Page 1

SERVICE

MANUAL

NUMBER 22

MARINE ENGINES

IN-LINE DIESEL

D2.8L D-Tronic Serial Number 0K000001 and Above. . . . . . . .

D4.2L D-Tronic Serial Number 0K000001 and Above. . . . . . . .

Printed in U.S.A. 90-860074--1 FEBRUARY 2002

90- i

2002, Mercury Marine

Page 2

Page 3

Notice

Throughout this publication, Dangers, Warnings and Cautions (accompanied by the

International HAZARD Symbol

concerning a particular service or operation that may be hazardous if performed incorrectly

or carelessly. OBSERVE THEM CAREFULLY!

These Safety Alerts alone cannot eliminate the hazards that they signal. Strict compliance

to these special instructions when performing the service, plus common sense operation,

are major accident prevention measures.

) are used to alert the mechanic to special instructions

DANGER

Immediate hazards which will result in severe personal injury or death.

WARNING

Hazards or unsafe practices which could result in severe personal injury or death.

CAUTION

Hazards or unsafe practices which could result in minor personal injury or product

or property damage.

90-860074--1 FEBRUARY 2002 Page i

Page 4

Notice to Users of This Manual

This service manual has been written and published by the Service Department of Mercury

Marine to aid our dealers’ mechanics and company service personnel when servicing the

products described herein.

It is assumed that these personnel are familiar with marine product servicing procedures.

Furthermore, it is assumed that they have been trained in the recommended service

procedures of Mercury MerCruiser product, including the use of mechanics’ common hand

tools and the special Mercury Marine or recommended tools from other suppliers.

We could not possibly know of and advise the marine trade of all conceivable procedures

and of the possible hazards and/or results of each method. Therefore, anyone who uses

a service procedure and/or tool, which is not recommended by the manufacturer, first must

completely satisfy himself that neither his nor the products safety will be endangered.

All information, illustrations and specifications contained in this manual are based on the

latest product information available at the time of publication. As required, revisions to this

manual will be sent to all dealers contracted by us to sell and/or service these products.

We reserve the right to make changes to this manual without prior notification.

Refer to dealer service bulletins, operation maintenance and warranty manuals and

installation manuals for other pertinent information concerning the products described in

this manual.

It should be kept in mind, while working on the product, that the electrical system is capable

of violent and damaging short circuits or severe electrical shocks. When performing any

work where electrical terminals could possibly be grounded or touched by the mechanic,

the battery cables should be disconnected at the battery.

Any time the intake or exhaust openings are exposed during service they should be covered

to protect against accidental entrance of foreign material which could enter the cylinders and

cause extensive internal damage when the engine is started.

It is important to note, during any maintenance procedure replacement fasteners must have

the same measurements and strength as those removed. Numbers on the heads of the

metric bolts and on the surfaces of metric nuts indicate their strength. American bolts use

radial lines for this purpose, while most American nuts do not have strength markings.

Mismatched or incorrect fasteners can result in damage or malfunction, or possibly personal

injury. Therefore, fasteners removed should be saved for reuse in the same locations

whenever possible. Where the fasteners are not satisfactory for re-use, care should be

taken to select a replacement that matches the original.

Page ii 90-860074--1 FEBRUARY 2002

Page 5

Engine Mechanical Components

Many of the engine mechanical components are designed for marine applications. Unlike

automotive engines, marine engines are subjected to extended periods of heavy load

and wide open throttle operation and, therefore, require heavy-duty components. Special

marine engine parts have design and manufacturing specifications that are required to

provide long life and dependable performance. Marine engine parts also must be able to

resist the corrosive action of salt or brackish water that will rust or corrode standard

automotive parts within a short period of time.

Failure to use recommended Mercury / Quicksilver service replacement parts can result in

poor engine performance and/or durability, rapid corrosion of parts subjected to salt

water and possibly complete failure of the engine.

Replacement Parts

Use of parts other than the recommended service replacement parts, will void the warranty

on those parts that are damaged as a result.

Electrical and fuel system components on Mercury MerCruiser Engines and Stern

Drives are designed and manufactured to comply with U.S. Coast Guard Rules

and Regulations to minimize risks of fire or explosion.

Use of replacement electrical or fuel system components, which do not comply to

these rules and regulations, could result in a fire or explosion hazard and should

be avoided.

When servicing the electrical and fuel systems, it is extremely important that all

components are properly installed and tightened. If not, any electrical component

opening would permit sparks to ignite fuel vapors from fuel system leaks, if they

existed.

WARNING

90-860074--1 FEBRUARY 2002 Page iii

Page 6

Models Covered in This Manual

Sterndrive (MCM) Serial Number

D2.8L D-Tronic 0K000001 and Above

D4.2L D-Tronic 0K000001 and Above

Inboard (MIE) Serial Number

D2.8L D-Tronic 0K000001 and Above

D4.2L D-Tronic 0K000001 and Above

Page iv 90-860074--1 FEBRUARY 2002

Page 7

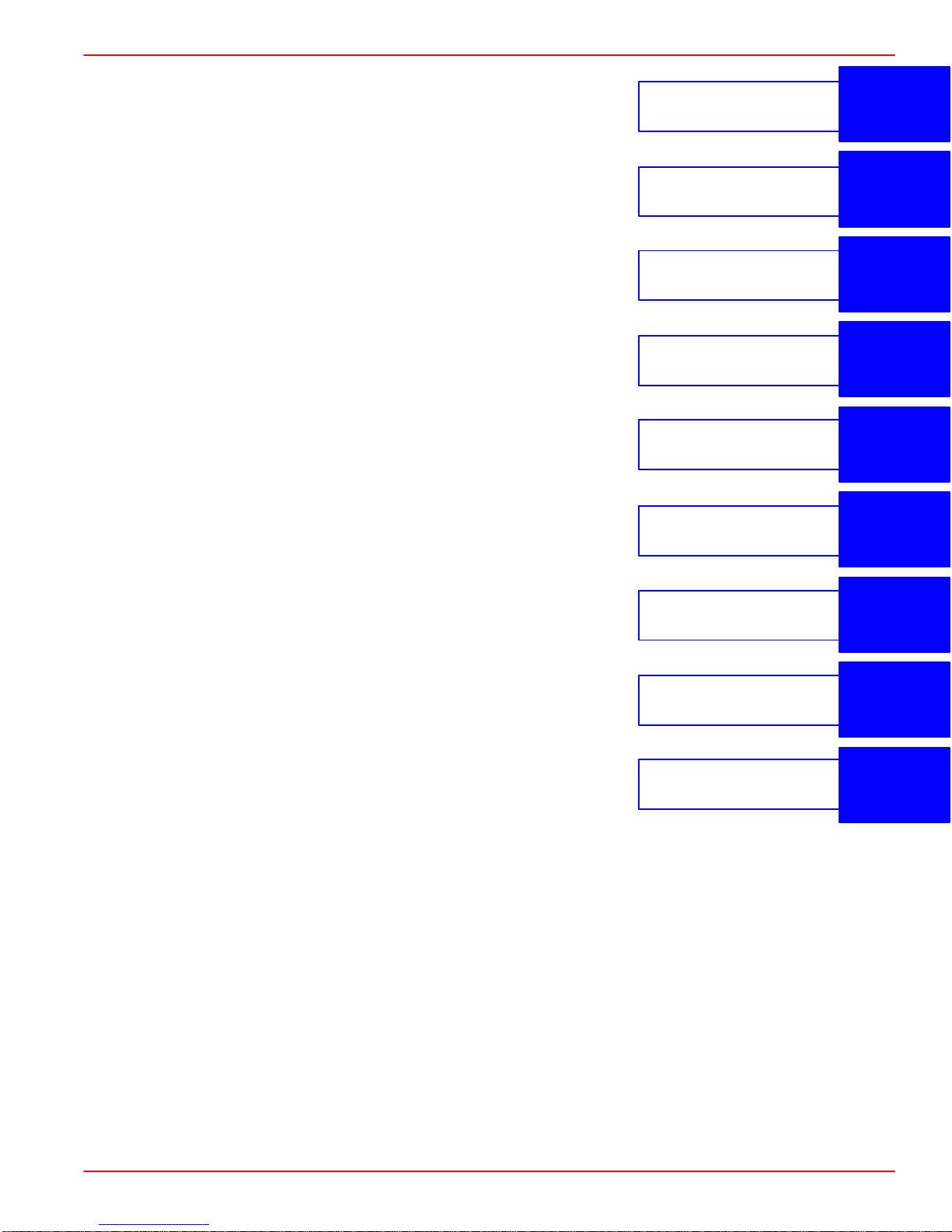

Service Manual Outline

Section 1 - Important Information

A - General Information

B - Maintenance

C - Troubleshooting

Section 2 - Removal and Installation

A - Sterndrive (MCM) Models

B - Inboard (MIE) Models

Section 3 - Engine Mechanical

A - D2.8L D-Tronic And D4.2L D-Tronic Engines

Section 4 - Electrical System

A - Starting System

B - Charging System

C - Glow Plug System (If Equipped)

D - Instrumentation

E - Wiring Diagrams

Section 5 - Fuel System

A - Description

B - Fuel Delivery Pump and Fuel Filter

C - Injectors

D - Injection Pump

E - EDI Diagnosis

Section 6 - Cooling System

A - Seawater Cooling System

B - Closed Cooling System

Section 7 - Intake And Exhaust System

A - Intercooler

B - Intake / Exhaust Manifold, Elbows and Risers

C - Turbocharger

Section 8 - Drive System

A - ZF / Hurth Transmissions

B - Propeller Shaft Models

Section 9 - Power Steering System

A - Pump And Related Components

Important Information

1

Removal And Installation

2

Engine Mechanical

3

Electrical System

4

Fuel System

5

Cooling System

6

Intake And Exhaust System

7

Drive System

8

Power Steering System

9

90-860074--1 FEBRUARY 2002 Page v

Page 8

IMPORTANT INFORMATION

Section 1A - General Information

Introduction 1A-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Use This Manual 1A-3. . . . . . . . . . . . . . .

Page Numbering 1A-3. . . . . . . . . . . . . . . . . . .

Engine Serial Number / Decal Locations 1A-4.

Operation / Duty Cycle 1A-5. . . . . . . . . . . . . . . . .

IMPORTANT INFORMATION

Section 1B - Maintenance

Torque Specifications 1B-3. . . . . . . . . . . . . . . . . .

Special Tools 1B-3. . . . . . . . . . . . . . . . . . . . . . . . .

Tools 1B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 1B-3. . . . . . .

Engine Specifications 1B-4. . . . . . . . . . . . . . . . . .

Sterndrive (MCM) Engines 1B-4. . . . . . . . . . .

Inboard (MIE) Engines 1B-5. . . . . . . . . . . . . .

Capacities 1B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engines 1B-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Drives 1B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmissions 1B-6. . . . . . . . . . . . . . . . . . . . . .

Maintenance Schedules 1B-7. . . . . . . . . . . . . . . .

Maintenance Intervals 1B-7. . . . . . . . . . . . . . .

Sterndrive (MCM) Engines 1B-8. . . . . . . . . . .

Inboard (MIE) Engines 1B-11. . . . . . . . . . . . .

Engine External Views 1B-13. . . . . . . . . . . . . . . .

Starboard Side View 1B-13. . . . . . . . . . . . . . .

Front View 1B-14. . . . . . . . . . . . . . . . . . . . . . . .

Port Side View 1B-15. . . . . . . . . . . . . . . . . . . .

Rear View 1B-16. . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil 1B-17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Level 1B-17. . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Engine Oil and Oil Filter 1B-19. . .

Fuel 1B-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Precautions 1B-21. . . . . . . . . . . . . . . . . . . . . . .

General Information 1B-22. . . . . . . . . . . . . . . .

