Page 1

gomerlin.com.au

gomerlin.co.nz

MT50EVO

Sectional Garage Door Opener

Installation and Operating Instructions

Owners Copy: SAVE THESE INSTRUCTIONS for future reference

This manual contains IMPORTANT SAFETY information

DO NOT PROCEED WITH THE INSTALLATION BEFORE READING THOROUGHLY

Page 2

TM

Trademark of The Chamberlain Group, Inc.

® Registered Trademark of The Chamberlain Group, Inc.

© 2014, The Chamberlain Group Inc.

Page 3

WARNING!

START BY READING THESE IMPORTANT SAFETY INSTRUCTIONS

•Failuretocomplywiththefollowinginstructions mayresultinseriouspersonalinjuryorproperty damage.

• Read and follow all instructions carefully.

• The garage door opener is designed and tested to offer safe service, provided it is installed and operated in

strict accordance with the instructions in this manual.

These safety alert symbols mean WARNING : A possible risk to personal safety or property

damage exists.

Keep garage door balanced. Do not let the garage door

opener compensate for a binding or sticking garage door.

Sticking, binding or unbalanced doors must be repaired

efore installing this opener.

b

Do not wear rings, watches or loose clothing while

installing or servicing a garage door opener. Wear gloves,

safety goggles and suitable protective clothing where

appropriate.

Frequently examine the door installation, in particular

cable, springs and mountings for signs of wear, damage or

imbalance. Do not use if repair or adjustment is needed

since springs and hardware are under extreme tension

and a fault can cause serious personal injury.

To avoid serious personal injury from entanglement,

remove all ropes, chains and locks connected to the

garage door before installing the door opener.

Installation and wiring must be in compliance with your

local building and electrical codes.

The safety reverse system test is very important. Your

garage door MUST reverse on contact with a 40 mm

obstacle placed on the floor. Failure to properly adjust the

opener may result in serious personal injury from a closing

garage door. Repeat the test once a month and make

any necessary adjustments.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety.

Use the Manual Release only for the seperation of the

carriage from the drive and - if possible - ONLY with the

door closed. Do not use the red handle to push the door

up or pull it down. Operation of the emergency release can

lead to uncontrolled movements of the door, if springs are

weak or broken or if the door is unbalanced. Mount the

release handle of the emergency release at a height less

than 1.8 m from the floor.

Warning: If your garage has no service entrance door, a E1702M outside quick release must be installed. This

accessory allows manual operation of the garage

CONTENTS PAGE

SAFETY INSTRUCTIONS . . . . . . . . . . .1

BEFORE YOU BEGIN . . . . . . . . . . . . . .2

DOOR TYPES . . . . . . . . . . . . . . . . . . . .2

CARTON INVENTORY . . . . . . . . . . . . .3

RAIL SIZES . . . . . . . . . . . . . . . . . . . . . .3

TOOLS REQUIRED . . . . . . . . . . . . . . . .4

HARDWARE PROVIDED . . . . . . . . . . . .4

COMPLETED INSTALLATION . . . . . . . .4

CONTROL PANEL . . . . . . . . . . . . . . . . .5

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . .6

INSTALLATION . . . . . . . . . . . . . . . . .7-10

OPERATE THE MANUAL RELEASE . .10

ADJUSTMENT . . . . . . . . . . . . . . . .11-12

INSTALL THE PROTECTOR

SYSTEM (OPTIONAL) . . . . . . . . . . . . .13

door from outside in case of power failure.

INSTALL WIRELESS WALL

BUTTON . . . . . . . . . . . . . . . . . . . . . . . .14

INSTALL WARNING LABELS . . . . . . .14

WIRELESS PROGRAMMING . . . . . . .15

USING YOUR OPENER . . . . . . . . . . .16

CARE OF YOUR OPENER . . . . . . . . .16

REPLACE BATTERIES IN

REMOTE . . . . . . . . . . . . . . . . . . . . . . .16

ACCESSORIES . . . . . . . . . . . . . . . . . .17

ACCESSORY WIRING DIAGRAM . . . .17

REPLACEMENT PARTS . . . . . . . . . . .18

TROUBLESHOOTING . . . . . . . . . . . . 19

SPECIFICATIONS . . . . . . . . . . . . . . . .20

WARRANTY . . . . . . . . . . . . . . . . . . . . .21

1

The Protector SystemTMmust be used for all installations

where the closing force as measured on the bottom of the

door is over 400 N (40 kgf). Excessive force will interfere with

he proper operation of the Safety Reverse System or damage

t

the garage door.

SPECIAL NOTE: Merlin strongly recommends that The

Protector System

After installation, ensure that the parts of the door do not

extend over public footpaths or roads.

Install the wireless wall control (or any additional wall control) in

a location where the garage door is visible, at a height of at

least 1.5 m and out of the reach of children. Do not allow

children to operate push button(s) or transmitter(s). Serious

personal injury from a closing garage door may result from

misuse of the opener.

Permanently fasten the Warning LabelsinProminentPlaces,

adjacent to Wall Controls and on manual release mechanism as

a reminder of safe operating procedures.

Activate opener only when the door is in full view, free of

obstructions and the opener is properly adjusted. No one

should enter or leave the garage while the door is in motion.

Automatic Door- The door may operateunexpectedly, therefore

do not allow anything to stay in the path of the door.

Do not allow children to play near the door, or with door

controls. Keep remotes away from children.

Disconnect electric power to the garage door opener before

making repairs or removing covers.

If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons in

order to avoid hazard.

This opener should not be installed in a damp or wet space

exposed to weather.

To avoid damage to very light doors (such as fibreglass,

aluminium or steel doors), an appropriate reinforcement should

be added. To do so, contact the door manufacturer.

SAVE THESE INSTRUCTIONS

M

T

be installed on all garage door openers.

Page 4

BEFORE YOU BEGIN:

1. Look at the wall and ceiling above the garage door. (The opener and header bracket must be securely fastened to structural

supports.)

. Do you have a finished ceiling in your garage? If so, a support bracket and additional fastening hardware (not supplied) may

2

be required.

3. Do you have an access door in addition to the garage door? If not, model E1702M Outside Quick Release Accessory is

required. This accessory allows manual operation of the garage door from outside in case of power failure.

4. Complete the following test to make sure your garage door is balanced and is not sticking or binding:

• Lift the door about halfway. Release the door. If balanced, it should stay in place, supported entirely by its springs.

• Raise and lower the door to see if there is any binding or sticking, 20 kgf is the absolute maximum allowable force to raise or

lower the door in any position. If your door binds, sticks, or is out of balance, call a trained door technician.

