Page 1

gomerlin.com.au

gomerlin.co.nz

Residential & Light Duty Commercial Door Opener

Installation and Operating Instructions

Owners Copy: Please keep these instructions for future reference

This manual contains IMPORTANT SAFETY information

DO NOT PROCEED WITH THE INSTALLATION BEFORE READING THOROUGHLY

MJ3800

Page 2

START BY READING THESE IMPORTANT SAFETY INSTRUCTIONS

ARNING

W

• Failure to comply with the following instructions may result in serious personal injury or property damage.

• Read and follow all instructions carefully.

The garage door opener is designed and tested to offer safe service provided it is installed and

•

operated in strict accordance with the instructions in this manual.

These safety alert symbols mean WARNING : A possible risk to personal safety or

property damage exists.

Keep garage door balanced. Do not let the garage door

pener compensate for a binding or sticking garage door.

o

Sticking, binding or unbalanced doors must be repaired

before installing this opener.

Do not wear rings, watches or loose clothing while

installing or servicing a garage door opener. Wear gloves,

safety goggles and suitable protective clothing where

appropriate.

Frequently examine the door installation, in particular

cable, springs and mountings for signs of wear, damage or

imbalance. Do not use if repair or adjustment is needed

since springs and hardware are under extreme tension

and a fault can cause serious personal injury.

To avoid serious personal injury from entanglement,

remove all ropes, chains and locks connected to the

garage door before installing the door opener.

Installation and wiring must be in compliance with your

local building and electrical codes.

The safety reverse system test is very important. Your

garage door MUST reverse on contact with a 40 mm

obstacle placed on the floor. Failure to properly adjust the

opener may result in serious personal injury from a closing

garage door. Repeat the test once a month and make

any necessary adjustments.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety.

Use the Manual Release only for the seperation of the

carriage from the drive and - if possible - ONLY with the

door closed. Do not use the red handle to push the door

up or pull it down. Operation of the emergency release can

lead to uncontrolled movements of the door, if springs are

weak or broken or if the door is unbalanced. Mount the

release handle of the emergency release at a height less

than 1.8 m from the floor.

The Protector SystemTMmust be used for all installations

here the closing force as measured on the bottom of the

w

door is over 400 N (40 kgf). Excessive force will interfere with

the proper operation of the Safety Reverse System or damage

the garage door.

SPECIAL NOTE: Merlin strongly recommends that The

Protector System

After installation, ensure that the parts of the door do not

extend over public footpaths or roads.

Install the wireless wall control (or any additional wall control) in

a location where the garage door is visible, at a height of at

least 1.5 m and out of the reach of children. Do not allow

children to operate push button(s) or transmitter(s). Serious

personal injury from a closing garage door may result from

misuse of the opener.

Permanently fasten the Warning Labels in Prominent Places,

adjacent to Wall Controls and on manual release mechanism as

a reminder of safe operating procedures.

Activate opener only when the door is in full view, free of

obstructions and the opener is properly adjusted. No one

should enter or leave the garage while the door is in motion.

Automatic Door- The door may operate unexpectedly, therefore

do not allow anything to stay in the path of the door.

Do not allow children to play near the door, or with door

controls. Keep remotes away from children.

Disconnect electric power to the garage door opener before

making repairs or removing covers.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons in

order to avoid hazard.

This opener should not be installed in a damp or wet space

exposed to weather.

To avoid damage to very light doors (such as fibreglass,

aluminium or steel doors), an appropriate reinforcement should

be added. To do so, contact the door manufacturer.

SAVE THESE INSTRUCTIONS

TM

be installed on all garage door openers.

NOTE: If your garage has no service entrance door, a CM1702 outside quick release must be installed.

This accessory allows manual operation of the garage door from outside in case of power failure.

CONTENTS PAGE

SAFETY INSTRUCTIONS . . . . .2

CARTON INVENTORY . . . . . . .3

ACCESSORIES . . . . . . . . . . . 3

SPECIFICATION . . . . . . . . . . .4

TOOLS REQUIRED . . . . . . . . .4

PREPARE & TEST THE DOOR . .4

DOOR REQUIREMENTS . . . . . .5

ASSEMBLY . . . . . . . . . . . . . . .6

INSTALLATION . . . . . . . . .7-10

CONNECT ELECTRIC POWER .10

INSTALL MULTI-FUNCTION DOOR

CONTROL . . . . . . . . . . . . . .10

INSTALL THE PROTECTOR

SYSTEM . . . . . . . . . . . . . . .11

AUTO CLOSE . . . . . . . . . . . .13

ADJUSTMENT . . . . . . . . .14-17

WIRELESS PROGRAMMING 18-19

REPAIR PARTS . . . . . . . . . . .20

DIAGNOSTIC CHART . . . . . . .21

TROUBLESHOOTING . . . . . . .22

CARE OF YOUR OPENER . . . . 23

OPERATION OF YOUR OPENER 23

WARRANTY . . . . . . . . . . . . .24

2

Page 3

Manual

TM

CM128 Wireless

Wall Button

2 x C945 3ch

rolling code

transmitters

Opener

L

O

C

K

L

I

G

H

T

Multi function

door control

CM475 Battery

Backup Unit

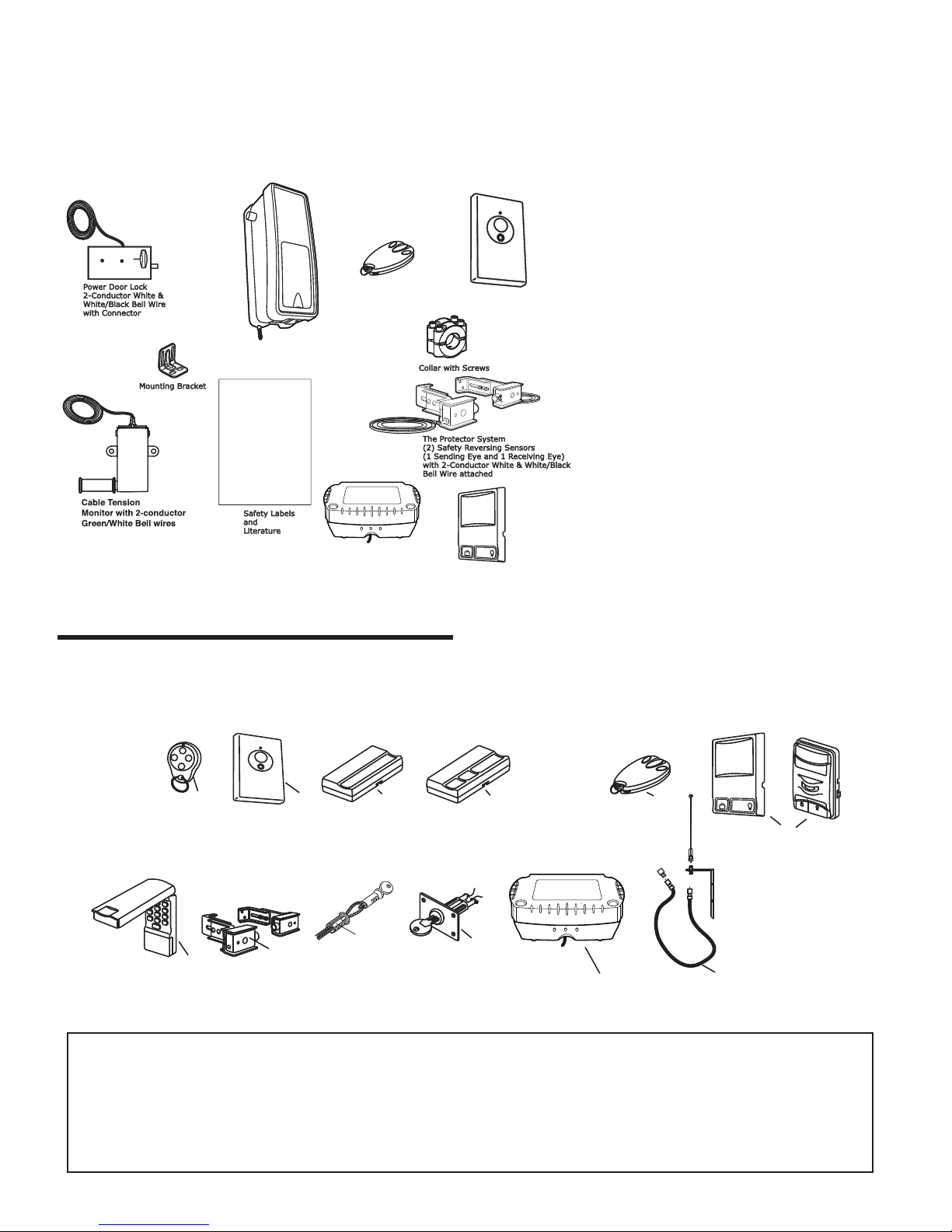

CARTON INVENTORY

5

3

1

10

11

2

4

C840

CM128

760E

CM1702

C77

C940 C943

C945

7

8

9

CM844

12

L

O

CK

L

I

G

H

T

6

L

O

C

K

L

I

G

H

T

C98

845AML

CM475

our door opener is packaged in one carton which contains the opener and the parts illustrated below.

Y

Note that accessories will depend on the model purchased. If anything is missing, carefully check the

packing material.

