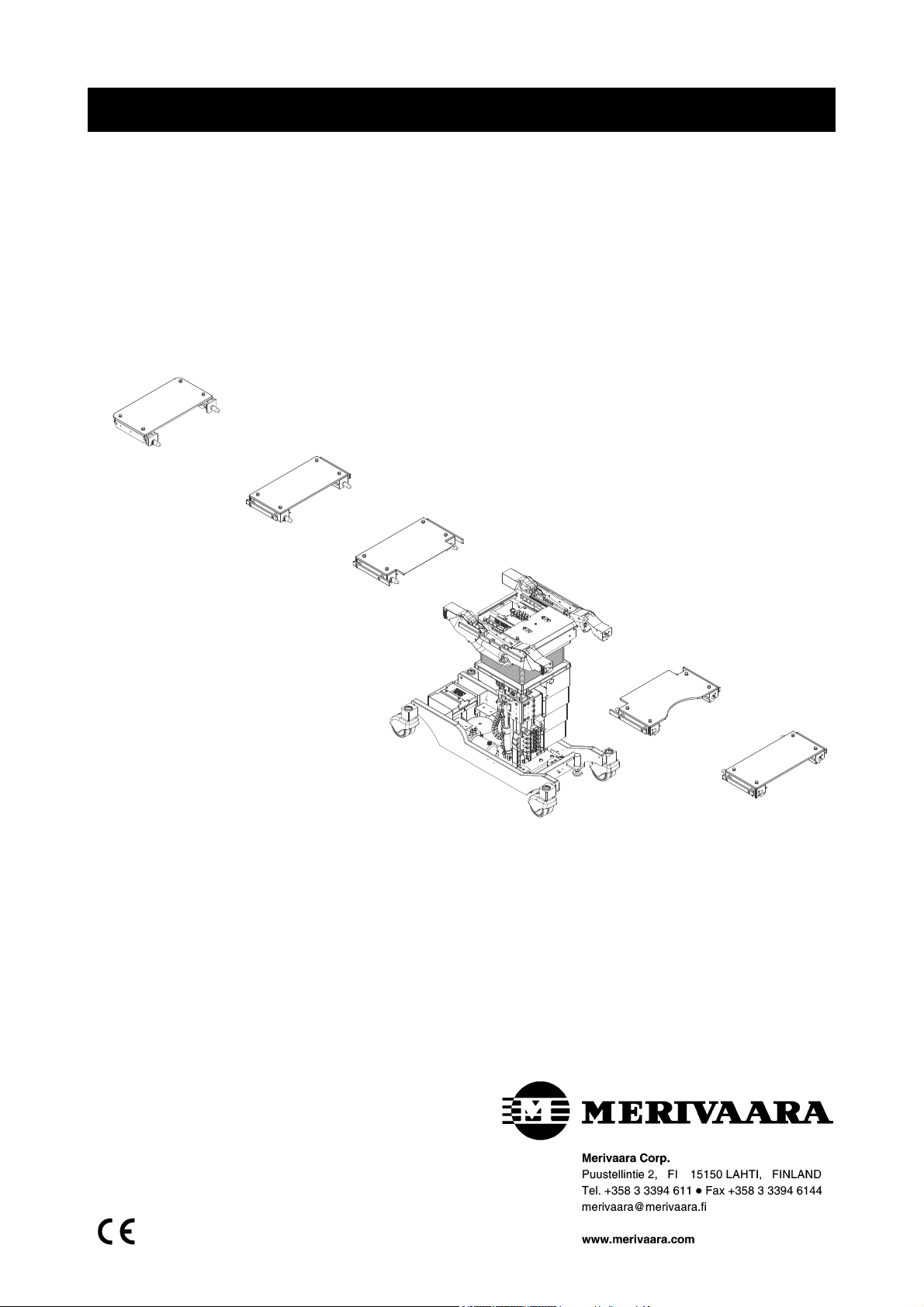

Merivaara PromeriX Service manual

MAINTENANCE MANUAL

PromeriX operating table

Type: Instructions Complete: 13.3.2007

Document: DO1085-2-2.en Version: 2-2 29.1.2009

1 WARNINGS, NOTES AND INSTRUCTIONS 5

2 GENERAL 10

2.1 Intended use 10

2.2 Operating characteristics 11

3CLEANING 12

3.1 Cleaning instructions 12

3.2 Cleaning 12

3.3 Disinfection 12

3.4 Mattresses and pads 12

4 MAINTENANCE INSTRUCTIONS 13

4.1 Safety during maintenance procedures 13

4.1.1 Daily service 13

4.1.2 Monthly service 13

4.1.3 Annual service 14

4.2 Troubleshooting and checklist 14

5 TECHNICAL DATA 18

5.1 Identification plate 18

5.1.1 Illustrated designations and symbols 18

5.2 Properties and materials 19

5.2.1 Surface materials 19

5.3 Specifications 20

5.3.1 Environmental specifications 20

5.3.2 Electrical specifications 20

5.3.3 Classification data 20

5.3.4 Adjustment ranges 21

5.3.5 Weights and dimensions 21

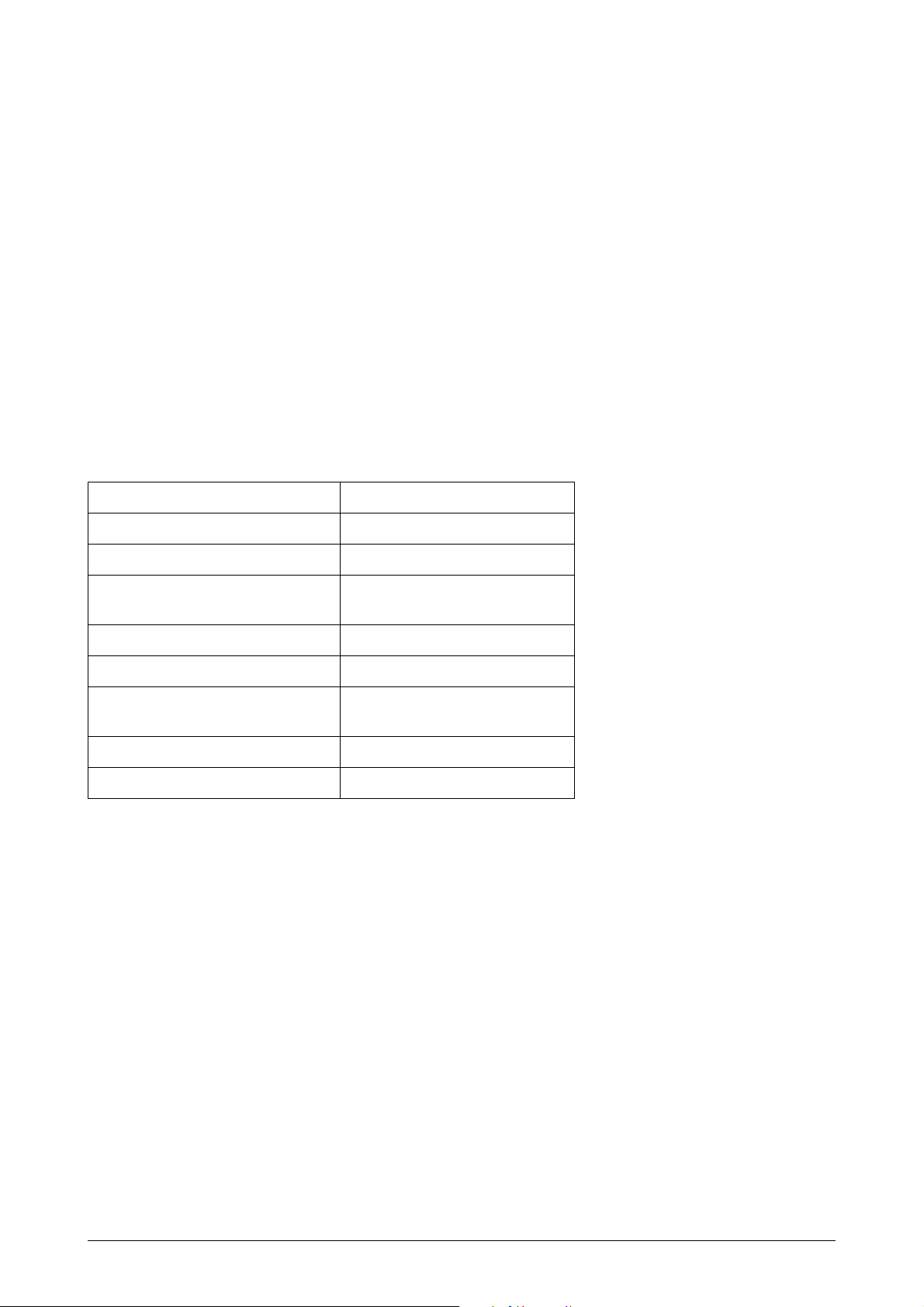

6 MAIN COMPONENTS 22

6.1 Structure 22

6.2 Removal of casings 23

6.2.1 Table base casings 23

6.2.2 Column casing shrouds lifted up 23

