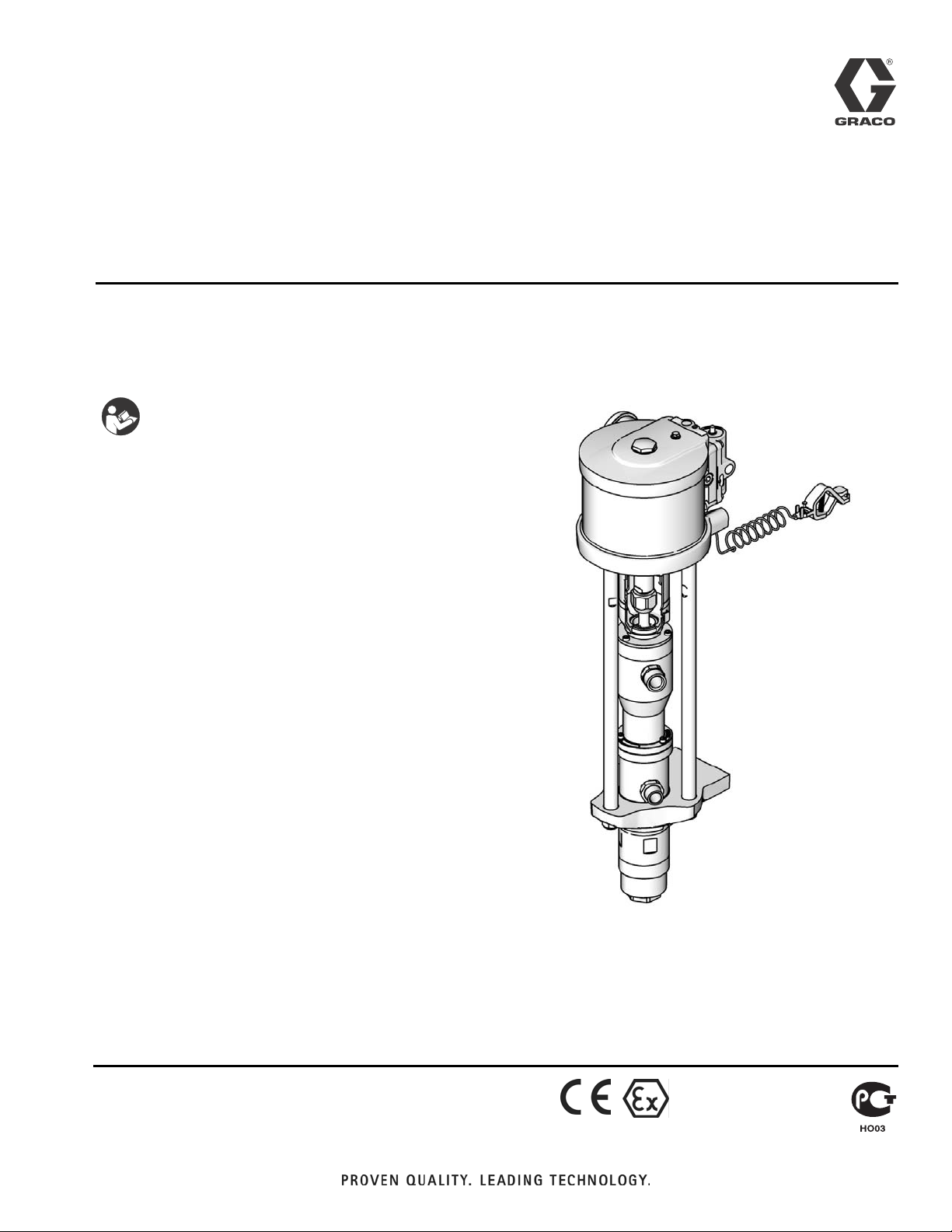

Merkury Innovations 312795E User Manual

Instructions-Parts

™

Merkur

Bellows

312795E

Pump Assembly

For pumping isocyanates, UV coatings, and other moisture-sensitive materials. For

professional use only.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

See page 7 for model information, including maximum

working pressure.

