Page 1

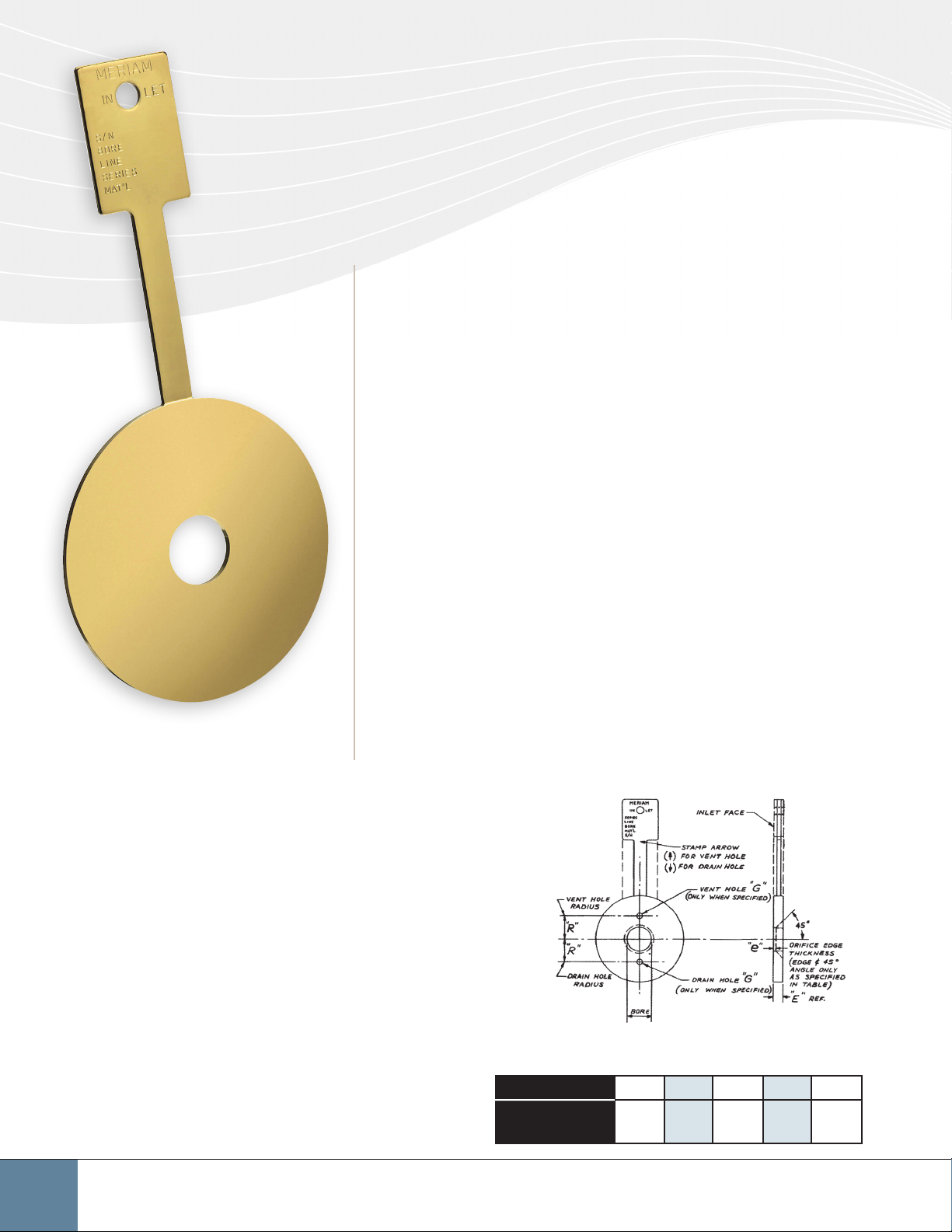

Model 951

Orice Plates

Concentric-Segmental-Eccentric

The most common primary ow element is the concentric orice plate,

often called the “sharp-edged” orice plate. Its main advantages are: low

cost, accuracy, ease of installation, variety of construction material and

quick delivery. Much test data has been compiled about orice plates

and, with the necessary information, an exacting design can be made

providing for excellent metering accuracy.

Engineered for each application, Meriam orice plates are precision bored

to exact dimensions with a sharp upstream edge to ensure accuracy.

Orice information is stamped on the unique handle. This handle is

designed to facilitate storage of the plate without damage to the orice

bore.

Standard Meriam orice plates are 304 Stainless Steel. Monel, brass, P.V.C.,

316 Stainless Steel and other materials are available. Meriam orice plate

dimensions meet ISA specications. Meriam can provide blank orice

plates for your own boring, too.

