Page 1

eng i

Thank You

Thank you for choosing MotorGuide® VariMAX™. With VariMAX,

MotorGuide capitalized on many years of experience to provide

you with a motor designed to deliver Digital Variable Speed Control

and maximum time on the water.

We designed VariMAX with a BluVis™ Function Display to show

precise speed setting and battery voltage so you are always in

control. The VariMAX Digital Advantage lets you dial in the exact

speed for your boat to match the fishing conditions of the day while

providing significantly longer run times on your battery charge.

The VariMAX motor and its controls are designed to be very

intuitive. You will need to properly install the handle, so please take

the time to read this manual. Remember to keep your receipt and

immediately register your trolling motor. A warranty card is

enclosed or you can complete registration on the internet at

www.motorguide.com.

At MotorGuide, we believe there are some things you should Never

Stop doing.

NEVER STOP LEARNING, NEVER STOP IMPROVING,

AND NEVER, EVER STOP FISHING.

Warranty Message

The product you purchased comes with a Limited Warranty from

MotorGuide. The terms of the policy are set forth in the Warranty

Information section of this manual. The policy statement contains

a description of the duration of coverage, important disclaimers

and limitations of damages, and other related information.

Please review this important information.

The description and specifications contained herein were in effect

at the time this manual was approved for printing. MotorGuide,

whose policy is one of continued improvement, reserves the right

to discontinue models at any time, to change specifications,

designs, methods, or procedures without notice and without

incurring obligation.

MotorGuide, Lowell, Michigan U.S.A.

Litho in U.S.A.

© 2010 Mercury Marine

VariMAX 90-8M4002696 1010

Page 2

ii eng

© 2010, Mercury Marine. All Rights Reserved. Reproduction in whole

or in part without permission is prohibited.

VariMAX and BluVis are trademarks of Brunswick Corporation.

Mercury, Mercury Marine, MerCruiser, Mercury MerCruiser, Mercury

Racing, MotorGuide, Gator, Machete, Mercury Precision Parts,

Mercury Propellers, Mariner, Quicksilver, #1 On The Water, Alpha,

Bravo, Bravo Two, Pro Max, OptiMax, Sport‑Jet, K‑Planes,

MerCathode, SmartCraft, Total Command, VesselView, Zero Effort,

Zeus, M with Waves logo, Mercury with Waves logo, and SmartCraft

logo are all registered trademarks of Brunswick Corporation. Mercury

Product Protection logo is a registered service mark of Brunswick

Corporation.

Page 3

eng iii

Warranty Information

MotorGuide Limited Warranty..............................................................1

General Information

Recording Serial Number....................................................................4

Boater's Responsibilities.....................................................................5

Protecting People in the Water............................................................5

Passenger Safety Message.................................................................6

Safe Boating Suggestions...................................................................6

Product Overview and Assembly

Component Identification.....................................................................8

Attaching the Handle...........................................................................9

Extending and Retracting the Handle................................................12

Installing the Propeller.......................................................................13

Wiring and Battery Information

Battery Precautions...........................................................................15

Standard Practices and Procedures..................................................15

Battery Recommendations................................................................15

BluVis Battery Voltage Indicator........................................................16

Single, Parallel, and Series Circuit Battery Connection.....................17

Mount Installation

Transom Mount Installation...............................................................21

Pontoon Mount Installation................................................................21

Gator 20.8 Breakaway Installation.....................................................22

Gator Flex 360...................................................................................24

Page 4

iv eng

Operation

Installing the Motor into the Bow Mount............................................27

Removing the Motor from the Bow Mount.........................................27

Stowing the Trolling Motor.................................................................27

Deploying the Trolling Motor..............................................................29

Adjusting the Steering Tension..........................................................31

Adjusting the Motor Depth.................................................................31

Speed Control....................................................................................32

Direction Control................................................................................33

Maintenance and Storage

Trolling Motor Care............................................................................37

Inspection and Maintenance Schedule.............................................37

Storage Preparation..........................................................................38

Battery Inspection..............................................................................38

Propeller Replacement......................................................................39

Custom Applications

Repositioning the Top Housing.........................................................41

Setting the Direction Control Switch..................................................42

Motor Control Wiring..........................................................................46

Owner Service Assistance

Troubleshooting.................................................................................47

Service Assistance............................................................................48

Mercury Marine Service Offices........................................................48

Page 5

WARRANTY INFORMATION

eng 1

MotorGuide Limited Warranty

KEEP YOUR ORIGINAL PURCHASE RECEIPT OR BILL OF SALE.

1. For recreational use customers, MotorGuide electric trolling motors

are warranted to the original retail purchaser to be free from defects

in material or workmanship for two (2) years.

2. To obtain warranty service, the purchaser should deliver or return

the unit (postage prepaid and insured) to any MotorGuide

authorized service dealer. DO NOT RETURN TO PLACE OF

PURCHASE unless they are an authorized service center.

Products returned by mail should be carefully packaged and

include a note describing the nature of the problem and/or service

requested, customer address and phone number. A copy of the

receipt, Bill of Sale, registration verification, or other proof of

purchase is required with the return of the product for warranty

consideration. Warranty claims will not be accepted without

presentation of purchase receipt for trolling motor, other verification

of registration, or bill of sale for boat package.

3. MotorGuide, at its discretion, will repair or replace items covered

under the terms of this warranty. Neither MotorGuide nor

MotorGuide service dealers are responsible for damages to

MotorGuide products due to repairs performed by anyone other

than an authorized MotorGuide service dealer. Neither MotorGuide

nor Mercury Marine is responsible for failure or damage caused by

improper installation, set‑up, preparation, or previous service or

repair errors.

4. For commercial use and government use customers, MotorGuide

electric trolling motors are warranted to the original retail purchaser

to be free from defects in material or workmanship for one (1) year.

Commercial use is defined as any work or employment‑related use

of the product, or any use of the product which generates income,

for any part of the warranty period, even if the product is only

occasionally used for such purpose such as rental fleets, guides,

fish camps, or similar operations. Warranty is not transferable to

any subsequent purchaser. The Mercury Product Protection plan

is not available to commercial use or government use customers.

Page 6

WARRANTY INFORMATION

2 eng

5. Warranty coverage is available to customers that purchase from

an authorized dealer or retailer that is authorized by MotorGuide

Marine to distribute the product in the country in which the sale

occurred. Warranty coverage and duration varies by the country in

which the owner resides. This warranty applies to MotorGuide

trolling motors sold and used in the United States. This limited

warranty begins on the date the product is first sold to a purchaser

or the date on which the product is first put into service, whichever

occurs first. MotorGuide accessories are covered by this limited

warranty for a coverage period of one (1) year from the date of retail

sale. The repair or replacement of parts, or the performance of

service under this warranty, does not extend the life of this warranty

beyond its original expiration date. Promotional warranties are not

included in this statement and coverage may vary by promotion.

Product either sold or put into service more than six years from date

of manufacture is excluded from warranty coverage.

6. This warranty does not apply to normal worn parts, for example,

worn cables, adjustments, or product damage due to; 1) neglect,

lack of maintenance, accident, abnormal operation, or improper

installation or service; 2) abuse, such as, bent metal columns, bent

armature shafts, broken control cables, etc., accidents,

modifications, misuse, excessive wear or damage caused by an

owner’s failure to provide reasonable and necessary installation or

care; 3) use of an accessory or part not manufactured by

MotorGuide or Mercury; 4) alteration or removal of parts; 5)

opening the lower unit (motor) by anyone other than an authorized

MotorGuide service center will void this warranty.

