Merivaara Patient Bed Optima Service manual

USE AND MAINTENANCE INSTRUCTIONS

OPTIMA MINOR

Type: Use and maintenance instructions Completed: 4.4.2005

Document:

DO1053-1-0.en Version: 1-0 11.8.2010

Dear Merivaara product owner, The safe and fault-free use and maintenance of the equipment requires

Expertise is essential

The patient is the most important part of treatment.

This is precisely why the equipment used in

treatment must be absolutely safe and convenient

to use. As a health care professional, you deserve

the very best tools, allowing you to concentrate on

your own field of expertise. Merivaara is an expert

in providing hospital equipment.

Merivaara products have been designed to

function

efficiently and flexibly during the various stages of

treatment. They assist you in the performance of

your work, without distracting you from the task at

hand.

Our integrated equipment system includes state-

of-the-art equipment for hospital procedures and

hospital room environments as well as for nursing

homes and

home care applications.

careful adherence to these instructions. When mounting accessories to the equipment, the instructions

provided with them must be followed closely. Always keep the instructions for accessories together with this

manual.

Warnings and observations found in this instruction manual are indicated as follows:

WARNING! Please observe to ensure patient safety.

NOTE! Please observe in order to avoid causing damage to the equipment or its parts.

Lubricate during maintenance and when replacing parts.

1 TECHNICAL SPECIFICATIONS 1

1.1 Intended use 1

1.2 Type plate 1

1.2.1 Figure symbols 1

1.3 Properties and materials 2

1.3.1 Operating conditions 2

1.3.2 Classifications data 2

1.3.3 Surface materials 3

1.3.4 Adjustment ranges 3

1.3.5 Dimensions 4

2PRODUCT USE 5

2.1 Implementation 5

2.1.1 Special instructions 5

2.2 Structure and adjustments 6

2.2.1 Brakes and castors 6

2.2.1.1 Castors with individual brakes 6

2.2.1.2 Castors with central brake system 6

2.2.2 Hydraulic/gas spring-assisted adjustments 7

2.2.2.1 Height adjustment, hydraulic 7

2.2.2.2 Back section adjustment, gas spring 7

2.2.3 Electrical adjustments 8

2.2.3.1 Hand control functions on electrically-operated bed 8

2.2.3.2 Height adjustment 8

2.2.3.3 Back section adjustment 8

3CLEANING 9

3.1 Bed, operating table and trolley 9

3.1.1 Cleaning 9

3.1.2 Disinfecting 9

3.1.3

Mattresses and pads 9

4 MAINTENANCE AND REPAIR 10

4.1 Preventative maintenance 10

4.2 Troubleshooting 11

4.3 Castors and brakes 12

4.3.1 Castors with individual brakes 12

4.3.2 Castors with central brake system 12

4.3.2.1 Brake adjustment 12

4.4 Hydraulic height adjustment 13

4.4.1 Pump removal 13

4.4.2 Pedal removal 13

4.4.3 Pump bleeding 13

4.5 Gas spring adjusters 14

4.5.1 Removal of back section gas spring 14

4.5.2 Removal of Trendelenburg adjustment gas springs 14

4.5.3 Removal of gas spring from protective sleeve 14

4.6 Control unit and motors 15

4.6.1 Removal of control unit and height adjustment motor 15

4.6.2 Removal of back section motor 16

4.7 Schematic 17

5 SPARE PARTS 18

5.1 Height-adjustable lower frame and lift levers 18

5.1.1 Height adjuster and motor 19

5.1.2 Height adjuster hydraulic pump 20

5.2 Central braking system and castors 21

5.3 Back section adjustment gas spring 22

5.4 Back section adjustment motor 23

5.5 Trendelenburg adjustment gas springs 24

6 ACCESSORIES 25

6.1 Accessories 25

6.1.1 Operating conditions 25

6.1.2 Surface materials 25

6.2 Accessory serial numbers and weights 26

6.3 Rail 27

6.4 Knee-bend support 28

6.5 Accessory rail for back section 29

7RECYCLING 30

7.1 Metals and plastics 30

7.1.1 Gas springs 30

7.1.2 Hydraulics 30

1.1 Intended use

1. TECHNICAL SPECIFICATIONS

Model number

Serial number

Safe working load (SWL)

(incl. patient, mattress and accessories)

Enclosure rating

Input voltage, frequency and input power

Periodical operation (max) 1min / 10min

Model number

Serial number

Safe working load (SWL)

(incl. patient, mattress and accessories)

Recycled separately

CE certified device

WEIGHT: 110 kg

B-type device

Merivaara's delivery bed Optima Minor is intended for use in hospital maternity wards.

The Optima Minor delivery bed meets IEC 601-2-38, IEC 601-1-2 (EMC) and SFS-EN 60601-1 standards.

