Page 1

1

MJ3800MYQ

Residential Sectional Wi-Fi Garage Door Opener

Installation and Operating Instructions

gomerlin.com.au

gomerlin.co.nz

Owners Copy: Please keep these instructions for future reference

This manual contains IMPORTANT SAFETY information

DO NOT PROCEED WITH THE INSTALLATION BEFORE READING THOROUGHLY

®

Page 2

2

START BY READING THESEI MPORTANT SAFETY INSTRUCTIONS

Keep garage door balanced. Do not let the garage door

opener compensate for a binding or sticking garage door.

Sticking, binding or unbalanced doors must be repaired

before installing this opener.

Do not wear rings, watches or loose clothing while

installing or servicing a garage door opener. Wear gloves,

safety goggles and suitable protective clothing where

appropriate.

Frequently examine the door installation, in particular

cable, springs and mountings for signs of wear, damage

or imbalance. Do not use if repairor adjustment is needed

since springs and hardware are under extreme tension and

a fault can cause serious personal injury.

To avoid serious personal injury from entanglement,

remove all ropes, chains and locks connected to the

garage door before installing the door opener.

Installation and wiring must be in compliance with your

local building and electrical codes.

The safety reverse system test is very important. Your

garage door MUST reverse on contact with a 40mm

obstacle placed on the floor. Failure to properly adjust the

opener may result in serious personal injury from a closing

garage door. Repeat the test once a month and make any

necessary adjustments.

Use the Manual Release only for the seperation of the

carriage from the drive and - if possible - ONLY with the

door closed. Do not use the red handle to push the door

up or pull it down. Operation of the emergency release can

lead to uncontrolled movements of the door, if springs are

weak or broken or if the door is unbalanced. Mount the

release handle of the emergency release at a height less

than 1.8m from the floor.

The Protector System

TM

must be used for all installations

where the closing force as measured on the bottom of the

door is over 400N (40kgf). Excessive force will interfere

with the proper operation of the Safety Reverse System or

damage the garage door.

SPECIAL NOTE: Merlin strongly recommends that The

Protector System

TM

be installed on all garage door

openers.

Do not use with a door incorporating a wicket door

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety.

After installation, ensure that the parts of the door do

not extend over public footpaths or roads.

Install the Smart Control Panel (wired wall control) or

any additional wall control (or any additional wall control)

in a location where the garage door is visible, at a

height of at least 1.5m and out of the reach of children.

Do not allow children to operate push button(s) or

transmitter(s). Serious personal injury from a closing

garage door may result from misuse of the opener.

Permanently fasten the Warning Labels in Prominent

Places, adjacent to Wall Controls and on manual release

mechanism as a reminder of safe operating procedures.

Activate opener only when the door is in full view, free

of obstructions and the opener is properly adjusted. No

one should enter or leave the garage while the door

is in motion.Do not allow children to operate push

button(s) or remote(s).

WARNING: Automatic Door - The door may operate

unexpectedly, therefore do not allow anything to stay in

the path of the door.

Do not allow children to play near the door, or with

door controls. Keep remotes away from children.

Disconnect electric power to the garage door opener

before making repairs or removing covers.

If the supply cord is damaged, it must be replaced by

the manufacturer, its service agent or similarly qualified

persons in order to avoid hazard.

This opener should not be installed in a damp or wet

space exposed to weather.

To avoid damage to very light doors (such as fibreglass,

aluminium or steel doors), an appropriate reinforcement

should.

SAVE THESE INSTRUCTIONS

• Failure to comply with the following instructions may result in serious personal injury or property damage.

• Read and follow all instructions carefully.

• The garage door opener is designed and tested to offer safe service provided it is installed and operated in strict accordance with

the instructions in this manual.

START BY READING THESE IMPORTANT SAFETY INSTRUCTIONS

The safety reverse system test is very important. Your unbalanced. Mount the release handle of the

emergency release at a height less than 1.8m from the floor.

Page 3

3

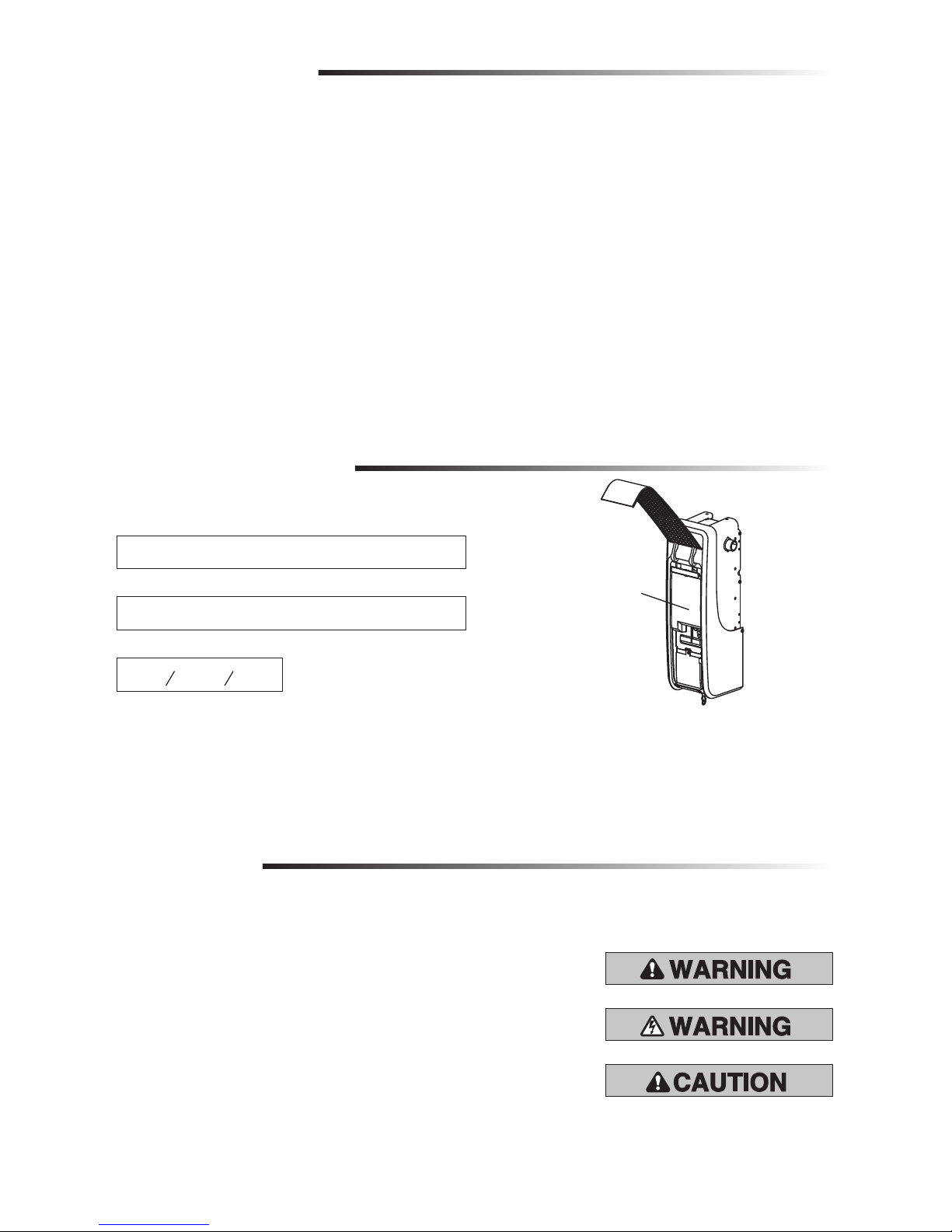

Introduction

myQ® Serial Number

When you see these Safety Symbols and Signal Words on the following pages, they

will alert you to the possibility of serious injury or death if you do not comply with the

warnings that accompany them. The hazard may come from something mechanical or

from electric shock. Read the warnings carefully.

When you see this Signal Word on the following pages, it will alert you to the possibility of

damage to your garage door and/or the garage door opener if you do not comply with the

cautionary statements that accompany it. Read them carefully.

Mechanical

Electrical

Safety Symbol and Signal Word Review

This garage door opener has been designed and tested to offer safe service provided it is installed, operated, maintained and tested in

strict accordance with the instructions and warnings contained in this manual.

Table of Contents

myQ SERIAL NUMBER 2

UNATTENDED OPERATION 2

INTRODUCTION 2

Safety Symbol and Signal Word Review ...... 2

Planning ........................................................ 4

Before You Connect with Your Smartphone 5

Preparing Your Garage Door ........................ 6

Tools Needed ................................................ 6

Carton Inventory ........................................... 7

Included Accessories .................................... 7

Hardware ....................................................... 7

Additional Items You May Need ................... 7

ASSEMBLY 8

Attach the Collar to the

Garage Door Opener ..................................... 8

Attach Mounting Bracket to

Garage Door Opener ..................................... 8

ASSEMBLY 9

Wiring Diagram ............................................. 9

INSTALLATION 10

Position and Mount the

Garage Door Opener ................................... 10

Attach the Emergency Release Rope

and Handle .................................................. 11

Install Automatic Door Lock ....................... 11

Attach the Cable Tension

Monitor (Required) ..................................... 12

Install the Door Control

(Smart Control Panel®) ............................... 13

Install myQ Remote LED Light ................... 14

Install the Protector SystemTM ................... 15

Connect Power ............................................ 18

Install the Battery Backup ........................... 19

ADJUSTMENT 20

Program the Travel ..................................... 20

Test the Safety Reversal System ................ 21

Test the Protector SystemTM ...................... 21

Test Cable Tension Monitor ........................ 22

Test Automatic Door Lock .......................... 22

To Open the Door Manually ........................ 22

OPERATION 23

Using Your Garage Door Opener ................ 24

Connect with Your Smartphone ................. 25

Using the Door Control ............................... 26

PROGRAMMING 27

E960M Premium+ Remote Control ............ 27

Reprogramming myQ® Remote

LED Light..................................................... 28

To Erase the Memory .................................. 28

MAINTENANCE 29

Care of Your Garage Door Opener .............. 29

TROUBLESHOOTING 30

Diagnostic Chart .......................................... 30

Additional Troubleshooting ......................... 31

REPAIR PARTS 32

Installation Parts ......................................... 32

Garage Door Opener Assembly Parts ......... 33

ACCESSORIES 34

WARRANTY 35

Date of Purchase:

Write down the following information for future reference:

Product S/N:

myQ® Serial Number:

Serial Numbers

Unattended Operation

The Timer-to-Close (TTC) feature, the myQ® Smartphone Control app, and myQ® Garage Door are examples of unattended close and are

to be used ONLY with sectional doors. Any device or feature that allows the door to close without being in the line of sight of the door is

considered unattended close.

myQ Remote LED Light must be installed to enable use of Timer To Close or myQ Smartphone Control of the door.

