Page 1

M2 Series

IP40

Instruction Manual 9R68-A

M202 PRECISION ABSOLUTE MANOMETER

M2 – SERIES USER MANUAL

M202

Precision Absolute Manometer

Meriam Process Technologies’ M202 Precision Absolute

Manometer is a microprocessor based pressure sensing device

used to directly measure pressure relative to absolute zero.

Models are available to measure pressure ranges up to 900mm

Hg Abs and 2000mm Hg Abs. Pressure can be displayed in a

variety of engineering units. All units include a Tare function,

a Min/Max function, selectable damp rates and altitude

displayed in feet or meters. The M202 can also display

barometric pressure corrected to sea level.

ATEX rating:

0539

Ex ia IIC T4

(Tamb. -5ºC to +50ºC)

DEMKO 06 ATEX 0615699

II 1 G

Mar, 2008

Precision Absolute Manometer

M202

www.meriam.com

page 1 of 36

Page 2

M2 Series

Instruction Manual 9R68-A

Table of Contents

User Interface ................................................................................ 3

1. Keypad Functions ............................................................... 3

ON/OFF & BACK KEY...................................................... 3

MIN/MAX & UP KEY ....................................................... 3

TARE & DOWN KEY........................................................ 3

PRGM & ENTER KEY....................................................... 4

BACKLIGHT KEY ................................................................. 4

2. Zeroing the Manometer....................................................... 5

3. Program Mode .................................................................. 10

Units Select ............................................................................ 11

Displaying Altitude (US Standard Atmosphere 1962)............ 12

Display User Defined Altitude ............................................... 12

Pressure Corrected to Sea Level............................................. 15

Damp Rate Select................................................................... 17

User Info Select...................................................................... 18

Auto Shut-Off ........................................................................ 19

Lockout Select........................................................................ 20

Header Name.......................................................................... 21

Contrast Select ....................................................................... 22

Data Logging.......................................................................... 23

Leak Test................................................................................ 24

Re-Calibration ............................................................................. 25

RE-CALIBRATION – 1 Point EDIT and START................. 27

RE-CALIBRATION – 5 Point EDIT ..................................... 28

RE-CALIBRATION – 5 Point START.................................. 29

RE-CALIBRATION – Restore Factory Defaults................... 30

Specifications .............................................................................. 31

Certification/Safety/Warnings ..................................................... 33

Changing the Batteries................................................................. 34

Contact Information..................................................................... 36

Mar, 2008

www.meriam.com

page 2 of 36

Page 3

M2 Series

User Interface

Instruction Manual 9R68-A

Mar, 2008

Tare

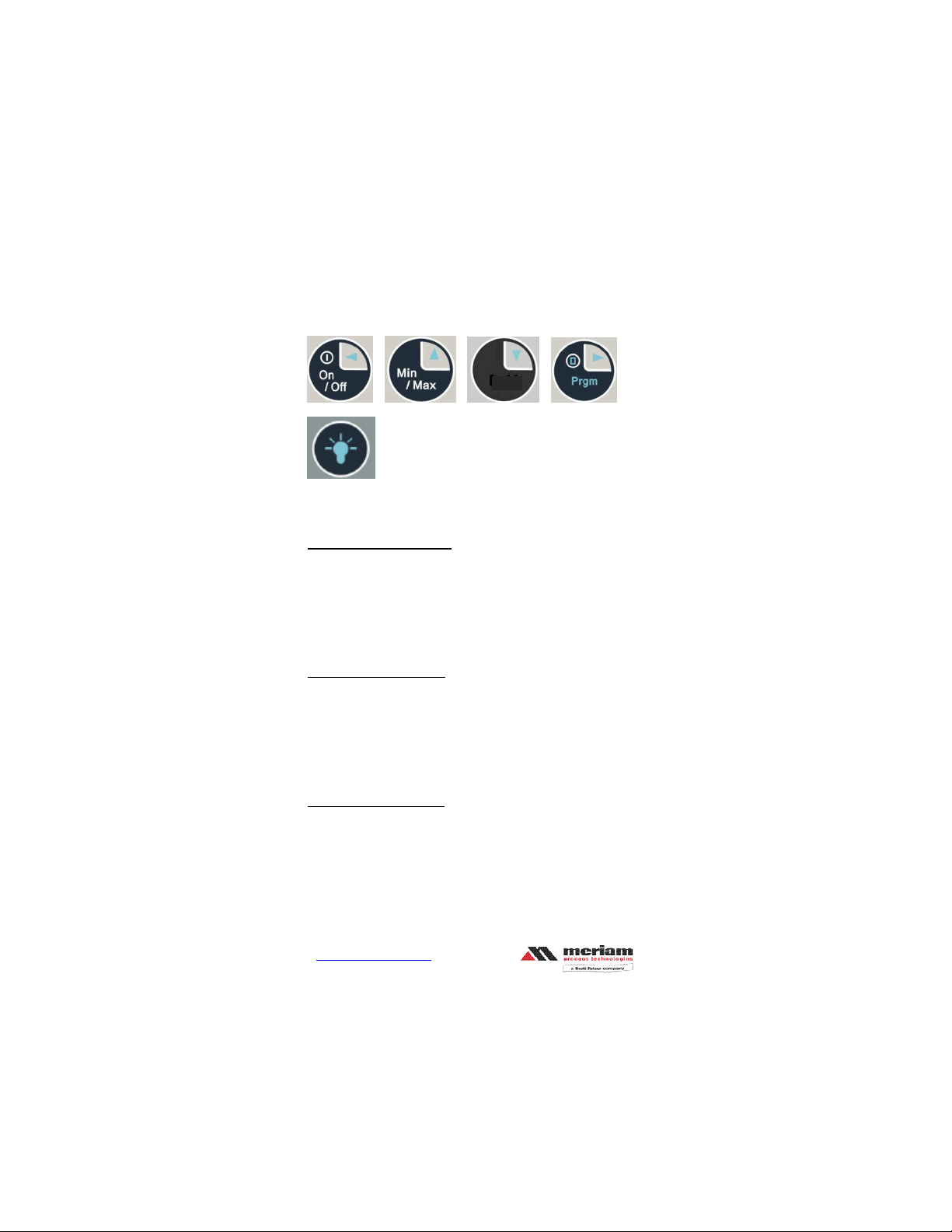

1. Keypad Functions

ON/OFF & BACK KEY

Turns the manometer on and enters the unit into the Measure

Mode. Pressing the key while in the Measure Mode turns the unit

off. It also serves as a backspace key when editing in the Program

Mode. The key takes the user out of a programmable register

without changing the previous setting. Pressing this key repeatedly

will return the user to the Measure Mode and then shut off the

manometer.