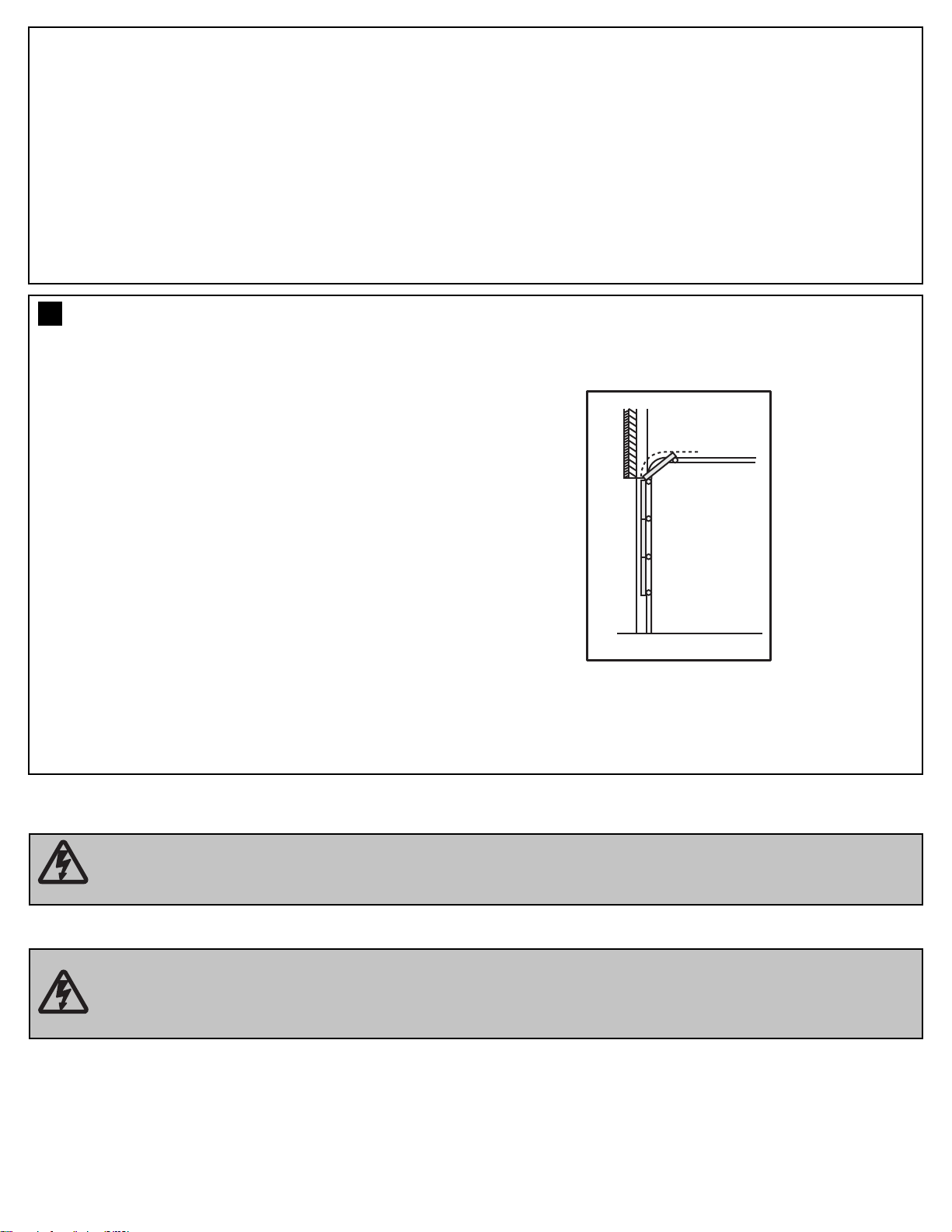

DOOR TYPES

1

A. Sectional Door with curved track

To suit spring balanced Residential Sectional doors

up to 13.0 m2.

Electrical Connection

A 240 V General Purpose Outlet (GPO) ie. Power Point must be available in close proximity to the powerhead.

This fitting is not part of the Opener hardware and must be supplied by the consumer.

In the event of a power outage or the unit being disconnected from the power source, the door MUST be operated and

supervised so that it completes a full UP and DOWN cycle with no obstructions in place to ensure that the unit

automatically checks that the safety force settings are correct.

2

Page 5

1

2

3

4

5

6

7

8

9

11

10

12

OwnersC opy:SAVETHESEINSTRUCTIONSforfuturerefere nce

MT50EVO

S

ectionalGarage Door Opener

Installationand Operating Instructions

Thismanualcontains IMPORTANTSAFETYinformation

DONOTPROCEEDWITH THEINSTALLATIONBEFOREREADING THOROUGHLY

N

2966N2966N2966N2966

g

omerlin.com.au

gomerlin.co.nz

132A2890

CARTON INVENTORY

2

our garage door opener, rail and hardware are packed in a single carton.

Y

1) Opener

(

(2) Hand held transmitter (2)

(3) Curved door arm

(4) Hanging bracket (2)

(5) Rail brackets (3)

(6) Header bracket

7) Door bracket

(

(8) Hardware bag

(9) Rail assembly

(10) Manual

(11) Warning Labels

(12) Rail centre bracket

3

RAIL SIZES AVAILABLE

DOOR HEIGHT:

Sectional Doors

Up to 2.5 m 3300 mm segmented 3150 mm 3450 mm

RAIL LENGTH: CEILING FIXING

POINT:

OVERALL LENGTH:

NOTE: The Ceiling Fixing Point is measured back from the lintel (see item 1 to 7 of “completed installation”). Also

allow 300 mm back from the fixing point for installation of the powerhead (item 7 to 9 of “completed installation”).

3

Page 6

1

2

3

4

5

7

8

9

10

11

6

12

13

6

9 (4x)

8 (8x)

7 (4x)

6 (1x)

5 (1x)

1 (1x)

2 (1x)

3 (4x)

4 (4x)

