Page 1

EDR4 1179 G2.16 10/03

1

Page 2

EDR4 1179 G2.16 10/03

2

Important safety instructions for

installation

To prevent fire or shock hazard, do not expose the opener to rain or moisture.

To avoid electrical shock do not open the cabinet without disconnecting the opener from the mains.

WARNING Incorrect installation can lead to severe injury. Follow all installation instructions.

Garage doors are under great spring tension. Do not attempt to adjust spring tension. Do not

loosen any brackets under spring tension. Do not remove springs from the door. Merlin does not

accept responsibility for damage or injury resulting from installing this opener. Unless you have

appropriate training, refer door adjustments to the door manufacturer.

To avoid difficulty during installation, do not connect the opener to the mains or run the door opener

until instructed to do so.

Do not use force sensitivity adjustments to compensate for a binding or sticking garage door.

Excessive force may damage the garage door.

Before installing the drive remove all unnecessary ropes or chains and disable any equipment, such

as locks, that is not needed for powered operation.

Before installing the drive check that the door is in good mechanical condition and that it is correctly balanced. Check that it opens and closes properly.

Install the actuating member for the manual release (red handle on a rope) such that it rests at a

height of less than 1.8 m.

Install any fixed control, wired or wireless, within sight of the door but away from moving parts and

at a height of more than 1.5 m.

Install the drive such that all moving parts (except the door and the manual release) are at a height

of more than 1.8 m.

Permanently attach the label warning against entrapment in a prominent place, or near any fixed

control.

Permanently fix the label concerning the manual release adjacent to its actuating member (thread

the cord through the holes in the manual release warning card).

After installation, ensure that the mechanism is properly adjusted and that the drive reverses when

the door contacts a 40mm (50mm for UK) high object placed on the floor.

The appliance is not intended for use by young children or infirm persons without supervision.

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person in order to avoid a hazard.

CE compliance after installation (EC countries only)

It is the responsibility of the installer of the opener to ensure that the forces measured at the

leading edge of the door are within the guidelines of BSEN 60335-2-95:2001. This may require

adjustment of the drive and may also require adjustment of the door. Specialised measurement

equipment may be required. Contact Merlin for assistance if necessary. If the measured forces

exceed the guidelines then Merlin M102 non-contact sensors must be fitted.

Page 3

EDR4 1179 G2.16 10/03

3

Site Requirements

Electrical Power Supply

The opener is for 220-240 Volts AC - 50 Hz. There must be an earthed power point within 1.6

metres of the mounting position.

Garage Door

This opener is designed for a residential overhead garage door up to 6 m wide, either sectional or

one-piece tilting. Using the standard length pole and chain it is suitable for door heights up to 2.2

m. Alternative poles and chains are available to suit door heights up to 2.4 m and 3.1 m. Contact

Merlin for solutions to suit door heights up to 4.5 m.

Check that it is possible to raise the door by hand through the full height of the opening. The door

should operate smoothly, lifting up and down without the door or door mechanism binding. The door

must not jam in the tracks.

A properly balanced tilt door will stop of its own accord at about the two thirds closed position.

(Springs may need adjustment accordingly).

For one piece tilt doors over 4.5 m in width built out of cedar or ply it is advisable to use the smaller

15 tooth sprocket.

A properly sprung sectional door will either close of its own accord for the last 500mm of its travel

or it will require a very light added force. If the door springs back, it is advisable to have the spring

tension adjusted. Springs can only be adjusted safely by a trained professional.

If in doubt about whether the door is suitable for automation consult Merlin.

Tilt door clearances

The opener has been designed to fit most existing doors. The minimum installation clearance from

the garage ceiling to the top edge of the door during any part of the door’s travel is 100mm.

The header bracket is to fit as close as practical above the top of the door, in the centre.

The door bracket is to fit at the highest possible point of the door, in the centre. The bracket may be

fixed vertically or horizontally to suit. A solid fixing point is required.

The overall length of the opener when assembled depends on the length of pole fitted. The overall

length is 400mm more than the length of the pole.

Clear space of around 600mm is required behind the fully open door.

