Meriam M400-CI0300-02, M400-CI1000-02, M400-CI3000-02, M400-AI1000-02, M400-GI3000-02 User manual

...Page 1

ZM4 Instruction Manual 9R87-B June 2012

MM44 SSeerriieess HHaannddhheelldd PPrreessssuurree

aanndd LLoooopp CCaalliibbrraattoorr

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

ZM4 Instruction Manual 9R87-B June 2012

Table of Contents

Certification and Safety .............................................................. 4

Product Overview ........................................................................ 6

Keys and Functions .................................................................... 7

Measure Mode ............................................................................. 9

Main Unit Setup ......................................................................... 10

Power Management Setup........................................................ 11

Data Logging Setup .................................................................. 12

Date & Time Setup..................................................................... 14

Security Setup ........................................................................... 15

Pressure Sensor Setup ............................................................. 17

Damping Setup .......................................................................... 18

Calibration Setup....................................................................... 19

Field Recalibration .................................................................... 20

Units Selection Setup ............................................................... 21

Volts/mA Sensor Setup............................................................. 22

Volts/mA Mode Setup ............................................................... 23

Volts/mA Source and Sink Setup ............................................ 24

Volts/mA Auto Step Setup........................................................ 25

Volts/mA Auto Ramp Setup ..................................................... 26

Changing Batteries .................................................................. 27

Accessing SD Card ................................................................... 28

Downloading Data Using USB Interface ................................. 29

Installing Wire Stand ................................................................. 30

Range Specifications ................................................................ 31

Specifications ............................................................................ 33

Zeroing and Field Recalibration .............................................. 36

Applications ............................................................................... 37

Contact Meriam ......................................................................... 40

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

ZM4 Instruction Manual 9R87-B June 2012

Figures

Figure 1: Inputs and Outputs 6

Figure 2: Keypad Functions 7

Figure 3: Keypad Functions 8

Figure 4: Measure Mode Display 9

Figure 5: Main Unit Setup Display 10

Figure 6: Power Management Setup Display 11

Figure 7: Data Logging Setup Display 12

Figure 8: Data Logging Status Display 13

Figure 9: Date & Time Setup Display 14

Figure 10: Security Setup Display 15

Figure 11: Password Change Display 16

Figure 12: Pressure Sensor Setup Display 17

Figure 13: Damping Setup Display 18

Figure 14: Pressure Sensor Calibration Setup Display 19

Figure 15: Field Recalibration Display 20

Figure 16: Pressure Units Selection Display 21

Figure 17: Volts/mA Sensor Setup Display 22

Figure 18: Volts/mA Mode Select Display 23

Figure 19: Volts/mA Source and Sink Setup Display 24

Figure 20: Volts/mA Auto Step Setup Display 25

Figure 21: Volts/mA Auto Ramp Setup Display 26

Figure 22: Changing Batteries 27

Figure 23: Accessing SD Card 28

Figure 24: Installing Wire Stand 30

Thank you for purchasing this product. Meriam has been providing

innovative, reliable, cost effective measurement and calibration solutions for

100 years. The M400 Single Sensor or M402 Dual Sensor Handheld

Pressure Transmitter Calibrator continues this legacy and is the first of its

kind for the process measurement industry.

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

ZM4 Instruction Manual 9R87-B June 2012

Certification/Safety/Warnings

Fire/Explosion Hazard. This instrument is not intrinsically

safe. DO NOT use in areas that may contain flammable

gas or vapors, combustible dusts or ignitable fibers where an unintended

spark can cause a fire/explosion.

Do not exceed the Pressure Limits listed in the

Specifications section of this manual. Failure to operate

within the specified pressure limit could result in minor or moderate injury

Substitution of components may impair operation and safety.

Disconnect power before servicing.

The product should not be powered with a combination of new and old

batteries.

The product should not be powered with a combination of batteries from

different manufacturers.

User must use a wrench on the pressure manifold

when installing user’s 1/8” NPT fitting. Do not tighten

the fitting without using a wrench on the pressure manifold. Failure to use a

wrench on the manifold will damage the plastic enclosure and void warranty

No torque should be applied to the manifold with respect to plastic enclosure.

Safety Information

Failure to follow all instructions could result in injury. Read,

understand and follow all safety warnings and instructions provided

with this product. Also, meet or exceed your employer’s safety

practices.

In no event shall Meriam be liable for any indirect, special, incidental,

consequential or punitive damages or for any lost profits arising out of or

relating to any services provided by Meriam or its affiliates. It is not possible

for Meriam to identify all foreseeable uses/misuses, therefore all persons

involved in commissioning, using or maintaining this product must satisfy

themselves that each intended application is acceptable.

