Page 1

IMPORTANT

INFORMATION

1

D

OUTBOARD INSTALLATION

Page 2

Table of Contents

Page

Determining Recommended Outboard

Mounting Height 1D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notice to Installer and Owner 1D-2. . . . . . . . . . . . . . . . . .

Boat Horsepower Capacity 1D-2. . . . . . . . . . . . . . . . .

Outboard Remote Control 1D-2. . . . . . . . . . . . . . . . . .

Selecting Accessories For The Outboard 1D-2. . . . .

Selecting Steering Cables and Remote Control

Cables 1D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locate Center line Of The Outboard 1D-3. . . . . . . . .

Drilling Outboard Mounting Holes 1D-3. . . . . . . . . . . .

Lifting Outboard 1D-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastening Outboard To The Transom 1D-4. . . . . . . .

Single Steering Cable and Steering Link

Rod Installation 1D-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Ride Guide Steering Cable to the

Outboard 1D-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Link Rod Installation 1D-5. . . . . . . . . . . . . . .

Co-Pilot Installation (Tiller Handle models) 1D-6. . . . . . .

Remote Control Installation 1D-7. . . . . . . . . . . . . . . . . . . .

Required Side Mount Remote Control or Ignition

Key Switch Assembly 1D-7. . . . . . . . . . . . . . . . . . . . . . . . .

Boats Equipped with Side Mount

Remote Control 1D-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Boats Equipped with Panel Or Console Mount

Remote Control 1D-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Remote Wiring Harness to the Engine 1D-7

Shift and Throttle Cable Installation to the Outboard1D-8

Shift Cable Installation 1D-8. . . . . . . . . . . . . . . . . . . . .

Throttle Cable Installation 1D-9. . . . . . . . . . . . . . . . . .

Battery Connections 1D-10. . . . . . . . . . . . . . . . . . . . . . . . .

Set Up Instructions For Oil Injection System 1D-10. . . .

Filling The Oil Injection System 1D-10. . . . . . . . . . . . .

Bleeding Air From The Oil Injection System 1D-11. .

Adjusting The Oil Injection Pump 1D-11. . . . . . . . . . .

Trim Tab Adjustment 1D-12. . . . . . . . . . . . . . . . . . . . . . . . .

90-830234R3 DECEMBER 19971D-0 - IMPORTANT INFORMATION

Page 3

Notice to Installer and Owner

Outboard Remote Control

This manual as well as safety labels posted on the

outboard use the following safety alerts to draw your

attention to special safety instructions that should be

followed.

W ARNING

WARNING – Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION

CAUTION – Hazards or unsafe practices which could

result in minor injury or product or property damage.

Boat Horsepower Capacity

U.S. COAST GUARD CAPACITY

MAXIMUM HORSEPOWER XXX

MAXIMUM PERSON

CAPACITY (POUNDS) XXX

MAXIMUM WEIGHT

CAPACITY XXX

Do not overpower or overload your boat. Most boats

will carry a required capacity plate indicating the

maximum acceptable power and load as determined

by the manufacturer following certain federal guidelines. If in doubt, contact your dealer or the boat manufacturer.

W ARNING

Using an outboard that exceeds the maximum

horsepower limit of a boat can: 1. cause loss of

boat control 2. place too much weight at the transom altering the designed flotation characteristics of the boat or 3. cause the boat to break apart

particularly around the transom area. Overpowering a boat can result in serious injury , death, or

boat damage.

The remote control connected to your outboard must

be equipped with a start-in-gear protection device.

This prevents the engine from starting when the outboard is in gear.

WARNING

Avoid serious injury or death from a sudden unexpected acceleration when starting your engine. The design of this outboard requires that

the remote control used with it must have a built

in start-in-gear protection device.

Selecting Accessories For

The Outboard

Genuine Mercury Marine Quicksilver Accessories

have been specifically designed and tested for your

outboard.

Mercury Marine Quicksilver accessories are available from Mercury Marine dealers.

Some accessories not manufactured or sold by Mercury Marine are not designed to be safely used with

your outboard or outboard operating system. Acquire

and read the installation, operation, and maintenance manuals for all your selected accessories.

WARNING

Check with your dealer before installation of accessories. The misuse of acceptable accessories or the use of unacceptable accessories can

result in serious injury , death, or product failure.

