Meritor Differential Carriers Maintenance Manual

Single-Reduction

Differential Carriers

Maintenance Manual 5

Revised 10-06

Standard Carriers

Including: Single Axles,

Rear of Tandem Axles,

Front Drive Steering

Axles

Excluding RS and

RT Series (Rear Only),

Single-Reduction Axles

and RF Series Front

Drive Axles

Service Notes

Before You Begin

This manual provides instructions for Meritor’s

early production non-RF, -RS or -RT Series axles.

Before you begin procedures:

1. Read and understand all instructions an

procedures before you begin to service

components.

2. Read and observe all Caution and Warning

safety alerts that precede instructions or

procedures you will perform. These alerts help

to avoid damage to components, serious

personal injury, or both.

3. Follow your company’s maintenance and

service, installation, and diagnostics

guidelines.

4. Use special tools when required to help avoid

serious personal injury and damage to

components.

Safety Alerts, Torque Symbol

and Notes

A Warning alerts you to an

WARNING

CAUTION

T

NOTE

instruction or procedure

that you must follow

exactly to avoid serious

personal injury and

damage to components.

A Caution alerts you to an

instruction or procedure

that you must follow

exactly to avoid damage to

components and possible

serious injury.

A torque symbol alerts you

to tighten fasteners to a

specified torque value.

A Note provides

information or suggestions

that help you correctly

service a component.

Access Information on

ArvinMeritor’s Website

Additional maintenance and service information

for ArvinMeritor’s commercial vehicle systems

component lineup is also available at

www.arvinmeritor.com.

To access information, click on Products &

Services/Tech Library Icon/HVS Publications.

The screen will display an index of publications

by type.

Additional Information

For complete maintenance and service procedures

for all single-reduction differential carriers, call

ArvinMeritor’s Customer Service Center at

800-535-5560 to order the following publications.

앫 Traction Controls package contains two videos —

Splitting the Difference T-87127V and

Driver-Controlled Full Locking Main Differential

T-9007V. $50. Order T-95125V for this package or

each video is available individually as well.

앫 Technical Electronic Library on CD. Features

product and service information on most

ArvinMeritor, ZF Meritor and Meritor WABCO

components. $20. Order TP-9853.

How to Obtain Tools and Supplies

Specified in This Manual

Kiene Diesel Accessories, Inc., 325 S. Fairbanks

Street, Addison, IL 60101. Call the company’s

customer service center at 800-264-5950, or visit

their website at kienediesel.com.

SPX/OTC Service Solutions, 655 Eisenhower Drive,

Owatonna, MN 55060. Call the company’s service

center at 800-533-6128, or visit their website at

otctools.com.

Table of Contents

Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Section 1: Introduction

Standard Single-Reduction Carriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Axle Models Covered in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Section 2: Disassembly

Axle Shaft Removal Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Brass Drift Method

Air Hammer Vibration Method

Remove Differential Carrier from Axle Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Carrier Removal from Axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Remove the Differential and Ring Gear from the Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Disassemble the Differential and Ring Gear Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Remove the Drive Pinion and Bearing Cage from Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Disassemble the Drive Pinion and Bearing Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Section 3: Preparing the Parts for Assembly

Cleaning Ground and Polished Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cleaning Rough Parts

Cleaning Axle Assemblies

Drying Parts After Cleaning

Preventing Corrosion on Cleaned Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Inspecting Parts

Repair or Replacement of Parts, General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Repair Axle by Welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Bending or Straightening Drive Axle Housings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Removing Dri-Loc

Section 4: General Information

Installing Fasteners with Pre-Applied Adhesive, Meritor Liquid Adhesive 2297-C-7049,

Loctite

Installing New Fasteners with Pre-applied Adhesive Patches

Installing Original or Used Fasteners Using Meritor Liquid Adhesive 2297-C-7049 or

Loctite

Application of Meritor Adhesive 2297-T-4180 in Bearing Bores for the Differential

Application of Three Bond 1216 or Equivalent Silicone Gasket Material . . . . . . . . . . . . . . . . . . . . . . . .27

Installing Tight Fit Yokes and POSE™ Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

General Yoke and U-Joint Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Gear Set Information (Drive Pinion and Ring Gear Marks)

Section 5: Assembly

Assemble the Drive Pinion, Bearings and Bearing Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Adjusting Preload of Pinion Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Adjusting Shim Pack Thickness for the Pinion Cage (Depth of Pinion) . . . . . . . . . . . . . . . . . . . . . . . . . .41

Installing the Drive Pinion, Bearing Cage and Shim Pack into the Carrier . . . . . . . . . . . . . . . . . . . . . . . 43

Installing Tight Fit Yokes and POSE™ Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Assemble the Main Differential and Ring Gear Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Inspecting the Rotating Resistance of the Differential Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Install the Differential and Ring Gear Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Adjust Preload of Differential Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Method 1

Method 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Inspect Runout of Ring Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Ring Gear Backlash Adjustment

Inspect Tooth Contact Patterns of the Gear Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Install and Adjust the Thrust Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Install Differential Carrier into Axle Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Straight Holes, Nuts and Hardened Washers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Tapered Dowel, Hardened Washer and Hardened Nut

®

Fasteners

®

680 Liquid Adhesive or Equivalent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

®

680 or Equivalent

Table of Contents

Section 6: Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Axle Lubricant Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Section 7: Fastener Torque Information

Torque Values for Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

General Information

American Standard Fasteners

Metric Fasteners

Section 8: Adjustments and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Section 9: Vehicle Towing Instructions (Non-DCDL)

Before Towing or Drive-Away . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

After Towing or Drive-Away . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

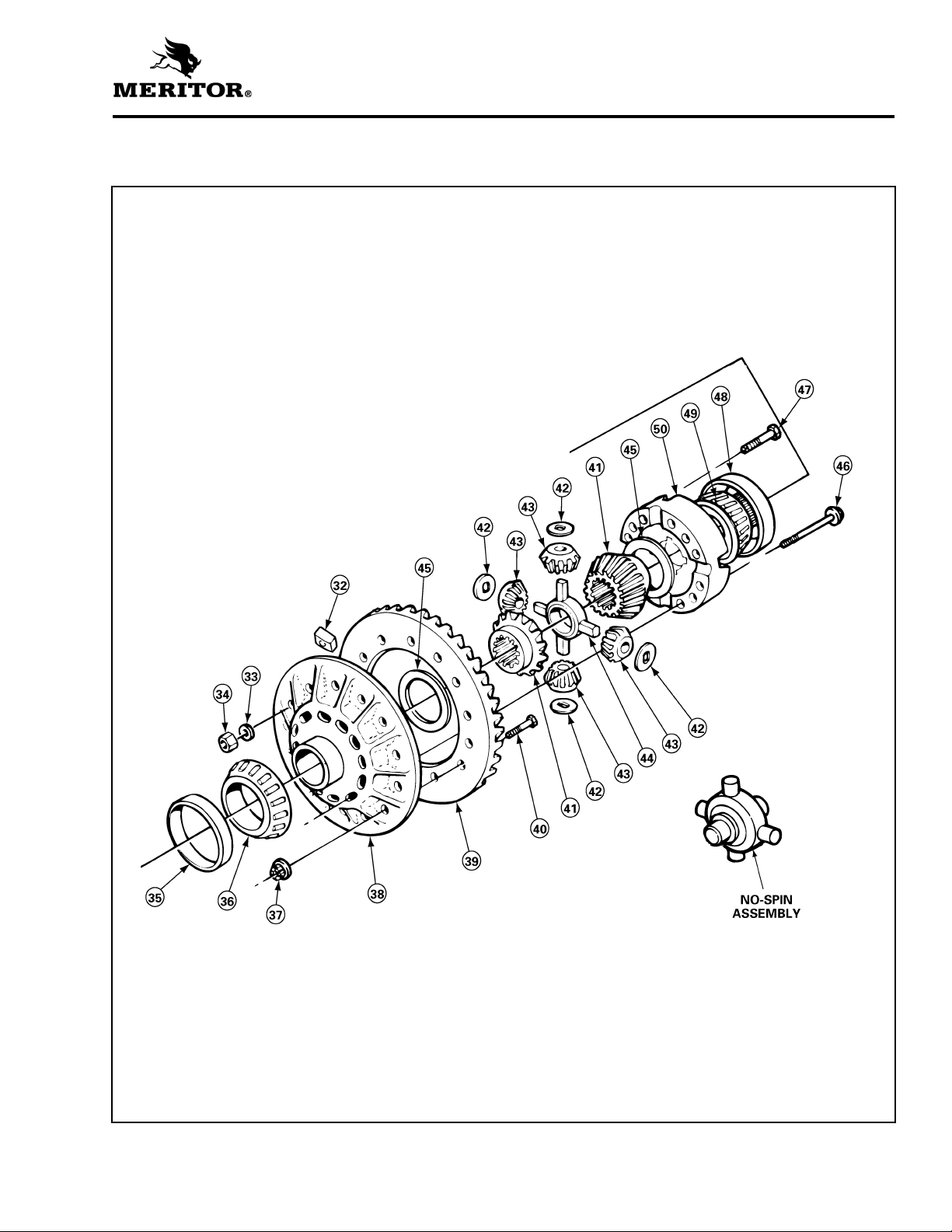

Exploded View — Legend

Exploded View

1 Nut — Drive Pinion

2 Washer — Drive Pinion*

3 Input Yoke* or Flange*

4 Deflector

5 Oil Seal

6 Capscrew — Bearing Cage

7 Washer

8 Bearing Cone — Pinion Outer

9 Bearing Cup — Pinion Outer

10 Bearing Cage — Drive Pinion

11 Shims

12 Spacer— Pinion Bearing

13 Bearing Cup — Pinion Inner

14 Bearing Cone — Pinion Inner

15 Drive Pinion

16 Spigot Bearing

16A Snap Ring

17 Carrier

18 Thrust Screw*

19 Jam Nut* — Thrust Screw*

20 Adjusting Ring — L.H.

26 Washers* — Lock Plate

27 Capscrews* — Lock Plate*

28 Adjusting Ring — R.H.

29 Plug* — Oil Fill Hole (carrier)

30 Washer* — Capscrew/Plug*

31 Capscrew/Plug — Sensor Hole

32 Thrust Block*

33 Washers* — Differential Case

34 Nuts* — Differential Case

35 Bearing Cup — Differential L.H.

36 Bearing Cone — Differential L.H.

37 Nuts* — Ring Gear and Case Half

38 Case Half — Flange

39 Ring Gear

40 Bolts* or Rivets* — Ring Gear and

Case Half

41 Side Gears —Differential

42 Thrust Washers — Differential Pinion

43 Pinions — Differential

44 Spider — Differential

45 Thrust Washers — Differential Side

Gear

21 Cotter* or Pin*

22 Caps — Differential Bearing

23 Washers

24 Capscrews — Differential Bearing Cap

25 Lock Plate* — Adjusting Ring

* Some Meritor carriers do not have these described parts.

