Page 1

8I20 THREE PHASE MOTOR DRIVE MANUAL

V1.9

Page 2

CAUTION!

THE 8I20 USES VOLTAGE AND POWER LEVELS THAT REPRESENT

A HAZARD TO LIFE AND LIMB.

THE 8I20 IS INTENDED FOR USE BY OEMS THAT WILL

INTEGRATE IT INTO A SYSTEM WITH INTERLOCKS AND OTHER

SAFETY FEATURES TO PREVENT USERS FROM CONTACTING

HAZARDOUS POTENTIALS OR BEING INJURED BY MECHANISMS

POWERED BY THE 8I20.

WHEN CHANGING JUMPERS OR OTHER OPERATIONS THAT

REQUIRE PHYSICAL CONTACT TO THE 8I20 CARD:

1. DISCONNECT MOTOR POWER AT THE 8I20

2. DISCONNECT MOTOR U,V,W AT AT THE 8I20. EVEN WITH NO

POWER APPLIED TO THE 8I20, A SPINNING SERVO MOTOR CAN

GENERATE LETHAL VOLTAGES.

3. WAIT 5 MINUTES FOR ON CARD MOTOR POWER CAPACITORS

TO DISCHARGE.

WHEN TESTING THE 8I20 ON THE BENCH IT IS SUGGESTED TO

AT THE MINIMUM:

1. CONNECT THE 8I20'S CHASSIS GROUND CONNECTION TO A

SECURE BUILDING GROUND.

2. USE A ISOLATED MOTOR POWER SUPPLY

3. TEST FIRST WITH A LOW VOLTAGE MOTOR POWER SUPPLY

4. TAKE EXTREME CARE WITH SERVO SYSTEMS, EXPECT THEM

TO RUN_AWAY WHEN FIRST TESTED.

Page 3

Table of Contents

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

HARDWARE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

LOGIC POWER SOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SETUP/OPERATE MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SERIAL PORT TERMINATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CONNECTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

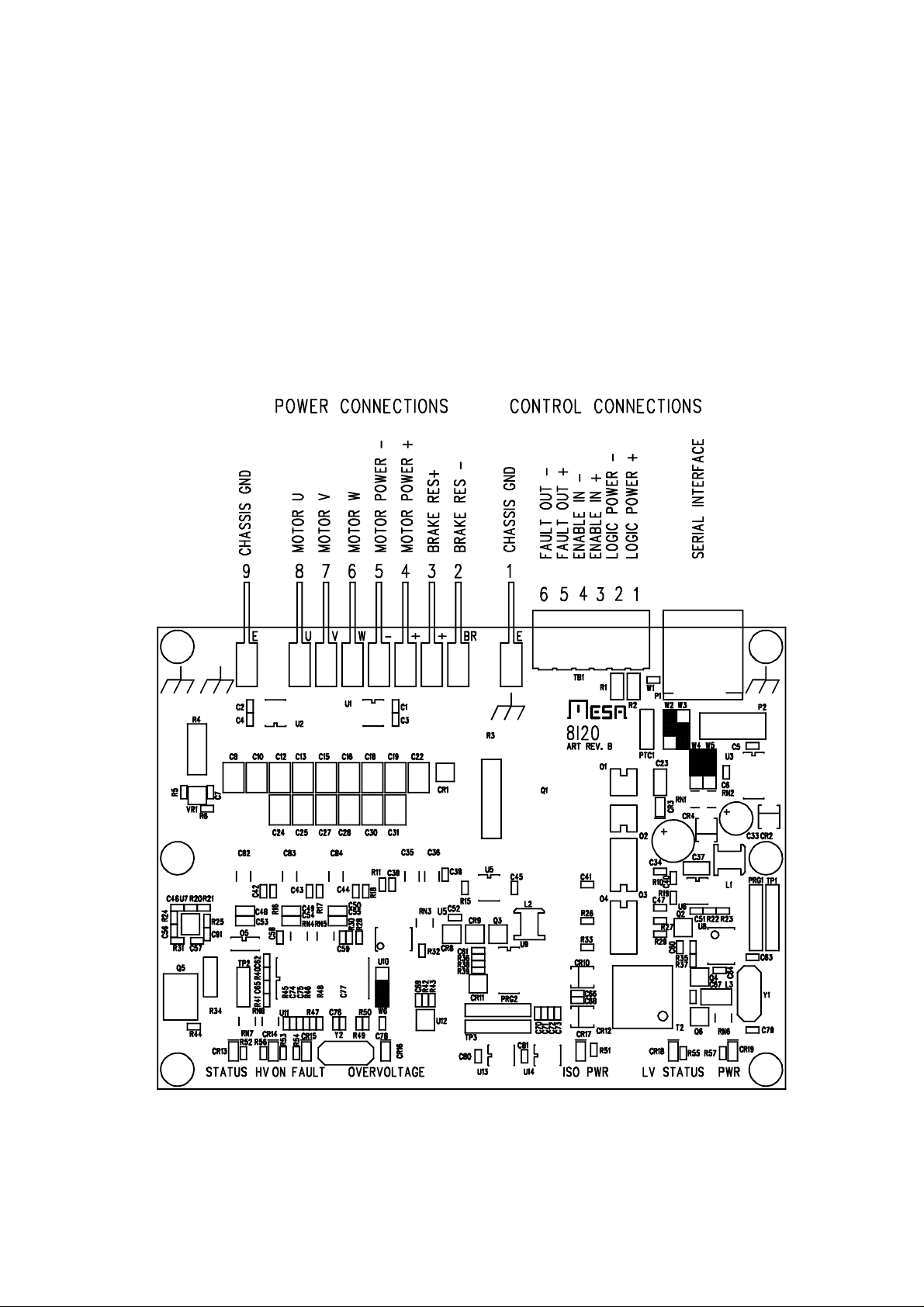

CONNECTOR LOCATIONS AND DEFAULT JUMPER POSITIONS . . . . . . . . 3

MOTOR/POWER/BRAKE CONNECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

LOGIC POWER/FAULT CONNECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

RS-422 SERIAL CONNECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LOGIC POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

MOTOR POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

MOTOR BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

MOTOR CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ENABLE INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

FAULT OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

FAULT CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CLEARING FAULTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

FAULT MASK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

STATUS REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

STATUS LEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

HEATSINKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DRIVE PARAMETER SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PC HOST ADAPTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SETUP COMMUNICATION WITH 8I20 . . . . . . . . . . . . . . . . . . . . . . . . 12

WPD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

RPD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MAIN DRIVE SETUP PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . 13

MAXCURRENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

BRAKEONV and BRAKEOFFV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

OPERATE MODE BAUD RATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CURRENT LOOP TUNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

iii

Page 4

Table of Contents

CONTROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MULTI AXIS CONTROLLERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

HOSTMOT2 8I20 INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SOFTDMC 8I20 INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

ANYTHING I/O INTERFACE DAUGHTER CARDS . . . . . . . . . . . . . . . 16

REFERENCE INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

HEATSINK PLATE DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

LBP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

LBP DATA READ/WRITEWCOMMAND . . . . . . . . . . . . . . . . . . . . . . . 20

EXAMPLE COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

LOCAL LBP COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

LOCAL LBP READ COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

LOCAL LBP WRITE COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

RPC COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

EXAMPLE RPC COMMAND LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

CRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8I20 PARAMETERS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SSLBP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

