещества, о которых

известно, что они вызывают рак, врожденные

дефекты или другие повреждения

репродуктивной системы. Примеры таких

химических веществ:

-свинец в краске с содержанием свинца,

-минеральная пыль от строительного кирпича,

цемента и других веществ кирпичной кладки,

а также

-мышьяк и хром из химически обработанной

древесины.

Степень риска зависит от того, как часто вы

выполняете этот вид работ. Чтобы уменьшить

воздействие химических веществ: работайте в

помещениях с достаточной вентиляцией и с

использованием разрешенных средств

индивидуальной защиты, например, с

респираторами, разработанными специально

для фильтрации микроскопических частиц.

Это также касается пыли от других материалов,

например, некоторых видов древесины

(древесная пыль дуба или бука), металла,

асбеста. Другие известные заболевания — это,

например, аллергические реакции,

заболевания дыхательных путей. Не

допускайте попадания пыли внутрь организма.

Необходимо соблюдать директивы,

действующие в отношении материалов,

персонала, вариантов применения и мест

проведения работ, а также национальные

предписания (например, положения об охране

труда, правила утилизации).

Обеспечьте удаление образующихся частиц, не

допускайте образования отложений в

окружающем пространстве.

Для специальных работ используйте

подходящую оснастку. Это позволит сократить

количество частиц, неконтролируемо

выбрасываемых в окружающую среду.

Используйте подходящее устройство удаления

пыли.

Для уменьшения пылевой нагрузки:

-не направляйте выбрасываемые из

электроинструмента частицы и отработанный

воздух на себя, находящихся рядом людей

или на скопления пыли,

-используйте вытяжное устройство и/или

воздухоочиститель,

-хорошо проветривайте рабочее место и

содержите его в чистоте с помощью п ылесоса.

Подметание или продувка только поднимают

пыль в воздух.

-Защитную одежду следует обрабатывать

пылесосом или стирать. Не продувать одежду

воздухом, не выбивать и не сметать с нее

пыль.

Page 15

РУССКИЙ ru

4. Обзор

См. стр. 2.

1Опорный фланец

2Шпиндель

3Кнопка фиксатора шпинделя

4Переключатель для включения/выключения

5Рукоятка

6Дополнительная рукоятка

7Защитный кожух

8Гайка с двумя торцевыми отверстиями

9Ключ под два отверстия

10 Зажимной винт

11 Зажимное кольцо

* в зависимости от модели / не входит в объем

поставки

5. Ввод в эксплуатацию

Перед вводом в эксплуатацию проверить,

совпадают ли указанные на заводской

табличке значения напряжения и частоты сети

с параметрами электросети.

Перед инструментом всегда подключать

устройство защиты от тока утечки (УЗО) с

макс. током отключения 30мА.

5.1Установка дополнительной рукоятки

Работать только с установленной

дополнительной рукояткой (6)! Прочно

привинтить дополнительную рукоятку с левой

или с правой сторон инструмента.

5.2Установка защитного кожуха

Из соображений безопасности

использовать только такой защитный

кожух, который предусмотрен для

соответствующего шлифовального

инструмента! См. также главу 9.

«Принадлежности»!

Защитный кожух для шлифования

Предназначен для работ с шлифовальными

кругами, ламельными шлифовальными

тарелками, алмазными отрезными кругами.

См. рисунок C на стр. 2.

-Ослабить зажимной винт (10) так, чтобы

зажимное кольцо (11) защитного кожуха

расширилось в достаточной степени.

-Установить защитный кожух (7) в показанное

положение.

-Повернуть защитный кожух таким образом,

чтобы его закрытая зона была обращена к

вам.

- Прочно затянуть зажимной винт (10).

Проверить прочность посадки — защитный

кожух (7) не должен проворачиваться.

Использовать только те

рабочие инструменты,

которые выступают из-под

защитного кожуха не

более чем на 3,4 мм.

6. Установка шлифовального

круга

Перед любой переналадкой: извлечь

сетевую вилку из розетки. Инструмент

должен находиться в выключенном состоянии,

а шпиндель должен быть неподвижным.

Для работ с отрезными кругами в целях

безопасности использовать специальные

защитные кожухи для абразивного отрезания

(см. главу 9.«Принадлежности»).