Diesel Fuel In Cold Weather 1B-22. . . . . . . .

Fuel Filter 1B-23. . . . . . . . . . . . . . . . . . . . . . . .

Closed Cooling System 1B-28. . . . . . . . . . . . . . .

Coolant Requirement 1B-28. . . . . . . . . . . . . .

Checking Level 1B-29. . . . . . . . . . . . . . . . . . . .

Draining 1B-30. . . . . . . . . . . . . . . . . . . . . . . . . .

Filling 1B-32. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sacrificial Anodes 1B-33. . . . . . . . . . . . . . . . . . . .

Removal 1B-33. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 1B-33. . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 1B-34. . . . . . . . . . . . . . . . . . . . . .

Reassembly 1B-34. . . . . . . . . . . . . . . . . . . . . .

Installation 1B-34. . . . . . . . . . . . . . . . . . . . . . . .

Flushing Seawater System 1B-35. . . . . . . . . . . .

SternDrive (MCM) Models 1B-35. . . . . . . . . .

Inboard (MIE) Models 1B-36. . . . . . . . . . . . . .

Inspect Water Pickups 1B-38. . . . . . . . . . . . . . . .

SternDrive Gear Housing 1B-38. . . . . . . . . . .

Inboard Though the Hull Pickup 1B-38. . . . .

Lubrication 1B-39. . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Break-In 1A-6. . . . . . . . . . . . . . . . . . . . . . .

Initial Break-In Procedure 1A-6. . . . . . . . . . . .

Mercury/Quicksilver Lubricants, Sealants

And Adhesives 1A-7. . . . . . . . . . . . . . . . . . . . . . .

Throttle Cable 1B-39. . . . . . . . . . . . . . . . . . . . .

Shift Cable 1B-39. . . . . . . . . . . . . . . . . . . . . . . .

Engine Coupler / U-joint Shaft Splines 1B-40

U-joints 1B-41. . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Shaft Extension Models 1B-42. . . . . . .

Sterndrive Unit and Transom

Assembly 1B-42. . . . . . . . . . . . . . . . . . . . . . . .

Continuity Circuit 1B-43. . . . . . . . . . . . . . . . . . . . .

Continuity Circuit (continued) 1B-44. . . . . . . . . .

MerCathode 1B-45. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Mounts 1B-45. . . . . . . . . . . . . . . . . . . . . . .

Electrical System 1B-45. . . . . . . . . . . . . . . . . . . . .

Power Steering 1B-46. . . . . . . . . . . . . . . . . . . . . .

Checking Fluid Level 1B-46. . . . . . . . . . . . . . .

Filling and Bleeding 1B-48. . . . . . . . . . . . . . . .

Transmission 1B-49. . . . . . . . . . . . . . . . . . . . . . . .

Checking Fluid Level 1B-49. . . . . . . . . . . . . . .

Power Trim 1B-50. . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Fluid Level 1B-50. . . . . . . . . . . . . . .

Filling 1B-51. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Lube Monitor 1B-52. . . . . . . . . . . . . . . . . . .

Checking Fluid Level 1B-52. . . . . . . . . . . . . . .

Filling 1B-52. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seawater Strainer 1B-53. . . . . . . . . . . . . . . . . . . .

Air Filter 1B-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 1B-54. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 1B-54. . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 1B-55. . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1B-55. . . . . . . . . . . . . . . . . . . . . . . .

Drive Belts 1B-56. . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 1B-56. . . . . . . . . . . . . . . .

Inspection 1B-57. . . . . . . . . . . . . . . . . . . . . . . .

Engine Water Circulating Pump Belt 1B-57. .

Alternator Belt 1B-58. . . . . . . . . . . . . . . . . . . . .

Power Steering Pump Belt 1B-60. . . . . . . . . .

Vacuum Pump Belt 1B-62. . . . . . . . . . . . . . . .

Battery 1B-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging System 1B-64. . . . . . . . . . . . . . . . . . . . .

Corrosion and Corrosion Protection 1B-64. . . . .

Saltwater Operation 1B-64. . . . . . . . . . . . . . . . . .

Freezing Temperature and Cold Weather

Operation 1B-65. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cold Weather or Extended Storage 1B-66. . . . .

Power Package Layup 1B-66. . . . . . . . . . . . .

Draining 1B-67. . . . . . . . . . . . . . . . . . . . . . . . . .

Recommissioning 1B-73. . . . . . . . . . . . . . . . . . . .

Page vi 90-860074--1 FEBRUARY 2002

Page 9

IMPORTANT INFORMATION

SECTION 1C - Troubleshooting

Precautions 1C-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Poor Boat Performance and/or Poor

Maneuverability 1C-5. . . . . . . . . . . . . . . . . . . . . .

Improper Full Throttle Engine RPM 1C-6. . . . . .

RPM Too High 1C-6. . . . . . . . . . . . . . . . . . . . .

RPM Too Low 1C-6. . . . . . . . . . . . . . . . . . . . . .

Engine Cranks Over But Will Not Start Or

Starts Hard 1C-7. . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 1C-7. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System 1C-7. . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous 1C-9. . . . . . . . . . . . . . . . . . . . . .

Engine Will Not Crank Over or Starter

Inoperative 1C-9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Glow Plugs Inoperative 1C-10. . . . . . . . . . . . . . .

Charging System Inoperative 1C-11. . . . . . . . . .

Noisy Alternator 1C-11. . . . . . . . . . . . . . . . . . . . . .

Engine Operates Poorly at Idle 1C-12. . . . . . . . .

Engine Operates Poorly At High Rpm 1C-13. . .

Poor Fuel Economy 1C-14. . . . . . . . . . . . . . . . . .

Engine Smoking 1C-15. . . . . . . . . . . . . . . . . . . . .

Black Smoke 1C-15. . . . . . . . . . . . . . . . . . . . . .

Blue Smoke 1C-16. . . . . . . . . . . . . . . . . . . . . . .

White Smoke 1C-16. . . . . . . . . . . . . . . . . . . . .

Exhaust Gas Temperature 1C-17. . . . . . . . . . . . .

High 1C-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low 1C-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turbocharger 1C-18. . . . . . . . . . . . . . . . . . . . . . . .

Engine Noise 1C-19. . . . . . . . . . . . . . . . . . . . . . . .

Valve Cover Area 1C-20. . . . . . . . . . . . . . . . . .

Cylinder Area 1C-20. . . . . . . . . . . . . . . . . . . . .

Camshaft Area 1C-21. . . . . . . . . . . . . . . . . . . .

Crankshaft Area 1C-22. . . . . . . . . . . . . . . . . . .

Miscellaneous 1C-23. . . . . . . . . . . . . . . . . . . . .

Oil Pressure 1C-23. . . . . . . . . . . . . . . . . . . . . . . . .

Low Oil Pressure 1C-25. . . . . . . . . . . . . . . . . .

High Oil Pressure 1C-25. . . . . . . . . . . . . . . . . .

Excessive Oil Consumption 1C-26. . . . . . . . .

Water / Coolant in Engine 1C-27. . . . . . . . . . . . .

Important Information 1C-27. . . . . . . . . . . . . .

Water / Coolant In Crankcase Oil 1C-27. . . .

Water / Coolant On Top Pistons 1C-28. . . . .

Engine Overheats 1C-29. . . . . . . . . . . . . . . . . . . .

Cooling System 1C-29. . . . . . . . . . . . . . . . . . .

Mechanical 1C-30. . . . . . . . . . . . . . . . . . . . . . .

Power Steering 1C-31. . . . . . . . . . . . . . . . . . . . . .

Poor, Erratic or No Assist 1C-31. . . . . . . . . . .

Noisy Pump 1C-32. . . . . . . . . . . . . . . . . . . . . . .

Fluid Leaks 1C-32. . . . . . . . . . . . . . . . . . . . . . .

Insufficient Water Flow From Belt Driven

Seawater Pump 1C-33. . . . . . . . . . . . . . . . . . . . .

ZF / Hurth Hydraulic Transmission 1C-34. . . . . .

REMOVAL AND INSTALLATION

Section 2A - Sterndrive (MCM) Models

Torque Specifications 2A-3. . . . . . . . . . . . . . . . . .

Special Tools 2A-3. . . . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 2A-4. . . . . . .

Removal 2A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2A-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Installation / Alignment 2A-7. . . . . . .

Engine Connections 2A-15. . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION

Section 2B - Inboard (MIE) Models

Torque Specifications 2B-3. . . . . . . . . . . . . . . . . .

Tools/Lubricants/Adhesives 2B-3. . . . . . . . . . . . .

Removal 2B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Removal 2B-4. . . . . . . . . . . . . . . . . . . .

Installation 2B-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Installation and Initial

Alignment 2B-7. . . . . . . . . . . . . . . . . . . . . . . . .

Throttle Cable Installation and

Adjustment 2A-21. . . . . . . . . . . . . . . . . . . . . . .

Shift Cable Installation and

Adjustment 2A-23. . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Shift Problems 2A-28. . . . . .

Battery Cables 2A-30. . . . . . . . . . . . . . . . . . . .

Engine Final Alignment 2B-11. . . . . . . . . . . . .

Engine Connections 2B-18. . . . . . . . . . . . . . .

Throttle Cable Installation and

Adjustment 2B-21. . . . . . . . . . . . . . . . . . . . . . .

Shift Cable Installation And

Adjustment 2B-21. . . . . . . . . . . . . . . . . . . . . . .

Battery Cables 2B-21. . . . . . . . . . . . . . . . . . . .

90-860074--1 FEBRUARY 2002 Page vii

Page 10

ENGINE

Section 3A - Engine Mechanical

Identification 3A-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 3A-4. . . . . . . . . . . . . . . . . .

Tools 3A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 3A-6. . . . . . . . . . . . . . . . . . . . . . .

Special Tools (continued) 3A-7. . . . . . . . . . . .

Snap-On Tools 3A-8. . . . . . . . . . . . . . . . . . . . .

Kent-Moore Tools 3A-8. . . . . . . . . . . . . . . . . . .

Lubricants/Sealants/Adhesives 3A-9. . . . . . . . . .

Engine Specifications 3A-10. . . . . . . . . . . . . . . . .

Piston Rings 3A-10. . . . . . . . . . . . . . . . . . . . . .

Cylinder Liner Diameter 3A-10. . . . . . . . . . . .

Cylinder Liner Protrusion 3A-11. . . . . . . . . . .

Head Gaskets 3A-11. . . . . . . . . . . . . . . . . . . . .

Cylinder Head 3A-11. . . . . . . . . . . . . . . . . . . . .

Oil Pump 3A-12. . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 3A-12. . . . . . . . . . . . . . . . . . . . . . . . .

Valve Lifter 3A-12. . . . . . . . . . . . . . . . . . . . . . . .

Rocker Arm 3A-13. . . . . . . . . . . . . . . . . . . . . . .

Valve Adjustment 3A-13. . . . . . . . . . . . . . . . . .

Valve 3A-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Seat 3A-13. . . . . . . . . . . . . . . . . . . . . . . .

Valve Guide 3A-14. . . . . . . . . . . . . . . . . . . . . . .

Valve Spring 3A-14. . . . . . . . . . . . . . . . . . . . . .

Crankshaft 3A-15. . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft (continued) 3A-16. . . . . . . . . . . . .

Connecting Rods 3A-17. . . . . . . . . . . . . . . . . .

Connecting Rod Crank Pin Bore 3A-17. . . . .

Connecting Rod Bushings 3A-17. . . . . . . . . .

Pistons 3A-17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel 3A-17. . . . . . . . . . . . . . . . . . . . . . . . .

Precautions 3A-18. . . . . . . . . . . . . . . . . . . . . . . . .

General Information 3A-19. . . . . . . . . . . . . . . . . .

Engine Rotation 3A-19. . . . . . . . . . . . . . . . . . .