MIN/MAX & UP KEY

In the Measure Mode activates the Min/Max function of the

manometer. When activated the minimum value is displayed on the

upper left of the display and the maximum value on the upper right.

This key also deactivates and resets this function. The key is

used to scroll through the programmable registers when the unit is

in the Program Mode. Once a programmable register is selected

the key can be used to edit that register.

TARE & DOWN KEY

In the Measure Mode toggles on/off the Tare function. The Tare

function is designed to set the display value to “0”. With Tare

activated, the letter “T” appears in the lower left of the display.

The key is used to scroll through programmable registers with

the unit in the Program Mode. Once a programmable register is

selected the key can be used to edit that register.

www.meriam.com

page 3 of 36

Page 4

M2 Series

Instruction Manual 9R68-A

PRGM & ENTER KEY

Puts the manometer into the Program Mode from the Measure

Mode. When in the Program Mode, pressing this key selects the

programmable register to be edited (with prompt for password if

Lockout is set). After the register has been edited, pressing the

PRGM key enters the new setting into the manometer’s nonvolatile memory. This key also acts as a forward space key

when editing user input such as the header name and user units.

BACKLIGHT KEY

The BACKLIGHT key, represented by the standard light bulb

symbol, toggles the display backlight between green and off.

Mar, 2008

www.meriam.com

page 4 of 36

Page 5

M2 Series

Instruction Manual 9R68-A

2. Zeroing the Manometer

The M202 Precision Smart Manometer is a stable and precise

instrument. However, on occasion the M202 should have a new

zero taken. This is done to remove zero drift that can occur since

the manometer was last zeroed. The M202 can be zeroed only if

the new applied zero is within ± 1% FS of the original factory

calibration zero. This prevents accidental zeroing at atmospheric

pressure or other relatively high pressures. If outside this limit a

“ZERO RANGE ERROR” message appears and the manometer

will not zero.

The M202 provides three mechanisms for re-zeroing:

1. Referenced to Absolute Zero: This traditional and

preferred method takes a “snapshot” of the measured pressure

when a vacuum of less than 100 microns Absolute is applied

to the sensor.

2. Factory Zero: This method restores the calibration curve to

the original zero taken at the factory. Note that this feature is

intended for comparison purposes, and should not be used for

real pressure measurement, as any zero-drift will not be

compensated.

3. User-Adjusted Zero: This method allows the user to enter

any pressure value when a known reference is applied (for

example, the local barometer). The manometer will compare

its actual measured value with the entered value, and calculate

a new zero reference based on the offset.

1. To zero the manometer using Referenced to Absolute

Zero, start with the unit turned OFF and use the following

keystroke sequence:

Mar, 2008

www.meriam.com

page 5 of 36

Page 6

M2 Series

Instruction Manual 9R68-A

Mar, 2008

Keystroke Display

1. Press ON/OF button. The display briefly shows

2. Connect the 355 to a

vacuum source capable

of a vacuum of 100

microns absolute

pressure or less.

3. Pull a full vacuum. Display should read close to

4. Press MIN/MAX and

TARE keys at the same

time. (See figure 1

below.)

5. Press the PRGM key. Top line of display reads

the header name and full

scale range of the unit in the

last engineering units

selected. The manometer

then goes into the Measure

Mode where the applied

pressure and engineering

unit of measure are

displayed.

zero. (See note on next

page)

Top line of display reads

“ZEROING SOURCE:”

Bottom line of display reads

“REF TO ABS ZERO”

“ZERO IN PROGRESS”

while bottom line counts

down from 9. Zeroing is

complete when unit returns

to Measure Mode.

Figure 1

Tare

www.meriam.com

page 6 of 36

Page 7

M2 Series

2. To zero the manometer using Factory Zero, start with the

unit turn ON and in Measure Mode and use the following

keystroke sequence:

Keystroke Display

Instruction Manual 9R68-A

Mar, 2008

1. Press MIN/MAX and

TARE keys at the

same time. (See

figure 1 above.)

2. Press or arrow

key until desired zero

function is shown on

the bottom line.

3. Press the PRGM key.

NOTE: The M202 can be zeroed only if the new applied zero

is within ± 1% FS of the original factory calibration zero. If

outside this limit a “ZERO RANGE ERROR” message

appears and the manometer will not zero. Contact the factory

for support in this case.

3. To zero the manometer using User-Adjusted Zero, start

with the unit turn ON and in Measure Mode and use the

following keystroke sequence:

Top line of display reads

“ZEROING SOURCE:”

Bottom line of display

reads “REF TO ABS

ZERO”

Bottom line of display

reads “FACTORY ZERO”

Zeroing is complete when

unit returns to Measure

Mode.

www.meriam.com

page 7 of 36

Page 8

M2 Series

Instruction Manual 9R68-A

Mar, 2008

Keystroke Display

1. Apply a known,

accurate pressure

source. This may be

true atmospheric

pressure, with known

reference defined by a

local barometer.

2. Press MIN/MAX and

TARE keys at the

same time. (See

figure 1 above.)

3. Press or arrow

key until desired zero

function is shown on

the bottom line.

4. Press the PRGM key. Top line of display shows

5. Press any of or

arrow key or the

PRGM key to begin

editing.

Example: set current

pressure value to 29.5

In Hg @ 0º C.

Top line of display reads

“ZEROING SOURCE:”

Bottom line of display

reads “REF TO ABS

ZERO”

Bottom line of display

reads “USER ADJ.

ZERO”

the current non-zero

compensated pressure

value. Bottom line of

display shows the same

value, along with the

engineering unit.

Top line of display

continuously updates.