EN

ti15361a

II 2 G c IIB T3 (200°C)

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important Two-Component Material Information . 5

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 5

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 5

Keep Components A and B Separate . . . . . . . . . 5

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 5

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 5

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pump Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Component Identification . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Information . . . . . . . . . . . . . . . . . . . . . 10

Prepare the Operator . . . . . . . . . . . . . . . . . . . . 10

Prepare the Site . . . . . . . . . . . . . . . . . . . . . . . . 11

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mount the Pump . . . . . . . . . . . . . . . . . . . . . . . . 12

Air and Fluid Hoses . . . . . . . . . . . . . . . . . . . . . . 12

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Relief Procedure . . . . . . . . . . . . . . . . 14

Flush the Pump Before First Use . . . . . . . . . . . 14

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Prime and Adjust the Pump . . . . . . . . . . . . . . . 15

Shutdown and Care of the Pump . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Preventive Maintenance Schedule . . . . . . . . . . 16

Tighten Threaded Connections . . . . . . . . . . . . . 16

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

General Information . . . . . . . . . . . . . . . . . . . . . . 18

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Disconnect the Pump . . . . . . . . . . . . . . . . . . . . 18

Reconnect the Pump . . . . . . . . . . . . . . . . . . . . . 20

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Parts That Vary by Model . . . . . . . . . . . . . . . . . 23

Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Wall Mounting Kits . . . . . . . . . . . . . . . . . . . . . . . 24

Cart Mounting Kit 24E879 . . . . . . . . . . . . . . . . . 24

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 26

Pump Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wall Bracket Mounting Dimensions . . . . . . . . . . . 31