NoSPIN® is a registered trademark of Tractech, a division of Dyneer Corp.

46 Capscrews — Differential Case

47 Bolts* — Differential Case

48 Bearing Cup — Differential R.H.

49 Bearing Cone — Differential R.H.

50 Case Half — Plain

1

Exploded View

Single-Reduction Differential Carrier

2

Exploded View

3

Section 1

Introduction

Section 1Introduction

Standard Single-Reduction

Carriers

NOTE: For carriers with a differential lock, refer

to Maintenance Manual 5A.

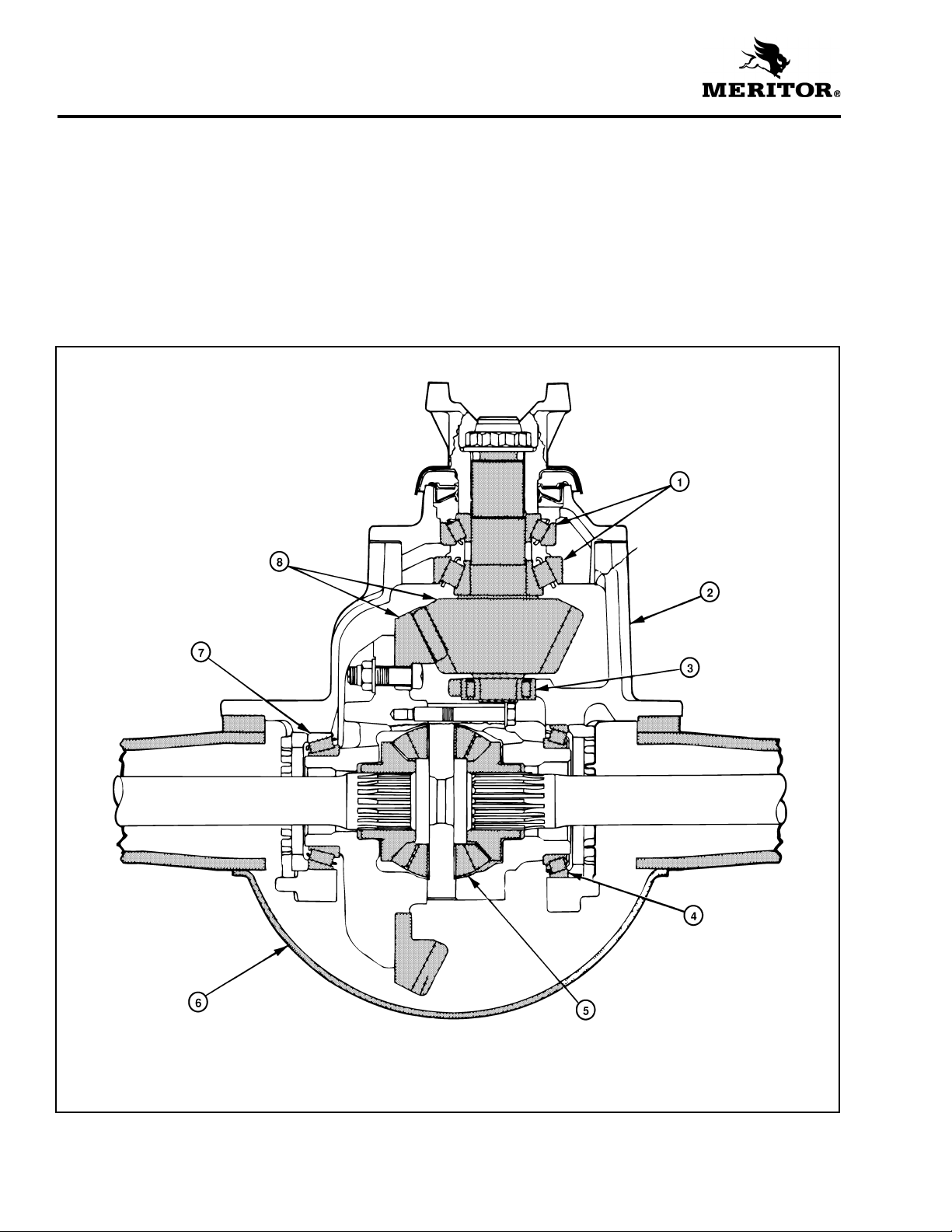

Meritor single-reduction standard carriers,

Figure 1.1, are used in most Meritor single axles,

rear of tandem axles and front drive steering axles.

Figure 1.1

The single-reduction carrier models are front

mounted into the axle housing. These carriers

have a hypoid drive pinion and ring gear set and

bevel gears in the differential assembly.

A straight roller bearing (spigot) is mounted on the

head of the drive pinion. All other bearings in the

carrier are tapered roller bearings.

When the carrier operates, there is normal

differential action between the wheels all the time.

1 TAPERED ROLLER BEARINGS

2 CARRIER

3 STRAIGHT ROLLER BEARING

4 TAPERED ROLLER BEARING

4

5 BEVEL DIFFERENTIAL GEARS

6 HOUSING

7 TAPERED ROLLER BEARING

8 HYPOID DRIVE PINION AND RING GEAR

Axle Models Covered in This Manual

The following table lists all axle models covered in

this manual.

Single Drive Axles:

A-150 E-100 F-140 H-172 Q-100 R-163

B-100 E-105 G-161 L-100 Q-145 R-170

B-140 E-150 H-100 L-140 RL-170 S-170

B-150 F-100 H-140 L-155 R-100 U-140

C-100 F-106 H-150 L-172 R-140 W-170

D-100 F-120 H-162 M-172 R-155

D-140 F-121 H-170 QT-140 R-160

Rear Axle of Tandem Axles:

SDHD SL-100 SQHD SSHD SU-170

Section 1

Introduction

For All RS & RT

Single-Reduction

Axle Model Series,

Refer to

Maintenance

Manual 5A.

SFHD SLHD SR-170 ST-170 SUHD

SHHD SQ-100 SRHD STHD SW-170

Front Drive Steering Axles:

FDS-75 FDS-85 FDS-93 FDS-1807 FDS-2100 FDS-2107 FDS-2111

FDS-78 FDS-90 FDS-1600 FDS-1808 FDS-2101 FDS-2110 FDS-2117

5

Section 2

Disassembly

Section 2 Disa ssemb ly

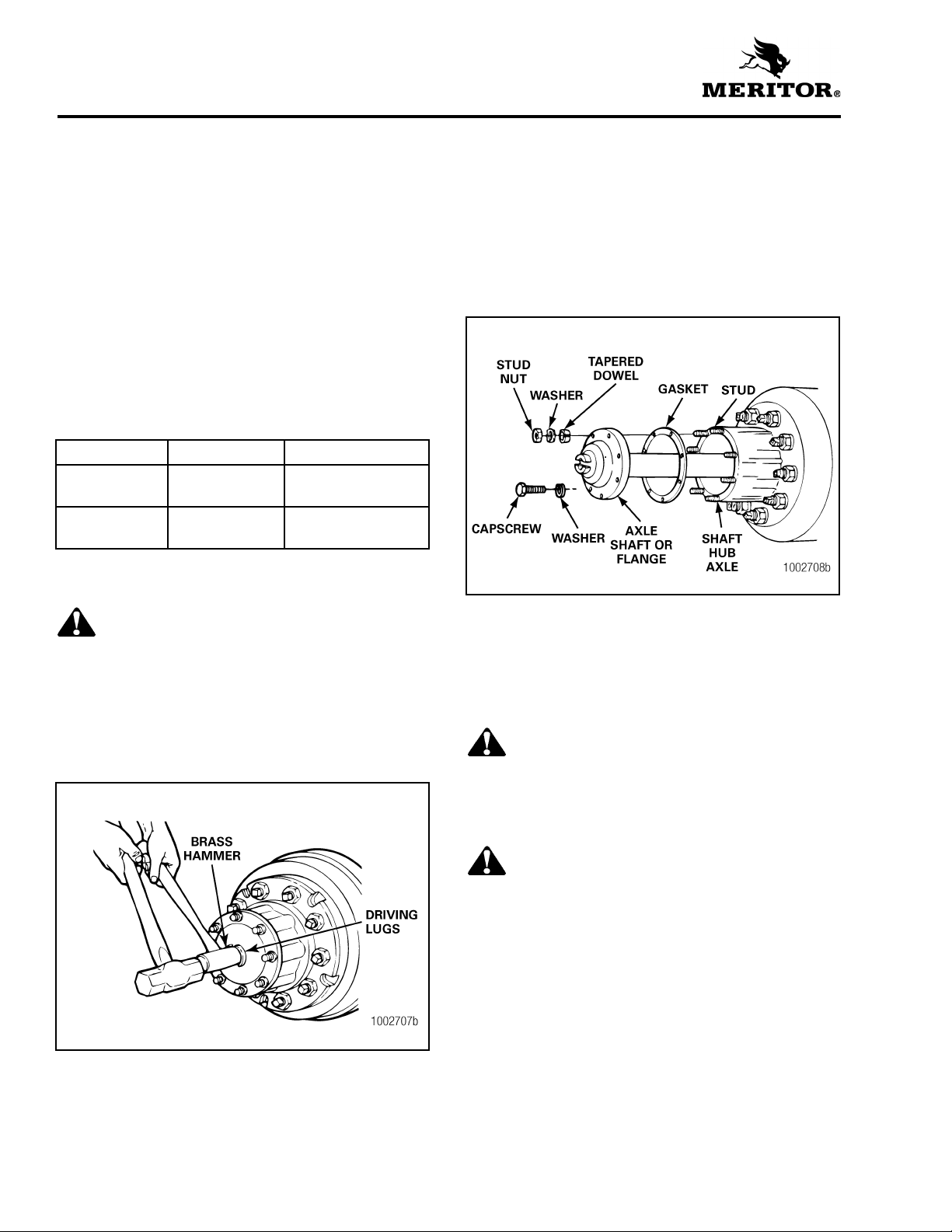

Axle Shaft Removal Methods

Meritor Recommends Using

Special Tools

To help prevent serious personal injury and

damage to components when you remove the axle

shaft from the housing, Meritor recommends that

you use the tools in the table below. Refer to the

Service Notes page at the front inside cover of this

manual for information on how to contact the

manufacturers to obtain the tools.

