Metabo W 23-180, W 23-230, W 25-230, W 21-230 User Manual

Made in Germany / Fabriqué en Allemagne

W 23-180

W 23-230 & W 25-230

W 21-230

Instructions for use ........... page 2-8

Instructions d’utilisation . . ..... page 9-15

170 24 9770 - 0205

1

2

3

4

WS_Nafta_Canada_9770_0205 18.12.2007 13:17 Uhr Seite 1

4.3 Avoid accidental starting. Be sure switch is off

before plugging in. Carrying tools with your finger on

the switch or plugging in tools that have the switch on

invites accidents.

4.4 Remove adjusting keys or wrenches before

turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in

personal injury.

4.5 Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enable

better control of the tool in unexpected situations.

4.6 Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes, hard hat

or hearing protection must be used for appropriate conditions.

5 Tool Use and Care

5.1 Use clamps or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable and

may lead to loss of control.

5.2 Do not force tool. Use the correct tool for your

application. The correct tool will do the job better and

safer at the rate for which it is designed.

5.3 Do not use tool if switch does not turn it on or

off. Any tool that cannot be controlled with the switch is

dangerous and must be repaired.

5.4 Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such preventive

safety measures reduce the risk of starting the tool

accidentally.

5.5 Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in the

hands of untrained users.

5.6 Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools with sharp

cutting edges are less likely to bind and are easier to

control.

5.7 Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many accidents

are caused by poorly maintained tools.

5.8 Use only accessories that are recommended by

the manufacturer for your model. Accessories that

may be suitable for one tool may become hazardous

when used on another tool.

6 SERVICE

6.1 Tool service must be performed only by

qualified repair personnel. Service or maintenance

performed by unqualified personnel could result in a

risk of injury.

6.2 When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unau-

thorized parts or failure to follow maintenance instructions may create a risk of electric shock or injury.

GENERAL SAFETY RULES

1 WARNING! Read and understand all instructions. Failure to follow all instructions listed below may

result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS.

2 Work Area

2.1 Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

2.2 Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power Tools create sparks which

may ignite the dust or fumes.

2.3 Keep bystanders, children, and visitors away

while operating a power tool. Distractions can cause

you to lose control.

3 Electrical Safety

3.1 Grounded tools must be plugged into an outlet

properly installed and grounded in accordance with

all codes and ordinances. Never remove the

grounding prong or modify the plug in any way. Do

not use any adapter plugs. Check with a qualified

electrician if you are in doubt as to whether the

outlet is properly grounded. If the tools should elec-

trically malfunction or break down, grounding provides

a low-resistance path to carry electricity away from the

user.

Applicable only to Class I (grounded) tools.

3.2 Double insulated tools are equipped with a

polarized plug (one blade is wider than the other).

This plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the

plug. If it still does not fit, contact a qualified

electrician to install a polarized outlet. Do not

change the plug in any way. Double insulation

eliminates the need for the three-wire grounded power

cord and grounded power supply system.

Applicable only to Class II (double insulated) tools.

3.3 Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body

is grounded.

3.4 Don’t expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

3.5 Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet. Keep

cord away from heat, oil, sharp edges or moving

parts. Replace damaged cords immediately.

Damaged cords increase the risk of electric shock.

3.6 When operating a power tool outside, use an

outdoor extension cord marked “W-A” or “W”.

These cords are rated for outdoor use and reduce the

risk of electric shock.

4 Personal Safety

4.1 Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol or medication. A moment of

inattention when operating power tools may result in

serious personal injury.

4.2 Dress properly. Do not wear lose clothing or

jewelry. Contain long hair. Keep your hair, clothing

and gloves away from moving parts. Loose clothes,

jewelry or long hair can be caught in moving parts.

2

ENGLISH

WS_Nafta_Canada_9770_0205 18.12.2007 13:17 Uhr Seite 2

Before using a grinder or installing a new

wheel, inspect the grinding wheel for

chips and cracks. Remove bad wheels

immediately. Run the tool at no load for

one minute, holding the tool in the

direction away from people. Wheels with

flaws will normaly break apart during this

time.

Carefully handle both the tool and

individual grinding wheels to avoid

chipping or cracking. Install a new wheel

if tool is dropped while grinding. Do not

use a wheel that may be damaged.

Fragments from a wheel that bursts during

operation will fly away at great velocity

possibly striking you or bystanders.

Warning! Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals

known to cause cancer, birth defects or

other reproductive harm. Some examples of

these chemicals are:

– Lead from lead-based paints,

– Crystalline silica from bricks and cement

and other masonry products, and

– Arsenic and cromium from chemically

treated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as dust masks that are specially

designed to filter out microscopic particles.