Hardware Inventory

INSTALLATION HARDWARE

Hex Screw #14-10x1-7/8" (4)

Screw #6x-1" (2)

Hex Screw #6x1-1/4” (2)

Carriage Bolt 1/4"-20x1/2" (2)

an Head Screw 1/4"-20x1/2" (2)

P

Hex Head Screw #8x1" (2)

Self Tapping Screw #10-32 (2)

Wall Anchor (2)

Wall Anchor (Screw-In) (2)

Handle

Rope

Insulated Staples (10)

Lock Template

ACCESSORIES

PROTECTOR SYSTEM

TM

(IR)

INSTALLATION HARDWARE

Screw 10-32x3/8" (4)

Carriage Bolt 1/4"-20x1/2" (4)

Wing Nut 1/4"-20 (2)

Hex Nut 10-32x3/8" (4)

Hex Nut 1/4-20 (4)

Hex Head Screw 1/4-20x1-1/2" (2)

Hex Head Screw 14-10 x 1-1/2" (4)

Insulated Staple (10)

(1) Model CM844 4 Channel remote control

(2) Model CM128 Wireless Wall Button

(3) Model C940 1 Channel visor remote control

(4) Model C943 3 Channel visor remote control

(5) Model C945 3 Channel mini remote control

(6) Model 845AML Multi-Function Door Control

or Model C98 Motion Detecting Control Panel

(7) Model C840 Keyless Entry System

(8) Model C77 The Protector System

(9) Model CM1702 Quick Release Lock

(10) Model 760E Outside Keyswitch

(11) Model CM475 Battery Backup

(12) Model ANT4X-1 433MHz Antenna, cable and adaptor

3

TM

Page 4

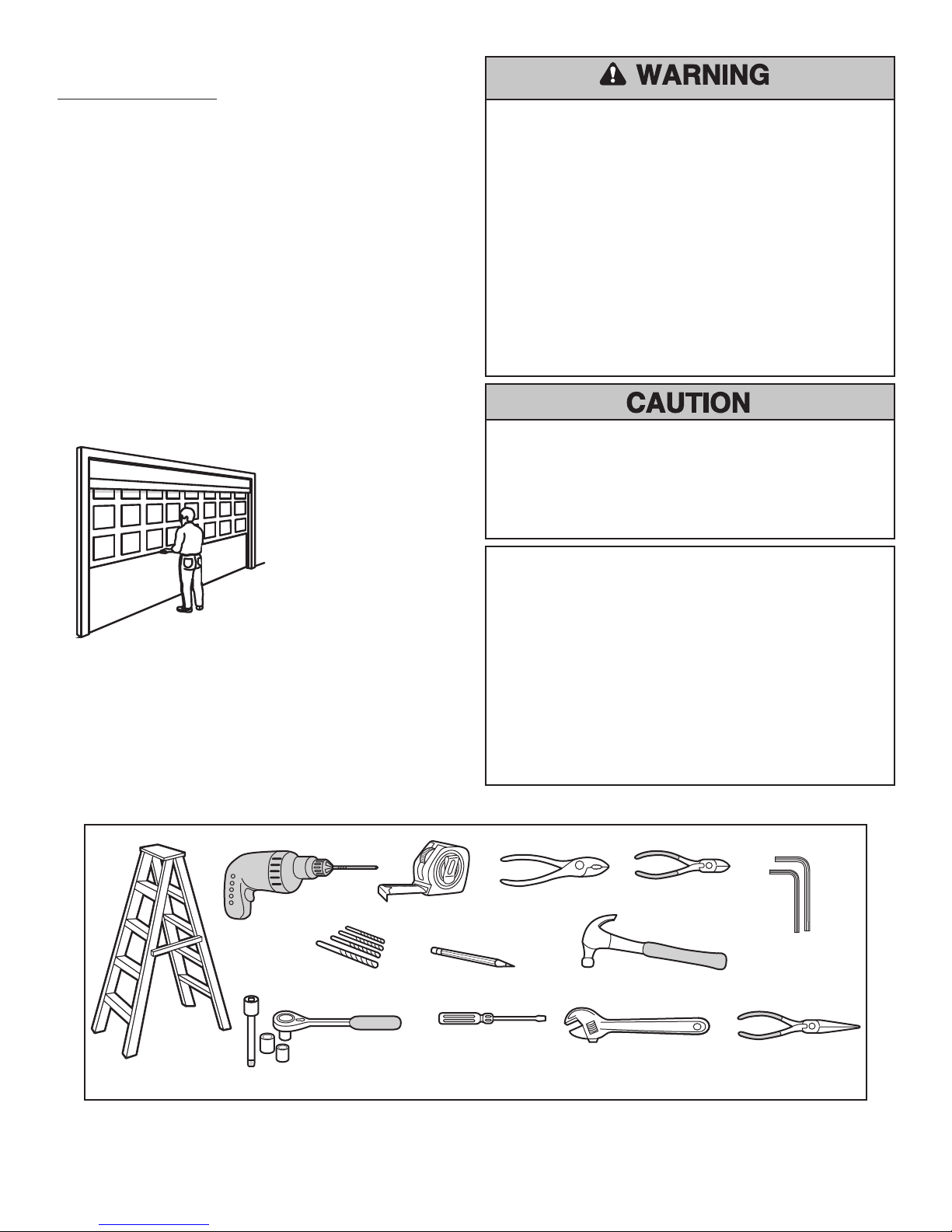

PREPARING YOUR DOOR

Pliers

Wire Cutters

Claw Hammer

Screwdriver

Adjustable End Wrench

1/4", 5/16" & 3/8" Sockets

and Wrench with 200mm Extension

Drill

Tape Measure

2

1

Stepladder

Pencil

3/16" and 1/8"

Hex Key Wrench

Needle Nose Pliers

5/32", 3/16", 5/16"

and 3/4" Drill Bits

Before you begin:

Disable locks.

•

• Remove any ropes connected to door.

• Complete the following test to make sure your

door is balanced and is not sticking or binding:

. Lift the door about halfway as shown. Release

1

the door. If balanced, it should stay in place,

supported entirely by its springs.

2. Raise and lower the door to see if there is any

binding or sticking, 20 Kgf is the absolute

maximum allowable force to raise or lower the

door in any position.

F YOUR DOOR BINDS

I

RAINED DOOR SYSTEMS TECHNICIAN

T

3. Verify equal cable tension on each side of

door. Cable tension should remain equal

during the entire travel of the door.

TICKS OR IS OUT OF BALANCE

, S

.

, C

ALL A

o prevent possible SERIOUS INJURY or DEATH:

T

• ALWAYS call a trained door systems technician if

door binds, sticks or is out of balance. An

unbalanced door may not reverse when required.

• NEVER try to loosen, move or adjust door, door

springs, cables, pulleys, brackets or their hardware,

ALL of which are under EXTREME tension.

• Disable ALL locks and remove ALL ropes connected

to the door BEFORE installing and operating the

door opener to avoid entanglement.

• This device is not intended for use by small children

or infirmed persons without supervision.

• young children should NOT be permitted to play

with the opener or transmitters.

To prevent damage to door and opener:

• ALWAYS disable locks BEFORE installing and

operating the opener.

Sectional Door

Tools needed

During assembly, installation and adjustment of

the opener, instructions will call for hand tools as

illustrated below.

Specifications

Volts: 230-240 ~ V 50 Hz

Power: 145 Watts

Rated Load: 10Nm

Fmax: 40Nm

Max door height: 4.2m (14’)

Max door width: 5.5m

Max: area 16m

2

Please note this opener contains both imperial and metric fasteners.

Torque Meter (not shown)

4

Page 5

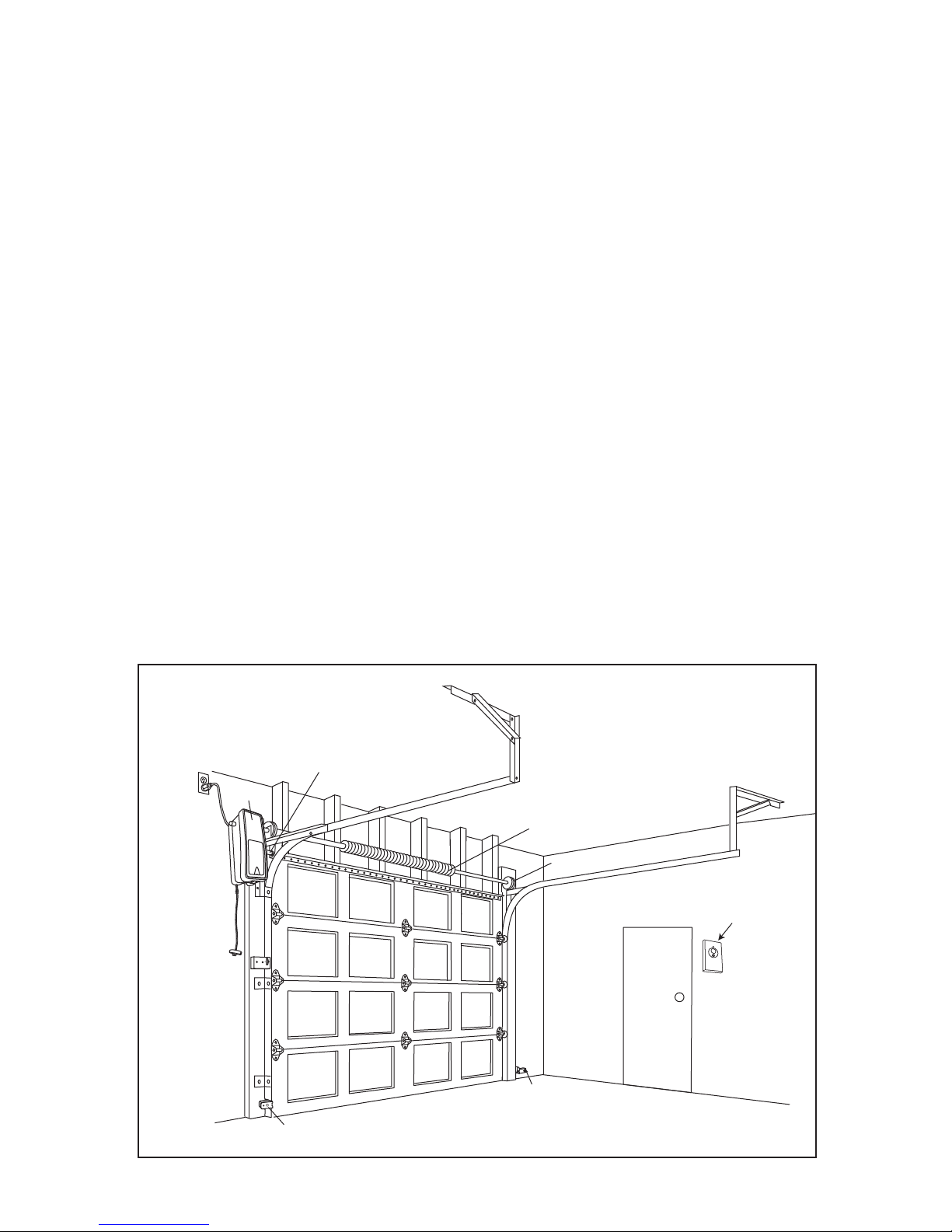

Safety

Reversing Sensor

Safety

Reversing

Sensor

Torsion Spring

Opener

Wireless wall button

Access Door

Gap between floor

and bottom of door must not exceed 6 mm (1/4”)

