Operation Manual

MIG-MAG Welding Unit

M 301 K/D

M 351 K/D/KW/DW

M 451 KW/DW

M 551 DW

MERKLE

Schweissanlagen-Technik GmbH

Industriestrasse 3

D-89359 Koetz,

Tel.: ++49-8221-915-0

Fax: ++49-8221-915-40

www.merkle.de

Germany

.

Content page

1st

Security indications before introduction 3

2nd Accident prevention regulations 3

2nd1 Safety instructions 3

3rd Duty cycle 5

4th

Instructions to avoid interferences due to electromagnetic influences EMC 5

5th

Technical Data 7

5.1 Model: M 301 K/D M 351 K/KW/D/DW 7

5.2 Model: M 451 KW/DW M 551 DW 8

6th

General Information MIG/MAG Welding Units 9

6th1 Metal Inert Gas Welding (MIG) 9

6th2 Metal Active Gas Welding (MAG) 9

6th3 Protective Gases 9

6th4 Welding Wires 9

6th5 Duty cycle 9

7th

Installation 9

7th1 Main Supply 9

7th2 Earth Lead (Work Cable) 9

7th3 Welding Torch 10

7th4 Gas Connection 10

7th5 Wire Installation 10

8th

Installation of the Machine 10

9th

Options 10

9th1 Welding Stainless Steel 10

9th2 Welding Aluminium 10

10th Maintenance 10

11th Cleaning 10

12.

MIG/MAG Series M 301/351/451/551 11

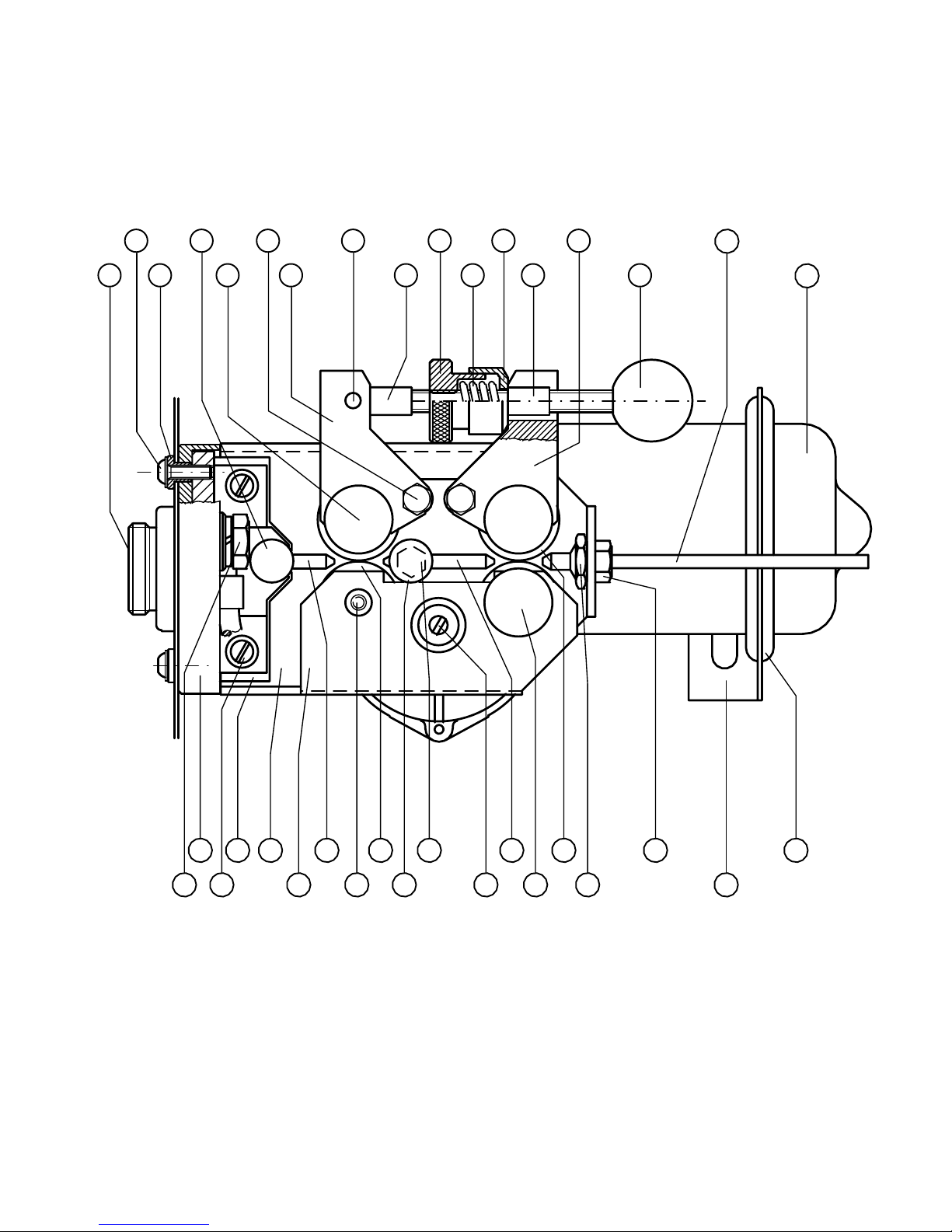

13th Wire feeder systems 11

13th1 Spare parts wire feeder model: DV-25 13

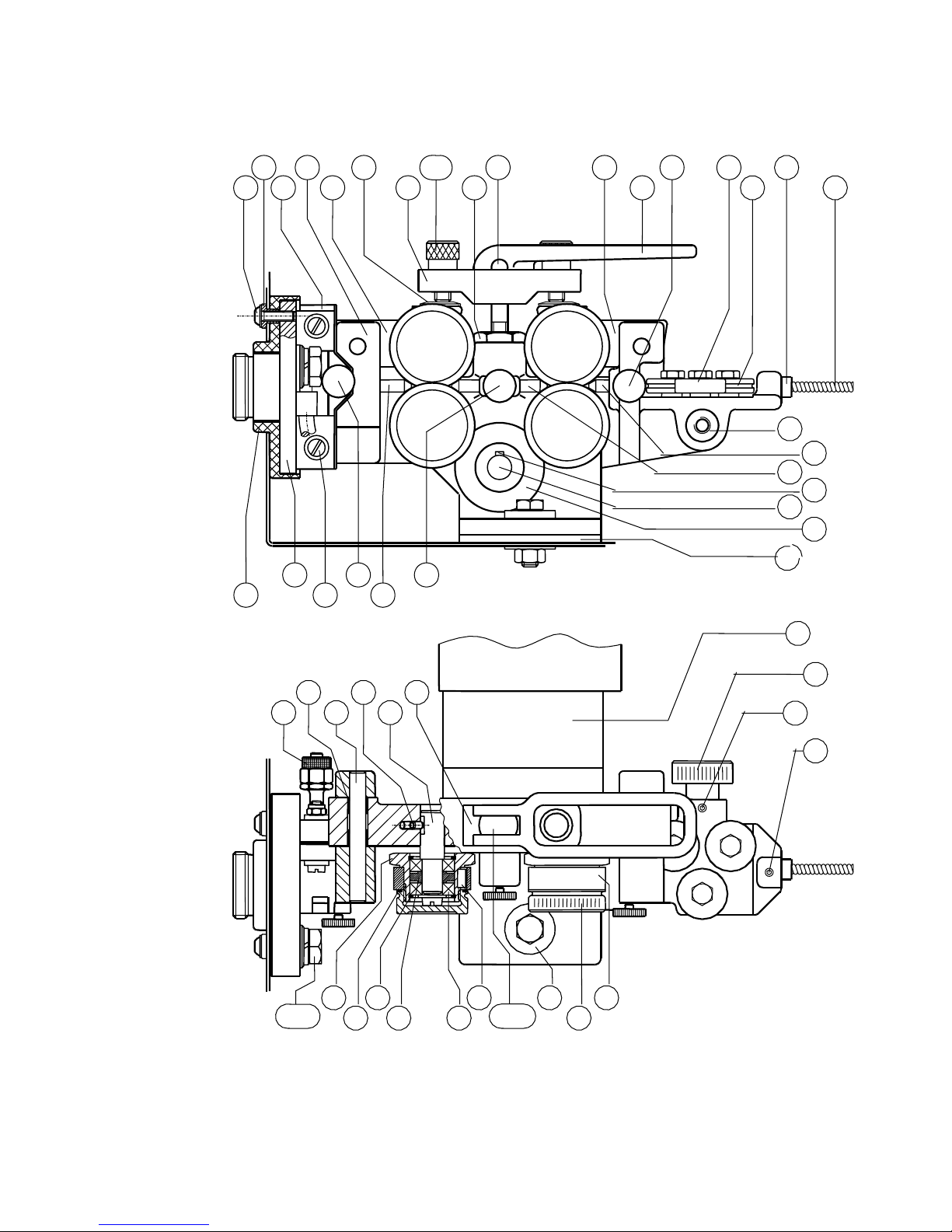

13th2 Spare parts wire feeder model: DV-30 16

1

14th Operation of the Unit: 21

15th Ein adjust worth 22

15th1 Voltage settings: M 301 K/D for mild steel 22

15th2 Voltage setting: M 351 K/D/KW/DW for mild steel 23

15th3 Voltage setting: M 451 KW / DW for mild steel 24

15th4 Voltage setting: M 551 DW for mild steel 25

16th Trouble Shooting 26

16th1 Machine does not operate after switching on the main switch 26

16th2 Machine does not react on the torch switch 26

16th3 Control LED (red) is on 26

16th4 Water pump is running, control LED (red) is on 26

16th5 Control LEDs (yellow) and (red) are on 26

16th6 Machine has no or too low welding current 26

16th7 Welding quality is poor 26

16th8 Problems with wire feeding and wire contacting 26

16th9 Burning of the liner 26

17th Spare part list and wiring diagram 27

17th1 Spare part list M 301 K/D 27

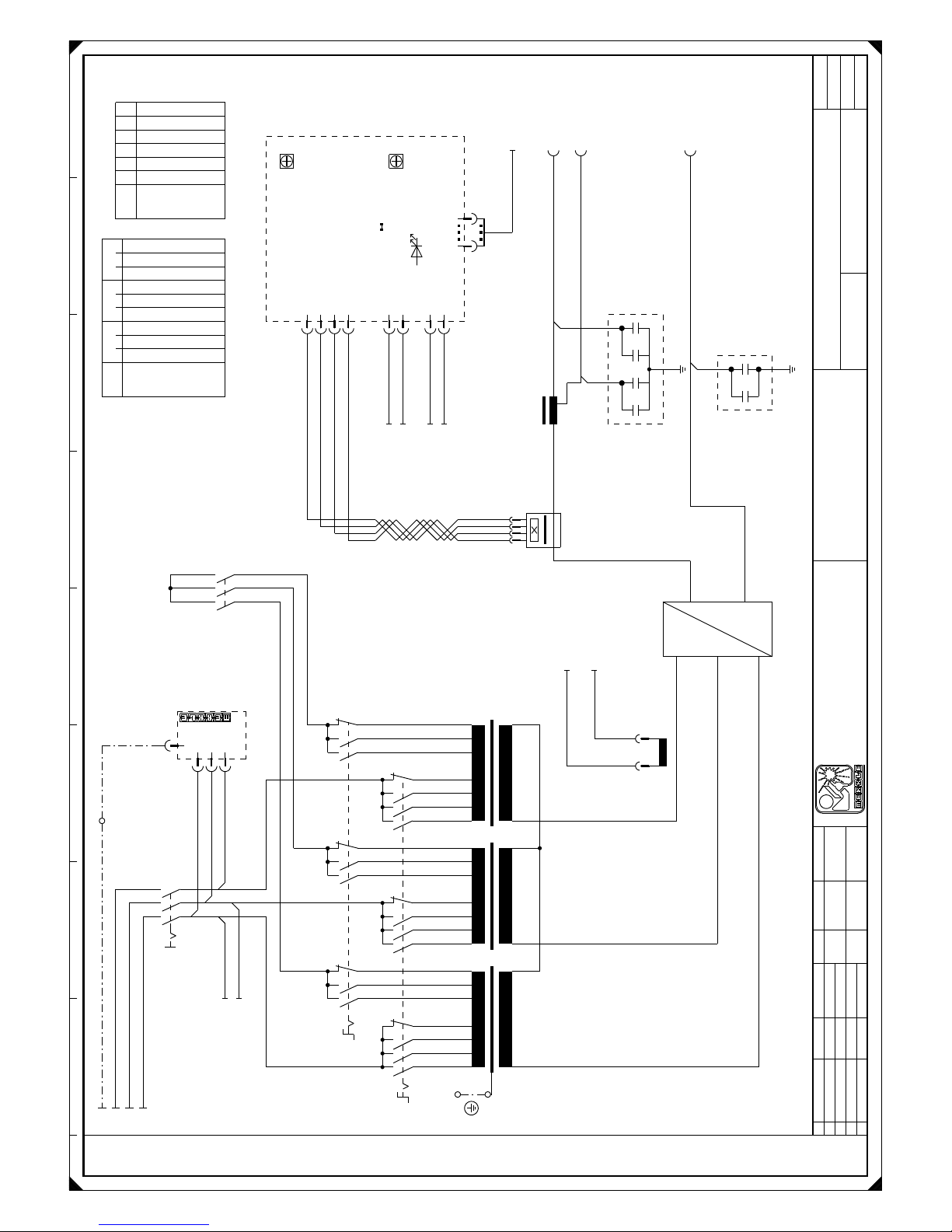

17.2 Wiring diagramm M 301 K/D 28

17th3 Spare part list M 351 K/D/KW/DW 34

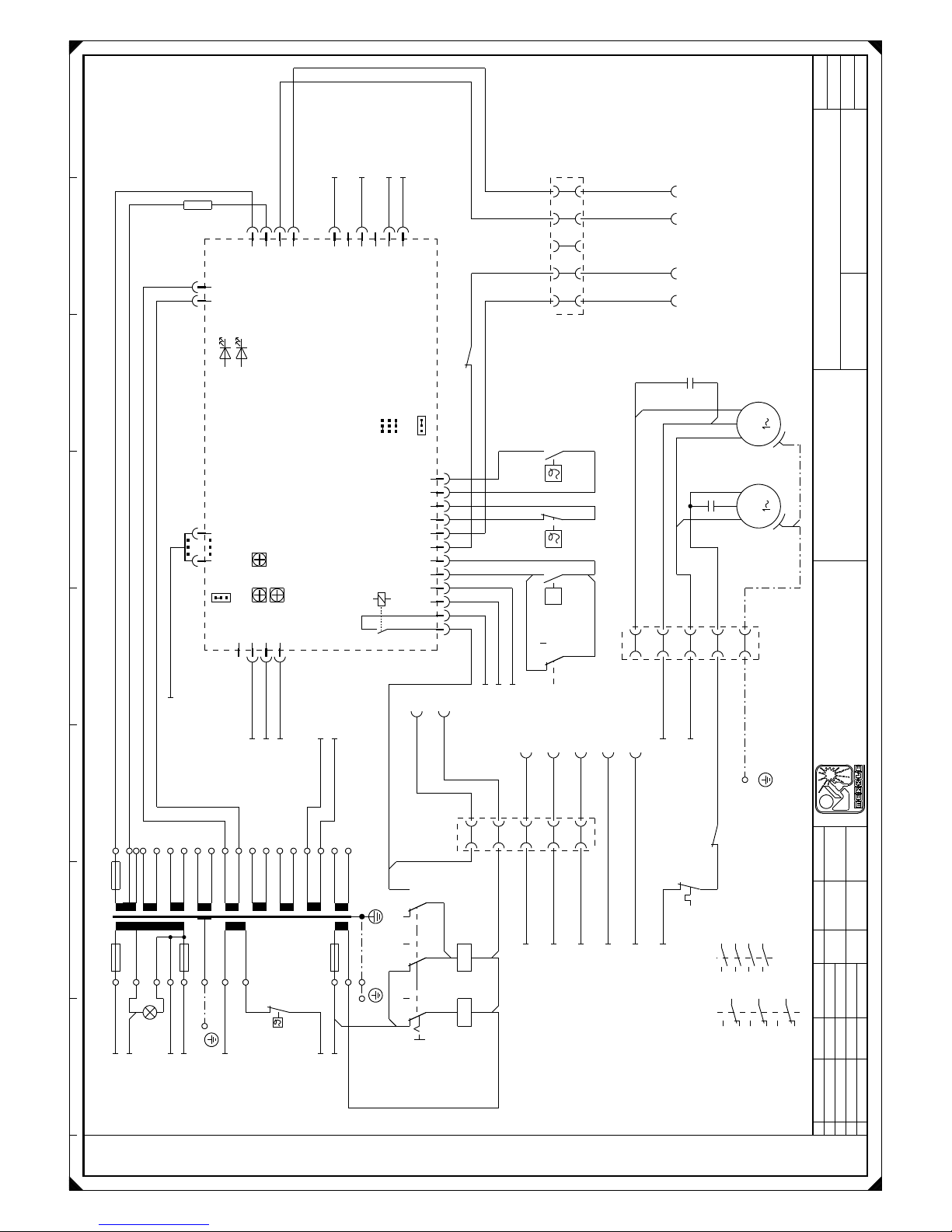

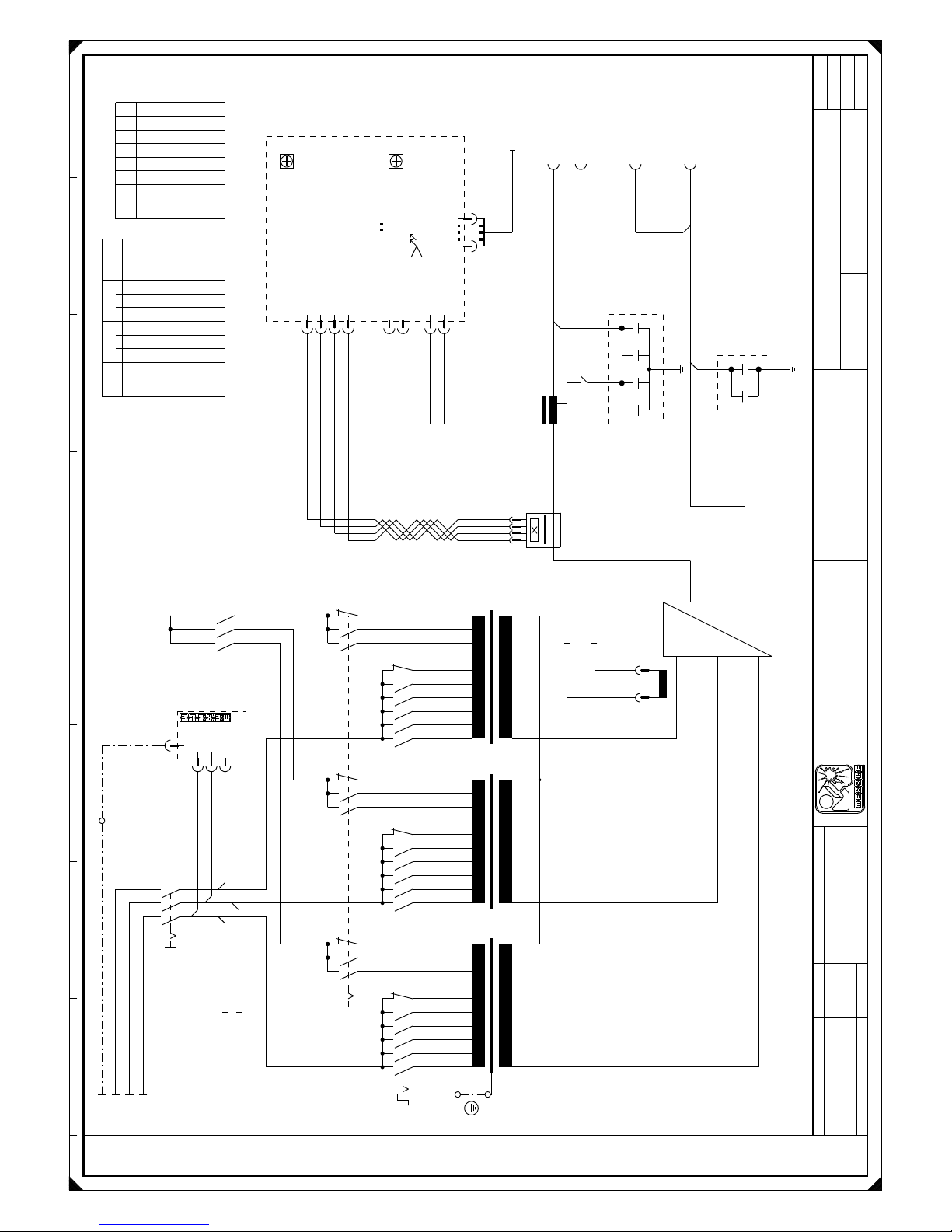

17.4 Wiring diagramm M 351 K/D/KW/DW 35

17th5 Spare part list M 451 KW/DW 46

17.6 Wiring diagramm M 451 KW/DW 47

17th7 Spare part list M 551 DW 53

17.8 Wiring diagramm M 551 DW 54

18e

EU-Conformity Attestation M 301 58

19e

EU-Conformity Attestation M 351 59

20e

EU-Conformity Attestation M 451 60

21e

EU-Conformity Attestation M 551 61

2

1st Security indications before introduction

The unit device is built after the recognized standards. Safe works are nevertheless only

possible if you read the operating instructions and the safety regulations contained in it

entirely and obey strictly. Install yourselves by trained staff of our establishments or

appointed dealers.

2nd Accident prevention regulations

The following accident prevention regulation is applied for welding with MIG/MAG welding

unit, type M 301, M 351, M451, M551:

BGV D1 (earlier VBG 15) * Welding, cutting and allied processes.

A copy of this regulation should be readily accessible in every welding shop. The stipulations

of this regulation are to be observed in the interests of safe and correct welding operation.

* Available from the trade association responsible or

Carl Heymanns-Verlag, Luxemburger Strasse 449, 50939 Cologne.

2nd1 Safety instructions

This unit is manufactured according to the requirements and stipulations of EN 60974.1 /

VDE 0544 part 1. BGV D1 (earlier VBG 15) of the trade association for precision

engineering and electrical engineering are as well valid.

1) In case of an accident, the cutting unit must be disconnected from the mains

immediately.

2) If electrical contact voltages arise, switch off the unit immediately, disconnect it from

the mains and proceed to inspection by a qualified electrician or by our Service

Department.

3) Before opening the unit, disconnect it from the mains supply.

4) Repair work may only be carried out by a skilled electrician or by our Service

Department.

5) Before the unit is put to operation, check it visually, as well as the torch and all cables

and connectors regarding possible external damages.

6) Personal protective equipment in accordance with DIN EN 175, DIN EN 379 and

DIN EN 169.

During the work, the welder’s body must be completely protected against radiation

and burns by means of protective clothing and face protection. Long gloves, aprons

and welding shields with welding filters conforming to DIN EN 470-1 and BGR 189

must be worn.

Synthetic clothing are excluded. Shoes must be closed, not opened (due to spatters). If

necessary, protective headwear must be worn (e.g. for overhead welding). If cover

glasses are used, these must be in accordance with the norms specified above.

As additional protection for the eyes against UV radiation, safety goggles with side

shields and corresponding face protection in accordance with BGR 192 and BGI 553

must be worn.

Accident prevention regulation BGV D1 § 27 stipulates that it is the responsibility of

the employer to provide suitable personal protective equipment, while § 28 stipulates

that it is the responsibility of the insured to wear suitable clothing.

3

7) Protection when welding under increased electrical risks

Welding rectifiers and welding power sources which can optionally be used for either

direct or alternating current must be marked "S" in accordance with EN 60974-1 and

BGI 534.

Use insulating materials to protect you against contact with electrically conductive

parts and damp floors. Wear dry, undamaged work clothing, long gloves and footwear

with rubber soles. Ventilate rooms, install extraction systems if required, and wear

respiratory protective equipment if necessary (see Procedural instructions BGV D1

§ 27 and BGI 533, Section 5).

8) In order to prevent stray currents and the effects thereof (e.g. destruction of electrical

protective ground conductors), the welding return cable (workpiece cable) must be

connected directly to the workpiece to be welded or to the table (e.g. welding table,

grid-type welding table, workbench) supporting the workpiece (see BGV D1 § 20).

When installing the ground connection, assure that there is a good electrical contact

(remove rust, paint, etc.).

9) During welding pauses, the welding torch is to be laid down on an insulated surface or

hung up in such a way that it is not in contact with the workpiece and its support

connected to the welding power source (see § 20 BGV D1).

In the case of longer work pauses, the welding unit must be switched off and the gas

cylinder valve must be closed.

10) The shielding gas cylinder must always be protected against tumbling downing using a

safety chain.

11) Under no circumstances the unit may be put into operation while it is opened

(e.g. for repair work). Apart from the safety regulations, sufficient cooling of the

electrical components provided by the fan cannot be guaranteed.

12) In accordance with BGV D1 § 5, people in the vicinity of the arc must also be

informed of the hazards and protected against them. Safety partitions (“welding safety

curtains”) must be erected in accordance with DIN EN 1598.

14) N

o

welding work may be carried out on containers in which gases, fuels, mineral oils

or similar substances have been stored Öeven if they have been empty for a long

timeÕ (risk of explosion). See § 31 of accident prevention regulation BGV D1.

15) Welds which will be subjected to high loads and which need to meet specific safety

requirements may only be carried out by specially trained and qualified welders.

15) Never bring the torch close to your face.

16) In areas at particularly high risk of fire, the welder must obtain a welding permit and

have this on his person throughout the duration of the welding work. On completion of

welding, a fire-guard must be delegated to ensure fire protection.

17) Ventilation measures must be applied in accordance with BGI 553, Section 9.

18) The hazard to eyesight must be indicated by means of a sign at the work site

"CAUTION! Do not look into the arc!".

4

3rd Duty cycle

The duty cylce measurings have been carried out in accordance with

EN 60974-1 / VDE 0544 part 1 (10 min working period).

60% duty cycle means:

After a 6 min. welding period a 4 min welding pause must be respected. The electrical

components are thermally protected against overheating.

4th Instructions to avoid interferences due to electromagnetic influences

EMC

The welding unit has been manufactured in accordance with the requirements of guideline

EN 50199 regarding electromagnetic compatibility. It is nonetheless the responsibility of the

user to ensure that the welding equipment is installed and operated in accordance with the

manufacturer’s instructions. If electromagnetic interference is detected, it is the responsibility

of the user of the welding equipment to find a solution with the technical assistance of the

manufacturer. In some cases, it may be sufficient simply to ground the welding current

circuit. In other cases, it may be necessary to build a complete shield for the welding power

source and workpiece using the input filters. In all cases, electromagnetic interference must be

reduced to avoid any possible malfunctions.

Note:

For safety reasons, the welding current circuit may or may not be grounded. No

modifications may be made to the grounding without the approval of an expert who is able to

determine whether the changes might increase the risk of accidents, e.g. by allowing parallel

welding current return paths which could destroy the ground conductors of other equipment.

Further instructions are contained in TEC 974-XX "Arc welding equipment – installation and

use".

a) Evaluation of the installation site

Before installing the welding equipment, the user must evaluate potential

electromagnetic problems in the vicinity. The following must be taken into

consideration:

a. Other power cables, control cables, signal and telecommunication cables above, below

and next to the welding equipment

¾ Radio and television transmitters and receivers

¾ Computers and other control devices

¾ The health of people in the vicinity, e.g. use of heart pacemaker and hearing aids

¾ Calibration and measuring equipment

¾ Interference immunity of other devices in the vicinity. The user must ensure the

electromagnetic compatibility of other devices used in the vicinity. This may require

additional safety measures.

b) Procedures to reduce emitted interference

1) Mains supply

Welding equipment is to be connected to the mains in compliance with the

recommendations of the manufacturer. If interference occurs, it may be necessary to

take additional precautions, e.g. filters for the mains connection. Make sure that the

power cable of welding equipment is installed in a fixed position shielded by means of

a metal conduit or similar. The entire length of the shield must be electrically

connected. The shield must be connected to the welding power source in the way to

obtain a good electrical contact between the metal conduit and the housing of the

welding unit.

5

2) Maintenance of the welding equipment

Welding equipment must be maintained regularly in accordance with the

recommendations of the manufacturer. All access and service doors and covers must

be closed and fastened securely when the welding equipment is in operation. No

modifications whatsoever may be made to welding equipment with the exception of

modifications and adjustments specified in the manufacturer’s operating instructions.

3) Welding cables

Welding cables should be kept as short as possible and routed close together on or

near the floor.

4) Equipotential bonding

It is advisable to interconnect all metallic parts in and next to the welding equipment.

Metallic parts connected to the workpiece can, however, increase the risk of the

welder receiving an electric shock by touching these metallic parts and the electrode

simultaneously. The welder must be electrically insulated against all these connected

metallic parts.

5) Grounding the workpiece

If the workpiece is not connected to the ground for electrical safety reasons, or due to

the size and position of the workpiece, e.g. steel structure or outer wall of a ship,

grounding the workpiece may in some cases, but not all, reduce emitted interference. It

must be ensured that grounding the workpiece will not increase the risk of accidents

for the user and cannot cause the destruction of other electrical equipment. If

necessary, the grounding of the workpiece must be carried out by means of a direct

connection to the workpiece. In countries where a direct connection is prohibited, the

connection must be made by means of suitable reactors, selected in accordance with

national regulations.

6) Shielding

Selective shielding of other cables and devices in the vicinity can reduce interference

problems. For special applications, it may be worth considering shielding the entire

welding system.

6

5th Technical Data

5.1 Model: M 301 K/D M 351 K/KW/D/DW

Primary:

Supply voltage: 3 x 400 3 x 400

Continuous current: 12 A 23 A

Max. current: 21 A 26 A

Continuous power: 8. 3 kVA 15.9 kVA

Frequency: 50 Hz (60 Hz) 50 Hz (60 Hz)

Secondary:

Open circuit voltage: 16 – 42 V 16 – 46 V

Welding voltage: 15 – 29 V 15 – 32 V

Welding current: 25 – 300 A 25 – 350 A

Duty cycle 35 % (10 min): 300 A

Duty cycle 40 % (10 min):

Duty cycle 60 % (10 min): 250 A (40°C) 350 A (40°C)

Duty cycle l00 %: 200 A (40°C) 300 A (40°C)

Protection class: IP 23 IP 23

Insulation: H H

Cooling: AF AF

Voltage setting: 14 steps 28 steps

Wire feed: potentiometer potentiometer

Operation modes: 2-stroke/4-stroke/ 2-stroke/4-stroke/

stitch/spot welding stitch/spot welding

Welding/intermission time: continuous setting continuous setting

Wire burn back: continuous setting continuous setting

Wire soft start: dynamic soft start automatic dynamic soft start automatic

Choke: 2 stage 60 % and 100 % 2 stage 60 % and 100 %

Torch cooling: gas cooled K/D: gas cooled

KW/DW: water cooled

Cooling system: integrated water pump

with efficient water pump

Torch connector: Euro connector Euro connector

Wire feed system: 4-roller drive DV-25 4-roller drive DV-25

(0.5-25 m/min.) (0.5-25 m/min)

option D/DW:

high performance feeder

DV-30 (0.5-30 m/min.)

with wire straightener

Fan control: automatic automatic

Digital display (option): for current and for current and

wire feed speed wire feed speed

with pre-display and with pre-display and

hold function hold function

Push Pull torch (option): D version: socket D/DW version: socket

Remote control (option): D version: wire feed speed D/DW version: wire feed speed

Norm: EN 60974-1 "S" / CE EN 60974-1 "S" / CE

Gas bottle holder: for 10 l, 20 l or 50 l for 10 l, 20 l or 50 l

cylinders cylinders

Weight: K: 130 kg, D: 150 kg K: 170 kg D: 190 kg

KW: 190 kg DW: 210 kg

Dimensions l x w x h (mm): K: 910 x 460 x 760 K/KW: 1040 x 530 x 830

D: 910 x 460 x 915 D/DW: 1040 x 530 x 990

7

5.2 Model: M 451 KW/DW M 551 DW

Primary:

Supply voltage: 3 x 400 3 x 400

Continuous current: 21 A 33 A

Max. current: 36 A 52 A

Continuous power: 14.5 kVA 22.8 kVA

Frequency: 50 Hz (60 Hz) 50 Hz (60 Hz)

Secondary:

Open circuit voltage: 17 – 52 V 18 – 62 V

Welding voltage: 15 – 36.5 V 15 – 42 V

Welding current: 25 – 450 A 25 – 560 A

Duty cycle 40 % (10 min): 450 A 560 A

Duty cycle 60 % (10 min): 420 A (40°C) 500 A (40°C)

Duty cycle l00 %: 340 A (40°C) 450 A (40°C)

Protection class: IP 23 IP 23

Insulation: H H

Cooling: AF AF

Voltage setting: 42 steps 42 steps

Wire feed: potentiometer potentiometer

Operation modes: 2-stroke/4-stroke/ 2-stroke/4-stroke/

stitch/spot welding stitch/spot welding

Welding/intermission time: continuous setting continuous setting

Wire burn back: continuous setting continuous setting

Wire soft start: dynamic soft start automatic dynamic soft start automatic

Choke: 2 stage 60 % and 100 % 2 stage 60 % and 100 %

Torch cooling: water cooled water cooled

Cooling system: integrated water pump integrated water pump

with efficient water pump with efficient water pump

Torch connector: Euro connector Euro connector

Wire feed system: 4-roller drive DV-25 4-roller drive

(0.5-25 m/min) DV-30 (0.5-30 m/min.)

option: 4-roller drive high performance feeder

DV-30 (0.5-30 m/min.) with wire straightener

high performance feeder

wire straightener

Fan control: automatic automatic

Digital display (option): for current and for current and

wire feed speed wire feed speed

with pre-display and with pre-display and

hold function hold function

Push Pull torch (option): DW version: socket socket

Remote control (option): DW version: wire feed speed

wire feed speed

Norm: EN 60974-1 "S" / CE EN 60974-1 "S" / CE

Gas bottle holder: for 10 l, 20 l or 50 l for 10 l, 20 l or 50 l

cylinders cylinders

Weight: KW: 200 kg 260 kg

DW: 220 kg

Dimensions l x w x h (mm): KW: 1040 x 530 x 830 1110 x 530 x 1065

DW: 1040 x 530 x 990

8

6th General Information MIG/MAG Welding Units

MIG/MAG welding is a system where the welding wire is the carrier of the electric arc.

Surrounding the contact tip (wire feed nozzle) is the gas nozzle, that emits the protective gas.

The welding bead is protected in this way from oxygen contamination.

6th1 Metal Inert Gas Welding (MIG)

In this technology inert gases are used. Mostly used are argon, helium, and mixtures of these

components. These gases do not react with other materials, they are inert. They are manly

used for welding aluminium, copper, titanium or other non ferrum metals.

6th2 Metal Active Gas Welding (MAG)

For MAG welding gases like CO2, argon, and mixtures of these components are

used. For special purposes also mixtures of C02, argon and oxygen can be used. Mild steel

and stainless steel is welded with theses gases.

6th3 Protective Gases

The gas flow is depended on several parameters:

- gas density

- material of work piece

- distance gas nozzle to work piece

- diameter of gas nozzle

- geometry of weld

For welding steel and stainless steel the gas flow is in the range of about 8 to 16 I at welding

currents of 40 -400 A. For welding aluminium the gas flow is about 30 % more.

6th4 Welding Wires

Different diameters of welding wires are available:

0.6 / 0.8 / 0.9 / 1.0 / 1.2 / 1.6 / 2.4 mm.

6th5 Duty cycle

The duty cycle is measured at temperature of 40°C and a 10 minutes period. At lower

temperatures the duty cycle is higher.

7th Installation

7th1 Main Supply

The main supply must be connected by a trained person. The main supply voltage is displayed

on the front or rear panel of the machine. A connection to protection earth must be done.

7th2 Earth Lead (Work Cable)

The earth lead must have an excellent ground. The clamp should be attached to a clean, paint

and rust free area on the work piece or on the welding table.

9

7th3 Welding Torch

Attach the hose assembly to the Euro-connector with the flange nut.

7th4 Gas Connection

Place the gas bottle on the gas bottle holder and secure it with the safety chain. Remove the

cap and open the bottle momentarily to purge the valve. Install the regulator on the bottle

valve. Connect the gas hose from the machine to the pressure reducer. Slowly open gas valve

and set the gas flow.

7th5 Wire Installation

Place the wire spool over the wire drive. Loosen the end and cut off the bent end

section. Hold the wire to prevent unwinding of the spool. Open the tightening lever and lift

the pressure finger. Feed the wire into the wire feed guide. Push the wire forward onto the

wire drive roller grooves. Close the tightening lever and switch on the machine.

Check the wire feeding: Place your hand 10 cm in front of the contact tip. Let the wire run

into your hand. If the wire is running, the pressure of the drive rollers is ok.

8th Installation of the Machine

Place the machine at least 0.80 m from a wall etc. to guarantee the cooling air can go through

the unit. The room temperature should not exceed 40°C.

9th Options

9th1 Welding Stainless Steel

Exchange the parts according to the table listed in section “wire feeder” A Teflon liner

in the torch hose must be used. As gases we recommend mixtures of argon and 2.5

%CO2.

9th2 Welding Aluminium

Do not use wire diameters less than 1.0 mm. Max. length of the torch should not exceed 3 m.

Use Teflon liner in the torch hose. See section 'wire feeder' for exchange of parts for welding

of aluminium.

10th Maintenance

The machine should be cleaned in regular intervals to guarantee a proper operation. The

length of the cleaning interval depends on the operation time, surrounding atmosphere etc.

IMPORTANT: Before opening the machine disconnect the main supply!

11th Cleaning

Welding unit: Open the side covers. Remove dust from all parts of the

machine.

10

Welding torch: Control the welding torch after welding of 50 kg wire.

Remove, clean and replace the wire core. Clean with a cleaning

solvent. Blow dry with compressed air. When replacing the

wire core, insure that there are no kinks. The gas nozzle must be

sprayed with a silicon-free spray to prevent the weld spatters

from sticking to the nozzle. The contact tip is a consumable

item and must be replaced as required.

Attention: Do put oil to the wire core or the drive roller on the

wire feed unit.

12. MIG/MAG Series M 301/351/451/551

The series M 301/351/451/551 consists of step switched MIG/MAG welding units form

300 to 560 A welding current. The features are:

- Precise setting of the welding current due to max. 42 steps.

- Selector: 2-stroke/4-stroke/stitch/spot welding.

- Adjustable intermission and welding time.

- Continuous setting of the wire burn back.

- Perfect ignition due to dynamical soft start automatic.

- Safty cut-off in 4-stroke operation.

- High speed wire insertion automatic.

- Automatic switching of the fan.

- 4-roller wire feeding system DV-25 as a standard.

- High performance wire feeder DV-30 as a standard in model M 551 DW and available

as an option for all D/DW versions.

- Digital read-out of the welding current (with hold function) and of the wire feed speed

(with pre-display) as an option.

- 2-stage choke mounted for reduced spatters.

- Integrated water cooling system with efficient water pump in version KW and DW.

- Lowered galvanized das bottle holder (10 l, 20 l or 50 l cylinders) assures a safe

positioning of the cylinders.

- Approved of operation in confined areas, S-symbol.

- Easy handling of the unit due to big and robust swivel and carrier wheels.

- Connection for push pull torch or remote control in version D or DW (option).

- NEW: wire adjusting automatic

Easy and precise setting of the correct wire feed speed in each welding range (only with

digital read out).

13th Wire feeder systems

11

12

1

2

3

4

5

6

7

8

9

10

11

12

13 15

16

17

19 20 21 23

242526

27

282930 32

33

22 34

14

31

E 2715-39

39

Drahtvorschubgetriebe DV-25

3518

13th1 Spare parts wire feeder model: DV-25

(If spare parts for the wire feeder are needed, always indicate number of the relative

positon and part number)

Pos Description _Part No._

Wire feed gear complete 002.0.2850

with motor and wire feed rollers

1 gear flange (brass part) 002.0.2875

gear flange (complete) 012.0.0287

(Euro connector preassembled)

2 lentil flat-head screw 090.0.0825

3 insulation bush 002.0.2877

4 knurled screw M 4 x 20 090.0.1002

5 bolt (roller) 002.0.2859

6 bolt 002.0.2864

7 rocking bar 002.0.2865

8 cylindrical pin 090.0.0571

9 thread pole M 8 x 90 002.0.2863

10 knurled nut 002.0.2862

11 compression spring 002.0.2690

12 pressure piece 002.0.2861

13 thread case 002.0.2860

14 rocking bar 002.0.2866

15 bullet button 002.0.2856

16 pvc liner 012.0.0377

17 permanent magnet motor 24 VDC 002.0.2630

18 hexagon screw 090.0.4335

washer 090.0.1208

spring ring 090.0.1408

13

Pos Description _Part No._

19 insulation plate 002.0.2876

20 gear insulation 012.0.0285

21 gear angle 002.0.2874

22 sheet steel protection 002.0.2870

23 outgoing nozzle (brass) 6 x 2 x 48 002.0.0367

Outgoing tube (brass) for alu/stainless steel 012.0.0369

6 x 0.6 x 45

24 bolt (roller) 002.0.2873

25 for mild steel/stainless steel:

drive roller with groove V ∅ 0,6 mm 002.0.2879

drive roller with groove V ∅ 0,8 mm 002.0.2880

drive roller with groove V ∅ 1,0 mm 002.0.2881

drive roller with groove V ∅ 1,2 mm 002.0.2882

for aluminium:

drive roller ∅ 0,8 mm alu 002.0.2884

drive roller ∅ 1,0 mm alu 002.0.2885

drive roller ∅ 1,2 mm alu 002.0.2886

drive roller ∅ 1,6 mm alu 002.0.2887

26 knurled screw M 4 x 10 090.0.1001

27 fastener 002.0.2869

28 drive pinion 002.0.2871

29 guidance nozzle (brass) for steel 5 x 1,5 x 40 002.0.2867

guidance nozzle for alu/stainless steel 012.0.0373

(pvc) 5 x 1,5 x 40

30 knurled screw 002.0.2857

31 pressure roller 002.0.2878

32 screw (brass) 025.1.1610

33 incoming nozzle 002.0.2891

34 retaining ring 002.0.2858

39 edge protection rubber (0,3 m) 001.0.0820

14

47

1

3

4

5-

7

8

10

11

14

15

16

17

18

21

22

23

24

26

27

28

29

30

31

45

33

34

37

38

39-

42

43

44

19

20

2

57

32

46

Wire feeder DV-30

12

50

48

49

51

52

57

58

25

63-

.

66

54

15

13th2 Spare parts wire feeder model: DV-30

(If spare parts for the wire feeder are needed, always indicate the number of the relative

positon and part number)

Pos Description _Part No._

Wire feeder block DV-30, without motor, without rollers 012.0.0352

1 Gear box DV-30 012.0.0353

2 left rocking bar 012.0.0276

3 pressure piece 012.0.0261

4 gripping yoke 012.0.0259

5 leveling screw 012.0.0260

6 compression spring 002.0.2688

7 screw 012.0.0266

8 cylindrical pin 090.0.0587

9 compression spring 002.0.2688

10 right rocking bar 012.0.0277

11 eccentric (tentering lever) 012.0.0258

12 knurled screw 090.0.1001

13 hexagonal screw 090.0.4313

14 guide roll 012.0.0239

15 adjusting roll 012.0.0238

16 clamping sleeve 2,5 x 4,5 025.1.1524

17 introductory liner 2,5 x 4,5 002.0.2905

18 sliding block 012.0.0257

19 incoming nozzle for steel 0,8-1,6 (brass) 012.0.0332

19 a incoming nozzle for alu and stainless steel 012.0.0267

0.8-1.6 (pvc)

16

Pos Description _Part No._

20 guidance nozzle for steel 0,8-1,6 (brass) 012.0.0274

20a guidance nozzle for alu and stainless steel 0.8-1.6 (pvc) 012.0.0269

21 feather 090.0.8815

22 DU bush (inside the gear block) 019.1.0121

23 gear (drive pinion) 012.0.0279

24 insulation plate 002.0.0144

25 leveling screw 003.0.1506

26 screw pin 090.0.3303

27 screw pin 090.0.3409

28 DU bush 019.1.0550

29 cylindrical pin 090.0.0598

30 screwpin 090.0.3413

31 bolt 012.0.0268

32 gear pre-assembled 012.0.0278

33 retaining ring 090.0.1814

34 spacing ring 012.0.0235

35 cylinder-head screw 090.0.0937

36 washer 090.0.1205

37 groove ball bearings 019.1.0261

38 feather 090.0.8810

39 eye bolt 090.1.2528

40 compression spring 002.0.2690

41 hexagonal nut 090.0.6055

42 insulation bush 002.0.0200

17

Pos Description _Part No._

43 knurled nut 012.0.0265

44 for mild steel and stainless steel:

drive roller V 1,0 and 1,2 mm ∅(2 pcs. needed) 012.0.0272

pressure roller (2 pcs. needed) 012.0.0271

drive roller V 0,8 and 1,6 mm ∅ (2 pcs. needed) 012.0.0273

pressure roller (2 pcs. needed) 012.0.0271

for aluminium:

drive roller U 1,0 and 1,2 mm ∅ (2 pcs. needed) 012.0.0281

pressure roller (2 pcs. needed) 012.0.0271

drive roller U 0,8 and 1,6 mm ∅ (2 pcs. needed) 012.0.0282

pressure roller (2 pcs. needed) 012.0.0271

for cored wire:

drive roller for cored wire 1,2 and 1,6 mm ∅ (2 pcs. needed) 012.0.0291

pressure roller (2 pcs. needed) 012.0.0271

drive roller for cored wire 2,0 and 2,4 mm ∅ (4 pcs. needed) 012.0.0292

drive roller for cored wire 2,8 and 3,2 mm ∅ (4 pcs. needed) 012.0.0293

45 O ring 013.8.0010

46 sliding block 012.0.0254

47 outgoing nozzle for steel 0,8-1,6 mm ∅ (brass) 012.0.0333

outgoing nozzle for cored wire 1,6-2,4 mm ∅ (brass) 012.0.0335

outgoing nozzle for aluminium 0,8-1,6 mm ∅ (pvc) 102.998

48 lentil flat-head screw 090.1.0825

49 insulation bush 002.0.2877

50 gear insulation 012.0.0285

51 insulating plate 002.0.2876

52 gear flange complete (euro connector) 012.0.0287

53 cylinder-head screw 090.0.0931

54 insulating bush 002.0.2877

55 washer 090.0.1204

56 self-locking screw nut 090.0.6053

18

Pos Description _Part No._

57 knurled screw 090.0.1002

58 screw nut (for gas) 002.0.2896

59 hexagonal screw 090.0.4328

60 washer 090.0.1207

61 spring ring 090.0.1407

62 screw nut 090.0.5008

63 hexagonal screw 090.0.4335

64 washer 090.0.1208

65 spring ring 090.0.1408

66 motor 42 VDC (DV-30) with tacho 002.0.2512

19

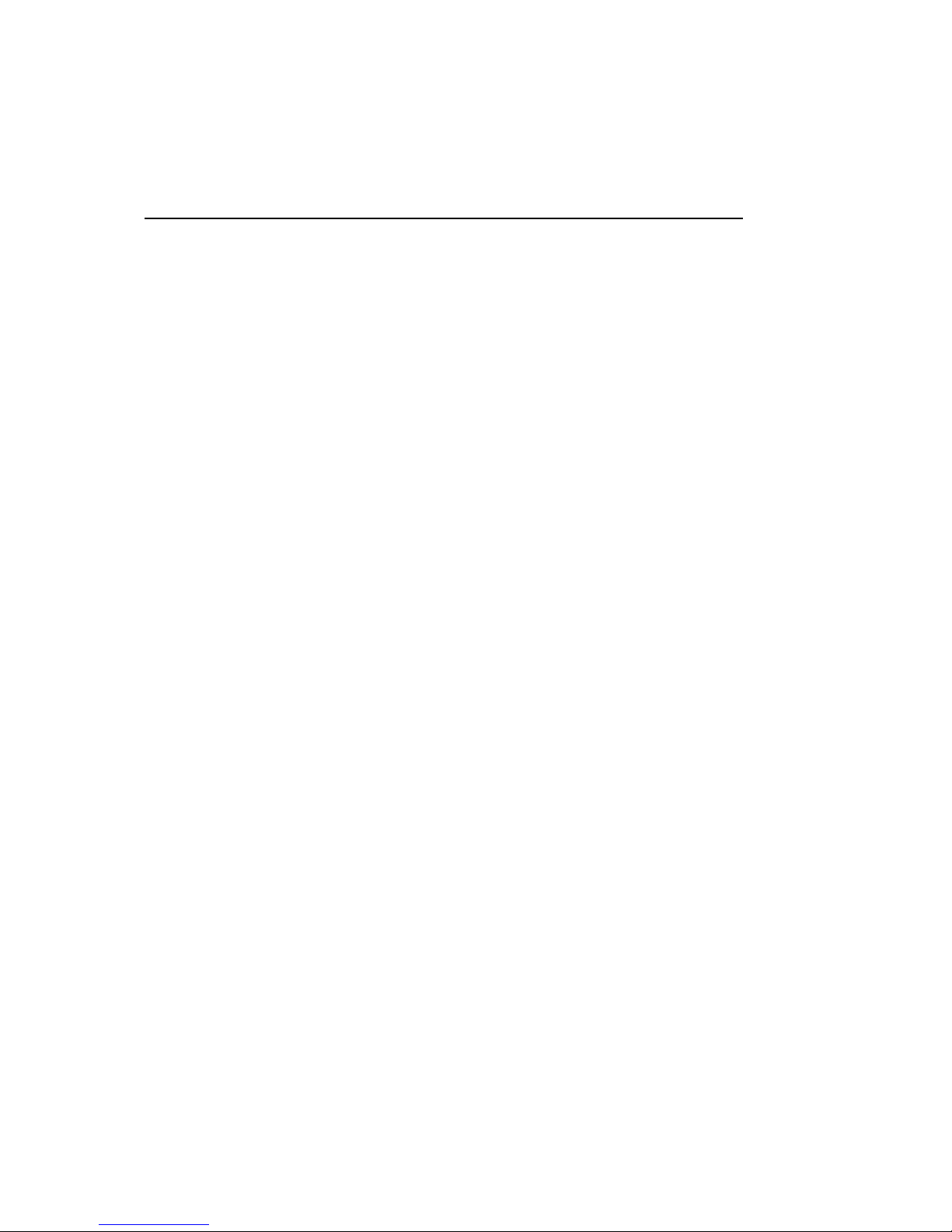

Front panel

5

HOLD

0

0.5

0.75

1.0

1.25

1.5

1.75

2.0 sec.

Drahtvorschub

Drahtvorschubgerät

Rückbrand

0.5

0.75

1.0

1.25

1.5

1.75

1

2

4-Takt/latch

2-Takt/2 steps

Intervall/stitch

Punkten/spot welding

external wire feeder

Pause

intermission

wire feed

wire burn back

Schweißzeit

timer

2.0 sec.

0,8

1,0

1,2

4

Hauptschalter/Grobstufe

main switch/coarse selector

2

1

1

1

2

2

7

1

2

3

4

Feinstufe

fine selector

2

5

6

8 9

10

11

12

13

14

3

Drahtvorschub

wire feed

[m/min]

1

5

10

15

20

5

25

1

10

15

20

25

30

DV-25

DV-30

17

16

15

E 2864-33E 2864-33

20

14th Operation of the Unit:

Front panel:

Pos. 1 Step selector/fine selector 7 steps

Pos. 2 Selector range 1/2 (M 301 )

Coars selector 4 steps (M 351), 6 steps (M 451/ M 551)

Pos. 3 Control lamp, unit is switched on

Pos. 4 potentiometer, intermission timer for stitch mode

Pos. 5 potentiometer, welding timer for stitch mode and spot welding

Pos. 6 LED (yellow) temperature protection

Pos. 7 LED (red) failure (only KW/DW version)

Pos. 8 Selector operation mode

Pos. 9 potentiometer, wire feed speed

Pos.10 Switch 'wire feed control'

With this switch the wire feed speed can either be adjusted at the machine

(potentiometer Pos. 9) or at the separate wire feeder unit (potentiometer Pos.

16, only models D/DW). When working with a compact machine (model

K/KW) this switch must be in position 'remote control off'

Pos.11 potentiometer, wire burn back

Pos.12 LED (green) hold (option)

Pos.13 Display wire feed speed m/min (option)

Pos.14 Display welding current A (option)

Pos.15 Socket, push pull or remote control (option)

Pos.16 potentiometer, wire feed speed at the separate wire feeder (only D/DW)

Pos.17 Switch, remote control wire feed (option)

2-stroke operation:

as long as the torch switch is pressed down, the welding current is on

4-stroke operation:

1 st stroke: torch switch pressed -welding on 2nd stroke: torch switch released

3rd stroke: torch switch pressed -welding off 4th stroke: torch switch released.

Stitch (interval) operation:

Welding current and wire feeder are switched on and off automatically. The welding time and

the intermission time can be controlled by the var. resistors Pos. 4 and Pos. 5.

Spot welding:

The spot welding time is can be adjusted by the var. resistor Pos. 5.

IMPORTANT: When operating a model 'W' with integrated water cooling system,

always check the filling of the water tank. When the machine is

stored or operated at temperatures below 0°C use 'MERKLE

coolant MKF' instead of water (part-no.: 107.822)

21

15th Ein adjust worth

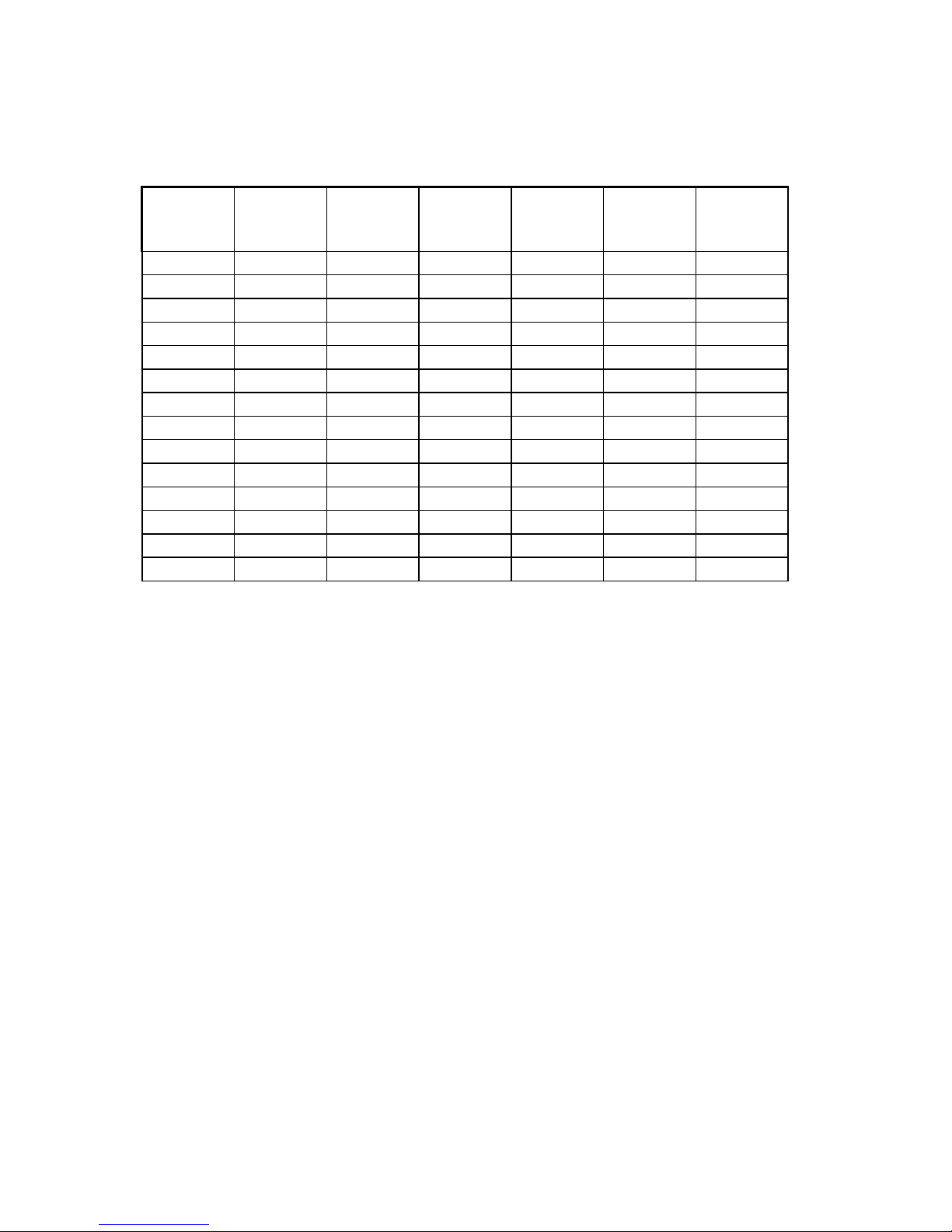

15th1 Voltage settings: M 301 K/D for mild steel

Range m/min. current (A) m/min. Current (A) m/min. current (A)

(fine /

coars)

wire 0,8 wire 1,0 wire 1,2

1 - 1 1,9 30 1,7 40

1 - 2 2,3 45 2,0 50

1 - 3 2,7 50 2,4 60 2,2 80

1 - 4 3,1 60 2,8 75 2,7 95

1 - 5 4,4 75 3,4 85 3,0 110

1 - 6 5,4 95 4,1 100 3,3 125

1 - 7 6,8 105 4,6 115 3,6 140

2 - 1 7,7 123 4,9 130 3,9 155

2 - 2 10,8

140

6,1 150 4,7 175

2 - 3 13,0 160 8,8 180 5,9 200

2 - 4 15,3 180 11,2 210 7,7 230

2 - 5 17,9 200 13,4 240 9,5 250

2 - 6 21,7 225 15,4 260 10,8 275

2 - 7 25,3 258 18,3 286 11,7 305

22

15th2 Voltage setting: M 351 K/D/KW/DW for mild steel

Range m/min. current (A) m/min. current (A) m/min. current (A)

(fine - coars) wire 0,8 wire 1,0 wire 1,2

1 - 1 2,3 40 1,7 50

1 - 2 2,5 45 1,8 53

1 - 3 2,8 50 2,0 57

1 - 4 3,2 60 2,2 60 2,0 80

1 - 5 3,5 65 2,6 63 2,2 90

1 - 6 3,8 70 2,6 67 2,3 100

1 - 7 3,9 2,7 70 2,4 110

2 - 1 4,0 80 2,8 75 2,6 120

2 - 2 4,5 85 3,1 80 2,8 123

2 - 3 5,0 90 3,4 90 3,0 127

2 - 4 5,5 90 3,7 100 3,2 130

2 - 5 5,7 95 3,9 105 3,3 135

2 - 6 6,0 100 4,0 110 3,4 140

2 - 7 6,8 110 4,1 120 3,5 145

3 - 1 7,6 120 4,8 130 3,8 150

3 - 2 8,2 125 5,2 140 4,3 160

3 - 3 9,0 132 5,8 150 4,8 170

3 - 4 9,8 140 6,4 165 5,5 190

3 - 5

11,0 150 7,0 172 5,9 200

3 - 6 13,0 160 8,0 180 6,3 215

3 - 7 14,3 170 9,0 190 6,8 230

4 - 1 15,8 180 10,2 210 7,6 245

4 - 2 17,9 190 11,6 220 8,1 255

4 - 3 19,0 200 13,3 230 8,8 270

4 - 4 20,5 215 14,3 240 9,4 284

4 - 5 22,8 230 15,2 255 9,9 295

4 - 6 24,5 250 16,1 270 10,6 310

4 - 7 25,0 260 17,7 280 11,3 328

23

15th3 Voltage setting: M 451 KW / DW for mild steel

Range m/min. current (A) m/min. current (A) m/min. current (A)

(fine - coars) wire 0,8 wire 1,0 wire 1,2

1 - 1 1,8 30 1,7 45

1 - 2 1,8 35 1,7 50

1 - 3 1,9 35 1,8 55

1 - 4 2,0 40 1,8 57

1 - 5 2,1 40 1,8 60

1 - 6 2,3 50 1,9 65

1 - 7 2,4 50 2,0 70

2 - 1 2,8 55 2,4 75 1,6 100

2 - 2 3,2 60 2,6 80 1,8 110

2 - 3 3,6 62 2,9 89 1,9 120

2 - 4 3,8 65 3,1 93 2,1 125

2 - 5 4,0 70 3,3 100 2,4 132

2 - 6 4,2 80 3,5 110 2,4 136

2 - 7 4,5 90 3,7 120 2,6 140

3 - 1 5,2 95 3,8 100 2,6 142

3 - 2 5,2 100 4,0 125 2,7 145

3 - 3 5,4 103 4,2 126 3,2 150

3 - 4 5,6 105 4,4 130 3,2 161

3 - 5 5,9 110 4,6 130 3,4 165

3 - 6 6,3 120 4,7 136 3,5 171

3 - 7 7,4 125 4,8 141 3,6 175

4 - 1 8,2 130 5,2 145 4,3 180

4 - 2 8,7 130 5,8 150 4,8 190

4 - 3 9,6 140 6,4 160 5,0 205

4 - 4 10,0 145 7,0 170 5,3 211

4 - 5 10,4 153 7,8 180 5,5 215

4 - 6 11,0 160 8,6 195 5,7 220

4 - 7 12,5 162 9,6 205 6,0 225

5 - 1 13,8 170 10,2 210 7,3 240

5 - 2 14,8 175 11,3 220 7,9 250

5 - 3 15,2 180 12,5 230 8,2 255

5 - 4 15,5 190 13,3 240 8,5 265

5 - 5 16,0 195 14,2 250 9,0 277

5 - 6 17,0 200 15,2 255 9,5 285

5 - 7 18,1 210 16,4 265 10,2 290

6 - 1 20,3 220 18,4 275 11,6 300

6 - 2 22,5 230 20,0 285 13,0 330

6 - 3 25,1 250 21,2 300 14,4 360

6 - 4 29,5 270 22,7 320 15,8 370

6 - 5 25,1 350 17,2 390

6 - 6 27,5 370 18,2 410

6 - 7 30,0 400 425 425

24

15th4 Voltage setting: M 551 DW for mild steel

Range m/min. current (A) m/min. current (A) m/min. current (A)

(fine / coars) wire 0,8 wire 1,0 wire 1,2

1 - 1 2,6 45 2,2 55

1 - 2 2,7 47 2,3 60

1 - 3 2,9 50 2,4 65

1 - 4 3,3 55 2,5 70

1 - 5 3,7 65 2,6 72

1 - 6 4,2 75 2,8 75

1 - 7 4,8 80 2,9 79

2 - 1 5,4 85 3,0 80 2,0 100

2 - 2 5,6 90 3,1 90 2,2 108

2 - 3 5,8 95 3,5 110 2,4 115

2 - 4 6,0 102 3,7 110 2,7 120

2 - 5 6,5 107 4,0 120 2,9 125

2 - 6 7,3 115 4,3 131 3,2 135

2 - 7 7,7 120 4,5 135 3,5 140

3 - 1 8,0 125 4,6 145 3,7 150

3 - 2 8,4 130 4,8 150 3,9 165

3 - 3 9,0 137 5,7 158 4,1 175

3 - 4 9,6 140 6,4 165 4,5 186

3 - 5 10,1 145 6,8 175 4,8 190

3 - 6 11,7 150 7,2 180 5,0 200

3 - 7 13,0 164 8,3 185 5,6 210

4 - 1 13,4 170 8,7 190 5,9 215

4 - 2 13,6 175 9,1 195 6,1 220

4 - 3 13,8 182 9,6 200 6,7 225

4 - 4 14,0 190 10,4 210 7,2 235

4 - 5 15,1 195 11,8 215 7,7 245

4 - 6 16,6 200 13,0 225 8,5 255

4 - 7 17,6 205 13,9 235 9,4 270

5 - 1 20,0 210 14,4 240 10,3 285

5 - 2 20,9 215 14,9 250 10,9 290

5 - 3 22,3 220 15,5 260 11,5 300

5 - 4 23,0 225 16,3 275 12,0 312

5 - 5 25,0 235 17,1 280 12,5 325

5 - 6 27,5 250 18,1 295 13,1 340

5 - 7 30,0 260 19,4 310 14,6 360

6 - 1 21,3 330 15,7 375

6 - 2 23,1 340 16,4 400

6 - 3 25,0 350 17,2 410

6 - 4 28,7 365 17,9 435

6 - 5 30,0 380 19,4 450

6 - 6 22,1 465

6 - 7 27,0 480

25

16th Trouble Shooting

16th1 Machine does not operate after switching on the main switch

a) Check main supply

b) Check main fuses

16th2 Machine does not react on the torch switch

a) Problem at the torch switch

b) Check internal fuses

16th3 Control LED (red) is on

a) Thermical protection switch for water pump is activated

b) Fuse is blown

16th4 Water pump is running, control LED (red) is on

a) Water pressure too low, check water level

b) Water pressure switch is not ok

16th5 Control LEDs (yellow) and (red) are on

a) Over temperature at transformer or rectifier. Wait for cooling down of the unit

16th6 Machine has no or too low welding current

a) Main contactor relays is not working

b) Bad or no contact at the earth lead

c) Torch hose completely or partially broken

d) Problem with rectifier in the machine

e) Only 2 main phases are connected, check main fuses

16th7 Welding quality is poor

a) No or not enough gas flow

b) Air is mixed into the protective gas. Open gas valve and close it again. Gas pressure must

remain in the gas hose. Check at the regulator.

c) Gas nozzle or tip holder are covered with spatters. Gas flow is not o.k.

d) Tip holder is not fixed properly. Air is mixed into the protective gas via the wire

e) Extremely oxidated work piece.

f) Air is coming to the welding area because of wind.

16th8 Problems with wire feeding and wire contacting

a) The hole in the contact tip has wrong diameter or contact tip must be changed.

b) Wire core is extremely dirty.

c) Kinks in the wire core.

d) Wrong diameter of the wire core.

e) Pressure at drive rollers is to low.

f) Wrong or old drive rollers.

g) Welding wire is not running in the axis of the drive rollers.

h) Mechanical resistance of the welding wire is too high.

16th9 Burning of the liner

a) Electrical connection between wire feed gear and welding current. Check wire

feeder for pieces of welding wire in the gear .

b) Check power cable or flange nut in the Euro-connector for a good connection.

26

17th Spare part list and wiring diagram

17th1 Spare part list M 301 K/D

electr. description part no.

-A0 pc board ME-EMV-1.3 (supply voltage filter) 00300070

-A1 pc board ME-MAG-5.1C 00300514

-A2 pc board ME-MAG-5.1 DIS (option digital display) 00300516

-A3 pc board ME-PPMR-2.1 00300493

(option push pull and remote control)

-A4 pc board ME-PPMR/AN-2.0 00300485

(option push pull and remote control)

-A5 LEM converter HTA 400-5 (option digital display) 01001615

-F1 fuse 4 A, slow 6,3x32 00301251

-F2 fuse 4 A, slow 6,3x32 00301251

-F3 fuse 10 A slow 5x20 00301199

-F5 temperature switch 112 °C opening 00100408

-F6 temperature switch 80°C opening 00100406

-H1 control lamp 230 V 00301238

lamp holder green 00301239

-K1 contactor A 12-30-10 42V 50/60 Hz 00100302

-L1 choke M 301 107040

-M1 wire feed motor 00202630

-M2 fan 230V 00101323

-M3 fan 230V 00101323

-Q1 switch WAM 271/10ZM/Z6 00100078

-Q2 switch WAM 276/10ZM/Z11/Z6 00100079

-R1 resistor 0,33 ohm 50 watt 03008612

-R2 potentiometer 10 kohm 00100502

-S1 switch 2-pol 00300900

-S2 switch 2-polig (option automated welding) 00300900

-T1 main transformer ME 301 3x400V 104590

-T2 control transformer El 96/59,7 100550

-T3 current converter (green) 02011124

-V1 rectifier 320 A 00100198

27

electr. description part no.

-X1 Euro connector 01200287

-X2 connector 1,5/2,5, 5 pol. 01700617

-X3 male connector 24 pol. 01500501

-X3 female connector 24 pol 01500500

-X4 male connector 24 pol

01500500

-X4 female connector 24 pol 01500501

-X5 connector 1,5/2,5, 5 pol. 01700617

-X6 socket 10-pol. 02110386

(option push pull and remote control)

-X7 male connector 6-pol. (option automated welding) 01500102

-X9 socket 35/50 mm² 00101101

-X10 socket 35/50 mm² 00101101

-X12 plug DIX SE 50/70 01201508

-X12 socket 35/50 mm² 00101101

-Y1 gas valve 42V/AC 00201602

-Z2 protection device 00300327

-Z3 protection device 00300330

17.2 Wiring diagramm M 301 K/D

28

1 2 3 4 5 6 7 8

-K1

1

2

3

4

5

6

-Q1

15 13 11 7 9 5

14/16

8/12 6/10

0

1 2

+OP1

-A5

Option:

Digitalanzeige

display

2 3 41

-T3

-X9

-

60%

-A0

ME-EMV-1.3ME-EMV-1.3

L1L2L3

PE

-T1

1-sw

2-sw

6-sw

7-sw

8-sw

1-bl

2-bl

6-bl

8-bl

7-bl

1-br

2-br

6-br

7-br

8-br

~

~

~

PE

Schwarz

Blau

Braun

-Q1

2

4

1

3

-M3

PE

M

-M2

PE

M

-X5

1

1

2

2

3

3

4

4

5

5

-X10

-

100%

-Z3

-Q2

135

7911

131517

Stufe 1-7

T2

S2

R2

-V1

~

~

~

+

-

~

=

-Z2

-X1

+

-L1

L1

L2

L3

PE

+SQ-A1-X2:9/2.4

+SQ-A1-X2:10/2.4

+OP1

-A2

P1

NO

Hold

Draht

wire

Strom

current

P1

P2

ME-MAG-5.1/DIS

X2

rot

I>0

X3

X4

1

2

1

2

1

2

3

4

1 10

X1

+SQ-T2:0V/2.2

+SQ-T2:400V/2.2

+SQ-A1-X1:1/2.7

+SQ-T2:0/230V/2.2

Erdungs-

schraube

Erdungs-

schraube

Erdungs-

schraube

+OP1-A1-X4/2.5

+SQ-T2:w10-0V/2.2

+SQ-T2:w10-9V/2.2

+OP2-X7:2/2.4

+OP2-X7:1/2.4

432

1

2

1

2

1

4321

sw

sw

sw

sw sw

bn

gr

sw-ws

sw-rt

sw

br

sw

ws

ws-sw

ws-bl

gn

gr

ws

sw

sw

sw

sw

/2.2

.2

.2

1234567

1 2 3

T1/R

XXX

XXX

X

1 2 3

T1/S

X

XXX

XXX

1 2 3

T1/T

X

X

XXX

X

X

Q2

Brenner

torch

Werkstück

work piece

Lüfter

fan

Option:

Digitalanzeige

display

Flachbandkabel

flat band cable

3PH-400V/50-60Hz/PE

Blatt

2

Bl.

1

Projektbez.

Auftragsnr.

Zeichnungsnr.

M301K

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

04.04.02

Siegner

10.04.02

Schweißstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

20.05.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

-R1

-Y1

-X2

7 7

8 8

16 16

17 17

18 18

-T2

400V0V230V

0/230V

W2-9V

W2-0V

W4-18V

W4-0V

W5-9V

W5-0V

W3-0V

W3-42V

W3-26V

PE

-H1

-F1

4At

-F2

4At

-F3

10At

+SQ-A2-X4:1/1.5

+SQ-A2-X4:2/1.5

-K1

A1

A2

+SQ-T2:w2-9V/2.2

+SQ-F5/2.2

+SQ-T2:230V/2.2

+SQ-X5:3/1.7

+SQ-Q1:3/1.2

+SQ-X5:2/1.7

+SQ-A1-X1:6/2.7

+SQ-A1-X1:3/2.7

+SQ-Q1:1/1.2

-F5

Trafo-Pr.

-A1

ME-MAG-5.1C

ge

Störung

failure

rt

T>

min P5

max P6

213

4

X3

5 12346789101112

X2

1 2

X6

X4

21345

6

X1

X5

4

3

2

1

JP2

HI

T-OFF

Lüfter/fan

Brennert.

torch switch

Wasser

water

Lüfter ein/fan on

Lüfternachlaufzeit/fan after-run time

Lüfterumschaltung/fan switching

ZÜNDV

soft start

JP1

ZV

ein/on

aus/off

+OP1-A2-X1/1.6

-F6

Gleichrichter

rectifer

-X2

1

1

2

2

5

5

3

3

4

4

-X1

A B

-M1

+

-

M

=

+OP6

-A6

+

-

2 13

X2

X3

10 1

10 1

Display

MAG

Uist

X4

X1

ME-MAG-5/ZW3

+OP6

-S3

1

2

3

+SQ-V1:+/1.4

+SQ-V1:-/1.4

+OP1-A1-X4/2.5

+OP1-A2-X1/1.6

+SQ-A1-X1:5/2.7

Erdungs-

schraube

432

1

21

4

3

2

1

6

5

4

3

2

1

12 11 10

9 8 7 6 5 4 3 2 1

+OP2

-S2

1

2

3

Hand/Automatik

hand/automatic

+OP2

-X7

1

2

3

4

5

6

+SQ-T3/1.3

+SQ-T3/1.3

+OP1-A2-X2:1/1.5

+OP1-A2-X2:2/1.5

+SQ-X2:3/2.5

+SQ-X2:4/2.5

+SQ-A1-X2:3/2.4

+SQ-F6/2.5

-X1

PIN-NR.

STROMPFAD

1

2

3

bn-ws

bn-gn

bn-sw

bl-ws

vio-ws

or-ws

bl-gn

bl-ws

bl-sw

bl-gn

bl-sw

gn

ge

or

bn

gn-sw

ws

vio

bl

rt

ge ge

or

rs

vio

ws

bn

bn-ws

sw-rt

sw-ws

rs

bn-gn

bl-sw

bn-sw

bl-ws bl-ws

vio

vio-sw

vio-ge

bl-gn

26

25

bl-gn

bl-ws

sw

bn

vio-ge

bn-sw

vio-sw

bn-gn

bn-ws

ws-bl

ws-sw

or-sw

sw

gr

bl-rt

ws

sw

bl-ws

.5

.2

1 2

3 4

/1.1

/1.1

/1.1

5 6

13 14

/1.7

.5

.5

BT.

Flachbandkabel

flat band cable

Spannung

Draht

Option:

Anzeige umschaltbar

Volt oder m/min

Flachbandkabel

flat band cable

Blatt

2

Bl.

2

Projektbez.

Auftragsnr.

Zeichnungsnr.

M301K

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

04.04.02

Siegner

10.04.02

Steuerstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

20.05.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

-K1

1

2

3

4

5

6

-Q1

15 13 11 7 9 5

14/16

8/12 6/10

0

1 2

+OP1

-A5

Option:

Digitalanzeige

display

2 3 41

-T3

-A0

ME-EMV-1.3ME-EMV-1.3

L1L2L3

PE

-T1

1-sw

2-sw

6-sw

7-sw

8-sw

1-bl

2-bl

6-bl

8-bl

7-bl

1-br

2-br

6-br

7-br

8-br

~

~

~

PE

Schwarz

Blau

Braun

-Q1

2

4

1

3

-M3

PE

M

-M2

PE

M

-X5

1

1

2

2

3

3

4

4

5

5

-Z3

-Q2

135

7911

131517

Stufe 1-7

T2

S2

R2

-V1

~

~

~

+

-

~

=

-Z2

-X10

-

100%

-X9

-

60%

-X12

-L1

L1

L2

L3

PE

+SQ-A1-X2:9/2.4

+SQ-A1-X2:10/2.4

+OP1

-A2

P1

NO

Hold

Draht

wire

Strom

current

P1

P2

ME-MAG-5.1/DIS

X2

rot

I>0

X3

X4

1

2

1

2

1

2

3

4

1 10

X1

+SQ-T2:0/230V/2.2

+SQ-A1-X1:1/2.7

+SQ-T2:400V/2.2

+SQ-T2:0V/2.2

Erdungs-

schraube

Erdungs-

schraube

Erdungs-

schraube

+OP1-A1-X4/2.5

4321

+SQ-T2:w10-0V/2.2

+SQ-T2:w10-9V/2.2

+OP2-X7:2/2.8

+OP2-X7:1/2.8

2

1

2

1

432

1

sw

sw

sw sw

br

gr

sw-ws

sw-rt

sw

br

sw

ws

ws-sw

ws-bl

gn

gr

ws

sw

sw

sw

sw

/2.2

.2

.2

1234567

1 2 3

T1/R

XXX

XXX

X

1 2 3

T1/S

X

XXX

XXX

1 2 3

T1/T

X

X

XXX

X

X

Q2

3PH-400V/50-60Hz/PE

+

Werkstück

work piece

Lüfter

fan

Option:

Digitalanzeige

display

Flachbandkabel

flat band cable

Blatt

4

Bl.

1

Projektbez.

Auftragsnr.

Zeichnungsnr.

M301D

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

04.04.02

Siegner

10.04.02

Schweißstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

20.05.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

-R1

-F6

Gleichrichter

rectifer

-T2

400V0V230V

0/230V

W2-9V

W2-0V

W4-18V

W4-0V

W5-9V

W5-0V

W3-0V

W3-42V

W3-26V

PE

-H1

-F1

4At

-F2

4At

-F3

10At

+SQ-T2:w2-9V/2.2

+SQ-F5/2.2

+SQ-T2:230V/2.2

+SQ-X5:3/1.7

-F5

Trafo-Pr.

+SQ-Q1:3/1.2

+SQ-A1-X1:6/2.7

+SQ-X5:2/1.7

+SQ-A1-X1:3/2.7

+SQ-Q1:1/1.2

-A1

ME-MAG-5.1C

ge

Störung

failure

rt

T>

min P5

max P6

213

4

X3

5 12346789101112

X2

1 2

X6

X4

21345

6

X1

X5

4

3

2

1

JP2

HI

T-OFF

Lüfter/fan

Brennert.

torch switch

Wasser

water

Lüfter ein/fan on

Lüfternachlaufzeit/fan after-run time

Lüfterumschaltung/fan switching

ZÜNDV

soft start

JP1

ZV

ein/on

aus/off

Erdungs-

schraube

-X2

1

1

2

2

5

5

3

3

4

4

-X3

10 9 12

+OP2

-S2

1

2

3

Hand/Automatik

hand/automatic

+OP1-A2-X2:1/1.5

+OP1-A2-X2:2/1.5

+SQ-X2:3/2.5

+SQ-X2:4/2.5

+SQ-A1-X2:3/2.4

+SQ-F6/2.6

+SQ-T3/1.3

+SQ-T3/1.3

-X2

7 7

8 8

16 16

17 17

18 18

-K1

A1

A2

+OP3-A3-X2:3/3.6

+OP3-A3-X2:4/3.6

18

17

16

8

7

23

-X3

24

+SQ-A2-X4:1/1.5

+SQ-A2-X4:2/1.5

21

432

1

6

5

4

3

2

1

4

3

2

1

12 11 10

9 8 7 6 5 4 3 2 1

+SQ-A1-X1:5/2.7

+OP2

-X7

1

2

3

4

5

6

+OP1-A2-X1/1.6

vio-ws

or-ws

bl-ws

or or

gn

ge ge

vio-ge

vio-sw

gn-sw

ws-rt

ws-br

ge

or

bn-ws bn-ws

rs

vio

bn-gn bn-gn

ws

br

bn-sw bn-sw

bl-ws bl-ws bl-ws

vio-sw

bl-gn

vio-ge

rs

sw-rt

sw-ws

bl-sw

vio

or-sw

vio-ws

bl-ws

sw

br

vio-ge

bn-sw

vio-sw

bn-gn

bn-ws

ws-bl

or-sw

ws-sw

sw

gr

bl-rt

ws

bl-sw

sw

bl-ws

.2

.5

1 2

3 4

/1.1

/1.1

/1.1

5 6

13 14

Flachbandkabel

flat band cable

Blatt

4

Bl.

2

Projektbez.

Auftragsnr.

Zeichnungsnr.

M301D

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

04.04.02

Siegner

10.04.02

Steuerstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

20.05.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

-X4

12

-M1

+

-

M

=

-R2

E

A

S

-Y1

3456789101112131415161718192021222324

1234567891011121314151617181920212223

+VB

-X4

24

+VB

-X3

1234567891011121314151718192021222324 16

A

Option:

PP-Brenner oder

Fernregleranschluß

pp-torch or

remote control

A

-X1

B

+

-

M

=

E

A

S

H

+VB

-X12

-X13

1

-X1

+

D

C

J

K

+OP3

-A3

rt

Freigabe/

enable

X4

ME-PPMR-2.1

X1

1

2

3

4

5

6

7

8

X2

1

2

3

4

5

6

1 10

X3

JP1

JP2

>3m

1A-träge/

slow

+OP3

-X6

B

+OP6

-S3

1

2

3

+OP3

-S1

4

5

6

65432

1

+SQ-T2:w3-0V/2.2

+SQ-T2:w3-42V/2.2

+SQ-X3:24/2.4

+SQ-X3:23/2.4

+SQ-X2:1/2.5

+SQ-X2:2/2.5

+OP1-A2-X1/1.6

+OP1-A1-X4/2.5

+SQ-V1:+/1.4

+SQ-V1:-/1.4

+OP6

-A6

+

-

2 13

X2

X3

10 1

10 1

Display

MAG

Uist

X4

X1

ME-MAG-5/ZW3

+OP3

-A4

ME-PPMR/AN 2.0

rt

+

rt

gn

0

-

110

X1

vio

bl

rt

bn

ws

vio-ge

vio-sw

ws-bn

ws-rt

gn-sw

gn-ws

gn

rt

DV-Gerät

wire feeder

BT.

PP-Motor

D

C

JKA

B

H

BT.

VB-Kabel

Drahtvorschub

wire feed

Brenner

torch

DV-25

Flachbandkabel

flat band cable

Draht

Spannung

Option:

Anzeige umschaltbar

Volt oder m/min

Flachbandkabel

flat band cable

Blatt

4

Bl.

3

Projektbez.

Auftragsnr.

Zeichnungsnr.

M301D

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

04.04.02

Siegner

10.04.02

DV-Kasten

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

20.05.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

DV

17th3 Spare part list M 351 K/D/KW/DW

electr. description part no.

-A0 pc board ME-EMV-1.3 (supply voltage filter) 00300070

-A1 pc board ME-MAG-5.1C 00300514

-A2 pc board ME-MAG-5.1 DI5 (option digital display) 00300516

-A3 pc board ME-PPMR-2.1 00300493

(option push pull and remote control)

-A4 pc board ME-PPMR/AN-2.0 00300485

(option push pull and remote control)

-A5 LEM converter HTA 400-5 (option digital display) 01001615

-C1 capacitor 6 uF, 420V/AC 00100425

-F1 fuse 4 A, slow 6,3x32 00301251

-F2 fuse 4 A, slow 6,3x32 00301251

-F3 fuse 10 A slow, 5x20 00301199

-F4 fuse 1 A 5x20 00301212

-F5 temperature switch 112 oC opening 00100408

-F6 temperature switch 80°C opening 00100406

-F7 temperature switch 40°C closing 00100345

-F8 water pressure switch 0,5 bar 00400204

-F9 bar thermical current protector 1 ,4 A 00300320

-H1 control lamp 230 V 00301238

lamp holder green 00301239

-K1 contactor A 16-30-10 42V 50/60 Hz 00100311

-L1 choke M 351 00101676

-M1 wire feed motor 24V-DC (DV 25) 00202630

-M2 fan 230V 00101301

-M3 water pump 230V 50Hz 00400530

-M4 wire feed motor 42V-DC (option DV-30) 00202512

-Q1 switch HLT 40/3ZM/X99/NR

00100014

-Q2 switch ST 63/32E 00100108

-Q3 switch WAM 227/32E/Z11/X97 00100098

-R1 resistor 0,33 ohm 50 watt 03008612

-R2 potentiometer 10 kohm 00100502

-S1 switch 2-polig 00300900

-S2 switch 2-polig (option automated welding) 00300900

34

electr. description part no.

-T1 main transformer M 351 00101675

-T2 control transformer El120/73,7 950VA 00300242

-T3 current converter (green) 02011124

-V1 rectifier 320 A 00100198

-X1 Euro connector 01200287

-X2 connector 1,5/2,5, 5 pol. 01700617

-X3 female connector 24 pol. 01500501

-X3 male connector 24 pol. 01500500

-X4 male connector 24 pol. 01500500

-X4 female connector 24 pol. 01500501

-X5 connector 1,5/2,5, 5 pol. 01700617

-X6 socket 10-pol. 02110386

( option push pull and remote control)

-X7 male connector 6-pol. (option automated welding) 01500102

-X9 socket 35/50 mm2 00101101

-X10 socket 35/50 mm2 00101101

-X12 socket 70/95mm2 500A 00101102

-X12 plug DIX SE 50/70 01201508

-Y1 gas valve 42V/AC 00201602

-Z2 protection device 00300327

-Z3 protection device 00300330

17.4 Wiring diagramm M 351 K/D/KW/DW

35

1 2 3 4 5 6 7 8

-A0

ME-EMV-1.3ME-EMV-1.3

L1L2L3

PE

-Q1

L1 L2 L3

T1 T2 T3

-X11

PE

-V1

~

~

~

-

+

~

=

-L1

100%

66%

-Z2

123

4

+OP1

-A5

2 3 41

2

112

-X11

PE

-T1

U1

U2

U3

U4

R1

R2

R3

V1

V2

V3

V4

S1

S2

S3

W1

W2

W3

W4

T1

T2

T3

~ ~ ~

PE

-Q2

1 2 3 4 1 2 3 4 1 2 3 4

L1

L2 L3

-Q3

S2

T2

1 3 5 7 9 11 13 15 17

R2

2 4 6 8 10 12 14 16 18

-T3

1

-X8

2

-Z3

L1

L2

L3

PE

+SQ-T2:-0V/2.2

+SQ-T2:9V/2.2

+OP2-X7:2/2.6

+OP2-X7:1/2.6

-X1

+

-X10

-X9

+OP1

-A2

P1

NO

Hold

Draht

wire

Strom

current

P1

P2

ME-MAG-5.1/DIS

X2

rot

I>0

X3

X4

1

2

1

2

1

2

3

4

1 10

X1

1 2 3 4

-K1

2

1

4

3

6

5

+SQ-T2:w1-400V/2.2

+SQ-T2:w1-0V/2.2

+SQ-A1-X2:9/2.5

+SQ-A1-X2:10/2.4

+OP1-A1-X4/2.5

sw

sw-ws

sw-rt

br

ws

ws-sw

ws-bl

gn

gr

ws

sw

sw

sw

sw sw

sw

sw sw

sw

sw

/2.2

3PH-400V/50-60Hz/PE

Q3

7 8 9 7 8 9 7 8 9

1234567

U

V

W

xxx

xxx

x

x

xxx

xxx

x

x

xxx

x

x

Q2

12345

6

1 2 3 4 5 6

x

x

x

x

x

x

Option:

Digitalanzeige

display

-

-

Option:

Digitalanzeige

display

Werkstück

work piece

Brenner

torch

Blatt

3

Bl.

1

Projektbez.

Auftragsnr.

Zeichnungsnr.

M351K

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

10.03.99

Siegner

30.03.99

Konrad

16.12.99

Schweißstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

20.05.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

-X2

7 7

8 8

16 16

17 17

18 18

1 2

123

4

1

3

5

6

346789101112 5

1

2

3

12

-F6

-F7

-R1

+SQ-T2:9V/2.2

+SQ-F5/2.2

+SQ-T2:230V/2.2

+SQ-X5:3/2.3

-A1

ME-MAG-5.1C

ge

Störung

failure

rt

T>

min P5

max P6

213

4

X3

5 12346789101112

X2

1 2

X6

X4

21345

6

X1

X5

4

3

2

1

JP2

HI

T-OFF

Lüfter/fan

Brennert.

torch switch

Wasser

water

Lüfter ein/fan on

Lüfternachlaufzeit/fan after-run time

Lüfterumschaltung/fan switching

ZÜNDV

soft start

JP1

ZV

ein/on

aus/off

-X5

55

11

22

33

44

-M2

PE

bl

schw

br

M

-C1

-K1

A1

A2

-X11

PE

+OP2

-X7

1

Option:

Automatenanschluß

machine welding connection

23456

+OP1-A2-X2:1/1.6

+OP1-A2-X2:2/1.6

+SQ-X2:3/2.6

+SQ-X2:4/2.6

+SQ-A1-X2:7/2.5

+SQ-A1-X2:8/2.5

+OP2

-S2

1

2

3

Hand/Automatik

hand/automatic

-X1

A B

-M1

+

-

M

=

+OP6

-A6

+

-

2 13

X2

X3

10 1

10 1

Display

MAG

Uist

X4

X1

ME-MAG-5/ZW1

+OP6

-S3

1

2

3

+SQ-V1:+/1.4

+SQ-V1:-/1.4

+OP1-A1-X4/2.5

+OP1-A2-X1/1.7

-T2

400V0V230V

0/230V

W2-9V

W2-0V

W4-18V

W4-0V

W5-9V

W5-0V

W3-0V

W3-42V

W3-26V

PE

-F1

4At

-X11

PE

-F2

4At

-F3

10At

+SQ-A2-X4:1/1.6

+SQ-A2-X4:2/1.6

+SQ-X2:17/2.6

-Y1

+OP1-A2-X1/1.7

-F5

Trafo-Pr.

+SQ-A1-X1:1/2.7

+SQ-A1-X3:1/2.4

+SQ-A1-X3:2/2.4

+SQ-A1-X3:3/2.4

+SQ-A1-X1:5/2.7

-H1

+SQ-Q1:T2/1.2

+SQ-A1-X1:6/2.7

+SQ-Q1:T1/1.2

+SQ-A1-X1:3/2.7

+SQ-X8:2/1.3

+SQ-X8:1/1.3

-X2

1

1

2

2

3

3

4

4

5

5

+SQ-X2:16/2.6

+SQ-X2:18/2.6

vio-ws

or-ws

gn

rs

vio

ws

br

gn-sw

bn

ws

vio

vio-ge

vio-sw

bl

rt

ws-br

or

ge

rs

gr

vio

ws

br br

br-ws

br-gn

br-sw

sw-rt

bl-ws bl-ws

sw-ws

bl-sw

or

vio-sw

bl-gn

ge

vio-ge

bl-gn

bl-gn

or-sw

vio-ws

sw

br

vio-ge

br-sw

vio-sw

br-gn

br-ws

ws-bl

or-sw

ws-sw

sw

gr

bl-rt

sw ws

sw

.6

.2

1 2

3 4

/1.4

/1.4

/1.4

5 6

13 14

Flachbandkabel

flat band cable

Lüfter

fan

Gleichrichter

rectifer

BT.

Flachbandkabel

flat band cable

Spannung

Draht

Option:

Anzeige umschaltbar

Volt oder m/min

Blatt

3

Bl.

2

Projektbez.

Auftragsnr.

Zeichnungsnr.

M351K

Änderung

Steuertrafo

Datum

gez.

gepr.

Name

Datum

Name

Konrad

10.03.99

Siegner

30.03.99

Konrad

14.10.00

Steuerstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

20.05.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

-A0

ME-EMV-1.3ME-EMV-1.3

L1L2L3

PE

-Q1

L1 L2 L3

T1 T2 T3

-X11

PE

-V1

~

~

~

-

+

~

=

-L1

100%

66%

-Z2

123

4

+OP1

-A5

2 3 41

2

112

-X11

PE

-T1

U1

U2

U3

U4

R1

R2

R3

V1

V2

V3

V4

S1

S2

S3

W1

W2

W3

W4

T1

T2

T3

~ ~ ~

PE

-Q2

1 2 3 4 1 2 3 4 1 2 3 4

L1

L2 L3

-Q3

S2

T2

1 3 5 7 9 11 13 15 17

R2

2 4 6 8 10 12 14 16 18

-T3

1

-X8

2

-Z3

PEL3L2

L3

+SQ-T2:w10-0V

+SQ-T2:w10-9V

+OP2-X7:2

+OP2-X7:1

-X10

-X9

-X12

+OP1

-A2

P1

NO

Hold

Draht

wire

Strom

current

P1

P2

ME-MAG-5.1/DIS

X2

rot

I>0

X3

X4

1

2

1

2

1

2

3

4

1 10

X1

1 2 3 4

-K1

2

1

4

3

6

5

+SQ-T2:w1-400V

+SQ-T2:w1-0V

+OP1-A1-X4

+SQ-A1-X2:10

+SQ-A1-X2:9

sw

sw-ws

sw-rt

br

ws

ws-sw

ws-bl

gn

gr

ws

sw

sw

sw

sw sw

sw

sw sw

sw

sw

3PH-400V/50-60Hz/PE

Q3

7 8 9 7 8 9 7 8 9

1234567

U

V

W

xxx

xxx

x

x

xxx

xxx

x

x

xxx

x

x

Q2

12345

6

1 2 3 4 5 6

x

x

x

x

x

x

Option:

Digitalanzeige

display

-

-

Option:

Digitalanzeige

display

Werkstück

work piece

+

Blatt

4

Bl.

1

Projektbez.

Auftragsnr.

Zeichnungsnr.

M351D

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

10.03.99

Siegner

30.03.99

Konrad

16.12.99

Schweißstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

21.05.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

-T2

sw1/sw2

w2-9V

w2-0V

400V

230V

0/230V

0/230V

0V

w3-0V

w3-37V

w3-42V

w4-18V

w4-0V

w5-9V

W5-0V

w6-9V

w6-0v

w7-18V

w7-0V

w8-18V

w8-0V

w9-18V

w12-42VPEw12-0V

w11-9V

w11-0V

w10-9V

w10-0V

w9-0V

w1

5A1A1A2A1A1A1A

1A

1A

1A

-F2

4At

-F3

10At

-F1

1At

-F5

Trafo-Pr.

-F4

1At

-X11

PE

-H1

-X11

PE

-K1

A1

A2

-X2

7 7

8 8

16 16

17 17

18 18

+SQ-A1-X3:1

+SQ-A1-X3:2

+SQ-A1-X3:3

1 2

123

4

1

3

5

6

346789101112 5

1

2

3

12

-F6

-F7

-R1

-X5

55

11

22

33

44

-X11

PE

+SQ-A1-X1:1

+SQ-T2:w1-0/230V

+OP3-A3-X2:3

+OP3-A3-X2:4

-X2

1

1

2

2

5

5

3

3

4

4

129

-X3

10

-M2

PE

bl

schw

br

M

-C1

16

17

18

23

-X3

24

7

8

+SQ-T2:w1-230V

+SQ-Q1:T2

+SQ-Q1:T1

+SQ-X5:2

+SQ-A1-X1:3

+SQ-A1-X1:6

+SQ-A1-X2:11

+SQ-A1-X1:5

+SQ-X2:17

+SQ-A2-X4:1

+SQ-A2-X4:2

+SQ-X8:2

+SQ-X8:1

+SQ-K1:A1

+SQ-T2:w12-42V

+SQ-T2:w2-9V

+SQ-F5

+SQ-T2:230V

+SQ-X5:3

+SQ-A1-X2:12

-A1

ME-MAG-5.1C

ge

Störung

failure

rt

T>

min P5

max P6

213

4

X3

5 12346789101112

X2

1 2

X6

X4

21345

6

X1

X5

4

3

2

1

JP2

HI

T-OFF

Lüfter/fan

Brennert.

torch switch

Wasser

water

Lüfter ein/fan on

Lüfternachlaufzeit/fan after-run time

Lüfterumschaltung/fan switching

ZÜNDV

soft start

JP1

ZV

ein/on

aus/off

+OP1-A2-X1

+SQ-X2:16

+SQ-X2:18

vio-ws

or-ws

gn

rs

vio

ws

br

or

ge

vio-ge

gn-sw

vio-sw

ws-br

gr

br

ws-rt

ws-br

br-ws br-ws

br-gn br-gn

br-sw br-sw

sw-rt

bl-ws bl-sw

sw-ws

bl-sw

or

bl-gn bl-gn

ge

bl-gn bl-gn

or-sw

vio-ws

sw

bl-ws

11

ws-bl

br

ws-sw

vio-sw

br-sw

vio-ge

br-gn

br-ws

or-sw

sw

gr

gr

bl-rt

ws

sw

gn-sw

sw

gn-ws

Flachbandkabel

flat band cable

Gleichrichter

rectifer

Lüfter

fan

Blatt

4

Bl.

2

Projektbez.

Auftragsnr.

Zeichnungsnr.

M351D

Änderung

Datum

gez.

gepr.

Name

Datum

Name

Konrad

10.03.99

Siegner

30.03.99

Steuerstromkreis

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

21.05.03

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

=

+

SQ

1 2 3 4 5 6 7 8

1

2

3

4

5

6

-X4

12

-Y1

3456789101112131415161718192021222324

1234567891011121314151617181920212223

+VB

-X4

24

+VB

-X3

1234567891011121314151718192021222324 16

A

+OP3

-X6

B

K

+

-

M

=

E

A

S

H

+VB

-X12

-X13

1

+OP2

-S2

1

2

3

Hand/Automatik

hand/automatic

+OP2

-X7

1

Option:

Automatenanschluß

machine welding connection

23456

-X1

+

A

B

-M1

+

-

M

=

J

+OP3

-A3

rt

Freigabe/

enable

X4

ME-PPMR-2.1

X1

1

2

3

4

5

678

X2

1

2

3

4

5

6

1 10

X3

JP1

JP2

>3m

1A-träge/

slow

D

C

+OP5

-M4

+

-

+

-

Motor für Option: DV-30

motor for option: DV-30

G

=

M

=

+OP3

-A4

ME-PPMR/AN 2.0

rt

+

rt

gn

0

-

110

X1

+OP1-A2-X2:1

+OP1-A2-X2:2

+SQ-X2:3

+SQ-X2:4

+SQ-A1-X2:7

+SQ-A1-X2:8

+SQ-T2:w3-0V

+SQ-T2:w3-42V

+SQ-X3:24

+SQ-X3:23

+SQ-A1-X5:1

+SQ-A1-X5:2

+OP6

-S3

1

2

3

+OP6

-A6

+

-

2 13

X2

X3

10 1

10 1

Display