6.1Фиксация шпинделя

-Нажать кнопку фиксатора шпинделя (3) и

крутить шпиндель (2) от руки до тех пор, пока

кнопка фиксатора шпинделя не

зафиксируется.

6.2Установка шлифовального круга

См. рисунок A на стр. 2.

-Установить опорный фланец (1) на шпиндель.

Фланец установлен правильно, если он не

проворачивается на шпинделе.

Только для W 650-100: навернуть

поддерживающий фланец двухштифтовым

ключом на шпиндель таким образом, чтобы

небольшой буртик (диаметром 16 мм) был

обращен наверх.

-Уложить шлифовальный круг на опорный

фланец (1). Шлифовальный круг должен

равномерно прилегать к опорному фланцу.

6.3Крепление/отвинчивание гайки с

двумя торцевыми отверстиями

Крепление гайки с двумя торцевыми

отверстиями (8):

Две стороны гайки с двумя торцевыми

отверстиями отличаются друг от друга.

Навинтить гайку с двумя торцевыми

отверстиями на шпиндель следующим образом:

См. рисунок B на стр. 2.

- X) Для тонких шлифовальных кругов:

буртик гайки с двумя торцевыми отверстиями

(8) обращен наверх для надежного зажима

шлифовального круга.

Y) Для толстых шлифовальных кругов:

Буртик гайки с двумя торцевыми отверстиями

обращен вниз для надежной фиксации гайки

на шпинделе (8).

Z) Только для W 650-100:

буртик гайки с двумя торцевыми отверстиями

обращен вниз, а ровная поверхность гайки —

наверх.

-Зафиксировать шпиндель. Затянуть гайку с

двумя торцевыми отверстиями (8) с помощью

ключа под два отверстия (9) по часовой

стрелке.

Отвинчивание гайки с двумя торцевыми

отверстиями:

-Зафиксировать шпиндель (см. главу 6.1).

Отвинтите гайку с двумя торцевыми

15

Page 16

РУССКИЙru

отверстиями (8) с помощью ключа (9) против

часовой стрелки.

7. Эксплуатация

7.1Включение/выключение

Инструмент необходимо всегда держать

обеими руками.

Подводить инструмент к заготовке только

во включенном состоянии.

Следить за тем, чтобы инструмент не

втягивал излишнюю пыль и опилки. При

включении и выключении держать его

подальше от скопившейся пыли. Не класть

инструмент до полной остановки двигателя.

Не допускать непреднамеренного запуска:

всегда выключать инструмент, если вилка

была извлечена из розетки, или если

произошел сбой в подаче электроэнергии.

В режиме непрерывной работы

инструмент продолжает вращаться, даже

если он вырвется из руки. Поэтому всегда

следует крепко держать инструмент двумя

руками за рукоятки, занимать устойчивое

положение и полностью концентрироваться на

выполняемой работе.

Инструменты с переключателем:

4

0

Включение: сдвинуть переключатель (4)

вперед. Для непрерывной работы нажать

переключатель вниз до фиксации.

Выключение: Нажмите на задний конец

переключателя (4), а затем отпустите его.

7.2Рабочие указания

Стандартное шлифование и шлифование

наждачной бумагой:

Прижимать инструмент с умеренным усилием и

перемещать е го по поверхности назад и вперед,

чтобы поверхность заготовки не

перегревалась.

Черновое шлифование: для получения

хорошего результата работать с установочным

углом 30°–40°.

Абразивное отрезание:

работать с умеренной подачей,

соответствующей обрабатываемому

материалу. Не допускать перекоса, не

нажимать и не раскачивать инструмент.

Обработка проволочными щетками:

Умеренно прижимать инструмент.

16

При абразивном отрезании всегда

работать во встречном

направлении (см. рисунок). Иначе

инструмент может неожиданно

выскочить из пропила. Следует

I

8. Очистка

При работе возможно скопление частиц

обрабатываемого материала внутри

электроинструмента. Это ухудшает

охлаждение электроинструмента.

Токопроводящие скопления могут нарушить

защитную изоляцию электроинструмента, что

сопряжено с опасностью поражения

электрическим током.

Через небольшие равные промежутки времени

тщательно удалять загрязнения из передних и

задних вентиляционных щелей

электроинструмента или продувать их сухим

воздухом. Перед этим отсоедините

электроинструмент от источника питания и

носите при этом защитные очки и респиратор.

