Defender

User Manual

™

530

Table of Contents

Introduction ............................ 1.0

Operation ................................... 2.0

Battery ........................................2.1

Activation ....................................2.2

Connections ................................. 2.3

Display Screen .............................2.4

Menu Navigation ..........................2.5

Set Up ......................................... 2.6

Measurements .............................2.7

Single .......................................... 2.8

Burst ........................................... 2.9

Continuous ..................................2.10

Data Port .................................... 3.0

DryCal Pro Software .....................3.1

Defender Firmware Upgrades ........ 3.2

Annual Maintenance & Cal ......... 4.0

Shipping ..................................... 5.0

Storage ....................................... 6.0

Defender 530 Specications ...... 7.0

Factory Default Settings ............ 8.0

Limited Warranty ....................... 9.0

Troubleshooting ......................... 10.0

Introduction

1.0

Operation

Data Port

Annual Maintenance and Calibration

Shipping

Storage

2.0

3.0

4.0

5.0

6.0

Defender 530 Specications

Factory Default Settings

Limited Warranty

Troubleshooting

7.0

8.0

9.0

10.0

1.0 Introduction

The Defender 530 measures both volumetric and standardized gas ow with a volumetric

ow accuracy of 1% and standardized ow accuracy of 1.2% of reading. It uses our Proven DryCal Technology to measure volumetric gas ow and is manufactured in our accred-

ited laboratory in Butler, NJ.

This manual will provide information needed to operate your Defender. If at any time you

have questions regarding its operation, please contact Mesa Labs through our Web site

(drycal.mesalabs.com) or call 973.492.8400 to speak with a member of our professional

customer service staff.

Your Defender

Your Defender comes with the following:

• AC Power Adapter/Charger

• PC Serial Cable

• Leak Test Caps (2); Save for use during the Leak Test

• Calibration Certicate

• Manual

Carrying cases and accessories are available for purchase from Mesa Labs or your distributor.