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 32

Related Manuals

Manual Description

312793 Merkur Bellows Displacement Pump

312796

312799

312798 Merkur Electrostatic Spray Packages

2 312795E

™

NXT

Air Motor

Merkur Bellows Spray Packages, AA

and Airless

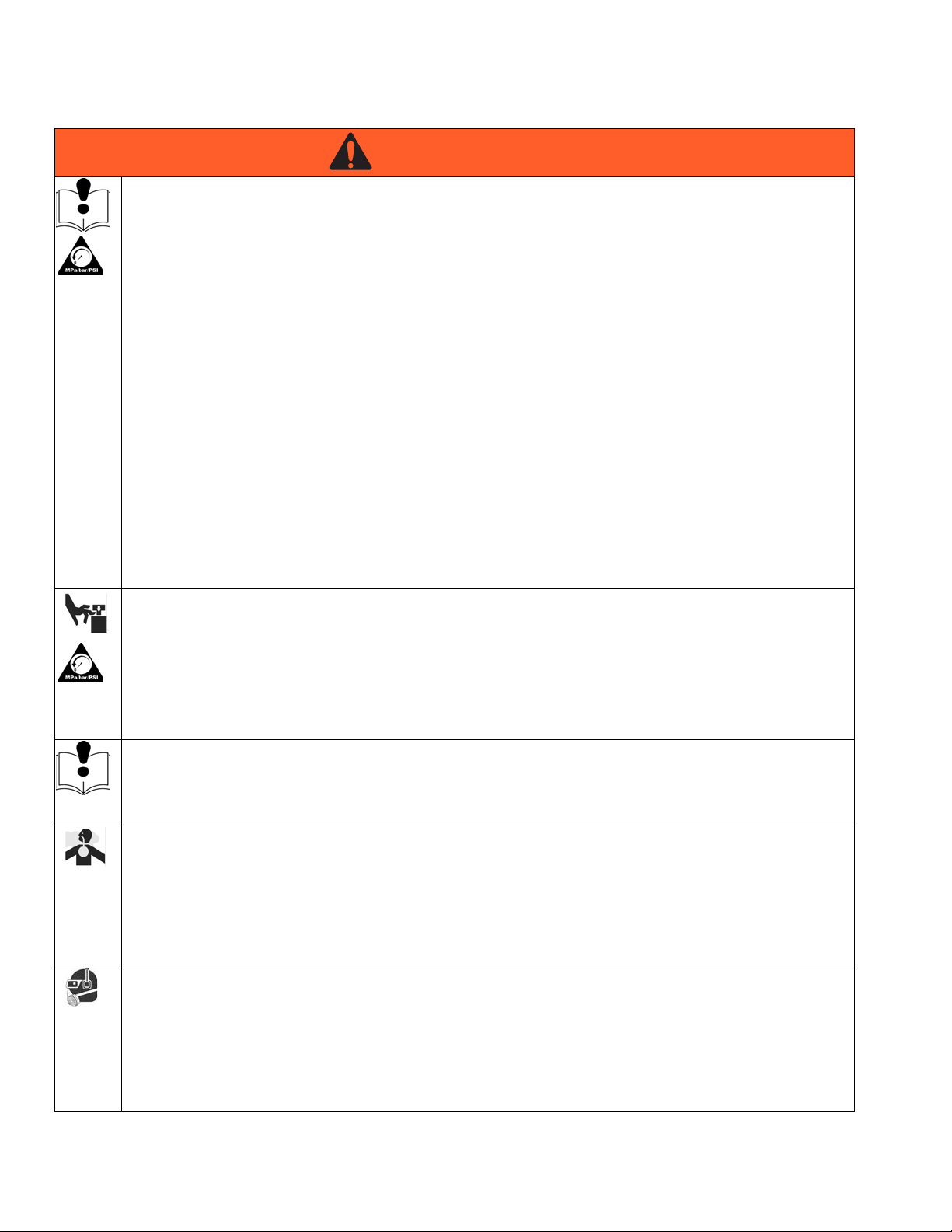

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

Static charge may build up on plastic parts during cleaning and could discharge and ignite flammable

