Page 1

PROPELLER INSTALLATION INSTRUCTIONS

12733

IMPORTANT: This document guides our dealers, boatbuilders, and company service personnel in the proper installation or

service of our products. If you have not been trained in the recommended servicing or installation procedures for these or similar

Mercury Marine products, have the work performed by an authorized Mercury Marine dealer technician. Improper installation or

servicing of the Mercury product could result in damage to the product or personal injury to those installing or operating the

product.

NOTE:

Propeller Installation

Some propeller installations may require the use of special OEM mounting hardware not included with this propeller. Use only

hardware specified by the engine OEM. Special trim tab or anodic plate may need to be purchased separately for propeller

clearance. Use the original propeller hardware or order replacements for worn or damaged parts.

Performing service or maintenance without first disconnecting the battery can cause product damage, personal injury, or death

due to fire, explosion, electrical shock, or unexpected engine starting. Always disconnect the battery cables from the battery

before maintaining, servicing, installing, or removing engine or drive components.

Rotating the propeller shaft may cause the engine to crank over and start. To prevent this type of accidental engine starting

and possible serious injury caused from being struck by a rotating propeller, always turn the ignition key or lanyard stop switch

to the "OFF" position and remove the spark plug leads from the spark plugs while servicing.

After completing installation, place these instructions with the product for the owner's future use.

WARNING

!

WARNING

!

