Page 1

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

Whipple Superchargers

93’-01’ 454/502 Magnum

Installation Instructions

Version A1R9

Last Updated April 1st, 2010

454/502 MagnumTBI_A1R9

1

Page 2

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

MUST KNOW INFORMATION!!

-EVERYBODY READ!!-

WATER FLOW – WATER FLOW – WATER FLOW

As of May 2002, Mercury Racing issued a service bulletin (attached to instructions) regarding engine

water block pressure. In this bulletin, it’s clear that Mercury Racing requires a minimum of 20-30lbs. of

engine water pressure at wide-open throttle (WOT). If this pressure is not achieved or not maintained,

you can have catastrophic engine failure of many types.

This leads us to your new supercharged engine. You’re no longer running a thermostat in the engine,

which was the largest water restriction in the stock system. Now, the largest restriction is the engine

itself, this means pressure is only increased by flow in this given application. Because you are taking

your stock engine and increasing the cylinder pressure for more peak power, to insure reliability, you

need more water to keep the engine cool and at the same time, you need more water pressure to keep

steam pockets from developing in your engine. With this in mind, you want a minimum of 25lpsi of block

pressure @ WOT, maximum 40psi @ WOT. If you do not have this pressure, you may hurt your engine.

Whipple Superchargers has provided a stainless restrictor for the thermostat housing that will restrict the

flow like a thermostat, but pressure still must be checked, as this may be too muc h restriction (ideally) or

not enough (means you need more). With this information in mind, you must understand, you must

have more flow as well as pressure, if you restrict the outlet water too much and don’t have proper flow,

you will heat the engine up, still develop steam pockets and it could lead to engine failure.

• Ideally, the intercooler should be fed from a separate source. The intercooler does not need

constant water flow at slow speeds. This means a separate pickup can be installed solely for

the intercooler.

• You can run the intercooler off the drive side draft inlets, but never the engine.

• Mercury dual style water pickups do not let more water in, in fact, they have less water flow.

Always block off the side draft inlets if your boat uses them on this dual style drives.

• Never run the engine off side draft inlets in the drive, never!

• If you have a stepped bottom or high “X” dimension, water flow may be very low at high

speeds and caution must be taken.

• Test block pressure at various trim angles and in turns.

• Lower boost and or timing does not mean you’re safer with less water, if steam develops, the

engine will fail regardless, it needs pressure to push the steam out.

WATER FLOW – WATER FLOW – WATER FLOW

454/502 MagnumTBI_A1R9

2

Page 3

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

WHIPPLE CHARGER INSTALLATION INSTRUCTIONS

454/502 MAGNUM MPI STAGE 1

This product is intended for use on STOCK, UNMODIFIED, WELL-MAINTAINED ENGINES. Installation on a

worn-out engine is not recommended and could result in failure of the engine or the supercharger. It is

recommended to perform a compression test of all cylinders, and perform a cylinder pressure leak down

procedure, check and change spark plugs, spark plug wires, distributor cap, and rotor if necessary. This

will indicate the condition of the engine for reference. Whipple also recommends accurate fuel pressure

and water block pressure gauges for constant monitoring during operation.

This system is designed around the Delphi MEFI 3 and 4 ECM systems. If you have a MEFI 1, you will

need a new ECM and you’ll have to modify the harness at the end of the instructions. It’s a good idea

to review this as you may want to modify this during the middle of the installation.

It is the purchaser’s responsibility to follow all installation instruction guidelines and safety procedures

supplied with the product as it is received by the purchaser to determine the compatibility of the product

with the vessel or the device the purchaser intends to install the product on.

Whipple Supercharger assumes no responsibility for damages occurring from accident, misuse, abuse,

improper installation, improper operation, lack of reasonable care, or all previously stated reasons

resulting from incompatibility with other manufacturers’ products.

**NOTICE: Installation of Whipple Supercharger products

signifies that you have read this document and have

agreed to the terms stated within.

It is the purchaser’s responsibility to follow all installation instruction guidelines and safety

procedures supplied with the product as it is received by the purchaser to determine the

compatibility of the product with the vessel or the device the purchaser intends to install the

product on.

Whipple Supercharger assumes no responsibility for damages occurring from accident, misuse,

abuse, improper installation, improper operation, lack of reasonable care, or all previously stated

reasons resulting from incompatibility with other manufacturers’ products.

There are no warranties expressed, implied, for merchantability or fitness for

engine failure, parts failure, any type of damage to vessel in any way, or

reimbursement for labor or inconvenience.

454/502 MagnumTBI_A1R9

3

Page 4

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

YOU MUST SEND YOUR ECU IN FOR REPROGRAMMING TO WORK WITH THE WHIPPLE

SUPERCHARGER SYSTEM. THERE ARE REPLACEMENT ECU’S AVAILABLE. ACCOMPANY EACH

COMPUTER WITH NAME, SHIPPING INFORMATION, CONTACT INFO, BOAT INFO AND IF ANY

MODIFICATIONS HAVE BEEN MADE TO THE ENGINE. WHIPPLE WILL PAY FOR STANDARD GROUND

FREIGHT IN THE CONTINETAL U.S. IF YOU WANT FASTER SERVICE OR SHIPPING FROM FROM

OUTSIDE THE CONTINENTAL U.S., PROVIDE PAYMENT INFORMATION FOR FREIGHT. SEND FACTORY

ECU TO:

WHIPPLE SUPERCHARGERS

ATTENTION: MARINE ECU RECAL DEPARTMENT

3292 N. WEBER

FRESNO, CA 93722

559.442.1261

For best performance and continued reliability the following are MANDATORY.

1. USE ONLY PREMIUM GRADE FUEL (91 OCTANE OR BETTER). NEVER USE LOWER OCTANE.

2. ALWAYS LISTEN FOR ANY SIGN OF ENGINE KNOCKING, IF PRESENT DISCONTINUE USE

IMMEDIATELY.

3. DO NOT OPERATE ENGINE IN BOOST IF THE FUEL PRESSRUE IS BELOW THE PRESSURE

SPECIFIED BY WHIPPLE INDUSTRIES.

4. NEVER CHANGE THE WHIPPLE COMPUTER CALIBRATION PROGRAM (ENGINE RUN FUEL, IGNITION

TIMING OR THE RPM LIMITER, NOTHING!) THIS COMPLETE SUPERCHARGER SYSTEM IS DESIGNED

AND ENGINEERED TO MAXIMUM PERFORMANCE FROM THE WHIPPLE CALIBRATION. ANY

MODIFICATIONS TO PROGRAM MAY CAUSE SERIOUS DAMAGE TO THE ENGINE.

WARNING! The most important precaution you must take with the WHIPPLE CHARGER is cleanliness.

This supercharger is a high quality, close tolerance compressor that cannot be subjected to dirt or any

type of foreign material. Foreign material entering the supercharger will automatically void all warranties.

DO NOT remove the protective seal on the supercharger prior to installation.

This system requires a major fuel system modification. Use extreme caution around the high flammable

fuel and fuel vapors.

Always wear appropriate safety goggles and gloves when required.

Always use caution around flammable liquids.

454/502 MagnumTBI_A1R9

1

4

Page 5

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

SYSTEM PERFORMANCE INFORMATION

A Mercruiser scanner is an electronic tool used to display various engine parameters. This scanner

can be installed and monitor all engine parameters while the boat is being operated. Some of these

are items are: RPM, TPS volts, KNOCK RETARD, COOLANT temp, IAC counts, and any TROUBLE

CODES. You can also put the engine in the set timing mode. You can purchase this scanner at

Whipple Industries for $600.

1.

TPS Voltage Setting- Before starting your engine, you must set the TPS voltage utilizing a

MerCruiser scan tool or a standard 0-5v volt meter. The proper TPS voltage is between .50 - .55

volts. The TPS is a 5v sensor. The blue wire is the signal wire.

Idle speed setting- Your modified ECU has a “desired” idle speed that varies with engine temp.

2.

The engine should idle at approx. 800rpm @ 75° and 725rpm @ 100°. The ECU will modify both spark

timing and the IAC position (counts). These numbers will constantly vary to maintain a smooth idle

in and out of gear. If you have a scan tool, timing should bounce in the positive range, approx. 0-16,

if it’s constantly lower, it needs more air. If it’s constantly higher (in neutral), then it needs less air.

For the IAC counts, 150 is max wide open meaning that its allowing as much air into the system as

possible, while 0 counts means the IAC is closed, it is not allowing air into the system. If the counts

are to low, adjust the closed throttle stop to close the throttle. If the counts are to high, adjust the

throttle to open more. Although this number will move, in neutral, you want it to start high when

engine fires and then count down to 0-40 counts. This will allow it to open to max when engine is

shifted into gear.

the learning of the IAC system.

Note: The engine must be turned off for 5 seconds and re-s tarted to p o perly reset

r

454/502 MagnumTBI_A1R9

5

Page 6

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

3.

Check cooling system water pressure. The cooling system must be able to operate efficiently.

Optimal performance and reliability will be gained if an external pick-up is installed for the Whipple

Intercooler water. To check the performance of your cooling system, install a 0-50psi. pressure

gauge on the water drain plug located on the bottom center of the block. The idle pressure may read

0-3psi. and full speed/RPM may read over 30psi. The minimum pressure allowed, for proper engine

cooling, is 30psi at WOT. 40psi should be the maximum, if exceeded, please contact Whipple

Industries. The reading should be obtained at high speed and high RPM. If the pressure is lower,

another water pickup must be installed. Consult with Whipple Industries for recommendations. The

Whipple intercooler will take water away from the engine if the water is teed from the stock system,

so block pressure must be checked before and after.

MEFI Engine management system. If your engine has a MEFI 1 ECM, your system must be updated

4.

to a MEFI 3 or 4 system. Follow the wire diagram at the end of the manual for converting.

