Page 1

XLR8

MGS524

24 Volt DC

SLIDING GATE OPENER

INSTALLATION MANUAL

For Professional Installation ONLY

For level gradient installations ONLY

Chamberlain Australia Pty Ltd

PO Box 1446

Lane Cove NSW 1595

Phone toll free: 1800 638 234

Chamberlain New Zealand Ltd

PO Box 100-221

North Shore 0745

Phone toll free: 0800 653 667

www.go-merlin.com

Page 2

2

PLEASE START BY READING THESE IMPORTANT SAFETY RULES

This safety alert symbol means "Caution" - failure to comply with such an instruction involves risk of personal

injury or damage to property. Please read these warnings carefully.

This gate drive mechanism is designed and tested to offer appropriately safe service provided it is installed and

operated in strict accordance with the following safety rules.

Incorrect installation and/or failure to comply with the following instructions may result in serious personal

injury or property damage.

I

nstallation and wiring must be in compliance

with your local building and electrical

installation codes. Power cables must only be

connected to a properly earthed supply.

Disconnect electric power to the system before

making repairs or removing covers.

A disconnecting device must be provided in the

permanently-wired installation to guarantee allpole disconnection by means of a switch (at least

3mm contact gap) or by a separate fuse.

When using tools and small parts to install or

c

arry out repair work on a gate exercise caution

and do not wear rings, watches or loose

clothing.

Make sure that people who install, maintain or

operate the gate drive and/or the control board

are qualified and follow these instructions.

Keep these instructions in a safe place so that

you can refer to them quickly when you need to.

Please remove any locks fitted to the gate in order

to prevent damage to the gate.

Frequently examine the installation for imbalance

and signs of wear or damage to cables, hardware

and mountings. Do not use if repair or

adjustment is necessary. Gates which stick or

jam must be repaired immediately. Employ a

qualified technician to repair the gate, never

attempt to repair it yourself.

Keep additional accessories away from children.

Do not allow children to play with pushbuttons

or remote controls. A gate can cause serious

injuries as it closes.

After the installation a final test of the full

function of the system and the full function of

the safety devices must be done.

The full protection against potential squeeze or

entrapment must work direct when the drive arms

are installed.

This drive cannot be used with a gate

incorporating a wicket door unless the drive

cannot be operated with the wicket door open.

IMPORTANT FITTING AND OPERATING INSTRUCTIONS

W

ARNING / ATTENTION

Lightweight gates must be substantially

reinforced to avoid gate damage. The best

solution is to check with your gate manufacturer

for an opener installation reinforcement kit.

Gate must not extend over public byway during

operation.

Activate opener only when the gate is in full

view, free of obstructions.

Do not allow children to play near the gate.

This appliance is not intended for use by

persons (including children) with reduced

physical sensory or mental capabilities, or lack

of experience and knowledge, unless they have

been given supervision or instruction

concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that

they do not play with the appliance.

PLEASE KEEP THESE INSTRUCTIONS

Entrapment protection devices MUST be

installed to protect anyone who may come

near a moving gate. Locate entrapment

protection devices to protect in BOTH the

open and close gate cycles. Locate

entrapment protection devices to protect

between moving gate and RIGID objects,

such as posts.

Controls must be far enough from the gate so

that the user is prevented from coming in

contact with the gate while operating the

controls.

Humidity and water destroy the control board.

Make sure under all circumstances that water,

humidity or dammed-up water cannot penetrate

the control board covering.

Automatic drive – Keep away from the area of the

gate since it may operate unexpectedly.

When opener is disengaged:

- gate must move freely when pushed by hand

- gate must not move on its own ie. no slope.

Do not install this opener on surfaces with a

gradient. Designed for flat surface installations

only.

Page 3

This sliding gate motor can be activated by hardware trigger inputs (keyswitches, keypads or induction

l

oops) as well as via the RF remote controls provided. The control board provides a variety of safety and

operating functions. Please familiarise yourself with these function to ensure the safest and most functional

automation of your gate.

A set of manual release keys is provided with your motor incase of power failure.

PLEASE LABEL THESE KEYS AND STORE IN A SAFE PLACE.

3

CONTENTS PAGE

SAFETY INSTRUCTIONS . . . . . . . .2

BEFORE YOU BEGIN . . . . . . . . . . .3

CARTON CONTENTS . . . . . . . . . . .3

INSTALLATION . . . . . . . . . . . . . .4-6

TYPICAL CONFIGURATION . . . . . .7

INSTALLATION OF CONTROL

BOARD . . . . . . . . . . . . . . . . . . . . . .7

WIRING OF CONTROL BOARD 8-10

ACCESSORIES . . . . . . . . . . . .11-12

JUMPER SETTINGS . . . . . . . . . . .13

INITIAL OPERATION/BASIC

SETTING . . . . . . . . . . . . . . . . . . . .14

PROGRAMMING THE TRAVEL

DISTANCE AND OPERATOR

FORCE . . . . . . . . . . . . . . . . . . . . .15

COMPLETION OF INSTALLATION/

PROGRAMMING . . . . . . . . . . . . . 16

SPARE PARTS . . . . . . . . . . . . . . .17

DIAGNOSIS LED . . . . . . . . . . . . . .18

FREQUENTLY ASKED

QUESTIONS . . . . . . . . . . . . . . . . .19

WARRANTY . . . . . . . . . . . . . . . . .20

BEFORE YOU BEGIN

• Ensure the gate is in working order and suitable for automation.

Check that any wheels are in good working order, the track is free from obstruction and that the gate moves

smoothly throughout itʼs travel. If not, have the gate serviced by a gate installer.

• Ensure the motor you are installing is suitable for the gate weight and duty cycle.

Operating frequency / Duty cycle: MGS Sliding gate drives have a maximum duty cycle of approx. 30% (i.e. 30% per

hour) and not intended for commercial applications.

CAUTION: This device is not intended to run in high duty cycle applications, frequent activations may engage the units

thermal overload circuit. When this occurs the unit will cease operations until such time as the motor cools.

• Gate size: When calculating the gates weight allow for the gateʼs length, a light weight long gate (long = 5m or more)

needs far greater force to set it in motion than a short gate or heavy gate.

• Gate weight: Ensure that allowance is made not only for the gateʼs weight but its length and mobility.

Example: A light gate that slides poorly is likely to need a stronger drive than a heavy, smooth-sliding gate.

NOTE: Gate weight is only an approximate indicator, the actual relevance of which can vary greatly.

• Climatic conditions. Gate operating in high wind areas may be affected by side pressure on the gate. Timber or

metal lined gates may require additional force to operate in high winds. It is essential that this is allowed for before

installation.

• Temperature: Extreme low outdoor temperatures can make it difficult to operate the gate due to changes in the

ground conditions. A higher powered again might be necessary.

High outdoor temperatures can cause the thermal protection mechanism to be activated sooner.

• Safety: Your CB202 control board has outputs for flashing lamp as well as safety inputs for, contact strips, loop detectors

and photo electric safety beams (1 set of PE beams is provided). Please ensure that you comply with the standards and

regulations relevant to your particular installation.

• Control unit: The control unit was developed specifically with safety aspects in mind. It is located in the motor

housing.