При продувке должна быть обеспечена

достаточная вытяжная вентиляция.

9. Принадлежности

Используйте только оригинальные

принадлежности Metabo.

См. стр. 4.

Используйте только такие принадлежности,

которые отвечают требованиям и параметрам,

перечисленным в данном руководстве по

эксплуатации.

AЗажим защитного кожуха для отрезных

работ/ защитный кожух для а бразивной

резки

Предназначен для работы с отрезными

кругами, алмазными отрезными кругами. При

установленном зажиме защитного кожуха для

отрезных работ защитный кожух можно

использовать для абразивной резки.

BЗащитный элемент для рук

Предназначен для работ с опорными

тарелками, шлифовальными тарелками,

кардощетками и алмазными сверлильными

коронками для керамической плитки.

Защитный элемент для рук устанавливается

под боковую дополнительную рукоятку.

CГайка с двумя торцевыми отверстиями

(8)

Полный ассортимент принадлежностей см. на

сайте www.metabo.com или в каталоге

принадлежностей.

10.Ремонт

Ремонт электроинструментов должен

осуществляться только

квалифицированными специалистамиэлектриками!

Для ремонта электроинструмента Metabo

обращайтесь в региональное

представительство Metabo. Адрес см. на сайте

www.metabo.com.

Списки запасных частей можно скачать с сайта

www.metabo.com.

Page 17

11. Защита окружающей среды

Утилизацию шлифовальной пыли выполнять

отдельно от бытовых отходов на

соответствующей площадке для спецотходов,

т. к. в составе пыли могут быть вредные

вещества.

Соблюдайте национальные предписания по

экологически безопасной утилизации и

переработке отслуживших машин, упаковки и

принадлежностей.

Только для стран ЕС: не утилизировать

электроинструменты вместе с бытовыми

отходами! Согласно европейской директиве 2012/19/ЕС по отходам электрического и

электронного оборудования и соответствующим национальным нормам отработавшие

электроинструменты подлежат сбору с целью

их последующей экологически безопасной

переработки.

12. Технические

характеристики

Пояснения к данным, приведенным на стр. 3.

Оставляем за собой право на изменения,

обусловленные техническим прогрессом.

Ø=макс. диаметр рабочего инструмента

=макс. допустимая толщина рабочего

t

max,1

t

max,3

M=резьба шпинделя

l=длина шлифовального шпинделя

n=частота вращения без нагрузки

P

P

m=вес без сетевого кабеля

Результаты измерений получены в

соответствии со стандартом EN60745.

~

Указанные технические характеристики имеют

допуски (предусмотренные действующими

стандартами).

сравнивать эмиссию шума различных

электроинструментов. В зависимости от

условий эксплуатации, состояния

электроинструмента или используемых

рабочих инструментов фактическая нагрузка

может быть выше или ниже. Для оценки

примерного уровня эмиссии следует учитывать

перерывы в работе и фазы работы с

пониженной шумовой нагрузкой. Определить

перечень мер, например, организационных

мероприятий, по защите пользователя с учетом

тех или иных значений эмиссии шума.

инструмента в области зажима при

использовании гайки с двумя

торцевыми отверстиями (8)

=обдирочный круг / отрезной круг:

макс. допустимая толщина рабочего

инструмента

(максимальная частота вращения)

=номинальная потребляемая мощность

1

=отдаваемая мощность

2

Инструмент класса защиты II

переменный ток

Значения эмиссии шума

Эти значения позволяют оценивать и

РУССКИЙ ru

Общее значение вибрации

трех направлений), расчет согласно EN 60745:

a

h, SG

a

h, DS

K

h,SG/DS

Типичный амплитудно-взвешенный уровень

L

pA

L

WA

KpA, KWA=коэффициент погрешности

=значение вибрации

(шлифование поверхности)

=значение вибрации

(шлифование шлифовальной

тарелкой)

= коэффициент погрешности

(вибрация)

звукового давления:

=уровень звукового давления

=уровень звуковой мощности

Используйте защитные наушники!

Информация для покупателя:

Сертификат соответствия:

Сертификат соответствия: № ТС RU C-

DE.БЛ08.В.01717, срок действия с 26.09.2018

по 25.09.2023 г., выдан органом по

сертификации продукции «ИВАНОВОСЕРТИФИКАТ» ООО «Ивановский Фонд

Сертификации»; Адрес(юр. и факт.): 153032,

Российская Федерация, Ивановская обл., г.