20 mm

50 mm

Drill Bits

10

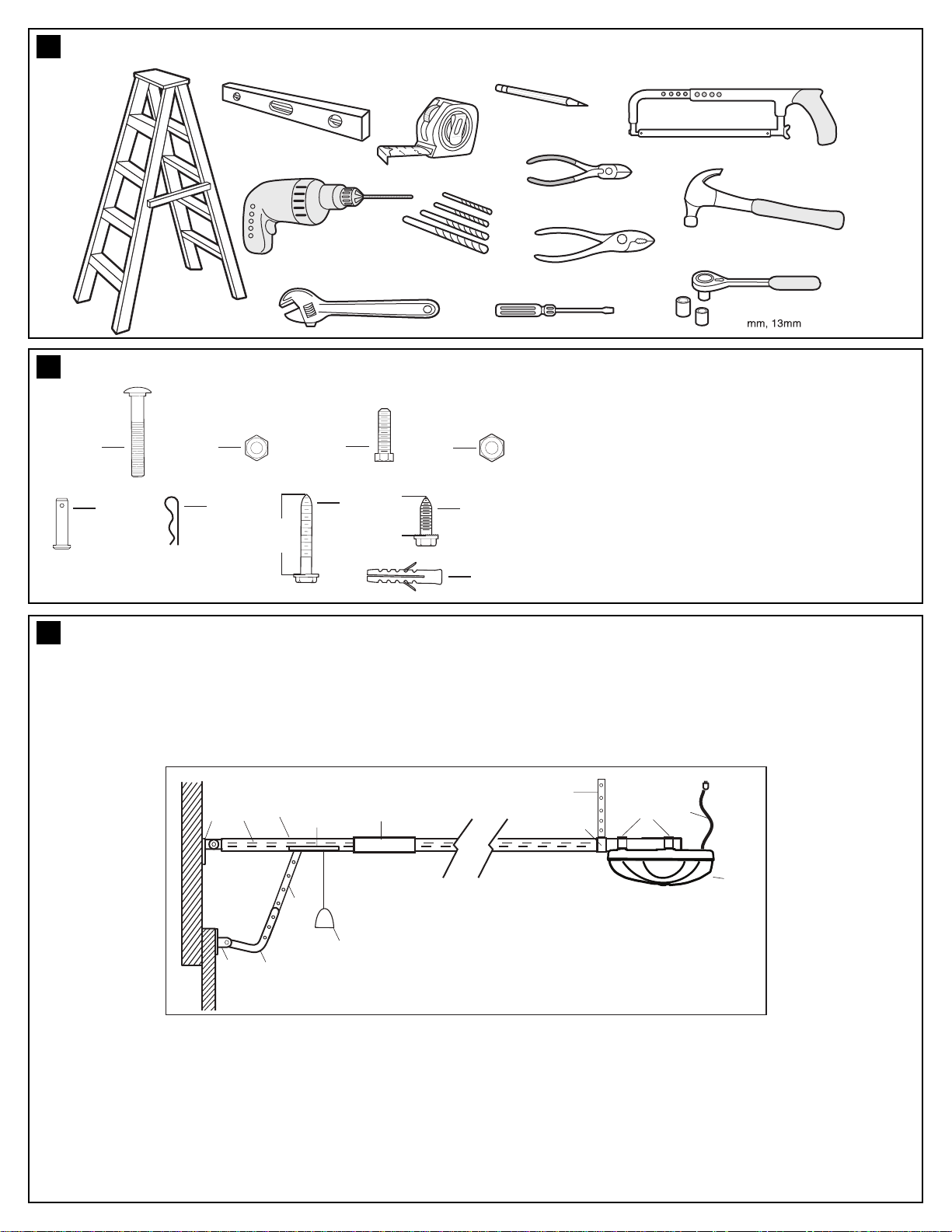

TOOLS REQUIRED

4

HARDWARE PROVIDED

5

(1) Truss headscrew 6 mm x 80 mm

(2) Lock nut M6

(3) Hexagonal head screw

(4) Nut M6

(5) Clevis Pin

(6) R clip

(7) Screw ST6 x 50 mm

(8) Screw ST6,3 x 18 mm

(9) Wallplug

COMPLETED INSTALLATION

6

As you proceed with the assembly, installation and adjustment procedures in this manual, you may find it helpful to

refer back to this illustration of a completed installation.

(1) Header bracket

(2) Chain

(3) Rail

(4) Trolley

(5) Rail connecting piece

(6) Rail bracket

(7) Hanging bracket

(8) Power cord

(9) Opener

(10) Manual release rope & handle

(11) Straight door arm

(12) Curved door arm

(13) Door bracket

4

Page 7

SP

123

123 2

1

2

3

4

7

6

5

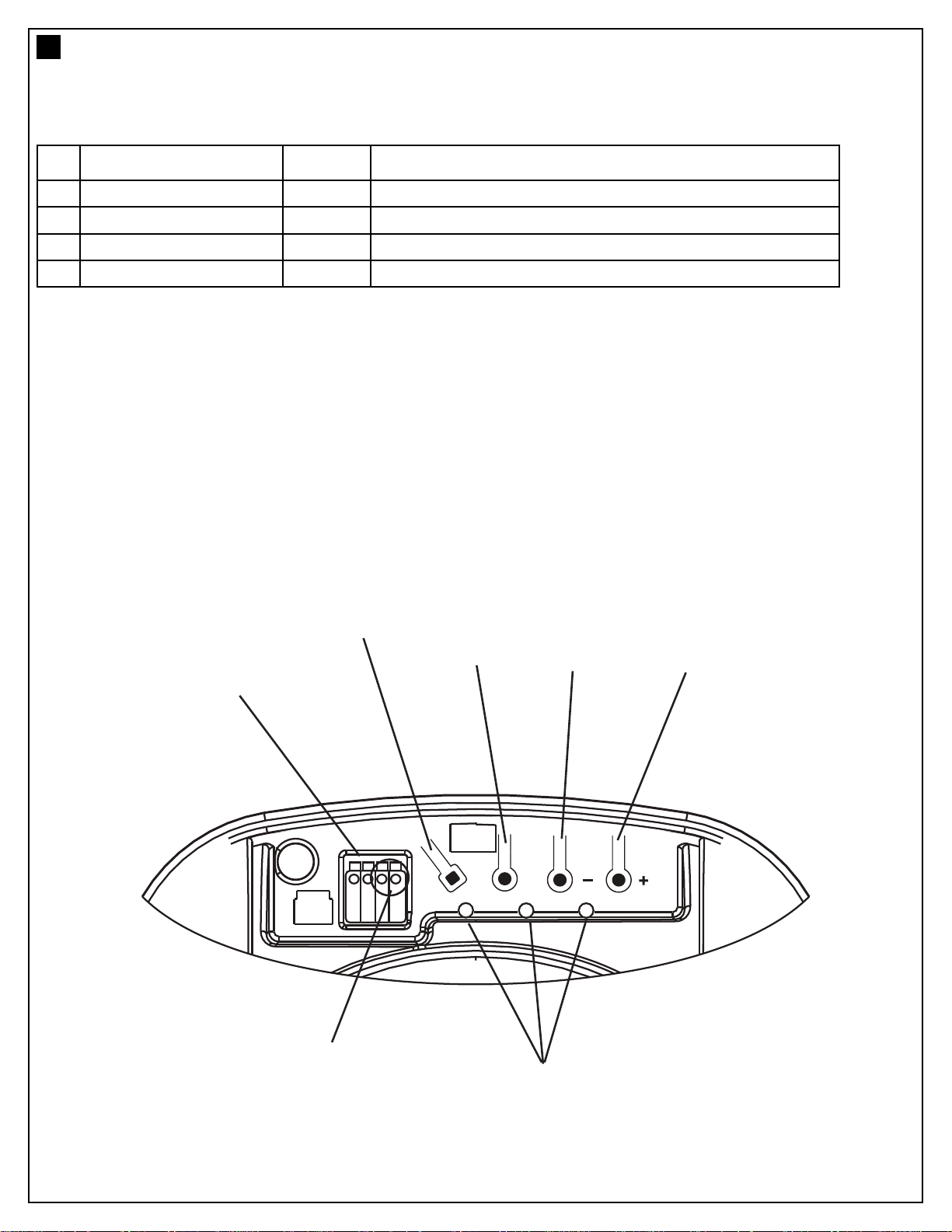

CONTROL PANEL (located under the lens cover)

7

1. Terminal Block: used for external accessories (see chart below).

No Function Polarity Comment

Push button +ve

1

Common -ve

2

2 Common -ve

IR Sensor +ve

3

2. S Button: used to “SAVE” the REMOTE CONTROLS.

3. P Button: used to “PROGRAM” the DOOR LIMITS.

4. - Button: used to drive door DOWN.

5. + Button: used to drive door UP.

6. Green Button: used to activate the door when remote controls are not available. Open - Stop - Close.

Dry contact input for push button wired wall controls:

Common terminal for push button and IR Beams:

Common terminal for push button and IR Beams:

Merlin IR Beam Input: (pulsing type only)

7. LEDs: 1. Remote Control Indicator

2. Program DOWN indicator, Door Operating & Passpoint indicator

3. Program UP indicator

5

Page 8

SSEMBLY SECTION

37 - 41 mm

1

1

3

4

5

2

4x

2x

X

20 mm

A

B

C

D

D

X

1

.

