Page 1

The PIT5000: Pipeline Integrity Tester

A Pipeline Hydrostatic Testing Device

Page 2

Introductory information

Disclaimer

Copyright

Notification Statements

Page 3

Notification Statements (continued)

Voids the computer warranty

Patent statement

Trademark statements

Patent and trademark information

Page 4

Safety Information

Preventing injury

Safety Symbols

Safety Symbols

Explaining the symbols

This is the Read Instruction Manual symbol. This symbol

indicates that you must read the instruction manual.

Indicates a potentially hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

Indicates information essential for proper product installation,

operation or maintenance.

Safety Symbols

Page 5

For your safety

Fire and/or explosion hazard

Control Panel

Power connections: DC and AC

Pressure limits and power issues

Specifications

Hazardous voltage inside.

Risk of electric shock or burn.

The control panel should only be removed by

authorized electrical technicians.

Page 6

Protect the PIT5000

Protect the PIT5000

Do not substitute parts

Page 7

Contents

A Pipeline Hydrostatic Testing Device ..............1

Introductory information ..................................2

Notification Statements ...................... 2

Notification Statements (continued) .. 3

Patent and trademark information .... 3

Safety Information .............................. 4

Safety Symbols .................................... 4

For your safety ..................................... 5

Protect the PIT5000 ............................ 6

Contents .............................................. 7

Meriam Contact Information .............. 8

Glossary ............................................... 9

Receiving, unpacking, and setting up the

PIT5000 ......................................................... 11

Add Note button ............................... 39

End Test button ................................ 40

Strip Chart tab .................................. 41

Strip Chart tab (continued) .............. 42

Data tab ............................................ 43

Details tab ......................................... 44

Details tab (reset, calibration, paths)

........................................................... 45

Details tab (do not delete these files)

........................................................... 46

Stroke Count tab .............................. 47

Stroke Count tab (continued) .......... 48

Stroke Count tab (continued) .......... 49

Stroke Count tab (continued) .......... 50

Shut down and disconnect .............. 51

Receiving and unpacking ................. 11

Hardware ....................................................... 12

Recommended power connections . 12

Temporary power connections ......... 13

Connecting the 12 V battery ............. 14

Computer mounting panel ................ 15

Control panel ..................................... 16

Software ........................................................ 23

First—Check the computer’s time .... 23

Second—zero the pressure ............... 25

Flexibility in the PIT5000 application

............................................................ 25

The main tabs in the application...... 25

Setup tab ........................................... 26

Report 2—the enhanced report ........ 35

Appendices ................................................... 52

Returning for repair or calibration .. 52

Troubleshooting Guide ..................... 53

Specifications ................................... 55

Specifications (continued) ............... 56

Part numbers .................................... 57

Data Panel ......................................... 36

Data Panel (continued) ..................... 37

Data Panel (Continued)..................... 38

Page 8

Meriam Contact Information

Meriam

Address

Meriam

10920 Madison Avenue

Cleveland | Ohio | 44102

USA

Telephone

US customers: (800) 817-7849

International customers: + 1 216 281 1100

Fax

US customers: + 1 216 281 0228

International customers: + 1 216 281 0228

E-mail addresses

Departments

E-mail addresses

Return Material Authorization /

Service & Repair Department

returnforms@meriam.com

Sales

sales@meriam.com

Website

www.Meriam.com

Local Meriam Representatives

Find a local Meriam

representative

Use this link to help you find Meriam representative on this

world map: REP LOCATOR.

Or, you may use this full website address to go to the same

location: http://www.meriam.com/representatives-map/

Page 9

Glossary

Words and phrases

Definitions

12 V car adapter cable

Also known as a cigarette lighter adapter. This is an optional cable

with DC-to-DC sockets.

Autoscale Graph

The Autoscale function automatically rescales the axes of the

currently selected graph based on the data it receives.

By default, autoscaling is always on.

Button or key

A button always refers to an area on the screen that you can

click to select functionality.

A key always refers to hardware push buttons on the keyboard

that you can press.

Control Panel

The Control Panel is located in the bottom of the carrying case. It

has the keyboard and these labeled areas: Power, Computer, and

Measure.

Data Panel

The Data Panel displays in the PIT5000 application on the right

side in all tabs. The panel displays different information including

flashing red alarms and the following four buttons: Start Program,

Begin Test, End Test, and Add Notes.

Digital Counter

A digital I/O device that provides 5 volts to the stroke counter and

converts the stroke count to a digital signal to the computer via

USB.

Dry contact set

The contacts in a Dry contact set do not have electrical power on

them. The dry contacts are for the (non-supplied) pump stroke

counter.

Edit box

Edit boxes (also known as fields) are for you to enter your data.

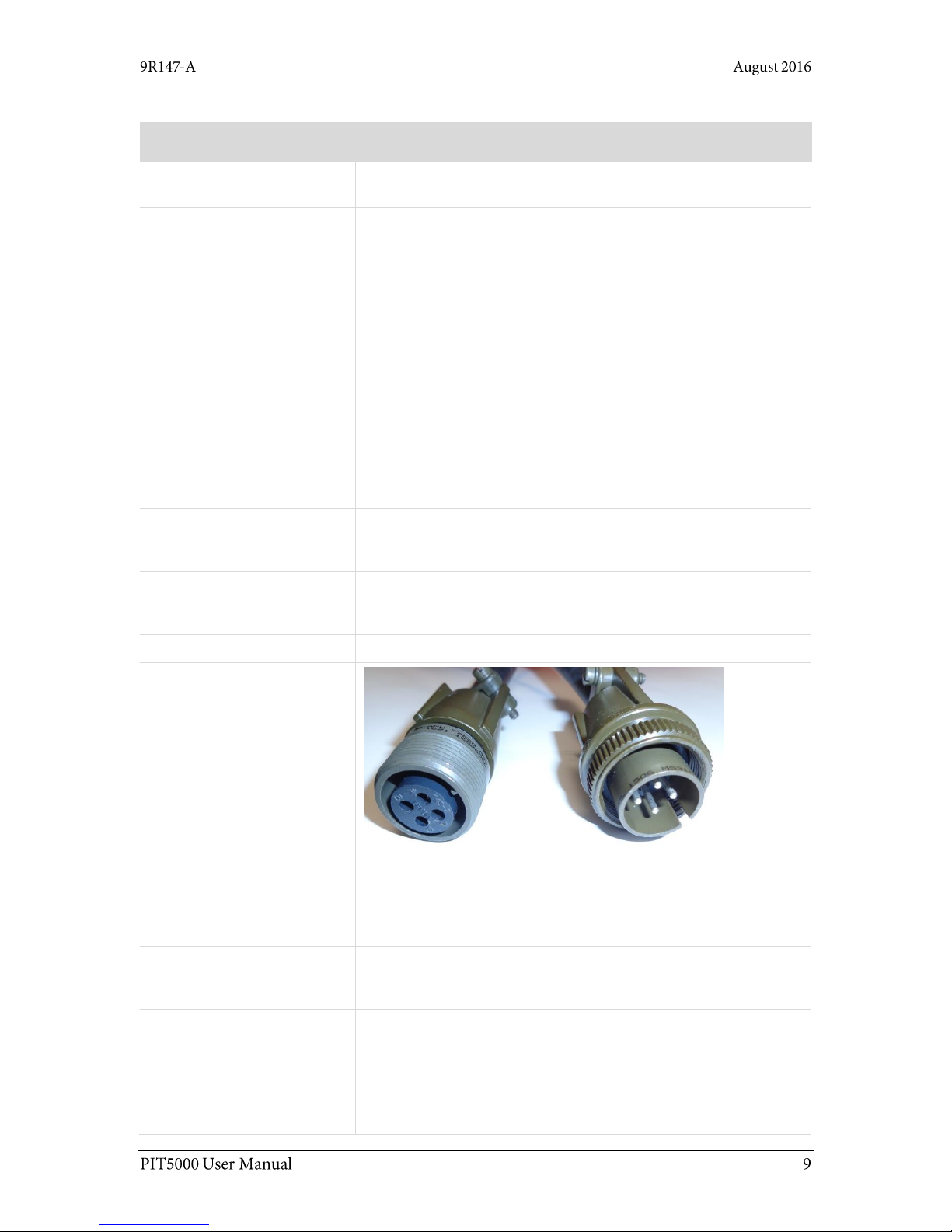

M12 connectors (M & F)

Male NPT

NPT is an abbreviation of National Pipe Thread (Tapered). This is a

standard male tapered pipe thread.

PIT5000

PIT is an acronym for Pipeline Integrity Tester.

P Leak Pressure

P Leak Pressure refers to Preliminary Leak Test Pressure. Some

customers perform a 15-minute leak test before going to higher

pressures.

Pressure

Pipe

You may see different ways of expressing these concepts in

printed material, on the PIT5000, and in the software. The most

common are:

Press

P Leak and PLeak

PTest

Page 10

Words and phrases

Definitions

PTest Instrument Pressure

PTest is an abbreviation of the words Pressure Test.

Instrument Pressure refers to the pressure of the PIT5000

device.

Quick-test connection

The Quick-test connection is located on the Control Panel in the

Measure pane.

RTD

RTD is an abbreviation of Resistance Temperature Detectors.

Strip Chart

Strip Chart is a tab in the PIT5000 application that displays a live

plot of pipe pressure (Press), ambient temperature (T-Amb) and

pipe temperature (T-Pipe) versus time in order to record the

hydrostatic test and its duration.

Stroke Count versus

Stroke Counter

Stroke Count refers to number of recorded pump strokes.

Stroke Counter refers to the digital counter that records pump

strokes. It is connected to the pump using the Stroke Counter

cable.

Temperature

Ambient

You may see different ways of expressing these concepts in

printed material, on the PIT5000, and in the software. The most

common are:

Tambient

T ambient

T-Amb

T Amb

Ambient Temp

Temperature

Pipeline

You may see different ways of expressing these concepts in

printed material, on the PIT5000, and in the software. The most

common are:

Pipeline Temp

Pipe Temperature

Pipe temp

T

T-Pipe or T-pipe

T Pipe

T

pipe

V dc

Volts direct current.

V ac

Volts alternating current.