Иваново, ул. Станкостроителей, д. 1; тел.

(4932)77-34-67; E-mail: info@i-f-s.ru; Аттестат

аккредитации № RA.RU.11БЛ08 от 24.03.16 г.

Страна изготовления: Китай

Производитель: "Metabowerke GmbH",

Metaboallee 1, D-72622 Nuertingen, Германия

Импортер в России:

ООО "Метабо Евразия"

Россия, 127273, Москва

ул. Березовая аллея, д 5 а, стр 7, офис 106

тел.: +7 495 980 78 41

Дата производства зашифрована в 10-значном

серийном номере инструмента, указанном на

его шильдике. 1 я цифра обозначает год,

например «4» обозначает, что изделие

произведено в 2014 году. 2 я и 3 я цифры

обозначают номер месяца в году п роизводства,

например «05» - май

Срок службы изделия составляет 7 лет. Не

рекомендуется к эксплуатации по истечении 5

лет хранения с даты изготовления без

предварительной проверки (дату изготовления

см. На этикетке).

(векторная сумма

17

Page 18

УКРАЇНСЬКАuk

Оригінальна інструкція з експлуатації

1. Використання за

призначенням

Кутова шліфмашина з оригінальним приладдям

Metabo призначена для шліфування,

шліфування наждачним папером, обробки

дротяними щітками та відрізання абразивним

диском металу, бетону, каменю та аналогічних

матеріалів без використання води.

За пошкодження, викликані експлуатацією не

за призначенням, несе відповідальність

виключно користувач.

Необхідно дотримуватись загальноприйнятих

правил запобігання нещасним випадкам, а

також правил техніки безпеки, наведених в цій

інструкції.

2. Загальні правила техніки

безпеки

Задля вашої власної безпеки та

захисту електроінструмента від

ушкоджень слід дотримуватись

вказівок, позначених цим символом!

ПОПЕРЕДЖЕННЯ — З метою зниження

ризику отримання тілесних ушкоджень

прочитайте цю інструкцію з експлуатації.

ПОПЕРЕДЖЕННЯ — Ознайомтеся з

усіма правилами та вказівками з

техніки безпеки. Недотримання правил та

вказівок з техніки безпеки може призвести до

ураження електричним струмом, пожежі та/або

тяжких тілесних ушкоджень.

Зберігайте правила та вказівки з техніки

безпеки для майбутнього використання.

Передавайте ваш електроінструмент тільки

разом з цими документами.

3. Спеціальні вказівки з

техніки безпеки

3.1Загальні вказівки з техніки безпеки

під час стандартного шліфування та

шліфування наждачним папером,

обробки дротяними щітками та

відрізання абразивними дисками:

Застосування

a) Цей електроінструмент призначений для

стандартного шліфування та шліфування

наждачним папером, обробки дротяними

щітками та відрізання абразивними

дисками. Приймайте до уваги усі вказівки та

рекомендації щодо техніки безпеки,

зображення та дані, які ви отримали разом

з цим пристроєм. Недотримання наступних

вказівок може призвести до удару електричним

струмом, пожежі та/або тяжких тілесних

ушкоджень.

18

b) Цей електроінструмент не призначений

для полірування. Використання, до якого

електроінструмент не призначений, може

призвести до пошкоджень та травм.

c) Не використовуйте приладдя, яке не було

передбачене та рекомендоване

виробником для відповідного

електроінструменту. Тільки те, що приладдя

підходить до вашого електроінструменту, не

гарантує безпечне використання.

d) Допустима кількість обертів

інструментальної насадки не повинна бути

менше вказаної на електроінструменті

максимальної кількості обертів. Приладдя,

яке обертається швидше допустимої швидкості,

може зламатися та розлетітися по сторонам.

e) Зовнішній діаметр та товщина

інструментальної насадки повинні

відповідати даним вашого

електроінструменту. Для інструментальних

насадок, габарити яких не відповідають

електроінструменту, не забезпечені достатній

захист та контроль.

f) Інструментальні насадки з різьбовою

вставкою повинні точно співпадати з

наріззю шліфувального шпинделя. Для

інструментальних насадок, які

встановлюють за допомогою фланця,

діаметр отвору інструментальної насадки

має відповідати монтажному діаметру

фланця. Інструментальні насадки, які не точно

прикріплені до електроінструменту,

обертаються нерівномірно, сильно вібрують та

можуть призвести до втрати контролю.