REGISTER MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

PROCESSOR INTERFACE REGISTERS . . . . . . . . . . . . . . . . . . . . . . 30

COMMAND REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DATA REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

LOCAL READ OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

LOCAL WRITE OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

NORMAL START . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8I20 DEVICE SPECIFIC SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

STOP LBP INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

STOP INDIVIDUAL CHANNELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

DOIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

INTERFACE REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

CS REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

INTERFACE REGISTER 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8I20 SPECIFIC INTERFACE REGISTER 0 DEFINITIONS . . . . . . . . . 34

INTERFACE REGISTER 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8I20 SPECIFIC INTERFACE REGISTER 1 DEFINITIONS . . . . . . . . . 34

NORMAL MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SETUP START . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SETUP MODE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

iv

Page 5

GENERAL

DESCRIPTION

The 8I20 is a low cost 2200W 400V three phase torque mode/voltage mode

amplifier for synchronous permanent magnet servo motors (Brushless AC servo) up to

approximately 3HP. The 8I20 will supply peak currents of 30A.

High side logic and gate power are derived from the low side allowing a wide

operational bus voltage range (24 to 400VDC) and host communication when bus voltage

is off. Low side power can be 5V +-5% or 8-40 V unregulated. 3750V RMS isolation is

provided between high and low side electronics. Hall effect current sensing is used along

with high speed bus voltage monitoring for an accurate, stable, and fast current/torque

control loop.

Host communications are provided by a low overhead 2.5 Mbps serial protocol over

isolated RS-422 link. Link speed allows up to 5 KHz update rates from host.

High side over current sensing protects the IGBT module from line-line and

line-ground faults. A brake output capable of 15A drive is provided. The brake output can

be driven at a presettable overvoltage setting.

Even though it uses a 40 MIPs DSP, the 8I20 is a 'dumb' amplifier suitable for

integration in host based motion control systems. The 8I20 requires reference angle and

requested current/torque or voltage values sent from a host controller. The 8I20 uses the

requested torque and reference angle to control the current loop. The 8I20 can echo status

information to the host controller including bus voltage, phase currents, card temperature,

and other parameters..

Both smart (SoftDMC) and host based (HostMot2) multi axiscontrollers are available

for the 8I20. Up to 32 axis of motion can be controlled by a single low cost FPGA based

controller.

8I20 1

Page 6

HARDWARE CONFIGURATION

GENERAL

Hardware setup jumper positions assume that the 8I20 card is oriented in an upright

position, that is, with the I/O and power connectora towards the top of the card, away from

the person doing the configuration;.

LOGIC POWER SOURCE

The 8I20's logic power can be supplied via the serial cable or via pluggable terminal

block TB1. Jumper W2 determines the power source,

W2 MODE

UP Logic side power from serial cable (5VDC)

DOWN Logic side power from TB1 (7 to 48VDC)

SETUP/OPERATE MODE

The 8I20 can run in setup mode or operate mode. In setup mode, the serial

interface baud rate is fixed at 115.2 KBaud and the motor drive circuits are disabled. In the

operate mode, the baud rate is set to 2.5 Mbaud (default) and the motor drive circuitry is

enabled. Setup mode is enabled to allow normal PC serial ports or USB serial adaptors

to communicate with the 8I20 for setup purposes. W6 controls the setup/normal mode

selection.

W6 MODE BAUD RATE

UP Operate mode 2.5 Mbps (default, can be changed)

DOWN Setup Mode 115.2 Kbps (fixed)

SERIAL PORT TERMINATION

The RS-422 serial port on the 8I20 can be terminated or un-terminated. Normally

the 8I20 is the serial cable endpoint so the port must be terminated. If the 8I20 is used with

other devices on a shared RS-422 interface, the 8I20 should only be terminated if it is the

last physical device on the RS-422 cable. W4 and W5 enable and disable the termination

W4,W5 MODE

UP,UP Terminated (default)

DOWN.DOWN Unterminated

8I20 2

Page 7

CONNECTORS

8I20 CONNECTOR LOCATIONS AND DEFAULT JUMPER POSITIONS

8I20 3

Page 8

CONNECTORS

MOTOR - POWER - BRAKE CONNECTORS

The motor, motor power and brake connections are brought out on .250" spade

terminals on the top edge of the 8I20 card. From left t right the terminal functions are:

1 Chassis Gnd

2 Brake resistor 3 Brake resistor +

4 Motor power +

5 Motor power 6 Motor W

7 Motor V

8 Motor U

9 Chassis Gnd

LOGIC POWER/FAULT CONNECTOR

TB1 is the logic power/ fault output/enable input connector. TB1 is a six terminal 3.5

mm pluggable screw terminal block. TB1 pinout is as follows:

1 Unregulated logic power +

2 Unregulated Logic power 3 Enable in +

4 Enable in 5 Fault out +

6 Fault out -

8I20 4

Page 9

CONNECTORS

SERIAL PORT

J1 is the 8I20s serial interface. J1 is a RJ-45 jack. The serial interface pinout is

compatible with standard 8 wire CAT5 Ethernet cables. J1 pinout is as follows:

1 RXA

2 RXB

3 TXA

4 GND

5 GND

6 TXB

7 +5V

8 +5V

J1s pinout is designed to match breakout cards like the 7I44. A standard CAT5 or

CAT5E cable can be used to connect the 8I20 to a 7I44. CAT5E cable is suggested if the

serial cable is used for powering the 8I20, as the larger wire size result in lower voltage

drop.

8I20 5

Page 10

OPERATION

LOGIC POWER

All logic on the 8I20 runs from 5V logic power. This can be supplied over the serial

cable, or via a on card 5V regulator. Jumper W2 determines the logic power source. When

jumper W2 is in the ‘UP’ position, 5V logic power is suppled by the serial cable. Due to

voltage drop in the serial cable. The 8I20 should only be powered via the serial cable when

serial cable length is 8 feet or less. Typical 5V power consumption is 350 mA.

Logic power can also be supplied via the on card regulator and TB1. When W2 is

in the DOWN position, logic power comes from the on card regulator which is fed by TB1.

Unregulated power to TB1 pins 1 and 2 is regulated to 5V logic power. Unregulated input

to TB1 pins 1 and 2 can range from 8 to 40 VDC

MOTOR POWER

Motor power is supplied to the 8I20 via spade lugs #4 and #5. Motor power can

range from 35 to 400 VDC. All communication to the 8I20 will work down to 0V motor

power but the under-voltage fault setting will prevent motor operation at lower then ~35

VDC unless the default setting is changed. Default over-voltage fault is set for 385 VDC.

Voltages high that 385VDC will result in a overvoltage fault.

The 8I20 has local high frequency bypassing but relies on the power supplies output

capacitors to supply dc power with less than ~15% ripple. The 8I20 also relies on power

supply output capacitors to store motor inductive energy. For this reason, power should not

be disconnected from the 8I20 power input terminals when in operation. The 8I20 motor

power leads should use 18 GA wire and must be shorter than 3 feet. That is, motor power

should not be routed more than 3 feet from the main power supply filter capacitors. Power

supply circuit breakers or fuses should be located on the power supply primary, not

between the 8I20 and power supply capacitors.