Page 4

4

Introduction

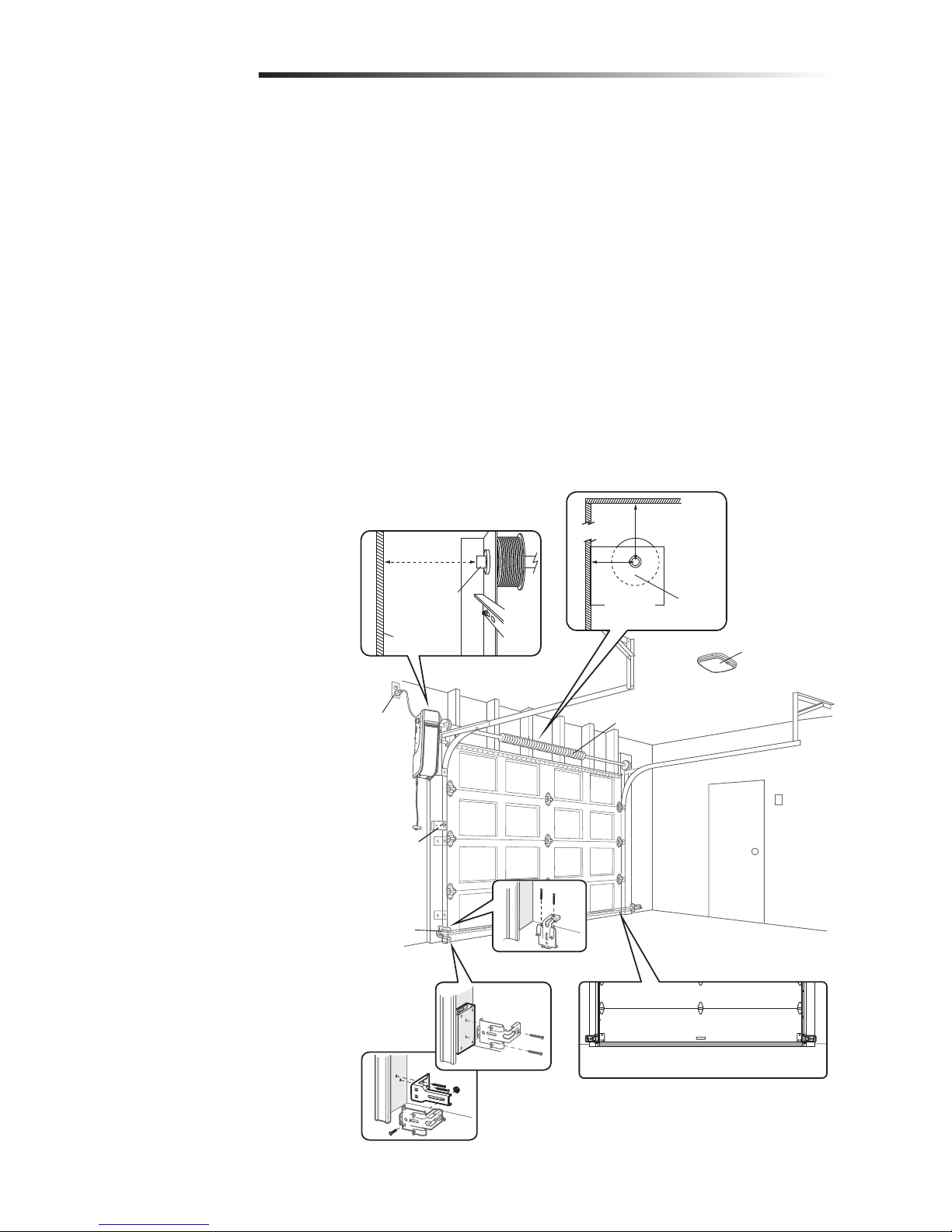

Planning

Survey your area to see if any of the conditions below apply to your installation.

Depending on your requirements, additional materials may be required.

THIS DOOR OPENER IS COMPATIBLE WITH:

• Doors that use a torsion bar and springs. The torsion bar must be 1" (2.5 cm)

diameter. NOT compatible with reverse wound drums.

• 3-4" (8-12 cm) drums good for 130 kg / 230 kg with installation of The Protector

System™ (Safety IR Beams).

• Standard lift sectional doors up to 10 ft. (3.0 m) high.

• Standard lift sectional door up to 18 ft (5.5 m) wide.

• Standard lift sectional door max area up to 180 sq. ft (16.5m2).

Review or inspect proposed installation area. The door opener can be installed on the left

or right side of door. Select the side that meets the requirements listed below.

a. Must have minimum of 2.5" (6.4 cm) between the wall and the center of the torsion

bar.

b. Must have minimum of 3" (7.6 cm) between the ceiling and the center of torsion bar.

c. Must have minimum of 8.5" (21.6cm) between the side wall (or obstruction) and the

end of torsion bar.

d. The torsion bar must extend at least

1.5" (3.81 cm) past the bearing.

This may vary depending on your

installation requirements.

e. An electric outlet is required within

6ft. (1.83 m) of the installation area.

If outlet does not exist, contact a

qualified electrician.

f. Depending upon building

construction, extension brackets or

wood blocks may be needed to install

safety reversing sensors and cable

tension monitor.

g. Alternate floor mounting of the

safety reversing sensors will require

hardware (not provided).

h. Check the seal on the bottom of the

door. Any gap between the floor and

the bottom of the door must not

exceed 1/4 inch (6 mm). Otherwise,

the safety reversal system may not

work properly.

NOTE: Inspect the torsion bar while the

door is raised and lowered. It is important

that there is no noticeable movement up

and down or left and right. If the movement

is not corrected, the life of the garage door

opener will be greatly reduced.

a

b

h

c

d

e

f

g

Torsion

bar

2.5"

(6.4 cm)

3"

(7.6 cm)

Wall or

obstruction

Torsion bar

8.5"

(21.6cm)

Safety

reversing

sensor

myQ® Remote

LED Light

Automatic

door lock

Door spring

Page 5

5

Before You Connect with Your Smartphone

Introduction

Monitor and control your garage door away from home using the myQ® app.

BEFORE YOU BEGIN:

You will need:

• Wi-Fi enabled smartphone, tablet or laptop

• Broadband Internet Connection

• Wi-Fi signal in the garage (2.4 Ghz, 802.11b/g/n required)

• Password for your home network (router's main account, not guest network)

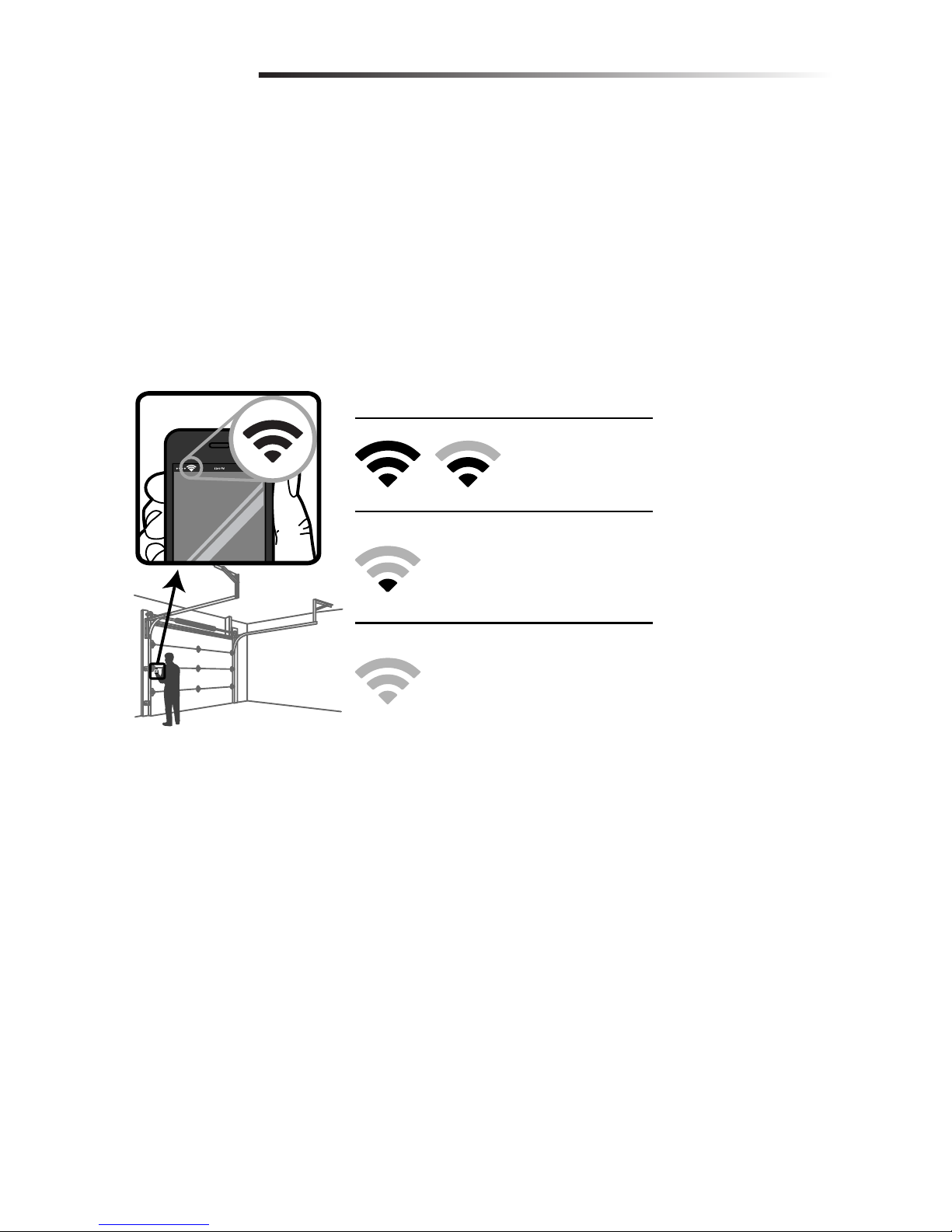

TEST THE WI-FI SIGNAL STRENGTH

Make sure your mobile device is connected to your Wi-Fi network. Hold your mobile

device in the place where your garage door opener will be installed and check the Wi-Fi

signal strength.

See page 24 to connect the garage door opener to a mobile device.

Check Signal Strength. If you see:

Wi-Fi signal is strong.

The garage door

opener will connect to

your Wi-Fi network.

Wi-Fi signal is weak.

The garage door opener may connect

to your Wi-Fi network. If not, try one

of the options below to improve the

Wi-Fi signal:

No Wi-Fi signal.

The garage door opener will not be

able to connect to your Wi-Fi network.

Try one of the options below to

improve the Wi-Fi signal:

• Move your router closer to the garage door opener to

minimize interference from walls and other objects

• Buy a Wi-Fi range extender

Page 6

6

Introduction

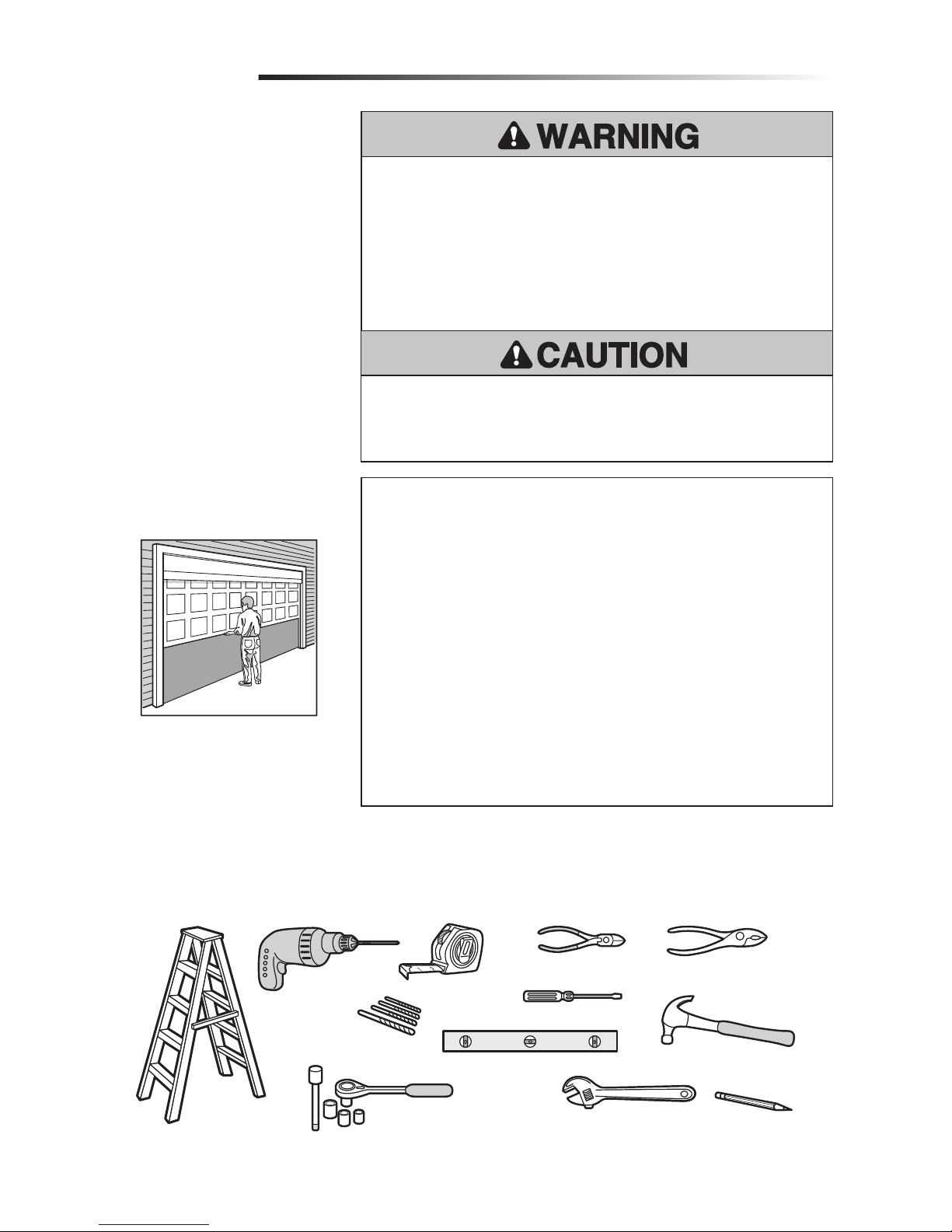

Preparing Your Garage

Door

BEFORE YOU BEGIN:

• Disable locks.