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

ZM4 Instruction Manual 9R87-B June 2012

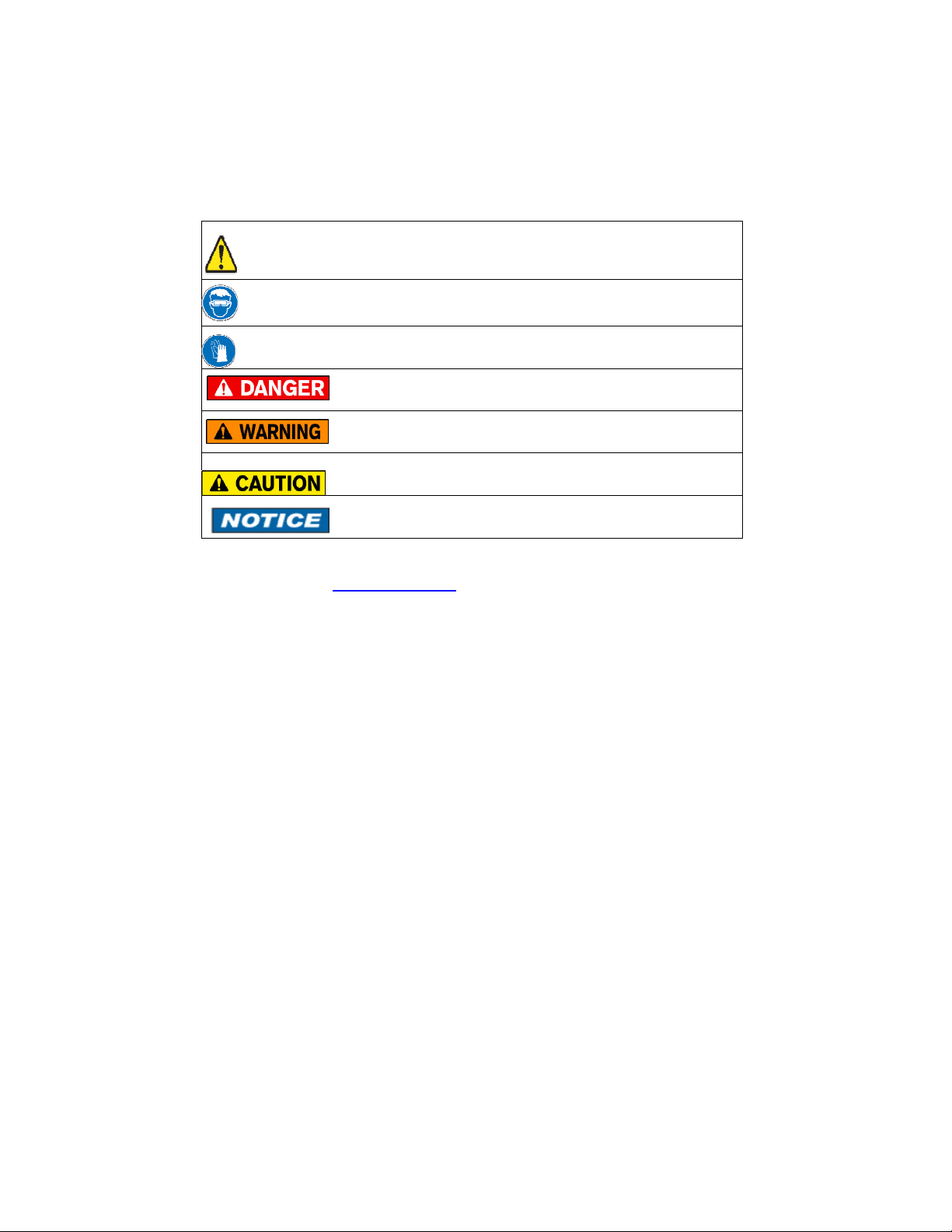

Safety Warnings

The table below defines the safety symbols, signal words and corresponding

safety messages used in the manual to identify potential hazards and are

intended to warn persons about hazards that could result in personal injury or

equipment damage.

This is the Safety Alert symbol. This symbol indicates a WARNING. Warnings

alert you to actions that can cause personal injury or pose a physical threat.

Please read these carefully.

This is the Safety Glasses symbol. This symbol indicates that you must wear

approved safety glasses during the task.

This is the Safety Gloves symbol. This symbol indicates that you must wear

approved safety gloves during the task.

Indicates a potentially hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

Indicates information essential for proper product installation,

operation or maintenance.

Information in this document is subject to change without notice. Check the

Meriam web site (www.meriam.com) for the latest manual revision.

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

ZM4 Instruction Manual 9R87-B June 2012

1

3

4

1

Product Overview

2

Figure 1: M4 Inputs and Outputs

Number Name Description

Pressure Manifold

Connection

Connects the calibrator to a pressure

source via 1/8” NPT Female.

