Operation Manual

Synergic Pulse Welding Unit

Model PU 400 DW

Model PU 520 DW

MERKLE

Schweissanlagen-Technik GmbH

Industriestrasse 3

D-89359 Koetz,

Germany

Tel.: ++49-8221-915-0

Fax: ++49-8221-915-40

www.merkle.de

.

Content page

1 Security indications before introduction 3

2 Accident prevention regulations 3

2.1

3 Duty cycle 5

4 Instructions to avoid interferences due to electromagnetic influences EMC 5

5 Technical Data: 7

6 Start Up 8

6.1 Installation of the Machine 8

6.2 Main Supply 8

6.3 Welding Torch 8

6.4 Gas Connection 8

6.5 Wire Installation 8

6.6 Earth Lead (Work Cable) 8

Safety instructions 3

6.7 Transport 9

7 Generalities of the welding unit 9

7.1 Model PU 400 DW / PU520 DW 9

7.2 Cooling of the power modul 9

7.3 Electronics 9

7.4 TEDAC-System 9

8 The indicated numbers below are refering to the drawing of the front panel 11

9 Operation of the Unit PU 400 / 520 DW 11

9.1 Switching on the machine 11

9.2 Selection of the welding process 12

9.3 Setting of the welding energy 12

9.4 Setting of the operation mode 12

9.5 Safety cut off 14

9.6 Adjusting of 'start current', 'down slope' time, 'final current' and 'intermission' time 14

10 Activation of the fixed TEDAC programs (jobs) 15

10.1 Generating your own TEDAC program 15

1

11 Pulse-Arc Welding Units PU 400 DW and PU 520 DW 16

11.1 Advantages – Point by point 16

11.2 Construction of the housing: 17

11.3 Locking of the control panel 17

12 Cleaning 18

13 Maintenance and Accident Prevention 18

14 Trouble Shooting 18

14.1 Machine does not operate after switching on the main switch 18

14.2 Machine does not react on the torch switch 18

14.3 Machine has no or too low welding current 18

14.4 Welding quality is not good 19

14.5 Problems with wire feeding and wire contacting 19

15 Aluminium Welding 19

16 Wire feeder systems 20

16.1 Spare parts wire feeder model: DV-25 22

16.2 Spare parts wire feeder model: DV-30 25

17 Torches - and Spare parts 29

17.1 MIG-MAG-welding torch model SB/SBT 502 W 29

17.2 Push-Pull-welding torch model PP/PPT 502 W 34

18 Stored programs PU 400 39

19 Spare parts and wiring diagram 40

19.1 Spare part list PU 400 DW 40

19.2 wiring diagram PU 400 41

19.3 Spare Part List PU 520 DW 49

19.4 wiring diagram PU 520 50

20 Stored programs PU 520 57

21 EU-Conformity Attestation PU 400 DW 59

22 EU-Conformity Attestation PU 520 DW 60

2

1 Security indications before introduction

The unit device is built after the recognized standards. Safe works are nevertheless only possible

if you read the operating instructions and the safety regulations contained in it entirely and obey

strictly. Install yourselves by trained staff of our establishments or appointed dealers.

2 Accident prevention regulations

The following accident prevention regulation is applied for pulse arc welding unit, model

PU 400 DW and PU 520 DW.

BGV D1 (earlier VBG 15) * Welding, cutting and allied processes.

A copy of this regulation should be readily accessible in every welding shop. The stipulations of

this regulation are to be observed in the interests of safe and correct welding operation.

* Available from the trade association responsible or

Carl Heymanns-Verlag, Luxemburger Strasse 449, 50939 Cologne.

2.1 Safety instructions

This unit is manufactured according to the requirements and stipulations of EN 60974.1 / VDE

0544 part 1. BGV D1 (earlier VBG 15) of the trade association for precision engineering and

electrical engineering are as well valid.

1) In case of an accident, the cutting unit must be disconnected from the mains immediately.

2) If electrical contact voltages arise, switch off the unit immediately, disconnect it from the

mains and proceed to inspection by a qualified electrician or by our Service Department.

3) Before opening the unit, disconnect it from the mains supply.

4) Repair work may only be carried out by a skilled electrician or by our Service

Department.

5) Before the unit is put to operation, check it visually, as well as the torch and all cables and

connectors regarding possible external damages.

6) Personal protective equipment in accordance with DIN EN 175, DIN EN 379 and

DIN EN 169.

During the work, the welder’s body must be completely protected against radiation and

burns by means of protective clothing and face protection. Long gloves, aprons and

welding shields with welding filters conforming to DIN EN 470-1 and BGR 189

must be worn.

Synthetic clothing are excluded. Shoes must be closed, not opened (due to spatters). If

necessary, protective headwear must be worn (e.g. for overhead welding). If cover glasses

are used, these must be in accordance with the norms specified above.

As additional protection for the eyes against UV radiation, safety goggles with side

shields and corresponding face protection in accordance with BGR 192 and BGI 553 must

be worn.

Accident prevention regulation BGV D1 § 27 stipulates that it is the responsibility of the

employer to provide suitable personal protective equipment, while § 28 stipulates that it is

the responsibility of the insured to wear suitable clothing.

3

7) Protection when welding under increased electrical risks

Welding rectifiers and welding power sources which can optionally be used for either

direct or alternating current must be marked "S" in accordance with EN 60974-1 and BGI

534.

Use insulating materials to protect you against contact with electrically conductive parts

and damp floors. Wear dry, undamaged work clothing, long gloves and footwear with

rubber soles. Ventilate rooms, install extraction systems if required, and wear respiratory

protective equipment if necessary (see Procedural instructions BGV D1 § 27 and BGI

533, Section 5).

8) In order to prevent stray currents and the effects thereof (e.g. destruction of electrical

protective ground conductors), the welding return cable (workpiece cable) must be

connected directly to the workpiece to be welded or to the table (e.g. welding table, gridtype welding table, workbench) supporting the workpiece (see BGV D1 § 20). When

installing the ground connection, assure that there is a good electrical contact (remove rust,

paint, etc.).

9) During welding pauses, the welding torch is to be laid down on an insulated surface or

hung up in such a way that it is not in contact with the workpiece and its support

connected to the welding power source (see § 20 BGV D1).

In the case of longer work pauses, the welding unit must be switched off and the gas

cylinder valve must be closed.

10) The shielding gas cylinder must always be protected against tumbling downing using a

safety chain.

11) Under no circumstances the unit may be put into operation while it is opened

(e.g. for repair work). Apart from the safety regulations, sufficient cooling of the

electrical components provided by the fan cannot be guaranteed.

12) In accordance with BGV D1 § 5, people in the vicinity of the arc must also be informed of

the hazards and protected against them. Safety partitions (“welding safety curtains”) must

be erected in accordance with DIN EN 1598.

14) N

welding work may be carried out on containers in which gases, fuels, mineral oils or

o

similar substances have been stored Öeven if they have been empty for a long timeÕ

(risk of explosion). See § 31 of accident prevention regulation BGV D1.

15) Welds which will be subjected to high loads and which need to meet specific safety

requirements may only be carried out by specially trained and qualified welders.

15) Never bring the torch close to your face.

16) In areas at particularly high risk of fire, the welder must obtain a welding permit and have

this on his person throughout the duration of the welding work. On completion of

welding, a fire-guard must be delegated to ensure fire protection.

17) Ventilation measures must be applied in accordance with BGI 553, Section 9.

4

18) The hazard to eyesight must be indicated by means of a sign at the work site

"CAUTION! Do not look into the arc!".

3 Duty cycle

The duty cylce measurings have been carried out in accordance with

EN 60974-1 / VDE 0544 part 1 (10 min working period).

60% duty cycle means:

After a 6 min. welding period a 4 min welding pause must be respected. The electrical

components are thermally protected against overheating.

4 Instructions to avoid interferences due to electromagnetic influences EMC

The welding unit has been manufactured in accordance with the requirements of guideline

EN 50199 regarding electromagnetic compatibility. It is nonetheless the responsibility of the user

to ensure that the welding equipment is installed and operated in accordance with the

manufacturer’s instructions. If electromagnetic interference is detected, it is the responsibility of

the user of the welding equipment to find a solution with the technical assistance of the

manufacturer. In some cases, it may be sufficient simply to ground the welding current circuit. In

other cases, it may be necessary to build a complete shield for the welding power source and

workpiece using the input filters. In all cases, electromagnetic interference must be reduced to

avoid any possible malfunctions.

Note:

For safety reasons, the welding current circuit may or may not be grounded. No

modifications may be made to the grounding without the approval of an expert who is able to

determine whether the changes might increase the risk of accidents, e.g. by allowing parallel

welding current return paths which could destroy the ground conductors of other equipment.

Further instructions are contained in TEC 974-XX "Arc welding equipment – installation and

use".

a) Evaluation of the installation site

Before installing the welding equipment, the user must evaluate potential electromagnetic

problems in the vicinity. The following must be taken into consideration:

a. Other power cables, control cables, signal and telecommunication cables above,

below

and next to the welding equipment

¾ Radio and television transmitters and receivers

¾ Computers and other control devices

¾ The health of people in the vicinity, e.g. use of heart pacemaker and hearing aids

¾ Calibration and measuring equipment

¾ Interference immunity of other devices in the vicinity. The user must ensure the

electromagnetic compatibility of other devices used in the vicinity. This may require

additional safety measures.

b) Procedures to reduce emitted interference

1) Mains supply

Welding equipment is to be connected to the mains in compliance with the

recommendations of the manufacturer. If interference occurs, it may be necessary to take

5

additional precautions, e.g. filters for the mains connection. Make sure that the power

cable of welding equipment is installed in a fixed position shielded by means of a metal

conduit or similar. The entire length of the shield must be electrically connected. The

shield must be connected to the welding power source in the way to obtain a good

electrical contact between the metal conduit and the housing of the welding unit.

2) Maintenance of the welding equipment

Welding equipment must be maintained regularly in accordance with the

recommendations of the manufacturer. All access and service doors and covers must be

closed and fastened securely when the welding equipment is in operation. No

modifications whatsoever may be made to welding equipment with the exception of

modifications and adjustments specified in the manufacturer’s operating instructions.

3) Welding cables

Welding cables should be kept as short as possible and routed close together on or near

the floor.

4) Equipotential bonding

It is advisable to interconnect all metallic parts in and next to the welding equipment.

Metallic parts connected to the workpiece can, however, increase the risk of the welder

receiving an electric shock by touching these metallic parts and the electrode

simultaneously. The welder must be electrically insulated against all these connected

metallic parts.

5) Grounding the workpiece

If the workpiece is not connected to the ground for electrical safety reasons, or due to the

size and position of the workpiece, e.g. steel structure or outer wall of a ship, grounding

the workpiece may in some cases, but not all, reduce emitted interference. It must be

ensured that grounding the workpiece will not increase the risk of accidents for the user

and cannot cause the destruction of other electrical equipment. If necessary, the grounding

of the workpiece must be carried out by means of a direct connection to the workpiece. In

countries where a direct connection is prohibited, the connection must be made by means

of suitable reactors, selected in accordance with national regulations.

6) Shielding

Selective shielding of other cables and devices in the vicinity can reduce interference

problems. For special applications, it may be worth considering shielding the entire

welding system.

6

5 Technical Data:

Model: PU 400 DW PU 520 DW

Primary:

Power supply 3 x 400 V (415V) 3 x 400V (415V)

Frequency 50 (60) Hz 50 (60) Hz

Continuous power 14.5 kVA 22,1 kVA

Continuous current 21 A 32 A

Max. current 27 A 42 A

Cos phi 0,95 0,9

Secondary:

No load voltage 80 V 77 V

Working voltage 15 - 34 V 15 - 40 V

Welding range 20 - 400 A 20 – 520 A

60 (10 min.) duty cycle 400 A 520 A

100 duty cycle 310 A 440 A

Protection class IP 23 IP 23

Insulation class H H

Cooling AF AF

Pulse frequency 20 - 500 Hz 20 - 500 Hz

Basic current 0 - 400 A 0 - 500 A

Pulse current 0 - 600 A 0-1000 A

Arc voltage 0-80V 0-77V

Pulse time 0,1 - 25,5 ms 0.1 -25.5 ms

Generator Inverter Transistor-cascada

Pulse form 144 pulse forms programmable

Ignition process 13 parameters programmable

Arc length automatic adjusting

Program storage EPROM and EEPROM for 144 programs

Welding process MIG/MAG, Pulse-Arc, Interpulse, stick electrode

Wire diameter 0.8/1.0/1.2/1.6 mm + 2 special

Material selection Programs for 12 materials

Operation mode 2-stroke, 4-stroke with down slope, 4-stroke

with start and final current., stitch, spot welding

Gas check Button with hold-funktion and timer

Digital read-out 2 displays for curr., voltage, wire

feeding speed, material thickness

with pre-indication and hold-function

Energy control continuous; wire feeder or TEDAC-torch;

4 programs recallable at the TEDAC-torch

Wire feeding system DC-tacho-motor with 4-roller dive 0.1-30 m/min.

Torch cooling integrated watercooling system

Norm EN 60974-1 "S" / CE

Weight 140 kg 270 kg

Dimensions L x W x H 1020x470x1015 1110 x 530 x 1065 mm

with wire feeder with wire feeder

and gas bottle holder and gas bottle holder

7

6 Start Up

6.1 Installation of the Machine

If the unit is brought from cold ambient temperatures into a tempered room, for example due to

transportation or from unheated storage depots, it must be adapted before being put to operation a

certain time according to the temperature difference onto the ambient temperature.

Place the machine at least 0.80 m from a wall etc. to guarantee the cooling air can go

through the unit. The room temperature should not exceed 40°C.

The room were the unit is placed should have a low degree of humidity

(max. 50 % at 40°C, max. 90 % at 20° C).

The unit has passed the quality control in accordance with IP 23.

The air in the surroundings must be free from extreme quantities of dust, free from acides and

corrosive gases etc. Otherwise use air filters.

6.2 Main Supply

The main supply must be connected by a trained person. The main supply voltage is displayed on

the front or rear panel of the machine. A connection to ground (GND) must be done.

6.3 Welding Torch

Connect the torch to the Euro-connector.

Gas Connection

6.4

Place the gas bottle on the gas bottle holder and secure it with the safty chain. Remove

the cap and open the bottle momentarily to purge the valve. Install the regulator on the

bottle valve. Connect the gas hose from the machine to the pressure reducer. Slowly open

gas valve and set the gas flow.

Wire Installation

6.5

Place the wire spool over the wire drive. Loosen the end and cut off the bent end section.

Hold the wire to prevent unwinding of the spool. Open the lightning lever and lift the

pressure finger. Feed the wire into the wire feed guide. Push the wire forward onto the

wire drive roller grooves. Close the lightning lever and switch on the machine.

Check the wire feeding: Place your hand 10 cm in front of the contact tip. Let the wire run

into your hand. If the wire is running, the pressure of the drive rollers is o.k.

6.6 Earth Lead (Work Cable)

The earth lead must have an excellent ground. The clamp should be attached to a clean, paint and

rust free area on the work piece or on the welding table.

8

6.7 Transport

If a transport by crane is required, the unit must be fixed at all lifting eyes.

7 Generalities of the welding unit

7.1 Model PU 400 DW / PU520 DW

The welding unit PU 400 DW is based on inverter technique, the welding unit PU 520 is a

secondary transistor-switch 20 kHz technologie and suitable for MIG/MAG, Pulse-Arc and

MMA/stick electrode welding. Continuous setting of the welding current up to 400 A (PU 400),

520 A (PU 500).

The unit can be characterized by numerous features:

¾ inverter power source with continuous setting of the current 20 - 400 A (PU 400),

the PU 520 with transistor- cascada with continuous setting of the current 20 - 520 A

¾ socket for remote control

¾ digital read out with pre-display and hold-function

7.2 Cooling of the power modul

The fans which are cooling the power modul are switched on automatically as soon as the arc is

enlighted.

7.3 Electronics

The electronic is divided in to 3 sections:

¾ Display, selection of the logic and the operation mode

¾ Adjusting and program parameters

¾ Supervision of the temperature, fan control

7.4 TEDAC-System

The TEDAC-System offers the possibility to adjust the energy from min. to max. by means of a

slide switch. The poti „energy“ is limiting the range of the welding current.

The multi-coloured LED at the handle inside shows the actual setting of the welding current.

red - max. energy

green - min. energy

9

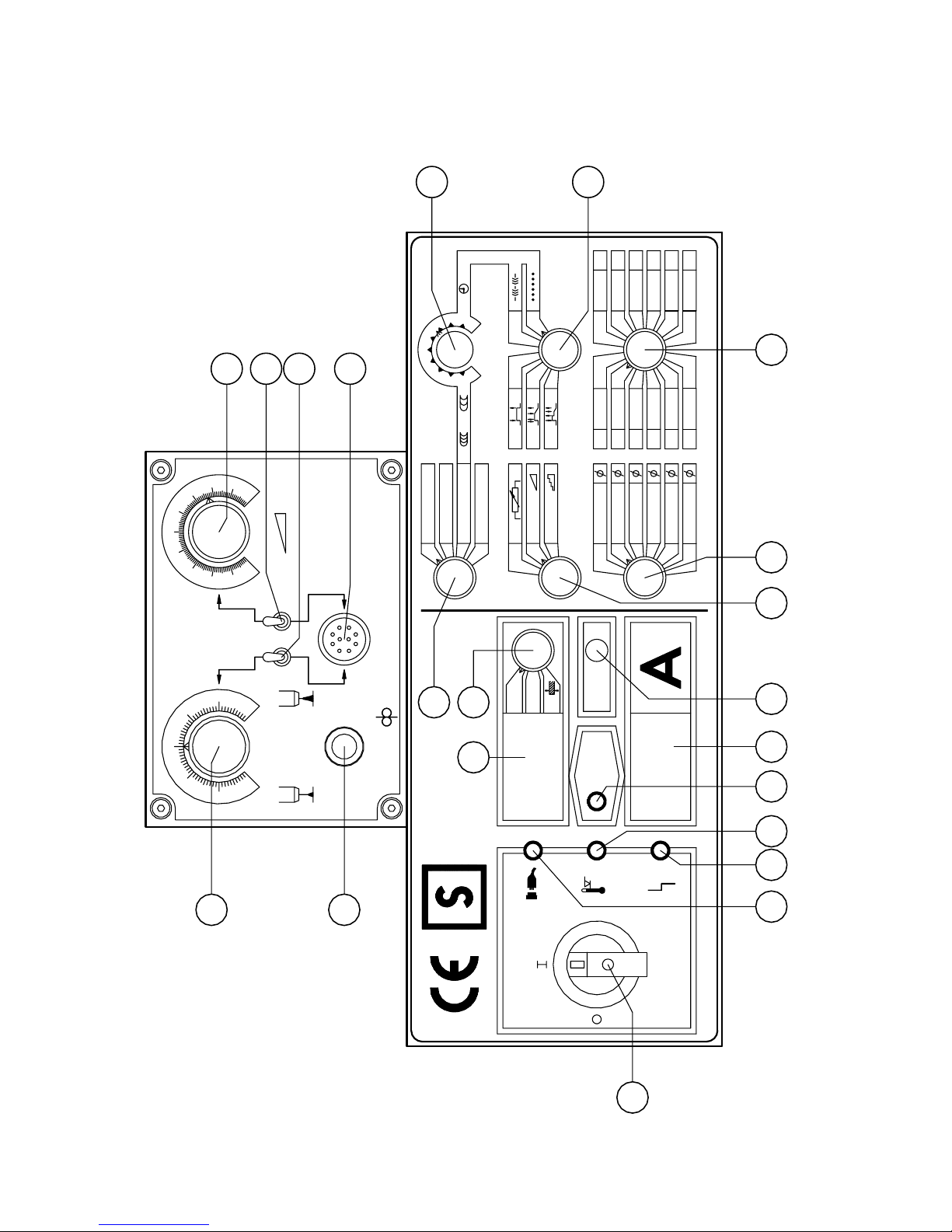

Front panel

8

8

9

7

10

6

5

4

0

18

25

26

80

90

70

60

50

40

30

100

%

Energie / energy

0

10

20

27

3

2

PULSE

MIG-MAG

1

ELECTRODE

INTERPULSE

TEDAC

TEDAC

4

789

SPECIAL

SPECIAL

AlSi

Al 4,5 Mn

654

1.0 mm

0.8 mm

10

SPECIAL

SPECIAL

CrNi

AlMg 3-5

3

1.2 mm

1.6 mm

12

11

SPECIAL

SPECIAL

SG 2+3

SG 2+3

1

2

2.SPECIAL

1.SPECIAL

E 2923-31

5

639

PP und Fernregelung

pp and remote control

20

15

25

10

5

0

5

10

15

30

%

voltage trim

Lichtbogenlänge

-+

30

25

20

17

Drahtvorschub

19

2

wire feed

7

10

V

V

m/min

mm

GAS

11

HOLD

121513 14

MAIN SWITCH

HAUPTSCHALTER

1

10

8

The indicated numbers below are refering to the drawing of the front

panel

1: main switch

2: selector welding process

3: selector location of energy adjustment

4: selector operation mode

5; selector material

6: selector wire diameter

7: selector read-out

8: variable resistor interpulse / welding timer

9: button gas test

10: digital read out, switchable

11: digital read out, amperage

12: LED HOLD

13: LED mains on

14: LED thermic protection

15: LED failure

17: variable resistor voltage trim / arc length (at the wire feed unit)

18: variable resistor energy (at the wire feed unit)

19: button wire currentless (at the wire feed unit)

21: trimmer down slope time (inside of the generator, on top of the front panel)

22: trimmer final current (inside of the generator, on top of the front panel)

23: trimmer start current (inside of the generator, on top of the front panel)

24: trimmer intermission time (inside of the generator, on top of the front panel)

25: switch remote control energy (at the wire feed unit, option)

26: switch remote control voltage trim (at the wire feed unit, option)

27: socket for remote control or push-pull torch (option)

9 Operation of the Unit PU 400 / 520 DW

9.1 Switching on the machine

Turn main switch ( 1) into position 1.

If the digital read-out (10) and (11) only indicate horizontallines the chosen welding program

does not exist.

For help see selection of the welding programs, otherwise the machine is ready for operation.

Selection of the welding programs

Selection of the material by means of the two selectors (5) and (6).

Put selector (5) in order to choose the material and selector (6) in order to choose the correct wire

diameter.

If the digital read-outs (10) and (11) are only indicating horizontal lines, the welding program

does not exist.

The list of welding programs is displayed at the inside of the wire feeder box.

11

9.2 Selection of the welding process

With selector (2) the welding process can be selected:

MIG-MAG, PULSE, INTERPULSE and STICK ELECTRODE WELDING. If the digital readouts (10) and (11) only show horizontallines, the chosen welding program does not exist.

1. MIG-MAG welding

With variable resistor ( 17) individual adaption of the arc voltage ( arc length)

2. PULSE welding

With variable resistor ( 17) individual adaption of the arc voltage ( arc length)

3. INTERPULSE welding

With variable resistor (17) individual adaption of the arc voltage (arc length). With

variable resistor (8) the interpulse parameters are changed, i.e. left turn is fine scaled

welding, right turn is coarse scaled welding.

Interval welding is not possible in interpulse operation.

4. STICK ELECTRODE welding

With variable resistor ( 17) arc-force is adjusted:

Left turn = no increasing of the welding current

Right turn = maximum increase of the welding current

9.3 Setting of the welding energy

With selector (3) the adjusting selector for the welding energy is chosen.

1. Variable resistor

In this position the energy is set by the variable resistor (18) at the machine. With switch (25) a

remote control box can be used.

2. TEDAC

The welding energy is adjusted by means of the slide switch on the TEDAC-torch and limited to

a maximum value by variable resistor (18).

3. Fixed welding programs (jobs)

See further functions

9.4 Setting of the operation mode

With selector (4) the operation mode is chosen.

2-stroke operation

Selector ( 4) in position “2-stroke”.

In this position the torch interruptor is used to start and to switch off the machine.

12

4-stroke operation

Selector (4) in position “4-stroke”.

Torch interruptor pressed: welding process is started

Torch interruptor released: welding in process

Torch interruptor pressed: welding, “down slope” of the welding current down

to the “final current”

Torch interrupter released: welding arc is cut off

4-stroke operation with special welding program

Selector (4) in position “special 4-stroke”

Torch interrupter pressed: the welding process is started with the “start current”

Torch interruptor released: welding with selected energy

Torch interrupter pressed: down slope” of the energy down to the “final current'”

Torch interruptor released: welding arc is cut off

4. Stitch operation

Selector ( 4) in position “stitch”.

The welding time can be adjusted by variable resistor (8) (range: 0.5- 2.5 sec.) Time of

intermission is adjusted by a trimmer inside the machine.

5. Spot welding

Selector ( 4) in position “spot welding”.

With variable resistor (8) the welding time can be adjusted (range: 0.5 -2.5 sec.)

With variable resistor (8) the start current is adjusted in relation to the selected welding

current (in % )

Insertion of the wire

With button (19) the wire is inserted without welding current.

The feeding speed increases slowly up to approximately 15m/min.

Testing shield gas

With button (9) the gas flow can be checked. Button (9) pressed: gas valve is switched on, Button

(9) released: gas valve is still switched on, Button (9) pressed: gas valve is still switched on

Button (9) released: gas valve is switched off or the gas valve is automatically switched off after

10 s

Digital read-outs

The welding unit is equipped with two digital read-outs.

These digital read-outs dispose of the pre-indication and HOLD-function of the welding

parameters, i. e. indication of the preselected welding current and welding voltage (or

wire feed speed or thickness of material).

13

After the welding process the last welding values are hold as long as LED (12) is enlighted or the

arc is enlighted again or the welding energy is changed.

Upper display (10):

With selector (7) following parameters can be displayed:

a) welding voltage in V

b) wire feed speed in m/min

c) material thickness in mm

Stick electrode welding: the actual welding voltage is always indicated.

Lower display (11 ):

The welding current is always indicated (in amps. )

9.5 Safety cut off

In case of no arc is established within about 2 s, the welding process is automatically cut off in

any selected operation mode.

9.6 Adjusting of 'start current', 'down slope' time, 'final current' and 'intermission' time

(These trimmers are located inside of the generator on top of the front panel pc-board)

1. Start current

With trimmer (23) the start current in the position “special 4-stroke”

can be adjusted

Left turn max. corresponds to -50 %,

right turn max. corresponds to + 50 % of the welding current chosen.

2. Final current

With trimmer (22) the final current in the down slope process (special 4-stroke operation)

can be adjusted.

The current is independent of the adjusted welding current -in case of the welding current

is inferior to the adjusted final current, there is no down slope.

3. Down slope time

The down slope time is adjusted by trimmer (21 )

4. Intermission time

Using interval welding the intermission time can be changed by trimmer (24) in the range

0.5s to 2.5s.

14

10 Activation of the fixed TEDAC programs (jobs)

Selecter (3) in position “fixed TEDAC programs (jobs)”

Activation of the welding programs by using the TEDAC slide switch on the TEDAC-torch.

Programs 1-4 correspond to: 1 = green

2 = yellow

3 = orange

4 = red

In this operation mode the variable resistors for the energy (18), the arc length (17) as well as

selector (2) are out of function. The welding process is selected by the fixed program.

Pre-indication of the upper digital read-out:

According to the position of selector (7) welding voltage in V,

wire feed speed in m/min or

thickness material in mm

Pre-indication of the lower digital read-out: welding current in A

The welding process is indicated by a point at the right side of the welding current display ( 11 ):

MIG-MAG no point

PULSE point at the right side

INTERPULSE side point is flashing

10.1 Generating your own TEDAC program

1) Press down button (9) and pull simultaneously the TEDAC-slide switch mounted

on the TEDAC-torch for about 5 s. Herewith you enter the program mode.

2) Press the TEDAC-slide switch on the TEDAC-torch towards the front to select the

individual program point (P1: green, P2: yellow, P3: orange, P4: red).

3) Set selector (2) on the desired welding process (MIG-MAG, PULSE, INTERPULSE).

4) Select the desired arc by the variable resistor ( 18 - energy) and the variable resistor

(17 - arc length).

5) Weld with these parameters and adjust them as requested.

6) Store this setting of these parameters by pulling the TEDAC-slide switch for about 5 s.

The storage is confirmed by the indication by the letters “STO” in the display for about 1 sec.

7) Herewith this program (job) is stored.

8) Proceed in the same way with the three remaining programs.

9) For leaving the program mode, press down button (9) and pull simultaneously the TEDAC-

slide switch mounted on the TEDAC-torch for about 5 s.

15

11 Pulse-Arc Welding Units PU 400 DW and PU 520 DW

11.1 Advantages – Point by point

¾ Compact and clearly arranged housing:

Generator, control panel, control and water cooling system are mounted in one housing.

¾ Rotating mounting of the wire feeder on the welding unit.

The swivelling axis is placed asymmetrically at the rear of the wire feeder and allows a wide

work area. The wire feeder rotates easily to the desired position without kinking the torch lead.

Due to this construction, the movements of the connection cable is reduced to a minimum.

¾ Safe transport due to the locking of the wire feeder. - Connection cables available in different

lengths: Quick and easy change due to clampable and pluggable couplings on both sides.

¾ Gas bottle holder for 10, 20 and 50 I cylinders. Lowered for an easy handling of the

cylinders. Galvanized: no corrosion due to possible frictions.

¾ Large swivel and carriage wheels for an easy handling in the workshop and in the plant. - 4

lifting eyes to transport the welding unit (option).

¾ Reduced electrical consumption in stand-by-operation. - Demand-on switching of the water

pump and ventilator.

¾ High efficiency factor due to a modern electronic.

¾ Special filters avoid radiation.

- tremendous time saving due to reduction of

working hours for cleaning

- high output of wire melting

- long endurance of torch consumables

- extended switch-on time when using machine welding.

¾ Safe, spatter reduced ignition due to a new ignition process controlled by 14

parameters:

- 2 independent ignition pulses

- precise soft start of the wire

- slag droplet on wire removed for re-ignition.

¾ 144 stored welding programs for

- different materials

- different wire diameters

- different protective gases

- Pulse-Arc, MIG/MAG and Interpulse welding.

16

¾ Multiples variations of the pulse parameters:

Manipulation of the arc characteristics and the penetration.

¾ Application of thicker wire diameters compared to MIG/MAG welding.

Savings due to purchase of thicker wire.

¾ Alloy elements are maintained due to

adaption of the pulse parameters when using high alloyed wire.

¾ Structure of the Pulse-Arc welding programs:

Flexible program structure with 35 free programmable

parameters. Perfect ignition due to 13 variable parameters

within the ignition process. 144 different pulse forms

programmable. Generating of different forms of welding

characteristic curves for the welding parameters possible.

¾ New procedure of MIG/MAG short arc welding process

Due to the new technology, already in short arc welding a very

spatter reduced weld is achieved. The range of

the non-desired mixed arc is reduced to a minimum.

¾ Comparison spatters MAG/Pulse-Arc welding:

Spatter emission in relation to the welding current

in percent. The comparison shows the outstanding

results in favour of the Pulse-Arc welding

and the traditional MAG welding using

CO? or mixed gas as protective gas.

11.2 Construction of the housing:

1) Easy to service and to open, all components clearly arranged with easy access.

2) Electronical components are dust protected placed in a separate department.

3) Easy mounting of the connection cable due to clamp-able and pluggable fittings.

4) Efficient cooling of all power components in the air tunnel.

11.3 Locking of the control panel

¾ reduction of the functions to a minimum:

Main switch, LED-displays, gas check, adjusting of the energy and arc length

(both at the wire feeder).

¾ only authorized persons can manipulate the operation modes and programs.

¾ in operation mode "Fixed Programs" the welder can activate 4 different free

programmable welding caracteristic curves at the TEDAC-torch.

17

12 Cleaning

IMPORTANT:

!!! Before opening the machine, disconnect it from mains !!!

Open the side covers. Remove dust from all parts of the machine.

Blow away the dust at the pcbs of the inverter withcompressed air –reduced pressure

(appr. 0,5 – 1 bar). We recommend to clean the unit in regular periods.

13 Maintenance and Accident Prevention

The maintenance of the welding machine consists of a regular cleaning and inspection. It depends

on the environment of the working area and the working hours.

The machine should be cleaned in regular intervals to guarantee a proper operation. The length of

the cleaning interval depends on the operation time, surrounding atmosphere etc.

ATTENTION: Before opening the welding machine, make sure

that it is disconnected from the mains supply. Wait for

components to be sufficiently cooled down !

Wait until the capacitors are discharged (appr. 3 min.)!

14 Trouble Shooting

14.1 Machine does not operate after switching on the main switch

a) Check main supply

b) Check main fuses

14.2 Machine does not react on the torch switch

a) Problem at the torch switch

b) Check internal fuses

14.3 Machine has no or too low welding current

a) Main relais is not working

b) Bad or no contact at the earth lead

c) Torch hose completely or partially broken

d) Problem with rectifier or IGBT- switches in the machine

e) Only 2 main phases are connected, check main fuses

18

14.4 Welding quality is not good

a) No or too low gas flow

b) Air is mixed into the protective gas. Open gas valve and close it again. Gas pressure

must remain in the gas hose. Check at the regulator.

c) Gas nozzle or tip holder are covered with spatters. Gas flow is not o.k.

d) Tip holder is not fixed properly. Air is mixed into the protective gas via the wire

e) Extremly oxidated workpiece.

f) Air is comming to the welding area because of wind.

14.5 Problems with wire feeding and wire contacting

a) Hole in the contact tip has wrong diameter or contact tip must be changed.

b) Wire core is extremly dirty.

c) Kinks in the wire core.

15 Aluminium Welding

1. Aluminium welding wire:

- Wire diameter 0.8 mm only with push pull torch

- Wire Al-Mg 3/5/4.5 Mn (1.0 mm), Al-Si, Al 99.5 (1.0 and 1.2 mm) torch lead max. 3 m

- For welding wire 1.6 mm we recommend a torch with a long torch head

- Do not store alu wire without the platic protection cover. Do not use alu wires with oxid.

2. Teflon liner:

- For wire 1.0 mm we recomend the teflon liner (red 2,0 x 4,0) (part-no. 022.1.0586)

- For 1.2 and 1.6 mm carbon teflon liner (yellow 2,7 x 4,7), (part-no. 022.1.0588)

- The carbon teflon liner must be installed without any break from the contact tip to the drive

roller

- Fix the clamping nut at the Euro connector only by hand

3. Wire feeder:

- Exchange the brass guidance nozzle to a pvc guidance nozzle (between the two drive rollers)

DV-25: part-no. 012.0.0373, DV-30: part-no. 012.0.0269

- Exchange the insertion nozzle at DV-30 from brass to pvc (part.-no: 012.0 0267)

- Exchange the guidance core at DV-30 to pvc (part-no: 022.1.0237)

- Install the outgoing tube in the Euro connector to support the teflon liner

Exchange the Outgoing tube (pvc) for alu/stainless steel:

DV-20: part-no. 103.001,

DV-25: part-no. 103.001,

DV-30: part-no. 102.998.

4. Wire feeding rollers:

- Exchage the two lower roller to aluminium rollers (U-groove), the rollers at the to may

remain pressure rollers without a groove

19

5. Pressure of the rollers:

- Reduce the pressure to a minimum.

- When the alu wire is stoped at the contact tip the rollers must turn without transporting the

wire.

6. Insertion of the wire:

- Insert the wire without a contact tip at the torch.

- Hold the torch cable straight, outherwise the wire could go through the line and the torch

lead.

7. Welding torch:

- We do not recommend the torch SB/SBT 154 G for aluminium welding. Use a ceramics gas

distributor (not fibre glas). Due to the high temperatures the fibre glass may emit a gas

which influences the welding process.

- The torches SB/SBT 300 W, SB/SBT 502 W and SB/SBT 600 W have an open cooling

system. Assures that the componets are tightly fitted. Only minimum parts of water will

make the aluminium welding impossible.

8. Protective gas:

- We recommend argon 4.6, mixtures argon-helium can be used for thick aluminium plates to

avoid or reduce a pre-heating.

- Gas flow for a gas nozzle 17 mm:

wire 1.0 mm: aprox. 12-14 l/min.

wire 1.2 mm: aprox. 14-16 l/min.

wire 1.6 mm: aprox. 18-22 l/min.

Avoid smaller gas nozzles.

- If the gas hose between gas valve and cylinder is long, an impulse of too much gas is ejected

during the ignition process which could cause porosity. Our wire feeder boxes have a special

reduction device installed.

- For gas hoses longer than 10 m we recommend the installation of a pressure regulator inside

the welding unit.

- We recommend a regulator with an integrated ball-flowmeter.

9. Position and distance of the torch:

- Aluminium is welded in forward position, the torch is tilt aprox. 10 - 20°.

- Distance torch to work piece aprox. 10-15 mm. If the distance is too large, the protective gas

shield is not assured.

- Avoid draught (air movement in the room).

10. Cleanliness:

- Aluminium work pieces must be without any dirtying. Clean with alcohol or special

aluminium cleaner

- Avoid the storage under high humidity.

- Remove oxid when aluminium pieces have been stroed a lon time.

11. Additional wire equipment:

- In our general catalogues in section 10 we offer complete packages for wire equipments.

12. Special 4-stroke:

- We recommend to operate in the special 4-stroke mode with a higher start current. The start

current, the down slop and the final current can be adjusted inside the machine behind the

front panel.

16 Wire feeder systems

20

Drahtvorschubgetriebe DV-25

2

1

4

3

6

5

7

8

10

9

11

12

14

13 15

16

17

19 20 21 23

3518

22 34

242526

27

282930 32

21

31

33

39

E 2715-39

16.1 Spare parts wire feeder model: DV-25

(If spare parts for the wire feeder are needed, always indicate number of the relative

positon and part number)

Pos Description _Part No._

Wire feed gear complete 002.0.2850

with motor and wire feed rollers

1 gear flange (brass part) 002.0.2875

gear flange (complete) 012.0.0287

(Euro connector preassembled)

2 lentil flat-head screw 090.0.0825

3 insulation bush 002.0.2877

4 knurled screw M 4 x 20 090.0.1002

5 bolt (roller) 002.0.2859

6 bolt 002.0.2864

7 rocking bar 002.0.2865

8 cylindrical pin 090.0.0571

9 thread pole M 8 x 90 002.0.2863

10 knurled nut 002.0.2862

11 compression spring 002.0.2690

12 pressure piece 002.0.2861

13 thread case 002.0.2860

14 rocking bar 002.0.2866

15 bullet button 002.0.2856

16 pvc liner 012.0.0377

17 permanent magnet motor 24 VDC 002.0.2630

18 hexagon screw 090.0.4335

washer 090.0.1208

spring ring 090.0.1408

22

Pos Description _Part No._

19 insulation plate 002.0.2876

20 gear insulation 012.0.0285

21 gear angle 002.0.2874

22 sheet steel protection 002.0.2870

23 outgoing nozzle (brass) 6 x 2 x 48 002.0.0367

Outgoing tube (brass) for alu/stainless steel 103.001

6 x 4 x 51

24 bolt (roller) 002.0.2873

25 for mild steel/stainless steel:

drive roller with groove V ∅ 0,6 mm 002.0.2879

drive roller with groove V ∅ 0,8 mm 002.0.2880

drive roller with groove V ∅ 1,0 mm 002.0.2881

drive roller with groove V ∅ 1,2 mm 002.0.2882

for aluminium:

drive roller ∅ 0,8 mm alu 002.0.2884

drive roller ∅ 1,0 mm alu 002.0.2885

drive roller ∅ 1,2 mm alu 002.0.2886

drive roller ∅ 1,6 mm alu 002.0.2887

26 knurled screw M 4 x 10 090.0.1001

27 fastener 002.0.2869

28 drive pinion 002.0.2871

29 guidance nozzle (brass) for steel 5 x 1,5 x 40 002.0.2867

guidance nozzle for alu/stainless steel 012.0.0373

(pvc) 5 x 1,5 x 40

30 knurled screw 002.0.2857

31 pressure roller 002.0.2878

32 screw (brass) 025.1.1610

33 incoming nozzle 002.0.2891

34 retaining ring 002.0.2858

39 edge protection rubber (0,3 m) 001.0.0820

23

Wire feeder DV-30

50

1

48

49

3

2

5-

4

8

7

10

11

57

14

15

16

17

51

52

54

57

47

12

18

20

22

24

19

21

23

66

26

25

27

58

28

29

30

31

46

.

63-

32

45

34

33

37

38

39-

42

43

44

24

16.2 Spare parts wire feeder model: DV-30

(If spare parts for the wire feeder are needed, always indicate the number of the relative

positon and part number)

Pos Description _Part No._

Wire feeder block DV-30, without motor, without rollers 012.0.0352

1 Gear box DV-30 012.0.0353

2 left rocking bar 012.0.0276

3 pressure piece 012.0.0261

4 gripping yoke 012.0.0259

5 leveling screw 012.0.0260

6 compression spring 002.0.2688

7 screw 012.0.0266

8 cylindrical pin 090.0.0587

9 compression spring 002.0.2688

10 right rocking bar 012.0.0277

11 eccentric (tentering lever) 012.0.0258

12 knurled screw 090.0.1001

13 hexagonal screw 090.0.4313

14 guide roll 012.0.0239

15 adjusting roll 012.0.0238

16 clamping sleeve 2,5 x 4,5 025.1.1524

17 introductory liner 2,5 x 4,5 002.0.2905

18 sliding block 012.0.0257

19 incoming nozzle for steel 0,8-1,6 (brass) 012.0.0332

19 a incoming nozzle for alu and stainless steel 012.0.0267

0.8-1.6 (pvc)

25

Pos Description _Part No._

20 guidance nozzle for steel 0,8-1,6 (brass) 012.0.0274

20a guidance nozzle for alu and stainless steel 0.8-1.6 (pvc) 012.0.0269

21 feather 090.0.8815

22 DU bush (inside the gear block) 019.1.0121

23 gear (drive pinion) 012.0.0279

24 insulation plate 002.0.0144

25 leveling screw 003.0.1506

26 screw pin 090.0.3303

27 screw pin 090.0.3409

28 DU bush 019.1.0550

29 cylindrical pin 090.0.0598

30 screwpin 090.0.3413

31 bolt 012.0.0268

32 gear pre-assembled 012.0.0278

33 retaining ring 090.0.1814

34 spacing ring 012.0.0235

35 cylinder-head screw 090.0.0937

36 washer 090.0.1205

37 groove ball bearings 019.1.0261

38 feather 090.0.8810

39 eye bolt 090.1.2528

40 compression spring 002.0.2690

41 hexagonal nut 090.0.6055

42 insulation bush 002.0.0200

26

Pos Description _Part No._

43 knurled nut 012.0.0265

44 for mild steel and stainless steel:

drive roller V 1,0 and 1,2 mm ∅(2 pcs. needed) 012.0.0272

pressure roller (2 pcs. needed) 012.0.0271

drive roller V 0,8 and 1,6 mm ∅ (2 pcs. needed) 012.0.0273

pressure roller (2 pcs. needed) 012.0.0271

for aluminium:

drive roller U 1,0 and 1,2 mm ∅ (2 pcs. needed) 012.0.0281

pressure roller (2 pcs. needed) 012.0.0271

drive roller U 0,8 and 1,6 mm ∅ (2 pcs. needed) 012.0.0282

pressure roller (2 pcs. needed) 012.0.0271

for cored wire:

drive roller for cored wire 1,2 and 1,6 mm ∅ (2 pcs. needed) 012.0.0291

pressure roller (2 pcs. needed) 012.0.0271

drive roller for cored wire 2,0 and 2,4 mm ∅ (4 pcs. needed) 012.0.0292

drive roller for cored wire 2,8 and 3,2 mm ∅ (4 pcs. needed) 012.0.0293

45 O ring 013.8.0010

46 sliding block 012.0.0254

47 outgoing nozzle for steel 0,8-1,6 mm ∅ (brass) 012.0.0333

outgoing nozzle for cored wire 1,6-2,4 mm ∅ (brass) 012.0.0335

outgoing nozzle for aluminium 0,8-1,6 mm ∅ (pvc) 102.998

48 lentil flat-head screw 090.1.0825

49 insulation bush 002.0.2877

50 gear insulation 012.0.0285

51 insulating plate 002.0.2876

52 gear flange complete (euro connector) 012.0.0287

53 cylinder-head screw 090.0.0931

54 insulating bush 002.0.2877

55 washer 090.0.1204

56 self-locking screw nut 090.0.6053

27

Pos Description _Part No._

57 knurled screw 090.0.1002

58 screw nut (for gas) 002.0.2896

59 hexagonal screw 090.0.4328

60 washer 090.0.1207

61 spring ring 090.0.1407

62 screw nut 090.0.5008

63 hexagonal screw 090.0.4335

64 washer 090.0.1208

65 spring ring 090.0.1408

66 motor 42 VDC (DV-30) with tacho 002.0.2512

28

17 Torches - and Spare parts

for torch model SB/SBT 502 W - PP/PPT 502 W

17.1 MIG-MAG-welding torch model SB/SBT 502 W

Technical data:

Cooling: water cooled

Mixed gas: 500 A 60 % duty cycle

CO2: 500 A 100 % duty cycle

Wire diameter:

Solid wire: 0.8 – 1.0 – 1.2 – 1.6 mm ∅

Aluminium wire: 1.0 – 1.2 – 1.6 mm ∅

Weight: approx. 1300 g/1 m H

The data are corresponding to (U = 14 + 0.05 x I)

29

MIG-MAG- welding torch model SB/SBT 502 W

30

MIG/MAG Hand Welding Torch,

Model SB/SBT 502 W, water cooled

Pos. Description Part No.

MIG/MAG hand welding torch 022.1.1587

model SB 502 W, 3 m, short version

MIG/MAG hand welding torch 022.1.1588

model SB 502 W, 4 m, short version

MIG/MAG hand welding torch 022.1.1581

model SB 502 W, 3 m, long version

MIG/MAG hand welding torch 022.1.1582

model SB 502 W, 3 m, long version

MIG/MAG hand welding torch 022.1.1601

TEDAC, SBT 502 W, 3 m, short vers.

MIG/MAG hand welding torch 022.1.1602

TEDAC, SBT 502 W, 4 m, short vers.

MIG/MAG hand welding torch 022.1.1603

TEDAC, SBT 502 W, 3 m, long vers.

MIG/MAG hand welding torch 022.1.1604

TEDAC, SBT 502 W, 4 m, long vers.

Standard wire equipment: mild steel 1.2

Spare parts and consumables:

1-6 Torch neck SB/SBT 502 W 022.1.1564

short version

1-6 Torch neck SB/SBT 502 W 022.1.1560

long version

2 Insulation sleeve for 022.1.1574

SB/SBT 502W

3 O-ring 14 x 4 VE 10 pcs 022.1.0077

4 Pressure sleeve for SB/SBT 502 W 022.1.1424

5 O-ring 12 x 4 VE 10 pcs 022.1.0076

6 water coat for SB/SBT 502 W 022.1.1572

7 Insualtion ring SB/SBT 502 W VE 10 pcs 022.1.1421

8 Tip holder SB/SBT 300/502 W VE 10 pcs 022.1.1578

9 Contact tip Cu-Cr-Zr 0.8 mm VE 10 pcs 045.1.1814

9.1 Contact tip Cu-Cr-Zr 1.0 mm VE 10 pcs 045.1.1815

9.2 Contact tip Cu-Cr-Zr 1.2 mm VE 10 pcs 045.1.1816

9.3 Contact tip Cu-Cr-Zr 1.6 mm VE 10 pcs 045.1.1817

31

Pos. Description Part No.

10 Diffusor SB/SBT 502W, ceramic VE 10 pcs 022.1.1567

10.1 Diffusor SB/SBT 502, fibreglass VE 10 pcs 022.1.1568

11 Gas nozzle 17 mm VE 10 pcs 045.1.4300

with fastening ring

11.1 Gas nozzle 14 mm VE 10 pcs 045.1.4301

with fastening ring

11.2 Spot welding gas nozzle VE 10 pcs 045.1.4304

with fastening ring

11.3 Gas nozzle 21 mm heavy duty VE 10 pcs 045.1.4305

with fastening ring

12 Contact tip AL/VA 0.8 mm VE 10 pcs 045.1.1812

12.1 Contact tip AL/VA 1.0 mm VE 10 pcs 045.1.1810

12.2 Contact tip AL/VA 1.2 mm VE 10 pcs 045.1.1811

12.3 Contact tip AL/VA 1.6 mm VE 10 pcs 045.1.1813

15 Handle MIG, complete 105.016

with trigger and cover cap

Only for SBT 502 W:

16 TEDAC pc-board ME-BE-10.0 022.1.0800

incl. slide switch and micro switch

18 Trigger for MIG/MAG torch 022.1.0796

19 Micro switch MIG/MAG torch 022.1.0797

20 Spring for switch VE 10 pcs 022.1.0131

21 Complete cable assembly, w.c. 022.1.1642

3 m, with Euro-connector,

without torch, without liner

21.1 Complete cable assembly, w. c. 022.1.1644

4 m, with Euro-connector,

without torch, without liner

22 Water-power-cable 3.0 m long 022.1.0281

22.1 Water-power-cable 4.0 m long 022.1.0282

23 Wire feeding hose cpl. 3.0 m long 022.1.1662

23.1 Wire feeding hose cpl. 4.0 m long 022.1.1664

24 Water hose flow, 3.0 m long 022.1.0290

24.1 Water hose flow, 4.0 m long 022.1.0291

25 Gas hose, 3.0 m long 022.1.0300

25.1 Gas hose, 4.0 m long 022.1.0301

26 Switch-cable, 3 m long 022.1.0148

26.1 Switch-cable, 4 m long 022.1.0149

27 Protective-hose, 3.0 m long 006.0.1055

27.1 Protective-hose, 4.0 m long 006.0.1054

28 Liner for steel (blue) 022.1.0246

0.6 - 0.8 (1.0) mm, 3 m long

28.1 Liner for steel (blue) 022.1.0247

0.6 - 0.8 (1.0) mm, 4 m long

28.2 Liner for steel (uncoated), 022.1.0248

1.0 - 1.6 mm, 3 m

32

Pos. Description Part No.

28.3 Liner for steel (uncoated), 022.1.0249

1,0 - 1.6 mm, 4 m

30 Euro-connection, at torch side 025.1.0150

31 Brass neck for Euro-connection 025.1.0200

32 Kinking-protection, intake 025.1.0100

33 Euro adapter nut 025.1.0300

34 Liner nut VE 10 pcs 025.1.1301

35 Water-return-hose 022.1.0295

36 Coupling nipple no. 3305 025.1.0400

37 Teflon liner for alu and stainl.st. 022.1.0586

0.8 - 1.2 mm, 3 m (red, 2.0 x 4.0)

with brass outgoing liner

37.1 Teflon liner for alu and stainl.st. 022.1.0588

(1.2) - 1.6 mm, 3 m (yellow, 2.7 x 4.7)

with brass outgoing liner

38.1 Collet for teflon liner 2.0 x 4.0 min 10 pcs 107.554

38.2 Collet for teflon liner 2.7 x 4.7 min 10 pcs 102.997

39.1 Outgoing nozzle pvc, DV-25 103.001

for aluminium and stainless steel

39.2 Outgoing nozzle pvc, DV-30 102.998

for aluminium and stainless steel, 0.8 - 1.6 mm

1.2 - 1.6 mm, 3 m (2.7 x 4.7 mm)

41 Kinking protection 022.1.1580

42 Spring for kinking protection 022.1.1579

43 Connection nipple for VE 10 pcs 045.1.0201

water-current-cable, torch side

44 Nipple for wire feeding hose at VE 10 pcs 045.1.0312

torch side

Protection hose 26 x 1.5 VE 120 m 027.2.0100

Water hose blue 5 x 1.5 VE 100 m 027.2.0130

Water hose red 5 x 1.5 VE 100 m 027.2.0125

PVC hose with textile 9 x 12 mm VE 100 m 006.0.0103

Only for SB 502 W:

45 Cover cap for TEDAC handle 022.1.0604

* max. length of torch lead for alu: 3 m

33

17.2 Push-Pull-welding torch model PP/PPT 502 W

Technical data:

Cooling: water cooled

Mixed gas: 500 A 60 % duty cycle

CO

: 500 A 100 % duty cycle

2

Wire diameter:

Solid wire: 0.8 / 1.0 / 1.2 / 1.6 mm ∅

Aluminium wire: 1.0 / 1.2 / 1.6 mm ∅

Weight: approx. 1850 g/1 m H

The data are corresponding to (U = 14 + 0.05 x I)

34

Push-Pull-welding torch model PP/PPT 502 W

35

Push Pull Hand Welding Torch,

Model PP/PPT 502 W, water cooled

Pos. Description Part No.

Push pull hand welding torch 021.1.0296

model PP 502 W, straight, 8 m

Push pull hand welding torch 021.1.0297

model PP 502 W, bent, 8 m

Push pull hand welding torch 021.1.0298

TEDAC, PPT 502 W, straight, 8 m

Push pull hand welding torch 021.1.0299

TEDAC, PPT 502 W, bent, 8 m

Standard wire equipment: mild steel 1.0

Spare parts and consumables:

1 Motor-block PP torch 021.1.0151

3 Wire feeding roller st. 0.8 mm (PP) 021.1.0251

3.1 Wire feeding roller st. 1.0 mm (PP) 021.1.0252

3.2 Wire feeding roller st. 1.2 mm (PP) 021.1.0253

3.3 Wire feeding roller st. 1.6 mm (PP) 021.1.0254

3.4 Wire feeding roller alu 0.8 mm (PP) 021.1.0255

3.5 Wire feeding roller alu 1.0 mm (PP) 021.1.0256

3.6 Wire feeding roller alu 1.2 mm (PP) 021.1.0257

4 Wire feeding motor, PP-torch 021.1.0272

5 Pressure-yoke cpl. PPL/PPW 021.1.0160

6 Pressure roller PP 021.1.0170

7 Fastening-yoke cpl. 021.1.0181

8 Spring DFO, 7x4, 3x9, 3x4x1.12 021.1.0182

for fastening yoke 021.1.0181

9 Intake-nozzle PP 307 021.1.0190

motor-block/intake

10 Kinking protection 021.1.0279

13 Guiding nut 021.1.0205

14 Torch handle, PP-torch, rear 021.1.0235

15 Torch handle, PP-torch, front 021.1.0236

16 Cover 021.1.0237

17 Spring lock 021.1.0185

18 Toorch interruptor 021.1.0335

19 Cover cap for TEDAC handle 022.1.0604

20 Variable resistor PP-torch 001.0.0506

21 Turn-knob 003.0.1508

22 Torch lead cpl. 8 m, PP/PPT 502 021.1.0285

without torch, with Euro-connection

36

Pos. Description Part No.

23 Wire feeding hose 8 m 021.1.0283

24 Gas hose 8 m 021.1.0260

25 Control cable cpl., 7-pole 021.1.0331

26 Protective hose 25 x 1.5 006.0.1053

27 Euro-connection, at torch side 025.1.0150

28 Kinking-protection, intake 025.1.0100

29 Brass neck for Euro-connection 025.1.0200

30 Euro adapter nut 025.1.0300

31 Wire core 8 m 021.1.0329

2.0 x 4.0 mm

31.1 Wire core 021.1.0325

BZ 0.6 - 1.6 mm, 8 m, cpl.

32 Liner nut 025.1.1301

33 Socket 10-pole (-) 021.1.0384

(for push pull torch)

34 Cable terminal cpl. with strain 021.1.0387

relief for energy switch, 410

35 Collet for teflon liner 2.0 x 4.0 107.554

36 Teflon liner 2.0 x 4.0 021.1.0326

Alu/stainl. steel 0.8 - 1.6 mm, 8 m

37.1 Outgoing nozzle pvc, DV-25 103.001

for aluminium and stainless steel

37.2 Outgoing nozzle pvc, DV-30 102.998

for aluminium and stainless steel

38 Spring for kinking protection 022.1.1579

39 Brass liner 0.2 m, (2.0 x 4.0) 107.810

40 Torch neck PP/PPT 502, straight 021.1.0097

41 Torch neck PP/PPT 502 W, 45° 021.1.0096

42 Insulation sleeve for SB/SBT 502W 022.1.1574

43 O-ring 14 x 4 VE 10 St 022.1.0077

44 O-ring 12 x 4 VE 10 St 022.1.0076

45 Pressure sleeve for SB/SBT 502 W 022.1.1424

46 water coat for SB/SBT 502 W 022.1.1572

47 Insualtion ring SB/SBT 502 W VE 10 St 022.1.1421

48 Tip holder SB/SBT 300/502 W VE 10 St 022.1.1578

49 Contact tip Cu-Cr-Zr 0.8 mm VE 10 St 045.1.1814

49.1 Contact tip Cu-Cr-Zr 1.0 mm VE 10 St 045.1.1815

49.2 Contact tip Cu-Cr-Zr 1.2 mm VE 10 St 045.1.1816

50 Diffusor SB/SBT 502W, ceramic VE 10 St 022.1.1567

50.1 Diffusor SB/SBT 502 VE 10 St 022.1.1568

51 Gas nozzle 17 mm VE 10 St 045.1.4300

with fastening ring

51.1 Gas nozzle 21 mm heavy duty VE 10 St 045.1.4305

with fastening ring

37

Pos. Description Part No.

52 Spot welding gas nozzle VE 10 St 045.1.4304

with fastening ring

53 Gas nozzle 14 mm VE 10 St 045.1.4301

with fastening ring

55 TEDAC pc-board ME-BE-10.0 022.1.0800

incl. slide switch and micro switch

56 Insertion element 021.1.0337

57 Water hose 8 m long 021.1.0271

58 Water-return-hose 022.1.0295

59 Coupling nipple no. 3305 025.1.0400

60 Water-power-cable 8 m long 021.1.0321

38

18 Stored programs PU 400

PU400

EPROM

1.73

Prg-Nr. material Gas diam. 0,8 diam. 1,0 diam. 1,2 diam. 1,6 1 Spezial 2 Spezial

1 SG 2+3 82 Ar/18 Co2

2 SG 2+3 100 Co2

3 Cr-Ni 97,5 Ar/ 2,5 Co2

4 Al-Mg 3-5 99,996 Ar

5 Al-Si 5 99,996 Ar

6 Al-Mg 4,5 Mn 99,996 Ar

7 Cu-Si 3 99,996 Ar

8

9 Fluxofil 31 82 Ar/18 Co2

10

11

12

Programs MIG/MAG

* * * *

* * * *

* * * *

* * *

* * *

* *

* *

* *

Programs Pulse

date: 20.03.02

Prg-Nr. Werkstoff Gas diam. 0,8 diam. 1,0 diam. 1,2 diam. 1,6 1 Spezial 2 Spezial

1 SG 2+3 82 Ar/18 Co2

2 SG 2+3 82 Ar/18 Co2

3 Cr-Ni 97,5 Ar/ 2,5 Co2

4 Al-Mg 3-5 99,996 Ar

5 Al-Si 5 99,996 Ar

6 Al-Mg 4,5 Mn 99,996 Ar

7 Cu-Si 3 99,996 Ar

8

9 Fluxofil 31 82 Ar/18 CO2

10 Cu-Al 8 99,996 Ar

11

12

* * * *

*

* * * *

* * * *

* * * *

* * 1,2 He30

* *

* *

* * * *

39

19 Spare parts and wiring diagram

Spare part list PU 400 DW

19.1

electr. description part no.

A0 pc-board ME-NF400/2.5 102.279

A1 pc-board ME-l-PG-1.0 003.0.0001

A2 pc-board ME-l-PI-1.0 003.0.0002

A3 pc-board ME-I-SD-1.1B 003.0.0003

A4 pc-board ME-I-RC-1.1 003.0.0004

A5 LEM-converter 010.0.1615

A6 pc-board ME-2QR-24/42-2.1C 003.0.0046

A7 pc-board ME-PPMR-2.1 003.0.0493

A8 pc-board ME-MTC-1.2 003.1.0042

E-prom MTC-MP-I.X 003.0.0381

E-prom PU4001.X 003.0.0382

A9 pc-board ME-MTC/M-2.0 100.198

A10 pc-board ME-MF-1.3 003.1.0000

A11 Platine ME-EMV-3.1 102.281

A12 pc-board ME-PPMR/AN2.0 003.0.0485

C1 capacitor 0,1 uF 1000V 001.0.0415

F1 fuse 4 A slow - control transformer prim. 400V 003.0.1251

F2 fuse 4 A slow - control transformer prim. 400V 003.0.1251

F3 fuse 10 A slow - control transformer sec. 37 V - 42V 003.0.1199

F4 fuse 1 A slow -control transformer sec. 42 V 003.0.1212

F6 water pressure switch 0,5 bar 004.0.0204

F7 thermic switch - 80 °C opening – rectifier 001.0.0406

F8 thermic current switch 1,4 A - water pump 003.0.0320

K1 relais 48V/AC 010.0.1961

relaissocket 010.0.1962

M1 wire feed motor 42 V DC (at DV-30) GR63X55 109.702

M2 fan 230 V AC - water cooling torch 001.0.1323

M3 fan 230 V AC - water cooling torch 001.0.1323

M4 fan 230 V AC - at the inverter 001.0.1323

M5 fan 230 V AC - at the inverter 001.0.1323

M6 water pump 230 V AC 004.0.0530

M7 wire feed motor 24 V DC (at DV25) 002.0.2630

Q1 main switch HLT 40 001.0.0014

40

electr. description part no.

-R1

-R2

-R3

-R4

-R5

-R7

-R8

potentiometer 10 kΩ

potentiometer 10 kΩ

resistor 330 Ω 50W

resistor 330 Ω 50W

NTC resistor 47 kΩ

resistor 0,02 Ω 50W

resistor 330 Ω 50W

001.0.0545

001.0.0545

030.0.4583

030.0.4583

010.0.1933

030.0.4580

030.0.4583

-S1 selector 2-pole (option socket machine welding) 003.0.0900

-S2 selector 2-pole-energy 003.0.0900

(option PP- and socket for remote control)

-S3 selector 2-pole voltage trim 003.0.0900

(option PP- and socket for remote control)

-S4 button wire feed 010.0.0325

-T1 Transformer and choke of inverter 020.1.1661

-T2 Control transformer EI 120/73,7 950VA 003.0.0242

-T3 Saturation transformer (green) 020.1.1124

-V1 Rectifier prim. 001.0.0285

-X1 Dinse-bush 70/95mm² 500A 001.0.1102

-X1 Socket DIX SE 50/70 012.0.1508

-X2 Dinse-bush 70/95mm² 500A 001.0.1102

-X3 Dinse-bush 70/95mm² 500A 001.0.1102

-X6 Euroconector 012.0.0287

-X7 Socket 6-pole (option machine welding) 015.0.0102

-X8 Support for bush 24-pol. 015.0.0501

-X8 Support for pins 24-pol. 015.0.0500

-X9 Conector 24-pole 015.0.0502

-X10 Socket 10-pole 021.1.0386

(option PP- and remote control)

Connector 10 pole (accessories) 021.1.0383

strain relief (accessories) 021.1.0388

-Y1 Gas valve 42V/AC 002.0.1602

-Z1 Protection device 003.0.0334

-Z2 Protection device 100.894

19.2 wiring diagram PU 400

41

1 2 3 4 5 6 7 8

-V4

-V3

-A2

-

+

+

T-Prim.

T-Prim.

16

1

ME-I-PI-1.0

X3

-A4

ME-I-RC-1.1

X1

87654321

-V5

2 4

31

-V7

2 4

31

-V10

2 4

31

-V8

2 4

31

-V9

2 4

31

-V1

-

+

-V2

1 2 3 4

1

2

-R3

-R4

1

2

+SQ

-X2

+SQ

-X3

+SQ

-A5

2 3 41

1 2 3 4

-T3

+SQ

-Q1

L1 L2 L3

T1 T2 T3

L1 L2 L3

PE

-X11

1

-R8

-V6

2 4

31

+SQ

-Z2

-X5

PE

+SQ

-X1

+SQ

-Z1

+INV-A3-X4/2.6

+INV-A3-X12/2.4

+INV-A3-X10:1/2.3

+INV-A3-X10:2/2.3

+INV-A3-X10:3/2.3

+INV-A3-X10:4/2.3

+INV-A3-X7:3/2.5

+INV-A3-X7:1/2.5

-A1

L1L2L3

+

F1F2F3

0,2A

0,2A

0,2A

21 3 4 1 10

1

2

U>Umax

U<Umin

rt

rt

Überst./

over current

U<

Prim.DC

gn

ME-I-PG-1.1

-

-

-

-

-

X1 X2

X4

rt

+

+

U>

1

2

X3

-

+

-T1

+SQ-T2:0V/2.1

+SQ-T2:400V/2.1

-R7

+SQ

-A0

L1

L2

L1´

L2´

PE

ME-NF400/2.5

+SQ

-A11

L1 L2 L3

PE

L1´L2´L3´

ME-EMV-3.1

+SQ

-X4

PE

sw

sw

sw

rt

bl

bl

bl

rt

br

br

br

br

br

br

rt

rt

bl

bl

bl

rt

bl

sw

sw

sw

ws

gr

gn

-

+

Werkstück/

work piece

Elektrode/

stick electrode

Brenner/

torch

+

3PH-400V/50Hz/PE

Blatt

7

Bl.

1

Projektbez.

Auftragsnr.

Zeichnungsnr.

PU400DW

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

01.04.99

Siegner

14.07.99

Konrad

15.11.99

Schweißstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

08.10.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

INV

1 2 3 4 5 6 7 8

-T2

sw1/sw2

w2-9V

w2-0V

400V

230V

0/230V

0/230V

0V

w3-0V

w3-37V

w3-42V

w4-18V

w4-0V

w5-9V

w6-9V

w7-18V

w7-0V

w8-18V

w8-0V

w9-18V

w12-42VPEw12-0V

w11-9V

w11-0V

w10-9V

w10-0V

w9-0V

w5-0V

w6-0V

w1

5A1A1A2A1A1A1A

1A

1A

1A

-F1

4A

-F2

4A

-F3

10A

-F4

1A

1

2

3

4

5

786

1

2

3

4

5

6

7

8

9

+INV-A1-X2/1.3

+INV-A2-X3/1.6

+SQ-A8-X2/3.4

14 3

1

2

3

4

3

4

789

101112

1

5

6

234

-M4

PE

M

-M5

PE

M

-M6

PE

bl

schw

br

M

-F8

+SQ-A0:L1´/1.2

+SQ-A0:L2´/1.2

+INV-A3-X9:1/2.6

+INV-A3-X9:2/2.6

+INV

-M2

PE

M

+INV

-M3

PE

M

-X4

PE

+INV

-X5

PE

+SQ-T2:230V/2.1

+SQ-T2:0/230V/2.1

+SQ-X8:7/3.1

+SQ-X8:8/3.1

+SQ-T2:w12-0V/2.1

+SQ-T2:w12-42V/2.1

+OP2-X7:1/3.8

+OP2-X7:2/3.8

+SQ-A5-X1:4/1.7

+SQ-A5-X1:3/1.7

+SQ-A5-X1:2/1.7

+SQ-A5-X1:1/1.7

+INV

-F7

Gleichrichter/

rectifier

+INV

-R5

NTC-IGBT

U

+INV

-R6

NTC-Trafo

U

+SQ-A6-X1:4/3.4

+SQ-A6-X1:3/3.4

+SQ-A8-X1:1/3.2

+SQ-A8-X1:2/3.2

+SQ-A8-X1:3/3.2

+SQ-A8-X1:4/3.2

-F6

P

+INV-A3-X8:12

2.6

+INV-A3-X8:11

2.6

-X4

PE

-X4

PE

+SQ-X8:21/3.1

-A3

Übertemp./over temp.

Untersp./under voltage

Störung/failure

WD.fehlt/no water pressure

T>50C°

POL

Start

I>0

rtrtrtrtrtrtrt

rt

Übersp./over voltage

rt

Idyn

Istat

PWM-ON

+15VP

gn gn ge

rt

UeILIUeT

LT

+5V

+15V

-15V

rtrtge

ge

gn gn gn

RES

I>0

HF

Gas

rt

rtgngn

rt

ge

ext

Res

intern

intern

I>0

Reg.

Spr.

PU500

X1

1 34

1

10

X4

123456789

101112

123

12345

6

X14

132

4

5

6

1

2

3

4

1

2

3

4

5

6

7

8

X6

X2

X10

X9

X8

Res.

I>0

TIG

MAG

Gas

1 16

Lüfter/fan

Idyn.

Istat.

X12

ME-I-SD-1.1

1234

-

U ist

1

2

3

4

5

6X57

8

9

10

X7

+

Lüfter/

fan

Wasserp./

pump

Wasserp./pump

+INV-R8/1.6

+INV-X11:1/1.7

sw

sw

sw

bl

br

rt

21

1

2

sw

sw

bl bl

rtswblswrt

bl1sw

22

18

10

9

gn 2

gr1ws

sw

4

3

22

19

6

5

8

7

4

3

sw

9

10bl11

12sw22sw18

Lüfter/

fan

Pumpe/

pump

Lüfter/

fan

Blatt

7

Bl.

2

Projektbez.

Auftragsnr.

Zeichnungsnr.

PU400DW

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

07.04.99

Siegner

14.07.99

Steuerstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

08.10.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

1

2

5

6

3

4

1

2

3

4

5

6

+SQ-T2:w3-42V/2.1

+SQ-T2:w3-0V/2.1

-X8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21

22

23

24

16

+SQ-T2:w4-18V/2.1

+SQ-T2:w4-0V/2.1

+SQ-T2:w5-9V/2.1

+SQ-T2:w5-0V/2.1

1

2

3

4

5

6

7

+INV-A3-X1/2.5

+INV-A3-X8:3/2.6

+INV-A3-X8:4/2.6

+INV-A3-X7:4/2.4

+SQ-A10-X1/4.5

1

2

3

4

-C1

+OP1

-A7

rt

Freigabe/

enable

X4

ME-PPMR-2.1

X1

1

2

3

4

5

6

7

8

X2

1

2

3

4

5

6

1 10

X3

JP1

JP2

>3m

1A-träge/

slow

-A8

1 16 1 2 3 4 5 6 1 10 1 34 1

2

3

4

1

2

3

4

5

6

7

8

1

2

3

4

120 1 19

1

X3

X14

X8

X9

X1

X6 X7 X5 X2

X15

ME-MTC-1.2

B

A

GND

X4

Energy

Korrektur/trim

Taster Draht/button wire feed

+5V

26

-A9

X12

X13

X11 X10

Um

UO

IO

Im

X13

JP2

PU250

RES.

PU500

PU400

11

1 1

ME-MTC/M-2.00

+OP1

-A12

ME-PPMR/AN 2.0

rt

+

rt

gn

0

-

110

X1

+OP2

-S1

1

2

3

Hand/Automatik

+INV-A3-X8:7/2.6

+INV-A3-X8:8/2.6

+SQ-X8:9/3.1

+SQ-X8:10/3.1

+SQ-T2:w12-42V/2.1

+OP2

-K1

A1

A2

+SQ-T2:w12-0V/2.1

+OP2

-K1

5

9

+OP2

-K1

6

10

+INV-A3-X5:8/2.3

+INV-F7/2.2

+INV-A3-X6:8/2.3

+INV-A3-X6:7/2.3

+OP2

-X7

12345

6

-A6

110

ge

X2

345

6

1

2

3

4

5

6

1

2

ME-2QR-24/42-2.1C

+

-

-

+

X1

42V/AC

TACHO

ANKER/

core

-15V

+15V

U Soll

+5V

GND

X3

Freigabe/

enable

Bremsen/

brake

Freigabe/

enable

gn

max

min

-A12

123456789101112

on

T/A

T/A

T/A

A/TC1C2C3C4R1R2R3R4

ME-2QR/DIP-1.0

10

9

11 11

14

17

12

16

14

13

24

23

12

11

21

10 22

9

11

14

17

12 23

16 19

10

9

9 2

10 1

11

12

26

4 25

23

3 24

22

22

18

19

20

26

25

.8

.8

5

1

2

3

468

7

9

10

11

12

.7 .7

ext. Absenken

auf Wunsch

Option: Push-Pull-Anschluß/

remote control

C1 nur bei DV 30/

C1 only at DV30

Option: Automatenanschluß/

machine welding connection

Blatt

7

Bl.

3

Projektbez.

Auftragsnr.

Zeichnungsnr.

PU400DW

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

07.04.99

Siegner

14.07.99

Steuerstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

08.10.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

+SQ-A8-X3/3.3

+INV

-A10

1 20

2

1

2

1

P4 P3 P2 P1

JP1

Absenkzeit/

down slope

Endstrom/

final current

Startstrom/

start current

Rückbrand/

burn back

Netz/

mains

Übertemp./

over temp.

Hold

Gas Test

A

V

mm

m/min

X1

2

1

S2

S3 S5

ME-MF-1.3

X2

0.6

0.8

1.0

1.Spec.

2.Spec.

3.Spec.

Poti

TEDAC

Festprg.

MIG/MAG

Elektrode

S1

S4

2

1

2

1

Schweißzeit

El-Hochstart

P5

Intervall

Punkten

ALSi

AL99S1S2

AL-MG

CrNi

SG 2+3

SG 2+3

Schalter/switch

S1 -S6

1 = extern

2 = intern

2-Takt

4-Takt

S-4Takt

Tig

123456789

101112131415161718

Störung/

failure

Blatt

7

Bl.

4

Projektbez.

Auftragsnr.

Zeichnungsnr.

PU400DW

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

07.04.99

Siegner

14.07.99

Frontplatine

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

08.10.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

+VB

-X8

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

-X9

24

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

-M1

+

-

+

G

=

M

=

+VB

-X9

24

-Y1

+OP1

-X10

B

A

K

J

H

G

F

E

D

C

M

=

E

A

S

E

A

S

-S4

-R1

E

A

S

-R2

E

A

S

-S2

123

-S3

123

B

A

-X6

+

+VB

-X1

-X12

1

+OP3

-M7

-

+

M

=

24

23

21

18

17

16

15

14

13

12

11

10

9

8

7

Energy

BT.

BT.

PP-Motor

Energy

B

A

Option:

PP-und Fernregleranschluß/

remote control

1

2

3

4

+DV

-X9

Motor für Option:

DV-25

Zentralanschluß

(Ansicht Maschinenfront)

EURO connector

(front view)

VB-Kabel/

connection cable

DV-Gerät DV-30

wire feeder

Taster Draht/

botton wire feed

Korrektur/

trim

Korrektur/

trim

Blatt

7

Bl.

5

Projektbez.

Auftragsnr.

Zeichnungsnr.

PU400DW

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

07.04.99

Siegner

14.07.99

DV-Kasten

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

08.10.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

DV

1 2 3 4 5 6 7 8

111

0

1 0

001 1 1 1

000

000

000

111

0 1

000

234

Reglerb.C(nF)

567

8

47

100

230

470

100

0

001

1

001

0

001

0

001

1

Reglerb.R(kOhm)

9

101112

499

221

100

49,9

0

0

0