A

B

C

D

D

A

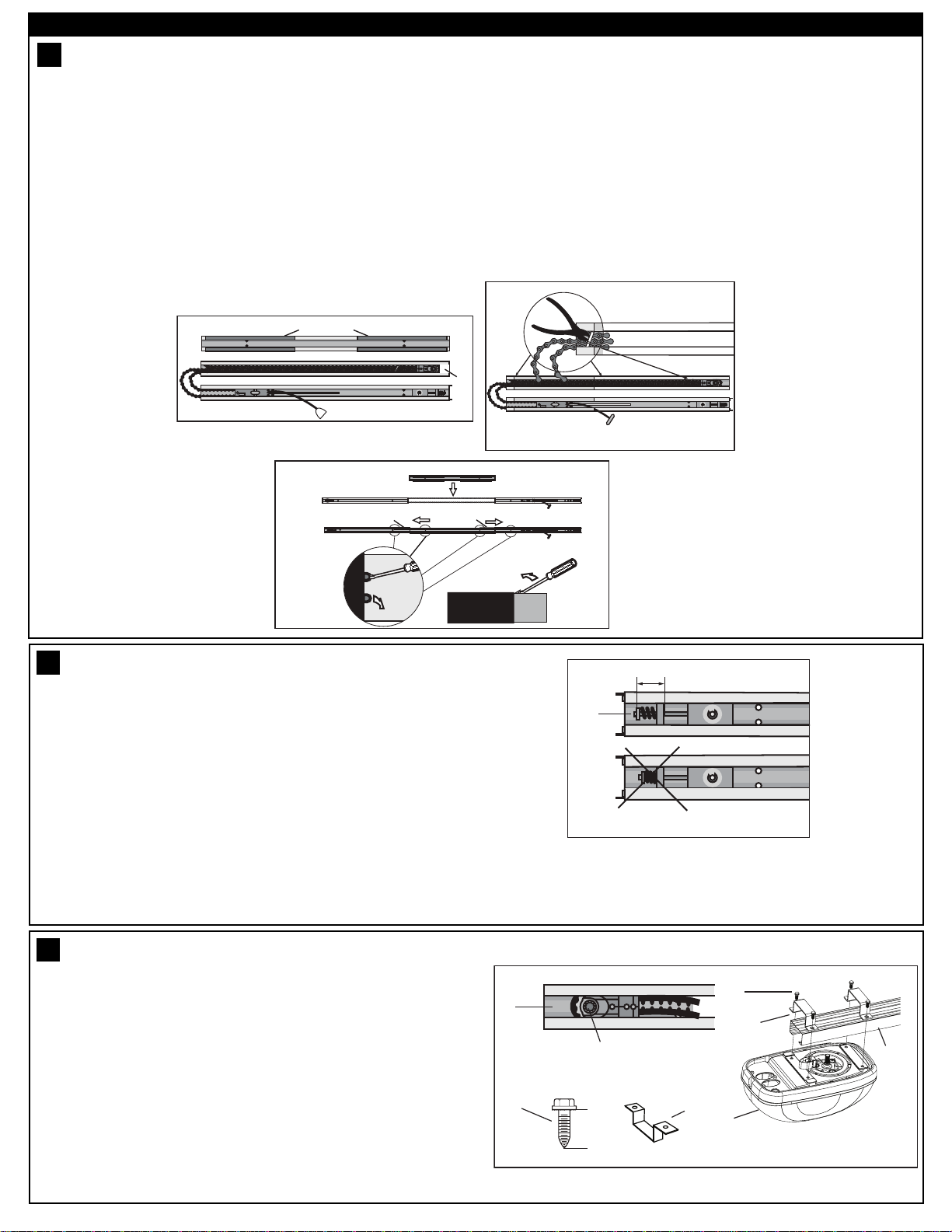

ASSEMBLING THE 3 PIECE SEGMENTED RAIL

8

The segmented rail is largely preassembled and consists of 3 parts. The carriage, push rod, release handle, the guide pulley

and the lintel bracket with chain tensioner are in the front part (A). The seating for the drive shaft and the sprocket are in the

rear part (B). Hardware items are placed in the rails during transportation - remove these. Lay the front and rear rail sections

one behind the other.

1. Remove cable ties that secure chain. Leave the transport lock (X) still in position.

. Pull apart the two rail sections completely in order to create a gap for the middle section (C). This rail is designed in such a

2

way so as to easily add the middle section. Slide the 2 connecting pieces (D) over the seams of the rail sections up to the

markings. To secure the connecting pieces, bend the sheet metal lugs outwards with a suitable tool. The assembly of the rail is

complete.

TIGHTEN THE CHAIN

9

Note: The spring must be able to compress and bounce

during operation. Final tensioning can be performed after

installation if necessary. Over tightening the chain may

overload the system and cause excessive wear.

1.Tension the chain by adjusting the nut (1), on the pulley

assembly, clockwise until the spring is engaged.

2.Continue tightening to compress the spring and remove all the

slack in the chain. DO NOT OVERTIGHTEN but ensure chain

is firm.

3.37-41 mm as indicated in the diagram is normal.

FASTEN RAIL TO OPENER

10

1.Remove transport lock (X). Check if the chain is seated on the

gearwheel. If it has slipped off during assembly, relax the

spring and tighten again.

2.Position the rail drive spocket (2) over the opener motor shaft

(3) and push down to install.

3.Secure the rail on the opener with two C-Rail brackets (4) and

the screws (5).

This completes the assembly of the door opener to the rail.

6

Page 9

INSTALLATION SECTION

Header Wall

2

Level

(

optional)

1

3

Structural

Supports

OPTIONAL

C

EILING

MOUNT

FOR

HEADER

BRACKET

Unfinished

Ceiling

4

2

2

50 mm

3

1

4

A

150 mm

(6")

1

2

3

5

5

1

2

Wear protective goggles when working overhead to protect your eyes from injury.

Disengage all existing garage door locks to avoid damage to the garage door.

To avoid serious personal injury from entanglement, remove all ropes connected to the garage door before

installing the opener.

HEADER BRACKET POSITIONING

11

he header bracket must be rigidly fastened to a

T

structural support of the garage. Reinforce the wall or

ceiling with a 40 mm (1-1/2") board if necessary. Failure

to comply may result in improper operation of safety

reverse system.

You can attach the header bracket either to the header wall

(1) or to the ceiling (3). Follow the instructions which will

work best for your particular requirements.

With the door closed, mark the vertical centre line (2) of the

garage door. Extend line onto header wall above the door.

Open door to highest point of travel. Draw an intersecting

horizontal line (4) on header wall at least 50 mm above high

point to provide travel clearance for top edge of door.

INSTALL THE HEADER BRACKET

12

NOTE: Refer to vertical centre and horizontal lines created in

the previous section for proper placement of header bracket.

A. Wall mount: centre the header bracket (1) on the vertical

centre line (2) with the bottom edge of the header bracket on

the horizontal line (4) (with the arrow pointing toward the

ceiling). Mark all of the header bracket holes (5). Drill 4.5 mm

(3/16") pilot holes and fasten the header bracket with wood

screws (3).

B. Ceiling mount: extend vertical centre line (2) onto the ceiling.

Centre the header bracket (1) on the vertical mark no more

than 150 mm (6") from the wall. Make sure the arrow is

pointing toward the opener. Mark all of the header bracket

holes (5). Drill 4.5 mm (3/16") pilot holes and fasten the header

bracket with wood screws (3). For concrete ceiling mount, use

concrete anchors provided.

ATTACH RAIL TO HEADER BRACKET

13

Attach the Rail to the Header Bracket

• Position the assembled opener on the garage floor below the

header bracket. Use foam packing material as a protective

base.

NOTE: If the door spring is in the way youʼll need help.

Have someone hold the opener securely on a temporary

support to allow the rail to clear the spring.

• Position the rail bracket against the header bracket.

• Align the bracket holes and secure with the 80 mm trusshead

screw and locknut (1) and (2).

7

Page 10

Rail

Door

50 mm spacer should

be used to determine

the correct mounting

position

Header

Bracket

50 mm (2”)

above the highest

point of travel

POSITION THE OPENER

14

Disengage the trolley mechanism (see section “Operating the manual release”) and slide it back towards the powerhead.

ecure the hanging push arm up into the rail assembly temporarily using tape or rope, to avoid a hazard.

S

SECTIONAL DOOR

You will need a 50 mm piece of timber or similar spacer to gauge the distance between door and rail.

1.Raise the opener onto support.

2.Open the door completely, place a 50 mm spacer between the door and the rail (as shown).

3.The final positioning of the rail should be relatively parallel to the horizontal door panels.