Sectional door clearance guidelines

For sectional doors using torsion springs the minimum allowable height from the top of the closed

door to the ceiling is 200mm.

For sectional doors using tension springs the minimum allowable height from the top of the closed

door to the ceiling is 280mm.

The header bracket is to fit 200-300mm above the top of the door at the centre or directly above

the torsion bar.

The door bracket is to fit in line with the top rollers in the top panel. It may fit vertically or horizontally.

A solid fixing point is required.

The overall length of the opener when assembled depends on the length of pole fitted. The overall

length is 400mm more than the length of the pole.

Clear space of around 600mm is required behind the fully open door.

Page 4

EDR4 1179 G2.16 10/03

4

Door Locks

Existing door locks must be removed or disabled. (The opener or the door can be damaged if you

try to use it to open a locked door).

One Piece doors opening over footpaths

Ensure parts of the door do not extend over public footpaths or roads.

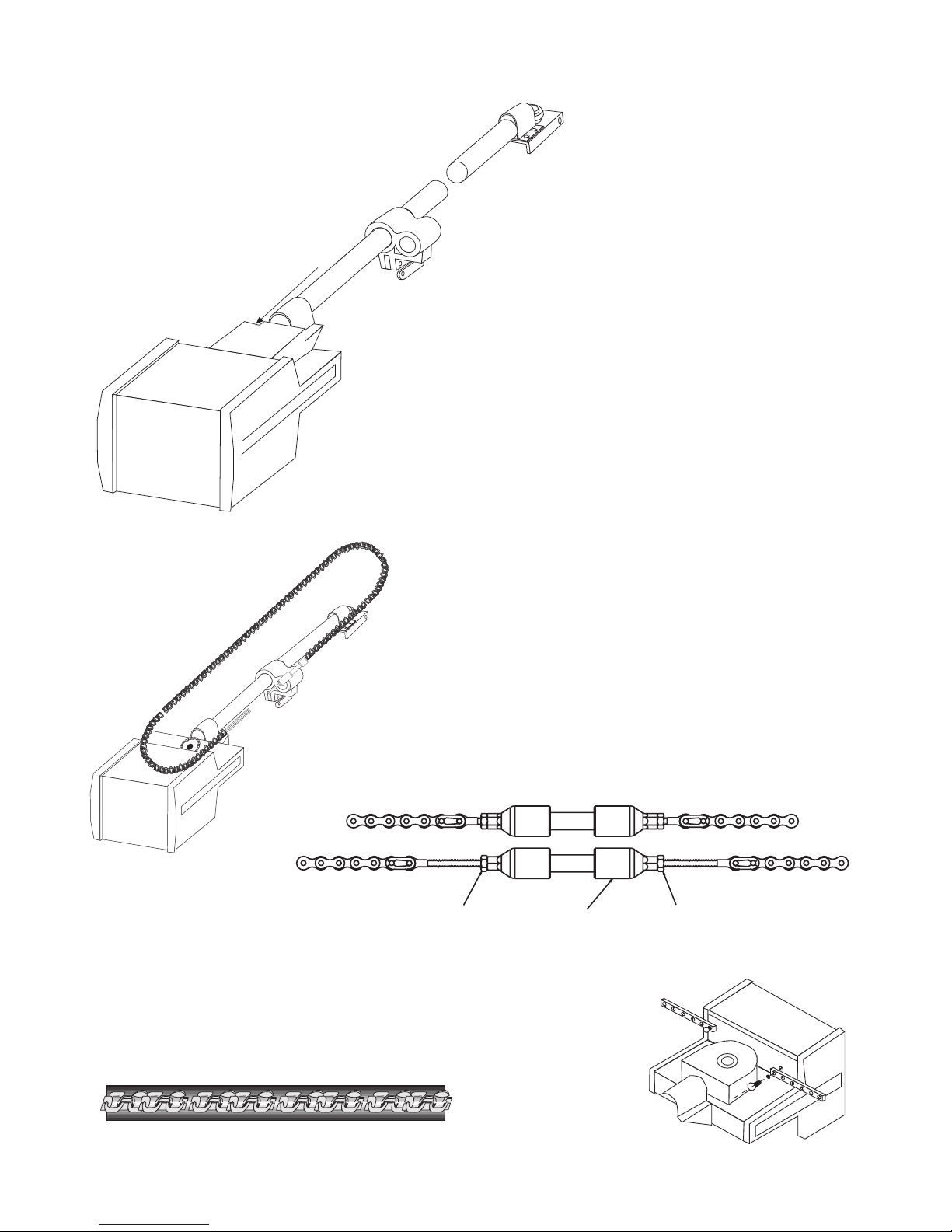

Contents of the package

Opener Light cover

Header bracket

Return pulley Trolley

Hardware pack

Door arm

Chain pack

L arm

Wall box pack

Visor clip

Transmitter

Battery

Door bracket

STEP 2:

If your door is greater than 3 m tall or if your door is greater

than 2.5 m tall and you will use the 15 T sprocket :

Switch the TALL DOOR option on the control panel into the ON position. This will allow the opener

to run for 40 seconds instead of 30.

If you have a sectional door and you want to have auto-closing:

Select the timing of your choice from the autoclose option switches on the control panel. The

options are off, 30 seconds, 60 seconds and 90 seconds.

For a 30 second delay: autoclose short ON

For a 60 second delay: autoclose long ON

For a 90 second delay: both short and long ON

NOTE Auto-closing will only work if the beam sensors are correctly fitted, correctly functioning and unobstructed.

WARNING Merlin does not recommend auto-closing of one piece tilt doors because

beam sensors will not prevent the door from hitting an object close to the outside of

the door.

STEP 1: Check the contents of the package.

Your package should contain: this manual, a warranty

sheet, one or more remote control transmitters, wall box

pack (some models only), hardware pack, chain pack,

trolley, header bracket, door bracket, door arm, L arm,