Page 11

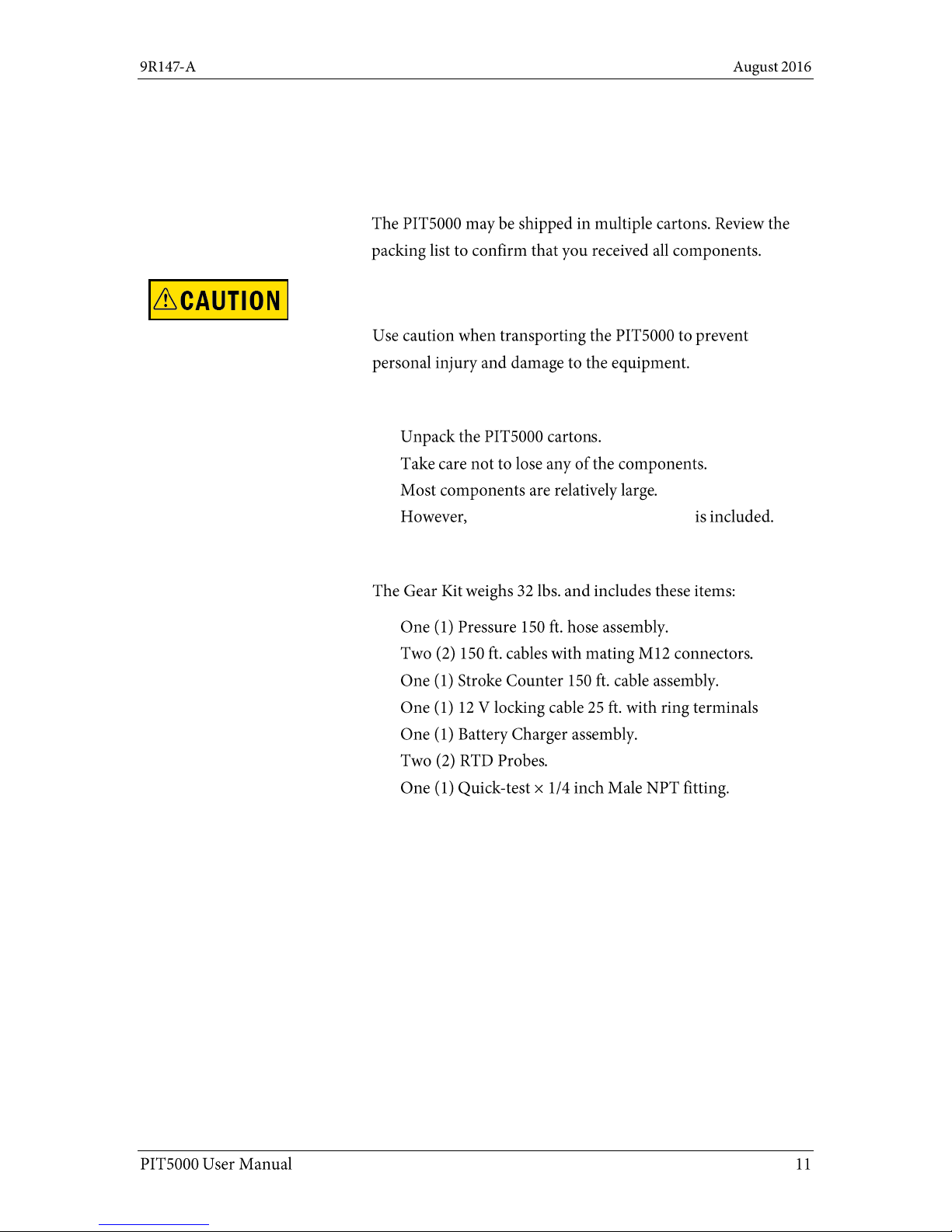

Receiving, unpacking, and setting up the PIT5000

Receiving the PIT5000

Unpacking the PIT5000

Don’t lose any of the components

a small 316SS adaptor fitting

Gear Kit

Receiving and unpacking

Page 12

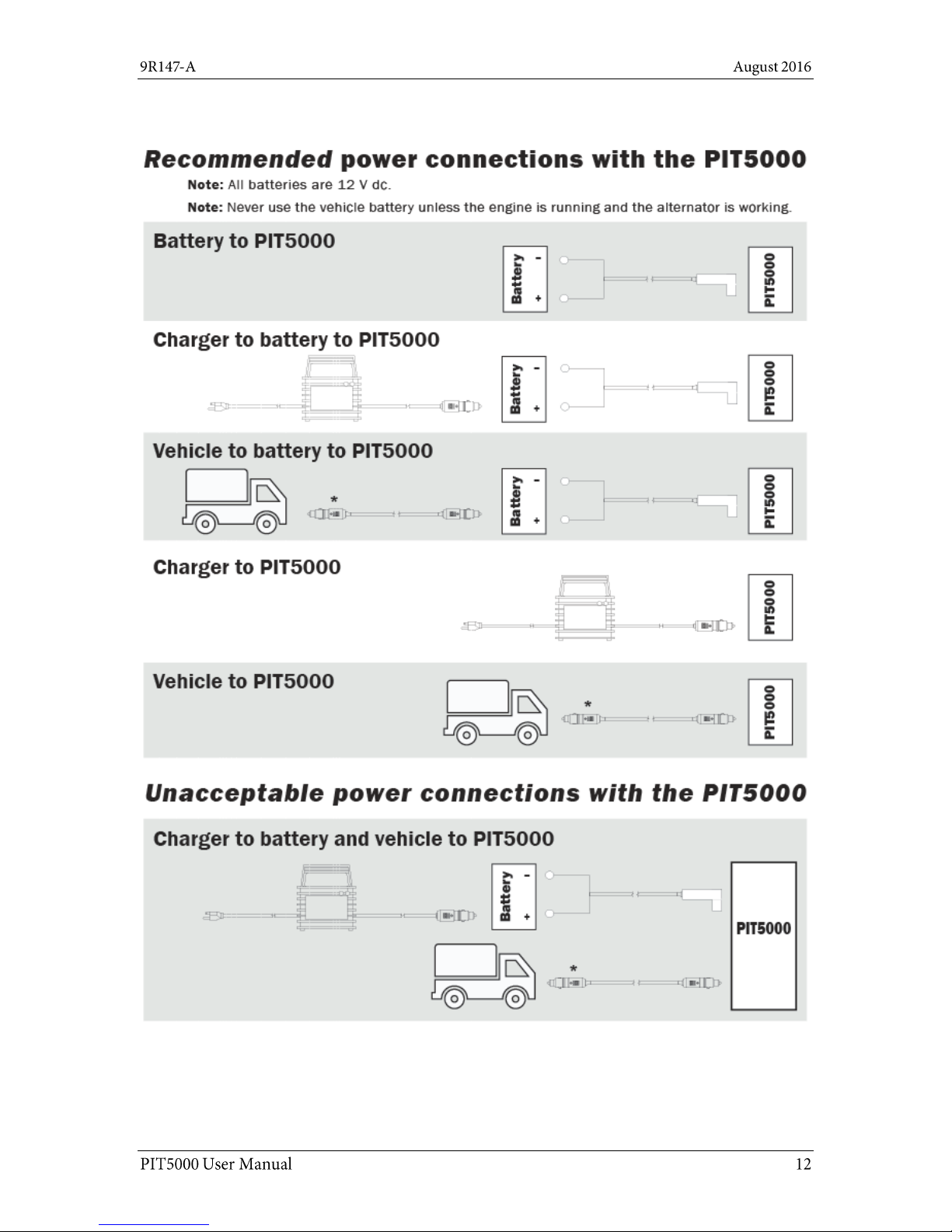

Hardware

Recommended power connections

Page 13

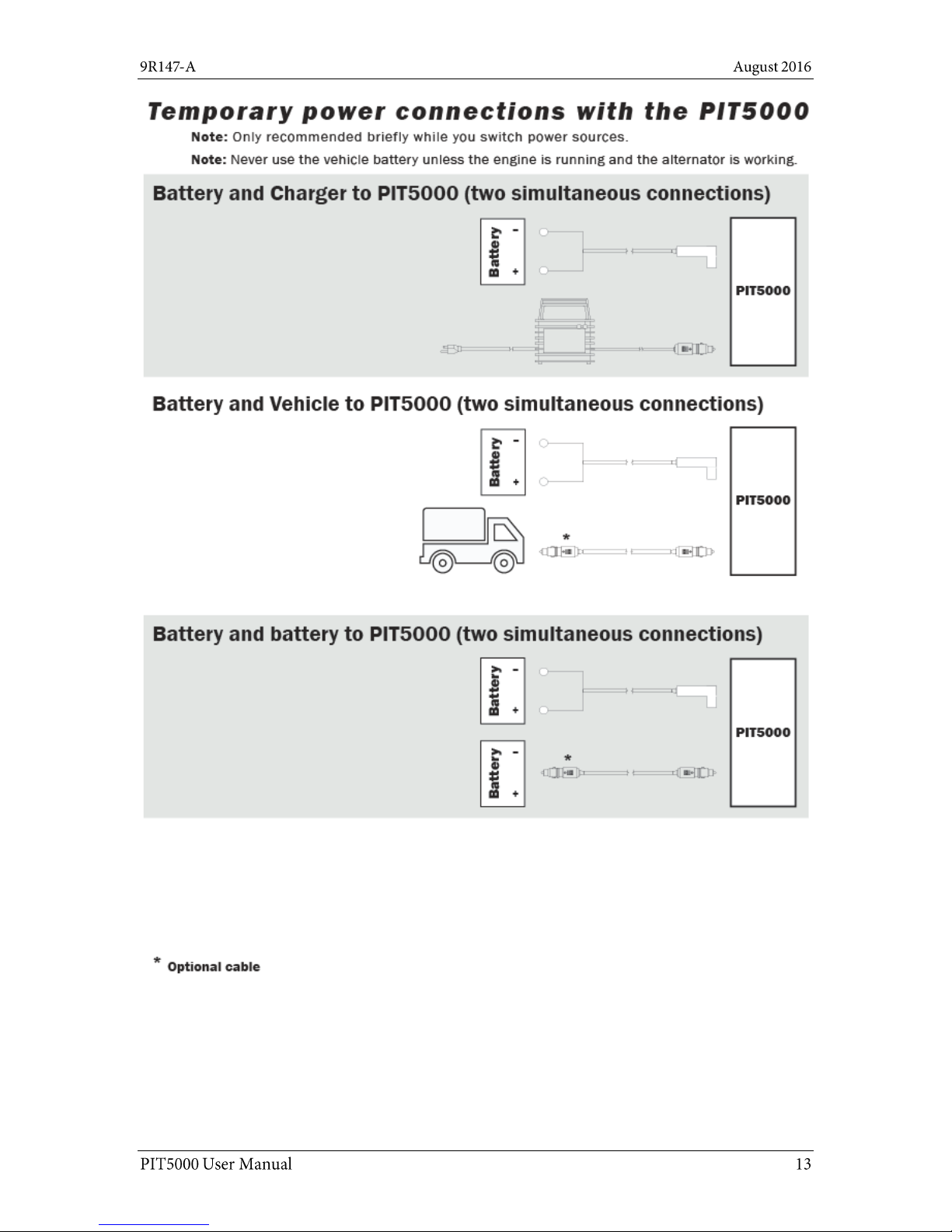

Temporary power connections

Page 14

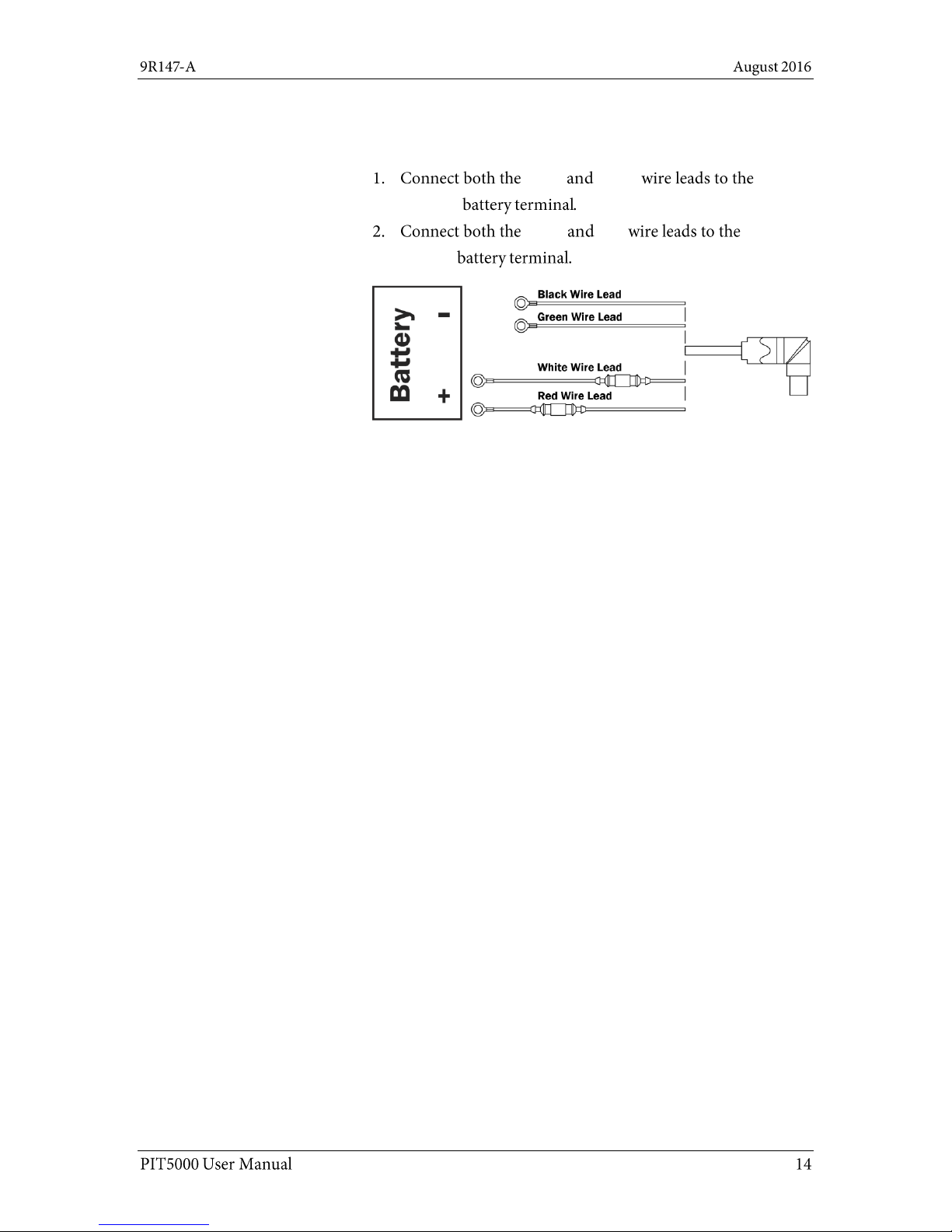

Connecting the 12 V battery

Four wires to two battery lugs

Black Green

negative

White Red

positive

Page 15

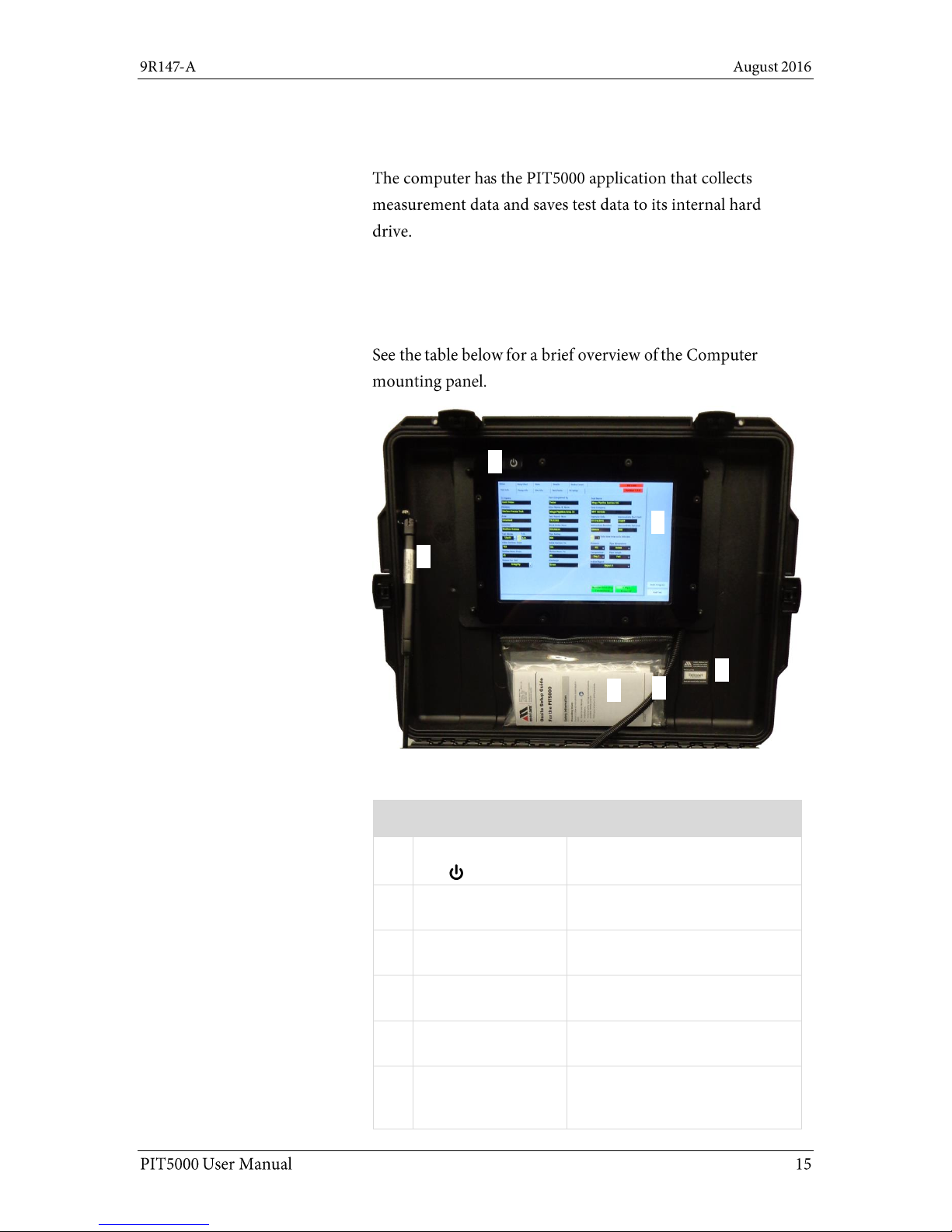

Computer mounting panel

The computer

Note: The computer has an internal battery but it is

normally powered by an external 12 V dc source.

Computer mounting panel

Computer mounting panel description

No.

Item

Description

1.

Power On button

The On / Off button is behind the

Plexiglas panel.

2.

Computer

Windows 10,

PIT5000 Application

3.

Nameplate

PIT5000 serial number, Meriam

address, power.

4.

Computer power

and USB cables

For the computer.

5.

Documentation

pouch

Onsite Setup Guide and NIST

Certificates.

6.

Lift support

This minimizes the risk caused

by an accidental closure. It

controls the closure speed.

