Merlin WeatherDrive MR550EVO Installation Manual

Rolling Garage Door Opener

Installation and Operating Instructions

Owners Copy: Please keep these instructions for future reference

This manual contains IMPORTANT SAFETY information

DO NOT PROCEED WITH THE INSTALLATION BEFORE READING THOROUGHLY

gomerlin.com.au

gomerlin.co.nz

MR550EVO

1

IMPORTANT

* The use of the Key Lockable Release is for use in Commercial

Applications ONLY, and not to be used when installed in a Residential

Application (refer safety standard AS/NZS 60335.2.95). An alternative exit

path from the building MUST BE AVAILABLE when using the Key Lockable

Feature.

* This Merlin Unit is rated to IP34 and has a UV stabilizer added, however, to

ensure the best operation of the opener the installer should ensure that it

is protected from the elements. It should not be exposed to driving water

or rain, or extended periods of direct sunlight. It must not be immersed in

water or sprayed directly by a garden hose or pressure cleaner.

2

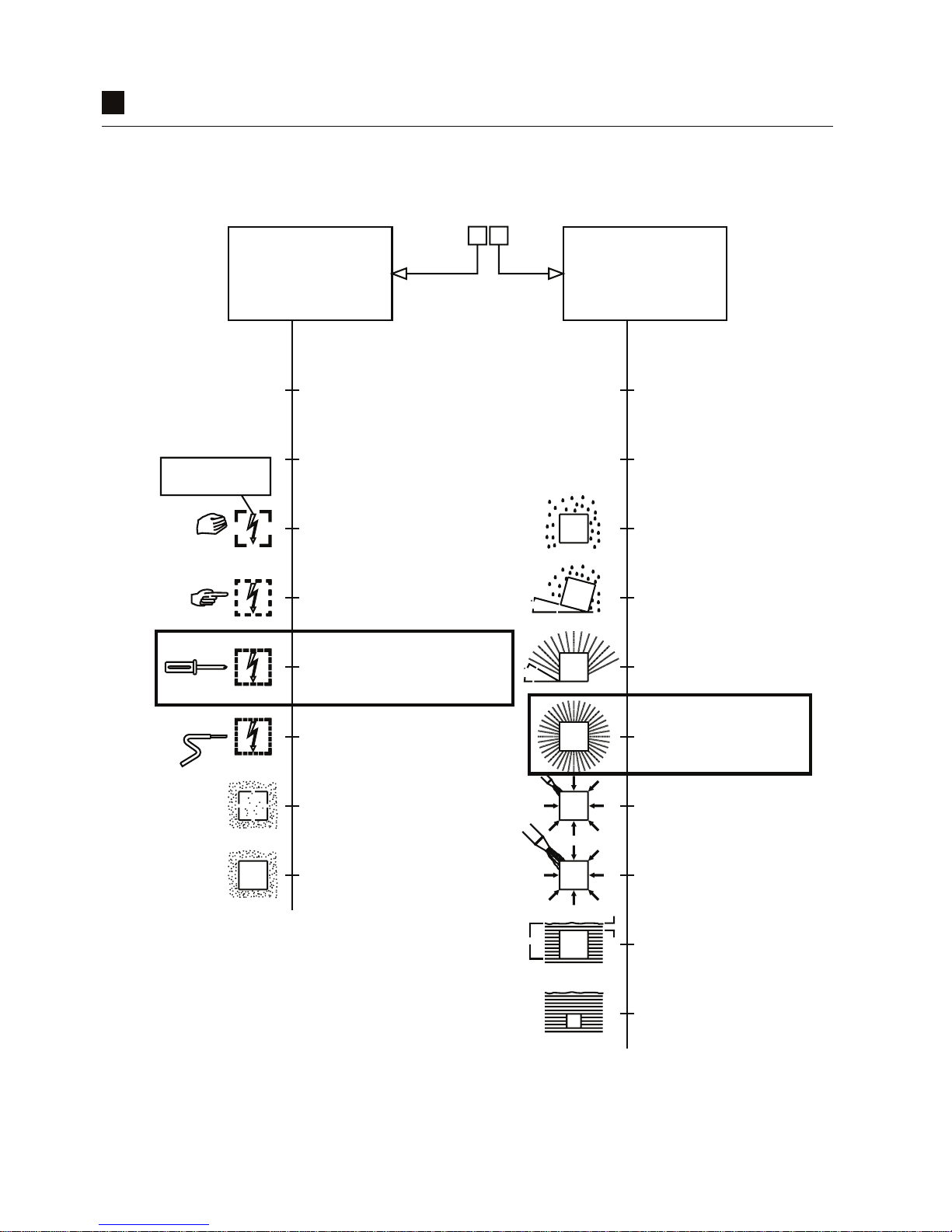

(live or moving)

indicateshazardousparts

T

he "ash" symbol

1000mmMIN

150mmMIN

indicatedby the IP code.