M400 = One Pressure Sensor

M402 = Two Pressure Sensors

USB Connection Connects the calibrator to a computer

2

using a USB Mini Type B to USB

Standard Type A cable.

Measure Volts/mA

3

Source Volts/mA

Terminals

4

Battery/SD Card

Access

Terminals for measuring or sourcing

both Volts and mA DC.

50VDC and 100mA max.

4x1.5V AA batteries and SD card for

data logging

NOTES:

Batteries must be installed for Volts/mA measurement and simulation

operation.

When the unit is attached to a high power USB port, everything except for

the Volts/mA sensor runs from USB power.

Volts/mA measurement or simulation should not be used with USB attached

unless the USB power source is isolated.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

ZM4 Instruction Manual 9R87-B June 2012

2

1

3

4

1

Keys and Functions

Figure 2: Keypad Functions

Number Key Description

Turns the power On and

Off.

2

3

Turns green backlight

On and Off.

Function Keys F1 – F4

Change depending on

Operation Mode

4

Adaptive interface wheel

scrolls up and down

through menu options or

increments or

decrements a value.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

ZM4 Instruction Manual 9R87-B June 2012

6

5

7

8

9

6

Keys and Functions

Figure 3: Keypad Functions

Number Key Description

5

7

8

9

Left Arrow – Navigates back out of

menu or moves cursor

Right Arrow – Navigates further

into menu structure, moves cursor,

or selects value

Sensor – Highlights sensor of

interest for configuring or viewing

settings

Units – Changes engineering units

of a pressure sensor that is

highlighted. Units for the Volts/mA

module are set automatically

according to the measure/simulate

mode.

Setup – Enters the setup menu for

the unit or individual sensor that is

selected or highlighted

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

ZM4 Instruction Manual 9R87-B June 2012

Measure Mode

Figure 4: Measure Mode Display with All Indicators Shown

Icon or Reference Function

HOLD Values are held on display for reference.

REC Data logging function is ON and calibrator is

recording information.

USB USB cable is connected to the calibrator.

100% Battery life as a percentage value.

10:35 AM Current time display.

P1: Type XXX Pressure Sensor #1, Type, and Full Scale

Range in units selected. See specifications

for further details.

P2: Type XXX Pressure Sensor #2, Type, and Full Scale

Range in units selected. See specifications

for further details. M400 units will have N/A

displayed on the screen.

VI: Mode Voltage/mA Sensor and current operation

mode selected.

▲▼ Indicators for Maximum and Minimum

measured or limit values.

T Tare indicator.

50.0% Simulation value as a percent of full scale

/ Indicator for auto simulation mode:

ramp(shown), step or paused.

RANGE Unit is operating with a soft or hard over

range limit. See over and under range table.

Hold Function Key to toggle the hold function of

the displayed values.

Mn/Mx Function Key to reset the displayed

maximum and minimum values.

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

ZM4 Instruction Manual 9R87-B June 2012

Main Unit Setup

Figure 5: Main Unit Setup Display

Reference Function

Contrast Adjust Adjust contrast of display. Active setting

shown on right.

Power Mgmt Adjust Auto Off Timer, Backlight Timer, or

Backlight Intensity to improve battery life.

Data Logging Start, Stop, and setup parameters for a data

log session.

Date & Time Adjust date and time.

Security Adjust security settings such as password,

feature lockouts, etc

Information Displays Product ID, Serial Number and

Firmware Version.

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

ZM4 Instruction Manual 9R87-B June 2012

Power Management Setup

Figure 6: Power Management Setup Display

Reference Function

Auto Off Timer Automatic power off timer selection. Active

setting shown on right.

Backlight Timer Automatic backlight shut off timer selection.

Active setting shown on right.

Backlight Level Backlight brightness control. Active setting

shown on right.

NOTE:

To maximize battery life, if the backlight is frequently used, reduce the

backlight level. Also consider using the backlight timer to avoid the backlight

being left on for long periods of time.

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

ZM4 Instruction Manual 9R87-B June 2012

Data Logging Setup

Figure 7: Data Logging Setup Display

Reference Function

Start Start the data log using the current settings.

Stop Stop or cancel the running data log.

Interval Adjust the data log interval time between 1

and 60 seconds. Active setting shown on

right.

Duration Adjust the data log duration time between 1

minute and 24 hours. Active setting shown

on right.

Log Name Adjust the name of the data log. Press right

arrow to bring up menu to enter name for

data log session.

Status Status of the data log session. Active status

displayed on right. Press right arrow to bring

up detailed information (shown in Fig. 8).

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

ZM4 Instruction Manual 9R87-B June 2012

Figure 8: Data Logging Status Display

The data log status display shows the configured Log Name, Interval and

Duration at the top.

At the bottom of the display, real-time data including Status, completion

percentage and remaining time are shown.