8

Page 11

1

2

X

A

B

C1

C

2

C3

HANG THE OPENER

100 mm

1

A

15

The opener must be securely fastened to a sound

structural support above the opener.

.Postion the opener as in the previous step. Check the rail

1

is centred over the door (fig. A).

.The mounting bracket must be mounted so far back that

2

the carriage is not obstructed. The carriage can not pass

through the bracket. Mounting at the very back (fig. B) is

ideal.

3.Bend ceiling fixtures (1) in such a way that they lie flat

against the ceiling. Depending on how large the distance

to the ceiling is, none, one or two of the support brackets

are to be mounted (fig C1, C2 and C3).

4.Secure the hanging brackets to the ceiling using

appropriate screws.

5.Place mounting bracket (2) around the rail, then align to

the ceiling fixture and bolt them together.

6.Centre Rail Support Brackets (kit contents item 12) can

be installed along the centre of the rail if required. This

will reduce flex in the rail that may occur with segmented

rails or rail extensions.

7.Check the opener is securely centred over the door.

Remove the 50 mm spacer, and any other assembly

tools. Operate the door manually and check for

unrestricted operation.

FASTEN DOOR BRACKET

16

The door bracket must be securely fastened to the frame or

a structural support on the door.

Mounting position for Sectional Doors

1.Align the bracket on the centre line, measure down 100 mm

from the door top edge.

2.Secure the bracket in this position on a structural support of

the door, using the most suitable variation of holes available.

9

Page 12

1

2

3

Trolley Sc

Fig. 1

5

ATTACH DOOR ARM TO TROLLEY

17

Make sure the garage door is fully closed. Pull the manual release cord

to disengage the trolley. Slide the trolley to around 300 mm from the

header bracket.

1.The straight door arm is already preassembled to the trolley.

2.Install the curved arm onto the door bracket using the Clevis pin (2)

and R-Clip (3) supplied.

3.Move the straight and curved arms together and secure using two

bolts and nuts provided (4). Ensure the angle of the straight arm is

around 20 degrees from vertical, when the door is fully closed.

.

18

OPERATING THE MANUAL RELEASE

DO NOT DISENGAGE THE OPENER TO MANUAL

OPERATION WITH CHILDREN , PERSONS OR OTHER

OBJECTS INCLUDING MOTOR VEHICLES WITHIN THE

DOORWAY : (The door is under significant tension and if the door

has developed a fault or incorrect tension, it may be unsafe and may

fall rapidly.)

The

Manual release mechanism enables the door to be manually operated

during power outages or in an emergency.

The RED Manual Release cord is preassembled to the trolley. When the

opener is installed the handle should be no higher then 1.8 metres from

the floor. The cord may need to be extended.

Attach the manual release Instruction Label to the cord as indicated in

fig 1.

DO NOT USE THE RED HANDLE TO OPEN AND CLOSE THE DOOR.

To operate the Manual Release:

1.The door should be fully closed if possible.

2. Pull and hold the manual release rope down, (fig A) at the same time

lift the door slightly. This will disengage the door from the trolley (fig B).

3. Release the rope and the door can now be opened by hand.

To Re-engage the Door:

1.Operate the opener with the remote control. When the trolley passes

the door position it will automatically re-engage the opener and move

the door.

10

Page 13

SP

1

2

3

SP

1

23

SP

123

SP

123

SP

123

123 2

123 2

123 2

123 2

123 2

2

3

4

5

6

-

+

P

S

1

3

2

3

2

2

1

-

+

P

S

1

3

2

3

2

2

1

1

▲

▐

▲

▐

Connect Electric Power

TO AVOID INSTALLATION DIFFICULTIES, DO NOT RUN THE GARAGE DOOR OPENER UNTIL INSTRUCTED TO DO SO.

Connect to properly fused and earthed power outlet.

- Ensure all ropes and installation tools have been removed from the door.

When the opener is switched ON, the operator light flashes a number of times and then remains ON.

-

ADJUSTMENT SECTION

PROGRAM THETRAVEL LIMITSAND FORCE SETTINGS

19

ravel limits regulate the points at which the door will stop

T

hen moving UP or DOWN. The travel limit buttons are located

w

under the light cover (figure 1).

NOTE: The opener will MOVE AUTOMATICALLY after setting the

DOWN limit at step 6. A complete UP DOWN cycle is performed

in order to “Set the Force” automatically. If the door is

interrupted during this process, the force will not be set and

the process will have to be repeated.

REFER TO THE DIAGRAMS:

1. Turn the Power ON and open the light cover. (The courtesy LEDs

will be on during this operation, and you may need to cover these

in order to see the program buttons clearly).

2. Press the “P” button until LED 3 starts flashing.

3. Press and hold the “+” button until the door moves to the desired

UP position. The “+” and “-” buttons can be used to move the

door UP and DOWN if required.

4. Press the “P” button to set the UP limit. LED 2 starts flashing.

5. Press and hold the “-” button until the door moves to the desired

DOWN position. The “+” and “-” buttons can be used to move

the door UP and DOWN if required.

6. Press and release the “P” button to set the DOWN limit. At this

point the opener will operate AUTOMATICALLY a complete cycle.

This will set the force of the motor, all LED indicators will stop

after this operation.

To prevent damage to vehicles, be sure fully open

door provides adequate clearance.

LIMITS AND FORCE ARE NOW SET.

SETTING THE FORCE (MANUAL LEARN IF REQUIRED):

If the limits are already set, the force can be set manually if

required.

1. Start with the door closed.

2. Disconnect the mains power from the opener for approx.10

seconds.

3. Using the remote control, Open and Close the door one complete

cycle.

The Force Setting has now been set manually.

Without a properly installed safety reversal

• Incorrect adjustment of garage door travel limits will

system, persons (particularly small children)

could be SERIOUSLY INJURED or KILLED by

a closing door.

interfere with proper operation of safety reversal

system.

• NEVER use force adjustments to compensate for a

binding or sticking garage door.

• After ANY adjustments are made, the safety reversal

system MUST be tested. Door MUST reverse on

contact with 40 mm high object laid flat on floor.

11

Page 14

1

40mm

20

TEST THE SAFETY REVERSE SYSTEM

The safety reverse system test is important. Garage door must reverse on contact with a 40 mm obstacle

aid flat on the floor. Failure to properly adjust opener may result in serious personal injury from a closing

l

garage door. Repeat test once a month and adjust as needed.

Procedure: With door opened place a 40 mm obstacle (1) laid flat on the floor under the garage door. Operate the

door in the down direction. The door must reverse off the obstacle. If the door stops on the obstacle, remove obstacle

and repeat Program the Limits and Force Steps, then repeat safety reverse test.

hen the door reverses off the 40 mm obstacle, remove the obstacle and run the opener through a complete travel

W

cycle. Door must not reverse in closed position. If it does, repeat Program the Limits and Force then repeat safety

reverse test.

12

Page 15

M

ount Bracket

With Square Holes

Screws

“C” Wrap

Lock Nuts

Mounting Bracket

w

ith slot

L

ock Nuts

Lag Screws

Carriage Bolts

(with Square Shoulders)

Garage

Wall

“

C” Wrap

M

ounting Bracket

with Square Holes

Garage

wall

“C” Shaped

Wrap

Mounting Brackets

with Square Holes

Carriage Bolts

Lock Nuts

Drill

9.5 mm

Holes

Garage

Track

Installing The Protector System toTrack

ALL INSTALLATIONS

I

nstalling The Protector System tothe Garage Wall

TM

T

M

“C” Wrap

Garage

Wall

Mounting Bracket

with Square Holes

Garage-

Floor

Mounting

Bracket

with Holes

Alternate Wall Mount

Sensor

Garage

Wall

Alternate Floor Mount

Mounting Bracket

with Slot

Mounting Bracket

with Square Holes

Holder

Sensor

Garage

Floor

Indicator Light

Indicator

Lamp

Attach with

concrete anchors

(not provided)

INSTALL THE PROTECTOR SYSTEMTM(OPTIONAL)

21

NOTE: This accessory must be used for all installations

where the closing force as measured on the bottom of the

oor is over 400 N (40 kgf).

d

PECIAL NOTE: Merlin strongly recommends that The

S

Protector System

TM

be installed on all garage door

openers.