Protection of persons and protection of equipment

by the IP codes two:

for electrical equipment is indicated

Protection provided by enclosures

objects.(see AS 1939, Clause 5)

againstingress of solid foreign

and protection of equipment

accessto hazardous parts,

protectionof persons against

The rst numeral indicates

(see AS 1939, Clause 6)

harmful ingress of water.

protection of equipment against

The second numeral indicates

X

0

1

2

3

4

5

6

X

1

2

3

4

5

6

7

8

0

(untested)

Protection unspecied

(untested)

Protection unspecied

Non-protected Non-protected

falling vertically.

Protection against drops of water

position (in any direction)

is tilted up to 15 from its normal

falling vertically when the object

Protection against drops of water

at up to 60 from the vertical.

Protection against spraying water

directions.

spraying water from all practicable

Protection against splashing and

directions.

jets of water from all practicable

Protection against low pressure

practicable directions.

strongjet of water from all

Protection against heavy seas or a

immersion.

Protection against temporary

thansecond numeral 7)

agreement,but no less severe

submersion (tests subject to

Protection against continous

than 50mm.

of equipment against objects larger

hazardous parts, and protection

againstaccidental access to

Protection of the back of the hand

than 12.5mm.

equipmentagainst objects larger than

to hazardous parts, and protection of

Protection of ngers against access

objects larger than 2.5mm (e.g. ball bearings)

and protection of equipment against

or wires (larger than 2.5mm diameter),

Protection of persons holding tools

objects larger than 1mm. (e.g. ball bearings)

and protection of equipment against

tools or wires (larger than 1mm diameter),

Protection of persons holding small

satisfactoryoperation of equipment.

sucient quantity to interfere with

Protection against entry of dust in

entry of dust.

Completeprotection against

CHARACTERISTIC NUMERALS

IP

1

5

3

0

IP RatingChart

3

CONTENTS PAGE

SAFETY INSTRUCTIONS . . . . . . 3

CARTON INVENTORY . . . . . . . . . .4

TOOLS REQUIRED . . . . . . . . . . . .4

DOOR REQUIREMENTS . . . . . . . .4

PREPARE & TEST THE DOOR . . .5

CONTROL PANEL . . . . . . . . . . . . . .6

MANUAL RELEASE KEY

LOCKABLE . . . . . . . . . . . . . . . . . . .7

PINNING THE DOOR . . . . . . . . . . .8

INSTALLATION PROCEDURE . . . .9

ADJUSTMENT & TESTING . . .10-11

INSTALL THE PROTECTOR

SYSTEM . . . . . . . . . . . . . . . . . . . .12

INSTALLING WIRELESS WALL

BUTTON . . . . . . . . . . . . . . . . . . . .13

TRAVEL SPEED . . . . . . . . . . . . . .13

STANDBY MODE . . . . . . . . . . . . .14

AUDIBLE BEEP . . . . . . . . . . . . . . .14

CONTROL PANEL E-LOCK . . . . .15

PARTIAL OPENING . . . . . . . . . . .15

WIRELESS PROGRAMMING . . . .16

OPERATING YOUR OPENER . . .17

MAINTAINING YOUR OPENER . . 17

CARE OF YOUR OPENER . . . . . 17

SPECIFICATION . . . . . . . . . . . . . .17

ACCESSORIES & WIRING . . . . . .18

SPARE PARTS . . . . . . . . . . . . . . .19

TROUBLESHOOTING . . . . . . . . .20

DIAGNOSTIC CHART . . . . . . . . . .21

WARRANTY . . . . . . . . . . . . . . . . .22

T

he opener must not be used on a wicket

d

oor (door within a door).

The Protector System

TM

must be used for all

installations where the closing force as

measured on the bottom of the door is over

400 N (40 kgf). Excessive force will interfere

with the proper operation of the safety reverse

system or damage the garage door.

After installation, ensure that the parts of

the door do not extend over public

footpaths or roads.

Install the wireless wall control (or any

additional wall control) in a location where

the garage door is visible away from

moving parts, at a height of at least 1.5 m

and out of the reach of children. Do not

allow children to operate push button(s) or

transmitter(s). Serious personal injury from a

closing garage door may result from misuse of

the opener.

