Page 1

Operation Manual

© 2018 Mercury Marine

Big Tiller

8M4504254 1017 eng

Page 2

eng

Page 3

Tiller Handle Components

Tiller Handle Component Location..................................................................... 1

Lanyard Stop Switch Operation

Lanyard Stop Switch........................................................................................... 2

Tiller Handle Adjustments

Adjustments........................................................................................................ 5

Gear Shifting

Gear Shifting....................................................................................................... 9

Troll Control (if Equipped)

Troll Control...................................................................................................... 10

Power Trim

Power Trim....................................................................................................... 11

Operation

General Information.......................................................................................... 12

Prestarting Instructions..................................................................................... 12

Starting the Engine........................................................................................... 13

Stopping the Engine......................................................................................... 15

Auxiliary Light (if Equipped)

Auxiliary Light (if Equipped).............................................................................. 16

eng i

Page 4

eng ii

Page 5

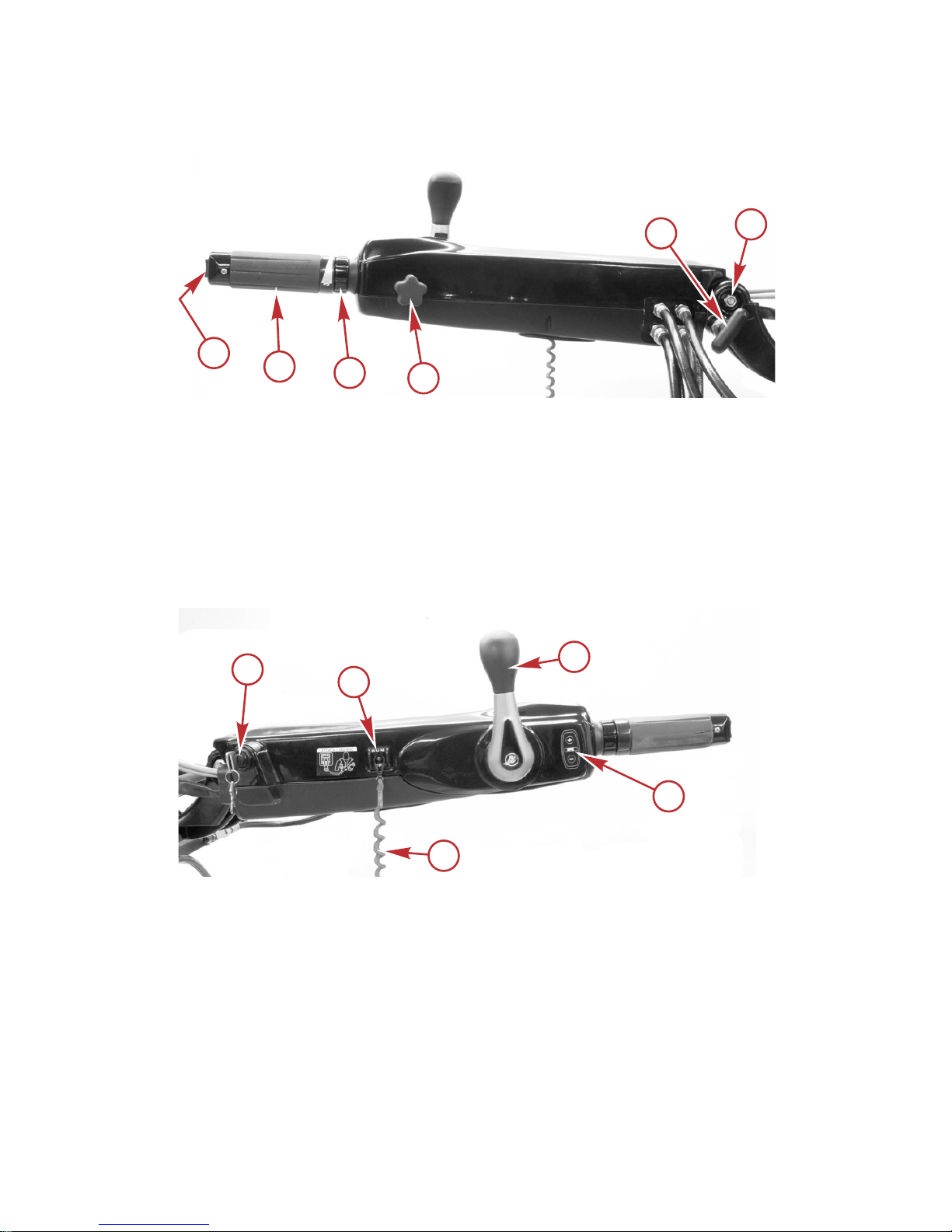

Tiller Handle Component Location

a - Power trim switch

b - Throttle grip

c - Steering actuator adjustment collar (power steering models)