앫 If the tools are not available when you remove

the axle shaft: Follow procedures for using the

Brass Drift Method or the Air Vibration Method.

Tool Part Number Manufacturer

Axle Shaft

Remover

Axle Stud

Cone Plier

K-1280 Kiene Diesel

Accessories, Inc.

7077 SPX OTC

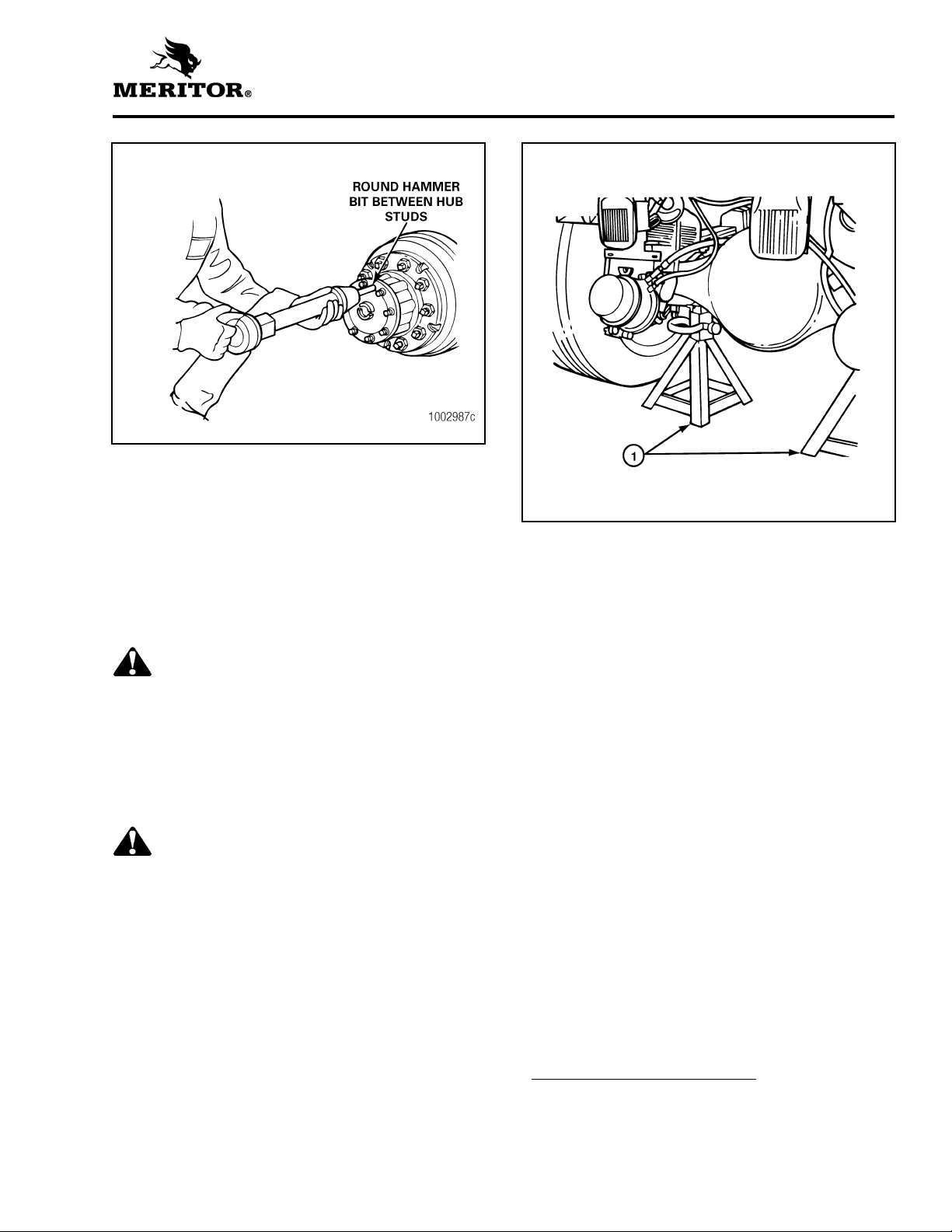

Brass Drift Method

2. Strike the end of the drift with a large hammer,

five to six pounds, and the axle shaft and

tapered dowels will loosen.

3. Mark each axle shaft before it is removed from

the axle assembly.

4. Remove the tapered dowels and separate the

axle shafts from the main axle hub assembly.

Figure 2.2.

Figure 2.2

WARNING

Do not strike the round driving lugs on the flange

of an axle shaft. Pieces can break off and cause

serious personal injury.

1. Hold a 1-1/2 -inch diameter brass drift or brass

hammer against the center of the axle shaft,

inside the round driving lugs. Figure 2.1.

Figure 2.1

5. Install a cover over the open end of each axle

assembly hub where an axle shaft was

removed.

Air Hammer Vibration Method

WARNING

Wear safe eye protection when using an air

hammer. When using power tools, axle

components can loosen and break off causing

serious personal injury.

CAUTION

Do not use a chisel or wedge to loosen the axle

shaft and tapered dowels. Using a chisel or wedge

can result in damage to the axle shaft, the gasket

and seal, and the axle hub.

1. Use a round hammer bit and an air hammer to

loosen the tapered dowels and axle shaft.

2. Place the round hammer bit against the axle

shaft or flange between the hub studs. Operate

the air hammer at alternate locations between

the studs to loosen the tapered dowels and

axle shaft from the hub. Figure 2.3.

6

Section 2

Disassembly

Figure 2.3

3. Mark each axle shaft before it is removed from

the axle assembly.

4. Remove the tapered dowels and separate the

axle shaft from the main axle hub assembly.

Figure 2.2.

Remove Differential Carrier

from Axle Housing

WARNING

To prevent serious eye injury, always wear safe eye

protection when you perform vehicle maintenance

or service.

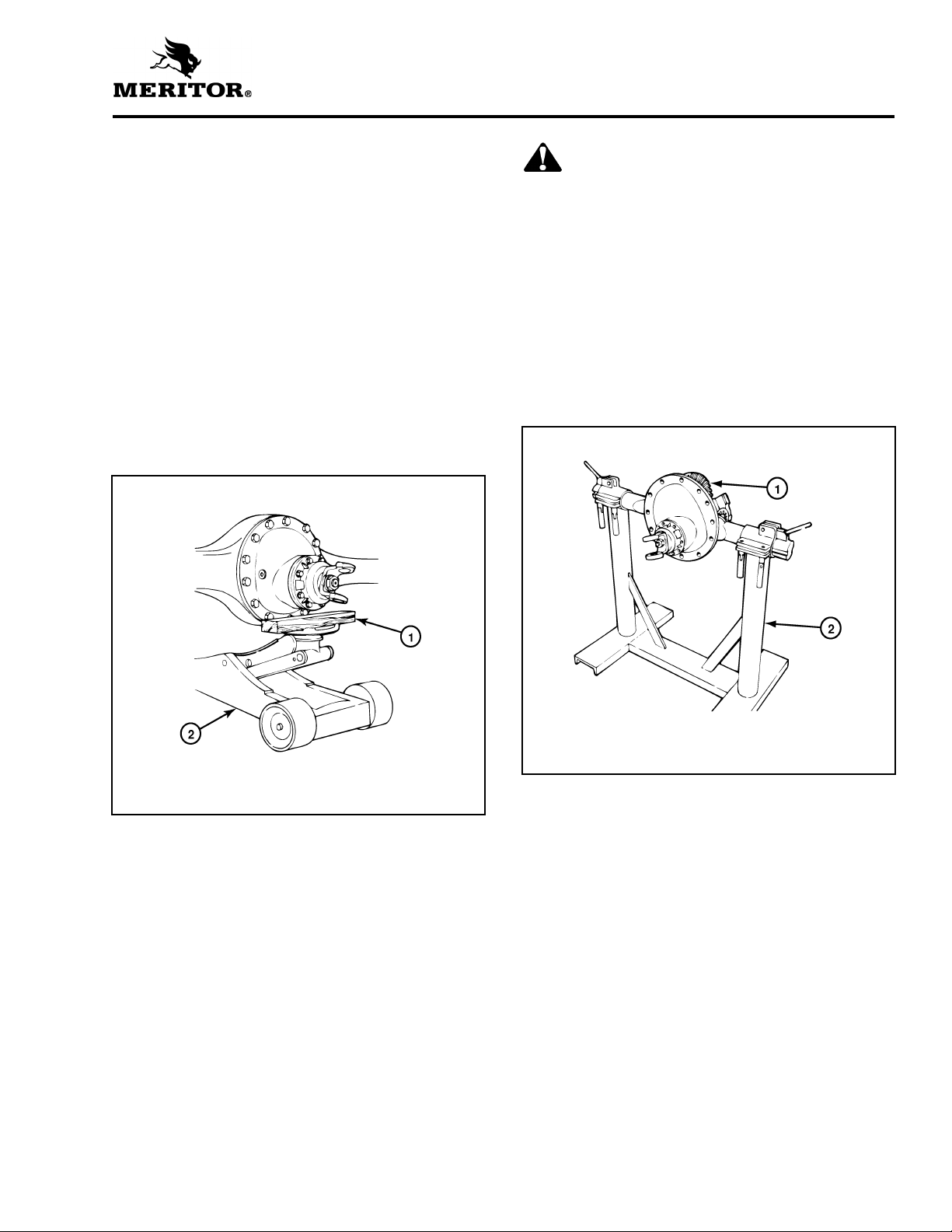

1. Raise the end of vehicle where the axle is

mounted. Use a jack or other lifting tool, and

place safety stands under each side of the axle.