6.2.3 Removing the column casings 24

6.2.4 Replacing castors 24

7ELECTRONICS 25

7.1 Special user attention 25

7.1.1 Warnings 25

7.1.2 Block diagram 26

7.2 Battery 27

7.2.1 Replacing the battery 27

7.2.2 Battery charge 27

7.2.3 Storage of batteries 28

7.3 Power supply unit 28

7.3.1 Specifications 29

7.3.2 Replacing power supply 29

7.4 Mains fuses 30

7.5 Hand control units 31

7.5.1 Hand control unit MV-CUC01 31

7.5.2 IR-remote controller unit MV-CUI01 31

7.5.3 Device address programming 32

7.5.4 IR-remote control programming sequence 32

7.5.5 IR-receivers 33

7.6 Override panel MV-CUO 01 33

7.7 Foot switch 34

7.8 Level sensor 34

7.9 Inductive sensor 35

7.10 Wire sensors 35

7.11 Sensor connections 36

7.12 Motion Process Controller MV-MPC01 37

7.12.1 General 37

7.12.2 Communication 37

7.12.3 PC connection 37

7.12.4 Connectors 37

7.12.5 Cables 38

7.12.6 MPC connections 38

7.13 Solenoid pin connector configuration 39

8 HYDRAULICS 40

8.1 Safety information 40

8.1.1 Lift column 40

Compiled by: Harri Uusitalo

Approved by: Arto Koski-Laulaja _______________________________________ Date: ___ . ___ . _______