d - Throttle grip friction knob

e - Tiller handle lock knob

f - Tiller handle tilt friction adjustment jam nut

a - Ignition key switch

b - Lanyard stop switch

c - Lanyard

d - Gear shift handle

e - Troll speed control switch (if equipped)

b

a

c

e

33022

d

f

a

b

c

d

e

65276

TILLER HANDLE COMPONENTS

eng 1

Page 6

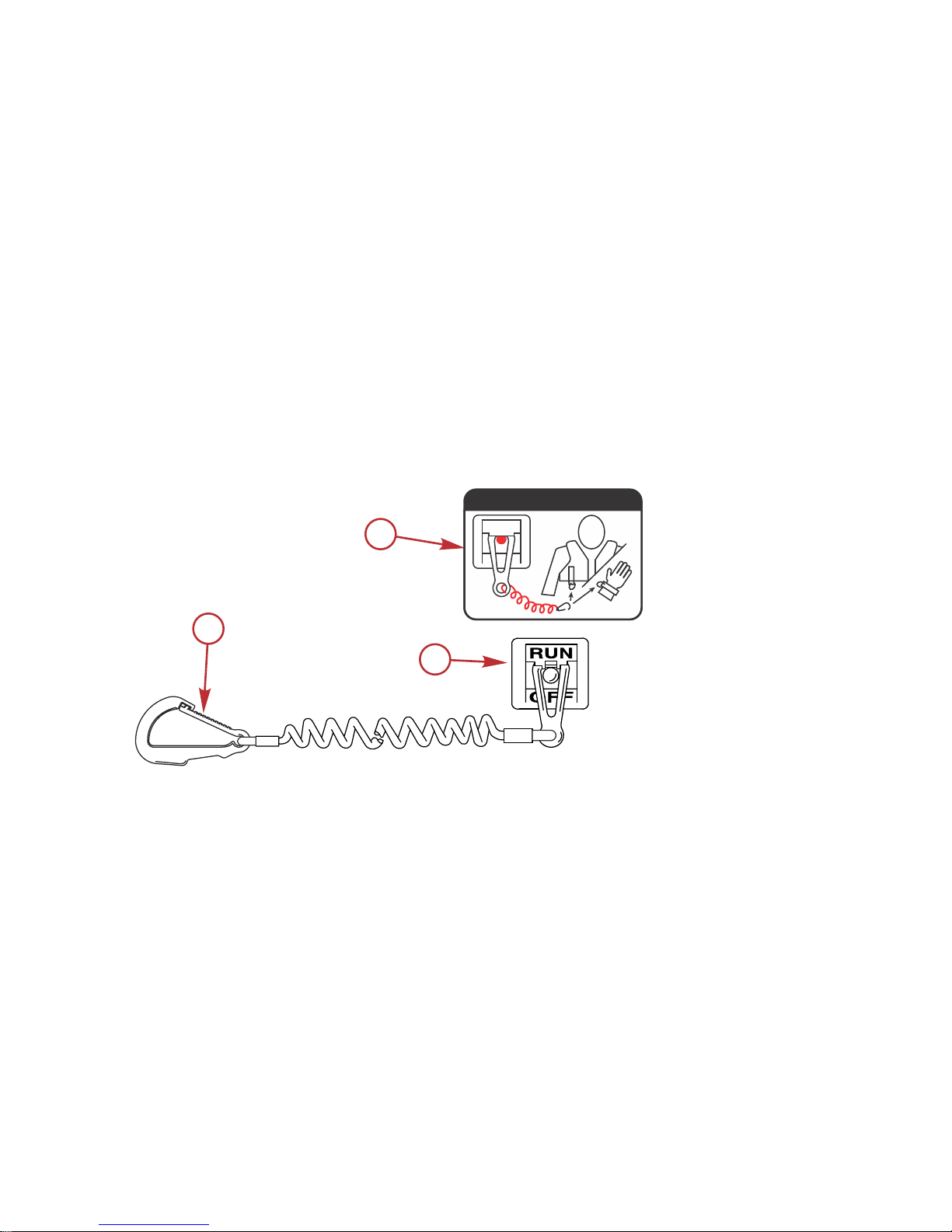

Lanyard Stop Switch

The purpose of a lanyard stop switch is to turn off the engine when the operator

moves far enough away from the operator's position (as in accidental ejection

from the operator's position) to activate the switch. Tiller handle outboards and

some remote control units are equipped with a lanyard stop switch. A lanyard

stop switch can be installed as an accessory ‑ generally on the dashboard or

side adjacent to the operator's position.