R BEAMS: By installing IR Beams, an open door is prevented

I

from closing if a person or object is located in the beam area. If

the door is already closing, it will return to the open position. A

closed door is not prevented from opening.

TM

If the Protector System

is installed and needs to be removed,

the opener will need to be reprogrammed (refer to paragraph 4

of the troubleshooting section).

NOTE: A complete set of installation and setup

instructions are supplied with the accessory item.

Figures 1, 2 and 3 show recommended assembly of bracket(s)

and "C" wrap based on the wall installation of the sensors on

each side of the door shown above, or on the door tracks

themselves. Figure 4 shows variations which may fit your

installation requirements better. Make sure the wraps and

brackets are aligned so the sensors will face each other

across the door.

• Connect each assembly to a slotted bracket, using the

hardware shown. Note alignment of brackets for left and

right sides of the door. Finger tighten the lock nuts.

• Use bracket mounting holes as a template to locate and drill

two (4.8 mm) diameter pilot holes on both sides of the door so

that the beam mounting height is no greater than 100 mm

above the floor.

• Attach bracket assemblies with carriage bolts as shown.

• Adjust right and left side bracket assemblies to the same

distance out from mounting surface. Make sure all door

hardware obstructions are cleared. Tighten the lock nuts.

• Centre each sensor unit in a "C" wrap with lenses pointing

toward each other across the door.

• Secure sensors with the hardware provided. Finger tighten

the wing nut on the receiving eye to allow for final adjustment.

Securely tighten the sending eye wing nut.

• Run wires from both sensors to the opener and connect the

two white only wires to terminal (2) and the black/white wires

to terminal (3) on your opener.

To prevent entrapment, install The Protector

System™ no higher than 100 mm above the floor.

isconnect power to the garage door opener

D

before installing The Protector System™.

figure 1

figure 2

figure 3

figure 4

13

Page 16

INSTALLING YOUR E138M WIRELESS WALL BUTTON (OPTIONAL)

+

1

service

www

chamber

ande

nfo@chamberande

B

B

A

2

114A3361

ForServiceCall

InstallationDate

3

132A2900

RISKOF ENTRAPMENT

RepeatSafety ReverseTest monthly.Door

mustreverse oncontact witha 40mmobstacle

placedon thefloor. Makenecessary adjustments.

AUTOMATICDRIVE:

Keepaway fromthe areaof thedoor sinceit may

operateunexpectedly.

EMERGENCYRELEASE:

Torelease, pulldown firmlyon thered handle.

114A3361

ForService Call

InstallationDate

22

NOTE: If adding a wireless wall control, program into the opener before mounting the unit as detailed in Wireless

Programming.

isconnect power to the opener before installing

D

this accessory to prevent accidental activation.

Locate minimum 1.5 m above the floor.

To install:

• Carefully pry open the E138M and locate the two screws for

mounting.

• Attach to the wall using the two screws provided. If mounting to a

plaster wall, wall plugs may be required.

NOTE: Do not overtighten screws.

• Replace the front cover plate.

INSTALL WARNING LABELS

23

Three warning labels are provided with this opener: attach as indicated in the fig 1.

• Danger of entrapment: place close to a fixed Wall Control(1).

• Service label: - place on the Manual Release cord (2).

• Caution Child Entrapment: (triangle label) - place on a low inside panel of the door (3).

14

Page 17

1

2

S

P

12

3

1232

2

2

3

4

3

Press and release

the “S” button

Enter a 4-digit

PIN of your

choice

? ? ? ?

_ _ _ _

Press and hold

the enter button

Opener light flashes

After the lights

flash release the

ENTER button

1

Locate the

“S” button

SP

123

1

23 2

S

P

12

3

123 2

WIRELESS PROGRAMMING (OPTIONAL ACCESSORIES)

24

Activate the opener only when door is in full view, free of obstruction and properly adjusted. No one should

enter or leave garage while door is in motion. Do not allow children to operate push button(s) or remote(s).

Do not allow children to play near the door.

NOTE: The transmitter(s) supplied with your opener are

reprogrammed by the factory.

p

If you purchase additional transmitters, the garage door opener must

be programmed to accept the new remote code.

Program the Receiver to Match Additional Transmitter Codes:

Using the “S” SAVE Button

1.Press and Hold the button on the hand-held remote or wall button that

you wish to use (1).

2.Press and release the “S” button on the opener (2).

3.Release the remote button when the opener light flashes. It has learnt

the code. If you release the remote control push button before the

opener light flashes, the opener has not learned the code.

Now the opener will operate when the remote control push button is

pressed.

To Erase all Remote Control Codes

1.Press and Hold the “S” button on the opener until the indicator LED

goes ON, and continue holding for approx. 8 seconds, until the

indicator LED goes out.

2.Release the button, all codes are now erased.

Wireless Keypad E840M

To set the keyless entry PIN:

1.Locate the “S” button on the garage door opener.

2.Press and release the “S” button. The LED 1 indicator light will glow

steadily.

3.Enter a 4-digit personal identification number (PIN) of your choice

on the keypad.

4.Press and hold the ENTER button. Check to see if the opener light

flashes. Release the ENTER button after the light flashes.

To change an existing keyless entry PIN:

1.Enter the existing programmed PIN that you want to change.

2.Press and hold the # button until the courtesy light flashes once.

3.Enter the new 4-digit PIN of your choice, then press the ENTER

button. The light will flash once.

4.To test, enter the new PIN, then press the ENTER button. The

garage door opener will activate.

15

Page 18

1

2

V

D

C

Pb Cd Hg

or

Carefully

RemoveBattery

(CR2032x1)

MAINTENANCE AND CARE OF YOUR OPENER

USING YOUR OPENER

25

1. Your opener can be activated by any of the following devices:

• Opener control panel: UP and DOWN Buttons and Green O.S.C.

• The Outside Keyswitch or Keyless Entry System (if you have

installed either of these accessories).

• The Remote Control Transmitter. Hold the push button down until

the door starts to move.

2. Opening the Door Manually: Door should be fully closed if

possible. Weak or broken springs could allow an open door to

fall rapidly. Property damage or serious personal injury could

result.

NOTE: For full instructions on how to operate the door manually

refer to section 18.

Do not use the manual release handle to pull the door open

or closed.

3. When the Opener is Activated by Remote Control:

1. If open, the door will close. If closed, the door will open.

2. If closing, the door will stop.

3. If opening, the door will stop (allowing space for entry and exit of

pets and for fresh air).

4. If the door has been stopped in a partially open or closed position,

it will reverse direction.

5. If an obstruction is encountered while closing, the door will reverse

to the UP limit.

6. If an obstruction is encountered while opening, the door will

reverse and stop.

7. The optional Protector System™ uses an invisible beam which,

when broken by an obstruction, causes a closing door to open

and prevents an open door from closing. It is STRONGLY

RECOMMENDED for homeowners with young children.

4. The opener lights will turn on under the following conditions:

When the opener is initially plugged in; when power is restored after

interruption or when the opener is activated.

27

REPLACE BATTERIES IN REMOTES

Battery of the remote control:

he batteries in the remote have an extremely long life.

T

If the transmission range decreases, the batteries must be

replaced. Batteries are not covered by the warranty.