Powered

Door Lock

Cable Tension

Monitor

Drum

DOOR REQUIREMENTS

Survey the area to see if any of the conditions

below apply to your installation. Additional

materials may be required. You may find it helpful

to refer back to this page as you proceed with the

nstallation of your opener.

i

Depending on your requirements, there are several

installation steps which may call for materials or

ardware not included in the carton.

h

This opener is compatible with:

• Doors that use a torsion bar, springs and a door

no more than 4.2m (14’) high.

• 100mm - 150mm drums (4” to 6”), NOT TO BE

USED on tapered drums over 150mm (6”).

• High lift and standard lift sectional doors up to

4.2m (14’) high.

• Doors up to 5.5m (18’) wide.

2

• Doors up to 16m

• 25mm (1”) torsion bar only.

• Review or inspect proposed installation area.

Opener can be installed on left or right side of

door. Select the side that meets the

requirements listed below.

• Must have minimum of 64mm (2 1/2”) between

the wall and the center of the torsion bar.

• Must have minimum of 76mm (3”) between the

ceiling and the center of torsion bar.

(170 sq ft)

• Must have minimum of 203mm (8”) between the

ide wall (or obstruction) and the end of torsion

s

bar.

• The torsion bar must extend at least 25mm to

00mm (1” to 4”) past the bearing plate.

1

• An electric outlet is required within 1.8m (6’) of

the installation area. If outlet does not exist,

ontact a qualified electrician.

c

• Depending upon building’s construction,

extension brackets or wood blocks may be

needed to install safety reversing sensors.

M

T

• A model CM475 EverCharge

Standby Power

Unit (SPU) is strongly recommended if there is

no access door to the building, as this opener

cannot be used in conjunction with an external

emergency release mechanism.

• Any gap between the floor and the bottom of the

door must not exceed 6mm (1/4”). Otherwise

the safety reversal system may not work

properly.

NOTE: Inspect the torsion bar while the door is raised

and lowered. It is important that there is no noticeable

movement up and down or left and right. If this type of

movement is not corrected, life of this opener will be

greatly reduced.

5

Page 6

ASSEMBLY STEP 1

C

o

l

l

a

r

S

c

r

e

w

C

o

l

l

a

r

S

c

r

e

w

S

e

t

S

c

r

e

w

C

o

l

l

a

r

S

c

r

e

w

C

o

l

l

a

r

S

c

r

e

w

S

e

t S

c

r

e

w

Socket Wrench

RIGHT

WRONG

Screw

#10-32

HARDWARE SHOWN ACTUAL SIZE

Attach the Collar to the Opener

To avoid installation difficulties, do not run the door

pener until instructed to do so.

o

• Loosen the collar screws.

• Attach collar to either the left or the right side of the

opener. Depending on Left or Right hand installation

ensure that the collar is seated all the way on motor

shaft until stop is reached (Figure 1).

• Position the collar so that the screws are accessible

when attached to the torsion bar.

• Tighten both sides of collar screws equally (Figure 2) to

secure collar to the opener (16Nm-19Nm of torque).

• Do not tighten set screws as yet.

To prevent possible SERIOUS INJURY or DEATH,

he collar MUST be properly tightened. The door

t

may not reverse correctly or limits may be lost

due to collar slip.

NOTE: Nylon Patch has been added to the collar

screws, so it is normal for some thread resistance to

be evident.

ASSEMBLY STEP 2

Attach Mounting Bracket to Opener

• Loosely attach slotted side of mounting bracket

to the same side of the opener as the collar,

using self-threading screws provided.

NOTE: Do not tighten until instructed. Illustrations

shown are for left side installation.

Right hand

installation

Figure 1

Figure 2

Left hand

installation

Alternate Mounting Kit (NOT SUPPLIED):

This kit allows model MJ3800 to be

mounted below the torsion bar in the

case where the torsion bar is not

round or the normal mounting area

is obstructed.

G480LM

6

Page 7

INSTALLATION

Staple

Torsion Bar

WARNINGWARNING

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL INSTALLATION

WARNINGS AND INSTRUCTIONS.

2. Install door opener ONLY on properly balanced and

lubricated the door. An improperly balanced door may

not reverse when required and could result in

SEVERE INJURY or DEATH.

3. ALL repairs to cables, spring assemblies and other

hardware MUST be made by a trained door systems

technician BEFORE installing opener.

4. Disable ALL locks and remove ALL ropes connected

to the door BEFORE installing opener to avoid

entanglement.

5 Mount emergency release handle no higher than 1.8m

above floor.

6. NEVER connect the door opener to power source

until instructed to do so.

7.NEVER wear watches, rings or loose clothing

while installing or servicing opener. They could be

caught in the door or opener mechanisms.

8. Install wall-mounted door control:

• within sight of the door.

• out of reach of children at minimum height of

1.5 m.

• away from ALL moving parts of the door.

9. Place entrapment warning label on wall next to multi

function door control.

10.Place manual release/safety reverse test label in plain

view on inside of the door.

11.Upon completion of installation, test safety reversal

system. Door MUST reverse on contact with a 40mm

(1 1/2”) high obstacle placed on the floor.

INSTALLATION STEP 1

Position the Opener

1. Close the door completely.

2. Slide the opener with collar over the end of the torsion

bar. Ensure that the collar does not touch the bearing

plate. Check to make sure the mounting bracket is

located on a solid surface such as wood, concrete or

door/flag bracket. Snug collar screws to help assure

proper alignment of opener. Mark the bracket holes. It

may be necessary to cut the torsion bar if it is too long

or damaged.

3. Loosen collar screws from torsion bar and remove the

opener. Drill 5mm (3/16”) pilot holes at the marked

locations. Drill through steel plate if needed.

4. Reinstall the opener by sliding the collar over the torsion

bar until pilot holes align with bracket. Securely tighten

collar screws that attach to the torsion bar to 16Nm19Nm of torque. Securely tighten both set screws firmly,

without damaging the opener.

5. Fasten bracket securely with 14-10x1-7/8" screws.

Tighten all mounting bracket hardware.

NOTE: The opener does not have to be flush to wall,

but it is essential it is mounted perfectly square to the

torsion bar. This will ensure smooth operation with

minimum stress at the connecting collar mount.

6. Use a staple to secure the antenna wire to prevent

antenna from being entangled in a door roller.

To prevent possible SERIOUS INJURY or DEATH:

• Concrete anchors MUST be used if mounting bracket

into masonry.

• NEVER try to loosen, move or adjust the door,

springs, cables, pulleys, brackets or their hardware,

ALL of which are under EXTREME tension.

• ALWAYS call a trained door systems technician if the

door binds, sticks or is out of balance. An unbalanced

door might not reverse when required.

• Opener MUST be mounted at a right angle to the

torsion bar to avoid premature wear on the collar.

7

Page 8

Staples

Lock Screw

1/4-20 x 1/2" (2)

Lock Template

Roller

Garage

Door Track

TOP

DRILL8mm

DRILL19mm

DRILL8mm

132A2505

TOP

DRILL5/16"

DRILL3/4"

DRILL5/16"

132A2505

Approx. 7.6cm

(3”)

Overhand

K

not

Emergency

Release Handle

Overhand

K

not

Rope

Opener

E

mergency

Release Cable

01

6+

%'

Warning Label

WARNING

INSTALLATION STEP 2

Attach the Emergency Release Rope and

Handle

• Thread one end of the rope through the hole in

the top of the red handle so “NOTICE” reads

right side up as shown. Secure with an overhand

knot at least 25mm (1") from the end of the

ope to prevent slipping.

r

• Thread the other end of the rope through the

loop in the emergency release cable.

• Adjust rope length so the handle is no higher

than 1.8m (6’) above the floor. Secure with an

overhand knot.

NOTE: If it is necessary to cut the rope, heat seal the

cut end to prevent unraveling.

INSTALLATION STEP 3

Install powered door lock

The lock is used to prevent the door from being

manually opened once the door is fully closed.

1.Select a door roller to mount the lock above.

Check for clearance. If possible select a roller on

the same side of the door as the opener. The

second roller up from the bottom is ideal in most

installations.

2.Ensure the door track surface is clean and

adhere lock template with bottom edge just

above the highest point on the roller (Figure 1).

3.Drill holes as marked on the template.

4.Fasten powered door lock to the outside of the

door track with hardware provided.