8.1.2 Warnings 40

8.2 Hydraulic unit 41

8.2.1 Removing the hydraulic unit 42

8.2.2 Hydraulic oil 42

8.3 Main valve block TLC3 43

8.3.1 Hydraulic circuit diagram 44

8.3.2 Substitution of TLC3 manifold 45

8.3.3 Exchange of TLC3 valve 47

8.3.4 Changing of solenoid coil at SP1 and TLC3 (valve system) 49

8.3.4.1 Remove the housing of the solenoid 49

8.4 Cylinders 50

8.4.1 Distribution block of table with sliding function 50

8.4.2 Distribution block of table without sliding function 51

8.4.3 Cylinder types 51

8.4.3.1 Leg and back section cylinder hose connections 51

8.4.3.2 Height cylinder connections 52

8.4.3.3 Trendelenburg cylinder connections 52

8.5 Floor lock cylinder type LF16 53

8.5.1 Connections 53

8.5.2 Cylinder type 53

8.5.2.1 Features 53

8.5.3 Floor lock support leg adjustments 54

8.5.4 Pressure switch and SP1 valve block 54

8.5.5 5th wheel cylinder block connection diagram 55

8.6 Seat section joint shields 56

8.6.1 Replacing joint shields 56

9RECYCLING 57

9.1 Metals and plastics 57

9.2 Hydraulic cylinders and gas springs 57

9.3 Oil 57

9.4 Electronic waste and batteries 58

ORDER FORM 59

NOTES 60

In order to ensure optimal surgical safety, all operating table users should carefully read the operating table

1. WARNINGS, NOTES AND INSTRUCTIONS

!

!

!

!

!

!

!

!!!

!

!

and maintenance instructions before using the table. The entire surgical ward staff should be familiar with the

correct use of the PROMERIX operating table as well as all warnings and observations concerning it.

Warnings and observations found in this instruction manual are indicated as follows:

WARNING! Please observe to ensure patient safety.

CAUTION! Please observe in order to avoid causing damage to the equipment or its parts.

NOTE! Please observe in order to improve operating table properties.

WARNINGS!

PromeriX operating table should only be used in facilities made for medical purposes.

IP X4 classification is valid only when the mains cord is disconnected.

Connect the mains cord only to earthed power supply.

PromeriX shall be operated from it’s internal battery if the integrity of the protective earth conductor

arrangement is in doubt.

Place the patient in the longitudinal center line of the table top.

In NORMAL mode max. patient weight with sliding seat section is 275 kg ( 600 lbs ).

In NORMAL mode max. patient weight without sliding seat section is 325 kg ( 700 lbs ).

In REVERSE mode max. patient weight is 180 kg ( 400 lbs ).

Adjust the table top to the horizontal position ( 0-position ) with the hand control unit before transporting a

patient on the operating table.

Transporting of patients weighing up to 180 kg ( 400 lbs ) is only allowed when table top is in horizontal posi-

tion ( 0-position ) and the height of the table is max 900 mm ( 3 ft ).

5

Transporting of patients weighing 180-225 kg ( 400-500 lbs ) is only allowed when the table is in NORMAL

!

!!!!!!!

!!!

!

!!!

!

mode, in horizontal position ( 0-position ) and in the lowest position.

Transporting of patients weighing 225-325 kg ( 500-700 lbs ) is not allowed.

Use extreme caution when transporting the table with a patient on. Transporting of the table with a patient on

requires two persons. To maximize patient safety utilize proper restraint methods during transport.

To avoid endangering the patient's respiratory system, nerve pathways and circulatory system, the patient

should be positioned properly and kept under observation!

Check that table top sections catches lock correctly. Incorrect attachment of table sections is dangerous and

can cause personal injury or equipment damage!

Use only accessories recommended by the table manufacturer.

When adjusting the operating table, take care to avoid collision between accessories and the operatingtable.

Do not use worn or damaged accessories. When using the table, ensure that all accessories are properly

mounted and check the function of accessory locking and adjustments.

When adjusting the operating table, take care that the fingers, hands or other parts of the body of the patient

are not placed between edges of back, leg or seat section frames and pivoting points.

Use only permitted table top configurations illustrated in this manual.

Ensure before adjusting the operating table that table top will not hit external obstacles.

Ensure before adjusting the operating table that NORMAL/REVERSE mode has been chosen correctly and is

the same as patient's orientation on the table top. After use of main switch NORMAL mode is set as default.

Always follow manufacturer instructions when using diathermy or defibrillation equipment.

When using high frequency surgical equipment take care to prevent the patient coming into contact with

metal parts of the operating table or accessories. Do not place the patient on wet or damp surfaces or electri-

cally conductive pads. Hazard of burn injuries!

Combustible anaesthetic gases must not be used with the Promerix operating table.

6

Use potential equalization conductor with patient monitoring equipment. Connector placed at the table base.

WARNINGS, NOTES AND INSTRUCTIONS

!

!!!!

!!!

!

!

When recharging the battery first plug the mains cord to table appliance inlet, after that to wall socket.

Main switch can be used as an emergency stopping device ( demanded by the standards ). Normally the

switch lever is in up position. When the lever is turned down in OFF position all table functions are cancelled.

Table movement stops immediately.

When recharging is completed disconnect the mains cord first from the wall socket, after that from the table

appliance inlet.

Disconnect the mains cord from the table and turn the main switch to OFF position before cleaning of the

table.

