Page 1

CONTENTS

Introduction

.....................................................................................................................................

1. Purpose

2. General recommendations

3. Technical data

4. Complete set of equipment

5. Design and operation principles

6. Operation procedure

..................................................................................................................................

....................................................................................................

.......................................................................................................................

...................................................................................................

...........................................................................................

............................................................................................................

6.1 Preparation for operation

6.2 Operation with electronic module

6.2.1 Beginning of work

6.2.2 “Measurement” mode

6.2.3 “Calibration” mode

6.2.4 “Processing” mode

6.2.5 Connection with computer

6.3 Probe operation

6.3.1 U1 ultrasonic probe

6.3.2 D1 dynamic probe

.............................................................................................

................................................................................

...........................................................................................

......................................................................................

.........................................................................................

..........................................................................................

...............................................................................

...........................................................................................................

..........................................................................................

............................................................................................

7. Technical maintenance and special conditions of operation

8. Precautions and troubleshooting

.........................................................................................

9. Manufacturer’s guarantee and service maintenance

..............................................

...........................................................

2

4

5

5

7

9

12

12

14

14

14

16

18

18

19

19

20

21

22

24

1

Page 2

INTRODUCTION

ThemanufacturerisMET Ltd. The CentreForPhysicalAndMechanicalMeasurements.

The License#000087-IRforproductionandmaintenanceofmeasuringequipmentwasissued

by the FederalAgencyforTechnicalRegulationandMetrologyofRF.Themailingaddressis:

POB 117,Moscow,124460, Russia.

The present Technical Reference and Operation Manual (hereinafter referred to as “TR”) is a

document which certifies the guaranteed by the manufacturer main parameters and technical

characteristicsofportablehardnesstesters in plastic / aluminum body of electronic module :

?Ultrasonic(MET-U1 / MET-U1A)

?Dynamic(MET-D1 / MET-D1A)

?Combined(MET-UD /MET-UDA)

MET-U1 Ultrasonic portable hardness tester is manufactured in compliance with TU 4271 –

001 – 18606393-01).

Certificate of Approval of this type measuring equipment #7951 is registered in SI State Register

under the number of 19623-00 and the equipment is recommended for application in the Russian

Federation.

Registration Certificate #MT 093 2004 is registered in the Industry Register of Measuring

Equipment Recommended to be used in Railroad Transport, Chapter “Measuring Equipment

Used in Locomotive Service”, in the Russian Federation.

Certificate of Approval of this type of measuring equipment #2567is registered in SI State

Register under the number of РБ 03 03 2047 03 and the equipment is recommended for

application in the republic of Byelorussia

.

Certificate of Recognition of Approval of this type of measuring equipment - Series E # 000980

– is registered in the State Register of measuring facilities under the number of # UA-MI/3p-6562004 and the equipment is recommended for application in Ukraine

under the number of 19623-

03.

Certificate of Recognition of Approval of measuring equipment # 2871 is registered in the

Register of the State System for Ensuring Uniform Measurement of the republic of Kazakhstan

under the number of KZ.02.03.01465-2006/19623-00, and the equipment is recommended to be

used and imported into the republic of Kazakhstan

.

MET-D1 Dynamic portable hardness tester is manufactured in compliance with TU 4271 –

003 – 18606393-03).

Certificate of Approval of measuring equipment, type #11910 is registered in SI State Register

under the number of 22736-02 and the equipment is recommended for application in the Russian

Federation.

Certificate of Approval of measuring equipment, type #2566 is registered in SI State Register

under the number of РБ 03 03 2046 03 and the equipment is recommended for application in the

republic of Byelorussia

.

Certificate of Recognition of Approval of this type of measuring equipment -- Series E #000982

- is registered in the State Register of measuring facilities under the number of #UA-MI/3p-6572004 and the equipment recommended for application in Ukraine

under the number of 22736-04.

2

Page 3

Certificate of Recognition of Approval of measuring equipment #2872 is registered in the

Register of the State System for Ensuring Uniform Measurement of the republic of Kazakhstan

under the number of KZ.02.03.01466-2006/22736-02, and the equipment is recommended to be

used and imported into the republic of Kazakhstan

MET-UD Combined portable hardness tester is manufactured in compliance with TU 4271 –

004 – 18606393-04).

Certificate of Approval of measuring equipment, type #11911 is registered in SI State Register

under the number of 22737-02 and the equipment recommended for application in the Russian

Federation.

Certificate of Approval of measuring equipment, type #2568 is registered in SI State Register

under the number of РБ 03 03 2048 03 and the equipment is recommended for application in the

republic of Byelorussia

Certificate of recognition of approval of measuring equipment, - Series E #000984 – is registered

in the State Register of measuring facilities under the number of #UA-MI/3p-658-2004 and the

equipment is recommended for application in Ukraine

Certificate of Recognition of Approval of measuring equipment #11469 is registered in the

Register of the State System for Ensuring Uniform Measurement of the republic of Kazakhstan

under the number of KZ.02.03.00433-2004/22737-02, and the equipment is recommended to be

used and imported into the republic of Kazakhstan

Hardness tester physical form may be slightly different from the models given in the pictures of

the present Technical Reference and Operation Manual. The manufacturer has the right to make

some changes in the tester design, which would not give any impact on the metrological

characteristics without any prior notification.

.

.

under the number of 22737-02.

.

3

Page 4

1. PURPOSE

1.1 Portable hardness tester (hereinafter referred to as the “hardness tester”) is designed to

measure hardness of metals and alloys. There are 8 independent hardness scales in the

hardness tester. Prior to the delivery, the manufacturer carries out the preliminary calibration

of hardness tester on 4 scales, Rockwell (HRC), Brinell (HB), Vickers (HV) and Shore

(HSD). Every scale in the hardness tester is calibrated on reference test blocks (i.e.

conversion tables are not used) graduated on the National Hardness Standards (Scientific

Research Institute for Physical-Technical and Radio-Technical Measurements (VNIIFTRI)

which is the main metrological institute of Russia in the field of hardness measurements, and

which keeps and maintains the state hardness primary standard machines on Rockwell and

Super-Rockwell (GET 30-94), Brinell (GET 33-85), Vickers (GET 31-06) and Shore D

(GET 161-04) scales.), which provides for the highest calibration level. Verification

Certificate of the approved by the state form is attached to every hardness tester.

1.2 In the hardness tester, there is also an tensile strength (R

) scale which, in compliance with

m

GOST 22791-77, enables to define tensile strength of carbon steel of pearlitic class by

automatic recalculation from Brinell hardness (HB) scale.

1.3 In the hardness tester, three additional scales (H1, H2, H3) are provided which make it

possible:

?toconducthardnesstestonotherscales(i.e.,RockwellB(HRB)scale,Superficial

Rockwell (HRNandHRT ) andother);

?toconduct hardnesstest on Leeb (HL) scale instead H1 scale during the measurement

by D1 dynamicprobe (rebound method);

? to conduct hardness test of metals which are significantly different by their properties

from steel (iron, aluminum and copper alloys etc.*).

To calibrate hardness tester, the user should dive not less than 3 samples of the tested article

material with different hardness (minimum, maximum and average).

Hardness tester calibration on the additional (H1, H2, H3) hardness scales can be made by

the manufacturer (according to the order, the service is free of charge) and the information

about it will be in the Technical Reference and Operational Manual (Attachment 2). The user

can make the calibration on additional hardness scales independently by himself following

the instruction of the present Technical Reference.

1.4 Hardness tester is equipped with microprocessor which enables to:

? Delete the measured hardness number in case of doubt in the correctness of the

measurement;

? Compute the average value of a series of the conducted measurements;

? Save the data in the non-volatile memory when hardness tester is switched off;

? Compute the average value from the data saved in the non-volatile memory;

? Transfer data from hardness tester non-volatile memory to the computer for further

printing out and diagramming;

1.5 The hardness tester enables to conduct hardness testing of a metal surface layer which was

fused, sprayed, mechanically or thermally or otherwise treated . Such hardness control is

impossible in case of fixed hardness testers which force through a superficial layer under big

loads. When hardness tester is used, the thickness of metal tested surface shall, at least, be

ten times more than the depth of the probe penetration (p.3). Hardness tester is designed for

non-destructive hardness control of large-sized equipment and the difficult for access places.

Such hardness control is not accessible for fixed hardness testers due to their technical and

design limitations.

Portable hardness testers in comparison with fixed hardness testers are characterized by a

higher productivity, the time of one measurement is 5 to 10 times less.

The hardness tester enables to conduct a quick test of a metal product hardness on site in the

process of operation or manufacturing, under the field or laboratory conditions in the sphere

4

Page 5

1.1 of mechanical engineering, metallurgy, power generation, ship building and railroad

transport, in aviation and space industry, in oil and gas sector, in maintenance and service

companies etc.

Pressure vessels of various purpose (reactors, steam generators, collectors, boiler drums, gas

holders etc.), turbine and generator rotors, pipelines, rolls, crankshafts, gears, parts of various

vehicles, industrial prefabricates articles (castings, forgings, sheets and plates) etc. (MI 2565-

99. Recommendations. “State System for Ensuring Uniform Measurement. Field of

application of hardness testing devices which are subject to verification”).