7. We reserve the right to improve the design of any trolling motor

without assuming any obligation to modify any trolling motor

previously manufactured.

Page 7

WARRANTY INFORMATION

eng 3

8. All serialized "Service‑Repair" trolling motors receive a one (1) year

warranty. Non‑serialized "Service‑Repair" electric trolling motors

are NOT warranted. "Service‑Repair" motor denotes a trolling

motor sold by MotorGuide that may be used, but has been

inspected and may have had minor repairs. Original retail

purchaser of a "Service‑Repair" motor is the first purchaser of the

motor after it is denoted as "Service‑Repair." "Service‑Repair"

motors have a blue sticker on the battery cable and box denoting

"Manufacturer Certified Service‑Repair Motor."

9. This warranty will not apply to 1) haul‑out, launch, towing and

storage, transportation charges and/or travel time, telephone or

rental charges of any type, inconvenience, or loss of time or

income, or other consequential damages; or 2) removal or

replacement of boat partitions or material because of boat design

for necessary access to the Product; or 3) disconnection and

reconnection of hard‑wired trolling motors.

10.TERMINATION OF COVERAGE: Warranty coverage may be

terminated for repossessed product, or product purchased at

auction, from a salvage yard, from a liquidator, from an insurance

company, from unauthorized marine dealers or boatbuilders, or

other third party entities.

11.ALL INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE

EXCLUDED FROM THIS WARRANTY, WARRANTIES OF

MERCHANTABILITY AND FITNESS ARE EXCLUDED FROM

THIS WARRANTY, IMPLIED WARRANTIES ARE LIMITED TO

THE LIFE OF THIS WARRANTY. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS OR THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND

YOU MAY ALSO HAVE OTHER LEGAL RIGHTS WHICH MAY

VARY FROM STATE TO STATE.

For Your Records:

Model Number _______________________________

Serial Number _______________________________

Page 8

GENERAL INFORMATION

4 eng

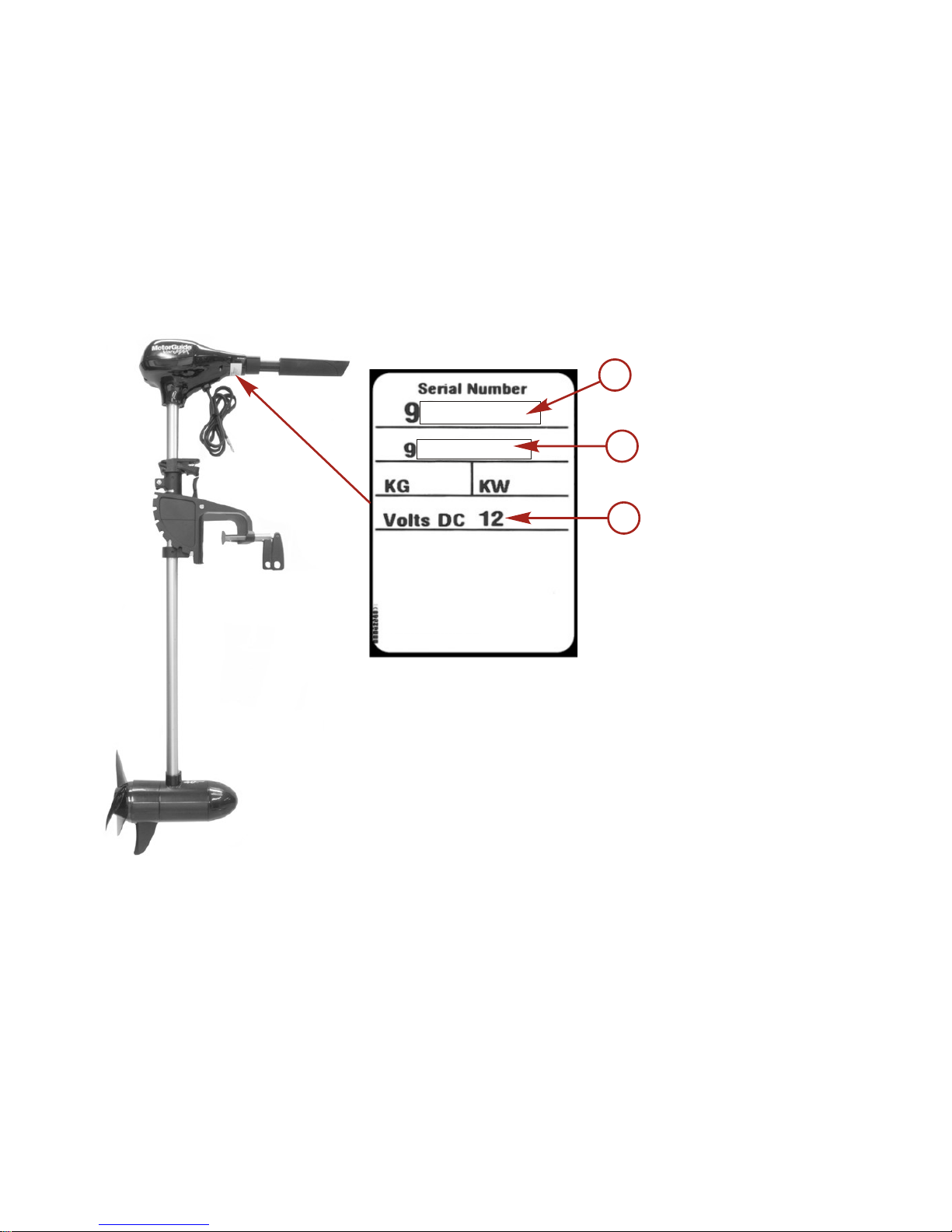

Recording Serial Number

Record the serial number for future reference. For warranty purposes,

complete the enclosed warranty card or register your trolling motor at

www.motorguide.com.

TRANSOM MOUNT

The transom mount serial number decal is located underneath the

bottom cover.

a - Serial number

b - Model identification number

c - Voltage

a

b

c

45651

Page 9

GENERAL INFORMATION

eng 5

Boater's Responsibilities

The operator (driver) is responsible for the correct and safe operation

of the boat and safety of its occupants and general public. It is strongly

recommended that each operator (driver) read and understand this

entire manual before operating the trolling motor.

Be sure at least one additional person on board is instructed in the basic

operation of the trolling motor in case the driver is unable to operate the

boat.

Protecting People in the Water

WHILE YOU ARE TROLLING

It is very difficult for a person in the water to take quick action to avoid

a boat heading in their direction, even at slow speeds.

21604

Always slow down and exercise extreme caution any time you are

boating in an area where there might be people in the water.

WHILE THE BOAT IS STATIONARY

!

WARNING

A spinning propeller, a moving boat, or any solid device attached to

the boat can cause serious injury or death to swimmers. Stop the

trolling motor immediately whenever anyone in the water is near your

boat.

Shut off the trolling motor before allowing people to swim or be in the

water near your boat.

Page 10

GENERAL INFORMATION

6 eng

Passenger Safety Message

Whenever the boat is in motion, observe the location of all passengers.

A sudden reduction in boat speed, such as a sharp change of boat

direction, could throw them off the boat.

Safe Boating Suggestions

In order to safely enjoy the waterways, familiarize yourself with local

and other governmental boating regulations and restrictions, and

consider the following suggestions.