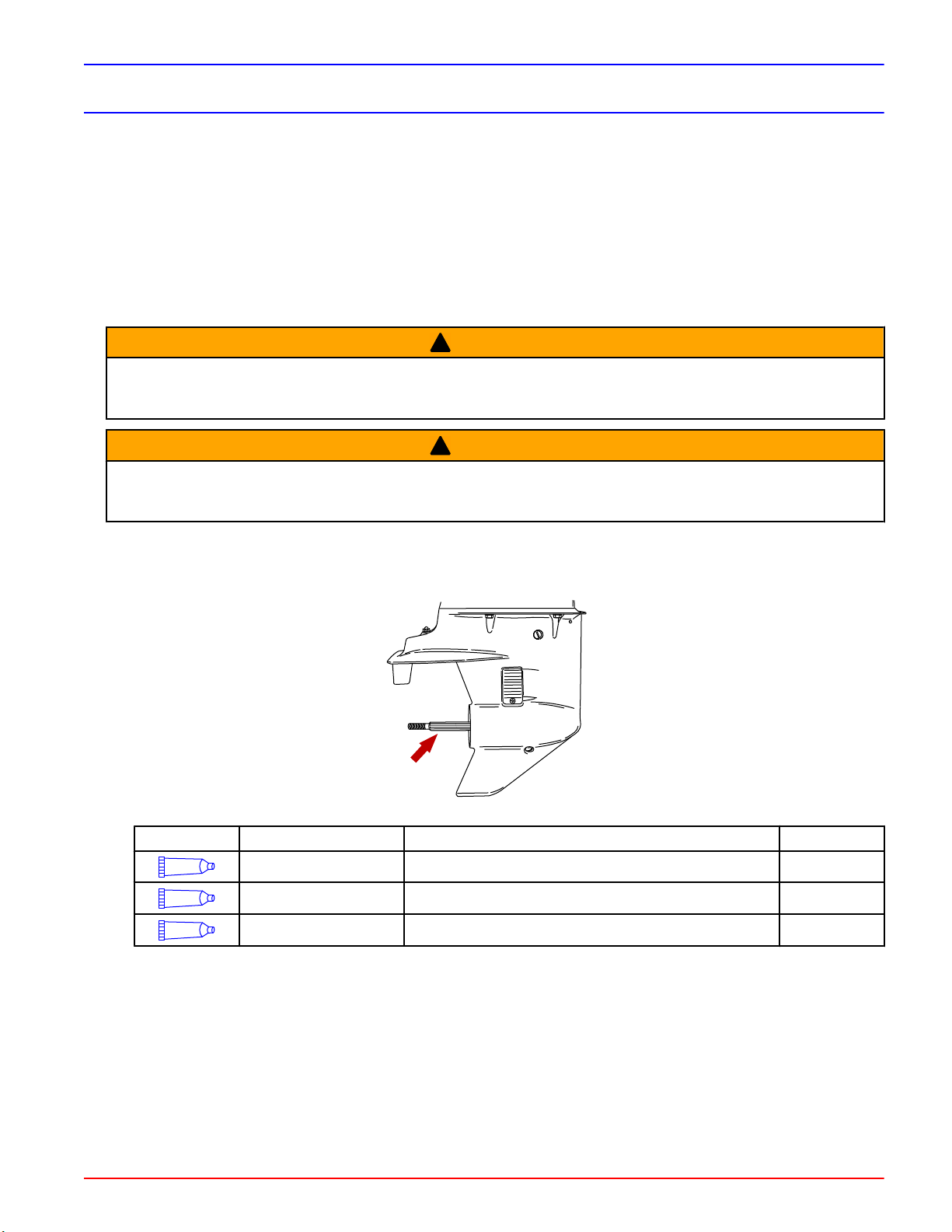

1. Disconnect all of the battery leads from the battery.

2. Remove the spark plug leads and ground them to the engine block.

3. Lubricate the propeller shaft splines with one of the following lubricants.

Tube Ref No. Description Where Used Part No.

