Meriam Bellows Gauges for Differential Pressure User Manual

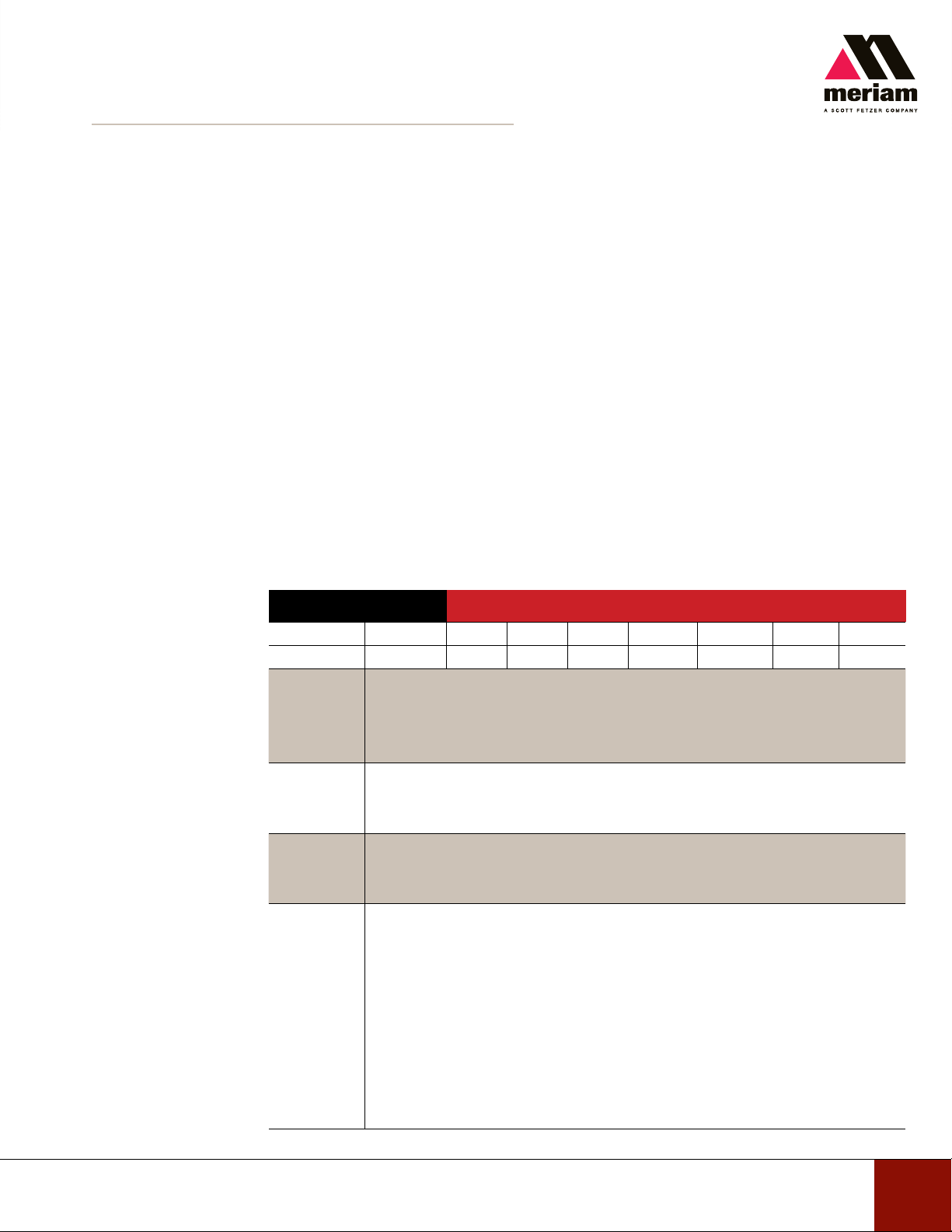

1120 Series Indicators

Indicator models 1123, 1124 and 1126 have 3”, 4½” and 6” dials

respectively. A variety of scales for differential pressure, flow and

level can be supplied. The 1120 Series is widely used in industrial

process plants, power plants, pollution control facilities and in the

cryogenic gas industry.

Bellows Gauges

1220 Series Indicating Switches

The Series 1220 Differential Pressure Indicating Switches are used

for on-off control or alarm. They also indicate flow, liquid level or

other process variables. These units are furnished with one or two

SPDT type switches with actuation set points easily adjustable over

most of the range of the instrument. The calibrated travel of the

pointer is 270° which gives good differential pressure indication

and switch resolution. Dials can be supplied with linear scales for

differential pressure, square root scales for flow, or custom scales

for level. The Series 1220 Switches are used extensively in power

plants, compressor stations and cryogenic applications.

1226X Explosion-Proof Switch

Meriam’s 1226X Explosion-Proof

Indicating Switch is CSA and U.L. listed,

meeting N.E.C. requirements for Class I,

Division I, Group D hazardous environments. Class I, Group D atmospheres

include gasoline, hexane, naphtha,

benzine, butane, propane, alcohol,

acetone, benzol, lacquer, solvent vapors,

and natural gas.

The explosion-proof housing is made from a strong, light-weight

aluminum alloy that is both non-rusting and non-sparking. A large

glass window provides full viewing of the 6” indicator. Front of

board, panel or pipe mounting can be supplied.