The lanyard is a cord usually 122–152 cm (4–5 feet) in length when stretched

out, with an element on one end made to be inserted into the switch and a snap

on the other end for attaching to the operator. The lanyard is coiled to make its

at‑rest condition as short as possible to minimize the likelihood of lanyard

entanglement with nearby objects. Its stretched‑out length is made to minimize

the likelihood of accidental activation should the operator choose to move

around in an area close to the normal operator's position. If it is desired to have

a shorter lanyard, wrap the lanyard around the operator's wrist or leg, or tie a

knot in the lanyard.

a - Lanyard cord clip

b - Lanyard decal

c - Lanyard stop switch

Read the following Safety Information before proceeding.

c

a

b

53910

OFF

RUN

ATTACH LANYARD

LANYARD STOP SWITCH OPERATION

2 eng

Page 7

Important Safety Information: The purpose of a lanyard stop switch is to stop

the engine when the operator moves far enough away from the operator's

position to activate the switch. This would occur if the operator accidentally falls

overboard or moves within the boat a sufficient distance from the operator's

position. Falling overboard and accidental ejections are more likely to occur in

certain types of boats such as low sided inflatables, bass boats, high

performance boats, and light, sensitive handling fishing boats operated by a

hand tiller. Falling overboard and accidental ejections are also likely to occur as

a result of poor operating practices such as sitting on the back of the seat or

gunwale at planing speeds, standing at planing speeds, sitting on elevated

fishing boat decks, operating at planing speeds in shallow or obstacle infested

waters, releasing your grip on a steering wheel or tiller handle that is pulling in

one direction, drinking alcohol or consuming drugs, or daring high speed boat

maneuvers.

While activation of the lanyard stop switch will stop the engine immediately, a

boat will continue to coast for some distance depending upon the velocity and

degree of any turn at shut down. However, the boat will not complete a full

circle. While the boat is coasting, it can cause injury to anyone in the boat's

path as seriously as the boat would when under power.

We strongly recommend that other occupants be instructed on proper starting

and operating procedures should they be required to operate the engine in an

emergency (if the operator is accidentally ejected).

!

WARNING

If the operator falls out of the boat, stop the engine immediately to reduce the

possibility of serious injury or death from being struck by the boat. Always

properly connect the operator to the stop switch using a lanyard.

!

WARNING

Avoid serious injury or death from deceleration forces resulting from

accidental or unintended stop switch activation. The boat operator should

never leave the operator's station without first disconnecting the stop switch

lanyard from the operator.

Accidental or unintended activation of the switch during normal operation is

also a possibility. This could cause any, or all, of the following potentially

hazardous situations:

• Occupants could be thrown forward due to unexpected loss of forward

motion ‑ a particular concern for passengers in the front of the boat who

could be ejected over the bow and possibly struck by the gearcase or

propeller.

• Loss of power and directional control in heavy seas, strong current, or

high winds.

• Loss of control when docking.

LANYARD STOP SWITCH OPERATION

eng 3

Page 8

KEEP THE LANYARD STOP SWITCH AND LANYARD CORD IN GOOD

OPERATING CONDITION

Before each use, check to ensure the lanyard stop switch works properly. Start

the engine and stop it by pulling the lanyard cord. If the engine does not stop,

have the switch repaired before operating the boat.

Before each use, visually inspect the lanyard cord to ensure it is in good

working condition and that there are no breaks, cuts, or wear to the cord.

Check that the clips on the ends of the cord are in good condition. Replace any

damaged or worn lanyard cords.