Permanently fasten the Warning Labels in

prominent places, adjacent to wall controls

and manual release mechanisms as a

reminder of safe operating procedures.

Activate opener only when the door is in

full view, free of obstructions and the

opener is properly adjusted. No one should

enter or leave the garage while the door is

in motion.

Do not allow children to play near the door,

or with door controls.

If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons in order to avoid hazard.

Disconnect electric power to the garage

door opener before making repairs or

removing covers.

KEEP THESE INSTRUCTIONS

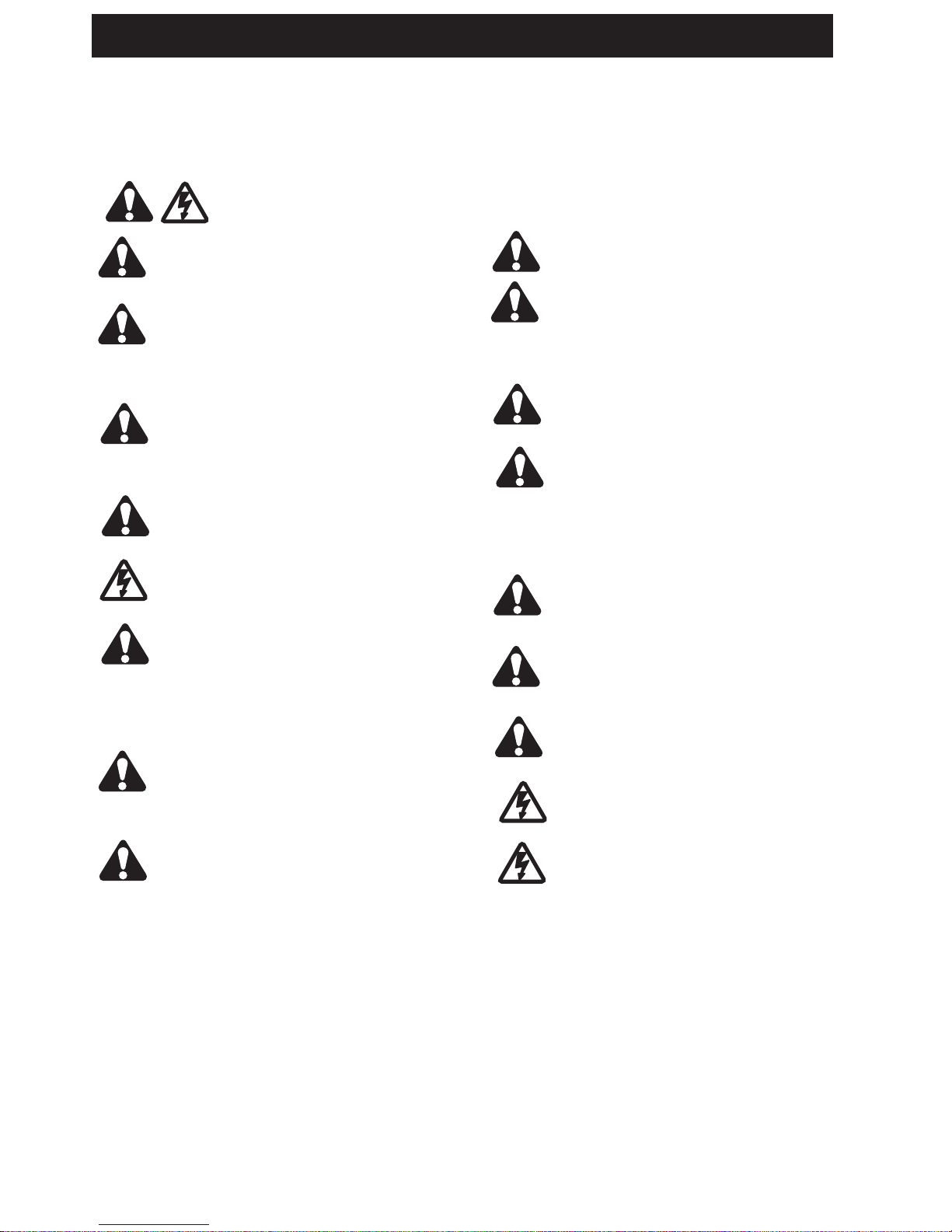

WARNING

•Failure tocomply withthe following instructionsmay resultinserious personalinjuryorpropertydamage.

•

Read and follow all instructions carefully.

• The garage door opener is designed and tested to offer safe service provided it is installed and

o

perated in strict accordance with the instructions in this manual.

These safety alert symbols mean WARNING : A possible risk to personal safety or

property damage exists.

