Page 1

9R143 Dated 3/2011

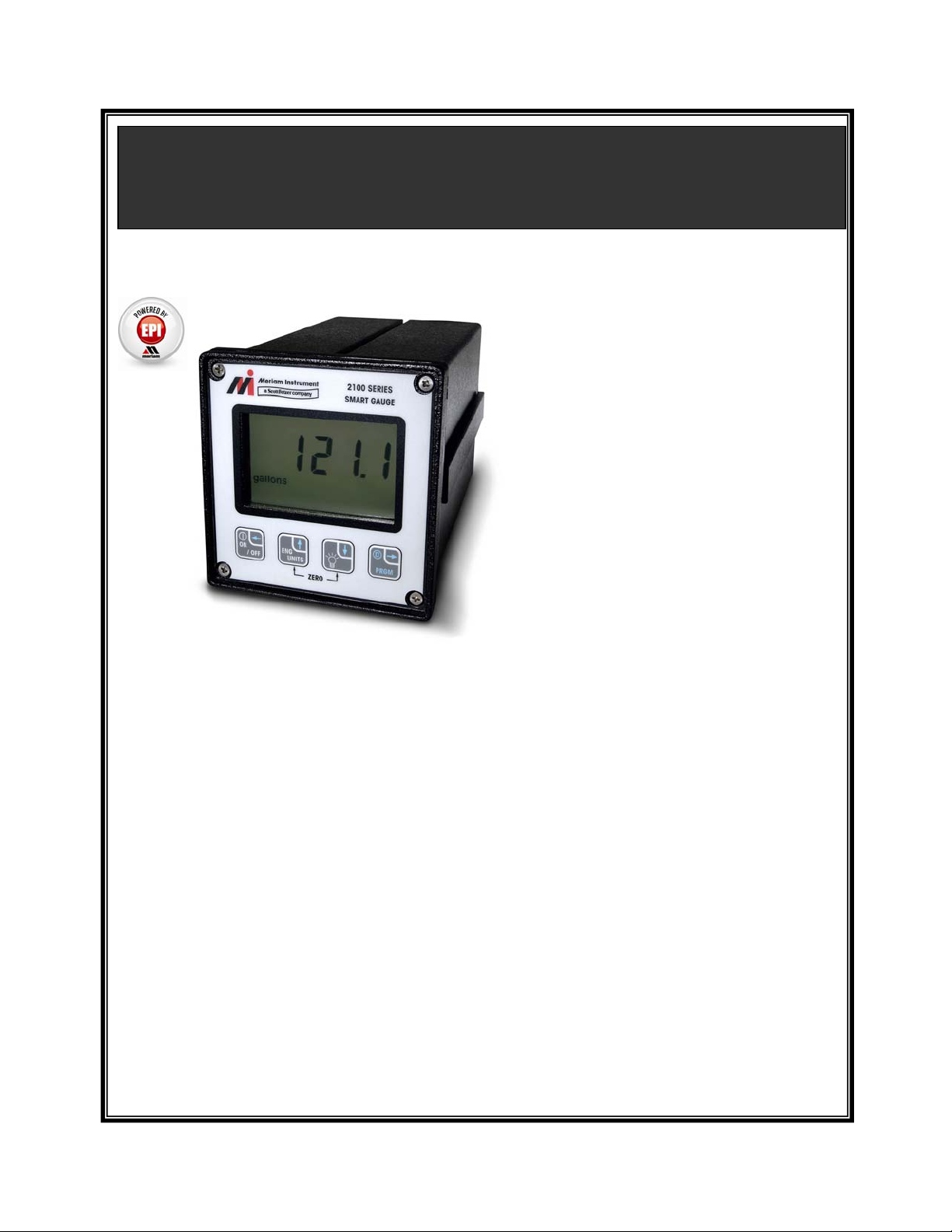

M2110L SMART LEVEL GAUGE

OPERATING INSTRUCTIONS

The Battery model is powered by its internal lithium batteries only. This model does not provide

any outputs or RS-232 communications.

SetPoint and Current Loop models have outputs that can be used for control or

indicating/recording functions. Both models also have RS-232 communications capability. In

addition to configuring the gauge, the RS-232 port can be used to monitor and log the measured

level/pressure data and output status. It can also be used as part of a control system with digital

capabilities.

The SetPoint model provides two SPDT relay outputs with adjustable deadband. This

configuration provides normally open or normally closed contact operation for fail-safety.

Switching SetPoint can be set from 0 to +120% of the full scale level/pressure range. The

SetPoint model is powered by 115/230 VAC, or 24VDC.

The Current Loop model provides a 4 to 20 mA output, and is intended to be used as a level

transmitter on a three or four wire loop. Zero and span are set through user-programmable

registers, from 0 to +120% of the full scale pressure range. The output is capable of normal and

reverse action. The Current Loop model is powered by 24VDC only.

Meriam’s M2110L Smart Level Gauge is

a microprocessor-based pressure sensing

device with algorithms to calculate level.

The various sensors provide dip- tube

bubbler accommodation, or direct head

level measurements. Three configurations are available: Battery, SetPoint,

and Current Loop models.

All models are programmable through the

front keypad, to allow configuration of

the gauge. The user’s program

information is stored in non-volatile

memory, and is retained when the power

to the gauge is removed. SetPoint and

Current Loop models can also be

configured through the RS-232 serial

communication connection.

i

Page 2

9R143 Dated 3/2011

Table of Contents

LEVEL DISPLAY.......................................................................................................................... 1

SAFETY WARNINGS................................................................................................................... 2

CERTIFICATION/SAFETY/WARNINGS ................................................................................... 3

KEYPAD FUNCTIONS:................................................................................................................ 4

PROGRAMMABLE REGISTER OVERVIEW ............................................................................ 6

PROGRAMMABLE REGISTER QUICK REFERENCE............................................................. 6

ENGINEERING UNITS................................................................................................................. 7

ZERO REFERENCE................................................................................................................. ..... 8

P0 – LOCKOUT CODE ................................................................................................................. 9

P1 – TIMEOUT VALUE.............................................................................................................. 10

P2 – DAMP RATE ....................................................................................................................... 11

P3 – RESIDUAL HYDROSTATIC PRESSURE......................................................................... 12

P4 – FULL TANK HYDROSTATIC PRESSURE ......................................................................14

P5 – SETPOINT OPTIONS.......................................................................................................... 15

P6 and P7 – SETPOINT (SET1 and SET2)................................................................................. 16

P8 – DEADBAND........................................................................................................................ 17

P9 – TANK CYLINDRICAL CAPACITY.................................................................................. 18

P10 – TANK ENDS CAPACITY................................................................................................. 19

P11 – TANK TYPE......................................................................................................................20

LOCKOUT CODE PROMPT....................................................................................................... 21

SERIAL PORT SERVICE............................................................................................................ 22

ERROR CODES........................................................................................................................... 24

INSTALLATION AND WIRING................................................................................................ 25

PRODUCT SPECIFICATIONS................................................................................................... 28

SERVICE & CALIBRATION...................................................................................................... 30

ii

Page 3

9R143 Dated 3/2011

LEVEL DISPLAY

Indicators

During normal operation, the gauge displays the level value in large numerals, and the bottom of the

display shows the current Engineering Unit. The top of the display will show PRGM when the gaug e is in

Program Mode (flashing when “view only”). For SetPoint models, the top of the display will show

SET1/SET2 to indicate activated outputs (or corresponding register opened in Program Mode). For

Current Loop models, the top of the display will show 4-20mA when the output is enabled (or

corresponding register opened in Program Mode).

Performance

The M2110L Smart Level Gauge retrieves analog data from its pressure sensor, and performs an analog-to-

digital (A/D) conversion for microprocessor-based data handling. The rate of A/D conversion will

typically be between 9 to 13 conversions per second, depending on the various operating conditions.

To make the display easier to read, only every fourth sample is updated on the display. (This results in a

display update rate of about 3 updates per second.) The internal calculations, outputs, and serial interface

are updated at the full conversion rate.

Resolution

The Smart Gauge has a 4½ digit display. The resolution of the data (decimal point positioning) is defined

by the range and sampling process. The resultant full scale display and data resolution is summarized in

the table below. Note that since the Smart Level Gauge display is primarily user-scaled to level units, the

full scale and resolution depends on the scale. If a specific value will not fit on the 4½ digit display,

however, the auto-range feature will decrease the resolution to allow the value to fit the display (for

example, increasing past 199.99 becomes 200.0). The auto-range feature restores the decimal resolution

with a built-in deadband of 5 display counts (for example, 200.0 must drop to 199.95 before the two-digit

decimal resolution is restored).

Note that the full scale display indication during power-up will not necessarily have the same decimal

resolution found during actual level monitoring.

