Page 1

WingMate

3

Installation and operation instructions

for MGA600 ARTICULATED Gate Motor.

DESIGNED FOR PROFESSIONAL INSTALLATION

ONLY

Chamberlain Australia Pty Ltd

PO Box 1446

Lane Cove NSW 1595

Phone Toll Free 1800 638 234

Chamberlain New Zealand Ltd

PO Box 100-221

North Shore 0745

Phone Toll Free 0800 653 667

www.go-merlin.com

Articulated Swing Gate Opener

For gates up to 3 meters

Owners Copy: Please keep these instructions for future reference

Page 2

1

Do not wear rings, watches or loose clothing while

servicing or installing a gate opener.

Installation and wiring must be in compliance with

your local building and electrical installation codes.

Power cables must only be connected to a properly earthed supply.

Entrapment between the moving gate and walls

due to the opening movement must be avoided by

using safety edges or IR sensors when necessary.

Please remove any locks fitted to the gate in order to

prevent damage to the gate. A special E-Lock is

available as accessory.

After installation, ensure that the gate opener system is properly adjusted and that the safety system and the manual release function correctly.

This drive must not be used with a gate incorporating a wicket door.

The actuating member of a biased-off switch, if installed, is to be located within direct sight of the

gate but away from moving parts. Unless it is key

operated, it is to be installed at a minimum height of

1.5m and not accessible to the public.

It is important to make sure that the gate always

runs smoothly. Gates which stick or jam must be

repaired immediately. Employ a qualified technician to repair the gate, never attempt to repair it

yourself.

Keep additional accessories away from children.

Do not allow children to play with any controls.

Keep remote controls away from children. Operate gate when it is in full view and no one is near

the gate. A gate can cause serious injuries or

death as it opens or closes.

Connect the gate opener to a properly

EARTHED general purpose 240 V mains power

outlet installed by a qualified electrical contractor.

DISCONNECT THE POWER CORD from the

mains power before making any repairs or removing covers. Only EXPERIENCED service

personnel should remove covers from the gate

opener.

Make sure that people who install, maintain or

operate the gate drive follow these instructions.

Keep these instructions in a safe place so that

you can refer to them quickly when you need to.

The gate drive system is to be regularly examined for any signs of wear and tear or damage.

The gate drive system must not be used if repair

or adjustments are needed.

This safety alert symbol means "Caution" - failure to comply with such an instruction involves risk of personal injury or

damage to property. Please read these warnings carefully.

This gate drive mechanism is designed and tested to offer appropriately safe service provided it is installed and operated

in strict accordance with the following safety rules.

Incorrect installation and/or failure to comply with the following instructions may result in serious personal injury or

property damage.

PLEASE START BY READING THESE IMPORTANT SAFETY RULES

IMPORTANT ADVICE: THESE INSTRUCTIONS ESSENTIALLY DESCRIBE THE INSTALLATION OF THE MGA600 DRIVE WITH THE ACCESSORY ARM ART-3, FOR INSTALLATION ON A SWING GATE

IF THE ART-1 FOLDING GATE ARM OR THE SPACE-SAVING ART-2 GATE ARM ARE INSTALLED IT IS ESSENTIAL TO FOLLOW THE INSTRUCTIONS INCLUDED WITH THOSE ITEMS. THE INSTALLATION WORK VARIES FROM THESE INSTRUCTIONS AT SOME POINTS.

WARNING AND SAFETY ADVICE IS EXCEPTED FROM THIS.

BEFORE YOU BEGIN

The MGA is suitable for use with wide pillars, up to about 30cm in width. The maximum recommended opening angle

of the gate is 125 degrees. Ensure that ample space is available next to the drive for the arms and assembly. Gates

exposed to a high wind load must be fixed with an electric lock for additional protection. While the drive is fitted with

internal limit switches, stops should also be mounted on the ground to prevent gate rattle or flutter. There are many

factors to consider when choosing the right drive mechanism. Assuming that a gate functions properly, "startup" is the

most difficult phase, once the gate is in motion, significantly less force is usually required to move it.

• Gate size: The gate size for this drive must not be more than 3.0m. Wind can brake or distort the gate, thereby in-

creasing the amount of force needed to move it considerably.

• Gate weight: The weight of the gate must not be more than 250kg.

• Effect of temperature: Be sure that the ambient temperature where the drive is installed will be between -20 to

+55C

0

deg since low outdoor temperature can prevent the motor from starting. High outdoor temperatures along with

frequent use can cause the motor thermal protection to operate. Wait 15 minutes if this has occurred.

Page 3

2

WAR NINGS

W

arnings and Precautions . . . . . . . . . . . . . . . . . . . . . . . .1

C

arton Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

GATE M OTOR INSTALLATION

Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Gate Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

G

ate Motor Installation . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

M

anual Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CO NTROL BOAR D INS TALLATION

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Safety Installation Information . . . . . . . . . . . . . . . . . . . . . .7

Control Board Specifications . . . . . . . . . . . . . . . . . . . . . . .8

Cable Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Mount The Control Box . . . . . . . . . . . . . . . . . . . . . . . .9-10

Wiring Single Motor To Control Board . . . . . . . . . . . .11-12

Wiring Dual Motors To Control Board . . . . . . . . . . . .13-14

Installation of Safety IR Beams . . . . . . . . . . . . . . . . . . . .15

B

AS IC CO NTROL BOAR D SETU P

BiPart Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

C

onnecting Control board to GPO . . . . . . . . . . . . . . . . .16

C

onnecting Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Setting the CAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-20

F

orce Setting/Timer to Close/Party mode . . . . . . . . . . .21

Program Remote Control Transmitters . . . . . . . . . . . . . .22

OP ERATI ON an d MAI N TENA N C E

Operation of your Gate Opener . . . . . . . . . . . . . . . . . . .23

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Control Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27-29

Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

M

anual

1.

2.

3.

4.

5.

6.

7.

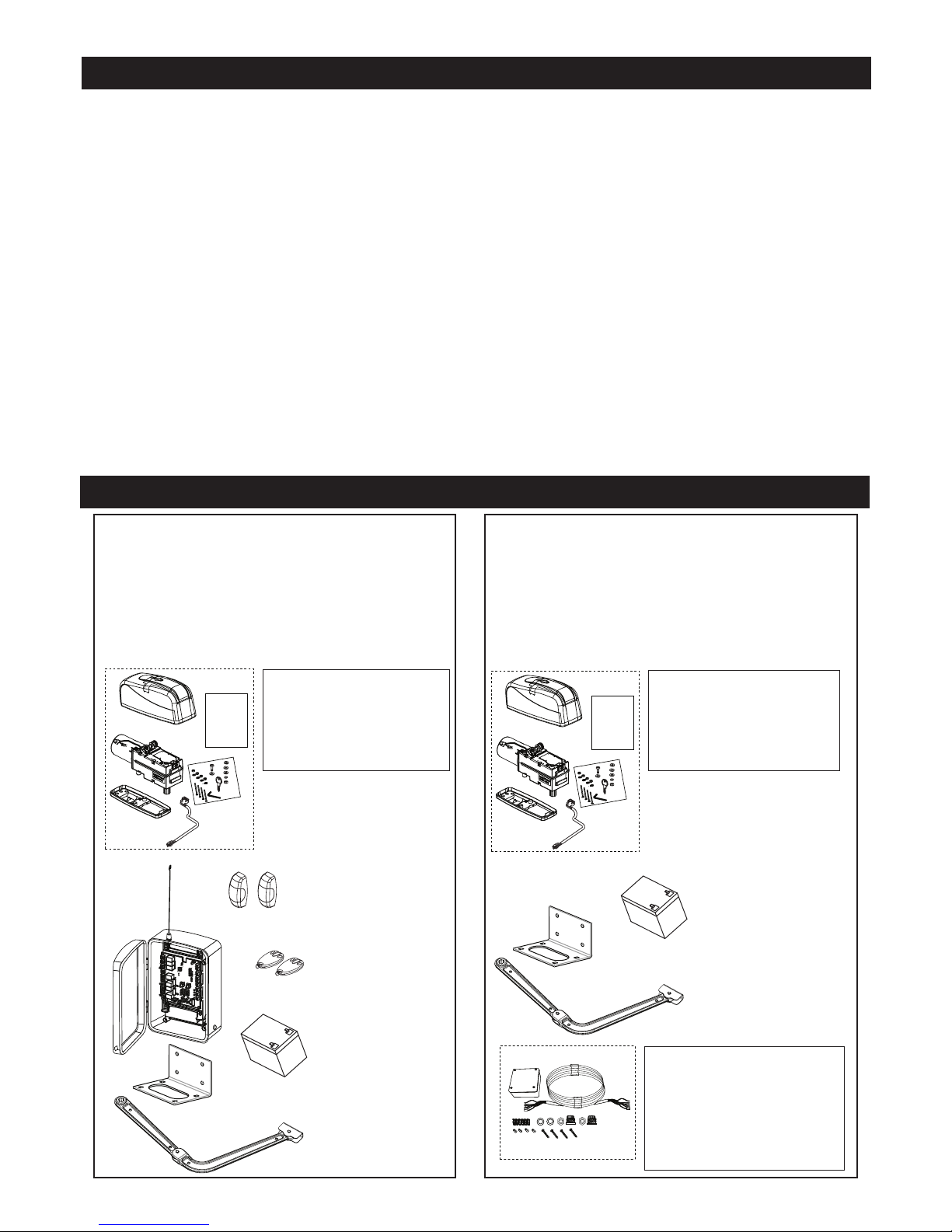

1. MGA Carton Contents:

• Motor x1

• Release key x1

• Hardwarebag x1

• Manual x1

MGA600M Carton Contents (Master Kit):

1. MGA x1

2. CB12ANZ (Control Board)

3. ART-3AL x1

4. ART-7 (041AART-0007) x1

5. Battery (MER150) to suit CB12ANZ x1

6. Transmitters C945 x2

7. 772ANZ IR Beams x1

Manual

1.