Disconnect the mains cord from the table before any service procedures. 100-240 V ~ used in power unit

placed in table base. Hazard of electric shock!

Promerix operating table has been tested to EN 60601-1-2 to ensure proper electromagnetic compatibility.

Other products used in the vicinity of Promerix operating table should also comply with this standard. If they

do not comply, interference between products in unintended responses may occur. Please contact the

appropriate manufacturer if any problems arise.

Portable and mobile RF-communications equipment can affect Promerix operating table.

7

CAUTIONS!

WARNINGS, NOTES AND INSTRUCTIONS

!

!

!

!

!

!

!

!

!

!

!

!

!

!

If the operating table has been in the cold, allow it to warm up at room temperature for at least 6 hours before

recharging the battery or switching on, to allow any condensation formed to evaporate.

Recharge the battery prior to use. See the starting instructions attached to table base panel.

OVERRIDE panel is only for returning the table top to the horizontal position in the case of electronic mal-

function. Override makes it possible to adjust table without the controlling processor and any of the pro-

grammed restrictions are not functioning.

Downwards adjusted leg or back section may hit the table base or column casings depending on the used

height or tilt angle adjustments. Can cause damage to the operating table and creating pinching hazard!

Do not place any objects on the base of the operating table! Danger of damage during adjustments!

The best place to store the hand control unit especially during transport is the lever under the head section.

Head and devided leg section 60475 gas springs can be disposed of as metal waste after nitrogen gas and

oil has been removed. Instructions for gas releasing available from your sales representative.

Operating table has been classified as splash proof equipment. Use of pressurized water is not allowed.

Cleaning and disinfecting should be made according to this manual.

Do not pull or push the shields of back and leg section joints. Check during adjustment that there is no fo-

reign obstacles between shields.

It is possible to adjust the SLIDE adjustment only when back or leg section are in horizontal or above hori-

zontal position. Slide adjustment will stop automatically before collision if back or leg section in under the

horizontal position.

SLIDE adjustment is only possible when table top is in horizontal position. Use of SLIDE adjustment is

restricted with tilted table top.

Mattresses should be cleaned only with neutral detergent ( ph 7-8 ).

The antistatic properties of the operating table require the use of original brand mattresses and antistatic

flooring.

8

NOTES!

WARNINGS, NOTES AND INSTRUCTIONS

!

It’s recommended to recharge the battery overnight after day’s use. Table will be always ready for use and

the battery will have longer service life.

If the main switch is turned to OFF position ( downwards ), all table functions are blocked including recharg-

ing of the battery. Check that the green led above the charging inlet lights up when you connect the mains

cord to the table.

When mains cord is connected to operating table the cooling fan of the power unit is activated causing a

humming sound. After disconnecting the mains cord the cooling fan still runs for few seconds.

Turn the main switch to OFF position ( downwards ) when the table is not in use or stored for longer period of

time. This eliminates the possibility of unintended use and is also saving the battery capacity.

Activate the floor lock before adjusting the table. Only trendelenburg and back rest adjustments are function-

ing if floor lock is not activated.

Cardboard packing material should be recycled. Wood and plastics are energy waste.

Batteries contain lead and if replaced, need to be recycled in accordance with local environmental regula-

tions.

Velcro tapes on table top plates can be cleaned with pressurized air. Velcro tape can also be replaced; spare

parts and instructions available from Merivaara service dpt.

Floor lock can be deactivated with a release knob placed at the table base if normal deactivating with hand

control unit or override panel can’t be done. Turn the knob 90° clockwise and the table will descend on to its

castors. Turn the knob back to its original position after releasing.

9

Merivaara Corporation conforms to all its operations ISO 9001 Quality Management and ISO 14001 Environ-

2. GENERAL

Expertise is essential

The patient is the most important part of treatment. This is precisely why

the equipment used in treatment must be absolutely

safe and convenient to use. As a health care

professional, you deserve the very best tools,

allowing you to concentrate on your own field of

expertise. Merivaara is an expert in providing

hospital equipment.

Merivaara products have been designed to function

efficiently and flexibly during the various stages of

treatment. They assist you in the performance of

your work, without distracting you from the task at

hand. Our modular equipment system includes

state-of-the-art equipment for hospital procedures

and hospital room environments as well as for

nursing homes and home care applications.

For more information on Merivaara products,

contact our Sales Office. For matters related to

equipment servicing, contact the Merivaara Service Department.

mental Management System Standards. In addition the Promerix operating table meets the following stan-

dards: EN 60601-2-46, EN 60601-1-2 ( EMC ) and EN 60601-1. The table complies with directive 93/42/EEC (

MDD ) product class I, and bears a CE marking based on this classification.

2.1 Intended use

Promerix Operating Table is intended for general surgical use. It is also well suited for:

• Day surgery

• ENT surgery

• Plastic surgery

• Orthopedics

• Arthroscopy

• Gynecology

• Urology

• Pediatrics

• Neurosurgery

10

2.2 Operating characteristics

Promerix is transportable electrohydraulic battery and mains operated operating table. It is microprocessor

controlled and it‘s function parameters are reprogrammable with special PC-operated service program. Table

can be connected to 100….240 VAC mains power and its secondary voltage is 24 VDC. The table electronics

are safely earthed and it has equipotential connection.