1

Page 4

9R143 Dated 3/2011

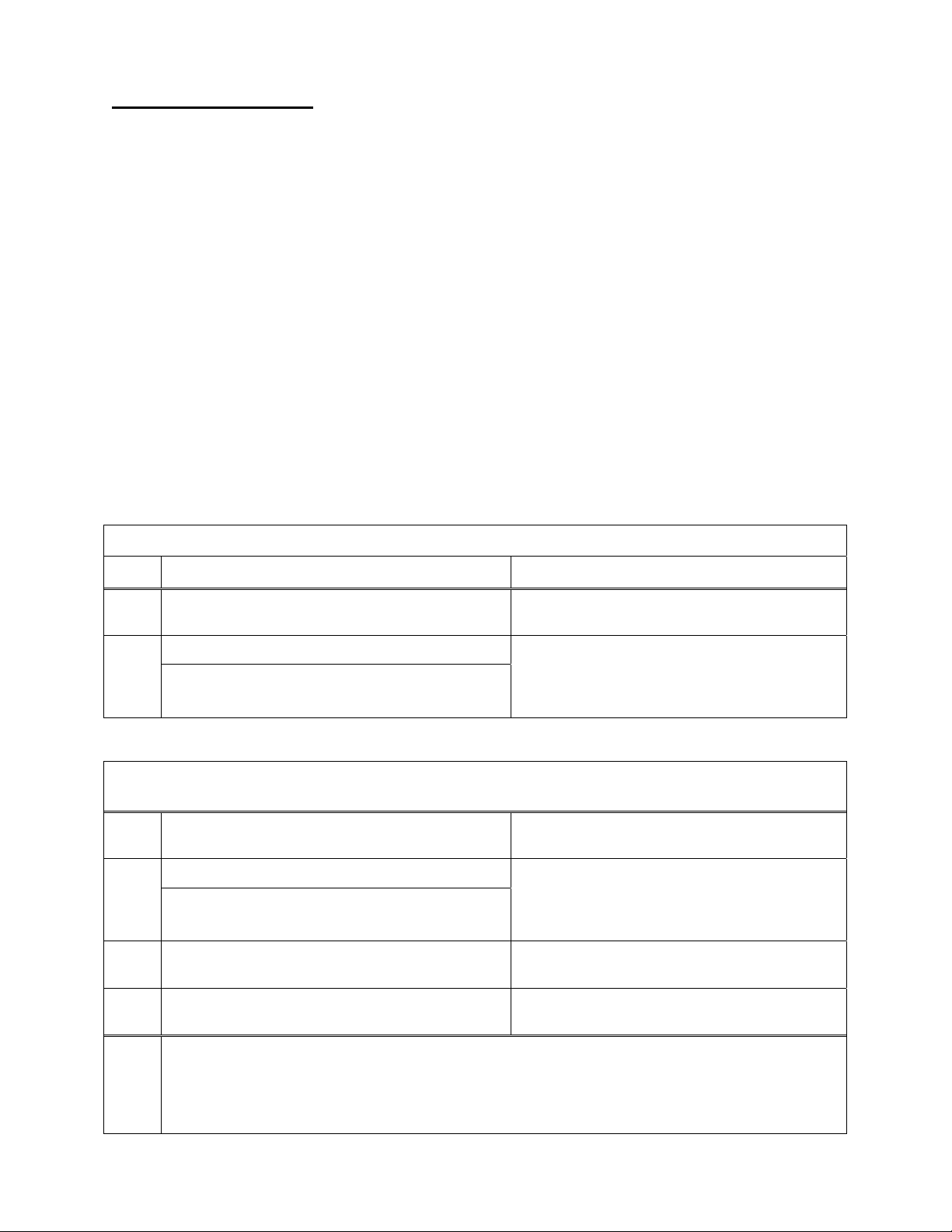

SAFETY WARNINGS

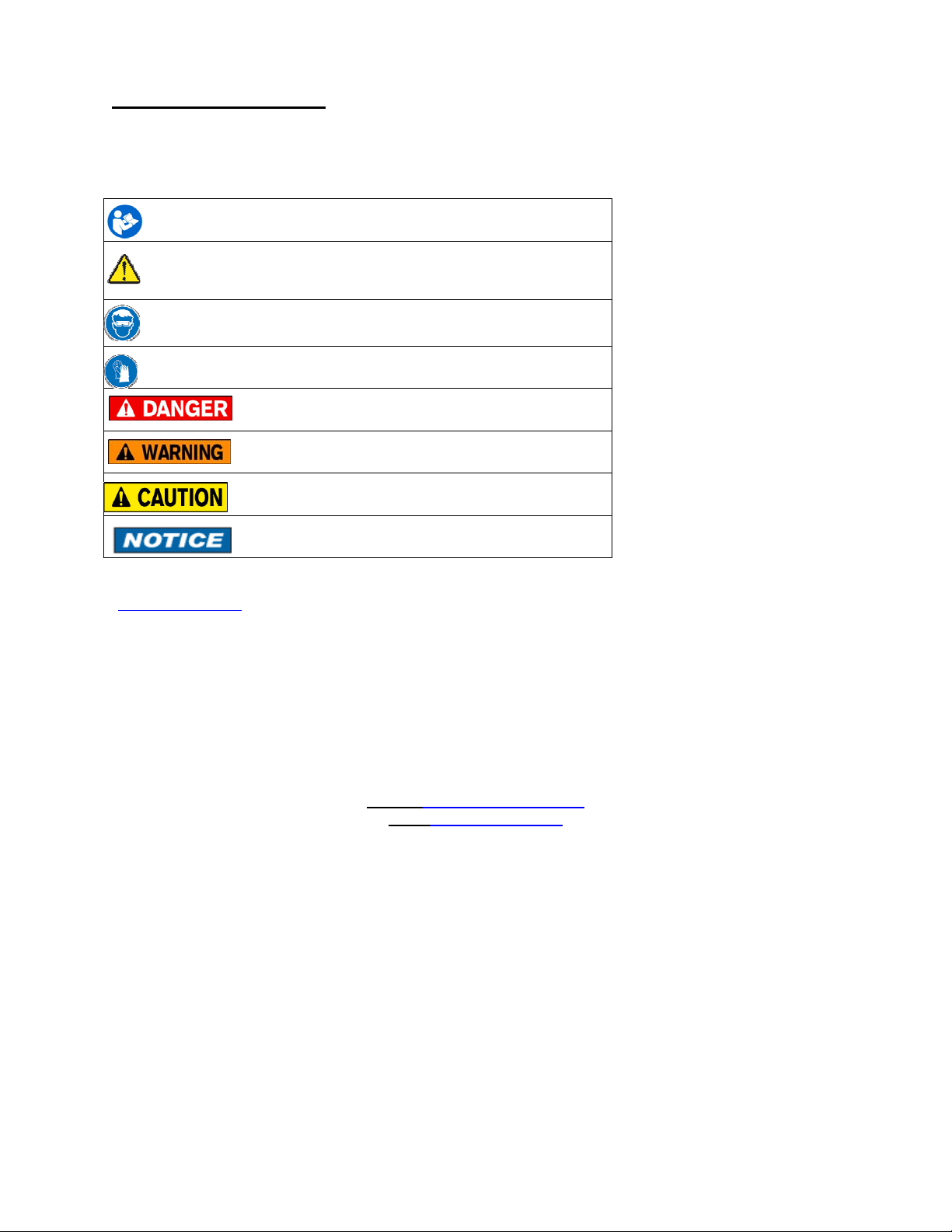

The table below defines the safety symbols, signal words and corresponding safety messa ges used in the

manual to identify potential hazards and are intended to warn persons about hazards that could result in

personal injury or equipment damage.

This is the Read Instruction Manual symbol. This symbol indicates

h that you must read the instruction manual.

This is the Safety Alert symbol. This symbol indicates a WARNING.

Warnings alert you to actions that can cause personal injury or pose a

physical threat. Please read these carefully.

This is the Safety Glasses symbol. This symbol indicates that you must

wear approved safety glasses during the task.

This is the Safety Gloves symbol. This symbol indicates that you must

wear approved safety gloves during the task.

Indicates a potentially hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

Indicates information essential for proper product

installation, operation or maintenance.

Information in this document is subject to change without notice. Check the Meriam web site

(www.meriam.com

For customer assistance please call your local Meriam representative or Meriam di.0

) for the latest manual revision.

Meriam Process Technologies

10920 Madison Avenue

Cleveland, Ohio 44102

Telephone: (216) 281-1100

Fax: (216) 281-0228

E-mail: meriam@meriam.com

Web: www.meriam.com

2

Page 5

9R143 Dated 3/2011

CERTIFICATION / SAFETY / WARNINGS

Fire/Explosion Hazard. This instrument is not intrinsically safe. DO NOT use or

service in areas that may contain flammable gas or vapors, combustible dusts or

ignitable fibers where an unintended spark can cause a fire/explosion.

Do not exceed the Pressure Limits listed in the Specifications section of this

manual. Failure to operate within the specified pressure limit could result in

death or serious injury.

Do not exceed the Maximum Input Voltage listed under “Input Power” in the Specification section

of this manual

Do not exceed the Switch Rating listed under “I/O” in the Specifications section of this manual.

Disconnect power before servicing.

Substitution of components may impair operation and safety.

3

Page 6

9R143 Dated 3/2011

/

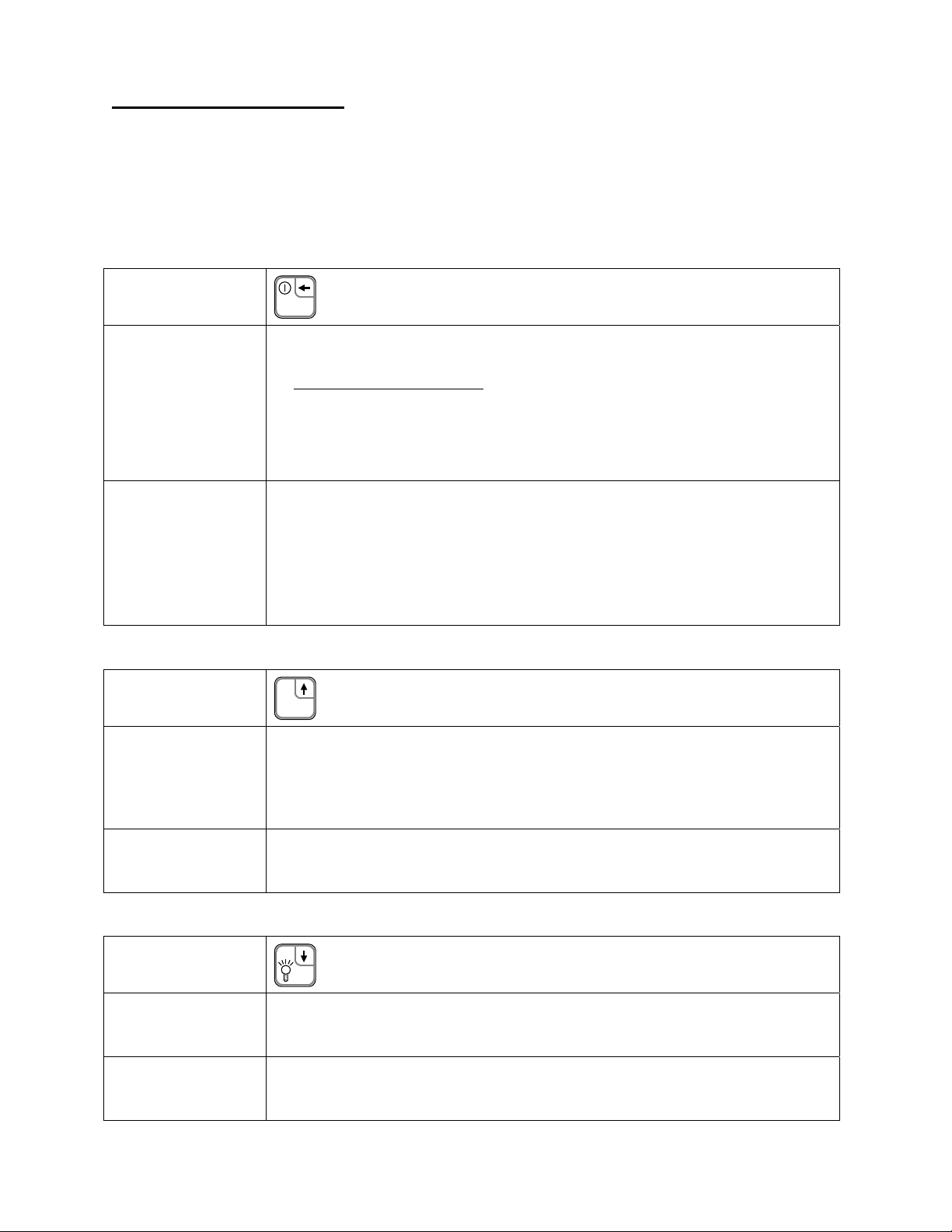

KEYPAD FUNCTIONS:

The keys on the front panel perform multiple functions. Their function differs depending on whether the gauge is in

Measure Mode or Program Mode.