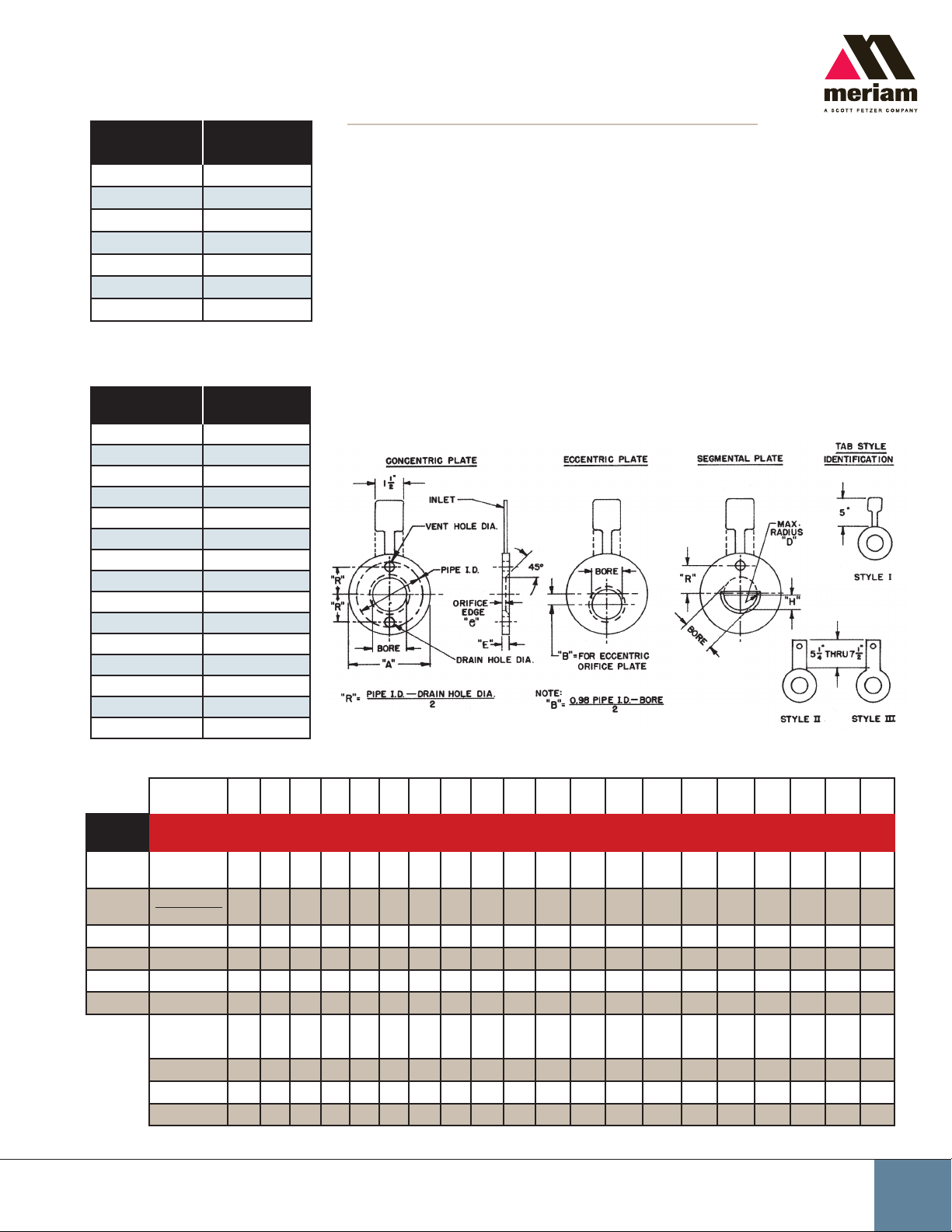

Orice Plates Design Criteria & Tolerances

Standards and specications for orice plates are listed by the ISA, AGA and

ASME.

All of these do not agree in all ways. Please indicate which specications you

require so we will provide your orice plates the way you want them.

Edges – Square and sharp, will not reect a beam of light when viewed without magnication.

Finish – 15-32 micro-inch roughness

Flatness – Flatness within 0.010 inches, per inch of dam height.

Bore – Orice bore tolerance in strict accordance with AGA. Gas Measurement Committee Report No. 3, ASME Fluid Meters Committee Report, and

with other societies’ recommendations.

Meriam has furnished many orice plates for nuclear and fossil red power

plants, chemical plants, reneries, steel mills and to original equipment

manufacturers for incorporation in their equipment and systems.

Meriam can also provide readout instruments and accessories for complete

ow metering installation.

84

Meriam Process Technologies www.meriam.com ph: 800.817.7849 fax: 216.281.0228

Line Pipe Size

Orifice Edge

Thickness “e”

Orice Edge Thickness

½”-1½” 2” - 3” 3½”-6” 8”-12” 14”-36”

1

/

1

64

”

/

1

32

”

/

1

16

8

”

/

” ¼”

Page 2

Tolerances for

Orice Bore

Model 951

Orifice Bore

Plus or Minus

Tolerances

Less Than .250” .0003

.250” to .499” .0004

.500” to 1.999” .0005

2.000” to 3.999” .0010

4.000” to 9.999” .0020

10.000” to 19.999” .0050

20.000” & up .0100

Vent/Drain

Hole Diameter

Orifice Bore

Less than 1.000” None

1.000 to 3.500”

3.501 to 4.125”

4.126 to 5.000”

5.001 to 6.000”

6.001 to 6.750”

6.751 to 7.500” ¼”

7.501 to 8.375”

8.376 to 9.250”

9.251 to 10.000”

10.001 to 10.875”

10.876 to 11.625”

11.626 to 12.500”

12.501 to 13.250”

13.251” & larger ½”

Vent or Drain

Holes “G”

3

32

/

1

8

/

5

32

/

3

16

/

7

32

/

9

32

/

5

16

/

11

32

/

3

8

/

13

32

/

7

16

/

15

32

/

Orice Plates

Concentric-Segmental-Eccentric

Orice Bore Calculations

The Meriam Engineering Department will

calculate orice bore sizes utilizing an inhouse

computer.