Figure 2.4.

Figure 2.4

1 SAFETY STANDS

3. Remove the plug from bottom of axle housing

and drain lubricant from the assembly.

4. Disconnect the driveline universal joint from

the pinion input yoke or flange on the carrier.

Figure 2.5.

5. Remove the capscrews* and washers or stud

nuts* and washers from the flanges of both

axle shafts.*

6. Loosen the tapered dowels* if applicable, in

the axle flanges of both axle shafts using either

the Brass Drift or the Air Hammer Vibration

method. Refer to Axle Shaft Removal Methods

in this section.

WARNING

Park the vehicle on a level surface. Block the

wheels to prevent the vehicle from moving.

Support the vehicle with safety stands. Do not

work under a vehicle supported only by jacks.

Jacks can slip or fall over. Serious personal injury

can result.

2. Place jack stands under each spring seat of the

axle to hold vehicle in the raised position.

Figure 2.4.

*Some Meritor carriers do not have these

described parts.

7

Section 2

Disassembly

Figure 2.5

1 FULL ROUND BEARING CUPS

2 END YOKE

3 YOKE SADDLE

4 WELD YOKE

5 BEARING STRAP

6 CAPSCREWS

7 EASY-SERVICE BEARING CUPS

8 U-JOINT CROSS

9 SLIP YOKE

8

10 CAPSCREWS

11 END YO K E

12 WELD YOKE

13 SLIP YOKE

14 U-JOINT CROSS

15 CAPSCREWS

16 END YOKE

17 WELD YOKE

18 SLIP YOKE

19 U-JOINT CROSS

20 CAPSCREWS

21 END YOKE

22 SLIP YOKE

23 TUBING

24 U-JOINT CROSS

25 WELD YOKE

Carrier Removal from Axle

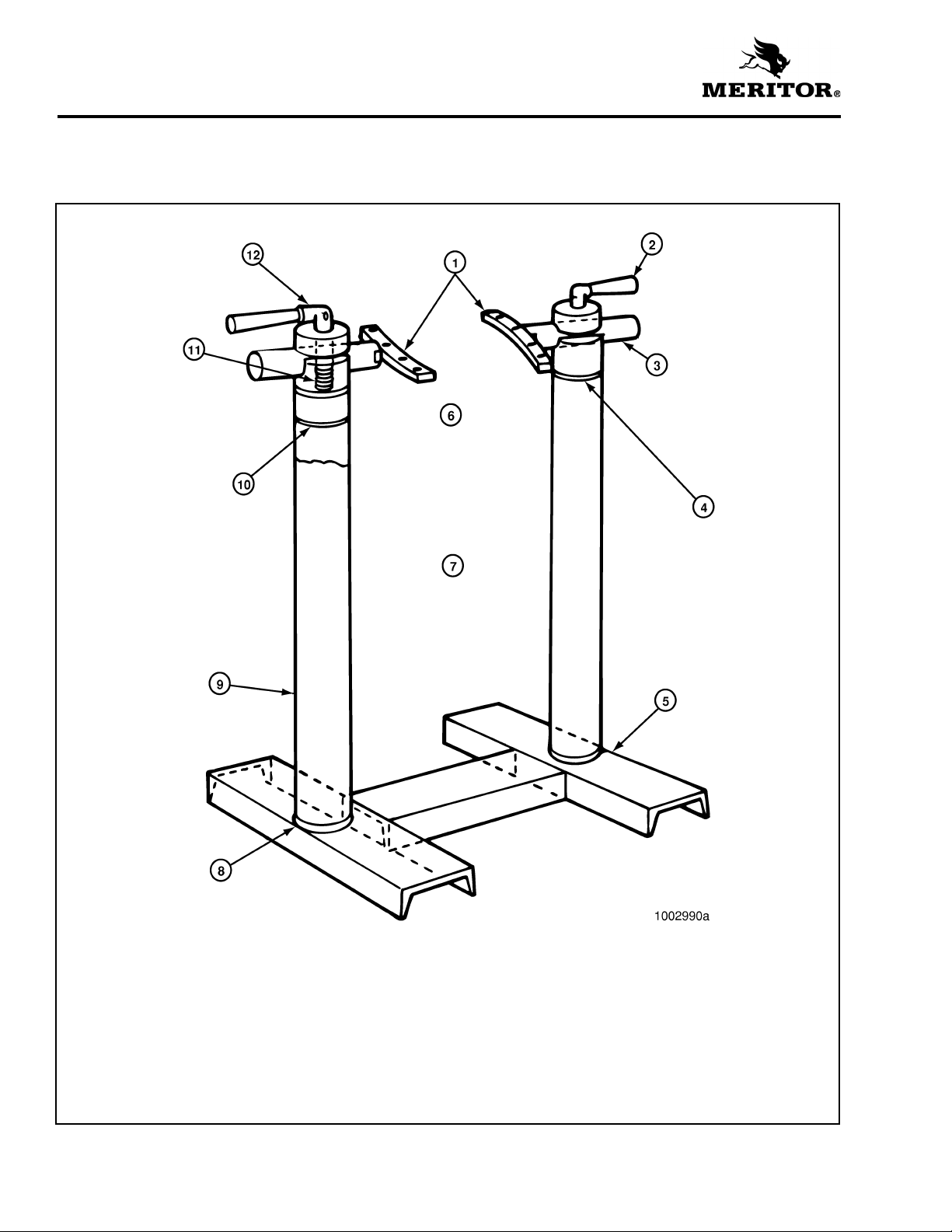

1. Place a hydraulic roller jack under the

differential carrier to support the assembly.

Figure 2.6.

2. Remove all but the top two carrier to housing

capscrews or stud nuts and washers.

3. Loosen the top two carrier-to-housing

fasteners and leave attached to the assembly.

The fasteners will hold the carrier in the

housing.

4. Loosen the differential carrier in the axle

housing. Use a leather mallet to hit the

mounting flange of carrier at several points.

5. After the carrier is loosened, remove the top

two fasteners.

Figure 2.6

Section 2

Disassembly

CAUTION

When using a pry bar be careful not to damage

the carrier or housing flange. Damage to these

surfaces will cause oil leaks.

6. Carefully remove the carrier from the axle

housing using the hydraulic roller jack. Use a

pry bar that has a round end to help remove

the carrier from the housing.

7. Lift the differential carrier by the input yoke or

flange and place the assembly in a repair

stand. Figure 2.7. Use a lifting tool for this

procedure. Do not lift by hand. A carrier stand

can be built by referring to Figure 2.8.

Figure 2.7

1 WOOD BLOCK

2 ROLLER JACK

1 DIFFERENTIAL CARRIER

2 REPAIR STAND

9

Section 2

Disassembly

A carrier stand, part number J 3409-D is available

from Kent-Moore, Heavy-Duty Division, 28635

Mound Road, Warren, MI 48092.

Figure 2.8

1 PLATES 8' LONG x 3/4" THICK x 1-1/4" WIDE WITH A

TONGUE TO FIT SLOT IN BAR WELD PLATES TO BAR

2 HANDLE 7" LONG WITH SLOT IN ONE END TO FIT CLAMP

SCREW

3 BAR 2" DIAMETER x 9" LONG WITH ONE END SLOTTED

TO FIT PLATE

4 WELD ALL AROUND AFTER PRESSING PLUG IN PIPE

5 WELD

6 SHAPE AND SIZE OF HOLES TO FIT CARRIER

CARRIER STAND

10

7 23-1/2" CENTER TO CENTER OF PIPE

8 CHAMFER END OF PIPE FOR WELDING

9 4” DIAMETER PIPE

10 PLUG 4" DIAMETER x 7" LONG WITH ONE END TURNED

3" LONG TO FIT PIPE. DRILL 2" HOLE AND MILL 3/16"

