Page 1

remote control openers

security at your fingertips

G703

residential gate opener for sliding gates

Installation instructions

EDR4 1204 04/03

Toll free helpline

Please have your serial number and

model name available before calling.

Australia 1800 638 234

New Zealand 0800 653 667

United Kingdom 0800 073 0112

www.merlingo.com

1

Page 2

Important safety instructions for

operation

WARNING Incorrect installation can lead to severe injury. Follow all

installation instructions.

Merlin Garage Openers Limited does not accept responsibility for damage or injury

resulting from installing this opener.

Before installing the drive remove or disable any equipment, such as locks, that is not

needed for powered operation.

Before installing the drive check that the gate is in good mechanical condition and that it

opens and closes properly.

Do not use force sensitivity adjustments to compensate for a binding or sticking gate.

Excessive force may damage the gate.

Install any fixed control, wired or wireless, within sight of the gate but away from moving

parts and at a height of more than 1.5 m.

After installation, ensure that the mechanism is properly adjusted and that the drive stops

when the gate contacts an obstruction.

Index

Site requirements

Gate

This opener is designed for residential sliding gates up to 8 metres long and less than 400

kg. The opener is rated to apply a maximum of 18 kg force (180 N).

Using a spring balance, check that less

than 15 kg force (150N) is required

to keep the gate moving by hand along

the full range of travel. The gate should

operate smoothly, opening and closing without sticking. The gate track

must be level.

It is recommended that stops are

added at each limit of the gate’s travel.

Level the gate

The gate track must remain level along

the full length of the gate’s travel.

Power supply

If the opener is to be mains-powered,

then the 3-pin power plug should be

shielded from the effects of weather.

The product is tested as a unit for

max

15kg

force

EDR4 1204 04/03

2

Page 3

electrical safety compliance and if the plug is cut off for hard-wiring, then the electrical

safety of the unit becomes the responsibility of the installing electrician.

An isolating switch is recommended, but all mains wiring should be in accordance with local

regulations, for example AS/NZS 3000:2000.

Low voltage cable sizes

Voltage will drop along low voltage cables over long distances. It is recommended to use

cable with conductors of the following minimum cross sectional areas. The table lists lengths

for twin-core cable, from the supply to the load.

For an optional solar panel, consider the total length from the panel to the controller board,

through to the battery.

Follow the table for minimum recommended conductor sizes for given lengths for each

power option..

Cable length From 10 W solar panel From controller to motor

to 12 V battery 12 V @ 6.5 A max

(for max 2% volt drop) (for max 5% volt drop)

3 m 1.0 mm

5 m 1.0 mm

10 m 1.0 mm

15 m 1.0 mm

20 m 1.0 mm

25 m 1.5 mm

30 m 1.5 mm

2

2

2

2

2

2

2

2.5 mm

4.0 mm

10 mm

16 mm

16 mm

16 mm

25 mm

2

2

2

2

2

2

2

Battery power with trickle charging

Due to the high cost of long runs of heavy cable, it may be more economic in some installations to operate the gates from a larger battery, which is charged from a remotely located

trickle charger.

For example, a 12V 500 mA plug pack can be located at the house, with only light gauge

wiring to the gate, controller, and battery some distance away. Due to varying gate loads

and duty cycles for each installation, this is a guide only.

Control box

Locate this in any convenient weather-protected position. All mounting holes and cable

entry or exits must be suitably sealed to prevent water from entering the enclosure. Cables

should exit the control box from below only.