Engine Firing Order 3A-19. . . . . . . . . . . . . . . .

Late Model Cylinder Head Gasket -

Torque Sequence and Specifications 3A-20

Early Model Cylinder Head Gasket -

Torque Sequence and Specifications 3A-25

Lubrication System - All Models 3A-28. . . . .

Examples of Bearing Failures 3A-29. . . . . . .

Compression Testing Procedure 3A-30. . . . .

Engine Cover 3A-31. . . . . . . . . . . . . . . . . . . . . . . .

Removal 3A-31. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-31. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-31. . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-31. . . . . . . . . . . . . . . . . . . . . . . .

Valve Covers 3A-32. . . . . . . . . . . . . . . . . . . . . . . .

Removal 3A-32. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-33. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-33. . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-34. . . . . . . . . . . . . . . . . . . . . . . .

Water Manifold 3A-37. . . . . . . . . . . . . . . . . . . . . . .

Exploded Views 3A-37. . . . . . . . . . . . . . . . . . .

Removal 3A-38. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-38. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-38. . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-39. . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Heads 3A-40. . . . . . . . . . . . . . . . . . . . . .

Exploded Views 3A-40. . . . . . . . . . . . . . . . . . .

Removal 3A-42. . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 3A-44. . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-44. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-45. . . . . . . . . . . . . . . . . . . . . . . .

Repair 3A-50. . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Plugs 3A-50. . . . . . . . . . . . . . . . . .

Assembly 3A-52. . . . . . . . . . . . . . . . . . . . . . . . .

Installation -

Using Early Model Gaskets 3A-55. . . . . . . . .

Installation -

Using Late Model Gaskets 3A-62. . . . . . . . .

Rocker Arm 3A-71. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 3A-71. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-71. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-71. . . . . . . . . . . . . . . . . . . . . . . .

Assembly 3A-72. . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-73. . . . . . . . . . . . . . . . . . . . . . . .

Timing Gear Cover 3A-77. . . . . . . . . . . . . . . . . . .

Exploded View 3A-77. . . . . . . . . . . . . . . . . . . .

Removal 3A-78. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-78. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-78. . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-79. . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 3A-81. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 3A-81. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-81. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-82. . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 3A-83. . . . . . . . . . . . . . . . . . . . . .

Installation 3A-83. . . . . . . . . . . . . . . . . . . . . . . .

Oil Pressure Relief Valve 3A-84. . . . . . . . . . . . . .

Removal 3A-84. . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 3A-85. . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-85. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-86. . . . . . . . . . . . . . . . . . . . . . . .

Assembly 3A-86. . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-87. . . . . . . . . . . . . . . . . . . . . . . .

Oil Pan and Oil Pick-Up Tube Assembly 3A-88.

Removal 3A-88. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-89. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-89. . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-89. . . . . . . . . . . . . . . . . . . . . . . .

Page viii 90-860074--1 FEBRUARY 2002

Page 11

ENGINE (continued)

Section 3A - Engine Mechanical (continued)

Adapter / Oil Thermostat 3A-91. . . . . . . . . . . . . .

Removal 3A-91. . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 3A-92. . . . . . . . . . . . . . . . . . . . . .

Cleaning and Inspection 3A-92. . . . . . . . . . . .

Testing 3A-92. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-93. . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 3A-95. . . . . . . . . . . . . . . . . . . . . . . . . . .

Exploded View 3A-95. . . . . . . . . . . . . . . . . . . .

Testing - Measuring Lobe Lift 3A-96. . . . . . . .

Removal 3A-96. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-98. . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-99. . . . . . . . . . . . . . . . . . . . . . . .

Camshaft Bearings 3A-100. . . . . . . . . . . . . . . . . .

Inspection 3A-100. . . . . . . . . . . . . . . . . . . . . . .

Removal 3A-100. . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-101. . . . . . . . . . . . . . . . . . . . . . .

Valve Lifters 3A-102. . . . . . . . . . . . . . . . . . . . . . . .

Removal 3A-102. . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-103. . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-103. . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-104. . . . . . . . . . . . . . . . . . . . . . .

Valve Push Rods 3A-105. . . . . . . . . . . . . . . . . . . .

Removal 3A-105. . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-105. . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-105. . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-105. . . . . . . . . . . . . . . . . . . . . . .

Connecting Rod / Piston Assembly 3A-106. . . .

Measuring Rod Bearing Clearance 3A-106. .

Removal 3A-107. . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 3A-108. . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-109. . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-109. . . . . . . . . . . . . . . . . . . . . . .

Assembly 3A-113. . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-114. . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal 3A-116. . . . . . . . . . . . . . . . . . . . . . .

Removal 3A-116. . . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-117. . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Main Bearings 3A-118. . . . . . . .

Removal 3A-118. . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 3A-123. . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-124. . . . . . . . . . . . . . . . . . . . . . .

Installation 3A-127. . . . . . . . . . . . . . . . . . . . . . .

Cylinder Liners 3A-136. . . . . . . . . . . . . . . . . . . . . .

Removal 3A-136. . . . . . . . . . . . . . . . . . . . . . . .

Identification 3A-137. . . . . . . . . . . . . . . . . . . . .

Cleaning and Inspection 3A-138. . . . . . . . . . .

Installation 3A-139. . . . . . . . . . . . . . . . . . . . . . .

Flywheel Housing, Coupler / Drive Plate And

Flywheel 3A-144. . . . . . . . . . . . . . . . . . . . . . . . . . .

Exploded View 3A-144. . . . . . . . . . . . . . . . . . .

Flywheel Housing 3A-148. . . . . . . . . . . . . . . . .

Sterndrive (MCM) Coupler / Inboard (MIE)

Drive Plate 3A-150. . . . . . . . . . . . . . . . . . . . . . .

Flywheel 3A-151. . . . . . . . . . . . . . . . . . . . . . . .

Engine Mounts 3A-152. . . . . . . . . . . . . . . . . . . . . .

Front Mounts 3A-152. . . . . . . . . . . . . . . . . . . . .

MIE (Inboard) Transmission Mounts 3A-153.

Engine 20-Hour Break-In Period 3A-154. . . . . .

After Break-in Period 3A-154. . . . . . . . . . . . . . . .

ELECTRICAL SYSTEMS

Section 4A - Starting System

Identification 4A-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 4A-3. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 4A-3. . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 4A-3. . . . . . .

Replacement Parts 4A-4. . . . . . . . . . . . . . . . . . . .

Starting System Components 4A-4. . . . . . . . . . .

Inspection 4A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Periodic Inspection 4A-6. . . . . . . . . . . . . . . . .

Testing Voltage 4A-6. . . . . . . . . . . . . . . . . . . . .

Removal 4A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Motor 4A-7. . . . . . . . . . . . . . . . . . . . . . .

Solenoid Switch 4A-8. . . . . . . . . . . . . . . . . . . .

Installation 4A-9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid Switch 4A-9. . . . . . . . . . . . . . . . . . . .

Starter Motor 4A-10. . . . . . . . . . . . . . . . . . . . . .

90-860074--1 FEBRUARY 2002 Page ix

Page 12

ELECTRICAL SYSTEMS

Section 4B - Charging System

Identification 4B-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Parts Warning 4B-3. . . . . . . . . . . .

Specifications 4B-4. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 4B-4. . . . . . . . . . . . . . . . . .

Special Tools 4B-5. . . . . . . . . . . . . . . . . . . . . . . . .

Lubricants/Sealers/Adhesives 4B-5. . . . . . . . . . .

Wire Color Code Abbreviations 4B-5. . . . . . . . . .

Precautions 4B-6. . . . . . . . . . . . . . . . . . . . . . . . . .

General 4B-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronic Diesel Injection (EDI)

Electrical System Precautions 4B-6. . . . . . .

Battery Precautions - Multiple EDI

Engines 4B-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging System Components 4B-8. . . . . . . . . .

Inspection 4B-9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Tests (Alternator

on Engine) 4B-10. . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL SYSTEMS

Section 4C - Glow Plug System

Identification 4C-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 4C-3. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 4C-4. . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 4C-4. . . . . . .

Special Tools 4C-4. . . . . . . . . . . . . . . . . . . . . . . . .

Description 4C-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Precautions 4C-4. . . . . . . . . . . . . . . . . . . . . . . . . .

Glow Plug Testing (Prior to Removal) 4C-5. . . .

Removal 4C-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 4C-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuitry Test 4B-10. . . . . . . . . . . . . . . . . . . . . . . .

Output Circuit 4B-11. . . . . . . . . . . . . . . . . . . . .

Excitation Circuit 4B-12. . . . . . . . . . . . . . . . . .

Sensing Circuit 4B-13. . . . . . . . . . . . . . . . . . . .

Current Output Test 4B-14. . . . . . . . . . . . . . . .

Exploded View 4B-16. . . . . . . . . . . . . . . . . . . .

Removal 4B-17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternator 4B-17. . . . . . . . . . . . . . . . . . . . . . . . .

Alternator Bracket 4B-17. . . . . . . . . . . . . . . . .

Installation 4B-18. . . . . . . . . . . . . . . . . . . . . . . . . .

Alternator Bracket 4B-18. . . . . . . . . . . . . . . . .

Alternator 4B-18. . . . . . . . . . . . . . . . . . . . . . . . .

Battery Isolators 4B-19. . . . . . . . . . . . . . . . . . . . . .

Dual Battery Charging Systems 4B-19. . . . .

Battery Isolator Diagram 4B-20. . . . . . . . . . . .

Inspection 4C-7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4C-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Glow Plug Actuator Relay and Auxiliary

Relay 4C-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing 4C-9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 4C-10. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 4C-10. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 4C-10. . . . . . . . . . . . . . . . . . . . . . . .

Installation 4C-10. . . . . . . . . . . . . . . . . . . . . . . .

Glow Plug Circuit Diagram 4C-11. . . . . . . . . . . . .

ELECTRICAL SYSTEMS

Section 4D - Instrumentation

Identification 4D-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Gauges 4D-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Panels 4D-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 4D-4. . . . . . . . . . . . . . . . . . . . . . . . .

Tools 4D-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 4D-4. . . . . . .

Wire Color Abbreviations 4D-4. . . . . . . . . . . . . . .

Precautions 4D-5. . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 4D-6. . . . . . . . . . . . . . . . . . .

Special Information 4D-6. . . . . . . . . . . . . . . . . . . .

Tachometer 4D-6. . . . . . . . . . . . . . . . . . . . . . . .

QSI Series Gauge Lighting Options 4D-7. . .

Gauges 4D-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 4D-8. . . . . . . . . . . . . . . . . . . . . . . . . .

Testing 4D-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4D-11. . . . . . . . . . . . . . . . . . . . . . . .

Senders 4D-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page x 90-860074--1 FEBRUARY 2002

Oil Pressure 4D-11. . . . . . . . . . . . . . . . . . . . . .

Water Temperature - Primary Station 4D-13.

Primary Station Switches 4D-15. . . . . . . . . . . . . .

Ignition Key Switch 4D-15. . . . . . . . . . . . . . . .

Audio Warning Test and Panel Light

Switch 4D-17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio Warning System 4D-19. . . . . . . . . . . . . . . .

Alarm 4D-19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pressure Switch 4D-20. . . . . . . . . . . . . . . .

Water Temperature Switch / Sender 4D-21. .

Transmission Fluid Temperature

Switch 4D-24. . . . . . . . . . . . . . . . . . . . . . . . . . .

Second Station Extension Harness 4D-26. . . . .

Remote Control / Neutral Start Safety

Circuit 4D-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Primary Station 4D-29. . . . . . . . . . . . . . . . . . . .

Secondary Station 4D-30. . . . . . . . . . . . . . . . .

Page 13

ELECTRICAL SYSTEMS

Section 4E - Wiring Diagrams

Wire Color Abbreviations 4E-3. . . . . . . . . . . . . . .

