Merrow Class A Instruction Manual

9

FOR

SETTING

MERROW

TRIMMING

MACHINE

REG. U. S.

UP

PAT.

TRADE

OFF.

AND

AND

eMi<^

AND

OPERATING

MARK

FOREIGN

COUNTRIES

£p^ed

OVERSEAMING

THE

MERROW

HARTFORD

MACHINE

6,

CONNECTICUT,

COMPANY

U.S.A.

THE

MERROW

MACHINE

COMPANY

INTRODUCTION

This book contains instructions for setting up and operating Merrow Class A Overseaming, Overedging, and

Hemming Machines together

The

Class A Machines include machines for overseaming and trimming simultaneously forming a one-thread

overseam, a two-thread overseam or finish, a three-thread overseam or finish, or a three-thread

thread

seam.

with

diagrams showing the location of various parts.

tight

needle

We also make other classes of machines including Class 60 Overseaming, Overedging, Butted Seaming and Hem

ming

Machines,

have been

Write

Machines.

for

We keep a record of each

ply

duplicatesifgiven

long

book

Plain

Crochet Machines, Blanket

and

favorably

containing

known

a descriptive list of

part

model contained in the various machines as they leave our factory, and can sup

the

NAMEofthe

Hemming

and

used by manufacturers

many

HOW

part

with

TO

STYLE

Machines,

throughout

partsincommon

ORDER

and

SERIAL

and

Shell Stitch Crochet Machines

the

world.

use

on

Merrow

Class A Overseaming

numberofMachine.