EDR4 1204 04/03

3

Page 4

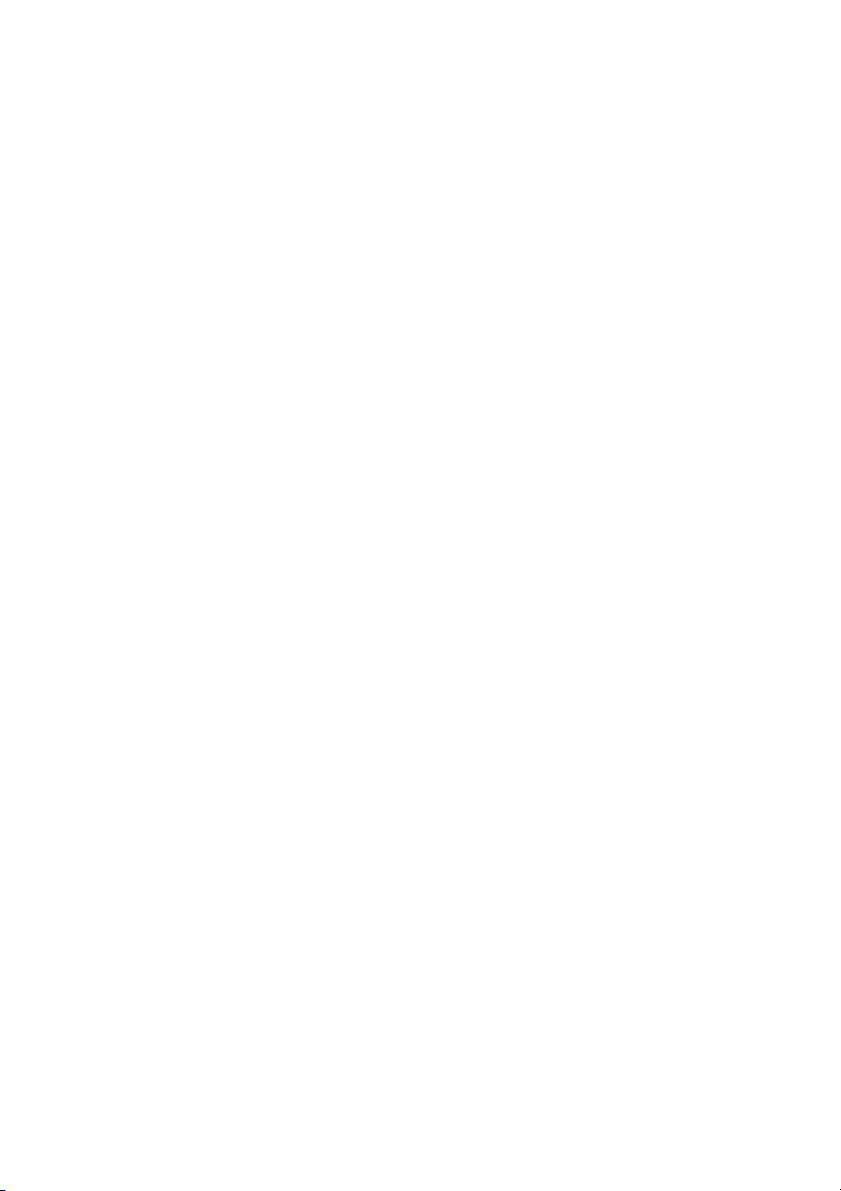

1 Opener

2 Receiving IR

sensor (3-wire)

3 Transmitting IR

sensor (2-wire)

4 Push-button

(must be rated

suitably for the

weather conditions)

5 Keyed switch

(must be rated

suitably for the

weather conditions)

6 Keypad (wireless

control; optionally wired power supply)

7 Enclosure for controller, receiver, and optional backup battery

NOTE The Merlin M122 wired pushbutton and M128 wireless pushbutton are not

waterproof, and are only rated for interior use.

The Merlin KWF1 keyed switch is not intended for use fully exposed to weather in

gate installations.

Merlin does not warranty any items used outside their published ratings or intended

use.