Bottom line of display data

is frozen, and the first digit

is blinking.

www.meriam.com

page 8 of 36

Page 9

M2 Series

6. Press the or

arrow key to set the

first digit to 0.

Instruction Manual 9R68-A

Mar, 2008

Current: xxx.xx

0xx.xx INHG

Using the UP arrow

key the character

sequence is 0 - 9, (-)

negative, (.) decimal

point. The (-) sign is

used if your location

is below sea level.

7. When the digit is

correct press the

PRGM key.

If an error is made use

the back space key

to move the cursor

back to the incorrect

digit. Press the UP

or DOWN arrow

keys to display the

correct value.

8. Continue this process

until the display reads

as shown at right.

9. Press the PRGM key

to enter the final

digit.

Note that the User Adjusted Zero feature will not accept

entries in altitude units (FEET or METERS). When the current

engineering unit is FEET, the User Adjusted Zero function

will automatically prompt for an entry in Inches of Mercury @

0º C. When the current engineering unit is METERS, the User

Adjusted Zero function will automatically prompt for an entry

in Millimeters of Mercury @ 0º C.

Cursor flashes to the right

of “0”.

Current: xxx.xx

029.50 INHG

Zeroing is complete when

unit returns to Measure

Mode.

www.meriam.com

page 9 of 36

Page 10

M2 Series

Instruction Manual 9R68-A

3. Program Mode

The program mode is used to configure the manometer for

Measure Mode operation. After the PRGM key is pressed in

Measure Mode, the top line of the display reads “PROGRAM

MODE”. The bottom line reads “UNITS SELECT”. Press the or

arrow keys to scroll through the Program Mode to the desired

register. The configurable registers found in the Program Mode

are Units Select, Damp Rate Select, User Info Select, Contrast

Select, Sea Level Select, Data Logging, Leak Test and Exit.

Press the PRGM key to select any of these configurable registers.

The manometer can be put into Program Mode at any time during

Measure Mode operation by pressing the PRGM key. If Lockout

is set, the correct code must be entered when prompted (see the

User Info / Lockout section of this manual for more information on

Lockout).

Mar, 2008

www.meriam.com

page 10 of 36

Page 11

M2 Series

Instruction Manual 9R68-A

Units Select

The standard engineering units available on the M202 Precision

Absolute Manometer are:

Inches of Mercury at 0° C (in Hg @ 0° C)

Millimeters of Mercury at 0° C (mm Hg @ 0° C)

PSI

kPa

mbars

Bars

Torr

Feet (Altitude displays)

Meters (Altitude displays)

To change the engineering units the manometer should be “ON”

and in Measure Mode. Then follow these steps:

Keystroke Display

1. Press the PRGM key. Top line reads “PROGRAM

2. Press the PRGM key. Top line reads “UNITS

3. Press the or arrow

key until desired engineering unit is displayed.

4. Press the PRGM key to

select the engineering unit.

5. Press the arrow key. Bottom line reads “EXIT”.

6. Press the PRGM key. Display returns to Measure Mode

MODE” and bottom line reads

“UNITS SELECT”.

SELECT” and bottom line shows

current engineering units.

Engineering units on bottom line

of display change.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

in new engineering unit.

Mar, 2008

www.meriam.com

page 11 of 36

Page 12

M2 Series

Instruction Manual 9R68-A

Displaying Altitude (US Standard Atmosphere 1962)

The model M202 is capable of displaying altitude in feet or meters

based on U.S. Standard Atmosphere1962 tables. To set the M202

to read out referenced to this altitude standard use the following

steps:

Keystroke Display

1. Press the PRGM key. Top line reads “PROGRAM

2. Press the PRGM key. Top line reads “UNITS

3. Press the or arrow

key until “USER UNIT

SELECT” is displayed.

4. Press the PRGM key. Top line reads “ALTITUDE

5. Press the PRGM key. Top line reads “PROGRAM

6. Press the key. Manometer returns to Measure

Display User Defined Altitude

User Defined Altitude is useful in determining elevation change

from a map elevation reference or from a survey trig marker

elevation. To set up the M202 to display altitude based on user

entered information, use the following steps:

Keystroke Display

1. Press the PRGM key. Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

SELECT” and bottom line shows

current engineering unit.

Top line reads “UNITS

SELECT”

Bottom line reads “FEET or

METERS”.

SELECT”. Bottom line reads

“STANDARD”.

MODE” and bottom line reads

“UNITS SELECT”.

Mode. Displays altitude

referenced to US Standard

Atmosphere 1962.

MODE” and bottom line reads

“UNITS SELECT”.

Mar, 2008

www.meriam.com

page 12 of 36

Page 13

M2 Series

Instruction Manual 9R68-A

2. Press the PRGM key. Top line reads “UNITS

3. Press the or arrow

key until “USER UNIT

SELECT” is displayed.

4. Press the PRGM key. Top line reads “ALTITUDE

5. Press the arrow key

once.

6. Press the PRGM key. Top line reads “VALUE=:

7. If the value shown in

step 6 is the correct

altitude, press the PRGM

key to accept and the

key to return to Measure

Mode.

If the value shown in step

6 is not the correct

altitude, press the key

8. Press the PRGM key.

Example: set altitude to

685 feet above sea level.

9. Press the or keys

to set the first digit to “6”.

Using the key the

provides the character

sequence 0 - 9, ( - )

negative, and (.) decimal

point. The ( - ) sign is used

if your location is below

sea level.

- OR -

SELECT” and bottom line shows

current engineering unit.

Top line reads “UNITS

SELECT”

Bottom line reads “FEET or

METERS”.

SELECT”. Bottom line reads

“STANDARD”.

Top line reads “ALTITUDE

SELECT”. Bottom line reads

“REF. TO USER”.

00000000”. Bottom line reads

“CHANGE?: NO”.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Top line reads “VALUE=:

00000000”. Bottom line reads

“CHANGE?: YES”.

Top line reads “USER MODEFEET”. Bottom line reads

“00000000”.

Top line reads “USER MODEFEET”. Bottom line reads

“60000000”.

Mar, 2008

www.meriam.com

page 13 of 36

Page 14

M2 Series

Instruction Manual 9R68-A

10. When the digit is

correct press the PRGM

key.