Selecting Steering Cables

and Remote Control Cables

Refer to “Quicksilver Accessories Guide” to determine correct length of steering cables and remote

control cables.

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-1

IMPORT ANT : Steering cables and remote control

cables must be the correct length. Sharp bends

on too-short cables result in “kinks”; too-long

cables require unnecessary bends and/or loops.

Both conditions place extra stress on the cables.

Page 4

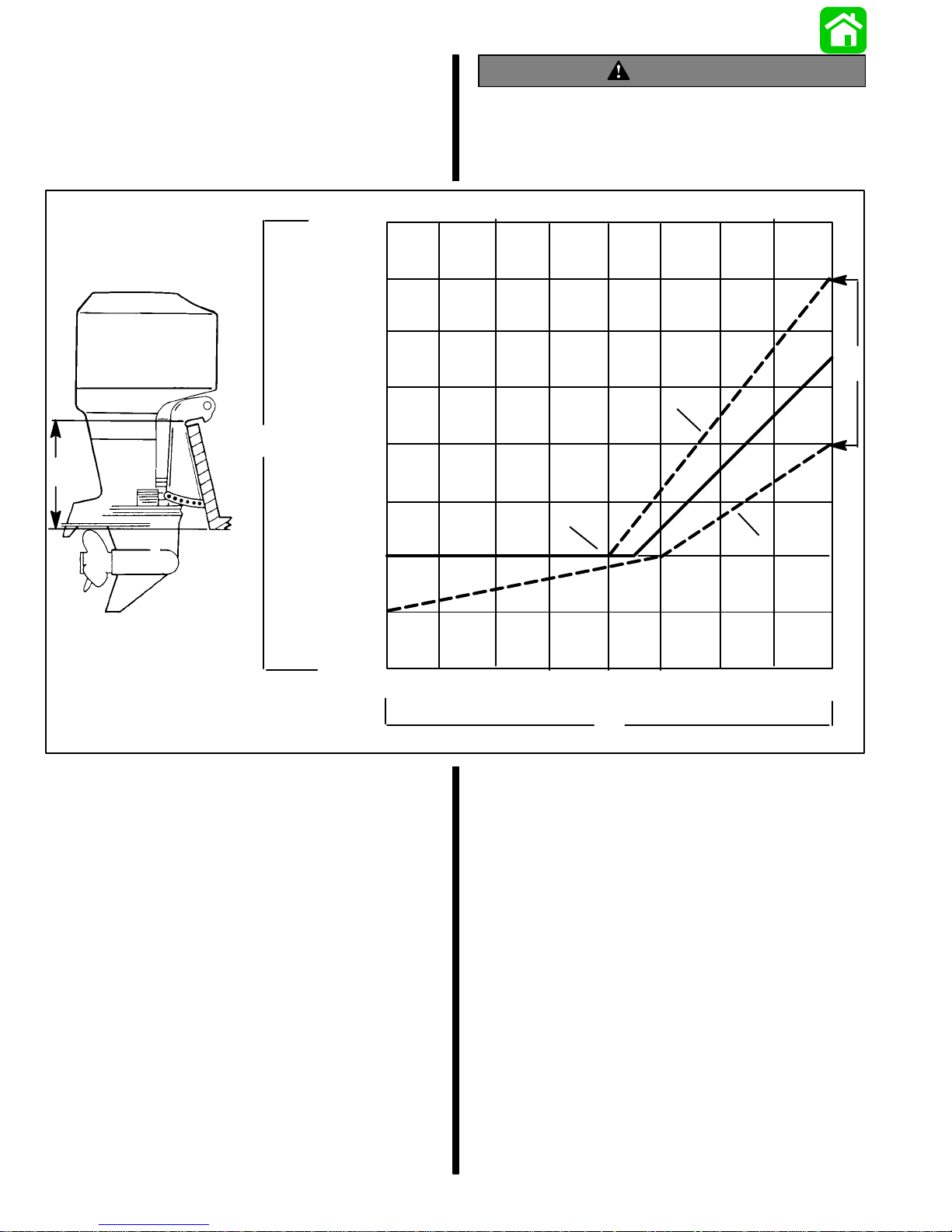

Determining Recommended

WARNING

Outboard Mounting Height

26 in.