Table top consists of fixed or sliding seat section and detachable 25 and 40-sections. You can rearrange the

sections as you wish depending on the surgical concept and operation. Look page 14. The width of the table

top is 540 mm, ( 21 1/4 inch ) without rails and length 2100 mm ( 82 inch ). Table top plates are x-ray translu-

cent material.

Promerix can be adjusted with cable connected hand control unit, IR-hand control unit or foot switch. Operat-

ing table can also be adjusted with override panel in case of electronical malfunction ( hand control unit or

table microprocessor defective ).

Safe and fault-free use and maintenance of the equipment requires careful acquainting to these instructions.

When mounting accessories to the equipment, the instructions provided with them must be followed closely.

Always keep the instructions for accessories together with this manual.

11

3.1 Cleaning instructions

3. CLEANING

!

Disconnect the mains cord from the table and turn the main switch to OFF position before cleaning of the

table.

Operating table has been classified as a splash proof equipment. Use of pressurized water is not allowed.

Cleaning and disinfecting should be made according to this manual.

Do not pull or push the shields of back- and leg section joints. Check during adjustment that there is no for-

eign obstacles between the shields.

Surface of the Promerix mattresses is electrically conductive. Cleaning of the mattresses should be done with

neutral detergent( pH 7-8 ) and warm water applied with a single use wipe.

3.2 Cleaning

• Remove accessories and mattresses.

• Clean by wiping down with a mild alkaline detergent ( pH 7-8 ).

3.3 Disinfection

• Remove accessories and mattresses.

• Disinfect only when necessary.

• Wipe down the equipment with the surface disinfectant used at the facility in accordance with manu-

facturer instructions, unless the surface disinfectant contains phenols and alcohol, which can corrode

plastic parts and mattresses.

NOTE! Dry the operating table carefully

immediately after cleaning or disinfecting.

3.4 Mattresses and pads

Read the care instructions for mattresses and pads.

12

4.1 Safety during maintenance procedures

4. MAINTENANCE INSTRUCTIONS

!!!!!

Maintenance allowed only to persons specialized to Promerix service work.

Disconnect the mains cord from the table before any service procedures. 100-240 V ~ is used power unit

placed in table base. Hazard of electric shock!

Turn the main switch to OFF position before connecting or disconnecting any of electronic connections or

components in order to protect them against voltage surges.

Static charges can cause sparks harming sensitive electronic components. Ground yourself to metallic parts

of table before touching electronic components.

Disconnecting any of the hydraulic hoses can cause uncontrolled and dangerous movement of the table.

Support the table parts before disconnecting any hydraulic hoses!

When mains cord is connected to operating table the cooling fan of the power unit is activated causing a

humming sound. After disconnecting the mains cord the cooling fan still runs for few seconds.

4.1.1 Daily service

• During normal cleaning, check-up general condition of the operating table. Contact service personnel

if needed.

• We recommend that you charge the table battery every day. This is to ensure sufficient battery charge

level and long service life.

• Check the mains cord condition.

• Promerix operating table must be cleaned carefully after each surgical procedure!

4.1.2 Monthly service

• Clean and lubricate guide pins, latches, spring-loaded pins and pivoting points with light machine oil

or spray vaceline.

• Check that castors roll smoothly and floor lock is functioning correctly.

• Test table functions by adjusting them to their extreme positions.

13

• Check hand control unit and foot switch cables, connector and plug.

!

4.1.3 Annual service

• Perform all daily and monthly service actions.

• Check the functioning of table section's latches.

• Check all cables and connectors, regarding injuries (kinks, cracks, wear)

• Visual check at the hydraulic hose connections and piston rods, regarding external leakage.

• Check of the oil level in the reservoir of the oil pump, if the level is too low fill up with filtrated

mineral oil (ARAL VITAM DE32).

• Oil change: every 5 years

All electrical repairs must be performed by a licensed electrician.

