Mercury Alpha, Bravo, MerCruiser Alpha 3.0L, MerCruiser Bravo 4.3L, MerCruiser Bravo 5.0L Installation Manual

...Page 1

The following are registered trademarks of

Brunswick Corporation: Merc, MerCathode,

Mercury MerCruiser, Mercury, Mercury

Marine, Quicksilver, Ride-Guide, Thruster

and Mercury Precision Parts.

GASOLINE ENGINE STERNDRIVE MODELS

INSTALLATION MANUAL

Models Covered

Alpha

Model Serial Number or Year

3.0L

Bravo

Notice

4.3L

5.0L

5.7L

Model Serial Number or Year

4.3L

5.0L

5.7L

NOTICE

After completing installation, these instructions should be placed with the

product for the owner’s future use.

NOTICE

Predelivery preparation instructions must be performed before delivering boat

to the product owner.

0M093621 and Above

0M093633 and Above

Page 1 of 137 Printed in U.S.A. - 2001, Mercury Marine 90-860172011 NOVEMBER 2001

Page 2

GASOLINE STERNDRIVE INSTALLATION MANUAL

Table Of Contents

General Information 3. . . . . . . . . . . . . . . . .

Notice to Boat Manufacturer/Installer 3. . . . .

Torque Specifications 4. . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 5. . . . . . . . . .

Special Tools 6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alpha Notice: Increased Trim-In Range

Capability 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bravo Three Notice: Trim-In Limit Insert 7. . . . .

Quicksilver Products 7. . . . . . . . . . . . . . . . . . . . . .

Accessories 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number Decal Placement 8. . . . . . . . . . . .

Corrosion Protection 8. . . . . . . . . . . . . . . . . . . . . .

Anti-fouling Paint 9. . . . . . . . . . . . . . . . . . . . . .

Boat Construction 10. . . . . . . . . . . . . . . . . . . . . . .

Transom Thickness and Surface 10. . . . . . . .

Engine Bed 11. . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Vertical Centerline 11. . . . . . . . . . .

Crankshaft Horizontal Centerline

(X-Dimension) 12. . . . . . . . . . . . . . . . . . . . . .

Transom Cutout 14. . . . . . . . . . . . . . . . . . . . . .

Seawater Connections - General

Information 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seawater Pickup 16. . . . . . . . . . . . . . . . . . . . .

Preliminary Connections 18. . . . . . . . . . . . . . . . .

Power Trim Pump 18. . . . . . . . . . . . . . . . . . . .

Fuel Inlet Fitting 19. . . . . . . . . . . . . . . . . . . . . .

Transom Connections 20. . . . . . . . . . . . . . . . . . .

Installing Gimbal Housing 20. . . . . . . . . . . . . .

Installing Inner Transom Plate 21. . . . . . . . . .

Connecting Speedometer Pickup 22. . . . . . .

Fluid Connections 23. . . . . . . . . . . . . . . . . . . .

Installing Steering System 25. . . . . . . . . . . . .

Transom Preparation 35. . . . . . . . . . . . . . . . . .

Driveshaft Extension Models 39. . . . . . . . . . . . . .

Engine Preparation 39. . . . . . . . . . . . . . . . . . . . . .

Engine Installation 40. . . . . . . . . . . . . . . . . . . . . . .

Exhaust System 43. . . . . . . . . . . . . . . . . . . . . .

Methods for Measuring Exhaust

Elbow Height 46. . . . . . . . . . . . . . . . . . . . . . .

Exhaust System Hose / Tube

Connections 48. . . . . . . . . . . . . . . . . . . . . . . .

Engine Alignment 49. . . . . . . . . . . . . . . . . . . . .

Hot Water Heater Installation 53. . . . . . . . . . .

Electrical Connections 55. . . . . . . . . . . . . . . . . . .

Installing Continuity Wire 55. . . . . . . . . . . . . .

Instrumentation Connections 56. . . . . . . . . . .

Trim Position Sender Connections 57. . . . . .

MerCathode Connections 57. . . . . . . . . . . . . .

Audio Warning System Connections 58. . . .

Power Trim Pump Connections 59. . . . . . . . .

Fluid Connections 61. . . . . . . . . . . . . . . . . . . . . . .

Gear Lube Monitor Hose 61. . . . . . . . . . . . . .

Power Steering Hoses 62. . . . . . . . . . . . . . . .

Bravo Models and Alpha Seawater

Cooled Models Using Sterndrive

Water Pickups 62. . . . . . . . . . . . . . . . . . . . . .

Alpha or Bravo Models Using

Alternative Water Pickups 63. . . . . . . . . . . .

Coolant Recovery System 66. . . . . . . . . . . . .

Shift Cable Installation 67. . . . . . . . . . . . . . . . . . .

Alpha Models - Drive Unit Not

Installed 67. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bravo Models 72. . . . . . . . . . . . . . . . . . . . . . . .

Throttle Cable Installation and

Adjustment 76. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sterndrive Unit Installation 77. . . . . . . . . . . . . . . .

Alpha Models 79. . . . . . . . . . . . . . . . . . . . . . . .

Bravo Models 82. . . . . . . . . . . . . . . . . . . . . . . .

All Models 86. . . . . . . . . . . . . . . . . . . . . . . . . . .

Speedometer Connection 87. . . . . . . . . . . . . . . .

Alpha Models 87. . . . . . . . . . . . . . . . . . . . . . . .

Bravo Models 88. . . . . . . . . . . . . . . . . . . . . . . .

Shift Cable Installation 89. . . . . . . . . . . . . . . . . . .

Alpha Models - Drive Unit Installed 89. . . . . .

Troubleshooting Shift Problems 95. . . . . . . . .

Predelivery Preparation 98. . . . . . . . . . . . . . . . . .

Power Steering Fluid 98. . . . . . . . . . . . . . . . . .

Filling Coolant Recovery Bottle 99. . . . . . . . .

Power Trim Pump 99. . . . . . . . . . . . . . . . . . . .