return pulley assembly, light cover, red release rope (with

manual release warning card) and one assembled door

opener.

CAUTION Do not plug in the power head to test it

before installation. The power head is shipped with

the limit switches set for a door in an open position. Operation before the correct point in the installation process can lead to a damaged door or

opener.

Preparing the opener

Page 5

EDR4 1179 G2.16 10/03

5

Assembly of pole,

return pulley,

power head and

trolley

Pole into powerhead

Trolley onto pole

Pole into return pulley

Attaching

mounting

strapping

Chain threading

300-500mm

Connecting the chain

Chain hangs no lower than the pole

Additional setup for trackless tilt doors (jamb fittings) only

The pole should be shortened for

a trackless tilt door.

STEP 3: Assemble the trolley and

header bracket to the pole. Slip the

pole into the return pulley assembly. Slide

the trolley over the pole.

Slip the pole into the power head. The return

pulley should be aligned with the sprocket.

STEP 4: Remove the sprocket cover from the power

head.

Additional setup for trackless tilt

doors (jamb fittings) only

Use the Chain on the smaller of the two sprockets.

STEP 5: Thread up the chain. The threaded end of the torpedo should

now be pointing back toward the power head.

Additional setup for trackless tilt

doors (jamb fittings) only

The chain will need to be shortened to suit the choice of pole

length and sprocket size.

STEP 6: Connect the two ends of the chain.

Slide the trolley over the torpedo and flip the release lever up to en-

gage the trolley with the torpedo. The trolley should be 300 to 500mm

from the power head.

STEP 7: Tension the chain.

STEP 8: Attach mounting strapping to the power head. Black 1/4” machine screws for the rubber

mounting bushes are in the hardware pack. Attach your mounting strapping using these screws.

Place a washer between the rubber bush and the strapping.

NOTE: The sprocket cover must be attached to the opener

using the screws provided.

Rotate adjuster Lock nutLock nut

Correct chain tension

Page 6

EDR4 1179 G2.16 10/03

6

Maximum height

marking on header

Header

Mark highest point

onto header

Installing the opener

WARNING Garage doors are under great spring tension. Do not remove the springs.

Merlin does not accept responsibility for damage or injury resulting from installing

this opener. Please read this manual fully before attempting installation.