Installation

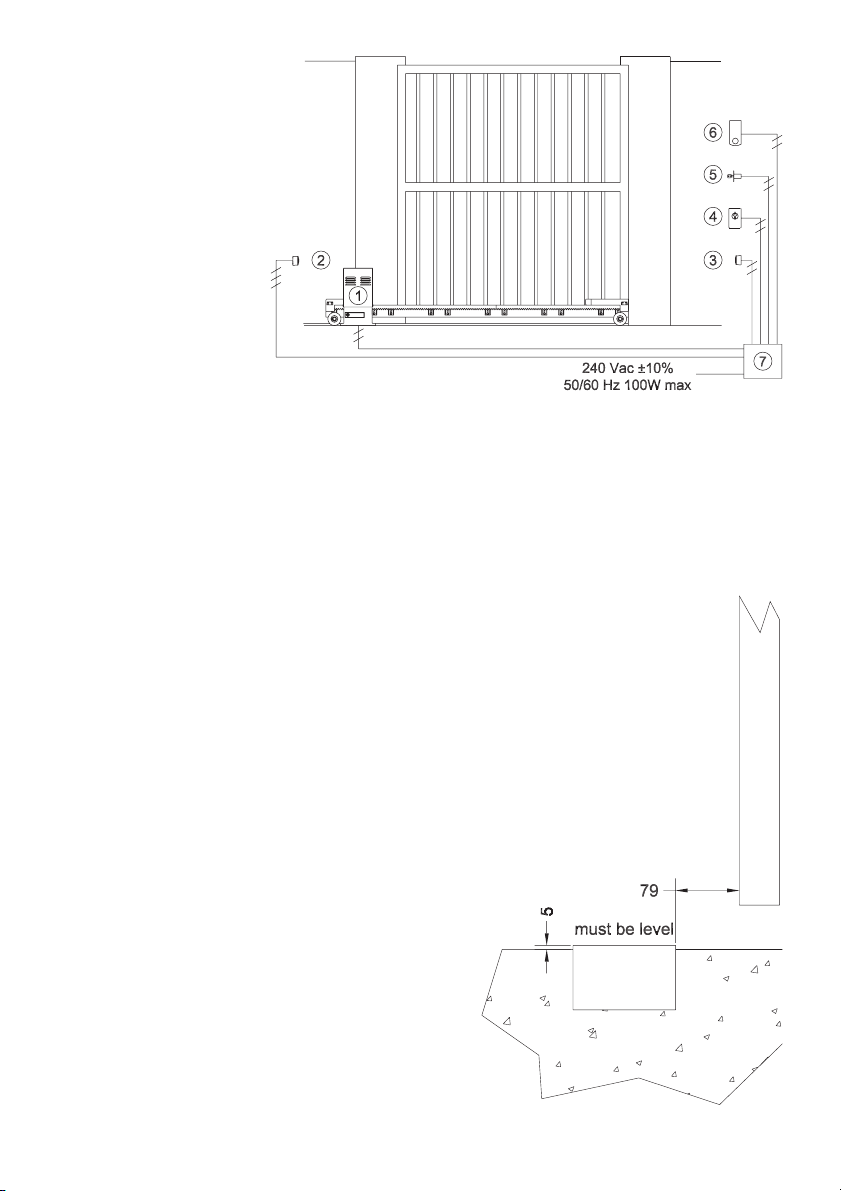

Position the foundation plate correct distance from the face of

the gate

Dig a 100 mm deep trench, which is larger than the foundation plate

(at least 250 x 150), in the position where the plate must be located.

Fill this with concrete and position the plate in the concrete.

Ensure the cable conduit aligns with the aperture in the plate. The

surface of the foundation plate must be level and 5 mm above ground.

The edge of the plate should be 79 mm from the face

of the gate that the rack bolts to.

Position the foundation plate correct distance from the ends of the gate

When the gate is fully to its right hand position

the right hand edge of the plate must be at least

300 mm from the left end of the gate.

When the gate is fully to the left hand position, the

right hand edge of the plate must be at least 175 mm

from the right end of the gate.