NOTE: If your garage has no service entrance door, a CM1702 or DMK1 outside quick release must be installed.

This accessory allows manual operation of the garage door from outside in case of power failure.

Keep garage door balanced. Do not let the

garage door opener compensate for a binding or

sticking garage door. Sticking, binding or

unbalanced doors must be repaired before

installing this opener.

Do not wear rings, watches or loose clothing

while installing or servicing a garage door opener.

Wear gloves and suitable protective clothing

where appropriate.

Frequently examine the door installation, in

particular cable, springs and mountings for signs

of wear, damage or imbalance. Do not use if

repair or adjustment is needed since springs and

hardware are under extreme tension and a fault

can cause serious personal injury.

To avoid serious personal injury from

entanglement, remove all ropes, chains and

locks connected to the garage door before

installing the door opener.

Installation and wiring must be in compliance

with your local building and electrical codes.

The safety reverse system test is very

important. Your garage door MUST reverse on

contact with a 40 mm obstacle placed on the floor.

Failure to properly adjust the opener may result in

serious personal injury from a closing garage

door. Repeat the test once a month and make

any necessary adjustments.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capablities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Automatic Drive - Keep away from the area of

the door as it may operate unexpectedly.

START BY READING THESE IMPORTANT SAFETY INSTRUCTIONS

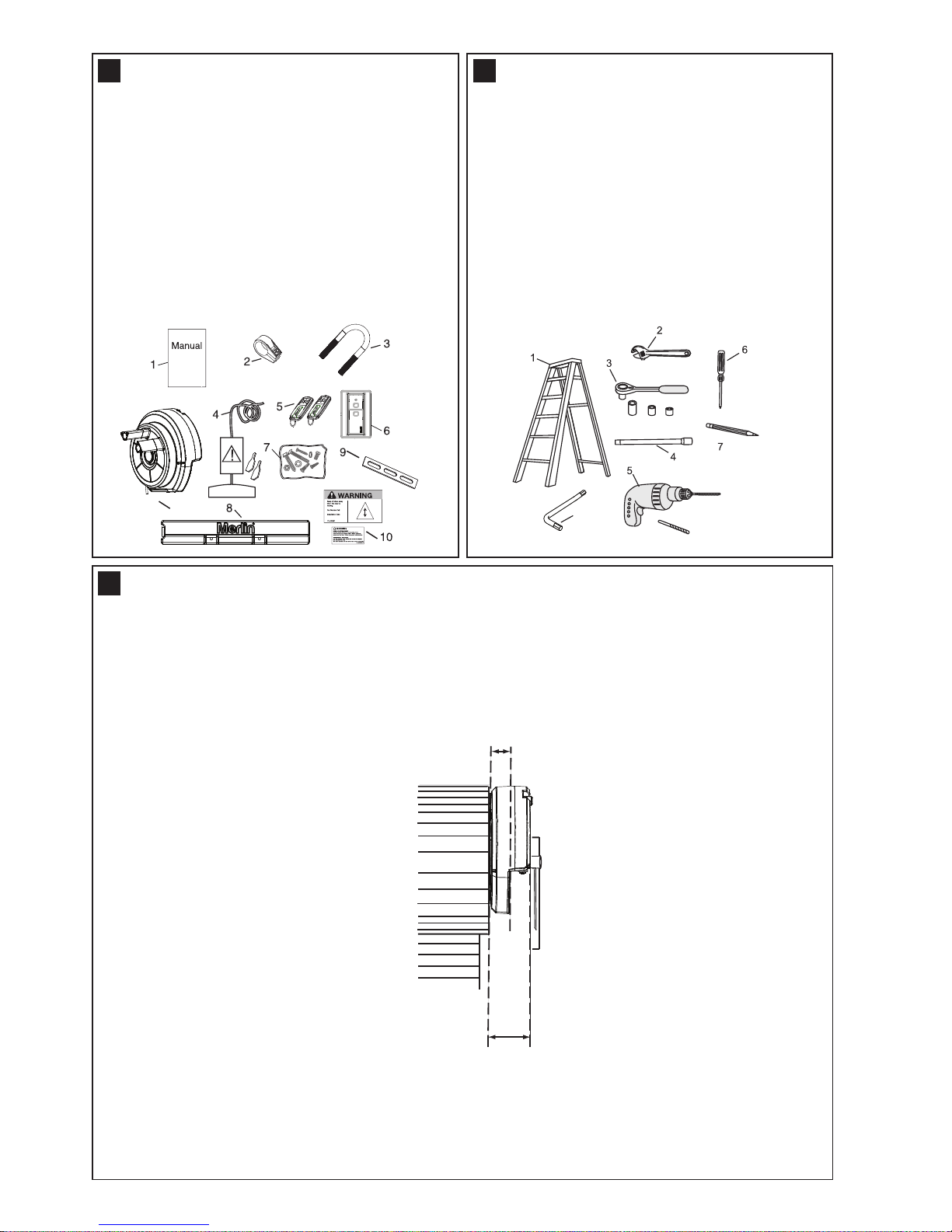

1. Instruction manual (this document)

2. Stop collar

3. Clamp bracket

4. Release handle, cord, keys and risk of entrapment

card

5. Premium+ transmitters (2)

6. Wireless wall button

7. Hardware bag

8. Weight bar

9. Clamp plate

10. Warning label and risk of entrapment label

11. Opener

C

ARTON INVENTORY

1

11

13 mm, 10 mm, 8 mm

5.5 mm

8

TOOLS REQUIRED

2

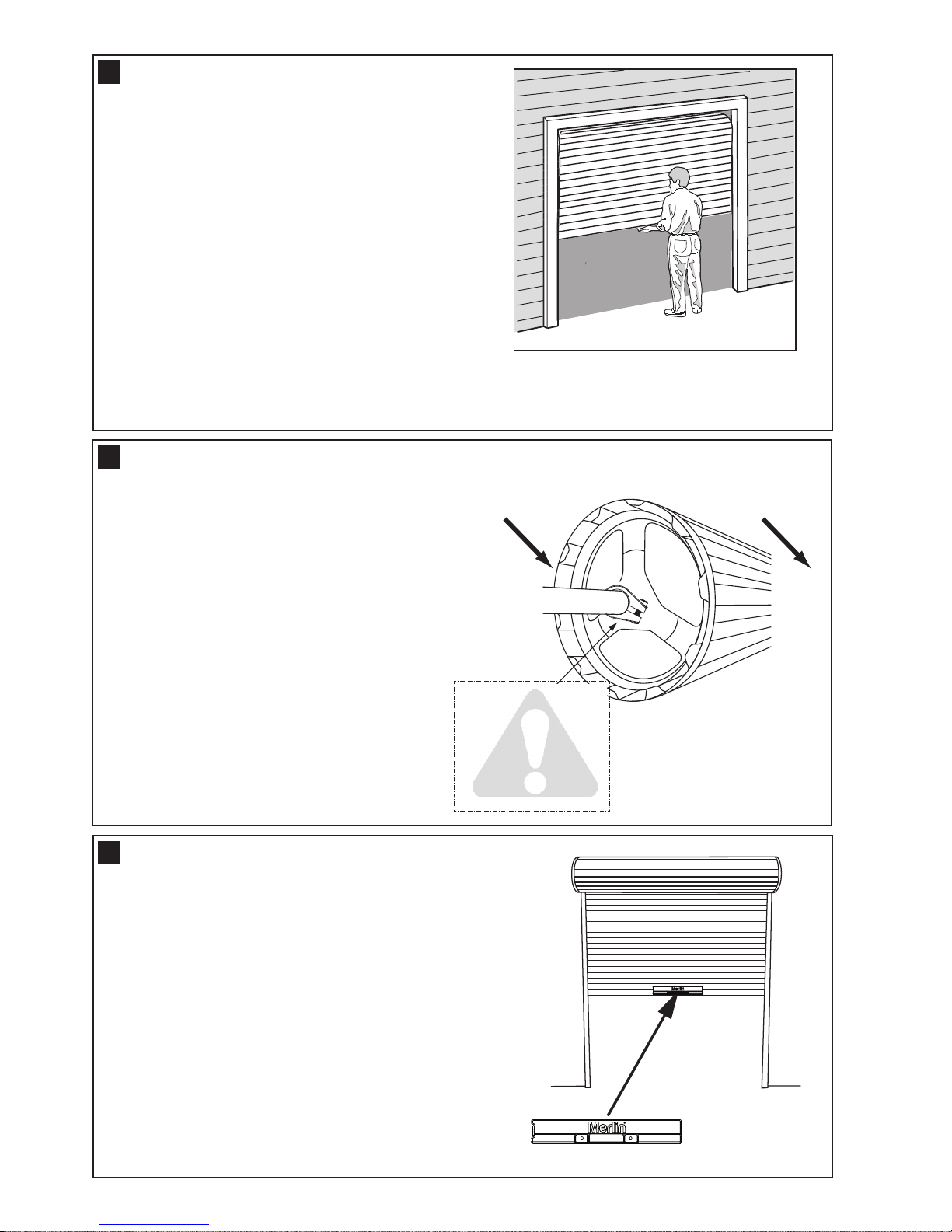

1. Ladder

2. Adjustable wrench for U-bolts already installed

on the door

3

. 8 mm socket, 10 mm socket and 13 mm extended

socket and socket wrench

4. 300 mm socket extension (for minimum side-room

installations)