STEP 1:

Check that there is a power point available and that there is adequate clearance to mount the

opener onto the door. Check that the door is in good mechanical condition, correctly balanced and opens properly.

STEP 2: Close the door.

STEP 3: Mark the centre line of the door using a tape meas-

ure and pencil. Mark on the header above the door and mark

the door itself at the top edges.

STEP 4: Check the installation height of the opener. Slowly

open the door and observe the point at which the top edge of

the door is closest to the ceiling. Measure the height of the top

edge of the door from the floor of the garage at this point. You

may have to clamp the door in position or use blocks to hold it.

STEP 5: Close the door again and mark this maximum door

height onto the header above the top edge of the door. (On tilt

doors with tracks, this maximum height might be as low as the

top edge of the closed door.) If a sectional door torsion bar or

spring is in the way, mark the next clear space on the wall above.

Extend the door centre line up to intersect with the new height line.

Additional setup for trackless tilt doors (jamb fittings) only

Mark a horizontal line 300mm above this maximum door height line. If there is insufficient space

above to allow the line to be 300mm above the maximum height, then draw the line 80mm below

the ceiling. Extend the door centre line up to intersect with the new height line.

STEP 6: Fit the header bracket to the header above

the top of the door. The header bracket must be attached to a rigid part of the garage such as a beam,

with the bottom edge of the bracket no lower than

the height line that has just been marked. The centre line of the door must align with the centre line of

the header bracket.

STEP 7: Place the opener assembly in the centre

of the garage floor, resting on its styrofoam or cardboard packing to protect the power head from

scratching by the garage floor.

Header bracket mounting

Header bracket

Max door

travel height

Door

opening

centre line

Two lag screws

Page 7

EDR4 1179 G2.16 10/03

7

STEP 8: Lift the return pulley assembly up to the header bracket and attach

by pushing the clevis pin through both

the header bracket and the return pulley assembly. Fit the clevis pin clip to

secure the clevis pin.

STEP 9: Lift the power head end of the

opener to the ceiling. Add temporary

support so that the pole is level to the

garage floor. Open the door.

STEP 10: Line up the centre of the

pole with the marked centre line of the

door.

STEP 11: Locate a ceiling joist in the

area where the straps will attach to the ceiling.

STEP 12:

Before attaching the

straps to the joists, set

the level of the opener.

Check that the door

does not hit the pole

when manually opening and closing. Allow

a minimum of 25mm

clearance between the top

edge of the door and the bottom of the pole.

Attaching the return pulley assembly to the

header bracket

Centre line of pole to

line up with centre line

of open door

Move until

pole lines up

with door

centre mark

Clevis pin & clip

Door closed

Protective cardboard

Correct angle to mount the opener for

a trackless tilt door

Maintain at least 25mm

clearance from moving door

At an

angle to

the floor

Additional setup for

trackless tilt doors

(jamb fittings) only

It is better to mount the opener at

an upward facing angle for trackless tilt doors. Allow the opener to

hang at the lowest possible point

that maintains at least 25mm

clearance between the pole and

the top edge of the closing door.

Page 8

EDR4 1179 G2.16 10/03

8

STEP 13: Fasten the straps solidly to the joists.

STEP 14: Close the door manually.

STEP 15: Attach the door bracket to the door.

Door arm examples

Door bracket,

lock nut,

trolley and clevis pin

Preferable for

sectional doors

Preferable for

tilt doors

OK for

tilt doors

Mounting strap methods

STEP 16: Connect one end of the straight door arm to the trolley. Attach to the trolley using the

short clevis pin and its clip.

Usually the straight arm is all that is required on tilting doors. Usually the L arm is attached between

the door and the straight arm for use with sectional doors. You may have to shorten or re-drill the

door arm.

You may need to use the L-arm to prevent fouling of the door in

the fully open position.

CAUTION When the door is fully closed the door arm

must not ever become vertical. The door arm must

remain at less than a right angle to the pole.

Disengage the trolley.

Connect the free end of door arm assembly to the door

bracket.