• Measure Mode is the normal operating mode for measuring and displaying level. This mode is always

default after power-up or reset.

• Program Mode is used to configure the various options of the gauge. This mode is denoted by a PRGM

indicator on the display.

ON/OFF /

Backspace Key

ON

Document Symbol: (Backspace←)

OFF

Measure Mode

Program Mode

ENG UNITS/Up

Arrow Key

Measure Mode

• Battery models: Toggles the gauge ON and OFF.

• SetPoint and Current Loop models: “Resets” the gauge.

Sequence of power-up or reset

1. Display test is performed (all segments of the LCD display are turned on).

2. Firmware revision is displayed.

3. Full scale (programmed level) is displayed in the last Engineering Unit used.

4. All prior register values are restored and activated.

5. Measure Mode displays level in the last Engineering Unit used.

Backspace function:

From Program Mode, this key will exit to Measure Mode.

When editing a register, this key is used to abort a programming operation and exit the

register without making any changes.

When editing a multi-digit value, each key press will backup one digit, until finally

exiting the register.

ENG

UNITS

Document Symbol: (Up↑)

Allows the Engineering Units to be changed (see page 7). During Engineering Unit

selection, the current unit indicator remains solid, and the “new” unit indicator is

flashing. Scrolling through the available units is done by pressing the Up↑ or Down↓

keys. The flashing unit is selected using the PRGM/Enter→ key, or the process may be

aborted by using the Backspace← key.

Program Mode

(and EU Selection)

Scroll up function. Scrolls up through the available programmable registers. Once a

register is opened, this key allows editing by scrolling up through the values in the

register.

Backlight/Down

Arrow Key

Measure Mode

Program Mode

(and EU Selection)

Toggles the display Backlight on and off. Note that the default Backlight status for the

Battery model is OFF to conserve battery life. The other models will retain the prior

Backlight status as default.

Scroll down function. Scrolls down through the available programmable registers. Once

a register is opened, this key allows editing by scrolling down through the values in the

register.

Document Symbol: (Down↓)

4

Page 7

9R143 Dated 3/2011

PRGM/Enter Key

Measure Mode

(and EU Selection)

Program Mode

Re-ZERO Key

Measure Mode

Program Mode

(and EU Selection)

PRGM

Selects Program Mode, which allows access to the programmable registers. This key is

also used to accept a new Engineering Unit selection.

Opens the selected programmable register for editing.

When the desired value is displayed, pressing the PRGM/Enter→ key accepts and

stores the value, and closes the register.

When editing a multi-digit value, each key press will accept the current digit and proceed

to the next, until finally accepting the complete value and closing the register.

ENG

UNITS

In Measure Mode, pressing the Up↑ and Down↓ keys at the same time resets the zero

reference of the gauge (see page 8).

In Program Mode, for convenience, this function will reset the current value to default.

For example, in Program Mode (but before opening a register), this function

Document Symbol: (PRGM/Enter→)

Document Symbol: (Up↑ and Down↓)

+

will reset the register scroll to P0.

After opening a register for editing, this function will reset the register’s data

value to default (typically 0).

Similarly, when selecting a new Engineering Unit, this function will reset the

selection to the first unit (gallons).

Note that even when using this “reset” function, the PRGM/Enter→ key must be

pressed to accept the new value (this allows for further editing after reset of the value).

5

Page 8

9R143 Dated 3/2011

PROGRAMMABLE REGISTER OVERVIEW

All M2110L Smart Level Gauges have programmable registers that allow the gauge to be configured to fit the level

measurement application. Programmable registers are numbered P0 through P11. Each register con tro ls a specific

aspect of the gauge’s performance.

Beginning on page 9 is a description of all programmable registers, and instructions for their use. Each register is

found on all M2110L Smart Level Gauge models, and performs the same function described for all models, except

as noted otherwise.

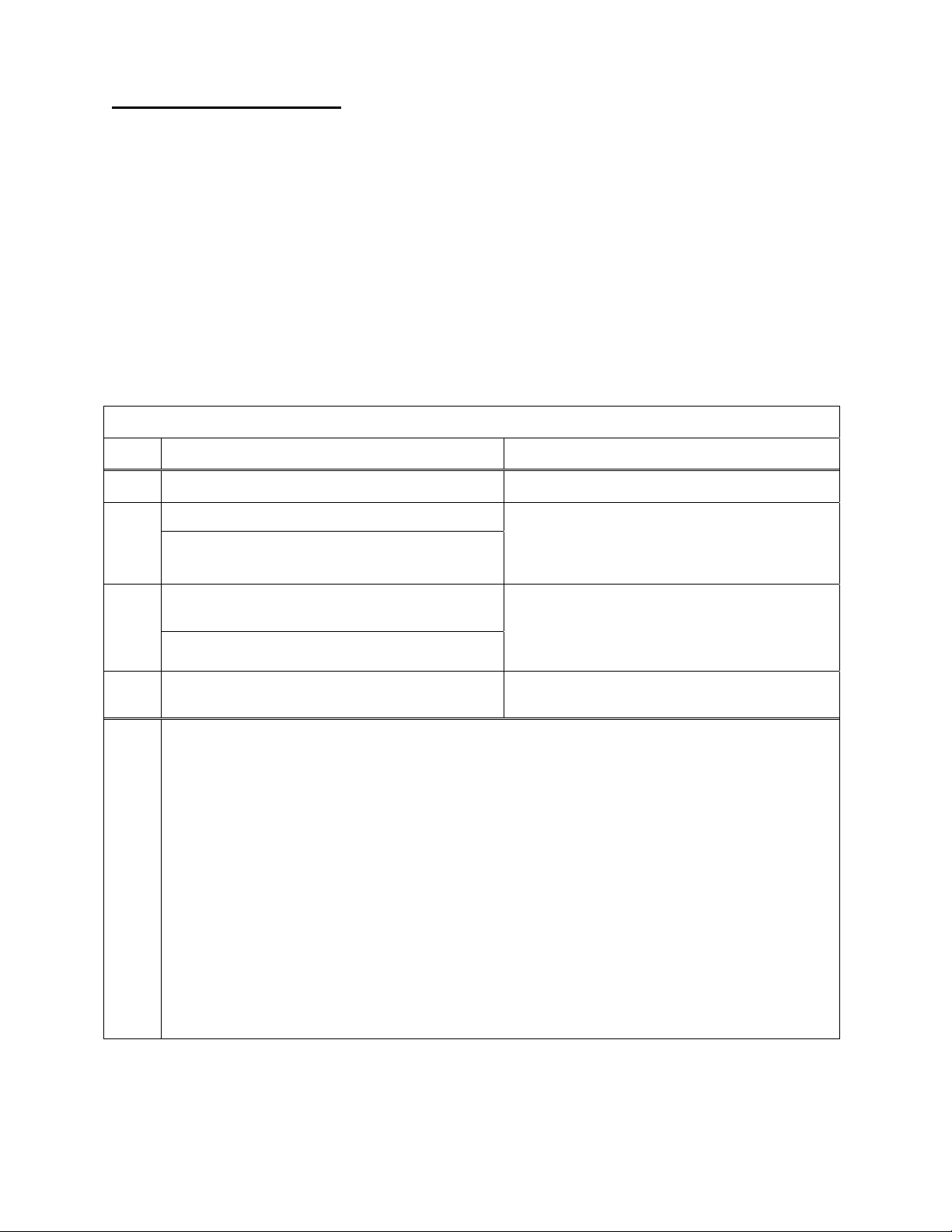

Px

P0

P1

P2

P3

P4

P5

PROGRAMMABLE REGISTER QUICK REFERENCE

Name Description Value Range Notes

Lockout Code Lockout for security. 00 to 99 00 = Disabled.

Timeout Automatic shutoff in minutes of keypad

inactivity.

Damp Rate Exponential damping time in seconds. 0.1, 0.2, 0.5, 1, 2, 5,

Residual

Hydrostatic

Pressure

Full Tank

Hydrostatic

Pressure

SetPoint Options

Identifies the unmeasured or added

hydrostatic pressure due to piping

configurations.

The pressure created by a full column

of fluid from the floor of the tank to the

top of the maximum level measured.

SetPoint Model: defines which relay

outputs are active.

Current Loop Model: defines the status

of the 4 - 20 mA output.

0 (disabled), 1, 2, 5,

10, 15, 25

10, 15, 25, 50

-9,999 to +9,999

O @ 20ºC.

inH

2

0 to 9,999 (Keypad)

0 to 19,999 (Serial)

0 = Disabled.

1 = SET1 only.

2 = SET2 only.

3 = Both enabled.

0 = 4-20 disabled

1 = 4-20 enabled

Battery model only.

0.1 = No Damping.