A damaged or cracked side handle must be

replaced. Never operate a machine with a

defective side handle.

SYMBOLS ON THE TOOL:

Class II Construction

V volts

Hz hertz

A amperes

../min. revolutions per minute

~ alternating current

n

0

no load speed

This symbol designates that

this tool is listed by Canadian

Standards Association, and

listed to Underwriters

Laboratories by Canadian

Standards.

SPECIFIC SAFETY RULES

Caution: Hold tools by insulated gripping

surfaces when performing an operation

where the tool may contact hidden wiring or

its own cord. Contact with a live wire will make

exposed metal parts of the tool "live" and shock

the operator.

Wear ear protectors when using the tool for

extended periods. Prolonged exposure to high

intensity noise can cause hearing loss.

Always wear eye goggles and hearing protection.

Use other available protective equipment such

as protective gloves, suitable protective work

clothing and helmet.

During machining, of metals

in particular, conductive

dust can form deposits

inside the machine. This

can lead to the transfer of electrical energy onto

the machine housing. This can mean a

temporary danger of electric shocks. This is why

it is necessary when the machine is running to

blow compressed air through the rear ventilation

slots of the machine regularly, frequently and

thoroughly. Here, the machine must be held

firmly.

It is recommended to use a stationary extraction

system and to place a ground fault circuit

interrupter (GFCI) downstream.

If the angle grinder is deactivated by the GFCI

circuit interrupter, the angle grinder must be

checked and cleaned. Cleaning the motor, see

Maintenance.

Ensure that sparks produced during work do not

constitute a risk to the user or other personnel

and are not able to ignite inflammable

substances. Endangered areas must be

protected with flame-resistant covers. Make sure

that fire-risk areas are always provided with

suitable fire extinguishers.

If operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your tool.

Electrician´s rubber gloves and footwear will

further enhance your personal safety.

When using grinding wheel attachments, the

guard must always be attached to the tool and

positioned for maximum safety, so the least

amount of wheel is exposed from the side the

tool is being operated.

Grinding wheels or any other accessory must

have a maximum safe operation speed greater

than the “no load RPM” marked on the tool´s

nameplate.

Always use auxiliary handle for maximum

control over torque reaction or kick-back.