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

ZM4 Instruction Manual 9R87-B June 2012

Date & Time Setup

Figure 9: Date & Time Setup Display

Use the arrow keys to highlight the appropriate field. Set the correct value

using the Adaptive Interface Wheel.

To save the new date & time press the Save key. All the fields will

temporarily display dashes while the new values are stored. To cancel

without saving, press the Exit key.

NOTE: The seconds field (ss) is not adjustable. The time can only be

adjusted to the nearest minute. When the Save key is pressed the seconds

are set to zero.

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

ZM4 Instruction Manual 9R87-B June 2012

Security Setup

The Security feature allows you to protect sensitive functions of the device.

At this time only the Field Recalibration functions can be protected. The lock

indicator shown in Fig 10 above indicates whether Field Recalibration is

locked or unlocked (as shown).

To change the security on Field Recalibration press the right arrow key when

“Field Recalibration” highlighted. The lock indicator to the right will toggle

between lock and unlock. If you have not entered the security password

since the current power cycle you will first be prompted to enter it. Use the

Adaptive Interface Wheel and arrow keys to enter the characters in the

password prompt screen. Once you have entered the correct password you

can modify the security function until the next time the unit is powered up.

NOTE:

The default password for factory new units is “PASSWORD”. It is strongly

suggested that the password be changed when the unit is first received.

Figure 10: Security Setup Display

Reference Function

Field recalibration Set the lockout of the Field Recalibration

function. Current lock setting shown on right.

Change Password Modify the existing password. Press right

arrow to bring up password change screen

(shown in Fig. 11).

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

ZM4 Instruction Manual 9R87-B June 2012

The Change Password function allows you to set a new password. The

screen shown in Fig. 11 shown below displays this function. Enter the current

password on the first line. Use the Adaptive Interface Wheel and arrow keys

to enter the characters. Using the Next key tab down to the New Password

line to redefine the password and then down to the Confirm Password line to

reenter the new setting. Press Enter to confirm the new password.

The password is 10 characters in length and is made up of any combination

of upper case alpha and numeric characters.

Figure 11: Password Change Display

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

ZM4 Instruction Manual 9R87-B June 2012

Pressure Sensor Setup

Figure 12: Pressure Sensor Setup Display

Reference Function

Damping Enable or disable damping and adjust value.

Active setting shown to the right.

Calibration Zero, Field Calibrate, or Restore Factory

Defaults

Reset Min/Max Resets Min/Max values

Resolution Choose Accuracy or Precision resolution on

display for selected sensor. Active setting

shown to the right.

Units Selection Engineering units selection list. Used to

select which units are available when the

Units key is pressed

Information Displays Sensor Type, Accuracy, Calibration

Date, Serial #, and Range

NOTE: Pressure Sensor Setup applies to both P1 and P2 sensors.

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

ZM4 Instruction Manual 9R87-B June 2012

Damping Setup

Figure 13: Damping Setup Display

Use the Type key to change the Damping Type. The options are a follows:

1) None. The measured value is not filtered or damped.

2) Exp(exponential), which uses a traditional damping algorithm with

response delays associated with the Damping Rate.

3) Smart, which employs a smart damping algorithm to produce and

instant response to a step change. After the step change it uses the

Damping Rate to damp the measurement exactly as in exponential

damping.

Use the arrow keys and the Adaptive Interface Wheel to set the Damping

Rate in seconds. The value can be adjusted between 0 and 32 seconds.

Press the Exit key to return to the main Pressure Sensor Setup menu.

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

ZM4 Instruction Manual 9R87-B June 2012

Calibration Setup

Figure 14: Pressure Sensor Calibration Setup Display

Reference Function

Zero Perform a zero adjustment of the pressure

sensor at the applied input.

Field recalibration Enter field recalibration procedure.

Functionality is described on the following

page. Lock setting for operation displayed on

right. See NOTE below.

Restore Defaults Perform a restore defaults function. Lock

setting for operation displayed on right. See

NOTE below.

NOTE:

If the Field Recalibration or Restore Defaults functions are locked you must

first unlock them to enter the function. See the Security section for more

details.

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

ZM4 Instruction Manual 9R87-B June 2012

Field Recalibration

Figure 15: Field Recalibration Display

The Field Recalibration Display contains the following:

1. The current calibration point and number of points displayed at the

top.

2. Under “Apply:” in the black highlighted area, the nominal calibration

point in the current pressure units for the sensor is displayed.

3. Under “Range:” the tolerance band around the nominal value.

4. The live pressure measurement in the current pressure units is

displayed at the bottom.

To run the field recalibration procedure:

1. Apply the pressure indicated in the “Apply:” field. The value must lie

within the tolerance band indicated by “Range:”

2. Press the Save key when you are at the correct input to calibrate.

The live display value will show dashes when the calibration point is

being saved.