MOTOR BRAKE

To prevent regenerated motor power from creating a over-voltage condition, the

8I20 can dump regenerated motor power into a user supplied brake resistor. The brake

circuitry can provide a maximum of 15 amps of braking current. At the maximum BrakeOn

setting of 385 VDC, this equals a ~25 Ohm resistor for maximum braking current.

Actual brake on/off voltages are programmable. Default brake on voltage is 360

VDC and default brake off voltage is 340 VDC. BrakeOn voltage must always be set higher

than BrakeOff voltage.

In addition to the programmable brake voltage settings, there is a fixed 385V

BrakeOn setting that cannot be changed. This is for 8I20 module protection.

8I20 6

Page 11

OPERATION

MOTOR CONNECTIONS

The U/V/W motor connections are the direct PWM outputs of the 8I20s bridge.

Larger motors may have enough winding to frame capacitance to generate considerable

ground noise. This noise source can be reduced by:

1. Make sure that the motor frame ground signal is returned to the frame ground on the

8I20 card.

2. Use a ferrite bead as a common mode choke around all phase wires, that is the U/V/W

motor wires pass through a single bead. Do not route the frame ground wire through the

bead. A suggested ferrite bead is: Laird-Signal Integrity Products 28B1122-100.

ENABLE INPUT

The 8I20 has a isolated 4-24V enable input. This input must be driven to enable

motor drive. If enable input is not driven, the 8I20 will go into a fault state, and turn off

motor PWM.

FAULT OUTPUT

The fault output is an isolated transistor (OPTO coupler) output. The fault output is

off in non-masked fault conditions and on in normal operation. The fault output can supply

a maximum of 5 mA of output current and will switch voltages up to 24 VDC. Normally the

fault outputs of all 8I20s would be wired in series.

FAULT CONDITIONS

The 8I20 monitors many parameters and reports fault conditions in the FAULT

register. When a non-masked fault occurs, the 8I20 turns off motor drive and the current

control loop. The following is a list of the fault conditions:

NAME BIT FUNCTION

WATCHDOGFAULT 0 Communication timeout fault

NOENABLEFAULT 1 No external enable fault

OVERTEMPFAULT 2 8I20 PCB temperature > 85C

CURRENTFAULT 4 8I20 high side overcurrent Fault

8I20 7

Page 12

OPERATION

FAULT CONDITIONS

NAME BIT FUNCTION

ULOOPCURRENTFAULT 5 U current >125% of MAXCURRENT

VLOOPCURRENTFAULT 6 V current >125% of MAXCURRENT

WLOOPCURRENTFAULT 7 W current >125% of MAXCURRENT

BUSLOVFAULT 8 Low motor voltage fault

BUSHIVFAULT 9 High motor voltage fault (settable)

MAXBUSVFAULT 10 High motor voltage fault (fixed at 400V)

MODULEFAULT 11 Module over temperature or low gate

OERRFAULT 14 8I20 serial port overrun error

voltage

FERRFAULT 15 8I20 serial port framing error

CLEARING FAULTS

Faults can not be cleared by writing the fault register but are cleared by setting the

CLEARFAULT flag. The host must then poll the state of CLEARFAULT until it is zero.

FAULT MASK

Certain faults can be masked so that they do not affect the external fault output.

Currently only the BUSLOVFAULT is maskable. A zero bit in the FAULTMASK register will

mask the corresponding fault bit.

8I20 8

Page 13

OPERATION

STATUS REGISTER

The 8I20 maintains a status register that reflects various internal 8I20 conditions.

NAME BIT FUNCTION

ILIMITEDSTATUS 0 Indicates that MAXCURRENT is not

BRAKESTATUS 1 Current brake on status

BRAKEWASONSTATUS 2 Brake has been applied status (sticky)

WDTO 4 DSP startup due to Hardware watchdog

SWR 5 DSP startup due to software reset (sticky)

EXTR 6 DSP startup due to external reset (sticky)

available due to 8I20 temperature/current

limiting.

timeout (sticky)

Sticky status bits remember events until low side power is removed or the status

register is cleared.

8I20 9

Page 14

OPERATION

STATUS LEDS

The 8I20 has 7 on card status LEDs located on the bottom edge of the 8I20 card.

The status LEDs in left to right order:

LED COLOR NAME FUNCTION

CR13 Green DSP Status Blinks with host communication

CR14 Yellow HV On On when motor power is present

CR15 Red Fault On when drive fault is present

CR16 Red OverVoltage/Brake On when brake is applied

CR17 Green Isolated power On when isolated power is present

CR18 Yellow LV status On when isolated inverter is OK

CR19 Green LV power On when logic power is present

HEAT SINKING

The 8I20 requires additional heatsinking unless used for low continuous power

servo applications. When used to deliver its rated continuous 2.2KW power, the 8I20 can

dissipate up to 65W. Heatsink thermal resistance should be chosen to keep the module

temperature below 100C. For example, in a 50C ambient environment and continuous

2.2KW load, keeping the module temperature below 100C with 65W of power dissipation

requires a total thermal resistance of 100-50/65 = 0.77 C/W. The 8I20s mounting plate

adds to the thermal resistance.

Two styles of 8I20 mounting plates are available, right angle and parallel. The right

angle plate has the advantage of tighter packing density but has higher thermal resistance.

The right angle mounting plate adds approximately 0.5C per watt to the 8I20s thermal

resistance. The parallel mounting plate adds only about 0.1C per watt thermal resistance.

So for a parallel mount 8I20, the external heatsink thermal resistance needed to sustain

the full 2.2 KW continuous power is 0.77-0.1 = 0.67 C/W.

Achieving 0.67 C/W in a reasonable size normally will require fan cooling.

8I20 10

Page 15

OPERATION

PC HOST ADAPTER

In order to run any of the command line utilities a RS-422 adapter is needed. Mesa

can provide a suitable adapter. Two such adapters are 3I21 or 3I22. These adapters

connects the RJ-45 RS-422 interface on the 8I20 to a DB9 serial port (3I21) or USB port

(3I22) and provide 5V link power.

MINIMAL HOST PC ADAPTER

A simple home made host adapter can be made by directly connecting RS-232

signals from a 9 pin PC serial port or USB RS-232 adapter to the 8I20s RS-422 signals

via a one ended CAT5 cable. A single resistor between RS-232 TXD and RS-422 RXB is

needed to prevent overloading the RS-232 TXD output

CAT5 PIN DE-9F PIN CAT5 SIGNAL DE-9F SIGNAL CAT5 COLOR

1 5 RXA GND ORANGE WHITE

2 3 RXB (1) TXD (1) ORANGE

3 XX TXA XX GREEN WHITE

4 5 GND GND BLUE

5 5 GND GND BLUE WHITE

6 2 TXB RXD GREEN

7 XX +5V (2) XX BROWN WHITE

8 XX +5V (2) XX BROWN

Notes:

1. Connect via 470 Ohm 1/4 watt resistor. All other signals directly connected

2. If not run from field power, +5V power must be supplied via the 8I20s serial cable

8I20 11

Page 16

OPERATION

DRIVE PARAMETER SETUP

The 8I20 has both working and EEPROM drive parameters. The working

parameters are volatile (lost at power down) 8I20 uses the working parameters for all

normal operations. At power up or reset, a subset of the working parameters get initialized

from non-volatile EEPROM memory. Because of this, when adjusting parameters the

working parameters can be changed ‘live’ but changing the EEPROM parameters will not

have any effect until the 8I20 is reset. All EEPROM parameters have a NV prefix.