2

2

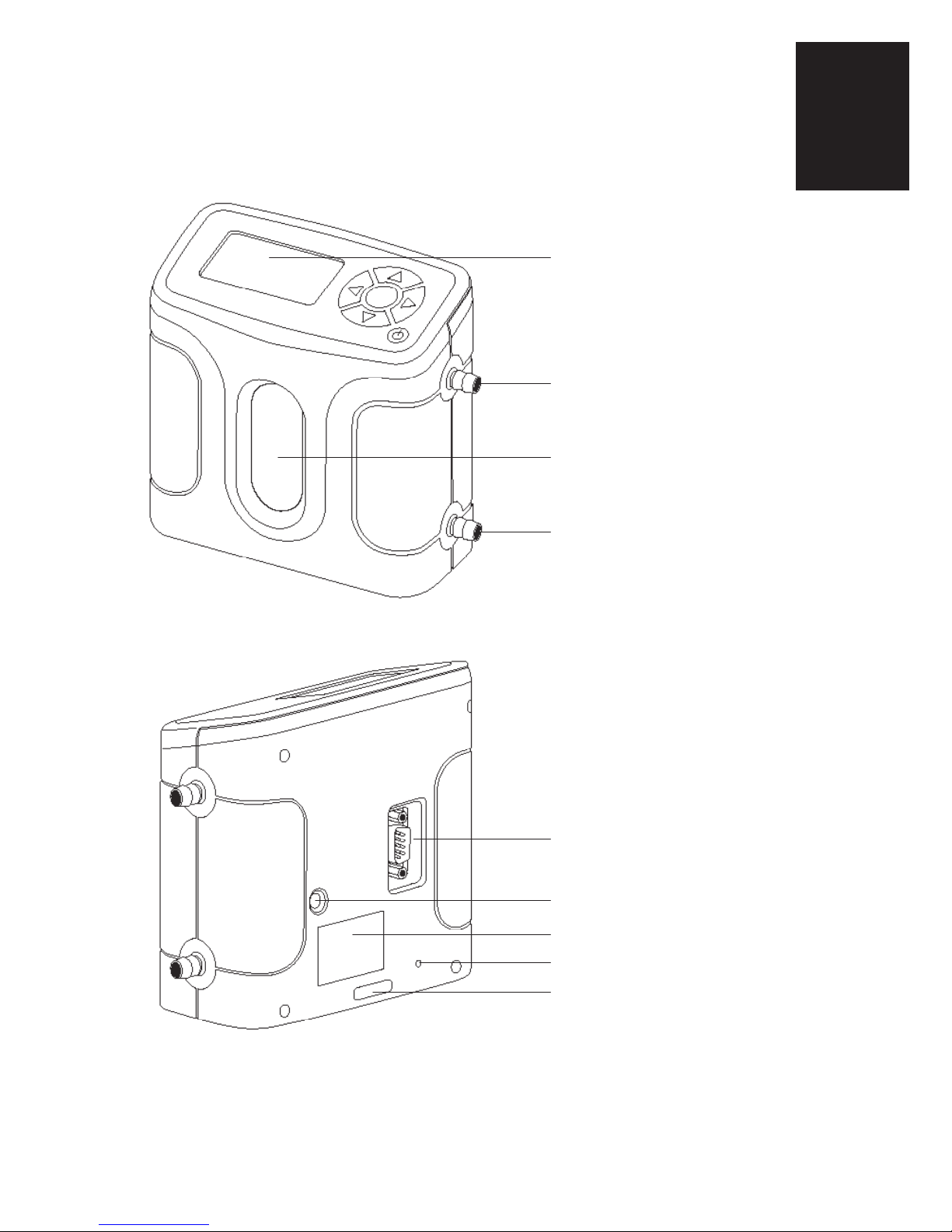

Display

Suction Fitting

Measuring Cell

Pressure Fitting

1.0

Data Port

3

Charging Jack

Calibration Label

Reset Button

Anti-tamper Label

3

2.0 Operation

2.1 Battery

Charging, installing and monitoring your Defender battery

Your Defender battery is charged at the factory, but we recommend that you make sure it

is fully charged before initial use.

• Connect the AC power adapter to the Defender’s Charging Jack (DC In).

• Plug the AC power adapter into an AC outlet.

Initial charging should take about eight (8) hours.

After the initial charge:

• You may continue to charge your Defender indenitely simply by leaving it connected to

the AC power adapter.

• Be sure to charge the battery at least every three (3) months, to maintain battery life.

The battery symbol on the LCD display indicates your Defender’s battery charge condition.

A shaded battery icon indicates a full charge. As the battery voltage drops, the indicator

will empty in 20% increments.

4

4

2.0

Disposal:

In compliance with the European Union CE directive 2006/66/EC the battery in your Defender should be removed for recycling prior to disposal of the Defender. The battery in

the Defender is a valve regulated sealed lead acid battery. Please note that opening the

Defender may damage connections so this procedure should only be used for battery disposal.

Procedure:

Remove ve Phillips head screws on the back of the Defender; one will be located under

the calibration void label. Lift off the rear cover and disconnect the two pin connector from

the battery to the printed circuit board. Lift the battery from the case.

5

5

2.2 Activation

Turning your Defender on and off

Simply press the power button.

• Press the On/Off button for 1 second to turn on your Defender.

• When rst turned on, your Defender displays an opening screen showing the product

name, model number and ow range.

• Press the On/Off button for 3 seconds to turn your Defender off.

2.3 Connections

Attaching your Defender to a device

Connect device to be calibrated to the appropriate Defender port. Use 1/4 inch diameter

tubing.

• Connect to outlet at top (suction tting) when a device draws air (such as sampler).

• Connection tubing to bottom inlet for devices that push air in (pressure devices).

6

6

2.0

2.4 Display Screen

Understanding the screen components

The Defender 530 provides a menu of operational settings and commands. The four directional arrow buttons on the control panel allow you to navigate through the menu and

select the desired settings for your Defender. Your location within the menu is highlighted

for easy identication.

2.5 Menu Navigation

Moving through operational menus

• Use the directional arrows , , and on the control panel to nd your way

through the menu.

• When your desired command is highlighted, simply press the ENTER button on the

control panel.

If you see a menu selection within angle brackets (<….>), that means you have multiple options for an item. Press the left or right (or ) arrow button to see the options.

If you wish to use the factory settings proceed to section 2.7 Measurements.

7

7

Defender 530 M

Range: 50–5,000 mL/min

with DryCal Technology®

MEASURE | SETUP

Control Panel

LCD Screen

On/Off Button

2.6 Set-up

Customizing the Defender to your needs

You can customize your Defender in the SETUP menu. Highlight SETUP in the introduction screen to enter the Setup Menu. Or, highlight SETUP after resetting and then exiting

a measurement mode screen. The SETUP menu has eight submenus.

• Readings • Date • Diagnostics

• Units • Preferences • About

• Time • Power

To select a submenu, use the directional arrow buttons to highlight the submenu and

press the Enter button.