• Remove any ropes connected to the

garage door.

Complete the following test to make sure

the garage door is balanced and is not

sticking or binding:

1. Lift the door halfway up. Release

the door. If balanced, it should stay

in place, supported entirely by its

springs.

2. Raise and lower the door to check for

binding or sticking.

If your door binds, sticks, or is out of

balance, call a trained door systems

technician.

To prevent damage to garage door and opener:

• ALWAYS disable locks BEFORE installing and operating the opener.

• ONLY operate garage door opener at 240V mains to avoid malfunction and

damage.

To prevent possible SERIOUS INJURY or DEATH:

• ALWAYS call a trained door systems technician if garage door binds, sticks, or is

out of balance. An unbalanced garage door may NOT reverse when required.

• NEVER try to loosen, move or adjust garage door, door springs, cables, pulleys,

brackets or their hardware, ALL of which are under EXTREME tension.

• Disable ALL locks and remove ALL ropes connected to garage door BEFORE

installing and operating garage door opener to avoid entanglement.

• This opener system is equipped with an unattended operation feature. The door

could move unexpectedly. NO ONE SHOULD CROSS THE PATH OF THE MOVING

DOOR.

Tools Needed

During assembly, installation and adjustment of the garage door opener, instructions will

call for hand tools as illustrated below.

Pliers

Wire Cutters

Claw Hammer

Screwdriver

Adjustable End Wrench

1/4", 5/16", and 3/8" Sockets

and Wrench with 6" Extension

Drill

Tape Measure

Stepladder

Pencil

5/32", 3/16", 5/16"

and 3/4" Drill Bits

Level

Sectional Door

SPECIFICATIONS

Volts ............................................240 Vac - 50 Hz, ONLY

Current .....................................................1.5 AMP

LED Light Current (independently powered) ........................0.2 AMPS

Power .................................................... 150 Watts

R/T 4 ...................................................... minutes

Rated Load ................................................... 10Nm

Max door height ....................up to 4.2 m (with max. door area 16.5m2)

Max door width.................... up to 5.5 m (with max. door area 16.5m2)

Max door area................................................16.5 m2

Max door weight ( 3 & 4 inch drum)...... 130 kg / 230 kg with installation of The

Protector System™ (Safety IR Beams).

Max lift under spring tension ...................................... 20 kg

Page 7

7

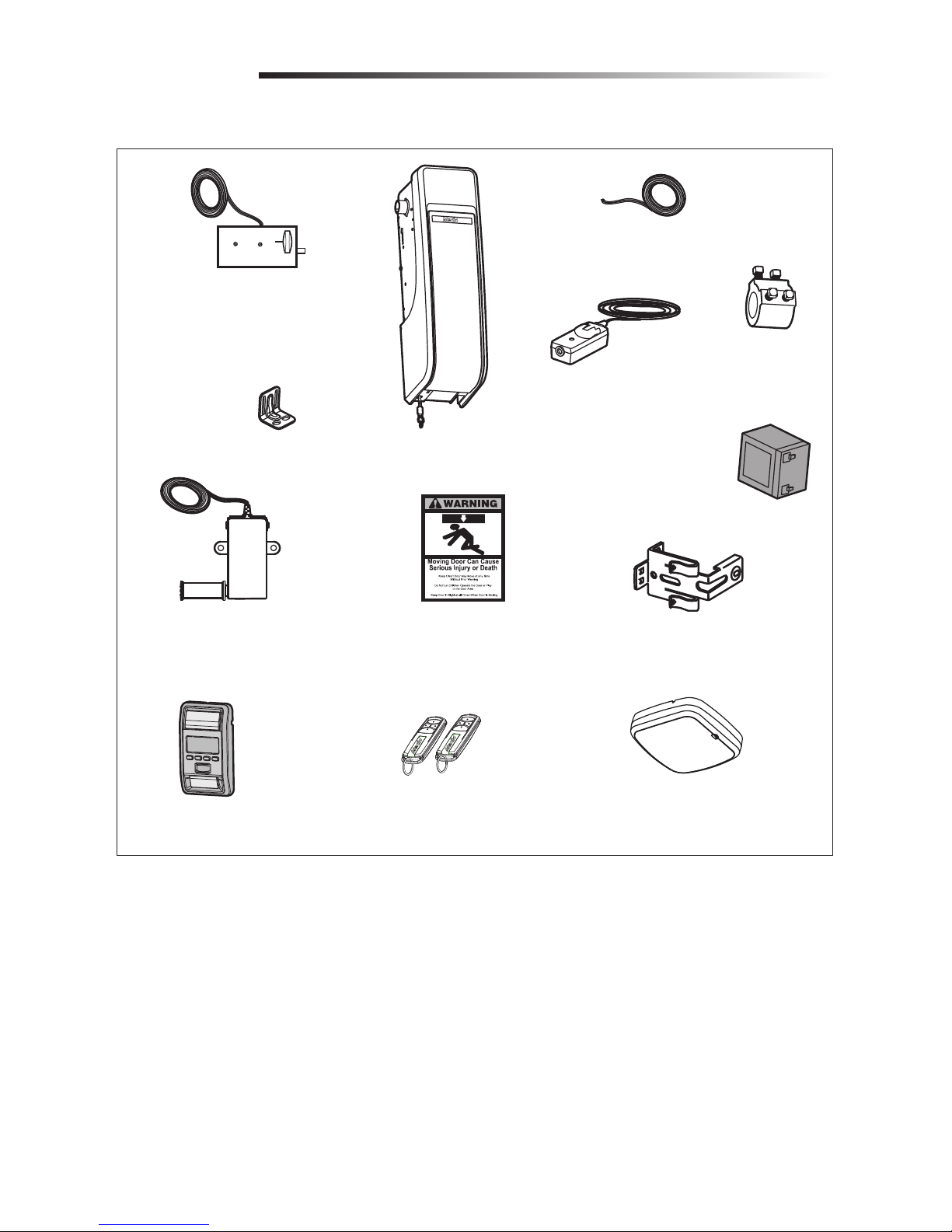

Carton Inventory

If anything is missing, carefully check the packing material.

Introduction

Automatic Garage Door Lock Model ???

with 2-Conductor White and White/Black

Bell Wire with Connector

NOTE: Older model 24V door locks

are incompatible

2 Conductor Bell Wire

White and White/Red

Garage Door Opener

Cable Tension Monitor with

2-Conductor Green/White Bell Wires

Mounting Bracket

Collar with

Set Screws

Safety Reversing Sensor Bracket (2)

The Protector System

®

(2) Safety Reversing Sensors

(1 Sending Sensor and

1 Receiving Sensor) with

2-Conductor White and

White/Black Bell Wire attached

Safety Labels

and Literature

Battery

Hardware

Additional Items You May Need

Extension brackets (Model 041A5281-1)

or wood blocks: Depending upon garage

construction, extension brackets or wood

blocks may be needed to install the safety

reversing sensor.

Fastening hardware: Alternate floor

mounting of the safety reversing sensor

will require hardware not provided.

90˚ connector for cable conduit or flex

cable adapter: Required for permanent

wiring.

Screw #10-32 (2)

Screw 14-10x2" (4)

Handle

Rope

Screw 1/4"-20x1/2" (2)

Drywall Anchor (Screw-In) (2)

Screw 8-32x1" (2)

Screw 6ABx1-1/4" (2)

Drywall Anchor (2)

Screw 6-32x1" (2)

Carriage Bolt 1/4"-20x1/2" (2)

Wing Nut 1/4"-20 (2)

REMOTE LIGHT HARDWARE:

myQ® Remote LED Light Model 827AU

Drywall Anchor (Screw-In) (2)

Screw #6x1" (2)

Included Accessories

4-Button Premium+

Remote Control

Model E960M (2)

MyQ

®

Remote LED Light

Model 827AU

(Garage Door Opener Light)

with Hardware Bag

Automatic Garage Door Lock Model ???

with 2-Conductor White and White/Black

Bell Wire with Connector

NOTE: Older model 24V door locks

are incompatible

2 Conductor Bell Wire

White and White/Red

Garage Door Opener

Cable Tension Monitor with

2-Conductor Green/White Bell Wires

Mounting Bracket

Collar with

Set Screws

Safety Reversing Sensor Bracket (2)