which

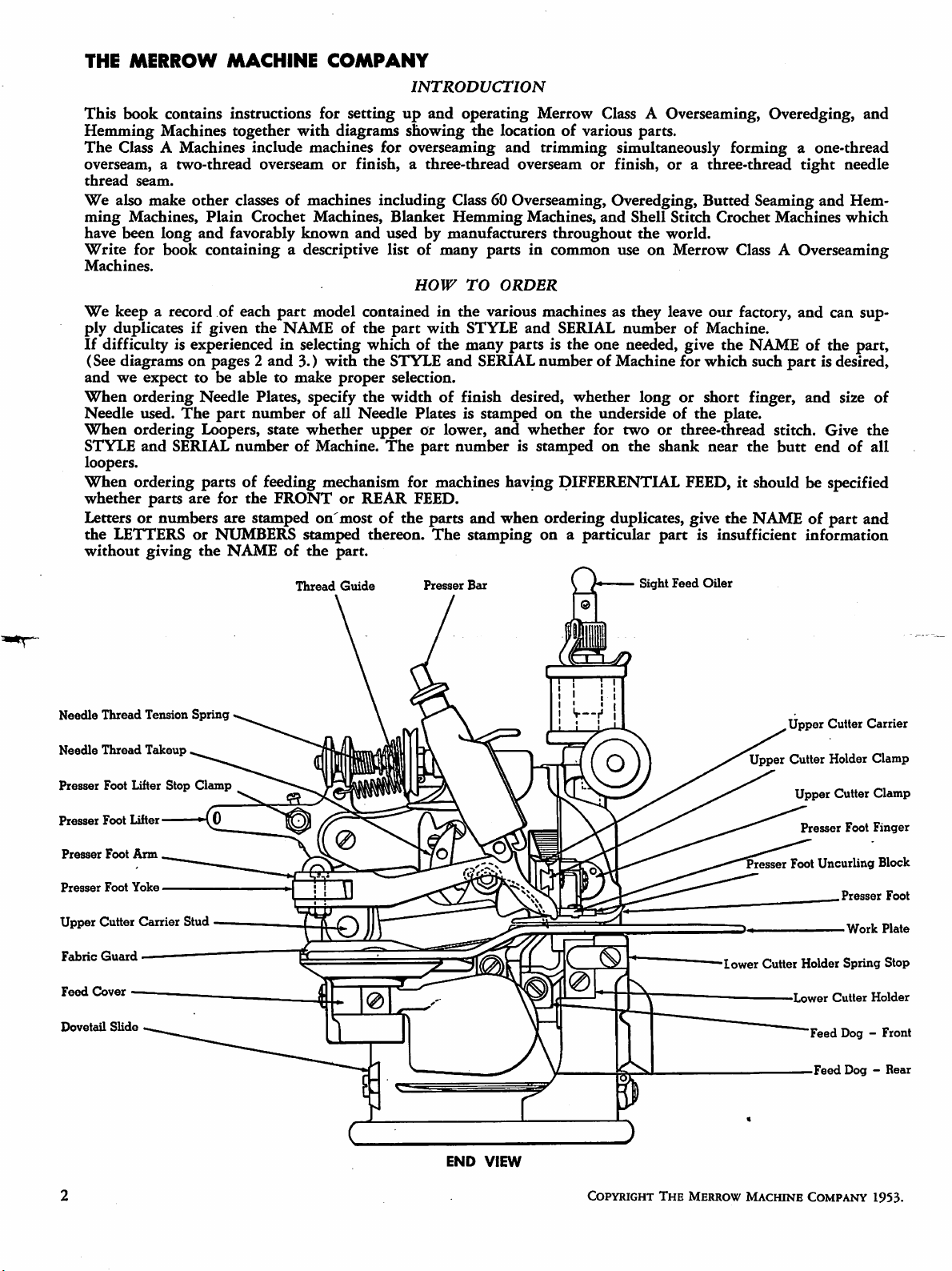

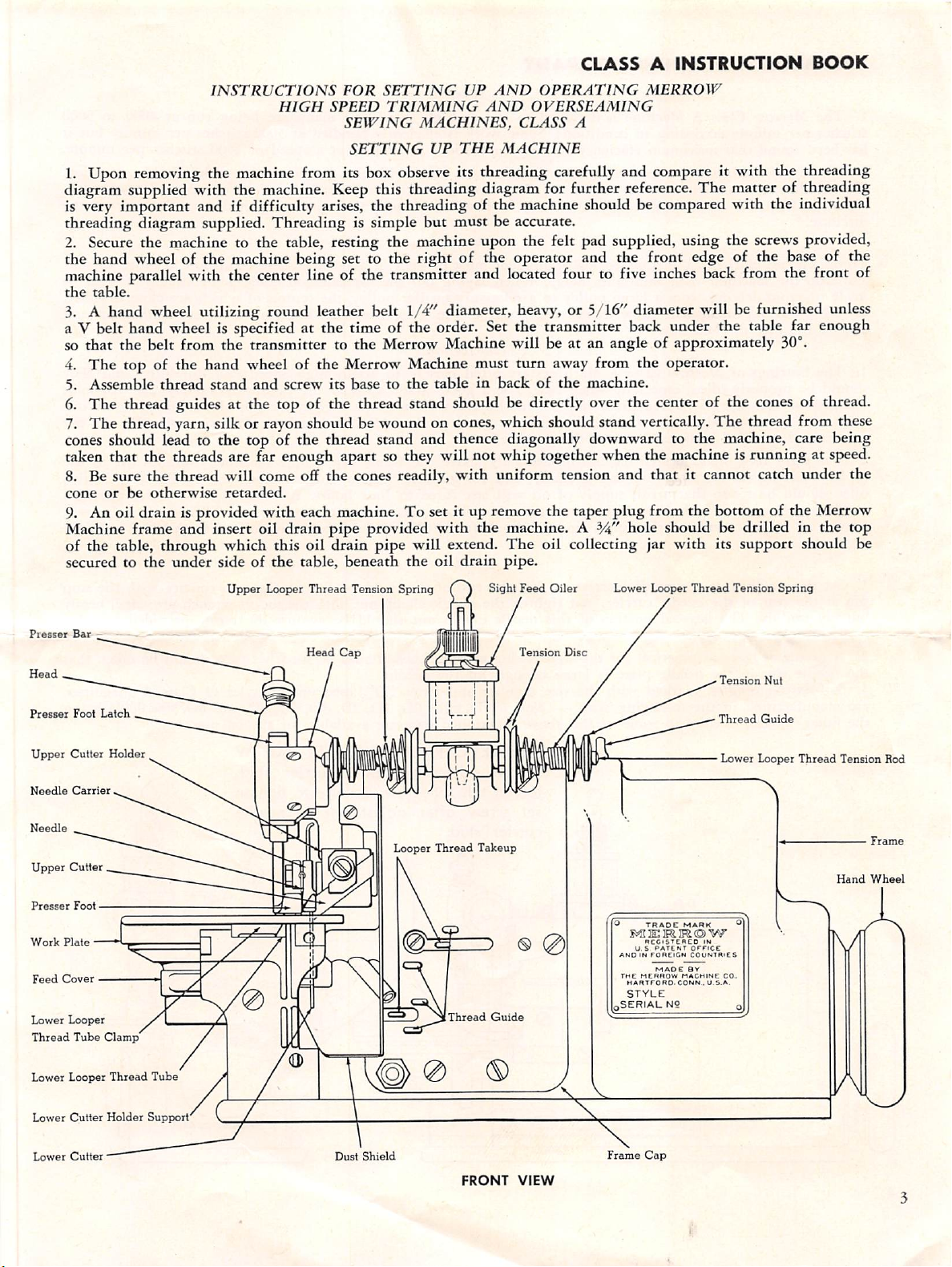

If difficulty is experienced in selecting which of the many parts is the one needed, give the NAME of the part,

(See diagrams on pages 2

and

we expect to be able to

When

Needle used.