vapors. To help prevent fire and explosion:

• Clean plastic parts only in a well ventilated area.

• Do not clean with a dry cloth.

• Do not operate electrostatic guns in equipment work area.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or ser-

vicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

312795E 3

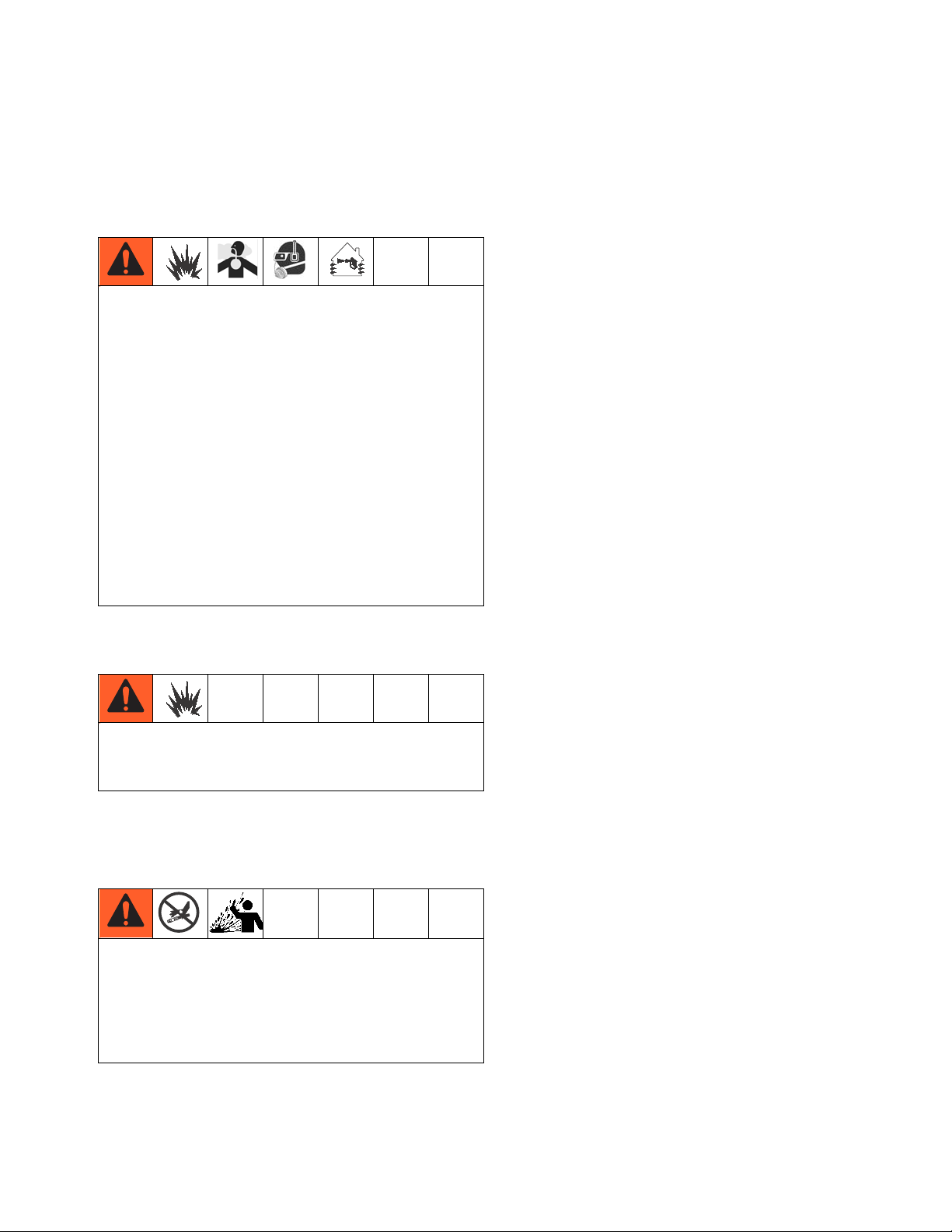

Warnings

WARNING

WARNINGWARNINGWARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system com-