Use flotation devices. It is the law to have an approved personal flotation

device of suitable size for each person aboard and have it readily

accessible.

Do not overload your boat. Most boats are rated and certified for

maximum load (weight) capacities, refer to your boat capacity plate. If

in doubt, contact your dealer or the boat's manufacturer.

Perform safety checks and required maintenance. Follow a regular

schedule and ensure all repairs are made properly.

Never be under the influence of alcohol or drugs while boating (it is the

law). Alcohol or drug use impairs your judgment and greatly reduces

your ability to react quickly.

Passenger boarding. Stop the trolling motor whenever passengers are

boarding or unloading.

Be alert. The operator of the boat is responsible by law to maintain a

proper lookout by sight and hearing. The operator must have an

unobstructed view particularly to the front. No passengers, load, or

fishing seats should block the operators view when operating the boat.

Underwater hazards. Reduce speed and proceed with caution

whenever navigating in shallow water.

Tripping hazards. To avoid a trip hazard, route all cables and wiring

neatly and out of the way.

Page 11

GENERAL INFORMATION

eng 7

Report accidents. Boat operators are required by law to file a Boating

Accident Report with their state boating law enforcement agency when

their boat is involved in certain boating accidents. A boating accident

must be reported if 1) there is loss of life or probable loss of life, 2) there

is personal injury requiring medical treatment beyond first aid, 3) there

is damage to boats or other property where the damage value exceeds

$500.00 or 4) there is complete loss of the boat. Seek further assistance

from local law enforcement.