1.2 The hardness tester can be applied for

? assessment of technological processes stability (equipment treatment, welding etc.);

? diagnostics of equipment with the purpose of assessment of its remaining safe life

(hardness control of pipelines, boilers etc.).

2. GENERAL RECOMMENDATIONS

2.1 The thorough study of the present Technical Reference and Operation Manual is a

mandatory condition for the hardness tester application! Only in this case you can use all

hardness tester possibilities and avoid such actions and errors which are likely to result in the

wrong test results. Read the present Technical Reference and Operation Manual attentively and

only after it start examining the hardness tester.

2.2 Operator’s training requires sufficient knowledge in the field of metal hardness measurement

and metrology on the whole.

2.2.1 In the process of the hardness tester operation, there is always a set of external factors

influencing the test accuracy:

? the condition of the tested article surface (surface stress, contamination, various coatings;

? ambient parameters (humidity, temperature, pollution etc.);

? homogeneity of the tested article material (p. 2.2.4).

2.2.2 The tested surface and the tested article as such shall correspond to the parameters given

in the hardness tester specifications (paragraph 3) and be prepared in the due form

(p.6.1.2). Otherwise, the correct results obtaining is not guaranteed.

2.2.3 The highest accuracy of the results is obtained in the process of testing conducted under

the conditions listed below:

?ambienttemperatureis5...45ºC

? relative humidity is 30 …80%;

2.3 In the process of hardness tester operation, no impact or vibration on it is allowed.

? atmospheric pressure is 84 … 106 kPa.

Careful operation and observation of all technical instructions hereof is the condition for

its reliable operation without maintenance for quite a long period of time.

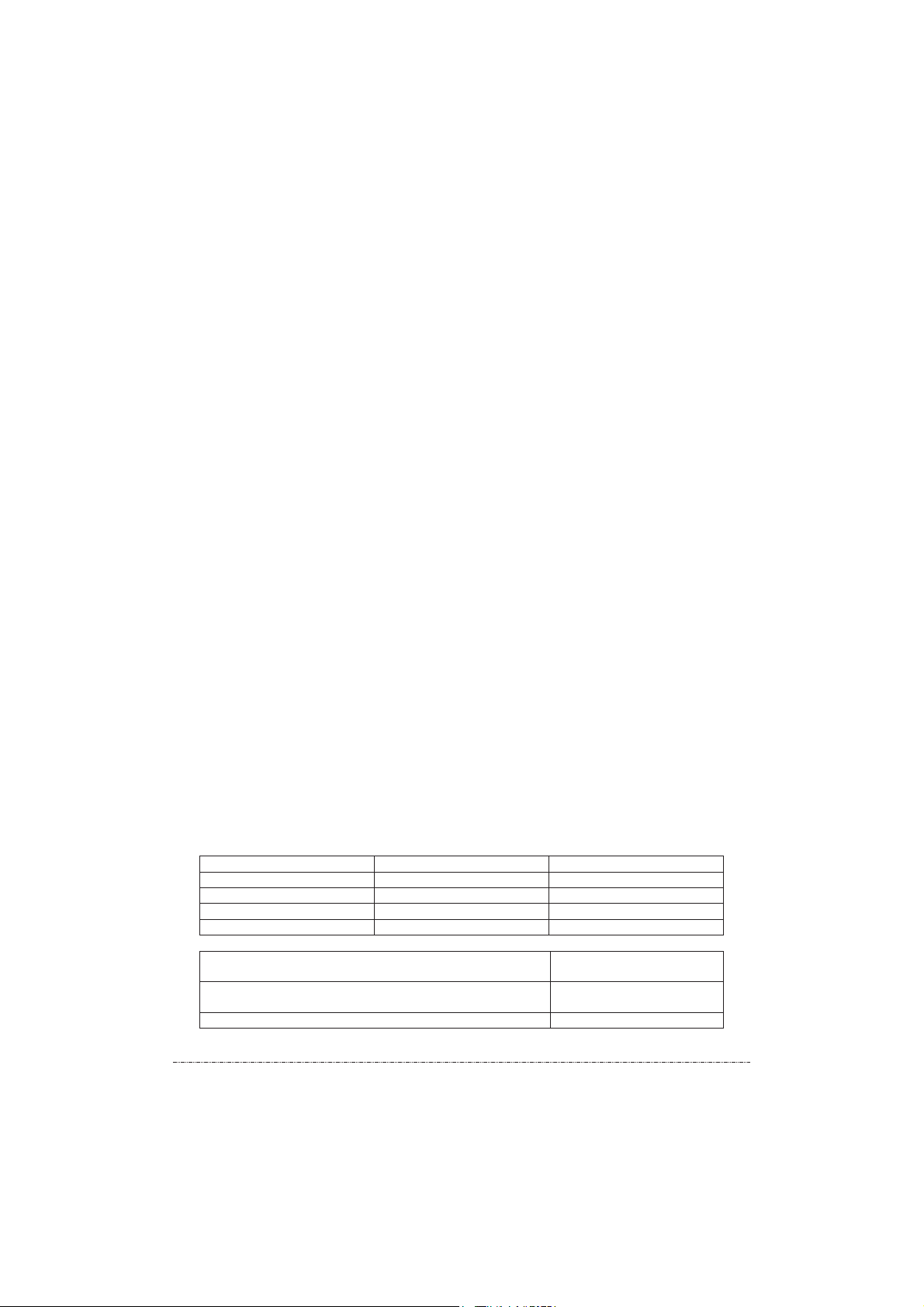

3. TECHNICAL DATA

Rockwell“C” 20…67 HRC ±2 HRC

Brinell 75…650 HB ±10 HB

Vickers

Shore23…102HV±2HSD

ConnectionwiththecomputerviaUSBport,diagrammingand

printingthedataout, data base

Measurements results processing, their averaging, recording and

archival data processing in the hardness tester memory

Non-volatile memory – data saving in archive when hardness Available

Scale Measurement range Error, not more than

75...999HV

Available

Available

±15HV

5

Page 6

Non-volatile memory – data saving in archive when hardness

Available

tester is switched off

Character LCD display: simultaneously displays a hardness

Available

scale, operating mode, archive number and discharge level

indication

LCD display lighting Available

The function of conversion from one hardness scale into another Available

Protective code excluding the possibility of an accidental

Available

hardness tester calibration reset

Hardness tester spatial position during measurements, no angle

correction is needed,

0

Number of current measurements for average value

0 … 360

1…99

determination

Battery (NiMH, C size) charging full time, hours

? Through AC line adapter

? Through USB port from a switched on computer

10

10

Time of uninterrupted operation with fully charged battery, not

- less than, hours:

- without lighting

- with lighting

- from AC mains

20

5

Unlimited

Hardness tester power supply:

- AC mains, V/Hz

- battery, V

consumed power, not more than, V-A

90-240 V, 50-60 Hz

1,2

1,5

Automatic power supply switch off, time, sec 150

Temperature range, ºC:

- during operation

- during storage and transportation

Relative humidity, % 30 … 80

Precious metals and stones

- silver, mg

- diamond (U1 ultrasonic probe), carat

Overall dimensions (length/diameter), max, mm

?electronicmodule in plastic body [in alum. body]

? carry case

Overall dimensions (length/width/height), mm

? ultrasonic probe

? ultrasonic short probe

? dynamic probe

? short dynamic probe

Mass (electronic module in plastic body [in alum. body]), kg:

- module + ultrasonic probe

- module + dynamic probe

- as a complete set (gross)

The number of testing result in the memory (archive) of the

module for every hardness tester probe 100

Time for one hardness testing, sec.

- ultrasonic probe

- dynamic probe

6

-5 … +45

- 15 … +65

16,8

0,07

145/80/40 [180/80/42]

240/180/75

160/225

80/40

140/25

80/25

0,36 [0,65]

0,31 [0.61]

1,0 [1.3]

4

2

Page 7

Tested surface roughness, R

- ultrasonic probe,

- dynamic probe

a

2,5

3,2

Tested surface radius of curvature, mm

- ultrasonic probe

- dynamic probe

5

10

Tested article mass, not less than, kg

- ultrasonic probe

- dynamic probe

0,01

3

Tested article thickness, not less than, mm

- ultrasonic probe

- dynamic probe

1

12

Size of indentation on the tested article surface with 45 HRC

hardness, mm

- ultrasonic probe

- dynamic probe

0,07

0,7

Depth of indentation into a tested article with 45 HRC hardness,

mm

- ultrasonic probe diamond pyramid

- dynamic probe hard alloy ball

30

300

Probe resource (minimum number of testing):