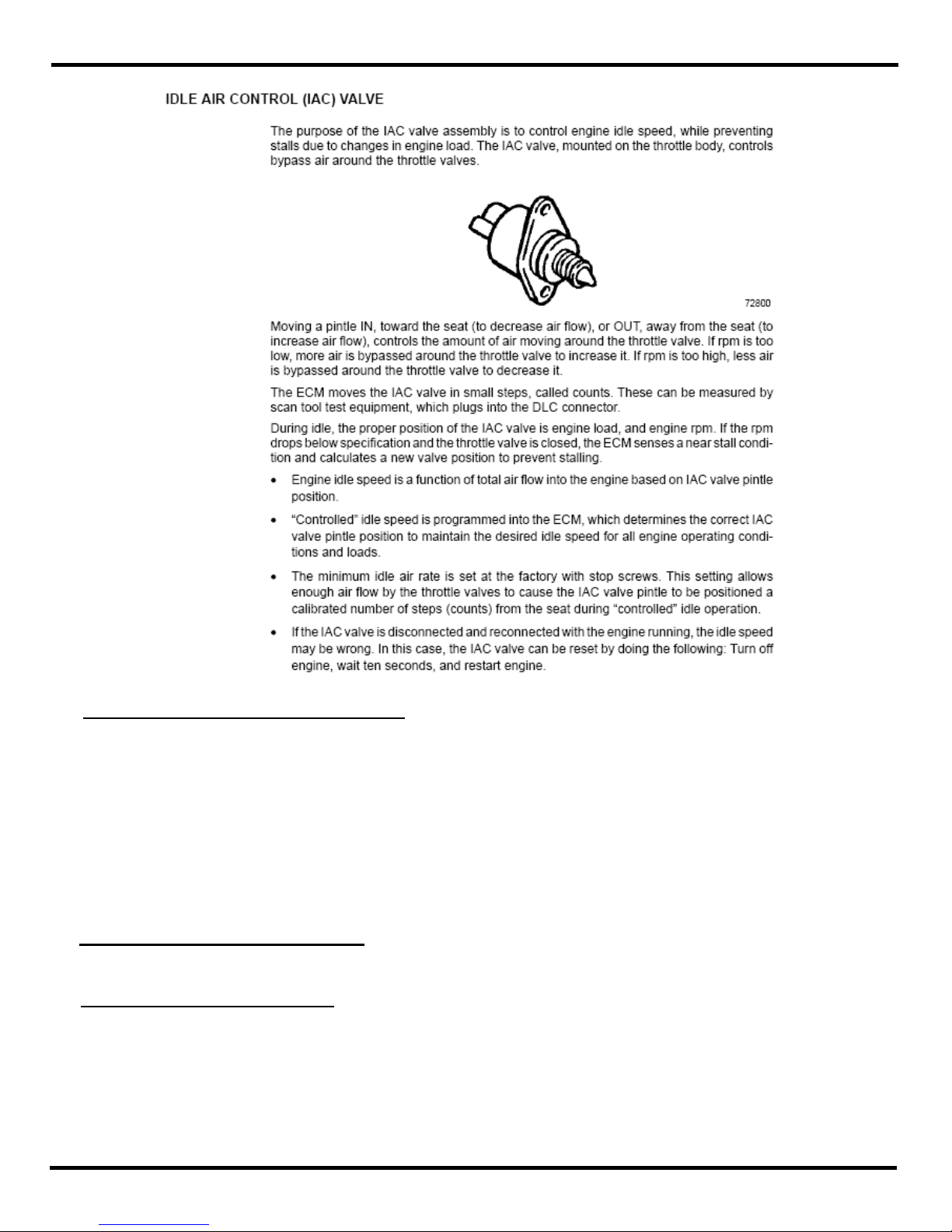

Supercharger By-pass system. The supercharger is installed with a by-pass system. This allows

4.

the supercharger to operate at higher efficiency under vacuum operation. It is advised to verify the

operation of the bypass valve. At idle and low engine loads, the bypass will be open. At hi gher loads

(engine in boost) the bypass will be closed. As the throttle is opened quickly the bypass valve will

close momentarily. This verifies the bypass will close and is functioning.

454/502 MagnumTBI_A1R9

6

Page 7

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

CLOSED

OPEN

Throughout this installation guide you will see the following symbols used:

NOTE

Used to indicate tips and information to aid in installation, maintenance, or use of the

supercharger.

!! CAUTION !!

Used to indicate precautions that must be taken to avoid damage to the

supercharger and associated components.

454/502 MagnumTBI_A1R9

SYMBOL KEY

7

Page 8

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

Ì WARNING!!

Used to indicate precautions that must be taken to avoid bodily injury as well as

damage to the supercharger and associated components.

COMMON ABREVIATIONS

SC Superc ger har

PSI Pressure

ECT Engine ant T Cool emperature

IAT Inlet A mperir Te ature

IAC Idle Air Control

TPS Thrott itionle Pos Sensor

MAP Manifo olutld Abs e Pressure

PCV Positiv nkcae Cra se Ventilation

WARNING!! CONSTANT ABUSE OF THE REV

LIMITER WILL CAUSE SEVERE ENGINE

FAILURE!!

STEP-BY-STEP INSTALLATION INSTRUCTIONS

1. Disconnect the battery power by selecting the disconnect mode on the battery switch or

removing the ground cable from all batteries.

2. Removal of stock parts:

(SERP) Loosen the stock adjustable idler nut to release tension of belt, remove the

stock belt.

(VBELT) Loosen accessories and remove factory v-belts.

Remove the factory crank pulley and clean the front surface, the new SC crank

pulley will mount to the surface of this later.

Unplug factory electrical plugs: Idle Air Control connector, Inlet Air Temp connector,

both Engine Coolant Temp connectors, Manifold Absolute Pressure connector, both

distributor connectors.

454/502 MagnumTBI_A1R9

8

Page 9

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

Remove stock throttle linkage and throttle body (throttle cable bolt and IAC motor)

and flame arrestor.

Remove factory shift cable bracket and mount on transom.

Loosen the belt tensioner holding nut. Release the tension on the Poly-V belt

and remove belt.

Remove the self-locking nut and washer holding throttle cable to the throttle

shaft and washer.

Install stock IAC motor on new throttle body with stock o-rings and stock torx.

Remove PCV valve and hose from intake manifold/valve cover.

Remove the distributor (replace if more than 100 hours or 2 seasons, only use

Mercury Marine distributors, other aftermarket replacements are not compatible with

the MEFI system). Note: It helps to mark the position of the distributor before

removal so it can be stabbed much closer to 8 degrees. You can take the distributor

cap off, crank engine over until pointer faces directly forward or scribe a mark on

the distributor housing marking the position of the rotor.

Remove MerCruiser fuel lines from stock fuel filter assembly (leave your factory line

routed to filter from tank).

Remove factory fuel lines and unplug factory fuel pump. Leave cool fuel unit in

place.

Inspect factory fuel line from tank. Make sure there are no restrictions such as

check valves, tight bends or anything smaller than 3/8” ID. Remove or replace any

restrictions found.

Remove thermostat housing and all it’s connecting hoses.

Remove entire intake manifold, both bottom and top assembly. Note: Must unplug

all injector connectors before removing and pull away from fuel rail.

Push factory-wiring harness to backside of motor so it’s out of the way.

Remove stock sensors from intake such as intake air temp sensor (located above #7

runner on intake) and 2 coolant temp senders (gauge and ECU).

Remove stock circulating water pump from block and all of it’s connecting hoses.

(SERP) Remove stock adjustable idler support bracket from engine (this requires

loosening of other brackets, reinstall them when done removing idler bracket).

454/502 MagnumTBI_A1R9

9

Page 10

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

(VBELT) Remove mechanical fuel pump from sea pump assembly and install

supplied fuel pump block off plate with the 3/8” x ½” socket head allens.

Separate the intake manifold from the intercooler/SC assembly by removing the 8

3/8” hex bolts.

3. Install factory sensors:

Install stock coolant temp sensors in new intake manifold by installing the single

post gauge sender into portside NPT port. Install the ECM sender (yellow/black

wires) to port side NPT. Use teflon pipe sealant on threads of sensors.

Install Inlet Air Temp sensor into 3/8” NPT located on the backside of manifold.

4. Intercooler and engine block water dump fittings: DO NOT RESTRICT OUTLET

Find visible location for both dumps above the water line. Remember, if you install

the stainless tee for the intercooler, it will run all the time, even when idling.

Mark your spots on the boat, and drill a hole using a ¾” drill or hole saw.

Apply marine type silicone to exposed wood and fiberglass as well as the back of

thru hull fittings.

While holding thru-hull fitting (do not let it rotate) on outside of boat, install the

supplied aluminum 8AN nut and tighten. Do the same for both thru-hull fittings.

Apply thread sealant to threads of supplied ¼” tee’s male thread. Install tee fitting

into thru-hull dump fitting that is tapped ¼” NPT. Install the 2 ¼” 90 degree

barbed fittings (apply thread sealant) into female ends of tee fitting.

Once tightened, wipe the excess silicone off and let the silicone dry.

5. (MEFI 1) You must upgrade to MEFI 3 or MEFI 4 ECM’s. It’s best to do the wiring mods

before you install the supercharger. Follow the wiring diagram at the end of the

instructions.

NOTE: It is beneficial to skip to instruction 23 at this time so you can install the

injector connectors while you have the blower off the intake.

6. Intake manifold installation:

Clean intake manifold and cylinder head surface.

NOTE. Apply thick bead of RTV silicone around all 4 water passages on cylinder heads.