1 2 3 4 5

6

Page 16

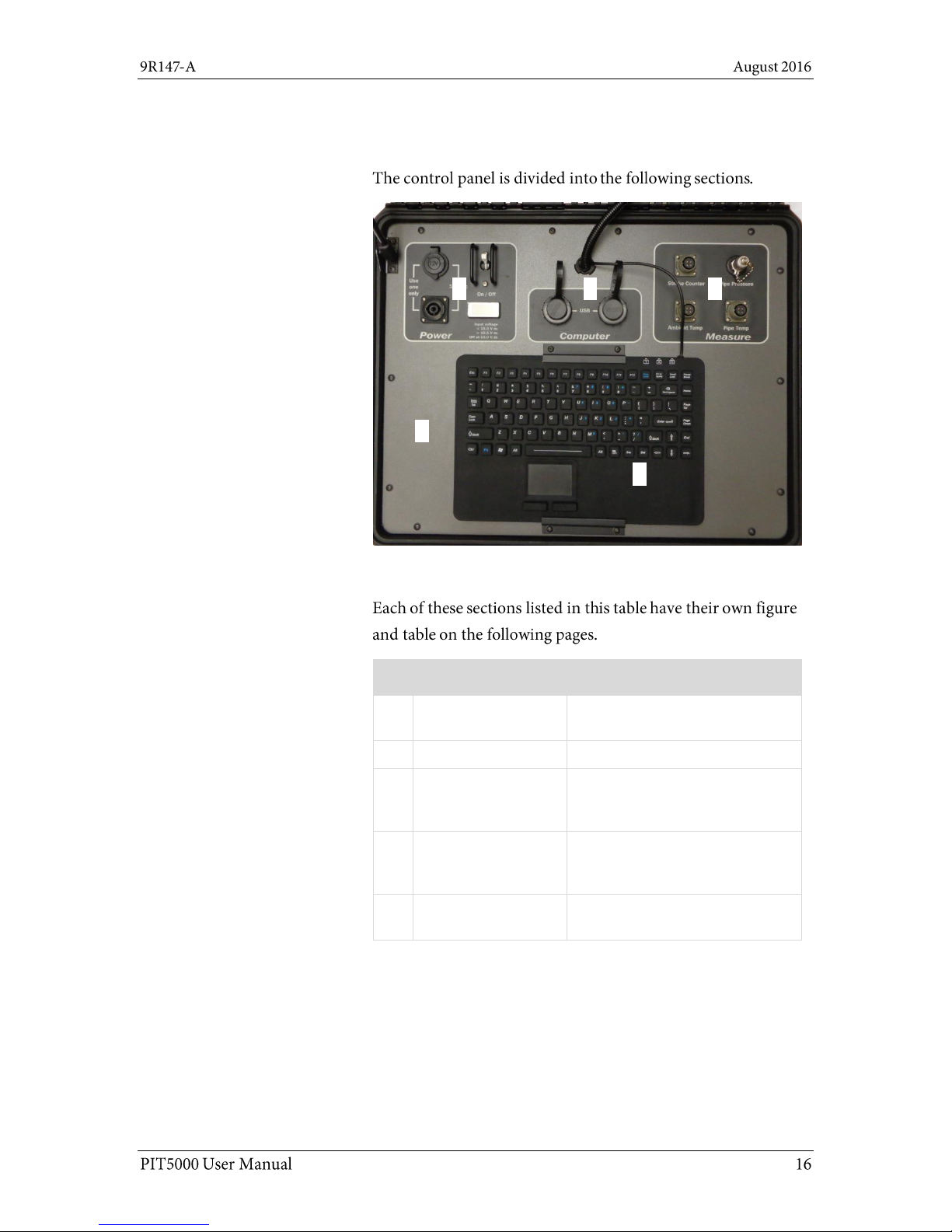

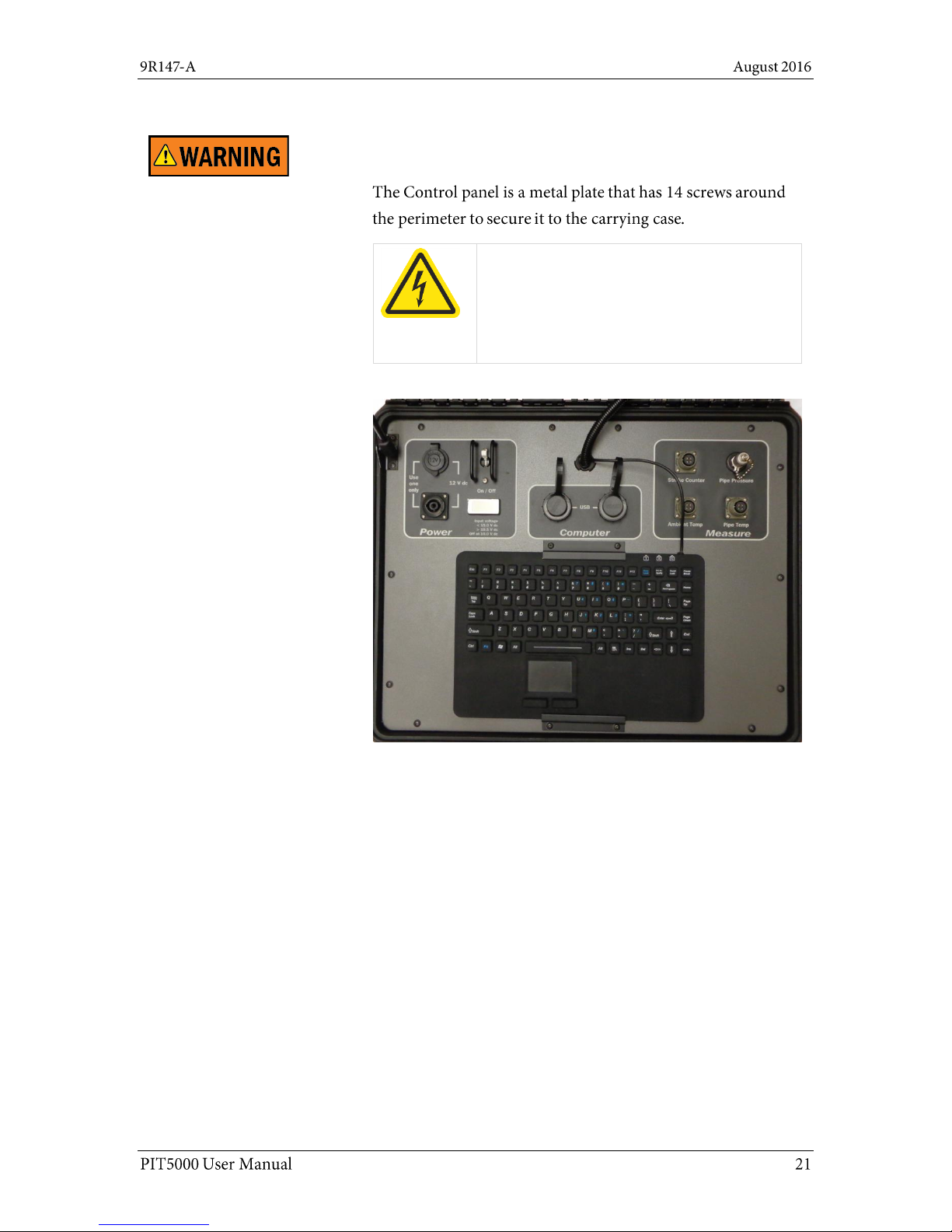

Control panel

Control Panel

Control Panel description

No.

Item

Description

1.

Power pane

Two power connections, toggle

switch, LCD display

2.

Computer pane

Two auxiliary USB ports

3.

Measure pane

Stroke counter connection,

connections for pressure and

temperature.

4.

Control panel plate

The control panel should only be

removed by authorized electrical

technicians.

5.

Keyboard

A waterproof and contaminateproof keyboard and touchpad.

1 2 3

4

5

Page 17

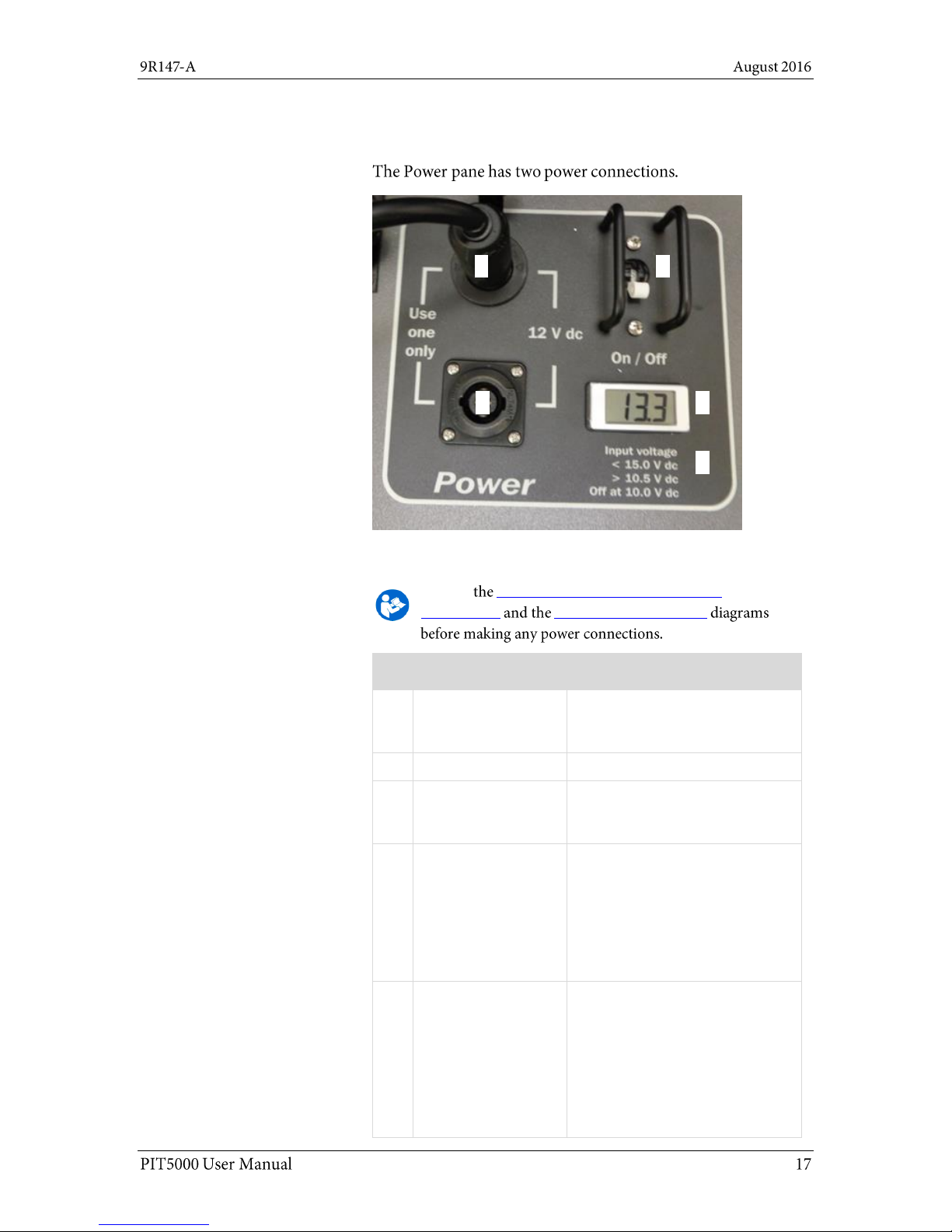

1. Power pane

Power pane

Power pane description

Review Recommended and unacceptable

connections Temporary connections

No.

Item

Description

1.

12 V car adapter

For connecting either the AC to

DC charger or the optional DC to

DC cable.

2.

Toggle switch

Move switch to turn On / Off.

3.

12 V dc power

locking cable

The locking cable is the preferred

battery connection. It provides

less energy loss.

4.

LCD display

Digital battery voltage indicator.

Note: If two batteries are

connected using both 12 V dc

connections on the Control

Panel, then this display averages

the voltage. This averaging

makes the LCD unreliable.

5.

Input voltage list

It reminds you of three levels:

1. The highest allowable is

15.0 V.

2. An audible alarm sounds

when the battery voltage

goes below 10.5 V.

3. The PIT5000 shuts off at

10.0 V.

1 2 3 4 5

Page 18

2. Power pane (continued)

Power source

On

Note: Fuses provide protection against an electrical

short.

AC power and the charger status

Review the Recommended and unacceptable

connections and the Temporary connections diagrams

before making any power connections.

DC power

Standard:

Optional:

Note: It can be used to power the PIT5000 anywhere a

compatible 12 V dc car adapter is available. This can be

especially useful when hydrostatic tests run longer than

anticipated and the battery level gets low.

Page 19

3. Computer pane

Computer pane

Measure pane

1 2 3

4

4. Measure pane

Page 20

4. Measure pane (continued)

1 – Optional: Connect the Stroke Counter cable

to the Measure pane

Measure

Stroke Counter

Note: The PIT5000 has a digital counter that is equipped

to supply power and count the strokes made by highpressure, plunger pumps during pressurization of the

pipe section under test and the subsequent pressure

test.