34

94

95

Special Lubricant 101 Propeller shaft splines 92-802865Q02

Anti-Corrosion Grease Propeller shaft splines 92-802867Q 1

2-4-C with Teflon Propeller shaft splines 92-802859A 1

Flo‑Torq I Propeller Installation

1. Install the thrust washer onto the propeller shaft.

2. Install the propeller.

90-830296005 FEBRUARY 2010 © 2010 Mercury Marine Page 1 / 7

Page 2

PROPELLER INSTALLATION INSTRUCTIONS

a

b

c

d

26903

b

13276

a

c

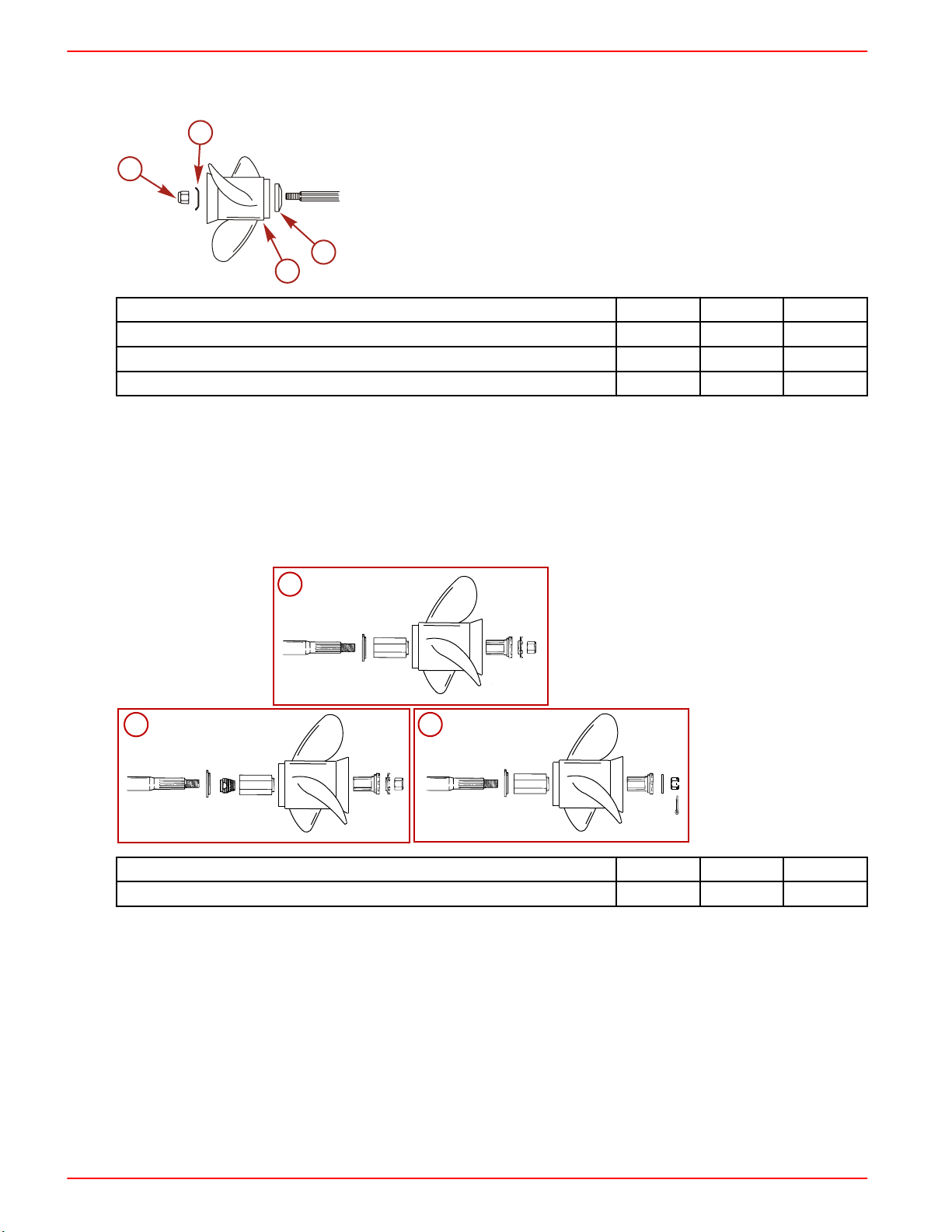

3. Install the tab washer, and secure with the nut. Tighten the nut to the specified torque. Bend the tabs on the tab washer

onto the nut.

a - Nut

b - Tab washer

c - Propeller

d - Thrust washer

Description Nm lb‑in. lb‑ft

6–15 hp propeller nut 11.3 100

18–25 hp propeller nut 22.6 16.7

30–60 hp propeller nut 74.6 55

4. Rotate the propeller to verify interference or binding does not exist between the gear housing and the propeller.

Flo‑Torq II Propeller Installation

1. Install and align all of the components.

2. Tighten the nut to the specified torque.

3. Bend the tabs of the tab washer into the rear thrust hub.

4. The propeller must be locked between the forward thrust washer and aft adapter. The propeller must not move on the

propeller shaft.

a - Mercury, Mariner,

Mercury MerCruiser,

Force, Honda®

b - Revolution 4,

Tempest Plus,

Trophy Plus, and

Bravo I

c - Mariner, Evinrude®,

Johnson®, OMC®,

Suzuki®, Yamaha®,

Tohatsu®, Nissan®,

Volvo®, Honda®

Description Nm lb‑in. lb‑ft

Propeller nut 74.6 55

5. Rotate the propeller to verify interference or binding does not exist between the gear housing and the propeller.

Flo‑Torq III and Flo‑Torq IV Propeller Installation

1. Install and align all of the components.

2. Tighten the nut to the specified torque.

3. Bend the tabs of the tab washer into the rear thrust hub.

Page 2 / 7 90-830296005 FEBRUARY 2010

Page 3

PROPELLER INSTALLATION INSTRUCTIONS

43667

43670

13340

a

b

4. The drive sleeve must be locked between the forward thrust washer and aft adapter.

a - Flo‑Torq III propellers

b - Flo‑Torq IV propellers

Description Nm lb‑in. lb‑ft

Propeller nut 74.6 55

5. Rotate the propeller to verify interference or binding does not exist between the gear housing and the propeller.

NOTE: A small amount of rotation play and forward aft play is normal.