454/502 MagnumTBI_A1R9

10

Page 11

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

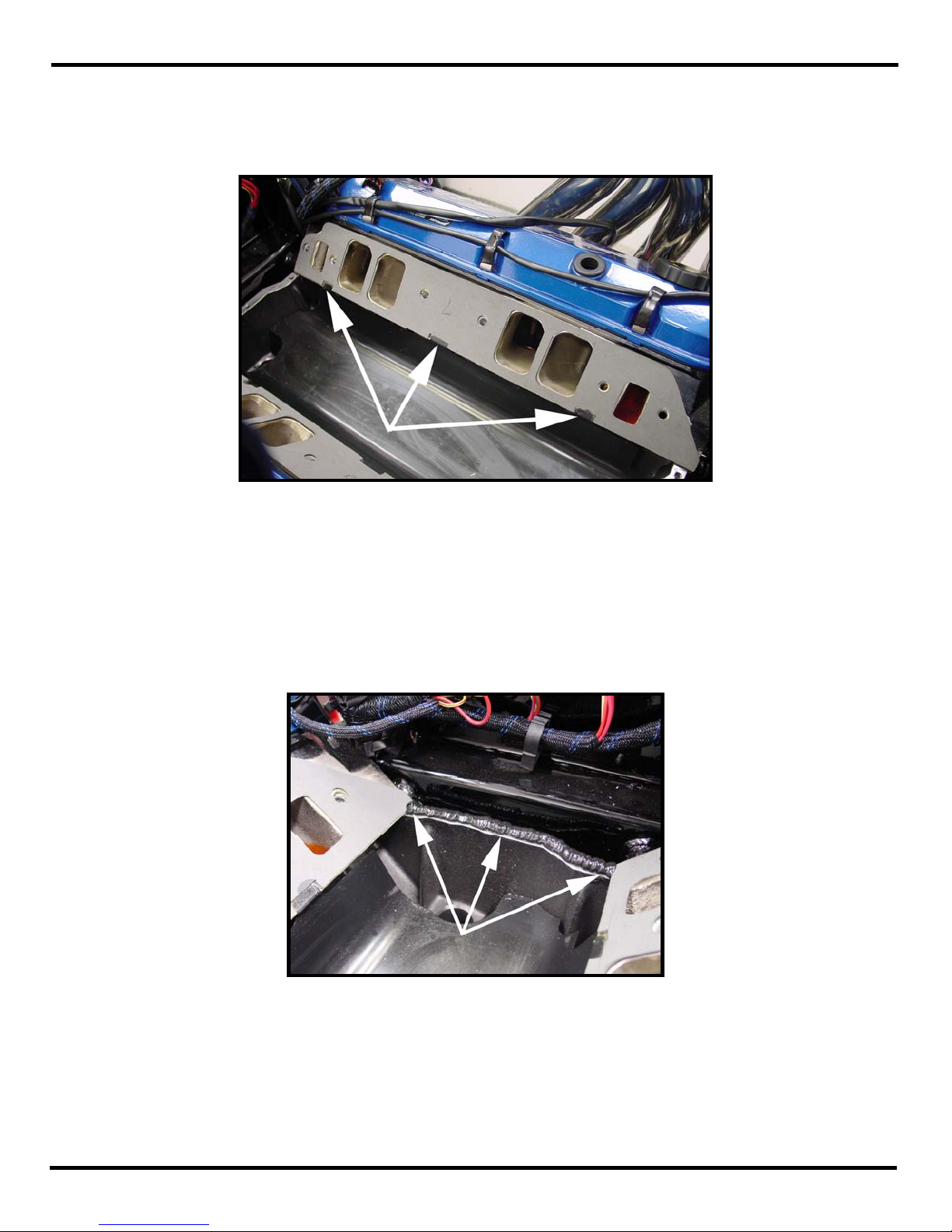

NOTE. Mark and cut the intake gaskets to clear the galley pan mounts if required. See

figure.

Install new supplied intake gasket to cylinder head.

NOTE. Apply a thick bead of black RTV silicone on the intake gaskets around the water

passages to insure sealing around the water passages.

NOTE. Apply a thick bead in the valley of the block, both front and rear. This should be

a minimum of 3/8” ID tall. See figure.

Install intake manifold using the 8 – 3/8” x 1.50” and 4 – 3/8” x 2.25” socket head

allens and the .680” stainless washers. Torque to 20 foot-pounds on your first pass,

torque to 35 foot-pounds on your second pass. Note: Install all bolts hand

tight and slide intake forward as much as possible, and then stab the

distributor to make sure everything lines up. If it does, proceed, if it does

454/502 MagnumTBI_A1R9

11

Page 12

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

not, you may have to file one of the openings, contact Whipple first.

Line up the distributor housing to the rotor as you marked previously. If it does not

line up, remove distributor and insert a screwdriver into the hole to turn the oil

pump drive shaft. Repeat this adjustment as needed until the distributor can be

firmly seated and all componets are in alignment.

Install hold down clamp over distributor and bolt it securely.

Reinstall distributor cap and secure in place.

Install the supplied manifold to intercooler housing gasket.

Install supercharger/intercooler assembly by lying on intake manifold with throttle

cable assembly as well. NOTE: While installing SC/intercooler assembly, you must

install the 3/8” x 1.5” hex bolt in the first throttle cable bracket/intercooler mounting

area. It’s too long to install afterwards.

Install all other intercooler mounting bolts hand tight and then slide the compressor

assembly forward. Now torque the (8) 3/8” intercooler-mounting bolts to 35ft. lbs.

Install new thermostat housing with the supplied 3/8” x ¾” socket head allen bolts

and new thermostat gasket. If installing the water restrictor, install flat side into

intake manifold thermostat register. Install supplied 3/8” x ¾” socket head allen in

extra 2 blank holes, use pipe sealant on threads. NOTE: Do not install a

thermostat, this system is made to run with NO THERMOSTAT.

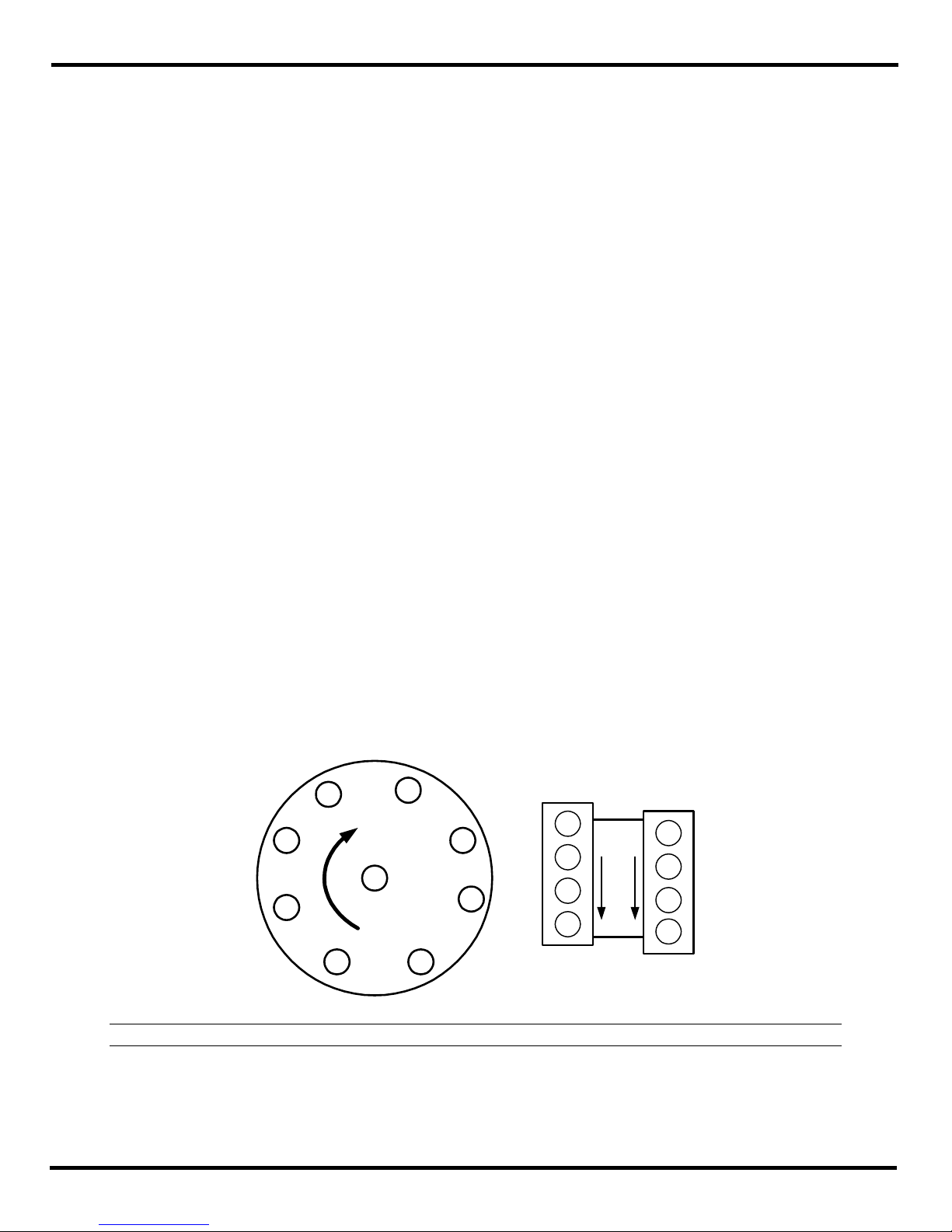

7. Install spark plug wires (replace if you have over 100 hours or 2 seasons on current wires). Firing

order is 1-8-4-3-6-5-7-2. (Whipple recommends MSD 8.5mm plug wires)

3

4 5

8

1 2

It is recommended to use a few tie straps for this step: they’re cheap!!!

8. Make sure the mounting surface of the new crank pulley on the front of the balancer is

perfectly flat. If necessary, remove the imperfections or paint with a good flat file.

6

8

6

7

4

2

F

R

O

N

T

7

5

3

1

454/502 MagnumTBI_A1R9

12

Page 13

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

(SERP) Install the Whipple dual serpentine crank pulley on the factory balancer

utilizing the 3/8” x 2.5” hex head bolts. Each bolt should get 1 AN flat washer (goes

against crank pulley) and lock washer. Apply a small amount of Red Loctite

threads to new longer crank pulley bolts and torque to 35 foot-pounds.

(VBELT) Install the Whipple triple V/serpentine crank pulley on to the factory

balancer utilizing the 3/8” x 3.5” hex head bolts. Each bolt should get 1 AN flat

washer (goes against crank pulley) and lock washer. Apply a small amount of Red

Loctite

9. Stainless water cross-over system:

TM

on threads to new longer crank pulley bolts and torque to 35 foot-pounds.

(VBELT) Install stainless water cross over utilizing the new gaskets and 4 3/8” x ¾”

socket head allen bolts. Inlet feed should be facing up, starboard side.