4

EDR4 1204 04/03

Page 5

Position the drive on the foundation plate

Insert 1 mm thickness shims under the drive and bolt the drive down

onto the foundation plate.

Centre the mounting bolts in the drive’s mounting slots.

Operate the manual release clutch, using the key

provided, pulling the lever fully out.

Fix the rack to the gate

The bolts attaching the rack to the gate

should be 79 mm above the top surface

of the foundation plate.

With the clutch released, slide the rack over

the pinion gear. Attach one end of the rack

to the gate, then slide the gate along, attaching each point of the rack as it passes

the pinion. Ensure sufficent rack protrudes

past the sprocket so that the limit actuators are able to be attached.

Remove the shims

Loosen the bolts holding

the drive on the foundation plate; remove the four

1 mm shims.

Retighten the four mounting bolts. This provides

the correct engagement

of the rack and pionion

teeth.

Adjust the limits

Allow the gate to slide

manually to each end position and fit the limit actuator cams to the rack,

such that the limit switch

is activated. This can be

fine tuned after the power

EDR4 1204 04/03

is connected to the drive.

5

Page 6

Connecting the board wiring

Merlin M001 coaxial antenna

connector (for MCX plug only)

Standard antenna wire

(must remove if using M001)

Battery +

Battery –

Battery polarity

LED (shines if

wires have reversed

polarity)

DC in +

DC in –

typ 12 V

min 10 V

max 20 V

Motor 1 OP

(red wire)

Motor 1 CL

(black wire)

dc out at supply voltage

and current for 2 sec at

start of opening cycle

antenna wire 27/40 MHz only

(must remove if using 433 MHz)

PE Cell (relay

contact type)

Open =

obstructed.

Closed = OK.

(must use jumper

Latch -

Latch +

wire if no PE cell

is fitted)

Push button

(momentary

contact only)

NOTE When powering any accessories from the board, (for example: gate latches,

additional receivers, keypads, PE beams) ensure the power supply has adequate

capacity. Measure the voltage at DC IN under full motor load. If it falls below 9 V dc

then the board, receiver, and some accessories, may not function correctly. In this

instance, remove accessories, upgrade the power supply, or provide additional power

supplies directly to each accessory.

6

EDR4 1204 04/03

Page 7

Connecting the

motor wiring

The controller board is rated for a total of

6.5A, therefore only a single G703 can be

controlled.

Connect it to the Motor 1 terminals.

If the actions of the gate appear to be reversed, reverse the

polarity of the motor wires.

Setting limits

Close the gates

Close the gates using any control. If the gate position is not correct, loosen the limit actuator

from the rack and move it as required.

Open the gates

Open the gates. If the gate position is not correct, loosen the limit actuator from the rack and

move it as required.

Board adjustments

Sensitivity

If the sensitivity is set to react to extremely light obstructions then the gates may fail to open

of close fully. After adjustment, check the force on an obstruction at the far end of the gate

does not exceed 150N (15 kg). Use a spring balance.

Travel time

Allow 3 – 5 seconds more than the normal travel time. This compensates for any possible

slow-down due to unusual loads and will allow the gates to fully open or close.

The yellow LED will stay on while the timer is active.

Auto-close

The jumper must be moved to the AUTO CLOSE position.

Turn the control clockwise to increase the time, from a minimum of 6 seconds up to a

maximum of around 210 seconds.

Consider the use of the multi-user option.

NOTE Non-contact sensor beams must be fitted when using auto-close.

Multi-user option

Move the jumper to the MU position. In this position every command will open the gate. The

only way to close the gate is to wait for the auto-close timer. The advantage of this mode is

that an opening gate with a car travelling through it can not be caught by someone pressing

EDR4 1204 04/03

7

Page 8

a remote control to close the gate. Autoclose must also be enabled, otherwise the gates

can never be closed.

Motor 1 open delay

This is not required for a single opener.

Motor 2 close delay

This is not required for a single opener.