In submenus, brackets (i.e., <...>) indicate different selection options. You can switch

back and forth by pressing the forward or backward (or ) arrow.

Highlight CONFIRM after making changes and press the Enter button to save the

8

changes made.

‘Conrmed, New Settings Will be Retained’ message will appear in the screen for a

brief period before it returns to Setup menu.

Highlighting EXIT and then pressing the Enter button will return you to the SETUP

menu without saving any submenu changes.

8

2.0

Readings

Choose the ow reading type to either volumetric ‘Vol’ or standardized ‘Std’. Volumetric

ow is the actual ow at the ambient temperature and pressure whereas the standardized ow indicates a ow rate at a specic temperature and pressure. Standardizing pres-

sure is set to a default value of 760 mmHg whereas standardizing temperature is an user

settable value set at ‘Std To’ in the ‘Units’ sub-menu.

Choose the number of measurements in the average from 1 to 100.

If you wish to incorporate a time delay between consecutive measurements, set Time

Between from 1 to 60 minutes.

Set the Sensor Factor to any value between 0.200 to 3.000. Sensor factor scales the read-

ing for calibrating MFCs and MFMs with surrogate gases. Sensor factor affects the ow

rate measurement only when the reading ‘Type’ is set to standardized ‘Std’.

9

9

Units

Measure gas Flow in cubic centimeters, milliliters, liters or cubic feet (all units are

per minute).

Measure Pressure in mmHg, kPa or PSI and Temperature in Celsius or Fahrenheit.

Set the standardizing temperature by setting ‘Std To’ to a value from 0 to 50 deg C or 32

to122 deg F. ‘Std To’ effects the ow rate measurement only when the reading ‘Type’ in

the ‘Reading’ sub-menu is set to standardized ‘Std’.

Time

Set the current time and the format.

The format can be selected as PM, AM, or 24H.

Date

Set the date and the format.

The format can be selected as DD (day)-MM (month)-YYYY (year) or MM (month)-

DD (day)-YYYY (year).

10

10

2.0

Preferences

Read Default

Select a preferred mode of measurement when the Defender is initially turned on.

Default Settings

Select <No> to allow the ‘Read Default’ change. Selecting <Yes> will reset your Defender

to the factory default settings. (Factory default settings are provided elsewhere in this

manual.)

Data Port

Set the data port interface by selecting:

<BIOS> to operate with Bios DryCal software.

<SKC> to operate with SKC CalCheck® Interface.

Magnication

Controls the amount of data on the display. Select <Zoom> to view only ow measurements in larger font, or select <Detail> to simultaneously view ow measurements,

temperature, and pressure in a smaller font.

Power

11

Power Save

By selecting <On>, your Defender will save power by turning off after ve minutes of

inactivity. However, it will not turn off when connected to the AC power adapter/charger.

Select <Off>, and your Defender will remain on until you manually turn it off.

Backlight

Select <On> to illuminate the LCD display or <Off > to conserve battery power.

11

Diagnostics

The Defender leak test is designed only to verify the

internal integrity of the instrument and alert you to an

internal leak. We recommend performing the Leak Test

only as an intermediate quality control check or whenever the integrity of the instrument is questioned due

to misuse or accidental damage.

Please note that a leak test is not a substitute for a

comprehensive examination of the unit’s overall performance and it does not ensure that your Defender is

operating accurately.

• Invert your Defender and allow the piston to travel to

the top.

• Cap the port under test using the supplied leak test

cap. Leave the other port uncapped.

• Press Enter on the control panel while the unit is still

inverted.

• Return the unit upright. The leak test will progress.

12

12

2.0

About

This screen provides basic information about your Defender, which may be an especially

helpful reference when speaking to a technical support representative or your distributor.

Out of Range

If the ow you are measuring is outside the Defender’s ow range, (see section 7 De-

fender Specications for ranges), the “Out of Range!” warning appears. Immediately

lower or disconnect the ow. When the ow is within the proper range, select RESET to

clear your Defender’s last measurement.

13

13

2.7 Measurements

Taking gas ow readings

To maintain the best possible accuracy and minimize thermal effects, Mesa recommends

fully charging your battery before taking measurements. If this is not possible, we recom-

mend disconnecting your Defender from its AC power adapter/charger while taking ow

measurements — or to run gas through your Defender for 10 minutes before starting the

ow measurement.

First steps

Press the power button.

• Press the On/Off button for 1 second to turn on your Defender.

• When rst turned on, your Defender displays an opening screen showing the product

name, model number and ow range.