SETUP COMMUNICATION WITH 8I20

To enable communication between a PC and the 8I20 three things are required:

1. 8I20 must have logic power (normally supplied via TB1)

2. Setup jumper must be in "SETUP" position = DOWN

3. A RS-422 adapter must connect from the PCs serial port/ USB serial adapter to the

8I20. This adapter is available from Mesa (3I21, 3I22 )or home made adapter shown above

4. The parameter read and write programs are simple command line utilities that require

some environment variables to be set before use:

SET COMPORT = COM1 ( set to match the serial port )

SET BAUDRATE = 115200

SET PROTOCOL = LBP

WPD

The WPD utility writes 8I20 parameters including non-volatile setup parameters. It

uses symbolic names for the parameters so numeric constants do not need to be

memorized, for example

WPD BRAKEONV 30000

Would set the working brake-on voltage parameter to 300V

(units of voltage are .1V)

WPD NVBRAKEONV 32000

Would set the EEPROM brake-on voltage parameter to 320V

8I20 12

Page 17

OPERATION

DRIVE PARAMETER SETUP

WPD

WPD FAULT 0

Would clear the FAULT parameter

RPD

The RPD utility reads a parameter from the 8I20. It uses symbolic names for the

parameters so numeric constants do not need to be memorized, for example:

RPD FAULT H

Would read the fault parameter as a Hexadecimal word

RPD BUSV

Would read the motor bus voltage (in units of 10 mv), that is a bus voltage of 320

would read as 32000

MAIN DRIVE SETUP PARAMETERS

For normal setup only a couple of parameters need to be changed to match a

specific motor. The most important are NVMAXCURRENT, NVBRAKEONV and

NVBRAKEOFFV.

MAXCURRENT

The MAXCURRENT parameter sets the full scale RMS motor current of the 8I20.

This is the single most important setup parameter needed to match the 8I20 to a specific

motor. This should be set to the maximum RMS motor current value (or to 30A if the motor

has a higher than 30 A RMS current rating). Current (torque) commands are signed 16 bit

numbers sent to the 8I20 and scaled such that:

RMS motor current = QISETPOINT * NVMAXCURRENT/3276700

MAXCURRENT is a unsigned 16 bit number with units of 10 mA, that is maximum

per phase current in Amperes is MAXCURRENT/100. Like most setup parameters,

MAXCURRENT is the working current limit, and NVMAXCURRENT is the non-volatile

EEPROM current limit.

For example:

WPD NVMAXCURRENT 2500

Would set the EEPROM maximum current parameter to 25A. This will not take

effect until the 8I20 is reset.

8I20 13

Page 18

OPERATION

DRIVE PARAMETER SETUP

BRAKEONV and BRAKEOFFV

BRAKONV and BRAKEOFFV set the brake on and brake off voltage thresholds.

These are used to clamp the rising motor bus voltage created when decelerating. When

decelerating, the 8I20 will charge the motor power supply filter capacitors with regenerated

energy .

The default values (on at 360V off at 340V) are chosen to match a 240V off line

power supply, and to protect the 8I20. If lower power supply voltages are used (with lower

filter capacitor voltage ratings) the BRAKEONV and BRAKEOFFV voltages should be set

lower to protect the power supply. It is suggested that BRAKEOFFV be set 20V lower than

BRAKEON. BRAKEONV and BRAKEOFFV are specified in units of 10mV. That is a

BRAKEONV value of 30000 would specify 300.0 V.

The startup values of BRAKEONV and BRAKEOFFV are set with the parameters

NVBRAKEONV and NVBRAKEOFFV.

For example:

WPD NVBRAKEONV 19000

WPD NVBRAKEOFFV 17000

Would be suitable values for a 120V line operated supply with a maximum rating

of 200V. Note that like all EEPROM parameters, these settings will not take effect until the

8I20 has been reset.

OPERATE MODE BAUD RATE

The operate mode baud rate default is 2.5 MBaud. This should not be changed

unless needed for non-standard applications. Baud rates are selected by writing an index

value to the NVBAUDRATE parameter. The index numbers for available baud rates are

as follows:

INDEX BAUD INDEX BAUD INDEX BAUD

0 9600B 1 19200B 2 38400B

3 57600B 4 115200B 5 230400B

6 460800B 7 921600B 8 1.25MB

9 2.5MB* 10 5MB 11 10MB

8I20 14

Page 19

OPERATION

CURRENT LOOP TUNING

The 8I20 has settable tuning parameters for its PI current control loop. The

parameters are KQP, KDP, KQI, and KDI. KQP and KDP are the Proportional terms and

KQI and KDI are the Integral terms. Normally KQP should equal KDP and KQI should

equal KDI. The Startup values of KQP, KDP, KQI, and KDI are set by the cooresponding

EEPROM parameters NVKQP, NVKDP, NVKQI, and NVKDI. Default values forNV KQP

and NVKDP are 50 and default values for NVKQI and NVKDI are 150000. These defaults

are suitable for a large range of motors, but may need to be changed to optimize current

loop operation for specific motors.

8I20 15

Page 20

CONTROLLERS

MULTI-AXIS CONTROLLERS

Two basic types of multi-axis controllers are available for use with the 8I20, host

based and "Smart". Host based controllers use the host computer to read encoders and

output angle and run a PID loop that outputs torque commands to the 8I20. The HostMot2

FPGA firmware suite is a host based motion controller that is compatible with the 8I20.

Smart controllers like SoftDMC take higher level motion commands from the host and

control all low level processes like reading encoders, running the PID loop and flagging

error conditions.

HOSTMOT2 8I20 INTERFACE

The Hostmot2 interface to the 8I20 is a smart serial interface for Mesa’s Anything

I/O series of FPGA cards that encapsulates the serial protocol details and presents a

simple parallel register set to the host computer. Registers for writing torque and angle and

registers for reading bus voltage, card status, communication status, and card temperature

are provided for all connected 8I20 cards.

The 8I20 Hostmot2 interface is a sserial module with specific firmware (SSLBP) for

8I20 card or other LBP interfaced cards. Each sserial module can support up to eight 8I20

cards. The sserial module supports the standard 2.5 M Baud communication rate and

torque update rates to 5KHz. With the default configuration, the Hostmot2 interface sends

reference angle (ANGLE parameter) and current (QSETPOINT parameter) commands and

receives bus voltage (BUSV parameter), 8I20 card temperature (TEMPERATURE

parameter), and 8I20 status and fault information (STATUS and FAULT parametera).

A complete host based controller will also need position sensing. This may consist

of quadrature encoders, SSI absolute encoders (including magnetic absolute types), or

resolvers. All three types of position sensors are available in the Hostmot2 firmware suite.

SOFTDMC 8I20 INTERFACE

SoftDMC is a smart multi-axis motion controller with built in motion profile generator,

programmable exception handling and a high performance FIFO based host interface.

SoftDMC is a firmware option for Mesa’s Anything I/O series of FPGA cards. For more

information on SoftDMC, please consult the SoftDMC manual.