ponent. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

SUCTION HAZARD

Powerful suction could cause serious injury.

• Never place hands near the pump fluid inlet when pump is operating or pressurized.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

4 312795E

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanate Conditions

Spraying or dispensing materials containing isocyanates creates potentially harmful mists, vapors, and

atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Material Self-ignition

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

Moisture Sensitivity of Isocyanates

Isocyanates (ISO) are catalysts used in two component

coatings. ISO will react with moisture (such as humidity)

to form small, hard, abrasive crystals, which become

suspended in the fluid. Eventually a film will form on the

surface and the ISO will begin to gel, increasing in viscosity. If used, this partially cured ISO will reduce performance and the life of all wetted parts.

NOTE: The amount of film formation and rate of crystallization varies depending on the blend of ISO, the

humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been contaminated from the other side.

• Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

Changing Materials

Keep Components A and B Separate

Cross-contamination can result in cured material in

fluid lines which could cause serious injury or damage equipment. To prevent cross-contamination of

the equipment’s wetted parts, never interchange

component A (isocyanate) and component B (resin)

parts.

312795E 5

• When changing materials, flush the equipment multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A side, but some use

ISO on the B side.

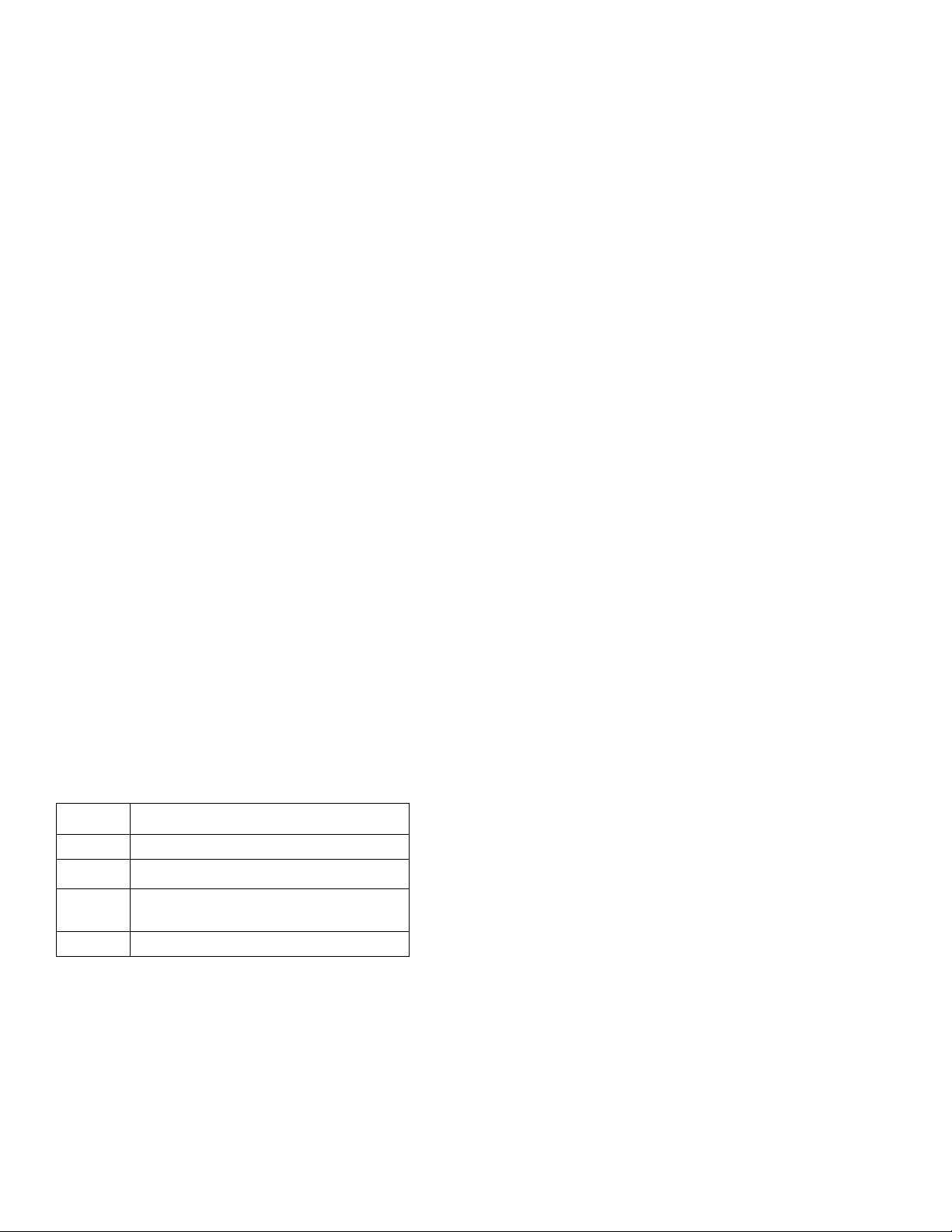

Models

Models

Check your pump’s identification marking (ID) for the 6-digit part number.

Use the following matrix to define the construction of your pump, based on

the six digits. For example, pump Part No. B05FA0 represents a 5 to 1

ratio, 150 cc pump, with no DataTrak, a low noise exhaust, and v-packings

To order replacement parts, see Parts section starting on page 22. The

digits in the matrix do not correspond to the reference numbers in the

Parts drawings and lists.

B05 F A 0

ID

ti12922a

Second and

First

Digit

B

(Bellows

style)

* Cycle refers to combination of one upstroke and one downstroke.

Third Digit

(Ratio)

05

12

15

23

24

25

35

5:1

12:1

15:1

23:1

24:1

25:1

35:1

Fourth Digit

(Displacement Pump

Volume Per Cycle)

B

D

F

50 cc

100 cc

150 cc

A

B

(Smarts/Exhaust)

DataTrak Compatible,

Fifth Digit

No DataTrak,

low noise exhaust

low noise exhaust

Sixth Digit

(Packings)