Bore calculations are based on the LK. Spink

precision bore calculations.

Tabulate your ow data and send it to Meriam

with your order for precise bore sizing.

”

”

”

”

”

”

”

”

”

”

”

”

Ordering Information

To order Meriam’s Model 951 orice plates

custom-made to your specications, please

contact your Meriam sales representative

with the following information:

• Flange Rating

• Line Size

• Bore Dimensions, if available

(if unknown, consult factory)

Line Pipe

Size

Meriam

Model

951C15

951B30

951B40 400# Series

951B60 600# Series

951B90 900# Series

951B150 1500# Series

125-150#

Series

250# Series

300# Series

Plate Thickness

‘E’ Meriam

STD

‘E’ AGA STD

‘E’ ISA STD

ASME

Dimensions Table

½” ¾” 1” 1¼” 1½” 2” 2½” 3” 4” 5” 6” 8” 10” 12” 14” 16” 18” 20” 22” 24”

“A” Orifice Plate O.D.

7

8

1

/

” 2¼” 2

—

1

8

2

/

”

1

8

2

/

” 2

1

8

2

/

” 2

2½” 2¾” 3

2½” 2¾” 3

1

8

/

”

— — — — —

— —

1

8

/

”

5

8

/

” 3” 3

7

8

2

/

”

7

8

2

/

” 3¼” 3¾” 4

5

8

2

/

”

5

7

8

8

/

” 2

/

” 3¼” 3¾” 4

5

7

8

8

/

” 2

/

” 3¼” 3¾” 4

1

8

/

” 3½” 3

1

8

/

” 3½” 3

1

1

8

8

/

”

/

”

1

8

/

”

1

1

8

8

/

”

/

”

3

1

7

3

8

8

/

” 4

3

8

/

” 5

3

8

/

” 5

3

8

/

” 5

5

8

/

” 6½” 6

5

8

/

” 6½” 6

1

8

/

”

1

8

/

”

1

8

/

”

1

8

/

”

8

/

” 5

1

8

/

” 5

1

8

/

” 5

1

8

/

” 5

1

8

/

”

1

8

/

”

1

8

/

”

1

8

/

”

/

” 4

7

8

/

” 5

7

8

/

” 5

1

1

8

8

/

”

/

”

1

1

8

8

/

”

/

”

1

1

8

8

/

”

/

”

7

8

8

/

” 6

/

” 7¾” 8¾” 11” 13

7

1

8

8

/

” 7

/

” 8½” 9

7

8

/

” 7” 8

7

8

/

” 7

5

8

/

” 8

7

8

/

” 8¼” 10” 11

1

8

/

”

1

8

/

”

1

8

/

”

1

8

/

”

3

/

5

8

/

” 9½” 10½” 12

1

8

/

” 9¾” 11

1

1

8

8

/

”

/

1

1

8

8

/

”

/

1

1

8

8

/

”

/

1

1

8

8

/

”

/

7

8

/

” 12

8

” 9¾” 12” 14

3

8

/

” 14

1

8

/

” 13

1

8

”

/

”

1

8

”

/

”

1

8

”

/

”

” ¼” ¼” ¼” ¼” ¼” ¼” ¼” ¼” ¼”

3

1

8

8

/

” 16

/

” 17¾” 20¼” 21

1

8

/

” 14¼” 16

5

8

/

” 15¾” 18” 19

1

8

/

” 17

7

8

/

” 17

1

8

/

”

1

8

/

” ¼” ¼” ¼”

1

8

/

”

5

8

/

” 19

1

8

/

” 16½” 19” 21

1

5

8

8

/

” 19

/

” 20½” 22

1

8

/

” 20½” 22¾” 25¼” 27¾” 29¾” — 35½”

1

1

8

8

/

”

/

” ¼” ¼” ¼” ¼” ¼” ¼”

1

1

8

8

/

”

/

”

5

7

8

8

/

” 23

/

” 26” 28¼”

1

8

/

” 21¼” 23½” 25¾” 27¾” 30½”

1

3

8

8

/

” 23

/

” 25½” 27

3

8

/

” 22¼” 24

1

8

/

” ¼” ¼” ¼” ¼”

1

8

/

” 26

5

1

8

8

/

” 25

/

” 27½” — 33”

3

3

8

8

/

”

/

”

5

/

7

7

8

/

” 28

/

3

3

8

8

/

”

/

8

” 30¼”

8

” 31

”

Orice Plates & Accutubes

3

¼”

¼”

1

8

/

”

8

/

”

85

Loading...

Loading...