ANYTHING I/O INTERFACE DAUGHTER CARDS

8I20 compatible daughter cards are available to simplify connecting the 8I20 to

Mesa’s Anything I/O FPGA cards. One interface card is the 7I44. The 7I44 provides 8

channels of RS-422/RS-485 serial communication interface. The 7I44 uses RJ-45

connectors for the serial interface. These connectors are compatible with the 8I20 so a

common CAT5 or CAT5E cable may be used to connect from the 7I44 to the 8I20. The

7I44 can also provide 5V power to the 8I20 subject to the CAT5/5E cable length

restrictions.

8I20 16

Page 21

REFERENCE INFORMATION

SPECIFICATIONS

LOGIC SUPPLY VOLTAGE 5V 4.5V 5.5V

5V CURRENT ---- 400 mA .

UNREGULATED SUPPLY VOLTAGE 8V 40V

MOTOR SUPPLY VOLTAGE 35V 400V

MAX MOTOR CURRENT 25C CASE ---- 30A RMS

MAX MOTOR CURRENT 70C CASE ---- 15A RMS

SWITCHING FREQUENCY ---- 20KHz Default is 12 KHz

V ISOLATION VBUS/LOGIC 3750V ---- RMS

MIN MAX NOTES

V ISOLATION VBUS/CASE/EARTH 2500V ---- RMS

POWER DISSIPATION 4 KW LOAD ---- 125W

(340V 10A/PHASE 12 KHZ PWM 60 HZ MODULATION)

THERMAL RESISTANCE ---- 0.5C/W RIGHT ANGLE

THERMAL RESISTANCE ---- 0.1C/W PARALLEL

TEMPERATURE -C VERSION 0oC 70oC

TEMPERATURE -I VERSION -40oC 85oC

8I20 17

Page 22

REFERENCE INFORMATION

HEATSINK PLATE DRAWING

8I20 18

Page 23

REFERENCE INFORMATION

LBP

LBP is a simple binary master slave protocol where the host sends read, write, or

RPC commands to the 8I20, and the 8I20 responds. All controller communication to the

8I20 is done via LBP. LBP commands always start with a command header byte. This

header specifies whether the command is a read or write or RPC, the number of address

bytes(0, or 2), and the number of data bytes(1 through 8).The 0 address size option

indicates that the current address pointer should be used. This address pointer will be post

incremented by the data size if the auto increment bit is set. RPC commands allow any of

up to 64 stored commands to be executed in response to the single byte command.

LBP DATA READ/WRITE COMMAND

0 1 WR RID AI AS DS1 DS0

Bit 7.. 6 CommandType: Must be 01b to specify data read/write command

Bit 5 Write: 1 to specify write, 0 to specify read

Bit 4 RPCIncludesData: 0 specifies that data is from stream, 1, that data is from

RPC (RPC only, ignored for non RPC commands)

Bit 3 AutoInc: 0 leaves address unchanged, 1 specifies that address is post

incremented by data size in bytes.

BIT 2 AddressSize: 0 to specify current address, 1 to specify 2 byte address.

Bit 1..0 DataSize: Specifies data size, 00b = 1 bytes, 01b = 2 bytes, 10 b= 4 bytes,

011b = 8 bytes.

When multiple bytes are specified in a read or write command, the bytes are always

written to or read from successive addresses. That is, a 4 byte read at location 0x21 will

read locations 0x21, 0x22, 0x23, 0x24. The address pointer is not modified after the

command unless the AutoInc bit is set.

8I20 19

Page 24

REFERENCE INFORMATION

LBP

EXAMPLE LBP COMMANDS

Write 4 bytes (0xAA, 0xBB,0xCC,0xDD) to addresses 0x010,0x011,0x012,0x013

with AutoInc so that the address pointer will be left at 0x014 when the command is

completed:

COMMAND BITS CT1 CT0 WR RID AI AS DS1 DS0

LBPWrite: 2 add 4 data

Write Address LSB 0 0 0 1 0 0 0 0

Write Address MSB 0 0 0 0 0 0 0 0

Write data 0 1 0 1 0 1 0 1 0

Write Data 1 1 0 1 1 1 0 1 1

Write Data 2 1 1 0 0 1 1 0 0

Write Data 3 1 1 0 1 1 1 0 1

Write 2 more bytes (0xEE,0xFF) at 0x014 and 0x015:

COMMAND BITS CT1 CT0 WR RID AI AS DS1 DS0

LBPWrite: 0 add 2 data

Write data 0 1 1 1 0 1 1 1 0

Write data 1 1 1 1 1 1 1 1 1

0 1 1 0 1 1 1 0

0 1 1 0 0 0 0 1

Read 8 bytes at 0x010,0x011,0x012,0x013,0x014,0x015,0x016,0x017:

COMMAND BITS CT1 CT0 WR RID AI AS DS1 DS0

LBPRead: 2 add 8 data

Read Address LSB 0 0 0 1 0 0 0 0

Read Address MSB 0 0 0 0 0 0 0 0

0 1 0 0 0 1 1 1

8I20 20

Page 25

REFERENCE INFORMATION

LBP

LOCAL LBP COMMANDS

In addition to the basic data access commands, there are a set of commands that

access LBP status and control the operation of LBP itself. These are organized as READ

and WRITE commands

LOCAL LBP READ COMMANDS

(HEX), all of these commands return a single byte of data.

0xC0 Get unit address

0xC1 Get LBP status

LBP Status bit definitions:

BIT 7 Reserved

BIT 6 Command Timeout Error

BIT 5 Invalid write Error (attempted write to protected area)

BIT 4 Buffer overflow error

BIT 3 Watchdog timeout error

BIT 2 Reserved

BIT 1 Reserved

BIT 0 CRC error

0xC2 Get CRC enable status (note CRCs are always enabled on the 8I20)

0xC3 Get CRC error count

0xC4 .. 0xC9 Reserved

0xCA Get Enable_RPCMEM access flag

0xCB Get Command timeout (character times/10 for serial)

0xCC .. 0xCF Reserved

0xD0 .. 0xD3 4 character card name

8I20 21

Page 26

REFERENCE INFORMATION

LBP

LOCAL LBP READ COMMANDS

0xD5 .. 0xD7 4 character configuration name (only on some configurations)

0xD8 Get low address

0xD9 Get high address

0xDA Get LBP version

0xDB Get LBP Unit ID (Serial only, not used with USB)

0xDC Get RPC Pitch

0xDD Get RPC SizeL (Low byte of RPCSize)

0xDE Get RPC SizeH (High byte of RPCSize)

0xDF Get LBP cookie (returns 0x5A)

8I20 22

Page 27

REFERENCE INFORMATION

LBP

LOCAL LBP WRITE COMMANDS

(HEX), all of these commands except 0xFF expect a single byte of data.

0xE0 Reserved

0xE1 Set LBP status (0 to clear errors)

0xE2 Set CRC check enable (Flag non-zero to enable CRC checking)

0xE3 Set CRC error count

0xE4 .. 0xE9 Reserved

0xEA Set Enable_RPCMEM access flag (non zero to enable access to RPC memory)

0xEB Set Command timeout (in mS for USB and character times for serial)

0xEC .. 0xEF Reserved

0xF0 .. 0xF6 Reserved

0xF7 Write LEDs

0xF8 Set low address

0xF9 Set high address

0xFA Add byte to current address

0xFB .. 0xFC Reserved

0xFD Set unit ID (serial only)

0xFE Reset LBP processor if followed by 0x5A

0xFF Reset LBP parser (no data follows this command)

8I20 23

Page 28

REFERENCE INFORMATION

LBP

RPC COMMANDS

RPC commands allow previously stored sequences of read/write commands to be

executed with a single byte command. Up to 64 RPC’s may be stored. RPC write

commands may include data if desired, or the data may come from the serial data stream.