The bed complies with directive 93/42/EEC (MDD) product class

classification.

1.2 Type plate

The type plate is located underneath the back section.

I, and bears a CE marking based on this

Type plates, upper electrically-operated and lower hydraulic gas spring-operated bed

1.2.1 Figure symbols

Consult accompanying documents

5

1.3 Properties and materials

1.3.1 Operating conditions

Ambient temperature +10 ... +40 °C

Ambient pressure 700 - 1060 mbar

Relative humidity 30 %- 75 %

Transport temperature - 10 ... +40 °C

Storage temperature +10 ... +40 °C

Safe working load (SWL)

(incl. patient, mattress and accessories) 180 kg

1.3.2 Classifications data

Electric shock protection Class I equipment (insulated)

Degree of shock protection B-type device

Fluid protection water-resistant device (IP54)

Cleaning and disinfecting see section 3. page 13

Combustible anaesthetic gas protection do not use with combustible gases

Function type periodical operation

Input voltage 230 V/50 Hz

Input power max. 250 VA

Output voltage 24 V

Noise level 43

Weight 110 kg

±2 dB

6

1.3.3 Surface materials

MAX.15

MAX. 3

MAX. 68

o1053d.pdf

Back section adjustment

Trendelenburg and anti-Trendelenburg adjustme

0 ° - 68 °

Anti-Trendelenburg MAX. 3 °

Tren dele nbur g MAX.1 5 °

Surface materials 34100 H 34100 SCK

Paint (glossy epoxy), frame parts X X

Chroming (pedal bars, adjuster levers) X X

Stainless steel (slide rail, basin) X X

ABS (casings) X X

PE (plugs) X X

POM (collision wheels) X X

TPO (Thermoplastic olefin), push bar profile X X

PU elastomer (push bar) X X

PUR (polyurethane) hand-held control cable X

PA 6 (polyamide), handles, motors X X

PA 9 (polyamide), control unit X

Lyranyl (PPE/HIPS) hand-held control X

Hygienic mattress (grey) cover 63% polyamide/37% PU X X

1.3.4 Adjustment ranges

7

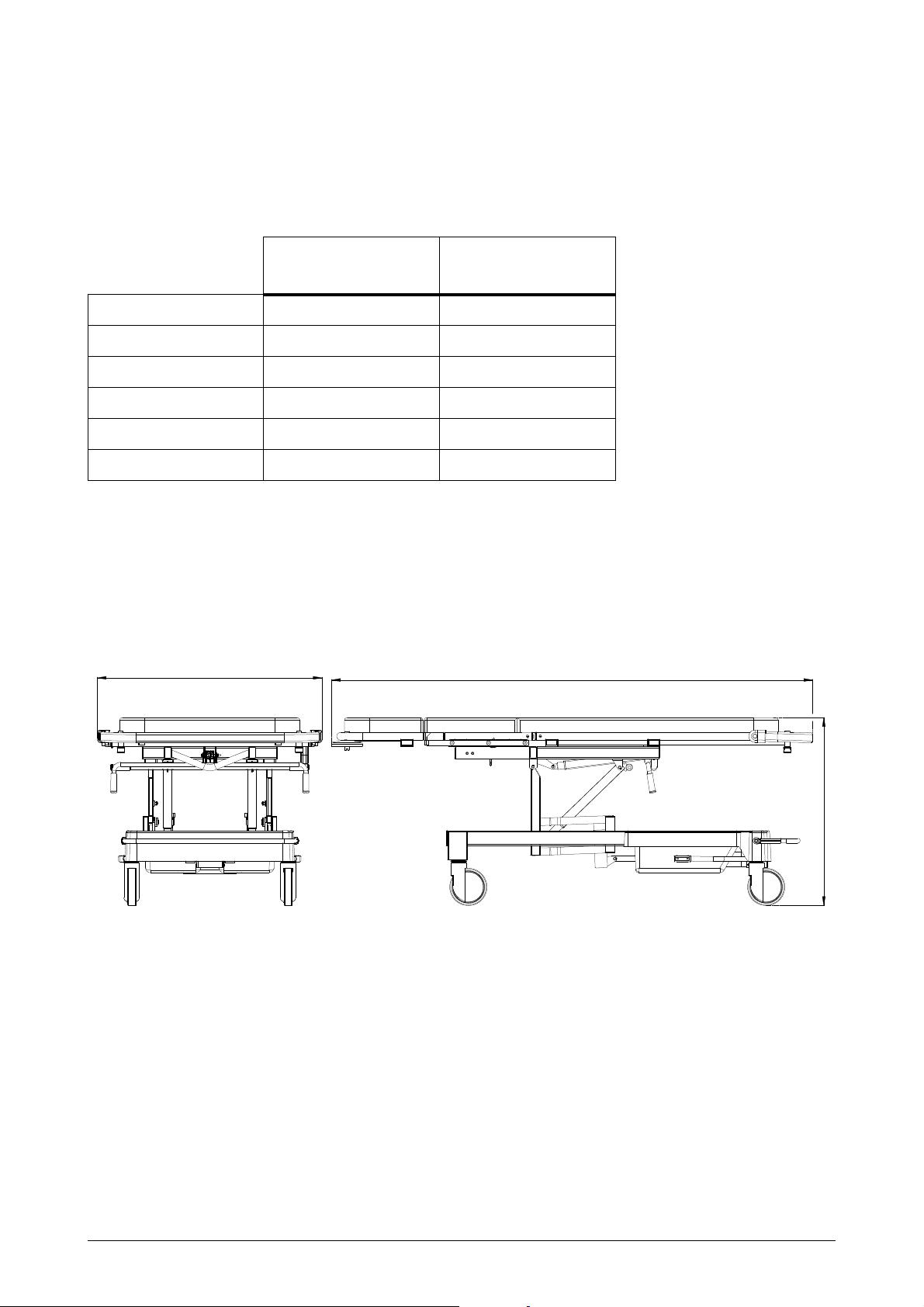

1.3.5 Dimensions

A

C

B

o1053c.pdf

Optima Minor

34100 H

Mattress base 3-section 3-section

Bed weight 110 kg 110 kg

Length (A) 1940 mm 1940 mm

Width (B) 910 mm 910 mm

Height (C) 650 - 1010 mm 650 - 1010 mm

Castors 125 mm 125 mm

Table 1. Dimensions

.

Optima Minor

34100 CSK

8

2.1 Implementation

2. PRODUCT USE

The bed is packaged pre-assembled. Check for damage that may have been caused during transport.

All packaging cardboard should be recycled. Wood and plastics are energy waste.

NOTE! If the bed has been stored in the cold, allow it to warm up to room temperature before

connecting power or using.

2.1.1 Special instructions

WARNING! On electrically-operated beds, ensure that the power cord does not get caught between moving

parts as they may damage or cut the cord when operated. A damaged power cord can result in

electrical shock!