Tools 4E-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 4E-3. . . . . . .

General Information 4E-3. . . . . . . . . . . . . . . . . . .

Sterndrive (MCM) Models 4E-4. . . . . . . . . . . . . .

Engine Wiring - Starting and Charging

System 4E-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

ECM and Fuel System Wiring 4E-8. . . . . . . .

Quicksilver Instrumentation Wiring 4E-10. . .

Power Trim System Wiring Diagram 4E-14. .

FUEL SYSTEM

Section 5A - Description

Introduction 5A-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Precautions 5A-4. . . . . . . . . . . . . . . . . . . . . . . . . .

Testing Procedure 5A-5. . . . . . . . . . . . . . . . . .

General Information 5A-6. . . . . . . . . . . . . . . . . . .

Basic Knowledge and Tools Required 5A-6.

Visual/Physical Inspection 5A-6. . . . . . . . . . .

Electrostatic Discharge Damage 5A-6. . . . . .

Diagnostic Information 5A-7. . . . . . . . . . . . . .

Terminology 5A-7. . . . . . . . . . . . . . . . . . . . . . . .

Electronic Control Module (ECM)

and Sensors 5A-9. . . . . . . . . . . . . . . . . . . . . . . . .

General Description 5A-9. . . . . . . . . . . . . . . . .

Computers and Voltage Signals 5A-9. . . . . .

MerCathode System Wiring Diagram 4E-15.

Inboard (MIE) Models 4E-16. . . . . . . . . . . . . . . . .

Engine Wiring - Starting and Charging

System 4E-16. . . . . . . . . . . . . . . . . . . . . . . . . .

ECM and Fuel System Wiring 4E-20. . . . . . .

Quicksilver Primary Instrumentation

Wiring 4E-22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Models With Early Connectors 4E-26. . . . . .

Models With 21-Pin Deutsch t

Connector 4E-28. . . . . . . . . . . . . . . . . . . . . . . .

Analog Signals 5A-9. . . . . . . . . . . . . . . . . . . . .

Analog Value Conditioning 5A-11. . . . . . . . . .

Digital Signals 5A-13. . . . . . . . . . . . . . . . . . . . .

Engine Control Module (ECM) 5A-15. . . . . . .

Speed Density System 5A-17. . . . . . . . . . . . .

ECM Input and Sensor Descriptions 5A-18. .

Fuel Management 5A-26. . . . . . . . . . . . . . . . . . . .

Control 5A-26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Modes Of Operation 5A-27. . . . . . . . . . . . . . .

Diagnosis and Testing 5A-30. . . . . . . . . . . . . . . .

ECM Reactions During Operation 5A-30. . . .

ECM Self-Diagnostics 5A-30. . . . . . . . . . . . . .

FUEL SYSTEM

Section 5B - Fuel Delivery Pump and Fuel Filter

Identification 5B-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 5B-3. . . . . . . . . . . . . . . . . . . . . . . . .

Torque 5B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools 5B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 5B-3. . . . . . .

Precautions 5B-4. . . . . . . . . . . . . . . . . . . . . . . . . .

Exploded View 5B-6. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Delivery Pump, Fuel Filter

and Related Components 5B-6. . . . . . . . . . .

Testing 5B-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5B-10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5B-11. . . . . . . . . . . . . . . . . . . . . . . . . .

Water Separating Fuel Filter 5B-13. . . . . . . . . . .

Removal 5B-13. . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5B-13. . . . . . . . . . . . . . . . . . . . . . . .

Water Drain Valve Operation 5B-15. . . . . . . . . . .

Purging Air From The Fuel System 5B-16. . . . .

90-860074--1 FEBRUARY 2002 Page xi

Page 14

FUEL SYSTEM

Section 5C - Fuel Injectors

Identification 5C-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 5C-3. . . . . . . . . . . . . . . . . . . . . . . . .

Torque 5C-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools 5C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bosch 5C-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 5C-4. . . . . . .

Precautions 5C-5. . . . . . . . . . . . . . . . . . . . . . . . . .

Description 5C-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Injector (Cutaway View) 5C-7. . . . . . . . . . .

FUEL SYSTEM

Section 5D - Injection Pump

Identification 5D-2. . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Code and Identification

Number Location 5D-2. . . . . . . . . . . . . . . . . . .

Specifications 5D-2. . . . . . . . . . . . . . . . . . . . . . . . .

Injection Pump 5D-2. . . . . . . . . . . . . . . . . . . . .

Timing 5D-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 5D-3. . . . . . . . . . . . . . . . . .

Special Tools 5D-3. . . . . . . . . . . . . . . . . . . . . . . . .

Tools 5D-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special EDI Tools 5D-4. . . . . . . . . . . . . . . . . . .

Kent-Moore Tools 5D-4. . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 5D-4. . . . . . .

Description 5D-5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Ratings 5D-6. . . . . . . . . . . . . . . . . . . . . . . . . .

Diesel Fuel in Cold Weather 5D-6. . . . . . . . . . . .

Exploded View 5C-8. . . . . . . . . . . . . . . . . . . . . . . .

Injector Test (Engine Misfiring) 5C-9. . . . . . . . . .

Removal 5C-10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 5C-12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing 5C-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C-13. . . . . . . . . . . . . . . . . . . . . . . .

Purging Air From Fuel Injectors

(Bleeding) 5C-16. . . . . . . . . . . . . . . . . . . . . . . . . .

Repair and Service 5D-7. . . . . . . . . . . . . . . . . . . .

General Information 5D-7. . . . . . . . . . . . . . . . .

Service Information 5D-7. . . . . . . . . . . . . . . . .

Precautions 5D-9. . . . . . . . . . . . . . . . . . . . . . . .

Exploded View 5D-10. . . . . . . . . . . . . . . . . . . . . . .

Fuel Injection Pump Removal 5D-11. . . . . . . . . .

Fuel Injection Pump Installation 5D-16. . . . . . . .

Installation With Engine Assembled 5D-16. .

Installation During Engine

Reassembly 5D-19. . . . . . . . . . . . . . . . . . . . . .

Fuel Injection Pump Timing 5D-23. . . . . . . . . . . .

Checking 5D-23. . . . . . . . . . . . . . . . . . . . . . . . .

Setting 5D-23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Engine - After Fuel Injection

Pump Installation and Timing 5D-28. . . . . . . . . .

Page xii 90-860074--1 FEBRUARY 2002

Page 15

FUEL SYSTEM

Section 5E - EDI Diagnosis

General Information 5E-2. . . . . . . . . . . . . . . . . . .

Introduction 5E-2. . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge and Tools Required 5E-2.

Visual/Physical Inspection 5E-3. . . . . . . . . . .

Electrostatic Discharge Damage 5E-3. . . . . .

Special Tools 5E-4. . . . . . . . . . . . . . . . . . . . . . .

Special EDI Tools 5E-4. . . . . . . . . . . . . . . . . . .

Kent-Moore Tools 5E-4. . . . . . . . . . . . . . . . . . .

Service Precautions 5E-5. . . . . . . . . . . . . . . . .

Diagnostic Information 5E-7. . . . . . . . . . . . . . . . .

Abbreviations 5E-7. . . . . . . . . . . . . . . . . . . . . .

ECM Self-Diagnosis 5E-8. . . . . . . . . . . . . . . .

Malfunction Indicator Lamp 5E-9. . . . . . . . . .

Intermittent Problems and

Malfunction Indicator Lamp 5E-10. . . . . . . . .

Reading Codes 5E-10. . . . . . . . . . . . . . . . . . . .

Clearing Codes 5E-13. . . . . . . . . . . . . . . . . . . .

Diagnosis of Driveability Concerns 5E-14. . .

ECM Input and Sensor Diagram 5E-15. . . . . . . .

ECM Connector Pin Layout 5E-16. . . . . . . . . . . .

Connector Chart 5E-17. . . . . . . . . . . . . . . . . . . . .

MAP (Manifold Air Pressure) Sensor 5E-20.

ECT (Engine Coolant Temperature)

Sensor 5E-22. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Temperature Sensor 5E-24. . . . . . . . . . .

RPM (Engine Speed) Sensor 5E-26. . . . . . . .

BARO (Atmospheric Pressure)

Sensor 5E-28. . . . . . . . . . . . . . . . . . . . . . . . . .

IAT (Intake Air Temperature) Sensor 5E-30.

Instrumented Injector

(Needle Movement Sensor) 5E-32. . . . . . . .

Fuel Quantity Actuator

(Pump Actuator) 5E-34. . . . . . . . . . . . . . . . . .

Fuel Quantity Sensor

(Control Sleeve Position Sensor) 5E-36. . . .

Timing Fault

(Timing Advance Regulation) 5E-38. . . . . . .

TP (Throttle Position)

Sensor / Low Idle Switch 5E-40. . . . . . . . . . .

Battery Voltage 5E-42. . . . . . . . . . . . . . . . . . . .

Battery (Switched K15) 5E-43. . . . . . . . . . . . .

Microcontroller Fault 5E-44. . . . . . . . . . . . . . .

ECM Reference Voltage

(u_ref - 2.5v) 5E-45. . . . . . . . . . . . . . . . . . . . .

Main Relay 5E-46. . . . . . . . . . . . . . . . . . . . . . .

Timing Actuator

(Timing Solenoid Valve) 5E-48. . . . . . . . . . . .

Glow Plug Main Relay

(Glow Plug Relay Actuator),

If Equipped 5E-50. . . . . . . . . . . . . . . . . . . . . . .

Glow Plug Auxiliary Relay, If Equipped 5E-52

Glow Plug Lamp (Glow Plug Display) 5E-54.

Glow Plug Lamp (Glow Plug Display) 5E-56.

MIL [Malfunction Indicator Lamp

(Diagnostic Lamp)] 5E-58. . . . . . . . . . . . . . . .

MIL [Malfunction Indicator Lamp

(Diagnostic Lamp)] 5E-60. . . . . . . . . . . . . . . .

Fuel Shut Off Valve [EAB

(Electrical Shut Off)] 5E-62. . . . . . . . . . . . . . .

EEPROM Fault (EEPROM and

Configuration) 5E-64. . . . . . . . . . . . . . . . . . . .

RPM Signal From Injector

(Secondary Engine Speed Sensor) 5E-66. .

Troubleshooting For EDI Systems 5E-68. . . . . .

Trouble Codes 5E-68. . . . . . . . . . . . . . . . . . . .

Display Terminology 5E-69. . . . . . . . . . . . . . .

Troubleshooting Charts 5E-74. . . . . . . . . . . . .

Repair Procedures 5E-93. . . . . . . . . . . . . . . . . . .

Service Precautions 5E-93. . . . . . . . . . . . . . . .

Replacement Parts Warning 5E-94. . . . . . . .

Torque Specifications 5E-95. . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 5E-95. . . .

System Components 5E-96. . . . . . . . . . . . . . .

Fuel Injection Pump Repair 5E-98. . . . . . . . .

Wiring Harness Service 5E-99. . . . . . . . . . . .

Relay, Module and Sensor Servicing

(On-Board Service) 5E-102. . . . . . . . . . . . . . . . .

Precautions 5E-102. . . . . . . . . . . . . . . . . . . . . .

Main Relay 5E-102. . . . . . . . . . . . . . . . . . . . . .

ECM (Electronic Control Module) 5E-104. . .

ECT (Engine Coolant Temperature)

Sensor 5E-106. . . . . . . . . . . . . . . . . . . . . . . . .

MAP (Manifold Absolute Pressure) /

IAT (Intake Air Temperature) Sensor 5E-108

Throttle Position (TP) Sensor 5E-110. . . . . . .

Instrumented Injector 5E-112. . . . . . . . . . . . . .

Engine RPM Speed Sensor 5E-112. . . . . . . .