5

. Drill and 5.5 mm drill bit

6. Philips-head screwdriver

7. Marker pen

8. 8 mm allen key

9. Door stand or similar device to safely support door

(not shown)

DOOR REQUIREMENTS

3

Ensure that there is at least 40 mm from the edge of the curtain to the edge of the bracket. If the roller door

drum is on the edge of the curtain or is a smaller diameter, additional clearance may be required.

95 mm

Minimum distance from

edge of curtain to edge of

door bracket 40 mm

Direct clamping

method

The maximum allowable door height is 5.5 m with a maximum curtain area of 15.0 m²* . The door must be spring

balanced.

*The Protector System™ (IR Beams) must be installed if the force at the edge of the closing door exceeds

400 N (40 kgf). Door axle diameter must not exceed 35 mm.

4

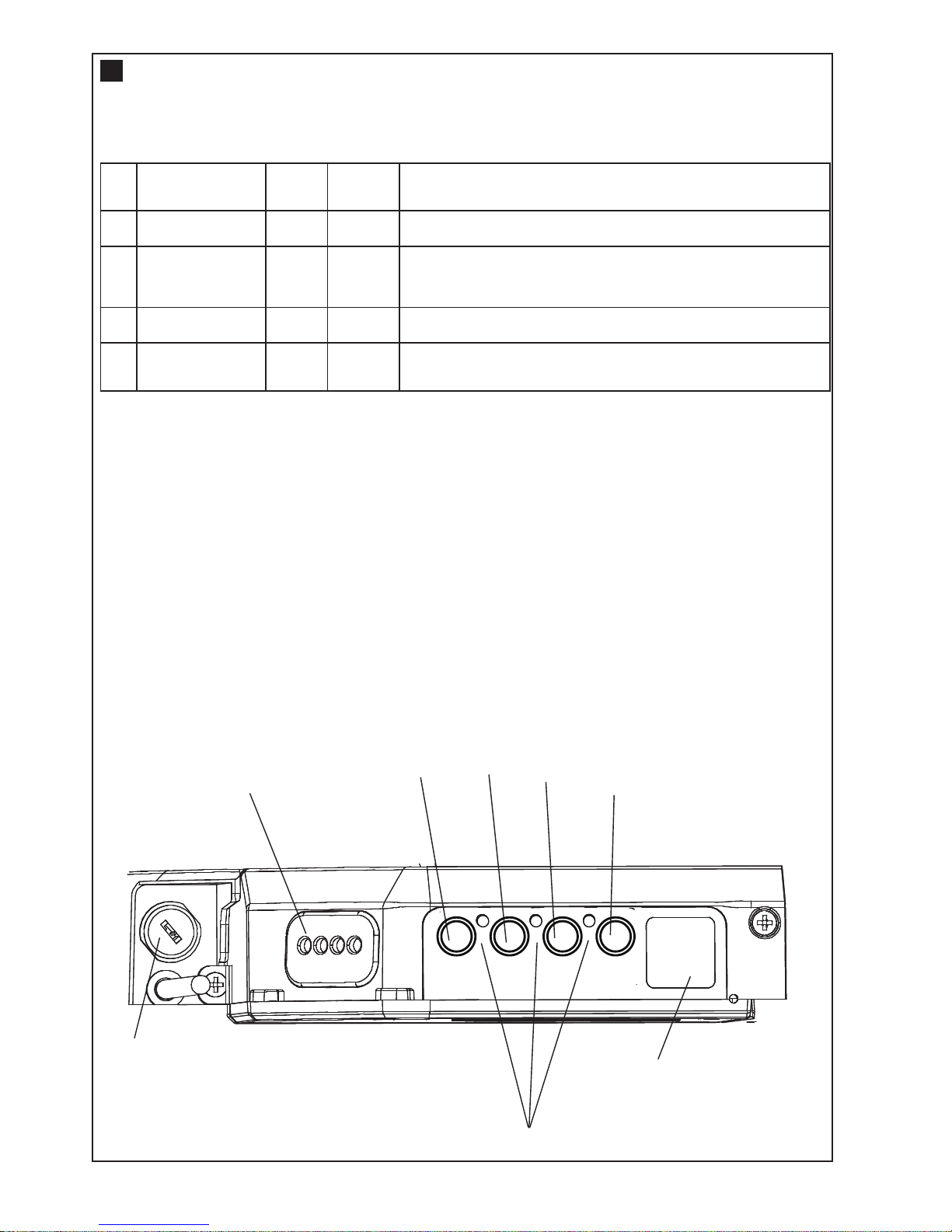

T

ESTING THE DOOR

4

Non opener side

Opener side

INSTALLING THE STOP COLLAR

5

• Place the weight in the centre of the door (as shown).