(SERP) Install stainless water cross over with new gaskets (figure 1), this requires

you to install the new billet belt system at the same time. Use the 4 aluminum

spacers that fit against the water cross over and through the new plate, use the 2 3/8” x 3.5” socket head allens and washers to secure starboard side of plate. See

figure 2 and following diagram. On the port side, use the supplied oil

cooler/power steering support bracket with 2 3/8” x 3.75” socket head allen bolts.

TM

on

10. Front plate/support installation:

Take the round support stands and tighten on setscrews. Tighten using the hex

area on stand.

Take front plate assembly and slide collar and front plate over the drive just slightly.

NOTE: ¼” allens in collar are not tight, must apply blue Loctite.

Install the 3/8” X 1” socket head allen bolts hand tight through front plate to support

stands and follow by aligning front plate with SC pulley and support stands. The

drive collar must be tightened evenly, do not just tighten the button head allen

454/502 MagnumTBI_A1R9

13

Page 14

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

bolts, snug the collar locking bolt and the collar to plate bolts.

Once aligned, remove blower pulley for access to drive collar bolts.

Remove drive collar socket head allen bolts one at a time so you don’t lose your

alignment, apply light amount of blue Loctite and tighten ¼” socket head allens on

collar.

Tighten the 3/8” x 1.5” button head allen bolts into support stands to secure front

plate. Torque to 22 ft. lbs.

Install blower pulley with the supplied 6mm x 14mm socket head allen bolts. Hold

drive hub from spinning by using a large metric allen in center of drive hub. Then

tighten blower pulley bolts to 120 inch pounds. NOTE: Install dry, no Loctite.

11. There are two ways of routing your fuel system. Ideally, you want to return all fuel to an

open port in the fuel tank(s). This will allow proper cooling of the fuel. You will then route

the inlet from the tank to the inlet of the fuel filter, then you will return all fuel to the tank.

If your boat does not have an open port for return, then you must utilize the fuel cooler and

inlet tee for returning fuel.

12. Assemble fuel pressure regulator:

Install barbed brass fitting with o-ring (be very careful, very breakable).

Install adjusting set screw and nut, do not install tight at this time.

Install –6 o-ring to –6 AN flare fitting into return side of regulator.

Install supplied 1/8” pipe plug into fuel pressure regulator. Apply light amount of

thread sealant to threads.

Install the –10 oring to the –10AN to –6AN fuel fitting (93-98 MEFI1 ONLY).

Install the –10AN to –6AN fuel fitting into either side of regulator (93-98 MEFI1

ONLY).

Install the –10AN plug fitting into fuel pressure regulator (either side) (93-98

MEFI1 ONLY).

13. Remote mount fuel pressure regulator with the supplied bracket and hardware. Ideally this

should be within 3 feet of the fuel rail.

454/502 MagnumTBI_A1R9

14

Page 15

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

Fuel Pressure

Regulator

Injector Fuel Rail

Fuel

Inlet From Tank

Cooler

IN

14. (93-98 MEFI1) Fuel system installation: NOTE: Never use thread/pipe sealant on o-ring

style fuel fitting.

IN

OUTOUT

Electric Fuel

Pump

Inspect factory fuel lines from tank(s), check for any restrictions such as check valves

and inline filters. All restrictions must be removed to allow proper fuel flow.

Remove factory fuel lines and fittings from stock fuel filter.

Install supplied ¼” NPT brass Tee to the stock fuel filter IN. Apply light amount of pipe

sealant to pipe thread.

Install factory barbed fitting into Tee fitting. Install factory 3/8” ID fuel hose from tank

and tighten clamp.

Install (1) ¼” NPT pipe to –6AN fuel fitting into ¼” NPT

brass tee fitting.

Install (1) ¼” NPT pipe to –6AN fuel fitting in the stock

fuel filter OUT.

Install supplied –10AN (3) o-rings to the –10AN to –6AN

454/502 MagnumTBI_A1R9

IN

IN

OUTOUT

15

Page 16

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

fuel fittings.

Install the supplied (2) –10AN flow to –6AN flare fittings in the inlet and outlet ports of

the new hi-flow fuel pump.

Install supplied (1) –10AN flow to –6AN flare fitting into inlet of fuel PSI regulator

(either side will work). Install supplied –10AN plug to empty inlet port of fuel PSI

regulator.

Pre-plan the fuel line routing so you can mount the fuel pump and fuel cooler in proper

locations. It’s best suited to install pump at a lower level than the fuel tank.

Find a secure location to mount hi-flow electric fuel pump. Note that this pumps

vibrates and can cause a harmonic noise if not mounted securely.

Install pipe sealant to fuel cooler –6AN steel fittings. Install fittings to cooler.

Find a secure mounting location for the fuel cooler, mount cooler. This can be located

anywhere in the factory water system after the sea pump outlet.

You must now manufacture fuel lines. Use only high quality, USCG

approved, high-pressure fuel lines!!

fuel lines from Whipple for a minimal charge. You must supply Whipple with line length

and type of fitting (90° or straight only).

You may order crimped 3/8” USCG approved

Manufacture fuel line utilizing 3/8” ID hose from the pump OUTLET to the –6 fitting on

the starboard side of the fuel rail –6 fitting.

Manufacture fuel line utilizing 3/8” ID hose from the port side fuel rail –6AN fitting to

the –6AN fitting to the inlet of fuel PSI regulator.

Manufacture a fuel line utilizing 3/8” ID fuel line from the regulator return to the new

supplied fuel cooler.

Manufacture another 3/8” ID fuel line from the fuel cooler to the –6 fitting you installed

into the brass ¼” Tee fitting (IN @ fuel filter).

Locate the barbed fitting on starboard side of intake manifold (5/32”). Install supplied

5/32” vacuum hose and route to fuel pressure regulator barbed port. Secure with zip

ties. Avoid tight bends and kinks.

15. (99-2002 MEFI3) Fuel system installation: NOTE: Never use thread/pipe sealant on o-

ring style fuel fitting.

Inspect factory fuel lines from tank(s), check for any restrictions such as check valves

and inline filters. All restrictions must be removed to allow proper fuel flow.

454/502 MagnumTBI_A1R9

16

Page 17

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

Remove factory fuel lines and fittings from stock fuel filter except for factory inlet.

Install supplied ¼” NPT pipe to 3/8” barbed fitting into

the stock fuel filter IN #1. Apply light amount of pipe

sealant to pipe thread. Face barbed fitting straight

down.

IN #2

IN #1

Install (1) ¼” NPT pipe to –6AN fuel fitting in the stock

fuel filter OUT #1.

OUT #1OUT #2

Install (1) ¼” NPT pipe to –6AN fuel fitting in the stock

fuel filter IN #2.

Install supplied –10AN (3) o-rings to the –10AN fuel fittings.

Install the supplied (2) –10AN flow to –6AN flare fittings in the inlet and outlet ports of

the new hi-flow fuel pump.

Install supplied (1) –10AN flow to –6AN flare fitting into inlet of fuel PSI regulator

(either side will work). Install supplied –10AN plug to empty inlet port of fuel PSI

regulator.

Pre-plan the fuel line routing so you can mount the fuel pump and fuel cooler in proper

locations.

Find a secure location to mount hi-flow electric fuel pump. Note that this pumps

vibrates and can cause a harmonic noise if not mounted securely.

Install rubber strips on fuel pump clamps, mount pump in clamps using the supplied

brackets, and tighten clamps. Make sure the rubber strips are on straight.

Install pipe sealant to fuel cooler –6AN steel fittings. Install fittings to cooler.

Find a secure mounting location for the fuel cooler, mount cooler. This can be located

anywhere in the factory water system after the sea pump outlet.

Install factory fuel line from tank to barbed fitting, secure with factory clamp (utilize

factory fuel line and clamp that routed to the first stock fuel pump).

You must now manufacture fuel lines. Use only high quality, USCG

approved, high-pressure fuel lines!!

fuel lines from Whipple for a minimal charge. You must supply Whipple with line length

and type of fitting (90° or straight only).

You may order crimped 3/8” USCG approved

Manufacture fuel line utilizing 3/8” ID hose from the pump OUTLET to the –6 fitting on

the starboard side of the fuel rail –6 fitting.

454/502 MagnumTBI_A1R9

17

Page 18

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

Manufacture fuel line utilizing 3/8” ID hose from the port side fuel rail –6AN fitting to

the –6AN fitting to the inlet of fuel PSI regulator.

Manufacture a fuel line utilizing 3/8” ID fuel line from the regulator return to the new

supplied fuel cooler.

Manufacture another 3/8” ID fuel line from the fuel cooler to the –6AN fitting you

installed into filter IN #2.

Locate the barbed fitting on starboard side of intake manifold (5/32”). Install supplied

5/32” vacuum hose and route to fuel pressure regulator barbed port. Secure with zip

ties. Avoid tight bends and kinks.