5.Run bell wire up wall to opener. Use insulated

staples to secure wire in several places.

6.Plug connector into the opener (Figure 2).

NOTE: Lock must be mounted within 3m (10') of the

power head.

To prevent possible SERIOUS INJURY or DEATH

from a falling door:

If possible, use emergency release handle to

•

disengage door ONLY when door is CLOSED.

Weak or broken springs or unbalanced door

could result in an open door falling rapidly

and/or unexpectedly.

• NEVER use emergency release handle unless

the doorway is clear of persons and

obstructions.

Figure 1

HARDWARE SHOWN ACTUAL SIZE

Figure 2

8

Page 9

WHT/GRN

To insert or release wire,

push in tab with

screwdriver tip

Cable Tension

Monitor

Strip wire (11mm)

WHT/GRN

C

able

T

ension

M

onitor

Cable Tension

Monitor Roller

Cable

2

"-6"

(5 cm15 cm)

Drum

T

orsion Bar

O

pener

1/8"-1/4"

(

3 mm-6 mm)

W

ith Door Closed

P

referred Orientation

#8

He

x He

ad

Sc

rew

(2)

Sc

r

e

w #6 (

2)

Wall A

nch

or (

2)

Staples

3/4" Min.

(18 mm Min.)

Wall

Drum

Cable

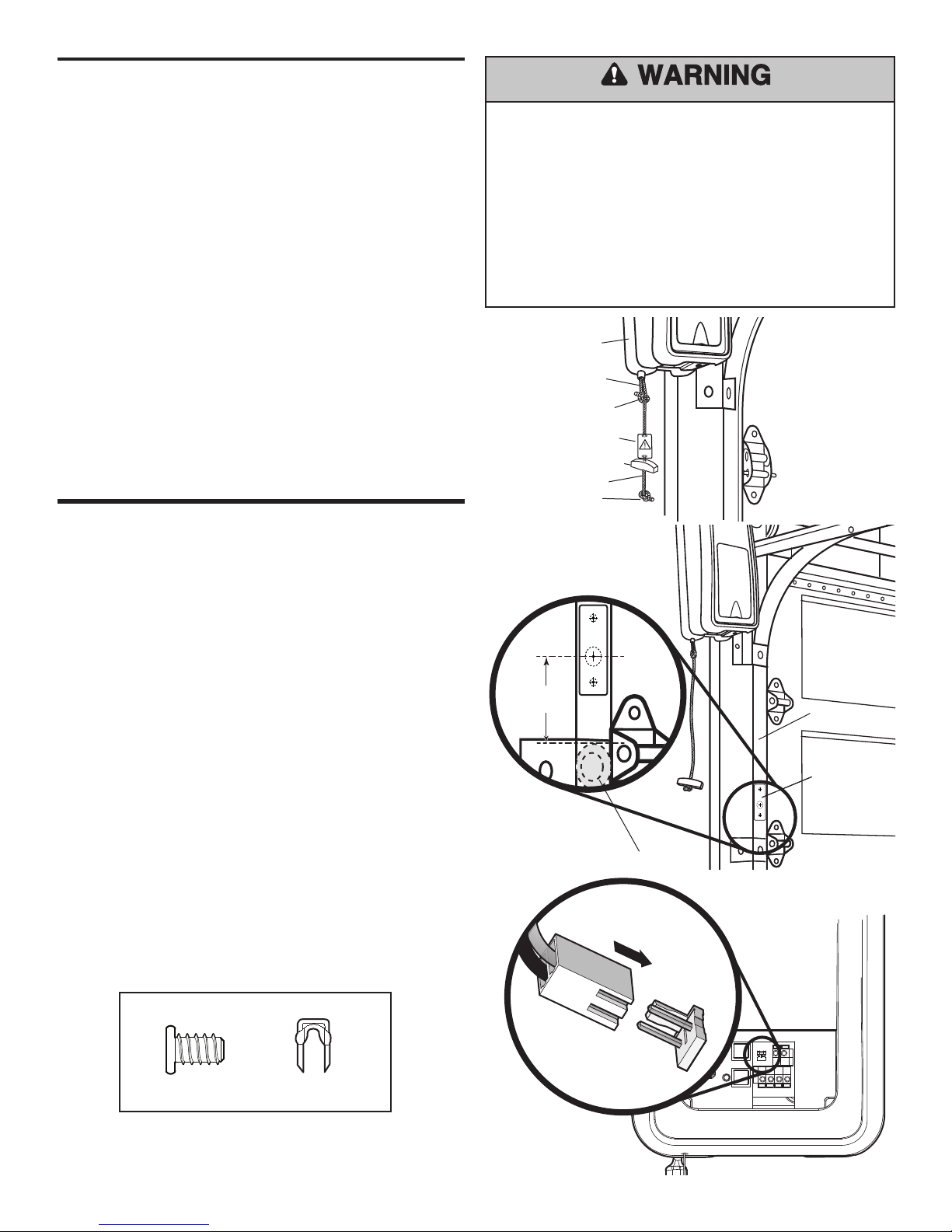

INSTALLATION STEP 4

Attach the Cable Tension Monitor (Required)

Your MJ3800 is supplied with a cable tension monitor.

his safety device is supplied to monitor the cable for

T

ANY slack that may occur and will reverse the door

when excessive slack is detected, eliminating service

calls.

The cable tension monitor MUST be connected and

properly installed before the door opener will move in

the down direction.

NOTE: The cable tension monitor is shipped for left

side installation. It is preferred that the cable tension

monitor be installed on the same side of the door as

the opener.

If required, it can be mounted on the opposite side of

door. Remove the snap-ring holding the roller in place

and reassemble it on the opposite side of the cable

tension monitor.

1.Position the cable tension monitor as shown

(Figures 1 and 2). The cable tension monitor

should be located as close to the drum as

possible.

NOTE: There must be no obstructions in the

installation area that prevent the cable tension

monitor or the cable itself from closing completely

when slack is detected.

2.Make sure cable tension monitor is located over

a wood support member.

NOTE: If the cable tension monitor can not be

mounted into wood with the lag screws provided, it

can be mounted into 25mm (1”) or greater pasterboard

using the wall anchors (2) and the #8 hex head screws

(2) provided in the hardware bag.

3.Mark and drill 5mm (3/16”) pilot holes for screws

(pilot holes are not required for anchors).

4.Attach the cable tension monitor to the wall

using the hardware provided. Make sure that the

roller is on top of the cable.

5.Run bell wire to opener. Use insulated staples to

secure wire in several places.

6.Connect bell wire to the green quick-connect

terminals (polarity is not important) (Figure 3).

NOTE: Cable must have tension through entire travel.

Make sure there is no slack in cable on opposite side

of the door during normal operation. If this condition

exists, adjust cables as required.

Figure 1

Figure 2

Figure 3

9

Page 10

To prevent possible SERIOUS INJURY or DEATH from electrocution or fire:

+

L

O

C

K

L

I

G

H

T

2

1

R

ED

WHT

Opener

Quick-ConnectTerminals

To Door Control

drycontact

Red

White

• Be sure power is not connected to the opener, and disconnect power to circuit BEFORE removing cover.

Door installation and wiring MUST be in compliance

•

with ALL local electrical and building codes.

• NEVER use an extension cord, 2-wire adapter or alter the plug in any way to make it fit outlet. Be sure the opener is grounded.

• If the supply cord is damaged, it must be replaced

by the manufacturer or it’s service agent or a

imiliarly qualified person in order to avoid harzard.

s

INSTALLATION STEP 5

INSTALLING THE MULTI-FUNCTION WALL

CONTROL

Note: any connection to your MJ3800 should be

voltage free and Normally open.

There are 2 screw terminals on the back of the multifunction door control. Strip about 6mm of insulation from

bell wire. Separate wires enough to connect the white/red

wire to R terminal screw 1 and the white wire to W terminal

screw 2.

Fasten the multi-function door control to an inside garage

wall with sheet metal screws provided. Drill 4mm holes and

use anchors if installing into plasterboard wall. A convenient

place is beside the service door and out of reach of

children.

Run the bell wire up the wall and across the ceiling to the

garage door opener. Use insulated staples to secure wire.

The receiver quick connect terminals are located on the

control board. Connect the bell wire to the terminals as

follows: white/red to red and white to white.

INSTALLATION STEP 6

Installing the Wireless Wall button (CM128)

Control must be mounted out of the reach of children

at a height of 1.5m with an unobstructed view of the

door.

• Ensure your MJ3800 opener is switched off whilst

installing your wireless door control to prevent

accidental activation.

• Remove the cover from the CM128.

• Mount CM128 as shown using the screws

provided if mounting into a wall box (not

provided).

• If mounting directly on the wall use wall anchors

(provided) to fix unit to the plasterboard wall.

• Replace the cover plate and affix the warning label

adjacent the wall controller.

To prevent possible SERIOUS INJURY or DEATH from

a falling door:

• If possible, use emergency release handle to

disengage door ONLY when door is CLOSED. Weak

or broken springs or unbalanced door could result in

an open door falling rapidly and/or unexpectedly.

• NEVER use emergency release handle unless the

doorway is clear of persons and obstructions.

Disconnect power to the opener whilst installing

this accessory to prevent accidental activation.

Locate minimum 1.5m above the floor.

Fix the emergency door release label adjacent to the

opener.

NOTE: The wireless wall button supplied with your opener should be preprogrammed by the

factory. If adding a new wireless wall button, program into the opener before mounting the unit.