The Protector System

®

(2) Safety Reversing Sensors

(1 Sending Sensor and

1 Receiving Sensor) with

2-Conductor White and

White/Black Bell Wire attached

Safety Labels

and Literature

Smart Control Panel

®

Model 880AUW

Battery

Page 8

8

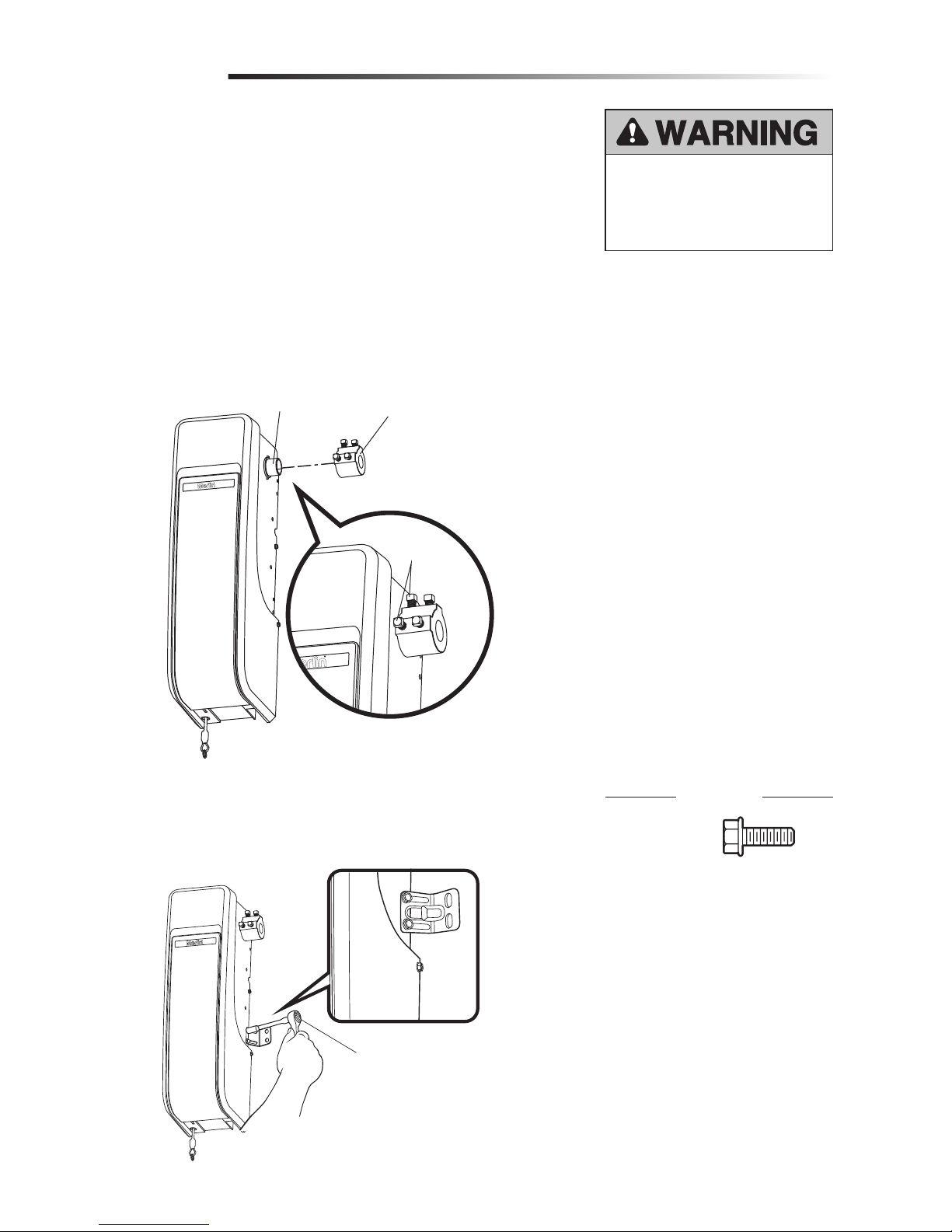

Set

Screws

Collar

Motor

Shaft

The garage door opener can be installed on either side of the door (see Planning section

page 4). The illustrations shown are for installation on the left side.

1. Loosen the set screws.

2. Attach collar to the garage door opener motor shaft. The side of the collar with the

larger hole should be placed on the motor shaft. Ensure that the collar is seated all

the way on motor shaft until stop is reached.

3. Position the collar so the screws are facing out and are accessible when attached to

the torsion bar.

4. Securely tighten the 2 square head set screws closest to the motor shaft by turning

the screws 1/4 - 1/2 turn after making contact with the motor shaft.

Attach the Collar to the Garage Door Opener

Assembly

1

To prevent possible SERIOUS INJURY

or DEATH, the collar MUST be properly

tightened. The door may NOT reverse

correctly or limits may be lost due to

collar slip.

Attach Mounting Bracket to Garage Door Opener

2

1. Loosely attach slotted side of mounting bracket to the same side of the garage door

opener as the collar, using screws provided.

NOTE: Do not tighten screws until instructed.

Socket Wrench

HARDWARE

Screw

#10-32 (2)

Page 9

9

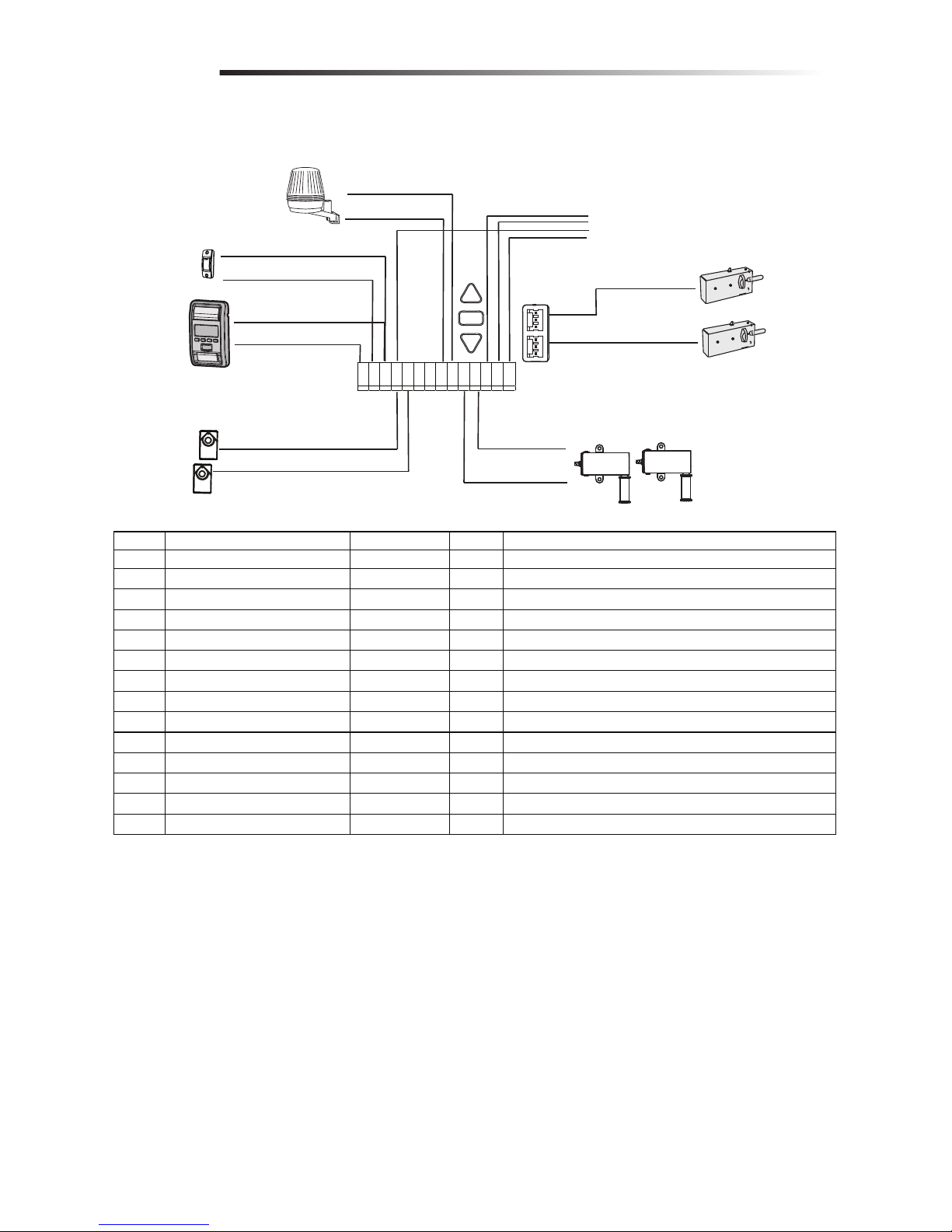

Wiring

1 2 3 4 5 6 7 8 9 10 1112 1314

Flasher

Contact Closure

E-Serial

Safety Sensor

Door Lock

Max Qty - 2 supported

Cable Tension Monitor

Max Qty-2 supported

Open/Stop/Close

wall station

Pin#

Function

Color

Polarity

Comment

1

E-serial push button

Green

+

For Encrypted serial communication (Wall control)

2

Push Button

Red

+

Dry contact (contact closure)

3

Ground

White

-

Wall controls (dry contact and E serial)

4

Ground

White

-

IR sensors

5

IR-Sensor

Grey

+

IR sensors

6

Green

+

7

Green

-

8

Flasher

Black/Gray

+

Flashing Light output

9

Flasher & OCS Ground

White

-

Flashing Light ground

10

Cable tension monitor

Green

+

Connection for a cable tension monitor

11

Cable tension monitor

Green

-

Connection for a cable tension monitor

12

OCS wall station - Open

Green

Open/Stop/Close wall station

13

OCS wall station -Stop

Green

Open/Stop/Close wall station

14

OCS wall station - Close

Green

Open/Stop/Close wall station

CONTROL PANEL - (located under front cover of the opener. Lift to access)

Page 10

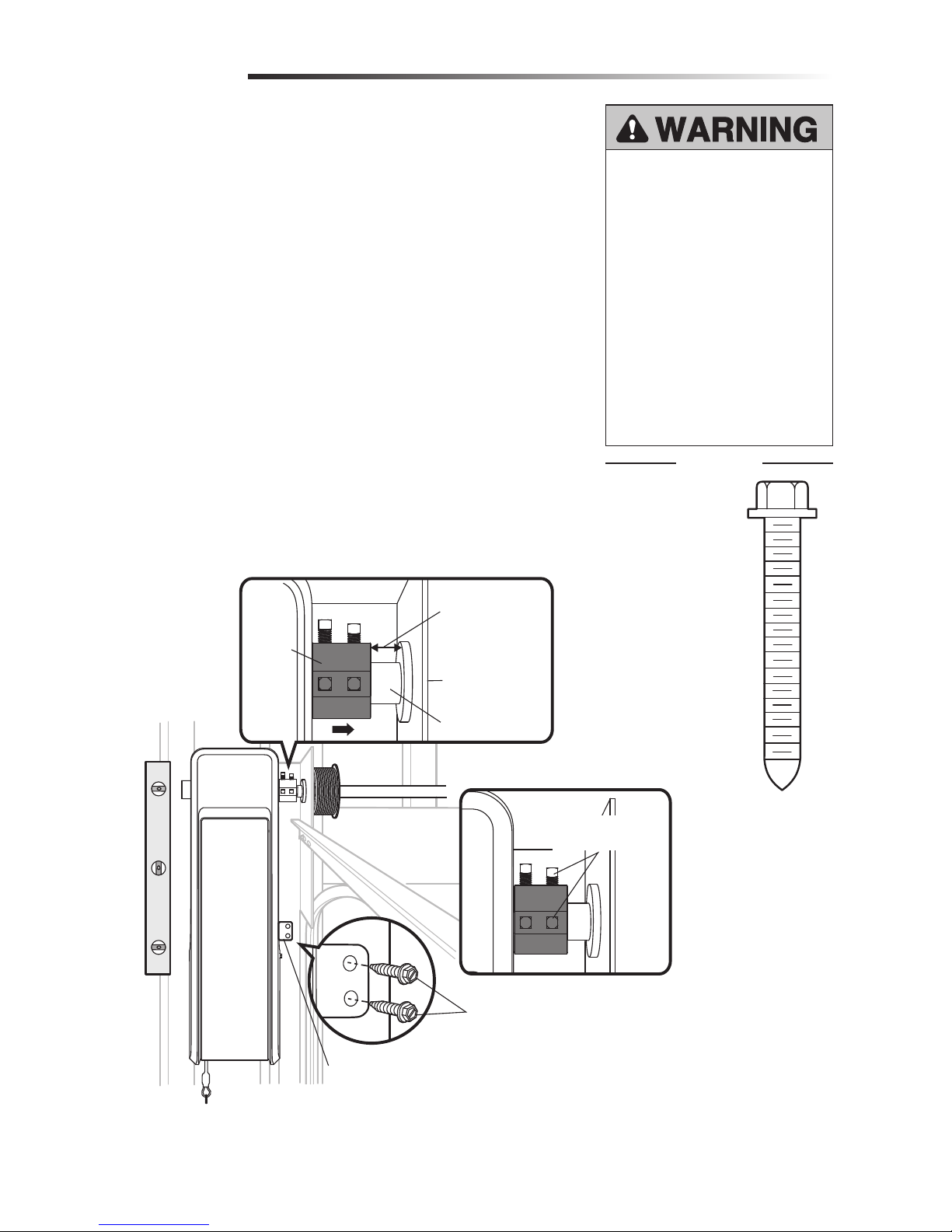

10

Set screws

(Torsion bar)

Bearing

Plate

Shaft

Collar

Torsion Bar

.25" (.6 cm) min.

space between

bearing and

shaft collar

Mounting Bracket

Screws 14-10 x 2"

Installation

HARDWARE

Position and Mount the Garage Door Opener

1

NOTE: For additional mounting options refer to the accessories on page 34.

1. Close the garage door completely.

2. Slide the garage door opener onto the end of the torsion bar. If the torsion bar is too

long or damaged, you may need to cut the torsion bar.