Trim Position Sender Adjustment 100. . . . . .

Propeller Selection 101. . . . . . . . . . . . . . . . . . .

Propeller Installation 102. . . . . . . . . . . . . . . . .

Battery 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Running Engine 107. . . . . . . . . . . . . . . . .

Boat In The Water Tests 111. . . . . . . . . . . . . . .

Cold Weather and Extended Storage 114. . . . .

Draining Instructions 114. . . . . . . . . . . . . . . . . . . .

3.0L Single Point Drain 115. . . . . . . . . . . . . . .

V6 And V8 Seawater (Raw-Water)

Cooled Models 119. . . . . . . . . . . . . . . . . . . . .

V6 And V8 Closed Cooled Models 122. . . . .

All Models 124. . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagrams 126. . . . . . . . . . . . . . . . . . . . . . .

Instrumentation 126. . . . . . . . . . . . . . . . . . . . . .

Power Trim System 128. . . . . . . . . . . . . . . . . . . . .

MerCathode System Wiring Diagram 129. . . . .

MCM Gasoline Engine Wiring Diagrams 130. . .

3.0L Engines 130. . . . . . . . . . . . . . . . . . . . . . . .

MCM 4.3L, 5.0L And 5.7L Alpha

Engines 131. . . . . . . . . . . . . . . . . . . . . . . . . . .

MCM 4.3L Bravo Engines 132. . . . . . . . . . . . .

MCM 5.0L and 5.7L Bravo Engines 133. . . .

Water Flow Diagrams 134. . . . . . . . . . . . . . . . . . .

181 cid / 3.0L Engines 134. . . . . . . . . . . . . . . .

V8 Engines - Seawater Cooled 135. . . . . . . .

V6 and V8 Engines - Closed Cooled 136. . .

Predelivery Inspection 137. . . . . . . . . . . . . . . . . .

Page 2 of 137 90-860172011

Page 3

General Information

Notice to Boat Manufacturer/Installer

Throughout this publication, Warnings and Cautions (accompanied by the International

Hazard Symbol ! ) are used to alert the manufacturer or installer to special instructions

concerning a particular service or operation that may be hazardous if performed incorrectly

or carelessly. –– Observe Them Carefully!

These Safety Alerts, alone, cannot eliminate the hazards that they signal. Strict compliance

to these special instructions when performing the service, plus common sense operation,

are major accident prevention measures.

Hazards or unsafe practices which could result in severe personal injury or death.

Hazards or unsafe practices which could result in minor personal injury or product

or property damage.

IMPORTANT: Indicates information or instructions that are necessary for proper

installation and/or operation.

GASOLINE STERNDRIVE INSTALLATION MANUAL

WARNING

CAUTION

NOTE: Refer to the Mercury MerCruiser Product Applications Manual - Gasoline Sterndrive

Models for application recommendations.

This installation manual has been written and published by Mercury Marine to aid the boat

manufacturer (OEM) in the installation of the products described herein.

It is assumed that these personnel are familiar with marine product installation.

Furthermore, it is assumed that they are familiar with, if not trained in, the recommended

installation procedures of Mercury MerCruiser product.

We could not possibly know of or advise the marine trade of all conceivable installations and

of the possible hazards and/or results of each installation. Therefore, the OEM is

responsible for any installation that does not fulfil the requirements of this manual.

It is the responsibility of the boat manufacturer to select the appropriate

engine/transom/drive package (including the correct gear ratio and propeller) for a given

boat. Mercury recommends that any new or unique hull/power package combination be

thoroughly water tested prior to sale, to verify that the boat performs as desired, and that

the engine runs in the appropriate rpm range.

It is recommended that a Mercury Marine Sales Application Engineer (SAE) be contacted

for assistance.

All information, illustrations and specifications contained in this manual are based on the

latest product information available at time of publication. As required, revisions to this

manual will be sent to all OEM boat companies.