2.

3.

4.

5. JB12M

1. MGA Carton Contents:

• Motor x1

• Release key x1

• Hardwarebag x1

• Manual x1

5. JB12M CONTENTS:

• Junction Box x1

• Extension Cable - Six Conductor

(12.2m) x1

• Terminal Block - 12 Connectors x1

• Anchors x4

• Phillips Head Mounting Screws x4

• Strain Relief with Mounting Nut x2

MGA600S Carton Contents (Slave Kit):

1. MGA x1

2. ART-3AL x1

3. ART-7 (041AART-0007) x1

4. Battery (MER150) to suit CB12ANZ x1

5. JB12M (LA400-JB40 kit) x1

T A B L E O F C O N T E N T S

C A R T O N C O N T E N T S

Page 4

3

I

NSTALLATION CHECKLIST - PREPARATIONS

Check the carton contents and read the instructions carefully. Make sure your gate equipment operates perfectly. The

gate must run evenly and smoothly and must not stick at any point. Remember that the ground level may be several

centimeters higher in winter. The gate must be stable and as free of backlash as possible in order to prevent any unwanted

t

o and fro movement. The more smoothly the gate leaf runs, the more sensitive the force adjustment must be.

N

ote down any materials you still need and obtain them before starting to install. Heavy-duty plugs, bolts, gate stops,

cables, distribution boxes, tools, etc.

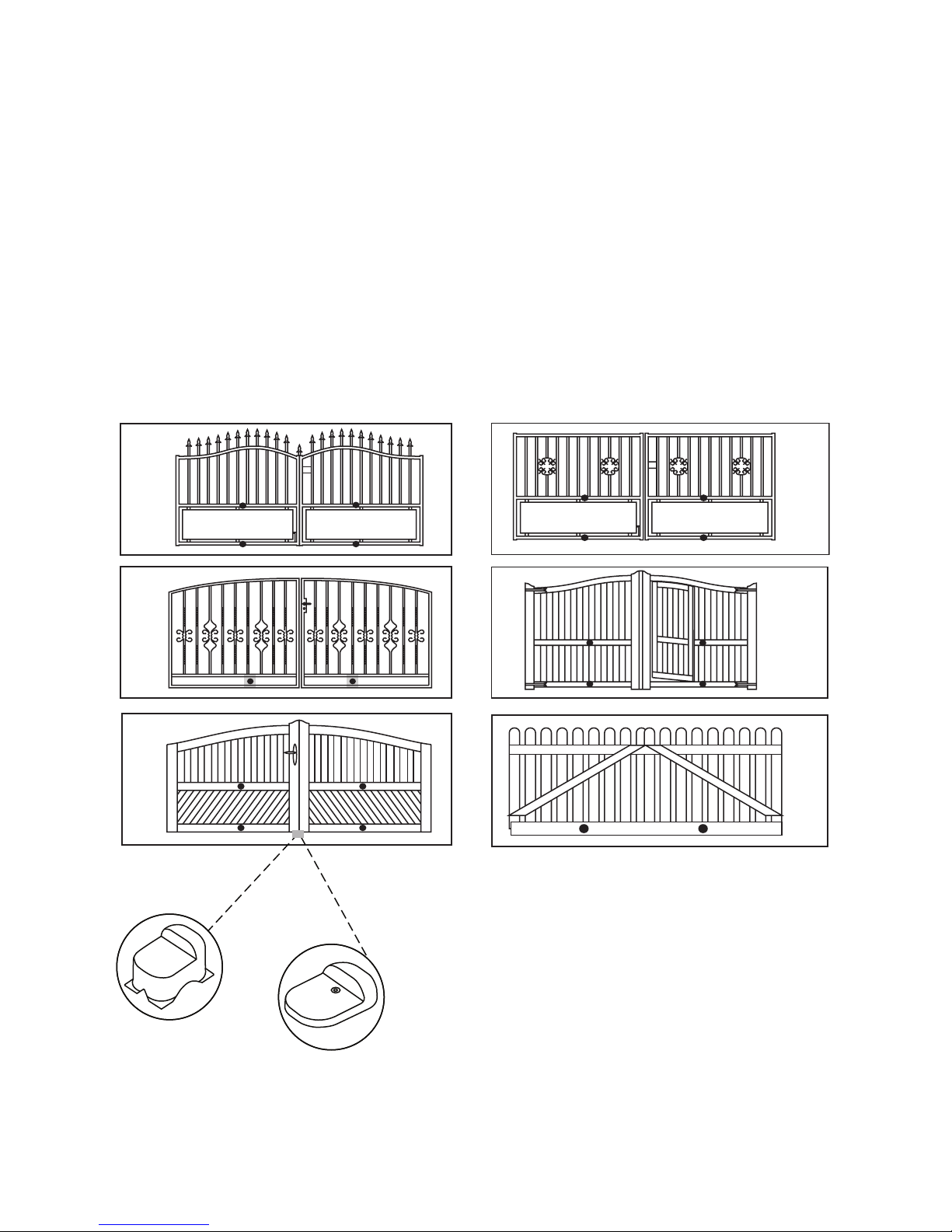

GATE TYPES

T

he gate type determines the location where the drive mechanism is installed. If the gate stop is on the ground, the drive

mechanism must also be installed at a height that is as low as possible so that it cannot twist the gate. Use only parts of

the gate frame for fixing purposes.

For steel gates, the gate fitting must be attached to the main frame. If you are uncertain whether the available support is

sufficiently stable, reinforce it.

In the case of wooden gates, the gate fitting must be through bolted. It is advisable to fit a plate from the outside so that

the fixing brackets cannot become loose over time. Thin wooden gates must also be reinforced in order to withstand the

stresses encountered.

FOR TWO GATE APPLICATION A FIXED GATE STOP MUST BE INSTALLED.

Gate stops save wear and tear on the drive mechanism, gate and fittings. Operating a

gate without fixed limit stops results in poor performance. It is often dangerous, leads

to premature wear in the case of heavy gates often exposed to wind stress.