If an error is made use the

back space key to move

the cursor back to the

incorrect digit. Press the

or arrow keys to

display the correct value.

11. Continue the process

until the display reads as

shown at right.

12. Press the PRGM key

to enter the final value.

13. Press the key to

return to Measure Mode.

To set the unit to read in meters, select METERS from the UNITS

SELECT menu. Then follow the same steps as outlined above.

Because the local barometer varies with weather conditions, the

USER DEFINED ALTITUDE must be reentered each time the

M202 is to be used in this mode. To adjust the unit to the current

barometric pressure without changing the base altitude, select

“NO” in step 6 in the table above by pressing the PRGM key. The

M202 will display the current altitude referenced to prevailing

local barometric pressure. To maximize accuracy the local altitude

should be reset whenever better altitude information is available.

Cursor flashes to the right of the

“6”. Example: “60

Top line reads “USER MODEFEET”. Bottom line reads

“685.0000”.

Top line reads “PROGRAM

MODE”. Bottom line reads

“UNITS SELECT”.

Top line reads “altitude

referenced to 685”. Bottom line

reads “U 685 FEET”.

000000”.

Mar, 2008

www.meriam.com

page 14 of 36

Page 15

M2 Series

Pressure Corrected to Sea Level

Pressure reduction to Sea Level is required so that barometric

readings can be compared at different elevations. The correction to

sea level is done using a “hypsometric equation”. This equation

simulates a “fictitious column of air” which extends downward

from the instruments location to sea level. This fictitious column is

assumed to be similar to the actual air column over nearby lower

elevations. Some properties are related to observed conditions

while others must be assumed. Barometric pressures given by the

National Weather Service and used at airports are always corrected

to sea level.

To set the unit to display pressure corrected to sea level:

Keystroke Display

1. Determine the elevation of

the instrument above sea

level, in meters. 700 meters

will be used as an example.

2. From Measure Mode press

the PRGM key.

3. Press the key 4

times.

4. Press the PRGM key. Top line reads “SEA LEVEL

5. Press the or key

to indicate the correction

to sea level status.

6. To turn on the correction,

set ENABLED on the 2

line & press the PRGM key.

-OR-

To turn off the correction, set

DISABLED on the 2

and skip ahead to step 12 .

nd

nd

line

Instruction Manual 9R68-A

Mar, 2008

Top line reads “PROGRAM

MODE”. Bottom line reads

“UNITS SELECT”.

Top line reads “PROGRAM

MODE”. Bottom line reads

“SEA LEVEL SELECT”.

SELECT”. Bottom line reads

either “ENABLE” or

“DISABLED”.

Bottom line toggles between

“ENABLE” and

“DISABLED”.

Top line reads “VALUE=:

00000000”. Bottom line reads

“CHANGE?: NO”.

www.meriam.com

page 15 of 36

Page 16

M2 Series

Instruction Manual 9R68-A

7. To change the value press

the key to toggle the

display to “YES”.

8. Press the PRGM key. Top line reads “SEA LEVEL

9. Press the or arrow

keys to set the correct value

in the first digit.

10. When the value is correct

press the PRGM key.

11. Repeat steps 9 and 10

above until the correct

elevation is entered.

12. Press the PRGM key to

continue moving the cursor

to the right. When the last

digit is entered the unit will

leave the sea level select

mode and return to the

Program Mode.

13. Press the key. The

display will return to the

Measure Mode. When the

Correction to Sea Level is

ENABLED, the display will

have the letter “S” at the

beginning of the 2

nd

line.

Top line reads “VALUE=:

00000000”. Bottom line reads

“CHANGE?: YES”.

METERS”. Bottom line reads

0000000”.

“0

Top line reads “SEA LEVEL

METERS”. Bottom line reads

“7

0000000”.

Cursor moves over to the next

digit.

Top line reads “SEA LEVEL

METERS”. Bottom line reads

“7

00.0000”.

Top line reads “PROGRAM

MODE”. Bottom line reads

“UNITS SELECT”.

Display reads;

“S 803.1 TORR”

Mar, 2008

www.meriam.com

page 16 of 36

Page 17

M2 Series

Instruction Manual 9R68-A

Damp Rate Select

Adjustable exponential type damping is available to steady the

display when measuring pulsating pressures. The M202 has a range

of damping rates; 0.1, 0.2, 0.5, 1, 2, 5, 10, or 25 seconds. Damping

is done by averaging new data from the pressure sensor against

previously collected data. The microprocessor collects data from

the sensor every 0.1 seconds. The display updates every 0.5

seconds, showing the current 0.1 second pressure reading. When set

at 25 seconds, the display updates every 0.5 seconds with the

average of the previous 25 seconds readings. Therefore, it takes up

to 25 seconds from the time pressure is applied until the manometer

displays the full scale applied pressure. Min/Max display updates

every 0.1 seconds.

To set the damp rate:

Keystroke Display

1. Enter Program Mode by

pressing the PRGM key.

2. Press the key.

3. Press the PRGM key. Top line reads “DAMP RATE

4. Press the or keys

until the desire damp rate is

displayed on the bottom line.

5. Press the PRGM key. Top line reads “PROGRAM

6. Press the key.

7. Press the PRGM key. Returns to Measure Mode.

Top line reads “PROGRAM

MODE”. Bottom line reads

“UNITS SELECT”.

Bottom line reads “DAMP

RATE SELECT”.

SELECT”. Bottom line shows

current value.

Bottom line shows damp rate

settings in seconds.

MODE”. Bottom line reads

“UNITS SELECT”.

Bottom line reads “EXIT”.

Mar, 2008

www.meriam.com

page 17 of 36

Page 18

M2 Series

Instruction Manual 9R68-A

User Info Select

The User Info Select registers are designed to provide the user with

information on the hardware and software in the manometer. This

register provides read only information on the sensor’s serial

number, software version and date of manufacture. It also allows

the user to edit the Auto Shut-Off, Lockout and Start-Up Header

Name features.

To access the User Info Select registers, follow the steps below. To

configure a User Info Select register, follow the steps shown on the

following page.

Keystroke Display

1. From the Measure Mode

press the PRGM key.