Page 12

PRODUCT OVERVIEW AND ASSEMBLY

8 eng

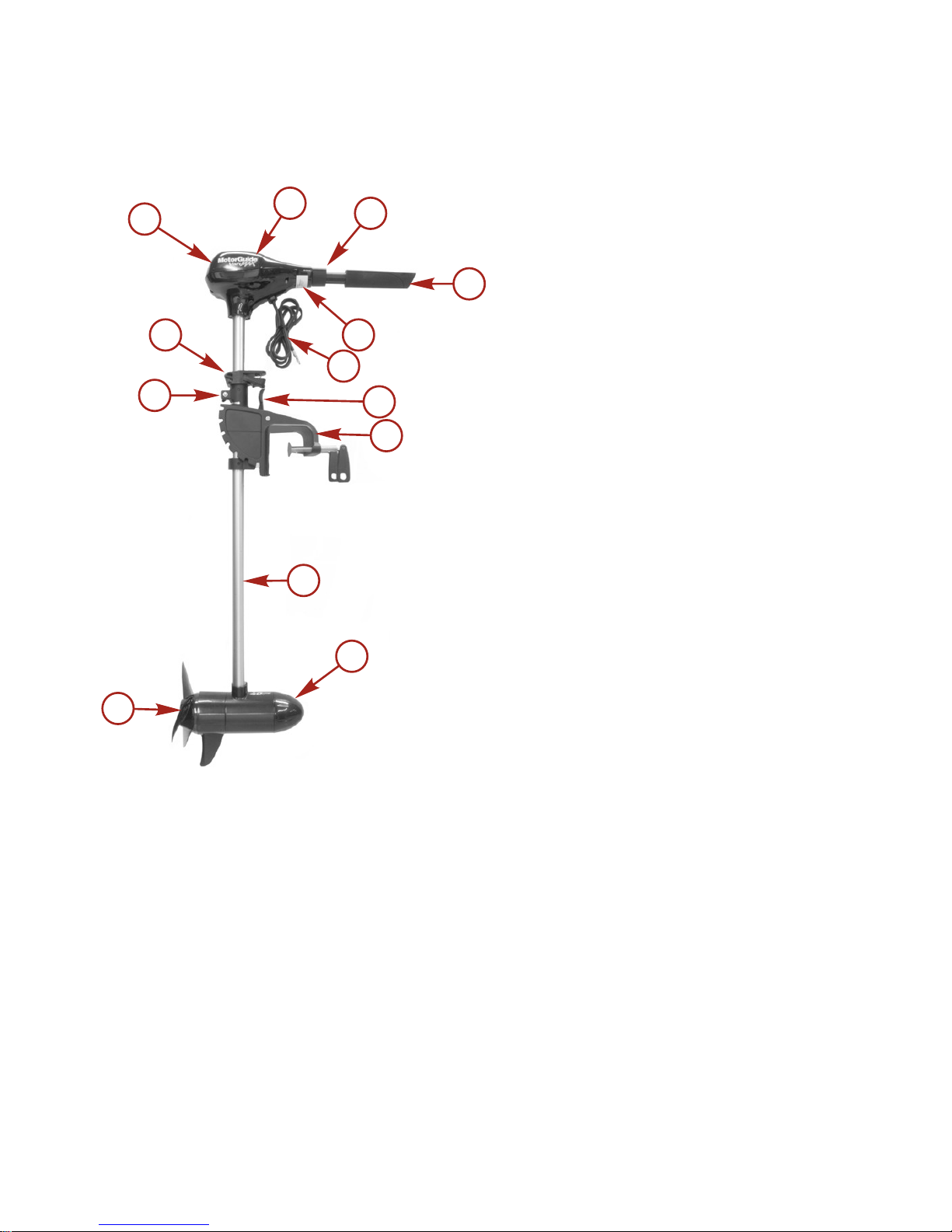

Component Identification

TRANSOM MOUNT

a - Top housing

b - BluVis function display

c - Cam lock

d - Extendable speed control

handle

e - Serial number

f - Battery cables

g - Tilt lock release lever

h - Clamp bracket

i - Column

j - Lower unit

k - Propeller

l - Steering tension collar

m -Depth adjustment collar

a

b

c

d

e

f

g

h

i

j

k

l

45654

m

Page 13

PRODUCT OVERVIEW AND ASSEMBLY

eng 9

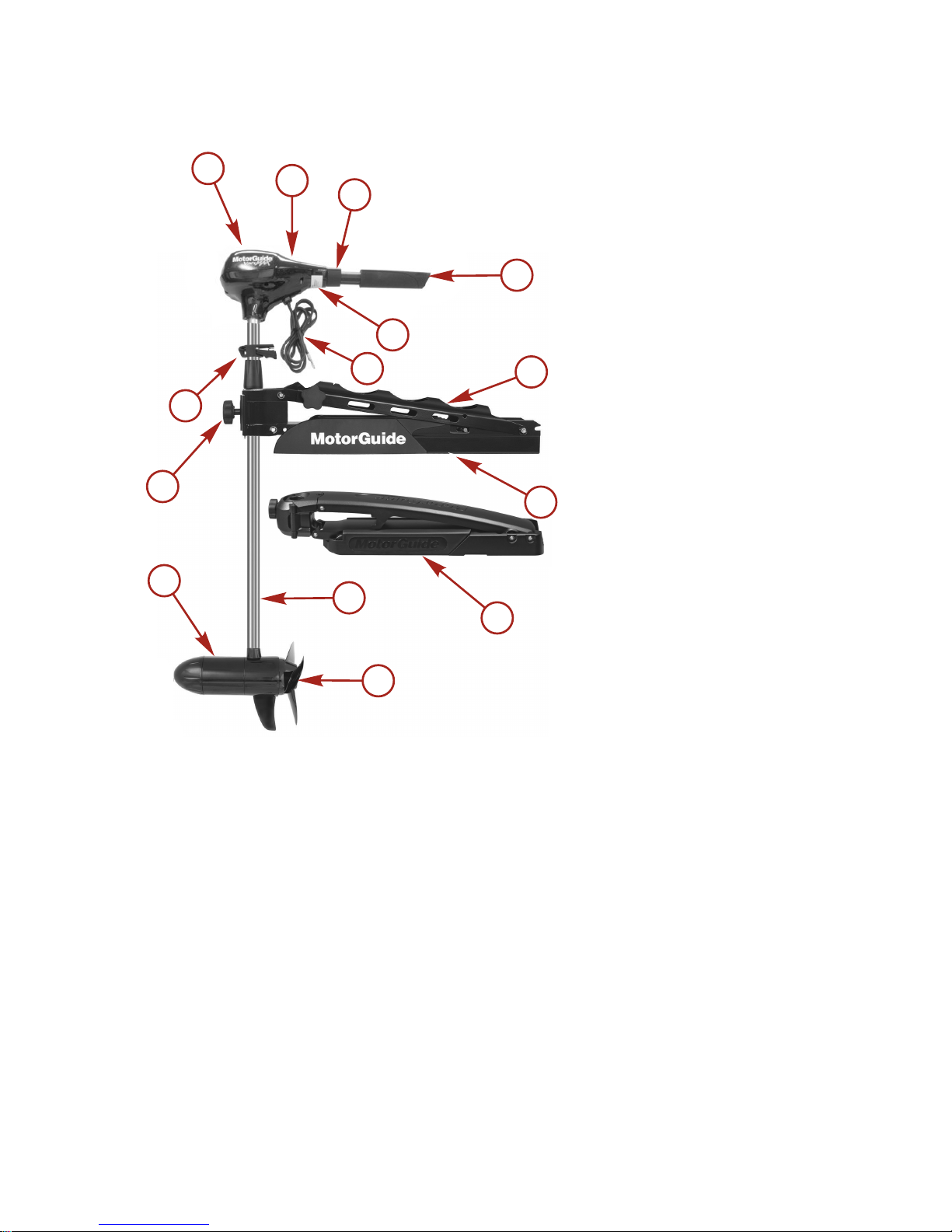

VARIMAX BOW MOUNT

a - Top housing

b - BluVis function display

c - Cam lock

d - Extendable speed

control handle

e - Serial number

f - Battery cables

g - Gator 20.8 breakaway

h - Decket

i - Gator Flex 360

j - Column

k - Propeller

l - Lower unit

m -Steering tension collar

n - Depth adjustment

collar

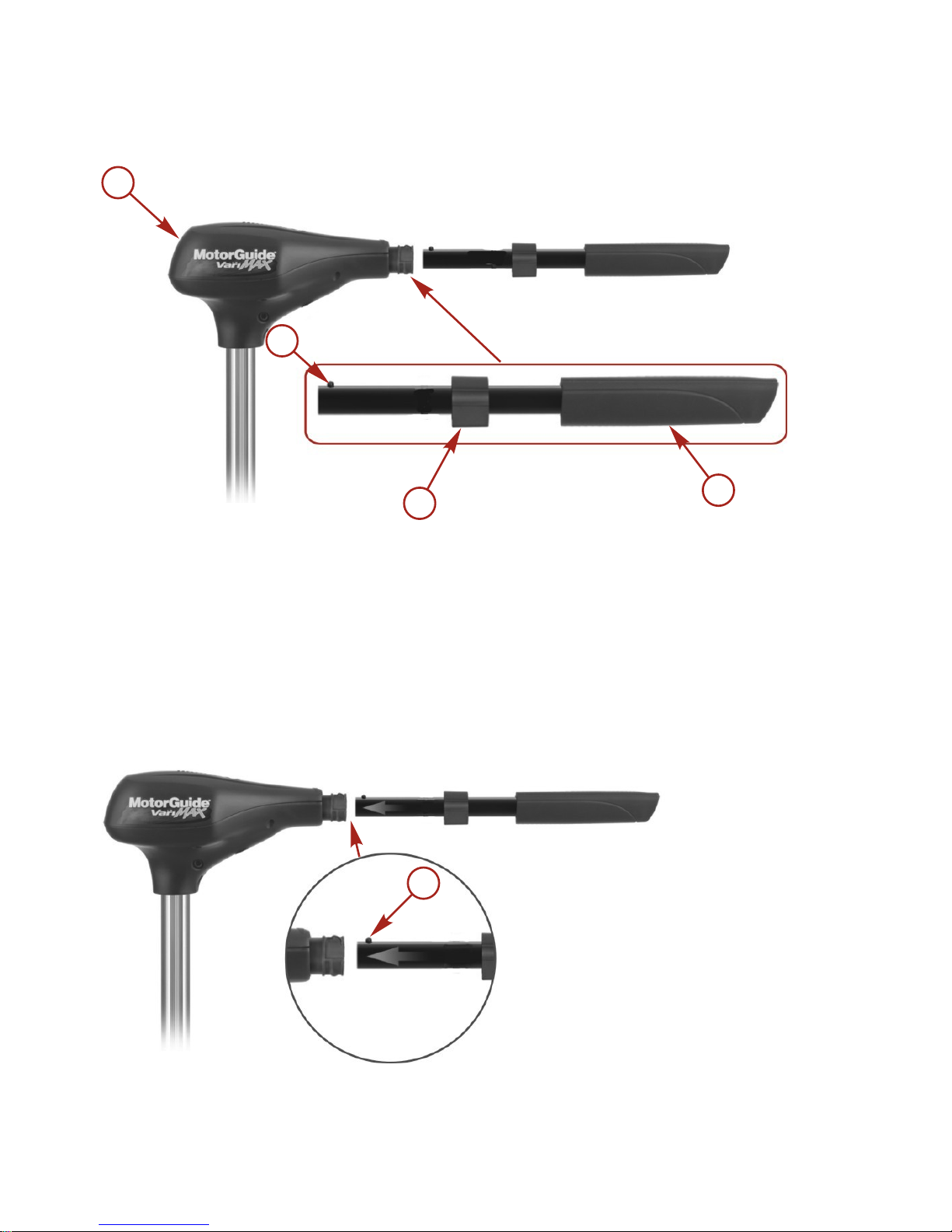

Attaching the Handle

NOTE: For proper installation, assemble the trolling motor on a flat, level

surface.

1. Ensure the battery cables are disconnected from the power source.

i

h

a

g

l

k

j

e

d

c

b

f

h

i

m

n

45746

Page 14

PRODUCT OVERVIEW AND ASSEMBLY

10 eng

2. Align the handle to the top housing using the flat groove on the

extension handle. The handle extension spring should face up.

a - Top housing

b - Handle extension spring

c - Cam lock

d - Handle

3. Press the handle extension spring in while inserting the handle into

the top housing. Adjust the handle to the desired length.

a - Handle extension spring

a

b

c

d

45687

a

45690

Page 15

PRODUCT OVERVIEW AND ASSEMBLY

eng 11

4. Rotate the cam lock clockwise 180°. Move the cam lock flush

against the top housing.

180°

39062

5. To secure the handle, hold the handle steady while rotating and

tightening the cam lock clockwise 180°. Verify that the flat surfaces

of the handle, cam lock, and top housing are in alignment.

a - Top housing

b - Cam lock

c - Handle

a

b

c

45694

Page 16

PRODUCT OVERVIEW AND ASSEMBLY

12 eng

Extending and Retracting the Handle

1. Firmly grasp the handle, then rotate and loosen the cam lock

counterclockwise 180°.