Idle Speed Setting Circuit 5E-113. . . . . . . . . .

90-860074--1 FEBRUARY 2002 Page xiii

Page 16

COOLING SYSTEM

Section 6A - Seawater Cooling System

Torque Specifications 6A-3. . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 6A-3. . . . . . .

Tools 6A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seawater (Raw Water) System

Specifications 6A-4. . . . . . . . . . . . . . . . . . . . . . . .

Seawater Pump Delivery Rates 6A-4. . . . . . .

Seawater Pickup Connections 6A-4. . . . . . . .

Precautions 6A-5. . . . . . . . . . . . . . . . . . . . . . . . . .

Seawater Pickup Connection 6A-5. . . . . . . . . . .

Seacock 6A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seawater Strainer 6A-6. . . . . . . . . . . . . . . . . . . . .

Exploded View - Seawater Pumps 6A-7. . . . . . .

D2.8L D-Tronic 6A-7. . . . . . . . . . . . . . . . . . . . .

D4.2L D-Tronic 6A-8. . . . . . . . . . . . . . . . . . . . .

Seawater Flow Diagram 6A-10. . . . . . . . . . . . . . .

Seawater Pump 6A-12. . . . . . . . . . . . . . . . . . . . . .

Removal 6A-12. . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 6A-13. . . . . . . . . . . . . . . . . . . . . .

Cleaning 6A-17. . . . . . . . . . . . . . . . . . . . . . . . .

COOLING SYSTEM

Section 6B - Closed Cooling System

Specifications 6B-4. . . . . . . . . . . . . . . . . . . . . . . . .

Capacity 6B-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostats 6B-4. . . . . . . . . . . . . . . . . . . . . . .

Pressure Cap 6B-4. . . . . . . . . . . . . . . . . . . . . .

Coolant 6B-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 6B-5. . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 6B-5. . . . . . .

Tools 6B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 6B-5. . . . . . . . . . . . . . . . . . . . . . .

Tools 6B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams and Exploded Views 6B-6. . . . . . . . . .

Coolant Flow Diagram 6B-6. . . . . . . . . . . . . . .

Heat Exchanger / Coolant Tank

and Related Components 6B-8. . . . . . . . . . .

Engine Water Circulating Pump 6B-10. . . . . .

Checking Coolant Level 6B-11. . . . . . . . . . . . . . .

Testing Closed Cooling System 6B-12. . . . . . . .

Testing Coolant for Alkalinity 6B-12. . . . . . . .

Pressure Testing System 6B-12. . . . . . . . . . .

Testing for Cylinder Head

Gasket Leak 6B-14. . . . . . . . . . . . . . . . . . . . . .

Testing Pressure Cap 6B-15. . . . . . . . . . . . . .

Coolant Change Interval 6B-17. . . . . . . . . . . . . .

Coolant Requirement 6B-17. . . . . . . . . . . . . . . . .

Inspection 6A-18. . . . . . . . . . . . . . . . . . . . . . . .

Assembly 6A-19. . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A-25. . . . . . . . . . . . . . . . . . . . . . . .

Seawater Strainer 6A-27. . . . . . . . . . . . . . . . . . . .

Exploded View 6A-27. . . . . . . . . . . . . . . . . . . .

Removal 6A-28. . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A-30. . . . . . . . . . . . . . . . . . . . . . . .

Oil / Power Steering / Transmission

Fluid Coolers 6A-31. . . . . . . . . . . . . . . . . . . . . . . .

General Information 6A-31. . . . . . . . . . . . . . . .

Exploded View 6A-32. . . . . . . . . . . . . . . . . . . .

Location of Coolers 6A-33. . . . . . . . . . . . . . . .

Inspection Before Removal 6A-34. . . . . . . . .

Cleaning Without Removal 6A-34. . . . . . . . . .

Engine Oil Cooler 6A-35. . . . . . . . . . . . . . . . . .

Power Steering 6A-40. . . . . . . . . . . . . . . . . . . .

Transmission Fluid Cooler 6A-42. . . . . . . . . .

Installation 6A-43. . . . . . . . . . . . . . . . . . . . . . . .

Draining Closed Cooling System 6B-17. . . . . . .

Cleaning Closed Cooling System 6B-19. . . . . . .

Using A Cleaner 6B-19. . . . . . . . . . . . . . . . . . .

Heat Exchanger and Cooler Cleaning 6B-19

Flushing The Closed Cooling System 6B-20

Filling The Closed Cooling System 6B-21. . . . .

Thermostats 6B-22. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6B-22. . . . . . . . . . . . . . . . . . . . . . . . .

Testing 6B-23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6B-25. . . . . . . . . . . . . . . . . . . . . . . .

Heat Exchanger 6B-26. . . . . . . . . . . . . . . . . . . . . .

Testing 6B-26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair 6B-26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6B-27. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Inspection 6B-28. . . . . . . . . . . .

Installation 6B-29. . . . . . . . . . . . . . . . . . . . . . . .

Water Circulating Pump 6B-31. . . . . . . . . . . . . . .

Removal 6B-31. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Inspection 6B-31. . . . . . . . . . . .

Installation 6B-32. . . . . . . . . . . . . . . . . . . . . . . .

Coolant Manifold 6B-33. . . . . . . . . . . . . . . . . . . . .

Corrosion Protection 6B-33. . . . . . . . . . . . . . . . . .

Auxiliary Hot Water Heater Connections 6B-33.

Page xiv 90-860074--1 FEBRUARY 2002

Page 17

INTAKE AND EXHAUST SYSTEM

Section 7A - Intercooler

Torque Specifications 7A-3. . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 7A-3. . . . .

Exploded Views 7A-4. . . . . . . . . . . . . . . . . . . . .

D2.8L Intercooler 7A-4. . . . . . . . . . . . . . . . .

D4.2L Intercooler 7A-6. . . . . . . . . . . . . . . . .

Intercooler 7A-8. . . . . . . . . . . . . . . . . . . . . . . . . .

INTAKE AND EXHAUST SYSTEM

Section 7B - Manifolds, Elbows And Risers

Torque 7B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 7B-3. . . . . . .

Description 7B-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Exploded Views 7B-4. . . . . . . . . . . . . . . . . . . . . . .

Typical Intake / Exhaust Manifold 7B-4. . . . .

Sterndrive (MCM) Exhaust Systems 7B-5. . .

Inboard (MIE) Exhaust Systems 7B-6. . . . . .

Representative View of Complete

Inboard Exhaust System 7B-7. . . . . . . . . . . .

Locating and Installing The Sterndrive

(MCM) Exhaust System 7B-8. . . . . . . . . . . . . . .

INTAKE AND EXHAUST SYSTEM

Removal 7A-8. . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 7A-11. . . . . . . . . . . . . . . . . . . . .

Cleaning and Inspection 7A-13. . . . . . . . . . .

Assembly 7A-14. . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A-17. . . . . . . . . . . . . . . . . . . . . . .

Locating And Installing The Inboard (MIE)

Exhaust System 7B-9. . . . . . . . . . . . . . . . . . . . . .

Exhaust Pipe - Sterndrive (MCM) 7B-11. . . . . . .

Removal 7B-11. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 7B-11. . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7B-12. . . . . . . . . . . . . . . . . . . . . . . .

Intake / Exhaust Manifold 7B-13. . . . . . . . . . . . . .

Removal 7B-13. . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Inspection 7B-14. . . . . . . . . . . .

Installation 7B-15. . . . . . . . . . . . . . . . . . . . . . . .

Section 7C - Turbocharger

Identification 7C-3. . . . . . . . . . . . . . . . . . . . . . . .

Turbocharger Specifications 7C-3. . . . . . . . . .

Torque Specifications 7C-4. . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 7C-4. . . . .

Description 7C-5. . . . . . . . . . . . . . . . . . . . . . . . .

Turbocharger 7C-5. . . . . . . . . . . . . . . . . . . .

Wastegate 7C-5. . . . . . . . . . . . . . . . . . . . . . .

Exploded Views 7C-6. . . . . . . . . . . . . . . . . . . . .

Turbocharger And Related

Components 7C-6. . . . . . . . . . . . . . . . . . . .

Boost Pressure Control (Wastegate)

Components 7C-8. . . . . . . . . . . . . . . . . . . .

Turbocharger 7C-9. . . . . . . . . . . . . . . . . . . . . . .

Testing Turbocharger Boost Pressure 7C-9

Checking Turbine Bearings

(Assembled) 7C-10. . . . . . . . . . . . . . . . . . . . .

Removal 7C-11. . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 7C-15. . . . . . . . . . . . . . . . . . . . .

Cleaning 7C-17. . . . . . . . . . . . . . . . . . . . . . . .

Inspection 7C-18. . . . . . . . . . . . . . . . . . . . . . .

Assembly 7C-19. . . . . . . . . . . . . . . . . . . . . . . .

Installation 7C-21. . . . . . . . . . . . . . . . . . . . . . .

Boost Pressure Control 7C-28. . . . . . . . . . . . . .

Exhaust Pipe 7C-28. . . . . . . . . . . . . . . . . . . . .

Valve 7C-31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wastegate 7C-33. . . . . . . . . . . . . . . . . . . . . . .

90-860074--1 FEBRUARY 2002 Page xv

Page 18

DRIVES

Section 8A - ZF/Hurth Transmissions

Identification 8A-3. . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 8A-4. . . . . . . . . . . . . . . . . . . . . . . . .

Operating Specifications 8A-4. . . . . . . . . . . . .

Ratios and Part Numbers 8A-4. . . . . . . . . . . .

Fluid Specifications 8A-4. . . . . . . . . . . . . . . . .

Torque 8A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools 8A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 8A-5. . . . . . .

Important Information 8A-6. . . . . . . . . . . . . . . . . .

Engine 8A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission 8A-6. . . . . . . . . . . . . . . . . . . . . . .

Propeller 8A-6. . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission / Propeller Rotation 8A-7. . . . .

Section 8B - Propeller Shaft Models

Lubricants / Sealants / Adhesives 8B-2. . . . . . .

Checks Made with Boat In Water 8B-3. . . . .

Checks Made with Boat Out of Water

and Shaft Installed 8B-5. . . . . . . . . . . . . . . . .

POWER STEERING

Transmission Fluid Level 8A-8. . . . . . . . . . . . . . .

Checking 8A-8. . . . . . . . . . . . . . . . . . . . . . . . . .

Filling 8A-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing 8A-9. . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Removal 8A-12. . . . . . . . . . . . . . . .

Transmission Inspection 8A-13. . . . . . . . . . . . . .

Transmission Installation 8A-13. . . . . . . . . . . . . .

Shift Control And Cables 8A-15. . . . . . . . . . . . . .

Transmission Shift Lever And Shift

Cable Bracket 8A-15. . . . . . . . . . . . . . . . . . . .

Shift Cable Installation and

Adjustment 8A-16. . . . . . . . . . . . . . . . . . . . . . .

Pressure And Temperature Tests 8A-21. . . . . . .

Transmission Repair 8A-21. . . . . . . . . . . . . . . . . .

DRIVES

Checks Made with Propeller Shaft

Removed from Boat 8B-7. . . . . . . . . . . . . . . .

Strut 8B-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 9A - Pump And Related Components

Torque Specifications 9A-2. . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 9A-2. . . . . . .

Description 9A-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Exploded Views 9A-3. . . . . . . . . . . . . . . . . . . . . . .

Power Steering Pump 9A-3. . . . . . . . . . . . . . .

Related Components 9A-4. . . . . . . . . . . . . . . .

Power Steering Pump 9A-5. . . . . . . . . . . . . . . . . .

Removal 9A-5. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 9A-6. . . . . . . . . . . . . . . . . . . . . . . . .

Checking Fluid Level 9A-8. . . . . . . . . . . . . . . . . .