2. Press the arrow key

twice

3. Press the PRGM key. Bottom line shows serial

4. Press the arrow key. Software version number

5. Press the arrow key. Manufacture date shown.

6. Press the arrow key.

See instructions to set

AUTO SHUT-OFF later in

this manual.

7. Press the arrow key.

See instructions for using

LOCKOUT later in this

manual.

8. Press the arrow key.

See instructions for editing

the Header later in this

manual.

9. Press the arrow key to

go back to “USER INFO

SELECT” screen.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Bottom line changes to “USER

INFO SELECT”.

number.

shown.

Top line reads “AUTO SHUT

OFF” and bottom line reads

“ENTER TO SELECT”.

Top line reads “LOCKOUT

CODE” and bottom line reads

“ENTER TO SELECT”.

Top line reads “HEADER

NAME” and bottom line reads

“MERIAM”. The cursor flashes

at bottom left.

Top line reads “PROGRAM

MODE” and bottom line reads

“USER INFO SELECT”.

Mar, 2008

www.meriam.com

page 18 of 36

Page 19

M2 Series

Instruction Manual 9R68-A

Auto Shut-Off

Enabling the Auto Shut-Off feature allows the manometer to turn

itself off after a user selected period of keypad inactivity.

Selectable options include DISABLED, 10 Minutes (which is the

factory shipped default), 20 Minutes, 30 Minutes, 45 Minutes and

60 Minutes. Disabling this feature limits the manometer to being

turned off by using the ON/OFF key only.

To configure auto shut-off follow these steps:

1. Follow steps 1-6 in the

User Info Select table.

2. Press the PRGM key,

then the up or down

arrow keys until the

desired shut-off time is

shown.

3. Press the PRGM key. Desired Auto Shut-Off time is

4. Press the left arrow key

twice.

Note: The “Auto Shut-Off” timer is suspended during Data

Logging and Leak Test sessions to prevent accidental loss of

information. Auto Shut-Off is re-instated after completion of DataLogging or Leak Test sessions.

Keystroke Display

Top line reads “AUTO SHUTOFF” and bottom line reads

“ENTER TO SELECT”.

Top line reads “AUTO SHUTOFF” and bottom line toggles to

“DISABLED”, “10”, “20”, “30”,

“45” and “60” minutes .

selected, top line reads “AUTO

SHUT-OFF” and bottom line

reads “ENTER TO SELECT”.

Returns to Measure Mode.

Mar, 2008

www.meriam.com

page 19 of 36

Page 20

M2 Series

Instruction Manual 9R68-A

Lockout Select

Enabling the Lockout feature prevents unauthorized users from

making changes to the configuration of the manometer. To enter

the Program Mode, the user must first enter the “password” (twodigit Lockout Code) within approximately 40 seconds when

prompted. Failure to enter the correct two digit code within

approximately 40 seconds will return the unit to Measure Mode.

Any two-digit numeric code can be programmed. The factory

Lockout Code of 00 (which is the default as shipped from the

factory) disables the Lockout.

To set the Lockout Code follow these steps:

Keystroke Display

1. From the Measure

Mode press the PRGM

key. If the Lockout is set,

enter the correct

“password” when

prompted.

2. Press the up arrow key

twice.

3. Press the right arrow

key then the up arrow key

four times.

4. Press the right arrow

key, then press the up or

down arrow keys to

change the first digit.

Press the right arrow key

to proceed.

5. Press the right arrow

key when the desired code

is set. Lockout is

activated.

6. Press the left arrow key

twice.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Bottom line reads “USER INFO

SELECT”.

Top line reads “LOCKOUT

CODE” and bottom line reads

“ENTER TO SELECT”.

Bottom line shows the old

Lockout Code. The cursor flashes

at the first position while the

value is changed, the cursor

moves to the right position once

the right arrow key is pressed.

Top line reads “LOCKOUT

CODE” and bottom line reads

“ENTER TO SELECT”.

Returns to Measure Mode.

Mar, 2008

www.meriam.com

page 20 of 36

Page 21

M2 Series

Instruction Manual 9R68-A

Header Name

Follow the steps below to edit the Header Name.

Keystroke Display

1. From the Measure Mode

press the PRGM key.

2. Press the up arrow key

twice.

3. Press the PRGM key. Bottom line shows serial

4. Press the up arrow key

five times.

5. If header is correct press

backspace key. If editing is

desired proceed to step 7.

6. Press the left arrow key. Returns to Measure Mode.

7. Press the up or down

arrow keys to set the

correct alpha-numeric

value.

8. Press the right arrow key

to accept entry.

9. Repeat steps 8 and 9

until the desired Header is

shown.

10. If an error is made press

the back arrow key until the

cursor is over the incorrect

value. Follow step 8 to

correct. Press the right

arrow key to advance the

cursor without changing

values.

11. When the Header is

complete press the PRGM

key until header accepted.

12. Press the left arrow key. Returns to Measure Mode.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Bottom line changes to “USER

INFO SELECT”.

number.

Top line reads “HEADER

NAME” and bottom line reads

“MERIAM”. The cursor flashes

at bottom left.

Top line reads “PROGRAM

MODE” and bottom line reads

“USER INFO SELECT”.

Displays a number between 0

and 9, a letter from A to Z, / or a

blank space.

Cursor advances one space to

right.

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Mar, 2008

www.meriam.com

page 21 of 36

Page 22

M2 Series

Contrast Select

The Contrast Select register allows the user to adjust the character

contrast of the LCD display to provide the best visibility for the

ambient light conditions.

To adjust the contrast, follow these steps:

Keystroke Display

1. From the Measure Mode

press the PRGM key.

2. Press the key three

times.

3. Press the PRGM key. Top line reads “CONTRAST

4. Press the or keys to

increase or decrease the

contrast value. A low

number gives maximum

contrast and a high number

gives minimum contrast.

5. Press the PRGM key. Top line reads “PROGRAM

6. Press the key. Returns to Measure Mode.

If an error is made during the contrast adjustment, pressing the key

returns the display to the previous contrast setting.

Instruction Manual 9R68-A

Mar, 2008

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Bottom line reads

“CONTRAST SELECT”.

SELECT”. Bottom line shows a

numerical value.

LCD lightens or darkens

depending on the value set.