Page 5

4

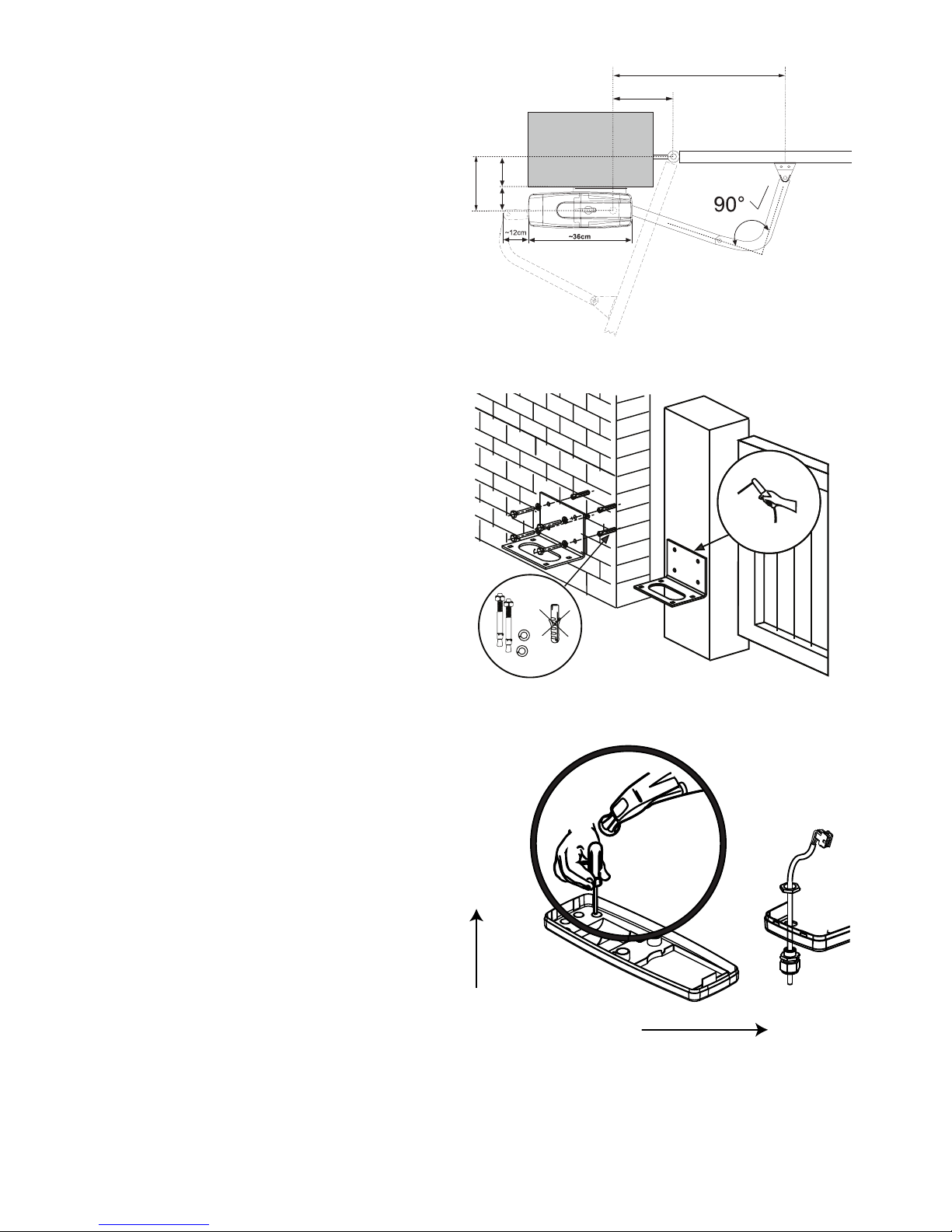

M

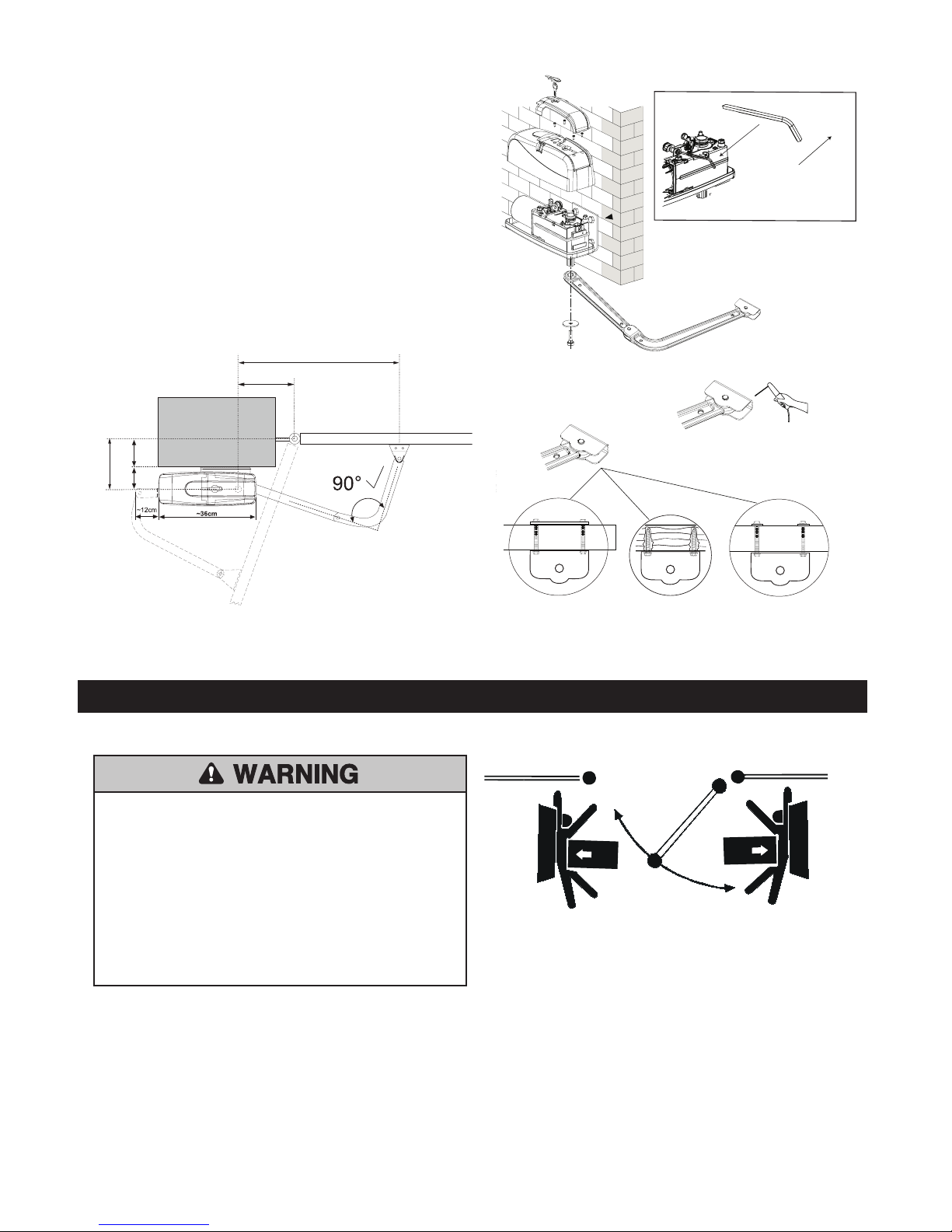

OUNTING REQUIREMENTS

The gate drive mechanism is suitable for use in conjunction

with pillars with a max. thickness of 30cm. The amount of

room around the pier affects the opening angle and the pos

ition of the arms. The drive mechanism is equipped with

built-in limit stops for both the OPEN and CLOSE directions. A different opening angle can be set for the left-hand

wing as compared with the right-hand one.

A=38,5cm

8,5cm

30cm

C

B=60-70cm

7-8 cm = 90°

max. 10 cm

=

INSTALLATION

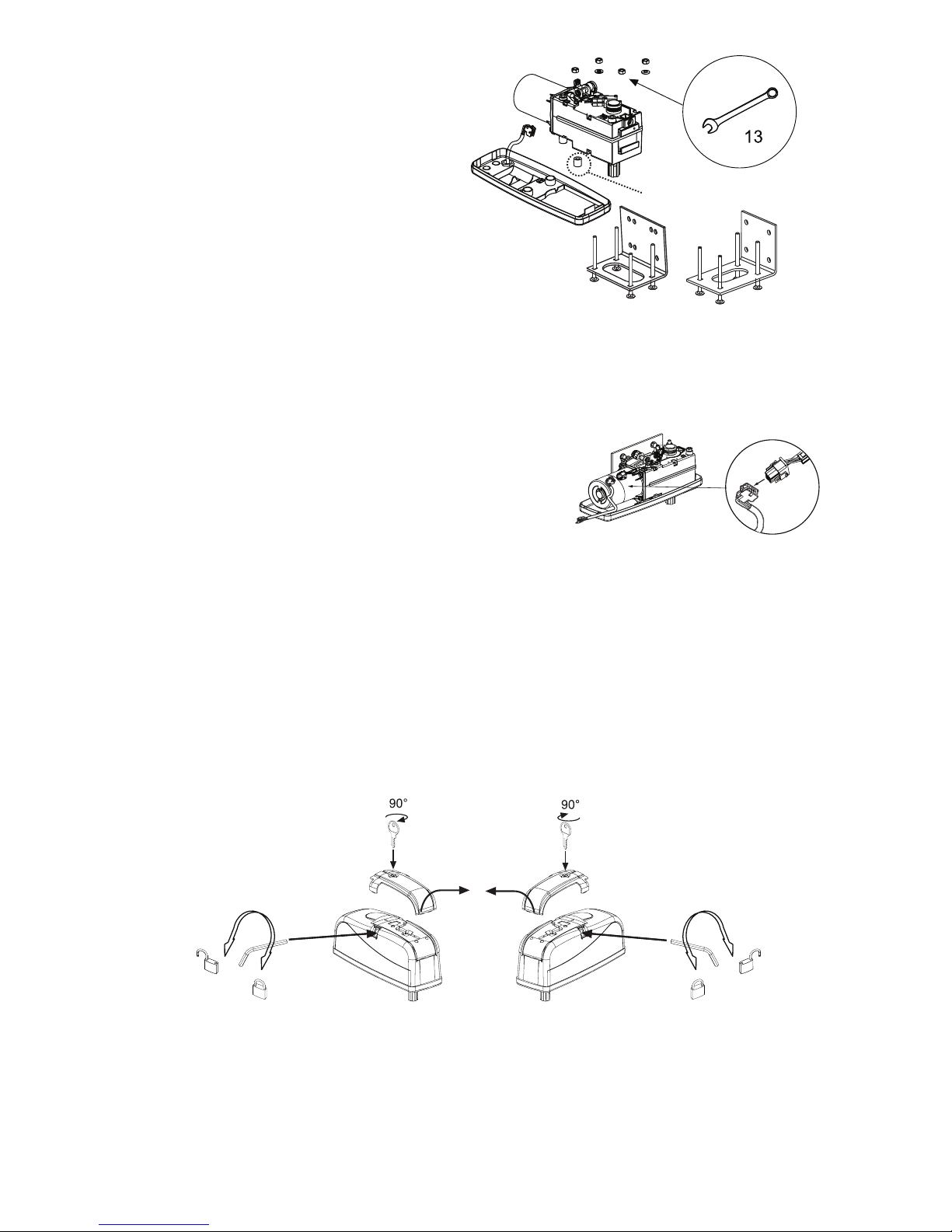

Step 1 Install Motor Bracket

For Stone or reinforce concrete pillars use Dynabolts or

Chemical anchors (not supplied) to mount the motor support bracket onto the wall at the desired height. The gate

motor exerts a considerable force, ensure the wall is suitable. It may be necessary to use metal reinforcing, if so

weld the bracket onto the brace to prevent damage to the

wall and or motor.

If fastening to brickwork CHEMICAL ANCHORS should

be used and metal reinforcing is highly recomended.

DO NOT USE PLASTIC ANCHOR TO MOUNT THE

BRACKET IN PLACE.

Step 2 Prepare the Motor Housing

Taking note of the the Motorʼs orientation, carefully knock

out one of the four tap in the base housing as illustrated to

allow for cable entry. Several openings for the cable have

been pre-punched in the base and need only be broken

through. Place the base plate onto a solid surface whilst

breaking the holes through to prevent the PVC base plate

from breaking. A small, flat screwdriver should be used for

breaking the holes through. For this purpose, tap on the

screwdriver handle with the palm of the hand from the inside. Repeat this as necessary at several points on the premarked circle. The pre-punched area can then be easily

removed and the strain relief supplied as standard fitted in

its place.