0

V-packings

1

U-cup

packings

6 312795E

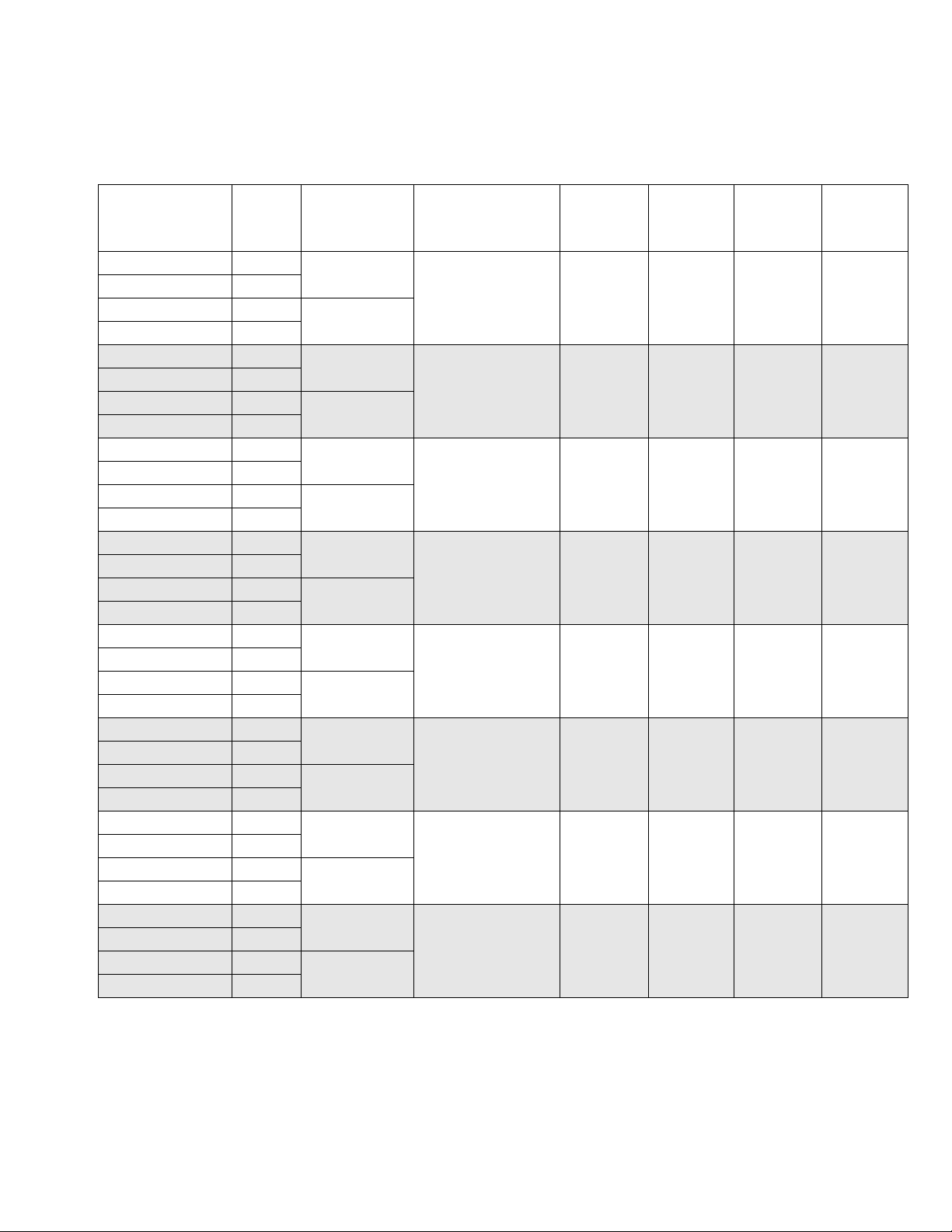

Pump Data

Pump Data

Air

Model, Series

B05FA0, Series A M04LN0

B05FB0, Series A M04LT0

B05FA1, Series A M04LN0

B05FB1, Series A M04LT0

B12DA0, Series A M07LN0

B12DB0, Series A M07LT0

B12DA1, Series A M07LN0

B12DB1, Series A M07LT0

B15BA0, Series A M04LN0

B15BB0, Series A M04LT0

B15BA1, Series A M04LN0

B15BB1, Series A M04LT0

B15FA0, Series A M12LN0

B15FB0, Series A M12LT0

B15FA1, Series A M12LN0

B15FB1, Series A

B23DA0, Series A M12LN0

B23DB0, Series A M12LT0

B23DA1, Series A M12LN0

B23DB1, Series A

B24FA0, Series A M18LN0

B24FB0, Series A M18LT0

B24FA1, Series A M18LN0

B24FB1, Series A M18LT0

B25BA0, Series A M07LN0

B25BB0, Series A M07LT0

B25BA1, Series A M07LN0

B25BB1, Series A M07LT0

B35DA0, Series A M18LN0

B35DB0, Series A M18LT0

B35DA1, Series A M18LN0

B35DB1, Series A M18LT0

Motor

M12LTO

M12LTO

Displacement

Pump

LB150A

LB150B

LB100A

LB100B

LB050A

LB050B

LB150A

LB150B

LB100A

LB100B

LB150A

LB150B

LB050A

LB050B

LB100A

LB100B

Maximum Fluid

Working Pressure

psi (MPa, bar)