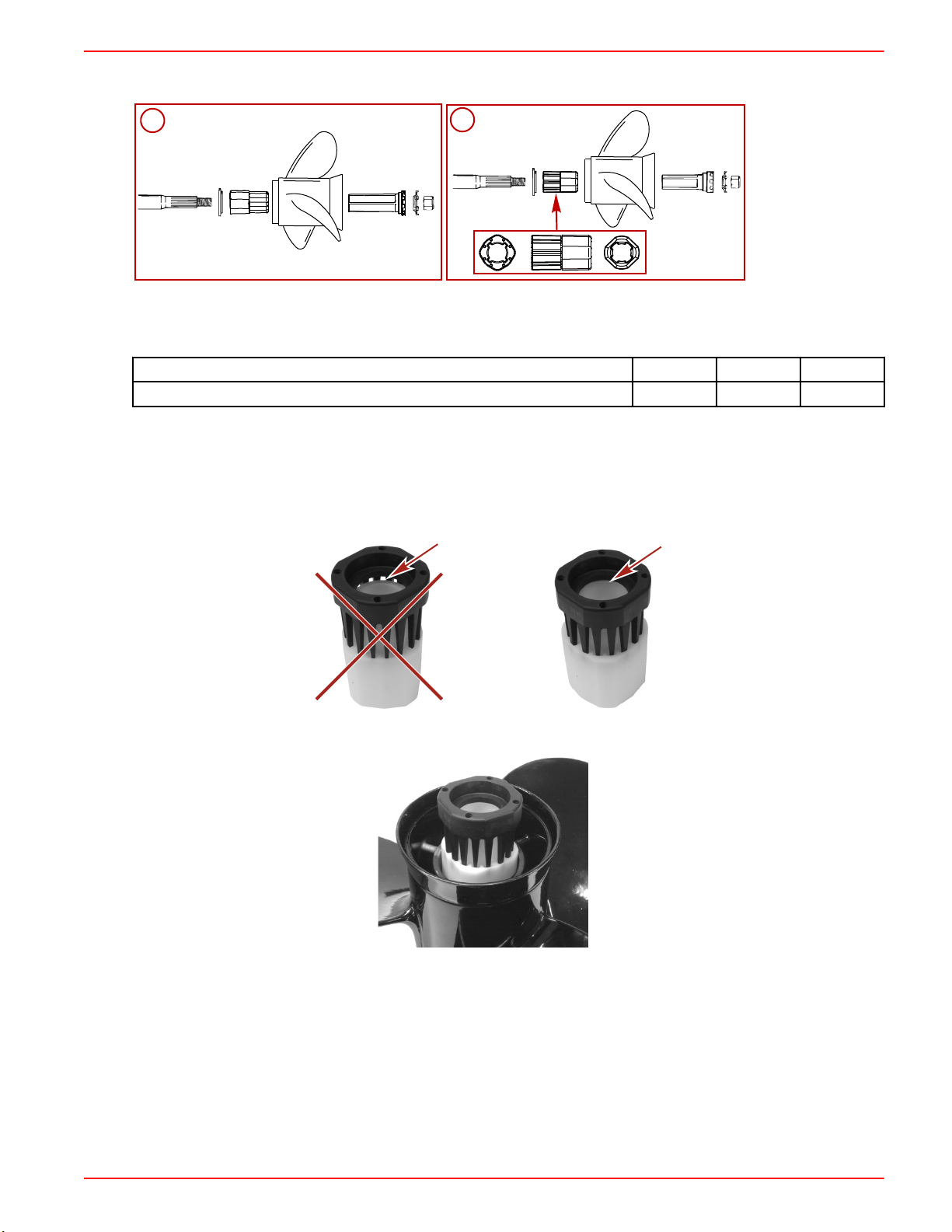

Flo‑Torq Reflex Drive Hub Installation

Installing the Drive Sleeve into the Propeller

1. Assemble the drive sleeve with the aft drive sleeve. Ensure there is no gap between the drive sleeve and the aft drive sleeve.