3. Press the Next key to advance to the next calibration point. Repeat

steps 1&2 above.

4. Repeat steps 1-3 until you reach the last point.

5. At the last point the Next key is replaced with a Done key. When you

have finished calibrating the last point press the Done key.

6. A Calibration complete screen appears with Exit and Save keys.

Press Exit to discard the field recalibration. Press Save to store the

field recalibration results.

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

ZM4 Instruction Manual 9R87-B June 2012

Units Selection Setup

Figure 16: Pressure Units Selection Display

This selection list shows which pressure units are displayed when the

Units key on the M4 is pressed. The units with the check mark to the

right will be displayed. Those without the check mark will be skipped.

To enable or disable a pressure unit, use the Adaptive Interface Wheel to

scroll to the desired unit. Press either arrow key to check or uncheck the

unit. The arrow keys will toggle the unit between checked and

unchecked.

To enable all 32 units press the All function key. To uncheck all the units

press the Clear key.

Press Exit to return to the main Pressure Sensor Setup menu.

NOTE: At least one pressure unit must be selected before exiting.

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

ZM4 Instruction Manual 9R87-B June 2012

Volts/mA Sensor Setup

Figure 17: Volts/mA Sensor Setup Display

Reference Function

Mode Choose Volts Measure, mA Measure, 24V

Source, Volts Source, mA Source, or mA

Sink

Damping Enable or disable damping and adjust value.

Active setting shown to the right.

Calibration Perform a Zero, Field Calibration, or Restore

Factory Defaults

Reset Min/Max Resets Min/Max value

Resolution Choose Accuracy or Precision resolution on

display for selected sensor. Active setting

shown to the right.

Information Displays Sensor Type, Accuracy, Calibration

Date, Serial # and Range

NOTE:

Description of Mode setup is described in the following pages. Damping and

Calibration are described in the preceding pages covering Pressure Sensor

setup.

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

ZM4 Instruction Manual 9R87-B June 2012

Volts/mA Mode Setup

Figure 18: Volts/mA Mode Select Display

Reference Function

V Measure Selects the voltage measure mode.

I Measure Selects the current measure mode.

24V Source Selects the 24V loop source mode.

V Source Selects the voltage source mode. Brings up

menu (described on following page) to select

manual or automatic voltage simulation.

I Source Selects the current source mode. Brings up

menu (described on following page) to select

manual or automatic current simulation.

I Sink Selects the current sink mode. Brings up

menu (described on following page) to select

manual or automatic current sink. This is

also known as transmitter simulation mode.

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

ZM4 Instruction Manual 9R87-B June 2012

Volts/mA Source and Sink Setup

Figure 19: Volts/mA Source and Sink Setup Display

Reference Function

Manual Selects manual simulation. Brings up a

menu to set the initial simulation value and

start simulating.

Auto Step Selects auto step simulation. Brings up a

menu to configure the auto step procedure.

Auto Ramp Selects auto ramp simulation. Brings up a

menu to configure the auto ramp procedure.

Start Quick Ramp Starts a quick ramp simulation. The module

will continuously ramp between zero and full

scale in 15 seconds.

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

ZM4 Instruction Manual 9R87-B June 2012

Volts/mA Auto Step Setup

Figure 20: Volts/mA Auto Step Setup Display

Reference Function

Start Select to start the Auto Step simulation.

Mode: Volts/mA mode for the simulation. For

reference only, cannot be modified here.

Begin Value: Starting simulation value. Brings up edit

display to change the value.

End Value: Ending simulation value. Brings up edit

display to change the value.

Num Steps: Number of steps in the procedure. Brings up

edit display to adjust the value between 1

and 10.

Dwell Time: Time to pause at each step before

advancing to the next step. Brings up edit

menu to select the value between Manual, 5

or 10 seconds.

Startup Delay:

(not shown in Fig 20)

Delay after pressing Start key before

simulation begins. Brings up edit menu to

select the value between None, 30 or 60

seconds.

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

ZM4 Instruction Manual 9R87-B June 2012

Volts/mA Auto Ramp Setup

Figure 21: Volts/mA Auto Ramp Setup Display

Reference Function

Start Select to start the Auto Ramp simulation.

Mode: Volts/mA mode for the simulation. For

reference only, cannot be modified here.

Begin Value: Starting simulation value. Brings up edit

display to change the value.

End Value: Ending simulation value. Brings up edit

display to change the value.

Ramp Time: Time to ramp between the Begin and End

values. Brings up edit display to adjust the

value between 1 and 300 seconds.

Startup Delay:

Delay after pressing Start key before

simulation begins. Brings up edit menu to

select the value between None, 30 or 60

seconds.