MODE” and bottom line reads

“UNITS SELECT”.

www.meriam.com

page 22 of 36

Page 23

M2 Series

Instruction Manual 9R68-A

Data Logging

Data Logging can be used to record pressure measurements. Two

record modes are supported: automatic and manual. In automatic

mode, a pressure value is captured every 5 seconds for 20 minutes,

resulting in 240 stored values. In manual mode, a pressure value is

captured each time the PRGM key is pressed up to 240 values. The

data collected during a logging session can be viewed upon

completion.

1. From the Measure Mode

press the PRGM key.

2. Press the up arrow key

four times.

3. Press the PRGM key. Top line reads “DATA

4. Press the PRGM key. Top line reads “RECORD

5. Press the PRGM key at

AUTO to start automatic

logging or at MANUAL to

start manual logging mode.

6. To stop recording values

at any time, press the key.

7. To access recorded

values, press the key.

8. To view recorded values,

press the PRGM key.

9. Press the key 3 times. Returns to Measure Mode.

The “Auto Shut-Off” timer is disabled for Data Logging sessions.

Be sure to end the session to re-enable the Auto Shut-Off timer.

Keystroke Display

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Bottom line reads “DATA

LOGGING”.

LOGGING” and bottom line

reads “RECORD”.

MODE” and bottom line reads

“AUTO” or “MANUAL”.

Top line reads

“RECORDING X” and

bottom line reads “XX.XX

UNITS”. AUTO records value

every 5 seconds. Manual

records value each time PRGM

key is pressed.

Top line reads “DATA

LOGGING” and bottom line

reads “RECORD”.

Top line reads “DATA

LOGGING” and bottom line

reads “VIEW”.

Top line reads “DATA LOG:

1” and bottom line displays

the value. Continue pressing

the key to view all values.

Mar, 2008

www.meriam.com

page 23 of 36

Page 24

M2 Series

Leak Test

The Leak Test feature allows the user to determine the leak rate in

the pneumatic system being monitored. Once configured, Leak

Test monitors the measured pressure over time and displays the

leak rate in the pressure units per minute at the conclusion of the

test. The maximum configurable leak test period is 1440 min (1

day). Pressing any key during the leak test will abort the test.

To enable Leak Test follow these steps:

Keystroke Display

1. From the Measure Mode

press the PRGM key.

2. Press the down arrow key

twice.

3. Press the PRGM key. Top line reads “LEAK TEST”

4. Press the PRGM key. Top line reads “Leak Test

5. Use the up, down & right

keys to input test period

6. Press the PRGM key. Top line reads “LEAK TEST”

7. Press the up arrow key

once.

8. Press the PRGM key.

The “Auto Shut-Off” timer is disabled for Leak Test sessions. Be sure to end

the session to re-enable the Auto Shut-Off timer.

Instruction Manual 9R68-A

Mar, 2008

Top line reads “PROGRAM

MODE” and bottom line reads

“UNITS SELECT”.

Bottom line reads “LEAK

TEST”

and bottom line reads

“CONFIGURE”.

Period” & bottom “X.X MIN”.

Bottom line reads desired

period; Ex. “ 20.0 MIN”.

and bottom line reads

“CONFIGURE”.

Top line reads “LEAK TEST”

and bottom line reads “PRGM

TO START”.

Top line displays MIN/MAX

pressure values at left/right.

Bottom line reads the current

pressure value and units.

At end of test period, top line

displays the leak rate in units

per minute. Bottom line shows

the current pressure reading.

www.meriam.com

page 24 of 36

Page 25

M2 Series

Instruction Manual 9R68-A

Re-Calibration

The Manometer can be re-calibrated in the field for zero, span, and

linearity. The proper primary standards must be available prior to

calibrating the Manometer. These standards should meet the

accuracy requirements for your company or industry. Meriam

Process Technologies follows the guidelines established by ANSI /

NCSL Z540-1-1994 which requires that the primary standard be 4

times more accurate than the unit under test.

The re-calibration is not

Calibration Procedure. It is intended to correct the curve fit if the

actual sensor characteristics change slightly over time.

For sensors up to 200 PSI, Meriam recommends a ±0.0015% of

reading deadweight tester. For sensors 200 PSI and above, a

±0.0030% of reading deadweight tester is recommended. If

calibrating using inches of water units, be sure to match the

reference temperature of water in both the unit under test and the

M2.

1-point (within upper 50% of Full Scale), 5-point (nominal values

of 0%, 25%, 50%, 75% & 100% of Full Scale), and restore factory

default re-calibration options are offered. For the 5-Point recalibration, points 2, 3 and 4 can be adjusted within ±1% of

reading around the nominal values. Point #5 can be adjusted within

-1% of reading around nominal. Point #1 is fixed.

For example: for a 2000 inH2O sensor, Point # 2 (25%) can be

edited form 495 to 505 inH2O. Point #5 (100%) can be edited

from 1980 to 2000 inH2O.

The unit can only be re-calibrated if the calibration points are

within 5 times the accuracy of the original factory calibration (e.g.

@ 0.05% accuracy, the point limit is ±0.25% of Full Scale). If the

re-calibration procedure generates a new value outside this limit

the procedure will fail. In this case the unit would need to be

returned to the factory for service.

intended to replace the Factory Lab

Mar, 2008

www.meriam.com

page 25 of 36

Page 26

M2 Series

Instruction Manual 9R68-A

Once a re-calibration has been performed (either 1-point or 5point) the unit will continue to allow future re-calibrations only

with that type of re-calibration. In order to enable the other recalibration type, the user must first restore the re-calibration data to

the factory defaults.

Mar, 2008

www.meriam.com

page 26 of 36

Page 27

M2 Series

Instruction Manual 9R68-A

RE-CALIBRATION – 1 Point EDIT and START

To perform a 1-point re-calibration, apply a pressure between 50%

and 100% of Full Scale and then follow these steps:

Keystroke Display

1. With unit OFF, press and

hold the MIN/MAX key,

turn the unit on by pressing

the ON/OFF key, then

release MIN/MAX.

2. Press the up arrow key

until “START” is displayed

on the bottom line.