- ultrasonic probe

- dynamic probe

200000

50000

Pressureforceonultrasonicprobe,notlessthan,H9,8

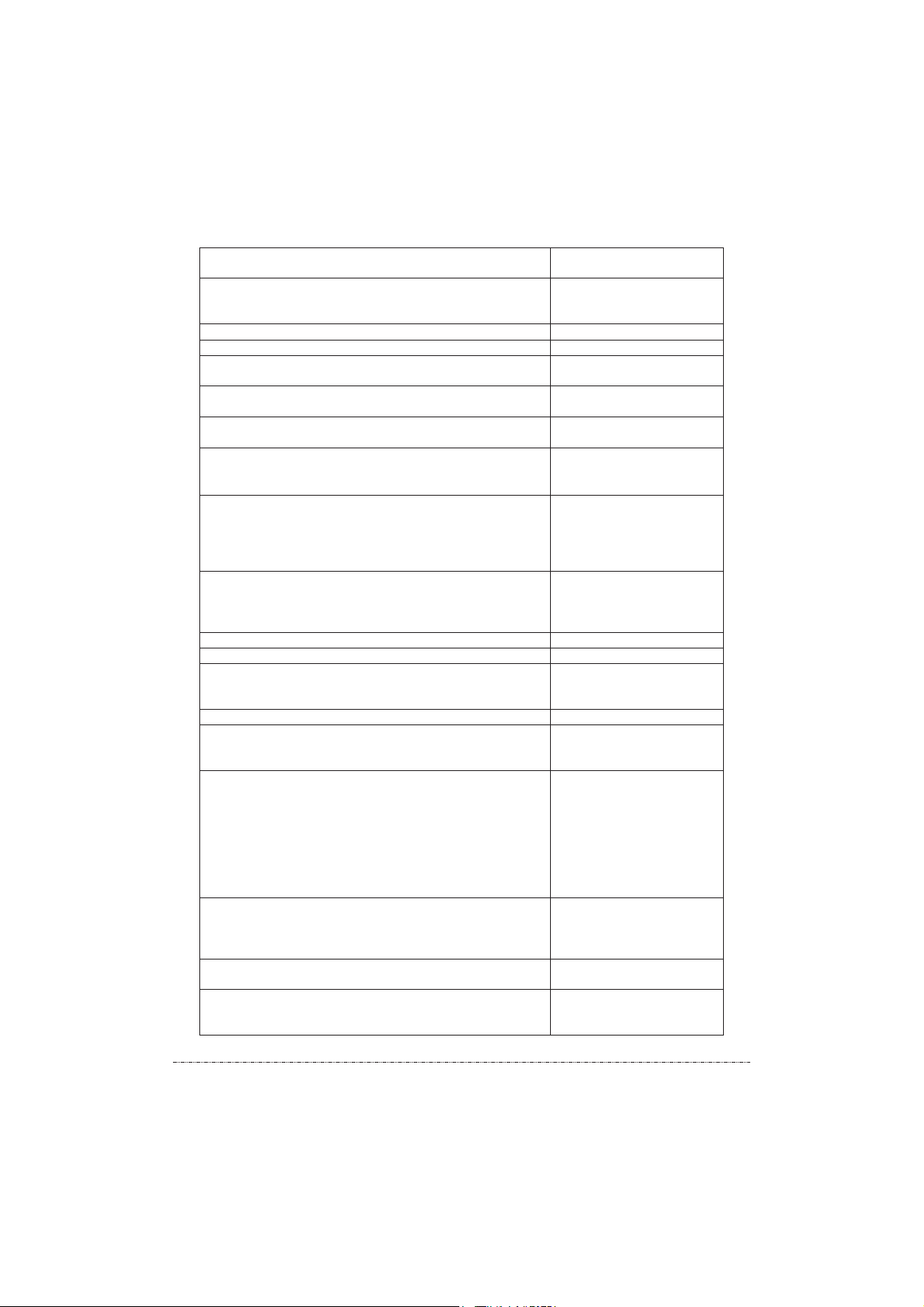

4. COMPLETE SET OF EQUIPMENT

Name Piece, number

Electronicmodule in plastic or aluminum body 1

Case for hardness tester fixing on the forearm, belt, neck 1

Connecting cable for power supply and data transfer to the computer via

USBport 1

U1ultrasonicprobe(forMET-U1/U1A;MET-UD/UDAhardnesstesters) 1

Connectivecableforultrasonicprobe(forMET-U1/U1A;MET-UD/UDA

hardness testers) 1

D1dynamicprobe(forMET-D1/D1A;MET-UD/UDAhardnesstesters) 1

Connectivecablefordynamicprobe(forMET-D1/D1A;MET-UD/UDA

hardness testers) 1

Batterycharger1

NiMhbatteryCsize (plastic body) / AA size (aluminum body) 1 / 4

Carrycase1

TechnicalReferenceandOperationManual1

VerificationCertificateof“VNIIFTRI”FGUP1

USB Cableforcomputerconnection 1

CD with a software and technical support materials 1

7

Page 8

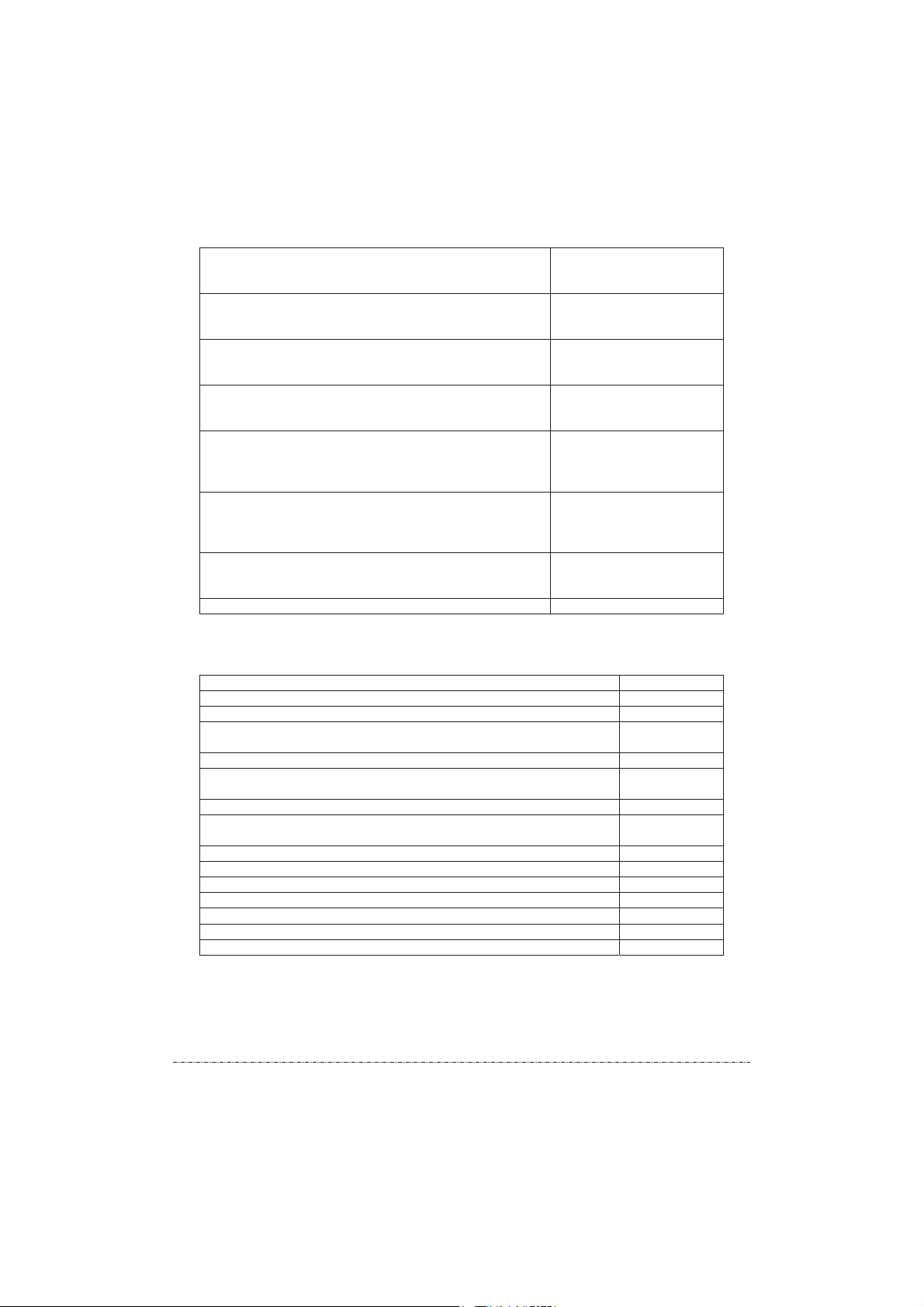

ADDITIONAL ITEMS

(shall be additionally paid)

Reference hardness blocks

(GOST 9031-75; 8.426-81) verified at FGUP “VNIIFTRI” for

hardness tester readings verification and calibration by user

MTR type (Rockwell): HRC, HRA, HRB

MTSR type (Super-Rockwell): HRN, HRT

MTB type (Brinell): HB

MTV type (Vickers): HV

MTSh type (Shore): HSD

Lapping fluid Dynamic probe: for setting test blocks and small-mass articles which were

preliminary fixed on to the testing plate. Ultrasonic probe

: for fixing articles thinner than 1 mm

to the supporting plate of the holder.

Stand for U1 ultrasonic probe is used for testing of small-sized items under the condition of

reliable fixin.

1) To fix the probe in the tube of the stand. 2) To install the spring on top of the probe.

3) To close the upper part of the tube by the iron cup, pressing the spring by the

cup when closing. 4) To install the stand with the probe and the electronic

modulus on the desk in the position convenient for the operator. 5) With the help

of the eccentric handle, to open the probe in the maximum upward position.