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

ZM4 Instruction Manual 9R87-B June 2012

Changing Batteries

Loosen the two screws in the battery cover and lift off cover. Remove the

batteries by gently applying pressure to the positive side and pull upward. To

install batteries (Four (4) AA 1.5 volt alkaline batteries) insert the negative

side against the spring and gently apply pressure to lock in the positive side.

The positive (+) and negative (-) battery polarity markings are located in the

bottom of the case for the lower batteries and on the top of case for the

upper batteries, as shown in the illustration. Once the batteries are secured

in the battery compartment, replace battery cover and tighten the two flat

head screws. The battery door is universal and can be installed in either

direction.

Figure 22: Changing Batteries

Warning – To avoid erratic readings replace batteries when

warning message appears.

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

ZM4 Instruction Manual 9R87-B June 2012

Accessing SD Card

To install the SD™ card simply insert the card in the slot and press down

until you hear a click. The card has only one orientation for correct alignment.

Please make sure you are inserting a SANDISK P/N SDSDB-2048-A11 or

equivalent. Further details on the card are provided under the specification

section.

NOTE:

There is a Lock located on the side of the SD™ card. When the Lock is

pressed down information can only be read from the card. To write or save

information to the card make sure it is Unlocked before installing.

Figure 23: Accessing SD Card

28

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

ZM4 Instruction Manual 9R87-B June 2012

Downloading Data Using USB Interface

The M4 has the capability to download the information stored on the SD card

to a computer via the USB cable provided with the unit or via an SD card

reader. The Meriam Setup Utility which allows you to download the data is

provided on the CD or available at www.meriam.com. Please install the USB

drivers before installing the program. The USB Interface is for the exchange

of data only. See precaution in Product Overview section regarding

measurements taken with USB connected.

The data file is downloaded as a .bin file and converted over to a .csv file for

direct use in Microsoft Excel™. Select Device Native

Output (USB) and press the Find Device button to find the M4.

Once the device is found press the Data Log Utility button and follow screen

instructions.

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

ZM4 Instruction Manual 9R87-B June 2012

Installing Wire Stand

All M4 units come standard with an installed rear hand strap and a separate

wire stand. To install the wire stand first pull down on the loose end of the

Velcro strap to separate it, then carefully pull the strap through the lower

bracket. Next remove the two Phillips screws that secure the top metal

bracket.

Locate the plastic bag that contains the wire stand, rubber mounting bracket,

and two Phillips screws. Align the plastic mounting holes with the two brass

inserts. Please make sure the straight edge is facing upward toward the

pressure manifold as shown in the illustration. Secure the plastic mounting

block to the enclosure by tightening the screws.

Figure 24: Installing Wire Stand

30

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

ZM4 Instruction Manual 9R87-B June 2012

Specifications – Range

+/- 0.025% of Full Scale unless otherwise noted below.

TYPE &

RANGE

DN0010 0 TO 10 in H2O Differential, Non-isolated. (±0.05%)

DN0028 0 TO 28 in H2O Differential, Non-isolated.

DN0200 0 TO 200 in H2O Differential, Non-isolated

DN0415 0 TO 415 in H2O Differential, Non-isolated

DN2000 0 TO 2000 in H2O Differential, Non-isolated

DI0001 0 TO 1 PSI Differential, Isolated

DI0005 0 TO 5 PSI Differential, Isolated

DI0015 0 TO 15 PSI Differential, Isolated

DI0030 0 TO 30 PSI Differential, Isolated

DI0100 0 TO 100 PSI Differential, Isolated

DI0300 0 TO 300 PSI Differential, Isolated

DI0500 0 TO 500 PSI Differential, Isolated

GI0015 0 TO 15 PSI Gauge, Isolated

GI0030 0 TO 30 PSI Gauge, Isolated

GI0050 0 TO 50 PSI Gauge, Isolated

GI0100 0 TO 100 PSI Gauge, Isolated

GI0300 0 TO 300 PSI Gauge, Isolated

GI0500 0 TO 500 PSI Gauge, Isolated

GI1000 0 TO 1000 PSI Gauge, Isolated

GI3000 0 TO 3000 PSI Gauge, Isolated

CI0015 -15 TO +15 PSI Compound, Isolated

CI0030 -15 TO +30 PSI Compound, Isolated

CI0050 -15 TO +50 PSI Compound, Isolated

CI0100 -15 TO +100 PSI Compound, Isolated

CI0300 -15 TO +300 PSI Compound, Isolated

CI0500 -15 TO +500 PSI Compound, Isolated

AI0017 0 TO 17 PSIA Absolute, Isolated (0-900 mm Hg)

AI0038 0 TO 38 PSIA Absolute, Isolated (0-2000 mm Hg)

AI0100 0 TO 100 PSIA Absolute, Isolated (0-5200 mm Hg)

AI1000

Accuracy statements include the combined affects of

linearity, repeatability, hysteresis and temperature over the

specified operating temperature range.