Fuel Pressure

Regulator

Injector Fuel Rail

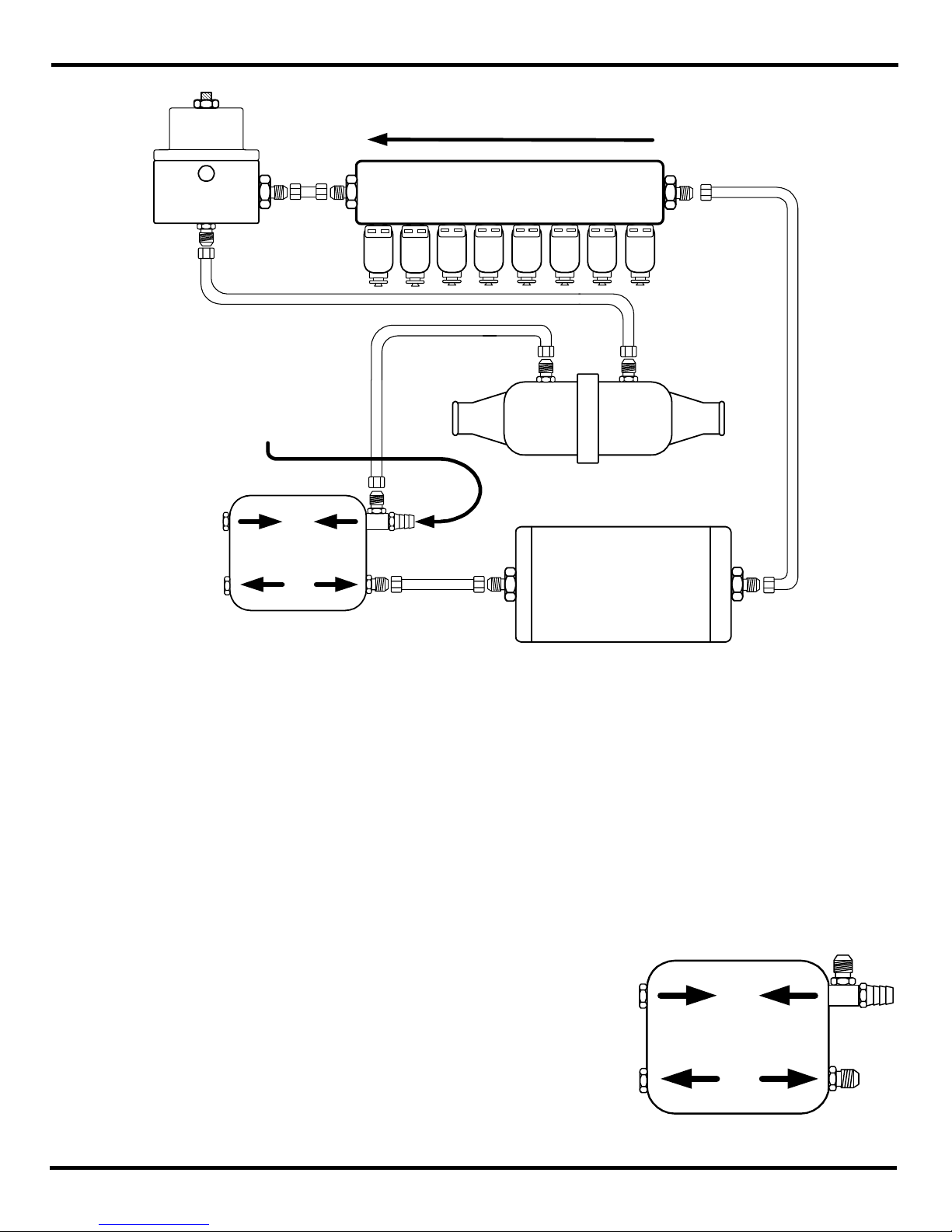

16. Water routing:

Inlet From Tank

IN

Fuel Pressure

Check Point

Fuel

Cooler

IN

OUTOUT

Electric Fuel

Pump

(SERP) Use the supplied “U Bend” hose to connect too water crossover inlet

(figure 4) from the factory oil cooler. Cut supplied hose and fit so there are no

kinks of any kind (see following diagram for reference). Secure hose with factory

clamp off.

454/502 MagnumTBI_A1R9

18

Page 19

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

90 Degree

Supplied Hose

Cut Supplied

Hose to fit

Factory

Power

steering

cooler

(SERP) Install intercooler water supply (preferably separate pickup) from external

pickup or supplied tee. The tee should be installed after the sea pump, preferably

near the starter. Secure with #20 hose clamps.

(VBELT) Utilize factory hose from factory coolers. Utilize the supplied U bend hose

and couple to the factory hose. Use the supplied intercooler tee or hose coupler.

Cut hose to fit. Some hoses may need to be replaced if worn or cracked.

Intercooler tee or hose

coupler

Factory

90 Degree

Supplied Hose

hose, cut to

fit

Factory

Power

steering

cooler

Install supplied 5/8” ID hose from intercooler tee to the port side –10AN intercooler

454/502 MagnumTBI_A1R9

19

Page 20

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

inlet and secure with #10 hose clamps.

Install 5/8” ID hose from starboard side intercooler fitting and route to fuel cooler

and secure with #10 hose clamps.

Route 5/8” ID hose from fuel cooler to intercooler dump fitting you installed earlier.

Install brass – 8 push lock fitting to intercooler dump fitting and follow by pushing

the 5/8” ID hose on push lock fitting.

Install factory hose and clamps to new thermostat housing and bottom water feed

on stainless exhaust.

Install supplied tee with dual ¼” fittings and male pipe into the thru-hull fittings that

is threaded on the inside. Use pipe sealant on all fittings.

Make up ¼” ID hose from the fittings coming out of the back of the intake manifold

to the water dump fitting with the tee installed. Secure with hose clamps.

17. Take factory PCV valve and take straight plastic top off. 93-97 engines will receive PCV

valve to install into port side valve cover. Route 3/8” hose to barbed fitting coming from

throttle body.

Install new 3/8” ID hose with new 90-degree plastic fitting onto PCV valve.

Insert PCV valve in port side valve cover. Route hose to 90 degree fitting on throttle

body as shown in figure 5.

18. Utilize the factory 1/2” hose that was used on the breathers to install the small breather.

You may mount this wherever you want, or cut real short and let it sit there (see figure 6).

Secure both ends with #6 hose clamps.

19. Install factory 6 rib grooved idler on Whipple plate on diagonal position with adjusting

setscrew up and down. Use the tee nut to slide back and forth, the idler spacer to space

idler out correctly and the idler washer that centers the hex bolt on front side of idler

bearing.

20. (VBELT) Install the 2 new supplied v-belts to accessories. You will reutilize one factory

belt.

21. (SERP) Install new 6 rib belt as shown in this diagram: Once installed tighten by using the

all thread stud on the bottom of the idler as shown in following diagram.

454/502 MagnumTBI_A1R9

20

Page 21

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

Alternator

Adjusting

Set Screw

Sea

Pump

Crank Pulley

22. (99-2002 MEFI 3) Relocate factory “Merthacode” assembly on back side of head with the

supplied steel bracket (center of plate has 2 cutouts). Use supplied 3/8” x ¾” socket head

stainless bolts and 3/8” S.S. AN washers to secure.

23. Locate the barbed fitting on starboard side of intake manifold. Install supplied 7/32”

vacuum line to this and route to map sensor that is located on backside of front plate.

Secure with zip ties.

24. Locate the barbed fitting on port side of intake manifold (5/32”). Install supplied 5/32”

vacuum hose and route to fuel pressure regulator barbed port. Secure with zip ties.

25. Fill supercharger with oil to middle of knurled area on dipstick, 5W-50 synthetic engine oil.

DO NOT OVERFILL SUPERCHARGER OIL LEVEL. NOTE: The SC oil system takes a

maximum of 5.4oz of oil).

Power Steering

Pulley Or Idler

Make sure the SC is sitting square/flat.

Remove -3AN allen plug and fill SC with WHIPPLE SC OIL ONLY!!

Fill to the middle of the sight glass. NOTE: The W140AX compressor takes a maximum of 5.8 fl/oz.

Reinstall -3AN allen plug.

NOTE: After running the SC, the oil level will lower due to oil filling the bearings. The proper level should be

between the bottom of the sight glass and the middle.

Change SC oil every 50 HOURS and only use WHIPPLE SC OIL ONLY!!

!! CAUTION !!

Severe damage to the compressor will occur if you overfill the supercharger front gear case.

454/502 MagnumTBI_A1R9

21

Page 22

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

WHIPPLE SC OIL LEVEL

Fill to center of oil sight glass. 5.8 fl/oz. or 155cc.

DO NOT OVERFILL, WILL VOID WARRANTY!!

26. WIRING INSTRUCTIONS: MEFI1 MUST UPGRADE TO MEFI3 OR MEFI4.

Locate all 8 injector connectors and remove protective plastic “split loom” to expose

wires. At the same time, remove the TPS and IAC wires from the same loom.

Trace the pink, blue and green wires from the injector connectors back to main

portion of wiring harness. The pink wire will run into a wiring solder connection,

where it’s being fed by a black wire.

Cut the blue, green and pink wires that you traced leaving approx. a few inches for

a proper wiring connection.

Utilize the supplied weather style butt connectors or solder wires to the supplied

injector pigtail (allows for easy access to injector wiring). Blue to blue, green to

green, black to pink. If using the butt connectors, use heat gun to shrink connector

to seal wires from water. If you soldered the wires, use heat shrink tubing over

wires and seal with electric tape.

Re-loom the harness with the factory split loom and route the injector harness

pigtail, TPS and IAC connectors towards the port-rear of engine.

Plug in the IAC extension harness (one yellow end, one black end) to factory IAC

connector and route to starboard/rear of engine.

454/502 MagnumTBI_A1R9

22

Page 23

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

Some may need to separate the supercharger from the intercooler housing by

removing the 3 3/8” hex bolts to get to the injector connectors. If you separate

them, clean the silicone from the 2 surfaces and reseal with black RTV silicone when

putting back together. Torque to 35 ft. lbs.

Plug in factory TPS connector to new TPS sensor.

Plug in factory IAC connector to IAC motor on starboard side.

Install factory connector to Inlet Air Temp sensor.

Connect brown engine coolant temp sensor wire for gauge.

Connect factory engine coolant temp sensor to sensor in manifold.

Find the factory map sensor connector and plug in the wiring extension. Now install

the new orange map sensor connector to the map sensor located on the front plate.

See figure 7.

Locate the factory electric fuel pump connector. This connector has a gray wire (Pin

A), which is the turn on wire and a black wire (Pin B), which is a ground.

Cut the factory connector off, strip wires and connect to supplied relay harness (see

following diagram for reference). Connect the new harness gray wire to factory

gray wire. Connect new harness black wire to factory black wire (preferable solder

and heat shrink). Mount relay and fuse on back of engine or transom.

Route red wire from fuse junction to battery power.

Route orange wire to electric fuel pump positive +. (10 or 12 ga only!!!)