180°

45695

2. Extend or retract the handle to the desired length.

38656

Extending handle

38662

Retracting handle

Page 17

PRODUCT OVERVIEW AND ASSEMBLY

eng 13

3. To secure the handle, hold the handle steady while rotating and

tightening the cam lock clockwise 180°. Verify that the handle, cam

lock, and top housing are in alignment.

45684

Cam lock and top housing in alignment

Installing the Propeller

!

WARNING

Performing service or maintenance without first disconnecting the

battery can cause product damage, personal injury, or death due to

fire, explosion, electrical shock, or unexpected motor starting. Always

disconnect the battery cables from the battery before maintaining,

servicing, installing, or removing motor components.

1. Rotate the motor shaft to insert the propeller pin horizontally.

a - Propeller pin

2. Install the propeller onto the motor shaft by engaging the propeller

onto the propeller pin.

a

45685

Page 18

PRODUCT OVERVIEW AND ASSEMBLY

14 eng

3. Install the propeller nut. Tighten securely.

a - Propeller pin

b - Propeller

c - Propeller nut

d - Propeller

wrench

4. Use a MotorGuide propeller wrench or pliers to tighten the propeller

nut another ¼ turn.

Recommended MotorGuide Accessory Description Part Number

MotorGuide prop wrench kit MGA050B6

a

b

c

d

45696

Page 19

WIRING AND BATTERY INFORMATION

eng 15

Battery Precautions

!

WARNING

An operating or charging battery produces gas that can ignite and

explode, spraying out sulfuric acid, which can cause severe burns.

Ventilate the area around the battery and wear protective equipment

when handling or servicing batteries.

When charging batteries, an explosive gas mixture forms in each cell.

Part of this gas escapes through holes in the vent plugs and may form

an explosive atmosphere around the battery if ventilation is poor. This

explosive gas may remain in or around the battery for several hours

after it has been charged. Sparks or flames can ignite this gas and

cause an internal explosion, which may shatter the battery.

The following precautions should be observed to prevent an explosion:

1. Do not smoke near batteries being charged or which have been

charged very recently.

2. Do not break live circuits at terminals of batteries, because a spark

usually occurs at the point where a live circuit is broken. Always be

careful when connecting or disconnecting cable clamps on

chargers. Poor connections are a common cause of electrical arcs

which cause explosions.

3. Do not reverse polarity of battery terminal to cable connections.

Standard Practices and Procedures

• Do not use the main engine battery to power the trolling motor.

• Disconnect the trolling motor from the battery when charging and

after each use.

• Route the trolling motor wires on the opposite side of the boat from

other miscellaneous boat wiring.

• Connect boat accessories directly to the main engine battery.

Battery Recommendations

• Use a 12 volt, deep cycle marine battery.

• Install a 50 amp manual reset circuit breaker in line with the trolling

motor positive leads within 180 cm (72 in.) of the batteries.

Page 20

WIRING AND BATTERY INFORMATION

16 eng

• Use 13 mm (6 gauge) battery cables if extending the existing wire

beyond the standard battery cable.

Recommended MotorGuide Accessory Description Part Number

Trolling motor power plug 8M4000953

Trolling motor sp (receptacle) 8M4000954

50 amp alligator clips 8M4000287

6 gauge battery cable and terminals with 50 amp manual reset

circuit breaker

MM309922T

50 amp manual reset circuit breaker MM5870

BluVis Battery Voltage Indicator

Use the BluVis function display to determine battery voltage level. The

battery indicator will display the voltage for four seconds when the motor

is connected to the battery and when the speed control is turned off.

Refer to the diagram below to reference remaining battery voltage for

12 and 24 volt battery connections.

27 volts

26 volts

25 volts

24 volts

23 volts

22 volts

21 volts

20 volts

19 volts

18 volts

13.5 volts

13 volts

12.5 volts

12 volts

11.5 volts

11 volts

10.5 volts

10 volts

9.5 volts

9 volts

12 volt

24 volt

45682

Page 21

WIRING AND BATTERY INFORMATION

eng 17

Single, Parallel, and Series Circuit Battery Connection

!

CAUTION

Disconnecting or connecting the battery cables in the incorrect order

can cause injury from electrical shock or can damage the electrical

system. Always disconnect the negative (‑) battery cable first and

connect it last.

Recommended MotorGuide Accessory Description Part Number

6 gauge battery cable and terminals with 50 amp manual reset

circuit breaker

MM309922T

50 amp manual reset circuit breaker MM5870

SINGLE 12 VOLT BATTERY CONNECTION

1. Install a 50 amp manual reset circuit breaker in line with the trolling

motor power cable positive lead and the battery positive (+)

terminal.

2. Connect the black trolling motor power cable negative lead to the

battery negative (–) terminal.

3. Connect a jumper cable (common ground bond) from the trolling

motor battery negative (–) terminal to the engine battery negative

(–) terminal.

Page 22

WIRING AND BATTERY INFORMATION

18 eng

NOTE: Vessels with multiple batteries, must have a common ground

bonding circuit. Not establishing a common ground between the vessel

batteries, may cause severe corrosion, electrolysis, or an electrical

shock.

a - Power cables to trolling motor

b - 50 amp manual reset circuit breaker

c - Trolling motor battery

d - Engine starting battery

e - Power cables to engine

f - Common ground bond

12 VOLT PARALLEL CIRCUIT BATTERY CONNECTION

1. Install a 50 amp manual reset circuit breaker in line with the trolling

motor power cable positive lead and the battery positive (+)

terminal.

2. Connect a jumper cable between both of the trolling motor battery

positive (+) terminals.

3. Connect a jumper cable between both of the trolling motor battery

negative (–) terminals.

4. Connect the black trolling motor power cable negative lead to the

battery negative (–) terminal.

RED

BLK

BLK

REDRED

abcde

44291

f

Page 23

WIRING AND BATTERY INFORMATION

eng 19

5. Connect a jumper cable (common ground bond) from the trolling

motor battery negative (–) terminal to the engine battery negative

(–) terminal.

NOTE: Vessels with multiple batteries, must have a common ground

bonding circuit. Not establishing a common ground between the vessel

batteries, may cause severe corrosion, electrolysis, or an electrical

shock.

a - Power cables to trolling motor

b - 50 amp manual reset circuit breaker

c - Trolling motor batteries

d - Engine starting battery

e - Power cables to engine

f - Common ground bond

24 VOLT SERIES CIRCUIT BATTERY CONNECTION

1. Install a 50 amp manual reset circuit breaker in line with the trolling

motor power cable positive (+) lead and battery "c" positive (+)

terminal.

2. Connect a jumper wire (reference grey) between the negative (–)

terminal on battery "c" to the positive (+) terminal on battery "d."

3. Connect the trolling motor negative (–) lead to the negative (–)

terminal on battery "d."

RED

BLK

BLK

REDRED

abcde

c

44292

f

Page 24

WIRING AND BATTERY INFORMATION

20 eng

4. Connect a jumper cable (common ground bond) from the trolling

motor battery "d" negative (–) terminal to the engine battery

negative (–) terminal.