Warm up time = 5 minutes.

Unit should be zeroed at working ambient temperature before use

0 TO 1000 PSIA Absolute, Isolated (0-52000 mm Hg)

31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

ZM4 Instruction Manual 9R87-B June 2012

Specifications - Over and Under Range

Soft Under & Over Range:

Indicates pressure is outside of the accuracy specification of the sensor. RANGE indicator will

appear.

Hard Under & Over Range:

Indicates pressure is significantly outside of the measurement range of the sensor. RANGE

indicator will appear. Display will read “-----“. Red backlight will illuminate.

Certified Range:

Sensor is operating within the range of its accuracy specification.

NOTE:

The over/under range threshold is set in the sensor. The value, as shown above, is typically set

to +/-20% of Full Scale.

32

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

ZM4 Instruction Manual 9R87-B June 2012

Specifications

Pressure:

Accuracy: ±0.025% of Full Scale

Temperature Performance: Accuracy includes all affects of temperature from

-20º to +50º C (-4º to +122º F)

Engineering Units: 32 user selectable pressure units

Pressure Limits:

DN sensors: 2x range when pressurized on P1 (HI) side only, 150 PSI when

applied simultaneously to P1 (HI) and P2 (LO) sides.

DI sensors: 3x range when pressurized on P1 (HI) side only, 3x range or 150

PSI (whichever is less) on P2 (LO) side only 1000 PSI when applied

simultaneously to P1 (HI) and P2 (LO) sides.

GI, CI, & AI sensors: 2x range

Media Compatibility:

DN sensors: Non-isolated for clean, dry, non-corrosive gases only (Brass,

316L SS, Silicon gel)

DI sensors: Isolated for fluids compatible with 316L SS and Viton

GI, CI, AI sensors: Isolated for fluids compatible with 316L SS

Connections:

Pressure: 1⁄8” NPT (female)

Electrical: Standard banana jacks on ¾” centers

Loop Power:

Accuracy: 24VDC (see load line below)

Voltage & Current Measurement:

DC Voltage Range: -50 to +50V auto-ranging

DC Current Range: -100 to +100 mA

Accuracy: (±0.015% of Reading ±0.002 units)

Accuracy of DC mA when 24V loop powered: (±0.02% of Reading ±0.002

units)

Resolution: 0.001 V, 0.001 mA, 0.0001 V, 0.0001 mA

Temperature Performance: Included in accuracy specification

Voltage & Current Source:

DC Voltage Range: 0 – 24 V

DC Current Range: 0 – 24 mA

Accuracy: (±0.015% of Reading ±0.002 units)

Resolution: 0.001 V, 0.001 mA

Temperature Performance: Included in accuracy specification

33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

ZM4 Instruction Manual 9R87-B June 2012

24V Source: Ty pical Load Line

25.0

24.0

23.0

22.0

21.0

20.0

Output Volts (V)

19.0

18.0

17.0

0 5 10 15 20 25

Current (mA)

Power: Four (4) AA 1.5 volt alkaline batteries provide 30+ hours of

continuous measurement service or 10 hours of service in 24V Source mode

when powering a transmitter at 20 mA output. Meriam recommends the unit

be powered up for a minimum of 5 minutes to operate at the full accuracy

specification of the instrument.

Display: 128 x 128 pixel (2” x 2” viewable) monochrome display with

backlight

Enclosure: 8.5” L x 3.75” W (max.) x 2.25” D (max.), polycarbonate case,

Softflex® over-molded bumpers, IP40

M4 single sensor: 1.5 – 1.8 lbs, M4 dual sensor: 1.8 lbs

34

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

ZM4 Instruction Manual 9R87-B June 2012

Specifications

Environmental Conditions:

Calibrated: -4 to 122°F (-20 to 50°C)

Storage: -40 to 140°F (-40 to 60°C)

Humidity: 5 – 95%, non-condensing

Altitude: Operating 2000 Meters, Storage 1000 Meters

Safety:

EMC: EN 61326-1, Class A

IEC 61010-1, CAT-1 Voltage Protection

Environmental: RoHS, WEEE, Pollution Degree 2

Shock: 1 Meter Drop Test per IEC 61010-1

This instrument is intended for a temporary connection to industrial lowvoltage current loops and not intended for a permanent connection.

“This product complies with the essential requirements of the European

Directives for Low Voltage, EMC, RoHS, & WEE and carries the CE marking

accordingly”.

Cleaning: Clean product with mild soap and damp rag. To avoid damaging

the plastic lens and case do not use solvents or abrasive cleansers.