Filling and Bleeding 9A-8. . . . . . . . . . . . . . . . . . . .

Page xvi 90-860074--1 FEBRUARY 2002

Page 19

THIS PAGE IS INTENTIONALLY BLANK

90-860074--1 FEBRUARY 2002 Page xvii

Page 20

THIS PAGE IS INTENTIONALLY BLANK

Page xviii 90-860074--1 FEBRUARY 2002

Page 21

SERVICE MANUAL NUMBER 22

GENERAL INFORMATION

IMPORTANT INFORMATION

Section 1A - General Information

Table of Contents

Introduction 1A-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Use This Manual 1A-3. . . . . . . . . . . . . . .

Page Numbering 1A-3. . . . . . . . . . . . . . . . . . .

Engine Serial Number / Decal Locations 1A-4.

Operation / Duty Cycle 1A-5. . . . . . . . . . . . . . . . .

1

A

Engine Break-In 1A-6. . . . . . . . . . . . . . . . . . . . . . .

Initial Break-In Procedure 1A-6. . . . . . . . . . . .

Mercury/Quicksilver Lubricants, Sealants

And Adhesives 1A-7. . . . . . . . . . . . . . . . . . . . . . .

90-860074-–1 FEBRUARY 2002

Page 1A-1

Page 22

GENERAL INFORMATION

SERVICE MANUAL NUMBER 22

THIS PAGE IS INTENTIONALLY BLANK

Page 1A-2

90-860064--1 FEBRUARY 2002

Page 23

SERVICE MANUAL NUMBER 22

For information and procedures on Troubleshooting, refer to SECTION 1C.

Refer to appropriate Sterndrive Service Manual for transom assembly and sterndrive unit repair.

Introduction

This comprehensive overhaul and repair manual is designed as a service guide for the

models previously listed. It provides specific information, including procedures for

disassembly, inspection, assembly and adjustment to enable dealers and service

mechanics to repair and tune these engines.

Before attempting repairs, it is suggested that the procedure first be read through to gain

knowledge of the methods and tools used and the cautions and warnings required for safety.

How to Use This Manual

This manual is divided into sections that represent major components and systems.

GENERAL INFORMATION

NOTICE

NOTICE

Some sections are further divided into parts that more fully describe the component.

Page Numbering

Two number groups appear at the bottom of each page. The following is an example and

description.

Page 1A-3

a

a-Section Number

b-Section Part

c-Page Number

d-Manual Number

e-Revision Number 1

f-Month Printed

g-Year Printed

c

b

90-860074--1 FEBRUARY 2002

d

e

f

g

90-860074-–1 FEBRUARY 2002

Page 1A-3

Page 24

GENERAL INFORMATION

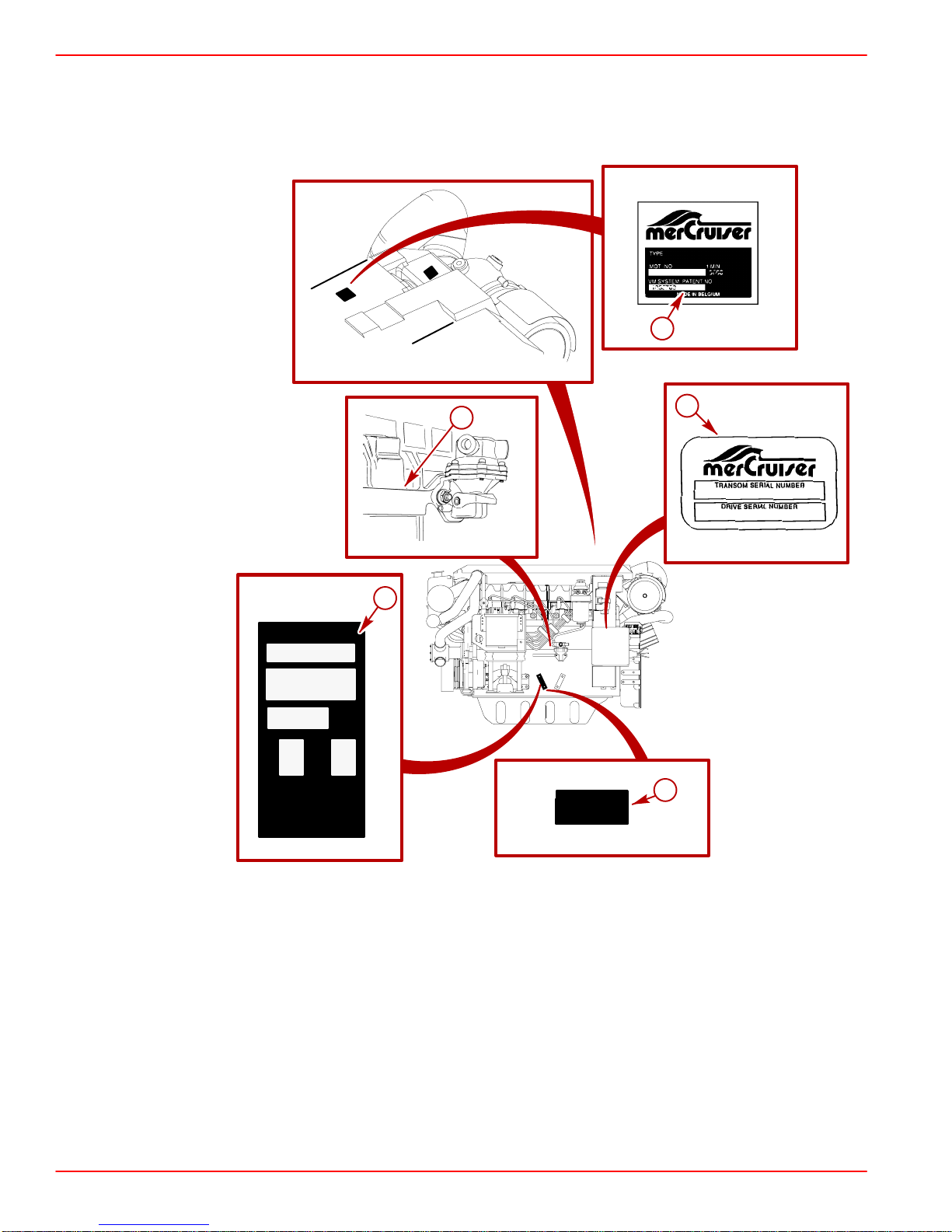

Engine Serial Number / Decal Locations

SERVICE MANUAL NUMBER 22

SERIAL NUMBER

H

P

L

B

K

W

K

G

MARINE POWER

EUROPE INC

MADE IN ITALY

MAX

RPM

a

75301

71675

d

b

7332

3

75388

73929

a

75298

BS

M12 11 3

O:

93_ _

c

71688

Typical Sterndrive (MCM) Engine Shown - Inboard (MIE) Similar

a-Serial Number Plate

b-Manufacturer’s Serial Number (Stamped in Block)

c-Exhaust Gas Emissions Certificate Number (Example)

d-MerCruiser Specification Decal

Page 1A-4

90-860064--1 FEBRUARY 2002

Page 25

SERVICE MANUAL NUMBER 22

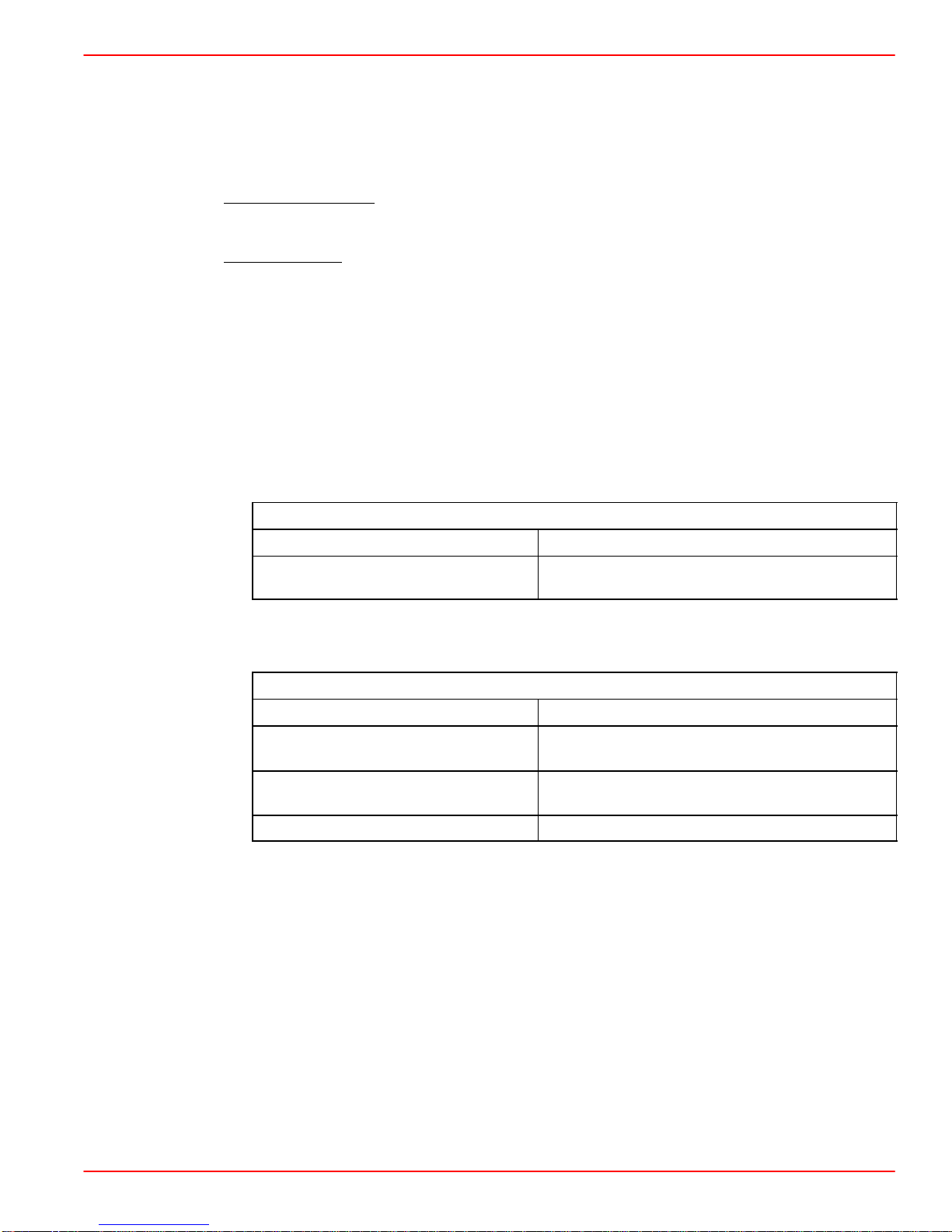

Operation / Duty Cycle

It is the operator’s responsibility to operate within the following specified operational

capability, or duty cycle, as applicable to engine and installation:

NOTE:

Pleasure duty rating

recreation.

GENERAL INFORMATION

applies to recreational planing craft used exclusively for pleasure and

Light duty rating

applies to planing boats where the use of full rated power at maximum rated

rpm is limited (as stated above). Examples of Light Duty applications include, but are not

limited to: search and rescue craft, fast patrol boats, fire boats, dive boats, and limited

season fishing boats such as sport-fish charter boats. Application to common commercial

crafts having full-displacement or semi-displacement hulls exceeds the recommended

operational capability, or duty cycle.

IMPORTANT: Damage caused by improper application or failure to operate within the

operational capability, or duty cycle, will not be covered by the Mercury MerCruiser

Diesel Limited Warranty.