WIDE SLOT 2" FROM TOP

11 SCREW 3-1/2" LONG x 5/8" DIAMETER WITH FLATS ON

END TO FIT HANDLE AND 2-1/2" LENGTH OF THREAD

ON OTHER END

12 DRILL 3/8" HOLE THROUGH HANDLE AND SCREW

Section 2

Disassembly

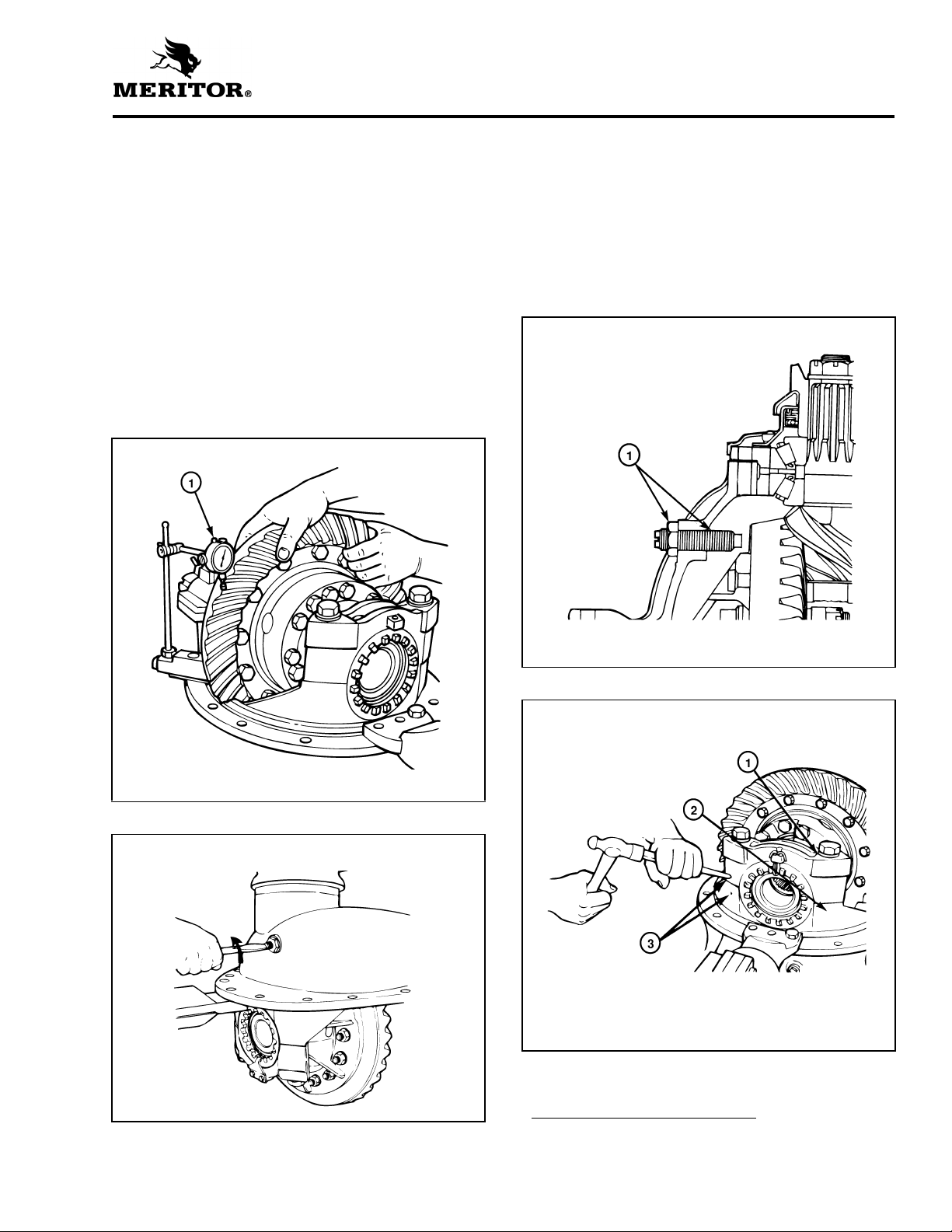

Remove the Differential and

Ring Gear from the Carrier

NOTE: Before working on the differential carrier,

inspect the hypoid gear set for damage. If

inspection shows no damage, the same gear set

can be used again. Measure the backlash of the

gear set and make a record of the dimension.

Figure 2.9. (Refer to “Ring Gear Backlash

Adjustment” in Section 5, Steps 1-5.) During

differential reassembly, adjust the backlash to the

original recorded dimension when the gear set is

installed into the carrier.

1. Loosen the jam nut* on the thrust screw*.

Figure 2.10.

Figure 2.9

2. Remove the thrust screw* and jam nut* from

the differential carrier. Figure 2.11.

3. Rotate the differential carrier in the repair stand

until the ring gear is at the top of the assembly.

4. Mark one carrier leg and bearing cap to

correctly match the parts during carrier

assembly. Mark the parts using a center punch

and hammer. Figure 2.12.

Figure 2.11

1 DIAL INDICATOR

Figure 2.10

1 THRUST SCREW AND JAM NUT

Figure 2.12

1 BEARING CAP

2 CARRIER LEG

3 MATCH MARKS

*Some Meritor carriers do not have these

described parts.

11

Section 2

Disassembly

5. Remove the cotter keys*, pins* or lock plates*

that hold the two bearing adjusting rings in

position. Use a small drift and hammer to

remove pins. Each lock plate is held in position

by two capscrews. Figure 2.13.

6. Remove the capscrews and washers that hold

the two bearing caps on the carrier. Each cap is

held in position by two capscrews and

washers. Figure 2.14.

7. Remove the bearing caps and bearing

adjusting rings from the carrier. Figure 2.15.

8. Safely lift the main differential and ring gear

assembly from the carrier. Place the assembly

on a work bench. Figure 2.16.

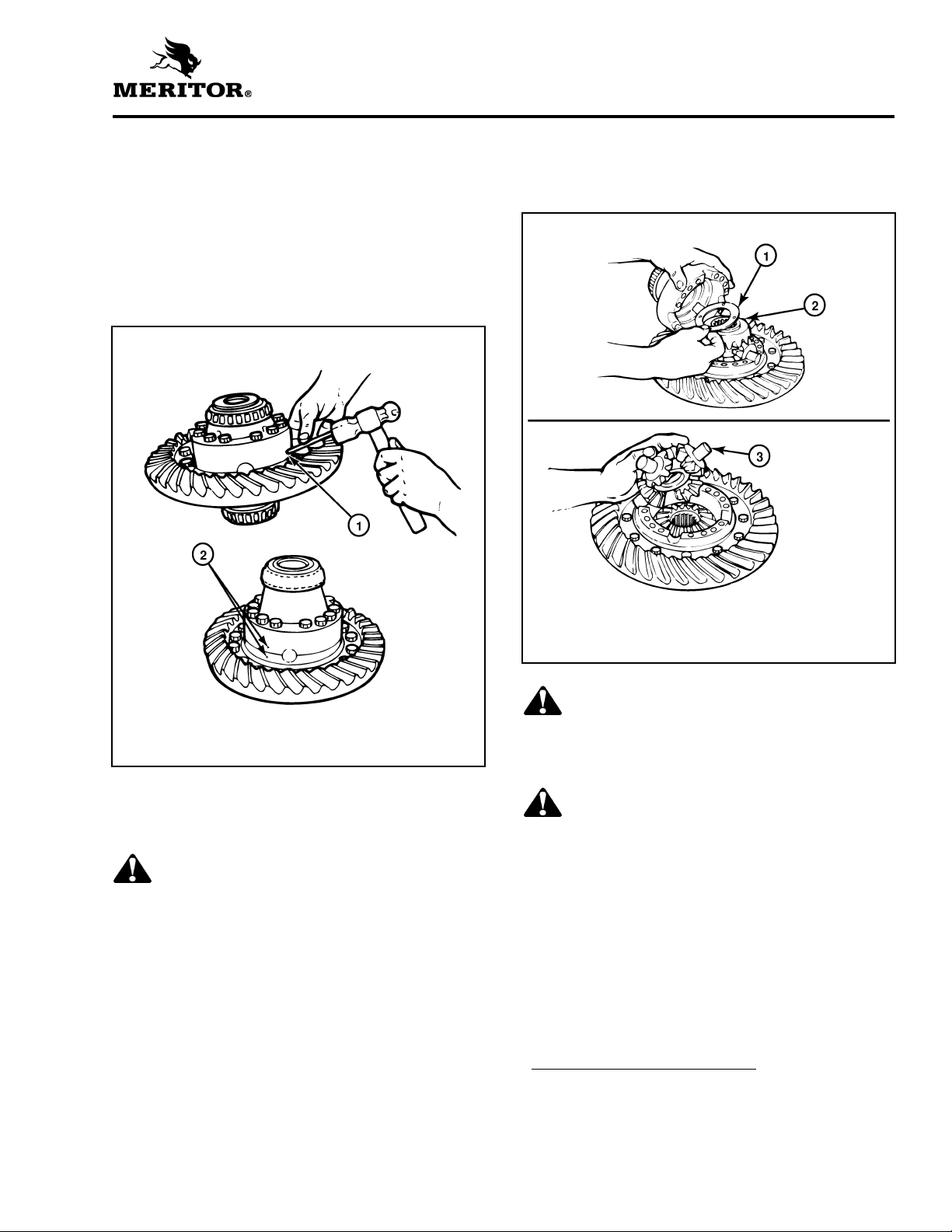

Figure 2.13

Figure 2.14

1 BEARING CAP

Figure 2.15

1 REMOVING COTTER KEY

2 REMOVING LOCK PLATE

*Some Meritor carriers do not have these

described parts.

12

1 BEARING CAP

2 BEARING ADJUSTING RING

Figure 2.16

Section 2

Disassembly

Disassemble the Differential

and Ring Gear Assembly

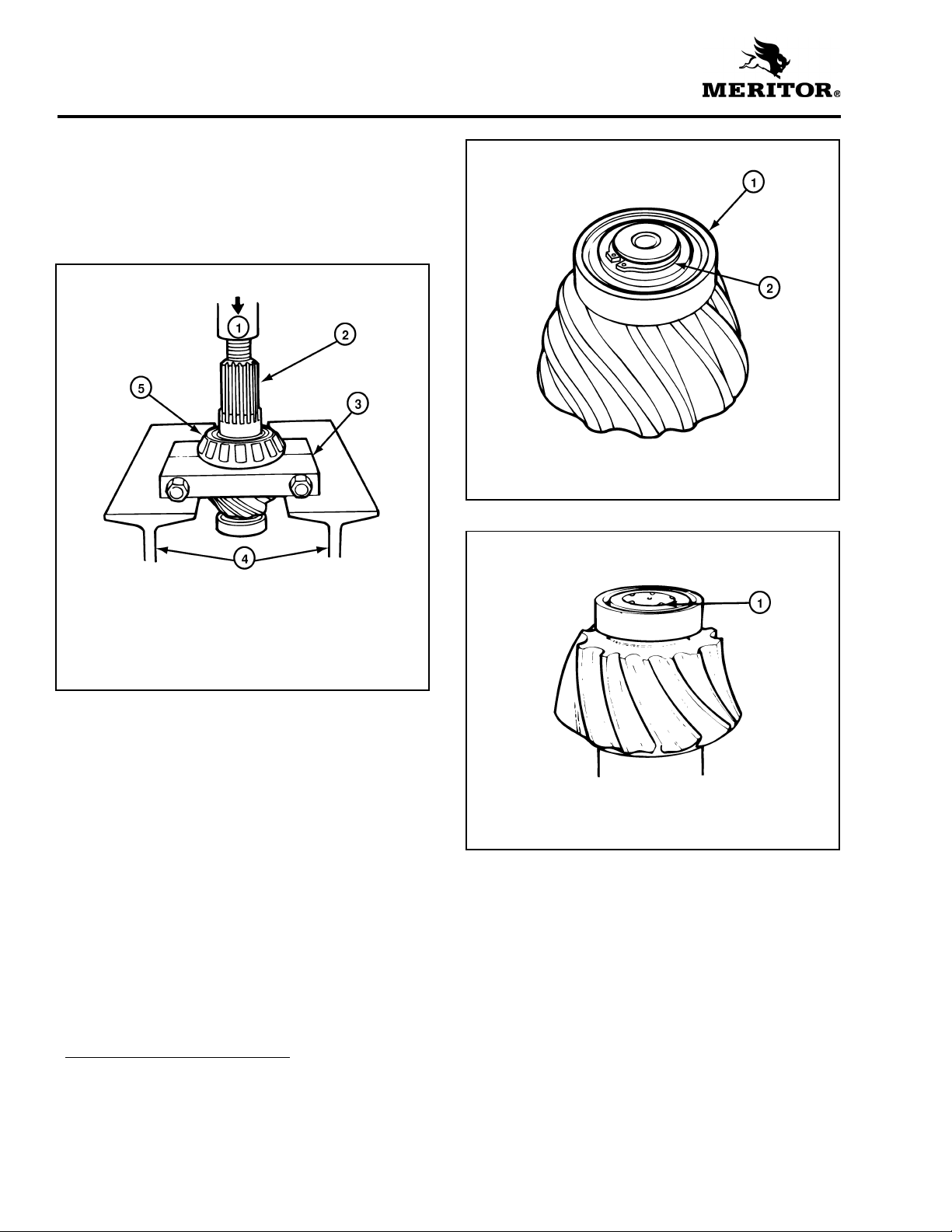

1. If the matching marks on the case halves of the

differential assembly are not visible, mark each

case half with a center punch and hammer. The

purpose of the marks is to match the plain half

and flange half correctly when you assemble

the carrier. Figure 2.17.