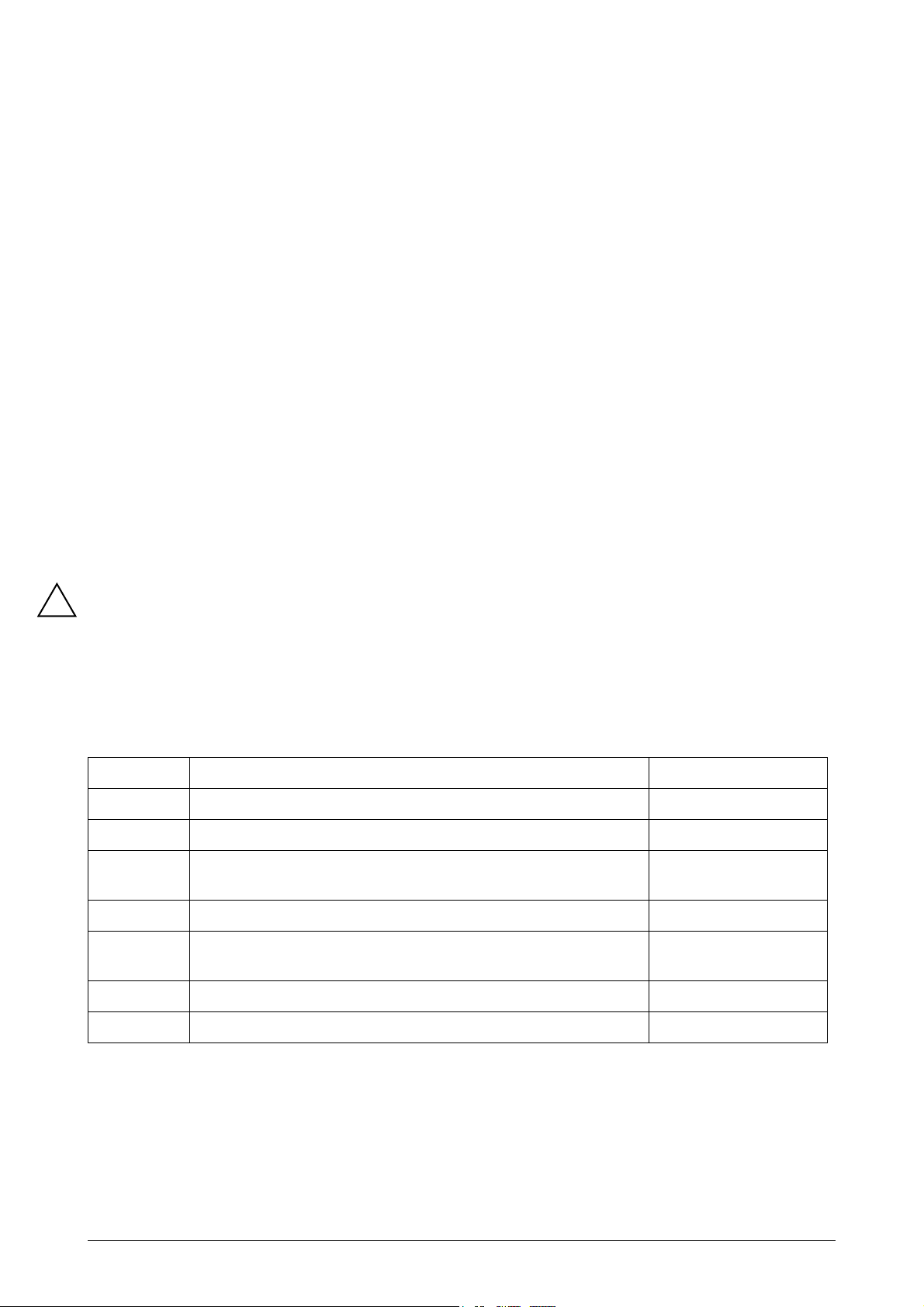

4.2 Troubleshooting and checklist

POSSIBLE SITUATIONS:

PROBLEM: Table will not activate when pressing ON/OFF-button PROCEDURE:

CAUSE: -Main Switch in OFF position Turn to ON position

-Hand Control Unit not connected properly Check the connection

-Faulty Hand Control Unit Replace the hand control unit

-Broken Hand Control Unit cable Replace the cable

-Empty batteries Connect mains cable

and recharge batteries

-Battery fuse blown Check and replace

-Faulty MPC Replace MPC

14

PROBLEM: Table adjustment not functioning when pressing function

!

!

button, table activated

CAUSE: -Floor lock not activated Press activation button

-Making adjustment table program restricts Check the table posi-

-Adjustment already in its end position Check the table posi-

PROCEDURE:

tioning

tioning

-Faulty hand control unit or IR-control unit not programmed cor-

rectly.

PROBLEM: Table movement won’t stop although function button is

released

CAUSE: -Severe functioning failure of electronics. Malfunctions are

always recorded in the Error Log.

-Faulty hand control unit MAIN SWITCH to OFF

-Valve is mechanically stuck or stays open constantly Contact service, new

-Short circuit in the transistor controlling the solenoid Contact service

-Damaged solenoid or sensor wires Contact service

Check the control unit

PROCEDURE:

MAIN SWITCH to OFF

position!

Use service program

manual to resolve error

code.

position!

Contact service

valveblock or

solenoid is needed

PROBLEM: Back section moves when leg section button is pressed or

vice versa

CAUSE: -Normal/Reverse – mode wrongly selected Check the selected

PROBLEM: Audial signal when using IR-hand control unit PROCEDURE:

CAUSE: - Indicates that the operating table floor lock is not activated! Press the floor lock but-

- Cause no marking into the Error Log Reset by pressing the

PROCEDURE:

mode

ton steadily

ON/OFF button.

!

15

PROBLEM: Table not responding to IR-hand control unit commands PROCEDURE:

!

CAUSE: -Control unit wrongly aimed Aim towards the table

-Distance between table and control Check the distance

-IR-receiver blocked Check

-IR-control unit battery depleted Replace batteries

-IR-control unit wrongly coded Set codes again

-Emergency situations use override panel buttons!

PROBLEM: Table motion stops during adjustment PROCEDURE:

CAUSE: - A simultaneous commands will stop the table movement Release another of the

pressed buttons

- Can cause if foot control and hand control units are pressed

at the same time.

PROBLEM: One piece leg section can not be adjusted PROCEDURE:

CAUSE: -One piece leg sections not attached to seat section correctly Check the latches

-Faulty inductive sensor Contact service

PROBLEM: Hydraulic unit starts but no movement occurs PROCEDURE:

CAUSE: -Valve block solenoid defective or loose Contact service

-Table adjustment in its end position Check the table posi-

PROBLEM: The table changes position by itself PROCEDURE:

Use one control unit at

the time

tioning

- Control unit buttons are accidentally pressed or pinched Check the control unit

16

CONTACT:

Further information of PromeriX service, product support and spare parts are available from your local dealer

or from Merivaara Corp.