2. Insert the drive sleeve assembly onto the propeller and push the drive sleeve assembly onto the propeller.

90-830296005 FEBRUARY 2010 Page 3 / 7

Page 4

PROPELLER INSTALLATION INSTRUCTIONS

43671

a

43668

a

b

c

d

e

43652

a

b

43672

3. Install the aft washer onto the drive sleeve assembly and lightly tap the drive sleeve assembly into the propeller. The aft

washer will contact the propeller when the drive sleeve assembly is properly seated.

a - Aft washer

IMPORTANT: The Flo‑Torq Reflex drive hub requires the use of the thrust washer that is included with the drive hub kit.

Mercury Outboard Application

1. Install the thrust washer onto the propeller shaft.

2. Install the propeller.

3. Install the aft washer, the tab washer, and secure with the propeller nut included with the kit. Tighten the nut to the specified

torque. Bend the tabs on the tab washer onto the nut.

IMPORTANT: The Flo‑Torq Reflex drive hub requires the use of the propeller nut included with the drive hub kit. The use

of a propeller nut that was not included with the Flo‑Torq Reflex drive hub kit will result with the nylon portion of the locknut

not fully engaging the propeller shaft threads.

a - Thrust washer (Mercury/Yamaha)

b - Propeller

c - Aft washer

d - Tab washer

e - Nut

4. Rotate the propeller to verify interference or binding does not exist between the gear housing and the propeller.

Description Nm lb‑in. lb‑ft

Nut 74.6 55

NOTE: A small amount of rotation play and forward aft play is normal.

Honda and Yamaha Outboard Application

1. Install the correct thrust washer onto the propeller shaft.

Yamaha application

a b - Honda application

2. Install the propeller.

Page 4 / 7 90-830296005 FEBRUARY 2010

Page 5

PROPELLER INSTALLATION INSTRUCTIONS

a

b

c

d

e

43653

a

b

c

d

e

43654

3. Install the aft washer, the tab washer, and secure with the propeller nut included with the outboard. Tighten the nut to the

specified torque. Bend the tabs on the tab washer onto the nut.

4. Rotate the propeller to verify interference or binding does not exist between the gear housing and the propeller.

NOTE: A small amount of rotation play and forward aft play is normal.

Honda outboard application

a - Thrust washer (Honda)

b - Propeller

c - Aft washer

d - Tab washer

e - Nut

Description Nm lb‑in. lb‑ft

Nut 74.6 55

Yamaha outboard application

a - Thrust washer (Mercury/Yamaha)

b - Propeller

c - Aft washer

d - Tab washer

e - Nut

Description Nm lb‑in. lb‑ft

Nut 74.6 55

Bravo Three Propeller Installation

IMPORTANT: Mercury Marine Bravo Three propellers are matched sets. Do not operate the drive without a front and rear

propeller of the same pitch.

1. Apply a liberal amount of one of the following lubricants to the inner and outer propeller shafts.

2. Slide the forward thrust hub onto the outer propeller shaft with the tapered end of the hub facing aft.

3. Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the outer shaft.

4. Secure it with the forward propeller nut and tighten to the specified torque.

5. Slide the aft thrust hub onto the inner propeller shaft with the tapered end of the hub facing aft.

6. Align the splines of the propeller with the splines on the shaft and slide the propeller into place on the inner shaft.

90-830296005 FEBRUARY 2010 Page 5 / 7

Page 6

PROPELLER INSTALLATION INSTRUCTIONS

a

b

c

d

e

f

g

h

43655

i

j

k

a

b

c

6403

7. Secure it with the aft propeller nut and tighten to the specified torque.

Tube Ref No. Description Where Used Part No.

a - Outer propeller shaft

b - Inner propeller shaft

c - Forward thrust hub

d - Forward propeller

e - Forward propeller nut

f - Aft thrust hub

g - Aft propeller

h - Aft propeller nut

i - Anode

j - Washers

k - Screw

34

94

95

Description Nm lb‑in. lb‑ft

Forward propeller nut 136 100

Aft propeller nut 81 60

Anode screw 27 20

IMPORTANT: Check the tightness of both propellers after 20 hours of operation. Tighten the propeller nuts if necessary.

Do not operate the vessel with a loose propeller.