6) To put the tested item on the stand base. 7) With the help of collet fixture, by

moving the arm, to fix the distance between the probe tip and the test block

surface of not more than 1 mm. 8) To switch the instrument on and to measure

hardness by lowering the eccentric handle down.

INSTRUCTION FOR -U1 STAND OPERATION:

МЕТ

Battery operated grinder for preparation of testing area on the tested article, lessens surface

roughness, removes rust, wear hardening, scaling and joint weld processing.

Set of replaceable attachments for probes – for hardness testing of cylindrical and spherical

forms.

U1/2 short ultrasonic probe is a short model of U1 ultrasonic probe for testing within a limited

space (inner pipe diameter, sleeves etc.)

D1/2 dynamic probe is a short model of D1 dynamic probe for testing under the condition of

limited space.

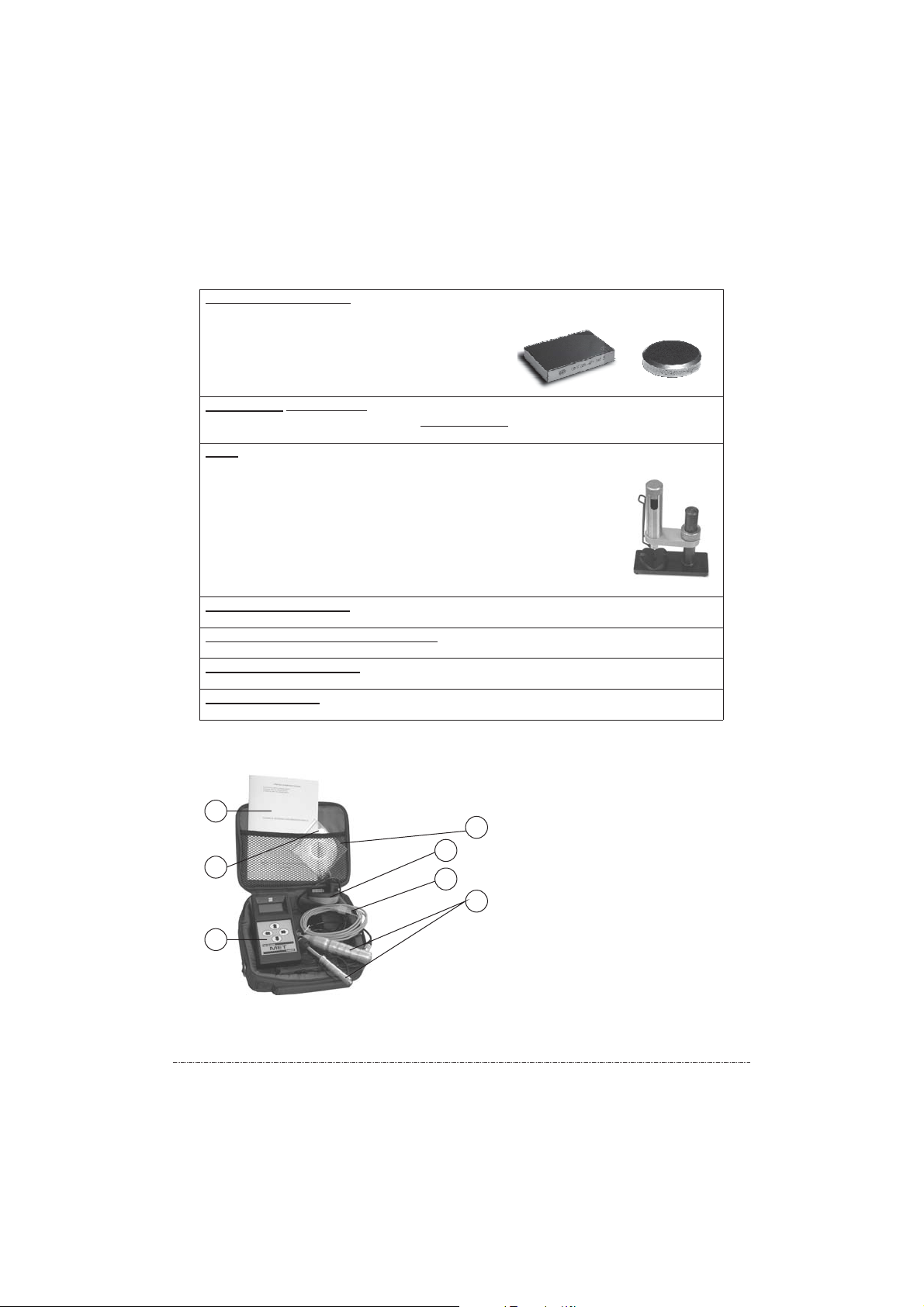

Hardness tester complete set (fig.1):

3

1

5

6

7

2

1 – carry case

2 – probes

3–

Technical Reference and

Operation Manual

4–

electronic module

battery charger

5–

CD

6–

USB cable for computer

7–

4

8

Page 9

5. DESIGN AND OPERATION PRINCIPLES

5.1 Hardness tester is a small-sized instrument designed to measure hardness. It consists of an

electronic module connected with a probe. The choice between ultrasonic and dynamic probe is

made depending on mass, configuration, structure, degree of mechanical and thermal treatment

of a tested article.

1

2

MET-UD combined portable hardness tester (fig.2):

1 – electronic module

2 — U1 ultrasonic probe

3 – D1 dynamic probe

3

Measurement result does not depend on the electronic module and probe spatial position.

5.2 Ultrasonic probe (ultrasonic contact impedance method – UCI) is a separate device

connected with electronic module by cable. Ultrasonic and dynamic probes differ in size only.

5

1

6

2

3

7

The probe basic part is a steel rod with Vickers diamond pyramid at the tip (the angle between

the facets is 136º), which as an acoustic resonator (vibrator) of the in-built ultrasonic frequency

self-excited oscillator. When the pyramid is forced on to the tested article under the calibrated

spring fixed load , the resonator natural frequency depending on the hardness of metal changes.

The oscillator natural frequency relative change is transformed by the electronic module into the

hardness number of the selected scale and is then shown on the display.

This method is suitable for hardness testing of articles with different mass and thickness

and, especially, of articles with thin walls and small mass.

The design of ultrasonic probe makes it possible to conduct testing without any visible imprints

on the surface in hard-reach places (for example, gear teeth etc.), of thin articles (for example,

pipelines etc.), where it is impossible to conduct measurements by dynamic probe.

It should be taken into account that the result of the testing conducted by ultrasonic method

depends on E - elasticity modulus of the tested article.

Limitation: it is not allowed to test articles with coarse-grain structure (for example, iron)

and articles with mass less than 10 kilo or thickness less than 1 mm!

In some separate cases, testing of an article with mass less than 10 kilo and wall thickness less

than 1 mm is possible but only under the condition of using additional accessories to ultrasonic

probe. For a consultation it is required to contact the manufacturer.

4

U1 Ultrasonic probe (fig.3):

1 – sleeve

2 – packing fit ring

3 – packing lower surface

4 – sleeve face

5 – probe body

6 – connective cable

7 – electronic module male connector

9

Page 10

RECOMMENDATION. To test articles with wall thickness less than 2 mm and R of surface

curvature less than 18 mm, it is recommended to use accessories to ultrasonic probe (holder,

replaceable attachments etc. – see paragraph 4)

5.3 Dynamic probe (rebound method) is a device connected with electronic module by cable. D1

dynamic probe and D1/2 short dynamic probe differ in size and spring retracting principle.

D1 dynamic probe (fig.4):

1 – start button

2 – the probe body upper part

3 – the probe body lower part

4 – inductor

5 – hammer

6 -- probe connector plug

7 – electronic module male connector

8 – tester body male connector

Hardness testing principle is based on the determination of the ratio of the stroke and rebound

speed of the hammer which is located inside the probe. At the end of the hammer, there is a

hardmetal ball which contacts directly with the tested surface at the moment of the stroke. Inside

the hammer, there is a permanent magnet. After pushing the start button and with the help of the

preliminary taken up spring, the hammer is forced on to the tested surface. During this process,

the hammer is moving inside the inductor and induces its own electro-motive force. The signal

from the inductor outlet is sent to the electronic module inlet where it is transformed into the

hardness number of the selected scale and is then shown on the display. Hardness testing is

carried out in compliance with ASTM A965-02 “Standard Test Method for Leeb Hardness

Testing of Steel Products”.

This method is suitable for hardness testing of massive articles, coarse-grain articles and

cast and forged pieces.

The probe design enables to conduct a large number of tests over a unit of time, and to operate it

does not require any special skills as, for example, in case of ultrasonic probe.

Limitation: it is not allowed to test articles with the mass less than 3 kilo or thickness less

than 12 mm!

Testing of articles with mass less than 3 kg and thickness less than 12 mm is possible if:

? cast iron testing plate (GOST 10905-86) or certified metal plate with the mass not less

than 5 kg is available;

? lapping liquid for the tested article lapping to the support plate is available;

? the testes article shall be lapped to the support plate TIGHTLY.

When testing of magnetized materials is carried out, the error may increase due to the steel

magnetic field impact on the readings of the hammer movement inside the inductance coil speed.