Merivaara service +358 3 3394 6152

Merivaara service fax +358 3 3394 6249

E-mail merivaara@merivaara.fi

Internet www.merivaara.com

17

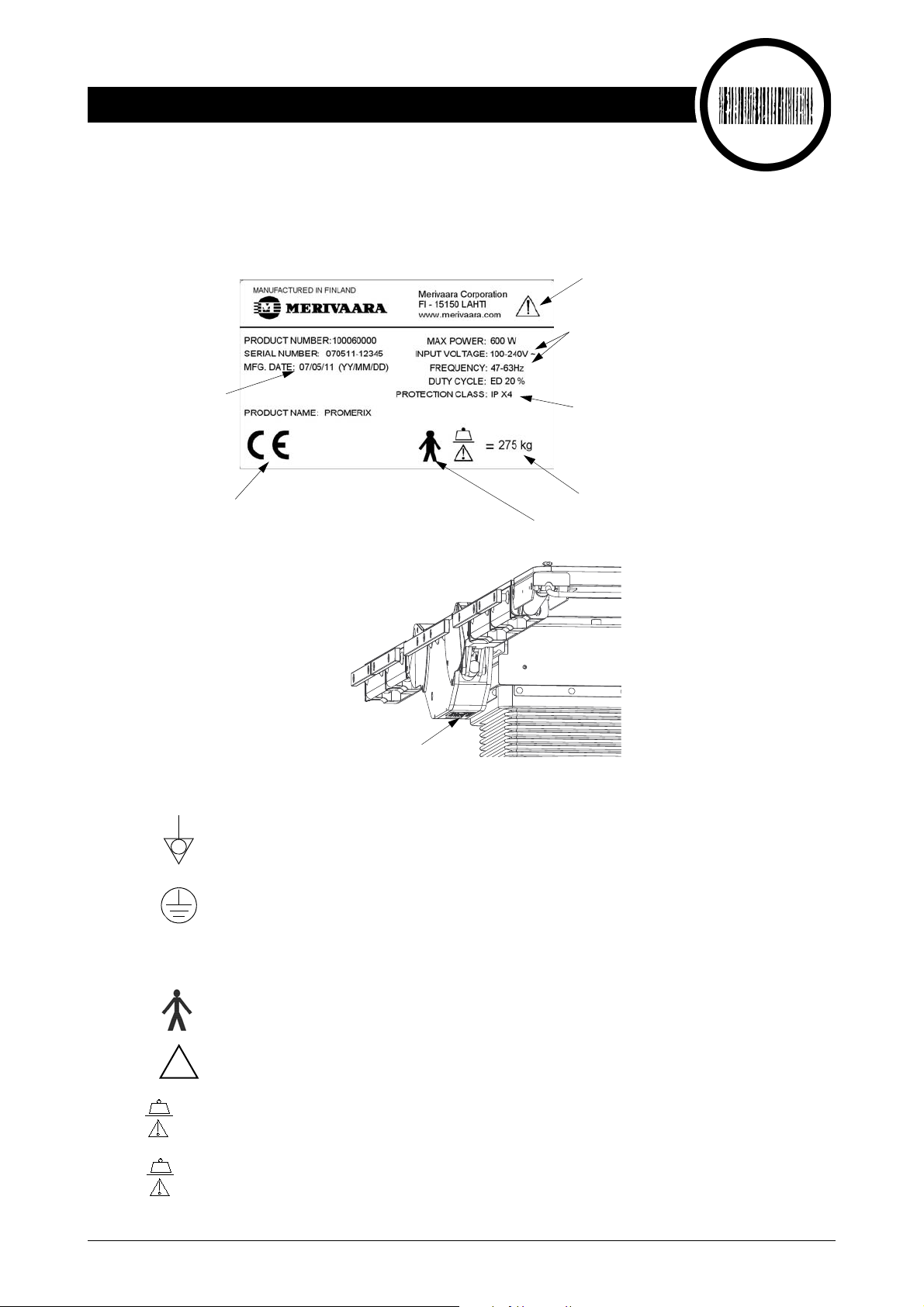

5.1 Identification plate

5. TECHNICAL DATA

Primary voltage and frequency

Safe max. working load

B-type applied part

CE approved device

Splash proof

Consult accompanying documents

Ingress Protection

=180 kg

275

=180 kg

325

Maximum load without slide ( including patient, mattresses and accessories )

ID-plate

Identification plate is located in the joint, under of the seat section.

5.1.1 Illustrated designations and symbols

~ Alternating current

!

