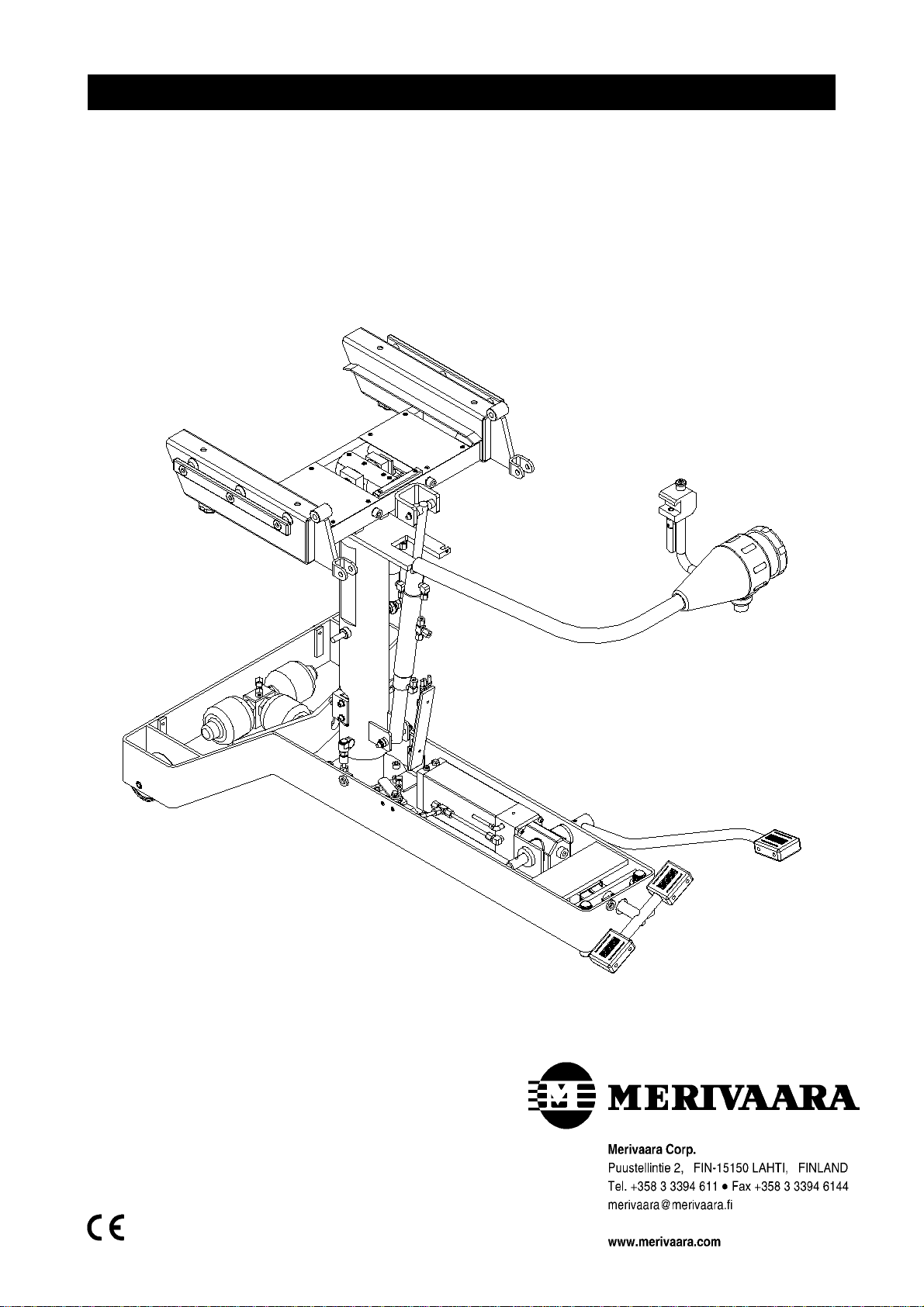

Merivaara OP-1700 Service manual

MAINTENANCE MANUAL

OPERATING TABLE OP 1700

o1025a.eps

1GENERAL 4

2 TECHNICAL SPECIFI CATIONS 5

2.1 Identification plate 5

2.2 Properties and materials 5

2.2.1 Conditions 5

2.2.2 Adjustments 5

2.2.3 Dimensions 6

2.2.4 S urface material s 6

3PRODUCT USE 7

3.1 Special instructions 7

3.1.1 Warnings 7

3.1.2 Important 7

3.2 Main components 8

4CLEANING 9

4.1 Daily cleani ng and disinfecti ng 9

4.1.1 Disinfecting 9

4.1.2 Drying 9

5 MAINTENANCE AND REPAIR 10

5.1 Maintenance procedures 10

5.1.1 Daily maintenance 10

5.1.2 Monthly maintenance 10

5.1.3 Annual maintenance 10

5.2 Troubleshooting 11

5.3 Removal of protective casings 12

5.3.1 Removal of base casing 12

5.3.2 Removal of column casings 12

Compiled by: Mika Similä Type:

Approved by: Arto Koski-Laulaja Document:

Maintenance manual Complete: 29.5.2001

DO1025.en Version: 01 - 10.12.2001

2

5.4 Brake and column clearan ce 13

5.4.1 Removal of brake pins and plugs 13

5.4.1.1 Brake adjustment 13

5.4.2 Castors 13

5.4.3 Adjustment of column clearance 13

5.5 Hydraulics 14

5.5.1 Hy draulic pressures 14

5.5.1.1 Pressure release 14

5.5.1.2 Checking pressure 14

5.5.1.3 Pressure adjustment 14

5.5.2 Gauging oil level 14

5.5.3 Removal of hyd raulic pump 14

5.5.3.1 De-airing hydraulic pump 15

5.5.4 Removal of pressure accumulators 15

5.6 Cylinder replacement 15

5.6.1 Re moval of height adjuster cylinder 15

5.6.2 Removal of side tilt cylinder from column 16

5.6.3 Removal of Trendelenburg cylinder from column 16

5.6.4 Replacement of back section gas spring 17

5.7 Selector 17

5.8 Replacement of gas springs 18

5.8.1 Replacement of leg section gas spring 18

5.8.1.1 Removal of gas spring from protective sleeve 18

5.8.2 Replacement of headrest gas spri ng 18

5.9 Connection of hydraulics 19

6RECYCLING 20

6.1 Metals and plastics 20

6.1.1 Gas springs 20

6.1.2 Hydraulics 20

3

1. GENERAL

Dear operating table owner. The safe and fault-free use and maintenance of the equipment requires careful

adherence to these instructions. When mounting ac cessories to the equipment, the in structions prov ided

with them must be followed closely. Always keep the instructions for accessories together with this manual.

Warnings and obser vations in this instruction manua l are indicated as f ollows:

WARNING! Please observe in order to ensure pati ent safety.

NOTE! Please observe in order to avoid causing damage to the equipment or its parts.

• Warnings and Notes are given on page 7, 15, 16 and 20.

The OP 1700 operating table complies with the IEC 601-2-46 and SFS-EN 60601-1 standards. The table

complies with directive 93/42/EEC (MDD) product class I and bears a CE marking based on this

classification.

Intended use

The Merivaara OP 1700 op erating table is intended for general surgery appli cations as well as most

specialise d ar ea s of surgery.

Your Specialist for integrated Medical

Furniture and Equipment Systems.

Merivaara products form an integrated furnishing system

for clinical, hospital and nursing home enviroments. The

comprehensive range of Merivaara products includes

high-quality tools and equipment needed in a variety of

medical procedures.

Merivaara products feature flexible design, turn easily into

ideal working positions and offer high patient comfort.

Daily nursing procedures are readily accommodated by

the safe and easy operation of all Merivaara products.

The comprehensive selection of (available) accessories

make our products ideal for several speciality procedures.

You can get more information on Merivaara products,

from our Sales Office. For matters related to equipment

servicing, please contact the Merivaara After Sales

Department.