5.4 Hardness tester electronic module (fig.5)

isaseparatedeviceinaplastic or aluminum body:

1

2

3

*Onthefrontsidethereis:

1) LCD (hereinafter referred to as the “display”);

1

2) four functional push buttons (?, ?, ?, ?);

3) hardness tester type indication;

*onthebacksidethereis:

1)serialnumber;

6

7

5

:

1

2

3

4

1

2

3

4

2) hardness tester operation diagram;

3) manufacturer data;

4) closed compartment for battery;

10

Page 11

1 2

*on the upper end there is:

1) four-pin plug for connecting to a computer or a charger;

2) five-pin plug for probe connection

5.5 On the electronic probe back side, there is hardness tester operation diagram :(fig.6)

HRC HB HV HSD Rm H1 H2 H3

TEST CALIBRATION PROCESSING

Measurement & archive

Measurement on test block 1

Sample limits setting

and average value

Archive

Scale corection

determination

Measurement on test block 2

Scale corection

5.6 Menu is used for hardness tester operation control. Every level of the menu allows the

selection of parameters or modes of operation.

o The first level – “scale” – allows to choose the current (operational) hardness scale from

the following: HRC, HB, HV, HSD, R

ordered.

o The second level - “measurement-calibration-processing” - allows to select the current

(operational) hardness tester mode: measurement, calibration or processing.

o The third level – “YES/NO” allows to confirm or cancel the selected operation and get

back to the former operations by pushing ?button.

5.7 Push buttons ?and ?allow to choose the menu level, and push buttons ? and ? allow to

select a parameter within the level.

5.8 Hardness tester power supply.

5.8.1 The battery located in the closed compartment from the electronic module back side is the

source of the hardness tester power supply. Battery should be installed in compliance with given

polarity.

If hardness tester is not in operation for more than fourteen days, the battery shall taken out from

the electronic module compartment.

5.8.2 The battery charge indication is shown under “battery” symbol in the electronic probe

display upper part. Three dark squares inside the symbol show the battery full charge. As the

battery discharges, the squares disappear one by one from top to bottom. One dark square or

absence of any square means the necessity to charge the battery. “Battery” symbol is shown

on the display under any hardness tester mode of operation. 5.8.3 Battery charging can be from

AC mains through a charger .(fig.7)

, H1, H2 or H3 and also other scales as it is

m

11

Page 12

4

Charger

1 – red optical diode

USB port for power cable male connector2–

3 USB mail connector of power cable–

4 – 4-pin plug of connective cable for connecting

to electronic module

It is allowed to charge the battery and work with the hardness tester simultaneously.

It is prohibited to connect the charger to the electronic probe without the battery.

5.8.4 The charger is connected to the electronic module (with the installed battery only!) through

connective power cable pin plug is equipped with a rotating cylindrical. Connective cable fourlock (fig.8).

To connect the charger, make the following steps:

o Turn the lock counterclockwise up to the stop;

o Bring the plug of the charger into coincidence with the electronic module plug so that they

coincide;

o Insert the plug up to the stop by pushing slightly;

o Turn the lock clockwise up to the stop.

A specific flick of the lock confirms that the operation was done correctly. The charger is

connected to the electronic module. Plug in the USB connective cable. The charger is switched

to the electronic module.

5.8.5 Connect the charger to the AC mains. When the power is on, the optical diode will be red.

The battery charging process has started. After the charger has been connected to the AC mains,

the “battery” symbol squares on the switched on hardness tester

display will get one by one darker from bottom to top. It means that the

battery charging has begun. In the process of charging, the battery and

the charger case may get slightly warm which is not a defect.

5.8.6 The battery can be charged via USB port. To charge hardness test (with the installed

battery) via USB port, first connect a four-pin plug to the hardness tester electronic module (see

paragraph 5.8.4) and after that USB port plug to the computer. The battery charging process has

started. Hardness tester itself shall be switched off.

5.8.6 Hardness tester NiMh battery does not contain any heavy metals harmful for health.

Nevertheless, for environmental protection purpose, do not throw used batteries away to the

household rubbish container. You may send it back to the manufacturer or utilize in compliance

with the rules for used batteries utilization.

(fig.9)

3

1

2

lock

6. OPERATION PROCEDURE

6.1 PREPARATION FOR OPERATION

6.1.1 VISUAL INSPECTION

Make visual inspection of the device, make sure that there is no mechanical damage of the

electronic probe, connective cable. Check the integrity of the seals on the electronic module (in

the battery compartment) and the probe. (paint on the thread connection). Inside the probe, there

is a seal destroyed when the probe is disassembled (shall be opened by the manufacturer

only!)

12

Page 13

6.1.2 TESTED ARTICLE PREPRATION

The mandatory requirements to the tested article:

? During the testing period, the tested article shall be under no load from the main

operational loads.

? The article mass and thickness shall comply with paragraph 3 requirements.

The mandatory requirements to the article surface shall correspond to the parameters given in

? The roughness and radius of curvature of the tested surface shall correspond to the

parameters given in paragraph 3.

? The area of the tested surface shall be free from humidity or contamination (oil, dust

etc.), lubricants, scale, oxide film, rust.

? The distance between the supposed centre of the tested area and the edge of the tested

article surface or the next imprint shall not be less than 3,5 of the diameter (length of

diagonal) of the imprint (paragraph 3).

? In case there is a decarburized layer, surface hardening or nitration case within the tested

area, this surface layer shall be removed (only for U1 ultrasonic probe).

To prepare the area of the tested surface it is recommended to use grinder (additional equipment,

paragraph 4) or polishing paper, after that it is necessary to clean the area with a cleaning cloth.

In the course of the surface preparation procedure it is necessary to take the precaution measures

against the possible change in the hardness of the tested article due to heating or hardening of the

tested surface in the process of the mechanical treatment. The recommend depth of the layer to

be removed:

Forged or drop forged surface : not less than 2 mm;

? ? Cast articles surface : not more than 4 mm;

For pipes : from 4% to 5% from the wall thickness, but not more than 2 mm.?

6.1.3 PROBE CONNECTION

Probe shall be connected to the electronic module by a connective cable. The connective cable

connection to:

? U1 ultrasonic probe

: plug the cable into the probe connector hole and move it as far as it

will go, after that tighten the metal fixing device;

? D1 dynamic probe

: plug into the inductor connector hole as far as it will go (in some

models, there is no such connector hole)

Probe with the connective cable is connected to the electronic module through five-pin plug

equipped with a rotating cylindrical lock (paragraph 5.8.4).

To connect the probe, make the following steps:

o turn the lock counterclockwise up to the stop;

o bring the five-pin probe plug into coincidence with the electronic module plug so that

they coincide;

o Insert the plug up to the stop by pushing slightly;

o Turn the lock clockwise up to the stop.

A specific flick of the lock confirms that the operation was done correctly. The probe is

connected to the electronic module.

6.1.4 POWER SUPPLY SWITHCING ON

o Press ?button for some time (-2 sec);

o After switching for a short time the words “probe connection” will appear for a short time

(-2 sec);

o Electronic module will recognize the type of the connected probe and the relevant words,

either “ultrasonic probe” or “dynamic probe” will appear on the display (-2 sec);

o After these steps, hardness tester will automatically start operation in the mode which

was used before it was switched off.

13

Page 14

6.1.5 POWER SUPPLY SWITHCING OFF

o Power supply switching off takes place automatically without any operation with push

buttons or probe (-150 sec)*;

o It takes place if ? and ? buttons are pushed simultaneously;

o It takes place in case the battery is discharged;

* Due to the hardness tester power supply automatic switch off, the time of its operation

increases without any additional battery charging.

6.1.6 DISPLAY LIGHTING

Display lighting is switched on and off by short-time (-1 sec) pushing ?button from the menu

first level (scale).

Hardness tester operation under the negative ambient temperature (<0C) shall be with the

lighting on.

Attention! Operation with display lighting reduces the time of the device operation since

the battery charges faster!

6.2 OPERATION WITH ELECTRONIC MODULE

6.2.1 BEGINNING OF WORK

6.2.1.1 SCALE SELECTION

o Start work with the first level – “scale” – by pushing ?button. In the display upper part,

words “XXX scale” will appear, where “XXX” is a hardness scale (paragraphs 1.1 and 1.3),

and in the display right side, “battery” symbol will appear (5.8.2).

o Select the hardness scale you need by pushing ? and ? buttons.

o Confirm the selection of the required for you hardness scale by pushing ?button. After that

you will get to the second level automatically.

6.2.1.2 OPERATION MODE SELECTION

o Select the required for you operation mode – “measurement” or “calibration”, or

“processing” by pushing ? or ? buttons.

o Conform the required for you mode by pushing ?button. The hardness tester is ready for

operation.

6.2.1.3 OPERATION CANCELING

To cancel an operation or to return to the previous one use ?button.

6.2.2 “TESTING” MODE

6.2.2.1 “Measurement” mode and all operations within this mode shall be conducted separately

for U1 ultrasonic probe and D1 dynamic probe. The given below operations can be performed in

this mode:

o archive

o testing and recording

6.2.2.2 “ARCHIVE” OPERATION

Hardness tester operation in “measurement” duty always starts with the “Archive” operation.