RPCs allow significant command compression which improves communication bandwidth.

The 8I20 has some pre-loaded RPCs for normal current (torque) mode operation.

LBP RPC COMMAND

1 0 RPC5 RPC4 RPC3 RPC2 RPC1 RPC0

Bit 7..6 CommandType: must be 10b to specify RPC

Bit 5..0 RPCNumber: Specifies RPC 0 through 63

In the 8I20 LBP implementation, RPCPitch is 0x8 bytes so each RPC command has

native size of 0x08 bytes and start 0x8 byte boundaries in the RPC table area. RPCs can

cross RPCPitch boundaries if larger than RPCPitch RPCs are needed. The stored RPC

commands consist of LBP headers and addresses, and possibly data if the command

header has the RID bit set. RPC command lists are terminated by a 0 byte.

The RPC table is accessed at addresses 0 through RPCSize-1 This means with a

RPCPitch of 0x8 bytes, RPC0 starts at 0x0000, RPC1 starts at 0x008, RPC2 starts at

0x0010 and so on.

Before RPC commands can be written to the RPC table,the RPCMEM access flag

must be set. The RPCMEM access flag must be clear for normal operation.

8I20 24

Page 29

REFERENCE INFORMATION

LBP

EXAMPLE RPC COMMAND LIST

This is an example stored RPC command list. Note RPC command lists must start

at a RPCPitch boundary in the RPC table but an individual RPC list can extend until the

end of the table. This particular RPC example contains 2 LBP commands and uses 7 bytes

starting at 0x0028 (RPC5 for 0x08 pitch RPC table)

Command1. Writes two data bytes to address 0x10, 0x11 with 2 data bytes supplied by

host

Command2. Reads two data bytes from address 0x12,0x13

COMMAND BITS CT1 CT0 WR RID I AS DS1 DS0

LBPWrite: 2 add 2 data

Write Address LSB 0 0 0 1 0 0 0 0

Write Address MSB 0 0 0 0 0 0 0 0

LBPRead: 2 add 2 data

Read Address LSB 0 0 0 1 0 0 1 0

Read Address MSB 0 0 0 0 0 0 0 0

Terminator

The data stream for this RPC would consist of these 3 bytes:

COMMAND BITS CT1 CT0 R5 R4 R3 R2 R1 R0

RPC 5

Data 0 for Command 1 0 1 0 1 0 1 0 1

Data 1 for Command 1 1 1 0 0 1 1 0 0

0 1 1 0 0 1 0 1

0 1 0 0 0 1 0 1

0 0 0 0 0 0 0 0

1 0 0 0 0 1 0 1

8I20 25

Page 30

REFERENCE INFORMATION

CRC

LBP on the 8I20 uses CRC checking of all commands and data to insure validity.

The CRC used is a 8 bit CRC using the same polynomial as the Dallas/Maxim one wire

devices (X^8+X^5++X^4+X^0). The CRC must be appended to all LBP commands and all

returned data will have a CRC byte appended. Commands with no returned data (writes

or RPCs with no reads) will still cause a CRC byte to be returned, this CRC byte will always

be 00H.

FRAMING

Since LBP is a binary protocol with no special sync characters, the packet framing

must be determined by other methods. The 8I20s LBP implementation uses two different

framing models depending on whether it is in setup mode or operate mode.

In setup mode, framing is done by determining the end of the command by preparsing the data stream. This is done so that relaxed interface timing is acceptable. Nonrealtime systems such as Windows and Linux cannot guarantee exact serial data timing

so timing based framing cannot be used. Timing based framing is still used to maintain

synchronization in case of aborted packets or noise but the timeout is set to the maximum

time (25.5 character times) or ~2.2 mS at 115200 baud. Because normal communication

will be framed by pre-parsing, this timeout delay need not be inserted between subsequent

commands.

When running in operate mode, the 8I20 uses timing based framing exclusively.

Timing based framing is more robust in noisy environments where bad packets may be

present, but it requires strict timing of the serial data stream. Packets sent to the 8I20 in

real time mode must be sent in a single packet with less than the LBP command timeout

between characters. The command timeout is set by SSLBP to be 4 character times (16

uSec at 2.5M baud). In operate mode, a delay of 16 uSec must always be inserted

between packets.

8I20 26

Page 31

REFERENCE INFORMATION

PARAMETERS

The 8I20 has many user settable parameters, but normally only a very few need be

changed in normal operation The following is a short list of 8I20 parameters for reference

only:

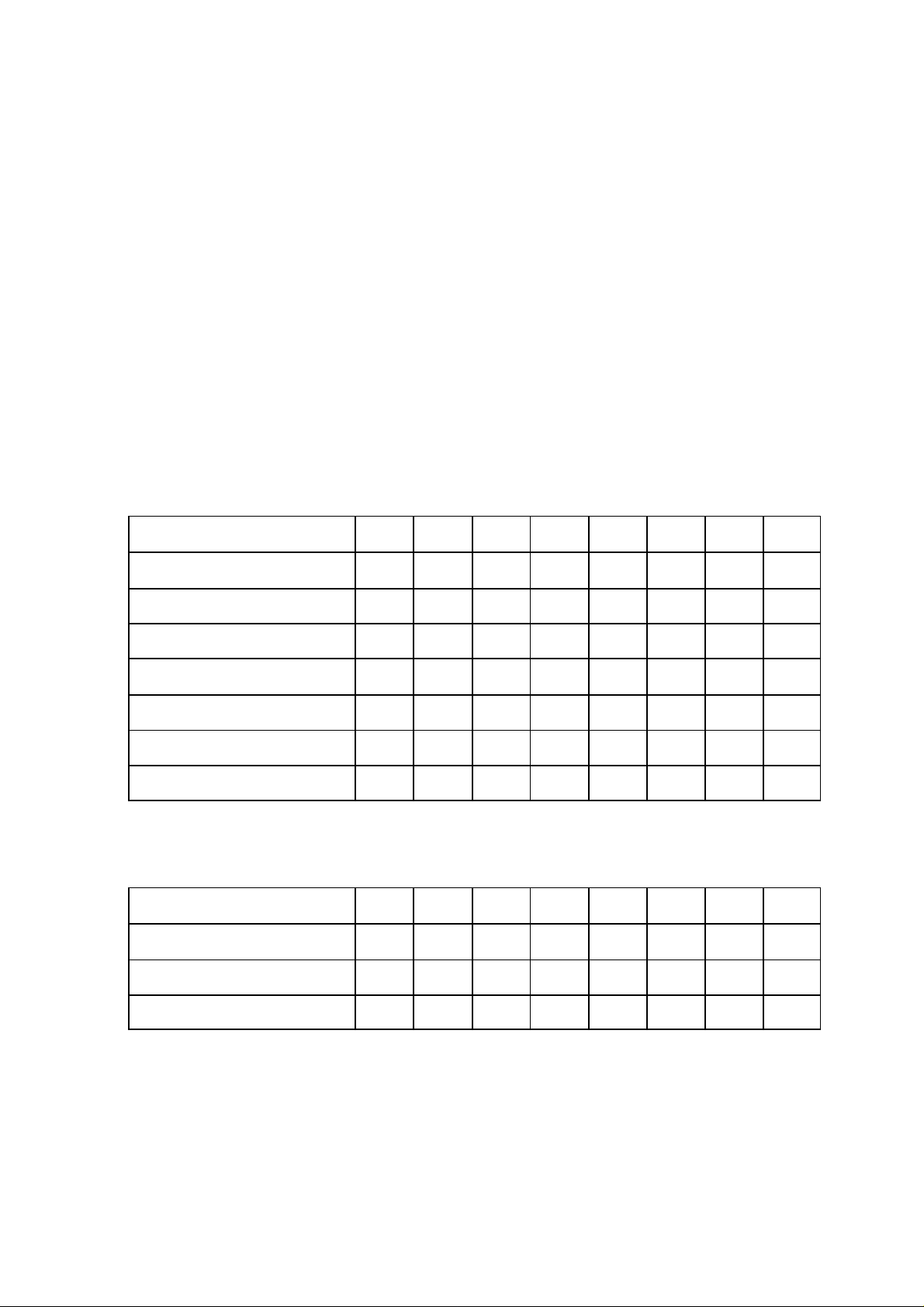

PARAMETER TYPE SCALING FUNCTION

BRAKEOFFV UINT 10 mV Set working brake off voltage

NVBRAKEOFFV UINT 10 mV Set non-volatile brake off voltage

BRAKEONV UINT 10 mV Set working brake on voltage

NVBRAKEONV UINT 10 mV Set non-volatile brake on voltage

BUSV UINT 10 mV Read motor bus voltage

BUSOVERV UINT 10 mV Set working bus overvoltage

threshold

NVBUSOVERV UINT 10 mV Set non-volatile bus overvoltage

threshold

BUSUNDERV UINT 10 mV Set working bus undervoltage

threshold

NVBUSUNDERV UINT 10 mV Set non-volatile bus undervoltage

threshold

MAXCURRENT UINT 10 mA Set working full scale current

NVMAXCURRENT UINT 10 mA Set non-volatile full scale current

8I20 27

Page 32

REFERENCE INFORMATION

PARAMETERS

DEADZONE UINT Set working pwm anti-deadzone

NVDEADZONE UINT Set non-volatile pwm anti-

FAULT UINT 8I20 fault register

STATUS UINT 8I20 status register

deadzone

8I20 28

Page 33

REFERENCE INFORMATION

PARAMETERS

KDP UINT Set working diloop p term

NVKDP UINT Set non-volatile diloop p term

KDI ULONG Set working diloop I term

NVKDI ULONG Set non-volatile diloop I term

KDIL UINT Set working diloop I limit

NVKDIL UINT Set non-volatile diloop I limit

KQP UINT Set working qiloop p term

NVKQP UINT Set non-volatile qiloop p term

KQI ULONG Set working qiloop I term

NVKQI ULONG Set non-volatile qiloop I term

KQIL UINT Set working qiloop I limit

NVKQIL UINT Set non-volatile qiloop I limit

DSETPOINT INT Set "Direct" current

QSETPOINT INT Set "Quadrature" current

ANGLE UINT 2*PI/65536 Set reference angle, 65536 = 360

electrical degrees

TEMPERATURE UINT 0.01C/ 8I20 card temperature C in 1/100

degree per count.

8I20 29

Page 34

REFERENCE INFORMATION

SSLBP

GENERAL

SSLBP is a firmware option to HostMot2s SSERIAL serial interface that allows

simple communication to LBP based peripherals. SSERIAL is a part of the HostMot2

motion interface firmware for MESA’s Anything-I/O FPGA cards.

REGISTER MAP

SSLBP has two global processor interface registers and three per channel remote

device interface registers. For more details on mapping of these registers in HostMot2

memory space, see the REGMAP file that is included with the HostMot2 source

distribution.

PROCESSOR INTERFACE REGISTERS

There are two processor interface registers, the COMMAND register and the DATA

register. These registers allow low level communication to SSLBP’s interface processor

for issuing global commands, discovery, and debug operations.

COMMAND REGISTER

The commands register is a 16 bit register (right justified in the 32 bit interface) with

the following format:

W M R D S T T T N N N N N N N N

W = BIT 15 Write bit, set high for write commands

M = BIT 14 ROM enable/ reset bit, set high to reset processor / download ROM

R = BIT 13 Request bit, set high for read or write command

D = BIT 12 DoIt bit, set high for DoIt commands

S = BIT 11 Start/Stop bit, actual operation depends on N:

T = 0,0,0 Stop LBP interface

T = 0,0,1 Start LBP interface in normal mode

T = 1,1,1 Start LBP interface in setup mode

N bits determine which channels start or do data transfer with remote device. A set

bit indicates that the corresponding channel will start or do a data transfer.

8I20 30

Page 35

REFERENCE INFORMATION

SSLBP

DATA REGISTER

SSLBP has a global 8 bit data register for debug and custom setup purposes. This

register allows access to internal SSLBP parameters. The data register is right justified in

the 32 bit Hostmot2 register.

LOCAL READ OPERATIONS

The sequence used for reading a local SSLBP variable is as follows:

1. The parameter address ORed with the Request bit (bit 13) is written to the command

register.

2. The host polls the command register until it reads as zero.

3. The host reads the parameter byte from the data register

LOCAL WRITE OPERATIONS

The sequence used for writing a local SSLBP variable is as follows:

1. The host polls the command register until it reads as zero.

2. The host writes the data byte to the data register

3. The host writes the command register with the the parameter address Ored with both

the Request bit (bit 13) and the Write bit (bit 15)

NORMAL START

When the FPGA is first configured or after a STOP command, all local

communication, error and status parameters are initialized and all LBP communication

channels are idle. A normal START command begins to establish communications with

all remote LBP devices. A normal start command is issued by writing a Start bit with type

bits of 0,0,1 with a bit mask of the desired channels to start in the low byte (0x9NN) to the

command register. Once a start command has been issued, all channels that are selected

in the bit mask will be probed to determine if a LBP device exists. If a device exists on a

channel, the SSLBP firmware will acquire the device type and device unit ID from the

remote device. When the command completes (the command register is clear), the data

register can be read to determine if all selected channels have started. A 1 bit in any

position in the data register indicates that the corresponding channel has failed to start. If

a channel has failed to start, more information about the failure can be determined by

reading the CS register.

8I20 31

Page 36

REFERENCE INFORMATION

SSLBP

8I20 DEVICE SPECIFIC SETUP

A normal start command does specific setup operations when it detects a 8I20

remote device. This setup includes clearing any faults, setting the qsetpoint current to 0

A, enabling the current control loop and setting the 8I20s watchdog timer to 40 mS. If no

errors have occurred and all faults are clearable, the SSLBP firmware enters a "chatter"

loop where it repeatedly asks the 8I20 for a cookie character. This keeps the 8I20's

watchdog fed while waiting for the first DOIT command. Once a DOIT command has been

executed, the firmware no longer "chatters" and the host interface must send DOIT

commands at greater than 40 mS intervals or the 8I20s watchdog will bite, disabling its

output.