1126P-2 Portable Indicator

The 1126P-2 is designed for portable applications. Typical examples are periodic measurements

of the pressure drop across

filters, balancing of flow rates in

heating and cooling systems and

checking of back flow prevention

devices. Meriam’s 1126P-2 consists of an 1126 D/P Indicator with 3-valve manifold and piping, 2

hoses and quick disconnects. Each instrument system is assembled

as a complete package with all the accessories mounted in a rugged, light weight case. When used as a flow measuring device, the

instrument normally comes with a 0-100% square root scale. With

all flow elements designed for the same differential, multiplying the

scale reading by the primary element’s full flow design value gives

readings directly in flow units. Scales in flow units, inches of H20,

PSI and metric units are also available.

for Differential Pressure,

Flow and Level

The Meriam Model 1120 Differential Pressure Unit is a proven and reliable

sensing element used in all Meriam Bellows Gauges. It is available in ranges

as low as 0-30” w.c. or as high as 0-500 PSI. The light weight and compact

differential pressure unit incorporates a rupture-proof and leak-proof bellows

plus other features that ensure ruggedness and reliability. This basic unit is

suitable for activating indicators, recorders, transmitters, switches, and

controllers and is available as a separate assembly for that purpose.

The 1120 consists of a high and a low pressure bellows connected to each

side of a center plate. The bellows are enclosed in end housings which in turn

are bolted to the center plate. The interior of the bellows and center plate is

completely filled with a clean, low freezing point, non-corrosive fill fluid. As

differential pressure is applied, this fill fluid moves between the bellows

through a field adjustable dampening valve in the center plate. Other external

dampening devices are not required for measurements of pulsating differential

pressure. Also, the Meriam 1120 incorporates a special design which

completely isolates the process fluid from the center plate.

When differential pressure is applied to the high and low pressure connections,

the high pressure bellows contracts, forcing fluid through the center plate into

the low pressure bellows which expands. The resulting linear motion of the low

pressure bellows is converted to a 6° rotary motion of the output shaft through

temperature compensating linkage. Over-range protection up to the pressure

rating of the housing is provided by two fluid shut off valves located on this

linkage. The output shaft is part of a low friction, “O” ring sealed shaft and

bearing assembly which carries the rotary motion to the external area of the

bellows unit and into the instrument case.

56

Meriam Process Technologies www.meriam.com ph: 800.817.7849 fax: 216.281.0228

Bellows Gauges

for Differential Pressure,

Flow and Level

Features

1020 & 1120 Accuracy

30” w.c. range 1.50% FS

50” w.c. thru 500 PSID range 0.75% FS

Option: 100” w.c. thru 50 PSID range 0.50% FS

1220 Accuracy

Before switch activation 0.75% FS

At switch activation point 2.00% FS

After switch activation 1.50% FS

Zero Elevation

100% of range (150 PSID maximum)

Suppression

15% of range with 270° pointer travel

Ordering

Information

To order any one of Meriam’s

Bellows Gauges, custommade to your specifications,

please contact your Meriam

sales representatives with

the following information:

• Model Number

• Housing Material

• Safe Working Pressure

• Bellows Material

• Differential Range

• Type of Scale

(Linear or Sq. Rt.)

• Type of Mounting

Specifications

Model

Dial Size

Housing

Bellows

Mounting

(Except 1126P)

Features

Operating Temperature

-60°F to +200°F

Full Scale Displacement

30” w.c. thru 130” w.c. range .19 Cu. In.

135” w.c. thru 60 PSID range .12 Cu. In.

75 PSID thru 500 PSID range .06 Cu. In.

1220 Switch Type

Snap action SPDT

1220 Switch Setting

Increasing -10 to 100% of differential or 10” of water

whichever is greater

Decreasing - 5% or 5” of water whichever is greater

Between set points -15% of FS minimum

1220 Switch Rating

5 amps at 125V or 250V AC

3 amps inductive or 5 amps resistive at 30VDC

Mounting Dimensions

1220 Switch Setting Accuracy

1.00% FS

1220 Dead Band

1 switch (nominal) 7% FS

2 switch (nominal) 10% FS

1020 1123 1124 1126 1224 1226 1226X 1126P-2

No Dial 3” 4½” 6” 4½” 6” 6” 6”

End Housing Center Plate Static Working Pressure Process Connections

Brass Brass 500 or 1000 PSI ¼” NPT

316 SS 316 SS or Brass (500 SWP Only) 1500, 3000 or 6000PSI ¼” & ½” NPT

Monel 316 SS 1500, 3000 or 6000PSI ¼” & ½” NPT

Beryllium Copper (30” w.c. Minimum—60 PSID Maximum)

316 Stainless Steel (50” w.c. Minimum—500 PSID Maximum)

Monel (50” w.c. Minimum—60 PSID Maximum)

Flush Panel using indicator case for mounting

3

4

Wall or

/

” NPT using universal mounting bracket

Pipe Saddle or Wall using “H” mounting Bracket and 2” U-Bolts

Special scales and ranges available Optional bellows fill fluid

Simple zero, span and linearity adjustment Additional relay options available for 1220 Series

Temperature compensation for varying ambients 270” pointer travel; red set pointer

Break-resistant acrylic viewing window Valves and Piping

NEMA 4, Die-cast aluminum case with gasketed

cover

Low friction “O” ring sealed shaft output Option for meeting NACE MR-01-75 requirements

Optional anti-parallax mirror dial Terminal Strip

CE approval for 1120 and 1220 Series (option) Built-in pulsation dampening (field adjustable)

CSA approved 1226 Models

Model 1020 Request File No. 1020:420

Model 1123 Request File No. 1123:420

Model 1124 Request File No. 1124:420

Model 1126 Request File No. 1126:420

Model 1224 Request File No. 1224:420

Model 1226 Request File No. 1226:420

Model 1226X-1 Request File No. 1226X-1:420

Model 1226X-2 Request File No. 1226X-2:420

Special cleaning for oxygen service

Measurement Instrumentation

57

Loading...

Loading...