2 - Pressure hose

Measure

3 & 4 - Connect the RTD cables to the Measure

pane

Ambient Temp

Note: The two RTD cables are identified by M12

connectors at both ends.

Optional: Pipe Temp

Note: If you do not require the pipe temperature, you

can clear this measurement from the Setup > Test Info

sub-tab.

Page 21

5. Control panel

Control panel plate

Hazardous voltage inside.

Risk of electric shock or burn.

The control panel should only be removed by

authorized electrical technicians.

Page 22

6. Industrial Keyboard

Keyboard

Note: No mouse is included.

Serial number label

7. Serial number label

Page 23

Software

Time impacts data logging and reports

Important: You cannot change the time zones,

only the time.

One easy step to check the time

Window

Window

Second—zero the pressure

First—check the computer’s time

Page 24

If the time is incorrect

Set the time in Windows 10

End Test Yes

Date and time settings

Time & Language

Page 25

Second—zero the pressure

Zero the pressure

Note: Since ambient air pressure depends on altitude

and weather, you should use the PIT5000 application to

zero for the current conditions.

Setup

PC Setup Zero Pressure

No required edit boxes to fill-in

Setup Report 1

Report 2

Note: Enter the data your testing requires and consider

entering N/A in edit boxes that you do not need. N/A

would quickly identify them as not required information

on reports.

Overview

Flexibility in the PIT5000 application

The main tabs in the application

Page 26

Setup tab

The Setup tab has five (5) sub-tabs

the Setup sub-tabs

Start Program

Setup tab locked

Setup

Start Program Begin Test

Note: The information remains viewable. A small button

appears to the right of the main tabs. It has a downarrow to view the various sub-tabs. See the section

called Locked data for more information.

Page 27

Test Info sub-tab—Report 1 (the original report)

Test Info sub-tab

Report 1

Active Report

Report 2.

Test Info figure for Report 1

Change engineering units in Test Info

Pressure Temp, Length

Start Program

Pressure

psi, kg/cm2, kPa, bar

Temperature

deg F, deg C

Length

feet, meters

Stroke Volume

gallons, liters

Page 28

Test Info sub-tab—Report 1 (continued)

T-Pipe Required button

T-Pipe Required

T-Pipe Not Required

Data Save Interval in minutes

Data Save

Interval in minutes

Data Save Interval in minutes

Examples:

Data

Reports 1 and 2

Page 29

Pump Info sub-tab

Enter pressure pump information

Stroke Count Required YES

Pump Model Number Pump Serial Number

If the stroke count function is required

Stroke Start Pressure

Note: This number appears in the Stroke Start view-only

box in the Test Limits sub-tab.

Stroke Rate Target.

Note: The Pump Contact Switch Closed indicator

provides visual verification that the contacts are opening

and closing before you start the data logging process.

Page 30

Pump Info sub-tab (continued)

If the stroke count function is not required

Stroke Count Required

NO

Report 1

Report 1 Test Info

Enter one pressure and several elevation points

Note: The application uses this information to calculate

the pressures at the other elevations.

Report 2

Report 2

Report 2—enhanced report

Site Info sub-tab—Report 1 (the original report)

Page 31

Test Limits sub-tab

The Test Limits

Enter the information for your Test Limits

Test Time:

Note: The Test Time appears as Elapsed Time in the

Data Panel after you click Start Program or Begin Test

buttons

PTest Instrument Pressure:

PIT5000 Pressure Site Info

Note: Once a test begins, the PTest edit box in the Data

Panel flashes red when the pressure goes above or

below the PTest Limits.

P Leak Pressure:

Note: Some customers perform a 15-minute, preliminary

leak test before going to higher pressures.

Stroke Start: Stroke Start

Pressure Pump Info

Pressure Rate Limits:

Pressure Rate

PTest High and Low Limits:

Page 32

PC Setup sub-tab

The Get Cal Data button

PC Setup

Note: Measurement device serial numbers are not

stored in the computer’s memory. They are retrieved

from the measurement device each time you click the

Get Cal Data button.

The Communication Port

Get Cal Data

COM3

Page 33

PC Setup sub-tab (continued)

Build Report button

Page 34

Locked data

View locked information

Setup

Start Program

Setup

Note: The button is located to the right of the Stroke

Count tab.

Example of a locked data sub-tab

Test Info

Data Panel

Note: the flashing red alarm in the Data Panel indicates

the range is above or below the range that you specified.

Page 2 of Site Info is not viewable

Note: This applies only to Report 2.

Page 35

Report 2—the enhanced report

The advantage of Report 2

Test Info tab for Report 2

Report 2

Site Info tab for Report 2

Site Info Report 1

Next

Site Info tab has a second page

Back

Page 36

Data Panel

Where is the Data Panel located?

What does the Data Panel display

before you click the Start Program

button?

Page 37

Data Panel (continued)

What does the Data Panel display

after you click the Start Program

button?

Note: This data is logged in a report.

The stroke count would be included

in the logged data at this time if you

had entered that information in the

Pump Info sub-tab.

Start Program

Begin Test

Note: You can monitor the pressure

and temperature readings before

beginning a timed test. After you are

satisfied that your initial test criteria

is met, you start the timed test by

clicking the Begin Test button.

What does the Data Panel display

after you click the Begin Test

button?

Note: this Elapsed Time is identical to

what you see displayed in the Details

tab.

Page 38

Data Panel (Continued)

What does the Data Panel display

when a timed-test is complete?

Time Complete

Note: Data logging continues until

you click the End Test button.

The Data Panel also displays

flashing red alarms

Setup

Page 39

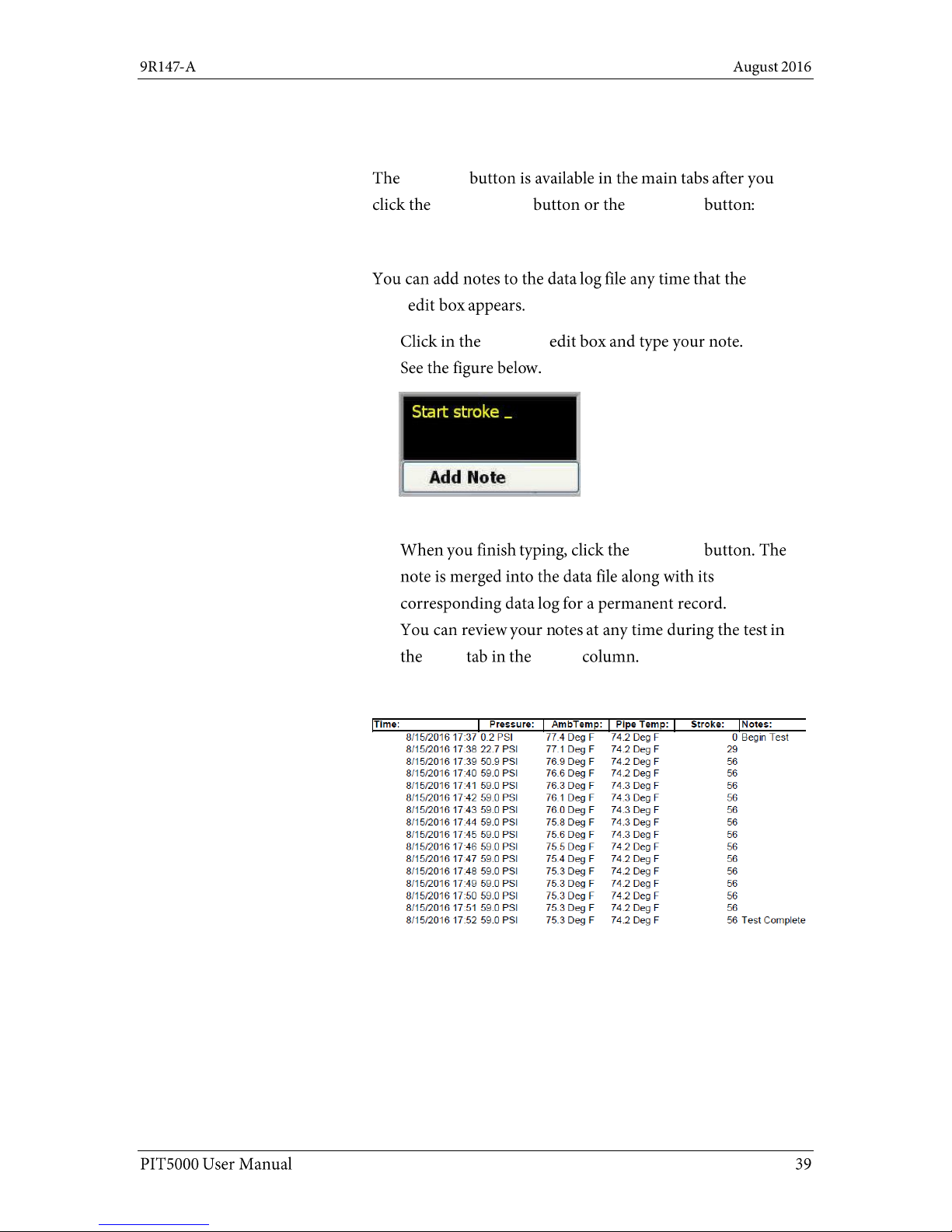

Add Note button

What is the Add Note button?

Add Note

Start Program Begin Test

When can notes be added?

Add

Note

Add Note

Note: A note has a limit of 60 characters.

Add Note

Data Notes

Examples of notes added to the data log

Page 40

End Test button

What happens when the End Test button is

clicked?

Do you really want to stop the test?

1. Yes, I want to STOP the test.

Note: Clicking YES stops the test, saves the reports,

and closes the PIT5000 application. The application

will continue to display until the reports are saved.

The longer the data log, the longer you will have to

wait for the application to finish saving the files.

2. No, I want to continue.

Note: Clicking NO returns you to the ongoing test.

Clicking the Close button (the “X”) on the dialog box

is the same as clicking NO.

Ready to shut down and disconnect?