4

2. TECHNICAL SPECIFICATIONS

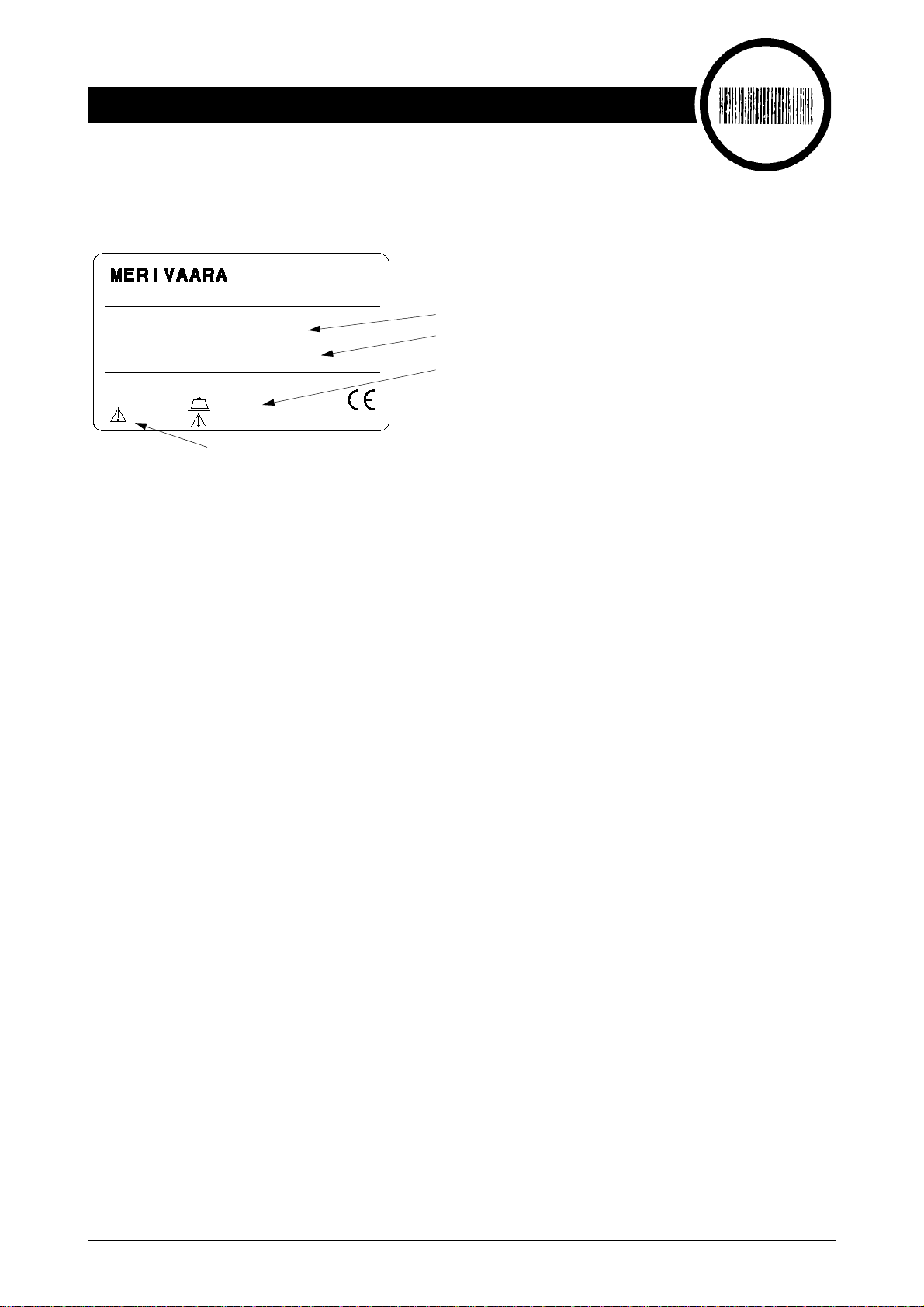

2.1 Identification plate

The identification plate is located underneath the seat.

INSTRUMENTARIUM CORP.

MODEL 12345/6789

SERIAL NO 1234-5678910

FI-15150 LAHTI

MADE IN FINLAND

Model number

Serial number

Safe working load

(incl. patient, mattress and accessories)

