Page 1

www.mercury-security.com

2355 MIRA MAR AVE. LONG BEACH, CA 90815-1755, (562) 986-9105 FAX (562) 986-9205

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

BR20 Magnetic Card Reader

Installation and Maintenance

(1) This device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause un-

1. General:

The BR20 magnetic stripe card reader is designed for reading standard or high-coercivity magnetic stripe cards. The

BR20 also provides a 12-key keypad for PIN entry and provides a TTL interface. The following paragraphs describe

instructions for installing and maintaining the card reader. The BR20 does not support the tamper switch option.

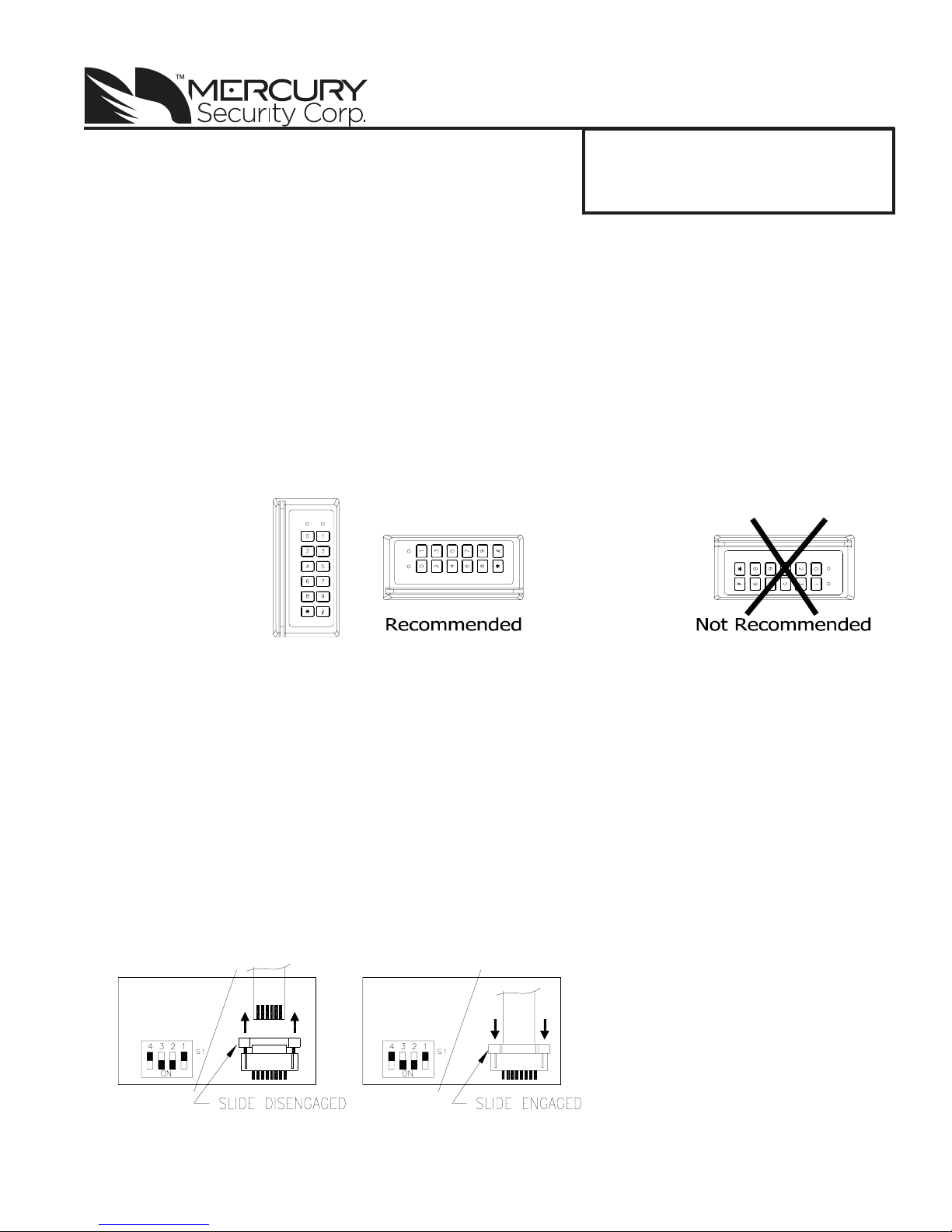

2. Mounting the Reader:

Find a suitable location to anchor the reader mounting bracket. The reader may be mounted vertically or horizontally.

See recommended orientation. The mounting of the reader does not require a junction box. However, rigid conduit

is required for outdoor application. A single gang junction box may be used to provide a transition to rigid conduit.