90-860172011 Page 3 of 137

Page 4

GASOLINE STERNDRIVE INSTALLATION MANUAL

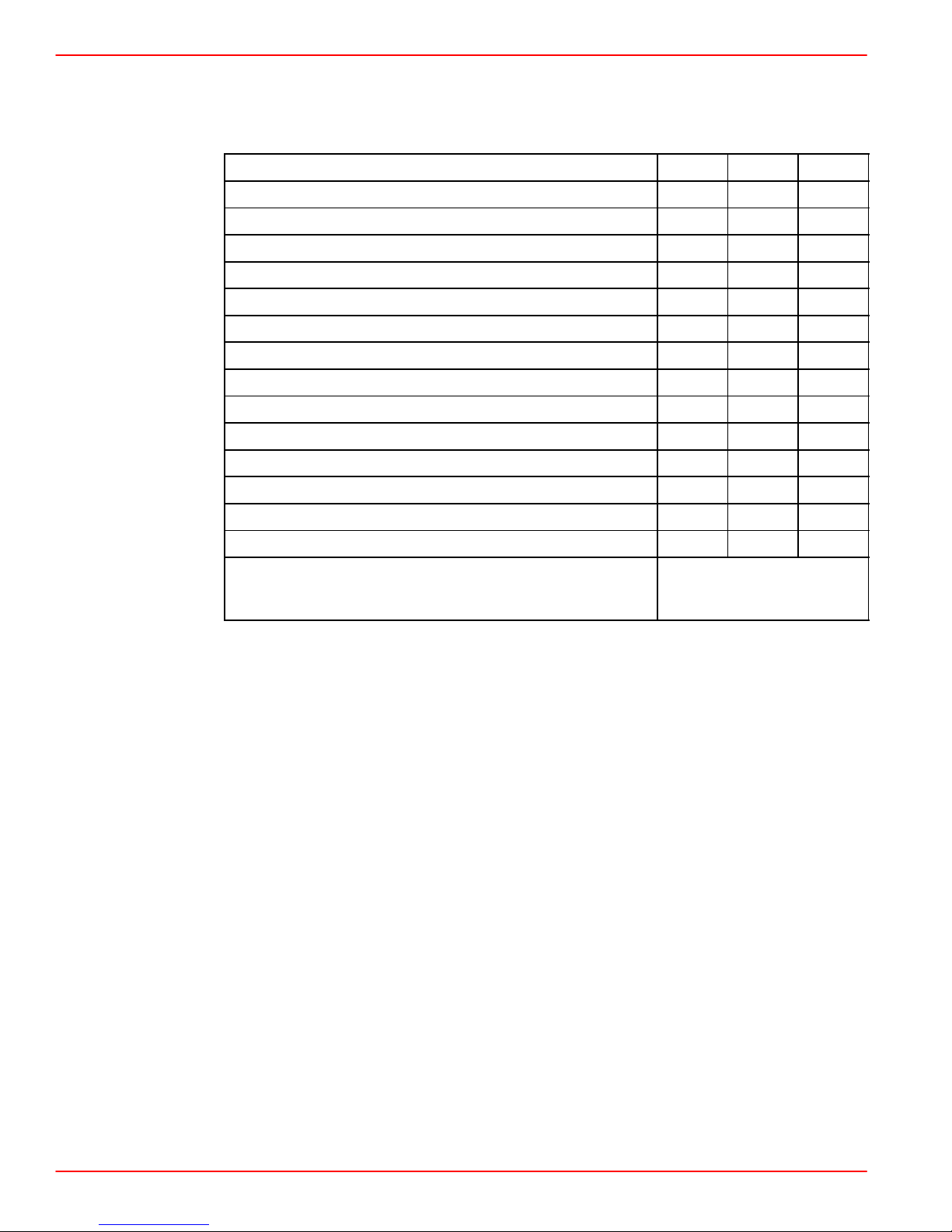

Torque Specifications

NOTE: Securely tighten all fasteners not listed below.

Description

Nm lb-in. lb-ft

Gear Lube Monitor Fitting 9 80

Speedometer Pickup Barb Fitting 1.5 13

Exhaust Pipe or Block-off Plate 31 23

Power Steering Hydraulic Hose Fittings 31 23

Power Trim Pump Hose Fittings 14 125

Propeller Nut Alpha One, Bravo One and Bravo Two

1

75 55

Front Propeller Nut Bravo Three 136 100

Rear Propeller Nut Bravo Three 81 60

Rear Engine Mounts 51 38

Steering Cable Coupler Nut 48 35

Steering System (Pivot Bolts) 34 25

Sterndrive Unit Fasteners 68 50

Transom Assembly Fasteners 31 23

Seawater Pickup Fitting 5 45

Finger tight + 1-3/4 to

Fuel Inlet Fitting

2-1/4 turns with a wrench.

DO NOT overtighten.

1

Amount specified is MINIMUM.