Ensure the collar does NOT touch the bearing.

3. Use a level to position and vertically align the garage door opener. Verify the

mounting bracket is located on a solid surface such as wood, concrete or door/flag

bracket. If installing on drywall, the mounting bracket MUST be attached to a stud.

4. When the garage door opener is properly aligned, mark the mounting bracket holes.

If necessary, tighten collar screws on the torsion bar to hold garage door opener in

place while marking holes.

NOTE: The garage door opener does not have to be flush to wall.

5. Remove the garage door opener from torsion bar. Drill 3/16 inch pilot holes at the

marked locations. Drill through metal door rail plates if necessary.

6. Slide the garage door opener back onto the torsion bar until pilot holes align with

bracket.

7. Tighten the 2 square head set screws on the torsion bar. For a hollow torsion bar,

tighten screws 3/4 - 1 full turn after making contact with the bar. For a solid shaft

torsion bar, tighten screws 1/4 - no more than 1/2 turn after making contact with

the shaft. If installing on a keyed torsion bar, DO NOT tighten the screws into the

keyway.

8. Secure the mounting bracket to the wall and to the garage door opener. Use the

14-10 x 2" screws to secure the mounting bracket to the wall.

To prevent possible SERIOUS INJURY

or DEATH:

• Concrete anchors MUST be used if

mounting bracket into masonry.

• NEVER try to loosen, move or

adjust garage door, springs,

cables, pulleys, brackets or their

hardware, ALL of which are under

EXTREME tension.

• ALWAYS call a trained door

systems technician if garage door

binds, sticks or is out of balance.

An unbalanced garage door might

NOT reverse when required.

• Garage door opener MUST be

mounted at a right angle to the

torsion bar to avoid premature

wear on the collar.

Screw

14-10 x 2" (2)

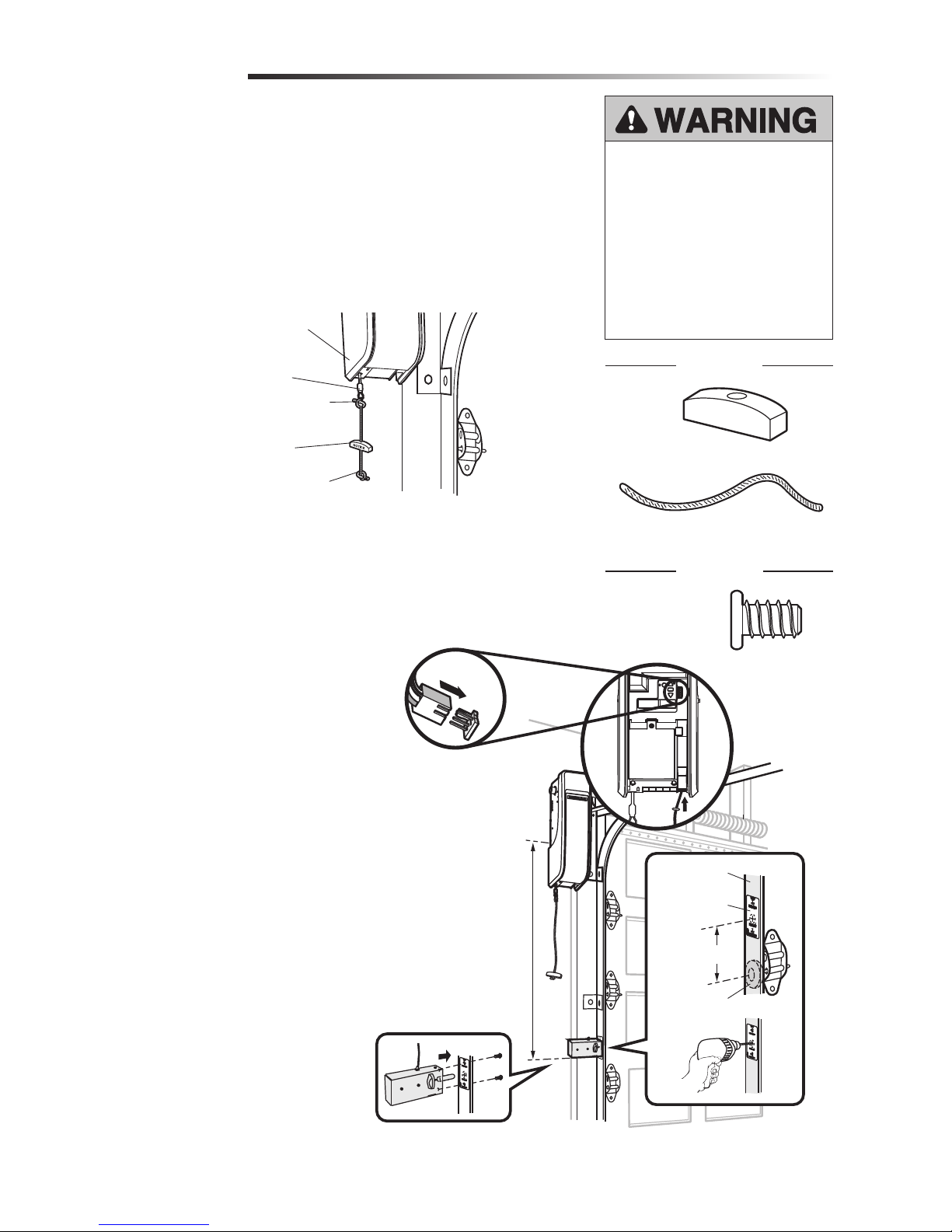

Page 11

11

Attach the Emergency Release Rope and Handle

Install the Automatic Door Lock

2

3

1. Insert one end of the emergency release rope through the handle. Make sure that

“NOTICE” is right side up. Secure with an overhand knot at least 1" (2.5 cm) from

the end of the rope to prevent slipping.

2. Insert the other end of the emergency release rope through the hole in the trolley

release arm. Mount the emergency release within reach, but at least 6 feet (1.83 m)

above floor, avoiding contact with vehicles to prevent accidental release and secure

with an overhand knot.

NOTE: If it is necessary to cut the rope, heat seal the cut end with a match or lighter to

prevent unraveling.

Installation

The automatic garage door lock (model 841ANZ) is used to prevent the door from

being manually opened once the door is fully closed, see Accessories page 34

Garage Door

Opener

Emergency

Release Cable

Overhand

Knot

Overhand

Knot

Emergency

Release Handle

To prevent possible SERIOUS INJURY

or DEATH from a falling garage door:

• If possible, use emergency release

handle to disengage door ONLY when

garage door is CLOSED. Weak or

broken springs or unbalanced door

could result in an open door falling

rapidly and/or unexpectedly.

• NEVER use emergency release handle

unless garage doorway is clear of

persons and obstructions.

HARDWARE

Screw 1/4"20x1/2" (2)

Rope

Handle

HARDWARE

10 feet (3.05 m)

max.

3" (7.6 cm)

Door Track

Roller

Lock

Template

1

2

3

4

5

6

NOTE: Older model 24 V door locks are

incompatible.

1. The lock must be mounted within

10 ft. (3.05m) of door opener If

possible, mount on same side as

door opener. The third roller from the

bottom is ideal for most installations.

2. Ensure rail surface is clean and attach

the lock template to the track so

that the bolt hole is approximately 3"

(7.6cm) from the center of a door

roller.

3. Drill holes as marked on the template.

4. Fasten automatic door lock to

the outside of the door track with

hardware provided.

5. Run bell wire up wall to door opener.

Use insulated staples to secure wire

in several places. Insert wire through

the bottom of the door opener.

6. Plug the connector into either plug in

the door opener.

A secondary door lock can be installed on

the opposite side of the door following the

instructions above.

Page 12

12

HARDWARE

Attach the Cable Tension Monitor (Required)

4

Drum

Cable

To insert or

release wire,

push in tab with

screwdriver tip

(to cable tension monitor)

(to garage door opener)

Refer to Wiring

Diagram on page 9

Wall

2"-6"

(51 - 153mm)

Approx. 3/4" (19 mm)

Cable

Tension

Monitor

Cable Tension

Monitor Roller

1/8"-1/4"

(3-6 mm)

Installation

The cable tension monitor MUST be

connected and properly installed before

the garage door opener will move in the

down direction.

The cable tension monitor detects ANY

slack that may occur in the cables and

will reverse the door, eliminating service

calls.

SIDE VIEW

Screws

#8-32x1" (2)

Drum

Cable Tension

Monitor Roller

Screw

14-10x2" (2)

NOTE: The cable tension monitor is shipped for left side installation. It is recommended

that the cable tension monitor be installed on the same side of the door as the door

opener. For right side installation, remove the snap-ring holding the roller in place and

reassemble it on the opposite side of the cable tension monitor.

1. Make sure the door cable is approximately 3/4" (19 mm) from the mounting surface.

Door adjustments or shimming may be required to achieve proper depth for the door

cable.

2. Position the cable tension monitor so the roller is 2"-6" (51 - 153mm) from the drum

and the roller extends 1/8"-1/4" (3 - 6mm) past the cable. Make sure cable tension

monitor is located over a wood support member and the roller is free from any

obstructions.

NOTE: There must be no obstructions in the installation area that prevent the cable

tension monitor from closing completely when slack is detected.

3. Mark and drill 3/16" pilot holes for screws (pilot holes are not required for anchors).

4. Attach the cable tension monitor to the wall using the hardware provided. Make sure

that the roller is on top of the cable.

5. Run bell wire to door opener. Use insulated staples to secure wire.

6. Connect bell wire to the green quick-connect terminals on the door opener (polarity

is not important).

NOTE: Cable must have tension through entire door travel. Make sure there is no

slack in cable on opposite side of door during normal operation. If slack occurs

during door travel, adjust cables as required.

A second cable tension monitor may be installed for additional security. When two cable

tension monitors are installed, the door will not move in the down direction or will reverse

if one of the monitors detects slack or is disconnected.

If one of the cable tension monitors is removed, unplug both monitors from the opener.

Then plug in the monitor you wish to use and unplug and plug in the opener three times

to relearn the monitor to the opener.

Page 13

13

Install door control within sight of garage door, out of reach of small children at a

minimum height of 5 feet (1.5 m) above floors, landings, steps or any other adjacent

walking surface, and away from ALL moving parts of door.

Your garage door opener is compatible with up to 2 Smart Control Panels or 4 of any

other Security+ 2.0® door controls. NOTE: Older Merlin door controls and third party

products are not compatible.

For gang box installations it is not necessary to drill holes or install the drywall anchors.

Use the existing holes in the gang box.

1. Strip 7/16" (11 mm) of insulation from one end of the wire and separate the wires.

2. Connect one wire to each of the two screws on the back of the door control. The

wires can be connected to either screw. PRE-WIRED INSTALLATIONS: Choose

any two wires to connect, but make note of which wires are used.

3. Mark the location of the bottom mounting hole and drill a 5/32" (4 mm) hole.

4. Install the bottom screw, allowing 1/8" (3 mm) to protrude from the wall.

5. Position the bottom hole of the door control over the screw and slide down into

place.

6. Lift the push bar up and mark the top hole.

7. Remove the door control from the wall and drill a 5/32" (4 mm) hole for the top

screw.

8. Position the bottom hole of the door control over the screw and slide down into

place. Attach the top screw.

9. Run the white and red/white wire from the door control to the garage door opener.

Attach the wire to the wall and ceiling with the staples (not applicable for gang box

or pre-wired installations). Do not pierce the wire with the staple as this may cause

a short or an open circuit.

10. Connect the wire to the red and white terminals on the garage door opener. The

wires can be connected to either terminal.

11. Fasten the warning placard to the wall next to the door control.

NOTE: DO NOT connect the power and operate the garage door opener at this time. The

door will travel to the full open position but will not return to the close position until the

safety reversing sensors are connected and properly aligned. See page 15.