+Val: Dip Tube

- Val: Direct Head

Pressure in inH

@20°C.

Not found on

Battery model.

O

2

P6

P7

P8

P9

P10

P11

SET1 Controls SET1 relay or 4.00 mA value. –20% to +120% FS User defined value.

SET2 Controls SET2 relay or 20.0 mA value. –20% to +120% FS User defined value.

Deadband Sets the amount of deadband in percent

of full scale for relays.

Tank Cylindrical

Capacity

Tank Ends

Capacity

Tank Type Identifies type of tank. 0 = Linear/Vertical

The capacity, in Engineering Units, of

only the cylindrical portion of the tank.

The capacity, in Engineering Units, of

only the dished ends of a hori zont al

cylindrical tank (includes both ends).

Or, total capacity for spherical tanks.

0 (disabled), 0.1,

0.2, 0.5, 1, 2, 5, 10%

0 to 9,999 (Keypad)

0 to 19,999 (Serial)

0 to 9,999 (Keypad)

0 to 19,999 (Serial)

1 = Non Linear

SetPoint model

only.

P9 = 0 for spherical

tanks.

P10 = 0 for linear

tanks, or cylindrical

tanks with flat ends.

6

Page 9

9R143 Dated 3/2011

ENGINEERING UNITS

The following Engineering Units are available on the M2110L Smart Level Gauge:

1. Gallons

2. Pounds

3. Cubic Feet

4. Liters

5. Percent

6. Kilograms

7. Cubic Meters

8. InH2O – Inches of Water Column (density reference temperature: 20°C)

9. User Units – User Defined Units

STEP BY STEP: CHANGING ENGINEERING UNITS

Step Action Display

1

2

3

4

Notes

Gauge should be in the normal Measure Mode. Normal Level Display.

Press the ENG UNITS (Up↑) key.

If the lockout is active, the gauge will now prompt for entry of

the lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired Engineering Unit.

The Zero function (Up↑ and Down↓) will reset the scroll to the

first unit and allow selection to continue.

Press the PRGM/Enter→ key when the desired

unit is flashing.

1. When scrolling through Engineering Units, User Units are denoted by all units flashing.

2. In Measure Mode, User Units are denoted by no Engineering Unit indicators shown on the bottom

of the display.

3. Changing the Engineering Unit will automatically update the SetPoint and Capacity registers as

appropriate (refer to the Automatic Update section on pages 16, 18, and 19 for further explanation).

4. If programmed in a volumetric unit (gallons, liters, feet

to other volumetric units using the ENG UNITS (Up↑) key, and likewise for mass units (pounds,

kilograms). However, the Smart Level Gauge will not convert between volumetric units, mass

units, and/or user units. Percent (%) and InH

programmed.

Current Engineering Unit1 indicator flashes.

The current Engineering Unit indicator remains

solid since it is active, and the unit to be selected

flashes as the list is scrolled.

The display switches to the new Engineering Unit

and returns to Measure Mode.

3

, meter3), the Smart Level Gauge will convert

O are available regardless of what unit was

2

2

5. At any time, the Backspace← key will abort the process and return to Measure Mode.

6. If there is no keypad activity for approximately 1 minute, the operation is aborted and the gauge

returns to Measure Mode unchanged.

7

Page 10

9R143 Dated 3/2011

ZERO REFERENCE

Zeroing the gauge consists of accepting the current applied pressure value as the zero pressure reference. To set the

zero reference pressure, all pressure sources should be disconnected from the gauge, and its temperature should be

stable.

The Smart Level Gauge displays tank level as a function of the applied pressure. This pressure is linearly offset

from the zero reference value, before applying the tank level calculations.

AFFECT ON OUTPUTS

The SetPoint and Current Loop outputs are calculated based on the displayed level. Since re-zeroing the

gauge may change the displayed level, the outputs may change accordingly. For safety purposes, if the

outputs are active (defined by register P5; see page 15), an extra step is required to warn the operator and

confirm the desired action. For clarity, both scenarios are described below, step-by-step.

FACTORY ZERO

The “Factory Zero” can be restored through the serial port service only (SetPoint and Current Loop mode ls

only). This is the value set during calibration of the sensor, and is typically 0.0.

RANGE CHECK

The Smart Gauge can be zeroed only when the applied pressure is within ±5% of sensor full scale. If the

applied pressure is greater than 5% of full scale, an error code will be displayed when zeroing is attempted.

STEP BY STEP: RE-ZEROING THE GAUGE (Disabled Outputs, P5=0)

Step Action Display

1

2

Gauge should be in normal Measure Mode, with

applied pressure ready for zeroing (typically vented).

Press the Up↑ and Down↓ keys simultaneously.

If the lockout is active, the gauge will now prompt for entry of the

lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

Normal level display, near 0.0 (or offset from the

Residual Hydrostatic Pressure, P3).

The display will flash “0000” several times while

the new zero is taken, and then return to Measure

Mode with the new zero activated.

WHEN OUTPUTS ARE ACTIVE (P5>0) ...

1

2

3

Gauge should be in normal Measure Mode, with

applied pressure ready for zeroing (typically vented).

Press the Up↑ and Down↓ keys simultaneously.

If the lockout is active, the gauge will now prompt for entry of the

lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

Press PRGM/Enter→ before the countdown

1

expires

. This acknowledges the warning.

Normal level display, near 0.0 (or offset from the

Residual Hydrostatic Pressure, P3).

The display will begin countdown from

“0005” to “0000”.

The display will again countdown from

“0005” to “0000”.

SetPoint and Current

Loop models only

4

Notes

Press ZERO again (Up↑ and Down↓) before the

countdown expires

1. During steps 2 or 3, if the countdown expires, the gauge will return to Measure Mode un chan ged.

2. During steps 2 or 3, the Backspace← key will abort the process and return to Measure Mode.

3. The zero reference value is snapshot immediately when the ZERO keys are pressed. This temporarily

stored value is accepted once the zeroing process is complete (or discarded if not completed).

1

. This confirms the zero action.

The display will flash “0000” several times while

the new zero is taken.

8

Page 11

9R143 Dated 3/2011

P0 – LOCKOUT CODE

This feature provides security in the Smart Gauge. It is designed to prevent unauthorized personnel from tampering

with or inadvertently changing the configuration of the gauge. The lockout is con trolled by a 2-digit setting in the

P0 register. Once a lockout code is entered, the gauge will prompt for the lockout code before allowing any changes

(similar to a “password”). Changes include Engineering Unit selection, re-zeroing, or entering Program Mode.

Following an operator action, if the correct code (password) is not entered when prompted, an error message is

briefly displayed. If the operator action was changing Engineering Units or re-zero the gauge, the gauge will simply

return to normal Measure Mode operation, without accepting any change. If the operator action was entering

Program Mode, the gauge will enter a “view-only” status (see page 21), denoted by the PRGM indicator flashing.

In Program Mode (and during lockout code prompting), the register value is shown as “L xx” to assist in

identifying the register. The “L ” indicates “Lockout”, and “xx” will consist of the current value.

All Models

QUICK REFERENCE: P0, LOCKOUT CODE

Px

Name Description Value Range Notes

P0 Lockout Code Lockout for security. 00 to 99 00 = Disabled.

STEP BY STEP: P0, LOCKOUT CODE

Step Action Display

1

2

3

4

5

6

7

Notes

Gauge should be in the normal Measure Mode. Normal Pressure Display.

Press the PRGM/Enter→ key.

If the lockout is active, the gauge will now prompt for entry of

the lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

Press PRGM/Enter→ again, to open the register.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired numeric value for the flashing digit.

The Zero function (Up↑ and Down↓) will reset the entire

register to 00 and allow editing to continue.

Press the PRGM/Enter→ key to accept the digit.

Repeat steps 4 and 5 for the second digit. The complete 2-digit value will be accepted, and

Press the Backspace← key to activate the lockout

and return to Measure Mode.

1. After step 2, the Backspace← key will abort the process and return to Measure Mode.

2. After steps 3 or 4, the Backspace← key will abort the current digit and close the register (since it is

the first digit).

3. After step 5, the Backspace← key will abort the current digit and backup to the first digit. Another

Backspace← will abort the process and close the register.

4. After step 6, the PRGM/Enter→ key will again open the register for edit.

5. During any programming operation, if there is no keypad activity for approximately 1 minute, the

operation is aborted and the gauge returns to Measure Mode unchanged.

The PRGM annunciator shows at the top of the

display, and the display shows the register name

“P0”.

The display will show “L xy” with the first digit

flashing for edit (indicating L

“L _x”, where “_” is the digit being edited

(flashing).

The next digit begins flashing for edit.

the register is closed (display shows P0 for

selection).

Normal Pressure Display.

ockout Code xy).

9

Page 12

9R143 Dated 3/2011

P1 – TIMEOUT VALUE

This register sets the length of time (in minutes) for automatic shutoff. The Battery model will automatically shutoff

if there is no keypad activity for this length of time. This feature can be disabled by selecting 0 in the register,

which allows the gauge to remain on indefinitely, or until the ON/OFF key is pressed (battery life may be reduced).

During programming, the choices found in the register correspond to the actual timeout values, in minutes.

Battery Models Only

QUICK REFERENCE: P1, TIMEOUT

Px

Name Description Value Range Notes

P1 Timeout Automatic shutoff in minutes of

keypad inactivity.

0 (disabled),

1, 2, 5, 10, 15, 25

Battery model

only.

STEP BY STEP: P1, TIMEOUT

Step Action Display

1

2

Gauge should be in the normal Measure Mode. Normal Pressure Display.

Press the PRGM/Enter→ key.

If the lockout is active, the gauge will now prompt for entry of

the lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

The PRGM annunciator shows at the top of the

display, and the display shows the register name

“P0”.

3

4

5

6

7

Notes

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register.

The Zero function (Up↑ and Down↓) will reset the scroll to P0

and allow selection to continue.

Press PRGM/Enter→ to open the register.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register value.

The Zero function (Up↑ and Down↓) will reset the scroll to

default and allow editing to continue.

Press the PRGM/Enter→ key to accept the desired

value.

Press the Backspace← key to activate the register

setting and return to Measure Mode.