Equipotentiality

Protective grounding

B-type applied part

Attention, consult accompanying documents

Maximum load with slide ( including patient, mattresses and accessories )

18

5.2 Properties and materials

5.2.1 Surface materials

Surface materials used in Promerix table with possibility to skin contact:

Epoxy coated steel Frame constructions

Zinc plated steel Frame constructions

Stainless steel Accessory rails, casings, frame construc-

tions

Aluminium bronze Pivots

High pressure laminate Table top plates

PUR Mattresses

Anodized aluminium Table top section sides

Polycarbonate ( PC ) Hand control unit B-cover and battery cover

Silicon Hand control unit A-cover

EPDM-rubber Bellows

ABS+PMMA Base and castor covers

PC/ABS-composite Override panel

ABS IR-receivers

19

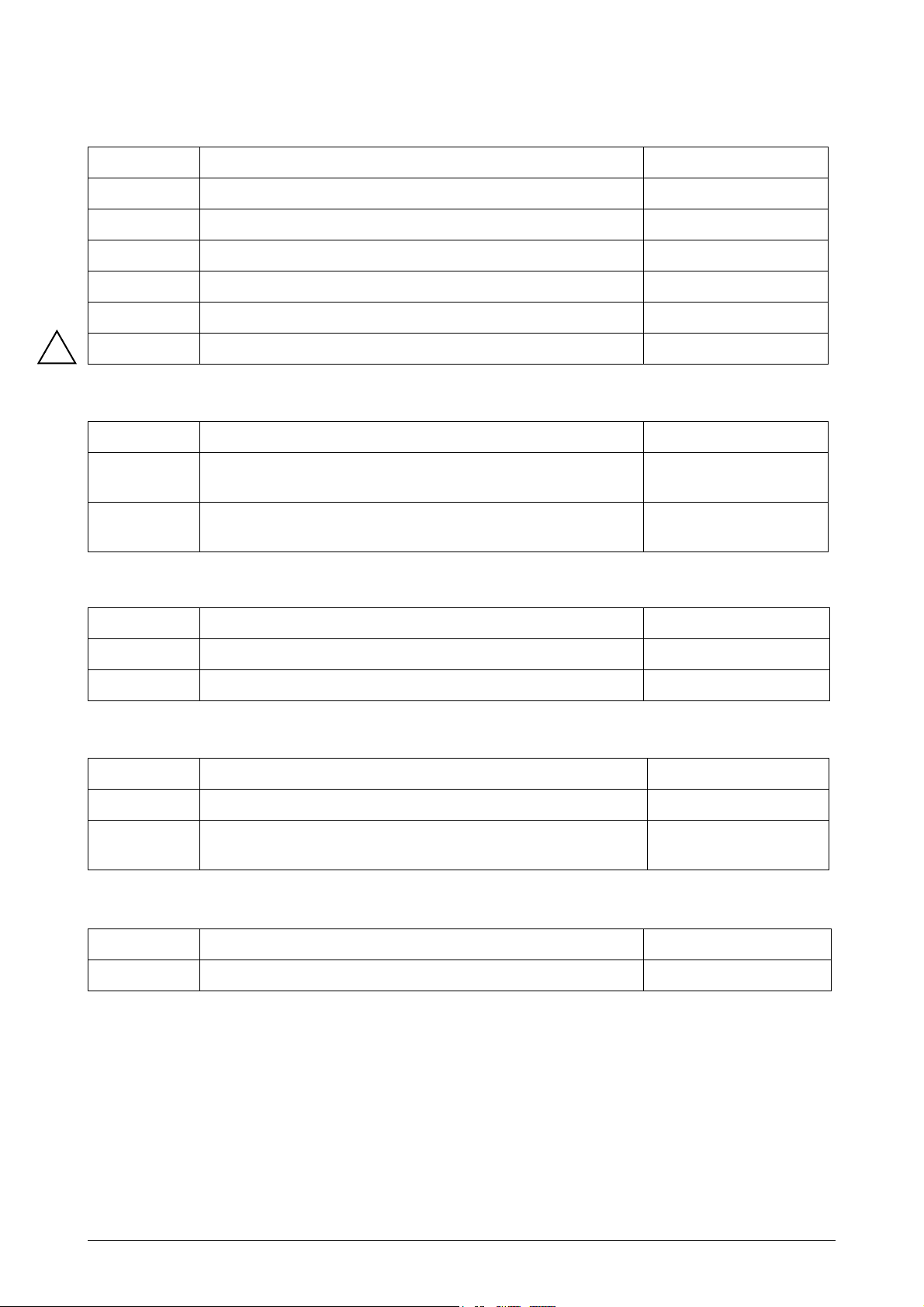

5.3 Specifications

!

5.3.1 Environmental specifications

Promerix is designed to be used in following environmental conditions:

Ambient temperature +10 ... +40 °C

Ambient pressure 700 ... 1060 mbar

Relative humidity 30 % ... 75 %

Transport temperature - 10 ... +40 °C

Storage temperature +10 ... +40 °C

5.3.2 Electrical specifications

Primary voltage 100 - 240 V~

Frequency 47 - 63 Hz

Secondary voltage Nom. 24V DC

Maintenance free sealed lead

acid battery

Max. power consumption 600 W

Main fuses F10A ( 5x20 2 pcs )

Normal recharging time 5 - 10 h ( depending on battery

Operation time with full battery approx. 180 min.

Max. uninterrupted operating time 2 min / 10 min ( ED 20 % )

If you would like more detailed information, please contact the Merivaara service department.

5.3.3 Classification data

Promerix is classified according to EN 60601-1 as follows:

Electric shock protection Class I equipment, internally powered

Degree of electric protection B-type

24V / 18 Ah

charge level )

Protection against liquids IP X4 / Splash proof equipment

Cleaning and disinfecting According to instructions, on page 13

Operating Rate Intermittent operation / ED 20%

Protection against flammable anaesthetic gases Do not use with combustible gases

Safe working load 325 / 275 / 225 / 180 kg incl. patient, mattresses and

accessories.

20

Loading...

Loading...