When

ordering Needle Plates, specify the

The

part

ordering

Loopers, state

STYLE and SERIAL number of Machine.

loopers.

and

3.)

with

the

make

proper

STYLE

selection.

and

SERIAL

number

widthoffinish desired, whether

number of all Needle Plates is stamped on

whether

upperorlower,

The

part

number

and

whether

is stamped on

of Machine for which such

long

or short finger, and size of

the

underside of

for

two

the

the

or three-thread stitch. Give

shank near the

plate.

part

butt

is desired,

the

endofall

When ordering parts of feeding mechanism for machines having DIFFERENTIAL FEED, it should be specified

whether

Letters or numbers are stamped on most of the parts and when ordering duplicates, give the NAME of

the

without

parts

LETTERS

giving

are

for

the

FRONTorREAR

or NUMBEl^

the

NAMEofthe

stamped

part.

thereon.

FEED.

The

stamping

part

and

on a particular part is insufficient information

Needle

Needle

Presser

Presser

Presser

Presser

Upper

Fabric

Feed

Dovetail

Thread

Thread

Foot Lifter

Foot

Foot

Foot

Cutter

Guard

Cover

Slide

Tension

Takeup

Lifter

Arm

Yoke

Carrier

Stop

Stud

Thread

Guide

Presser

Bar

Sight

Feed

Oiler

lower

Upper

Cutter

Cutter

Holder

Upper Cutter Clamp

Presser

Foot

Uncurling

Cutter

Holder

Lower

Feed

Carrier

Clamp

Foot

Finger

Block

Presser

Work

Spring

Cutter

Holder

Dog - Front

Foot

Plate

Stop

END

VIEW

Copyright

The

Merrow

Machine

Feed

Dog-Rear

Company

1953.

INSTRUCTIONS

1. Upon

removing

the

machine

diagram supplied with the

very

is

important and if difficulty

HIGH

from

machine.

FOR

SPEED

SEWING

SETTING

its box

Keep

arises,

CLASS

SETTING

TRIMMING

observe

UP

AND

OPERATING

AND

OVERSEAMING

MACHINES,

UP

THE

CLASS

MACHINE

its threading carefully and

A

this threading diagram for further

the threadingof the

machine

shouldbecompared

A

INSTRUCTION

MERROW^

compare

reference.

BOOK

it with the threading

The matterof threading

with the individual

threading diagram supplied. Threading is simple but must be accurate.

2.

Secure

the hand wheel of the machine being set to the right of the operator and the front edge of the

machine

the

3. A hand

the machine to the table, resting the machine upon the felt pad supplied, using the

parallel with the center line of the transmitter and

table.

wheel

utilizing round leather belt 1/4" diameter,

located

heavy,

four to

five

or 5/l6" diameter will be

inches

back

screws

from

furnished

provided,

base

of the

the front of

unless

a V belt hand wheel is specified at the time of the order. Set the transmitter back under the table far enough

so

that

the

belt

from

the

transmittertothe

Merrow

Machine

willbeatanangleofapproximately

30°.

4. The top of the hand wheel of the Merrow Machine must turn away from the operator.

5.

Assemble

6. The thread guides at the top of the thread stand should be directly over the center of the

thread

stand

and

screw

its

basetothe

tableinbackofthe

machine.

cones

of thread.

7. The thread, yarn, silk or rayon should be wound on cones, which should stand vertically. The thread from these

cones

should lead to the top of the thread stand and thence diagonally downward to the machine, care being

taken that the threads are far enough apart so they will not whip together when the machine is running at speed.

8. Be sure the thread will come off the cones readily, with uniform tension and that it cannot catch under the

cone

or

be

otherwise

9. An oil drain is provided with each machine. To set it up

retarded.

remove

the taper plug from the bottom of the Merrow

Machine frame and insert oil drain pipe provided with the machine. A hole should be drilled in the top

of the table, through which this oil drain pipe will extend. The oil collecting jar with its support should be

securedtothe

under

sideofthe

Upper

Looper

table,

Thread

beneath

Tension

the

Spring

oil

drain

Sight

pipe.

Feed

Oiler

Lower

Looper

Thread

Tension

Spring

Piesser

Presser

Upper

Needle

Needle

Upper

Presser

Work

Feed

Lower

Thread

Lower

Bar

Foot

Cutter

Carrier

Cutter

Foot

Plate

Cover

Looper

Tube

Looper

Latch

•

-

Clamp'

Holder

Thread

Tube

Head

Cap

Looper

Thread

Thread

Takeup

Guide

Tension

Disc

TRAOe

BCGISTEBEO

U.S

PATENT

ANDINronClCN

MADE

THE

MERROW

HARTFORO.CONN..

STYLE

SERIAL

NO

MARK

OTICe

COUNTRIES

BY

MACHINE

IN

U.S.A

Tension

Thread

Lower

CO.

Nut

Guide

Looper

Thread

Tension Rod

Hand

Wheel

Lower

Cutter

Holder

Lower

Support'

Cutter

C

Dust

Shield

FRONT

VIEW

Frame

Cap

Loading...

Loading...