Shut down and disconnect

Transfer folders or files to a USB Flash Drive

End Test

File Explorer

D:\PIT5000\DATA

Important:

Page 41

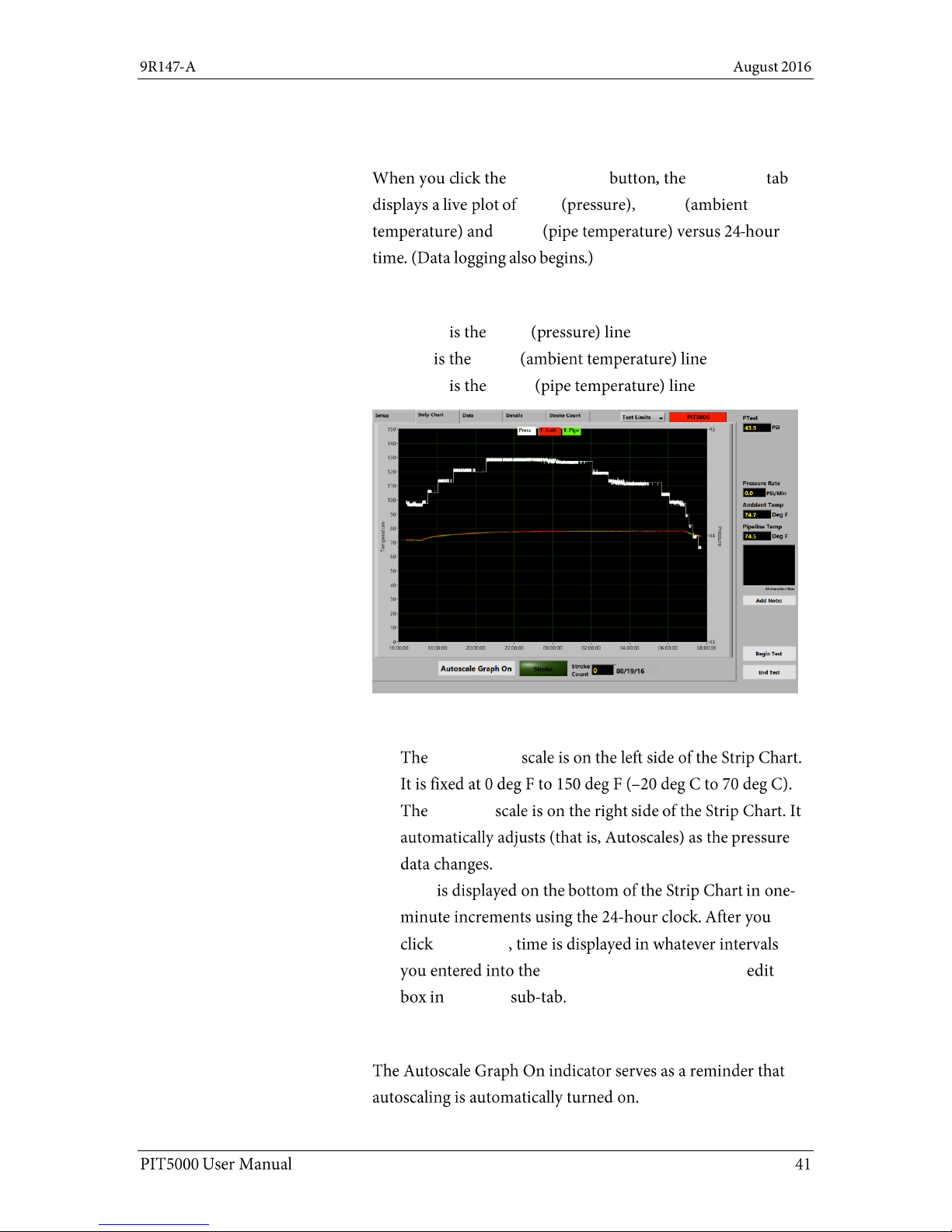

Strip Chart tab

View a live plot of pressure and temperature

Start Program Strip Chart

Press T-Amb

T-Pipe

Strip Chart colors

White Press

Red T-Amb

Green T-Pipe

Strip Chart scales

Temperature

Pressure

Time

Begin Test

Data Save Interval in Minutes

Test Info

Autoscale Graph On

Page 42

Strip Chart tab (continued)

Stroke indicator

Stroke

Stroke indicator

Gray

Green

Double Stroke

Yellow

Double Stroke

Red

Double Stroke

The Stroke Count number box

Total

Count Stroke Count

Page 43

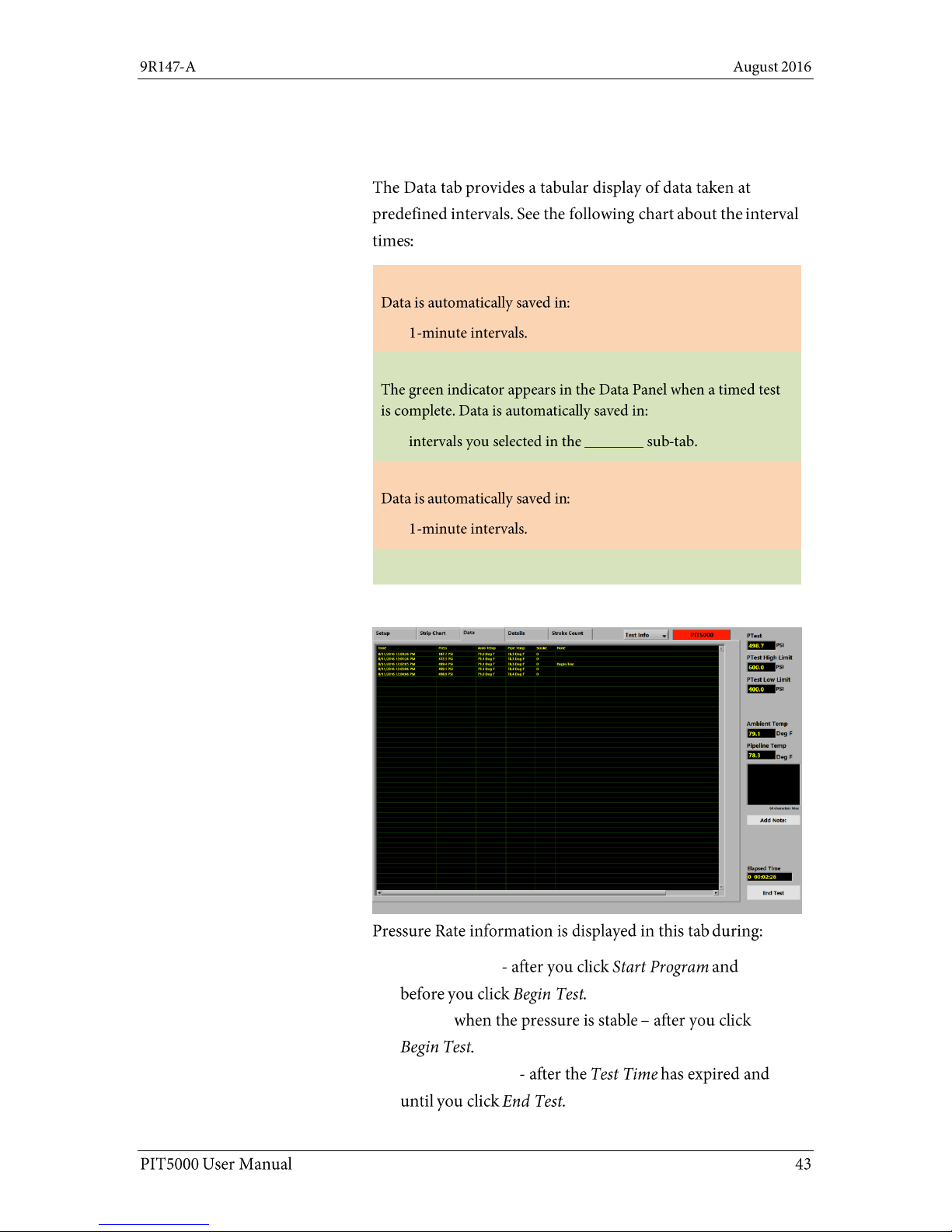

Data tab

Data tab overview

Between Start Program and Begin Test:

Between Begin Test to Time Complete:

Test Info

After Time Complete:

Data logging stops at End Test.

Pressure Rate information

Pressurization

Testing

Depressurization

Page 44

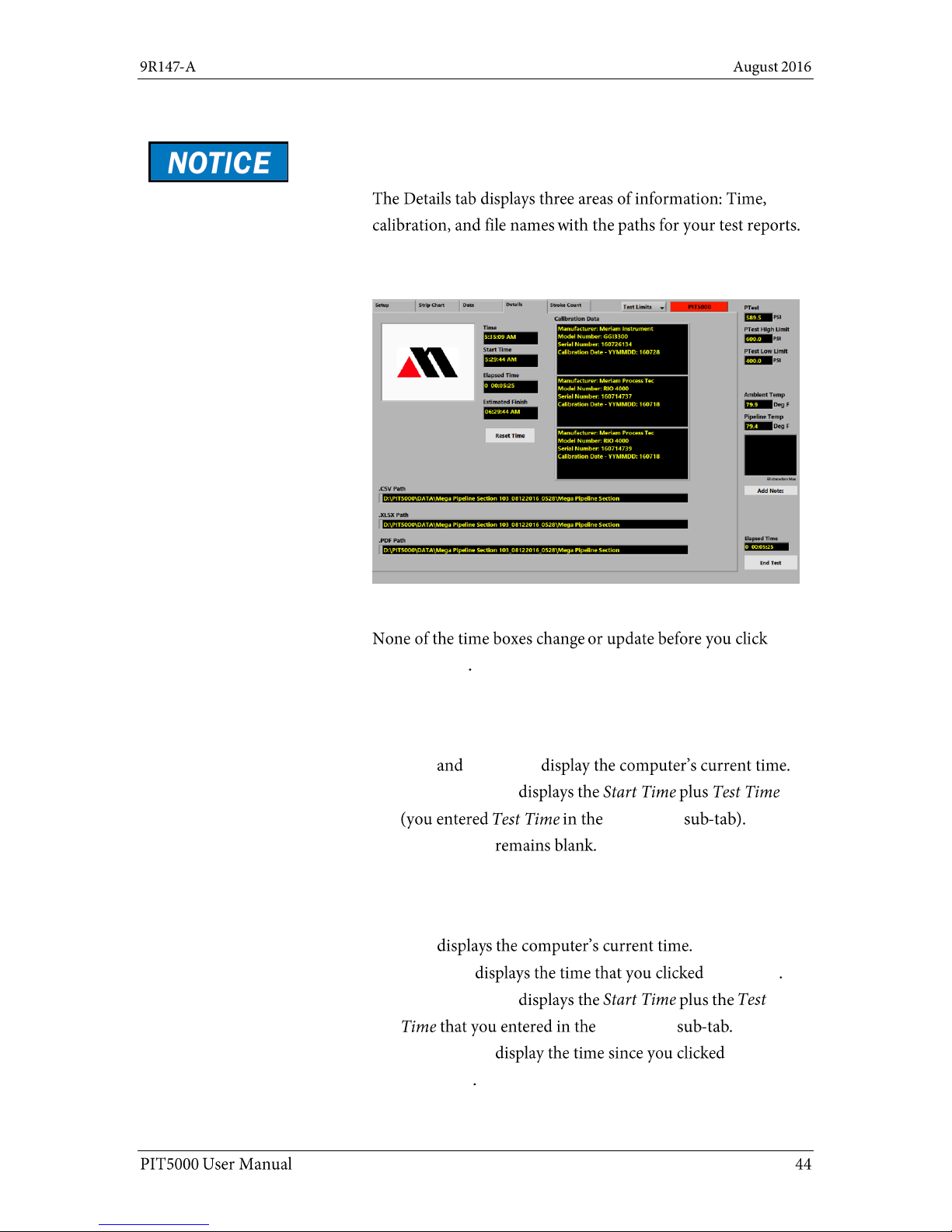

Details tab

The Details tab

Important: Live readings display in this tab only after

you click Start Program.