0

4

1

S

L

G

-

1

2

5

S

A

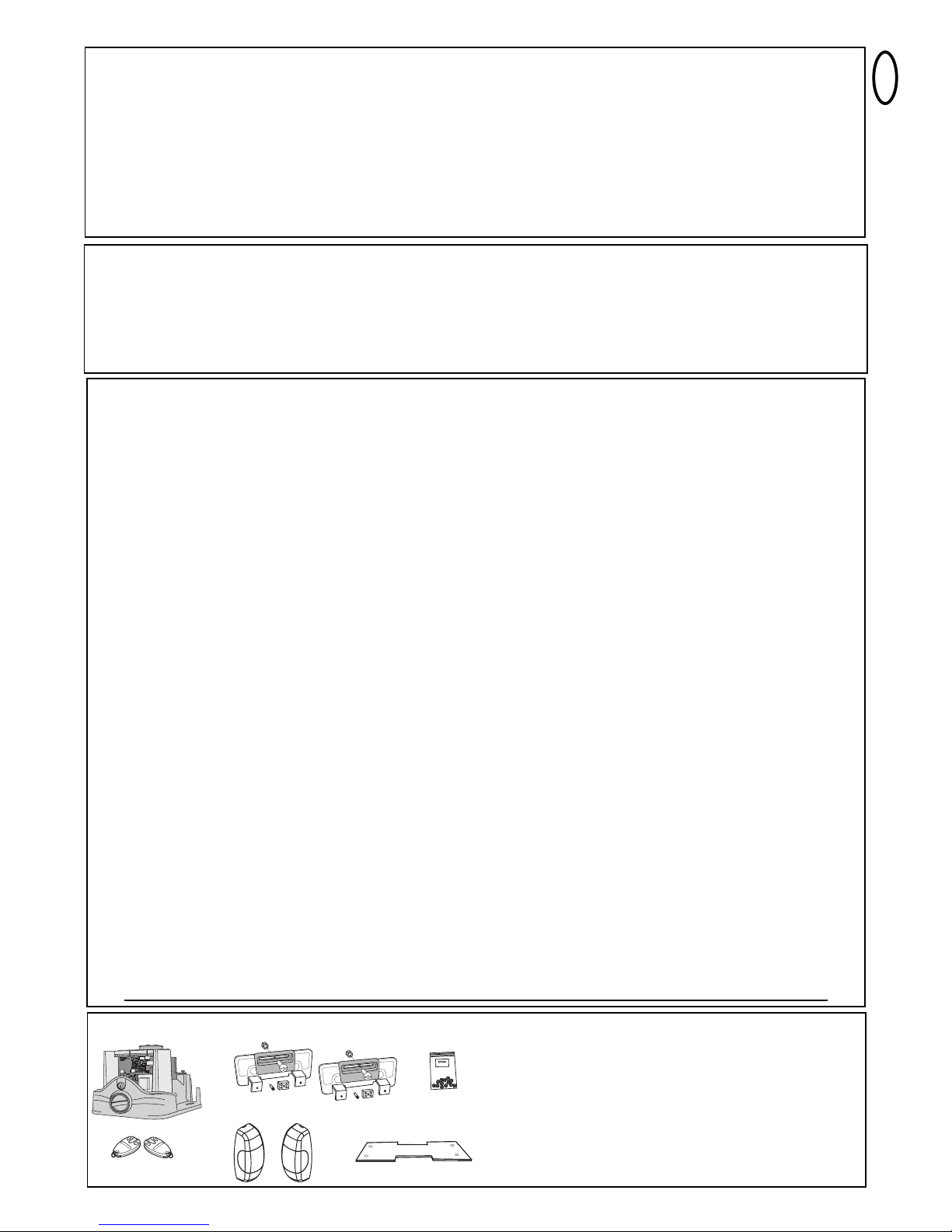

located under the

motor cover.

• PE safety beams (1 set)