(660m

m)

25 in.

(635m

m)

24 in.

(609m

m)

23 in.

(584m

m)

e

e

22 in.

(560m

m)

21 in.

(533m

m)

20 in.

(508m

m)

19 in.

(482m

m)

Boat instability can occur at high speeds by

installing engine at the wrong transom height.

Contact the boat manufacturer for their recommendations for a specific engine installation.

b

c

a

d

10

NOTE: Add 5 in. (127mm) for XL models and 10 in.

(254mm) for XXL models to listed outboard mounting

height.

a. This solid line is recommended to determine

the outboard mounting height.

IMPORTANT: Increasing the height of outboard

generally will provide the following: 1) Less

steering torque, 2) more top speed, 3) greater

boat stability , but, 4) will cause more prop “break

loose” which may be particularly noticeable

when planing off or with heavy load.

b. These broken lines represent the extremes of

known successful outboard mounting height

dimensions.

c. This line may be preferred to determine out-

board mounting height dimension, if maximum speed is the only objective.

20 30 40 50 60 70 80

f

d. This line may be preferred to determine out-

board mounting height dimension for dual

outboard installation.

e. Outboard mounting height (height of out-

board transom brackets from bottom of boat

transom). For heights over 22 in. (560mm), a

propeller, that is specifically designed for surfacing operation, such as the “Laser” and “Mirage” series, usually are preferred.

f. Maximum boat speed anticipated.

90-830234R3 DECEMBER 19971D-2 - IMPORTANT INFORMATION

Page 5

Locating Center Line Of The

Outboard

Locate (and mark with pencil) the vertical centerline

(a) of boat transom.

BA

a

DC

a - Centerline of Transom

NOTE: When drilling into a fiberglass boat, place

masking tape directly onto boat where mounting

holes will be drilled to help prevent fiberglass from

chipping.

Use a 17/32 inch (13.5mm) diameter drill bit and drill

4 mounting holes perpendicular to and thru transom.