Install the Door Control (Smart Control Panel)

5

Installation

To prevent possible SERIOUS INJURY or

DEATH from electrocution:

• Be sure power is NOT connected

BEFORE installing door control.

• Connect ONLY to 7-28 VOLT low

voltage wires.

To prevent possible SERIOUS INJURY or

DEATH from a closing garage door:

• Install door control within sight of

garage door, out of reach of small

children at a minimum height of 5 feet

(1.5 m) above floors, landings, steps

or any other adjacent walking surface,

and away from ALL moving parts of

door.

• NEVER permit children to operate or

play with door control push buttons or

remote control transmitters.

• Activate door ONLY when it can be

seen clearly, is properly adjusted,

and there are no obstructions to door

travel.

• ALWAYS keep garage door in sight

until completely closed. NEVER permit

anyone to cross path of closing garage

door.

HARDWARE

To insert or

release wire,

push in tab with

screwdriver tip

7/16" (11 mm)

Screw 6ABx1-1/4" (Standard installation) (2)

Screw 6-32x1"

(pre-wired) (2)

Drywall

Anchors (2)

Insulated Staples

(Not shown)

(to garage door opener)

(to door control)

Refer to Wiring

Diagram on page 9

Page 14

14

Screws

Light Lens

Drywall

Anchors

6-1/8" (15.6 cm)

Cord Retainer

Channel

The myQ Remote LED Light is designed to

plug directly into a standard 240V outlet.

Select an appropriate location on the

ceiling or wall to mount the light within 6

feet (1.83 m) of an electrical outlet so that

the cord and light are away from moving

parts.

NOTE: If installing light on drywall and a

ceiling joist cannot be located, use drywall

anchors provided. No pilot hole is required

for drywall anchors.

1. Drill pilot holes 6-1/8" (15.6 cm) apart

if mounting to joist.

OR

Screw in drywall anchors 6-1/8"

(15.6cm) apart if mounting to

drywall.

2. Determine the length of power cord

needed to reach the nearest outlet.

Wind any excess cord around cord

retainer on the top side of the light

base. Route the cord through the

channel so the light mounts flush.

3. Open the light lens.

4. Mount the light with the screws

provided.

5. Close the light lens.

6. Plug in the light to the outlet.

NOTE: The LED light is very bright.

DO NOT stare at the light while on a

ladder.

Your garage door opener remote light has

already been programmed at the factory to

operate with your opener. Any additional or

replacement remote lights will need to be

programmed.

Install myQ® Remote

LED Light

6

Installation

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

•. DO NOT alter the plug.

•. myQ Remote LED Light is intended for ceiling or wall mount

and indoor applications ONLY.

Drywall Anchor (screw-in) (2)

HARDWARE

Screw #6x1" (2)

Page 15

15

The safety reversing sensor must be connected and aligned correctly before the

garage door will move in the down direction. This is a required safety device and

cannot be disabled.

NOTE: Merlin recommends to install the safety reversing sensors on each installation.

For use of myQ or Timer-To-Close features the installation of the safety reversing

sensors are required.

IMPORTANT INFORMATION ABOUT THE SAFETY REVERSING SENSOR

When properly connected and aligned, the safety reversing sensor will detect an obstacle

in the path of its electronic beam. The sending sensor (with an amber indicator light)

transmits an invisible light beam to the receiving sensor (with a green indicator light).

If an obstruction breaks the light beam while the door is closing, the door will stop and

reverse to full open position, and the opener lights will flash 10 times.

The sensors must be installed inside the garage so that the sending and receiving sensors

face each other across the door, no more than 3.9 inches (10 cm) above the floor. Either

can be installed on the left or right of the door as long as the sun never shines directly into

the receiving sensor lens.

The mounting brackets are designed to clip onto the track of sectional garage doors

without additional hardware.

If it is necessary to mount the sensors on the wall, the brackets must be securely fastened

to a solid surface such as the wall framing. Extension brackets (see accessories) are

available if needed. If installing in masonry construction, add a piece of wood at each

location to avoid drilling extra holes in masonry if repositioning is necessary.

The invisible light beam path must be unobstructed. No part of the garage door (door

tracks, springs, hinges, rollers or other hardware) may interrupt the beam while the door

is closing.

Be sure power is NOT connected to the

garage door opener BEFORE installing

the safety reversing sensor.

To prevent SERIOUS INJURY or

DEATH from a closing garage door:

• Correctly connect and align the

safety reversing sensor. This

required safety device MUST NOT

be disabled.

• Install the safety reversing sensor

so beam is NO HIGHER than 3.9"

(10 cm) above garage floor.

Installation

Safety Reversing

Sensor

3.9" (10 cm) max.

above floor

Safety Reversing

Sensor

3.9" (10 cm) max.

above floor

Invisible Light

Beam Protection

Area

Install the Protector SystemTM

7

Facing the door from inside the garage.

Page 16

16

Installation

NOTE: This accessory must be used for all myQ installations and

all other installations where the closing force as measured on the

bottom of the door is over 400 N (40 kgf).

SPECIAL NOTE: Merlin strongly recommends that The Protector

SystemTM be installed on all garage door openers.

SAFETY BEAMS: By installing Safety Beams, an open door is

prevented from closing if a person or object is located in the beam

area. If the door is already closing, it will return to the open position.

A closed door is not prevented from opening.

If the Protector System

TM

is installed and needs to be removed, the

opener will need to be reprogrammed .

Assembly Process:

The Safety Beams are supplied preassembled, complete with two

sensors, wiring and wall brackets.

Install the mounting brackets and sensors to either side of the inside

of the garage door, and at a height of no greater than 100 mm off

the garage floor.

The brackets are designed to be used for Wall or Floor fixing, with a

variety of hole combinations to achieve the desired results (fig 1).

Drill the required holes and install the brackets with wall plugs and

screws provided. Ensure they do not obstruct the door movement.

Align the Safety Beams to face each other and tighten if necessary.

The wiring should exit from the bottom of the housing to maintain

the correct IP rating and continued operation.

One sensor is a Sending Eye , the other is a Receiving Eye. Try to

avoid positioning these in direct sunlight as this may interfere with

the operation of the beams.

Install Cabling:

Run both sets of Safety Beam cables up the door tracks, across the

door header and back to the Power Head (see fig 2 & 4).

Clean the contact area with alcohol wipes (provided) and secure the

self-adhesive Cable Mounts to the rails. Attach the cable with cable

ties.

Ensure the cable is well supported and does not interfere or get

damaged by movement of the door panels or spring hardware.

INSTALLING THE BRACKETS

Be sure power to the opener is disconnected. Install and align the brackets so the safety reversing sensors will face each other across

the garage door, with the beam no higher than 3.9" (10 cm) above the floor. Choose one of the following installations.

g.1

Cable Tie Mount

at the top

Cable Tie Mount

at the middle

Cable Tie Mount

close to the Beam

100 mm Cardboard

template

Beam and Bracket

assembly

view 1

view 2

g.2

To prevent entrapment, install Safety

Beams no higher than 100 mm above

the floor.

Disconnect power to the garage door

opener before installing Safety Beams.

Page 17

17

Installation

INSTALL THE PROTECTOR SYSTEMTM (CONTINUED)

Connect cable to the Opener:

Disconnect the mains Power from the Opener.

At the Powerhead Control Panel located under the front cover of the

opener. Lift to access the “External Accessory Terminal Block”.

Twist both WHITE wires together and both GREY wires together.

Connect the WHITES to the white mark screw terminal of the 2-way

connector, and the GREYS to the grey mark screw terminal (see fig 3).

Push the 2-way connector into the control panel quick release terminals B

& C (see wiring diagram on page 9).

Ensure the white wires go to B and the grey wires go to C.

Loop and secure the excess cabling above the opener assembly.

Test the Safety Beam operation:

Remove all obstacles from the path of the door. Connect the mains Power

to the opener.

1. Using a remote control, check the Opener operates in both directions.

2. Obstruct the beams with the door fully OPEN, the door should not

move and the Courtesy light will Flash 10 times.

3. Obstruct the beams with the door travelling DOWN, the door should

STOP and return to the UP position. The Courtesy light will Flash 10

times.

4. Obstruct the beams with the door travelling UP, the door should

continue to the OPEN position.

Status indicators on the Safety Beams:

Normal Operation --Low standby Mode --

Safety Beams misaligned-Safety Beams obstructed--

For further diagnostics refer to the TROUBLESHOOTING section on page

30.

Emergency Overide:

NOTE: The door can't be closed using the myQ app if an obstruction of

Safety Beam failure has occurred.

However, if needed, the door can be closed by using the programmed

button of a Smart Control Panel (880AUW), Keyless Entry Keypad

(E840M) or the Control button located on the bottom of the opener.

Follow the process below:

With the door open Press the programmed button once and release.

Press and “HOLD” the button again, and continue to HOLD untl the door

has completely closed.

NOTE: If the button is released at any point during the downward

movement, the door will stop and return to the OPEN position. In this

case repeat the previous process again. The “DOOR CLOSE” process

will need to be performed each time the door needs to be CLOSED,

until the obstruction is removed or repairs are made to the Safety Beam

System.

Refer to Wiring

Diagram on

page 9

CABLE END

3 X CABLE TIE MOUNT

WITH CABLE TIE

OPENER

BEAM 1

BEAM 2

1 X 2-WAY CONNECTOR

WITH LEADS AND CABLE

COLOUR MARK

3 X CABLE TIE MOUNT

WITH CABLE TIE

White x2

Grey x2

g. 3

Page 18

18

Connect Power

8

Installation

To avoid installation difficulties, do not

run the garage door opener at this time.

To reduce the risk of electric shock, your

garage door opener has a grounding type

plug with a third grounding pin. This plug

will only fit into a grounding type outlet. If

the plug doesn’t fit into the outlet you have,

contact a qualified electrician to install the

proper outlet.

CONNECT POWER

1. Plug in the garage door opener into a

grounded outlet.

2. DO NOT run garage door opener at

this time.

To prevent possible SERIOUS INJURY or DEATH from electrocution or fire:

• Garage door installation and wiring MUST be in compliance with ALL local electrical

and building codes.

• NEVER use an extension cord, 2-wire adapter or change plug in ANY way to make it

fit outlet. Be sure the opener is grounded.

Page 19

19

To reduce the risk of FIRE or INJURY

to persons:

• Disconnect ALL electric and battery

power BEFORE performing ANY

service or maintenance.

• Use ONLY Merlin part #041A6357-2

for replacement battery.

• DO NOT dispose of battery in fire.

Battery may explode. Check with local

codes for disposal instructions.

ALWAYS wear protective gloves and

eye protection when changing the

battery or working around the battery

compartment.

When in Battery Backup mode, myQ® Smartphone Control and wireless myQ devices

will be disabled. In battery backup mode, the automatic garage door lock will unlock

when the garage door is opened, and will remain disabled until power is restored.

1. Unplug the garage door opener.

2. Use a Phillips head screwdriver to remove the battery cover on the garage door

opener.

3. Partially insert the battery into the battery compartment with the terminals facing

out.

4. Connect red (+) and black (-) wires from the garage door opener to the

corresponding terminals on the battery.

5. Replace the battery cover.

6. Plug in the garage door opener.

BATTERY STATUS LED

GREEN LED:

All systems are normal.

• A solid green LED light indicates the battery is fully charged.

• A flashing green LED indicates the battery is being charged.

ORANGE LED:

The garage door opener has lost power and is in battery backup mode.

• A solid orange LED with beep, sounding approximately every 2 seconds, indicates

the garage door opener is operating on battery power.

• A flashing orange LED with beep, sounding every 30 seconds, indicates the battery

is low.

RED LED:

The garage door opener's 12V battery needs to be replaced.

• A solid red LED with beep, sounding every 30 seconds, indicates the 12V battery will

no longer hold a charge and needs to be replaced. Replace the battery back up to

maintain the battery backup feature.

NOTE: Battery does not have to be fully charged to operate the garage door opener.