• Hardware bag

• Merlin C945 Mini remotes x 2

• Motor with housing

• PCB CB202 logic board

• Limit magnets (1&2) and

mounting accessories

• Base plate

MGS524 Carton contents

Page 4

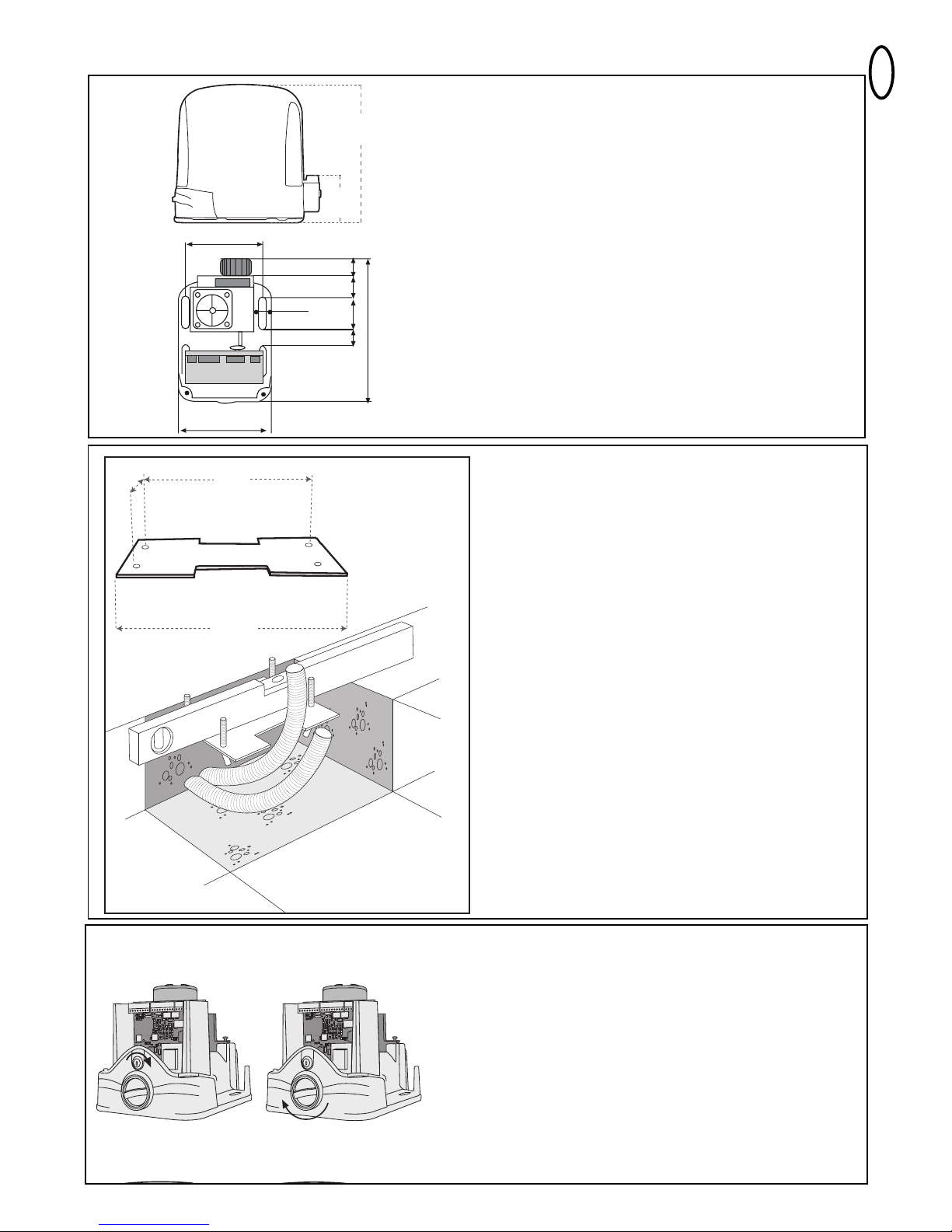

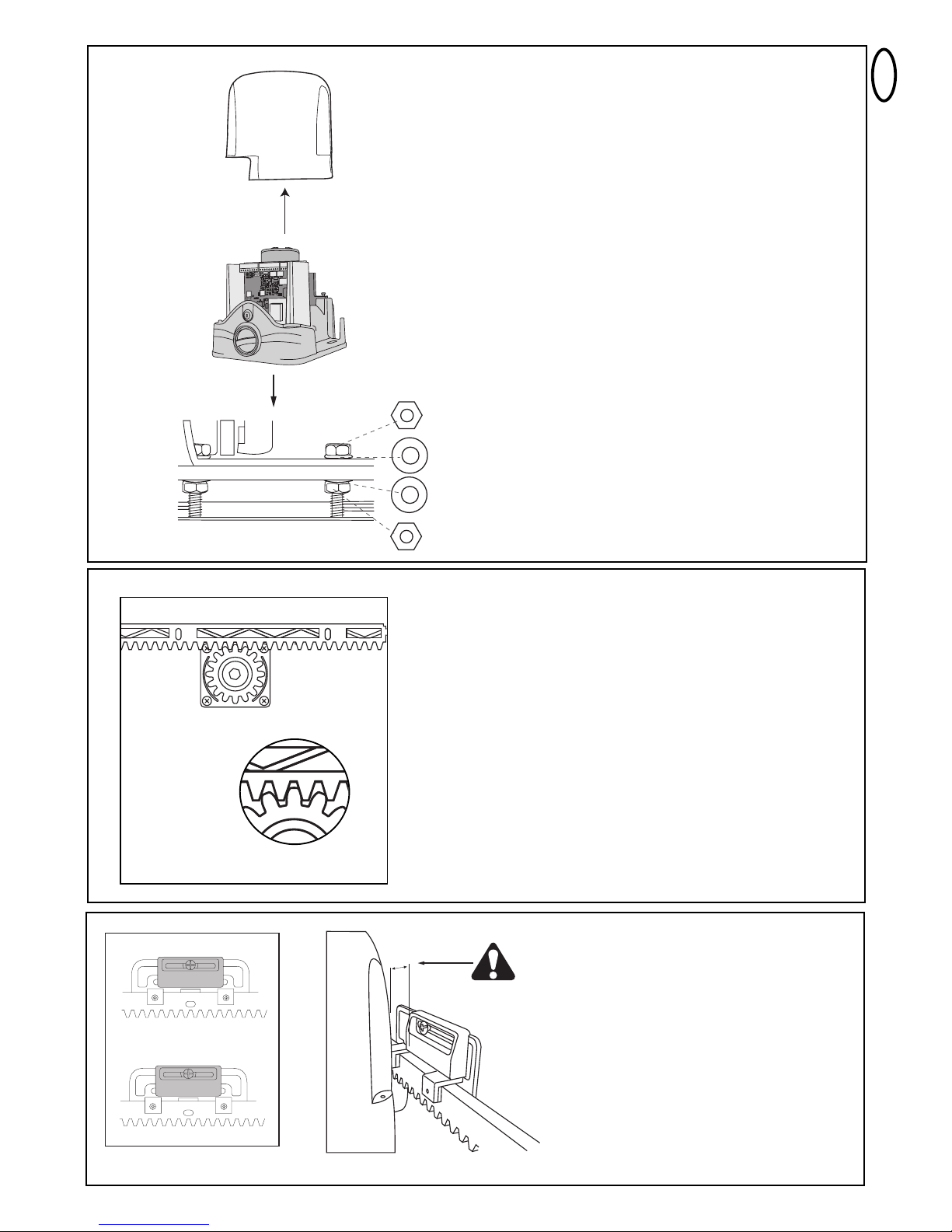

Positioning the motor and plinth.

B

efore preparing the plinth for use ensure that you have the correct

orientation and location for the motor.

No part of the motor or pinion should extend past the gate.

The motor plinth and all electronics should be located within the

propertyʼs boundaries.

The motor can be adjusted up and down and back and forth to some

degree however planning the location of your plinth and conduit exit will

save you time and effort.

Installing the base plate.

Where possible the base plate provided should be

installed into a concrete plinth.

The Base plate should be installed into a concrete plinth

of approximate 500mm x 500mm x 500mm for maximum

strength.

Ensure that a conduit is installed before adding the

concrete and that the exit point for the conduit is on the

correct side of the base plate in relation to the motor.

The plate has two recesses, ensure that the conduit

exits to the rear of the motor, this will facilitate the

passage of wire through the grommet located at the

base of the control box housing.

NOTE: For best results make sure the plinth

is level and has adequate drainage. Pooled

water around the base of the motor will

damage the gate motor.

200

215

1

2

40

60

28

30

270 mm

75 mm

160

160 mm

1

0

0

mm

180 mm

gate side

rear of motor

4

Installation

1.Turn key 180

2.Turn release mechanism 270

0

0

Manual release

In the case of a power failure or to move the gate freely

during installation the drive pinion must be disengaged.

To release the drive pinion.

• Turn the key 180 degrees to unlock

the release mechanism

• Turn the release mechanism 270

degrees to the right to release the

pinion.

NOTE: The gate should move freely once the drive

pinion has been released.

Page 5

5

Mounting the Rack

To ensure the best gate travel the rack should follow the gates

movement. The rack should be fastened to the gate in section

follow the contours of the gateʼs travel. Release the gate drive as

detailed above first. Lay one section of rack across the drive

pinion parallel to the ground. Allowing for 1-2mm of clearance

between and the drive pinion and the rack to avoid pressure and

possible damage to the gears. Allowance should be made for

later adjusted to the rack, mark the first hole at the end of your

rack. Fasten the rack in place, role the gate forward and fasten

the remaining sections of rack using the same method.

Caution: You must have rack installed along the entire length

of its travel including the start and stop limits.

1-2mm clearance

between drive and rack.

M

ounting the Motor

Hand tighten one of the nuts provided onto each of

t

he four posts (tighten to about 15mm from the base

of the plate) then place a washer (provided) onto

each post.

Remove the cover from the motor and fit the motor

onto the threaded posts. Position the motor and

drive pinion approximately in place (some

adjustments may be required).

Place a washer onto each post then hand tighten

the nuts provided onto the post, some final

adjustments will be required so do not tighten the

nuts yet.

NOTE: Remove any foam packing from the motor

assembly.

Fitting the Magnets

Your MGS gate kit contains two magnets,

marked one and two. These indicate to the

gate motor the gate position it is essential that

they are fitted correctly and securely.

Magnets must be installed between

10-15mm from the limit switch

(see page 6).

A (1)

B (2)

max. 15mm

B (2)

A (1)

B (2)

Page 6

6

320001 (1 x 1m)

202097 (4 x 1m)

320003 (2 x 1m)