If a single gang junction box is used, a wall plate (optional) may be used to cover the junction box. The reader is then

secured to the mounting bracket using a screw. Refer to figures for reader dimensions and typical junction box usage.

3. Reader Wiring:

The reader has a RJ-11 modular jack for easy field connection. A short piece of pre-terminated cable is supplied with

each standard reader for field wiring. The pre-terminated cable has nonstandard color. Refer to pin number if the pre-

terminated cable is not used. Cable with wires of 24AWG or larger are recommended for field wiring.

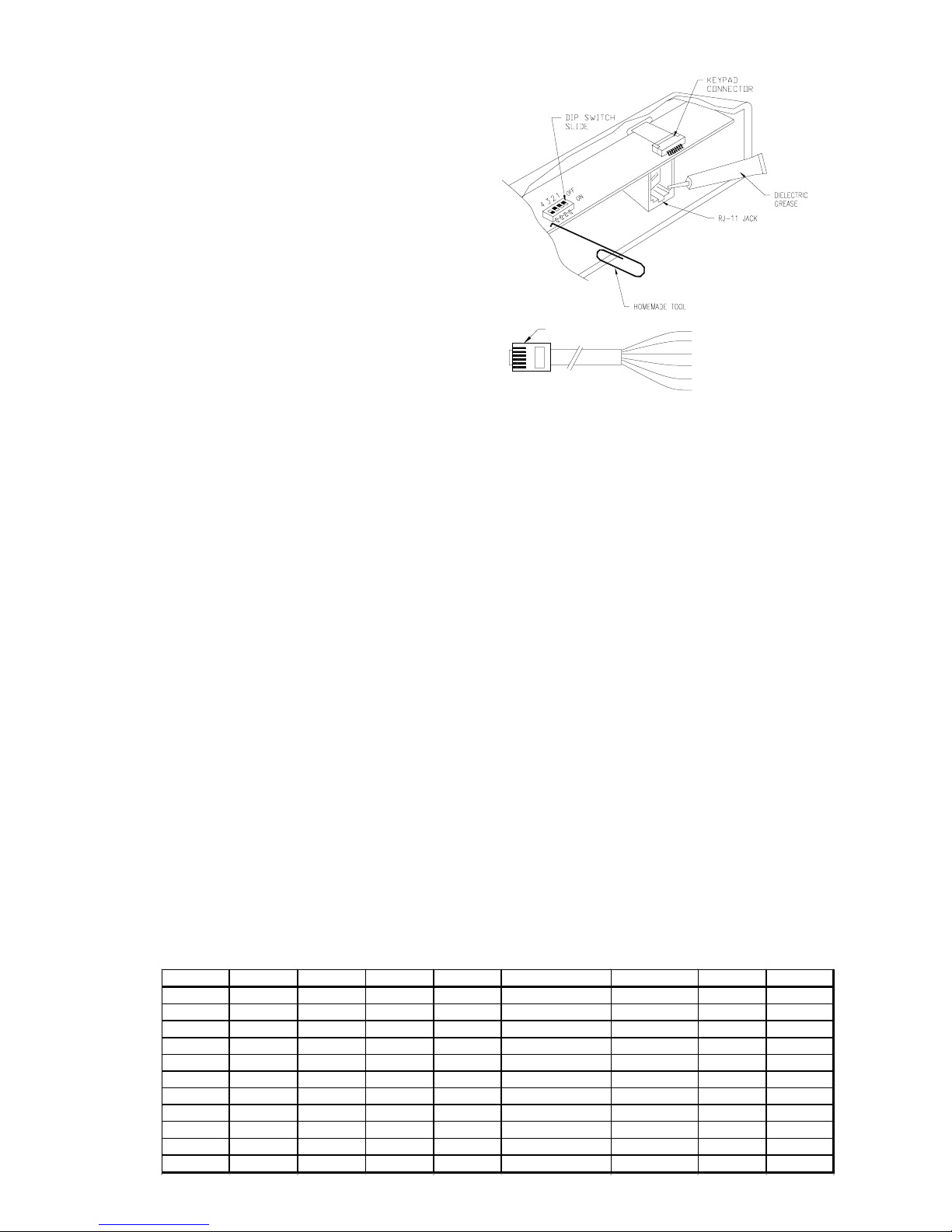

4. Connecting the Keypad:

The BR20 provides a 12-key keypad for PIN entry. The flex tail of the keypad is connected to the electronic board via

a ZIF (zero insertion force) connector. The contacts are engaged/disengaged by a moving slide. Care must be

exercised when connecting and disconnecting the keypad. When connecting the keypad to the board, open the slide

as shown. Insert the electronics into the housing and insert flex tail in the ZIF connector. Then, close the slide to engage

the contacts. To disconnect the keypad, follow the previously described steps in reverse.