10

Page 11

Mounting Bracket

With Square Holes

#10-32x3/8"

Screws

"C" Wrap

#10-32

Lock Nuts

ALL Installations

Mounting Bracket

with Slot

1/4"-20

Lock Nuts

1/4x1-1/2"

Lag Screws

1/4-20x1/2" Carriage Bolts

(

with square shoulder)

Inside

Garage

Wall

"C" Wrap

Mounting Bracket

w

ith Square Holes

"C" Wrap

Inside

Garage

Wall

Mounting

Bracket with

Square Holes

Garage

Floor

Mounting

Bracket

with Slot

Alternate Wall

Mount

Sensor

Inside

Garage

Wall

Alternate Floor

Mount

Mounting Bracket

with Slot

Mounting Bracket

with Square Holes

"C"

Wrap

Sensor

Garage

Floor

Indicator Light

Indicator Light

Attach with

concrete anchors

(not provided)

I

nside

Garage

W

all

"C" Shaped

Wrap

Mounting Bracket

with Square Holes

1/4-20x1/2"

Carriage Bolts

1

/4"-20

Lock Nuts

Drill 3/8"

(9,5mm) Holes

G

arage

Door Track

G

arage DOOR Track Installation

G

arage WALL Installation

1/4-20x1-1/2"

Hex Bolt

"C" Wrap

Wire

Sensor

Wing Nut

Indicator

Light

INSTALLATION STEP 7

Install The Protector System

When installed the safety reversing sensor must be

connected and aligned correctly before the door

pener will move in the down direction. This safety

o

device is provided for your safety and should not be

disabled.

OTE: The speed will also be increased by

N

down direction.

INSTALLING THE BRACKETS

Be sure power to the opener is disconnected.

Figures 1, 2 and 3 show recommended assembly of

bracket(s) and "C" wrap based on the wall installation of

the sensors on each side of the door shown above, or on

the door tracks themselves. Figures 4, 5 & 6 show

variations which may fit your installation requirements

better. Make sure the wraps and brackets are aligned

so the sensors will face each other across the door.

• Connect each assembly to a slotted bracket, using the

• Use bracket mounting holes as a template to locate and

• Attach bracket assemblies with 1/4"x1-1/2" lag screws as

• Adjust right and left side bracket assemblies to the same

• Centre each sensor unit in a "C" wrap with lenses

• Secure sensors with the hardware shown in Figure 6.

• Run wires from both sensors to the opener as shown on

• Connect both sets of wires to the opener terminals as

• Plug in the opener. If your opener has the Multi-Function

If the indicator lights are flashing (and the invisible light

beam path is not obstructed), alignment is required.

• Loosen the receiving eye wing nut to allow slight rotation

• When indicator lights are glowing in both units, tighten the

hardware shown. Note alignment of brackets for left

and right sides of the door. Finger tighten the lock

nuts.

drill (2) (4.8mm) diameter pilot holes on both sides of the

door, (100mm). Max height is (100mm).

shown.

distance out from mounting surface. Make sure all door

hardware obstructions are cleared. Tighten the nuts

securely.

pointing toward each other across the door.

Finger tighten the wing nut on the receiving eye to allow

for final adjustment. Securely tighten the sending eye wing

nut.

Page 12. Use insulated staples to secure the wire to the

wall and ceiling.

shown page 12.

Door Control, make sure the Lock Feature is off. Red

indicator lights in both the sending and receiving eyes will

glow if wiring connections and alignment are correct.

of unit. Adjust sensor vertically and/or horizontally until the

red indicator light glows.

wing nut in the receiving eye unit.

figure 1

TM

1

/3i

n the

Be sure power is not connected to the door opener

BEFORE installing the safety reversing sensor.

To prevent SERIOUS INJURY or DEATH from a closing

door:

• Correctly connect and align the safety reversing

sensor. This required safety device MUST NOT be

disabled.

• Install the safety reversing sensor so beam is NO

HIGHER than 100mm (4”) above the floor.

figure 2

figure 3

figure 4

figure 5

figure 6

11

Page 12

CONNECT ELECTRIC POWER

SPU Cord

Connector

C

M475 EverCharge

S

tandby Power Unit

TM

L

O

C

K

L

I

G

H

T

Actuator

Button

LED Indicator

light

LIGHT

LOCK

TO AVOID INSTALLATION DIFFICULTIES, DO NOT RUN THE GARAGE DOOR OPENER UNTIL INSTRUCTED TO DO SO.

Connect to properly fused and earth power outlet.

INSTALLATION STEP 8

Mounting the Evercharge Standby Power

Unit (SPU)

If the CM475 Standby power supply unit is part of this

installation it should be installed at this time.

• The SPU can be mounted to either the ceiling or a wall

within 3' (.9 m) of the opener.

• Position the SPU as desired to a structural support

(ceiling joist or wall stud).

• Attach the SPU to the support using the mounting holes

on either side of the SPU.

• Secure the SPU using the 1-1/2" lag screws (2) provided

with the SPU unit.

• Connect the SPU cord into the connector on the bottom

of the opener.

• Follow all instructions included with the CM475 unit to

test for proper operation and testing of the SPU.

USING THE MULTI-FUNCTION DOOR CONTROL

THE MULTI-FUNCTION DOOR CONTROL

Press the push bar to open or close the door. Press again to reverse

the door during the closing cycle or to stop the door while it's

opening.

Light feature

The Light function is not available with the

MJ3800.

Lock feature

Designed to prevent operation of the door from hand-held transmitters whilst still allowing the door to open and close

from the Door Control, the Outdoor Key Switch and the Keyless Entry Accessories. To activate, press and hold the Lock

button for 2 seconds.

To turn off, press and hold the Lock button again for 2 seconds. The Lock feature will also turn off whenever the “learn”

button on the opener panel is activated.

Note: This feature does not operate the Powered door lock.

12

Page 13

Invisible Light Beam

Protection Area

S

ensor

Sensor

Safety Reversing Sensor

Bell Wire

Bell Wire

Opener

Safety Reversing Sensor

Power Door Lock

Quick-Connect Terminals

WHT/BLK

WHT

Sensor

Connections

To Power

Door Lock

To Multi-function

Control Panel

Connect Wire to

Quick-Connect

Terminals

red

white

MAX height

100mm (4”)

MIN height

50mm (2”)

UTOMATIC CLOSE TIMER FUNCTION

A

TM

Note: Requires the Chamberlain Protector System

(IR-sensors) to be installed. If Protector SystemTM(IR-sensors) is

installed to enable the timer to close function (first time), install sensors, close the garage door and wait for 5 minutes.

A Multi-function Door Control is required to enable and disable the auto-close function.

Enable: Push and hold lock button on the Multi-function Door Control until the electric lock toggled twice. Release the

lock button, at the same time watch the LED light in the center of the actuator button from the Multi-function Door

Control.

1x flash 10 seconds Auto-Close

2x flash 45 seconds Auto-Close

3x flash 2 minutes Auto-Close

4x flash 3 minutes Auto-Close

5x flash OFF Auto-Close

Factory setting is OFF. Repeat the procedure until the Multi-function Door Control shows the required number of flashes.

Auto close is NOT recommended for households with

young children.

Door may operate unexpectedly, therefore do not

allow anything to stay in the path of the door.

TROUBLESHOOTING THE SAFETY REVERSING

SENSORS

1. If the sending eye indicator LEDs are both flashing

after installation, check for:

• Electric power to the opener.

• A short in the white or white/black wires. These can occur at staples, or at opener connections.

• Incorrect wiring between safety reversing sensors and opener.

• A broken wire.

2. If the sending eye indicator light glows steadily but the receiving eye indicator light doesn't:

• Check alignment.

• Check for an open wire to the receiving eye.

3. If the receiving eye indicator light is dim, realign

either sensor.

NOTE: When the invisible beam path is obstructed or misaligned while the door is closing, the door will reverse.

If the door is already open, it will not close and the LED indicator light will flash 10 times. See page 21.

13

Page 14

BLACK

ORANGE

Push and hold

until the door

is at desired UP

position then

release

Figure 2

Press to stop

door at desired

DOWN position

BLACK

ORANGE

Figure 4

ADJUSTMENT STEP 1

Orange

B

utton

(down)

I

ndicator

Light

B

lack

Button

(

up)

Program the Travel Limits

Travel limits regulate the points at which the door will

top when moving up or down. Follow the steps below

s

to set the limits.

Figure 1

To program the travel limits:

Adjust the position of the door by using the black

and orange buttons. Black moves the door UP

(open) and orange moves the door DOWN (close).

1. Setting the UP position: Press and hold the black

button until the yellow indicator light starts

flashing slowly then release.

2. Push and hold the black button until the door

reaches the desired UP (open) position (Figure

2).

NOTE: Check to be sure the door opens high enough

for your vehicle to pass under.

3. Push the transmitter, wireless wall button or

multi-function door control (Figure 3). This sets

the UP (open) limit and begins closing the door.

NOTE: Excessive movement of the opener will cause

premature wear. See Troubleshooting section.

4. Immediately when the door begins to move

down, press and release either the black or

orange button. This will stop the door.

5. Setting the DOWN position: Push and hold the

orange button until the door reaches the desired

DOWN (closed) position (Figure 4).

6. Once the door is closed, check for proper

pressure on the door (you should be able to

manually push the door down 2mm). If there

appears to be too much pressure on the door,

you may toggle the door back and forth using

the black and orange buttons to reach the

desired position.

7. Push the transmitter, wireless wall button or the

multi-function door control (Figure 3). This sets

the DOWN (close) limit and should bring the

door to the open position.

• If the opener is not stopping exactly where you

would like it, repeat steps 1 through 7 and

program the limits again.

• When the unit stops in both the desired up

(open) and down (close) positions, proceed to

Adjustment Step 2, Setting the Force.

Without a properly installed safety reversal

system, persons (particularly children) could be

ERIOUSLY INJURED or KILLED by a closing

S

door.

• NEVER learn forces or limits when door is

inding or sticking. Repair door first.

b

• Incorrect adjustment of the door travel limits

will interfere with proper operation of safety

reversal system.

• After ANY adjustments are made, the safety

reversal system MUST be tested. Door MUST

reverse on contact with 40mm high (1 1/2”)

object on floor.

To prevent damage to vehicles, be sure fully

open door provides adequate clearance.

Figure 2

Figure 3

or

Figure 4

14

Page 15

ADJUSTMENT STEP 2

O

range

Button

I

ndicator

Light

B

lack

B

utton

BLACK

O

RANGE

P

ush Orange button

twice to enter

u

nit into Force

Adjustment Mode

Setting the Force

The force setting button is located on the front panel.

The force setting measures the amount of force

required to open and close the door.

1. Locate the orange button on the unit (Figure 1).

. Push the orange button twice to enter unit into

2

Force Adjustment Mode (Figure 2). The LED

(Indicator Light) will flash quickly.

3. Push the transmitter, wireless wall button or

multi-function door control (Figure 3). The door

will travel to the DOWN (close) position. Push

the transmitter, wireless wall button or multifunction door control again, the door will travel

to the UP (open) position. Push the transmitter,

wireless wall button or multi-function door

control a third time to send the door to the

DOWN (close) position.

The LED (Indicator Light) will stop flashing when

the force has been learnt.

The unit has learnt the forces required to open and

close your door.

The door must travel through a complete cycle, UP

and DOWN, in order for the force to be set

properly. If the unit cannot open and close your

door fully, inspect your door to ensure that it is

balanced properly and is not sticking or binding.

See page 4, “Preparing your door.”

Figure 1

Figure 2

Figure 3

or

ADJUSTMENT STEP 3

Test Cable Tension Monitor

If your cable tension monitor has been activated

the unit will not close (the LED will flash 9 times).

See (Figure 1) page 9.

ADJUSTMENT STEP 4

Test Powered Door Lock

TEST

Without a properly installed safety reversal

system, persons (particularly children) could be

SERIOUSLY INJURED or KILLED by a closing the

door.

• NEVER learn forces or limits when door is

binding or sticking. Repair door first

• Too much force on door will interfere with

proper operation of safety reversal system.

• After ANY adjustments are made, the safety

reversal system MUST be tested. Door MUST

reverse on contact with 40mm (1 1/2”) high

obstacle on floor.

• With the door fully closed, the powered door lock

bolt should be protruding through the track.

• Operate the door in the open direction. The

powered door lock should retract before the door

begins to move.

• Operate the door in the down direction. When

the door reaches the fully closed position, the

powered door lock should automatically activate

to secure the door.

NOTE: If the powered door lock does not function, the

lock can be manually released by sliding the manual

release handle to the open position.

15

Page 16

40mm (1 1/2”) obstacle

Without a properly installed safety reversal

Safety Reversing Sensor

Safety Reversing Sensor

ystem, persons (particularly children) could be

s

SERIOUSLY INJURED or KILLED by a closing the

door.

Safety reversal system MUST be tested every

•

month.

• If one control (force or travel limits) is

adjusted, the other control may also need

adjustment.

• After ANY adjustments are made, the safety

reversal system MUST be tested. Door MUST

reverse on contact with 40mm (1 1/2”) high

obstacle on the floor.

ADJUSTMENT STEP 5

Test the Safety Reversal System

TEST

• With the door fully open, place a 40mm (1 1/2”)

obstacle on the floor, centered under the the door.

• Operate the door in the down direction. The door must

reverse on contact with the obstruction. Upon

successful safety reversal test proceed to “Adjustment

tep 6 ”.

S

ADJUST

• If the door stops on the obstruction, it is not traveling

ar enough in the down direction. Complete

f

Adjustment Steps 1 and 2 Programming the Limits

and Forces.

• Repeat the test.

• When the door reverses on the 40mm (1 1/2”)

obstacle, remove the obstruction and run the opener

through 3 or 4 complete travel cycles to test

adjustment.

• If the unit continues to fail the Safety Reverse Test,

call for a trained door systems technician.

IMPORTANT SAFETY CHECK:

Test the Safety Reverse System after:

• Each adjustment of limits, or force controls.

• Any repair to or adjustment of the door (including

springs and hardware).

• Any repair to or buckling of the floor.

• Any repair to or adjustment of the opener.

Without a properly installed safety reversing

sensor, persons (particularly children) could be

SERIOUSLY INJURED or KILLED by a closing

door.

ADJUSTMENT STEP 6

Test The Protector System

• Press the transmitter push button to open the door.

• Place the opener carton in the path of the door.

• Press the transmitter push button to close the door.

The door will not move and the LED indicator light will

flash twice.

The door opener will not close from a transmitter if the

indicator light in either sensor is flashing or off (alerting

you to the fact that the sensor is misaligned or

obstructed).

If the opener closes the door when the safety

reversing sensor is obstructed, do not operate the

door. Call for a trained door systems technician.

®

16

Page 17

OPERATION

WARNINGWARNING

N

O

T

I

C

E

Emergency

Release Handle

WARNING

Powered Door Lock

Manual Releas

Lock Bolt

“Locked”

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL WARNINGS AND

INSTRUCTIONS.

2. ALWAYS keep transmitters out of reach of children.

NEVER permit children to operate or play with the

wireless wall button, multi-fucntion door control or

transmitters.

3. ONLY activate the door when it can be seen clearly,

it is properly adjusted and there are no obstructions

to door travel.

4. ALWAYS keep the door in sight until completely

closed. NO ONE SHOULD CROSS THE PATH OF THE

MOVING DOOR.

5. NO ONE SHOULD GO UNDER A STOPPED,

PARTIALLY OPENED DOOR.

6. If possible, use emergency release handle to

disengage door ONLY when the door is CLOSED.

Weak or broken springs or unbalanced door could

result in an open door falling rapidly and/or

unexpectedly.

7. NEVER use emergency release handle unless the

doorway is clear of persons and obstructions.

8. After ANY adjustments are made, the safety

reversal system MUST be tested.

9. Safety reversal system MUST be tested every

month. The door MUST reverse on contact with

40mm (1 1/2”) high obstacle on the floor.

0. ALWAYS KEEP THE DOOR PROPERLY BALANCED

1

(see page 3). An improperly balanced door may

not reverse when required and could result in

SEVERE INJURY or DEATH.

11. ALL repairs to cables, spring assemblies and other

hardware, ALL of which are under EXTREME

tension, MUST be made by a trained door systems

technician.

12. ALWAYS disconnect electric power to the door

opener BEFORE making ANY repairs or removing

covers.

13. Permanently fix the Emergency release instruction

Label adjacent to the release handle.

14.

SAVE THESE INSTRUCTIONS.

EMERGENCY DOOR RELEASE

To prevent possible SERIOUS INJURY or DEATH from a falling door:

• If possible, use emergency release handle to disengage door ONLY when door is CLOSED. Weak or

broken springs or unbalanced door could result in an open door falling rapidly and/or unexpectedly.

• NEVER use emergency release handle unless the doorway is clear of persons and obstructions.

ADJUSTMENT STEP 7

To Open the Door Manually

Disengage door lock before proceeding. The door should be fully

closed if possible. Pull down on the emergency release handle

until a click noise is heard from the unit and lift the door

manually. To reconnect the door to the opener, pull down the

emergency release handle straight down a second time until a

click noise is heard from the unit. The door will reconnect on the

next UP or DOWN operation.

Test the emergency release:

• Make sure the door is closed.

• Pull the emergency release handle. The door should then be

able to be opened manually.

• Return the door to the closed position.

• Pull the emergency handle a second time.

• Reconnect the door to the opener.

17

Page 18

WIRELESS PROGRAMMING

1

3

C943

C

945

Your door opener has already been programmed at the factory to operate with your hand-held transmitter. The

door will open and close when you press the large centre button.

Below are instructions for programming your opener to operate with additional Security

To Add or Reprogram a Hand-held Transmitter

USING THE “LEARN” BUTTON

To Erase All Codes From

To deactivate any unwanted

transmitter, first erase all codes:

Press and hold the orange “learn”

button on opener until the learn

indicator LED goes out

(approximately 6-9 seconds).

Note:All previous codes are now erased.

Reprogram each transmitter or keyless entry you

wish to use.

3-Button Transmitters

1. Press and hold button you wish

to program to the opener.

1

If provided with your garage door opener, the large button

is factory programmed to operate it. Additional buttons on

any 3-button transmitter or mini-transmitter can be

programmed to operate other Merlin Professional garage

door openers or gate openers.

+

transmitters.

Opener Memory

2. The orange LED (indicator light)

will flash to indicate it is

receiving signal from the

transmitter.

3. Press and release the orange

button. The LED turns off

(approx. 2 sec).

2

Figure 1

3

18

Page 19

TO ADD, REPROGRAM OR CHANGE A KEYLESS ENTRY PIN

or

Carefully

Remove Battery

USING THE “LEARN” BUTTON

1. Press and release the orange

“learn” button on opener. The

earn indicator LED will glow

l

steadily for 30 seconds.

2. Within 30 seconds, enter a four

digit personal identification

number (PIN) of your choice on

the keypad. Then press and hold

the ENTER button.

3. Release the button when the

opener LED turns off.

To change an existing, known PIN

If the existing PIN is known.

1.Press the four buttons for the present PIN, then

press and hold the # button.

The LED on the opener will turn on.

2.Press the new 4-digit PIN you have chosen, then

press Enter.

The indicator LED will turn off. Code has been learnt.

Test by pressing the new PIN, then press Enter. The

door should move.