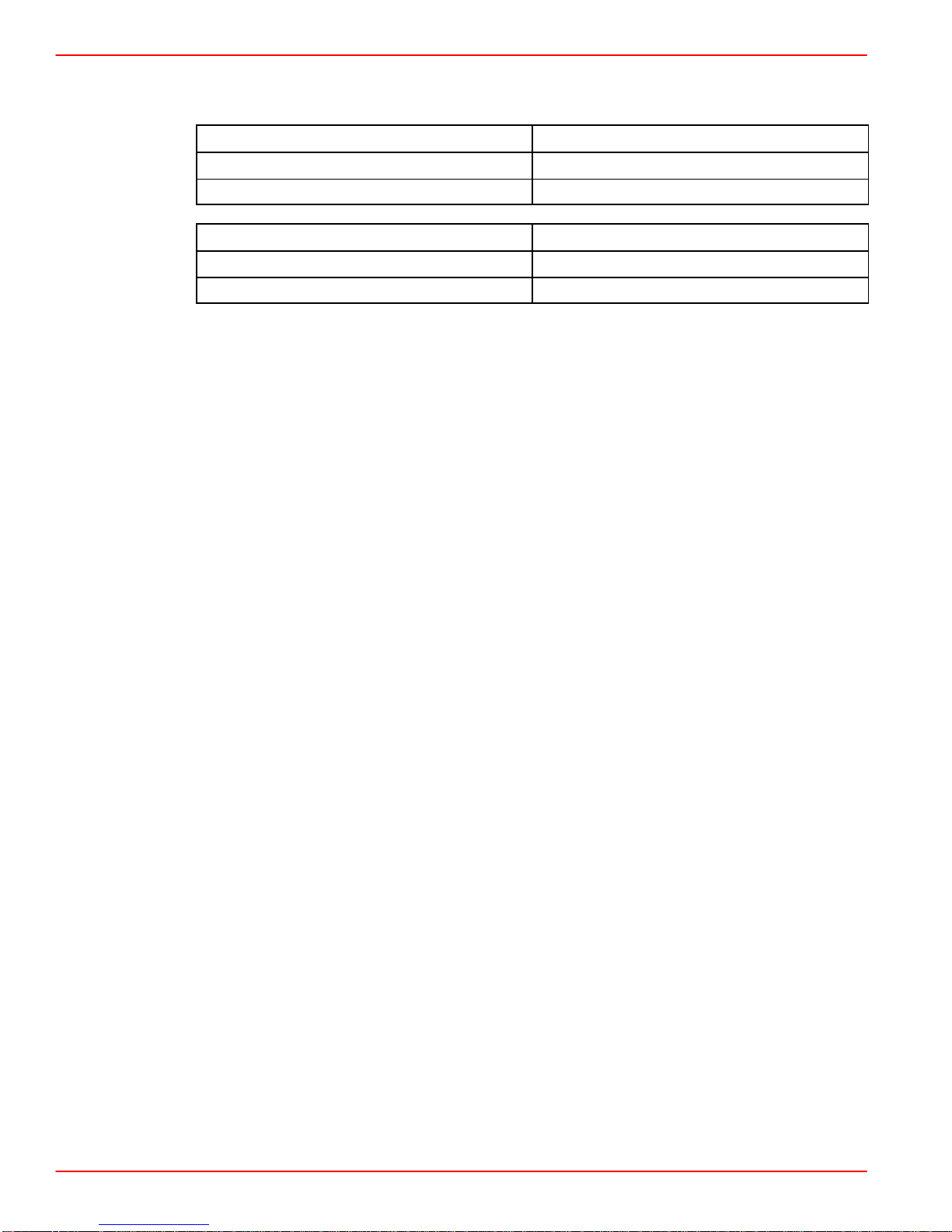

PLEASURE DUTY RATING / DUTY CYCLE

Specified Operating RPM Range 3600 - 3800

Wide Open Throttle (WOT)

Operation

LIGHT DUTY RATING / DUTY CYCLE

D2.8L D-Tronic and D4.2L D-Tronic

Limited to short periods of time.

D2.8L D-Tronic and D4.2L D-Tronic

Specified Operating RPM Range 3600-3800

Wide Open Throttle (WOT)

Operation

Continuous cruising RPM

Limited to less that 10% of operating time.

Limited to 90% or less of wide open throttle

RPM

Annual operating time Not to exceed 500 hours

90-860074-–1 FEBRUARY 2002

Page 1A-5

Page 26

GENERAL INFORMATION

Engine Break-In

Initial Break-In Procedure

The following procedure must be used on new and rebuilt diesel engines. This break-in

procedure allows the proper seating of the pistons and rings, which greatly reduces the

likelihood of problems.

IMPORTANT: It is recommended that the boat not be accelerated hard until this

procedure has been completed.

IMPORTANT: Never operate the starter motor longer than 15 seconds at a time, to

avoid overheating the starter motor. If engine does not start, wait 1 minute to allow

the starter motor to cool; then, repeat starting procedure.

1. Refer to appropriate Starting, Shifting and Stopping section in the Operation,

Maintenance and W arranty Manual provided with the product and start the engine. Allow

the engine to idle until it has reached normal operating temperature.

2. Operate the engine in gear for 3 minutes at each of the following rpms: 1200 rpm, 2400

rpm and 3000 rpm.

3. Operate the engine in gear for 3 minutes at each of the following rpms: 1500 rpm, 2800

rpm and 3400 rpm.

SERVICE MANUAL NUMBER 22

4. Operate the engine in gear for 3 minutes at each of the following rpms: 1800 rpm, 3000

rpm and WOT.

Page 1A-6

90-860064--1 FEBRUARY 2002

Page 27

SERVICE MANUAL NUMBER 22

GENERAL INFORMATION

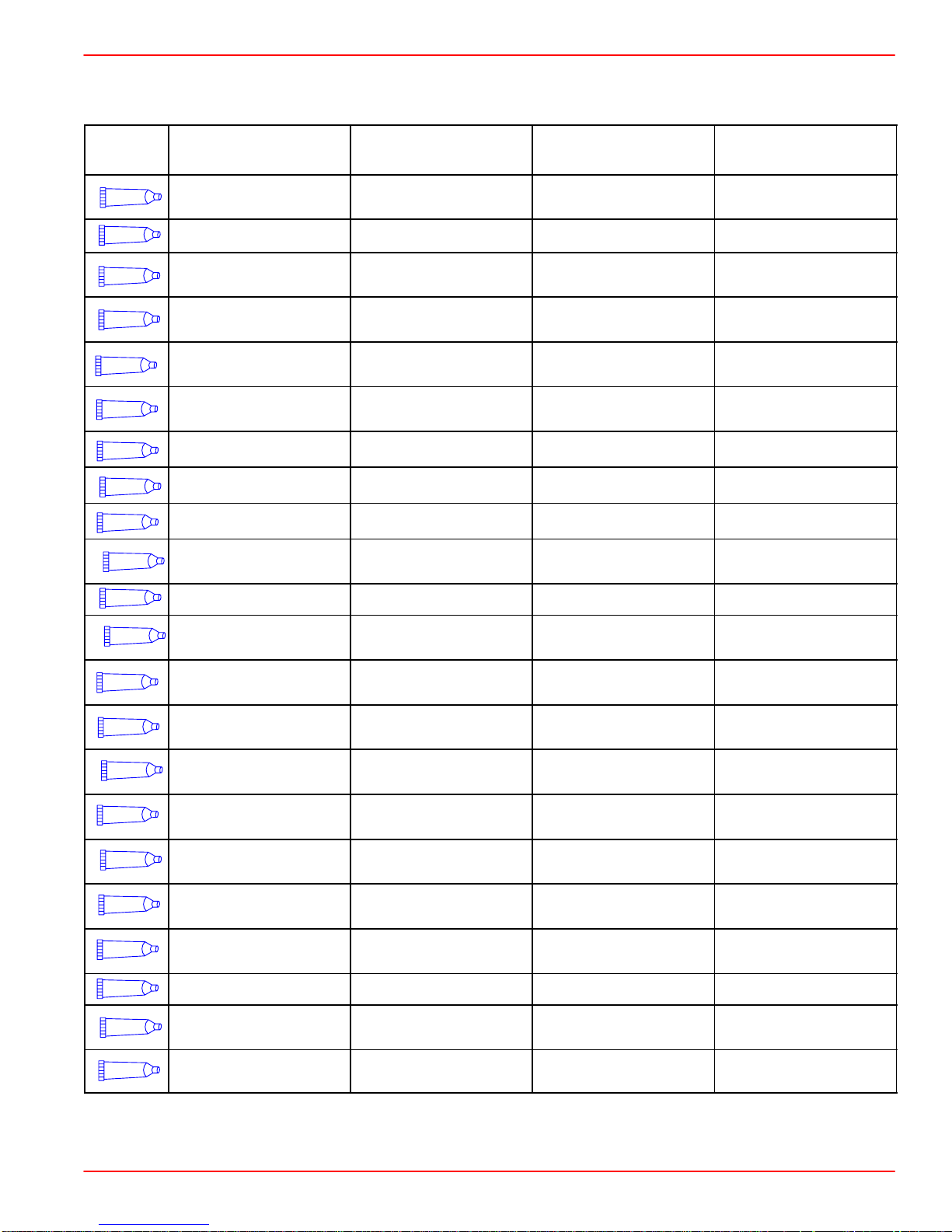

Mercury/Quicksilver Lubricants, Sealants And Adhesives

Tube

Ref. #

4

6

7

9

12

14

19

25

27

33

Description Container Size

Needle Bearing Assy.

Lubricant

8 oz (226.8 g) tube N/A 92-802868A1

Mercury Part

Number

Quicksilver Part

Number

Dielectric Grease 8 oz (226.8 g) can N/A 92-823506-1

Loctite 271 - Thread

Locker

Loctite 567 PST Pipe

Sealant

Loctite Master Gasket

Kit

2 Cycle Premium

Outboard Oil

10 ml tube N/A 92-809819

50 ml tube N/A 92-809822

N/A 92-12564-2

1 US qt (0.94 L) 92-802813A1 92-802813Q1

Perfect Seal 16 oz (0.45 kg) can N/A 92-34227-1

Liquid Neoprene 8 oz (226.8 g) can N/A 92-25711-3

Bellows Adhesive 1.5 oz (42.5 g) tube N/A 92-86166Q1

Loctite 680 Retaining

Compound

10 ml tube N/A 92-809833

51

66

94

95

110

114

34

82

91

79

87

42

Special Lubricant 101 8 oz (226.8 g) tube 92-802865A1 92-802865Q1

U-Joint and Gimbal

Bearing Grease

Loctite 222 Thread

Locker

Loctite 242 Thread

Locker

4 Cycle 25W40

Engine Oil

Premium Gear

Lubricant

High Performance

Gear Lube

Engine Coupler

Spline Grease

Anti-Corrosion

Grease

10 ml tube N/A 92-809818

10 ml tube N/A 92-809821

1 US qt (0.94 L) 92-802846A1 92-802846Q1

1 US qt (0.94 L) 92-802854A1 92-802854Q1

14 oz (0.39 kg)