1

2

1

2

OR

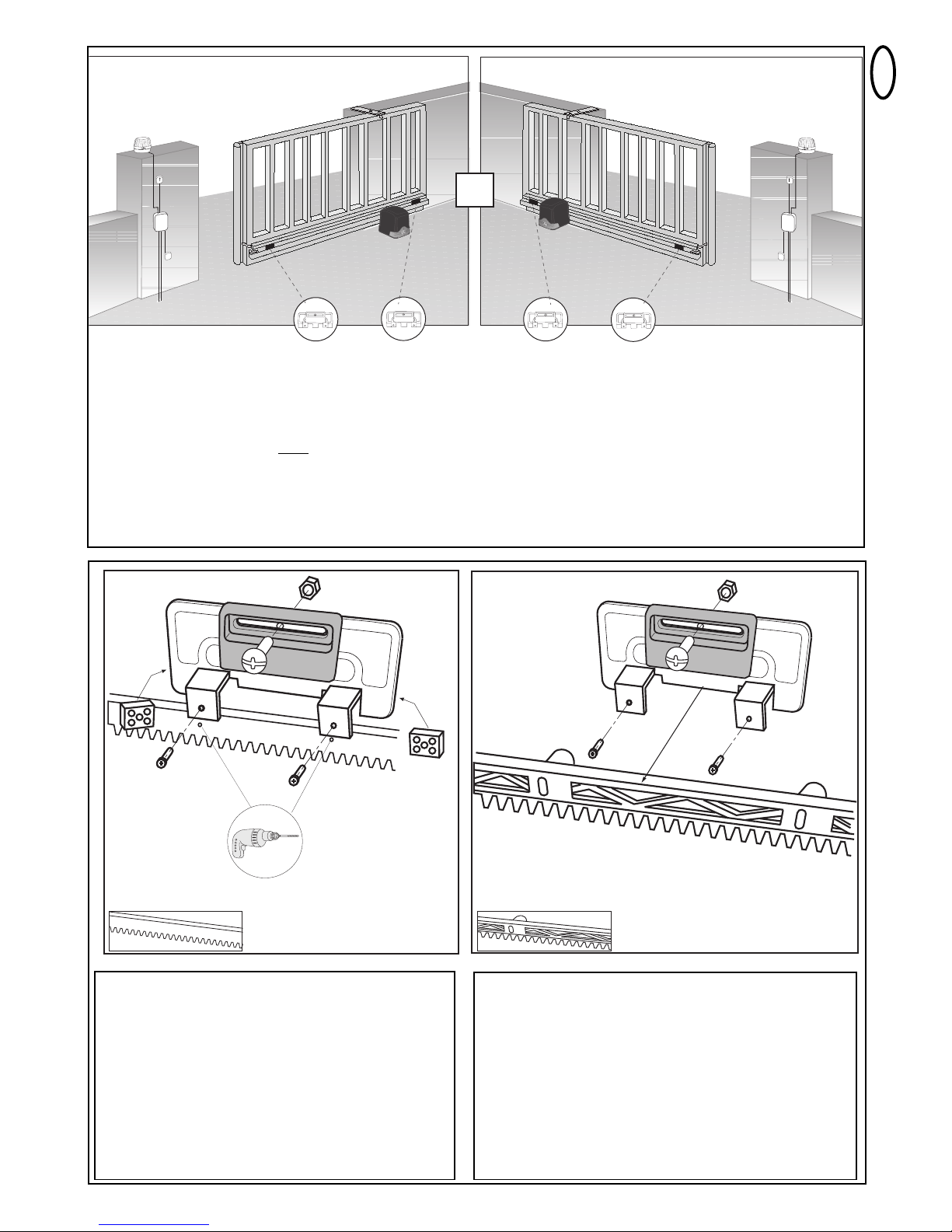

Installing the magnet bracket steel rack.

Identify your start and stop limit. Using the magnet

bracket mark two holes as shown above. Drill two

holes into the rack then install the spacers provided

into the back tabs using the raised pins to position.

Once the spacers are in place, fit the bracket over

the rack and tighten the screws. Install the start and

stop limit magnets as outlined above using the bolt

and nylex nut provided.

Installing the magnet and bracket for nylon

rack.

Identify your start and stop limit. Fit the bracket over the

rack and tighten the screws. Install the start and stop

magnets as outlined above using the bolt and nylex nut

provided.

Installing the Limit Magnets

Caution: The magnet limit switches are polarity sensitive and can be installed in either of the positions as

marked above.

NOTE: Motor Wiring does NOT need to be reversed for left and right hand opening.

Caution: You must have rack installed along the entire length of its travel including the start and stop limits.

HEAVY DUTY STEEL RACK

PVC NYLON RACK

Page 7

7

TYPICAL CONFIGURATION OF A

SLIDING GATE UNIT

1. Drive with control board

The drive is located on a height-adjustable

mounting plate.

2. Photocell min. 150- max200 mm (optional)

First photocell.

Detects low objects.

3. Photocell max. 700 mm (optional)

Second photocell.

Detects vehicles and higher objects.

4. Flashing light (optional)

Important visual information indicating gate

movement.

5. Safety edge (optional)

Detects obstacles and avoids risks

produced by gate movement.

Safety edges can be mounted on the gate

or on the pillars. If the gate has openings

exceeding 45mm, a safety edge is

required on the pillar (accessory).

If required, safety edges must be mounted

at a height of up to 2.5m.

1

2

3

4

5

2

3

INSTALLATION OF CONTROL BOARD

The CB202 control board was designed for installation in a special

covering under the housing of the sliding gate drive.

The installation of the electrical controller is allowed only after the

completion of the mechanical installation. All work on the controller

must be performed after disconnecting it from the mains power supply.

Turn on the power only when it is prompted in the section INITIAL

OPERATION/ BASIC SETTING.

To operate, at least the following connections have to be established: -

- “Power supply”

- Transformer “Input & Transf”

- Motor “MOTOR”

- Plug limit switch “LIMIT SWITCH”

- Plug "RPM/ENCODER"

If necessary assemble the following optional connections:

- photocells

- safety edge

- flashing light

- external antenna

- key switch or other external control devices

NOTE: Plastic housing may need to be

loosened to tighten the Power Cable

Gland.

Page 8

8

W

IRING OF CONTROL BOARD

The cables for the power supply and the connected equipment can

be routed from below into the sliding gate operator through the

rubber seal at the bottom of the control box.

The controller is to be mounted with the terminal strips down as

shown in the picture.

The usage of shielded cable in order to connect the motor to control

board is highly recommended. Magnetic and inductive influence of

the signal in the cables can produce electric noise and may disturb

the function of the gate .

Generally avoid:

- 230 V and low voltage in the same power line. Not allowed by

electrical rules.

- Wiring of the photocells, switches, flashing lamps require a cable

separately from the motor wiring.

- Other wirings like telephone intercoms, lights for garden etc. must

be in separate cables.

- Rigid copper cables especially when thicker diameters are difficult

to manage during the installation and may result in bad

connections with functional issues. Use flexible cables instead.

- Cable material not suitable for outside use. Use cables suitable for

outside use and underground. Run the cables in conduits if the

cable is not suitable for placing in the ground (armoured or suitably

protected). Consult a local electrician if required.

General wiring sizes:

The numbers mentioned in the table below are minimum

requirements. It is always possible to use larger diameters.

- 230 V Supply Power to controller: min. 0,75mm² 3-pole

- Switches, infrared sensors, flashing lamp: See table etc.

min. 0.5mm²

Terminals:

The terminal blocks on the controller can be removed (pull) to

facilitate a convenient wiring and are pushed back only while

installing the controller. Even if a terminal strip is not in use, it must

be pushed back. The wiring is done as described in the wiring

diagram.

Plugs (available on the motor):

These plugs must be connected to the controller (plugged in).

The cable of the connectors are not routed from below, but from the

back of the controller (see picture).

1. 230 V transformer feeder TRANSF IN - connect to terminal

2. Limit switch

3. Motor connector RPM/Encoder - remove the extender cable from

RPM lead to enable connection.

4. Connect Green earth lead to Power lead.

Radio

The radio system is supplied as a small radio PCB module separate

to the main controller and plugged in when needed as shown in the

wiring diagram. A short cable antenna is always pre-assembled at

the factory.

NOTE: Transmitter will not work if the module is not plugged in.

Operator Model

External antenna

(Remove original

antenna of logic board)

Switches, Flashing lamp

etc.