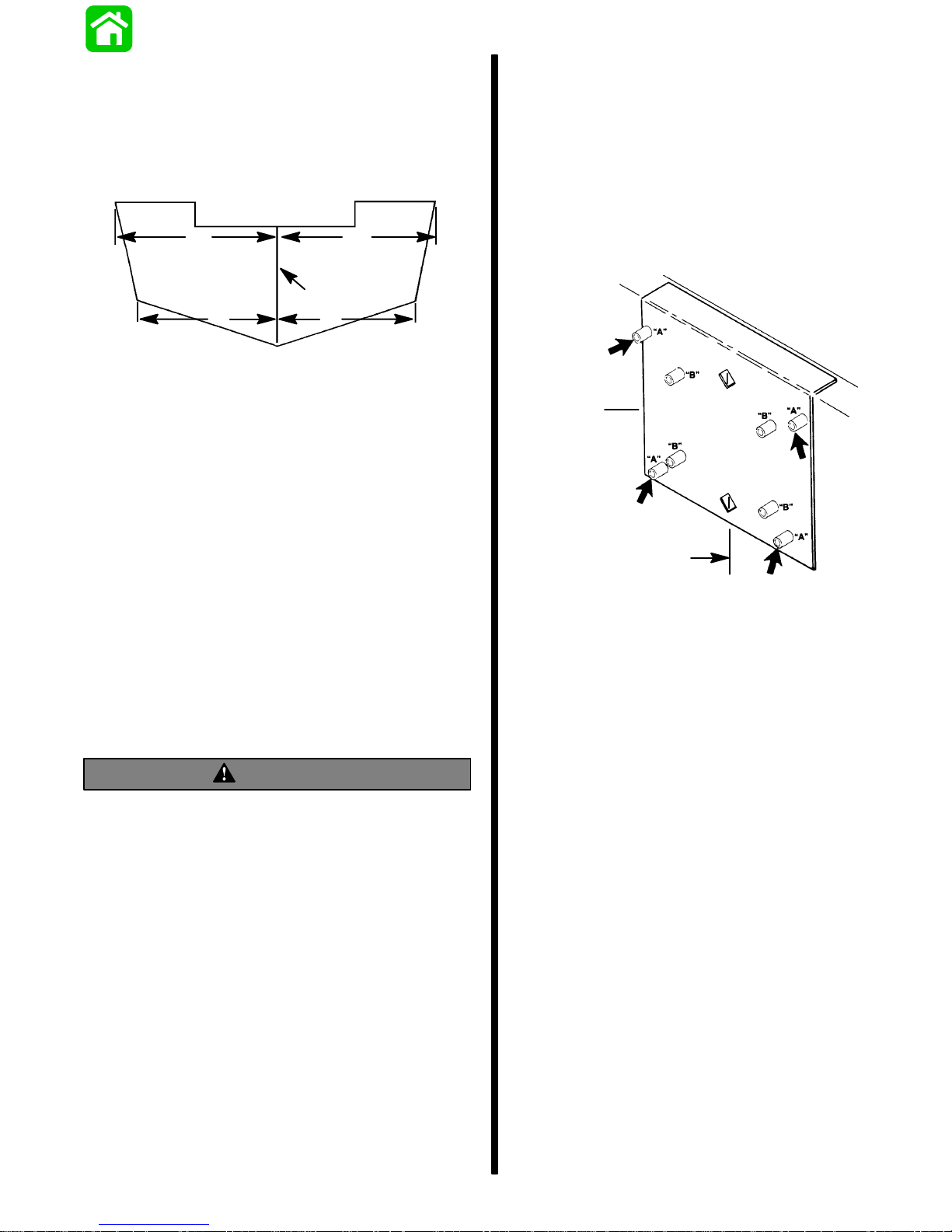

IMPORTANT: If using “Transom Drilling Fixture”

(part number 91–98234A2), use drill guide holes

marked “A” when drilling outboard mounting

holes.

NOTE: Dimensions “A” & “B” and “C” & “D” are equal

length.

IMPORT ANT : During installation of dual outboards,

the following is recommended. A minimum of 221/2

inches (570mm) centerline to centerline width is recommended. This is required to alleviate cowling interference during lock to lock turns if one outboard

would be in the full tilt position, while the other outboard(s) are in the vertical running position.

Drilling Outboard Mounting Holes

IMPORT ANT : Before drilling any mounting holes,

carefully read “Determining Recommended Outboard Mounting Height,” preceding. There is a

3/4 inch (19mm) difference between outboard

mounting holes in transom brackets.

WARNING

DO NOT, under any circumstances, allow upper

outboard mounting bolts to be closer than 1 inch

(25.4mm) from top of boat transom. Upper

mounting bolts must never be installed thru

shims.

b

a

a – Centerline of Transom

b – Transom Drilling Fixture (91–98234A2)

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-3

Page 6

Lifting Outboard

Installing Outboard To Boat

WARNING

Verify that the lifting ring is threaded into the flywheel a minimum of 5 turns and that hoist has a

maximum lift capacity over 500 lbs. (227 kg) BEFORE lifting outboard.

1. Electric Start Models – Remove plastic cap from

center of flywheel. Thread lifting ring into flywheel

hub a minimum of 5 turns. Replace plastic cap after installation.

b

a

Transom

IMPORT ANT : If boat is equipped with thru tilt tube

steering, steering cable end must be installed

into tilt tube of outboard (port outboard only for

dual outboard installations) before securing outboard to transom. Refer to ”Steering Cable and

Steering Link Rod Installation” following.

Refer to “Determining Recommended Outboard Motor Mounting Height”, preceding and position outboard on boat transom, to align mounting holes in

transom bracket that will place the outboard nearest

to the recommended mounting height.

CAUTION

Marine sealer must be used on shanks bolts to

make a water-tight installation.

IMPORT ANT: DO NOT use an impact driver when

tightening transom bolts.

Apply marine sealer to shanks of mounting bolts (not

threads) and secure outboard to transom with 4 bolts,

flat washers and locknuts, as shown. Be sure that installation is water-tight.

a - Lifting Ring

b - Plastic Cap – Replace After Installation

2. Manual Start Models – Use lifting eye on engine

and lift outboard on boat transom.