Install the Battery Backup

9

Installation

Red wire (+)

Battery Status LED

Black wire (-)

Page 20

20

While programming, the UP and DOWN buttons can be used to move the door as needed.

1. Press and hold the Adjustment Button until the UP Button begins to flash and/or a

beep is heard.

2. Press and hold the UP Button until the door is in the desired UP position.

3. Once the door is in the desired UP position press and release the Adjustment Button.

The garage door opener lights will flash twice and the DOWN Button will begin to

flash.

4. Press and hold the DOWN Button until the door is in the desired DOWN position.

5. Once the door is in the desired DOWN position press and release the Adjustment

Button. The garage door opener lights will flash twice and the UP Button will begin

to flash.

6. Press and release the UP Button. When the door travels to the programmed UP

position, the DOWN Button will begin to flash.

7. Press and release the DOWN Button. The door will travel to the programmed DOWN

position. Programming is complete.

If the garage door opener lights are flashing 5 times during the steps for Program the

Travel, the programming has timed out. If the cable tension monitor is not installed or

is sensing too much slack in the cable, the garage door opener light will flash 5 times.

Ensure the cable tension monitor is correctly installed then follow the steps for Program

the Travel. If the garage door opener lights are flashing 10 times during the steps for

Program the Travel, the safety reversing sensors are misaligned or obstructed (refer

to page 15). When the sensors are aligned and unobstructed, cycle the door through a

complete up and down cycle using the remote control or the UP and DOWN buttons.

Programming is complete. If you are unable to operate the door up and down, repeat the

steps for Programming the Travel.

Travel limits regulate the points at which the door will stop when moving up or down.

Program the Travel

Adjustment

Without a properly installed safety

reversal system, persons (particularly

small children) could be SERIOUSLY

INJURED or KILLED by a closing

garage door.

• Incorrect adjustment of garage

door travel limits will interfere with

proper operation of safety reversal

system.

• After ANY adjustments are made,

the safety reversal system MUST

be tested. Door MUST reverse on

contact with 1-1/2" (40 mm) high

object on the floor.

1

1 2

3

5

4

6 7

PROGRAMMING BUTTONS

UP Button

Adjustment

Button

DOWN Button

To prevent damage to vehicles, be

sure fully open door provides adequate

clearance.

Page 21

21

TEST

1. With the door fully open, place a 1-1/2 inch (40 mm) board on the floor, centered

under the garage door.

2. Press the remote control push button to close the door. The door MUST reverse

when it makes contact with the board.

ADJUST

If the door stops but does not reverse:

1. Review the installation instructions provided to insure all steps were followed;

2. Repeat Program the Travel (see Adjustment Step 1);

3. Repeat the Safety Reversal test.

If the test continues to fail, call a trained door systems technician.

IMPORTANT SAFETY CHECK:

Test the Safety Reverse System after:

• Each adjustment of limits.

• Any repair to or adjustment of the door (including springs and hardware).

• Any repair to or buckling of the floor.

• Any repair to or adjustment of the garage door opener.

Test the Safety Reversal System

Test the Protector SystemTM

1. Open the door. Place an obstruction in the path of the door.

2. Press the remote control push button to close the door. The door will not move

more than an inch (2.5 cm), and the garage door opener lights will flash 10 times.

The garage door opener will not close from a remote control if the LED in either

safety reversing sensor is off (alerting you to the fact that the sensor is misaligned or

obstructed).

If the garage door opener closes the door when the safety reversing sensor is

obstructed (and the sensors are no more than 6 inches [15 cm] above the floor), call

for a trained door systems technician.

Without a properly installed safety

reversal system, persons (particularly

small children) could be SERIOUSLY

INJURED or KILLED by a closing

garage door.

• Safety reversal system MUST be

tested every month.

• After ANY adjustments are made,

the safety reversal system MUST

be tested. Door MUST reverse on

contact with 1-1/2" (40 mm) high

object on the floor.

Without a properly installed safety

reversing sensor, persons (particularly

small children) could be SERIOUSLY

INJURED or KILLED by a closing

garage door.

2

3

Adjustment

Safety Reversing Sensor

Safety Reversing Sensor

1-1/2" (40 mm) object

Page 22

22

1. With the door fully closed, push on the front of the cable tension monitor. A click

should be heard. If there is no click, the roller may be hitting the jamb and not

allowing the switch to detect slack in the cable. Make sure the cable tension monitor

is mounted flush with the wall and the roller is free from any obstructions.

If your cable tension monitor has been activated the UP and DOWN arrows will flash

diagnostic code 3-5, see page 30.

Test Cable Tension Monitor

Test Automatic Door Lock

To Open the Door Manually

4

5

6

Adjustment

To prevent possible SERIOUS INJURY

or DEATH from a falling garage door:

• If possible, use emergency release

handle to disengage door ONLY when

garage door is CLOSED. Weak or

broken springs or unbalanced door

could result in an open door falling

rapidly and/or unexpectedly.

• NEVER use emergency release handle

unless garage doorway is clear of

persons and obstructions.

Automatic

Door

Lock

Manual

Release

Lock Bolt “Locked”

Emergency

Release Handle

UP and

DOWN

arrows

Cable Tension

Monitor

Roller

Disengage any door locks before proceeding. The door should be fully closed if possible.

Pull down on the emergency release handle until a click noise is heard from the door

opener and lift the door manually.

To reconnect the door to the door opener, pull the emergency release handle straight

down a second time until a click noise is heard from the door opener. The door will

reconnect on the next UP or DOWN operation.

TEST THE EMERGENCY RELEASE:

1. Make sure the door is closed.

2. Pull the emergency release handle. The door should then be able to be opened

manually.

3. Return the door to the closed position.

4. Pull the emergency handle a second time.

5. Reconnect the door to the door opener.

1. With the door fully closed, the automatic door lock bolt should be protruding

through the track.

2. Operate the door in the open direction. The automatic door lock should retract before

the door begins to move.

3. Operate the door in the down direction. When the door reaches the fully closed

position, the automatic door lock should move into lock position to secure the door.

NOTE: If the automatic door lock does not function, the lock can be manually

released by sliding the manual release handle to the open position.

Page 23

23

FEATURES

Your garage door opener is equipped with

features to provide you with greater control

over your garage door operation.

Alert2Close

The Alert2Close feature provides a visual

and an audible alert that an unattended

door is closing.

TIMER-TO-CLOSE (TTC)

The TTC feature automatically closes the

door after a specified time period that can

be adjusted using a TTC enabled Smart

Control Panel (880AUW). Prior to and

during the door closing the garage door

opener lights will flash and the garage door

opener will beep.

myQ

®

myQ allows you to control your garage

door opener from your mobile device or

computer from away from home. myQ

technology uses a 900Mhz signal to

provide two way communication between

the garage door opener and myQ enabled

accessories. The garage door opener has

an internal gateway that allows the garage

door opener to communicate directly with

a home Wi-Fi® network and access your

myQ account.

Using Your Garage Door Opener

THE PROTECTOR SYSTEMTM

(SAFETY REVERSING SENSORS)

When properly connected and aligned,

the safety reversing sensors will detect

an obstruction in the path of the infrared

beam. If an obstruction breaks the infrared

beam while the door is closing, the door

will stop and reverse to full open position,

and the opener lights will flash 10 times.

If the door is fully open, and the safety

reversing sensors are not installed, or are

misaligned, the door will not close from

a remote control. However, you can close

the door if you hold the button on the door

control or keyless entry until the door is

fully closed. The safety reversing sensors

do not affect the opening cycle. For more

information see page 21.

ENERGY CONSERVATION

For energy efficiency the garage door

opener will enter sleep mode when the

door is fully closed. The sleep mode

shuts the garage door opener down until

activated. The sleep mode is sequenced

with the garage door opener light; as the

light turns off the sensor LEDs will turn

off and whenever the garage door opener

lights turn on the sensor LEDs will light.

The garage door opener will not go into the

sleep mode until the garage door opener

has completed 5 cycles upon power up.

LIGHTS

The garage door opener light will turn on

when the opener is initially plugged in;

power is restored after interruption, or

when the garage door opener is activated.

The light will turn off automatically after

4-1/2 minutes.

LIGHT FEATURE

The garage door opener is equipped with

an added feature; the lights will turn on

when someone enters through the open

garage door and the safety reversing

sensor infrared beam is broken. For added

control over the light on your garage door

opener, see page 26.

USING YOUR GARAGE DOOR

OPENER

The garage door opener can be activated

through a wall-mounted door control,

remote control, wireless keyless entry or

myQ® accessory. When the door is closed

and the garage door opener is activated

the door will open. If the door senses an

obstruction or is interrupted while opening

the door will stop. When the door is in any

position other than closed and the garage

door opener is activated the door will

close. If the garage door opener senses

an obstruction while closing, the door will

reverse. If the obstruction interrupts the

sensor beam the garage door opener lights

will blink 10 times. However, you can close

the door if you hold the button on the door

control or keyless entry until the door is

fully closed. The safety reversing sensors

do not affect the opening cycle. The safety

reversing sensor must be connected and

aligned correctly before the garage door

opener will move in the down direction.

BATTERY BACKUP

The battery backup system allows access

in and out of your garage, even when the

power is out. When the garage door opener

is operating on battery power, the garage

door opener will run slower, the light will

not function, the Battery Status LED will

glow solid orange, and a beep will sound

approximately every 2 seconds.

Operation

MEMORY CAPACITY

SECURITY+ 2.0® ACCESSORIES MEMORY CAPACITY

Remote Controls Up to 40

Door Controls Up to 2 Smart Control Panels or 4 of any other

Security+ 2.0® door controls

Keyless Entries Up to 4

myQ® Acccessories Up to 16

Page 24

24

7. Using the wall control follow the

instructions highlighted by pressing the

menu button, going to “Program” and then

in the “Program” screen select the first

option “myQ wi-fi opener”.

8. You should then hear a beep from your

opener, if you do select “Yes”.

9. The app should then begin to “Look for

devices”, you should then find a device

with a myQ name. The exact name will

match the last few characters of the myQ

serial number which can be found under

the cover of the opener.

10. Once you have selected the opener,

follow the remaining few prompts within

the app to complete the myQ wi-fi setup.

LED Definition

Blue Off - Wi-Fi is not turned on.

Blinking - Garage door

opener is in Wi-Fi learn

mode.

Solid - Mobile device

connected to the garage

door opener.

Blue and

Green

Blinking - Attempting to

connect to router.

Green Blinking - Attempting to

connect to the Internet

server.

Solid - Wi-Fi has been set

up and garage door opener

is connected to the Internet.

NOTES:

The myQ® Smartphone Control WILL NOT

work if the garage door opener is operating

on battery power.

To erase the Wi-Fi settings, see page 28.

If you need help adding devices to your

myQ account or to learn more, visit

gomerlin.com.au or gomerlin.co.nz and

contact our customer service team.

Operation

The Wi-Fi® Garage Door Opener is

compatible with up to 16 myQ enabled

accessories. Up to 10 devices can be

paired to the Wi-Fi garage door opener’s

internal gateway. These devices can be

controlled with the myQ app. These devices

include any combination of myQ garage

door openers, Wi-Fi garage door openers,

myQ light controls. A Merlin myQ Gateway

(828AU) can be added if you need to

control more than 10 devices using the

myQ app. Up to 6 devices can be paired

to garage door opener itself (controlled

by garage door opener through 900MHz).

These devices include any combination

of myQ light controls or a garage door

opener.

You will need:

• Wi-Fi enabled smartphone, tablet or

laptop

• Broadband Internet Connection

• Wi-Fi signal in the garage (2.4 Ghz,

802.11b/g/n required), see page 5

• Password for your home network

(router's main account, not guest

network)

• myQ® serial number located on the

garage door opener

SYNCHRONISE THE DOOR CONTROL

To synchronize the door control to the

garage door opener, press the push bar

until the garage door opener activates (it

may take up to 3 presses).The garage door

opener must run through a complete cycle

before it will activate Wi-Fi® programming.