Infrared Sensors

Distance

0m - 6m

Coax cable (Satellite

cable)

50 or 75 Ohm

0,5mm²

0,5mm²

Distance

6m - 10m

Coax cable (Satellite

cable)

50 or 75 Ohm

0,5mm²

0,5mm²

Distance

10m - 12m

Coax cable (Satellite

cable)

50 or 75 Ohm

0,75mm²

0,75mm²

Distance

12m – xx

Coax cable (Satellite cable)

50 or 75 Ohm

(max. 25m)

Min. 0,75mm²

Max. 30m

Min. 0,75mm²

Max. 20m

Blue

240VAC

Grey

(low voltage)

1

2

3

NOTE: MGS524 is factory terminated (ie. power cord is wired into

CB202 controller).

Consult a qualified electrician if your product requires alternative

iinstallation.

WIRE SIZES:

NOTE: The terminals are designed for a Max. cable diameter of 1.5m2(flexible wire).

Page 9

9

230V~

+/- 10%

50Hz

Model

CM475

(enclosure

required)

Ω

8.2

+

+

+

+

+

+

opening beam

closing beam

closing beam

closing beam

PHO1

PHO2

Radio

4

33MHz

Jumper OFF

Jumper ON

BLBL

Grey

WIRING DIAGRAM

TECHNICAL DATA OF CONTROL BOARD

Voltage: 230 V~ ±10% 50 Hz

Transformer: 230 V / 24 V, 105 VA

Output Motor: 24 VDC

Consumption max.: max. 400 W (in operation)

Consumption Standby: max. 4 W (without accessories)

Operating temperature: -20º C ÷ 55º C

Modes: Standard, Automatic

Measurements: 145 x 110 mm (without box)

Protection class Box: IP45

Fuse: 2 x 2 A (slow blow fuse)

Remote control: max. 180 x Rolling Code

feasible frequencies: 433 MHz

The motor control unit is a highly modern electronic unit controlled by

a microprocessor. It has all wiring facilities and functions required for

safe operation. The electronics can be used for the precise

adjustment of the push-pull torque. The gate can be held by hand if

the fitting/setting is correct. During operation, the gate can be

stopped at all times via remote control, push-button or key-operated

switch. The gate wing requires a firm stop for the “OPEN” and

“CLOSED” positions.

Humidity and water will destroy the control board. Make sure under

all circumstances that water, humidity or dammed-up water cannot

penetrate the control board. All openings and cable entries must be

sealed watertight.

Page 10

10

DESCRIPTION OF LED´S (LIGHT EMITTING DIODE)

DESCRIPTION COLOUR STATUS

STOP / 8.2 kOhms green Stop Switch

ON: Stop Active

OFF: OK

(Requires wire bridge if no

switch is connected)

EDGE green Safety Edge 8.2KOhm

ON: Activated

OFF: OK

(Requires 8.2KOhm resistor if not used)

“Key symbol” red Key-switch 2-wing opening

ON: Activated

OFF: OK

PHO 1 red Photocell 1 (close)

ON: OK, photocell connected

OFF: No photocell connected

PHO 2 red Photocell 2 (adjustable)

ON: OK, photocell connected

OFF: No photocell connected

OPEN LIM yellow limit switch GATE OPEN

CLOSE LIM yellow limit switch GATE CLOSED

LEARN yellow Programming indicator

ON: (flashing) programming is active

OFF: off

DGN red Diagnostic, also refer to page 18

CH1 red Remote control programming for

complete opening

ON: New remote can be

programmed

OFF: off

CH2 red Remote control programming for

partial opening (Refer to CH1)

DESCRIPTION OF TERMINALS

Description Function

230 VAC

50 Hz

POWER SUPPLY connector

TRANSF IN 230 V to transformer

INPUT 24 V 24 V from transformer

30VDC output 30 VDC battery kit terminal

for CM475 + enclosure

Motor blue cable

Motor red cable

24 V / 150 mA flashing light (accessory)

Key symbol keyswitch

COM negative pole

PHOTO2 photocells 2 (accessory)

PHOTO1 photocells 1 (accessory)

COM negative pole

STOP stop switch or

8.2 kOhms safety edge with 8.2 KOhms

(accessory)

RPM / ENCODER socket for rpm-sensor

LIMIT SWITCH socket for limit switch

RADIO MODULE SCKT socket for radio PCB module

ANT terminal for antenna

2A 2x slow blow fuse included 250V/2A

DESCRIPTION OF PUSH BUTTONS P1, P2, & P3

Button Function

P1+P2+P3 Limit setting: Push P1+P2+P3 simultaneously. The LED LEARN starts to flash as long as feature is activated.

P1 Button P1 operates Motor. Deactivate: Wait for 20 seconds or disconnect logic board from power.

P1 Force / travel distance - setting “BASIC DEFAULT”; from position CLOSE LIM

P1 + P2 Force / travel distance - setting “INSTALLER FORCE SETUP”; from position CLOSE LIM; with optional Soft-Stop setting

P2 ; P3 Timer to close. Factory setting: off. When the photocell beam is interrupted, the gate closes immediately without delay.

Refer to Timer to Close section (page 16).

P3 Software-reset to factory defaults. Push & hold for 10 seconds. Does not reset memory (see section “radio”).

Radio jumper + P1 Programming Remote for Channel 1

Command for OPEN completely

Radio jumper + P2 Programming Remote for Channel 2

Command for OPEN partially

Page 11

11

A

CCESSORIES (also refer to wiring diagram)

STOP SWITCH (OPTIONAL) MODEL: 600084

A stop switch to stop the movement of the gate in any direction can be connected to this output.

Also see STOP/8.2kOHM under “Jumper Settings”.

FLASHING LAMP (OPTIONAL) MODEL: FLA24-2

A flashing lamp can be connected to the control board. It warns when the gate is being moved. The flashing light should be fitted as high as

possible and in good clear view. The control board emits a constant signal that the lamp converts to a flashing signal.

Cable cross-section: 0.5 mm2or more.

Voltage: 24 V DC

KEY SWITCH (OPTIONAL) MODEL: 100010, 100027, 100034, 100041

The system can be operated by key switch (connectors: key symbol and COM). Also see OPEN/PED under “Jumper Settings”.

BACKUP BATTERY (OPTIONAL) MODEL: CM475 (24V/DC)

The terminals serve to reload an externally installed storage battery.

The integrated recharger is loaded and in case of power failure the battery provides power. A new fully charged storage battery may provide

power for more than 24 hours. Storage batteries are subject to deterioration and lose capacity. Due to extensive use they lose capacity even

faster. Replace storage batteries after approx. 2-3 years. CM475 is not for outside use and requires a suitable enclosure.

SAFETY EDGE (OPTIONAL) MODEL: 600046, 600053, 600077, 600060

A safety edge working according to the 8.2 kilo ohm principle can be connected to the control board, i.e. a 8.2 kilo ohm test resistor is attached

to the end of the safety edge. It ensures that the electric circuit is monitored permanently. The control board is supplied with an 8.2 kilo ohm

resistor installed. Several safety edges are connected in series. Cable cross-section: 0.5 mm

2

or more.

Also see STOP/8.2kOHM under “Jumper Settings”.

ANTENNA (OPTIONAL) MODEL: ANT4X-1LM

The control board is supplied with a wire antenna as standard. An external antenna (accessory) can be connected to terminals as shown.

A larger range (radio) can thus be achieved. For best range results mount antenna as high as possible.

PHOTOCELLS (INCLUDED) MODEL: 772ANZ

The photocells are for safeguarding the gate and must be used.

The fitting location depends on the gate’s design. EN12453

specifies that a pair of photocells must be installed at a height of

200 mm and activated to “Close”. The photocells consist of a

transmitter and a receiver and must be opposite each other. The

photocell is mounted on the wall using small screws and wall plugs.

To enable the “Automatic Closing” function, the Chamberlain failsafe

photocell must be installed.

Programming of IR sensors:

- connect IR sensors

- program the travel of the gate

- special feature: Fast closing gate

(see “Description of the Push Buttons P1, P2 & P3”)

Deletion of IR sensors:

Disconnecting already connected IR sensors will cause the control

board to block the functionality of the terminals it was connected to.

To delete IR sensors correctly:

- disconnect IR sensors

- cut control board from current shortly

- program the travel of the gate.

Diagnosis of the photocell

LED constant = OK

LED flashes = photocell disables control board

LED off = no current, incorrect connection or polarity

Diagnosis on the control board

LED constant = OK

LED off = OK no photocell connected

LED flashes = photocell disables control board

Connection between 1 & COM:

Active when gate is closing (reverses gate to open)

Connection between 2 & COM:

adjustable:

Jumper “PHO 2 MODE” unplugged >> active when gate is closing

Jumper “PHO 2 MODE” plugged >> active when gate is opening

230V~

+/- 10%

50Hz

Model

CM475

(enclosure

required)

Ω

8.2

+

+

+

+

+

+

opening beam

closing beam

closing beam

closing beam

PHO1

PHO2

Radio

433MHz

Jumper OFF

Jumper ON

BLBL

Grey

Page 12

12

Radio

433MHz

LOOP DETECTOR (OPTIONAL)

Jumper OPEN/PED must be plugged

Loop detectors react to metal and the most common use is for cars

or trucks but not for bikes or pedestrians.

Exit loop / Gate Opening Loop

An exit loop is behind the gate and opens the gate when closed,

keeps it open or re-opens the gate.

The jumpers OPEN/PED must be PLUGGED (in place).

The gate requires installed photocells and timer to close activated.

In addition, the feature “Fast closing” can be activated.

Refer to section “Description of Push Buttons P1, P2 & P3”

BRN GRN WHT YEL

SECOND

C

OM

P

HOTO

3 2 1

C

OM

E

DGE

8.2KΩ

STOP

PH

O

1

PH

O

2

P

ED

E

DGE

C

H1

CH2

1/2 MOTOR

P1

P2

P3

OPEN/STEP

LIGHT/SPY

OBSTACLE

SPEED 1

SPEED 2

RADIO

PHO 3

L

EARN

DGN

L

IGHT

CONTACT

PED

COM

STOP

NO

Model

203292

OPEN/PED

Jumper ON

RADIO AND RADIO PROGRAMMING

Insert radio module on designated pins, if not pre-installed.

PROGRAM / DELETE REMOTE CONTROLS

The receiver has two channels CH1 and CH2.

The respective LEDs CH1 and CH2 are assigned to these two channels.

Receiving a signal from a programmed remote control button, CH1 fully

opens the gate.

Receiving a signal from another programmed remote control button,

CH2 partially opens the gate (pedestrian mode).

PROGRAMMING

1. Insert (connect) jumper “RADIO”

2. Briefly push button P1 (for CH1) or P2 (for CH2) and the respective

LED lights up.

3. Press and hold a selected button on your remote control until LED

goes out after short flashing. Done!

Repeat for all remote controls (a maximum of 180 remote controls

can be programmed to each channel).

Important: To finish programming, remove (disconnect) jumper “Radio”!

Note: Make sure NOT to program the same remote control button to

CH1 and CH2, otherwise the gate will NOT work properly.

DELETE

1. Insert (connect) Jumper “Radio”.

2. Press and hold buttons P1 (for CH1) or P2 (for CH2) until the

respective LED goes out again (approx. 10 seconds).

Single remote controls can not be deleted. All remotes programmed

to this channel are deleted.

Important: To finish deleting, remove (disconnect) jumper “Radio”

Page 13

13

RADIO

The radio jumper is required to program remote controls.

For programming procedure please refer to page 12, section “radio”

FREE: No programming of remote controls possible

PLUGGED: Programming of remote controls possible

Important: Keep jumper “RADIO” disconnected

(removed) if not in use!

STOP/8,2 KOhm

Defines whether the terminal STOP/8,2KOhm is used for an

emergency stop or a safety edge. With an emergency stop any

movement of the gate will be stopped. When used for a safety edge

the gate reverses for 1 second.

FREE: Factory setting is 8,2KOhm. Safety edge or

8.2kOhm resistor is required.

PLUGGED: Emergency stop required. In this case the

resistor must be removed and replaced by the

switch or a switch circuit.

OPEN/PED

Defines if a key switch opens the gate completely or partially.

FREE: opens partially (ca. 100 -150 cm)

PLUGGED: opens completely

Note: If the jumper OPEN/PED is plugged and timer to close is

activated as well, the functionality of the terminals “key symbol” and

“COM” changes. See section “Loop Detector” above.

PHO 2 MODE

Defines whether the second photocell is active in closing or in closing

& opening.

FREE: active in closing

PLUGGED: active in opening

OBSTACLE

Factory-equipped with fixed wire jumper. Cutting through increases the

operating power at the control.

CAUTION: If the jumper is severed, the gate system should be

secured with additional safety devices (contact strip, etc.).

Werkseitig mit fester Drahtbrücke ausgestattet. Durchtrennen erhöht

die Arbeitskraft an der Steuerung.

JUMPER SETTINGS

Page 14

14

BASIC SETTING (to identify magnet position):

1. Bring the gate manually to a position between the two

limit switches OPEN - CLOSE and lock drive.

2. Press buttons P1, P2 and P3 at the same time for about

2-3 sec. LED "LEARN" starts to flash.

3. Now watch the gate. The gate can be moved in both

directions using the button P1. Press the button P1

several times (1-2 seconds each time) to understand the

function of the button. If none of the buttons are pressed

for about 15 seconds, the control switches back to normal

operation. Repeat step 2 in this section.

4. Fully open the gate with the button P1.

Keep P1 pressed until the controller turns off by itself at

the limit switch OPEN. (Do not release beforehand).

Control: The LED "OPEN LIM" (yellow) = limit switch

OPEN should now light up and the gate can be opened

as required. Otherwise, change the limit switch position

before further settings are made.

5. Close the gate with the button P1 till it is turned off at the

limit switch CLOSED. (Do not release beforehand).

Control: The LED "CLOSE LIM" (yellow) = limit switch

CLOSED should now light up and the gate can be closed

as desired.

Basic setting is completed.

- Wait for “learn” to stop flashing

- Proceed to next step

2

.

2.

2

.

2.

2.

2

.

2.

2

.

2.

2.

INITIAL OPERATION / BASIC SETTING

Proceed step by step. When in doubt, start again at the beginning. Take sufficient time to make these settings.

1. Are all components required for operation connected? Motor, photocells, safety contact strip, stop switch.

2. Limit switches are fixed to the rack?

3. Setting of jumpers => all removed (settings can be done later on)

5. Make sure nobody is present in the gate area.

Now connect control board to power

Page 15

15

1. The gate is at the limit switch CLOSED.

2. Press P1 and P2 simultaneously for a longer time (about

5-6 seconds) until the gate opens.

Release buttons! LED “LEARN” flashes.

3. Press P1. Soft-stop in the OPENING direction starts from

this position.

4. Press P1 again when the gate moves in CLOSING

direction, soft-stop starts from this position.

When LED "LEARN" goes out, the programming is

completed successfully.

2.

2.

2.

2.

2.

2

.

2

.

2.

PROGRAMMIING THE TRAVEL DISTANCE AND OPERATOR FORCE

Below are two methods of configuring the opener ’s travel

1. Basic Default Setup - Slowest travel

2. Installer setup - Faster travel (optional soft start/soft stop)

1. BASIC DEFAULT FORCE SETTING

(Default speed - fast start then slows down)

1. The drive is at the limit switch CLOSED.

LED "CLOSE LIM" glows.