Top of door

Angle iron

Door Bracket mounting

Top of door

Door

Centre line of

door

Top of door

150mm

Either

Door bracket

Page 9

EDR4 1179 G2.16 10/03

9

STEP 17:

If a wall control box is included in

your opener then locate a convenient position to mount the wall control box. The garage door should be

visible from this location. There

should be no moving parts of the

door or opener within 1.8 metres of

this box and the box should be

placed higher than 1.5 metres from

the floor.

Connect the wire to the manual control accessory terminals on the rear

of the power head. Take care to keep

frayed wire ends from shorting

across terminals.

Route wire from the power head to the location for the wall control box. Allow some slack in the

wire to the power head. Connect the wire to the two terminals inside the wall control box. Mount

the box to the wall.

CAUTION Keep the push button cable at least 60mm clear of mains power cables if it is

parallel to them. Do not run the push button wiring through the same cavities in the wall as

the mains power. Mains and low voltage wiring can cross with no problems.

STEP 18: Remove or disable any door locking mechanism. Remove unnecessary ropes or chains

STEP 20: Fit the light cover into position and lock the cover securely.

STEP 21: Manually raise the door and re-engage the trolley.

STEP 22: Attach the red release rope through the hole in the trolley release lever. The handle

must be fitted at a height of less than 1.8 metres.

Ensure the release cord is threaded through the manual release warning card.

Page 10

EDR4 1179 G2.16 10/03

10

Setting the door travel limits

NOTE Repeated operation of the opener in a short

period of time during setup may trigger the thermal cutout of the motor. In this case you will have

to wait for approximately five minutes for the motor to cool sufficiently to continue the installation

process. If the unit has overheated you will hear

the relays clicking in response to the transmitter

or pushbutton but the motor will not operate. After

cooling down, normal operation is able to resume.

The limit adjustment screws are inside the lamp cover and

are marked as up limit and down limit. One full turn of either

screw results in around 250mm of trolley travel.

STEP 1: Plug the opener into an earthed three-pin 220-240V outlet and switch on the power.

The opener’s courtesy lamp may turn on, or may flash for five seconds.

STEP 2: Remove the lamp cover by turning the catch on its underside. Remove the green control

panel cover to expose the setup controls. Observe

the red and green indicator LEDs. The red LED will

stay on continuously at the fully closed position. The

green LED will stay on continuously at the fully open

position. Identify the green operate button.

Ensure the door is engaged on the trolley.

STEP 3: Press and hold the green operate button

to move the door up and down into the required

fully open or fully closed positions. Each time the

operate button is pressed the door will stop or move

in the opposite direction.

STEP 4: When the door is at the fully closed position, turn the down-limit screw (located adjacent to

the courtesy lamp) until the red close-LED stays

on continuously.

STEP 5: When the door is at the fully open position, turn the up-limit screw (located adjacent to

the courtesy lamp) until the green up-LED stays

on continuously.

STEP 6: If the door can not be moved sufficiently

far then look at the red and green LEDs. If one of

these is on continuously then the door has stopped

at a limit point. Adjust that limit to allow more travel.

One turn of a limit adjustment screw results in

250mm of door travel.

exit delay

Light door

roller: L

tall door

auto-

close

on

on

R

on

short

long

open

auto

open

force

operate

learn delete

close

auto

close

force

program

remove

for setup

manual

control

Door travel

limit adjustments

Page 11

EDR4 1179 G2.16 10/03

11

Additional setup for trackless tilt doors (jamb fittings) only

The aim of these steps is to make the opener push in the direction that the door edge is moving.

Preferably the door edge is being forced upward slightly as the closing cycle begins.

You must adjust the top limit of travel so that if you sight along the fully open door the sight line

intersects the pole in front of the trolley - not behind the trolley.

If the door does not open far enough after setting the top limit of travel correctly then it will be

necessary to make some installation changes. You will

need to try some or all of: raising the location of the header

bracket further, lowering the

power head further or increasing the length of the door arm

further.

WARNING The door

is not safe for unsupervised operation until the

force sensitivity has been be

set.