Thread the Terminated Loom through the gland nut and into

the hole knocked out for cable entry. Thread the gland over

the cable and through the knockout hole as illustrated. Fasten the Gland in place firmly with the nut. Hand tighten the

bottom nut, allowing around 200mm of cable to protrude.

Knock out

PILLAR SIDE

Gate

Wall or

Pillar

Page 6

5

S

tep 3 Mounting the motor to the Wall Bracket.

Once the Wall Bracket has been mounted, the drive can be

fitted. The drives can be used left or right without conversion.

Using the hardware provided fit the Base Plate onto the Wall

Bracket. Place the Spacer provided into place as illustrated,

then insert the bolts provide through the square hole in the

Walll Bracket.

Ensure the connection cable is correctly positioned, and the

bolts are fitted correctly. Hand tighten the nuts to secure the

motor in postion, then using the washers and nuts provided

to fasten the motor securely in place using 13mm spanner

(not provided).

ART-7

Standard Base

Plate

ART-6

For Narrow

Pillars

or

Spacer

Step 4 Connect Motor to Loom.

Connect the Connection Cable in the motor as illustrated (fig1).

Step 5 Manual Release.

The release lock for the casing is located under the rubber waterproof cover. Use the socket spanner supplied in the

hardware bag to lift the cover up. The release key located beneath the hood should be inserted into the side openings

and turned approx. 180 degrees until it cannot turn any further. The drive has now been released. To re-engage it, the

key should be turned back to its original position.

NOTE: Take care when unlatching the drive for manual operation. The gate panel can move in an uncontrolled

way, especially if it is mounted in a sloped position.

fig 1

Page 7

6

I N S T A L L A T I O N

To prevent SERIOUS INJURY or DEATH from a moving gate:

• Entrapment protection devices MUST be installed to protect

anyone who may come near a moving gate.

• Locate entrapment protection devices to protect in BOTH

the open and close gate cycles.

• Locate entrapment protection devices to protect between

moving gate and RIGID objects, such as posts.

• A swinging gate shall NOT open into public access ways.

01-G0665F18

SA FETY PREC A UTIO NS FOR SW ING an d O RNAM ENTAL “G RILL TY P E GATE S”

NOTE: It is recommended an E-lock or Maglock be used on gates over 2m for added security against vandalism and adverse

weather.

Disengage

A=38,5cm

8,5cm

30cm

C

B=60-70cm

7-8 cm = 90°

m

ax. 10 cm

=

Step 6 Fit the Gate Arm.

Use the Relase Key provided in your hardware bag to

Disenage the Motor by turning the Hex head nut located

on the top of the motor.

Assemble your Gate Arm and fasten in place using the

bolt and washer provided.

The Gate Arm exerts considerable forces on the gate and

all fixings. For this reason the Gate Arm MUST BE FASTENED SECURELY to the gate frame. Where possible

Weld the bracket in place for metal gates. For Timber

gates through bolts should be used.

Use the Mounting Requiments outlined below for mounting requirements and bracket locations.

Page 8

7

S A F E T Y I N S T A L L A T I O N I N F O R M AT I O N

Warning - To reduce the risk of SEVERE INJURY or DEATH from an incorrect installation:

1. Vehicular gate systems provide convenience and security. Gate systems are comprised of many component parts. The gate operator is only one component. Each gate system is specifically designed for an individual application.

2. Gate operating system designers, installers and users must take into account the possible hazards associated with each individual

component. Poorly designed, installed or maintained gate systems may be dangerous to users and bystanders. Gate installers

and designers should therefore take steps to reduce the publicʼs exposure to potential hazards.

3. A gate operator can generate a great deal of force during operation, installers must be mindful of this fact. Safety features must be

incorporated into every design. Specific safety features include:

•

Gate Edges • Guards for exposed rollers • Photoelectric Sensors

• Vertical Posts • Instructional and Precautionary Signage

4

. A gate opener should only be installed where:

a. The operator is appropriate for the construction and the usage class of the gate.

b

. All exposed pinch points are eliminated or guarded, and guarding is supplied for exposed rollers.

5. The operator is intended for installation only on vehicular gates only, pedestrians should be supplied with a seperate access

6

. The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when

opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

7. The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

8. Controls must be far enough from the gate so that the user is prevented from coming in contact with the gate while operating the

controls.

9. Any warning signs must be clearly visible, on each side of the gate.

10. For a gate operator utilising a non-contact sensor:

a. Reference ownerʼs manual regarding placement of non-contact sensor for each type of application.

b. Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle trips the sensor while the gate is still

moving.

c. One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the perimeter

reachable by a moving gate or barrier.

11. For a gate operator utilizing a contact sensor such as an edge sensor:

a. A hard wired contact sensor shall be located and its wiring arranged so the communication between the sensor and the gate

operator is not subject to mechanical damage.

b. A wireless contact sensor such as the one that transmits radio frequency (RF) signals to the gate operator for entrapment pro-

tection functions shall be located where the transmission of the signals are not obstructed or impeded by building structures,

natural landscaping or similar obstruction. A wireless contact sensor shall function under the intended end-use conditions.

c. One or more contact sensors shall be located at the leading edge, trailing edge and post mounted both inside and outside of a

vehicular horizontal slide gate.

d. One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

e. One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if the bottom

edge of a swing gate is greater than 15cm (6”) above the ground at any point in its arc of travel, one or more contact sensors

shall be located on the bottom edge.

IMPO RTANT SAFE OPERATING/MAINTENANCE

INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. NEVER allow children to operate or play with gate

controls. Keep the remote control away from children.

3. ALWAYS keep people and objects away from the

gate. NO ONE SHOULD CROSS THE PATH OF

THE MOVING GATE.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an

object activates the non-contact sensors. After adjusting the force or the limit of travel, retest the gate

operator. Failure to adjust and retest the gate operator properly can increase the risk of INJURY or

DEATH.

5. Use the manual release ONLY when the gate is not

moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the

ownerʼs manual. Have a qualified service person

make repairs to gate hardware.

7. The entrance is for vehicles ONLY. Pedestrians

MUST use separate entrance.

8. This appliance is not intended for use by persons

(including children) with reduced physical sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a

person responsible for their safety.

Page 9

8

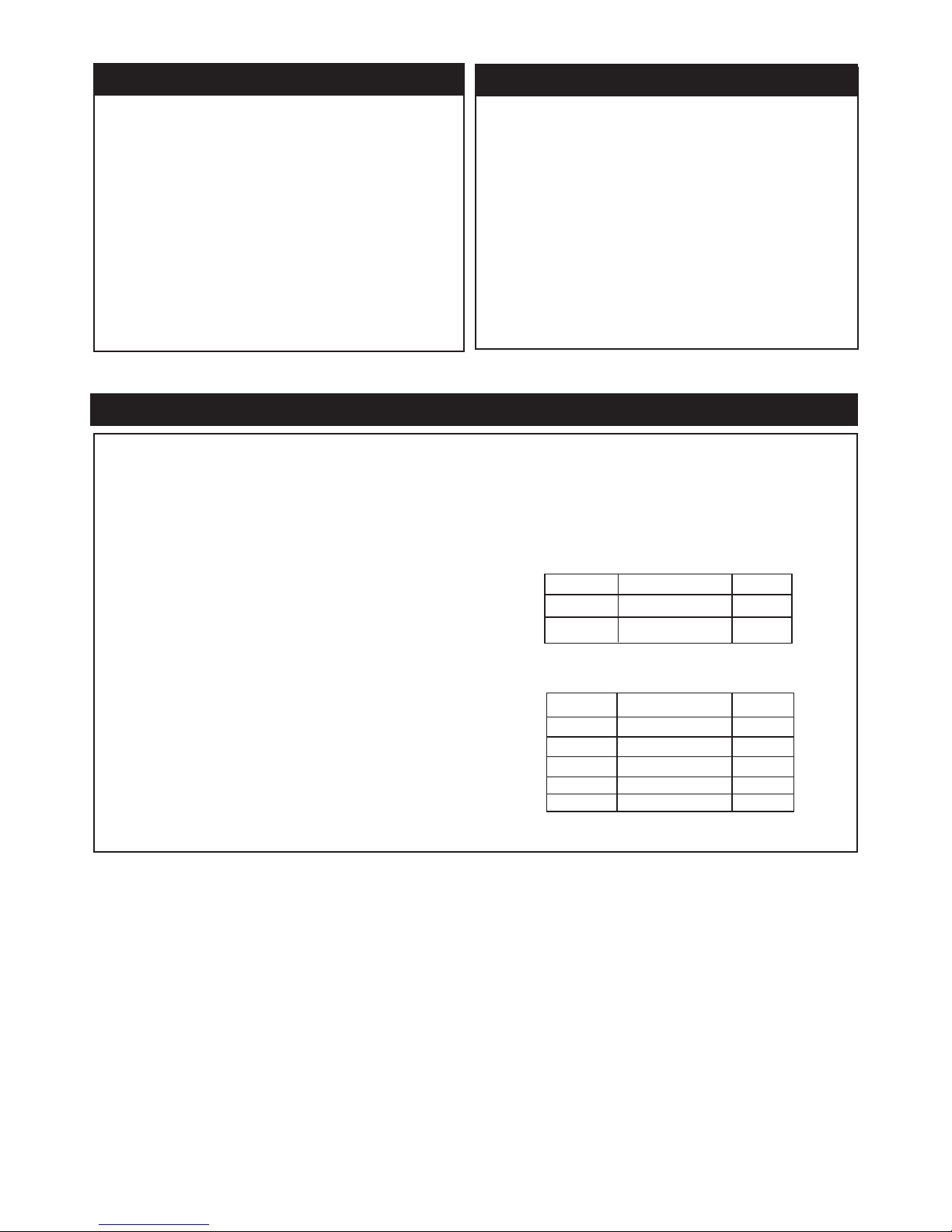

* Solar Powered Panels - The size of these depends on: the duty cycle of the gates; the hours of sunlight; and the number and type of accessories fitted. 30 watts is recommended for Residential use. The

conductor size needs to be in accordance with Table 1 below, as a minimum.