The Time boxes before “Start Program”

Start Program

The Time boxes between “Start Program” and

“Begin Test”

Time Start Time

Estimated Finish

Test Limits

Elapsed Time

The Time boxes between “Begin Test” and

“End Test”

Time

Start Time Begin Test

Estimated Finish

Test Limits

Elapsed Time

Begin Test

Page 45

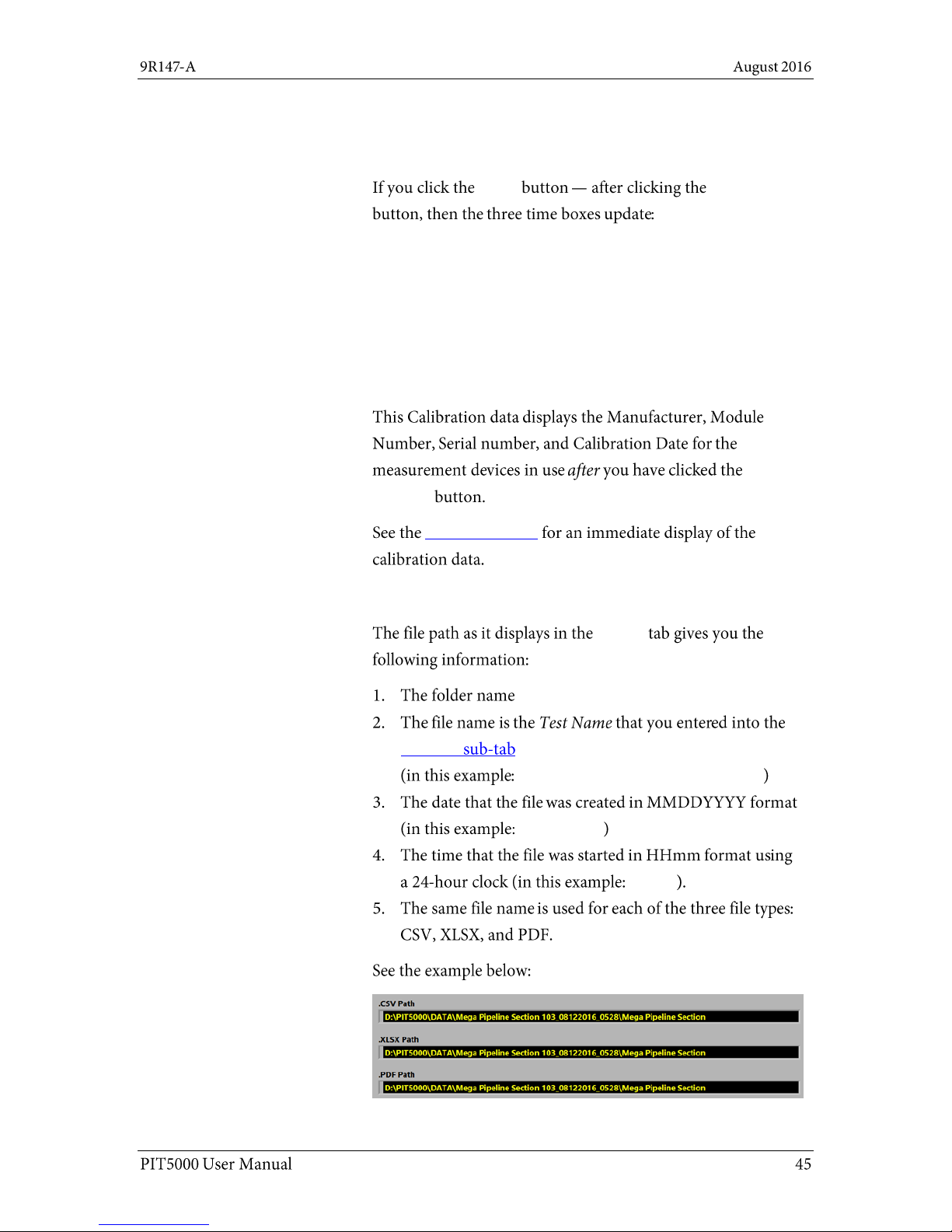

Details tab (reset, calibration, paths)

The Reset Time button

Reset Begin Test

Start Time = the time when the Reset button was clicked.

Elapsed Time = 0.

Estimated Finish = Start Time + Test Time.

Note: The Timed Test resumes until you reach the new

Estimated Finish.

Calibration data

Start

Program

PC Setup sub-tab

What does the path name mean?

Details

D:\PIT5000\Data.

Test Info

Mega Pipeline Section 103_

08122016_

0528_

Page 46

Details tab (do not delete these files)

Do not delete these files or folders

\DATA

PIT Report.xlsx

PIT Report Macro.xlsx.

\DATA

Page 47

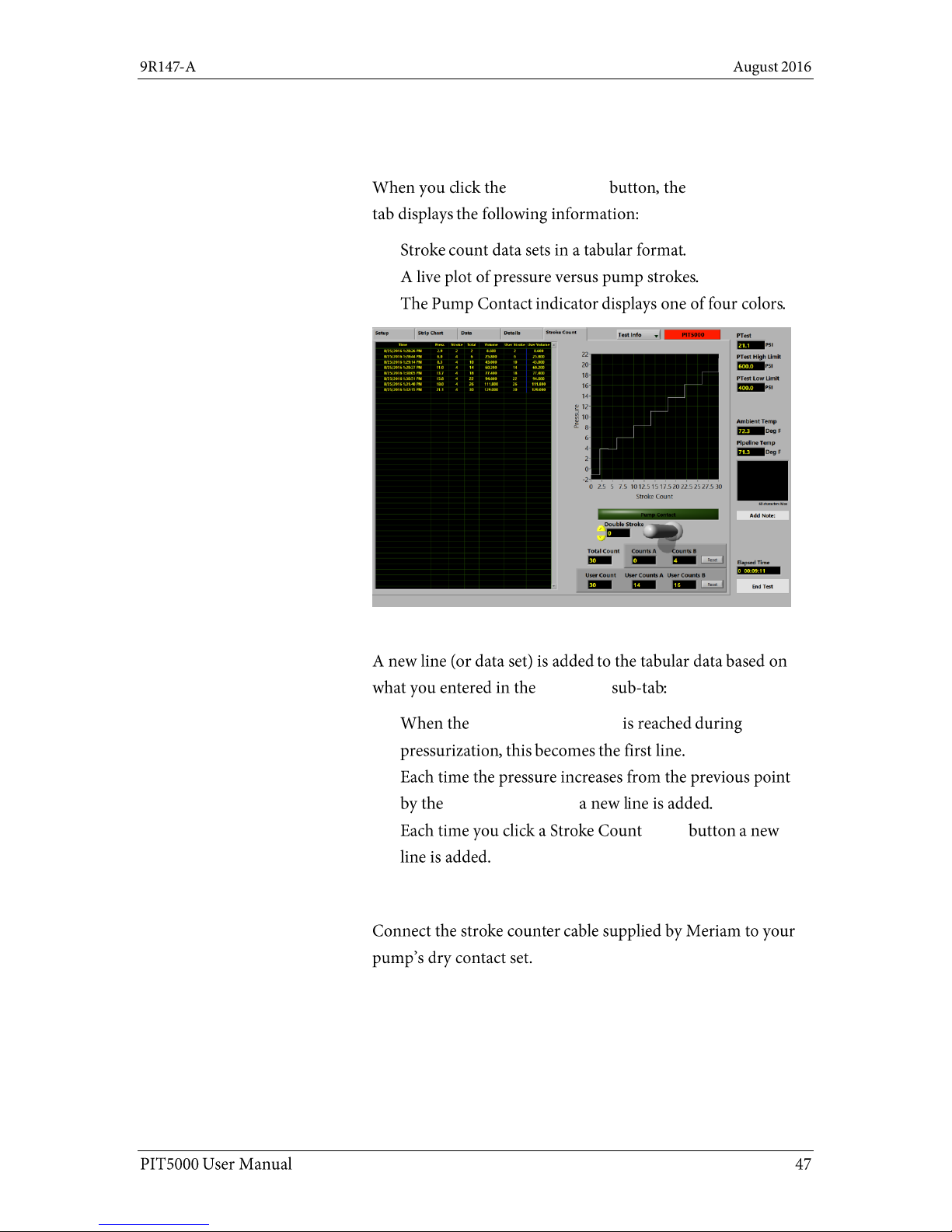

Stroke Count tab

Stroke Count description

Start Program Stroke Count

The tabular data

Pump Info

Stroke Start Pressure

Stroke Rate Target

Reset

Connect your set of dry contacts

Note: The PIT5000 supplies +5 V dc output to the dry

contact set and counts pump strokes based on contact

closures.

Page 48

Stroke Count tab (continued)

Pump Contact indicator

Gray

Green

Double Stroke

Yellow

Double Stroke

Red

Double Stroke

Proper interpretation of Stroke Counter data

Double Stroke Count box

Data Panel

Stroke Rate Target

Double Stroke

Page 49

Stroke Count tab (continued)

The function of the animated toggle switch

Describing the animated toggle switch figure

Counts A

Counts B

Note: When the toggle switch points right, then Counts A

represents the previous interval stroke count and

Counts B represents the current interval stroke count.

Total Count of strokes

Total Count

Stroke Start Pressure

PTest

Instrument Pressure

Page 50

Stroke Count tab (continued)

Counts A and Counts B Reset

Reset

Note: the Count Reset buttons do not affect the Total

Count edit box.