Page 4 of 137 90-860172011

Page 5

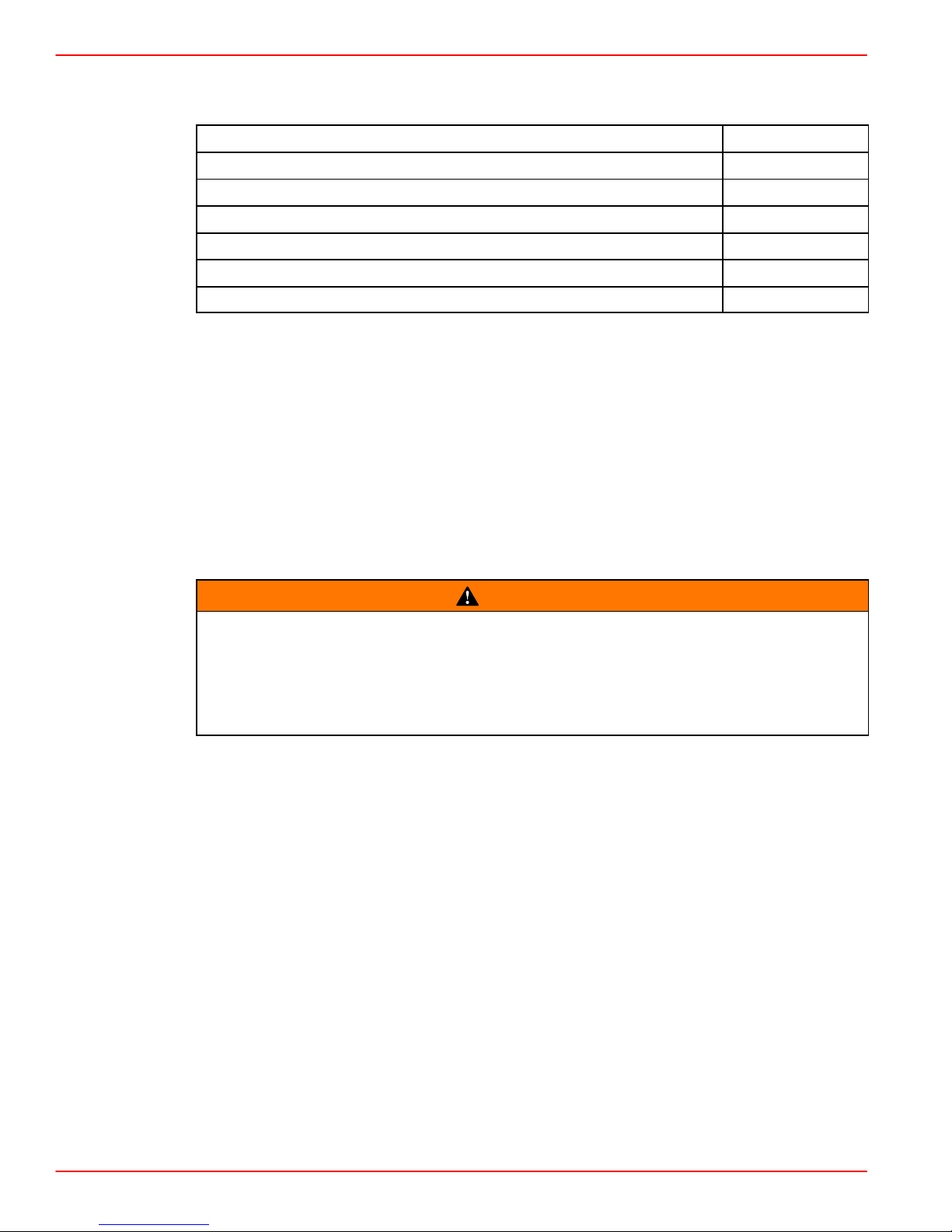

Lubricants / Sealants / Adhesives

Description Where Used Part Number

GASOLINE STERNDRIVE INSTALLATION MANUAL

Coupler Splines

Engine Coupler Spline Grease

2-4-C Marine Lubricant With

Teflon

Special Lubricant 101

Dexron III - Automatic

Transmission Fluid

Power Trim and Steering Fluid

Liquid Neoprene

Drive Unit Pilot

U-Joint O-rings

92-816391A4

Drive Shaft Splines

Anchor Pins

Trim Cylinder Hardware

O-ring Seals

92-825407A3

Shift Cable End

Propeller Splines

Pivot Bolts

Power Steering Bushings

Clevis Pin

92-13872A1

Steering Cable End

Propeller Splines

Power Steering Pump Obtain Locally

Power Steering Pump

Power Trim Pump

92-90100A12

Battery Terminals

MerCathode Connections

92-25711-2

Speedometer Barb Fitting

Fuel Inlet Fitting

Loctite 592 PST

Seawater Inlet Hose Fitting

Obtain Locally

Threads

Seawater Inlet Plastic Plug

Threads

Loctite 271 Seawater Inlet Nut 92-809820

Power Trim Pump

SAE 30W Engine Oil

Shift Cable Pivot Points

Obtain Locally

SAE 10W40 Engine Oil Power Trim Pump Obtain Locally

Marine Caulking

Seawater Inlet Mounting

Surfaces

Obtain Locally

Power Tune Exhaust Tubes 92-802878-57

Quicksilver High Performance

Gear Lube

Sterndrive Unit 92-802853A1

Silicone Sealant Or Equivalent Screw Shaft Obtain Locally

Equivalent products may be used.