Operation of the grinder without the side handle

could cause loss of control of the grinder,

3

ENGLISH

WS_Nafta_Canada_9770_0205 18.12.2007 13:17 Uhr Seite 3

4

ENGLISH

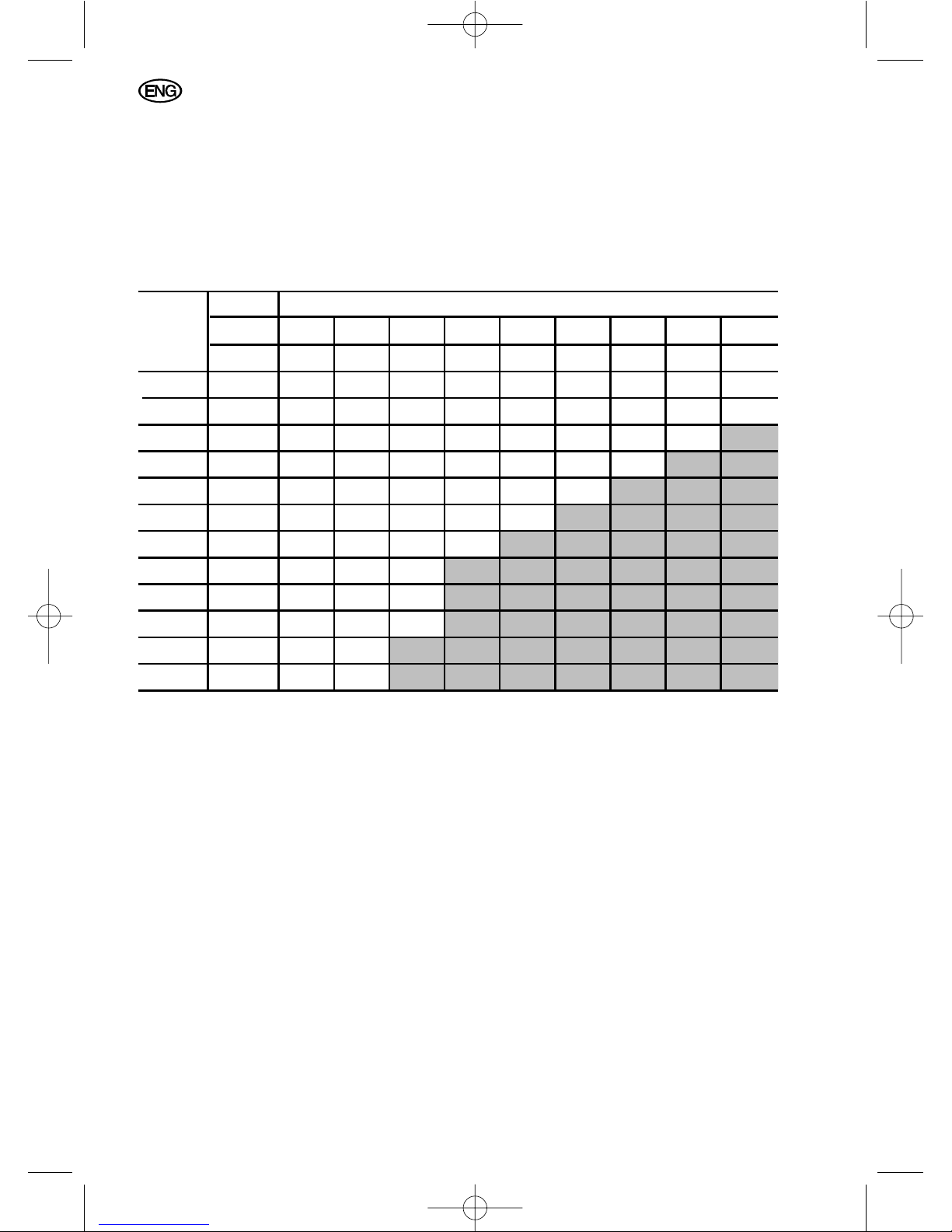

Ampere Volts Length of Cord in Feet

Rating 120 V 25Ft. 50Ft. 100Ft. 150Ft. 200Ft. 250Ft. 300Ft. 400Ft. 500Ft.

Range 230V 50Ft. 100Ft. 200Ft. 300Ft. 400Ft. 500Ft. 600Ft. 800Ft. 1000Ft.

0- 2 18 18 18 16 16 14 14 12 12

2- 3 18 18 16 14 14 12 12 10 10

3- 4 18 18 16 14 12 12 10 10 8

4- 5 18 18 14 12 12 10 10 8 8

5- 6 18 16 14 12 10 10 8 8 6

6- 8 18 16 12 10 10 8 6 6 6

8 - 10 18 14 12 10 8 8 6 6 4

10 - 12 16 14 10 8 8 6 6 4 4

12 - 14 16 12 10 8 6 6 6 4 2

14 - 16 16 12 10 8 6 6 4 4 2

16 - 18 14 12 8 8 6 4 4 2 2

18 - 20 14 12 8 6 6 4 4 2 2

Recommended Minimum Gage for Cord Extensions for Portable Electric Tools

Gage sizes in shaded areas are normally not available as flexible extension cords.

USE PROPER EXTENSION CORD

Make sure your extension cord is in good condition. When using an extension cord, be sure

to use one heavy enough to carry the current your product will draw. An undersized cord will cause

a drop in line voltage resulting in loss of power and overheating. The table below shows the correct

size to use depending on the cord length. If in doubt, use the next heavier gage. The smaller the

gage number, the heavier the cord.