CONNECT YOUR GARAGE DOOR

OPENER TO YOUR HOME WI-FI

NETWORK

1. Ensure your smartphone is connected to

the wi-fi internet connection.

2. Download the myQ app on your

smartphone from the App Store® or

Google Play™ store.

Sign up to create a myQ account or sign in

using an existing account.

3. Ensure you are in the “Devices” screen

within the app and then press the plus

symbol on the top right hand side to add

a device and move into the “Device Setup”

screen.

4. There shall be a list of different devices

to select from, select “Garage Door Opener

with Wi-Fi Wall Installed”. There should

also be images of the different devices to

select from and the “Garage Door Opener

with Wi-Fi Wall Installed” should have the

image of the Commander Ultimate opener.

5. Once you have selected “Garage Door

Opener with Wi-Fi Wall Installed”, it should

take you to the next screen highlighting

“What You Need” which lists access to

your Wi-Fi garage door opener, Strong

Wi-Fi signal inside your garage and Your

Wi-Fi password. If you have access to

all three listed, then proceed to the next

screen by selecting “Next” at the bottom of

the screen.

6. The following screen should highlight to

locate the wall control. Once you located

the wall control, proceed to the next step

by selecting “Next” at the bottom of the

screen.

Navigation

Buttons

An LED on the garage door

opener will indicate Wi-Fi

status. See table above.

LED

Learn

Button

Connect With Your Smartphone

Page 25

25

Operation

Using the Door Control

SYNCHRONISE THE DOOR CONTROL

To synchronise the door control to the garage door opener, press the push bar until the garage door opener activates (it may take up to 3

presses). Test the door control by pressing the push bar, each press of the push bar will activate the garage door opener.

Up to 2 Smart Control Panels or 4 of any other

Security+2.0® door controls can be connected to the

garage door opener.

PUSH BAR

Press the push bar to open or close the door.

NAVIGATION BUTTONS

Use the navigation buttons to make selections and

program features.

LIGHT BUTTON

Press the LIGHT button to turn the garage door opener

lights on or off. When the lights are turned on they will

stay on until the LIGHT button is pressed again, or until

the garage door opener is activated. Once the garage door opener is activated the lights will turn off after the specified period of time (the

factory setting is 4-1/2 minutes). The LIGHT button will not control the lights when the door is in motion.

SCREEN

The screen will display the time and temperature until the menu button is pressed, and then it will display the menu options. If there is a

problem with the garage door opener the screen will display the Diagnostic Code. Refer to the Troubleshooting section.

The following features are accessible through the screen using the navigation buttons:

LEARN A DEVICE

Any compatible remote controls, wireless keyless entry, Wi-Fi garage door openers, or myQ® accessories can be programmed to the

garage door opener by accessing the menu and using the navigation buttons.

LOCK

The LOCK feature is designed to prevent activation of the garage door opener from remote controls while still allowing activation from

the door control and keyless entry. This feature is useful for added peace of mind when the home is empty (i.e. vacation).

TIMER-TO-CLOSE (TTC)

DO NOT enable TTC if operating a one-piece door. TTC is to be used ONLY with sectional doors. Factory default is set to off. TTC can

be set to automatically close your garage door from the fully open position after a specified period of time (1, 5, 10 minute intervals or

a custom setting up to 99 minutes). The garage door opener will beep and the lights will flash before closing the door. The screen on

the door control can display the status of the TTC. TTC WILL NOT work if the garage door opener is operating by battery power or if the

safety reversing sensors are misaligned. This feature is NOT intended to be the primary method of closing the door. A keyless entry

should be installed in the event of an accidental lock out when using this feature.

NOTE: Before enabling the TTC for the first time, or if you experience a power outage, cycle the garage door opener open and closed to

allow the TTC to set.

AUTOMATIC LIGHT

Motion Sensor

Factory default is set to on. This feature automatically turns on the garage door opener lights when motion is sensed. The lights will

come on for the set period of time, then shut off. If using the garage door opener light as a work light disable the motion sensor,

otherwise the light will turn off automatically if you are beyond the range of the sensor.

Light Feature

The lights will turn on when someone enters through the open garage door and the safety reversing sensor infrared beam is broken.

MAINTENANCE ALERT (MAS)

This feature assists the homeowner in ensuring the garage door opener system stays in good working condition. When the garage door

opener needs to be serviced (approximately 4500 garage door opener cycles) the command (yellow) and service (red) LEDs will begin

to alternately flash back and forth. The factory setting for the MAS feature is off and can be activated at time of installation. Contact your

installing dealer for service.

Push Bar

LIGHT

button

Screen

Motion

Sensor

Navigation

Buttons

Page 26

26

Operation

SETUP

The features on the door control can be

programmed through a series of menus on

the screen and the navigation buttons.

Refer to the descriptions below.

SCREEN

The main screen displays the time,

temperature, and current battery charge (if

applicable)

FEATURES

Press the navigation button below "MENU"

to view the Features menu.

SETTINGS

Press the navigation button below the

down arrow till you see TEMPERATURE to

view the Settings menu.

SERVICE

Press and hold the LIGHT button, then

press the second navigation button to view

the Service menu.

To program a remote control or keyless

entry to the garage door opener using the

door control, see page 26

Navigation Buttons

Set the time, choose 12 or 24 hour clock and

show/hide clock.

For sectional doors ONLY. Set the

Timer-to-Close feature off/on and set the time

interval before door closes. NOTE: DO NOT

enable TTC if operating a one-piece door. TTC is

to be used ONLY with sectional doors.

Enable/disable lock.

Set up Wi-Fi*, add remote controls, MyQ

®

devices, an extra remote button to control your

garage door opener lights, or a keyless entry.

* The garage door opener must run through a

complete cycle before it will activate Wi-Fi

®

programming. For help related to Wi-Fi, visit

WiFiHelp.LiftMaster.com.

Display the temperature in Fahrenheit or Celsius

and show/hide the temperature.

Select a language.

Set duration for garage door opener light to

stay on after operation, selectable range of

1-1/2 to 4-1/2 minutes. Turn the Motion sensor

off/on, and turn the entry light feature off/on.

Adjust the contrast of the screen.

Displays software version information.

Turn the Maintenance Alert (MAS) on/off.

Displays the number of remote controls, MyQ

®

devices, door controls and keyless entries

currently programmed to operate the garage

door opener.

Displays any errors that have occurred.

Page 27

27

Programming

E960M Premium+ Remote Control

Your remote control has been programmed at the factory to operate with your garage

door opener. If the remote does not work or you would like to program additional

devices, follow the programming steps below.

Up to 40 Security+ 2.0® remote controls can be programmed to the garage door

opener. Older Merlin remote controls are NOT compatible, see page 34 for compatible

accessories. Programming can be done through the door control or the learn button

on the garage door opener. To program additional accessories refer to the instructions

provided with the accessory or visit gomerlin.com.au or gomerlin.co.nz.

TO ADD, REPROGRAM, OR CHANGE AN E960M PREMIUM+ REMOTE

CONTROL/E840M KEYLESS ENTRY PIN USING THE DOOR CONTROL

1. Press the navigation button below "MENU" to view the Features menu.

2. Use the navigation buttons to scroll to "PROGRAM".

3. Select "REMOTE" or "KEYPAD" to program from the program menu.

4. Remote Control: Press the button on the remote control that you wish to operate

your garage door.

Keyless Entry: Enter a 4-digit personal identification number (PIN) of your choice on

the keyless entry keypad. Then press the ENTER button.

The garage door opener lights will flash (or two clicks will be heard) when the code has

been programmed. Repeat the steps above for programming additional remote controls

or keyless entry devices. If programming is unsuccessful, program the remote using the

learn button.

1

2

3

PIN

????

4

Press

to continue.

Press

to continue.

PROGRAM AN E960M PREMIUM+ REMOTE CONTROL USING THE LEARN

BUTTON ON THE GARAGE DOOR OPENER

1. Press and release the remote control button you wish to use and then press any

other button to exit programming.

2. Press and release the Learn button on the garage door opener. The Learn LED will

light. Within 30 seconds...

3. Press the remote control button programmed in step 2 until the garage door opener

light flashes or two clicks are heard.

1 2 3

LEARN

Button

“click”

“click”

To program other types of remote controls or keyless entries see the instructions included with the device or visit gomerlin.com.au or

gomerlin.co.nz.

Page 28

28

Programming

Program the myQ® Remote LED Light

Your garage door opener remote light has already been

programmed at the factory to operate with your opener.

Any additional or replacement remote lights will need to be

programmed.

PROGRAM A DOOR OPENER TO THE myQ REMOTE LED

LIGHT

1. Press the LEARN button on the light until the green LED

comes ON.

2. Press the LEARN button on the door opener. OR

On the Smart Control Panel go to Menu > Program>

myQDevice.

3. The code has been programmed when the remote light blinks

once.

PROGRAM A REMOTE CONTROL TO THE myQ REMOTE

LED LIGHT

1. Press the LEARN button on the light until the green LED

comes ON.

2. Press the button on the remote control that you wish to

operate the light.

3. The code has been programmed when the remote light blinks

once.

To program the light with other accessories, refer to the manual

for your accessory.

ADD THE myQ REMOTE LED LIGHT TO myQ ACCOUNT

1. Press the LEARN button on the light until the green LED

comes ON.

2. Login to the myQ app and add the myQ Remote LED Light.

TO ERASE ALL PROGRAMMING FROM THE myQ

REMOTE LED LIGHT

1. Press and hold the LEARN button until the LED turns off

(6-10 seconds). All programming is now erased.

LEARN

Button

Black Adjustment Button

To Erase the Memory

ERASE ALL REMOTE CONTROLS AND KEYLESS ENTRIES

1. Press and hold the LEARN button on garage door opener

until the learn LED goes out (approximately 6 seconds). All

remote control and keyless entry codes are now erased.

Reprogram any accessory you wish to use.

ERASE ALL DEVICES (Including myQ enabled

accessories)

1. Press and hold the LEARN button on garage door opener

until the learn LED goes out (approximately 6 seconds).

2. Immediately press and hold the LEARN button again until the

learn LED goes out. All codes are now erased. Reprogram

any accessory you wish to use.

ERASE THE WI-FI NETWORK FROM THE GARAGE DOOR

OPENER

1. Press and hold the black adjustment button on the garage

door opener until 3 beeps are heard (Approximately 6

seconds).

ERASE A myQ ACCOUNT

Go to mymerlin.com.au or mymerlin.co.nz to delete your myQ

account.

Smart Control Panel

Door Opener

LEARN Button

LEARN Button

Page 29

29

Maintenance

MAINTENANCE SCHEDULE

EVERY MONTH

• Manually operate door. If it is unbalanced or binding, call a trained door systems

technician.

• Check to be sure door opens and closes fully. Adjust limits if necessary (see

Adjustment Step 1).

• Repeat the safety reversal test. Make any necessary adjustments (see Adjustment

Step 2).

EVERY YEAR

• Oil door rollers, bearings and hinges. The garage door opener does not require

additional lubrication. Do not grease the door tracks.

DURING THE THIRD AND FIFTH YEARS AFTER PRODUCT IS INSTALLED

• The garage door and the Unit is professionally maintained and serviced by

a Professional Dealer, at a minimum, during the third and fifth years of the

Chamberlain Limited Warranty period such that the spring balanced door operates

according to manufacturer specifications. If your door binds, sticks, or is out of

balance, then it must not be used until serviced by a trained door technician or

Professional Dealer. The garage door service fee will be at the purchaser’s expense.

myQ Remote LED Light

• Unplug the light before cleaning.

• Use a lightly dampened cloth for cleaning.

• DO NOT use liquid cleaners on the light lens.

Care of Your Garage Door Opener

To prevent possible SERIOUS INJURY

or DEATH:

• NEVER allow small children near

batteries.

• If battery is swallowed, immediately

notify doctor.

To reduce risk of fire, explosion or

chemical burn: