USER MANUAL

LogiTIG

240 AC/DC

200 AC/DC

Content

1 The LogiTIG 200 AC/DC and 240 AC/DC

1.1 Intended Purpose

1.2 Transport

1.3 Positioning in the work place

1.3.1 Positioning

1.3.2 Use in conjunction with a power generator

1.3.3 Extension Cables

1.4 Start up Procedure

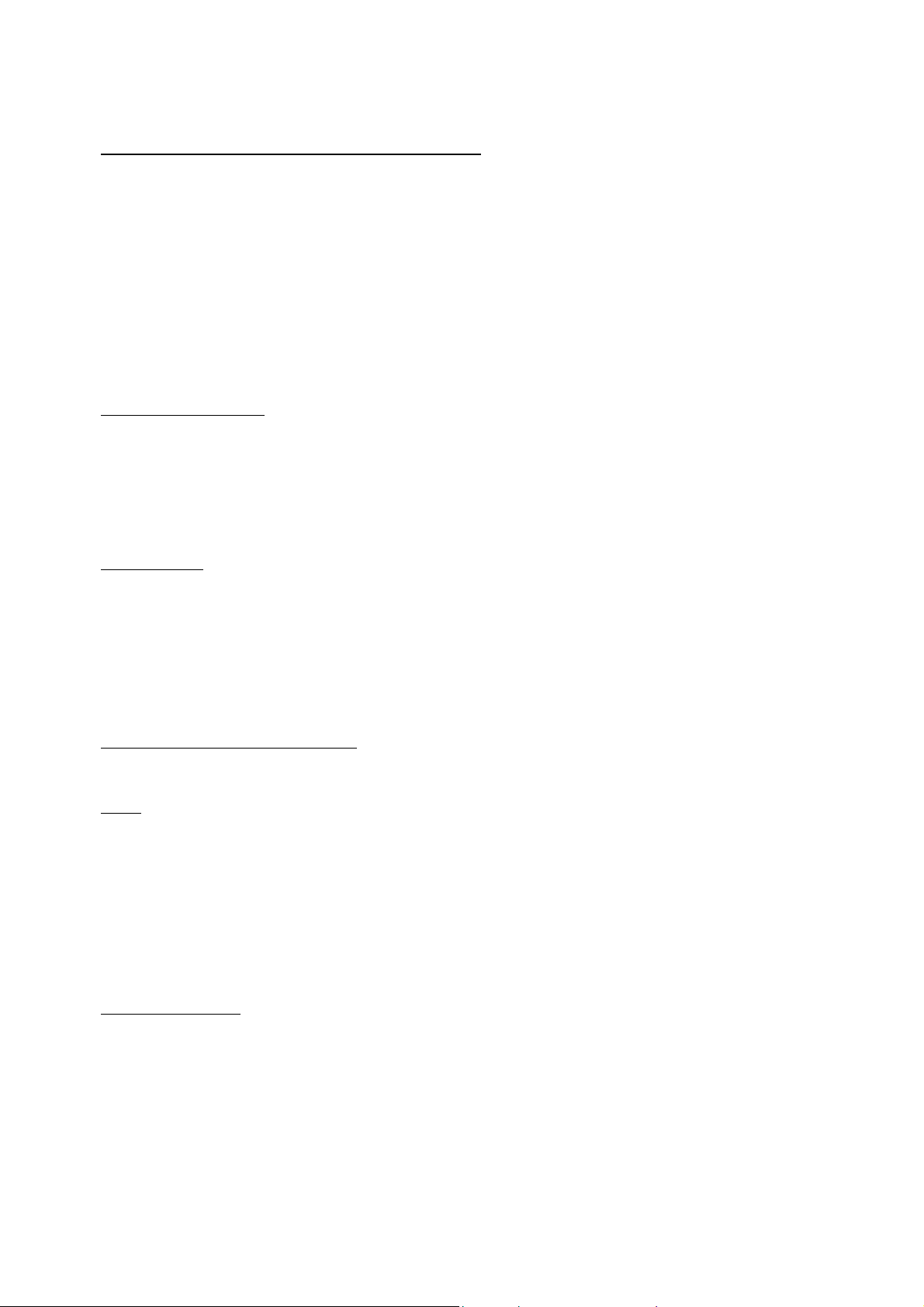

1.5 Illustration of the control panel and accessories attachments

1.6 Operation control in standard mode

2 TIG Welding

2.1 Process

2.2 Employment of the Process

2.3 Connection to the Mains

2.4 Joint preparation

2.5 Gas nozzle and welding current

2.6 TIG mode (standard operation)

2.6.1 Setting the welding current

2.6.2 TIG welding application

2.7 TIG Operation in standard mode

2.7.1 The DC welding mode

2.7.2 Alternating current (AC) welding mode

3 Electrode Welding (MMA Welding)

3.1 Process

3.2 MMA Preparation

3.3 Operation procedure

3.3.1 Display Details

3.3.2 Electrode Welding mode

3.4 Welding process

4 TIG – Expert Mode

5 Set-up Menu

6 Parameter adjustment range

7 Trouble shooting

8 Servicing

9 TIG hand welding torch – and spare parts

1. The LogiTIG 200 AC/DC and 240 AC/DC

The LogiTIG 200 AC/DC and the 240 AC/DC and are equipped with top of the line inverter

technology, they are designed to carry out the TIG and MMA welding processes in both AC and DC

current.

The welding machine is universally employable.

This series of machines lends itself well to on sight welding work. This is thanks high level of

mobility due to its extremely compact (space saving) design and reduced weight characteristics,

this coupled with the fact that it can also be run on a single phase 230V system (180A max)

1.1 Intended Purpose

This welding equipment it designed for the following processes

• MMA welding

• TIG welding with a shielding gas

All other processes undertaken with this machine are strongly ill advised and should not be

practised.

1.2 Transport

Before transporting this machine disconnect the gas line between the gas bottle and the welding

machine. During the transport make sure that the machine is secured in case of an accident.

DANGER:

• The gas bottle must be removed for the purpose of transportation.

• If not removed there is a danger of injury through falling gas bottles.

• DANGER OF EXPLOSION

1.3 Positioning in the work place

The machine should be placed in dry ambient areas and is designed only to be used in covered

protected environment.

Note:

• Never weld in open areas in the rain.

• Always check the proposed area for EMV activity

Should there be any disturbances then these must be eliminated before any

welding can take place.

• Danger is also present through electrically conductive components

• Isolation matting should be available for the protection of the operator from electric

shocks

1.3.1. Positioning

Attention

Cooling fans are employed in this machine to cool the power unit, therefore it is imperative that:

• Fresh air is allowed easy access to entry point (front) of the machine and the exiting air is

also free of any constricting obstacles.

• There should be an all round free space of approx. 80cm around the machine.

• In workshops with a high dust concentration an air filter should be employed on the

machine (optional extra).

• The machine should be placed on firm even ground.

• Ensure that the machine entry temperature is between -10 and +40°C

• Care should be taken to ensure that the rooms humidity is correct (up to 50% at 40°C and

90% at 20°C).

• The surrounding environment should be where possible free of excessive dust, acid and

corrosive gases.

• By higher concentrations of the above an air filter must be employed.

1.3.2. Use in conjunction with a power generator

• The power output of the generator should be at least 10% higher than the power intake of

the welding machine.

• The output voltage of the generator must also have a regulated open circuit voltage.

Switching on

First start the power generator and then switch on the welding machine.

Switching off

First switch off the welding machine and then the power generator.

By not adhering to the above advice YOU take the risk of damaging the machine through power

spikes.

1.3.3 Extension cables

Cautionary measures in the use of extension cables:

• The cable should be in a good and safe condition.

• The cable should always be fully removed from the cable drum.

• The maximum cable length should not exceed the conductor cross section value.

When these rules are not adhered to there is a real risk of overheating.

1.4 Start up Procedure

During the start-up process information about your machine is displayed on the Multi-Functional

display. You can according to the machine version various settings can be carried out.

• Start Process

• Turn the main power switch to position “I”.

• The software will be loaded and the Multi-Functional display (MFD) will show the

following information:

- Display version

- Machine version

- The last selected welding program

• During the start up process no setting changes can be made!

In the factory delivered condition the welding unit is set in “standard mode”. In this condition the

basic welding parameters are available. The operation is also simple. Should you require more

functions than are presently available then the machine can be switched to an “expert Mode”. The

procedure for this is explained in “Set-up menu” (chapter 7)

Special functions

• Resetting to factory settings (see Chapter 8)

Reset process explanation

• Colour adjustment of the MFD panel:

Select set-up menu

Press button I

1

The display panel background and script colour can be changed, i.e. black

/white to white/black

• Actual Welding Parameter will show all welding conditions one after the other

Press buttons I

and I2 together for 2 seconds.

1

• HIGH CURRENT / BIPOWER Technology (only LogiTIG 240 DC)

According to the power supply the maximum output available:

• Mains connection to 3 Ph 400 V-N-PE (32A):

TIG welding current up to 240A

MMA welding up to 200A

• With adapter 400/230V (16A)

TIG welding current up to 180A

MMA welding current up to 160A limited

• Duty Cycle (dc)

The Duty Cycle measurement is carried out according to EN 60974-1 / VDE 0544 in 10

Minute working cycles.

This has a value of 60% dc:

After a 6 minute welding period there must follow a 4 minute cooling phase.

The performance parts are Temperature controlled against overheating, after they have

switched off they will automatically re-activate when the temperature drops.

These values apply to working temperatures up to 40 °C and a maximum height above sea

of 1000m NN. Higher temperatures, attached air filters and higher altitudes will affect the

duty cycle values.

1.5 Illustration of the control panel and accessories attachments

Front panel controls

Position Sign Function___________________________________

1 Menu button button for Menu Functions (only in expert mode)

2 Display Panel shows Welding parameters

3 Incremental potentiometer endless rotary control for the setting of parameters

4 Status Display machine status and Warning indicators

5 Buttons 1-4 function buttons, module and menu functions

6 t

7 I

parameter buttons for setting of the down slope time

down

parameter button for setting the end current

end

8 Gas Test button for Gas test

9 I

10 I

11 t

12 I

13 t

14 t

parameter button for setting the 2nd welding current

2

parameter button for setting the 1st welding current

1

parameter button for setting the pre-gas flow time

gas

parameter button for setting the start current

start

up

and t2 parameter button for setting the I1and I2 current times

1

parameter button for setting the upslope time

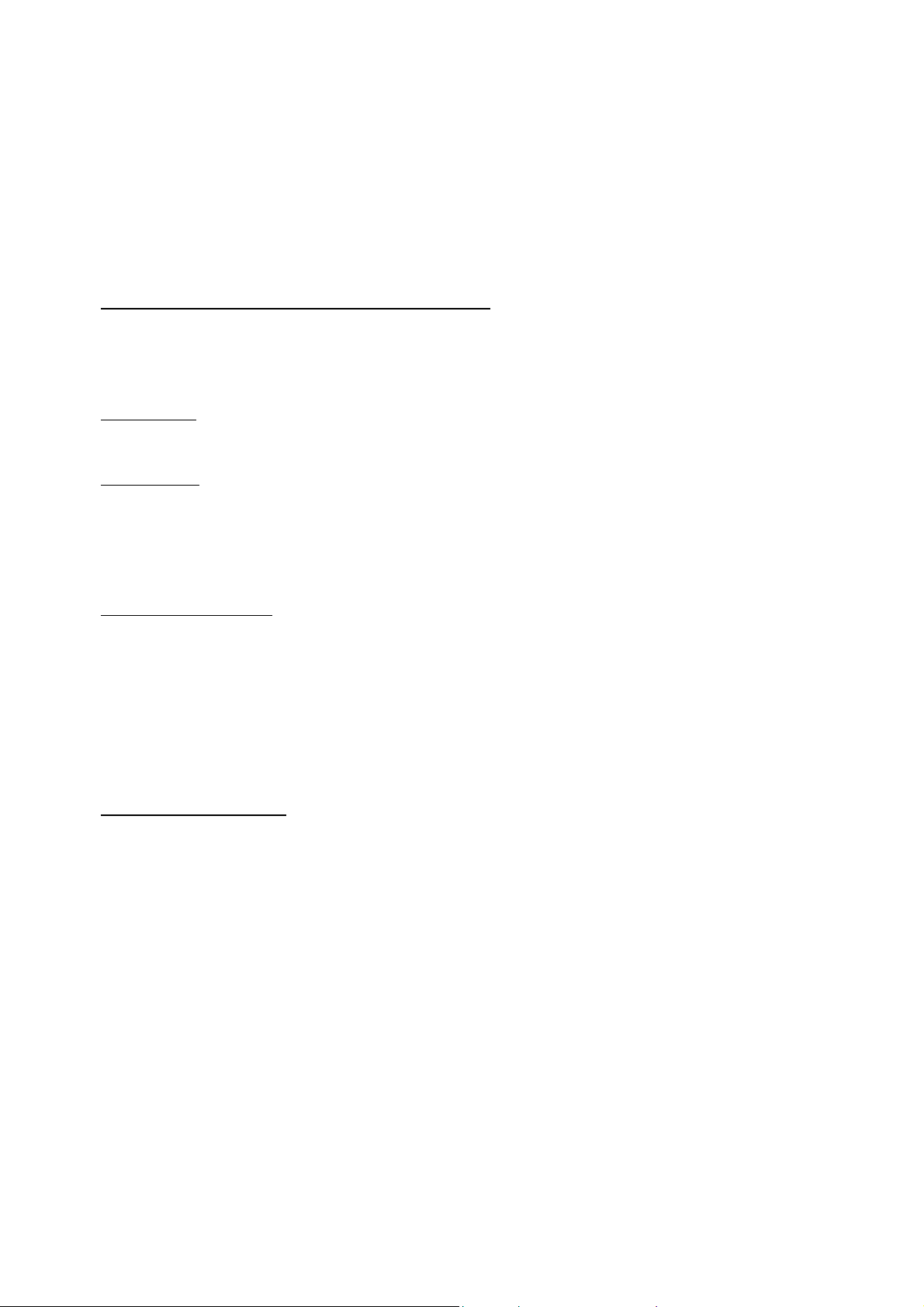

LED status/warning display

Position Sign Function _________________________________

4a Machine status display shows the machine has no-load current at the Poles

4b Network connection shows that the machine is switched on

4c Warning light temperature shows that the machine is overheating

4d Defect warning light shows that the machine has a defect

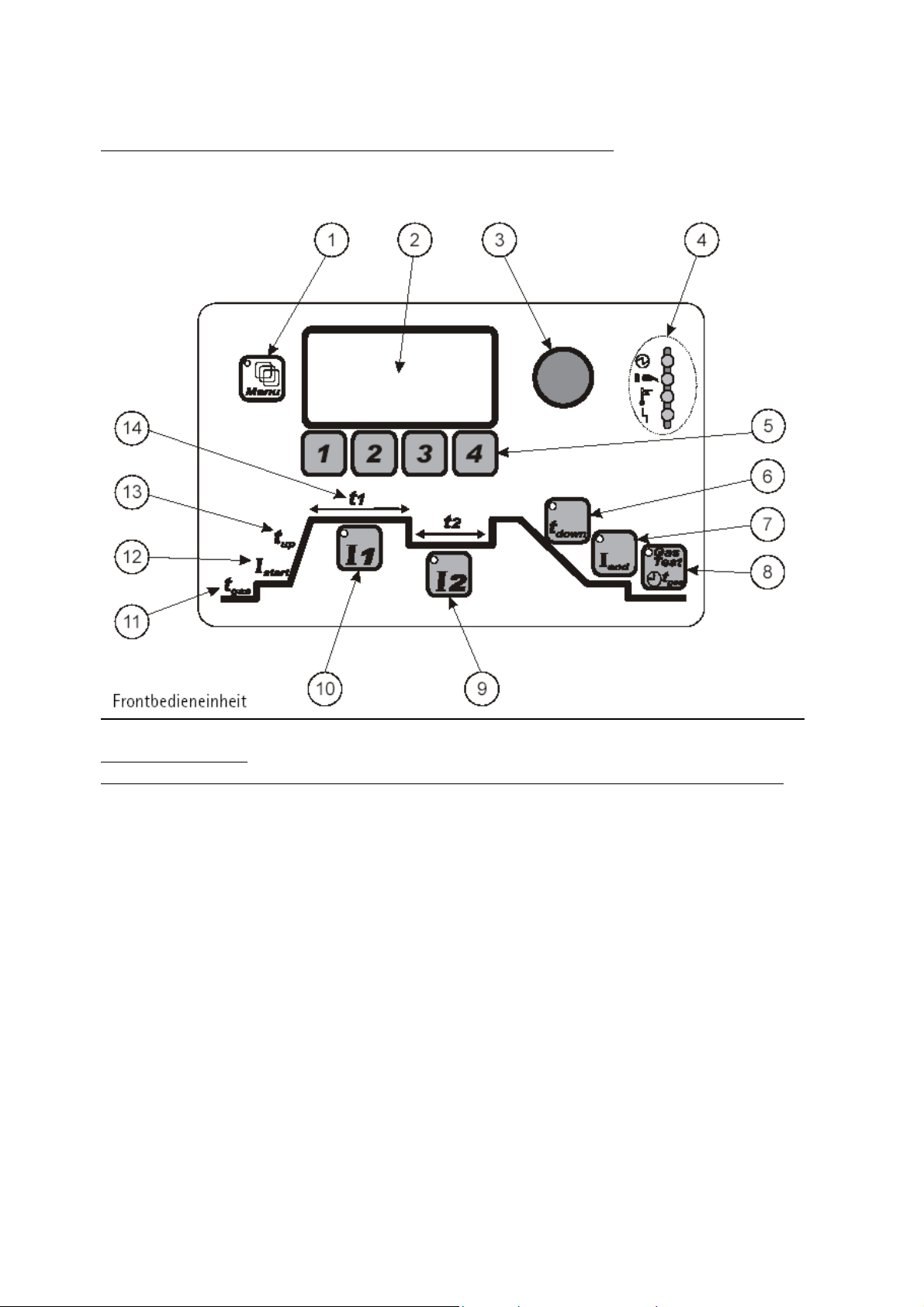

Connection adapters

Position Sign Function ____________________________

15 control cable remote control

16 control cable torch control

17 - Pole Busch TCG connection: combined Gas, TIG current and

MMA electrode holder

18 + Pole Busch Earth cable and MMA electrode holder connection

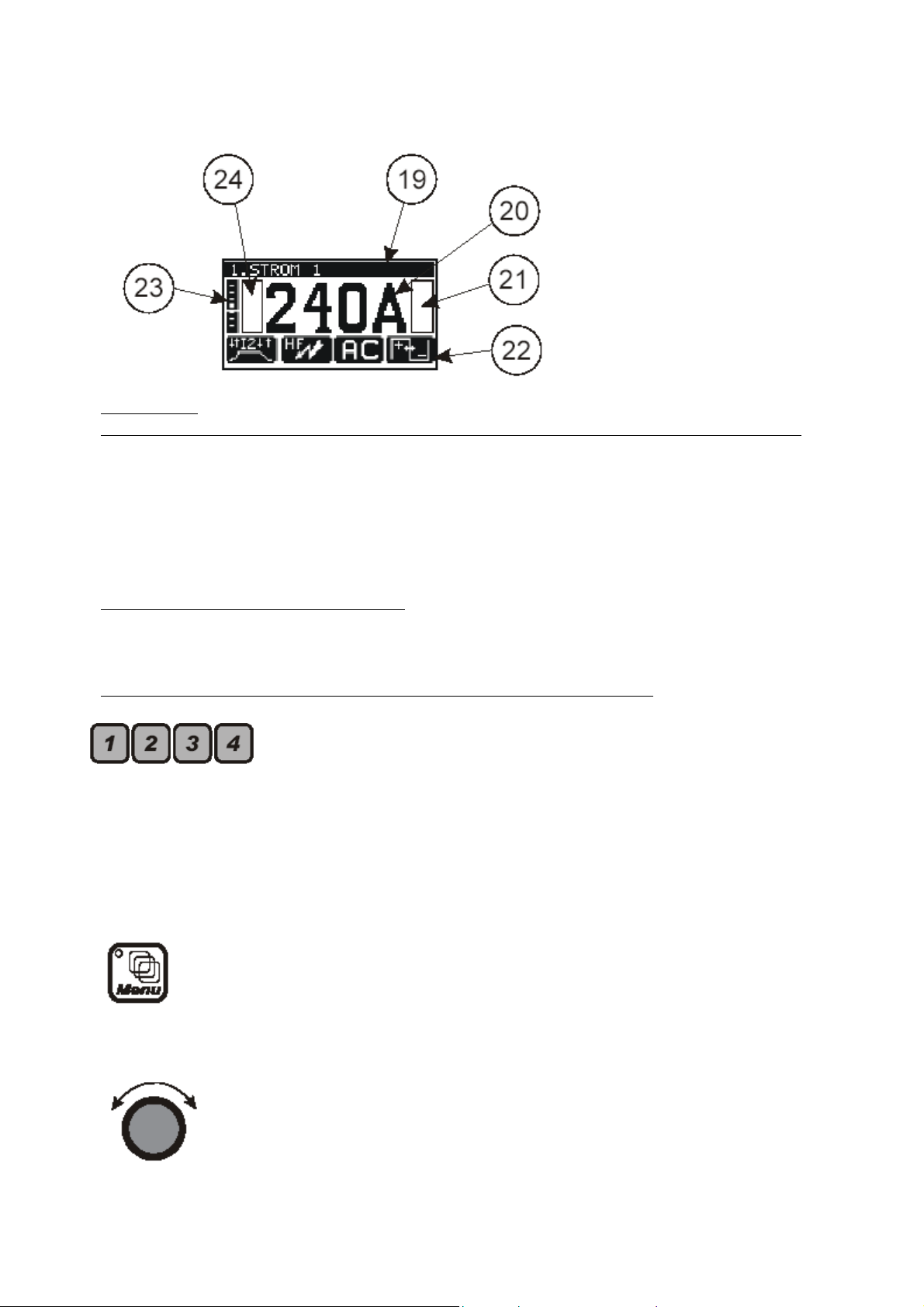

Display panel

Position Sign Function ____________________________

19 text field shows the parameter mode

20 parameter displays shows the actual parameter value selected

21 flag display field right shows the activated flags

22 pictogram line shows the selectable menus/modus functions

23 AC – balance scale graphic display for the AC balance value

24 flag display field left shows the activated flags

1.6 operation control in standard mode

The following diagrams clarify the function and pictogram in the display panel when used in the

standard mode of the welding unit.

Control button illustrations to be imported from the original document

Function buttons F1, F2, F3, and F4 for:

• Selection of the mode in connection with the pictogram on the

display, through the repeated use of the buttons.

• Selection of the parameters according to the pictogram in the

display and the adjustment of the values using the incremental

switch.

Menu button (in standard mode inaccessible)

• button for selection of the menu function

Incremental potentiometer

• continuous potentiometer without rotary limiter

• adjustment of the value of the selected parameter

Parameter button (PB) for the direct adjustment of the main welding

current I

. Integrated into the button is an LED.

1

• The LED button lights up:

When the current I

When the current I

is being adjusted

1

is active in the welding process

1

• If the main welding current I

welding current I

will adjust itself proportionately.

2

is adjusted, at the same time the

1

Parameter button (PB) for the adjustment of the welding current I2.

Integrated into the button is an LED.

• The LED button lights up:

When current I

is being adjusted

2

When the current I2 is active in the welding process

Should the I

welding current I

• The welding current I

current be altered, it will have no effect on the main

2

.

1

is only available in the following processes

2

Slow pulsing

Quick pulsing

4-stroke with current I

2

PB for the selection of the down slope t

is an LED.

• The down slope time of the welding current I

activated I

• Welding process with 2 welding currents I

• The function is active in:

PB for the selection of the end current I

is an LED.

• In the selected time the active welding current will be reduced until it

reaches the I

. Integrated into the button

down

until the end current is

1

end

and I2:

1

Both welding currents near themselves in the selected

time of the end current I

end

Pulse-setting

Stroke-modus

. Integrated into the button

end

current value.

end

PB “Gas-test”. Integrated into the button is an LED.

Warning light indicators

Setting the gas post flow

• Press button once

LED in button will light up

Post gas time can be set using the incremental parameter

Selecting the gas test function

• Press the button twice

LED in button will blink

The gas valve will open

The timer will run backwards

The gas valve will be closed automatically on reaching

zero

The gas valve can be manually closed by pressing the

button once more

After the completion of the gas test

The LED in the button will stay lit

Then the gas post flow can be set using the

incremental potentiometer

(as described in “gas post flow”)

Displaying the gas post flow function

• After the welding process has ended

The LED button will blink

The gas post flow will continue for the selected time

• Automatic purging of the gas line will follow:

When switching from MMA mode to TIG mode, when the

electrode is used.

During the running up of the welding unit whilst in TIG

mode.

Welding unit status indicator

• LED is lit

No load current is at the connecter bushes

Network connection status indicator

• LED lights up when:

The welding unit is connected to a mains adapter

The mains switch is switched on

Warning light – overheating of the power components

LED will blink when:

• The working temperature is 5°C before its critical limit is reached

• Advance warning that the welding process will be automatically

interrupted

LED is constantly lit

• Overheating temperature has been reached

• Before the welding process:

No welding process will be available until the unit has

cooled to a normal working temperature

• During the TIG welding process:

In 2-stroke and 4-stroke mode the welding current will be

reduced until it reaches the end currant. The welding

process will only be interrupted when the end current is

reached

With a foot control and an automated or robot unit the

program will be interrupted without the down slope

process being activated

Remote controls: if one of the following is in use: torch

trigger or foot control, the display panel will show the

following defect message, “release trigger”

• During the MMA welding process :

The welding process will be immediately interrupted

Defect warning light

This LED illuminates when there is a defect in the machine:

• Before the welding process has begun

No welding process possible

• During the TIG and MMA welding process

Welding process will be immediately interrupted

Warning lights and fault messages in the display unit

• “Release the trigger”

One of the following control elements is in use

Torch trigger, foot switch or control contact

• “Water pressure failure”

Flag Symbol

HOLD flag after the end of a welding process.

• The flag symbol shows the user that the welding parameters used

have been saved.

• The storage of the information is transient,

After an interruption the welding process will re-begin

with the same parameters.

Every parameter changed wipes the previously stored

parameter from the parameter settings.

The recalling of the previous weld settings through the

machine is then not possible.

• TIG welding parameters

The chosen parameters of the last used cycle before the

Down slope T

will be saved by the machines memory.

down

AC – Balance Scale

(The display is visible in conjunction with the TIG Modus function

“AC – Balance Amplitude”)

• The display is only visible in AC modus

• The vertical display represents the percentual share of the

positive half wave during the complete welding process (in

time).

• Indicator is positioned in the middle.

The positive and negative share of the wave is

identical.

• The indicator is positioned in the upper half of the scale

The positive half wave is larger than the negative half

wave

• Indicator in the lower half of the scale

The negative half wave is larger than the positive half

wave.

• One Pixel in the Horizontal translates to an adjustment of 3%.

2. TIG Welding

TIG Stands for Tungsten-inert-gas welding.

2.1 Process

A non consumable electrode made of tungsten or a tungsten alloy produces a welding arc. The

welding arc burns between the electrode and the work piece and is protected by an inert shielding

gas. The electrode and the molten pool are protected from the oxidising effects of the oxygen.

The inert gases used for this process are Argon; sometimes Helium or a mixture gas containing

both components can also be used.

The filler material is manually fed into the weld pool for manual welding process and mechanically

in the case of cold wire feed units.

2.2 Employment of the Process

The TIG process can be found employed joining foil and thin sheet together between 0.3 – 4.0mm

in one run, it is also used to join thicker pieces of material together (up to 12mm) when it can be

simultaneously welded from both sides. Thicker material would only be joined using the TIG

process when special technical demands dictate that TIG is the only process permit-able.

The TIG process produces a very high quality weld bead. The process therefore lends itself to

automatic welding as the process is easily controllable. In conjunction with special weld

preparations the process can be used on thicker materials for carrying out the root run. The

remainder fill and capping runs would be carried out using the MIG/MAG and Pulse-arc process.

2.3 Connection to the Mains

Mains connector

• Make sure that the machines main switch is in the “0” position

• The male connector is securely plugged into the correct mains current

Torch and hose assembly

• Combination connector (TGC-connector) must be connected to the minus pole (17)

connector.

• Turn the connector clockwise through 180

• The control socket should be connected plugged into socket 16 and secured using by

turning the twist connector until secure.

Earth return lead

• The earth return lead should be connected to the plus pole connector and turned

through 180º to secure.

• The earth clamp should then be secured to the work piece.

Gas bottle connection

• Lay the correct spanner for connecting the regulator within easy reach of the bottle.

• Remove the protective valve cap from the bottle.

• The gas valve should then be purged to remove all foreign bodies from the valve area.

• The gas pressure gauge connection should then be checked to see that it is also clean.

• The gas pressure gauge can now be screwed to the bottle and secured tightly using the

spanner. Make sure that the gasket ring in the valve nut is securely in place and not

damaged in any way. If so then replace with a new one.

º

to ensure secure connection.

2.4 Joint preparation

The TIG process requires that the weld joint is dry and free from grease and oil or any other sort of

dirt contamination. The necessary edge preparation depends on the thickness and the position of

the weld along with the job itself. These conditions are standardized in DIN 8552, part 1.

2.5 Gas nozzle and welding current

During the welding process using a shielding gas it is essential that the weld pool is covered with

the Argon gas and therefore protected from the harmful effects of contamination (oxidization)

from normal air in the shielding gas area. To guarantee such welding conditions the following

parameters must be finely tuned:

• Gas Flow

• Gas nozzle size

• Required welding current

Extreme care needs to be taken to avoid gas turbulence as this phenomenon has the undesired

effect of allowing air into the protective gas mantle.

Using a standard gas nozzle does not always guarantee turbulence free welding. Using the so

called “Gas lens” a special nozzle is used to allow the gas to flow freely without any turbulence.

The gas lens concentrates the gas flow in such a way that it allows a greater gap between the

work piece and welding torch. This in turn allows the tungsten electrode to be fixed with a

protrusion of up to 10mm outside the gas nozzle. This then allows the easy access of corners and

other difficult to get to joints.

Through a longer protrusion of the weld electrode the dead spot becomes smaller and the view of

the weld pool is greatly improved. The “gas lens” also allows under the same current conditions a

much reduced gas consumption.

Using the TIG process the optimal setting of the welding current is especially important; the end of

the tungsten electrode must be equally burdened:

• Using a current too low for the tungsten electrode, the arc is not able to cover the

complete tip of the electrode and therefore wanders on the tip and is not stable which

in turn affects the weld process.

• Contrarily the overloading of the electrode causes it to melt, so that tungsten can be

transferred to the weld pool. The inclusion of Tungsten in the weld pool is a weld

defect that should be removed and redone.

2.6 TIG mode (standard operation)

In the following chapter you will learn about how to operate the machine in the standard mode.

At the end you will be able to use machine in the standard TIG process and also correctly set your

own welding conditions.

2.6.1 Setting the welding current

Before the start of the welding process

• Select the required welding current through the incremental potentiometer dial (3)

• This indicated value is 100% and is displayed on the display in Amperes.

During the welding process

The operator has several methods available to adjust the weld current.

• Through the incremental potentiometer (3)

• Using a remote control unit;

Torch potentiometer

Hand remote control

Foot remote control

The current value set using the incremental potentiometer automatically determines the end value

for the hand potentiometer. During the welding process the display shows the value of the

condition set using the remote control system.

A change through the use of the remote control varies the welding current between 0% and 100%

in reference to the incremental potentiometer selected welding current.

The display shows the ampere value of the welding current.

Welding current after interruption

• Interruption <5 s:

The last selected conditions (on the incremental potentiometer or remote control)

would be reselected

• Interruption >5 s:(forced interruption)

The welding current will return to the value last selected through the incremental

potentiometer.

2.6.2 TIG welding application

2-stroke operation

During the complete welding program the torch trigger must be kept pressed, after the release of

the trigger the selected down slope program is engaged, after that the selected gas post flow.

• Select the F1 button on the front panel

• Torch trigger press and hold

The torch will ignite

The welding process will start with welding current I

1

• Release the torch trigger

The down slope LED will light up (I

LED extinguishes)

1

After the down slope program has run the LED will be extinguished

The welding program is ended

The gas test LED will light up

The gas post flow will now activate

Gas test LED is extinguished, the post flow gas is ended

Note: During the ending of the welding process in the 2-stroke operation, the end current I

end

is

not activated.

4-stroke operation

With the pressing of the trigger the start current (I

(t

) is introduced as programmed until the welding current has reached the requested setting (I1).

up

If the torch trigger is then pressed again then the down slope (t

current (I

) is reached. Once the trigger is then released the arc is extinguished and the post flow

end

) is activated, after it is released the up slope

start

) is activated until the end

down

gas is activated.

4-Stroke operation with a secondary pulse welding current I

2

The trigger functions are the same as in the standard 4-stroke operation. The only difference

occurs during the welding process whereby the quick pressing of the trigger activates the

secondary pulse current I

current (I

).

1

, a repeated pressing of the trigger then returns the original welding

2

If the trigger is depressed for longer than 0.5 seconds then the welding current down slope is

activated and followed by the post gas flow.

Manual Pulsing

• Press The torch trigger(TT):

Arc is ignited

The process is started with welding current I

I

-LED on display panel will illuminate

1

1

• Press TT and release (<0,5 s):

Current I

I

LED on display panel will illuminate (I1 LED will be extinguished)

2

will be activated

2

• Press TT and release (< 0,5 s)

Current I

I

LED on display panel will be activated (I2 LED will be extinguished)

1

will be reactivated.

1

• TT press and Hold ( > 0,5 s)

The down slope LED t

After the t

End current (I

sequence has run the t

down

) LED is illuminated and the end current is active

end

will illuminate on the panel (I1 LED extinguished)

down

LED will extinguish

down

• Release the TT

End current LED is extinguished

Welding process will be ended

Gas post flow LED will be illuminated

Gas post flow will be ended

Gas post flow LED will be extinguished

Gas post flow LED will be extinguished, the cooling process is ended

2.7 TIG Operation in standard mode

2.7.1 the DC welding mode

With the TIG process mostly high alloyed steels are welded, generally speaking steel and copper

can be welded with DC (direct) current. To avoid a critical thermal loading of the electrode, the

welding torch should be connected to the Minus pole and the earth return lead to the plus pole of

the machine. The temperature on the minus pole is ca. 3600°C, the plus pole is ca. 4200°C.

When welding with DC current the electrode must be ground to a sharp point. The ignition can be

realized with a torch angle of 15-25° from the vertical.

By using bad practise methods (electrode comes into contact with the weld pool) the weld bead

can become contaminated with tungsten inclusions, this is classed as a weld defect. When this

occurs the contaminated electrode end should be broken off and a new point ground on the

electrode.

Overview of the TIG DC mode

2.7.2 Alternating current (AC) welding mode

Using alternating current (AC) Aluminium, magnesium and their alloys can be successfully welded.

The thermal loading of the tungsten electrode is much greater in the AC welding mode. During

the half wave “electrode on minus pole” the work piece is warmed more than the electrode, during

the half wave “electrode on plus pole” the area around the welding arc is electronically stripped of

the surface oxides to allow problem free welding.

With the correct conditions obtained for this welding process the electrode will form a ball at the

end of the electrode.

Overview of the TIG AC mode

TIG mode in standard operation

The method of operation can be selected by pressing button F1 until the desired method appears

in the display.

2-Stroke operation (see also chapter 4.7.2)

• As long as the Torch trigger (TT) is depressed and held, the

welding process is active

• When the TT is released and the welding current down

slope is activated.

4-Stroke operation (see also chapter 4.7.2)

• By pressing the TT the welding current is activated

• By pressing and holding the TT, the down slope cycle is

activated.

4-stroke operation with a second welding current I

also chapter 4.7.2)

• Manual Pulsing between I

and I2

1

Ignition method, select by pressing F2 until desired method is shown in display

High frequency ignition

• The welding arc is ignited through a high frequency

impulse without the need for contact between the work

piece and electrode.

Lift arc ignition

• This function is only available in the DC mode

• Operational procedure:

Bring the electrode tip into contact with the work

piece

Press the TT and lift the torch away from the work

piece

The arc will automatically ignite

• The ignition is completed using minimal current.

(see

2

DC or AC welding process selected through the F3 button:

Direct current operation

Alternating current operation

AC Balance selected through the F4 button

AC balance amplitude

• The time difference between the positive and negative

half wave is represented as a percentage. The cycle time

and the frequency are not effected.

• The percentual part of the positive half wave within the

whole wave is shown on the display. The difference

remaining from the complete 100% is the percentual

measure of the negative half wave.

Display value shows 50%: the percentage time of

the positive and negative half wave are identical.

Display value shows 90%: the positive half wave

percentage is 90%, the negative half wave value is

10%.

Current setting I

and I2, these values can be set through the parameter button I1 and I

1

• Press button I

and with the incremental rotary switch

1

select the desired welding current

• Press button I

and with the incremental rotary switch

2

select the desired secondary welding current

2

3 Electrode Welding (MMA Welding)

3.1 Process

The Merkle inverter system produces a welding current with drastically improved harmonic

content that lends itself extremely well to the welding of coated electrodes and specialist

electrodes.

It is now true to say that just about all weld able metals can now be successfully welded using the

electrode process without the need for a protective gas.

3.2 MMA Preparation

In the following chapter we will explain how to connect each individual part to the machine in

order that MMA welding can successfully be carried out.

Mains connection

• Ensure that the machines main switch is switched to the “0” position

• Now connect the mains connecter to the mains supply socket

Please read the technical information on the information plate supplied on the machine.

Electrode holder

• The Electrode holder should be connected to the plus pole Busch of the machine (18)

• Insert the connecter and then twist clockwise until secure

• Always make sure that the information in the manufacturers safety data sheet is adhered

to

Earth return cable

• The connector for the earth return lead for electrode welding should be connected to the

minus pole of the machine (17)

• The earth clamp should be connected to the work piece

3.3 Operation procedure

In the following chapter you will learn how to set and use the machine in the electrode welding

(MMA) mode. You will be able to use the machine in the electrode program and select the correct

conditions for welding.

3.3.1 Display Details

Above is a typical view of the display panel before welding

3.3.2 Electrode welding mode

Electrode Mode Display (MMA welding)

MMA welding can be selected by pressing the F1 button until the symbol for MMA welding

appears in the display:

Electrode (MMA) welding

• The electrical circuit will be checked:

When the machine is switched on in the MMA mode

When the machine is switched from the TIG to the MMA

process.

• If the welding circuit is proved to be complete the warning

message “electrode is live”

Welding current and time parameters can be selected by pressing the F2 button until desired

setting is displayed.

Set the desired MMA welding current using the incremental

potentiometer (3)

Hot start current

• For a guaranteed ignition of the MMA electrode

• The Hot start function increases the start current (I

predetermined time (T

) therefore ensuring that a smooth start

hot

is achieved to the welding process.

Hot start time

• Shows the time that the increased current will flow for.

Arc Force (current control regulation)

• Should the electrode come into contact with the weld pool

during the welding process an increase the welding current will

automatically take place.

• This form of current regulation ensures that the welding

electrode does not stick to the work piece.

Should this still occur then the current will automatically be

reduced in order that the electrode does not overheat.

Adjustment range:

Minimum current is the welding current I

The maximum current available is a maximum of 250% of

the current I

EL

The max. current value is determined through the machine

version.

EL

) for a

hot

Welding current Polarity is selectable through the F3 button

Direct current process

MMA welding with reversed polarity

• Only available when the welding program is active

• Only available when the TEDAC face shield is not connected

Alternating current process

Display settings are selectable through the F4 button

Single display mode

• The display shows the actual welding current

Double display mode

• The display shows:

The first display shows the welding current

The second display shows welding voltage

3.4 Welding process

Before starting the welding process ensure that you are wearing the correct protective clothing.

Insertion of Electrode

• Ensure that the electrode is correctly inserted into the electrode; the uncoated end must

be clamped into the electrode holder jaw.

• The electrode holder must always be rested in/on an isolated station.

• The electrode will ignite should it come into contact with the work piece.

Welding current selection

The welding current can be set using the rotary incremental potentiometer

• Before setting your current value please read the guide table below;

Guidelines for El ectrode Welding

El ec trode size 2 2,5 3,25 4 5 6

Current Reading 40-80 60-100 90-150 140-240 170-240 25 0-300

4. TIG – Expert Mode

Your welding machine is actually capable of a lot more than has been explained. To enable the

further functions the machine must be switched from the standard mode to the Expert mode. The

instructions on how to switch over to the expert mode is described in chapter 7. In the expert

mode the welder has the capability of further adjusting the welding parameters in 5 sub-menus;

this enables an optimum setting of the welding parameters.

• TIG Menu selection:

Press menu button 1

Sub-menu “1. Pulse Menu” is now active

Continue to press button 1 until the desired sub-menu is reached

Exiting the TIG menu is achieved by going through all the available sub menus to

the beginning or simply by pressing by pressing button I

The software will return to the last used welding programme.

.

1

Automatic Pulsing (only available to in the expert modus)

Slow Pulsing (Available in AC and DC mode)

• Using the menu button select 1: Pulse menu

Using button F1 select slow pulsing

With button F2 select the time for t

1

Using the incremental potentiometer select the time value for current I

Using button F3 select time for t

2

Using the incremental potentiometer select the time value for current I

• Button F4 is used to select the required wave form:

Hard wave form

Soft wave form

• TT press and hold

Arc ignition

Welding process starts

Welding current I

I

-button LED and I2-button LED illuminate alternately

1

and I2 pulse in the pre-programmed time

1

Quick Pulsing (only available in DC mode)

• Using the Menu button select 1. Pulse menu:

Using F1 select quick pulse mode

With the incremental potentiometer set the desired pulse frequency

Current I

and I2 will alternate at the desired pre-programmed frequency

1

1

2

TIG Menu Expert Operation

1. Pulse Menu

• Not available in the pre-programmed “4 stroke with I2” in standard mode

• Through the continuous pressing of button F1 you can select:

No pulse operation

Slow pulsing

• In the left hand side of the display panel this will appear

• Both LED’s (I

and I2) will alternatively illuminate

1

Further adjustments:

• The wave form can be selected using the F4 button

Soft wave form

Hard wave form

• Time adjustment (t

) of the welding current I1

1

Select time t1 using the F2 button and adjust using the incremental

potentiometer

• Time adjustment (t

• Select time t

) of the welding current I2

2

using the F3 button and adjust using the

2

incremental potentiometer

Quick Pulsing (only available in DC mode)

• Pulse frequency is set through the incremental potentiometer

• In the display panel this symbol will appear

• Both I

and I2 will illuminate constantly

1

• The display will show the pre-programmed pulse frequency

• Both welding currents (I

and I2) will alternate at the set pulse

1

frequency

Spot time

• Spot time value is set using the incremental potentiometer

• In the left hand side of the display panel this will appear

• At the end of the spot time welding phase the welding process

must be restarted

• The welding process can be stopped at any stage of the welding

process

The time value of the welding current I1 can be set using the F2 button:

Time value of welding current I

1

• Set time value on the incremental potentiometer

• During time t

current I1 is in operation

1

• Only selectable in the slow pulse mode

The time value of the welding current I

can be set using the F3 button:

2

Time value of welding current I

2

• Set time value on the incremental potentiometer

• During time t

current I2 is in operation

2

• Only selectable in the slow pulse mode

Wave form selection is achieved through the pressing of the F4 button

Soft flank wave form

• Only available in slow pulse

• The alternating between pulse currents I1 and I2 follows

continuously. This prevents the build-up of noise in the arc

during slow arc.

Hard Flank wave form

2. Start Menu

Gas pre flow time is selected using the F1 button

Start current is selected with the F2 button:

Up-slope time is selected with the F3 button

• Only available in slow pulse mode

• The alternating between the active current s I1 and I2 has a very

abrupt action.

• The gas pre-flow time (t

) is set using the incremental

gas

potentiometer

• The start current (I

) is set using the incremental potentiometer

start

• The up-slope time is set using the incremental potentiometer

• Cross-over time (t

welding current I

1

) from the start current (I

up

) to the main

start

Only active when no pulse program is in operation.

Display setting through the use of the F4 button

Single display-screen

• No Pulse program activated:

The display shows welding current I

• When Pulse mode is activated :

Shows the I1 and I2 alternatively

Two row display screen

• No Pulse mode activated:

The first row will show the welding current and the

second row will show the welding voltage

• Slow Pulse is activated:

The first row shows the current I

The first row shows the time t

• Fast Pulse is activated (only in DC mode):

The first row shows the current I

1

and the second I2

1

and the second t2

1

and the second I2

1

3. DC Menu

Ignition pulse adjustment is selected with the F3 button

Positive ignition pulse

• Using the incremental potentiometer select the desired start

current

Ignition Pulse time

• Using the incremental potentiometer select the desired pulse time

AC Menu

AC frequency is selected with the F1 button

• The welding frequency is set using the incremental potentiometer.

The AC frequency had a large effect on the weld bead and the arc

noise. With currents larger than 100 A it is recommended that a

frequency of 50 Hz is used in order that the amplitude of the weld

arc is kept to a minimum.

Wave Form is selectable through the pressing of the F2 button

Square wave form mode

Sinus wave form mode

Mixed wave form

Ignition pulse setting is with the use of the F3 button

Positive ignition pulse current

• Using the incremental potentiometer set the current value

Ignition Pulse time

• Using the incremental potentiometer set the time value

AC balance can be selected with the F4 button

• Amplitude proportion can be set using the Incremental

potentiometer

• The time percentage of the positive to negative half wave must be

set. The complete time and therefore frequency cannot be

changed.

• The figure in the display shows the percentage time of the

positive half wave in a total period length. The difference

between the shown value and 100% automatically gives the value

of the negative half wave.

The display shows a figure of 50%: the time percentage

of the positive and the negative half wave are identical.

Display shows 90%: the positive half wave is 90% and the

negative half wave is 10%.

4. Job Menu Be Aware:

The availability of the Job menus is dependant on the setting of

the set-up menu.

• The number of job programming space available is dependant

memory capacity

• A upgrading of the memory capacity is an option that is also

available.

The are different ways to select the memory banks

• Using the menu button on the control board:

4. Job selection

Using the incremental potentiometer select the

available memory space.

• Torch with two triggers

select the memory banks by pressing the second

trigger

this process is only available when no welding

program is active

Save to memory the actual welding parameter

• Using the incremental potentiometer select a memory space

the memory number will show in the display

• To save the program press F1

• A successful programming will show itself through:

a brief showing of a tick

number

the flag on the right side of the display (square

with a program number in it)

• The welding parameters are now saved to chosen program number

• The old program details (if the program was previously used) will

be overwritten and removed from the memory banks

• After exiting the menu this job program will be available to the

user as a welding program

Loading the selected job number with the saved parameters.

• Using the incremental potentiometer select the desired program.

The job number will show in the display

• To load the saved condition press F2

the flag

• The set parameters are now set for use as a welding program

• Should the operator change any part of the program during the

welding process:

the program number

from the display panel

will show in the right hand side of the screen

in the square will extinguish

next to the program

the flag

the operator is not working with a saved job

Removal of the parameters of a saved job

• Using the incremental potentiometer select the desired program

(the program number will show in the display)

• To remove the program press F3

the display will then ask you to confirm the removal of

the program

Removal

using F4 confirm the removal program

the program has been removed

the program will then return to the job-menu

Cancellation

by using the F2 button the removal can be cancelled

the job will remain as the job no originally

programmed

the program will return to the job-menu

will replace the program flag to show that

• After the successful removal of a saved program a tick will

appear for a short time next to the program number

• The removed program space will be replaced by a basic program

• The restoration of removed programs is not possible

Shows in an automatic run through, the saved program conditions in

the display panel

• Using the incremental potentiometer select a program space

• To start the automatic run through press the F4 button

• The amount of conditions shown depends on the amount of

conditions that have been saved

5. Electrode Menu

Electrode (Tungsten)

• Using the Incremental potentiometer select the desired electrode

size

there are six pre-programmed sizes to choose from

• with inconsistencies between the size of the needle and the

selected current value:

the flag

display

the welding process will not be interrupted

• The flag shows that the welding conditions chosen for the

electrode are not recommended conditions

Confirmation flag

• A short period of blinking at the end of programming shows that

the machine has confirmed the changing of the welding

conditions

• Shown by the confirmation button after the entering of the PIN

code

• Shown by the confirmation button when removing welding

parameters from a set program

Shows discrepancies between the chosen welding current and the

electrode size

• The program shows a condition that is not recommended for this

welding program

• The welding process will not be affected

The flag shows which version of the set up menu is in operation

• Full version: the flag will appear in the display during the switch

on phase

• Standard version: no fag will appear in the display when

switching the machine on

will appear in the right hand side of the

The slow pulse flag

• Shows that a slow pulse program has been selected

Fast pulsing flag

• Shows that a fast pulse program has been chosen

Flag for spot welding

• Shows that a spot welding program has been chosen

5. Set-up Menu

•

Select the set-up menu:

Switch the mains switch to position “I” and at the same

time press and hold the menu button (1) until the menu

button LED lights up

The set-up menu is exited when the menu button is

pressed

The software will return to the last used program

Set-up menu display panel

Language selection

Using F1 select the desired language

• German, English, Portuguese, Hungarian and Russian languages

• Further language options are available on consultation with

Merkle

Menu Version

Using F2 the operator can choose between the expert menu and the

standard menu

• Standard version:

Digital display shows text “Menu disabled”

the menu button has no function

• Expert version

the flag

shows on the left hand side of the display

using the menu button the complete range of parameter

menus is now available

Security features

Using the F3 button select the security code function

• Security code function protects the machine from use by

unwanted parties.

PIN-code programming

Warning: write down or remember your selected PIN-code

• The display will show “old PIN code” in display

• enter the old PIN code into the machine using the incremental

potentiometer and confirm with the button under the arrow

symbol

• Select “new PIN-code” in the display

• Enter a new PIN-code and confirm the new code by pressing the

button under the arrow symbol

Security code active

• After the machine has been switched on enter the correct PINcode

• After the code has been accepted the machine is ready for use

Correct code entered

The software will start in the last programmed mode with all the

parameters that were available during the last active phase of the

machine.

Wrong code entered

Operator will be asked to re-enter the correct code

Pin-code inactive

• After the completion of the switching on process the machine is

ready to use.

• The software will start in the last chosen mode with the

parameters that were active at the time of switching off

Job setting

Using the button F4 activate the job-menu

Job function active

• Only available in the TIG expert mode

Job function is inactive

In the TIG expert mode the job is not selectable

If the Job-menu is not activated in the set-up menu then the expert mode cannot be selected

6. Parameter adjustment range

min = minimum s = seconds Hz = Herz

max = maximum A = Ampere

def = default (basic program) ms = milliseconds

Description Short cut Adjustment

range

Hand welding arc

Electrode welding I

EL

min 20 A

def 120

max 150

Hot-Start time t

hot

min 0,01 s

def 10

max 200

Arc force Arcf min 100% % (respective

def 150%

max 250%

Anti-stick-current def 40 A

Anti-stick-time def 1 A

Ignition time min 2 ms

def 10

max 100

TIG-welding

Start current I

start

def 20 A

Main welding current I

1

min DC 3 A

min AC 5

def DC 100

Secondary welding current I

2

min 10 % (respective

def 50

max 200

End current I

end

def 20 A

AC Balance min 9 % (respective

def 40

max 91

Sinus Balance Min 20 %

max 80

Adjustment

value

Unit measure

)

I

el

I

)

el

Frequency)

Description Short cut Adjustment

range

Adjustment

value

Unit measure

Ignition pulse current min 20 A

def 80

max 150

Slow pulse time t1 for main

t

1

min 10 ms

welding current

def 500

max 2500

Ignition pulse current 2 t

2

min 10 ms

def 500

max 2500

Pre-flow Gas t

gas

min 0 s

def 0,4

max 2

Post flow gas t

gas

min 0 s

def 10

max 25

Up slope time t

up

min 0 s

def 0,4

max 2

Down slope time t

down

min 0 s

def 2

max 25

AC Frequency (Hard and mixed

min 50 Hz

wave)

def 100

max 200

AC-Frequency (Sinus-Mode) fix 50 Hz

Pulse Frequency DC min 50 Hz

def 2000

max 5000

7. Trouble shooting

You will receive an overview of all possible faults . The messages in the display screen are mostly

self explanatory and easily eliminated.

• Text in the display panel

•

Warning lights on the display panel

We have added a further category to our trouble shooting chapter, that of human error. Hear we

have covered things that the operator may not have thought of before stating the welding process.

Important:

After each fault report and trouble shooting the machine must go through a complete restart in

order to reset the machine.

When the machine is switched off the operator must wait at least 3 seconds before restarting.

Failure in Display Cause Action Required

Release trigger/button Torch trigger activated

Release trigger/button

Foot switch activated

Control button activated

Over voltage Internal voltage supply Notify service agent

Mains failure Notify service agent

Electrode earthed

The electrode has earthed and

caused a complete welding

Elektrode aus dem Stromkreis

entfernen

circuit

When switching from TIG to

electrode mode

When switching on the

electrode mode

Electrode failure The relationship of the chosen

electrode diameter to the

chosen current setting is

wrong

“Low water pressure”

Alternating with

- No water pressure after

the self testing phase

“Refill water” and

Failure LED is blinking

- Select another electrode

diameter

- Change the current to suit the

electrode.

- Check water levels and refill as

necessary

- Check that the water pump is

functioning

- Check the complete water

system

- After the problem has been

repaired restart machine

“Internal failure” Internal machine problem Notify service agent

NTC failure Internal machine failure Notify service agent

Failure in Display Cause Action required

Menu locked This function is dependant on

the machine model

Electrode overload

Elektrode is Cold

Over temperature light

flashing

Working temperature is 5°C

before reaching over

temperature

Over temperature light

illuminated

Welding machine is over

heated

Failure illuminated Mains over voltage/under

voltage

Press and hold the menu button

when switching on the machine,

release when button flashes

- No action required

- Welding Process possible

- Leave the welding machine

switched on

- No welding Prozess possible

- Automatic cooling system will

engage until working

temperature is reached.

Warning light will extinguish

and welding process can be

restarted

Test mains connector on another

connection point

Check Fuses

Failure flashes and the

display shows alternately

“water pressure failure”

and “refill water”

No arc ignition

The MMA mode is not

selectable and switches

automatically over to TIG

mode

Switch the machine off and restart after 3 seconds

Carry out instruction

Pre-flow gas is et too high Reduce pre-flow gas setting

Start current too low Increase the start current setting

No gas shield Gas line and bottle need to be

checked for fault

The electrode has contacted

to earth and caused a

Remove the electrode from the

circuit

completion of the welding

circuit

Other observations Cause Action required

Shielding gas flow

Gas bottle empty Gasflasche erneuern/austauschen

interrupted

Flash back arrester activated Reset flash back arrester

Pressure gauges set too low Increase setting

Torch shroud blocked Clean torch shroud

Gas line kinked and damaged Replace or repair gas line

Main fuse defect Change the main fuse The machine will not

switch on

Internal current safety system

Notify service agent

active

Torch trigger has no

function

Torch Potentiometer not

functioning

In 4-stroke mode the

current I

is not selectable

2

By MMA welding the

polarization cannot be

reversed (-DC)

Control method is set to foot

De-activate the foot control

controller

Hand- / Foot regulator

De-activate hand- / Foot regulator

connected

Foot regulator is connected De-activate the foot regulator

Only AC versins of this

Check the model type

machine offer this program

Einstellung

TEDAC shield is not

Remove TEDAC shield

recognised by the program

In Expert mode the sub

menu “Job” is not

Job Menu deactivated Select set-up menu and re-

activate Job Function

selectable

The machine becomes

warm very quickly even

Cooling fans are turning in

the wrong direction

Notify service agent

though the cooling fans

are functional

8. Servicing

The servicing schedule of the machine consists of a regular program of thorough cleaning and

inspections. The regularity of these programs is directly linked to the usage and the working

conditions of the work place.

WARNING

Cleaning:

• De-greasing agent: only de-greasing agents recommended for electronic equipment may

Inspection:

: before the any inspection or cleaning of the machine is undertaken:

• The time required to discharge the electrolytic capacitors must be adhered to,

approx 30 minutes.

• The machine must be disconnected from the mains supply

• Allow the machine to cool down.

be used on this machine

Remove top cover

Dirt and dust to be removed with a vacuum cleaner

Clean inner components

Replace top cover and secure

• Remove top cover

• Check the equipment for

Used and discarded pieces of welding wire

Loose connections

Where necessary repair any problems

• Check the torch and hoses along with the euro connector for :

Any areas that appear to have been damaged

Where possible repair

• Replace and secure top cover

9. TIG hand welding torch - and spare parts

9.1 TIG Hand Welding Torch Model TH 201 G

gas cooled, with Merkle TCG connector

Technical data:

Cooling: gascooled

DC range: 200 A, 40 % ED

AC range: 180 A, 40 % ED (at 30 % positive polarity)

Tungsten electrodes: 1.0 – 2.4 mm ∅

Weight: 230 g

without hose assembly

TIG Hand Welding Torch, Model TH 250 G, gas cooled

Pos. Description Part No._

TIG hand welding torch TH 201 G, 4 m 114.144

with Merkle TCG connector

leather/fabric hose assembly

TIG hand welding torch TH 201 G, 4 m 114.146

with Merkle TCG connector

leather/fabric hose assembly

TIG hand welding torch TH 201 G, 4 m 114.148

with Merkle TCG connector

and potentiometer,

leather/fabric hose assembly

With Euro Connector:

TIG hand welding torch 114.150

model TH 201 G-EURO, 4 m

with Euro connector,

leather/fabric hose assembly

TIG hand welding torch 114.152

model TH 201 G-EURO, 8 m

with Euro connector,

leather/fabric hose assembly

TIG hand welding torch 114.154

model TH 201 G-EURO, 8 m

with Euro connector and potentiometer

leather/fabric hose assembly

TIG hand welding torch 114.156

model TH 201 G-MAG, 8 m

with MIG/MAG Euro connector

for PU 300 K

leather/fabric hose assembly

Standard equipment: 2,4 mm, ceramic 10.0

Spare parts and consumables:

Pos. Description Part No._

3.1 Tungsten-electrode, grey min 10 pcs 013.0.0111

1.0 x 175 mm

3.2 Tungsten-electrode, grey min 10 pcs 013.0.0112

1.6 x 175 mm

3.3 Tungsten-electrode, grey min 10 pcs 013.0.0113

2.4 x 175 mm

8.1 Back cap "quick TIG" 1.0 mm, long 114.184

TH 161/201 G

8.2 Back cap "quick TIG" 1.6 mm, long 114.186

TH 161/201 G

8.3 Back cap "quick TIG" 2.4 mm, long 114.188

TH 161/201 G

9.1 Back cap "quick TIG" 1.0 mm, short 114.190

TH 161/201 G

9.2 Back cap "quick TIG" 1.6 mm, short 114.192

TH 161/201 G

9.3 Back cap "quick TIG" 2.4 mm, short 114.194

TH 161/201 G

10 Torch neck TH 161/201 G 114.196

11 O ring 9 x 1.5 min 10 pcs 022.1.0704

12.1 Ceramic nozzle 6.5, TH 161/201 G, min 10 pcs 104.260

TH 170/250 G, TH 450/451 W

12.2 Ceramic nozzle 8.0, TH 161/201 G, min 10 pcs 104.262

TH 170/250 G, TH 450/451 W

12.3 Ceramic nozzle 10.0, TH 161/201 G, min 10 pcs 104.264

TH 170/250 G, TH 450/451 W

12.4 Ceramic nozzle 12.5, TH 161/201 G, min 10 pcs 104.266

TH 170/250 G, TH 450/451 W

12.5 Ceramic nozzle 15.0 min 10 pcs 104.268

TH 250 G, TH 450/451 W

Pos. Description Part No._

Options for gas lense operation:

13 Gas lense for 114.214

TH 161/201 G TH 451 W

29 Adjustement wheel incl. 108.354

potentiometer for TH torch

31 Handle TIG torch, right and left 108.368

side (delivered without ball joint)

33 pc board for TIG double button 107.992

switch (for torch with ball joint)

34 Switch button (red) 107.994

for TIG torch with ball joint

35 Handle TIG torch, right and left 107.988

side (delivered without ball joint)

37 Ball joint for TIG torch handle 107.996

gas cooled incl. fixture nut

44 Merkle TCG connector plug 109.554

(gas cooled) incl. rubber housing

an 2 o-rings

45 O-ring 8 x 1.6 min 10 pcs 103.544

47 Round plug 5-pole for TIG torch 021.1.0380

(standard)

50.1 Power cable 4 m TH 201/250 G 106.868

50.2 Power cable 8 m TH 201/250 G 106.872

50.3 Power cable 8 m TH 201/250 G-MAG 107.048

51.1 Control cable 3 x 0.5 LiYY min 50 m 107.646

no shield

51.1 Control cable 3 x 0.5 LiYY 107.646

no shield

51.2 Control cable 5 x 0.5 LiYY min 50 m 107.242

no shield

51.2 Control cable 5 x 0.5 LiYY 107.242

no shield

54.1 Protection hose 4 m 114.332

leather/fabric for TIG torch

54.2 Protection hose 8 m 114.334

leather/fabric for TIG torch

58.1 Cable assembly 4 m, TH 201/250 G 106.866

incl. Merkle TCG connector,

control cable 3 x 0.5

58.2 Cable assembly 8 m, TH 201/250 G 106.870

incl. Merkle TCG connector,

control cable 3 x 0.5

Pos. Description Part No._

58.3 Cable assembly 8 m, TH 201/250 G 106.871

incl. Merkle TCG connector,

control cable 5 x 1.5

Cable assembly with Euro connector:

62.1 Brass body for TIG Euro connector 013.4.0048

incl. nut 5/8"

62.2 Brass body for MIG Euro connector 025.1.1401

incl. nut 5/8"

63 Euro adapter nut 025.1.0300

64.1 Kinking protection at machine side 013.4.0049

TIG Euro connector (set 3 pieces)

64.2 Kinking protection at machine side 025.1.1300

MIG Euro connector (set 3 pieces)

65 Round plug 5-pole for TIG torch 021.1.0380

(standard)

66.1 Cable assembly 4 m, TH 201/250 G 108.504

incl. Euro connector,

control cable 3 x 0.5

66.2 Cable assembly 8 m, TH 201/250 G 108.506

incl. Euro connector,

control cable 3 x 0,5

66.3 Cable assembly 8 m, TH 201/250 G 108.507

for torch with potentiometer

incl. Euro connector,

control cable 5 x 0.5

66.4 Cable assembly 8 m, TH 201/250 G-MAG 107.047

incl. Euro connector,

control cable 3 x 0.5

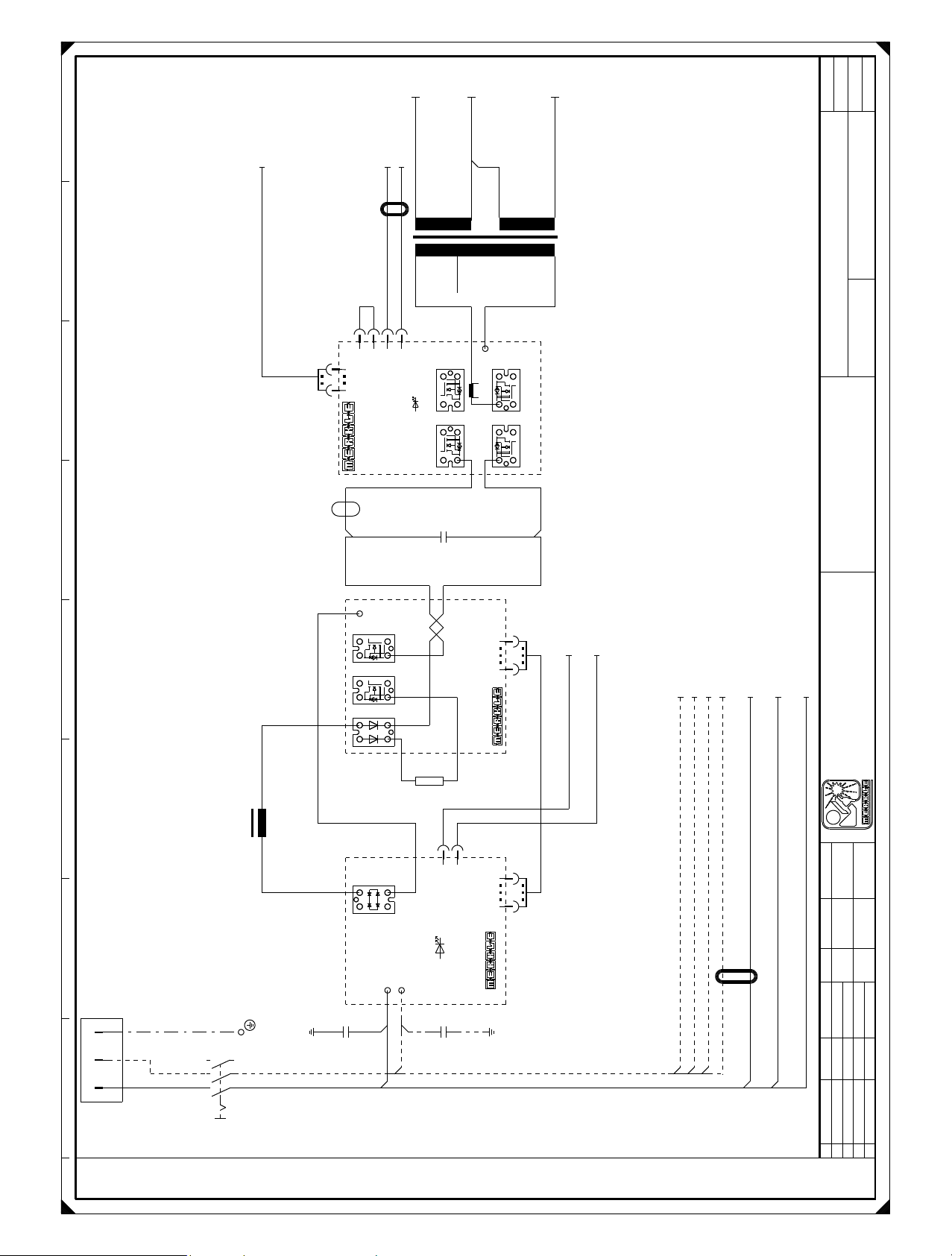

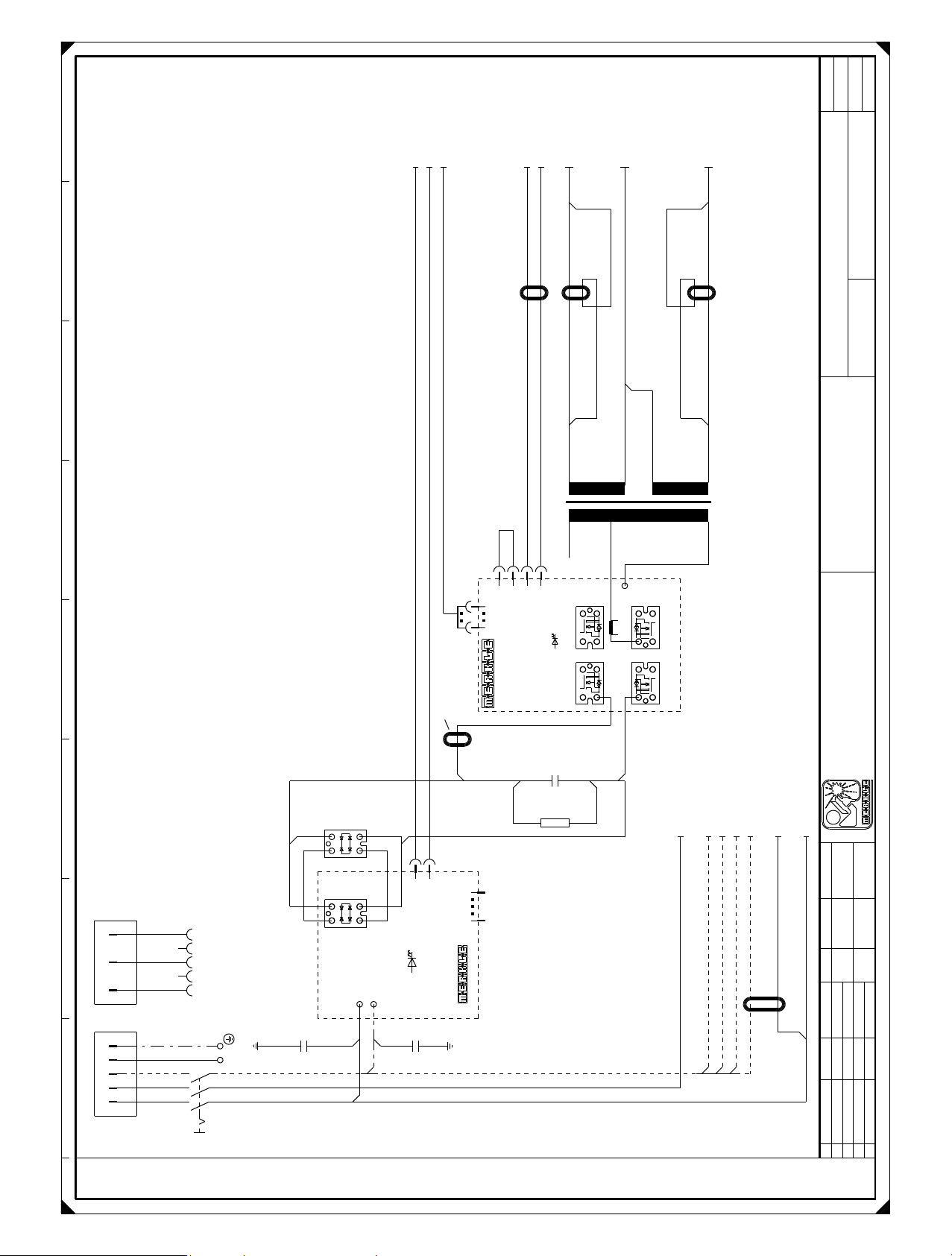

10. Wiring diagram LogiTIG 200/240 AC/DC

3/2.1

2/2.1

1/2.1

=

INV

+

1

Blatt

Bl.

4

+SQ-A3-X5/3.7

#447

Ferritring

ferrit ring

8 Windungen/

8 turns

+385V

+SQ-A4-X4:15/3.3

4 turns

Ferritring

ferrit ring

4 Windungen/

gr-sw

rt-sw

3

2

1

123

61

X3

X4

-A5

ME-I3-PSR-1.0

+SQ-A4-X4:16/3.3

3

2

45V45V

gr

310V

380V

4

4

12

4

-V7

3

Start

12

4

-V5

3

rt/2,5mm²

+

+

rt/2,5mm²

-C1

rt/2,5mm²

X1

2

3

4

3

4

1

0V

-V8

1 2

4x XFN44N50

-V6

1 2

bl/2,5mm²

bl/2,5mm²

bl/2,5mm²

-T1

Zeichnungsnr.

Projektbez.

Auftragsnr.

LOGITIG 200 AC/DC

Schweißstromkreis

X7

-V4

1

2

4

3

XFN44N50

1

2

-V3

4

3

XFN44N50

-V2

24

15k

-R1

230VAC

1

1

gn

bl

2

2

X4

Pr.DC.OK

3 1

DSEI2x61-06C

rt

+

+

~

~

-V1

4

1

sw/2,5mm²

-

-

2 3

~

~

VB040-08N06

-A1

X1

X2

-L1

ME-I3-PG-1.1

Erdungs-

PE

N

L1

1 2 3 4 5 6 7 8

schraube

L1 L2 L3

T1 T2 T3

-C2

0,022uF0,022uF

sw

bl

230V/50-60Hz/PE

+SQ

-Q1

110

-A2

X6

ME-I3-PFC-1.2

110

X5

-C3

+SQ-A4-X1:2/3.2

or-sw

#447

sw sw

+SQ-A4-X1:1/3.2

or-ws

+SQ-A4-X1:6/3.2

+OP1-X6:2/3.1

+SQ-M1/3.1

+SQ-A3-X2:1/3.5

bl

bl

bl

bl

Ferritring 8 Wdg.

ferritring 8 turns

bl bl

+OP1-X6:5/3.1

+SQ-A4-X1:8/3.2

sw

+SQ-A3-X2:3/3.5

sw

bn

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

Name

Konrad

Datum

11.04.06

gez.

gepr.

Name

Datum

20.11.07

Änderung

c

dab

Plotdatum:

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

42V~42V~

T70

+SQ

-A7

T0

D0

ignition generator

Zündgerät SIG 8.71/

DB

#433

-

+SQ-A4-X3:1/3.2

+SQ-A3-X11:4/3.5

+SQ

-X1

sw-gn

rs

rt

bl

sw/2,5mm²

#490

+

+SQ-A9-X4:1/4.7

+SQ-A3-X9:1/3.6

+SQ

-X2

bl

bl

+SQ-A3-X9:4/3.6

+SQ-A3-X4/3.6

rt

Ferritring

ferrit ring

8 Windungen/

#447

101

8 turns

bl

bl

rt

4

3

2

1

123

4

X4

ME-I2-WS-1.0

X1

UETWR

over temp

2

Bl.

INV

=

+

Blatt

4

+SQ-A4-X4:1/3.3

+SQ-A4-X4:2/3.3

+SQ-A4-X4:3/3.3

+SQ-A4-X4:4/3.3

ws-sw

ws-bl

ws-bn

ws-rt

1234

4 3 2 1

+

-

16

rtrtgn

Zeichnungsnr.

Projektbez.

Auftragsnr.

LOGITIG 200 AC/DC

X3 X2

1

-Z1

-A13

NTC montiert bei V12

SW/2,5mm²

ws sw

-R9

#447

rt

X8

X12X6X13

116

X1

NTCNTC

-V13 -V14

-A14

50W

-R5

-R6

3R3

bl bl

50W

X10

E2E2

X2

3

4

432

2

2

C2/E1 C2/E1

2

bl

1

1

X9

X4

X3

X5

X7

X11

ME-I3-WE-2.0A

Offset

1

1

Imax

-R7

1K0

rt

E1E1E2 E2

C1 C1

G2 G2G1 G1

-R4

3R3

3R3

50W

Schweißstromkreis

bl bl

bl bl

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

Name

Konrad

+SQ

2 Wdg.

2 turns

rt

+SQ-A9-X4:3/4.7

-L3

+SQ

sw/2,5mm²

sw/2,5mm²

2

+SQ

-L2

-R2

6,8R

-A11

X2

-V9

X4 X3

2

1

+

43

2

1

DSEI 2x61-06C

~

~

1

1

2

X1

43

ME-I3-SG-1.1+

-V10

-R3

6,8R

-A12

X2

4 3

-V11

X4 X3

-

1

2

DSEI 2x61-06C

~

4 3

~

2

1

1

2

X1

1

2

ME-I3-SG-1.1-

-V12

sw

ws

verdrillt

gnrtgr

1 2 3 4 5 6 7 8

Datum

11.04.06

gez.

Name

Datum

gepr.

20.11.07

2/1.8

1/1.8

3/1.8

+SQ-A3-X6:3/3.7

+SQ-A3-X6:2/3.7

+SQ-A3-X6:1/3.7

+SQ-A3-X6:4/3.7

Änderung

c

dab

Plotdatum:

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

=

SQ

+

3

Blatt

Bl.

4

+INV-A13-X2:1/2.6

+INV-A13-X2:4/2.6

+INV-A13-X2:3/2.6

+INV-A13-X2:2/2.6

ws-rt

ws-bn

ws-bl

ws-sw

+SQ-Q1:T2/1.1

+SQ-Q1:T3/1.1

bn

bl

+SQ-A5:X4

+INV-A13-X1/2.6

+SQ-A5-X3:4

+SQ-A5-X3:3

gr

gr-sw

-A6

bn-ws

#447

#447

ME-T4-Typ-1.1

1

X1

gn

10

1

87654321 654321

+SQ-A8-X5/4.7

+INV-A14-X2:1/2.3

+INV-A14-X2:2/2.3

+INV-A14-X2:3/2.3

+INV-A14-X2:4/2.3

sw

ws

gr

4

3

2

ISrtID

ge

110

4

X6

123

X4 X5

1 10 1 6

WD

gn

WK

gn

+60V

WD

0-45V

45V

X2 X3

230-B

230-N

1 2 3 4 5 6 7 8 1 2 3 4 5 6

WK-Rel

Lüfter

230V-A

21VAC

6

X1

65432

rt

0/21VAC

21VAC

5

4

+SQ-A8-X1/4.3

#447

#447

134

X15

X7

I>0

rt

ME-T4IF-1.3

WP

Not-Aus

-A3

HF

ge

rt

Stoe

rt

gn

Start

0/21VAC

11VAC

0-11VAC

1

2

3

1

Gas

Uist

X8

NTC

NTC

TH

TH

X9

+

-

42V-a

Gas

HF

X12

+24V

GND

+5V

NTC montiert bei V3

123412344321

sw

1234 56

4 3 2 1 6 5 4 3 2 1

X11

4 3 2 1

4 3 2 1

sw

-R8

+INV-A14-X3:2/2.4

+INV-A14-X3:1/2.4

rt

-Y1

bn-gn

Zeichnungsnr.

Projektbez.

Auftragsnr.

LOGITIG 200 AC/DC

Steuerung

3

2

1

2345678

1

21V

230V

4A

-F1

X1

8

7

8765432

sw

bl

1 2 3 4 5 6 7 8

+SQ-Q1:T1/1.1

vio-ge

vio-sw

gn-ws

8

7

6

5

4

21V

21V

0V

2

3

4

5

6

gr

or-sw

or-ws

+SQ-A1-X4:2

+SQ-Q1:T3/1.1

gn-sw

12

11

10

9

9

10111213141516

21V

21V

24V

10V

1

2

1

X2X4X3

1

M

-M1

+SQ-A1-X4:1

13

11V

-F2

1A

432

16

15

14

22V

45V

-A4

342

rs

PE

+SQ-A7:42V/2.5

1

1

gr

sw

Erdungs-

schraube

+OP1

-X6

bl

2

1

+SQ-Q1:T3/1.1

+SQ-Q1:T1/1.1

gn

bn

sw

ws

6

5

4

3

connection for

Option:

vio

watercooling unit

Wasserkühlgerätanschluß/

bl-rt

bl-ws

ge-sw

ge-sw

vio

bn

sw-gn

+SQ-A7:42V/2.5

+SQ-A8-X4:4/4.6

+SQ-A8-X4:3/4.6

+SQ-A8-X4:2/4.6

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

Name

Konrad

ge-sw ge-sw

Datum

11.04.06

gez.

gepr.

Name

rtblgnwsor

Datum

20.11.07

Änderung

+SQ-A8-X4:1/4.6

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

c

dab

Plotdatum:

+SQ-X2/2.8

+SQ-L3/2.5

4

Bl.

E

A

S

or

oder/

=

SQ

+

Blatt

4

rt

bl

4

3

2

1

4

3

2

1

-A9

ABCDE

ME-BT-4.0

bl-gn

bl-ws

bn-gn

4

5

6

65432

bn-gn

ge-rt

ge-sw

5

5

vio

X2

3

bl-ws

7

6

7

6

bn-ws

1

2

bn-ws

bl-gn

TEDAC-PWM(+)

TEDAC-IN(-)

X

torch poti

Brennerpoti/

110

X5

-A8

X

X

torch

BT2

switch 2

torch

BT1

switch 1

X

Gas

ME-TIG-4.3

end

I

down

t

or with torch poti

torch with 2 button

oder mit Brennerpoti/

Brenner mit Doppeltaster

Zeichnungsnr.

Projektbez.

Auftragsnr.

LOGITIG 200 AC/DC

Slave

1

X11

10

Test

1

X9

10

Frontplatte

-X5

54321

8

8

X4

234 1

X1

1

ws

vio

4 3 2 1

10 turns

#446 10Wdg.

432187654321

sw

1 2 3 410

X3 X4

1 2 3 4 5 6 7 8

+24V-Bn

Pwok-Or

GND-Gn

+5V-Rt

GND

10k-Poti

Fern/Netz

1 2 3 4 5 6 7 8

ABC

S

E A

control

hand remote

Handfernregler/

X10

X2

10

987654321

4321 5 6 7 8 9

Pol-Sync In

Pol-Sync Out

Robot-Ext

GND-Syn

GND-Rob

GND-Pot

Leit2-Poti

Leit1

+5V-Poti

Poti-Box on

341

X1

Menü

1 2 3 4

t1 t2

I1 I2

up

t

start

t

16 1

gas

t

X8

X8

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

1 6

#447

Name

#447

rt

gn

orbnbn

ws-sw ws-sw

gr

sw

bn-ws

vio

bl-gn

bl-ws

bn-gn

H

G

F

E

D

C

B

A

D

H

+SQ-A3-X12:4/3.4

ABCDE

+SQ-A3-X15/3.7

+SQ-A3-X12:3/3.4

+SQ-A3-X12:2/3.4

+SQ-A3-X12:1/3.4

S

E A

control

foot remote

Fußfernregler/

FT

-X4

J

I

F

G

electrode TEDAC

Elektrode TEDAC/

+SQ-A3-X7/3.7

Konrad

Datum

11.04.06

gez.

Name

Datum

Änderung

gepr.

20.11.07

c

dab

Plotdatum:

Vervielfältigung oder Weitergabe nur mit unserer schriftlichen Genehmigung gestattet

+SQ-A4-X1:2/3.2

+SQ-A4-X1:1/3.2

+SQ-A3-X5/3.7

or-ws

or-sw

4 turns

Ferritring

ferrit ring

4 Windungen/

+SQ-A4-X4:16/3.3

+SQ-A4-X4:15/3.3

3/2.1

2/2.1

1/2.1

1

SQ

=

+

Blatt

Zeichnungsnr.

Bl.

4

rt/2,5mm²

#447

Ferritring

ferrit ring

8 Windungen/

gr-sw

rt-sw

3

2

1

123

61

X3

X4

8 turns

ME-I3-PSR-1.1C/240

+310V

gr

4

4

-A5

rt/4mm²

+

+

Ferritring

ferrit ring

3

45V45V

380V

12

4

-V7

3

Start

12

4

-V5

3

2

310V

X1

3

4

3

IXFN55N50

4

bl/4mm²

1 2

1 2

2

Ferritring

-V8

-V6

ferrit ring

1

0V

-T1

Projektbez.

Auftragsnr.

LOGITIG 240 AC/DC

Schweißstromkreis

Merkle

Schweißanlagen-Technik GmbH

Industriestraße 3

D - 89359 Kötz

Telefon 08221 -915 - 0

Telefax 08221 - 32596

PE

N

L1

low power adapter

Low Power Adapter/

PE

L3

1 2 3 4 5 6 7 8

N

L2L1

High Power Anschluß/

high power connection

32A

PE

L3

N

L2L1

L1 L2 L3

Erdungs-

schraube

T1 T2 T3

-Q1

-