Opener position and open door position for trackless tilt door

Sight line intersects pole

in front of the trolley

Setting the force sensitivity

STEP 1: Remove the lamp cover by turning the catch on its underside. Remove the green control

panel cover.

STEP 2: Identify the green and the red control knobs marked open-force and close-force.

Note: The opener can be set to either determine its own safe operating force level, or it can be set

to allow a deliberately greater amount of force to be applied to the door.

STEP 3: To set the force levels automatically, press the program button and turn the control knobs

fully anticlockwise. Ensure that the door is engaged to the opener. Then operate the opener to

move the door in a single unobstructed movement from one limit position to the other. If no obstruction was sensed during this cycle then the opener will save the settings to memory. Operate

the opener to move the door back to the original limit position. Again, if no obstruction is sensed,

the settings will be stored in memory.

STEP 4: To set the force levels at some higher level, rotate the control knob to some position

clockwise from the auto-setting point.

STEP 5: If a very light door is being operated, and if a very gentle closing force is required, then

set the option switch marked ‘Light door’ to the ON position. Note that on a heavier door this

option switch position may result in unintended detections of obstructions.

NOTE: To reset the adaptive and automatic force settings at any time, press the program button

once.

Page 12

EDR4 1179 G2.16 10/03

12

Setting up wireless controls

Wireless controls can operate the opener, or the opener’s courtesy lamp, by sending coded radio

signals. These coded signals use high-security code-hopping.

Wireless controls can be hand-held or fixed to walls, such as a wireless keypad, or a wireless wallswitch.

Up to 20 Merlin wireless controls can be learned by the opener. After this, the 20th wireless control

is over-written in the opener’s memory.

All wireless controls can be deleted from the opener’s memory.

There is a learn button on the underside of the opener inside the lamp cover. The small button on a

Merlin M-122 wired wall-switch can also be used as the learn button.

If a setting is enabled in the opener, then it is possible to use any existing learned wireless control

as a learn button. (See separate section following.)

Remove the lamp cover by turning the catch on it’s underside. Remove the green control panel

cover to expose the setup controls. Identify the red learn button.

To learn a remote button to operate the opener:

Press the learn button for 1-2 seconds, until the courtesy lamp begins to flash slowly.

Press the desired remote button, wait 1 second, press the desired remote button again. The courtesy lamp will stop flashing once learning is complete.

To learn one remote button to operate the opener and another to operate the lamp:

Press the learn button for 1-2 seconds, until the courtesy lamp begins to flash slowly.

Press the desired remote button for control of the opener, wait 1 second, press the desired remote

button for control of the courtesy lamp. The courtesy lamp will stop flashing once learning is complete.

To delete all remote controls from the opener’s memory

Press and hold the Learn (or setup on some models) button for eleven seconds, until the courtesy

lamp stops flashing. After six seconds it will flash fast as a warning. If you release the learn (or

setup) button during this warning period then the memory will not be wiped.

Page 13

EDR4 1179 G2.16 10/03

13

Remote transmitter learning

Remote Transmitter Learning (RTL), when enabled, allows any existing learned wireless control to

be used as a learn button for the learning of additional wireless controls. Note that this feature

trades convenience for security. If it is chosen to disable RTL (the default setting at manufacture is

enabled) then the level of security is increased. It is recommended that after use this feature be

disabled.

To enable or disable RTL:

Remove the lamp cover by turning the catch on its underside. Remove the green control panel

cover to expose the setup controls. Identify the red learn button and the black program button.

Hold both of the these buttons down for three seconds until the courtesy lamp begins to flash.

Release both buttons.

Six flashes confirms that RTL is now enabled.

Four flashes confirms that RTL is now disabled.

To place the opener in learn mode using RTL:

Select any two or four button Merlin hand held remote control that is already learned in to the

opener. Call this the master remote.

Press the North and the South buttons together for 2-3 seconds.

The courtesy lamp on the opener will begin to repeat a cycle of flashing three times and pausing. If

you have several openers that operate from this master remote, then all these openers will begin to

flash their courtesy lamps.

Press the button on the master remote that would normally operate the opener that you want to

learn another remote into. Now that opener will go into learn mode, and any other openers that

were flashing will return to their normal standby state.