2. Press the button P1 until the gate starts to open.

(LED "LEARN" glows)

The automatic programme starts (slow speed).

3. The drive moves the gate to the limit switch OPEN,

stops briefly and then moves back to the limit switch CLOSED.

4. After reaching the limit switch CLOSED, the LED

"LEARN" goes out. The programming of the distance and

the force required is completed.

Proceed with “Radio and Radio Programming” and “Completion of Installation”.

2.

2.

2.

2.

2.

2.

2.

2.

2.

2.

2. INSTALLER FORCE SETUP

(Faster speed with optional soft stop function)

PROGRAMMING THE DISTANCE "ADVANCED" (INDIVIDUAL)

NOTE: The button P1 must be pressed firmly several times during this set up. Each press of the button will determine the position at which the softstop (slow rampdown speed) is activated. ie. The installer can set the soft stop function at any point of the travel.

Page 16

16

FORCE / TORQUE OF MOTOR

Thrust of the motor is set automatically while programming the travel

distance. Thrust can only be modified by programming the travel

distance again. If gate movement is impeded by weather or changes

to the installation (rust or inappropriate lubrication) it may have to be

repaired.

The control board complies with the latest EU guidelines.

One of these guidelines specifies that the closing forces

at the gate edge must not exceed 400N (40 kg) for the last 500 mm

before the gate is CLOSED. Above 500 mm, the maximum force at

the gate edge must not exceed 1400 N (140 kg). If this cannot be

ensured, a contact strip must be mounted on the gate at a height up

to 2.5 m or on the pillar on the opposite side (EN12453).

BATTERY DISPOSAL

Batteries and rechargeable batteries may not be disposed along with domestic waste, but are

obliged to be returned.

After use they can be returned free of charge locally e.g. in trade or at municipal collecting points.

Batteries and rechargeable batteries are marked with a crossed waste container as well as with the

chemical symbol which describes their toxic element, “Cd” for cadmium, “Hg” for mercury and “Pb”

for lead.

12VDC

Pb Cd Hg

COMPLETION OF INSTALLATION / PROGRAMMING

Once the travel distances are programmed, the remote controls can be programmed as well.

(Refer to “Radio and Radio Programming”)

1. You can now let the gate run 2 complete cycles by pressing a key on the remote or a connected switch and observe the

process. Close the gate again, WITHOUT making another setting.

2. Check operation of photocells, switch, flashing light, remotes, accessories, etc.

3. Advise people using the gate with regard to gate operation, safety functions and how to release the gate in order to operate it manually.

TIMER TO CLOSE (AUTO-CLOSE)

NOTE: Only possible with connected photocells. Time frames from 2 seconds up to 120 seconds are possible.

Activate:

1. Press and hold P2 until yellow LED starts flashing

2. Now count the time you wish to program

3. Press P2 again. Done!

Deactivate:

1. Press and hold P2 until yellow LED starts flashing.

2. Press P3. Yellow LED goes out. Done!

Page 17

17

P

CB Housing

0

41ASLG-1078

K

ey for Release

Mechanism

041ASLG-0054

Release Mechanism

041ASLG-0185SA

B

ase Housing

041ASLG-1150SA

L

imit Reader

0

41ASLG-0383SA

Gear Assembly

041ASLG-1004SA

Replacement Housing

0

41ASLG-0198

W

orm Gear

0

41ASLG-0310SA

Motor Assembly

0

41ASLG-0375SA

0

41ASLG-0353

MGS500

Transformer

041ASLG-0374

Magnets

041ASLG-0053M

L

ogic Board

C

B202

SPARE PARTS

Page 18

18

DIAGNOSIS LED

The LED diagnostics always shows the latest upcoming issue. If several issues are existing the LED diagnostics does not show them.

Example: The gates’ guiding rail is soiled and the drive performs a safety reversal due to too high force. After that the photocell beam got

interrupted. Diagnosis: As long as the photocell beam is interrupted the diagnosis LED flashes 6x respectively 7x.

Indication Description Remedy

1x blinking Motor has insufficient connection to control board Cables not wired or badly connected.

Check terminals precisely. Consider wire lengths

2x blinking Limit switch GATE CLOSED Progamming travel distance failed because the gate never

reached the limit switch GATE CLOSED. Repeat programming

the travel distance according to instructions

3x blinking Limit switch GATE OPEN Progamming travel distance failed because the gate never

reached the limit switch GATE OPEN. Repeat programming

the travel distance according to instructions

4x blinking Interruption of programming / no programming A: Button P1 was pressed too often during “programming travel

distance advanced”

B: The control board has never been programmed

5x blinking Force too high. Force very unsteady A: Gate to heavy or rough running

B: Gate blocked / or rough running at a certain position

C: Gate not balanced

D: Faulty mechanical installation

All: Consult gate dealer/specialist

6x blinking Photocells 1 block installation

A: Obstacle interrupts beam A: Remove obstacle

B: Poor alignment of the lenses B: Check alignment

C: Power supply for photocells not sufficient C: Check terminals and wire diameter

7x blinking Photocells 2 block installation refer to 6x blinking

8x blinking Emergency stop blocks installation A: Check wires and wiring

B: Check basic setting of control board (jumpers)

9x blinking Safety edge blocks installation

A: Obstacle pushes safety edge A: Remove obstacle

B: Safety edge defective B: Check wires, wiring and 8.2kOhm resistor

C: Power supply too low or wire damaged C: Check basic setting of control board (jumpers)

10x blinking Power supply to control board too low

A: 230V supply defective or faulty connection A: Check terminals/connections

B: Damaged wire in powercable B: Consult dealer/specialist

C: Back up battery (optional accessory) empty C: Charge battery min. 24h

11x blinking EEPROM Fault

Power up failed Replace contol board

12x blinking Defect on relay or major electrical component Replace logic board

A: Overload

B: Bad wiring (wrong)

D: Water in photocells (bad installation) Check wiring

E: A photocell was connected before Reprogram the travel distance from gate fully closed

but not removed (disconnected)

Page 19

19

The gate opener doesn’t respond at all; no LED is

on.

Possibly power failure.

1. Check conductor and zero conductor.

2. Check house fusing.

Check whether the radio module is

seated correctly.

Immediately after the gate has started moving, it

stops and reverses.

Obstacle in area of gate.

Gate rough running (consult dealer)

Check gate area for objects

Check photocells

Reprogram travel distance

Gate can only be opened

Photocell blocks Function and connection must be

checked

“Timer to close” doesn’t work.

Only works if the 2-cable photocell 770,771

or 772 installed.

The control board does not work any more using

the transmitter, only with the switch and even then

only as long as a button is pressed and kept

pressed.

Photocell, a contact strip or the emergency

stop disables the control board.

Only one photocell was connected for OPEN

At least 1 pair of photocells active in

OPEN or CLOSED must be connected

The gate opener doesn’t respond at all, although

the controller has been connected (LEDs are on).

1. Remote control not programmed.

2. LEDs indicate a fault.

3. Photocell connected incorrectly.

4. Motor terminal possibly not connected

properly.

1. Programming remote control.

2. Find and rectify fault(s) (see description of

diagnostic LEDs).

3. Check photocell connection / programming.

4. Check terminals and connections.

The remote control’s range is too short.

The installation of an external aerial is recommended as the controller with the short cable

aerial is located either behind the post or near ground level in most cases. The optimum

location of the aerial is as high as possible in all cases. An appropriate aerial with installation

kit can be obtained from Chamberlain as an accessory.

The gate must follow a slope.