Receiver setup

Mode jumper

This jumper must be removed. If it is not removed then the remote will only operate the gate

once for every two button presses. This jumper enables the latching output on the receiver

card.

Learning remotes

The receiver can learn up to 20 remotes. After 20 remotes, the 20th will be overwritten.

Only one button per remote can operate the receiver.

To learn a remote, press and hold the LEARN button until the receiver status LED goes out.

Press the desired button on the remote control and hold till the status LED flickers. Press it

again to confirm.

Remote Transmitter Learning (RTL)

This option allows a user to add remotes without accessing the receiver card. It does not

allow the deletion of remotes.

After 20 remotes, the 20th will be over-written.

If RTL is enabled the receiver status LED will double-flash in the standby state.

If RTL is disabled the receiver status LED will single-flash in the standby state.

To change state, hold the LEARN button down for three seconds as the power is reset.

Check the receiver status LED flashes to confirm the state change.

Merlin recommends enabling this option. Check for a double-flash on the receiver status

LED at standby.

Deleting remotes

All remotes can be deleted by pressing and holding the LEARN button for 11 seconds, until

the receiver status LED stops fast-flashing. This resets the receiver back to its default

settings. Check you still have the desired RTL state.

Common Access installations

To allow unlimited numbers of common access users, the M832C or M834C remote controls are required. These have a DIP switch code block that sets a fixed code for the main

button on the M832C or on two buttons of the four on the M834C. The remaining buttons

are high-security code-hopping.

The M834C is useful for separate entry and exit gates.

Common access remotes are only available in the full-sized remote controls.

8

EDR4 1204 04/03

Page 9

Adding an external antenna

Only connect a Merlin M001 to the MCX co-axial connector on the receiver card.

This antenna, cable and connector is tuned to give the best performance.

Snip the simple wire antenna from the receiver card so that only one antenna is active.

The ground plane of the M001 greatly improves the antenna’s performance. An alternative

is to mount the antenna through a metal plate that is at least as large in each direction as

the ground plane’s length. For optimum performance any ground plane should make good

electrical contact with the metal boss of the M001 antenna.

Contact Merlin for MCX extension cables if additional distance is required between the

controller and the antenna.

Optional extras

Keypad

The Merlin M840 keypad can accept a hardwired power supply to overcome the need for

replacement batteries. See the keypad documentation for full details, but any supply with

50 mA at 10 – 24 V ac or dc is suitable. Control of the gate opener is wireless using high

security code-hopping RF.

PhotoElectric (PE) sensor beams

You can fit any sensor beams with relay contact outputs that can be configured as open

contacts when obstructed and closed contacts when OK.

Merlin M103 sensor beams require three wires for the receiver beam and two wires for the

transmitter beam.

NOTE Beams must be fitted when Autoclose is enabled.

Battery backup

A trickle charging circuit is included in the controller board. Connect the 12 V 2 Ah battery

to the terminals. A mains supply will keep it charged.

Solar power

Contact Merlin for the correct board, battery and panel. However, if it is necessary to modify

an existing board, remove the resistor shown and connect as follows. In some applications

a larger battery, and possibly a larger solar panel, will be required.

It depends on: the duty cycle of the gates; the type of receiver

fitted; the hours of sunlight; and the number

and type of accessories fitted.

In many instances a 9Ah battery is required,

and a low-power 40 MHz receiver will be

required in order to use a 10W solar panel.

The standard panel is rated at a nominal

10W. If an alternative panel is self regulating, then the additional 6A diode shown

above is not necessary.