• Press the On/Off button for 3 seconds to turn your Defender off.

Connect device to be calibrated to the appropriate Defender port. Use ¼ inch diameter

tubing.

• Connect to outlet at top (suction tting) when a device draws air (such as sampler).

• Connect to inlet at bottom (pressure tting) when a device pushes air.

• Do not cap the unused port on the Defender.

• Select the reading type to Vol or Std. Set ‘Std To’ to the desired standardizing tem-

perature

• Choose the measurement type, Single, Burst, or Continuous, then press enter.

14

14

2.0

2.8 Single Measurement

Each time the ‘Enter’ button is pressed, one measurement will be made. When each

subsequent measurement is made, the current ow and average of all prior readings will

be displayed.

2.9 Burst Measurement

This setting functions in the same manner as ‘SINGLE’, but measurements continue

automatically until the preset number of measurements has been made. Operation then

ceases, and the last reading and average are displayed.

Press ‘Enter’ again to begin another preset sequence.

2.10 Continuous Measurement

This setting functions in the same manner as ‘BURST’, but new sequences will automati-

cally repeat until stopped by the user.

15

15

Note:

(010 in series) indicates the number of measurements. 10 is the factory-preset number.

Dene the number of measurement you prefer, from 1 to 100, by accessing the SETUP

menu.

In Continuous or Burst mode, select:

• PAUSE to terminate the current ow measurement but to leave the average ow mea-

surement and previous ow measurement on the screen. This allows you to resume

the ow measurement sequence if you wish to do so.

• RESET to terminate the ow measurement and clear the screen.

16

16

3.0 Data Port

3.1 DryCal Pro Software

Visit Mesa’s website to download your copy of DryCal Pro software (http://

www.mesalabs.com/drycal-pro/) . DryCal Pro captures ow data from your

Defender directly to a pre-congured table. The data can be exported to selectable Microsoft ofce environment.

To run DryCal Pro, you must have Windows® XP or 7, Microsoft Excel® 2003

and up, and a RS232 port, or if your PC does not have an RS-232 port you

will need a USB to RS-232 adapter.

3.2 Defender Firmware Upgrades

The Defender rmware is upgradable through the Data Port. Contact technical support for more information (biosdrycal@mesalabs.com).

2.0

3.0

17

17

4.0 Annual Maintenance and Calibration

Assuring top performance and accuracy

Your Defender is a precision measuring standard with moving parts

machined to extremely close tolerances. Various environmental factors,

product wear, drift of sensors, or inadvertent damage may adversely affect

your Defender’s measurement accuracy or general performance. For these

reasons, Mesa Labs highly recommends having your Defender annually

veried by an ISO 17025–accredited laboratory, such as our Butler, NJ facility, to ensure its measurement integrity.

For the ultimate in Defender maintenance and to take advantage of any

available software and mechanical upgrades, Mesa Labs offers an annual

non-mandatory Recertication program. This is a service package that

provides complete product refurbishment, testing and available upgrades;

3.0

4.0

calibration and NIST-traceable calibration certicates.

Recertication includes a 90-day service warranty should any related labor

or parts replacements prove faulty.

Turnaround time is generally two weeks from time of receipt. Expedited

48-hour turnaround is available.

18

18

5.0 Shipping

Tips and guidelines for sending your Defender to Mesa

If you are sending your Defender for repair or evaluation (rather than elective Recerti-

cation), contact Mesa Labs for technical support or troubleshooting assistance prior to

shipping the unit. Pro-vide us a detailed description of your issues. If we are unable to

resolve the situation by phone or email, we will issue you an RMA (return merchandise

authorization) number. Follow online instruction for proper return procedure.

You can obtain an RMA number through our automated web-based system at

drycal.mesalabs.com , emailing csbutler@mesalabs.com, or by telephone at

973.492.8400. Our web site address is www.mesalabs.com.

Note: Mesa Labs will not evaluate or service your instrument without an RMA number.

If we nd the issues you have identied are application related and not product related,

an evaluation fee will be charged.

Shipping

When shipping your Defender, be sure to follow some simple guidelines to avoid costly

damage to your property.

• Use adequate packing material. Whenever possible, use the original packing that came

with your Defender. Or use a Bios DryCal Pelican carrying case, which provides a hard

case shell for protection of your valuable equipment.

• Use a major freight carrier (e.g., FedEx, UPS) that supplies tracking numbers.

• Insure your Defender. Mesa Labs is not responsible for damage occurred during transit.

• Understand our mutual shipping obligations.

