Page 1

Installation Instructions

G900 Linear swing gate operator (discontinued)

Rev 01, May 03 © Merlin Garage Openers Limited Page 1 of 2

The Merlin G900 linear actuators are a compact, streamlined

design that provides good performance and quiet operation on

small to medium sized gates. The anodised aluminium finish

protects the drive system from the weather, ensuring low

maintenance. Suitable for single or double swing gates and

provide years of reliable service.

Control box

230v ac or 12v dc 2 wire 12v dc

80

850 365

Specs

Power options 230v. ac, 12v. dc, solar

Current 3 amp per motor

Maximum duty cycle 100%

Travel time 18-20 seconds

Maximum gate weight / length 180Kg / 3 meters

Maximum opening angle 110 deg

Gate stops required Yes

Gate lock required optional

Standard features

Auto close, adjustable 6-210 seconds

Adjustable force sensitivity

Leaf delay for electric locks or clash bars.

Multi-use function.

Optional Accessories

Battery back up

Solar power option

Safety beam sensors

Electric lock

Intercom

Keypad entry.

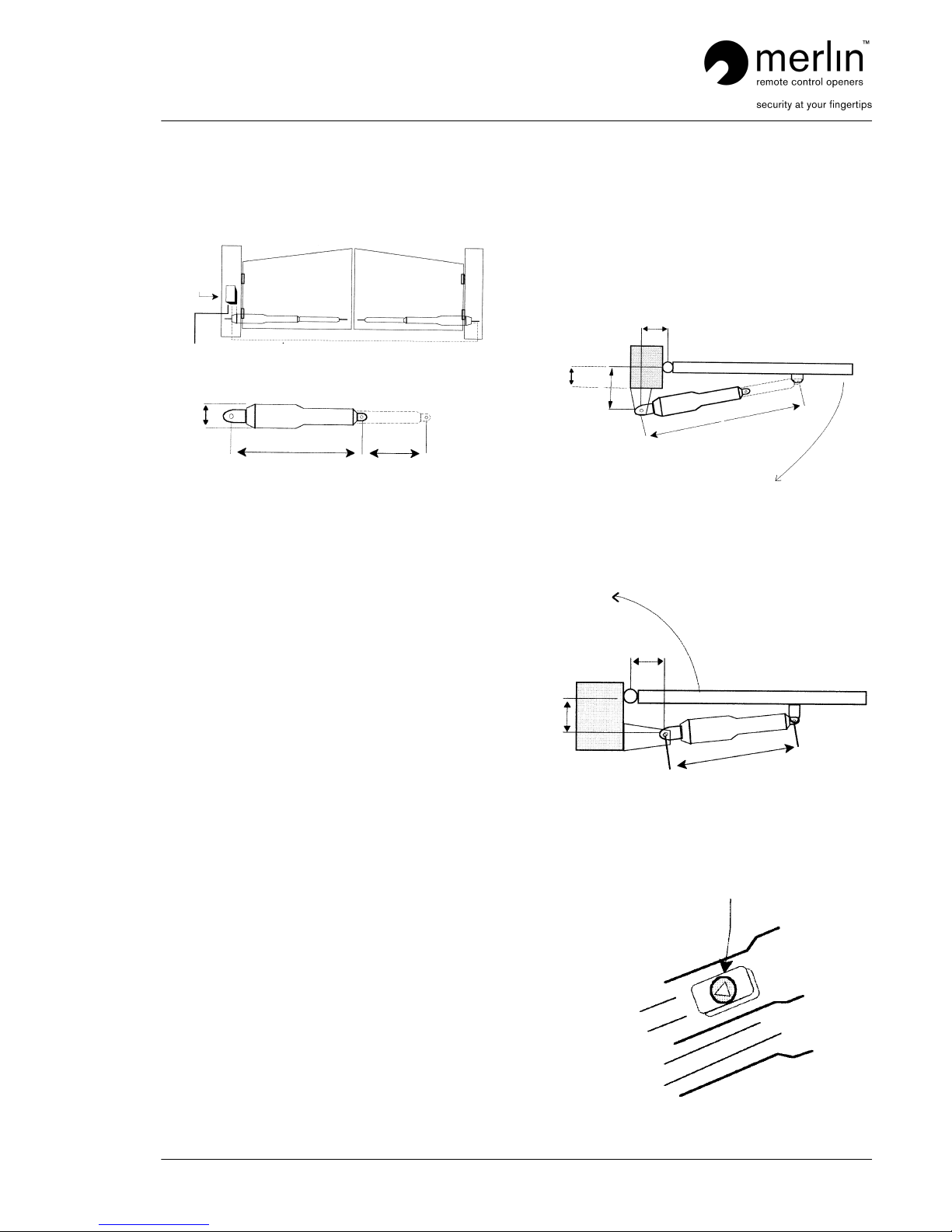

Step 1

Fasten the motor securely to the gatepost, and the gate

bracket to the gate as shown in fig A & B.

Correct geometry must be used.

Fig A

In swinging gates geometry

a

70mm max offset

b

c

Opening angles a b c

90 degrees 160mm 130mm 1215mm

110 degrees 160mm 100mm 1215mm

Fig B

Out swinging gates geometry

a

b

c

Opening angles a b c

90 degrees 160mm 130mm 850mm

110 degrees 160mm 100mm 850mm

To enable the opener to extend out to the gate bracket, turn

the manual release key.