NOTE: Vessels with multiple batteries, must have a common ground

bonding circuit. Not establishing a common ground between the vessel

batteries, may cause severe corrosion, electrolysis, or an electrical

shock.

a - Power cables to trolling motor

b - 50 amp manual reset circuit breaker

c - Trolling motor battery "c"

d - Trolling motor battery "d"

e - Series cable connection

f - Common ground bond

g - Engine starting battery

h - Power cables to engine

RED

BLK

BLK

REDRED

abc

44328

f

e

g

d

h

Page 25

MOUNT INSTALLATION

eng 21

Transom Mount Installation

NOTE: The transom mount will fit transoms up to 8.25 cm (3.25 in.)

thick.

IMPORTANT: Overtightening the transom clamp screws can weaken

or damage the mount bracket.

1. Place the transom mount onto the transom of the boat.

45673

2. Tighten the transom clamp screws securely.

Pontoon Mount Installation

IMPORTANT: Choose an area on the deck which allows 2.5 cm

(1 in.) clearance between the column and the bow of the boat for all

motor positions.

1. Select an appropriate area on the deck of the boat to install the

mount.

39066

Page 26

MOUNT INSTALLATION

22 eng

2. Place the pontoon mount base on the surface of the boat deck. Use

the mount base as a template to mark the location of the mount

holes.

37927

Pontoon mount holes

IMPORTANT: Using a larger drill bit, countersink the holes on

fiberglass boats to prevent the gel‑coat from cracking.

3. Drill the mounting holes with a 7 mm (1/4 in.) diameter drill bit.

Remove any debris.

4. Install four stainless steel washers and locking nuts onto the

mounting screws underneath the boat deck. Tighten securely.

Gator 20.8 Breakaway Installation

37805

Gator 20.8 Breakaway

IMPORTANT: Choose an area on the deck which allows a 7.6 cm

(3 in.) clearance between the column and the bow of the boat for all

motor positions.

Page 27

MOUNT INSTALLATION

eng 23

1. Select an appropriate area on the deck of the boat to install the

mount. Ensure that the forward mounting screws will not penetrate

the hull.

38094

Mount on deck

2. Place the bow mount base on the surface of the boat deck. Use the

mount base as a template to mark the locations of the front

mounting holes in the plastic decket and the rear mounting holes

on the mount base.

38097

Mount base mounting holes

3. Drill the mounting holes with a 7 mm (1/4 in.) diameter drill bit.

Remove any debris.

4. Redrill each mounting hole with a 13 mm (1/2 in.) diameter drill bit.

IMPORTANT: Use a larger drill bit to countersink the holes on

fiberglass boats to prevent cracking.

Page 28

MOUNT INSTALLATION

24 eng

5. Insert the rubber mounting isolators into the mounting holes.

Position the isolators in line with the mount base with the wider side

toward the outside of the mount base bracket.

39076

6. Place the mount base on the isolators and align the holes. Install

the two longer screws into the front mounting holes and the two

shorter screws into the rear mounting holes. Tighten all of the

mounting screws securely.

IMPORTANT: The mount base must lay flush against the isolators

before being bolted to the deck or the mount will bind making it difficult

or impossible to unlatch.

7. The bracket should fasten securely and evenly with the latch pins

in the latch. The bracket should release with a light, quick snap of

the rope handle.

Gator Flex 360

37806

Gator Flex 360

IMPORTANT: Choose an area on the deck which allows a 7.6 cm

(3 in.) clearance between the column and the bow of the boat for all

motor positions.

Page 29

MOUNT INSTALLATION

eng 25

1. Select an appropriate area on the deck of the boat to install the

mount. Ensure that the forward mounting screws will not penetrate

the hull.

39074

Mount on deck

2. Place the bow mount base on the surface of the boat deck. Use the

mount base as a template to mark the locations of the front

mounting holes in the plastic decket and the rear mounting holes

on the mount base.

39075

Mount base mounting holes

3. Drill the mounting holes with a 7 mm (1/4 in.) diameter drill bit.

Remove any debris.

IMPORTANT: Use a larger drill bit to countersink the holes on

fiberglass boats to prevent cracking.

4. Insert the rubber washers between the base of the mount and the

boat mounting surface. Install the steel washers and nylon locking

nuts onto the mounting screws underneath the boat deck. Tighten

securely with a Phillips screwdriver and 11 mm (7/16 in.) wrench.

Page 30

MOUNT INSTALLATION

26 eng

IMPORTANT: If necessary, shim the rubber washers with 25 mm

(1 in.) stainless steel washers to create a level mounting surface.

5. The mount base should fasten securely and evenly with the latch

pins in the latch. The base should release with a light, easy pull on

the rope handle.

6. Secure the decket to the mount base with the decket screws.

Page 31

OPERATION

eng 27

Installing the Motor into the Bow Mount

1. Turn the bracket door knob counterclockwise to loosen and open

the bracket door.

2. Place the motor column into the bracket and close the door.

3. Turn the bracket door knob clockwise to tighten the motor column

in the bracket.

a - Bracket door knob

Removing the Motor from the Bow Mount

1. Turn the bracket door knob counterclockwise to loosen and open

the bracket door.

2. Remove the motor column from the bracket and close the door.

Stowing the Trolling Motor

!

WARNING

Rotating propellers can cause serious injury or death. Never start or

operate the motor out of water.

!

CAUTION

Moving parts, such as hinges and pivot points, can cause serious

injury. Keep away from moving parts when stowing, deploying, or

tilting the motor.

a

44907

Page 32

OPERATION

28 eng

TRANSOM MOUNT

IMPORTANT: Ensure the mount is stowed while using the main engine

or trailering the boat. Ensure the steering tension collar is tightened

securely.

1. Firmly grasp the column and push the tilt lever towards the column.

a - Column

b - Tilt lever

IMPORTANT: Do not use the handle to stow or tilt the motor.

2. Tilt the motor toward you by pulling on the column while

simultaneously holding the tilt lever.

3. Once the motor is stowed, release the tilt lever. Verify the lock pin

is securely engaged. The motor should not tilt if the lock pin is

properly engaged.

4. Move the depth collar flush against the steering tension collar.

a

b

45664

Page 33

OPERATION

eng 29

5. Adjust the steering friction by turning the steering tension collar

knob.

a - Steering tension

collar

b - Depth collar

c - Column

d - Tilt lever

e - Lock pin

Deploying the Trolling Motor

!

WARNING

Rotating propellers can cause serious injury or death. Never start or

operate the motor out of water.

!

CAUTION

Moving parts, such as hinges and pivot points, can cause serious

injury. Keep away from moving parts when stowing, deploying, or

tilting the motor.

!

CAUTION

Avoid possible serious injury from the motor dropping suddenly when

adjusting the motor depth. Firmly grasp the motor shaft with one hand

when raising or lowering the motor.

TRANSOM MOUNT

IMPORTANT: Do not use the handle to tilt or deploy the motor.

a

b

45665

c

d

e

Page 34

OPERATION

30 eng

1. Firmly grasp the column and engage the tilt lever.

a - Column

b - Tilt lever

2. Adjust the angle of the motor to the desired position while

simultaneously holding the tilt lever.

3. Release the tilt lever. Verify that the lock pin is securely engaged.

4. Grasp the shaft with one hand and pinch the depth collar to lower

the trolling motor to the desired depth.

a - Tilt lever

b - Lock pin

c - Depth collar

a

b

45674

a

b

45675

c

Page 35

OPERATION

eng 31

Adjusting the Steering Tension

Adjust the steering tension collar to increase or decrease the effort to

turn the motor freely.