To prevent SERIOUS INJURY OR DEATH:

bserve the following instructions for the

o

battery

- NEVER allow small children near batteries.

- If battery is swallowed, immediately notify doctor.

- Danger of explosion if battery is replaced improperly.

- Replacement only by identical or equivalent type.

- Dispose of old battery properly. Batteries should not

be treated as household waste. All consumers are

required by law to dispose of batteries properly at the

designated collection points.

- Never recharge batteries that are not meant to be

recharged.

- Do not short-circuit batteries or take them apart.

- If necessary, clean contacts on batteries and contacts

before loading.

- Never expose batteries to excessive heat such as

sunshine, fire or the like!

Replacing battery (CR2032):

To replace battery, turn remote control around and open the

case with a screwdriver. Lift cover and lift control board below.

Slide battery to one side and remove. Observe polarity of

battery!

Assemble again in reverse direction.

Lights will turn off automatically after 3 minutes.

CARE OF YOUR OPENER

26

Once a Month

• Manually operate door. If it is unbalanced or binding, call a

qualified door technician.

• Check to be sure door opens & closes fully. Adjust limits

and/or force if necessary.

• Repeat the safety reverse test. Make any necessary

adjustments.

Once a Year

• Lightly grease the chain and inside the rail assembly where

the trolley slides.

• Internally the opener does not require additional lubrication.

To replace battery for optional remote control transmitters E943M, E940M & E945M, use a screwdriver blade to pry

open the case as shown. Insert battery positive side up.

16

Page 19

8

7

9

1

6

E840M

E128M

E1702M

C77

E940M

E943M

E945M

10

4

5

E950M

E138M

2

E952M

3

28

ACCESSORIES

(1) Model E128M Wireless wall button

(2) Model E138M Wireless wall button

(3) Model E952M 2 Channel remote control

(4) Model E950M 4 Channel remote control

(5) Model E940M 1 Channel visor remote control

NOTE: Only genuine Merlin accessories are approved for use with this opener. Generic compatible accessories are NOT approved for use with this opener.

(6) Model E943M 3 Channel visor remote control

(7) Model E945M 3 Channel mini remote control

(8) Model E840M Keyless entry system

(9) Model C77 The Protector System

(10) Model E1702M Quick release lock

TM

29

ACCESSORY WIRING DIAGRAM

17

Page 20

REPLACEMENT PARTS

If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent or similarly qualified persons

in order to avoid hazard.

RAIL REPLACEMENT PARTS

041A4017

Motor shaft adapter (PVC)

041A4021

Trolley latch (chain)

041A4016

Position tab (chain)

041A4001EV

Logic Board

041A4024

Transformer

041A4033

Motor Assembly

041A4004

Passpoint Assembly

041A4006

Cover & Lens

Assembly

041A4002

Led Light

041A4023

Power

Board

026B0182

Power Cord

30

18

Page 21

TROUBLE SHOOTING

31

1. Opener doesn't operate from either door control or

remote:

Does the opener have electric power? Plug lamp into

•

outlet. If it doesn't light, check the fuse box or the circuit

breaker. (Some outlets are controlled by a wall switch.)

• Have you disengaged all door locks? Review installation

instruction warnings on page 1.

Is there a build-up of ice or snow under door? The door

•

may be frozen to ground. Remove any obstruction.

• The garage door spring may be broken. Have it

replaced.

2. Door operates from door control but not from

remote:

• Replace batteries in the remote if necessary.

• If you have two or more remotes and only one operates,

review Program Your Opener, Remote and Keyless

Entry.

3. Remote has short range:

• Check the battery in the remote is fully charged.

• Change the location of the remote control in the car.

• A metal garage door, foil-backed insulation or metal

siding will reduce the transmission range.

4. Door reverses for no apparent reason and opener

light flashes 10 times:

7. Door opens but won't close:

• Check The Protector System™ (if you have installed

his accessory). If the light on the Beams are flashing,

t

correct the alignment.

• If opener light does not flash and it is a new installation,

repeat Programming the Travel Limits.

epeat the safety reverse test after the adjustment is

R

complete.

8. Opener strains:

Door may be unbalanced or springs are broken. Close

door and use manual release rope and handle to

disconnect trolley. Open and close door manually. A

properly balanced door will stay in any point of travel

while being supported entirely by its springs. If it does

not, call for professional garage door service to correct

the problem.

9. Opener hums briefly, then won't work:

• Garage door springs are broken. SEE ABOVE.

• If problem occurs on first operation of opener, door is

locked. Disable door lock.

Repeat safety reverse test after adjustment is complete.

10. Opener won't activate due to power failure:

• Check The Protector System™ (if you have installed this

accessory). If the light is flashing, correct alignment.

TM

If the Protector System

is installed and needs to be

removed, the Opener will need to be reprogrammed as

follows:

• Remove the IR Beam wiring from the Opener

• Turn the power OFF for 5 seconds

• Turn the power ON for 5 seconds

• Again turn the power OFF for 5 seconds

• Turn the power back on and test the opener for normal

operation.

5. The garage door opens and closes by itself:

• Make sure remote push button is not stuck "on".

• Delete transmitter codes to eliminate possible faulty

remotes.

6. Door stops but doesn't close completely:

Repeat Programming the Travel Limits.

Repeat safety reverse test after any adjustment of door

arm length, close force or down limit adjustments.

• Pull manual release rope and handle down once to

disconnect trolley. Door can be opened and closed

manually. When the power is restored, the next time the

opener is activated, the trolley will re-connect.

• The Outside Quick Release accessory (if fitted)

disconnects the trolley from outside the garage in case

of power failure.

11. The opener runs, but the carriage does not move:

• Check the carriage is not disengaged from the opener.

Operate the opener to reengage the trolley.

• In a new installation, the preassembled Motor Shaft

Adapter may have fallen out of the chain sprocket

assembly. This adapter is installed during the

manufacturing process and may have dislodged.

19

Page 22

SPECIFICATIONS - EntryLift - MT50EVO

32

Input Voltage...........230-240 Vac, 50 Hz

ax. Pull Force ......500 N

M

Power .....................80 Watt

Standby Power .......0.8 Watt (door fully closed)

Normal Torque........4 Nm

Max door weight......60 kgs Spring balanced

ax door area.........Sectional door 13.0 m

M

Motor

Type........................DC gearmotor permanent lubrication

Noise level ..............55 db at 1 metre

Drive Mechanism

Drive .......................Chain with one-piece trolley on

steel rail.

Length of Travel......2.5 m

Courtesy light..........8 LEDs

Light on Time..........3 min

Door Linkage ..........Adjustable door arm. Pull cord trolley release.

Safety

Personal .................Push button stop in UP and DOWN direction. Automatic safety reverse in both UP and DOWN direction.

Electronic................Automatic force adjustment

Electrical .................Transformer overload protector and low voltage push button wiring.

Limit Device ............Mechanical Passpoint/RPM sensor

Limit Adjustment .....Electronic

Soft-start/Soft-stop

Dimensions

Length (Overall).......3.45 m

Headroom Required 32 mm

Hanging Weight .......10 kg

2

Receiver

Memory Registers ...16 handset codes

1 keypad code

Operating

Frequency.................433.30/433.92/434.54 MHz

20

Page 23

CHAMBERLAIN LIMITED WARRANTY

Merlin

®

Professional EntryLift

M

T

MT50EVO

Sectional Garage Door Opener

Chamberlain Australia Pty Limited / Chamberlain New Zealand Limited

(Chamberlain), the manufacturer of Merlin®automatic garage door openers,

is committed to manufacturing and supplying high quality goods. As part of

this commitment, we seek to provide reliable service and support for our

goods and are pleased to provide you, the original purchaser, with this

Chamberlain Limited Warranty.