LANYARD STOP SWITCH OPERATION

4 eng

Page 9

Adjustments

THROTTLE GRIP FRICTION ADJUSTMENT

Turn the throttle grip friction knob to set and maintain the throttle at the desired

speed. The throttle grip friction knob can be adjusted to increase or decrease

the amount of effort needed to rotate the throttle grip. Turn the knob clockwise

to tighten friction or counterclockwise to loosen friction.

a - Throttle grip

b - Throttle grip friction knob

STEERING ACTUATOR ADJUSTMENT COLLAR (MODELS WITH

POWER STEERING)

Pivoting the throttle grip to the left or right engages the power steering. The

collar can be adjusted to increase or decrease the amount of effort needed to

pivot the throttle grip. Turn the collar counterclockwise to decrease effort or

clockwise to increase effort.

a - Steering actuator adjustment collar

33027

a

b

a

33048

TILLER HANDLE ADJUSTMENTS

eng 5

Page 10

TILLER HANDLE TILT FRICTION ADJUSTMENT

The tiller handle pivot bolt can be adjusted to increase or decrease the amount

of effort needed to move the tiller handle up and down. Loosen the jam nut on

the end of the pivot bolt and tighten or loosen the pivot bolt to obtain the

desired friction setting on the tiller handle. Hold the pivot bolt from turning and

tighten the jam nut to the specified torque.

a - Pivot bolt and jam nut

Description Nm lb‑in. lb‑ft

Tiller handle tilt friction jam nut 47 – 35

a

33353

TILLER HANDLE ADJUSTMENTS

6 eng

Page 11

TILLER HANDLE TILT LOCK—3 POSITION HANDLE

The tilt lock feature allows for the tiller handle to be tilted up and locked in

either the mid tilt angle position or full tilt angle position. When using the tilt lock

feature, move the tiller handle to the desired position and rotate the tilt lock

knob clockwise so that the cross pin will access the through slot. Push in the tilt

lock knob to engage the lock. Release the lock by pulling out the tilt lock knob

and turning it counterclockwise.

a - Mid tilt angle position

b - Full tilt angle position

c - Tilt lock knob

a

b

c

33369

TILLER HANDLE ADJUSTMENTS

eng 7

Page 12

TILLER HANDLE TILT LOCK—2 POSITION HANDLE

The tilt lock feature allows for the tiller handle to be tilted up and locked in the

full tilt angle position. When using the tilt lock feature, move the tiller handle to

the full tilt angle position and rotate the tilt lock knob clockwise so that the cross

pin will access the through slot. Push in the tilt lock knob to engage the lock.

Release the lock by pulling out the tilt lock knob and turning it

counterclockwise.

a - Full tilt angle position

b - Tilt lock knob

NOTE:

For V6 and V8 CMS applications only.

a

65288

b

TILLER HANDLE ADJUSTMENTS

8 eng

Page 13

Gear Shifting

IMPORTANT: Observe the following:

•

Never shift outboard into gear unless engine speed is at idle.

•

Do not shift outboard into reverse when the engine is not running.

• Your outboard has three gear shift positions to provide operation: forward

(F), neutral (N), and reverse (R).

• Reduce engine speed to idle before shifting.

• Always shift outboard into gear with a quick motion.

• After shifting outboard into gear, the throttle grip can be rotated to

increase speed.

F

N

33038

GEAR SHIFTING

eng 9

Page 14

Troll Control

Troll control allows the operator to maintain a set trolling speed without using

the throttle. Refer to the following table for the trolling speed range.

Trolling Speed Range

30–60 hp FourStroke 700–1000 RPM

75–150 hp FourStroke 550–1000 RPM

75–125 OptiMax 650–1000 RPM

135 hp and higher OptiMax 550–1000 RPM

135–200 Verado 4 cylinder 550–1000 RPM

V6 (175–225), V8 (200–300) CMS Mechanical 550–1000 RPM

V6 (175–225), V8 (200–300) CMS DTS 550–1000 RPM

The troll control can be shut off anytime by rotating the throttle grip out of the

idle setting, or by moving the shift handle back to neutral.

NOTE: Slight rotation of the throttle grip while steering the outboard may

disengage the troll control. Adjusting the throttle friction may prevent this.

Turn on the troll control as follows:

1. With the engine running, shift the engine into gear.

2. Set the throttle grip to the "START/SHIFT" position.

3. Press either the (+) or (–) button to turn on the troll control.

4. The RPM light will be illuminated when the troll control is turned on.

5. Press the (+) button to increase troll speed and (–) to decrease troll

speed.