5. Weather Proofing the Reader:

CAUTION: DO NOT DISCONNECT

KEYPAD WITHOUT DISENGAGING

THE CONNECTOR!

Information subject to change without notice.

CONFIDENTIAL: For installation and maintenance use only. DO NOT distribute.

Mercury Security Corporation, © 2008 BR20 Doc. 10107-0024 rev. 1.03 10/2008 Page 1

Page 2

The reader is rated to operate over an extended

temperature range and the electronics are conformal

coated against moisture. If the reader is expected to

be exposed to weather, use the dielectric grease to

coat the field connections. After field connection/

configuration is made, the grease is to be applied on

the DIP switch slides, keypad connection, and the

RJ-11 jack to seal out moisture.

Do not use sealant to seal reader case to the

wall. Doing so will trap water in the reader and may

cause damage to the reader.

MODULAR PLUG

6. TTL Interface:

6 (BLK) GND

5 (ORG) BUZZER/LED

4 (BRN) LED

3 (WHT) DATA 1/CLOCK

2 (GRN) DATA 0/DATA

1 (RED) +5 or +12Vdc

depends on model

The TTL interface has the standard 5-wire interface widely used in the access control application. In addition, an input

to control the buzzer is provided. Cable with minimum of 24AWG wires should be used.

Pin # Wire Signal Description

1 Re d Vin Power supply input, 5Vdc or 12Vdc, Model dependent

2 Green /Data (Mag) or Reader data output

/Data 0 (Wieg)

3 White /Clock (Mag) or Reader data output

/Data 1 (Wieg)

4 Brown LED LED input

1-wire control: 0V turns on the green LED

5V turns on the red LED

2-wire control: 0V turns on the red LED

5 Orange Buzzer/LED Buzzer/LED input

1-wire control: 0V turns on the buzzer

2-wire control: 0V turns on the green LED

6 Black Signal Ground Power supply return, DC ground

7. Grounding the Reader:

To avoid having ESD (electrostatic discharge) interfering with the operation of the reader, the reader casing shall be

grounded. This can be accomplished by tying the mounting bracket to earth ground locally (e.g. grounded conduit).

8. DIP Switch Setting:

The DIP switch on the BR20 reader is used to select a preset format, the functions for the LED and buzzer, and the

output signal format, etc. The preset format determines how the card is interpreted. Refer to the format specification

for detail. The settings are for STANDARD models ONLY. The BR20 does not support the tamper switch option.

FORMAT SW-4 SW-3 SW-2 SW-1 OUTPUT LED BUZZER TAM PER

0 ON ON ON ON DATA 1/DATA 0 1-W IRE LED YES NO

1 O N ON ON O F F CLOCK/ DATA 1-W IRE LE D YE S NO

2 O N ON OFF O N CLOCK / DA TA 1-WIRE LED YES YES

3 ON ON OFF OFF CLOCK/DATA 1-W IRE LED YES NO

4 O N OFF O N ON DA TA 1/ DA TA 0 1-W IRE LE D YE S NO

5 ON OFF ON OFF DATA 1/DATA 0 1-W IRE LED YES NO

6 ON OFF OFF ON DATA 1/DATA 0 1-W IRE LED YES NO

7 O N OFF O FF O FF DATA 1/ DA TA 0 1-W IRE LE D Y E S NO

Information subject to change without notice.

Mercury Security Corporation, © 2008 BR20 Doc. 10107-0024 rev. 1.03 10/2008 Page 2

12 OFF OFF ON ON CLOCK/DATA 2-WIRE LED NO NO

13 OFF OFF ON OFF DATA 1/DATA 0 2-WIRE LED NO NO

15 OFF OFF OFF OFF CLOCK/DATA 1-WIRE LED YE S YES

Page 3

9. BR20 Standard Format Code Summary:

The following formats are supported in standard models (31002-8000/31012-8000).

Unless otherwise indicated, the LED input line controls both LEDs (low=green, high=red); the BUZZER input

controls the buzzer (low = activate); a good read is signaled by a flash of the green LED; a bad read is signaled

by a flash of the red LED and a double beep of the buzzer.

Format 0 - 32-bit Wiegand compatible output from standard Northern Computer mag card. 16-bit facility code

and 16-bit user ID. Reverse read and error filter is enabled. Tamper monitor disabled.