g) Не використовуйте пошкоджені

інструментальні насадки. Перед кожним

використанням перевіряйте

інструментальні насадки: шліфувальні

диски на наявність відколів та тріщин;

тарілчасті шліфувальні круги на наявність

відколів, зносу та спрацьовування; дротяні

щітки на наявність слабо закріпленого або

пошкодженого дроту. У разі падіння

електроінструменту або інструментальної

насадки переконайтеся, що немає

пошкоджень, або візьміть непошкоджену

насадку. Після перевірки та встановлення

інструментальної насадки увімкніть

пристрій на хвилину на максимальні оберти,

в цей час користувач та інші люди повинні

триматися поза зоною обертання

інструментальної насадки. Пошкоджені

інструментальні насадки як правило ламаються

на цьому етапі тестування.

h) Використовуйте особисті засоби захисту.

Залежно від сфери використання обирайте

захисний щіток для обличчя, захист для

очей або захисні окуляри. Якщо потрібно,

використовуйте респіратор, засоби захисту

органів слуху, захисні рукавички або

спеціальний фартух, які захистять вас від

невеликих шліфувальних та сировинних

часточок. Очі повинні бути захищені від

Page 19

часточок, що розлітаються під час проведення

різних робіт. Респіратор або фільтрувальна

захисна маска повинні бути розраховані на пил,

що утворюється під час робіт. Якщо ви довгий

час зазнаєте впливу шуму, може статися

зниження слуху.

i) Слідкуйте за тим, щоб інші люди

знаходились на б езпечній відстані від вашої

робочої зони. Кожен, хто наближається до

робочої зони, повинен використовувати

засоби захисту. Відламки заготовки або

інструментальної насадки можуть відлетіти та

завдати шкоди навіть за межами робочої зони.

j) Тримайте електроінструмент тільки за

ізольовані поверхні під час роботи, якщо є

ризик зіткнення і нструментальної насадки з

прихованим електродротом або кабелем

самого інструменту. Контакт з

електропроводкою під напругою може

призвести до передачі напруги також на

металеві частини пристрою та спричинити

ураження електричним струмом.

k) Тримайте кабель живлення в стороні від

інструментальної насадки, що обертається.

Якщо ви втратите контроль над приладом,

можливе перерізання або захоплення

мережевого кабелю, що може призвести до

потрапляння вашої руки в зону обертання

інструментальної насадки.

I) Ніколи не відкладайте електроінструмент,

доки інструментальна насадка повністю не

зупиниться. Можливий контакт

інструментальної насадки, що обертається, з

поверхнею, що може призвести до втрати

контролю над електроінструментом.

m) Під час перенесення електроінструмент

не повинен працювати. Є ризик випадкового

захоплення вашого одягу та поранення тіла

інструментальною насадкою, що обертається.

n) Регулярно очищуйте вентиляційні отвори

вашого електроінструменту. Вентилятор

двигуна затягує пил усередину корпусу,

внаслідок чого велике скупчення металевого

пилу викликає ризик ураження електричним

струмом.

o) Не використовуйте електроінструмент

поблизу займистих матеріалів. Іскри можуть

викликати займання цих матеріалів.

p) Не використовуйте інструментальні

насадки, які потребують рідких

охолоджувальних засобів. Використання

води або інших рідких охолоджувальних засобів

може призвести до удару електричним

струмом.

3.2Віддача та відповідні правила безпеки

Віддача - це раптова реакція в результаті

застрягання або блокування інструментальної

насадки, щ о обертається: ш ліфувального диска,

тарілчастого шліфувального круга, дротяної

щітки та ін. - що веде до різкої зупинки

інструментальної насадки. Це викликає

неконтрольований рух електроінструменту в

УКРАЇНСЬКА uk

місті блокування у напрямку, протилежному

напрямку обертання інструментальної насадки.

Якщо, наприклад, шліфувальний диск

заблокований або застряг в заготовці, кромка

шліфувального диска, що занурена у заготовку,

викликає пошкодження диска та віддачу.

Шліфувальний диск рухається у напрямку

користувача або від нього, залежно від

напрямку обертання диска в момент

блокування. При цьому шліфувальні диски

також можуть ламатися.