STOP LBP INTERFACE

A STOP ALL command is issued to stop all channel communication. A STOP ALL

followed by a START command can be used after a fault condition to re-establish

communication with the remote LBP devices. Device discovery is only done once when

START command is issued to a STOPed SSLBP. This means that if cabling or devices

are changed, a STOP ALL command followed by a START command must be issued by

the host to detect the changes.

STOP INDIVIDUAL CHANNELS

In addition to stopping all channels, a individual stop command can be issued. A

individual stop command include a bitmask of the channels to stop in the least significant

8 bits of the command.

DOIT

In normal operation SSLBP is designed to write data from local registers to the

remote device and read remote device data for presentation to the host on a real time

basis. Synchronization is accomplished with the DOIT command. When a DOIT command

is written, all channel data from the host is sent to the remote devices and receive data is

requested. Completion of the DOIT command is signaled by SSLBP clearing the

COMMAND register. A DOIT command contains the DOIT bit and an 8 bit mask in the 8

LSBs that selects the channels that will transfer data. After DOIT command completion

the data register will contain a bit mask of channel status data. If any bit is set in the data

register, it indicates a problem with the transfer (all zeros indicates no faults or errors). The

data returned after a DOIT command can be used to minimize host access cycles by

avoiding the need to read the per channel status registers. If detailed fault information is

desired, the CS register and Interface1 register can be read on any channel that shows a

failed transfer.

8I20 32

Page 37

REFERENCE INFORMATION

SSLBP

INTERFACE REGISTERS

Three per channel interface registers are used to pass information from the host to

the remote LBP device and from the remote LBP device to the host. The registers are the

CS Register, Interface0 register and Interface1 register. These registers are all 32 bits in

width and read/write.

CS REGISTER

The CS register is used for local SSLBP, and remote LBP device status and control

information. Read access returns status information in both normal and setup mode. In

normal mode, writes to the CS register are not used. When read, the CS register has the

following format:

Byte3 = Remote LBP device mode

= 0x80 for 8I20

= 0x74 for 7I64

Byte2 = Communication state code (debug only)

Byte1 = Communication status code (0x00 for OK)

Bit 7 = CommunicationNotReady

Bit 6 = NoRemoteID

Bit 5 = CommunicationError

Bit 0 = RemoteFault

Byte0 = Communication error code (sticky, cleared only by stop)

Bit 7 = TooManyerrors

Bit 4 = ExtraCharacterError

Bit 3 = TimeoutError

Bit 2 = OverrunError

Bit 1 = InvalidCookieError

Bit 0 = CRCError

8I20 33

Page 38

REFERENCE INFORMATION

SSLBP

INTERFACE REGISTER 0

Interface register 0 is a general purpose 32 bit read/write register for transferring

data to and from the remote LBP device, After a start command and valid ready status,

interface register 0 reports the 32 bit device unit number. After DOIT has been asserted

bit definitions in interface register 0 are device specific.

8I20 SPECIFIC INTERFACE REGISTER 0 DEFINITIONS

Reads:

After DOIT is asserted:

MSW = Bus voltage in 10s of mV (unsigned 16 bit number)

LSW = Card Temperature in oC (insigned 16 bit number)

Writes:

MSW = QSETPOINT current, signed 16 bit number, 32767 sets current to

+MAXCURRENT and -32767 sets current to -MAXCURRENT

LSW = ANGLE, unsigned 16 bit number, 0 to 65535 = 0 to 359.9945 degrees.

INTERFACE REGISTER 1

Interface register 1 is a general purpose 32 bit read/write register for transferring

data to and from the remote LBP device. Bit definitions in interface register 1 are device

specific.

8I20 SPECIFIC INTERFACE REGISTER 1 DEFINITIONS:

Reads:

MSW = 8I20 FAULTS

LSW = 8I20 STATUS

Writes:

Writes to interface register 1 are not used in normal mode.

8I20 34

Page 39

REFERENCE INFORMATION

SSLBP

NORMAL MODE OPERATION

In normal mode the sequence of operations is as follows:

1. Issue stop command, wait for COMMAND register clear to verify stop command

completion.

2. Issue normal START command (0x9NN) with bitmask (NN) of channels to start.

3. Wait for COMMAND register clear to verify start command completion. (may be many

mS)

4. Read data register to verify that all selected channels started (a 1 in any channel

position bit means a fault in the channel that the bit represents)

5. Read device unit number (This can only be read before DOIT has been asserted)

6. Check command register, if not clear, cycle time is too short

7. Check data register, any 1 bits indicate previous DOIT command failed for in the

corresponding channels

8. Write per channel output data (CURRENT AND ANGLE for 8I20) to interface 0 register

9. Read Interface register 0 for bus voltage and temperature, note that this is stale data

from previous cycle (and invalid the first cycle)

10. Write DOIT command = 0x10NN where NN is the bit mask of channels to initiate

transfers.

11. Wait for next cycle, at next cycle time, loop to state 6

This sequence can be modified if a read-modify-write sequence is required, but for the

8I20, the read data is not time critical so the read data timing is not important.

SETUP START

When the FPGA is first configured or after a stop all command, all LBP

communication channels are idle. A SETUP START command first initializes and all local

communication, error and status parameters and begins to establish communications with

all remote LBP devices. Unlike the NORMAL START command, SETUP START does no

device specific setup but instead creates a pass-through access mode that allows the host

to read or write any remote LBP device parameter. This allows simple utilities to setup 8I20

volatile and non-volatile parameters.

8I20 35

Page 40

REFERENCE INFORMATION

SSLBP

SETUP MODE OPERATION

In setup mode the SSLBP interface is used as a passthrough device to allow

reading and writing parameters to the remote LBP device.

REMOTE READ EXAMPLE:

For a remote word read, the sequence of operations is as follows:

1. Issue a STOP command, wait for COMMAND register clear to verify stop command

completion.

2. Issue a setup START command (0xFNN) with bitmask (NN) of channels to start

3. Wait for COMMAND register clear to verify start command completion. (may be many

mS)

4. Read data register to verify that all selected channels started (a 1 bit means a fault in

the channel that the bit represents)

5. Write LBP word read command (0x45) in the MSByte ORed with the parameter address

to the selected channels CS register. (0x4500PPPP)

6. Issue a DOIT Command

7. Wait for the command register to be clear

8. Check that the data register is clear, any set bits indicate an error

9. Read the returned data from the selected channels Interface0 register

10. Repeat from step 5 for any additional remote data reads

8I20 36

Page 41

REFERENCE INFORMATION

SSLBP

REMOTE WRITE EXAMPLE:

For a remote word write, the sequence of operations is as follows:

1. Issue a STOP command, wait for COMMAND register clear to verify stop command

completion.

2. Issue a setup START command (0xFNN) with bitmask (NN) of channels to start

3. Wait for COMMAND register clear to verify start command completion. (may be many

mS)

4. Read data register to verify that all selected channels started (a 1 bit means a fault in

the channel that the bit represents)

5. Write the new parameter data to the selected channels Interface0 register (right justified)

6. Write LBP word write command (0x65) in the MSByte ORed with the parameter address

to the selected channels CS register. (0x6500PPPP) 6. Issue a DOIT Command

7. Wait for the command register to be clear

8. Check that the data register is clear, any set bits indicate an error

9. Repeat from step 5 for any additional remote parameter writes

8I20 37

Loading...

Loading...