The benefits given to you under this Chamberlain Limited Warranty are in

addition to any rights and remedies that you may have under Australian or

New Zealand consumer protection laws. Our goods come with guarantees

that cannot be excluded under the Australian Consumer Law, or New Zealand

Consumer Guarantess Act 1993. You are entitled to a replacement or refund

for a major failure and for compensation for any other reasonably foreseeable

loss or damage. You are also entitled to have the goods repaired or replaced

if the goods fail to be of acceptable quality and the failure does not amount to

a major failure.

Chamberlain’s warranty

What is covered

Chamberlain warrants to the original purchaser of the Merlin EntryLift

MT50EVO Sectional Door Opener (Unit) that all parts of the Unit, other than

remote controlled transmitters and accessories, globes and batteries, are free

from defects in materials and workmanship for a period of 24 months or 5,000

cycles (each opening & closing of the garage door equals 1 cycle) whichever

comes first, from the date of purchase when installed by a Professional dealer

appointed or authorised by Chamberlain in a residential premise with a

residential specified garage door that is designed for the sole purpose of a

single-family dwelling.

Chamberlain warrants that remote controlled transmitters and accessories

included with the Unit are free from defects in materials and workmanship for

a period of 12 months from the date of purchase.

What is not covered

Batteries and globes are not covered under the Chamberlain Limited

Warranty.

Travel costs incurred by Chamberlain or the Professional Dealer in either

travelling to or from areas outside a capital city metropolitan area. These costs

will be at the purchaser’s expense.

Additional access costs incurred by a Professional Dealer or Chamberlain in

obtaining access where the Unit is not readily accessible. These cost will be at

the purchaser’s expense.

Warranty Conditions

It is a condition of this Chamberlain Limited Warranty that the Unit is sold,

installed and serviced by a Professional Dealer appointed or authorised by

Chamberlain. A Merlin branded garage door opener purchased over the

internet and installed by a person other than a Professional Dealer will not be

covered by this Chamberlain Limited Warranty.

It is also a condition of this Chamberlain Limited Warranty that for the

operating life of the Unit:

1 the garage door is spring balanced, is operable by hand and opens

and closes with no more than a maximum of 20 kgs of lifting weight;

2 the garage door and the Unit is professionally maintained and serviced

by a Professional Dealer during the Chamberlain Limited Warranty period

such that the spring balanced door operates according to manufacturer

specifications. If your door binds, sticks, or is out of balance, then it must

not be used until serviced by a trained door technician or Profesional

Dealer. The garage door service fee will be at the purchaser’s expense;

3 the warranty is registered by completing the online form at

ww.gomerlin.com.au or www.gomerlin.co.nz; and

w

4 you retain your sales docket or invoice as proof of purchase, and attach it

to this manual to enable you to establish the date of purchase in the

unlikely event of a warranty service being required.

Making a claim

During the applicable Chamberlain Limited Warranty period, if you are

concerned that the Unit may be defective, call the Professional Dealer that

sold/installed the opener, or our service centre on the toll free number below

and a Chamberlain technician will diagnose the problem and arrange for this

to be rectified. Once the problem has been diagnosed, subject to your rights

under the applicable Australian and New Zealand consumer protection laws

with respect to major failures, Chamberlain or its Professional Dealer will

provide you with either, repairs to the Unit or a replacement Unit.

Repairs and replacement parts provided under this Chamberlain Limited

Warranty are provided free of charge and are warranted for the remaining

portion of the original warranty period.

This Chamberlain Limited Warranty provides benefits which are in addition to

your other rights and remedies as a consumer.

Exclusions - what voids the warranty

If our service centre determines that a warranty claim has been made in respect

of a failure or defect arising under or out of any exclusion detailed below such

that the claim is not covered under this Chamberlain Limited Warranty, we may,

subject to your other rights and remedies as a consumer, charge you a fee to

repair, replace and/or return the Unit to you.

This Chamberlain Limited Warranty does not cover any failure of, or defect in,

the Unit due to:

1 non-compliance with the instructions regarding specifications, installation,

operation, maintenance and testing of the Unit or of any product with which

the Unit is used;

2 any attempt by a person other than a Professional Dealer to repair, dismantle,

reinstall or move the Unit to another location once it has been installed;

3 tampering, neglect, abuse, wear and tear, accident, electrical storm,

excessive use or conditions other than normal domestic use;

4 problems with, or relating to, the garage door or garage door hardware,

including but not limited to the door springs, door rollers, door alignment or

hinges;

5 problems caused by electrical faults or replacement of batteries or light bulbs,

blown fuses, electrical surges, power surges or power strikes, fire, flood, rain,

water, lightning or storms;

6 water or moisture ingress that causes corrosion or electrical malfunction;

7 corrosion caused by sea air if located near a waterway, beach etc;

8 fitment to a commercial door or in a commercial operating application,

installation of a residential garage door opener in a commercial or industrial

premises other than a single-family dwelling.

9 lack of proper maintenance, service or care of the door and Unit;

10 any unauthorised modification to the Unit; or

11 damage caused by insects, pests or other after sale damage caused by

events or accidents outside Chamberlain’s reasonable control and not arising

under normal and standard operating conditions.

NB: A General Purpose Outlet (GPO) ie: power point must be supplied by the

consumer as this electrical fitting does not form a part of the Unit (opener).

If this Chamberlain Limited Warranty does not apply, you may have rights

available to you under the Australian and New Zealand consumer protection

laws.

Liability – Australia only

Except as set out in the Australian Consumer Law (being Schedule 2 of the

Competition and Consumer Act 2010) (as amended, consolidated or replaced):

1 all other guarantees, warranties and representations in relation to the Unit or

its supply are excluded to the extent that Chamberlain can lawfully exclude

them; and

2 under no circumstances will Chamberlain be liable for consequential,

incidental or special damages arising in connection with the use, or inability to

use, the Unit, other than those which were reasonably foreseeable as liable to

result from the failure.

Liability – New Zealand only

Except as set out in the Fair Trading Act 1986 and the Consumer Guarantees Act

1993 (as amended, consolidated or replaced):

1 all other guarantees, warranties and representations in relation to the Unit or

its supply are excluded to the extent that Chamberlain can lawfully exclude

them; and

2 under no circumstances will Chamberlain be liable for consequential,

incidental or special damages arising in connection with the use, or inability to

use, the Unit, other than those which were reasonably foreseeable as liable to

result from the failure.

Note

Chamberlain reserves the right to change the design and specifications of the

Unit without prior notification. Some features or accessories of the Unit may not

be available in certain markets or areas. Please check with your distributor.

Chamberlain service centre contact details

Australia

Phone toll free 1800 638 234

Fax toll free 1800 888 121

Email: customerservice@chamberlainanz.com

Website: gomerlin.com.au

CChhaammbbeerrllaaiinn AAuussttrraalliiaa PPttyy.. LLttdd..

Unit1, 75 Epping Road

North Ryde NSW 2113

(PO BOX 1446, Lane Cove NSW 1595)

New Zealand

Auckland phone 09 477 2823

Phone toll free 0800 653 667

Fax toll free 0800 653 663

Website: gomerlin.co.nz

Email: customerservice@chamberlainanz.com

21

Page 24

Warranty Registration

To validate your warranty you must complete

the registration form online at:

gomerlin.com.au/warranty

or

gomerlin.co.nz/warranty

TM

Trademark of The Chamberlain Group, Inc.

® Registered Trademark of The Chamberlain Group, Inc.

114A4687B

22

© 2014, The Chamberlain Group Inc.

Loading...

Loading...