1. After steps 2 and 3, the Backspace← key will abort the process and return to Measure Mode.

2. After steps 4 and 5, the Backspace← key will abort the edit and close the register.

3. After step 6, the PRGM/Enter→ key will again open the register for edit.

4. During any programming operation, if there is no keypad activity for approximately 1 minute, the

operation is aborted and the gauge returns to Measure Mode unchanged.

Display shows “P1”.

The display shows the current value.

All available choices are scrolled.

(Choices indicate actual Timeout in seconds.)

The value is accepted, and the register is closed.

Display shows “P1”.

Normal Pressure Display.

10

Page 13

9R143 Dated 3/2011

P2 – DAMP RATE

The Smart Gauge has a selectable damp rate, which is used to stabilize the display for applications with a pulsating

pressure source. The damp rate setting is roughly the length of time it will take for the gauge to ramp from one

stable pressure to another. The ramping is exponential, changing at a slower rate as the final value is approached.

The “time constant” of the exponential equation is roughly one-fifth of the damp rate setting. This means that the

damped value will be roughly 63% of final value after a time equal to one-fifth of the register setting. The value

will be roughly 86% of final value after a time equal to two-fifths of the register setting.

The damping function only affects the displayed value (LCD display and RS232 data); it does not

of the SPDT relays, the 4 to 20 mA outputs, or the response to over-pressure (“OP” indication).

All Models

affect the action

QUICK REFERENCE: P2, DAMP RATE

Px

Name Description Value Range Notes

P2 Damp Rate Exponential damping time in

seconds.

0.1, 0.2, 0.5, 1, 2,

5, 10, 15, 25, 50

0.1 = No

Damping.

STEP BY STEP: P2, DAMP RATE

Step Action Display

1

2

3

4

5

6

7

Notes

Gauge should be in the normal Measure Mode. Normal Pressure Display.

Press the PRGM/Enter→ key.

If the lockout is active, the gauge will now prompt for entry of

the lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register.

The Zero function (Up↑ and Down↓) will reset the scroll to P0

and allow selection to continue.

Press PRGM/Enter→ to open the register.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register value.

The Zero function (Up↑ and Down↓) will reset the scroll to

default and allow editing to continue.

Press the PRGM/Enter→ key to accept the desired

value.

Press the Backspace← key to activate the register

setting and return to Measure Mode.

1. After steps 2 and 3, the Backspace← key will abort the process and return to Measure Mode.

2. After steps 4 and 5, the Backspace← key will abort the edit and close the register.

3. After step 6, the PRGM/Enter→ key will again open the register for edit.

4. During any programming operation, if there is no keypad activity for approximately 1 minute, the

operation is aborted and the gauge returns to Measure Mode unchanged.

The PRGM annunciator shows at the top of the

display, and the display shows the register name

“P0”.

Display shows “P2”.

The display shows the current value.

All available choices are scrolled.

(Choices indicate actual damp rate in seconds.)

The value is accepted, and the register is closed.

Display shows “P2”.

Normal Pressure Display.

11

Page 14

9R143 Dated 3/2011

P3 – RESIDUAL HYDROSTATIC PRESSURE

The M2110L Smart Level Gauge will correctly measure level when used with a dip tube or as a direct-head pressure

reading of the tank’s fluid column. Register P3 is used to describe the unmeasurable pressure below the dip tube, or

the additional pressure created by a “dead leg” in the direct-head piping. This register must be specified in Inches of

Water Column at 20

o

C reference.

All Models

QUICK REFERENCE: P3, RESIDUAL HYDROSTATIC PRESSURE

Px

Name Description Value Range Notes

P3 Residual

Hydrostatic

Pressure

Dip Tube Application

The P3 register specifies the pressure created by the

height of the fluid below the dip tube to the bottom of the

tank. The volume in the tank below this point cannot

be measured! To compensate for this unmeasured

volume (optional), enter this register as a positive value.

Direct Head Measurement

Identifies the Pressure lost or

added due to piping

configurations.

The P3 register specifies the pressure caused by the

vertical “dead leg” of the piping to the gauge. This is

additional pressure applied to the gauge that is not

due to fluid volume in the tank. To compensate for

this pressure, enter this register as a negative value.

-9999 to +9999

inH2O @ 20ºC.

+Val:Dip Tube

-Val: Dir.Head

Note: The Low Pressure side is connected to the tank top on pressurized tanks only, as shown, using a differential

pressure, non-isolated model (DN) Smart Level Gauge. It is recommended that a gauge-pressure, isolated sensor

model (GI) Smart Level Gauge be used whenever possible for measuring fluid level (vented tank).

The differential pressure, non-isolated sensor (required for pressurized tanks) is compatible with clean, dry, noncorrosive gases only. This will work without modification in most bubbler system applications. However, when

corrosive liquids or vapors are in the tank, a diaphragm seal will be needed on the high and low pressure lines (or

on the high pressure line in a direct head pressure system). Consult the factory for information on diaphragm seal

selection, limitations, and the effects on overall gauge performance.

STEP BY STEP: P3, RESIDUAL HYDROSTATIC PRESSURE

Step Action Display

1

2

Gauge should be in the normal Measure Mode. Normal Pressure Display.

Press the PRGM/Enter→ key.

If the lockout is active, the gauge will now prompt for entry of

the lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

The PRGM annunciator shows at the top of the

display, and the display shows the register name

“P0”.

12

Page 15

9R143 Dated 3/2011

3

4

5

6

7

8

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register.

The Zero function (Up↑ and Down↓) will reset the scroll to P0

and allow selection to continue.

Press PRGM/Enter→ to open the register.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired numeric value for the flashing digit.

The Zero function (Up↑ and Down↓) will reset the entire

register to 0000 and allow editing to continue. The decimal

point and negative sign will not be affected, and the same digit

will be flashing.

Press the PRGM/Enter→ key to accept the digit.

Repeat steps 5 and 6 for the all remaining digits.

The Backspace← key will backup one digit at a time, or abort

and close the register if the first digit is flashing.

The PRGM/Enter→ key will accept one digit at a time, moving

to the next, or accept the complete value and close the register

after the decimal point edit.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired decimal point position, and to select

positive/negative.

If the Zero function (Up↑ and Down↓) is used during decimal

point editing, it will still reset the register’s value to 0000, and

not affect the decimal point position or negative sign.

Display shows “P3”.

The display will show the current value, with the

first zero flashing for edit.

“_xxx”, where “_” is the digit being edited.

The next digit begins flashing for edit.

After Enter→ when the last digit is flashing, the

decimal point flashes for edit.

Please read carefully note 4 below.

Decimal point moves accordingly.

Please read carefully note 4 below.

Negative Sign activates and de-activates when the

decimal point sequence is scrolled through

completely.

9

10

Notes

Press the PRGM/Enter→ key to accept the

complete value.

Press the Backspace← key to activate the register

The value is accepted, and the register is closed.

Display shows “P6” or “P7”.

Normal Pressure Display.

setting and return to Measure Mode.

1. Preceding/Trailing zeroes are determined by where the user places the decimal point. When opening

a register, the value is always shown padded with trailing zeroes.

2. Only 4 digits are available for editing (the ½ digit is not provided), plus the decimal point and

negative sign (negative is not applicable to register P4). This limits keypad value entries to ±9,999,

and also limits the available decimal point resolution (depending on the magnitude of the value). The

serial interface provides much more flexibility.

3. After steps 2 and 3, the Backspace← key will abort the process and return to Measure Mode.

4. The display does not have a physical decimal point that can be illuminated in the least significant

position (to the right of all digits on the display). Thus, if the decimal point is in that particular

position, there will be no decimal point blinking (which may be confusing). When scro lling through

the decimal point selection, it is important to take note that none blinking is a viable setting, and will

be seen in the scrolling sequence.

5. After step 9, the PRGM/Enter→ key will again open the register for edit.

6. During any programming operation, if there is no keypad activity for approximately 1 minute, the

operation is aborted and the gauge returns to Measure Mode unchanged.

13

Page 16

9R143 Dated 3/2011

P4 – FULL TANK HYDROSTATIC PRESSURE

This register is used by the gauge to draw a relationship between measured static pressure and actual level in volume

or mass units. This register must be set to the pressure created by a FULL COLUMN of vertical fluid in the tank, in

inches of water column at 20ºC reference temperature.

1

To calculate this value, multiply the specific gravity

the floor

convert the resultant pressure value to inches of water column at 20ºC reference (for example, to convert PSI to

InH

Note that the P4 value is not affected by installation type (bubbler system or direct head measurement). The value is

calculated in the same way for either system. The residual pressure (page 12) is not added to or subtracted from

this value.

2

of the tank to the top of the maximum level to be measured. Then, using the appropriate scale factor,

O @20ºC, multiply by 27.72978).

2

of the fluid (relative to water at 60°F) by the full distance from

All Models

QUICK REFERENCE: P4, FULL TANK HYDROSTATIC PRESSURE

Px

Name Description Value Range Notes

Full Tank

P4

Hydrostatic

Pressure

The pressure created by a full

column of fluid from the floor of

the tank to the top of the

0 to 9,999 (Keypad)

0 to 19,999 (Serial)

Pressure in

inH2O

@20°C.

maximum level to be measured.

STEP BY STEP: P4, FULL TANK HYDROSTATIC PRESSURE

The process of programming this register is exactly the same as other real-value programmable registers. Please

refer to that procedure on page 12.

1

When the specific volume is known, perform the calculation in a similar manner, but use the inverse of the specific

volume instead of the specific gravity.

2

For non-linear tanks, use the lowest point of the tank when figuring the full distance.

14

Page 17

9R143 Dated 3/2011

P5 – SETPOINT OPTIONS

This register defines the output action for SetPoint and Current Loop models. Note that if an output is disabled by

this register, the SetPoint value in its corresponding register (P6, P7) has no impact. Also note that a SetPoint value

(P6, P7) may be 0.0, which is a viable output setting; thus, in order to disable control action, register P5 should be

used to define the desired action.

In Measure Mode, the indicators “SET1” and/or “SET2” will illuminate when the corresponding relay is energized.