Page 2

Installation Instructions

G900 Linear swing gate operator (discontinued)

Rev 01, May 03 © Merlin Garage Openers Limited Page 2 of 2

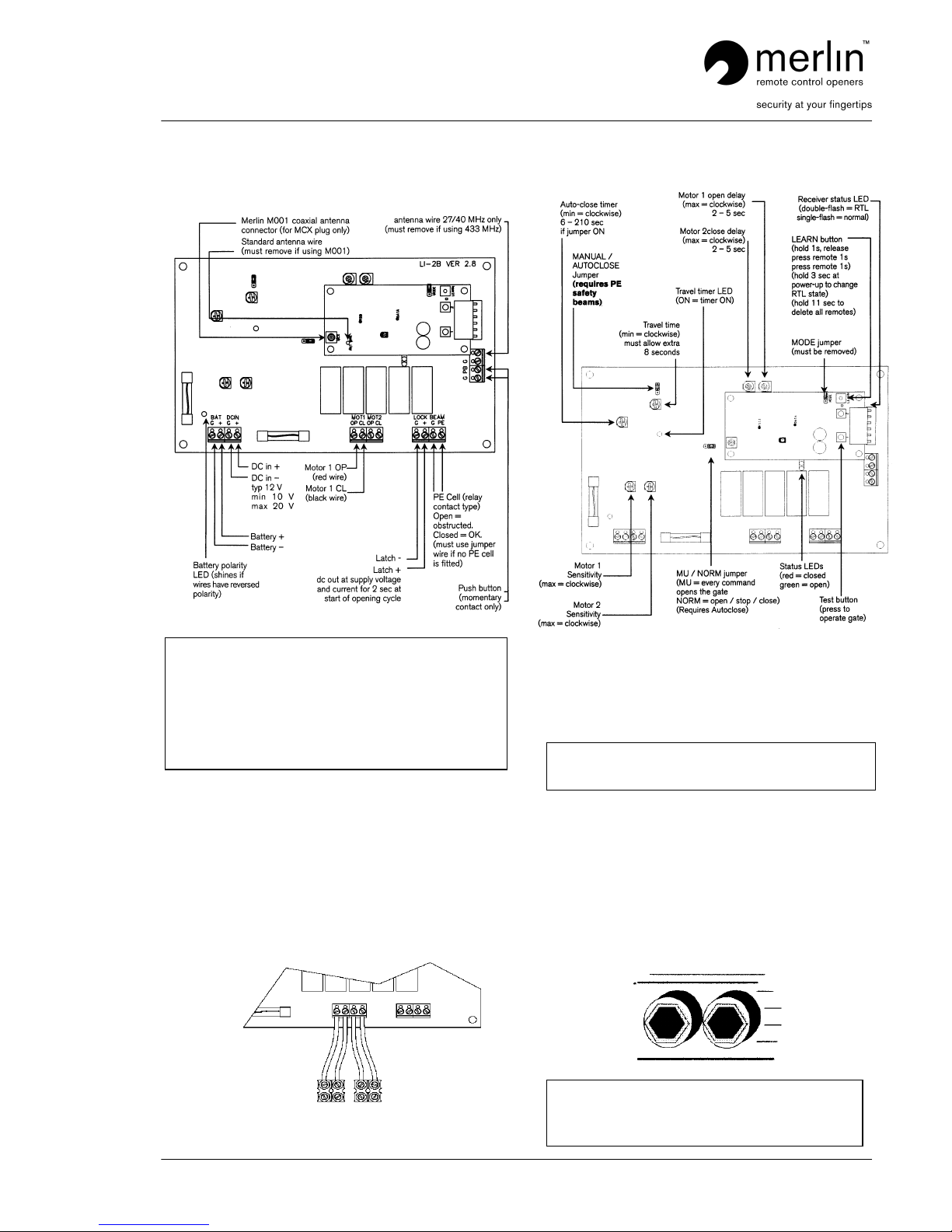

Step 2

Connect the wires to the control board

Note

Step 3

Connect the wires to the motors

Motor 1 is the left hand motor when facing out of the driveway.

If motor 1 is on the right hand side, reverse the polarity of the

motor wires.

If a single motor is fitted use the Motor 1 terminals. If a single

opener is fitted on the right hand side, reverse the polarity of

the motor wires.

If a motor pushes a gate outwards, reverse the polarity of the

motor wires.

OP CL OP CL

Left hand motor Right hand motor

Step 4

Control board set up.

Operate the gates by either a remote control or a push button.

The travel timer pot controls the operators. Adjust the timer so

that the motor/s complete their full open and close cycle plus

an extra 3 seconds of travel time.

the motor clutches will slip and make a clicking sound during

this period.

Note

Step 5

Set clutch torque level

There are two hex nuts on the under side of the motor

housing. These are factory set at approx 20kg and may not

require adjustment.

When the gates reach its stops the clutch should slip untill the

control board deactivates.

Note

When powering any accessories from the board, (for

example: gate latches, additional receivers, keypads, and PE

beams) ensure the power supply has adequate capacity.

Measure the voltage at the DC IN under full motor load. If it

falls below 9V then the board, receiver, and some

accessories, may not function correctly. In this instance,

remove accessories, upgrade the power supply, or provide

additional power supplies directly to each accessory

White

Black

White

Black

Reverse motor wires if open and close LED’s do not match

gate travel.

The same adjustment should be made to both screws

I.e.: if one nut is adjusted 1 turn clockwise, the other

must have the same adjustment.

Loading...

Loading...