=135 kg

Read instruction s

2.2 Properties and materials

2.2.1 Conditions

Ambient temperature +10 ... +40 °C

Ambient pressure 700 ... 1060 mbar

Relative humidity 30% ... 75 %

Transport temperature - 10 ... +40 °C

o1017b.eps

Storage temperature +10 ... +40 °C

Safe working load

(incl. patient, mattress and accessor ies) 135 kg

2.2.2 Adjustments

Side tilt

Back section - 15° ... +70°

Leg section - 90° ... +0°

Trendelenburg and anti-Trendelenburg - 25° ... +25°

Headrest - 40° ... +30°

±15°

5

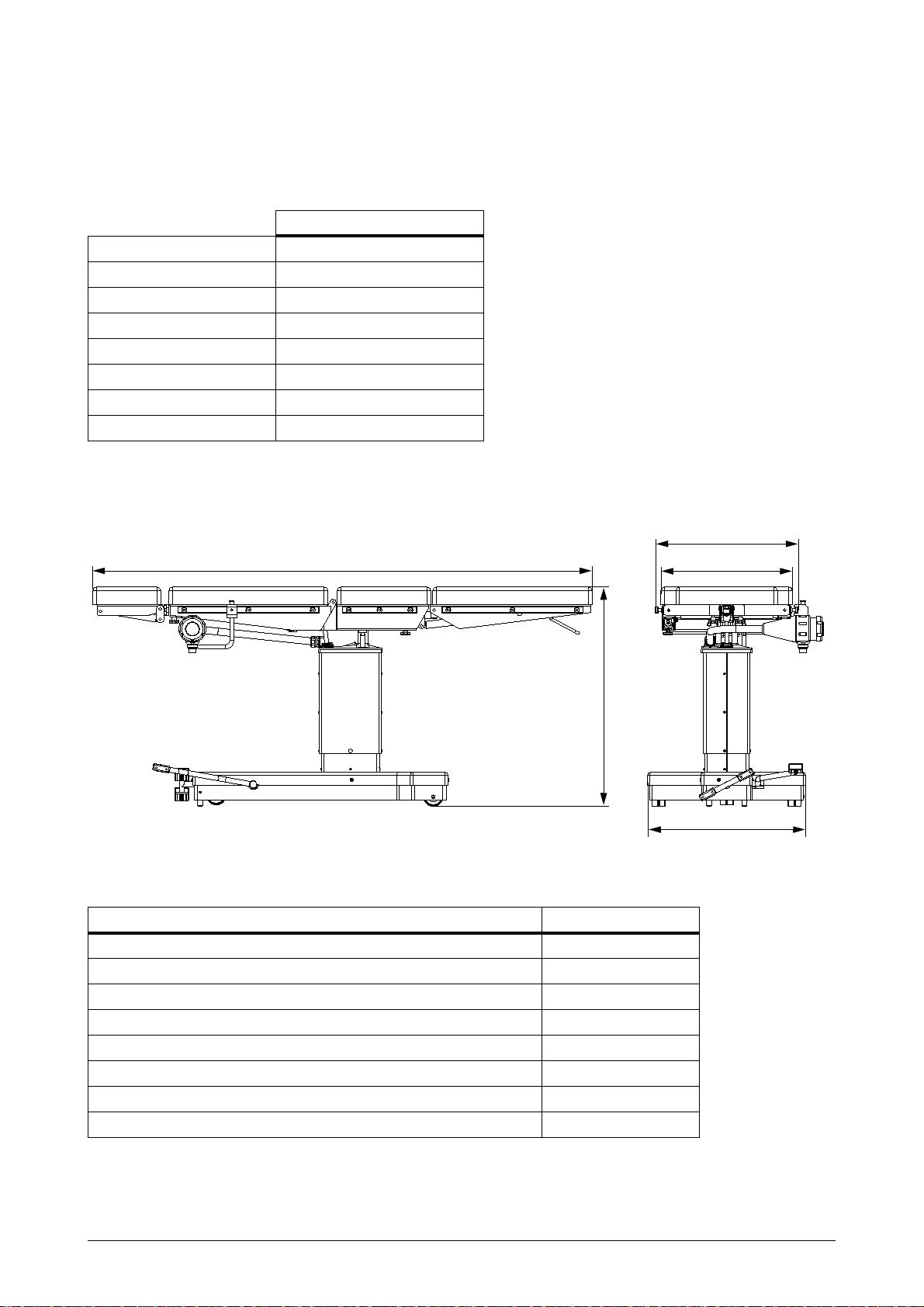

2.2.3 Dimensions

OP 1700

Operating table top 4 - piece

Operating table weight 145 kg

Length (A) 1950 mm

Width (B) 620 mm

Height (C) 730 - 1040 mm

Mattress width (D) 500 mm

Mattress base width (E) 555 mm

Castors 75 mm

Table 1. Dimensions

E

A

C

2.2.4 Surface materials

Surface materials OP 1700

Epoxy-powder coat, frame parts X

Stainless steel casing, columns, side rails X

Chroming, handles, adjuster levers, pedal tubing X

ABS (acrylonitrile/butadiene/styrene) protective casing X

PU integral, mattresses X

Rubber 61 bellows X

Anodised aluminium, selector valve X

LDPE (polyethylene), selector valve cover plug X

D

o1023b.eps

B

Table 2. Surface materials used on operating table.

6

3. PRODUCT US E

3.1 Special instructions

In order to guarantee op timal surgical safety all users of the operating table must thor oughly acquaint

themselves with the operating table operating instructions prior to using the table. Train the entire

surgery staff in the correct use of the OP 1700 operating table and all warnings and notes

related to it.

3.1.1 Warnings

When adjustin g the table, ensure that the patient’s fingers, hands or other parts of the body are not caught

between the moving parts of the back or leg section or the seat.

Adhere to the manufacturer’s instructions when using diathermic or defibrillating equipment.

3.1.2 Important

The anti-static properties of the operating table require the use of only Merivaara brand mattress sets and

anti-static flooring.