90-860172011 Page 5 of 137

Page 6

GASOLINE STERNDRIVE INSTALLATION MANUAL

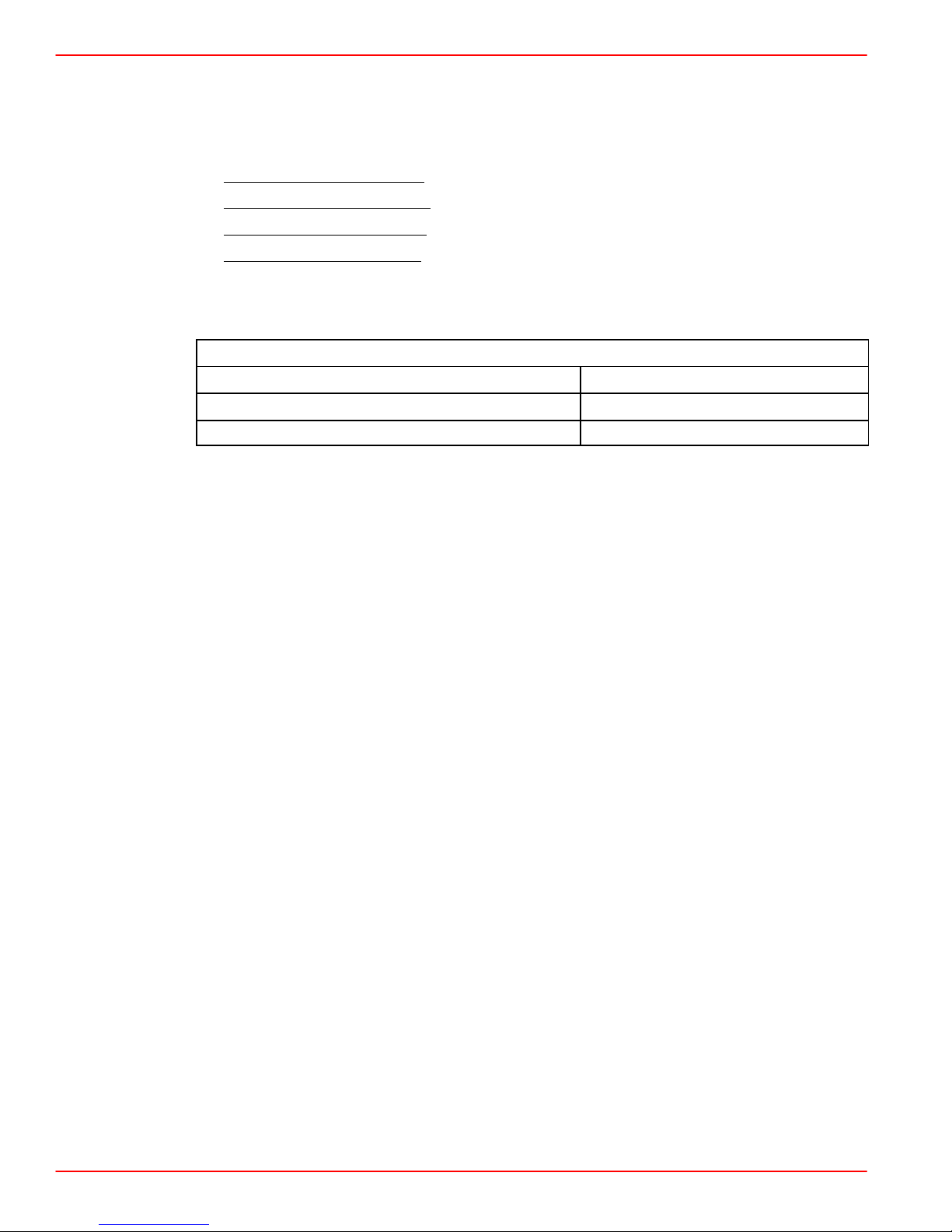

Special Tools

Description Part Number

Transom Drilling Fixture 91-43693A2

Engine Alignment Tool 91-805475A1

Shift Cable Adjustment Tool 91-12427

Engine Mount Drilling Fixture 91-806794A1

Tapered Insert Tool 91-43579

Shift Shaft Slide Stabilizer Tool 91-809815A1

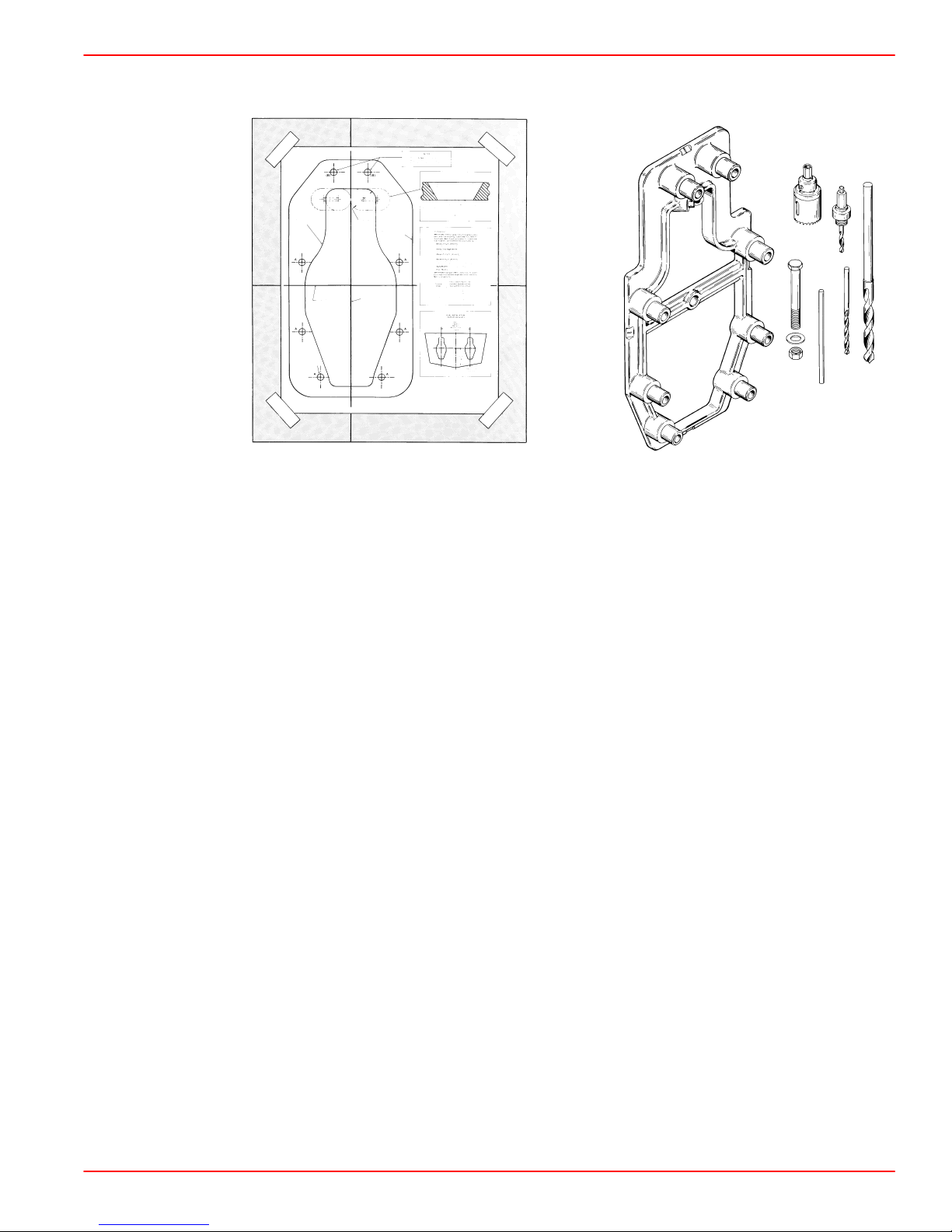

Alpha Notice: Increased Trim-In Range Capability

The Alpha trim cylinders provide the capability for an increased trim-in range. A spacer can

be removed from the trim cylinders to increase the trim-in range by approximately 1-1/2

degrees. This will improve the acceleration on some boats by forcing the bow down more

quickly. If the spacers are to be removed, the boat must be water tested to ensure that the

increased trim-in range does not cause any undesired boat handling characteristics

(bow-steer, chine-walk, etc.) if the sterndrive is trimmed in while the boat is operated at

higher speeds. The boat should be tested under all conceivable load conditions and

maneuvers to ensure that the additional trim-in does not pose a problem. The final decision

and responsibility for use of the additional trim-in range is left up to the boat manufacturer.

WARNING

It is recommended that only qualified personnel adjust the Trim-In Limit Spacer.

Boat must be water tested after adjusting or removing the device to ensure that the

modified trim-in range does not cause the boat to exhibit an undesirable boat handling characteristic if the sterndrive unit is trimmed in at higher speeds. Increased

trim-in range may cause handling problems on some boats that could result in personal injury.

Page 6 of 137 90-860172011

Page 7

GASOLINE STERNDRIVE INSTALLATION MANUAL

Bravo Three Notice: Trim-In Limit Insert

NOTE: Bravo One, Two and Three Models are equipped with a Trim-In Limit Insert.