Format 1 - Basic mag-stripe data output: send track 2 data without any verification or formatting using CLOCK/

DATA signaling. All reads are "good", card data sent as is. Tamper monitor disabled.

Format 2 - Mag-stripe data output with zero trim using CLOCK/DATA signaling. All reads are "good", trims

excess zero bits, otherwise send data as is. Tamper monitor enabled.

Format 3 - Mag-stripe data output with zero trim, reverse read correction, and error filter enabled using CLOCK/

DATA signaling. Tamper monitor disabled.

Format 4 - 26-bit Wiegand (8-bit fac. and 16-bit ID) compatible output from cards with 8 or more digits or AMC

encoding. See Format 5 for digit usage. Tamper monitor disabled.

Format 5 - 34-bit Wiegand (12-bit fac. and 20-bit ID) compatible output from cards with 8 or more digits or AMC

encoding. Tamper monitor disabled.

Digits in mag card Digits 26-bit Range 34-bit Range Digits 26-bit Range 34-bit Range

8 1-3 000-255 000-999 4-8 00000-65535 00000-99999

9 1-3 000-255 000-999 4-9 000000-065535 000000-999999

10 1-4 0000-0255 0000-4097 5-10 000000-065535 000000-999999

11 or more 1-5 00000-00255 00000-04097 6-11 000000-065535 000000-999999

AMC card 1-6 000000-000255 000000-004097 7-12 000000-065535 000000-999999

Facility Code User ID

Format 6 - 26-bit Wiegand compatible output from standard Northern Computer 32-bit mag-stripe card. The lower

8 bits of the 16-bit facility code is used as facility code. The 16-bit user ID is unaltered. Reverse read

and error filter is enabled. Tamper monitor disabled

Format 7 - Mag-stripe data output with zero trim and reverse read correction using DATA 1/DATA 0 signaling.

Tamper monitor disabled.

Format 12 - Mag-stripe data output: send track 2 data without any verification or formatting using CLOCK/DATA.

All reads are "good", card data is sent as is. 2-wire LED control. No buzzer control. Tamper monitor

disabled.

Format 13 - Mag-stripe data output with zero trim and reverse read correction using DATA 1/DATA 0 signaling.

2-wire LED control. No buzzer control. Tamper monitor disabled.

Format 15 - (factory test) mag-stripe data output: verify track 2 data and send track 2 data without formatting using

CLOCK/DATA signaling. Zero trim, reverse read, bad card filter, and tamper monitor enabled.

10. Keypad Data Signaling:

Keypad data is transmitted on the data lines as 8-bit blocks. They are encoded and sent using the same signaling

method as selected for the card data output (clock/data or data 1/data 0). If Dorado 8-bit keypad data format is required

order the -K1 option. Card data, and keypad data blocks are separated by a minimum of 100 milliseconds. See following

for codes:

10110000 - 0 (ASCII '0', odd parity, MSB first) 00110001 - 1 (ASCII '1', ...)

00110010 - 2 (ASCII '2', ...) 10110011 - 3 (ACSII '3', ...)

00110100 - 4 (ASCII '4', ...) 10110101 - 5 (ASCII '5', ...)

10110110 - 6 (ASCII '6', ...) 00110111 - 7 (ASCII '7', ...)

00111000 - 8 (ASCII '8', ...) 10111001 - 9 (ASCII '9', ...)

00101010 - * (ASCII '*', ...) 00100011 - # (ASCII '#', ...)

Information subject to change without notice.

11010011 - SAFE (ASCII 'S', ...) 01010100 - ALARM (ASCII 'T', ...)

Mercury Security Corporation, © 2008 BR20 Doc. 10107-0024 rev. 1.03 10/2008 Page 3

Page 4

11. Reader Verification:

The reader performs a self-test when power is first applied to the unit. If power-on test is successfully completed, the

reader will turn on both LEDs for approximately 1 second and sound the buzzer for 1 short beep. Then the reader is

ready for normal operation.

If further verification of the reader hardware is needed, the reader may be temporarily set to format 3. With this format

selected, the reader will read and verify standard ANSI track 2 encoded card. If no read error is detected, the green

LED will flash. Otherwise, the red LED will flash and the buzzer will sound two short beeps to indicate an error. The

LED input can be used to verify the LED function; and the buzzer input for the buzzer function. The reader will echo

a key press with a brief flash of both LEDs and a short beep of the buzzer. Reset to the required format for normal

operation after test.