500 (3.4, 34) 2.4 (9.0) 1 in. npt 3/4 in. npt 1/4 in. npt

1200 (8.3, 83) 1.6 (6.0) 3/4 in. npt 3/8 in. npt 1/2 in. npt

1500 (10.3, 103) 0.8 (3.0) 3/4 in. npt 3/8 in. npt 1/4 in. npt

1500 (10.3, 103) 2.4 (9.0) 1 in. npt 3/4 in. npt 1/2 in. npt

2300 (15.9, 159) 1.6 (6.0) 3/4 in. npt 3/8 in. npt 1/2 in. npt

2400 (16.5, 165) 2.4 (9.0) 1 in. npt 3/4 in. npt 1/2 in. npt

2500 (17.2, 172) 0.8 (3.0) 3/4 in. npt 3/8 in. npt 1/2 in. npt

3500 (24.1, 241) 1.6 (6.0) 3/4 in. npt 3/8 in. npt 1/2 in. npt

Flow Rate

at 60 cpm

gpm (lpm) Fluid Inlet

Fluid

Outlet Air Inlet

312795E 7

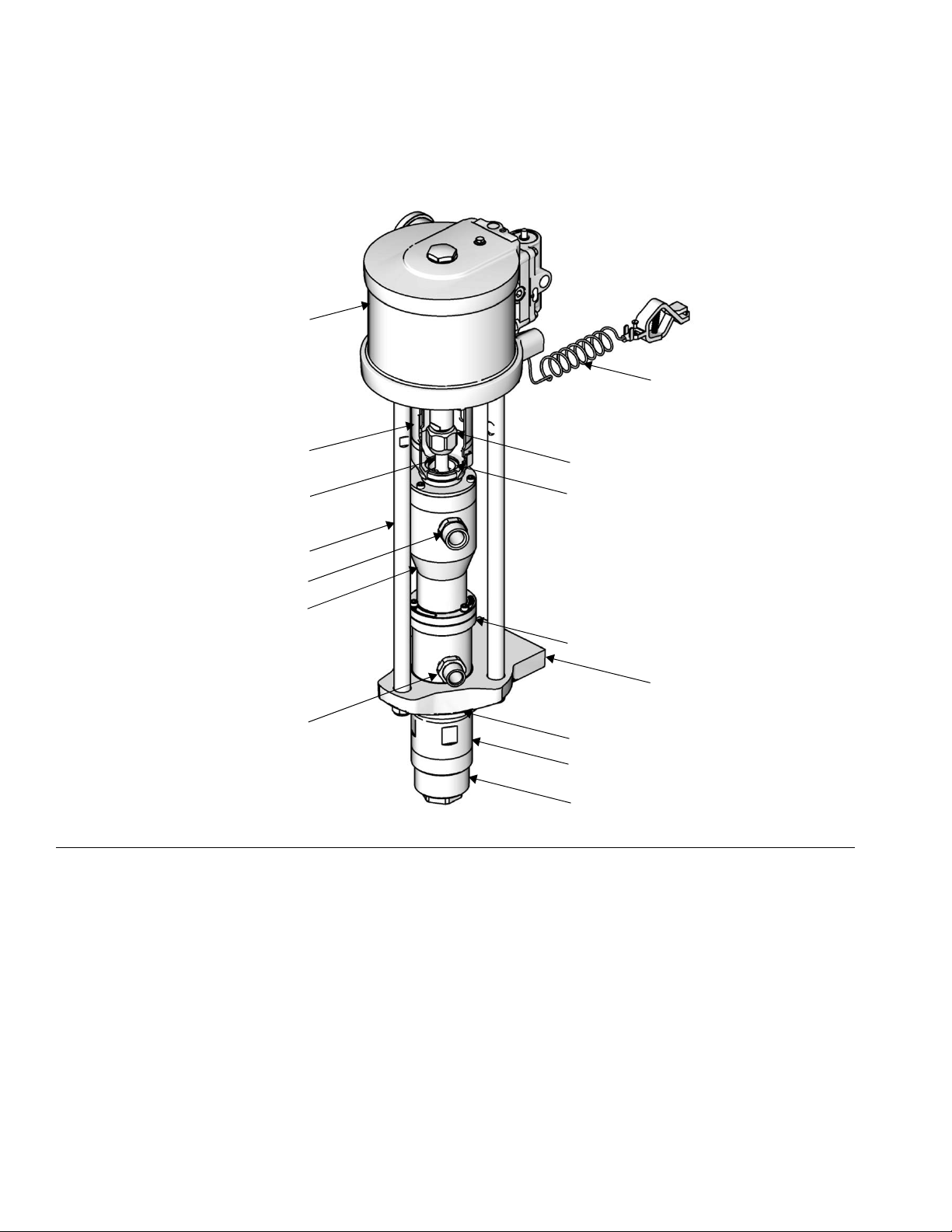

Component Identification

Component Identification

A

H

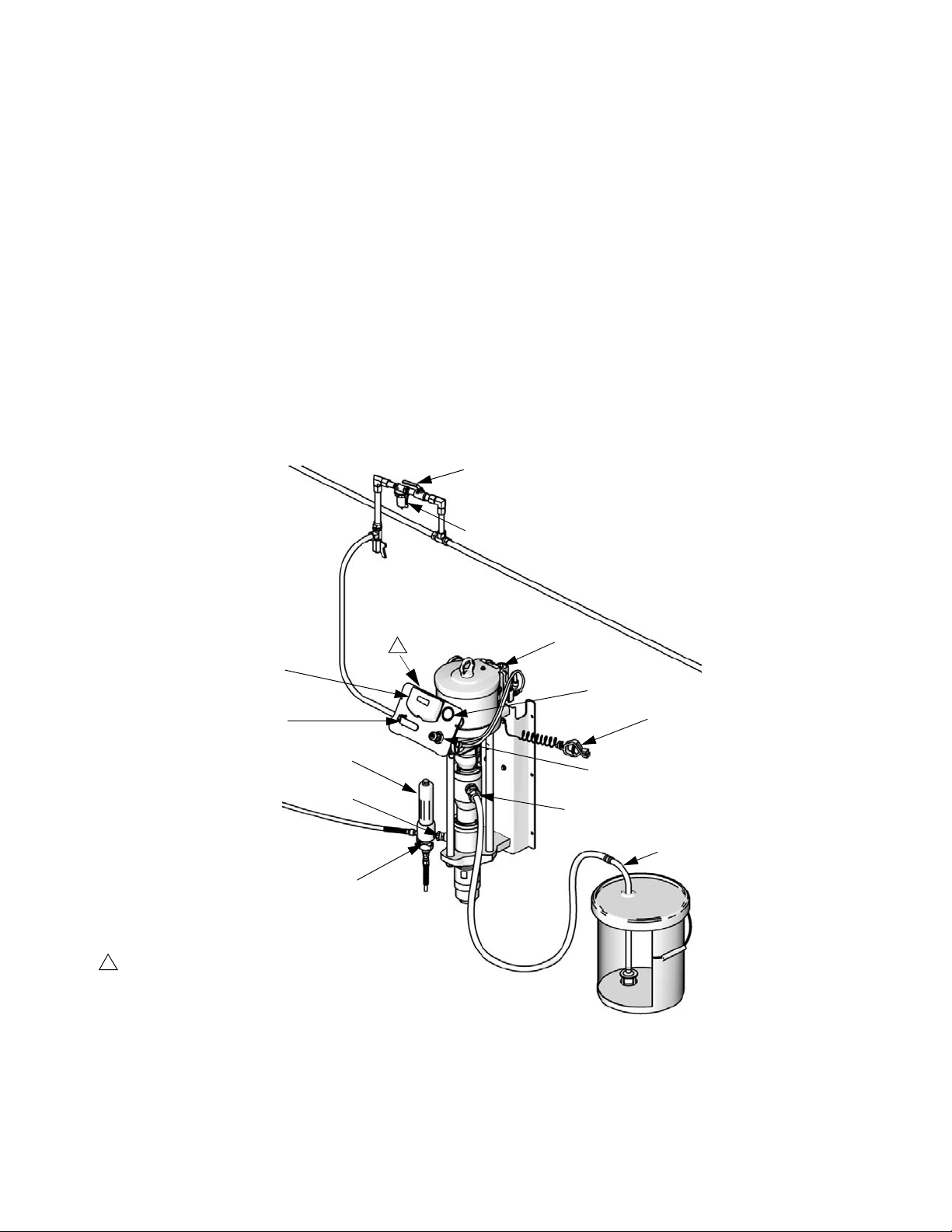

FIG. 1. Component Identification

Key:

A Air Motor

B Coupler Shield

C Connecting Rod

D Tie Rod

E Fluid Inlet

F Bellows Chamber

G Fluid Outlet

B

C

J

K

D

E

F

L

M

G

N

P

R

H Ground Wire

J Coupling Nut

K Coupling Collar

L Packing Nut

M Pump Adapter

NJam Nut

P Cylinder

RFoot Cap

ti15361a

8 312795E

Component Identification

312795E 9

Installation

Installation

General Information

NOTE: Reference numbers and letters in parentheses in

the text refer to the callouts in the figures and the parts

drawing.

F

IG. 2 and FIG. 3 are only guides for selecting and

installing system components and accessories. Contact

your Graco distributor for assistance in designing a system to suit your particular needs.

NOTE: Always use Genuine Graco Parts and Accessories, available from your Graco distributor. If you supply

your own accessories, be sure they are adequately

sized and pressure-rated for your system.

1

F

E

P

R

Prepare the Operator

All persons who operate the equipment must be trained

in the operation of all system components as well as the

proper handling of all fluids. All operators must thoroughly read all instruction manuals, tags, and labels

before operating the equipment.

A

B

J

G

S

H

T

U

V

1

Use alternate mounting holes (on bracket, not

visible) to mount air controls vertically.

ti15363a

FIG. 2: Typical Wall-Mount Installation

10 312795E

Loading...

Loading...