* Battery Powered with trickle charging - Due to the high cost of long runs of heavy cable, it may be more

economical in some installations to operate the gates from a battery, which is charged from a remotely

located trickle charger.

For example: a 15 VAC 2.5 Amp plug pack can be

located at the house, with appropriate wiring to the

gate, controller, and battery some distance away.

Follow Table 1 for minimum recommended

conductor sizes for different distances.

WIRING: All wiring must be arranged to prevent water

entering the controller enclosure. Do not wire mains

voltage and low voltage control wires in the same conduit.

* Low voltage motor cable sizes - Voltage will drop along

low voltage cables over long distances. It is

recommended to use cable with conductors of the

following minimum cross sectional areas. Table 2

lists lengths for twin-core cable, from a 12 V supply and

5 Amp load.

Cable length

Conductor size mm

AWG#

Up to 30 m 1.5 mm 16

Up to 100 m 2.5 mm 14

2

2

2

Cable length

Conductor size mm

AWG#

3 m 1.5 mm 16

5 m 2.5 mm 14

10 m 4 mm 12

15 m 6 mm 10

20 m 10 mm 8

2

2

2

2

2

2

TABLE 2 - Motor Cable

TABLE 1

C A B L E S I Z E S

Main Output (Motor) 12vdc Battery run,Operational

between 11vdc and 14vdc.

Accessory power 12vdc nominal Class II battery

(500ma max length conversion)

Power Consumption 30 Watts max (during battery

Charging).

T

emperature -20

o

C

to +50

o

C

Protection Fuse Battery 1 ATC20A

Protection Fuse Battery 2 ATC20A

C A R T O N I N V E N T O R Y

CB12ANZ CONTROL BOARD KIT

1x PVC – Box

1x CB12-Logic Board (pre-mount)

1x Charge transformer (pre-mount)

1x Antenna

S P E C I F I C AT I O N

Page 10

9

Transformer

Transformer

Mount the Control Box

T

he control box MUST be mounted within 1.5m of the

gate operator. Mount the control box as high as possible

for best radio reception

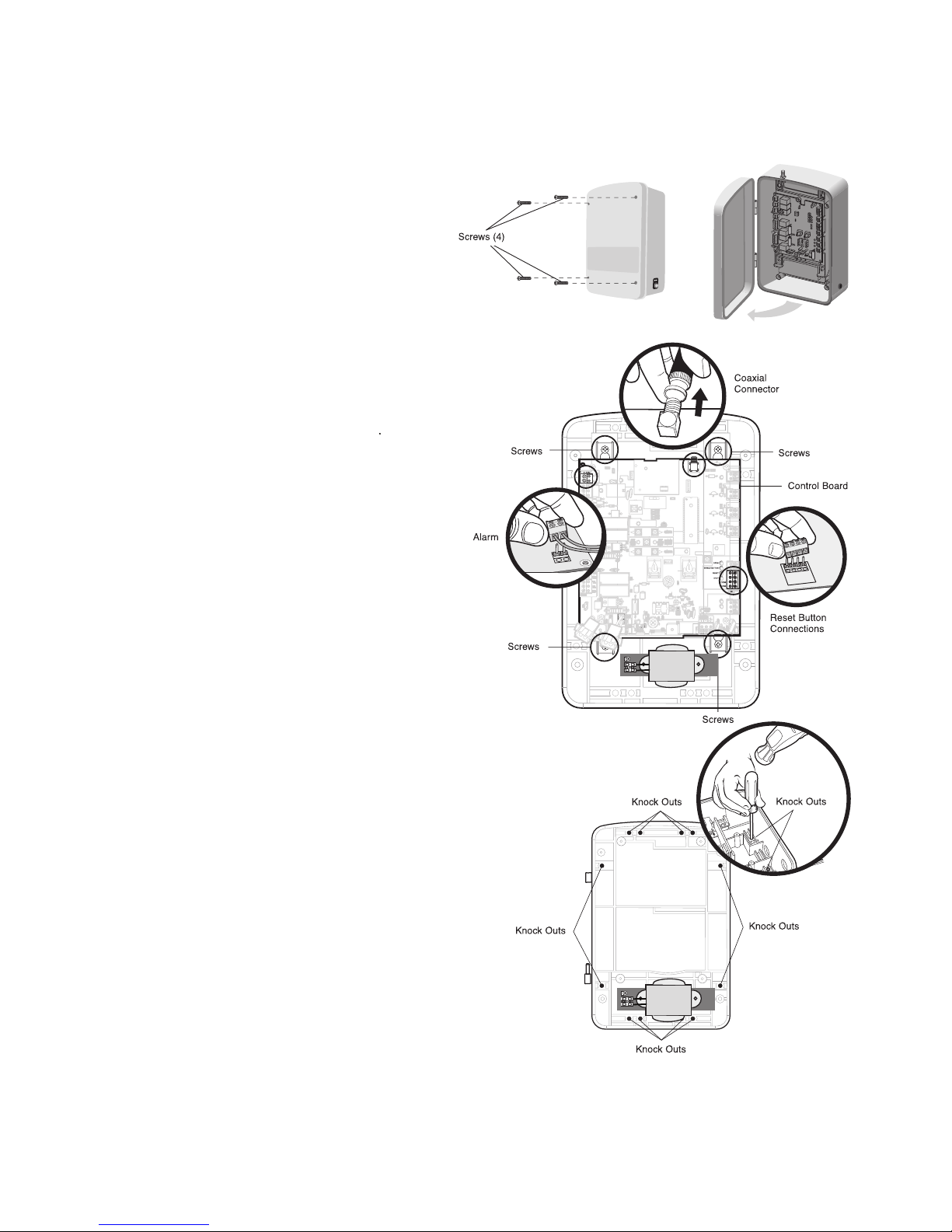

1. Open the Control Box

Remove the screws and open the box.

3. Select Mounting Holes

Select holes to be used for mounting and knock out using

a screw driver and hammer.

2. Remove the Control Board

Disconnect reset button, alarm and internal coaxial

connector. Loosen screws and remove Control Board.

Set aside IR beams, remotes, antenna, hardware bag*

and battery looms.

*Hardware bag includes, cable glands, fixing screws,

replacement fuse and three wire nuts.

Page 11

10

Antenna

U-Bolt

(

Not Provided)

Wall

Concrete

Anchor

Square

Gate Post

Screw

1818

L1L1

K2K2

Z22Z22

F2F2

MOV1MOV1

D1D1

OPEN

S

INGLEBUTTON

R

ESET

STOP

CHGRCHGR

OVLDOVLD

C

OM

COM

D129D129

Z4Z4

D2D2

C11C11

C13C13

D16D16

F9F9

K1K1

F

3F3

K3K3

K4K4

F1F1

Z12Z12

GATE2GATE 2

GATE1

GRGR

WHWH

YLYL

BLBL

R

DRD

BRBR

GRGR

WHWH

Y

LYL

B

LBL

RDRD

BRBR

F

7F7

24V24V

CTRLCTRL

OVLDOVLD

TIMERTIMER

RUNNINGRUNNING

G

ATE2GATE 2

S

ETSET

O

PENOPEN

LIMITLIMIT

S

ETSET

C

LOSECLOSE

LIMITLIMIT

L

EARNLEARN

LIMITSLIMITS

GATE1GATE 1

LEARNLEARN

XMITTERXMITTER

L

OCK/LOCK /

O

NON OFFOFF

C69C69

PWRPWR

ACPWRACPWR

/SOLAR/SOLAR

R329R329

R27R27

MOV2MOV2

R4R4

C2C2

B

IPART DELAYBIPART DELAY

L

OCK

Q9Q9

R9R9

ØØ

F

8F8

C

73C73

C

72C72

C71C71

C7C7

ØØ

R42R42

Ø

Ø

R

423R423

J24 J23 3J24 J23 3

ØØ

A 32VA 32V

3 3

ØØ

A 32VA 32V

J21J21

3030

3030

C64C64

R22R22

U

2U2

K6K6

JU1JU1

JU1JU1

J

U2JU2

DB1DB1

R

184R184

A

LARM

1818

K2K2

Z22Z22

F2F2

MOV1MOV1

D1D1

D

129D129

Z4Z4

D2D2

C11C11

C13C13

D16D16

F9F9

K1K1

F3F3

K3K3

K4K4

F1F1

Z12Z12

GATE2GATE 2

G

RGR

W

HWH

YLYL

B

LBL

R

DRD

B

RBR

F7F7

24V24V

GATE2GATE 2

SETSET

OPENOPEN

LIMITLIMIT

S

ETSET

CLOSECLOSE

LIMITLIMIT

L

EARNLEARN

L

IMITSLIMITS

GATE1GATE 1

C69C69

R329R329

R27R27

MOV2MOV2

R4R4

C2C2

Q9Q9

R9R9

ØØ

F8F8

C73C73

C72C72

C71C71

C7C7

ØØ

R42R42

ØØ

R423R423

J24 J23 3J24 J23 3

ØØ

A 32VA 32V

3 3

ØØ

A 32VA 32V

J21J21

3030

3030

C64C64

R22R22

U2U2

K

6K6

JU1JU1

JU2JU2

D

B1DB1

Screws

Screws

Screws

Control Board

Reset Button

Connections

Coaxial

C

onnector

Alarm

Battery 1Battery 1

Single GateSingle Gate

Battery 2Battery 2

Two GatesTwo Gates

Transformer

Transformer

Screws

IMPORTANT NOTE:

E

nsure watertight

connection seal

with silicon sealant

FAILURE to ensure

watertight seals may

render your product

unusable and will

v

oid warranty

4. MOUNT THE CONTROL BOX

Secure the control box to mounting surface (post, wall, column,

etc.) using the four fixing screws provided. If fixing to masonary

or tube steel you will require additional hardware (not provided).

5. INSTALL THE BATTERY/BATTERIES AND CONTROL BOARD

Attach antenna. Install batteries and connect battery looms. Reinstall

control board, alarm, and reset button. Re-connect internal coaxial connector.

NOTE: Make sure battery leads are on the left side of the control box

and not pinched.

Do NOT

connect battery looms to the control board at this time.

NOTE: Before proceeding to the next page, please ensure gate motors are installed.

IMPORTANT NOTE:

Waterproof all knockout holes using silicon sealant.

Page 12

11

Typical motor install

illustrated.

M

o

v

i

n

g

G

a

t

e

C

a

n

C

a

u

s

e

I

n

j

u

r

y

o

r

D

e

a

t

h

K

E

E

P

C

L

E

A

R

!

G

a

t

e

m

a

y

m

o

v

e

a

t

a

n

y

t

i

m

e

w

i

t

h

o

u

t

p

r

i

o

r

w

a

r

n

i

n

g

.

D

o

n

o

t

l

e

t

c

h

i

l

d

r

e

n

o

p

e

r

a

t

e

t

h

e

g

a

t

e

o

r

p

l

a

y

i

n

t

h

e

g

a

t

e

a

r

e

a

.

T

h

i

s

e

n

t

r

a

n

c

e

i

s

f

o

r

v

e

h

i

c

l

e

s

o

n

l

y

P

e

d

e

s

t

r

i

a

n

s

m

u

s

t

u

s

e

s

e

p

a

r

a

t

e

e

n

t

r

a

n

c

e

W

atertight Connector Nut (Provided)

Please observe the WARNINGS outlined on Pages 1 and 7 of this manual.

Page 13

12

Z

22

R

91

C

LOSE

EDGE

R

94

R92

R93

L

1

R1

R2

Z

1

K5

K6

K2

F3

1

0A32V

D

1

Ø

OPENEDGE/

P

HOTO

OPEN

P

HOTO

CLOSE

P

HOTO

R227

R2

Ø

7

Z2

Ø

R

223

P1

Z9

Z8

F

2

F6

D4D2R9

C64

JMPR1

R

224

U4

CONTROL

I

NPUTS

FORCE

TIMERTO

CLOSE

OFF MAX

O

PEN

SINGLEBUTTON

R

ESET

STOP

SHADOW

I

NTERRUPT

C

HGR

OVLD

COM

C

OM

COM

F

USE

OPEN

LOOP

I

NPUTS

P

OWER

BATT1BATT2

F120A 32V

R35

D9

Z3

Z

4

U3

D1

D

27

F

5

C11

C13

C12

D15

4

R 2C

R

1

Ø

1

R1

ØØ

R9

Ø

Q

9

K

1

R196

Q

22

D8

K3

K

4

D21

D22

C

4

A

CCESSORY

O

VLD

D6

JMPR2

M

OV1

M

OV2

D

B1

U2

Z12

24VAC/

SOLAR

INPUT

G

ATE2

A

CCESSORY

POWER

M

AGLOCK

A

LARM

GATE1

C

C

NC

NO

NO

GRN

WHT

YEL

BLU

RED

BRN

GRN

WHT

YEL

BLU

RED

BRN

F

4

1

0A32V

F7

24V

C

OM

O

VLD

TIMER

RUNNING

GATE2

S

ET

OPEN

LIMIT

S

ET

CLOSE

LIMIT

LEARN

LIMITS

DIAGNOSTIC

G

ATE1

J

4

L

EARN

XMITTER

MAGLOCK

ON OFF

F2

F6

U4

M

AX

FUSE

OPEN

C13

C4

Z1

10

D1Ø

Z12

ACCESSORY

P

OWER

GATE 1

GRN

WHT

YEL

BLU

RED

BRN

T

erminal blocks

c

an be removed

t

o simplify wiring.

B

rown

G

reen

W

hite

Y

ellow

B

lue

R

ed

Watertight Connector Nut

O

perator Cable

CONTROL BOX

Transformer

M

o

v

i

n

g

G

a

t

e

C

a

n

C

a

u

s

e

I

n

j

u

r

y

o

r

D

e

a

t

h

K

E

E

P

C

L

E

A

R

!

G

a

t

e

m

a

y

m

o

v

e

a

t

a

n

y

t

i

m

e

w

i

t

h

o

u

t

p

r

i

o

r

w

a

r

n

i

n

g

.

D

o

n

o

t

l

e

t

c

h

i

l

d

r

e

n

o

p

e

r

a

t

e

t

h

e

g

a

t

e

o

r

p

l

a

y

i

n

t

h

e

g

a

t

e

a

r

e

a

.

T

h

i

s

e

n

t

r

a

n

c

e

i

s

f

o

r

v

e

h

i

c

l

e

s

o

n

l

y

P

e

d

e

s

t

r

i

a

n

s

m

u

s

t

u

s

e

s

e

p

a

r

a

t

e

e

n

t

r

a

n

c

e

Operator Cable

3. CONNECT OPERATOR TO CONTROL BOARD

Extend operator cable and wires to GATE 1 connector and connect as shown.

Tighten watertight connector nut.

IF INSTALLING ONE OPERATOR, PROCEED TO PAGE 15.

If installing two operators, continue to the next page.

Page 14

13

T

ransformer

M

o

v

i

n

g

G

a

t

e

C

a

n

C

a

u

s

e

I

n

j

u

r

y

o

r

D

e

a

t

h

K

E

E

P

C

L

E

A

R

!

G

a

t

e

m

a

y

m

o

v

e

a

t

a

n

y

t

i

m

e

w

i

t

h

o

u

t

p

r

i

o

r

w

a

r

n

i

n

g

D

o

n

o

t

l

e

t

c

h

i

l

d

r

e

n

o

p

e

r

a

t

e

t

h

e

g

a

t

e

o

r

p

l

a

y

i

n

t

h

e

g

a

t

e

a

r

e

a

T

h

i

s

e

n

t

r

a

n

c

e

i

s

f

o

r

v

e

h

i

c

l

e

s

o

n

l

y

P

e

d

e

s

t

r

i

a

n

s

m

u

s

t

u

s

e

s

e

p

a

r

a

t

e

e

n

t

r

a

n

c

e

1. CONNECT SECOND OPERATOR TO CONTROL BOARD MGA600

NOTE: Junction box and extension kit part number JB12M is included in the slave kit

(MGA600S) for this function.

• Before digging, contact local underground utility locating companies.

• Trench across driveway to bury the extension cable.

• Use PVC conduit to prevent damage to cables.

• Insert extension cable through watertight connector nut and through an available

watertight connector mounted in the control box.

• Extend cable and wires to GATE 2 connector and connect as shown.

• Secure extension cable to control box using watertight connector nut.

FAILURE TO INSTALL THE SLAVE OPENER WITH CORRECT CABLE WILL VOID YOUR

WARRANTY.

Page 15

14

Transformer

Page 16

15

IIRR SSAAFFEETTYY BBEEAAMMSS 777722AANNZZ

IR Safety Beams are recommended to reduce the risk of personal injury and vehicle damage.

EN1243 specifies that IR Beams be installed at a height of 200 mm and activated

t

o “close”.

The sensors consist of a transmitter and receiver installed opposite to each other

across the gate access.

INSTALLATION

Install the beams opposite each other in the position required to maintain safe

access, using small screws and wall plugs.

Using suitable cable, (2 wire) connect the beams to each other and to the control

box Safety Sensor inputs (see wiring diagram page 24).

Use “open” photo and “Closed” photo as required.

PROGRAMMING of IR BEAMS

This is automatically achieved when programming the “Travel Limits” of the gate.

See programming section.

IR BEAM DIAGNOSTIC LEDs

NOTE: Remove sensor covers to access.

LED ON = Power and alignment OK

LED FLASHING = Obstruction or misalignment

LED OFF = No power or sleep mode

TO DISABLE IR BEAMS - remove wires from the terminals and reset limits.

See programming section.

+

+

+

772ANZ - Removing Cover

Page 17

16

Control Box

External GPO

CAUTION!