Figure 2.17

5. If the ring gear needs to be replaced, remove

the bolts*, nuts*, and washers* that hold the

gear to the flange case half.

Figure 2.18

1 MATCH MARKS

2 MATCH MARKS

2. Remove the capscrews* and washers* or

bolts*, nuts* and washers that hold the case

halves together.

WARNING

Use a brass or leather mallet for assembly and

disassembly procedures. Do not hit steel parts

with a steel hammer. Pieces of a part can break off

and cause serious personal injury.

3. Separate the case halves. If necessary, use a

brass, plastic or leather mallet to loosen the

parts.

4. Remove the differential spider (cross), four

pinion gears, two side gears and six thrust

washers from inside the case halves.

Figure 2.18.

1 THRUST WASHER

2 SIDE GEAR

3 SPIDER, PINIONS AND THRUST WASHERS

WARNING

Observe all warnings and cautions provided by the

press manufacturer to avoid damage to

components and serious personal injury.

CAUTION

Do not remove the rivets or rivet heads with a

chisel and hammer. Using a flat edge tool can

cause damage to the flange case.

6. If rivets* hold the ring gear to the flange case

half, remove the rivets as follows:

7. Carefully center punch each rivet head in the

center, on the ring gear side of the assembly.

*Some Meritor carriers do not have these

described parts.

13

Section 2

Disassembly

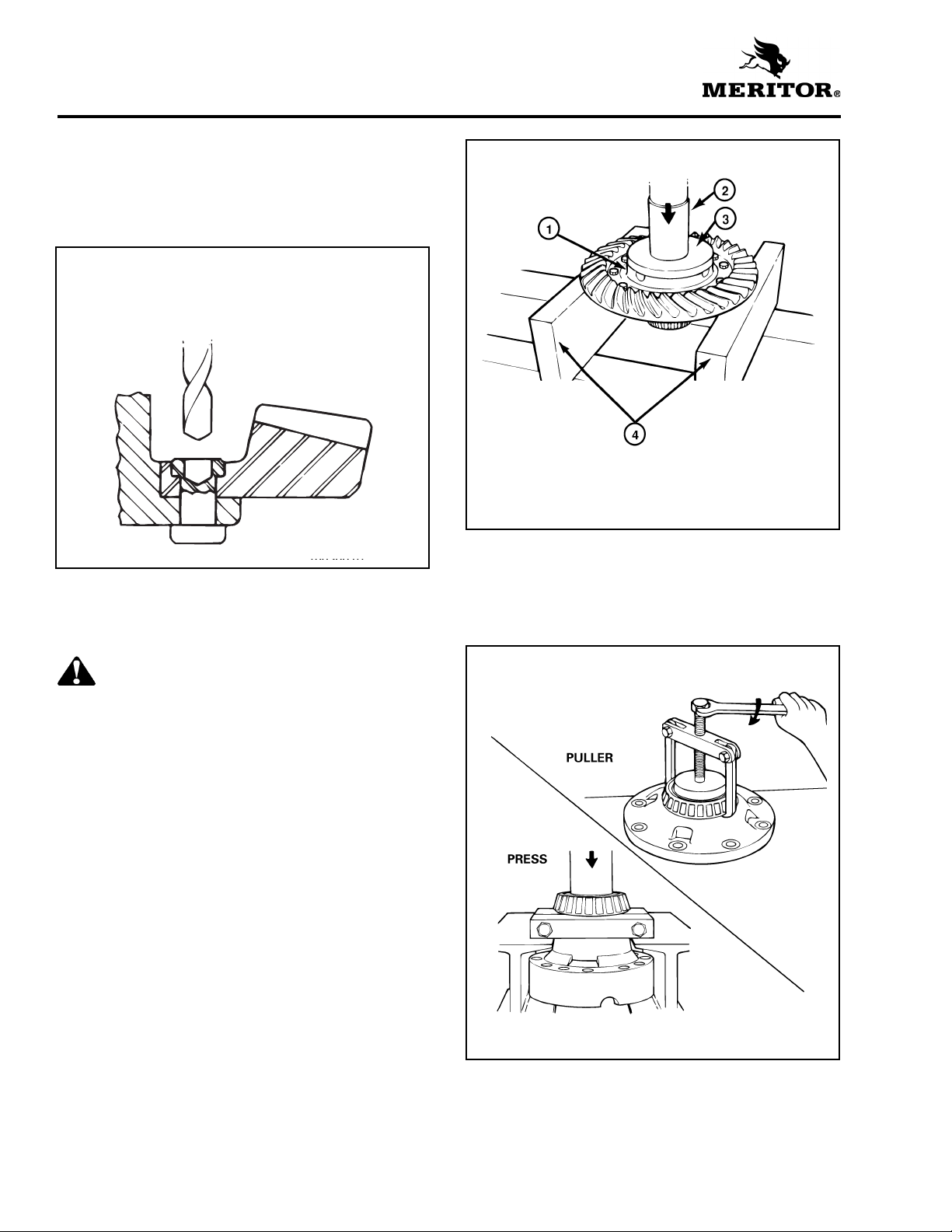

8. Drill each rivet head on the ring gear side of the

assembly to a depth equal to the thickness of

one rivet head. Use a drill bit that is 1/32 of an

inch smaller than the body diameter of the

rivets. Figure 2.19.

Figure 2.19

DRILLING RIVET FROM HEAD

9. Press the rivets through holes in the ring gear

and flange case half. Press from the drilled

rivet head.

Figure 2.20

1 CASE HALF

2 PRESS

3 PLATE

4 SUPPORTS

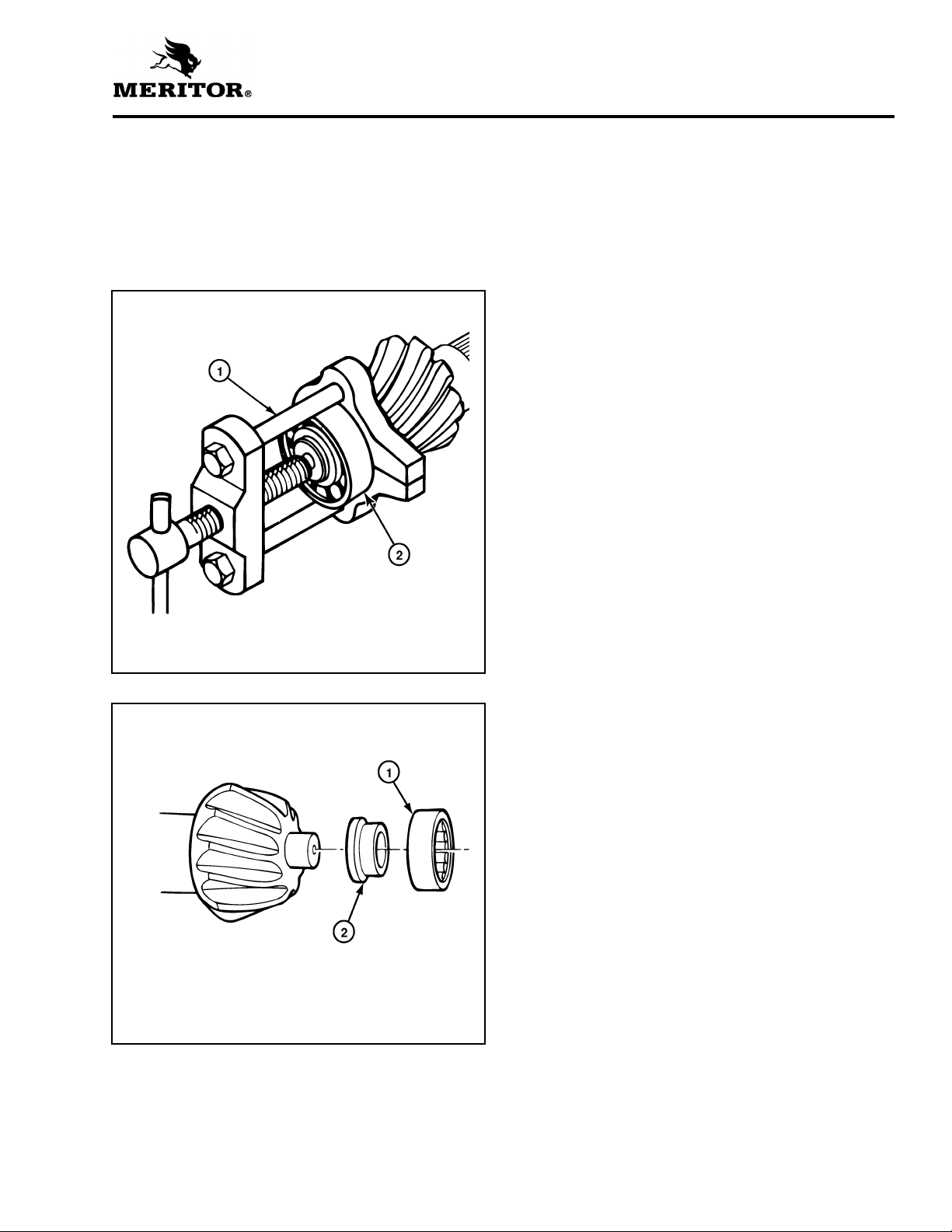

11. If the differential bearings need to be replaced,

remove the bearing cones from the case

halves. Use a bearing puller or press.