It has been brought to our attention that some boats (predominantly deep-Vee heavy boats)

will roll up on their side under certain, specific, operating conditions. The roll can be either

to port or starboard and may be experienced while moving straight ahead, or while making

a turn. The roll occurs most frequently at or near maximum speed, with the sterndrive unit

trimmed at or near full trim-in. While the boat will not roll completely over, the roll may be

sufficient to unseat the operator or passengers, and thereby create an unsafe situation.

The roll is caused by stern-lift created from excessive sterndrive unit trim-in. Under these

extreme stern-lift / bow-down conditions instability can be created which may cause the boat

to roll. Weight distribution to the stern can reduce stern-lift and, in some circumstances, help

to control the condition. Weight distribution in the bow, port or starboard, may worsen the

condition.

The T rim-In Limit Insert reduces stern-lift by preventing the sterndrive unit from reaching the

last few degrees of full trim under. While this device should reduce the rolling tendency, it

may not eliminate the tendency entirely. The need for this Trim-In Limit Insert, and its

effectiveness, can only be determined through boat testing and is ultimately the

responsibility of the boat manufacturer.

It is recommended that only qualified personnel adjust the Trim-In Limit Insert. Boat

must be water tested after adjusting the device to ensure that the modified trim-in

range does not cause the boat to exhibit an undesirable boat handling characteristic if the sterndrive unit is trimmed In at higher speeds. Increased trim-in range may

cause handling problems on some boats which could result in personal injury.

Quicksilver Products

Accessories

Quicksilver gauges, remote controls, steering systems, propellers and other accessories

are available for this product. Mercury MerCruiser recommends the use of Quicksilver parts

on all applications. Refer to Mercury Precision Parts / Quicksilver Accessories Guide for a

complete listing.

This Guide is available from:

WARNING

Mercury Marine

Attn: Parts Department

W6250 W. Pioneer Road

P.O. Box 1939

Fond du Lac, WI 54936-1939

Outside of U.S.A., order through Distribution Center or Distributor.

90-860172011 Page 7 of 137

Page 8

GASOLINE STERNDRIVE INSTALLATION MANUAL

Serial Number Decal Placement

There are three sets of engine, transom assembly and sterndrive serial number decal strips

provided with each power package. One should be used for each of the following:

• Engine Specification Decal

• Warranty Registration Card

• Operation, Maintenance and Warranty Manual identification page.

Affix serial number decals to specification / serial number decal.

Corrosion Protection

Mercury MerCruiser power packages are equipped with anodes to help protect them from

galvanic corrosion under moderate conditions. However, for severe conditions or if using

a stainless steel propeller, it is recommended that a Quicksilver Anti-Corrosion Anode Kit

and/or a MerCathode System be installed (some models have a MerCathode System as

standard equipment). A MerCathode Monitor also is available to allow the operator to check

the operation of the MerCathode System with the push of a button. (Refer to “Quicksilver

Mercury Precision Parts / Quicksilver Accessories Guide” for part numbers.)

Boats which are connected to AC shore power require additional protection to prevent

destructive low voltage galvanic currents from passing through the shore power ground

wire. A Quicksilver Galvanic Isolator can be installed to block the passage of these currents

while still providing a path to ground for dangerous fault (shock) currents. (Refer to Mercury

Precision Parts / Quicksilver Accessories Guide for part number.)

IMPORTANT: If AC shore power is not isolated from boat ground, the MerCathode

System and anodes may be unable to handle the increased galvanic corrosion

potential.

Refer to Marine Corrosion Protection Guide P/N 90-881813 01 for specific information about

marine corrosion.

Page 8 of 137 90-860172011

Page 9

Anti-fouling Paint

IMPORTANT: Corrosion damage that results from the improper application of

anti-fouling paint will not be covered by the limited warranty.

Painting Boat Hull or Boat Transom: Anti-fouling paint may be applied to boat hull and

boat transom but you must observe the following precautions:

IMPORTANT: DO NOT paint anodes or MerCathode System reference electrode and

anode, as this will render them ineffective as galvanic corrosion inhibitors.

GASOLINE STERNDRIVE INSTALLATION MANUAL

IMPORTANT: If anti-fouling protection is required for boat hull or boat transom

copper or tin base paints, if not prohibited by law, can be used. If using copper or tin

based anti-fouling paints, observe the following:

• Avoid an electrical interconnection between the Mercury MerCruiser Product,

Anodic Blocks, or MerCathode System and the paint by allowing a minimum of

1-1/2 in. (40 mm) UNPAINTED area on transom of the boat around these items.