cartridge

8 oz (226.8 g) tube 92-802867A1 92-802867Q1

92-802870A1 92-802870Q1

92-802837A1 92-802837Q1

92-802869A1 92-802869Q1

2-4-C with Teflon 8 oz (226.8 g) tube 92-802859A1 92-802859Q1

4 Stroke 10W30

Outboard Oil

Power Trim &

Steering Fluid

1 US qt (0.94 L) 92-802833A1 92-802833Q1

8 oz (226.8 g) 92-802880A1 92-802880Q1

90-860074-–1 FEBRUARY 2002

Page 1A-7

Page 28

GENERAL INFORMATION

SERVICE MANUAL NUMBER 22

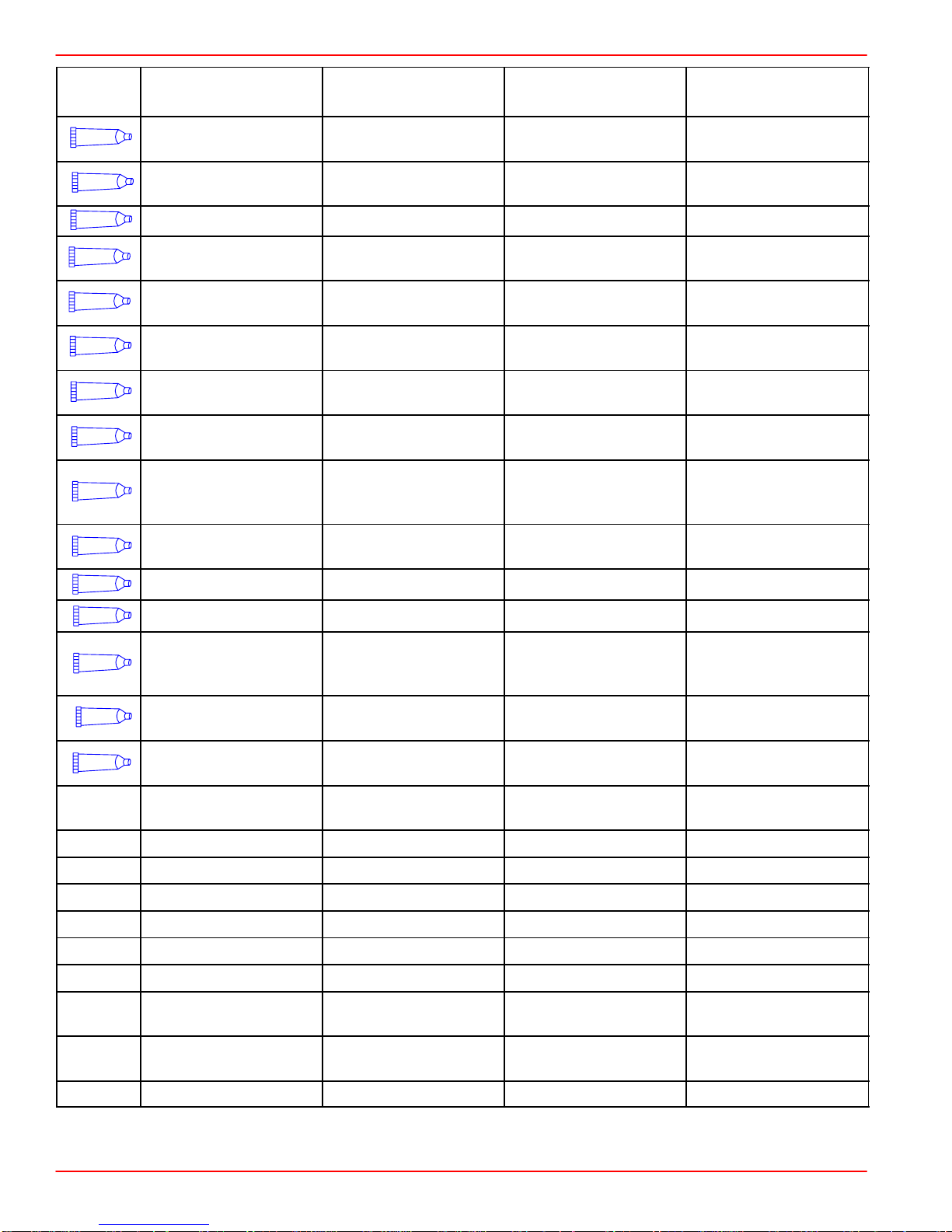

Tube

Ref. #

115

116

117

118

119

120

121

122

123

124

Description Container Size

Premium Plus 2 Cycle

TC-W3 Outboard Oil

RTV 587 Silicone

Sealer

1 US qt (0.94 L) 92-802824A1 92-802824Q1

3 oz (85.05 g) N/A 92-809825

Mercury Part

Number

Quicksilver Part

Number

Loctite 7649 Primer N 4.5 oz (127.57 g) N/A 92-809824

Storage Seal Rust

Inhibitor

Corrosion Guard

15W40 4-cycle Diesel

Engine Oil

Extended Life

Antifreeze/Coolant

Marine Engine

Coolant

12 oz (325 ml) spray

can

12 oz (325 ml) spray

can

92-802878-56 92-802878Q56

92-802878 55 92-802878Q55

1.06 US gal.(4 L) 92-877695K1 92-877695Q1

1 US gal. (3.78 L) 92-877770K1 92-877770K1

1.33 US gal. (5 L) N/A 92-813054A2

Fuel System

Treatment and

16 oz (437 ml) 92-802876A1 92-802876Q1

Stabilizer Concentrate

Heat Transfer

Compound

1.5 oz (42.5 g) tube N/A 92-805701 1

125

126

127

128

129

Liquid Gasket N/A 92-808137

T442 Sealant N/A 92-862258

Loctite 5900 Ultra

Black RTV Silicone

13 oz (371 g) tube N/A 92-809826

Sealant

Loctite Gasket

Remover

Sealer Kit, Two Part

Epoxy

Dexron III Automatic

Transmission Fluid

18 oz (532 ml) spray

can

N/A 92-809828 1

N/A 92-65150 1

Obtain Locally Obtain Locally

Loctite 592 Obtain Locally Obtain Locally

Loctite Quick Tite Obtain Locally Obtain Locally

Isopropyl Alcohol Obtain Locally Obtain Locally

Hot Glue Obtain Locally Obtain Locally

Loctite 609 Obtain Locally Obtain Locally

Loctite 405 Obtain Locally Obtain Locally

Cyanacrylate

Adhesive

3M Permabond

#3M08155

Obtain Locally Obtain Locally

Obtain Locally Obtain Locally

Loctite 262 Obtain Locally Obtain Locally

Page 1A-8

90-860064--1 FEBRUARY 2002

Page 29

SERVICE MANUAL NUMBER 22

GENERAL INFORMATION

THIS PAGE IS INTENTIONALLY BLANK

90-860074-–1 FEBRUARY 2002

Page 1A-9

Page 30

GENERAL INFORMATION

SERVICE MANUAL NUMBER 22

THIS PAGE IS INTENTIONALLY BLANK

Page 1A-10

90-860064--1 FEBRUARY 2002

Page 31

SERVICE MANUAL NUMBER 22

MAINTENANCE

IMPORTANT INFORMATION

Section 1B - Maintenance

Table of Contents

Torque Specifications 1B-3. . . . . . . . . . . . . . . . . .

Special Tools 1B-3. . . . . . . . . . . . . . . . . . . . . . . . .

Tools 1B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 1B-3. . . . . . .

Engine Specifications 1B-4. . . . . . . . . . . . . . . . . .

Sterndrive (MCM) Engines 1B-4. . . . . . . . . . .

Inboard (MIE) Engines 1B-5. . . . . . . . . . . . . .

Capacities 1B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engines 1B-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Drives 1B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmissions 1B-6. . . . . . . . . . . . . . . . . . . . . .

Maintenance Schedules 1B-7. . . . . . . . . . . . . . . .

Maintenance Intervals 1B-7. . . . . . . . . . . . . . .

Sterndrive (MCM) Engines 1B-8. . . . . . . . . . .

Inboard (MIE) Engines 1B-11. . . . . . . . . . . . .

Engine External Views 1B-13. . . . . . . . . . . . . . . .

Starboard Side View 1B-13. . . . . . . . . . . . . . .

Front View 1B-14. . . . . . . . . . . . . . . . . . . . . . . .

Port Side View 1B-15. . . . . . . . . . . . . . . . . . . .

Rear View 1B-16. . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil 1B-17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Level 1B-17. . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Engine Oil and Oil Filter 1B-19. . .

Fuel 1B-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Precautions 1B-21. . . . . . . . . . . . . . . . . . . . . . .

General Information 1B-22. . . . . . . . . . . . . . . .

Diesel Fuel In Cold Weather 1B-22. . . . . . . .

Fuel Filter 1B-23. . . . . . . . . . . . . . . . . . . . . . . .

Closed Cooling System 1B-28. . . . . . . . . . . . . . .

Coolant Requirement 1B-28. . . . . . . . . . . . . .

Checking Level 1B-29. . . . . . . . . . . . . . . . . . . .

Draining 1B-30. . . . . . . . . . . . . . . . . . . . . . . . . .

Filling 1B-32. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sacrificial Anodes 1B-33. . . . . . . . . . . . . . . . . . . .

Removal 1B-33. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 1B-33. . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 1B-34. . . . . . . . . . . . . . . . . . . . . .

Reassembly 1B-34. . . . . . . . . . . . . . . . . . . . . .

Installation 1B-34. . . . . . . . . . . . . . . . . . . . . . . .

Flushing Seawater System 1B-35. . . . . . . . . . . .

SternDrive (MCM) Models 1B-35. . . . . . . . . .

Inboard (MIE) Models 1B-36. . . . . . . . . . . . . .

Inspect Water Pickups 1B-38. . . . . . . . . . . . . . . .

SternDrive Gear Housing 1B-38. . . . . . . . . . .

Inboard Though the Hull Pickup 1B-38. . . . .

Lubrication 1B-39. . . . . . . . . . . . . . . . . . . . . . . . . .

1

B

Throttle Cable 1B-39. . . . . . . . . . . . . . . . . . . . .

Shift Cable 1B-39. . . . . . . . . . . . . . . . . . . . . . . .

Engine Coupler / U-joint Shaft Splines 1B-40

U-joints 1B-41. . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Shaft Extension Models 1B-42. . . . . . .

Sterndrive Unit and Transom

Assembly 1B-42. . . . . . . . . . . . . . . . . . . . . . . .

Continuity Circuit 1B-43. . . . . . . . . . . . . . . . . . . . .

Continuity Circuit (continued) 1B-44. . . . . . . . . .

MerCathode 1B-45. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Mounts 1B-45. . . . . . . . . . . . . . . . . . . . . . .

Electrical System 1B-45. . . . . . . . . . . . . . . . . . . . .

Power Steering 1B-46. . . . . . . . . . . . . . . . . . . . . .

Checking Fluid Level 1B-46. . . . . . . . . . . . . . .

Filling and Bleeding 1B-48. . . . . . . . . . . . . . . .

Transmission 1B-49. . . . . . . . . . . . . . . . . . . . . . . .

Checking Fluid Level 1B-49. . . . . . . . . . . . . . .

Power Trim 1B-50. . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Fluid Level 1B-50. . . . . . . . . . . . . . .

Filling 1B-51. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Lube Monitor 1B-52. . . . . . . . . . . . . . . . . . .

Checking Fluid Level 1B-52. . . . . . . . . . . . . . .

Filling 1B-52. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seawater Strainer 1B-53. . . . . . . . . . . . . . . . . . . .

Air Filter 1B-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 1B-54. . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 1B-54. . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 1B-55. . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1B-55. . . . . . . . . . . . . . . . . . . . . . . .

Drive Belts 1B-56. . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 1B-56. . . . . . . . . . . . . . . .

Inspection 1B-57. . . . . . . . . . . . . . . . . . . . . . . .

Engine Water Circulating Pump Belt 1B-57. .

Alternator Belt 1B-58. . . . . . . . . . . . . . . . . . . . .

Power Steering Pump Belt 1B-60. . . . . . . . . .

Vacuum Pump Belt 1B-62. . . . . . . . . . . . . . . .

Battery 1B-64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging System 1B-64. . . . . . . . . . . . . . . . . . . . .

Corrosion and Corrosion Protection 1B-64. . . . .

Saltwater Operation 1B-64. . . . . . . . . . . . . . . . . .

Freezing Temperature and Cold Weather

Operation 1B-65. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cold Weather or Extended Storage 1B-66. . . . .

Power Package Layup 1B-66. . . . . . . . . . . . .