The “4-20mA” indicator will illuminate when the Current Loop output is enabled. In Program Mode, the

indicators “SET1”, “SET2”, and “4-20mA” will illuminate as appropriate to assist when scrolling through the

register’s choices. Note that if P5 is set for active, the outputs will continue to update even in Program Mode,

according to the currently programmed values.

SetPoint & Current Loop Models Only

QUICK REFERENCE: P5, SETPOINT OPTIONS

Px

Name Description Value Range Notes

P5 SetPoint

Options

SetPoint model:

Defines which relay outputs are active.

Current Loop model:

Defines status of the 4-20 mA output.

0 = Disabled.

1 = SET1 only.

2 = SET2 only.

3 = Both enabled.

0 = 4-20 disabled

1 = 4-20 enabled

Not found on

Battery model.

STEP BY STEP: P5, SETPOINT OPTIONS

Step Action Display

1

2

3

4

5

6

7

Gauge should be in the normal Measure Mode. Normal Pressure Display.

Press the PRGM/Enter→ key.

If the lockout is active, the gauge will now prompt for entry of

the lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register.

The Zero function (Up↑ and Down↓) will reset the scroll to P0

and allow selection to continue.

Press PRGM/Enter→ to open the register.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register value.

The Zero function (Up↑ and Down↓) will reset the scroll to

default and allow editing to continue.

Press the PRGM/Enter→ key to accept the value.

Press the Backspace← key to activate the register

setting and return to Measure Mode.

The PRGM annunciator shows at the top of the

display, and the display shows the register name

“P0”.

Display shows “P5”.

The display shows the current value.

All available choices are scrolled.

The value is accepted, and the register is closed.

Display shows “P5”.

Normal Pressure Display.

Notes

1. After steps 2 and 3, the Backspace← key will abort the process and return to Measure Mode.

2. After steps 4 and 5, the Backspace← key will abort the edit and close the register.

3. After step 6, the PRGM/Enter→ key will again open the register for edit.

4. During any programming operation, if there is no keypad activity for approximately 1 minute, the

operation is aborted and the gauge returns to Measure Mode unchanged.

15

Page 18

9R143 Dated 3/2011

P6 and P7 – SETPOINT (SET1 and SET2)

SetPoint & Current Loop Models Only

SetPoint Model

These registers define the pressure points at which the SPDT relays will energize. The relay will energize

when the pressure exceeds its corresponding value, and de -energize when the pressure drops below the

value (minus deadband; see page 17). P6 defines the SET1 relay, and P7 defines the SET2 relay. P6 and

P7 settings are completely independent of each other; either may be greater, less than, or equal to the other.

Current Loop Model

These registers define the 4 to 20 mA output value. P6 (SET1) sets the 4.00 mA output and P7 (SET2) sets

the 20.00 mA output. (Thus, the output “zero” is defined by SET1, and the “span” is defined by SET2 –

SET1.) When the pressure is at the P6 value, the output will be 4.00 mA; when the pressure is at the P7

value, the output will be 20.00 mA. Other pressures provide an output that is linearly scaled between the

two values. For values beyond the defined range, however, the output is limited from 4.00 to 20.38 mA.

The P6 (4 mA) register can be set greater than the P7 (20 mA) re gister, t o create a reverse acting output.

The limits are –20% to +120% full scale, but P6 and P7 cannot be set at equal values.

Data Entry

Refer to the Step by Step table below for detailed instructions.

These registers are entered in the current Engineering Unit used by the gauge. (The current Engineering

Unit is illuminated during edit of these registers.) For example, if the gauge is set to read in gallons, and a

value of 110 is put into the P6 register, the SET1 relay will energize at 110 gallons.

In Program Mode, the indicators “SET1”, “SET2”, and “4-20mA” will illuminate as appropriate to assist

in identifying the register. For example, when scrolling to and/or editing P6, “SET1” will be illuminated,

indicating that SET1 is being edited. Likewise for P7 and “SET2”. Also, “4-20mA” will be illuminated if

the gauge is a Current Loop model, to indicate that the 4-20mA range is being edited.

Automatic Update

If the Engineering Unit is changed in measure mode (see page 7), the value in the P6 and P7 registers will

automatically change to reflect the new Engineering Unit. This allows changing the Engineering Unit in

Measure Mode without affecting the outputs. For the above example, changing the Engineering Unit to

liters will automatically update the P6 register to energize at 416.4 liters, which is equivalent to 110

gallons.

QUICK REFERENCE: P6/P7, SETPOINTS

Px

Name Description Value Range Notes

P6 SET1

P7 SET2

SetPoint model:

Controls SET1 relay.

Current Loop model:

Sets 4.00 mA value.

SetPoint model:

Controls SET2 relay.

–20% to +120%

of Full Scale

–20% to +120%

of Full Scale

User defined

values.

On Current

Loop models,

SET1 cannot

equal SET2.

Current Loop model:

Sets 20.00 mA value.

STEP BY STEP: P6/P7, SETPOINTS

The process of programming this register is exactly the same as other real-value programmable registers. Please

refer to that procedure on page 12.

16

Page 19

9R143 Dated 3/2011

P8 – DEADBAND

This register is found on the SetPoint model only. It sets the adjustable deadband for the SPDT relays. Deadband

can be set to 0%, 0.1, 0.2, 0.5, 1, 2, 5 and 10% of full scale. The relay will energize precisely at the value in its

corresponding P6 and P7 registers on increasing level. The relay will de-energize at a value equal to the

corresponding P6 and P7 register, minus the deadband value, on decreasing level. With a 0% deadband setting, the

relays will energize and reset precisely at the values in the corresponding P6 and P7 registers. During programming,

the choices found in the register correspond to the actual deadband values in percent full scale.

SetPoint Models Only

QUICK REFERENCE: P8, DEADBAND

Px

Name Description Value Range Notes

P8 Deadband Sets the amount of deadband in

percent of full scale for relays.

0, 0.1, 0.2, 0.5, 1,

2, 5, 10% FS

SetPoint model only.

0 = Disabled.

STEP BY STEP: P8, DEADBAND

Step Action Display

1

2

Gauge should be in the normal Measure Mode. Normal Pressure Display.

Press the PRGM/Enter→ key.

If the lockout is active, the gauge will now prompt for entry of

the lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

The PRGM annunciator shows at the top of the

display, and the display shows the register name

“P0”.

3

4

5

6

7

Notes

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register.

The Zero function (Up↑ and Down↓) will reset the scroll to P0

and allow selection to continue.

Press PRGM/Enter→ to open the register.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register value.

The Zero function (Up↑ and Down↓) will reset the scroll to

default and allow editing to continue.

Press the PRGM/Enter→ key to accept the desired

value.

Press the Backspace← key to activate the register

setting and return to Measure Mode.

1. After steps 2 and 3, the Backspace← key will abort the process and return to Measure Mode.

2. After steps 4 and 5, the Backspace← key will abort the edit and close the register.

3. After step 6, the PRGM/Enter→ key will again open the register for edit.

4. During any programming operation, if there is no keypad activity for approximately 1 minute, the

operation is aborted and the gauge returns to Measure Mode unchanged.

Display shows “P8”, and the “%” annunciator is

illuminated.

The display shows the current value.

All available choices are scrolled.

(Choices indicate actual Deadband in percent of

full scale.)

The value is accepted, and the register is closed.

Display shows “P8”.

Normal Pressure Display.

17

Page 20

9R143 Dated 3/2011

P9 – TANK CYLINDRICAL CAPACITY

The Smart Level Gauge calculates level based on measured hydrostatic pressure, by drawing a relationship between

the full tank hydrostatic pressure (register P4, page 14), and the total capacity of the tank (volume or mass). The

residual pressure (register P3, page 12) and tank type (register P11, page 20) are also considered in the calculations.

The P9 and P10 registers together specify the tank capacity referred to above. The P9 value may be entered in any

desired Engineering Unit, except InH2O (refer to page 7 for available units); User Units and Percent are also

acceptable. The value programmed in P9 depends on the type of tank, as described below:

LINEAR TANK Cylindrical/Flat Ends Cylindrical/Dished Ends Spherical

P9=Volume/mass of the

full tank. (The full volume

is comprised of the entire

cylindrical section.)

P9=Volume/mass of the

full tank. (The full volume

is comprised of the entire

cylindrical section.)

P9=Volume/mass of the

cylindrical portion only.

(Tank capacity minus

dished ends capacity.)

P9=0. (The full volume is

comprised essentially of 2

dished ends, entered in the

P10 register.)

All Models

QUICK REFERENCE: P9, TANK CYLINDRICAL CAPACITY

Px

Name Description Value Range Notes

P9 Tank Cylindrical

Capacity

The capacity, in Engineering

Units, in the cylindrical portion

of the tank only.

0 to 9,999

(Keypad)

0 to 19,999

P9 = 0 for

spherical

tanks.

(Serial)

Automatic Update

If the Engineering Unit is changed in Measure Mode (see page 7), the value in the P9 and P10 registers will

automatically change to reflect the new Engineering Unit. This allows changing the Engineering Unit in Measure

Mode and maintaining a correct level display.

STEP BY STEP: P9, TANK CYLINDRICAL CAPACITY

The process of programming this register is exactly the same as other real-value programmable registers. Please

refer to that procedure on page 12. However, the following notes are specific to the P9 and P10 register:

Notes

1. After completing the P9 or P10 value programming (step 9 on page 13), the gauge will then prompt

for Engineering Unit selection by flashing the current unit. To complete P9 or P10 programming,

proceed with Engineering Unit selection (described on page 7). This selection defines the units that

were programmed into P9 and P10. If the units are not to be changed, you may simply re-enter or

abort the Engineering Unit selection process (page 7).

2. Register P9 and P10 values always represent the same Engineering Unit. Therefore, if the unit is

changed during programming of one register, it may be necessary to re-program the other.

3. If the current Engineering Unit is InH

enter a view-only mode (see page 21). The registers cannot be changed in this mode. You must first

select a different Engineering Unit in order to program P9 or P10 (see page 7). This is required to

maintain level scaling relationships between hydrostatic pressure and the user’s fluid characteristics.