WARNING

Before operation, the outboard must be correctly

installed with four mounting bolts shown. Failure

to correctly fasten outboard could result in outboard ejecting off boat transom causing serious

injury, death, or property damage.

a

b

c

b

c

a - 1/2 Inch Diameter Bolts

b - Flat Washers

c - Locknuts

a

90-830234R3 DECEMBER 19971D-4 - IMPORTANT INFORMATION

Page 7

Single Steering Cable and

Steering Link Rod Installation

Steering Link Rod

Installation

NOTE: These instructions are for single cable–single

outboard installations. Instructions for mounting dual

engines are included with the applicable dual engine

attaching kit. Refer to “Quicksilver Accessories

Guide” to determine correct kit.

Refer to “Quicksilver Accessories Guide” to determine correct length of steering cable.

IMPORTANT: Steering cable must be correct

length. Sharp bends on too-short of a cable result in “kinks;” too-long of a cable require unnecessary bends and/or loops. Both conditions

place extra stress on the cable.

Install steering mount and steering wheel in accordance with installation instructions that accompany

each.

Installing Ride Guide Steering Cable

To The Outboard

IMPORTANT: Before installing steering cable in

tilt tube, lubricate entire cable end with Quicksilver 2-4-C Marine Lubricant.

IMPORT ANT: The steering link rod that connects

the steering cable to the engine must be fastened

using special washer head bolt (“a” – Part Number 10-14000) and self locking nuts (“b”& “c”–

Part Number 11-34863). These locknuts must

never be replaced with common nuts (non locking) as they will work loose and vibrate off freeing the link rod to disengage.

WARNING

Disengagement of a steering link rod can result

in the boat taking a full, sudden, sharp turn. This

potentially violent action can cause occupants to

be thrown overboard exposing them to serious

injury or death.

3. Assemble steering link rod to steering cable with

two flat washers (d) and nylon insert locknut (“b”

– Part Number 1 1-34863). Tighten locknut (b) until it seats, then back nut off 1/4 turn.

4. Assemble steering link rod to engine with special

washer head bolt (“a” – Part Number 10-14000)

and nylon insert locknut (“c”– Part Number

11-34863). First torque bolt (a) to 20 lb. ft. (27.0

N·m), then torque locknut (c) to 20 lb. ft. (27.0

N·m).

NOTE: Ride Guide steering cable is lubricated at the

factory and requires no additional lubrication at initial

installation.

1. Lubricate seal (a) inside of outboard tilt tube and

entire cable end (b) with Quicksilver 2-4-C Marine Lubricant.

2. Insert steering cable end thru outboard tilt tube

and secure steering cable to tilt tube with steering

cable attaching nut (c), as shown. Torque nut to

35 lb. ft. (47.5 N·m).

95

c

95

a

b

a

d

b

c

WARNING

After installation is complete (and before operating outboard), check that boat will turn right

when steering wheel is turned right and that boat

will turn left when steering wheel is turned left.

Check steering thru full range (left and right) and

at all tilt angles to assure interference-free movement.

95

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-5

2-4-C With Teflon (92-825407A12)

Page 8

Co-Pilot Installation (Tiller

Handle models)

WARNING

Avoid possible serious injury or death from loss

of boat control. The Co-pilot assembly must be

installed and adjusted to maintain sufficient

steering friction to prevent the outboard from

steering into a full turn if the tiller handle is released.

1. Thread the friction collar (a) onto the starboard

side of the tilt tube. Tighten securely and position

the adjustment knob toward front of outboard.

2. Insert pilot rod (b) into the friction collar.

a

IMPORT ANT : The co-pilot link rod (c) must be fastened using self locking nylon insert locknuts

(“f”& “g”– Part Number 11-45592).These locknuts must never be replaced with common nuts

(non locking) as they will work loose and vibrate

off freeing the link rod to disengage.

WARNING

Disengagement of the co-pilot link rod can result

in the boat taking a full, sudden, sharp turn. This

potentially violent action can cause occupants to

be thrown overboard exposing them to serious

injury or death.

3. Lubricate both ends of the link rod with Quicksilver 2-4-C w/Teflon Marine Lubricant. Install link

rod between the tiller handle mount and pilot rod

as shown.

b

f

e

d

c

e

g

c - Co-Pilot Link Rod

d - Spacer (Hidden) - Place in the Upper Mounting Hole

For The Link Rod.

e - Flat Washer

f - Locknut - Torque to 120 lb. in. (13.6 N·m)

g - Locknut - Tighten Until it Seats; DO NOT exceed 120 lb.

in. (13.6 N·m), Then Back Off The Locknut 1/4 Turn.