WS_Nafta_Canada_9770_0205 18.12.2007 13:17 Uhr Seite 4

5

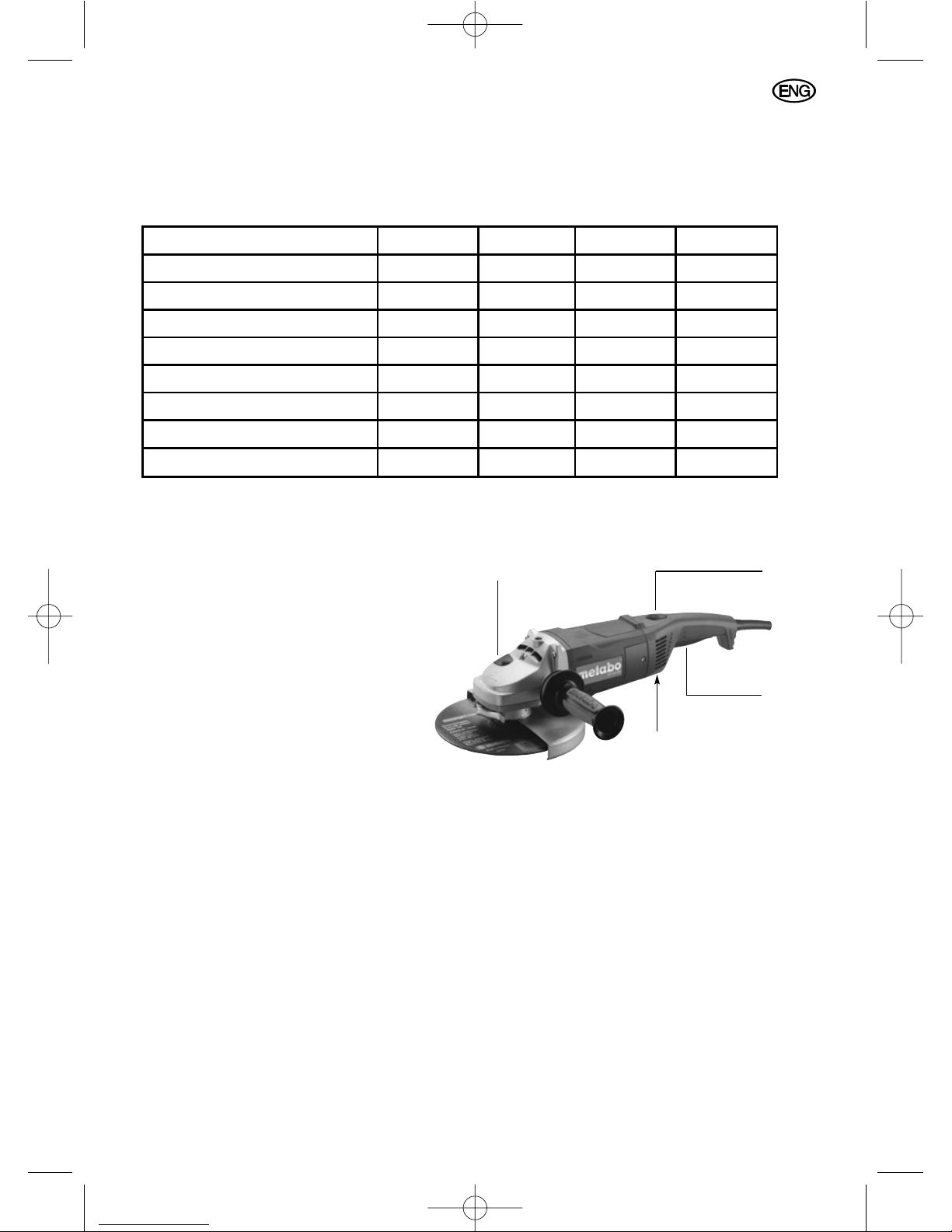

METABO ANGLE GRINDERS

MODELS: W 23-180, W 23-230, W 25-230

ANGLE SANDER: MODEL W 21-230

These angle grinders and sanders are of approved double-insulated construction

and comply with OSHA Standards.

Standard Equipment

Side handle /

Side handle with

vibration damping: 31.400.028/6.27360

Wheel guard:

W21-230 none

W23-180 31.602.589

W23-230 31.602.588

W25-230 31.602.588

Optional Equipment

All models:

Wheel mounting kit Type 27 whls. 55.039

Diamond wheel mtg.kit Ty 1 whls. 55.038

4" Cup wheel guard 23.142

5/8"-11 7" backing pad 23.281

5/8"-11 9" backing pad 23.282

Hand guard 30.332

W21-230, W23-230, W25-230:

5" Cup wheel guard 55.174

6" Cup wheel guard 55.178

W 21-230:

7" Wheel guard 31.602.589

9" Wheel guard 31.602.588

Different grades of grinding wheels, sanding discs, cup wheels and wire brushes as listed in

Metabo Corporation's industrial power tool catalog.

1. Spindle lock button

2. Lock-out button

3. On/Off switch

4. Swivel lock

Specifications W21-230 W23-180 W23-230

For grinding wheels up to

W25-230

N/A

For sanding discs up to

7" dia. 9" dia. 9" dia.

9" dia. 7" dia. 9" dia. 9" dia.

No-load speed 6,000 rpm 8,500 rpm 6,600 rpm 6,600 rpm

18 ampsRated 120 V AC 60 hz.

Watts

Spindle thread

Net weight

Length

15 amps 15 amps 15 amps

2100 2300 2300 2500

5/8-11 5/8-11 5/8-11 5/8-11

10.6 lbs. 10.8 lbs. 10.8 lbs. 11.7 lbs.

19" 19" 19" 19"

ENGLISH

1

2

3

4

WS_Nafta_Canada_9770_0205 18.12.2007 13:17 Uhr Seite 5

Loading...

Loading...