EDR4 1204 04/03

9

Page 10

Setting up the board

Auto-close timer

(min = clockwise)

6 – 210 sec

if jumper ON

MANUAL /

AUTOCLOSE

Jumper

(requires PE

safety

beams)

Travel time

(min = clockwise)

must allow extra

8 seconds

Motor 1 open delay

(max = clockwise)

2 – 5 sec

Motor 2close delay

(max = clockwise)

2 – 5 sec

Travel timer LED

(ON = timer ON)

Receiver status LED

(double-flash = RTL

single-flash = normal)

LEARN button

(hold 1s, release

press remote 1s

press remote 1s)

(hold 3 sec at

power-up to change

RTL state)

(hold 11 sec to

delete all remotes)

MODE jumper

(must be removed)

Motor 1

Sensitivity

(max = clockwise)

Motor 2

Sensitivity

(max = clockwise)

MU / NORM jumper

(MU = every command

opens the gate

NORM = open / stop / close)

(Requires Autoclose)

Status LEDs

(red = closed

green = open)

Test button

(press to

operate gate)

NOTE Reverse motor wires if open and close LEDs don’t match gate travel.

10

EDR4 1204 04/03

Page 11

Troubleshooting

Remote controls will not function while gate is moving

The total load on the power supply may be exceeding its capacity. Measure the voltage into

the board. If less than 9V dc when the motors are under load, then a higher capacity power

supply must be fitted, or some accessories removed, or separate power supplies provided

for the accessories.

Gate will not open or close

The gate should operate smoothly, opening and closing without sticking or requiring undue

force. Release the gate from the opener and check that it is possible to move the gate

freely by hand through the full range of the opening.

There may be a power failure. Plug another appliance into the power point to check. Opener

may require service. If solar powered, the battery may not be fully recharging.

SOLUTION: Operate the gate manually. Phone an installer for service.

Gate will open but not close

If a sensor beam is fitted then it may be obstructed or misaligned. The gate mechanism may

have broken, presenting an abnormal load, causing the safety system to activate.

SOLUTION: Look for anything blocking the beam sensor. Is the beam aligned correctly?

Release the manual release and check the gate can be operated easily by hand. Have your

gate repaired or serviced if it is heavy to move by hand.

Transmitter range is less than normal

Your transmitter battery may be going flat. If you have an external antenna then the wire

may be damaged.

SOLUTION: Replace the transmitter battery. Phone for service if the antenna wire is damaged

Transmitter doesn’t work some times

There may be occasional radio interference in your area. Your transmitter battery may be

going flat.

SOLUTION: Check for nearby baby monitors, remote control toys, cordless phones. Replace the transmitter battery.

Radio interference

Gate remote controls are required to operate in shared radio frequency bands. Regulations

permit other users to continuously operate higher powered devices such as baby monitors

or wireless headphones in these shared bands. These devices may cause radio interference that reduces the performance of the remote control. Switch off interfering devices if

possible. Remote controls and receivers that operate on alternative frequencies are available at additional cost.

Transmitter doesn’t work at all

Your transmitter battery may be flat.

EDR4 1204 04/03

SOLUTION: Replace the transmitter battery.

11

Page 12

Specifications

Mains power required 220 V to 240 V ac, 50 Hz, earthed

Extra Low Voltage required (optional) max 6.5 A at 12 V dc

Rated force max 180 N

Stand-by power consumption max 0.5 W

Operating power consumption max 80 W

Gate length max 8 m

Gate weight max 400 kg

Operating speed max 166 mm/second (less with load)

Replacement motor fuse 10 A (32 mm x 6.35 dia)

Replacement board fuse 0.5 A (32 mm x 6.35 dia)

Replacement backup battery 12 V 6.5 Ah sealed lead-acid

Replacement remote control battery Depends on model, either 4LR44 (6V) or

CR2025 (3V coin cell)

NOTE Any additions or alterations

outside of these specifications may

void the product’s warranty

Maintenance

In an area where ant or insect infestation

is likely, regularly spray around the opener

and any electrical installation with insecticide.

In normal conditions it is not expected that

any additional lubrication or service is required.

Keep the path of the gate free from debris and foliage.

12

EDR4 1204 04/03

Loading...

Loading...