90-830234R3 DECEMBER 19971D-6 - IMPORTANT INFORMATION

Page 9

Remote Control Installation

Shift and Throttle Cable

Refer to “Quicksilver Accessories Guide” to determine correct length of remote control cables.

IMPORT ANT : Remote control cables must be correct length. Sharp bends on too-short cables result in “kinks;” too-long cables require unnecessary bends and/or loops. Both conditions place

extra stress on the cables.

IMPORTANT: Install control cables to remote

control and mount remote control BEFORE attaching control cables to engine. Refer to installation instructions included with remote control.

Required Side Mount

Remote Control or Ignition

Key Switch Assembly

Boats Equipped with Side Mount

Remote Control

A Quicksilver Commander 2000 series Side Mount

Remote Control equipped with a warning horn must

be used with this outboard. This warning horn is necessary for the engine warning system.

Installation To The Outboard

Install the shift cable and throttle cable into the remote control and mount the remote control following

instructions which are provided the remote control.

NOTE: Install the shift cable before the throttle cable.

The shift cable is the first cable to move when the remote control handle is moved into gear.

Shift Cable Installation

1. Pull up the cowl seal and remove the port side

rubber grommet (a).

a

2. Position the remote control and outboard into

neutral.

3. Slide shift actuator (b) toward the rear of engine

(reverse gear) until resistance is felt. Measure

distance (c) between mounting stud and barrel

retainer.

a

a -Warning Horn

Boats Equipped with Panel Or

Console Mount Remote Control

A Quicksilver Ignition Key/Choke Assembly

equipped with a warning horn must be used with this

engine. This warning horn is necessary for the engine warning system.

a

4. Push the cable end (d) in (towards cable barrel)

until resistance is felt. Adjust the cable barrel (e)

to attain distance (c).

e

d

c

b

a - Warning Horn

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-7

Page 10

5. Place cable barrel into retainer and fasten the

cable end to mounting stud with nylon washer (f)

and locknut (g). Tighten locknut against the nylon

washer, then back-off the locknut 1/4 turn.

6. Check shift cable adjustments as follows:

a. With remote control in forward the propshaft

should lock solidly in gear. If it does not, adjust the cable barrel closer to the cable end

guide.

3. Adjust throttle cable barrel (b) so the barrel will be

able to slip into the retainer when the cable end

is on the mounting stud and there is a slight preload against the stop.

4. Check preload on throttle cable by placing a thin

piece of paper between adjustment screw and

stop. Preload is correct when the paper can be removed without tearing, but has some drag in it.

Readjust cable barrel if necessary.

5. Place the throttle cable barrel into the top retainer

hole and the cable end on the cable mounting

stud. Fasten throttle cable to the mounting stud

with nylon washer (c) and locknut (d). Tighten

locknut against the nylon washer, then back-off

the locknut 1/4 turn.

6. Lock the cable barrels in-place with cable latch

(e).

b. Shift remote control into neutral. The prop-

shaft should turn freely without drag. If not,

adjust the barrel away from the cable end

guide. Repeat steps a and b.

c. Shift remote control into reverse while turning

propeller. The propshaft should lock solidly in

gear. If not, adjust the barrel away from the

cable end guide. Repeat steps a thru c.

d. Return remote control handle to neutral. The

propeller should turn freely without drag. If

not, adjust the barrel closer to the cable end

guide. Repeat steps a thru d.

Throttle Cable Installation

NOTE: Attach Shift cable to engine prior to attaching

throttle cable.

1. Position the remote control handle into neutral

detent.

2. Position adjustment screw (a) against the stop.

a

b

d

c

e

7. Lubricate the port side rubber grommet and reinstall into cowl. Slip the grommet over the control

cables. Push the cowl seal back into place.

90-830234R3 DECEMBER 19971D-8 - IMPORTANT INFORMATION

Page 11

NOTE: The rubber grommet has to be lubricated to

ease installation.

f

f

f – Lubricant

Connecting Remote Wiring

Harness To The Engine

1. Pull up the cowl seal (a) and remove the starboard side rubber grommet (b).

b

a

2. Take hold of the engine connector (c) and install

the remote wiring harness plug (d). Connect

additional wire leads (if equipped) as shown.