Turn off the troll control as follows:

1. Rotate the throttle grip out of the "START/SHIFT" position, or move the

shift handle back to neutral.

2. The RPM light will go out when the troll control is turned off.

a - Speed control button

‑ increase speed

b - Speed control button

‑ decrease speed

c - RPM light

65117

c

a

b

TROLL CONTROL (IF EQUIPPED)

10 eng

Page 15

Power Trim

The power trim switch allows the operator to adjust the position of the outboard.

Refer to Power Trim Operation in the outboard owner's manual.

a - Power trim switch

a

33041

POWER TRIM

eng 11

Page 16

General Information

ALL MODELS

Never stand on or use the tiller handle as a step.

When the outboard is tilted up to its full range, make sure that the tiller handle

will not contact anything that can damage it.

If the tiller handle causes interference when the outboard is tilted up to the full

position, a tilt limit kit is available for models 75 hp and higher through Mercury

Marine. This kit will limit the upward tilting range of the outboard. Contact your

authorized dealer.

POWER STEERING MODELS

The power steering system has a manual steering override feature. This

feature allows the operator to steer the outboard in case the power steering

pump should ever become inoperative.

Low battery voltage may cause incorrect power steering pump operation.

Under certain operating conditions, a slight shudder may be felt in the throttle

grip. This is normal and is caused by a feedback from the power steering

pump.

Prestarting Instructions

ALL MODELS

• Before starting, read the prestarting check list, prestarting instructions,

and engine break‑in procedure in the Operation section of the outboard

owner's manual.

• Visually check the tiller handle for tightness and the steering system for

any loose components.

POWER STEERING MODELS

• Check that the manual steering override feature is functional. Before

starting the engine, manually steer the outboard through the entire range.

If the outboard cannot be steered manually, the manual steering override

feature will not function if needed. Have the outboard checked by your

authorized dealer.

• Remove the trailering clips if installed.

OPERATION

12 eng

Page 17

Starting the Engine

1. Open the fuel tank vent screw (in filler cap) on the manual venting type

fuel tanks.

19748

2. Models with primer bulb ‑ Position the fuel line primer bulb so the arrow

on the side of the bulb is pointing up. Squeeze the fuel line primer bulb

until it feels firm.

27348

3.

Set the lanyard stop switch to the "RUN" position. Refer to Lanyard Stop

Switch Operation.

19791

OPERATION

eng 13

Page 18

4. Shift outboard to neutral ("N") position.

F

N

33038

5. Rotate the throttle grip clockwise to the "START/SHIFT" position.

6. Starting a flooded engine ‑ Advance the throttle grip to half throttle

position.

a - Start/Shift

NOTE: For initial start of a new engine, or for an engine that ran out of fuel or

was drained of fuel, the fuel system should be filled by following the procedure

in the

Starting the Outboard

section of the outboard owner's manual.

7. Non‑DTS models ‑ Turn the ignition key to the "START" position. If the

engine fails to start within ten seconds, return the key to the "ON"

position, wait 30 seconds, and try again.

65328

a

OPERATION

14 eng

Page 19

8. 150 FourStroke and DTS models ‑ Turn the ignition key to the "START"

position and release the key. The electronic starting system will

automatically crank the engine for starting. If the engine fails to start, the

engine will stop cranking. Turn the key to the "START" position again until

the engine starts.

19804

9. After the engine starts, check for a steady stream of water flowing out of

the water pump indicator hole.

20766

IMPORTANT: If no water is coming out of the water pump indicator hole, stop

the engine and check the cooling water intake for obstruction. No obstruction

may indicate a water pump failure or blockage in the cooling system. These

conditions will cause the engine to overheat. Have the outboard checked by

your dealer. Operating the engine while overheated will cause engine damage.

WARMING UP ENGINE

Before beginning operation, allow the engine to warm up at idling speed for

three minutes.

Stopping the Engine

Reduce the engine speed and shift the outboard to neutral position. Turn the

ignition key to "OFF" position.

26843

OFF

ON

START

OPERATION

eng 15

Page 20

Auxiliary Light (if Equipped)

An auxiliary light is located on the bottom of the tiller handle. The light can be

turned on whenever the ignition key switch is in the "ON" or "RUN" position.

Turn the light on or off using the light switch in the light housing.

a - Auxiliary light

b - Light switch

a

b

33042

AUXILIARY LIGHT (IF EQUIPPED)

16 eng

Loading...

Loading...