1. To increase steering tension or to fasten the column in a fixed

position, tighten the friction knob clockwise.

2. To unfasten the column from a fixed position or to reduce steering

tension, turn the friction knob counterclockwise.

a - Friction knob

b - Steering tension collar

Adjusting the Motor Depth

!

CAUTION

Avoid possible serious injury from dropping the motor when adjusting

the motor depth. Firmly grasp the motor shaft with one hand when

raising or lowering the motor.

Adjust the depth of the motor to improve trolling motor performance in

various water depths.

IMPORTANT: When adjusting the motor depth, ensure the lower unit

is fully submerged to avoid propeller cavitation.

a

b

45670

Page 36

OPERATION

32 eng

1. Firmly grasp the column with one hand while holding the depth

collar.

2. Pinch the depth collar until the motor column slides freely.

3. Raise or lower to the desired depth.

a - Column

b - Depth collar

Speed Control

NOTE: Speed control is operable regardless of handle position.

a

b

45671

Page 37

OPERATION

eng 33

Rotate the handle clockwise to increase speed in both forward and

reverse directions. The BluVis function display indicates speed setting.

a - Rotate the handle clockwise

b - BluVis function display with speed settings

Direction Control

The push‑forward, pull‑reverse direction control lets you increase the

speed by turning the handle clockwise, whether in forward or reverse.

To shift and change the direction of the propeller, simply pull back or

push forward on the handle. The BluVis function display shows your

relative speed setting and direction when the propeller is moving.

IMPORTANT: To shift the motor and change the direction of the

propeller, the power must be below 60% to provide instant direction

control for forward and reverse. The motor will only shift if below the

60% speed setting to protect the motor from damage.

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

a

b

44855

Page 38

OPERATION

34 eng

TRANSOM MOUNT APPLICATION

To move the boat forward, pull the handle. To move the boat in reverse,

push the handle. The BluVis function display indicates the motor

direction.

39222

Reverse

39101

Forward

TRANSOM MOUNT—BACKTROLLING APPLICATION

To use the transom mount for backtrolling, reverse the top housing

position and toggle the direction control switch. Refer to Setting the

Direction Control Switch.

Page 39

OPERATION

eng 35

To backtroll, push the handle. To reverse backtroll, pull the handle. The

BluVis function display indicates the motor direction.

39223

Backtroll

39102

Backtroll reverse

Page 40

OPERATION

36 eng

BOW MOUNT APPLICATION

To move the boat forward, push the handle. To move the boat in

reverse, pull the handle. The BluVis function display indicates the motor

direction.

39224

39103

Reverse Forward

Page 41

MAINTENANCE AND STORAGE

eng 37

Trolling Motor Care

To keep your trolling motor in the best operating condition and retain its

dependability, your trolling motor must receive periodic inspections and

maintenance. Keep it maintained properly to ensure the safety of you

and your passengers.

!

WARNING

Neglecting to inspect, maintain, or repair your trolling motor can result

in product damage or serious injury or death. Do not perform

maintenance or service on your trolling motor if you are not familiar

with the correct service and safety procedures.

Record all maintenance performed and save maintenance work orders

and receipts.

SELECTING REPLACEMENT PARTS

Original MotorGuide Certified Tough replacement parts.

Inspection and Maintenance Schedule

BEFORE EACH USE

• Check the tightness of the battery lead connections.

• Visually inspect for loose or corroded wiring connections.

• Check the tightness of the propeller nut.

• Check the propeller blades for damage.

AFTER EACH USE

• Disconnect the battery cables from the power source or unplug the

motor from the boat.

• Check the propeller and propeller shaft for debris such as weeds

and fishing line. Remove all debris.

• Check the tightness of the propeller nut.

• Rinse the trolling motor with clean water to remove dirt and dust

that may scratch the surface.

Page 42

MAINTENANCE AND STORAGE

38 eng

EVERY 100 HOURS OF USE OR ANNUALLY

• Periodically lubricate all the pivot points with a nonaerosol,

nonsolvent based lubricant.

IMPORTANT: Never use an aerosol lubricant to grease or oil any part

of the unit. Many aerosol lubricants contain harmful propellants that

can cause damage to various parts of the trolling motor.

Tube Ref

No.

Description Where Used Part No.

95

2-4-C with Teflon Pivot points 92-802859A 1

• Check the tightness of bolts, nuts, and other fasteners.

• Inspect the battery. Refer to Battery Inspection.

Storage Preparation

The major consideration in preparing your trolling motor for storage is

to protect it from corrosion and damage caused by freezing of trapped

water.

Refer to the Inspection and Maintenance Schedule and complete the

appropriate care instructions to prepare your trolling motor for storage.

Store the trolling motor in a dry location where it will not be affected by

temperatures below ‑29 °C (‑20 °F).

IMPORTANT: Trolling motors stored in temperatures below 0 °C

(32 °F) should be operated slowly for a minimum of 15 minutes before

going above 30% operation.

Battery Inspection

The battery should be inspected at periodic intervals to ensure proper

trolling motor operation.

IMPORTANT: Read the safety and maintenance instructions which

accompany your battery.

1. Ensure that the battery is secured to the vessel.

2. Ensure that the battery cable terminals are clean, tight, and

correctly installed.

3. Ensure that the battery is equipped with a battery box to prevent

accidental shorting of the battery terminals.

Page 43

MAINTENANCE AND STORAGE

eng 39

Propeller Replacement

!

WARNING

Performing service or maintenance without first disconnecting the

battery can cause product damage, personal injury, or death due to

fire, explosion, electrical shock, or unexpected motor starting. Always

disconnect the battery cables from the battery before maintaining,

servicing, installing, or removing motor components.

REMOVING THE PROPELLER

1. Disconnect the battery cables from the power source.

2. While holding the propeller blade with one hand, use a propeller

wrench or pliers to remove the propeller nut.

IMPORTANT: If the propeller cannot be removed easily, hold one

blade and use a rubber mallet to lightly tap the backside of the opposite

blade. If the propeller cannot be removed, refer to Owner Service

Assistance ‑ Troubleshooting.

NOTE: If the propeller pin is bent, replace the propeller pin.

a - Propeller pin

b - Propeller

c - Propeller nut

d - Prop wrench

a

b

c

d

44934

Page 44

MAINTENANCE AND STORAGE

40 eng

Recommended MotorGuide Accessory Description Part Number

MotorGuide prop wrench kit MGA050B6

INSTALLING THE PROPELLER

1. Rotate the motor shaft to insert the propeller pin horizontally.

2. Install the propeller onto the motor shaft by engaging the propeller

onto the propeller pin.

3. Install the propeller nut. Tighten the nut securely.

4. Use a MotorGuide propeller wrench or pliers to tighten the propeller

nut another ¼ turn.

Page 45

CUSTOM APPLICATIONS

eng 41

Repositioning the Top Housing

VariMAX transom mount motors are configured at the factory for use

on the transom. The VariMAX motor head can be reversed (eight head

positions are available) to fit any application including bow, backtroller,

or sideways pulling applications. The BluVis lights can also be reversed

to keep the intuitive push‑pull feel and control consistent. If you have a

VariMAX bow mount or pontoon mount motor, it is already configured

for bow mount applications.

IMPORTANT: While configuring the top housing to a new position,

toggle the position switch for the appropriate mount application. Refer

to Setting the Direction Control Switch.