• Use a pencil to mark the two hole positions.

• If the door curtain does not have a handle you will need

to drill two 5.5 mm holes through the two marked

positions, then place the weight bar on the inside of the

door.

• Use the bolts, washers and nuts (provided) to

fasten the weight bar in place.

NOTE: If the door has a lifting handle, remove the

handle, nuts & bolts. Place weight bar over the

handle holes, insert extended bolts through the

weight bar & fasten handle back in place.

INSTALLING THE WEIGHT BAR (PROVIDED)

6

5

SAFETY CHECK!

Is the stop collar

installed?

YES: proceed to the next

step

NO: install the stop collar

before proceeding

Complete the following test to ensure your door is well

balanced, and not sticking or binding:

• Disable all locks and remove any ropes connected to the

garage door.

•

Lift the door to about halfway and then release it. The

door should remain spring balanced.

• Raise and lower the door to determine if there are any

sticking or binding points (15 kgf is the absolute maximum

allowable to raise or lower the door in any position).

• If your door does not hold in place or the door binds or

sticks, call a qualified door technician before installing the

opener.

• The stop collar (inset 1) is required to be installed on

the opposite side of the door to where the opener is

to be installed.

• Ensure the U-Bolt holding the door shaft to the door

bracket is tightly secure.

(NOTE: This U-Bolt must not be removed or loosened)

• Remove the bolt assembly from the plastic stop

collar. Open the collar as wide as possible and push

it onto the door shaft.

• Fit the stop collar hard against the boss of the

door drum. Reinstall the bolt assembly onto the

stop collar and tighten.