Note ! Keep in min d th at i f the o pera tin g ta ble s urf ace i s no t rai sed h igh enou gh when the leg s ectio n is

adjusted to its lowest position, it may strike the table base casing and cause damage to the

table.

7

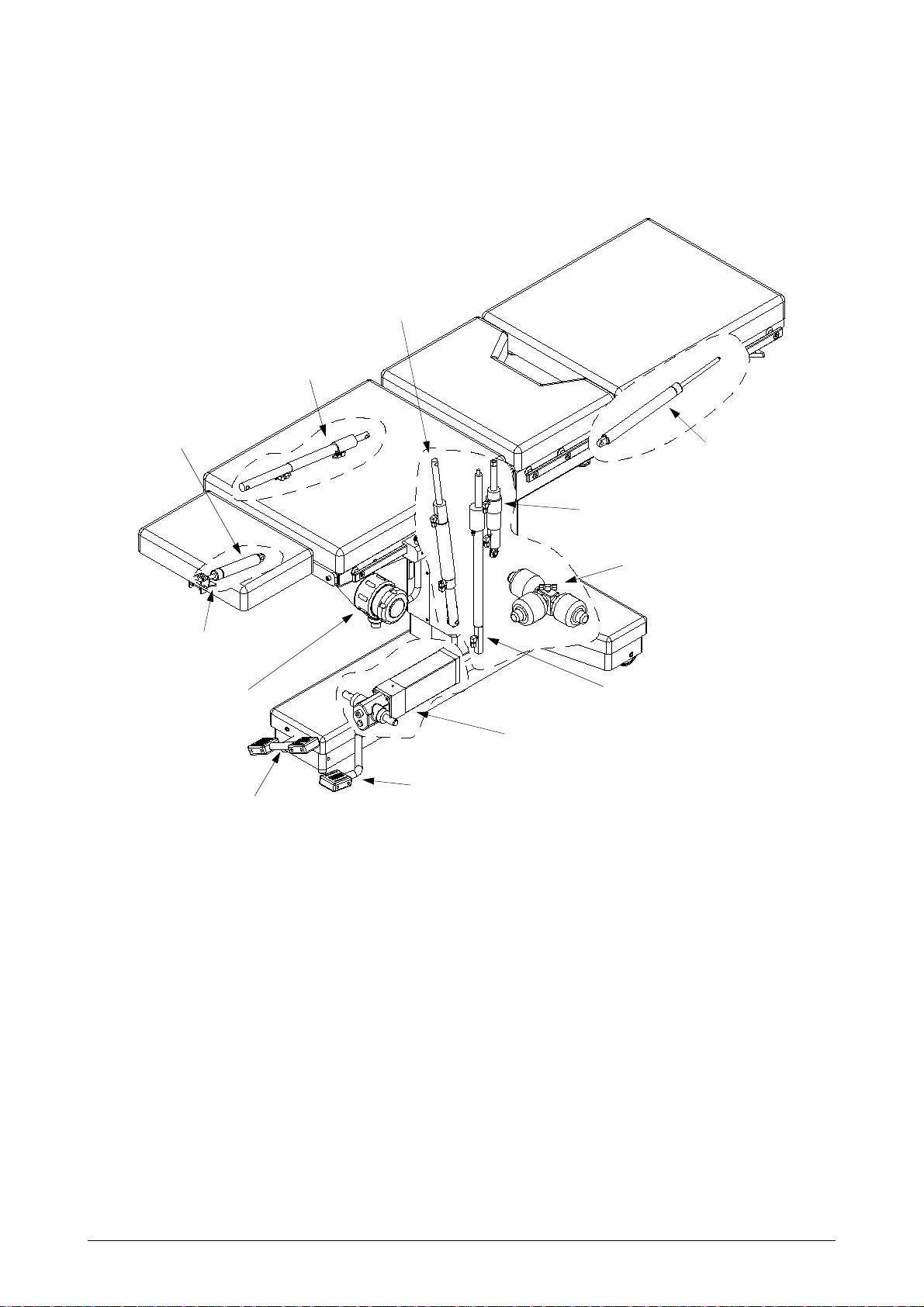

3.2 Main components

Trendelenburg

hydraulic cylinder

Back section

hydraulic cylinder, 2 pcs

Head section

gas spring

Leg section

gas spring, 2 pcs

Head section

handle

Selector

Brake pedal

height adjustment

hydraulic pump

Hydraulic pedal

Side tilt

hydraulic cylinder

Pressure accumulator

Height adjustment

hydraulic cylinder

o1025b.eps

8

Loading...

Loading...