O when P9 or P10 is opened for programming, the gauge will

2

18

Page 21

9R143 Dated 3/2011

P10 – TANK ENDS CAPACITY

The Smart Level Gauge calculates level based on measured hydrostatic pressure, by drawing a relationship between

the full tank hydrostatic pressure (register P4, page 14), and the total capacity of the tank (volume or mass). The

residual pressure (register P3, page 12) and tank type (register P11, page 20) are also considered in the calculations.

The P9 and P10 registers together specify the tank capacity referred to above. The P10 value may be entered in any

desired Engineering Unit, except InH2O (refer to page 7 for available units); User Units and Percent are also

acceptable. The value programmed in P10 depends on the type of tank, as described below:

LINEAR TANK Cylindrical/Flat Ends Cylindrical/Dished Ends Spherical

P10=0. (The full volume

is comprised of the entire

cylindrical section.)

P10=0. (The full volume

is comprised of the entire

cylindrical section.)

P10=Volume/mass of the

dished ends only (total of

both)

. (Total tank volume

minus cylindrical section.)

P10=Volume/mass of the

full tank. (The full volume

is comprised essentially of

2 dished ends.)

All Models

QUICK REFERENCE: P10, TANK ENDS CAPACITY

Px

P10 Tank Ends

Name Description Value Range Notes

P10 = 0 for

linear tanks, or

cylindrical tanks

Capacity

The total capacity of the dished

ends of a horizontal cylindrical

tank (includes both ends).

0 to 9,999 (Keypad)

0 to 19,999 (Serial)

with flat ends.

Automatic Update

If the Engineering Unit is changed in Measure Mode (see page 7), the value in the P9 and P10 registers will

automatically change to reflect the new Engineering Unit. This allows changing the Engineering Unit in Measure

Mode and maintaining a correct level display.

STEP BY STEP: P10, TANK ENDS CAPACITY

The process of programming this register is exactly the same as other real-value programmable registers. Please

refer to that procedure on page 12. However, the following notes are specific to the P9 and P10 register:

Notes

1. After completing the P9 or P10 value programming (step 9 on page 13), the gauge will then prompt

for Engineering Unit selection by flashing the current unit. To complete P9 or P10 programming,

proceed with Engineering Unit selection (described on page 7). This selection defines the units that

were programmed into P9 and P10. If the units are not to be changed, you may simply re-enter or

abort the Engineering Unit selection process (page 7).

2. Register P9 and P10 values always represent the same Engineering Unit. Therefore, if the unit is

changed during programming of one register, it may be necessary to re-program the other.

3. If the current Engineering Unit is InH

enter a view-only mode (see page 21). The registers cannot be changed in this mode. You must first

select a different Engineering Unit in order to program P9 or P10 (see page 7). This is required to

maintain level scaling relationships between hydrostatic pressure and the user’s fluid characteristics.

O when P9 or P10 is opened for programming, the gauge will

2

19

Page 22

9R143 Dated 3/2011

P11 – TANK TYPE

This register identifies the type of tank application, with respect to the vertical fluid pressure measurement.

Linear: The hydrostatic head change is proportional to the level change. For example, a cylindrical tank

standing vertically (first tank pictured on page 19) is linear because the change in pressure produced

by the fluid in the tank is proportional to the change in level (or mass).

Non-Linear: The hydrostatic head change is not

cylinder and spherical tanks (other tanks pictured on page 19) are non-linear, because the change in

pressure produced by the fluid in the tank is not

Non-Linear Tanks, the Smart Level Gauge discerns between a cylindrical tank with flat ends, a

cylindrical tank with dished ends, and a spherical tank by the settings in the P9 and P10 registers.

Refer to the examples on pages 18 and 19.

proportional to the level change. For example, horizontal

proportional to the change in level (or mass). For

All Models

QUICK REFERENCE: P11, TANK TYPE

Px

P11 Tank Type Identifies type of tank. 0 = Linear/Vertical

Name Description Value Range Notes

If P11=0, verify

1 = Non Linear

that P10=0.

STEP BY STEP: P11, TANK TYPE

Step Action Display

1

2

3

4

5

6

7

Notes

Gauge should be in the normal Measure Mode. Normal Pressure Display.

Press the PRGM/Enter→ key.

If the lockout is active, the gauge will now prompt for entry of

the lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register.

The Zero function (Up↑ and Down↓) will reset the scroll to P0

and allow selection to continue.

Press PRGM/Enter→ to open the register.

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired register value.

The Zero function (Up↑ and Down↓) will reset the scroll to

default and allow editing to continue.

Press the PRGM/Enter→ key to accept the desired

value.

Press the Backspace← key to activate the register

setting and return to Measure Mode.

1. After steps 2 and 3, the Backspace← key will abort the process and return to Measure Mode.

2. After steps 4 and 5, the Backspace← key will abort the edit and close the register.

3. After step 6, the PRGM/Enter→ key will again open the register for edit.

4. During any programming operation, if there is no keypad activity for approximately 1 minute, the

operation is aborted and the gauge returns to Measure Mode unchanged.

The PRGM annunciator shows at the top of the

display, and the display shows the register name

“P0”.

Display shows “P11”.

The display shows the current value.

All available choices are scrolled.

The value is accepted, and the register is closed.

Display shows “P11”.

Normal Pressure Display.

20

Page 23

9R143 Dated 3/2011

LOCKOUT CODE PROMPT

All Models

DESCRIPTION

When a gauge is “locked” for security purposes, it does not allow access to change its operating state

without first providing the lockout code. A gauge is “locked” by entering a lockout code in register P0

(See “STEP BY STEP: P0, LOCKOUT CODE” on page 9).

After pressing a key on a locked gauge for a desired function (ZERO, ENG UNITS, PRGM), “L 00” will

appear on the display, with the first 0 flashing. This is the prompt to enter the lockout code (similar to a

password).

VIEW-ONLY STATUS

If a user attempts to enter Program Mode without providing a correct lockout code (password), the gauge

briefly provides an error message, and then enters a “view-only” status, denoted by the PRGM indicator

flashing. In this mode, all registers (except the lockout code register itself) can be viewed, but not changed.

In this view-only status, the operator navigates through the registers exactly the same as if programming the

registers. However, the keys that would change a value are simply ignored by the gauge. Thus, the

PRGM/Enter→ key will open a register normally; the Backspace← key will close the register, and then

return to Measure Mode as expected.

STEP BY STEP: ENTERING A LOCKOUT CODE (When Prompted)

Step Action Display

1

2

3

4

After attempting to re-zero, change Engineering

Units, or enter Program Mode...

Press the Up↑ or Down↓ keys repeatedly to scroll

to the desired numeric value for the flashing digit.

Press PRGM/Enter→ key to accept the digit.

Repeat steps 2 and 3 for the second digit. The complete 2-digit value will be accepted.

The display will prompt “L 00” with the first zero

flashing for edit (indicating Lockout Code 00).

“L xy”, where “x” is the digit being edited.

The next digit begins flashing for edit.

If the correct code was entered, the gauge will perform the requested function. Otherwise, an

error message is displayed, and the gauge either returns to Measure Mode, or enters a “viewonly” status for the programmable registers (if Program Mode was requested).

Notes

1. After step 1 or 2, the Backspace← key will abort the process and return to Measure Mode.

2. After step 3, pressing the Backspace← key will abort the current digit and backup to the first digit.

Another Backspace← will abort the process and return to Measure Mode.

3. Between steps 1 and 4, the Zero function (Up↑ + Down↓) will clear the entire entry to “00” again.

4. Between steps 1 and 4, if there is no keypad activity for approximately 1 minute, the operation is

aborted and the gauge returns to Measure Mode unchanged.

21

Page 24

9R143 Dated 3/2011

SERIAL PORT SERVICE

SetPoint & Current Loop Models Only

The M2110L Smart Level Gauge SetPoint models and Current Loop models provide RS-232C communication

capability. To use the serial service, connect a standard “dumb terminal” (or personal computer with terminal

software) as shown in the wiring diagram on page 25. Set the terminal communication for 9600 baud, 8 data bits, no

parity, one stop bit, and no handshaking. The terminal should be able to display at least 24 lines and 70 columns.

THE MENU

All programmable items of the gauge are available from the menu. Included with the menu is a complete

summary of all data representing the current progra mming and operating status.

A sample view of the menu is shown below for reference. The top line identifies the gauge, firmware

revision, and copyright. The second line identifies the model (SetPoint, Current Loop), the full scale sensor

range, and the sensor identifier. Next is a reminder notice to the operator (explained below).

The Engineering Unit section is next. The first line shows the full scale for the current Engineering Unit,

which also identifies the current Engineering Unit. All available Engineering Units are shown with a

menu-selection number; the Engineering Unit is changed by simply selecting its corresponding menunumber at the terminal keyboard.

Finally, all programmable registers and functions are formatted on the menu. The menu item includes its

menu-selection character, and the current register data as applicable. To change an item, simply select its

character from the terminal keypad; the appropriate sub-menu, notes, and instructions are presented for

operator entry. Note that the serial menu typically provides more flexibility for entering data values,

compared with the gauge’s keypad (for example, more decimal digits of resolution are available).

SmartGauge/M2110L (vX.XX). (c)Copyright 2010 Meriam

SetPoint model. Sensor = 28.00 InH2O

-------------------------------------------------------------------Notice! Changing any value will PAUSE Gauge Operation; see manual!

-------------------------------------------------------------------Current Full Scale: 1000.0 GALs

1) GALs 4) Liter 7) KGs 0) User Units

2) LBs 5) n/a 8) M^3

3) FT^3 6) % 9) inH2O

-------------------------------------------------------------------A) P0, LockOut Code = Disabled

B) P2, Damp Rate = 0.2 Seconds

C) P3, Residual Press = 10.0000 InH2O

D) P4, FullTank Press = 180.0000 InH2O

E) P5, SetPoint Ctrl = Disabled

F) P6, SET1 = 0.0000 GALs

G) P7, SET2 = 0.0000 GALs

H) P8, Dead Band = 0.0 % Full Scale

J) P9, Cyl. Capacity = 1000.0000 GALs

K) P10,Dished End Cap = 0.0000 GALs

L) P11,Tank Type = Linear/Vertical

M) ReZero Gauge R) Restore Factory Zero

X) EXIT Interactive Menu

Select Choice:

ACCESSING THE MENU

When the gauge is powered up or reset, it will print the menu to the serial port. Also, hitting the ENTER

key from the terminal will refresh/reprint the menu. If the terminal is not connected when the gauge first

prints the menu, it will be missed; thus, if the terminal is connected after the gauge is already running, it

will show nothing. Pressing the ENTER key will establish communications and re-print the menu.