The courtesy lamp on the opener that is in learn mode will begin to flash slowly. If no signals are

received for 20 seconds, the opener will revert to its normal standby state.

To learn a button to operate the opener:

Press the desired remote button, wait 1 second, press the desired remote button again. The courtesy lamp will stop flashing once learning is complete.

To learn one remote button to operate the opener and another to operate the lamp:

Press the learn button for 1-2 seconds, until the courtesy lamp begins to flash slowly.

Press the desired remote button for control of the opener, wait 1 second, press the desired remote

button for control of the courtesy lamp. The courtesy lamp will stop flashing once learning is complete.

Improving the door security

If there is a clear gap above the top of the closed door it is possible in some cases for people to

gain unauthorised access to the garage after an opener is fitted. You can improve the security by

adding a strip of metal or wood over any gap to block access to the manual release rope.

Page 14

EDR4 1179 G2.16 10/03

14

Adding the Merlin M102

non-contact beam sensor (Optional)

Non-contact Near-Infra-Red beam sensors are optional but may be required in EC countries. Merlin strongly suggests they be fitted for increased levels of safety.

If sensors are fitted the opener will only close when the sensors are fully functional and where their

beam is unobstructed.

The sensors should be placed either side of the door opening, within 300mm of the door’s opening, and within 100mm of the floor. Choose positions that will protect the sensors from accidental

impact or water. If one sensor is marked ‘receiver’ then do not place that sensor where it will be

subjected to bright direct sunlight. The high level of Infra Red light in bright sunlight may temporarily prevent normal operation of the opener.

Switch off the power to the opener. Run the pair of cables from each sensor back to the accessory

terminals on the rear of the opener.

There is no need to connect the cables with any particular polarity.

Switch the power to the opener back on. Aim the sensors at each other using the adjustments

provided. When correctly aligned and unobstructed the sensor LEDs will stop flashing and stay on

continuously.

The door can open regardless of the sensor beam. Only the closing operation is affected by the

state of the beam. If the beam is obstructed or if the sensors are not functioning then the door may

still be closed by holding the manual control button down for at least two seconds, and keeping it

held until the door is closed.

N

I

R

L

i

g

h

t

b

e

a

m

M

a

x

7

m

e

t

r

e

s

Non contact beam sensor

Page 15

EDR4 1179 G2.16 10/03

15

Specifications

Replacement light bulb E27 45mm Round, 40W maximum, RC preferred

Mains power required 220V to 240 V, 50 Hz, single phase AC, earthed

Suitable for sectional doors, one piece tilt doors. Note that counterweight

type doors are not suitable for automating

Stand-by power consumption 3 W

Operating power consumption 900 W

Net weight 15kg (installed using typical pole and strapping)

Trolley speed depending on sprocket and load: 75 to 135mm/sec

Rated force 770N

Standard pole length 2750mm to suit chain supplied

Standard assembled overall length pole length + 400mm = 3150mm

Standard trolley travel pole length - 275mm = 2480mm

Minimum headroom required 100mm between the top edge of the door and the ceiling

while the door is closing or opening

Minimum backroom required 600mm back from the rear edge of a fully opened door,

depends on door arm chosen.

Ambient operating temperature +5

0

C to +400C.

3150 (Standard)

Minimum 453

Minimum 215

170

205

80

65

Overall dimensions

Page 16

EDR4 1179 G2.16 10/03

16

27

Merlin does not accept responsibility for damage or injury resulting from installing this opener.

Merlin reserves the right to change the design and specification without prior notification. Some

features or accessories may not be available in certain markets or areas. Please check with your

distributor.

Merlin service centres

New Zealand

Auckland phone 09 415 4393

Phone toll free 0800 653 667 or 0800 MERLIN

Fax toll free 0800 653 663

Australia

NSW, Vic, Qld, WA

Phone toll free 1 800 638 243

Fax toll free 1 800 640 243

England

Phone toll free 0800 073 0112

Fax toll free 01709 514 534

www.merlingo.com

Loading...

Loading...