Віддача є наслідком невірного а бо помилкового

використання електроінструменту. Запобігти

з'явленню віддачі допоможуть відповідні

заходи, які описані нижче.

a) Міцно тримайте електроінструмент, ваші

тіло та руки повинні перебувати в

положенні, яке гарантує можливість

протистояти віддачі. Завжди

використовуйте додаткову рукоятку, якщо

вона є, для максимального контролю над

віддачею та реактивними моментами під

час розгону. За умови вживання відповідних

заходів безпеки користувач здатний

контролювати сили віддачі та реакції.

b) Не тримайте руки поблизу

інструментальної насадки, що обертається.

Інструментальна насадка може в м омент віддачі

травмувати вашу руку.

c) Уникайте знаходження в зоні,

в яку електроінструмент потрапить при

віддачі. При віддачі

електроінструмент рухається в напрямку,

протилежному напрямку обертання

шліфувального диска в момент блокування.

d) Працюйте особливо уважно біля кутів,

гострих кромок тощо. Не допускайте

рикошету інструментальної насадки від

заготовки та її заклинювання.

Інструментальна насадка, що обертається,

може заклинитися біля кутів, гострих кромок та

при рикошеті. Наслідком є в трата контролю або

віддача.

e) Не використовуйте зубчасті пилкові

диски або диски для ланцюгової пилки. Такі

інструментальні насадки часто викликають

віддачу або втрату контролю над

електроінструментом.

3.3Особливі вказівки з техніки безпеки

під час шліфування та абразивного

відрізання:

a) Використовуйте тільки ті абразивні

інструменти, що рекомендовані для вашого

електроінструменту, і захисний кожух, що

передбачений для цих абразивних

інструментів. Для абразивних інструментів, щ о

не п ередбачені для в ашого електроінструменту,

не гарантований достатній захист, отже немає

гарантії безпеки.

b) Шліфувальні диски вигнутого профілю

мають бути в становлені таким

шліфувальна поверхня не виступала над

площиною захисного краю. Неправильно

чином, щоб їх

19

Page 20

УКРАЇНСЬКАuk

встановлений шліфувальний круг, який

виходить за межі захисного краю, не може бути

затемнений належним чином.

c) Захисний кожух треба надійно

встановити на електроінструмент і для

максимальної безпеки налаштувати таким

чином, щоб відкритою залишалася лише

найменша частина абразивного

інструменту. Захисний кожух допомагає

захистити користувача від уламків,

випадкового контакту з абразивним

інструментом та іскор, від яких може зайнятися

одяг.

d) Абразивні інструменти повинні

використовуватися тільки за

призначенням.

Наприклад: забороняється виконувати

шліфування бічною поверхнею відрізного

круга. Відрізні диски призначені для зняття

матеріалу кромкою круга. Сили, що впливають

на круг з бічної с торони, можуть стати п ричиною

його руйнування.

e) Для установки шліфувального диска

завжди використовуйте справний

затискний фланець потрібного розміру і

форми. Відповідні за формою і розміром фланці

фіксують шліфувальний диск і знижують ризик

його розлому. Затискні фланці для відрізних

кругів можуть відрізнятися від затискних

фланців для інших шліфувальних дисків.

f) Не використовуйте зношені шліфувальні

диски від електроінструментів більшого

розміру. Шліфувальні диски, виготовлені для

електроінструментів більшого розміру, не

розраховані на високу частоту обертання

малогабаритних електроінструментів і тому

можуть зруйнуватися.

3.4Додаткові вказівки з техніки безпеки

при відрізанні абразивними дисками:

a) Уникайте блокування відрізного круга та

занадто високого притискного зусилля. Не

виконуйте занадто глибокі розрізи.

Перевантаження відрізного круга прискорює

його знос і збільшує схильність до перекосу або

блокування, а як наслідок - можливість віддачі

або руйнування.

b) Уникайте знаходження в зоні перед

відрізним кругом, що обертається, і позаду

нього. При зміщенні відрізного круга в

оброблюваній деталі в напрямі від себе

електроінструмент у випадку віддачі може

відскочити прямо на вас разом з диском, що

обертається.

c) У разі заклинювання відрізного круга або

переривання роботи вимкніть інструмент і

дочекайтеся, поки круг повністю

зупиниться. Ніколи не намагайтеся

витягнути відрізний круг, що обертається, з

розрізу - можлива віддача. Встановіть і

усуньте причину заклинювання.

d) Не вмикайте інструмент знову, якщо він

все ще знаходиться в оброблюваній деталі.