To set a temporary PIN

You may authorise access to visitors or service people

with a temporary 4-digit PIN. After a programmed

number of hours or number of accesses, this

temporary PIN expires and will no longer open the

door. It can be used to close the door even after it

has expired. To set a temporary PIN:

1.Press the four buttons for your personal entry PIN

(not the last temporary PIN), then press and hold

the * (star button).

2. Press the temporary 4-digit PIN you have chosen,

then press Enter.

3.To set the number of hours this temporary PIN will

work, press the number of hours (up to 255), then

press * (star button).

OR

3.To set the number of times this temporary PIN will

open door, press the number of times (up to 255),

then press # (hash button).

The indicator light will turn off when the temporary

PIN has been learnt.

Test by pressing the four buttons for the temporary

PIN, then press Enter. The door should move. If the

temporary PIN was set to a certain number of

openings, remember that the test has used up one

opening. To clear the temporary password, repeat

steps 1-3, setting the number of hours or times to 0

in step 3.

One Button Close: Opener can be closed by pressing

only the ENTER button if the one button close feature

has been activated. This feature has been activated

at the factory. To activate or deactivate this feature

press and hold buttons 1 and 9 for 10 seconds. The

keypad will flash twice when the one button close is

active. The keypad will flash four times when one

button close is deactivated.

The Transmitter Battery

To prevent possible SERIOUS INJURY or DEATH:

• NEVER allow small children near batteries.

• If battery is swallowed, immediately notify

doctor.

To reduce risk of fire, explosion or chemical

burn:

• Replace ONLY CR2032 batteries.

• Do NOT recharge, disassemble, heat above

75°C or incinerate.

To replace battery, use a screwdriver blade to pry open

the case as shown. Insert battery positive side up.

Dispose of old battery properly.

19

Page 20

1

N

O

T

I

C

E

6

7

8

3

4

5

2

REPAIR PARTS

041C0169-2

041A6408

041A6348-9

0

4

1

A6

3

2

0

-5

041A6095

0

41A6

2

26-6

Installation Parts

KEY PART

NO. NO. DESCRIPTION™

1 041A6102-1 Electric powered door lock

2 CM128 Wireless wall button

3 C77 Protector system

4 041A6388 Collar with set screws

5 C945 3ch rolling code transmitter

TM

(IR Beams)

Opener Assembly Parts

6 041A4582 Emergency release rope & handle

assembly

041B4494-1 2-Conductor bell wire - white &

white/red

7 041A6104-1 Cable tension monitor

8 041C0902 Mounting bracket

20

Page 21

Diagnostic Chart

“

Learn”

B

utton LED

or Diagnostic

L

ED

“

Learn”

But ton

I

nstalled

Safety Reversing

Sensor

Your door opener is programmed with self-diagnostic

capabilities. The “Learn” button/diagnostic LED will flash a

number of times then pause signifying it has found a

potential issue. Consult Diagnostic Chart below.

1 FLASH

Safety reversing sensors

wire open (broken or

disconnected).

OR

2 FLASHES

Safety reversing sensors

wire shorted or black/white

wire reversed.

3 FLASHES

multi-function

door control or

wire shorted.

4 FLASHES

Safety reversing sensors

slightly misaligned

(dim or flashing LED).

Symptom: One or both of the Indicator lights on the safety reversing sensors do not

glow steady.

• Inspect sensor wires for a short (staple in wire), correct wiring polarity

(black/white wires reversed), broken or disconnected wires, replace/attach as

needed.

• Disconnect all wires from opener.

• Remove sensors from brackets and shorten sensor wires to 30-60mm (1-2”)

from back each of sensor.

• Reattach sending eye to opener using shortened wires. If sending eye indicator

light glows steadily, attach the receiving eye.

• Align sensors, if the indicator lights glow replace the wires for the sensors. If the

sensor indicator lights do not light, replace the safety reversing sensors.

Symptom: LED is not lit on multi-function door control.

• Inspect Multi-Function Door Control/wires for a short (staple in wire), replace as

needed.

• Disconnect wires at multi-function door control, touch wires together. If opener

activates, replace multi-function door control.

• If opener does not activate, disconnect multi-function door control wires from

opener. Momentarily short across red and white terminals with jumper wire. If

opener activates, replace multi-function door control wires.

Symptom: Sending indicator light glows steadily, receiving indicator light is dim or

flashing.

• Realign receiving eye sensor, clean lens and secure brackets.

• Verify door track is firmly secured to wall and does not move.

5 FLASHES

Symptom: The RPM Sensor = Short travel 150-200mm (6-8").

Possible RPM sensor

failure. Unplug to reset.

• Unplug unit to reset. Try to operate opener, check diagnostic code.

• If it is still flashing 5 times and opener moves 150-200mm (6-8"), the unit’s APE

(Absolute Positioning Encoder) may need to be replaced, for details contact your

Chamberlain reseller.

9 FLASHES

Cable tension monitor

reversal.

Symptom: Door reverses while closing.

• Check for possible door obstructions and remove.

• Check that the cable tension monitor is properly connected to the opener.

• Replace the cable tension monitor.

21

Page 22

TROUBLESHOOTING

1. The opener doesn't operate from either the multifunction door control, wireless wall button or the

transmitter:

• Does the opener have electric power? Plug a lamp into

the outlet. If it doesn't light, check the fuse box or the

circuit breaker. (Some outlets are controlled by a wall

switch.)

• Have you disabled all door locks? Review installation

instruction warnings on page 7.

• Is there a build-up of ice or snow under the door? The

door may be frozen to the ground. Remove any

restriction.

• The door spring may be broken. Have it replaced (see

page 5 for reference).

2. Opener operates from the transmitter, but not from

the Wireless Wall Button:

• Check the LED on the Wireless Wall Button to ensure

the LED turns on when button is pushed. If the LED is

weak or not on Change the batteries. (Remove cover

and replace with CR2032 batteries X 2)

• If the LED turns on and is strong check to ensure the

unit is programmed into the unit (see page 19).

3. The door operates from the multi-function door

control but not from the transmitter:

• Is the door push bar flashing? If so, Lock mode is

engaged. Make sure it is off by pressing the

Lock button for two seconds.

• Program the opener to match the transmitter code.

(Refer to instructions on the opener panel.) Repeat with

all Transmitter.

4. The transmitter has short range:

• Change the location of the transmitter in your car.

• Check to be sure the antenna on the side or back panel

of opener extends fully downward.

• Some installations may have shorter range due to a

metal door, foil backed insulation, or metal

siding.

5. The door opens and closes by itself:

• Be sure that all transmitter push buttons are off.

• Remove the bell wire from the mulit-function door

control terminals and operate from the transmitter only.

If this solves the problem, the multi-function door

control is faulty (replace), or there is an intermittent

short on the wire between the control console and the

opener.

• Clear memory and re-program all transmitters.

6. The door doesn't open completely:

• Check powered door lock.

• Is something obstructing the door? Is it out of balance,

or are the springs broken? Remove the obstruction or

repair the door.

7. The door opens but won't close:

• Check cable tension monitor (see installation step 4).

• If the opener LED is flashing, check the safety

reversing sensor. See Installation Step 8.

• If the opener LED is not flashing and it is a new

installation. See Adjustment Step 2. For an existing

installation, see below.

Repeat the safety reverse test after the adjustment

is complete.

8. The door reverses for no apparent reason and

opener LED doesn’t flash:

Check cable tension monitor (see installation step 4).

•

• Is something obstructing the door? Pull the emergency

release handle. Operate the door manually. If it is

unbalanced or binding, call a trained door systems

technician.

• Clear any ice or snow from the floor area where the

door closes.

• Review Adjustment Step 2.

Repeat safety reverse test after adjustments.

9. The door reverses for no apparent reason and

opener LED flashes for 5 seconds after reversing:

• Check the safety reversing sensor. Remove any

obstruction or align the receiving eye. See Installation

Step 8.

10. The opener strains to operate door:

• The door may be out of balance or the springs may be

broken. Close the door and use the emergency

release handle to disconnect the door. Open and close

the door manually. A properly balanced door will stay

in any point of travel while being supported entirely by

its springs. If it does not, disconnect the opener and

call a trained door systems technician.

11.The opener motor hums briefly, then won't work:

• The door springs may be broken. See above.

• If the problem occurs on the first operation of the

opener, door may be locked. Disable the powered door

lock.

12.The opener won't operate due to power failure:

• Manually open the powered door lock.

• Use the emergency release handle to disconnect the

door. The door can be opened and closed manually.

When power is restored, pull manual release a second

time.

• If an EverCharge Unit is connected, the opener should

be able to operate up to 20 times without power.

13. Door loses limits.

• Collar not tightened securely. Tighten collar

(see Assembly Steps 1 and 2) and reprogram limits

(see Adjustment Step 1).

14. The opener moves when the door is in operation:

• Some minor movement is normal for this product. If it

is excessive the collar will wear prematurely.

• Check to make sure the torsion bar is not moving

left/right excessively.

• Check to make sure the torsion bar is not visibly

moving up and down as it rotates.

• Check that the opener is mounted at a right angle to

the jackshaft. If not, move the position of the mounting

bracket.

15. Power lock makes noise when operating.

®

• Call your local Merlin

dealer or Chamberlain customer

service for replacement power lock.

22

Page 23

OPERATION OF YOUR OPENER

LO

C

K

L

IG

H

T

L

O

C

K

L

IG

H

T

Your merlin®Security+opener and hand-held

transmitter have been factory-set to a matching

code which changes with each use, randomly

accessing over 100 billion new codes. Your opener

ill operate with up to 64 merlin

w

transmitters and one Keyless Entry System. If you

purchase a new transmitter, or if you wish to

deactivate any transmitter, follow the instructions in

the Programming section.