Figure 2.21.

WARNING

Observe all warnings and cautions provided by the

press manufacturer to avoid damage to

components and serious personal injury.

10. Separate the case half and ring gear using a

press. Support the assembly under the ring

gear with metal or wood blocks and press the

case half through the gear. Figure 2.20.

Figure 2.21

14

Section 2

Disassembly

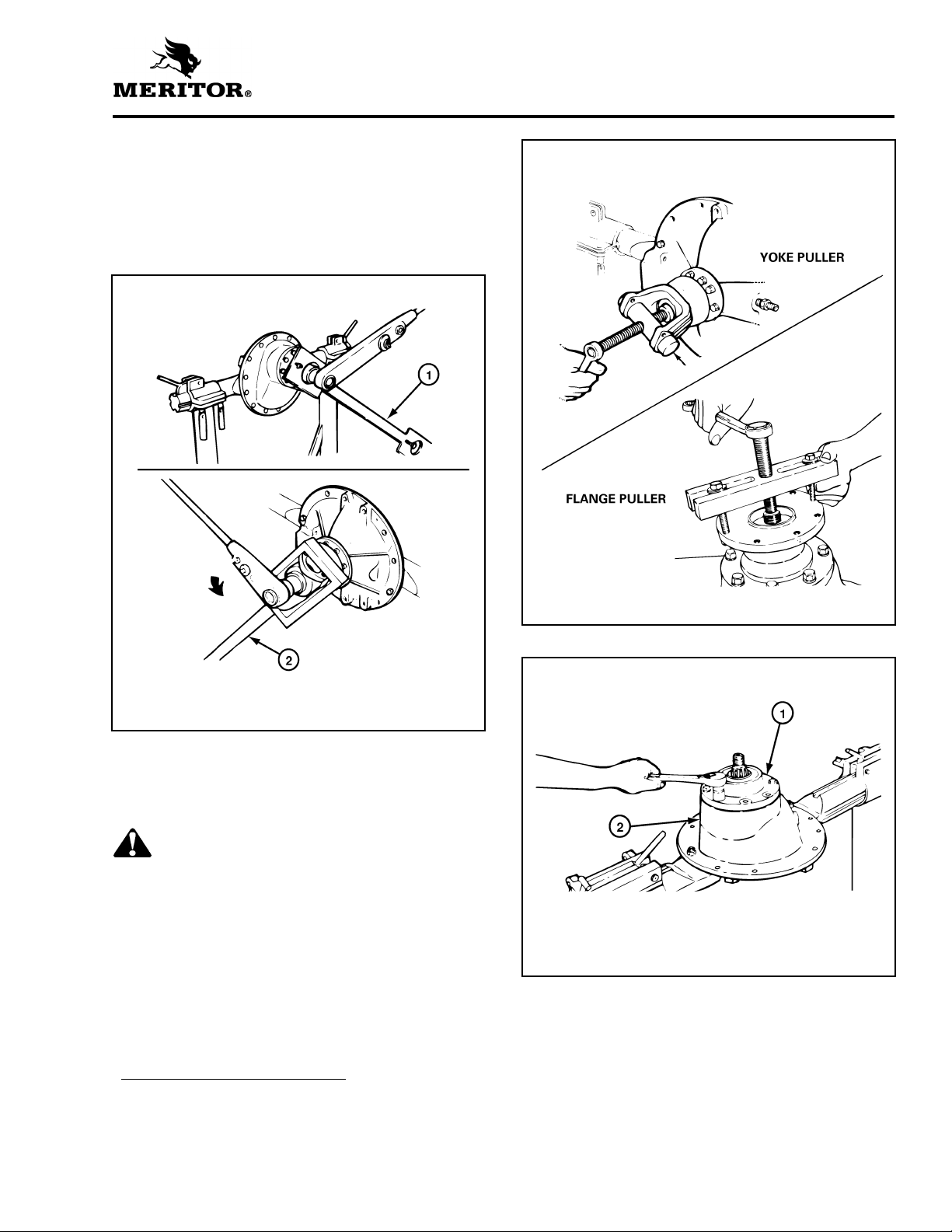

Remove the Drive Pinion and

Bearing Cage from Carrier

1. Fasten a flange bar to the input yoke or flange.

When the nut is removed, the bar will hold the

drive pinion in position. Figure 2.22.

Figure 2.22

Figure 2.23

1 FLANGE BAR

2 YOKE BAR

2. Remove the nut and washer* from the drive

pinion. Figure 2.22.

3. Remove the yoke or flange bar.

CAUTION

Do not use a hammer or mallet to loosen and

remove the yoke or flange. A hammer or mallet

can damage the parts and cause driveline runout,

or driveline imbalance problems after carrier to

driveline assembly.

4. Remove the yoke or flange from the drive

pinion. If the yoke or flange is tight on the

pinion, use a puller for removal. Figure 2.23.

5. Remove the capscrews and washers that hold

the bearing cage in the carrier. Figure 2.24.

*Some Meritor carriers do not have these

described parts.

Figure 2.24

1 BEARING CAGE

2 CARRIER

15

Section 2

Disassembly

WARNING

Use a brass or leather mallet for assembly and

disassembly procedures. Do not hit steel parts

with a steel hammer. Pieces of a part can break off

and cause serious personal injury.

CAUTION

Do not use a pry bar to remove the bearing cage

from the carrier. A pry bar can damage the bearing

cage, shims and carrier.

6. Remove the drive pinion, bearing cage and

shims from the carrier. If the bearing cage is

tight in the carrier, hit the bearing cage at

several points around the flange area with a

leather, plastic or rubber mallet. Figure 2.25.