3. Press the PRGM key. Top line reads “RE-CAL

4. Press the PRGM key. Top line reads “CAL POINT”

5. Press the up/down arrow

keys to edit the selected

digit. Use the left/right arrow

keys to change the cursor

position. Value entered must

be 50-100% of FS.

6. Press the right arrow key

while on the right most digit

to proceed.

7. Apply the input pressure

indicated using an

appropriate reference

standard; press PRGM key.

8. Press the left arrow key. Returns to Measure Mode

Top line reads “RE-CAL”.

Bottom line reads “EDIT”.

Top line reads “RE-CAL”.

Bottom line reads “START”.

START”.

Bottom line reads “1-POINT”.

and bottom line displays the

cal point value.

Bottom line displays the cal

point value. The cursor flashes

at the first position while the

value is changed, then moves

to the right position when the

right arrow key is pressed.

Top line reads “APPLY:”

Bottom line displays the “CAL

POINT” value.

Top line reads “RE-CAL”.

Bottom line reads “START”,

Manometer has been

recalibrated.

Mar, 2008

www.meriam.com

page 27 of 36

Page 28

M2 Series

RE-CALIBRATION – 5 Point EDIT

To edit the calibration points for a 5 Point re-calibration follow the

steps below.

NOTE: If the factory default values are acceptable, skip this

section and proceed to the re-calibration 5-Point START procedure.

Keystroke Display

1. With unit OFF, press and

hold the MIN/MAX key,

turn the unit on using the

ON/OFF key, then release

2. Press the PRGM key. Top line reads “CAL POINT

3. Press the up/down arrow

keys to edit the selected

digit. Use the left/right

arrow keys to change the

cursor position.

0% go directly to step 4.

4. Press the right arrow key

while on the right most digit

to proceed.

5. Repeat steps 3 and 4 for

CAL POINTS 2, 3, 4 and 5.

6. After editing CAL

POINT 5 press the right

arrow key while on the right

most digit to proceed.

7. To perform the 5-point

re-cal, press the up arrow

key until START is

displayed on the bottom

line.

OR

To exit without performing

the 5-point re-cal press the

left arrow key

Note: For

Instruction Manual 9R68-A

Mar, 2008

Top line reads “RE-CAL”.

Bottom line reads “EDIT”.

1”. Bottom line displays the

cal point value.

Bottom line displays the cal

point value. The cursor flashes

at the first position while the

value is changed, then moves

to the right position when the

right arrow key is pressed.

Top line reads “CAL POINT

2”. Bottom line displays the

cal point value.

Top line reads “CAL POINT

2/3/4/5”. Bottom line displays

the cal point value.

Top line reads “RE-CAL”.

Bottom line reads “EDIT”.

Top line reads “RE-CAL”.

Bottom line, “START”.

Continue with 5-Point Recalibration procedure at step 3

on next page.

OR

Returns to Measure Mode.

www.meriam.com

page 28 of 36

Page 29

M2 Series

Instruction Manual 9R68-A

RE-CALIBRATION – 5 Point START

To begin the 5-point re-calibration procedure, turn the unit OFF

and follow the steps below.

Keystroke Display

1. Press and hold the

MIN/MAX key and turn the

unit on by pressing the

ON/OFF key.

2. Press the up arrow key

until “START” is displayed

on the bottom line.

3. Press the PRGM key. Top line reads “RE-CAL

4. Press the up arrow key

until “5-POINT” is

displayed on the bottom

line.

5. Press the PRGM key. Top line reads “POINT 1 –

6. Vent P1 and P2 ports to

atmosphere and

simultaneously press the

MIN/MAX and HOLD

keys, then release.

7. Press the right arrow key

while on the right most

digit to proceed.

8. Apply the indicated

calibration point pressure

using external pressure

standards. After pressure is

stable, press the right arrow

key.

9. Repeat step 8 for CAL

POINTS 4 and 5.

Top line reads “RE-CAL”.

Bottom line reads “EDIT”.

Top line reads “RE-CAL”.

Bottom line reads “START”.

Bottom line reads “1-POINT”.

Top line reads “RE-CAL

START”.

Bottom line reads “5-POINT”.

ZERO:”

Bottom line displays live

applied pressure.

Unit takes new zero. Top line

reads “ POINT 1 - ZERO:”

Bottom line displays live

applied pressure. POINT 1 has

been taken.

Top line reads “POINT 2 APPLY:”.

Bottom line displays the cal

point value to apply.

Top line reads “POINT 3 APPLY:”.

Bottom line displays the cal

point value to apply.

Top line reads “POINT 4/5 APPLY”

Bottom line displays the cal

point value.

Mar, 2008

www.meriam.com

page 29 of 36

Page 30

M2 Series

Instruction Manual 9R68-A

10. Use up or down arrow

keys to select NO or YES

when asked “Save?” the

Re-Calibration data.

11. Press the PRGM key at

YES to save the ReCalibration data or at NO to

exit without saving.

12. Press the left arrow key. Returns to Measure Mode.

RE-CALIBRATION – Restore Factory Defaults

To restore the re-calibration data to the factory defaults, follow

these steps:

Keystroke Display

1. With unit OFF, press and

hold the MIN/MAX key,

turn the unit on using the

ON/OFF key, then release.

2. Press the up arrow key

twice.

3. Press the PRGM key. Top line reads “RESTORE

4. Use the up and down

arrow keys to select YES or

NO when asked to restore

defaults.

5. Press the PRGM key at

YES to restore the Factory

Default Calibration data or

at NO to exit without

restoring.

6. Press the left arrow key. Returns to Measure Mode.

Top line reads “SAVE?”.

Bottom line reads “NO” or

“YES”.

Top line reads “RE-CAL”.

Bottom line reads “START”.

Re-cal is complete.

Top line reads “RE-CAL”.

Bottom line reads “EDIT”.

Top line reads “RE-CAL”.

Bottom line reads “RESTORE

DEFAULTS”.

DEFAULTS”.

Bottom reads “YES” or “NO”.

Top line reads “RESTORE

DEFAULTS”.

Bottom reads “YES” or “NO”.

Top line reads “RE-CAL”.

Bottom line reads “RESTORE

DEFAULTS”. Factory

defaults have been restored.