NOTE: The rubber grommet can to be lubricated to

ease installation.

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-9

c

d

Page 12

3. Push the connector and plug into the holder (e).

e

Battery Connections

CAUTION

For dual outboard installations, the black (–) battery cable of each engines starter motor ground

circuit, MUST BE connected to each other by a

common circuit (cable) capable of carrying the

starting current of each engine’s starter motor.

[i.e. A locally obtained battery cable connected

between the negative (–) terminal of each outboards cranking battery].

CAUTION

Failure to observe correct polarity when connecting battery cables to battery, will result in

damage to the charging system.

4. Insert the battery cables and remote wiring harness into the rubber grommet. Reinstall the starboard side rubber grommet into the cowl. Push

the cowl seal back in place.

1. Connect battery cables (from engine) to battery.

Connect red battery cable to positive terminal

and black battery cable to negative (–) battery

terminal.

Set Up Instructions For Oil

Injection System

CAUTION

Oil injected engines additionally , must be run on

a 50:1 gasoline/oil mixture during the engine

break-in period. Refer to engine break-in procedure in the Operation & Maintenance Manual.

CAUTION

If an electric fuel pump is to be used on engines

with oil injection, the fuel pressure at the engine

must not exceed 4 psig. If necessary, install a

pressure regulator between electrical fuel pump

and engine and set at 4 psig maximum.

90-830234R3 DECEMBER 19971D-10 - IMPORTANT INFORMATION

Page 13

Filling The Oil Injection System

1. Open the cowl cap (a). Turn the oil fill cap (b) to

the left and remove.

a

Bleeding Air From The Oil Injection

System

IMPORT ANT : If air exists in either the oil pump inlet hose (a) or oil pump outlet hose (b), the air

MUST BE bled from the hose(s) or engine damage may occur.

BLEEDING AIR FROM THE OIL PUMP INLET

HOSE

b

2. Use the dipstick (c) to check oil level.

3. Hook the dipstick (d) on the tank during filling.

c

d

4. Slowly fill the oil tank with the specified oil. Do Not

overfill – add only enough oil to bring the oil level

up to the bottom of the fill neck (e).

Note:The oil tank capacity for three cylinder models

is 3.2 qt. (3.0 liters) and four cylinder models is 5.13

qt. (4.9 liters).

5. Install oil filler cap (b) and re-tighten. Reinstall the

cowl cap.

1. With the engine not running, place a shop towel

below the oil pump.

2. Loosen bleed screw (c) four turns and allow oil to

flow out of the bleed hole until no air bubbles exist

in the inlet hose (a).

BLEEDING AIR FROM THE OIL PUMP OUTLET

HOSE

3. If any air bubbles are present in the outlet hose

(b), they can be purged from the hose by removing link rod (d) from the oil pump and rotating the

pump arm (e) full clockwise while operating engine at 1000 to 1500 RPM.

b

c

e

b

FULL

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-11

a

d

e

Page 14

Adjusting The Oil Injection Pump

Trim Tab Adjustment

When carburetor linkage is at idle position, alignment

mark (a) on oil injection arm should be in-line with

mark (b) on pump as shown. If necessary , adjust link

rod (c).

b

Propeller steering torque will cause your boat to pull

in one direction. This steering torque is a normal thing

that results from your outboard not being trimmed so

the propeller shaft is parallel to the water surface.

The trim tab can help to compensate for this steering

torque in many cases and can be adjusted within limits to reduce any unequal steering effort.

NOTE: Trim tab adjustment will have little effect reducing steering torque if the outboard is installed with

the anti-ventilation plate approximately 2 inches

(50mm) or more above the boat bottom.

Operate your boat at normal cruising speed, trimmed

to desired position. Turn your boat left and right and

note the direction the boat turns more easily.

If adjustment is necessary, loosen trim tab bolt and

make small adjustments at a time. If the boat turns

more easily to the left, move the trailing edge of trim

tab to the left. If the boat turns more easily to the right

move the trailing edge of trim tab to the right. Retighten bolt and retest.

c

a

90-830234R3 DECEMBER 19971D-12 - IMPORTANT INFORMATION

Loading...

Loading...