240 VAC

1

818

R93

L1L1

K2K2

Z22Z22

P1P1

F2F2

MOV1MOV1

D1D1

Q12Q12

U4U4

OFFOFF MAXMAX

OPEN

SINGLE BUTTON

RESET

STOP

CHGR

O

VLD

CTRL PWR

COM

D

129D129

Z4Z4

U3U3

D2D2

D44D44

C11C11

C13C13

C12C12

D16D16

F9F9

R1R1ØØ11

R1R1

ØØØØ

Q

22Q22

F3F3

K3K3

K4K4

R196R196

F1F1

G

ATE 2GATE 2

G

ATE 1GATE 1

GRGR

WHWH

Y

LYL

B

LBL

RDRD

BRBR

F7F7

24V24V

C

TRL

OVLD

T

IMERTIMER

RUNNINGRUNNING

GATE 2GATE 2

SETSET

OPEN

SETSET

CLOSECLOSE

LIMITLIMIT

L

EARNLEARN

L

IMITSLIMITS

GATE 1GATE 1

LOCK /LOCK /

ONON OFFOFF

C69C69

O

FFOFF MAXMAX

J2J2

ØØ

P

WR

AC PWR

/SOLAR

D8D8

D4D4

R9R9

R329R329

R27R27

R4

C2C2

B

IPART DELAYBIPART DELAY

LOCKLOCK

R9R9

ØØ

Q6Q6

J19J19

R182R182

C1

Ø1Ø1

C

75C75

C73C73

C72C72

C

71C71

C7C7

ØØ

C66C66 C65C65

C68C68

C33C33

F11F11

R186R186

R

42R42

ØØ

R423R423

J24 J23 3J24 J23 3

ØØ

A 32VA 32V

3 3

ØØ

A 32VA 32V

J21J21

3030

3030

C64C64

R22R22

U2U2

J18J18

K6K6

JU1JU1

JU1JU1

JU2JU2

DB1DB1

R184R184

MOV1MOV1

CHGR

OVLD

AC PWR

/SOLAR

MOV2

R4

C2

JU1

LE BUTTON

K2

K1K1

SET

OPEN

LIMIT

C73

C

72

C71

DIAGNOSTIC

OPEN

SINGLE BUTTON

RESET

STOP

C

TRL PWR

CTRL

OVLD

PWR

C

ONNECTING OPTIONAL SOLAR PANEL (NOT SUPPLIED)

If you are using a SOLAR PANEL, the Transformer MUST be unplugged and removed.

Terminate the Solar Panel into the AC PWR/SOLAR Terminals as illustrated below.

N

OTE: Solar Panel should be 12 Volt, up to 30 Watt with class 2 output.

Two batteries are also recommended for solar systems.

CONNECTING POWER TO THE CONTROL BOARD UNIT

For outdoor connection, a properly earthed WEATHER PROOF POWER

POINT MUST BE USED.

NOTE: Connection of Power must comply to local electrical standards.

Page 18

17

1

8

18

R

93

R93

L

1

L1

D42

D42

K2

K2

D

1

D1

Ø

Ø

Z22

Z22

P1

P1

F2

F2

MOV1

MOV1

D1

D1

Q12

Q12

U

4

U4

OFF

OFF

MAX

MAX

OPEN

OPEN

SINGLE BUTTON

SINGLE BUTTON

R

ESET

RESET

STOP

STOP

CHGR

CHGR

OVLD

OVLD

COM

COM

COM

COM

D129

D129

Z4

Z4

U

3

3

U

D2

D2

D

44

D44

C11

C11

C

13

C13

C12

C12

D16

D16

F9

F9

R1

R1ØØ11

R1

R1

Ø

Ø

ØØ

K1

K1

Q

22

Q22

F

3

F3

K3

K3

K4

K4

R

196

R196

F

1

F1

Z12

Z12

GATE 2

GATE 2

G

ATE 1

G

ATE 1

MAGR

MAGR

S

OL

SOL

GR

GR

WH

WH

YL

YL

BL

BL

RD

RD

B

R

BR

GR

GR

WH

WH

YL

YL

BL

BL

RD

RD

B

R

BR

F7

F7

24V

24V

CTRL

CTRL

O

VLD

OVLD

T

IMER

TIMER

RUNNING

RUNNING

GATE 2

GATE 2

S

ET

SET

O

PEN

OPEN

LIMIT

LIMIT

S

ET

SET

C

LOSE

CLOSE

LIMIT

LIMIT

LEARN

LEARN

L

IMITS

LIMITS

GATE 1

GATE 1

L

EARN

LEARN

XMITTER

XMITTER

LOCK /

LOCK /

ONONOFF

OFF

C69

C69

O

FF

OFF

M

AX

MAX

J2

J2

Ø

Ø

PWR

PWR

AC PWR

AC PWR

/

SOLAR

/SOLAR

D8

D8

D4

D4

R9

R9

R329

R329

R27

R27

MOV2

MOV2

R4

R4

C2

C2

B

IPART DELAY

BI

PART DELAY

L

OCK

LOCK

GND

GND

Z

1

Z1

R1

R1

R

2

R2

K5

K5

F

12

F12

Q9

Q9

R

9

R9

ØØ

F

8

F8

Q6

Q6

Q1

Q1

J19

J19

R182

R182

C1

C1

Ø

1

Ø1

C

75

C75

C

73

C73

C

72

C72

C71

C71

C7

C7

ØØ

C66

C66

C65

C65

C68

C68

C33

C33

F11

F11

R186

R186

R

42

R42

Ø

Ø

R

423

R423

J24 J23 3

J24 J23 3

Ø

Ø

A 32V

A 32V

3

3

Ø

Ø

A 32V

A 32V

J21

J21

30

30

30

30

C64

C64

R

22

R22

U

2

U2

J18

J18

K

6

K6

JU1

JU1

JU1

JU1

JU2

JU2

D

B1

DB1

D

36

D36

R

184

R184

Battery Connectors

Battery Connection (dual gate/solar)

Battery Connection (single gate)

Battery Connectors

Control Board

Board Connectors

Board Connectors

OR

CONNECT BATTERIES

The batteries are charged in circuit by using the transformer (provided).

Locate the two white battery plugs on the left-hand side of the control box.

Connect the plug from the battery to connector on the control board. Either connector can be used for a single battery.

NOTES: Batteries will degrade over time depending on temperature and usage. For best performance, the batteries

s

hould be changed every 3 years. Batteries do not perform well in extremely cold temperatures. For locations where

the temperatures are below -20° C (-4°F) contact technical support.

Page 19

18

Closed position

Open position

Use a screwdriver to push the CAM firmly to the

position.

Note: Firmly push the holes on top of the CAM to adjust.

To avoid burring the CAM do not push directly on the cam lobe.

CLICK

Micro switch should be starting to engage.

Adjust CAM so that you hear a click 10 degrees

BEFORE the gate is fully open.

Micro switch should be starting to engage.

Adjust CAM so that you hear a click 10 degrees

BEFORE the gate is closed.

SSEETTTTIINNGG TTHHEE CCAAMMSS FFOORR MMGGAA660000

The CAM switches must be set before proceeding with

any programming. Either CAM can be used for “open”

or “closed” position.

To set the CAM switches, disengage the motor using

the Hex key provided.

R

emove the top cover of the motor to allow access to

the CAM located at the top of the motor (keys to acc

ess the cover are provided with the gate operator).

Manually move the gate through one complete action.

The micro switches make a clicking sound as the CAM

begins to engage them.

Open Limit:

Set the CAM so the open limit microswitches click about 10 degrees before the desired open position.

Closed Limit:

The closed limit microswitch should click about 10 degrees before the gate is at the desired closed position.

NOTE: The cams are set for use as passpoints (references) NOT THE OPEN AND CLOSED POSITIONS.

A useful rule of thumb is to set the click to the point at which the soft stop & soft stop engage.

Limit programming detailed on pages 19 and 20.

Page 20

19

Page 21

20

left

r

ight

NOTES:

Page 22

21

TIMER TO

CLOSE

TTC can be temporarily disabled by pressing RESET

button (located on the outside side of the control box)

when the gate is fully open. This will allow the gate to

remain open until another command is received. After

the next command to the operator, TTC returns to the

previously set time period.

TTC OFF MAXIMUM time

180 seconds

Page 23

22

C840

Page 24

23

MANUAL RELEASE

The release lock for the casing is located under the rubber

weatherproof cover. Use the socket spanner supplied in the

hardware bag to lift the cover up. The release key located beneath the hood should be inserted into the side openings and

turned approx. 180 degrees until it cannot turn any further. The

drive has now been released. To re-engage it, the key should

be turned back to its original position.

NOTE: Take care when unlatching the drive for manual

operation. The gate panel can move in an unconditional way,

especially if it is mounted oin a sloped postion.

OPERATION OF YOUR GATE OPENER

Page 25

24

CAUTION!

240 VAC

Transformer

Page 26

25

CCOONNTTRROOLL IINNPPUUTTSS

Refer to Wiring Diagram on page 24.

WIRE STOP BUTTON (OPTIONAL)

A jumper wire is factory installed between the stop and

common input.

Stop (N/C) - Stop only (does not reset alarm).

NOTE: Stop jumper is required for normal operation

(

the Stop LED will be lit except when the control board

goes into Sleep Mode). Remove only if remotely

mounted Stop button is added.

OPEN

Opens only or reverses a closing gate.

SBC (SINGLE BUTTON CONTROL) INPUT

This input will command the gate to

OPEN / STOP / CLOSE / STOP in sequence.

RESET CONTROL INPUT

The control box has a factory installed internal reset button.

These terminals are intended for use with a single reset

button that is installed within a line of sight of the gate.

This input functions to reset the alarms. This input will

NOT stop the gate.

NOTE: All control inputs must be Normally Open (N.O.)

dry contact type.

C2

CONTROL

INPUTS

OPEN

SINGLE BUTTON

RESET

STOP

COM

COM

C

OM

COM

M

M

CONTROL

INPUTS

OPEN

SINGLE BUT TO N

RESET

STOP

POWER

CONTROL

INPUTS

OPEN

SINGLE BUTTON

RESET

STOP

COM

COM

COM

COM

M

M

CONTROL

INPUTS

OPEN

SINGLE BUT TO N

RESET

STOP

POWER

Page 27

26

Page 28

27

Page 29

28

Page 30

29

SYMPTOM POSSIBLE SOLUTION

Gate opens but does not • An open input is continuously activated. Check the open loop or vehicle probe to

eseht rof noitarepo dna snoitcennoc yfireV .stcejbo fo raelc era yeht erus ekam .esolc

.secived

• Low battery. Measure the voltage across the battery. Voltage should be above

11.5Vdc. Replace battery if required.