12. Maintenance:

The reader is designed to provide continuous service with minimal routine maintenance. However, contaminants (such

as magnetic oxides from badges and dirt) tend to accumulate on the read head. Without regular cleaning, these

contaminants will shorten the read head life and increase the probability of card read error. A maintenance schedule

should be developed base on the card reader environment (dirty or clean) and the usage frequency (light traffic or heavy

traffic). Extreme case may require daily cleaning.

Head cleaning may be done by using a disposable, pre-saturated magnetic head cleaning card. These cards are readily

obtainable from a number of sources (e.g. Clean Team Co., www.cleanteam.com, 800-888-8830; KIC Products,

www.kicproducts.com, 207-514-7030; System ID, www.systemid.com, 888-648-4452).

The reader exterior surface is covered with high strength polymer and polyester membrane. It may be cleaned with

a soft cloth and mild detergent if required.

13. Specifications:

The reader is for use in low voltage, class 2 circuits only.

Power: Voltage 5Volt Model: 5.8 Vdc (4.9 to 6.4 Vdc)

Current 50mA (25mA typical.)

Data output: Clock/data or data 1/0 pair

Timing clock/data: period 1mS

LED input: 1-wire mode input not driven: LEDs OFF

2-wire mode input < 0.8Vdc: Red LED ON

Buzzer/LED: 1-wire mode input not driven or > 3.5Vdc: buzzer OFF

2-wire mode input < 0.8Vdc: Green LED ON

Mechanical: Dimension 2.59" (66mm) W x 1.30" (33mm) H x 5.50" (140mm) L

Weight 11.3 oz. (320 g) nominal

Material Case, Die cast aluminum, gray powder coat standard.

Card: 75 bpi, ANSI X4.16, Track 2 standard, Speed 3 to 50 ips

Read Head: 1,000,000 passes typical.

Distance: 500' (152m) with 18 AWG wires.

Information subject to change without notice.

Environmental: Temperature -55 to +85 degrees C, storage

Humidity 0-100% RHNC

Mercury Security Corporation, © 2008 BR20 Doc. 10107-0024 rev. 1.03 10/2008 Page 4

12Volt Model: 12 Vdc (10.2 to 13.8 Vdc)

setup/hold time 400uS, clock pulse width 200uS typical

data 1/0: period, 1mS for Wiegand data, 1mS for mag stripe data

pulse width 50uS typical

input > 3.5Vdc: Red LED ON

input < 0.8Vdc: Green LED ON

input < 0.8Vdc: buzzer ON

Mounting, stainless steel

Wall plate, 18 CRS, gray powder coat standard

-40 to +75 degrees C, operating

Page 5

14. Product Identification:

Reader product identification is provided on labels. These labels have information on program ID, revision, product ID,

supply voltage, and copyright notice. These labels are located on the circuit board and the back of the reader.

Manual revision, See appropriate

manual for FORMAT information.

15. Reader Mounting Dimensions:

1.30 [33]

2X Ø .18 [4.5]

MOUNTING HOLE

WALL STUD

3.30 [84]

2.60 [66]

0.99 [25]

DIMENSION: INCH [mm]

Fitting Rigid Conduit to Junction Box

Information subject to change without notice.

Mercury Security Corporation, © 2008 BR20 Doc. 10107-0024 rev. 1.03 10/2008 Page 5

Optional Wall Plate (part# WP10)

Page 6

Warranty

Mercury Security Corporation warrants the product is free from defects in material and workmanship under normal use and service with proper maintenance for

two years from the date of factory shipment. Mercury Security Corporation assumes no responsibility for products damaged by improper handling or installation.

This warranty is limited to the repair or replacement of the defective unit.

There are no expressed warranties other than set forth herein. Mercury Security Corporation does not make, nor intends, nor does it authorize any agent or

representative to make any other warranties, or implied warranties, and expressly excludes and disclaims all implied warranties of merchantability or fitness for

a particular purpose.

Returned units are repaired or replaced from a stock of reconditioned units. Returns must be accompanied by a return authorization number (RMA) obtained from

customer service, and prepaid postage and insurance.

Liability

The card readers should only be used to control exits from areas where an alternative method for exit is available. This product is not intended for, nor is rated

for operation in life-critical control applications. Mercury Security Corporation is not liable under any circumstances for loss or damage caused by or partially caused

by the misapplication or malfunction of the product. Mercury Security Corporation's liability does not extend beyond the purchase price of the product.

Information subject to change without notice.

Mercury Security Corporation, © 2008 BR20 Doc. 10107-0024 rev. 1.03 10/2008 Page 6

Loading...

Loading...