454/502 MagnumTBI_A1R9

23

Page 24

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

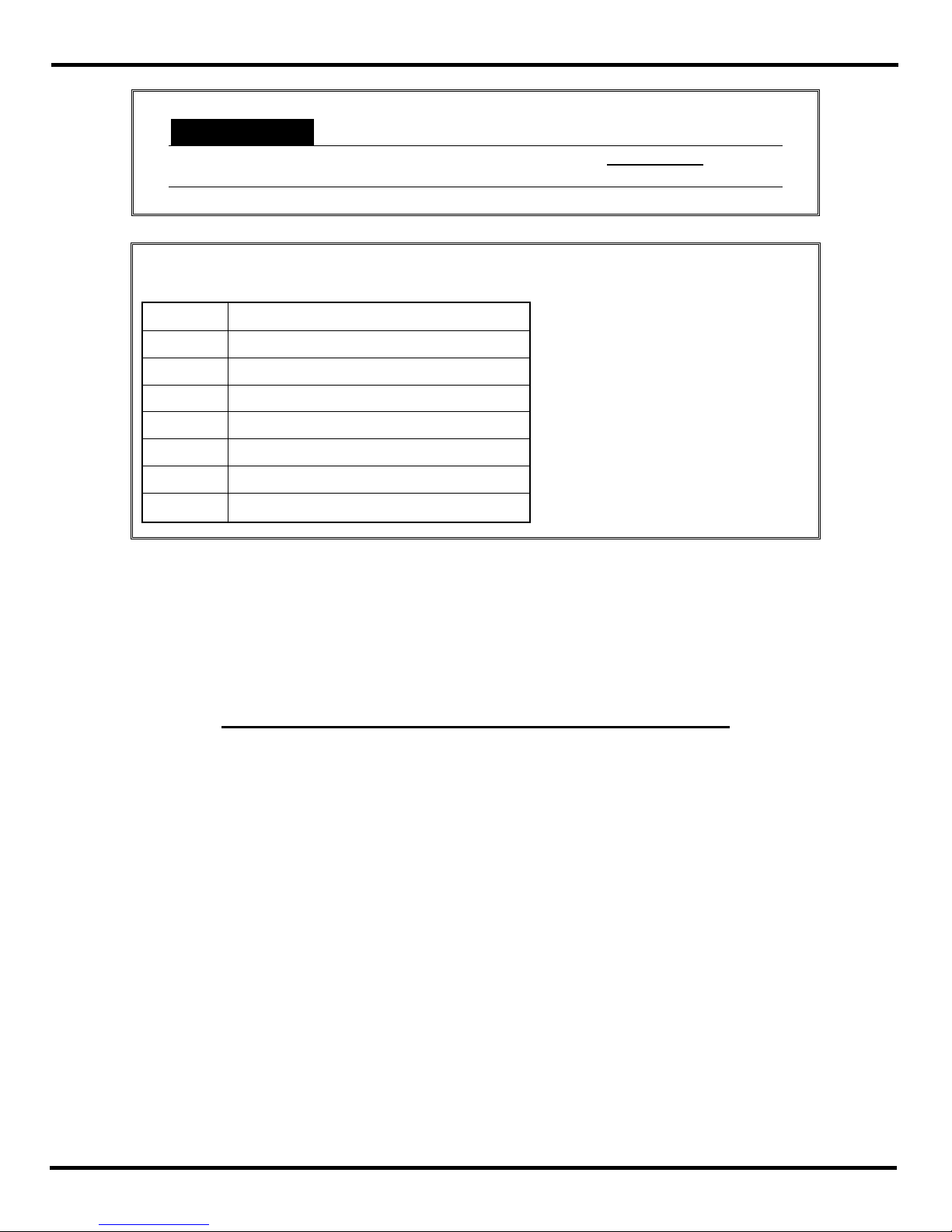

Relay Pin Connection Wire Color

Red

RELAY PIN LAYOUT

ATo Fuel Pump +Orange

D Factory Pum p G r ound Blac k

E Battery Power + Red

F Factory Tu rn ON Wire Gray

Battery

Power

25 Amp

Fuse

GM Relay

14089936

+

-

Ground to

Battery

10 or 12 ga

Orange

Black

Factory

Wires

Gray

Black

Connector

A

B

Stock

Cut Off

Gray

10 or 12 ga

-

Electric Fuel

Pump

+

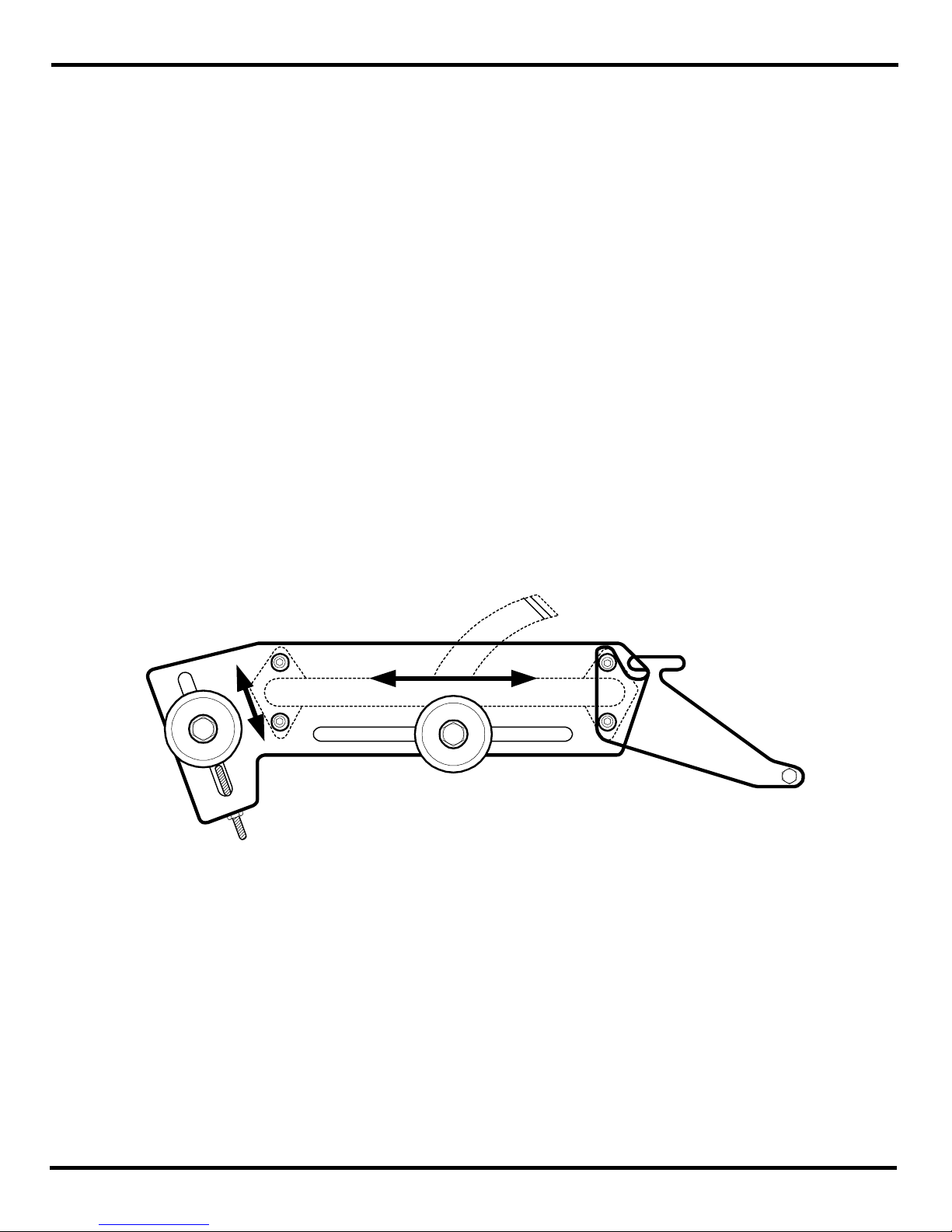

27. Install SC belt by releasing the tension from the tensioner and loosening the mounting bolt

on the sliding idler.

Once belt is on all pulleys, push the sliding idler towards starboard side until you can

release the tensioner so that it’s pointing at a 5 O’clock position. Notice the stops on

the tensioner, it must have play both forward and backwards to work properly. See

following diagram.

454/502 MagnumTBI_A1R9

24

Page 25

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

28. Throttle linkage installation: (See figure 8)

Install factory throttle linkage anchor bolt into “L” adapter.

Install factory throttle linkage bolt in throttle arm.

Adjust linkage so that the linkage barely fits on the linkage bolt, so that the linkage

is always being forced to it’s maximum closing position.

Adjust heim joints as needed.

Tighten all bolts, allens, etc. on throttle assembly.

Verify that the linkage does not go over center at any time. Should be able to go

back and forth 100% without binding.

BEFORE STARTING THE ENGINE

MAKE SURE THE THROTTLE CABLE OPERATION IS CORRECT. WITH THE ENGINE OFF,

MOVE THE THROTTLE A FEW TIMES TO FULL OPEN AND CLOSED POSITIONS. THERE

SHOULD BE NO BINDING OR STICKING AND SHOULD OPERATE FREELY.

PRIME FUEL PUMP WITH FUEL!! DO NOT RUN THIS PUMP DRY UNDER ANY

CIRCUMSTANCES!! THERE ARE NO WARRANTIES FOR PUMPS RAN DRY.

29. Adjust fuel pressure TEMPORARILY: DO NOT RUN PUMP DRY!!!!

Install quality mechanical fuel pressure gauge (do not use electric gauges to tune)

454/502 MagnumTBI_A1R9

25

Page 26

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

to 1/8” pipe fitting on adjustable regulator.

Prime fuel system so that filter is full of 91-octane gas.

Turn key “on” and quickly bleed air from fuel line anywhere on pressure side.

Turn key to on position, look at pressure and adjust close to 40lbs. This is

temporary to get the engine running.

30. You must set base ignition timing at 8 degrees.

Connect timing light to number 1 ignition wire.

Start the engine and let idle (may have to give some slight throttle).

Connect the appropriate tool (timing tool #91-805747A1), Rinda scan tool or jump pins A &

B on the DLC with a bare wire/paper clip to hold the engine in base timing mode.

Manually adjust throttle so engine RPM is steady 1500rpm.

If you have a Rinda scan tool, set the engine in “service mode” which will set it in base

timing mode.

Shine the timing light at the timing mark indicator located on the timing chain cover.

Adjust the distributor until you get the desired 8 degrees BTDC. Clockwise to retard timing,

counter-clockwise to advance timing.

Torque distributor bolt down bolt to 30 foot-pounds.

Verify that the motor is 8 degrees BTDC after the distributor was tighten, adjust if needed.