• (Optional Accessory) Entry system output is connected to the OPEN input, and is

“stuck” opening. Verify entry system connections and operations.

• Obstruction blocking close photo eyes, shadow loop, or safety loop. Check eyes for

alignment and verify all connections and operation for safety devices.

• (Optional Accessory) Close safety edge is damaged or on an obstruction. Verify

operation and connection of close edge.

.yaled derised ot detsujda dna NO si esolC ot remiT eht taht yfireV • esolc ton seod etaG

automatically with Timer to • Gate opened by a force obstruction reversal. Check the Diagnostic LED and clear

Close enabled. gate path of any obstructions.

• The Interrupt loop or Shadow loop is obstructed (optional accessories).

• Obstructed close safety sensor or safety edge (optional accessory). Check

connections and operations of safety devices.

• Low battery. Measure the voltage across the battery. Voltage should be above

11.5Vdc. Replace battery if required.

• An open input is continuously activated. Check the open loop or vehicle probe to

make sure they are clear of objects. Verify connections and operation for these

devices.

• (Optional Accessory) Entry system output is connected to the OPEN input, and is

“stuck” opening. Verify entry system connections and operation.

• Operator in “Party” mode after RESET button pressed while at the OPEN limit. Use

a remote or the SBC to close the gate and reopen it. Verify that the

TIMER RUNNING LED is flashing.

Alarm constantly sounds • Double entrapment occurred. Two successive obstructions were encountered while

for 5 minutes. Sounds moving the gate. Press the RESET button and ensure that the gate path is clear of

whenever a command is all obstructions. Check the FORCE setting to make sure it is properly set.

issued.

Alarm is beeping 3 times on • Low battery. Measure the voltage across the battery. Voltage should be above

a command. 11.5Vdc. Replace battery if required.

era stimiL esolC dna nepO eht fI .rehtegot esolc oot tes era stimiL esolC dna nepO • .wols oot snur etaG

set within the ramp down distance of each other, the gate will run at slow speed all

the time.

• The gate is starting within the ramp down distance from the Open or Close Limit.

Gate will run slow to limits if motion is started within the ramp-down distance from

the limit.

taht yfireV .NO ot hctiws yaleD trapiB/kcoL eht edilS .tes ton yaleD trapiB/kcoL • .1 etaG erofeb sesolc 2 etaG

Gate 1 starts moving first on open and last on close.

• Gate is excessively heavy or hinges are bad. Verify that the gate is within the ratings

for this product. Disconnect the arms and verify that both gates swing easily.

Lubricate or replace hinges as necessary.

• Gate is unbalanced. Disconnect the arms and verify that both gates swing easily in

both directions. If the gates are harder to move in one direction verses the other, the

gate is not properly balanced and the hinges must be adjusted.

• Bad motor connection. Check the motor wires and connections for possible loose or

corroded terminals.

evoba eb dluohs egatloV .yrettab eht ssorca egatlov eht erusaeM .yrettab woL • .gninnur nehw speeb mralA

11.5Vdc. Replace battery if required.

Gate does not open/close at • In windy areas, an automatic gate lock for close and a hard stop for open is

the same place each time. recommended to ensure the gate stops in the same place each time.

• Periodic limit adjustments may be necessary.

Page 31

30

ART-6

041AART-0007

041ABSC-0005

041ASWG-0454

ART-3AL

041AART-1022SA

041AART-1025SA

Antenna 001C3196-3

K001A6426

041AART-1002SA

041AART-1004

041AART-0003

041ABSC-1010

041AART-1005

041ABSC-1011

041AART-0063SA

041ABSC-0027

041ABSC-0017

041AART-0010

041AART-0002

041AART-1003SA

041ASLG-0054K

ART-2

SSPPAARREESS

Page 32

31

01-36622

5 problems caused by electrical faults or replacement of batteries;

6 water or moisture ingress that causes corrosion or electrical

malfunction;

7 corrosion caused by sea air if located near a waterway, beach etc;

8 fitment in a commercial operating application; or

9 solid panel gates installed in an unprotected wind affected location

resulting in the gate not closing;

10 non use of cable provided for second gate arm connection.

NB: A General Purpose Outlet (GPO) ie: power point must be supplied

by the consumer as this electrical fitting does not form a part of the

Unit (opener). Excludes solar installations.

If this Chamberlain Limited Warranty does not apply, you may have

rights available to you under the Australian Consumer Law.

Liability – Australia only

Except as set out in the Australian Consumer Law (being Schedule 2

of the Competition and Consumer Act 2010) (as amended, consolidated or replaced):

1 all other guarantees, warranties and representations in relation to

the Unit or its supply are excluded to the extent that Chamberlain

can lawfully exclude them; and

2 under no circumstances will Chamberlain be liable for

consequential, incidental or special damages arising in connection

with the use, or inability to use, the Unit, other than those which

were reasonably foreseeable as liable to result from the failure.

Liability – New Zealand only

Except as set out in the Fair Trading Act 1986 and the Consumer

Guarantees Act 1993 (as amended, consolidated or replaced):

1 all other guarantees, warranties and representations in relation to

the Unit or its supply are excluded to the extent that

Chamberlain can lawfully exclude them; and

2 under no circumstances will Chamberlain be liable for

consequential, incidental or special damages arising in connection

with the use, or inability to use, the Unit, other than those which

were reasonably foreseeable as liable to result from the failure.

Note: We request that you retain your sales docket or invoice as

proof-of-purchase and attach it to this manual to enable you to

establish the date of purchase in the unlikely event of a warranty

service being required. Chamberlain reserves the right to change

the design and specifications of the Unit without prior

notification. Some features or accessories of the Unit may not be

available in certain markets or areas. Please check with your distributor.

Chamberlain service centre contact details

Australia

Phone toll free 1800 638 234

Fax toll free 1800 888 121

Chamberlain Australia Pty. Ltd.

PO BOX 1446

Lane Cove NSW 1595

New Zealand

Auckland phone 09 477 2823

Phone toll free 0800 653 667

Fax toll free 0800 653 663

Email: customerservice@chamberlainanz.com

Website: www.go-merlin.com

CHAMBERLAIN LIMITED WARRANTY

Merlin Professional MGA600

Articulated Swing Gate Opener

Chamberlain Australia Pty Limited / Chamberlain New Zealand Limited

(Chamberlain), the manufacturer of Merlin® automatic gate openers, is

committed to manufacturing and supplying high quality goods.

As part of this commitment, we seek to provide reliable service and

support for our goods and are pleased to provide you, the original purchaser, with this Chamberlain Limited Warranty.

We also provide the following statement as required by the Australian

Consumer Law: In Australia, in addition to your rights under this Chamberlain Limited Warranty, our goods come with guarantees that cannot

be excluded under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and for compensation for any

other reasonably foreseeable loss or damage. You are also entitled to

have the goods repaired or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a major failure.

Chamberlain’s warranty

Chamberlain warrants to the original purchaser of the Merlin® Swing

Gate Opener (Unit) that all parts of the Unit, other than remote controlled transmitters and accessories, globes and batteries, are free from

defects in materials and workmanship for a period of 24 months from the

date of purchase when installed in a residential premise with a residential specified gate that is designed for the sole purpose of domestic

domicile. Chamberlain warrants that remote controlled transmitters and

accessories included with the Unit are free from defects in materials

and workmanship for a period of 12 months from the date of purchase.

Batteries and globes are not covered under the Chamberlain Limited

Warranty.

It is a condition of this Chamberlain Limited Warranty that the Unit is

sold, installed and serviced by a Professional Dealer appointed by

Chamberlain. A Merlin® branded gate opener purchased over the internet and installed by a person other than a Professional Dealer will not

be covered by this Chamberlain Limited Warranty.

During the applicable Chamberlain Limited Warranty period, if you are

concerned that the Unit may be defective, for prompt on-site service call

the Professional Dealer that sold/installed the opener, or our service

centre on the toll free number below and a Chamberlain technician will

diagnose the problem and arrange for this to be rectified. Once the

problem has been diagnosed, subject to your rights under the Australian Consumer Law with respect to major failures, Chamberlain or

its Professional Dealer will provide you with:

1. repairs to the Unit

or

2. a replacement Unit.

Repairs and replacement parts provided under this Chamberlain Limited

Warranty are provided free of charge and are warranted for the remaining portion of the original warranty period.

This Chamberlain Limited Warranty provides benefits which are in addition to your other rights and remedies as a consumer.

Exclusions

If our service centre determines that a warranty claim has been made in

respect of a failure or defect arising under or out of any exclusion detailed below such that the claim is not covered under this Chamberlain

Limited Warranty, we may, subject to your other rights and remedies as

a consumer, charge you a fee to repair, replace and/or return the Unit to

you. This Chamberlain Limited Warranty does not cover any failure of,

or defect in, the Unit due to:

1 non-compliance with the instructions regarding installation,

operation, maintenance and testing of the Unit or of any product

with which the Unit is used;

2 any attempt by a person other than a Professional Dealer to repair,

dismantle, reinstall or move the Unit to another location once it has

been installed;

3 tampering, neglect, abuse, wear and tear, accident, electrical storm,

excessive use or conditions other than normal domestic use;

4 problems with, or relating to, the gate or gate hardware, including

but not limited to the gate;

TM

Trademark of The Chamberlain Group, Inc.

® Registered Trademark of The Chamberlain Group, Inc.

© 2012 Chamberlain Group, Inc

Loading...

Loading...