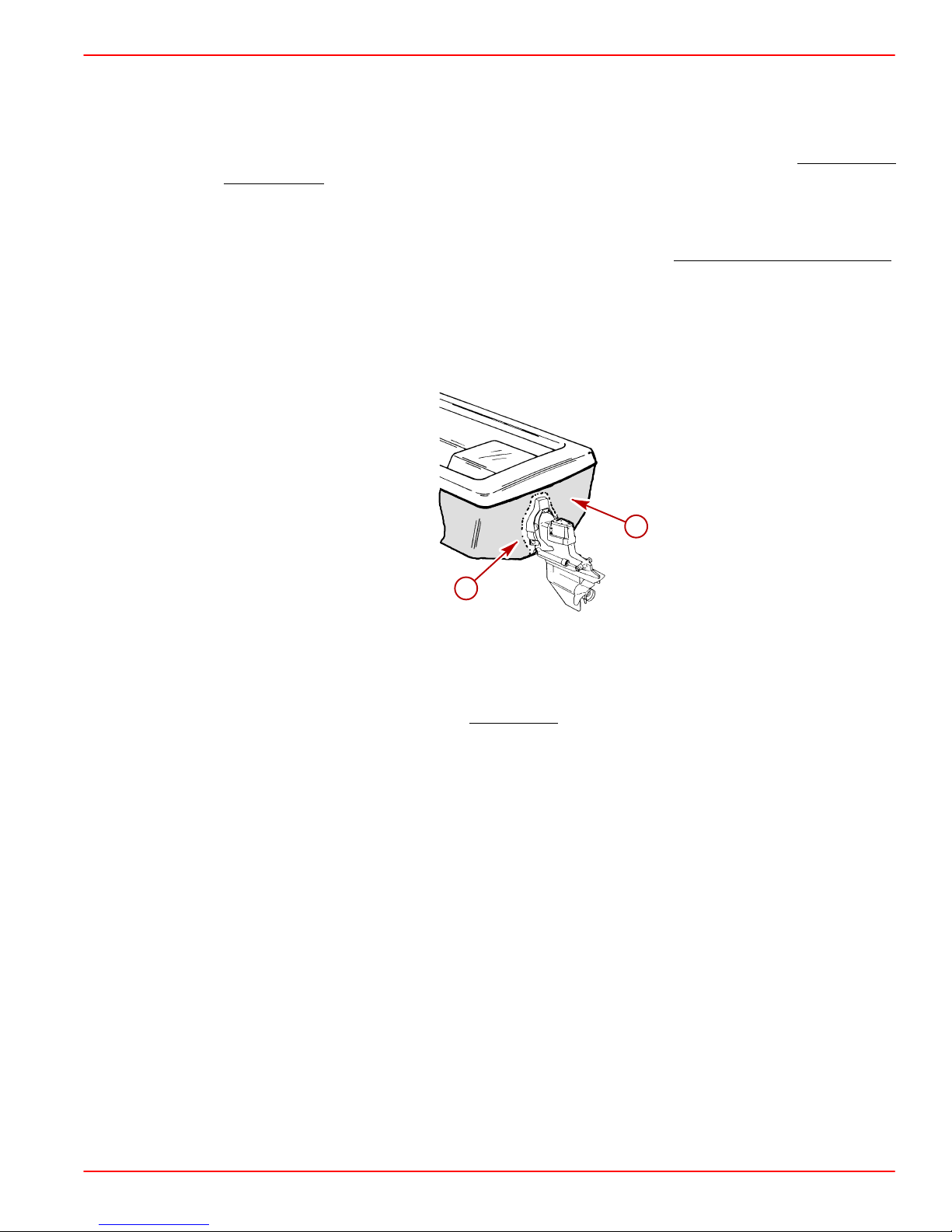

a

b

a-Painted Boat Transom

b-Minimum 1-1/2 in. (40 mm) UNPAINTED Area Around Transom Assembly

NOTE: Sterndrive unit and transom assembly can be painted with a good quality marine

paint or an anti-fouling paint that DOES NOT

could conduct electrical current. Do not paint drain holes, anodes, MerCathode system or

items specified by boat manufacturer.

contain copper, tin, or any other material that

71176

,

90-860172011 Page 9 of 137

Page 10

GASOLINE STERNDRIVE INSTALLATION MANUAL

Boat Construction

Transom Thickness and Surface

IMPORTANT: Transom thickness and surface plane (flatness) must be controlled

where the sterndrive unit mounts.

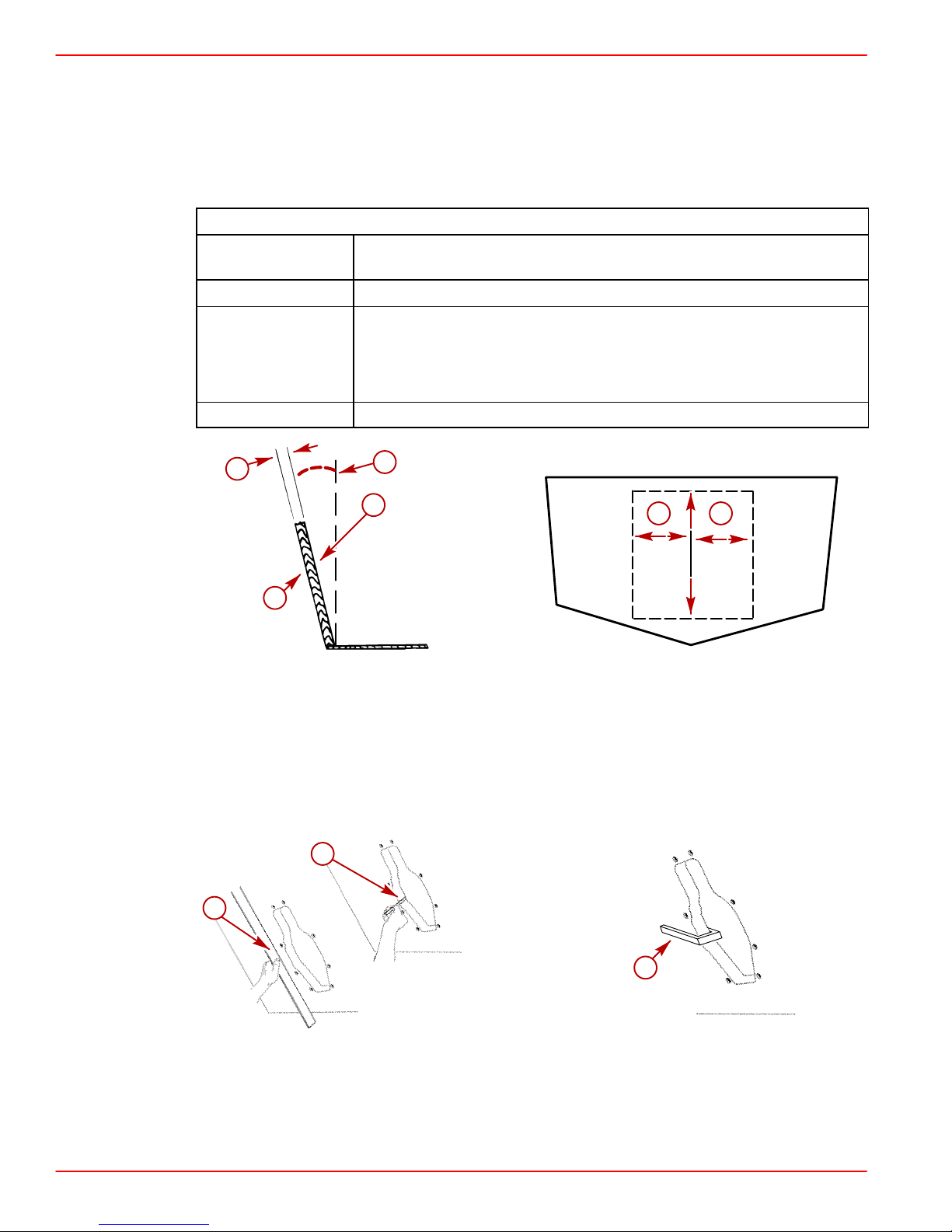

Thickness Between 2 - 2-1/4 in. (51 - 57 mm) for 8 in. (203 mm) to either

side of the vertical centerline

Parallelism Inner and outer surfaces must be parallel within 1/8 in. (3 mm)