Set scan tool to “normal mode” or remove the base timing tool.

YOU MUST USE A HIGH QUALITY, HIGH ACCURACY MECHANICAL

FUEL PRESSURE GAUGE ONLY!!! NEVER ADJUST WITH AN

With NO vacuum reference, adjust fuel pressure regulator by turning top allen

454/502 MagnumTBI_A1R9

ELECTRIC GAUGE!!

26

Page 27

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

screw on regulator (clockwise for more pressure, counter clockwise for less) until

you reach 40 lbs. of fuel pressure. Tighten nut on regulator so allen does not

vibrate out.

Install 5/32” vacuum/boost line onto regulator barbed fitting. Secure lines with zip

ties. With motor running in vacuum, pressure should drop once line is connected

and will rise above 40 under boost. Under full boost, the fuel pressure must hold a

steady 45lbs. of pressure (+/- 2lbs). If not, there is a restriction in the line.

IDLE SPEED SETTING

31. Some motors may need an idle adjustment. First, you must understand the ECU has a

desired idle speed that the motor is always going to try to achieve. The rpm idle speed

should be 750 rpm once motor is up in the 80+ range of engine coolant temperature.

On the starboard side of throttle body, there’s the linkage arm that is pushed over a

splined shaft. Remove the linkage arm from the throttle body so you can have

better access to the throttle stops.

You must adjust the setscrew to raise or lower the idle speed. Note that this is

where the throttle stops in the relaxed or returned position.

Engines that idle to high:

This means either there’s a vacuum leak, too much timing or there is too much air

going by the throttle blades. To lower airflow at idle, take the set screw/throttle

stop and lower it. This allows the throttle blade to close more when returned. Make

small adjustments such as 1/8

454/502 MagnumTBI_A1R9

th

turns. NOTE: Don’t forget to tighten locking

27

Page 28

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

nut after adjustment.

Engines that idle to low:

This means either there’s not enough air being fed to engine or not enough timing.

To increase airflow at idle, take the set screw/throttle stop and raise it so when the

throttle is in its relaxed position, it will be slightly open more. Make small

adjustments such as 1/8

after adjustment.

th

turns. NOTE: Don’t forget to tighten locking nut

To raise the voltage, you must make the setscrew (acts as throttle stop when in

returned position) open the throttle blade more. This will raise the RPM (if it’s

loping between 600-1000, open the blade). If the RPM is to high, you must close

the blade (lower the voltage). If you do have a scanner, watch the IAC count. You

want it to be between 20-50. You must shut the motor off for 5 seconds to reset

the IAC motor. If you do not have a scanner, you can adjust this setscrew until you

see the motor idles around 750 on the tachometer, the motor should not hunt more

than 100 RPM.

Rev engine up past 2500 rpm and bring back at a rapid rate. The motor should not

die, it should come back to the desired idle speed within 1-5 seconds. If it dies,

then it needs more air so follow instructions for engines that idle too low.

Motors that idle high only after revving the engine or there are no more adjustments

to be made:

This means the TPS voltage is slightly off and that it does not return to its “Closed

Loop Idle System.” To fix this, you must loosen the TPS sensor (located on port

side of throttle body) and push the top out towards the back of the boat. This will

lower the TPS voltage. Tighten allens and try starting it again. You may want to

use the scanner or a volt-meter (0-5volt sensor output) to watch the voltage come

down. Ideal voltage should be in the range of 0.45 – 0.55 volts.

CRITICAL!!!

LAKE TEST

POST-INSTALLATION CHECKLIST

After installing the Whipple supercharger kit it is imperative that the following checklist be

performed. Failure to perform these simple tests may result in severe engine damage.

1. Make sure 91 octane or higher is in the vessel. If unsure, then drain the tank completely

454/502 MagnumTBI_A1R9

28

Page 29

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

empty and fill with 91 or higher.

2. With the thermostat removed, under full throttle operation, near full speed, block pressure

should be a minimum of 25lbs. and maximum of 40lbs. If block pressure is not present,

severe engine damage may occur. The motor should have 0-2lbs. at idle and should

progressively get higher as speeds increase. A low water nose style pickup or external pickup

may need to be installed. The Mercury side hole pickups will not generate enough water flow

for proper operation. If you have an XZ drive with dual water pickups, it WILL be necessary

to plug side draft holes to increase pressure.

3. Fuel pressure is the most critical parameter and must be checked during wide-open throttle

operation. Install a quality fuel pressure gauge to the extra port at the auxiliary fuel rail

added by Whipple (1/8” pipe). Attach the fuel pressure gauge with a long enough hose so

that it may be visible during operation. Under WOT, full boost, max rpm, the fuel pressure

should be 45 lbs (+/- 2lbs). This procedure takes two people – one to drive and the other to

observe the gauge. Perform the test in a safe area. If it does not maintain fuel pressure, you

must find the restriction, as this results in a lean air to fuel condition.

MAINTENANCE AND SERVICE

It is recommended that the following items be checked at normal service intervals.

1. Check supercharger oil every 10-15 hours of operation.

2. Clean idle air motor filter every 10-15 hours.

3. Remove and clean flame arrestor elements every 10-15 hours.

4. Change supercharger oil every 50 hours or every season, which ever comes first.

5. Check the supercharger/accessory drive belt. Adjust or replace as required.

6. Inspect and replace fuel filter every 50 hours.

7. Replace factory spark plugs every 50 hours.

8. Back flush intercooler every 50 hours or once a season.

9. Follow your standard Mercury Marine service intervals.

DO NOT!!!

1. Never run octane less than 91.

2. Do not use octane booster, these are very hard on the spark plugs and only increase a few

points. Example: 87 octane with octane booster, may raise a few “points” to 87.5, which is

not acceptable.

3. Never operate engine if overheating.

4. Never operate engine in boost if water temp exceeds 140.

5. Do not operate engine in boost if water pressure has fallen below standard levels.

6. Do not operate engine in boost if fuel pressure falls below standard levels.

454/502 MagnumTBI_A1R9

29

Page 30

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

7. Do not tee the vacuum/boost line feeding the Map sensor, use the other pipe holes located

in the manifold.

8. Do not design your own fuel system, the system is designed for use and installation as we

specify.

9. Do not run more timing than 8 degrees base.

10. Never run a hotter spark plug, only run factory replacements or one heat range colder.

Gap plugs to .032”.

454/502 MagnumTBI_A1R9

30

Page 31

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

31

Page 32

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

32

Page 33

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

33

Page 34

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

34

Page 35

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

MEFI4 DIAGNOSTIC INFORMATION ONLY

MEFI4 PIN CONFIGURATION

J1 CONNECTOR

J1 Pin Description Color Connector pin Connector Type

J1-1 Knock signal #2 (N/A) Light Green (N/A) (N/A)

J1-2 Diagnostic "test" terminal Black/White Pin B 10 Way/DLC

J1-3 Master/Slave (N/A) Yellow Pin B 2 Way

J1-4 Empty

J1-5 Emergency Stop (N/A) Pink (N/A) (N/A)

J1-6 Fuel pump relay control Dark Green/White Relay Pin 85 Fuel pump relay

J1-7 Empty

J1-8 Audio warning horn Dark Green/Black

J1-9 Empty

J1-10 Empty

J1-11 Fuel injector driver B Blue Injectors Pin B Injector connector

J1-12 Empty

J1-13 Distributor Reference "low" Red/Black Pin A 4 Way/Distributor

J1-14 Tachometer output Gray Engine harness gray

J1-15 Idle air control B "low" Green/Black Pin A 4 Way/IAC

J1-16 Idle air control A "high" Blue/White Pin D 4 Way/IAC

J1-17 Knock signal #1 Blue Knock Sensor Single way

J1-18 Oil level

J1-19 Empty

J1-20 Shift interrupt (N/A) White Shift sensor

J1-21 Empty

J1-22 Empty

J1-23 Empty

J1-24 Gear lube switch Tan/Black

J1-25 Empty

J1-26 Fuel injector driver A Green Injectors Pin B Injector connector

J1-27 Malfunction indicator lamp Brown/White Pin E 10 Way/DLC

J1-28 ECM ground Black Engine block Eyelet

J1-29 ECM ground Black Engine block Eyelet

J1-30 Idle air control B "high" Light Green/White Pin B 4 Way/IAC

J1-31 Idle air control A "low" Light Blue/Black Pin C 4 Way/IAC

J1-32 Empty

SYSTEM/IGNITION RELAY

Pin Description Color Connector Pin

30 12V Power/B+ Red

85 Ground Black

86 To ignition Pink

87 Ignition/Injector Fused Red J2-19

454/502 MagnumTBI_A1R9

35

Page 36

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

FUEL PUMP RELAY

Pin Description Color Connector Pin

30 12V Power/B+ Red Relay #86

85 Trigger from ECM Dark Green/Black J1-6

86 Inj./ECM 10A fuse Black J2-19

87 Fuel pump trigger ON Gray Pin A Pin A

87A N/A N/A

MEFI4 PIN CONFIGURATION

J2 CONNECTOR

J2 Pin Description Color Connector pin Connector Type

J2-1 Battery feed Orange

J2-2 5 Volt reference Gray TPS-A/MAP-C 3 Way

J2-3 Sensor ground Black TPS-B/MAP-A (2) 2 Way/(3) 3 Way

J2-4 Fuel PSI signal ECT-A/IAT-B

J2-5 Emergency Stop

J2-6 Empty

J2-7 ECT coolant sensor signal Yellow Pin B 3 Way/Coolant

J2-8 MAP sensor signal Light Green Pin B 3 Way

J2-9 Empty

J2-10 Serial data Orange Pin G 10 Way/DLC

J2-11 Empty

J2-12 Empty

J2-13 Empty

J2-14 Empty

J2-15 Ignition bypass Tan/Black Pin B 4 Way/Distributor

J2-16 Distributor Reference "high" Purple/White Pin C 4 Way/Distributor

J2-17 Empty

J2-18 Empty

J2-19 Ignition feed Pink #30,#86 Ignition/Inj Relay

J2-20 Oil PSI switch Blue/White

J2-21 IAT sensor signal Tan Pin A 2 Way

J2-22 Empty

J2-23 TPS sensor signal Blue Pin C 3 Way

J2-24 Empty

J2-25 Empty

J2-26 Empty

J2-27 Empty

J2-28 Empty

J2-29 Empty

J2-30 Empty

J2-31 Ignition control White Pin D 4 Way

J2-32 Empty

454/502 MagnumTBI_A1R9

36

Page 37

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

Knock signal #2 (N/A)