Indication on the display is shown on the figure below (fig.10):

HV

838

Archv. ?: 63

Attention! During the first operation it is recommended to skip the “archive” operation

and proceed with “measurement and recording” operation. For this purpose, push ?

button and then got to paragraph 6.2.2.3.

14

Page 15

6.2.2.2.1 The meaning of words and symbols on the display

“HV” Vickers hardness scale;

“838” the measured value on Vickers scale;

“Archive #63” - the number of the archive cell in which measurement #838 on Vickers scale

(HV) is stored;

“battery” is battery charge symbol.

6.2.2.2.2 Archive cell number changing

The change of the archive cell number is done by pushing ? or ? buttons. The change of the

archive cell number (Archive #63) will result in the change of the readings of the measured value

(838) into the readings of another measured value saved under the relevant archive number (#61;

63; 60, 64 etc.). The hardness scale (HV), however, will remain unchanged.

It means that if you conducted your measurement on HRC scale and sent it to the archive under

#3 and #4, and the archive is looked through from HV-838-Archive #63, the hardness tester will

automatically transfer HRC and HB hardness scales into HV scale and will show the values of

cells ##1, 2, 3 and 4 on HV scale.

6.2.2.2.3 Conversion of the measured value from one hardness scale into another

? select the scale you need (paragraph 6.2.1.1)

? turn to “archive” operation (paragraph 6.2.2.2)

? by pushing ? or ? buttons, look through the archive;

? all values obtained earlier in other hardness scales will be automatically converted into

the selected by you scale.

Attention! Conversion from one hardness into another has an error.

6.2.2.2.4 To process data in the archive, (mean value computing and archive clearing) switch to

“processing” mode (paragraph 6.2.4)

6.2.2.3 MEASUREMENT AND RECORDING” OPERATION

6.2.2.3.1 Start “measurement and recording” operation by pushing ?button in order to finish and

go out from the “archive” operation. Indication on the display is shown on the figure below

(fig.11).

HB

07

375

Measur ?: 01.

6.2.2.3.2

“ ” Brinell hardness scale;

“ ” current measurement number

“ ” the measured value on Brinell hardness scale (HB);

“measurement №01” the number of the archive cell which is offered for recording of the

measured value on Brinell hardness scale (HB);

“probe” symbol of the probe;

“battery” symbol of the battery.

6.2.2.3.3 Blinking probe symbol means that the hardness tester is ready to conducting

measurements. How to use the probe in the process of “measurement and archive” operation is

described in paragraph 6.3. After the sound signal, the measured on the selected by you hardness

scale value appears on the display (paragraph 6.2.1.1). The measurement number (07) and the

measured value (375) on the hardness scale (HB) correspond to every conducted measurement.

The archive cell number (measure №01) remains unchanged.

6.2.2.3.4. Conducted measurements mean value is computed by pushing ?button. The number of

measurements which are taken for the mean value calculation is show in the current

measurement number (07), i.e. having conducted 7 measurements and by pushing ?button, you

will obtain the mean value.

After the mean value computation, the hardness tester will automatically start the “archive”

operation for you to save the obtained result. If you do not want to save the result and want to

continue your measurement, push ?button to switch to “measurement and recording” operation.

The meaning of words and symbols on the display.

HB

07

375

15

Page 16

6.2.2.3.5 Deleting measurement hardness value

(375) within the “measurement and recording”

operation is made by ? button pushing. It is recommended to delete the last measurement result

in case there appear some doubts in the correct measurement procedure.

6.2.2.3.6 Recording in the archive

shall be started from selecting the cell number and “archive”

operation (paragraph 6.2.2.2.2), after that go to “measurement and archive” operation by pushing

?button.

o to set -00- in the current measurement (07), transition from “measurement and recording”

operation to “archive” and back by pushing ?button two times shall be performed;

o Recording the measured hardness value (375) or mean value (paragraph 6.2.2.3.4) into the

archive is done by ? button pushing. In doing so, the number of the archive cell for

measurement recording (measure №01) will be automatically increased by 1 (measure №2).

o It is recommended to set “00” in the current measurement number for every new set of

measurements.

o Recording into the archive of the measured hardness number (375) or mean value (paragraph

6.2.2.3.4) shall be made by pushing ?button. In this case, the number of the archive cell for

measurement recording (measure №1) will remain unchanged. This is convenient for

changing the archive cell content .

6.2.3 “CALIBRATION” MODE

6.2.3.1 Shall be carried out by highly skilled personnel only and only in the case of production

necessity.

It is not allowed to use reference hardness blocks the shelf life of which has expired (2 years

from the last comparison) or the surface of which was used by more than half (GOST 9031-75)

6.2.3.2 “Calibration” mode and all operations under this mode shall be performed separately for

U1 ultrasonic probe and D1 dynamic probe.

It is recommended to perform hardness tester operation in “calibration” mode when not less than

two squares of the battery charge indication is on.

6.2.3.3 The process of hardness tester calibration by users means bringing mean hardness value

of a reference hardness block measured by the hardness tester into the line (equality) with its

nominal value (engraved on one of its sides in compliance with GOST 9032-75).

Hardness tester calibration by users on HRC, HB, HV, HSD scales allows to introduce a

correction to hardness tester calibration established by the manufacturer straight after the

hardness tester had been manufactured. (paragraph 1-1). Calibration makes it possible to restore

the accuracy of hardness tester readings under the condition of the possible wear and tear of the

probe mechanical parts (spring, hammer) in the process of long and intensive operation.

6.2.3.4 It is recommended to perform hardness tester calibration by users in the period between

verifications in the listed below cases:

o If in the process of the hardness tester verification on the reference hardness block the

readings are stable but differ from the nominal value of the reference hardness block;

o after long period of storage (more than 3 months);

o After intensive operation (more than 200.000 measurements for U1 ultrasonic probe and

50.000 for D1 dynamic probe);

o In case of considerable change in the conditions of operation (ambient temperature, humidity

etc.)

6.2.3.5 For hardness tester calibration by user, it is necessary to have two reference hardness

blocks with maximum and minimum values on the controlled part of the hardness scale.

Examples:

o For calibration along the whole “C” Rockwell scale, TWO reference hardness blocks are

required with the values of (25?5) HRC and (65?5) HRC.

o If you do not use the whole range of “C” Rockwell but only the range of 20?40 HRC,

perform the calibration on reference hardness blocks with the values of (25?5) HRC and

(45?5) HRC.

16

Page 17

6.2.3.6 “CALIBRATION” OPERATION

Select the scale (paragraph 6.2.1.1) and enter into “Calibration” mode. (paragraph 6.2.1.2).

6.2.3.6.1 Enter the code (it is in the sealed envelope inside the Technical Reference and

Operation Manual). Push ?button. The display indication in the “Calibration” mode is show on

the Figure below (fig.12).

HRC

02

64,2

Calib. ?: 02

6.2.3.6.2 The meaning of words and symbols on the display

“HRC” Rockwell hardness scale;

“02” current measurement number

“64,2” the measured value on Rockwell hardness scale (HRC);

“Calibrat№2” calibration number;

“probe” blinking symbol;

“battery” symbol of the battery charge.

6.2.3.6.3 Measurements on reference hardness block #1 (step 1) – obtaining of mean hardness

number. Take one reference hardness block. Conduct not less than FIVE measurements!

Average the obtained values by pushing ?button. Confirm the end of this step by pushing ?

button.

6.2.3.6.4 Correction (step 2) – bring into the line (equality) the measured by the hardness tester

MEAN and NOMINAL hardness value (paragraph 6.2.3.3). By pushing ? or ? buttons change

the MEAN value of the hardness tester up to the NOMINAL value on the hardness reference

block. When the value coincide (become equal), push ?button.

6.2.3.6.5 Measurement on reference hardness block №2 (step3) –repeat the actions described

in paragraph 6.2.3.6.3.

6.2.3.6.6 Correction (step 4) – repeat the actions described in paragraph 6.2.3.6.4. Pushing ?

button will lead to the completion of the step and going out from “Calibration” mode.

6.2.3.6.7 Verification of the hardness tester re adings after the conducted calibration.

Measure the hardness of reference hardness block №1 (not less than 5 measurements) and

compute its mean value (paragraph 6.2.2.3.4). The obtained value shall correspond to its nominal

value within the hardness tester error (paragraph 3).

If the obtained value exceeds the hardness tester error limit (paragraph 3), then perform “CLEAR

(paragraph 6.2.3.5)

6.2.3.7 “CLEAR CALIBRATION” OPERATION

6.2.3.7.1 Hardness tester calibration by users requires highly skilled professional personnel. If

you failed to introduce the correction to the hardness tester calibration for the second time or if

you doubt the results of the conducted “Calibration” operation, it is recommended to perform

“Clear cal.” operation. To obtain technical support, keep in touch with the maintenance service

of the hardness tester manufacturer.

6.2.3.7.2 To clear calibration correction introduced independently, perform the following steps:

o select the scale (paragraph 6.2.1.1);

o enter “Calibration” mode (paragraph 6.2.1.2);

o enter the code;

o push ? button.

After performing “Clear cal.” operation the hardness tester will get to the initial hardness tester

calibration set by the manufacturer straight after manufacturing (paragraph 1.1)

function (paragraph 6.2.3. ) and repeat “CALIBRATION” operationCALIBRATION” 6

.