Product Features: sensor zero and tare, field recalibration with password

protection, sensor damping (exponential & smart), running

minimum/maximum, units select, flexible data logging, adjustable power off

timer, adjustable backlight off timer, adjustable display contrast and backlight

brightness, battery monitor, clock/calendar, field reprogrammable, keypad

with adaptive interface wheel for alpha-numeric selection and menu

navigation

Engineering Units: (32 selectable) PSI, inW20C, inW4C, inW60F, ftW20C,

ftW4C, ftW60F, mmW20C, mmW4C, mmW60F, cmW20C, cmW4C,

cmW60F, mW20C, mW4C, mW60F, inHg0C, mHg0C, cmHg0C, mmHg0C,

torr, kg/cm2, kg/m2, Pa, hPa, kPa, MPa, Bar, mBar, ATM, oz/in2, lb/ft2

35

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

ZM4 Instruction Manual 9R87-B June 2012

Zeroing and Field Recalibration

To maintain the accuracy of the M4 it is recommended that both the pressure

and Volts/mA sensor be zeroed prior to use. Zero is located on the main

measure screen once the sensor is selected or under the Sensor setup

screen. Differential and Gauge sensors shall be vented to atmosphere before

executing a zero. Absolute pressure sensors must be pulled down to a

complete vacuum of 200 microns or less for optimum results.

To zero the Volts/mA sensor the shorting plug included with the unit must be

installed across the banana jacks. Follow the instructions on the screen to

perform the zero.

Periodic recalibration of M4 may be needed to maintain optimum

performance. The calibration menu is located under each sensor in the setup

menu. Simply follow the screen and apply the values requested.

Field recalibration should only be executed by qualified personnel using

suitable primary standards. These standards should meet the accuracy

requirements of your company or industry. Meriam recommends using

primary standards at least 4 times more accurate than the unit under test.

For pressure transmitters up to 200 PSI, Meriam recommends a deadweight

tester of at least ±0.0015% of reading for field recalibration. For transmitter

ranges of 200 PSI and above, a deadweight tester of at least ±0.0030% of

reading. When calibrating using a dead weight tester referenced to inches of

water, be sure the M4’s inches of water reference temperature matches that

of the dead weight tester.

If an error is made during field recalibration the restore factory defaults option

is located under the sensor in the setup menu.

36

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

ZM4 Instruction Manual 9R87-B June 2012

Applications

The M4 is designed to power up a transmitter to calibrate the pressure

channel and channel and mA output. The unit under test should be isolated

from the process and taken out of the loop before starting the calibration.

Please make sure you have the proper sensor and range before starting the

calibration. The Full Scale range of the sensor is displayed next to the sensor

location in the current engineering units.

To calibrate the transmitter under test, insert test leads into the bottom of the

M4. Observe loop polarity using the color coded standard banana jacks (Red

+) and (Black -). If the loop requires power, the M4 will source 24V and

measure the mA in the loop. The 24V source mode is located under the VMA

setup menu. Field devices with compliance voltage about 19V may not be

able to be calibrated. See the load line curve under specifications.

37

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

ZM4 Instruction Manual 9R87-B June 2012

Applications (continued)

If you are using a DN or DI (Differential Pressure Sensor) the high pressure

port (P1) is teed into the pressure source and transmitter high side (H) and

low pressure port is vented to atmosphere. If you are using a GI or CI

(Gauge Sensor) there is only one pressure connection.

In addition to reading gauge pressure the M4 can also be used to measure

pressure drop across a pressurized system. Examples include orifice plates,

pitot tubes, filters, or valves. A push to read, three valve, or five valve

manifold is recommended to avoid damage to the sensor.

38

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

ZM4 Instruction Manual 9R87-B June 2012

Applications (continued)

Vacuum calibration can be performed by venting the high pressure

connection (P1) and applying vacuum to the lower pressure connection (P2).

Atmospheric pressure is the reference for all vacuum measure elements.

Absolute pressure calibrations use an AI sensor which has an internal

absolute zero reference. You will notice when powering up an M4 with an AI

sensor, it will read the local barometric pressure. Simply connect the vacuum

(or pressure) source to the single port of the manifold. To zero an absolute

sensor a full vacuum of 200 micron or less must be applied.

39

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

ZM4 Instruction Manual 9R87-B June 2012

Contact Meriam

In the event an M4 requires service or must be returned for repair, please

contact Meriam at the numbers listed below.

DO NOT send any unit in for repair without first contacting Meriam for a

Return Material Authorization (RMA) number. If this number has not

been obtained and clearly marked on the return packaging, the unit will

be returned at the shipper’s expense. An RMA number will be provided by

the Meriam Repair Department when you call, fax or e-mail your information.

Certification for Non-Hazardous Materials will also be required. The RMA

number must accompany all incoming packages to insure proper tracking,

processing and repair work.

To assist us in processing your repair request, please have the Model &

Serial Number of the unit available when you call. This information is located

on the M4 label.

40

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...