19

19

6.0 Storage

Protecting your Defender when not in use

If you need to store your Defender for an extended period, please follow these guidelines:

• Always store it in a clean, dry place.

• If possible, leave it attached to its AC power adapter/charger while in storage.

• If your Defender cannot be attached to its AC power adapter/charger while in storage,

please do the following:

– Fully charge it before extended storage. If the battery is not fully charged prior

to storage, it might be permanently damaged.

• Fully charge it at least once every three months.

• Recharge the battery for at least 8 hours prior to reusing your Defender after storage.

20

20

7.0 Defender Series 530 Specications

Technical data about your Defender

Models:

530L, from 5-500 scc/min

530M, from 50-5,000 scc/min

530H, from 300-30,000 scc/min

Measurements:

Standardized Accuracy: ±1.2% of reading

Volumetric Accuracy: ±1% of reading

Time per Measurement: 1-15 seconds (approximate)

Type: Single, Continuous or Burst

Volumetric Flow Units: cc/min, mL/min, L/min, cf/min

Standardized Flow Units: scc/min, smL/min, sL/min, scf/min

Pressure Units: mmHg, PSI, kPa

Temperature Units: °C, °F

Basics:

Dimensions (H x W x D): 5.5 x 6 x 3 in / 140 x 150 x 75 mm

Weight: 29 oz / 820 g

Conguration: Integrated ow measuring cell, valve and timing mechanism

Temperature & Pressure Sensors: In the ow stream

Press Accuracy: 3.5 mmHg (typical), 7.0 mm (max);

Temp Accuracy: 0.8° C (typical), 1.3° C (max)

AC Power Adapter/Charger: 12VDC, >250ma, 2.5 mm, center positive

Battery: 6V rechargeable, sealed lead-acid, 6-8 hours typical operation

21

6.0

7.0

21

Battery Operational Time (5 cycles/min): 3 hrs backlight on, 8 hrs backlight off

Pressure & Suction Fittings: ¼” barbed tube

Display: Backlit graphical LCD

Usage:

Flow Modes: Suction or Pressure

Operating Pressure (Absolute): 15 PSI

Operating Temperature: 0-50°C

Ambient Humidity: 0–70%, non-condensing

Storage Temperature: 0–70°C

Warranty: 1 year; battery 6 months

DryCal Pro Software:

DryCal Pro Software System Requirements

• Windows® XP, Windows® 7

• Microsoft Excel® 2003 and up

• RS-232 port, or if your PC does not have an RS-232 port you will need a USB to RS-232

adapter

22

22

8.0 Default Settings

Original factory settings for your Defender

The Defender is set with the following Default settings from the factory:

• Reading Type – Vol

• Number in Average – 10

• Time Between – 0

• Flow Units – cc/min

• Pressure Units – mmHg

• Temperature Units – C

• Standardizing Temp – 21.1 C

• Measurement Mode – Single

• Magnication – Zoom

• Backlight – On

• Power Save – On

• Time Format – 24H

• Date Format – MM-DD-YYYY

7.0

8.0

23

23

9.0 Limited Warranty

Outlining our responsibilities

The Defender 500 Series is warranted to the original end user to be free from defects in

materials and workmanship under normal use and service for a period of one year from

the date of purchase as shown on the purchaser’s receipt. The Defender 500 Series’ battery is warranted for six months from the original purchase date. If the unit was purchased from an authorized reseller, a copy of an invoice or packing slip showing the date

of purchase may be required to obtain warranty service.

The obligation of Mesa Laboratories, Inc. under this warranty shall be limited to repair or

replacement (at our option), during the warranty period, of any part that proves defective in material or workmanship under normal use and service, provided the product is

returned to Mesa Laboratories, Inc., transportation charges prepaid.

Notwithstanding the foregoing, Mesa Laboratories, Inc. shall have no liability to repair or

replace any Mesa Laboratories, Inc. product:

1. That has been damaged following sale, including but not limited to damage resulting

from improper electrical voltages or currents, defacement, misuse, abuse, neglect, ac-

cident, re, ood, terrorism, act of God or use in violation of the instructions furnished

by Mesa Laboratories, Inc.

2. When the serial number has been altered or removed.

3. That has been repaired, altered or maintained by any person or party other than

Mesa’s own service facility or a Mesa authorized service center, should one be established.

This warranty is in lieu of all other warranties and all other obligations or liabilities aris-

ing as a result of any defect or deciency of the product, whether in contract or in tort

or otherwise. All other warranties, expressed or implied, including any implied warranties

of merchantability and tness for a particular purpose, are specically excluded.