Special Lubricant 101 Propeller shaft splines 92-802865Q02

Anti-Corrosion Grease Propeller shaft splines 92-802867Q 1

2-4-C Marine Lubricant

with Teflon

Propeller shaft splines 92-802859A 1

Propeller Inspection and Maintenance

• Inspect the leading edge of the propeller frequently for nicks, gouges, and damage.

• Propellers with large, deep dents, gouges, or torn metal should be replaced or repaired.

• Mineral deposits on stainless steel propellers can be caused by an inoperative or missing MerCathode system.

NOTE: Mineral deposits can be removed with household cleaners such as vinegar or other cleaners that remove lime and

mineral deposits.

Leading edge

a b - Fatigue crack

c - Cup

Page 6 / 7 90-830296005 FEBRUARY 2010

Page 7

PROPELLER INSTALLATION INSTRUCTIONS

13391

abc

d

Propeller Basics

Consult the engine's Owners, Operation and Maintenance Manual for the recommended wide‑open throttle (WOT) operating

range of the engine.

Select a propeller that allows the engine to operate within the WOT RPM operating range.

IMPORTANT: Always perform WOT RPM tests with the boat in its normal configuration; i.e. fuel load, passenger load, equipment

load, skiers, etc.

Use the following information to help select the proper propeller for the vessel:

• Adding 25 mm (1 in.) of propeller pitch will reduce the WOT RPM by 150 to 200 RPM.

• Subtracting 25 mm (1 in.) of propeller pitch will increase the WOT RPM by 150 to 200 RPM.

• Switching from a three blade to a four blade propeller with the same pitch generally reduces WOT RPM by 50 to 100 RPM.

Performance Vent System

The performance vent system (PVS) was created to help our customers optimize Mercury Propellers on their personal boat and

unique boating conditions. PVS allows the boater to custom tune the venting of the propeller blades to dial in the perfect

acceleration and cruising performance.

On acceleration, exhaust is drawn out of the vent hole located behind each propeller blade. When the next propeller blade strikes

this aerated water, less force is required to push through the aerated water versus solid water. This allows the engine RPM to

rise more rapidly. Once on plane speed is reached, water flowing over the vent holes seal the exhaust gas in the hub, allowing

the propeller to again operate in solid nonaerated water. By varying the size of the exhaust vent hole, the rate at which the engine

RPM rises can now be controlled.

Laser II, Trophy Plus, and Tempest Plus propellers are shipped with medium PVS vent plugs; and Mirage Plus, Offshore,

Revolution 4, and HighFive propellers are shipped with solid PVS vent plugs offering all‑around performance for most boating

situations.

Acceleration Problem/Solution

1. Slow/sluggish acceleration to plane (engine unable to push solid water away quickly).

• Solution: Increase ventilation by using a plug with larger holes.

2. Over ventilation ‑ the load on the propeller is significantly reduced by the mixing of exhaust into the water stream causing

an engine overrevving condition before the vessel is on plane.

• Solution: Decrease ventilation by using a plug with a smaller hole or use a solid plug.

a - Solid plug

b - Large ‑ 12 mm (0.470 in.)

c - Medium ‑ 9 mm (0.350 in.)

d - Small ‑ 7 mm (0.280 in.)

Products of Mercury Marine

W6250 Pioneer Road

Fond du Lac, WI 54936-1939

90-830296005 FEBRUARY 2010 Page 7 / 7

Mercury, Mercury Marine, MerCruiser, Mercury MerCruiser, Mercury Racing, MotorGuide, Mercury Precision Parts,

Mercury Propellers, Mariner, Quicksilver, #1 On The Water, Alpha, Bravo One, Bravo Two, Bravo Three, Pro Max,

OptiMax, Sport-Jet, K-Planes, MerCathode, RideGuide, SmartCraft, Zero Effort, VesselView, Zeus, Axius, Total

Command, Skyhook, SeaCore, M with Waves logo, Mercury with Waves logo, and SmartCraft logo are all trademarks

or registered trademarks of Brunswick Corporation. Mercury Product Protection logo is a registered service mark of

Brunswick Corporation.

Loading...

Loading...