22

Page 25

9R143 Dated 3/2011

IMPACT ON OPERATION

Use of the serial port service is independent of the operating mode of the gauge, and vice versa. It is not

necessary to change to Program Mode to use any of the menu’s features, including changing Engineering

Units, editing programmable registers, and re-zeroing. The gauge continues its active operation regardless

of the serial port service, except for the pausing explained in the next paragraph. Any keypad activity from

the front panel of the gauge will also be processed regardless of the serial port status. If entries are made

through the keypad and the serial port simultaneously, the last entry received will be active.

While the serial port is transferring data, the other functions of the gauge are paus ed to allow this task to

complete. In this paused state, the display is frozen and the outputs are not updating. Typically, the data

transfers are very short (for example, printing the menu), and thus the interruption is minimal. However,

selecting a programmable register for edit will completely stop normal gauge operation, because the gauge

is awaiting the operator’s input (data value or selection from a sub-menu). During this state, the display is

blanked to prevent mis-readings. As soon as the operator selection or entry is complete, the gauge resumes

normal operation.

The Notice of “PAUSE Gauge Operation” near the top of the menu is a reminder about this explanation. It

is particularly important when a gauge is in service as an in-process instrument, since the gauge will not

respond to process conditions while it is paused.

TIMEOUT

When the menu is displayed, it has no impact on gauge operation or performance. Therefore, the menu will

remain displayed indefinitely, or until the operator takes action or the gauge is reset. When the gauge is

stopped awaiting operator input, however, the gauge’s display is blanked and the outputs are frozen (for

example, awaiting input while editing a register). In this state, if there is no terminal keyboard activity for

approximately one minute, the operation will time-out, and the gauge is returned to its operating mode.

DATA MONITORING

Selecting “X” from the menu will EXIT the menu and begin data monitoring. (If the gauge was in

Program Mode, it will be returned to Measure Mode to allow data monitoring. The “X” menu item will

include this message as appropriate, when refreshed.)

During data monitoring, every analog-to-digital conversion from the pressure sensor is displayed on the

terminal. The additional load of the continuous serial communication will slightly reduce the overall

performance of the gauge. The resulting data rate will typically be about ten (10) conversions per second,

depending on various operating conditions. Note that the data sent to the terminal will be damped

according to the damp rate set in register P2 (see page 11).

The data includes the pressure value and Engineering Units, as well as the output status as appropriate

(SET1 ON, SET2 ON, or the 4-20 mA value). Note that this status indication is the internal calculated

value, as there is no feedback hardware on the gauge. Finally, “Over Pressure!” is indicated if the input

pressure exceeds 120% of the full scale sensor range (this indication acts immediately, regardless of the

damp rate setting).

If the gauge is taken out of Measure Mode, the data monitoring function will pause with a message. (The

menu is available at this time, as it is at any time, by hitting ENTER from the terminal.) When the gauge is

returned to Measure Mode, if the menu was not activated, data monitoring will automatically resume.

Data logging can be accomplished be invoking the appropriate logging function of the terminal software.

To EXIT the data monito ring function, simply hit ENTER on the terminal to restore the menu.

LOCKOUT

If the lockout feature is active (see register P0, page 9), the serial menu will prompt for the lockout code

when necessary. For security purposes, an asterisk (*) is displayed instead of the character as it is typed.

When entering a new lockout code through the serial port, however, the code is displayed as it is typed,

since there is no confirmation step.

23

Page 26

9R143 Dated 3/2011

ERROR CODES

All Smart Gauge models have an error/message feature to inform the operator of problems with the operation or

programming of the gauge. These Error Codes and messages are identified and described in the table below.

ERROR DESCRIPTION

“OP”

E001

E002

E003

E004

E006

E007

E008

Overpressure warning. The measured pressure exceeds the full scale pressure by

20% of full scale or more (high or low) . Sensor is at risk of permanent damage!

Automatic Shutoff timer has expired (Battery model only); gauge is shutting down

normally.

Requested ZERO value is not within 5% of full scale pressure, and therefore ignored.

Requested SET1 or SET2 is out of range. Must be greater than 0, and less than

+120% Full Scale.

Requested new SET1 or SET2 value is equal to the other programmed value on

Current Loop models. This configuration is not acceptable. If attempting to disable

the output, simply set programmable register P5 to 0 (see page 15).

User Entered incorrect Lockout Code. Gauge is locked. A view-only status will be

entered if Program Mode was requested (see page 21).

Requested Full Tank Hydrostatic Pressure Value (P4) is invalid. Value must be > 0.

Requested Cylindrical or End Volume (P9/P10) invalid. Value must be > 0 or = 0.

E010

Full Scale Range for Engineering Units selected is beyond scale of display (>19,999).

This message would be seen, for example, during reset/power up of a gauge

programmed for 10,000 gallons, with liters last selected, since the corresponding full

scale display of 37,853 liters will not fit on the 4½ digit display.

E020

Low Battery (or power supply) Warning. This error will show repeatedly

approximately every 10 seconds, so long as the voltage supply remains low.

E030*

EEProm Error. Display alternates between “E030” and a sub-error code.

* Error codes of 030 and above indicate hardware or other internal problems; if the problem

cannot be corrected by cycling the input power supply on and off, please take note of the error

code and operating conditions, and contact Meriam Instrument at (216) 281-1100.

24

Page 27

9R143 Dated 3/2011

INSTALLATION AND WIRING

The SetPoint model

utilizes the multifunction terminal strip

shown at the left. This

terminal strip has a

NEMA 1 rating.

SPDT relays are not

powered by the gauge

internally. Jumpers

from the 24Vdc,

GND

Note: The Smart Gauge comes with 1/8” FNPT pressure port(s). Gauge and Absolute models

only use one pressure port. The unused port vents the enclosure/sensor to atmosphere. DO NOT

REMOVE THE SINTERED PLUG (ALLEN HEAD FITTING). The Smart Gauge should be

panel-mounted or held firmly in one hand while a small wrench is used to tighten the 1/8”

MNPT pipe thread. Do not tighten the fitting without using a wrench on the manifold.

115Vac or 230Vac

power sources can be

used if required.

The Current Loop

model uses a cannon

connector that is

designed to meet

NEMA 4X

requirements. The

charts at the left show

the terminal and wiring

arrangement. Wiring

schematics for the

three and four wire, 4

to 20 mA loops are

shown on page 26.

25

Page 28

CURRENT LOOP MODEL LOOP WIRING

24VDC

+LOOP

SMART

GAUGE

- LOOP

GROUND

R

24 VDC/ 50 mA

Power Supply

+

-

Gauge & Loop Power

3 WIRE SINKING

24VDC

+ LOOP

SMART

GAUGE

- LOOP

GROUND

R

LOOP

+ Power Supply

24 VDC

20mA

-

4 WIRE FLOATING

Note: R = Receiving Device

24VDC

+LOOP

SMART

GAUGE

-LOOP

GROUND

9R143 Dated 3/2011

24 VDC/ 50 mA

Power Supply

+

R

-

Gauge & Loop Power

4 WIRE SOURCING

+

Power Supply

24 VDC/ 30 mA

-

26

Page 29

OUTLINE DIMENSIONS

( )

PANEL MOUNTING

PANEL MOUNTING CUTOUT DIMENSIONS

9R143 Dated 3/2011

3.60" +/- 0.010

(92)

DIMENSIONS IN MILLIMETERS

3.60" +/- 0.010

(92)

1. Make a ¼ DIN panel cutout per drawing.

2. Remove the two 6-32 socket head screws in the

grooves at the rear of the gauge.

3. Slide the panel mount jacks out of the groove.

4. Insert the gauge through the front of the panel.

5. From the rear, insert the panel mount jacks in the

grooves on the side of the gauge, and slide them

firmly against the panel.

6. Replace the two 6-32 socket head screws in the

grooves behind the panel mount jacks.

7. Tighten the panel mount jack against the panel

with the two socket head screws.

8. Refer to the note on page 25 when making

pressure connections.

27

Page 30

PRODUCT SPECIFICATIONS

9R143 Dated 3/2011

TYPE & RANGE:

DN: Differential Non-isolated

DI Differential Isolated

GI: Gauge Isolated

CI Compound Isolated

AI Absolute Isolated

MEDIA COMPATIBILITY:

for clean, dry, non-corrosive gases. Isolated sensor for

fluids compatible with 316SS.

ACCURACY*:

reading in InH

linearity, repeatability, hysteresis and temperature).

AC-powered gauges require 15 minute warm-up.

NIST certification supplied.

ZERO DRIFT:

prior to measurement eliminates this effect.

TEMPERATURE:

Storage: -40 °F to 140 °F (-40 °C to 60 °C)

Operating: -4 °F to 122 °F ( -20 °C to 50 °C)

PRESSURE LIMITS:

sensors. 2x range for DN sensors when pressurized on

high side only; 150 PSI static when applied to both

sides of the sensor simultaneously. 3x range for DI

sensors when pressurized on high side only, 1000 PSI

static when applied to both sides of the sensor

simultaneously. 3x range or 150 PSI on low side

whichever is less.

± 0.05% of Full Scale for Pressure

O@20°C (includes combined effects of

2

± 0.015% of Full Scale. Zeroing

Non-isolated sensor

2x range for AI, GI, and CI

Sensor Ranges

DISPLAY: 4 1/2 digit, 0.6 inch (15.24 mm) LCD.

PRESSURE CONNECTIONS:

Brass on non-isolated, 316SS on isolated sensors.

INPUT POWER:

selectable 110V AC 50/60 Hz, 220V AC 50/60 Hz, or

24V DC power. Included are an RS 232C interface

and two programmable SPDT relays, rated 1.0 amp

resistive @ 24V DC, 0.5 amp resistive @ 115V AC.

Battery models are powered by two Lithium “D”

Cells. Battery Life is approximately 100 days at a

100% duty cycle.

I/O:

Included are an RS 232C interface and two