Diagnostic "TEST" terminal

Master/Slave (N/A)

Emergency stop (N/A)

Fuel pump relay control

Audio warning horn

Fuel injector driver B

Distributor reference "LOW"

Tachometer output

Idle air control B "LOW"

Idle air control A "HIGH"

Knock signal #1

Oil level (N/A)

J1 MEFI 4

Shift interupt (N/A)

Gear lube switch

Fuel injector driver A

Malfunction indicator lamp

ECM ground

ECM ground

Idle air control B "HIGH"

Idle air control A "LOW"

Battery feed

5 Volt reference

Sensor ground

Engine coolant temp sensor signal

Manifold PSI sensor signal

Serial data

Ignition bypass

Distributor reference "HIGH"

Ignition feed

J2 MEFI 4

Oil PSI switch

Inlet air temp sensor signal

Throttle position sensor signal

Ignition control

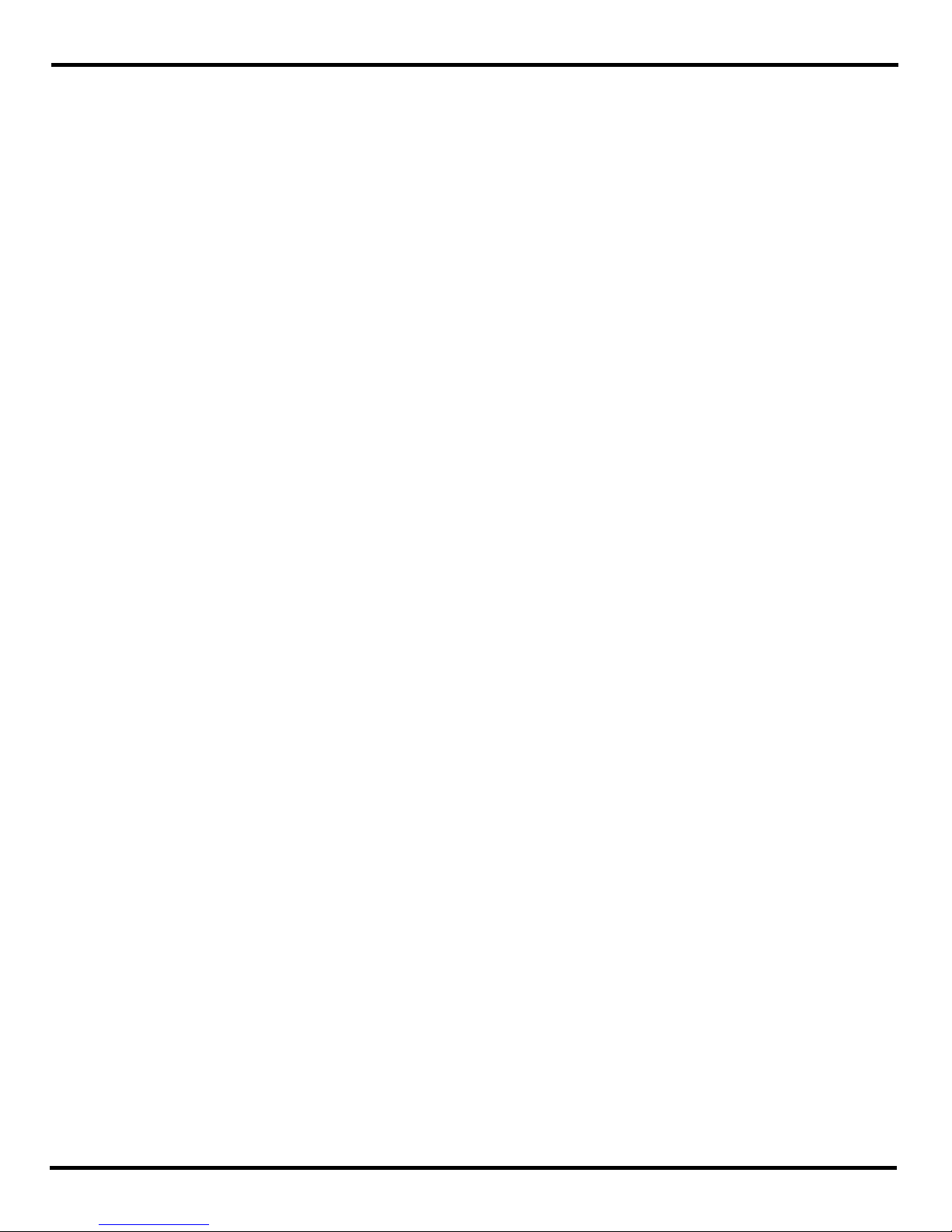

IAC MOTOR

IAC B "LOW"

A

IAC B "HIGH"

B

IAC A "LOW"

C

IAC A "HIGH"

D

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Solder joint

Solder joint

Solder joint

Solder joint

Knock

A

B

C

Solder joint

ECT SENSOR

A

B

TPS SENSOR

A

B

C

IAT SENSOR

A

B

MAP SENSOR

A

B

C

3-way

female

Master/Slave

A

B

Ground

ECT Signal

5V reference

Ground

TPS Signal

IAT Signal

Ground

Ground

MAP signal

5V reference

Driver A

Driver B

Driver A

A

12V

12V

Driver B

A

B

C

D

E K

B

male

3-way

C

F

G

H

J

Distributor 2-way

Power

A

Ground

B

Distributor 4-way

Dist "LOW"

A

Bypass

B

Dist "HIGH"

C

IGN control

D

A

Fuel INJ #1

B

A

Fuel INJ #2

B

A

Fuel INJ #3

B

A

Fuel INJ #4

B

A

Fuel INJ #5

B

A

Fuel INJ #6

B

A

Fuel INJ #7

B

A

Fuel INJ #8

B

Solder joint

4-way male

D

Horn

Switch

C

IGN on

B

Tach

A

out

A

B

A

B

Horn

Switch

IGN on

Tach

30

Fuel Pump Conn.

12V

GroundAB

4-way female

D

C

B

A

out

30

87

8586

87

8586

Solder joint

Solder joint

Solder joint

Solder joint

Solder joint

A

15AMP

B

C

10AMP

D

E

15AMP

F

454/502 MagnumTBI_A1R9

37

Page 38

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

38

Page 39

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

39

Page 40

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

40

Page 41

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

41

Page 42

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

42

Page 43

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

43

Page 44

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

44

Page 45

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

45

Page 46

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

46

Page 47

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

454/502 MagnumTBI_A1R9

47

Page 48

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

2-BAR MAP SENSOR SCALE

5.0

4.5

4.0

3.5

3.0

2.5

Sensor Vol t a ge

2.0

1.5

1.0

0.5

0.0

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

Manif old PSI (KPA)

200

454/502 MagnumTBI_A1R9

48

Page 49

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

LIMITED WARRANTY

All merchandise manufactured by Whipple Industries is fully warranted against defects in workmanship and

materials to the original purchaser of the Whipple Supercharger System. The limited warranty must be signed,

dated and returned to Whipple Industries within 14 days of the purchase date accompanied by a copy of the

original sales invoice.

If an item is suspected of being defective, return it to Whipple Industries for inspection after obtaining the proper

Return Authorization Number. If an item is determined to be defective, we will repair or replace it at our discretion

within a period of one year from the shipping date on your invoice.

Whipple Industries Inc. limited warranty specifially does not apply to products which have been (a) modified or

altered in any way, (b) subjected to adverse conditions suach as misuse, neglect, accident, improper installation or

adjustment, dirt, or other contaminants, water, corrosion or faulty repair; or (c) used in other than those specifically

recommended by Whipple Industries Inc. All products designed for off-road use are considered racing parts and

carry no warranty, either expressed or implied, as we have no control over how they are used.

On warranty items, repair/replacements will be limited to parts manufactured by Whipple Industries and will not

include claims for labor or inconvenience. All other merchandise distributed by Whipple Industries is warranted in

accordance with the respective manufacturer's own terms of warranty. This warranty is expressly made in lieu of

any and all other warranties expressed or implied, including the warranties of merchantability and fitness.

Whipple Industries will not be responsible for any other expenses incurred by the customer under the terms of this

warranty, nor shall it be responsible for any damages either consequential, special, contingent, expenses or injury

arising directly or indirectly from the use of these products.

Whipple Industries reserves the right to determine whether the terms of the warranty, set out above, have been

properly complied with. In the event that the terms are not complied with, Whipple Industries shall be under no

obligation to honor this warranty. By signing this form, you understand and agree to the terms above.

NAME (Print) ADDRESS

SIGNATURE CITY STATE ZIP

DATE PHONE

SC SERIAL # EMAIL

VIN OR VESSEL #

(Found on compressor bearing plate)

(Optional)

454/502 MagnumTBI_A1R9

49

Page 50

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

TRANSOM

LEADING

EDGE

.375"

1.125"

.75"

TRAILING

EDGE

BOTTOM OF BOAT

WATER FLOW

~ For transom intercooler water pickups, install as shown in diagram.

~ For engine water pickups, you want your trailing edge to only hang between .325-.625”.

~ When running separate water pickups, the fuel cooler must be in the factory water loop

and not routed in the intercooler loop. The fuel cooler needs water at idle and slow boat

speeds, the intercooler will not feed it if it’s not in the sea pump system.

454/502 MagnumTBI_A1R9

50

Page 51

Whipple Charger Installations Instructions for Mercury 454/502 Magnum Engines

Thru hull

fitting

Sea pump

Intercooler out Intercooler in

Fuel cooler Oil cooler

Thru hull

fitting

Power steering

Manifold bleed/drain

(1/4" line)

Transom pickup

cooler

Engine block

Exhaust inlet

Exhaust inlet

Water system routing for use without intercooler tee

454/502 MagnumTBI_A1R9

51

Loading...

Loading...