Figure 2.25

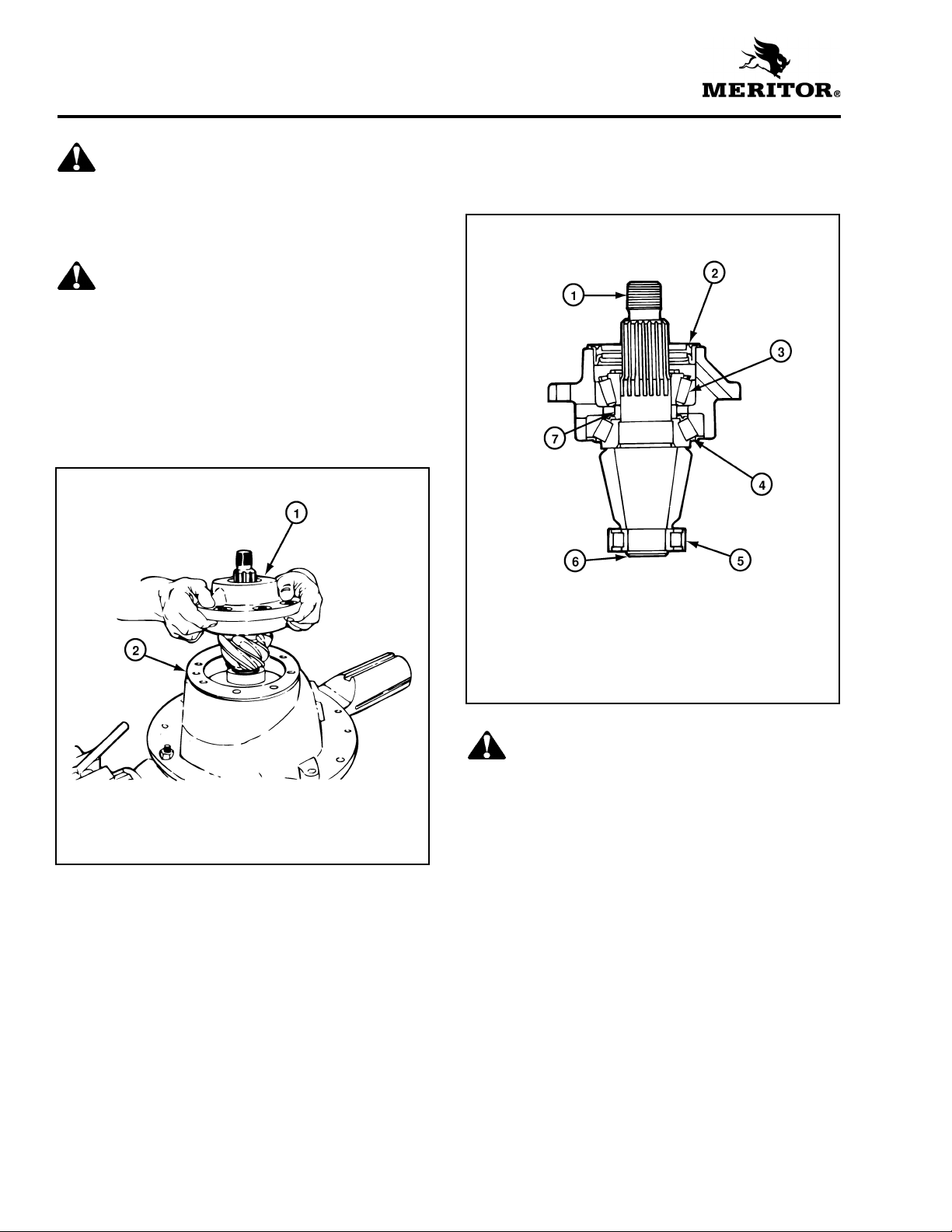

Disassemble the Drive Pinion

and Bearing Cage

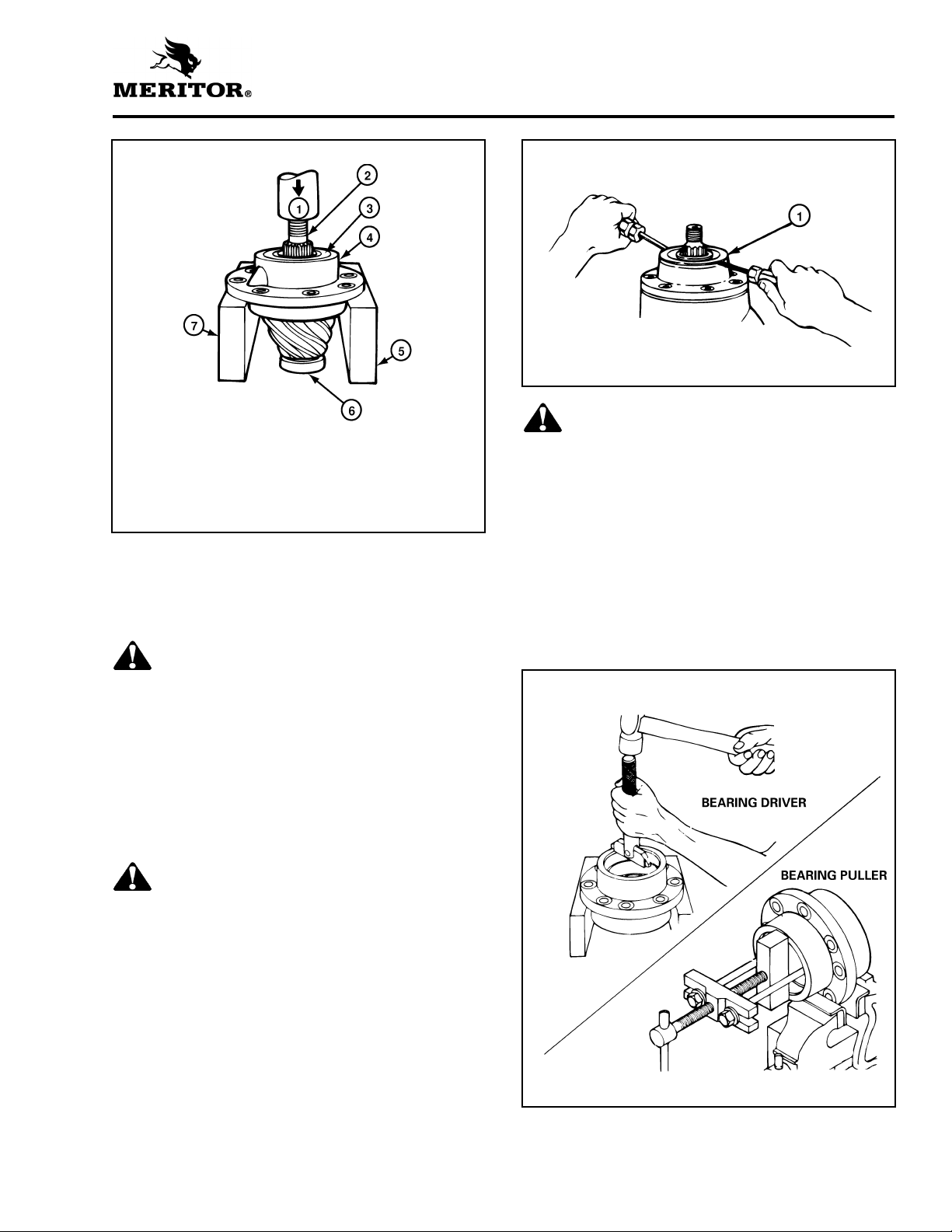

Figure 2.26

1 DRIVE PINION

2 OIL SEAL

3 OUTER BEARING (CUP AND CONE)

4 INNER BEARING (CUP AND CONE)

5 SPIGOT BEARING

6 SNAP RING

7 BEARING SPACER

1 DRIVE PINION AND BEARING CAGE

2 SHIMS

7. If the shims are in good condition, keep the

shims together for use later when the carrier is

assembled.

8. If shims are to be discarded because of

damage, first measure the total thickness of

the pack. Make a note of the dimension. The

dimension will be needed to calculate the

depth of the drive pinion in the carrier when

the gear set is installed.

16

WARNING

Observe all warnings and cautions provided by the

press manufacturer to avoid damage to

components and serious personal injury.

1. Place the drive pinion and bearing cage in a

press. The pinion shaft must be toward the top

of the assembly. Figure 2.27.

Section 2

Disassembly

Figure 2.27

1 PRESS

2 DRIVE PINION

3 OIL SEAL

4 BEARING CAGE

5 SUPPORT

6 SPIGOT BEARING

7 SUPPORT

2. Support the bearing cage under the flange area

with metal or wood blocks. Figure 2.27.

3. Press the drive pinion through the bearing

cage. Figure 2.27.

Figure 2.28

1 OIL SEAL

WARNING

Observe all warnings and cautions provided by the

press manufacturer to avoid damage to

components and serious personal injury.

6. If the pinion bearings need to be replaced,

remove the inner and outer bearing cups from

the inside of cage. Use a press and sleeve,

bearing puller, bearing driver or a small drift

hammer. The type of tool used depends on the

design of the bearing cage. Figure 2.29.

When a press is used, support the bearing cage

under the flange area with metal or wood blocks.

WARNING

Use a brass or leather mallet for assembly and

disassembly procedures. Do not hit steel parts

with a steel hammer. Pieces of a part can break off

and cause serious personal injury.

NOTE: The inner bearing cone and bearing spacer

will remain on the pinion shaft.

4. If a press is not available, use a leather, plastic

or rubber mallet to drive the pinion through

the bearing cage.

CAUTION

Be careful when removing the seal. Do not

damage the wall of bore. Damage to the bore wall

can result in oil leaks.

NOTE: When the oil seal has been removed,

always replace it with a new triple-lip (main) seal

during component reassembly.

5. If the pinion oil seal is mounted directly in the

outer bore of the bearing cage, remove the

seal at this time.

Be careful that you do not damage the

mounting surfaces of the bearing cage.

Figure 2.28.

Figure 2.29

17

Section 2

Disassembly

7. If the pinion bearings need to be replaced,

remove the inner bearing cone from the drive

pinion with a press or bearing puller. The

puller MUST fit under the inner race of the

cone to remove the cone correctly without

damage. Figure 2.30.

Figure 2.30

Figure 2.31

1 SPIGOT BEARING

2 SNAP RING

Figure 2.32

1 PRESS

2 DRIVE PINION

3 BEARING PULLER

4 SUPPORTS

5 INNER BEARING CONE

8. If the spigot bearing needs to be replaced,

place the drive pinion in a vise. Install a soft

metal cover over each vise jaw to protect the

drive pinion.

9. Remove the snap ring* from the end of drive

pinion with snap ring pliers that expand.

Figure 2.31.

NOTE: Some spigot bearings are fastened to

the drive pinion with a special peening tool.

Figure 2.32.

1 PEENING POINTS

*Some Meritor carriers do not have these

described parts.

18

10. Remove the spigot bearing from the drive

pinion with a bearing puller. Figure 2.33.

NOTE: Some spigot bearings are a two-piece

assembly. Remove the inner race from the pinion

with a bearing puller. Remove the outer race/roller

assembly from carrier with a drift or a press.

Figure 2.34.

Figure 2.33

Section 2

Disassembly

1 BEARING PULLER

2 SPIGOT BEARING

Figure 2.34

1 REMOVE OUTER RACE AND ROLLER ASSEMBLY FROM

CARRIER

2 REMOVE INNER RACE FROM PINION

19

Section 3

Preparing the Parts for Assembly

Section 3Preparing the Parts for Assembly

Cleaning Ground and

Polished Parts

WARNING

To prevent serious eye injury, always wear safe eye

protection when you perform vehicle maintenance

or service.

Solvent cleaners can be flammable, poisonous and

cause burns. Examples of solvent cleaners are

carbon tetrachloride, emulsion-type cleaners and

petroleum-based cleaners. To avoid serious

personal injury when you use solvent cleaners,

you must carefully follow the manufacturer's

product instructions and these procedures:

앫 Wear safe eye protection.

앫 Wear clothing that protects you skin.

앫 Work in a well-ventilated area.

앫 Do not use gasoline, or solvents that contain

gasoline. Gasoline can explode.

앫 You must use hot solution tanks or alkaline

solutions correctly. Follow the manufacturer's

instructions carefully.

CAUTION

Use only solvent cleaners to clean ground or

polished metal parts. Hot solution tanks or water

and alkaline solutions will damage parts. Isopropyl

alcohol, kerosene or diesel fuel can be used for this

purpose. If required, use a sharp knife to remove

gasket material from parts. Be careful not to

damage the ground or polished surfaces.

1. Use a cleaning solvent to clean ground or

polished parts or surfaces. Kerosene or diesel

fuel oil can be used for this purpose. Do not

use gasoline.

2. Use a tool with a flat blade, if required, to

remove sealant material from parts. Be careful

not to damage the polished or smooth

surfaces.

3. Do not clean ground or polished parts with

water or steam. Do not immerse ground or

polished parts in a hot solution tank or use

strong alkaline solutions for cleaning, or the

smooth sealing surface may be damaged.

Cleaning Rough Parts

WARNING

Solvent cleaners can be flammable, poisonous and

cause burns. Examples of solvent cleaners are

carbon tetrachloride, emulsion-type cleaners and

petroleum-based cleaners. To avoid serious

personal injury when you use solvent cleaners,

you must carefully follow the manufacturer's

product instructions and these procedures:

앫 Wear safe eye protection.

앫 Wear clothing that protects you skin.

앫 Work in a well-ventilated area.

앫 Do not use gasoline, or solvents that contain

gasoline. Gasoline can explode.

앫 You must use hot solution tanks or alkaline

solutions correctly. Follow the manufacturer's

instructions carefully.

1. Clean rough parts with the same method as

cleaning ground and polished parts.

2. Rough parts can be cleaned in hot solution

tanks with a weak or diluted alkaline solution.

3. Parts must remain in hot solution tanks until

heated and completely cleaned.

4. Parts must be washed with water until all

traces of the alkaline solution are removed.

Cleaning Axle Assemblies

1. A complete axle assembly can be steam

cleaned on the outside to remove dirt.

2. Before the axle is steam cleaned, close or place

a cover over all openings in the axle assembly.

Examples of openings are breathers or vents in

air chambers.

Drying Parts After Cleaning

CAUTION

Damage to bearings can result when they are

rotated and dried with compressed air.

1. Parts must be dried immediately after cleaning

and washing.

2. Dry the parts using soft, clean paper or cloth

rags.

20

3. Except for bearings, parts can be dried with

compressed air.

Loading...

Loading...