.

17

Page 18

6.2.4 “PROCESSING” MODE

6.2.4.1 “Processing” mode and all operations within this mode shall be conducted separately for

U1 ultrasonic probe and D1 dynamic probe.

6.2.4.2 Within this mode the listed below operations can be carried out:

o compute mean value;

o clear archive.

Select the scale (paragraph 6.2.1.1). Enter the “processing” mode (sequence of buttons is:

???). Select the necessary for you operation by ? or ? button and confirm your selection by

pushing ?(yes).

6.2.4.3 “MEAN VALUE” OPERATION

“Mean value” operation is used for mean value computation within any interval of the archive

cell (sample interval). Display indication is shown on the Figure below (fig.13).

HSD

96,7

>01 07Avrg.

6.2.4.3.1 The meaning of words and symbols on the display

o “HSD” Shore hardness scale;

o “96,7” mean hardness value on Shore scale (HSD);

o “>01 mean 07” sample interval;

o “battery” battery charge symbol.

The display shows the result of the hardness mean value (96,7) on Shore scale (HSD) for the

archive cells from number one through number seven (<01 mean 07)

6.2.4.3.2 Setting the limits for sample mean value computation:

o Push ?button to move < or > sign to the left initial (>01) or the last right (<07) sample limit;

o Every push of ? or ? button will decrease or increase the left (>01) and the right (<07)

number of the sample limits by one;

o The sample mean value is computed and shown on the display automatically (“96,7”)/

“Mean val.” operation does not change the archive cells content. “Mean val.” operation is

performed only for filled in cells within the sample limits.

6.2.4.4 “CLEAR ARCHIVE” OPERATION

“Clear archive” operation is designed for deleting from the hardness tester memory ALL content

of the archive cells, i.e. reducing to zero of ALL data.

In the “Processing” operation mode, select “clear archive” operation by pushing ? or ? button.

Push ?(yes) button. The words “Please, wait, clear archive” will appear and in two seconds the

archive will be deleted.

6.2.5 CONNECTION WITH COMPUTER

6.2.5.1 The function is for date transfer from hardness tester non-volatile memory (“archive”

e, paragraph 6.2.2.2) to the computer for the purpose of saving, processing, looking through

mod

and selection from the general volume what is necessary for graphs preparation and the further

printing out of the results.

6.2.5.2 Hardness tester soft-are is suitable for WINDOWS (from 98 version to XP).

6.2.5.3 Operation procedure

? Connect the power and data transfer cable to hardness tester electronic module through

four-pin plug (paragraph 5.4) and to the switched on computer via USP port. It is not

required to switch the hardness tester on.

? Insert the attached CD into the computer.

? Install USB driver from “InstallDRVMET” file in compliance with the “Instructions for

USB driver installation”.

? Install “MET hardness tester” soft-ware going to “InstallMET” file and double clicking

on “SETUP_EXE_EXE” file.

18

.

Page 19

? Operate “MET hardness tester” software going to “All software” in the start menu on

your computer.

? In the opened window, of “MET hardness tester” soft-ware, push “?Help” button and set

the operation of the computer with the hardness tester in compliance with “Inquiry”

section.

6.2.5.4 When hardness tester is connected to the switched on computer via USB port, the

battery charging takes place.

6.3 WORK WITH PROBE

6.3.1 U1 ULTRASONIC PROBE

6.3.1.1 Check if the probe packing for (yellow colour, hereinafter referred to as the “packing”) is

installed correctly: the end face of the probe sleeve shall coincide with the packing lower

surface. If the end face is deepened into the sleeve or sticks out, it shall be reinstalled. For this

purpose, unscrew the packing fit ring, match the packing lower surface with and the sleeve end

face in one surface, screw the sleeve fit ring.

Check whether the sleeve has been installed properly before the beginning of

measurement!

6.3.1.2 Fulfill the requirements to the tested article (paragraph 6.1.3), connect the probe to the

electronic module, switch on the hardness tester power supply (paragraph 6.1.4) and turn to the

“measurement” duty (paragraph 6.2.2.3).

6.3.1.3 Ultrasonic probe is extremely sensitive, that is why to operate it, the user should have

special skills and habits. In the process of testing, the article shall be fixed and the probe shall be

installed perpendicular to the measurement area. To avoid any damage to the diamond pyramid,

do not install and move the probe sharply along the tested surface. After pushing on the probe, it

is PROHIBITED to move it along the article surface!

To avoid wrong actions in the process of testing and to ensure reliable fixing, it is recommended

to use additional accessories to U1 ultrasonic probe: holder, lapping fluid, replaceable

attachments for cylindrical and spherical surfaces (paragraph 4).

6.3.1.4 THE FIRST MEASUREMENT

Loading diagram for U1 ultrasonic hardness probe (fig.14):

insta ll the probe make a light effort increase the effort keep the effort stop the effort

1,5 kg

S

measurement area resistance stop

o Blinking of “probe” symbol on the display means that the hardness tester is ready to conduct

measurements.

o Install the probe with its packing lower surface to the measurement area of the tested

article. Press the packing with two fingers of one hand to the measurement area and keep it

stable in the process of measurement. Take the body of the probe in the other hand.

o Press into the probe body slightly until the first resistance – diamond pyramid of the rod

comes up against the surface. Increase the effort immediately until the second resistance

(stop) – the diamond pyramid is forced into the surface. The effort should be made

smoothly*. Be sure that your hand does not shake so that the probe body is stable. For the

probe correct operation, it is necessary to apply an effort of not less than 14,7 N (1,5 kgf) to

its body and keep is stable in the process of measurement. Do not be afraid to apply an

excessive effort to the probe body, it will be limited by the stop.

19

Page 20

o Keep the constant effort on the probe body during 3-4 seconds. “Probe” symbol on the

display will stop blinking.

o After the sound signal and appearance of the hardness value on the electronic probe display,

stop making the effort on the probe body. The “probe” symbol on the display will start

blinking again, and the probe body will under the spring effort return to the initial position.

The first measurement has been completed, and the hardness tester is ready for the next

measurement.

*In case of sharp pressing on to the probe body, diamond pyramid can hit the surface of the

tested item, and due to this the measured hardness value will be incorrect.

6.3.1.5 EXPERIMENTAL MEASUREMENT

It is advisable to consider the first measurement as experimental measurement. In order to

acquire some experience of how to use the probe, it is recommended to conduct a number of

experimental measurements.

o After experimental measurement conducting, push ? button to delete the result and

exclude it from the article mean hardness value computation (paragraph 6.2.2.3.5).

o After a number of experimental measurements has been conducted for the purpose of

acquiring some experience of using the probe, you may use “Clear archive” function to

delete the results of the experimental measurements (paragraph 6.2.4.4).

6.3.1.6 ACQUIRING SOME EXPERINCE OF WORKING WITH THE PROBE

6.3.1.6.1 To acquire experience of working with the probe, it is recommended to use reference

hardness blocks. Measure the hardness of a reference hardness block (not less than 5

measurements) and compute its mean value. If the obtained value does not correspond to the

number of the reference hardness block, conduct one more measurement.

6.3.1.6.2 If the hardness tester readings are stable and the obtained mean value corresponds to

the reference hardness block rated value considering the hardness tester error (paragraph 3), you

may further proceed with the hardness tester.

6.3.1.7 The rules of U1/2 short probe operation are similar to those for U1 ultrasonic probe.

Holders for U1/2 are not produced.

6.3.2 D1 DYNAMIC PROBE

6.3.2.1 Be sure that the requirements to the tested article (paragraph 6.1.2) are observed, connect

the probe to the electronic module (paragraph 6.1.3), switch the power supply on (paragraph

6.1.4) and turn to the “measurement” mode (paragraph 6.2.2.3).

6.3.2.2 In the process of measurement, the article shall be fixed and the probe shall be fixed

perpendicular ! to the measurement area. At the moment of start button pushing, IT IS NOT

ALLOWED to move the probe along the tester surface.

6.3.2.3 THE FIRST MEASUREMENT

o Blinking of “probe” symbol on the display means that the hardness tester is ready to conduct

measurements.

o Install the probe to the article measurement area. With your one hand hold the inductor (the

probe lower body), with the other hand, hold the probe upper body. The upper probe body

shall be then moved to the lower body up to the stop and then set it free. The spring is taken

up and the probe upper part returns to the initial position independently.

o Press the launch button in the probe body upper part smoothly. Be sure that the probe does

not move and is properly pressed to the measurement area.

o After pushing the launch button and the hammer stroke at the measurement area, there will

be a sound signal after which the indication of the measured hardness value will appear on

the electronic module display.

6.3.2.4 EXPERIMENTAL MEASUREMENT

It is advisable to consider the first measurement as experimental measurement. In order to

acquire some experience of how to use the probe, it is recommended to conduct a number of

experimental measurements.

20

Page 21

o After experimental measurement conducting, push ? button to delete the result and

exclude it from the article mean hardness value computation (paragraph 6.2.2.3.5).

o After a number of experimental measurements has been conducted for the purpose of

acquiring some experience of using the probe, you may use “Clear archive” function to

delete the results of the experimental measurements (paragraph 6.2.4.4).