6

1

2

3

4

7

6

5

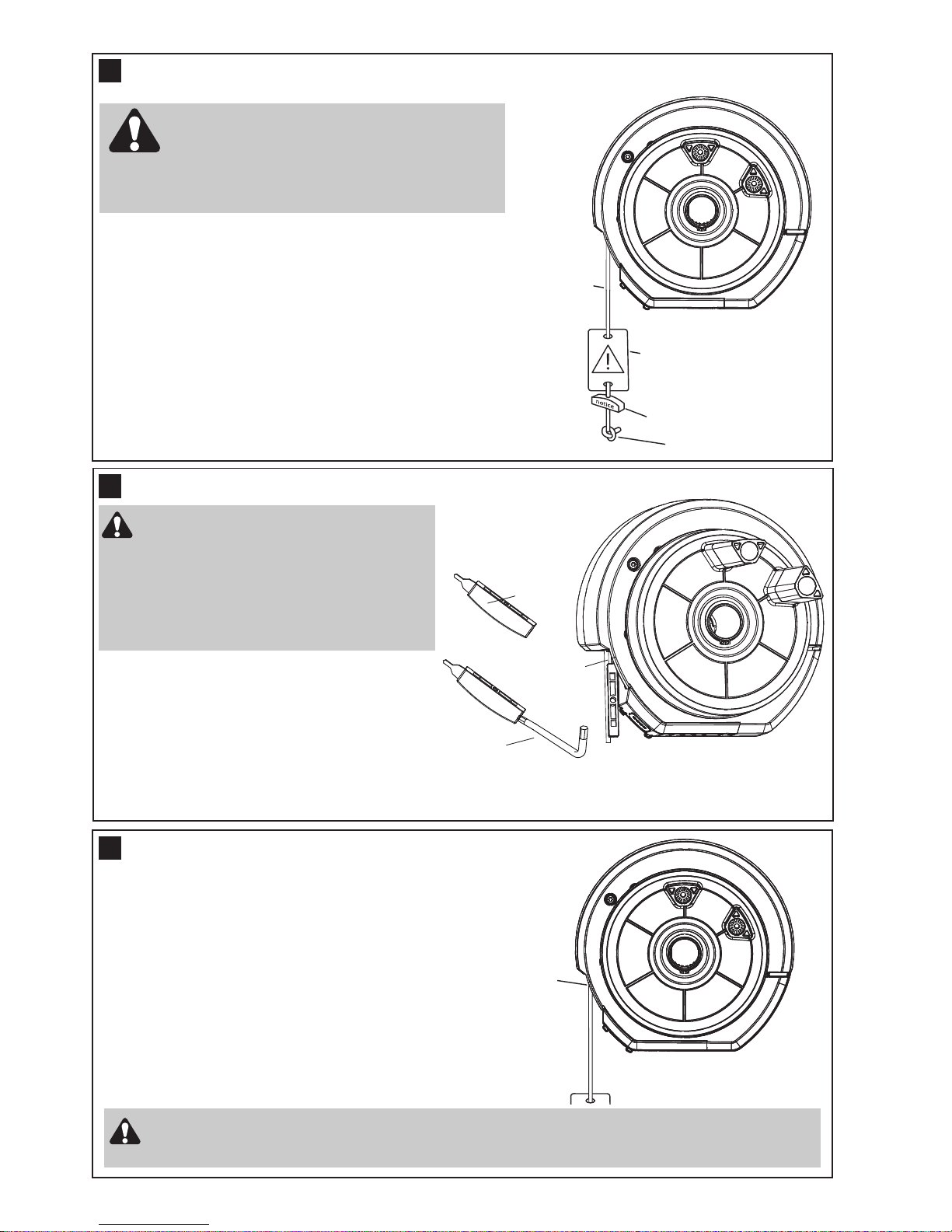

DNDN UPUP PP SS

11

22 33

8

4 3 2 1

1

. Terminal Block: used for external accessories (see chart below).

NOTE: The terminal block is weather protected by a rubber grommet.

When using external wiring, the cable holes can be punched through with a small screwdriver. These holes

should be sealed with silicon sealant in order to maintain the weather proof rating.

2. DN Button: used to drive door DOWN.

3. UP Button: used to drive door UP.

4. P Button: used to “PROGRAM” the DOOR LIMITS.

5. S Button: used to “SAVE” the “REMOTE CONTROLS”.

6. Key Lock: used to lock the engage/disengage mechanisim for commercial applications.

7. LEDs: 1. Program DOWN, and Diagnostic code indicator Number 1.

2. Program UP indicator.

3. Diagnostic code indicator Number 2.

8. Courtesy Light: turns on during operation and automatically turns off after 3 minutes.

No Function

Colour

Polarity Comment

1

Push button

Red

+ve

Dry contact input for push button wired wall controls:

2

Common

White

-ve

Common terminal for push button, IR Beams & accessory

power:

3 IR Beams

Grey

+ve

IR Beam Input: (pulsing type only)

4

Accessory Power

Green

+ve

24v dc 50 mA accessory output available for a universal

receiver (output not active in Low Standby mode)

C

ONTROL PANEL

7

Rope

Manual release

warning label

R

elease handle

Overhand knot

THE RELEASE HANDLE & CORD

8

7

Unlock

NOTE: Ensure the Key Lockable Release is not locked.

To disengage the opener

Pull the release cord down firmly,

(opener will make a clicking noise).

To re-engage the opener

Pull the release cord down firmly,

(opener will make a clicking noise).

Disable all locks and remove any ropes connected to the garage door.

Take care when operating the manual release as an open door may fall rapidly due to weak or

broken springs, or being out of balance.

OPERATING THE MANUAL RELEASE

10

The manual release mechanism enables the door to be

m

anually operated during power outages or in an emergency.

The RED Manual Release cord is preassembled to the

opener. When the opener is installed the handle should be no

higher then 1.8 metres from the floor. The cord may need to

be extended.

DO NOT DISENGAGE THE OPENER TO MANUAL

OPERATION WITH CHILDREN , PERSONS OR

OTHER OBJECTS INCLUDING MOTOR VEHICLES

WITHIN THE DOORWAY : (The door is under significant

tension and if the door has developed a fault or incorrect

tension, it may be unsafe and may fall rapidly.)

Lock or unlock

a

s required

I

nsert key into

Release Handle

8 mm allen key

(not provided)

• Turn OFF the opener mains power (so the door

cannot be activated).

• Insert the key into the Maual Release handle and

Lock or Unlock as required (an 8 mm allen key

can be used to extend the handle if needed).

• Keep the key in a safe place.

• Two keys are provided, if a replacement is needed,

refer to a locksmith.

KEY LOCKABLE RELEASE

9

The use of the Key Lockable Release is

for use in Commercial Applications

ONLY, and not to be used when installed

in a residential Application (refer safety

standard AS/NZS 60335.2.95). An

alternative exit path from the building

MUST BE AVAILABLE when using the

Key Lockable Feature

Loading...

Loading...