User Count

User Count

User Count User Volume

User Counts A

User Counts B

Reset

Reset

Page 51

Shut down and disconnect

Close the PIT5000 Application

End Test Data Panel

YES

Turn off the power

Off

Disconnect hose and cables

Page 52

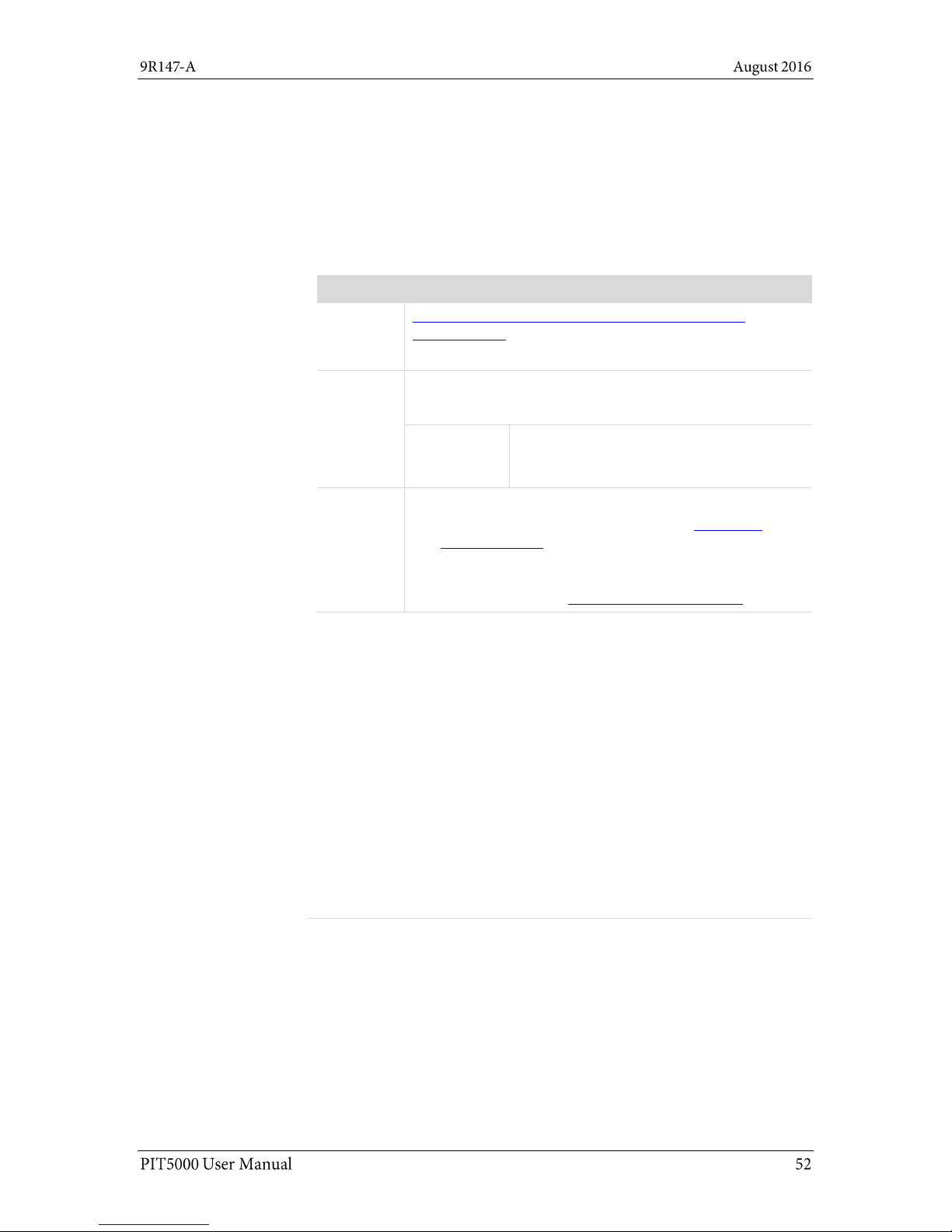

Appendices

First — Request a Number

In the event that a PIT5000 requires service and must be returned,

please contact Meriam using one of the methods listed in the following

table to request a Return Material Authorization (RMA) number:

Method

Information

Website:

http://www.meriam.com/resources/service-repairauthorization/

Complete the information online and submit the form.

Fax:

If you printed and completed the Service & Repair

Authorization form, then fax it to:

US and

International

Customers

+ 1 216 281 0228

E-mail:

We need the following information in the email:

Look for the serial number label in the Computer

mounting panel to locate the model number & the

serial number.

Give a brief description of the problem.

Send the e-mail to: returnforms@meriam.com

Return Material Authorization

Do not send any unit for repair unless you contacted Meriam for a Return

Material Authorization (RMA) number.

Important: If you have not received this number and have not clearly

marked it on the package being shipped back, we will return the unit at

your expense.

The Meriam Service & Repair Department will provide you with this

number when you complete the website form, fax or e-mail your

information.

An RMA number must accompany all incoming packages to insure proper

tracking, processing, and repair work.

Questions? Call Meriam

US Customers

(800) 817-7849

International customers

+ 1 216 281 1100

Ship the box to

Meriam

10920 Madison Avenue

Cleveland, Ohio 44102

USA

Returning for repair or calibration

Page 53

Troubleshooting Guide

Symptom

Problem

Correction

An alarm sounds

inside the PIT5000

case

Low battery voltage (< 10.5 V)

has occurred and the internal

power inverter’s audible alarm

sounds.

Connect charger to the battery and

recharge it.

The voltmeter on

control panel reads

approximately 10.0 V

or less.

The computer does

not turn on or there

are no pressure or

temperature

measurements being

read.

Low battery voltage

(< 10.0 V) has resulted in a

shutdown of the internal

power inverter.

No power is going to the

measurement device or

computer power cord.

Turn the computer off if

necessary.

Move the power toggle switch to

Off.

Connect the charger to the

battery and recharge it.

The PIT5000 battery

does not charge.

Check for proper charger

operation (output should be

12 V dc).

Replace charger if needed.

The voltmeter on the

control panel

reads > 10.5 V and

the computer does not

turn on or there are no

pressure or

temperature

measurements being

read.

The PIT5000 power toggle switch

may be in the Off position.

Move the PIT5000 power toggle

switch to the On position. Turn the

computer on.

Internal power inverter locked up.

Turn computer off if necessary.

Move the power toggle switch to

Off and wait 1 minute.

Connect the charger to the

battery and recharge it.

Internal power inverter fuse may

have blown.

You will have to return the device for

repair to Meriam because it indicates

something is not working properly.

One or both

temperature

measurements fail to

plot.

RTDs not properly connected.

Check the connections of the

RTD cable on the Control Panel

and at the RTD.

There is a bad cable.

Swap RTD cables to see if the

problem follows the cable (one

measurement fails).

Replace the RTD cable as

needed.

Page 54

Symptom

Problem

Correction

Measurements (Press,

T-Amb & T-Pipe) are

not being plotted on

the Strip Chart in

PIT5000 application

This may be a USB

communication port issue.

Check the Communication Port

setting in the Setup tab > PC Setup

sub-tab. It should display COM3.

The output measurement may

have locked up.

Turn the computer off.

Move the toggle power switch to

Off and wait 1 minute.

Move the toggle power switch to

On.

Turn the computer on.

This may be a malfunction of the

Serial to USB converter.

Replace Serial to USB converter.

The Stroke counter

does not update in the

PIT5000 application

The counter signal is not being

received by the digital counter.

Check connection of counter

cable at the Control Panel and at

the dry contacts at the pressure

pump.

Confirm the counter cable is

delivering 5 V dc to dry contacts.

The stroke counter

cable does not deliver

5 V dc to the dry

contacts you

connected at the

pump.

The PIT5000’s digital counter has

an output failure.

Check wiring to the digital

counter.

Replace the faulty wire as

necessary.

The computer and

measurement device

do not turn on.

The power source is not

connected.

Connect the 12 V supply.

The power toggle switch is in the

Off position.

Move the PIT5000 power toggle

switch to the On position.

The time that is

displayed on the Strip

Chart’s x-axis is

incorrect.

The computer’s clock needs to be

set.

Time zones are not used. Only

Universal Coordinated Time (UTC)

is used.

Set the clock on the computer.

The PIT5000 application uses the

computer clock for displaying

time.

The PIT5000

application did not

automatically start.

Start the PIT5000 application

manually.

Double click the PIT5000 icon on

desktop.

Page 55

Specifications

Case

Description

Durable case, hinged lid, four press & pull latches, weather resistant

when closed.

Dimensions

External dimensions: Length × Width × Depth.

25 in × 20 in × 12 in (63.5 cm × 50.8 cm × 30.48 cm).

Weight

The case weight with the PIT5000 equipment is 42 lbs.

Mobility

In-line wheels.

An extendable handle.

Three additional handles around the perimeter.

External Power

115 V ac to 12 V dc power supply (charger assembly) has a cord that

is 9.5 feet.

12 V dc has a cord that is 25 feet (12 V locking, ring terminals).

Pressure limits

PIT5000 sensor: 0 psi to 3300 psi

Do not exceed the sensor limit.

Full Scale calibrated range = 100 % of range.

The PIT5000 application does not alert you to pressure limits.

Stroke Counter

PIT5000 supplies +5 V output to pump for Stroke Counter function.

M12 connection to PIT5000 through the Meriam cable with number 8

spade terminals for connection to dry contacts.

Maximum count rate: 300 strokes per minute.

Connections

Pressure

Quick-test fitting and hose.

Temperature

One M12 (female) for ambient temperature.

One M12 (female) for pipe temperature.

Stroke Counter

M12 (female).

Power

12 V car adapter.

12 V locking connector.

Operating temperature range

Computer working

temperature

5 ºC to 35 ºC (41 ºF to 95 ºF)

Storage temperature

–20 ºC to 60 ºC (–4 ºF to 140 ºF)

Page 56

Specifications (continued)

Application update rates

Strip Chart

The Strip Chart updates once every two (2) seconds.

Data Logging

Between Start Program and Begin Test: Data is automatically

saved in one-minute intervals.

Between Begin Test to Time Complete:

The green indicator appears in the Data Panel when a timed

test is complete. Data is automatically saved in intervals you

selected in the Test Info sub-tab.

After Time Complete: Data is automatically saved in oneminute intervals.

Data logging stops at End Test.

Certifications

NIST traceable certificates for pressure and temperature modules.

CE mark for the measurement device.

CE mark for computer.

Page 57

Part numbers

Contact Meriam about these part numbers

sales@meriam.com

+ 1 216 281 1100 (800) 817-7849

Part

Numbers

Descriptions

Replacement parts

Z9A686

Battery Charger Assembly.

Z9A821

RTD Probe Assembly. Pt100, 4-wire, class A,

Alpha Coefficent 0.003 85

Z9A1383

RTD Cable Assembly, 150 Ft.

Z9A1385

High Pressure Hose Assembly, 150 Ft.

(rated for 5000 psi)

Z9A1386

Stroke Counter Cable Assembly, 150 Ft.

Z9A1395

Power cable 12 V Locking.

Z9P495

Quick-test Adapter.

Z9P555

Nylon Gear Bag.

Z9P562

Hose Reel.

Z9P1455

Fuse – 20 A 32 V ac / V dc for the 12 V locking

cable assembly.

Optional parts

Z9A685

12 V car adapter DC-to-DC cable.

Z9A805

Air Purge Kit.

Z9P511

Battery.

Z9P688

Battery Box.

Loading...

Loading...