6.3.2.5 Attention: the minimum distance between the measurement points (imprints) shall

be not less than 3 mm. Repeated measurements in one and the same point are not

admissible since it results in the increased hardness value indication due to the metal

hammering harden in the imprint area.

6.3.2.6 ACQUIRING SOME EXPERINCE OF WORKING WITH THE PROBE

6.3.2.6.1To acquire experience of working with the probe, it is recommended to use reference

hardness blocks. Measure the hardness of a reference hardness block (not less than 5

measurements) and compute its mean value. If the obtained value does not correspond to the

number of the reference hardness block, conduct one more measurement.

6.3.2.6.2 If the hardness tester readings are stable and the obtained mean value corresponds to

the reference hardness block rated value considering the hardness tester error (paragraph 3), you

may further proceed with the hardness tester.

6.3.2.7 The rules of D1/2 short probe operation are similar to those for D1 ultrasonic probe. The

difference is only in the mechanism of spring taking up (paragraph 6.3.2.3). To take it up, it is

necessary to use the metal rod attached to short probes with the help of which the hammer

should be placed back into the probe till the stop.

7. TECHNICAL MAINTENANCE, SPECIAL CONDITIONS OF OPERATION

7.1 On the whole, hardness testers do not require any special maintenance. However, for the

purpose of hardness tester stable operation, regular maintenance is advisable.

7.2 PROBE MAINTENANCE

Clean hardmetal ball and diamond pyramid from dust, mud and oil traces. Use soft cloth

impregnated with alcohol solution.

Check the probe operation regularly by conducting hardness measurements on hardness

reference blocks. Do not use reference test block with expired period between verifications

(more than 2 years).

7.3 ELECTRONIC MODULE MAINTENANCE

To clean from any pollution, use soft dry cloth. Do not use the water, since the hardness tester is

neither spray-proof nor water-proof due to the joints on its body.

Do not use any solvents, they can damage indication signs and writings on the front and back

sides of the body.

7.4 BATTERY MAINTENANCE

Thebatteryaveragelifeisnotlessthan3years.Thebatteryusedincompliancewiththe "C" or

"AA" internationalstandard.Itisdonefortheconvenienceofitsreplacementwhenitisrequired

or sharp reduction of the continuous operation time (paragraph 3) independently of the country..

Replacement is possible only by the battery with similar characteristics in compliance with the

marking on it. From environmental protection point of view, the best thing is to use the battery.

7.5 STORAGE

7.5.1 Hardness tester shall be kept in the carry case, the probe and the battery shall be

disconnected. We recommend to keep Verification Certificate in the carry case inner pocket.

7.5.2 If hardness tester is kept in the carry case for than 14 days, the battery shall be taken out

from its compartment in the electronic module.

7.5.3 It is recommended to keep hardness testers in closed premises with the relative humidity

not more than 80%, there shall be no mold, paints, acids, chemical agents and other chemicals,

the evaporation of which my give a harmful effect. Sharp fluctuations of temperature and

humidity which can result in dew formation are not allowed.

7.5.4 It is recommended to keep hardness testers in the carry case in any spatial position not

more than 5 pieces put on one another which is relevant to the load of 5 kg under the condition

of its even distribution along the carry case surface.

21

Page 22

7.6 TRANSPORTATION

7.6.1 Hardness testers transportation in the carry case shall be only in closed vehicles, where the

possibility of mechanical damage or atmospheric precipitation is excluded.

7.6.2The way packed in carry cases hardness testers are located inside the vehicle shall exclude

the possibility of their free movement both inside the carry case and inside the vehicle.

7.7 PUTTING INTO OPERATION AFTER STORAGE AND TRANSPORTATION

7.7.1 After storage or transportation under the temperature lower than -5°C, before starting

hardness tester operation, it is necessary to keep it not longer than 1 hour under the temperature

higher than +10°C and not less than 2 hours under the temperature higher than 0°C.

7.7.2 Before operating hardness tester which was stored for more than 3 months and transported

for more than 2 months, it is necessary to check such hardness tester on the reference hardness

test blocks. If the measured AV EARGED value of the hardness tester does nor correspond to the

reference hardness test block NOMINAL value within the error limits (paragraph 3), it is

necessary to calibrate the hardness tester (paragraph 6.2.3).

7.8 SPECIAL OPERATION CONDITIONS

7.8.1 Increased dust content and humidity

. Put the electronic module of hardness tester into a

transparent plastic bag. Tighten it at the level of connective cable a bit lower than the probe plug.

After the work under such conditions is finished, electronic module shall taken out of the plastic

bag and air it.

7.8.1 Negative temperature (<0°C)

. Electronic module is the most sensitive to low temperature

part of hardness testers, especially it is true for LCD. That id why it is mandatory to switch the

display lighting on (paragraph 6.1.6). If there is a possibility, keep hardness tester closer to your

body and protect id with your coat or keep in the inside pocket, taking it out time from time for

inputting the data into the archive.

8. PRECAUTIONS AND TROUBLESHOUTING

8.1 Treat the hardness tester with care. Any wrong treatment may result in the violation of the

present Technical Reference and Operation Manual regulations and, thus, lead to the

manufacturer hardness tester warranty cessation.

8.2 Always check the integrity of the cables, electronic module and probe. Provide immediate

replacement of the damaged parts by the original ones. This job shall be performed by skilled

personnel.

8.3 Do not expose the hardness tester to aggressive chemical medium.

8.4 Do not leave the hardness tester in the direct Sun.

8.5 Do not sink the hardness tester into any liquids. If the hardness tester gets wet, take the

battery out and leave for 24 hours to get dry.

If the hardness tester is used under the increased humidity or dust conditions, place the electronic

module into the plastic bag. After work period is over, it is mandatory to get the hardness tester

dry.

8.6 The list of the possible problems in the process of hardness tester operation is given in the

Table below.

22

Page 23

Problem Reason Solution

switch on

Readings on the

display do not

change

Display switched off

in the process of

measurement

Probe blinking

stopped in the

“measurement”

mode

Measurements

results are stable but

differ from reference

hardness block

nominal value

Big range of the

measurement results

The battery is discharged Charge (p. 5.8.4) or replace (p. 7.4)Display does not

The battery is not installed

correctly

There is no contact in the

connector of the probe with the

electronic module

Break in the connecting cable or

connector; fault of the probe of

electronic module

Testing of articles which do not

correspond to the hardness tester

specifications (paragraph 3), for

example, low hardness of the

article

Reference hardness test block has

expired inter-verification period

(more than 2 years)

The spring of the probe has been

worn out after long life

The tested material has not uniform

in its structure.

Tested area has not been prepared

properly

The diamond pyramid or hardmetal

ball are polluted.

The diamond pyramid tip or

hardmetal ball are damaged

D1 DYNAMIC PROBE

Reinstall, observe the indicated

polarity (p.5.8.1)

Check the connection reliability

(p.6.1.3)

Address the service centre (p.9.4)

Switch the hardness tester off by

pushing ?button. After one minute

switch the hardness tester on by

pushing ?button. If the hardness

tester does not switch on, take the

battery out from its compartment in

the electronic module. Install it

back in two minutes and switch the

hardness tester on by pushing ?

button. Carry out one measurement

for checking purpose on the

reference hardness test block. In

case the established error

(paragraph 3) is exceeded, make

the hardness tester calibration

(paragraph 6.2.3)

Calibrate the hardness tester

independently on the reference

hardness blocks (p.6.2.3)

Increase the number of

measurements

Polish additionally (p.6.1.2)

Clean from the polluted pieces

(p.7.2)

Address the service centre (p. 9.4)

23

Page 24

The probe is not enough pressed to

the tested article

The hardness reference block

surface is covered by the imprints

from the previous measurements

The packing on the probe body is

displaced

Too high hardness

indications after the

repeated use on the

samples with big

hardness

Too high hardness

indications when

hardness of cylinder

shaped articles with

surface hardening is

measured

9. MANUFACTURER’S GUARAMTEE AND SERVICE MAINTENANCE

9.1 Hardness tester guarantee period is 24 months from the date of the hardness tester

Acceptance Certificate issue (Annex 1). The guarantee maintenance is done upon the guarantee

coupon presentation.

9.2 Hardness tester guarantee period is considered to be expired in case the seal of the electronic

module or probe is violated.

9.3 The guarantee does not cover hardness tester battery.

9.4 In case your hardness tester does nor work , the following steps shall be done:

? Use the information from the Table, paragraph 8.6;

? Contact the manufacturer guarantee service for technical support (consultation)

? Prepare technically grounded reclamation document and send it together with the

hardness tester to the guarantee service at the address: 124460 Moscow, Zelenograd,

POB 117;

9.5 Post guarantee maintenance is conducted by the manufacturer service centre upon the

Customer request.

Hardmetal ball deformation

Influence of the articles surface

tensions

U1 ULTRASONIC PROBE

D1 DYNAMIC PROBE

Conduct the repeated test correctly

(p.6.3.2.3)

Use a new reference hardness

block (p. 6.3.2.6)

Check if it was installed correctly

(p. 6.3.1.1)

Calibrate the hardness tester

independently on the reference

hardness blocks (p.6.2.3)

Use U1 ultrasonic probe

(paragraph 6.2.3)

24

Loading...

Loading...