Activate your opener with any of the following:

• The hand-held transmitter: Hold top middle button

down until the door starts to move.

• The wireless wall button CM128 press and hold the

large round button down until the door starts to

move.

• The Keyless Entry (See Accessories): Must be

programmed before use. See Programming.

• Multi-Function Door Control

When the opener is activated (with the safety reversing

sensor correctly installed and aligned)

1. If open, the door will close. If closed, it will

open.

2. If closing, the door will reverse.

3. If opening, the door will stop.

4. If the door has been stopped in a partially open

position, it will close.

5. If obstructed while closing, the door will stop

and reverse. The LED indicator light will flash.

6. If obstructed while opening, the door will stop.

7. If fully open, the door will not close when the

beam is broken. The sensor has no effect in the

opening cycle.

If the sensor is not installed, or is misaligned, the

door won’t close from a hand-held transmitter or

wireless wall button. However, you can close the

door with the multi-function door control, the

Outside Keylock, or Keyless Entry, if you activate them

until down travel is complete. If you release them too

soon, the door will reverse.

®

S

ecurity

+

Using your C945 3ch Mini-Transmitter

Using your CM128 Wireless Wall Button

Using your Multi-Function Door Control

CARE OF YOUR OPENER

MAINTENANCE SCHEDULE

Once a Month

•

Manually operate door. If it is unbalanced or

binding, call a trained door systems technician.

• Check to be sure door opens & closes fully.

Adjust limits and/or force if necessary (see

Adjustment Steps 1 and 2).

• Repeat the safety reverse test. Make any

necessary adjustments (see Adjustment Step 5).

Once a Year

• Oil door rollers, bearings and hinges. The opener

does not require additional lubrication. Do not

grease the door tracks.

23

Page 24

CHAMBERLAIN LIMITED WARRANTY

Merlin®Professional MJ3800

Sectional Garage Door Opener

Chamberlain Australia Pty Limited / Chamberlain New Zealand Limited

(Chamberlain), the manufacturer of Merlin

committed to manufacturing and supplying high quality goods. As part of this

commitment, we seek to provide reliable service and support for our goods and are

pleased to provide you, the original purchaser, with this Chamberlain Limited

Warranty.

The benefits given to you under this Chamberlain Limited Warranty are in addition to

any rights and remedies that you may have under Australian or New Zealand

consumer protection laws. Our goods come with guarantees that cannot be

excluded under the Australian Consumer Law, or New Zealand Consumer

Guarantess Act 1993. You are entitled to a replacement or refund for a major failure

and for compensation for any other reasonably foreseeable loss or damage. You

are also entitled to have the goods repaired or replaced if the goods fail to be of

acceptable quality and the failure does not amount to a major failure.

Chamberlain’s warranty

What is covered

Chamberlain warrants to the original purchaser of the Merlin MJ3800 Sectional Door

Opener (Unit) that all parts of the Unit, other than remote controlled transmitters,

battery back up units and accessories, globes and batteries, are free from defects in

materials and workmanship for a period of 24 months or 5,000 cycles (each opening

& closing of the garage door equals 1 cycle) whichever comes first, from the date of

purchase when installed by a Professional dealer appointed or authorised by

Chamberlain in a residential premise with a residential specified garage door that is

designed for the sole purpose of a single-family dwelling. Chamberlain warrants the

motor component of the opener for 5 years or 15,000 cycles whichever comes first.

Chamberlain warrants that remote controlled transmitters and accessories included

with the Unit are free from defects in materials and workmanship for a period of 12

months from the date of purchase.

What is not covered

Batteries and globes are not covered under the Chamberlain Limited

Warranty.

Travel costs incurred by Chamberlain or the Professional Dealer in either travelling

to or from areas outside a capital city metropolitan area. These costs will be at the

purchaser’s expense.

Additional access costs incurred by a Professional Dealer or Chamberlain in

obtaining access where the Unit is not readily accessible. These cost will be at the

purchaser’s expense.

Warranty Conditions

It is a condition of this Chamberlain Limited Warranty that the Unit is sold, installed

and serviced by a Professional Dealer appointed or authorised by Chamberlain. A

Merlin branded garage door opener purchased over the internet and installed by a

person other than a Professional Dealer will not be covered by this Chamberlain

Limited Warranty.

It is also a condition of this Chamberlain Limited Warranty that for the operating life

of the Unit:

1 the garage door is spring balanced, is operable by hand and opens

and closes with no more than a maximum of 20 kgs of lifting weight;

2 the garage door and the Unit is professionally maintained and serviced

by a Professional Dealer, at a minimum, during the third and fifth years

of the Chamberlain Limited Warranty period such that the spring

balanced door operates according to manufacturer specifications. If

your door binds, sticks, or is out of balance, then it must not be used

until serviced by a trained door technician or Profesional Dealer. The

garage door service fee will be at the purchaser’s expense;

3 the warranty is registered by completing the online form at

ww.gomerlin.com.au or www.gomerlin.co.nz; and

w

4 you retain your sales docket or invoice as proof of purchase, and attach it

to this manual to enable you to establish the date of purchase in the

unlikely event of a warranty service being required.

Making a claim

During the applicable Chamberlain Limited Warranty period, if you are concerned

that the Unit may be defective, call the Professional Dealer that sold/installed the

opener, or our service centre on the toll free number below and a Chamberlain

technician will diagnose the problem and arrange for this to be rectified. Once the

problem has been diagnosed, subject to your rights under the applicable Australian

and New Zealand consumer protection laws with respect to major failures,

Chamberlain or its Professional Dealer will provide you with either, repairs to the

Unit or a replacement Unit.

Repairs and replacement parts provided under this Chamberlain Limited Warranty

are provided free of charge and are warranted for the remaining portion of the

original warranty period.

This Chamberlain Limited Warranty provides benefits which are in addition to your

other rights and remedies as a consumer.

114A4085E

®

automatic garage door openers, is

Exclusions - what voids the warranty

If our service centre determines that a warranty claim has been made in

respect of a failure or defect arising under or out of any exclusion detailed

below such that the claim is not covered under this Chamberlain Limited

Warranty, we may, subject to your other rights and remedies as a consumer,

charge you a fee to repair, replace and/or return the Unit to you.

This Chamberlain Limited Warranty does not cover any failure of, or defect

in, the Unit due to:

1 non-compliance with the instructions regarding specifications, installation,

operation, maintenance and testing of the Unit or of any product with

which the Unit is used;

2 any attempt by a person other than a Professional Dealer to repair,

dismantle, reinstall or move the Unit to another location once it has been

installed;

3 tampering, neglect, abuse, wear and tear, accident, electrical storm,

excessive use or conditions other than normal domestic use;

4 problems with, or relating to, the garage door or garage door hardware,

including but not limited to the door springs, door rollers, door alignment

or hinges;

5 problems caused by electrical faults or replacement of batteries or light

bulbs, blown fuses, electrical surges, power surges or power strikes, fire,

flood, rain, water, lightning or storms;

6 water or moisture ingress that causes corrosion or electrical malfunction;

7 corrosion caused by sea air if located near a waterway, beach etc;

8 fitment to a commercial door or in a commercial operating application,

installation of a residential garage door opener in a commercial or

industrial premises other than a single-family dwelling.

9 lack of proper maintenance, service or care of the door and Unit;

10 any unauthorised modification to the Unit; or

11 damage caused by insects, pests or other after sale damage caused by

events or accidents outside Chamberlain’s reasonable control and not

arising under normal and standard operating conditions.

NB: A General Purpose Outlet (GPO) ie: power point must be supplied by the

consumer as this electrical fitting does not form a part of the Unit (opener).

If this Chamberlain Limited Warranty does not apply, you may have rights

available to you under the Australian and New Zealand consumer protection

laws.

Liability – Australia only

Except as set out in the Australian Consumer Law (being Schedule 2 of the

Competition and Consumer Act 2010) (as amended, consolidated or

replaced):

1 all other guarantees, warranties and representations in relation to the Unit

or its supply are excluded to the extent that Chamberlain can lawfully

exclude them; and

2 under no circumstances will Chamberlain be liable for consequential,

incidental or special damages arising in connection with the use, or

inability to use, the Unit, other than those which were reasonably

foreseeable as liable to result from the failure.

Liability – New Zealand only

Except as set out in the Fair Trading Act 1986 and the Consumer

Guarantees Act 1993 (as amended, consolidated or replaced):

1 all other guarantees, warranties and representations in relation to the Unit

or its supply are excluded to the extent that Chamberlain can lawfully

exclude them; and

2 under no circumstances will Chamberlain be liable for consequential,

incidental or special damages arising in connection with the use, or

inability to use, the Unit, other than those which were reasonably

foreseeable as liable to result from the failure.

Note

Chamberlain reserves the right to change the design and specifications of

the Unit without prior notification. Some features or accessories of the Unit

may not be available in certain markets or areas. Please check with your

distributor.

Chamberlain service centre contact details

Australia

Phone toll free 1800 638 234

Fax toll free 1800 888 121

Website: gomerlin.com.au

CChhaammbbeerrllaaiinn AAuussttrraalliiaa PPttyy.. LLttdd..

Unit1, 75 Epping Road

North Ryde NSW 2113

(PO BOX 1446, Lane Cove NSW 1595)

Email: customerservice@chamberlainanz.com

TM

Trademark of The Chamberlain Group, Inc.

New Zealand

Auckland phone 09 477 2823

Phone toll free 0800 653 667

Fax toll free 0800 653 663

Website: gomerlin.co.nz

® Registered Trademark of The Chamberlain Group, Inc.

© 2014, The Chamberlain Group Inc.

Loading...

Loading...