24

In no event shall Mesa Labs be liable for any special, incidental or consequential damages for breach of this or any other warranty, express or implied whatsoever.

24

10.0 Troubleshooting

Answers to common operational questions

Mesa is ready to help you with any operational issue you may encounter with your Defender. But we may be able to save you some time by providing a short checklist of the

questions most commonly asked of our customer service and technical specialists.

Why won’t my Defender turn on?

If the Defender will not turn on, verify that the battery has been charged. When connect-

ed to the AC power adapter/charger and power is present a small green indicator light

should be visible through the front viewing window

My Defender won’t respond to push-button commands.

If the Defender fails to respond to push-button commands, you can perform a hard reset

of the Defender. This can be done by inserting a paper clip into the reset opening in the

back of the unit.

I’m not sure I have my Defender connected properly.

Verify that the ow source is connected to the pressure port of your Defender for pressure sources or to the suction port for verifying suction pumps. The unused port should

be at atmospheric pressure with any cap or plug removed. If you are calibrating a gas

that requires an exhaust line to vent the measurement gas, ensure that the tubing is of

sufcient diameter not to create a pressure drop greater then 5 inches of water.

How do I protect against leaks?

Ensure that hose and tube ttings are tight and leak free. The tubing connecting your

ow source (pump, mass ow controller, needle valve, sonic nozzle or restrictor) to the

meter should be kept as short as possible.

What do I do when my leak test fails?

First check to make sure that the leak test cap is on correctly and it is not leaking

through the leak test cap itself. If the leak test cap is correct perform leak test both at

the pressure and suction side. If it fails, contact Mesa Technical Support.

What’s the best way to connect to the lter medium?

25

When calibrating sampling pumps best results are obtained with the lter medium connected to the pump and the Defender connected to the inlet side of the lter medium

with a short piece of tubing.

25

Why am I experiencing a temperature increase in my Defender 530?

A temperature rise during initial battery charging, or while charging a fully

discharged battery is normal. To maintain the best possible accuracy Mesa

recommends fully charging your battery before taking measurements. If this is

not possible, we recommend disconnecting your Defender from its AC power

adapter/charger while taking ow measurements – or to run gas through your

Defender for 10 minutes before starting the ow measurement.

Why doesn’t my piston return to the bottom of the cell?

If the piston fails to return to the bottom of the cell after a measurement this

could be caused by:

• A discharged battery not providing enough power to operate the internal

valve properly (Try charging the Defender)

• Bright light shining into the unit resulting in an overload of the internal optical sensors (Try to operate the unit in a shaded location)

• Moisture or dirt inside the cell (Return the Defender to Mesa for service)

What is dead volume?

Dead volume is the gas volume between a ow generator and the instrument

taking the measurement. Since gas is compressible, this gas can act as a

spring between the ow source and the measurement instrument. For best accuracy, this volume should be kept to a minimum. We recommend keeping the

tubing length between the gas ow generator and your Defender to no more

than 0.5 meters/20 inches in length.

What is the difference between volumetric ow and

standardized ow?

As we know from the ideal gas law, the volume of a gas changes with a

change in temperature or pressure even when the number of molecules which

constitute the mass remains the same.

Volumetric ow rate is the rate at which a volume of a gas travels past a given

26

10.0

location. Volumetric Flow= As Measured Volume of Gas / Time

Standardized (mass) ow rate is expressed as the rate at which the volume

of a gas travels past a given location if the gas is at a specied temperature

and pressure. From the ideal gas law if the temperature and pressure are held

constant, the volume of the gas is proportional to the number of molecules.

Standardized Flow= Volume of Gas (at the standard

temperature and pressure) / Time

26

Proven

Our Commitment to You

We strive to provide the closest NIST-traceable, legal defensibility of any

ow calibration equipment manufacturer, and we actively maintain our NVLAP (NIST) ISO 17025 laboratory accreditation in order to support our

claims and continually improve our quality system and laboratory prociency. Thank you for purchasing our products. From all of us at Mesa, best

wishes for many years of accurate, defensible primary ow measurements.

© 2015 Mesa Laboratories, Inc. MK01-135 REV C

Mesa Laboratories, Inc.

10 Park Place

Butler, NJ, USA 07405

Phone: 973.492.8400

Toll Free: 800.663.4977

Fax: 973.492.8270

Email: csbutler@mesalabs.com

web: www.mesalabs.com

Loading...

Loading...