The bed’s safe working load is 180 kg. Only one person

NOTE! Do not operate the motors for more than one minute at a time (max. 1 min). Continuous

repetition of movements may overload and damage the motor.

Before moving the bed, the mattress base must be adjusted to its middle position (check visually).

When pushing the bed over a threshold or similar obstacle, always go with the head or foot of the bed first to

reduce the impact on castors or other mechanical parts.

Keep the mattress base of unattended beds in the lower position. (IEC 60601-2-38)

WARNING! When adjusting the bed, ensure that the patient’s fingers, hands or other parts of the body do

not get caught between the bed and accessories or the bed’s moving parts.

The bed can also be used with mobile personnel lifts.

may be on the bed when adjusting.

9

2.2 Structure and adjustments

o1053e.pdf

Extension/leg sectio

Push bar

Back section

Hand control

Trendelenburg adjustment handle

Power lead

Brake pedal

Accessory rail

for seat

Seat

Back section adjuster motor

Control unit

Height adjuster motor

o1011e.wmf

Optima Minor – With electric adjustment (without utility basket)

2.2.1 Brakes and castors

2.2.1.1 Castors with individual brakes

The bed is locked by depressing the brake lever on all four castors. The castor brake is released by lightly

pressing the release lever until the brake lever returns to its horizontal position.

2.2.1.2 Castors with central brake system

All castors can be locked and released with a pedal, which is mounted on the lower

frame at the head end of the bed. When the pedal is up, the tracking castor will lock

in its tracking position. When the pedal is in its middle position, all the castors will

turn; when the pedal is down, all castors are locked.

10

Optima Minor – With hydraulic or gas spring-assisted adjustment (without utility basket)

o1053f.pdf

Extension/leg section.

Seat

Push bar

Back section

Back section adjuster bar

Trendelenburg adjustment handle

Height adjuster pedal

Brake pedal

Accessory rail

for seat

p4-9286v.eps

p4-9284o.eps

2.2.2 .Hydraulic/gas spring-assisted adjustments

2.2.2.1 Height adjustment, hydraulic

Mattress base height is adjusted hydraulically using the foot pedal. The mattress

base is raised by depressing the hydraulic pedal. The mattress base is lowered

when the pedal is raised.

Adjustment range 360 mm.

2.2.2.2 Back section adjustment, gas spring

Gas-assisted adjustments are made using the handle on the side of the back section.

Turn the handle with one hand while holding the back section frame with the other and

move the back section into the desired position. Release the adjuster handle when

done.

Adjustment range 0 -68°.

11

Loading...

Loading...