Not recommended! Change gate! The gate can move in an uncontrolled (dangerous) manner if

the gate opener has been released. A stronger force is needed in the upwards direction of the

slope and then, in the opposite direction, the gate opener’s force is too strong.

FAQs

Pressing P1, P2 and P3 does not show any reaction

Jumper “RADIO” must be removed.

Check whether the radio module is

seated correctly.

Travel distance can’t be programmed. 1. Jumper setting not correct

2. See Diagnostic LED

3. Interferences in wiring of photocells, switch

or safety edge

4. Gate moves for 1 second only and stops

without reversal during programming

5. Magnetic limit switch

1: Follow the instructions of “initial operation”

closely

3: Remove for checking, then re-program

travel distance

4: Check RPM sensor/Encoder on control

board

5: Install magnetic limit switch properly

The operator sometimes moves slowly

Power failure Common procedure. After power failure the

operator performs a selftest. Depending on

the operator model this can take a few

seconds or a complete cycle. Do not interrupt

this test via remote control or switch,

otherwise the limits may change. If this is the

case reprogram travel distance using P1.

Control board does not work Travel distance not programmed Program travel distance. See initial

operation / diagnosis LED

Control board does not work with transmitter 1. Transmitter not programmed

2. Photocells block

3. Jumper “RADIO”

1.Program transmitter

2.Check photocells, check diagnostic LEDs

3. Jumper “RADIO” must be plugged.

Gate doesn’t open completely Gate heavy / rough running Re-program travel distance

Consult dealer/specialist

Limit switches OPEN and CLOSED not correctly

indicated

Incorrect programming

During programming the limit switch OPEN

must be reached using P1, then limit switch

CLOSED. Switching motor cables is not

required.

Gate opens instead of closing automatically

(timer to close activated)

Incorrect programming

Repeat programming as described in these

instructions

Page 20

20

5 problems caused by electrical faults or replacement of batteries;

6 water or moisture ingress that causes corrosion or electrical

malfunction;

7 corrosion caused by sea air if located near a waterway, beach etc;

8 fitment in a commercial operating application; or

9 solid panel gates installed in an unprotected wind affected location

resulting in the gate not closing;

10 gate travel encounters an incline/decline.

NB: A General Purpose Outlet (GPO) ie: power point must be

supplied by the consumer as this electrical fitting does not form a part

of the Unit (opener). Excludes solar installations.

If this Chamberlain Limited Warranty does not apply, you may have

rights available to you under the Australian Consumer Law.

Liability – Australia only

Except as set out in the Australian Consumer Law (being Schedule 2

of the Competition and Consumer Act 2010) (as amended,

consolidated or replaced):

1 all other guarantees, warranties and representations in relation to

the Unit or its supply are excluded to the extent that Chamberlain

can lawfully exclude them; and

2 under no circumstances will Chamberlain be liable for

consequential, incidental or special damages arising in connection

with the use, or inability to use, the Unit, other than those which

were reasonably foreseeable as liable to result from the failure.

Liability – New Zealand only

Except as set out in the Fair Trading Act 1986 and the Consumer

Guarantees Act 1993 (as amended, consolidated or replaced):

1 all other guarantees, warranties and representations in relation to

the Unit or its supply are excluded to the extent that

Chamberlain can lawfully exclude them; and

2 under no circumstances will Chamberlain be liable for

consequential, incidental or special damages arising in connection

with the use, or inability to use, the Unit, other than those which

were reasonably foreseeable as liable to result from the failure.

Note: We request that you retain your sales docket or invoice as

proof-of-purchase and attach it to this manual to enable you to

establish the date of purchase in the unlikely event of a warranty

service being required. Chamberlain reserves the right to

change the design and specifications of the Unit without prior

notification. Some features or accessories of the Unit may not be

available in certain markets or areas. Please check with your

distributor.

Chamberlain service centre contact details

Australia

Phone toll free 1800 638 234

Fax toll free 1800 888 121

Chamberlain Australia Pty. Ltd.

PO BOX 1446

Lane Cove NSW 1595

New Zealand

Auckland phone 09 477 2823

Phone toll free 0800 653 667

Fax toll free 0800 653 663

Chamberlain New Zealand Ltd

PO BOX 100221

North Shore 0745

Email: customerservice@chamberlainanz.com

Website: www.go-merlin.com

709269-2-C © 2012 Chamberlain Group, Inc

CHAMBERLAIN LIMITED WARRANTY

Merlin Professional MGS524

Sliding Gate Opener

Chamberlain Australia Pty Limited / Chamberlain New Zealand Limited

(Chamberlain), the manufacturer of Merlin® automatic gate openers, is

committed to manufacturing and supplying high quality goods.

As part of this commitment, we seek to provide reliable service and

support for our goods and are pleased to provide you, the original

purchaser, with this Chamberlain Limited Warranty.

We also provide the following statement as required by the Australian

Consumer Law: In Australia, in addition to your rights under this

Chamberlain Limited Warranty, our goods come with guarantees that

cannot be excluded under the Australian Consumer Law. You are

entitled to a replacement or refund for a major failure and for

compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the

goods fail to be of acceptable quality and the failure does not amount

to a major failure.

Chamberlain’s warranty

Chamberlain warrants to the original purchaser of the Merlin® Sliding

Gate Opener (Unit) that all parts of the Unit, other than remote

controlled transmitters and accessories, globes and batteries, are free

from defects in materials and workmanship for a period of 24 months

from the date of purchase when installed in a residential premise with a

residential specified gate that is designed for the sole purpose of

domestic domicile. Chamberlain warrants that remote controlled

transmitters and accessories included with the Unit are free from

defects in materials and workmanship for a period of 12 months from

the date of purchase.

Batteries and globes are not covered under the Chamberlain Limited

Warranty.

It is a condition of this Chamberlain Limited Warranty that the Unit is

sold, installed and serviced by a Professional Dealer appointed by

Chamberlain. A Merlin® branded gate opener purchased over the

internet and installed by a person other than a Professional Dealer will

not be covered by this Chamberlain Limited Warranty.

During the applicable Chamberlain Limited Warranty period, if you are

concerned that the Unit may be defective, for prompt on-site service call

the Professional Dealer that sold/installed the opener, or our service

centre on the toll free number below and a Chamberlain technician will

diagnose the problem and arrange for this to be rectified. Once the

problem has been diagnosed, subject to your rights under the

Australian Consumer Law with respect to major failures, Chamberlain or

its Professional Dealer will provide you with:

1. repairs to the Unit

or

2. a replacement Unit.

Repairs and replacement parts provided under this Chamberlain

Limited Warranty are provided free of charge and are warranted for the

remaining portion of the original warranty period.

This Chamberlain Limited Warranty provides benefits which are in

addition to your other rights and remedies as a consumer.

Exclusions

If our service centre determines that a warranty claim has been made in

respect of a failure or defect arising under or out of any exclusion

detailed below such that the claim is not covered under this

Chamberlain Limited Warranty, we may, subject to your other rights and

remedies as a consumer, charge you a fee to repair, replace and/or

return the Unit to you. This Chamberlain Limited Warranty does not

cover any failure of, or defect in, the Unit due to:

1 non-compliance with the instructions regarding installation,

operation, maintenance and testing of the Unit or of any product

with which the Unit is used;

2 any attempt by a person other than a Professional Dealer to repair,

dismantle, reinstall or move the Unit to another location once it has

been installed;

3 tampering, neglect, abuse, wear and tear, accident, electrical storm,

excessive use or conditions other than normal domestic use;

4 problems with, or relating to, the gate or gate hardware, including

but not limited to the gate;

TM

Trademark of The Chamberlain Group, Inc.

® Registered Trademark of The Chamberlain Group, Inc.

Loading...

Loading...