Перед продовженням роботи дочекайтеся,

20

поки інструмент досягне робочої частоти

обертання. Інакше можливе заїдання круга,

його вискакування з оброблюваної деталі або

поява віддачі.

e) Підпирайте плити або заготовки великого

розміру, щоб знизити ризик у випадку

заїдання відрізного круга. Великі заготовки

можуть прогинатися під власною вагою.

Оброблювану деталь слід підпирати з двох

сторін: близько місця виконання розрізу та

уздовж її кромки.

f) Будьте особливо обережні при виконанні

заглибних розрізів в стінах та інших зонах,

що не проглядаються. При заглибленні диска

під час різання можливий контакт з газо- і

водопроводами, електричною проводкою та

іншими об'єктами, що викликає віддачу.

3.5Особливі вказівки з техніки безпеки

при шліфуванні наждачним папером:

a) Не використовуйте наждачний папір

занадто великого розміру, дотримуйтесь

інструкцій виробника паперу щодо його

розмірів. Наждачний папір, що виступає за

межі тарілчастого шліфувального круга, може

стати причиною травм, блокування, розриву

наждачного паперу та віддачі.

3.6Особливі вказівки з техніки безпеки

при виконанні робіт з дротяними

щітками:

a) Приміть до уваги, що дротяні щітки

втрачають шматочки дроту також при

звичайному використанні. Не прикладайте

занадто високе притискне зусилля.

Відлітаючі шматочки дроту можуть легко

проходити скрізь тонку тканину одягу та/або

проникати в шкіру.

b) При використанні захисного кожуха не

допускайте його контакту з дротяною

щіткою. Тарілчасті і чашкові щітки під дією

притискного зусилля і відцентрових сил можуть

збільшувати свій діаметр.

3.7 Додаткові вказівки з техніки безпеки:

ПОПЕРЕДЖЕННЯ – Завжди надягайте

захисні окуляри.

Використовуйте еластичні вкладки, якщо вони

входять до комплекту абразивних інструментів і

виробник наполягає на їх використанні.

Дотримуйтесь рекомендацій виробника

інструменту та приладдя! Захищайте диски від

потрапляння мастила та ударів!

Зберігайте шліфувальні диски та поводьтеся з

ними відповідно до вказівок виробника.

Ніколи не використовуйте відрізні шліфувальні

диски для обдирних робіт! Треба уникати

бічного тиску на відрізний шліфувальний диск.

Заготовка повинна надійно прилягати до

поверхні та бути закріплена від зісковзування,

наприклад, за допомогою затискних пристроїв.

Для великих заготовок треба передбачити

достатню опору.

Page 21

При використанні інструментальних насадок з

різьбовою вставкою кінець шпинделя не

повинен торкатися перфорованої основи

абразивного інструменту. Переконайтеся, що

різьба інструментальної насадки має достатню

довжину для кріплення до шпинделя. Різьба

інструментальної насадки повинна співпадати з

різьбою шпинделя. Дані щодо довжини та

різьби шпинделя див. на стор. 3 та в розділі 12.

Технічні характеристики.

Рекомендується використовувати стаціонарну

витяжну установку і підключати пристрій

захисного відключення (ПЗВ). Після

відключення кутової шліфмашини пристроєм

захисного відключення треба перевірити та

почистити машину. Про чищення двигуна див. у

розділі 8. Чищення.

Не використовуйте пошкоджені, ексцентричні

та вібруючі інструментальні насадки.

Уникайте пошкодження газових та

водопровідних труб, електричної проводки та

несучих стін (статика).

Перед проведенням робіт з налаштування,

переоснащення або обслуговування витягніть

вилку з розетки.

Пошкоджену або потріскану додаткову

рукоятку слід замінити. Не експлуатуйте

машину з пошкодженою рукояткою.

Пошкоджений або потрісканий захисний кожух

слід замінити. Не експлуатуйте машину з

пошкодженим захисним кожухом.

Цей електроінструмент не призначений для

полірування. Гарантійні претензії не

приймаються при використанні не за

призначенням! У разі перегріву двигуна

електроінструмент може отримати