1. Ensure the battery cables are disconnected from the power source.

2. Loosen the top housing retaining bolt with a 5 mm diameter Allen

wrench. Do not fully remove the retaining bolt.

IMPORTANT: Do not fully remove the top housing retaining bolt or the

retaining nut may fall out. Do not raise the top housing off of the column.

Removing the top housing may disconnect the motor control wires. If

the wires disconnect, refer to Motor Control Wiring for wire orientation.

a - Allen wrench

3. Raise the top housing until the height pin disengages.

a - Height pin

a

44879

a

44885

Page 46

CUSTOM APPLICATIONS

42 eng

4. Rotate the top housing to the desired position and push the top

housing back down to engage the height pin.

a - Top housing

b - Eight position settings

5. Tighten the top housing retaining bolt with an Allen wrench. Tighten

the bolt to the specified torque.

Torque Description Nm lb‑in. lb‑ft

Top housing retaining bolt 8.5 75 –

a - Allen wrench

Setting the Direction Control Switch

VariMAX motors are configured to the intuitive push‑pull direction

control. To use the transom mount on the bow of the vessel, reverse

the top housing and toggle the direction control switch to set the motor

and BluVis function display orientation for a bow application. To reverse

the top housing, refer to Repositioning the Top Housing.

1. Disconnect the battery cables from the power source.

2. Loosen the top housing retaining bolt with an Allen wrench. Do not

fully remove the retaining bolt.

38638

a

b

a

44879

Page 47

CUSTOM APPLICATIONS

eng 43

IMPORTANT: Do not fully remove the top housing retaining bolt or the

retaining nut may fall out. Slowly raise the top housing off of the shaft

ensuring that the motor control wires do not disconnect. If the wires are

disconnected, refer to Motor Control Wiring.

a - Allen wrench

3. Remove the top housing from the column.

NOTE: On saltwater models, do not remove the heat sink grease on

the motor column. Heat sink grease will not wash out of clothing.

39092

Top housing removed from column

4. Turn the top housing upside down to expose the direction control

switch inside.

5. Slide the switch away from the handle.

a

44879

Page 48

CUSTOM APPLICATIONS

44 eng

NOTE: If necessary, use a flathead screwdriver to slide the direction

control switch.

B

A

39225

Transom mount application (default)

39064

B

A

Bow, pontoon mount, or backtrolling application

6. Install the top housing onto the motor column.

Page 49

CUSTOM APPLICATIONS

eng 45

7. Rotate the top housing to the desired position and push the top

housing back down to engage the height pin.

a - Top housing

b - Eight position settings

8. Retighten the top housing retaining bolt with an Allen wrench.

Tighten the bolt to the specified torque.

Torque Description Nm lb‑in. lb‑ft

Top housing retaining bolt 8.5 75 –

a - Allen wrench

38638

a

b

a

44879

Page 50

CUSTOM APPLICATIONS

46 eng

Motor Control Wiring

!

WARNING

Performing service or maintenance without first disconnecting the

battery can cause product damage, personal injury, or death due to

fire, explosion, electrical shock, or unexpected motor starting. Always

disconnect the battery cables from the battery before maintaining,

servicing, installing, or removing motor components.

IMPORTANT: Disconnect the VariMAX motor control wiring for service

only. Do not reconfigure the motor control wiring when reorienting the

motor top housing between transom and bow applications.

NOTE: If necessary, use needle nose pliers to connect the motor control

wires to their respective terminal. Ensure the wiring connection is

secure.

RED

BLK

B

A

45692

Transom mount application

BLK

RED

A

B

45693

Bow or pontoon mount application

Page 51

OWNER SERVICE ASSISTANCE

eng 47

Troubleshooting

NOTE: For service information, contact any certified MotorGuide

service center. For a full listing of MotorGuide service centers, go to

www.motorguide.com or contact any Mercury service office.

Symptom Possible Cause Resolution

Loss of power

Weak 12 volt trolling motor

battery

Check 12 volt battery charge.

Recharge or replace battery as

required.

Loose or corroded battery

connections

Inspect battery connections for

cleanliness and tightness.

Propeller is loose, damaged,

or off‑balance

Refer to Propeller

Replacement.

Wiring or electrical

connection faulty

Wire gauge from the battery to

the trolling motor is insufficient.

Six gauge wire is

recommended.

Excessive noise,

vibration

Motor shaft is bent Refer to a service center.

Propeller is loose, damaged,

or off‑balance

Refer to Propeller

Replacement.

Motor failure (all

speeds)

Weak 12 volt trolling motor

battery

Check 12 volt battery charge.

Recharge or replace battery as

required.

Loose or corroded battery

connections

Inspect battery connections for

cleanliness and tightness.

Wiring or electrical

connection faulty.

Wire gauge from the battery to

the trolling motor is insufficient.

Six gauge wire is

recommended.

Fuse on circuit breaker is

open

Replace the fuse or reset the

circuit breaker only after

determining the root cause of

the problem.

Magnets interfering with

armature

Turn off the power and manually

rotate the propeller. If the

propeller does not rotate freely

with a slight magnetic drag,

contact a service center.

Page 52

OWNER SERVICE ASSISTANCE

48 eng

Symptom Possible Cause Resolution

Motor rotates in the

wrong direction

Direction control switch is in

the wrong position

Refer to Setting the Direction

Control Switch.

BluVis function

display failure

Electrical Refer to a service center.

Wiring or electrical

connection faulty

Check the battery connection or

refer to a service center.

Difficulty removing

propeller

Bent propeller pin

Hold one blade and lightly tap

the opposite blade with a rubber

mallet.

Use a putty knife on both sides

of the propeller to apply equal

pressure.

Bent armature shaft Refer to a service center.

Service Assistance

Your satisfaction with your product is very important to us. If you have

a problem or question about your motor, contact your dealer or any

certified MotorGuide service center. For more service assistance

information, refer to Warranty Information.

The following information will be needed by the service office:

• Your name and address

• Daytime telephone number

• Model and serial number of your trolling motor

• Proof of purchase or registration verification

• Nature of problem

Mercury Marine Service Offices

For assistance, call, fax, or write. Please include your daytime

telephone number with mail and fax correspondence.

Page 53

OWNER SERVICE ASSISTANCE

eng 49

United States

Telephone

English ‑ (920) 929‑5040

Mercury Marine

W6250 W. Pioneer Road

Fond du Lac, WI 54936-1939

Francais ‑ (905) 636‑4751

Fax

English ‑ (920) 929‑5893

Francais ‑ (905) 636‑1704

Website www.motorguide.com

Australia, Pacific

Telephone (61) (3) 9791‑5822 Mercury Marine Australia

132-140 Frankston Road

Dandenong, Victoria 3164

Australia

Fax (61) (3) 9706‑7228

Europe, Middle East, Africa

Telephone (32) (87) 32 • 32 • 11 Marine Power - Europe, Inc.

Parc Industriel de Petit-Rechain

B-4800 Verviers,

Belgium

Fax (32) (87) 31 • 19 • 65

Mexico, Central America, South America, Caribbean

Telephone (954) 744‑3500 Mercury Marine

11650 Interchange Circle North

Miramar, FL 33025

U.S.A.

Fax (954) 744‑3535

Brunswick Asia Pacific Group

Telephone (65) 65466160 T/A Mercury Marine Singapore Pte Ltd

29 Loyang Way

Singapore, 508944

Fax (65) 65467789

Loading...

Loading...