Mar, 2008

www.meriam.com

page 30 of 36

Page 31

M2 Series

Instruction Manual 9R68-A

Specifications

Type, Range and Display Resolution:

Absolute Isolated (AI) Type:

17 psia (900 mmHg) – XXX.YY

38 psia (2000 mmHg) – XXX.YY

Accuracy:

M202-AI0017: ±0.02 % F.S. (F.S. = 900 mm Hg)

M202-AI0038: ±0.015 % F.S.* from 0-1000 mm Hg

±0.025% F.S.* from 1000-2000 mm Hg

*F.S. = 2000 mm Hg Absolute

Includes the combined effects of temperature, linearity,

repeatability, hysteresis and resolution.

Warm up time = 5 minutes.

Temperature:

Storage = -40°C to +60°C (-40°F to +140°F)

Operating = -5°C to +50°C (23°F to +122°F)

Media Compatibility:

AI: Absolute pressure sensors for use with gases and liquids

compatible with 316L SS

Pressure Limits:

AI units: 77 PSIA (4000 mm Hg Abs)

Connection:

1/8” female NPT, 316L SS. P1 is the pressure connection.

P2 is not accessible (factory plugged with metal disc)

Mar, 2008

User must use a wrench on the pressure manifold when

installing user’s 1/8” NPT fitting. Do not tighten the

fitting without using a wrench on the pressure

manifold. Failure to use a wrench on the manifold will

damage the plastic enclosure and void warranty No

torque should be applied to the manifold with respect

to plastic enclosure.

www.meriam.com

page 31 of 36

Page 32

M2 Series

Instruction Manual 9R68-A

Battery Type:

4 each AA alkaline batteries.

IMPORTANT!!! ATEX certified models require the use

of approved batteries only to maintain the ATEX

certification. Refer to Drawing. No. 9R000056 “M2

Intrinsically Safe Control Document” for a list of

batteries approved for hazardous atmospheres. A copy of

this drawing accompanies each unit shipped.

Remove and / or replace batteries in non-hazardous

areas only.

Battery Operation:

>100 hours continuous use, 1 year shelf life, auto power off

programmable at Disabled, 10, 20, 30, 60 or 90 minutes

Enclosure: (6.9” × 3.8” × 2.3”) Polycarbonate, Permanently

Static Dissipative, ESD Protection

Enclosure with Boot: (7.2” × 4.2” × 2.5”)

Mar, 2008

www.meriam.com

page 32 of 36

Page 33

M2 Series

Instruction Manual 9R68-A

Certification/Safety/Warnings

The following defines the certification and area classification of

the Manometer product.

Mar, 2008

Note the following WARNINGS and requirements:

• Substitution of components may impair Intrinsic Safety

• To prevent ignition of flammable or explosive atmospheres,

disconnect power before servicing.

• To prevent ignition of flammable or explosive atmospheres,

DO NOT open or service unit, including battery

compartment, in flammable or explosive atmosphere

DO NOT rub, clean or wipe the surface of the

membrane keypad as it may build a static charge

DO NOT mix old batteries with new or mix

batteries from different manufacturers

DO NOT replace batteries in explosive or

hazardous atmosphere

DO NOT use any battery type other than those

listed on Drawing. No. 9R000056 “M2 Intrinsically

Safe Control Document”.

• User must use a wrench on the pressure manifold when

installing user’s 1/8” NPT fitting. Do not tighten the fitting

without using a wrench on the pressure manifold. Failure to

use a wrench on the manifold will damage the plastic

enclosure and void warranty No torque should be applied to

the manifold with respect to plastic enclosure.

www.meriam.com

page 33 of 36

Page 34

M2 Series

Instruction Manual 9R68-A

Changing the Batteries

Adherence to the Specifications and Certification/Safety/Warnings

sections of this manual shall be enforced when changing batteries.

The manometer is powered by four, 1.5 volt AA size batteries.

When the output of the batteries under load drops, the display will

alternate between “LOW POWER DETECT” and “REPLACE

BATTERY”. Low power may affect performance. The unit should

not be used to measure pressure in this condition. All four batteries

should be replaced.

To replace the battery locate the battery compartment at the bottom

rear of the manometer, as shown here.

Mar, 2008

Remove the two screws on either side of the battery cover by

turning them counterclockwise until the fully disengaged from the

manometer base. Lift the cover from the back of the unit.

Remove the batteries by pulling the positive side first straight out

of the battery compartment. Note the positive (+) and negative (-)

battery polarity markings at the bottom of the compartment, as

shown here.

www.meriam.com

page 34 of 36

Page 35

M2 Series

Instruction Manual 9R68-A

To install the four batteries: 1) Make sure polarity of battery

matches the markings in the compartment. 2) 1st place the (+) end

of the battery into the bottom of the battery slot. 3) Then push in

(-) end of the battery until it is seated in the bottom of the battery

slot. The battery compartment has stand offs molded into the side

of the compartment. When a battery is installed with the polarity

reversed, the stand offs prevent the negative battery terminal from

contacting the positive terminal in the battery compartment. The

unit will not power up when a battery is installed this way. Should

this happen, simply reverse the battery to align the polarity.

With the batteries secured in the battery compartment, replace the

compartment cover. The cover has only one correct alignment.

The “WARNING

statement on the battery cover must be visible and aligned in the

middle of the manometer case. To secure the cover, torque the

screws clockwise to 1.6-1.8 in-lbs. Do not over tighten.

DO NOT OPEN IN EXPLOSIVE ATMOSPHERE

Mar, 2008

”

www.meriam.com

page 35 of 36

Page 36

M2 Series

Instruction Manual 9R68-A

Contact Information

If the Manometer can not be zeroed, recalibrated or is damaged, it

must be returned to the factory for servicing. In this case, contact

the Meriam Process Technologies representative in your area or

call the factory at the numbers listed below for a Return Material

Authorization (RMA) number.

All M202 Precision Absolute Manometers recalibrated at the

factory are returned with certificates of NIST traceability.

Meriam Process Technologies

10920 Madison Ave.

Ph. (216) 281-1100 FAX (216) 281-0228

Cleveland, OH 44102

sales@meriam.com

E-mail

www.meriam.com

Web

Mar, 2008

www.meriam.com

page 36 of 36

Loading...

Loading...