Flatness Transom surfaces in area where transom assembly will be

mounted (includes vertical as well as horizontal dimensions):

Inner Surface – Flat within1/8 in. (3 mm)

Outer Surface – Flat within1/16 in. (2 mm)

Angle 10 -16 Degrees

Transom Specifications

a

e

b

c

a-Transom Thickness

b-Inner Surface

c-Outer Surface

d-Transom Plate Coverage

e-Transom Angle

a

b

22170

d d

72700

a-Measuring Thickness

b-Measuring Flatness

c-Suitable Mandrel To Check For Uniform Transom Thickness

Page 10 of 137 90-860172011

70004

c

75479

Page 11

Engine Bed

Difference Between Starboard and Port Engine Mount 22-1/2 in. (572 mm)

Mount Adjustment Up and Down (minimum) 1/4 in. (6 mm)

NOTE: Although the engine mounts allow some adjustment, it is a good practice to ensure

that the front and rear mount locations in the vessel are parallel and in the same plane. This

may be checked by tying a string from the left front mount location to the right rear mount

location and another from right front to left rear. The strings should touch where they cross

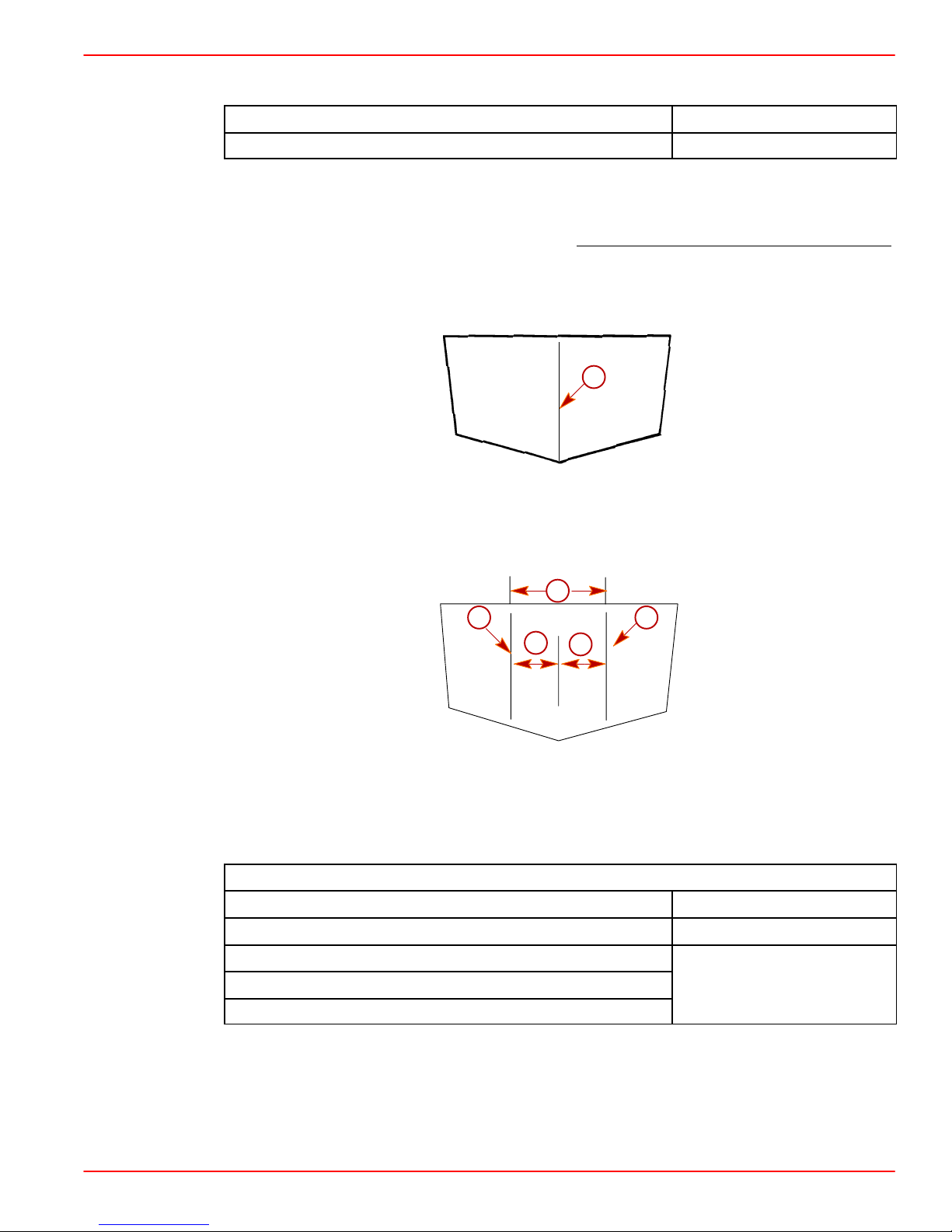

Crankshaft Vertical Centerline

1. Locate and mark boat vertical centerline on transom.

GASOLINE STERNDRIVE INSTALLATION MANUAL

.

a

71620

a-Vertical Centerline

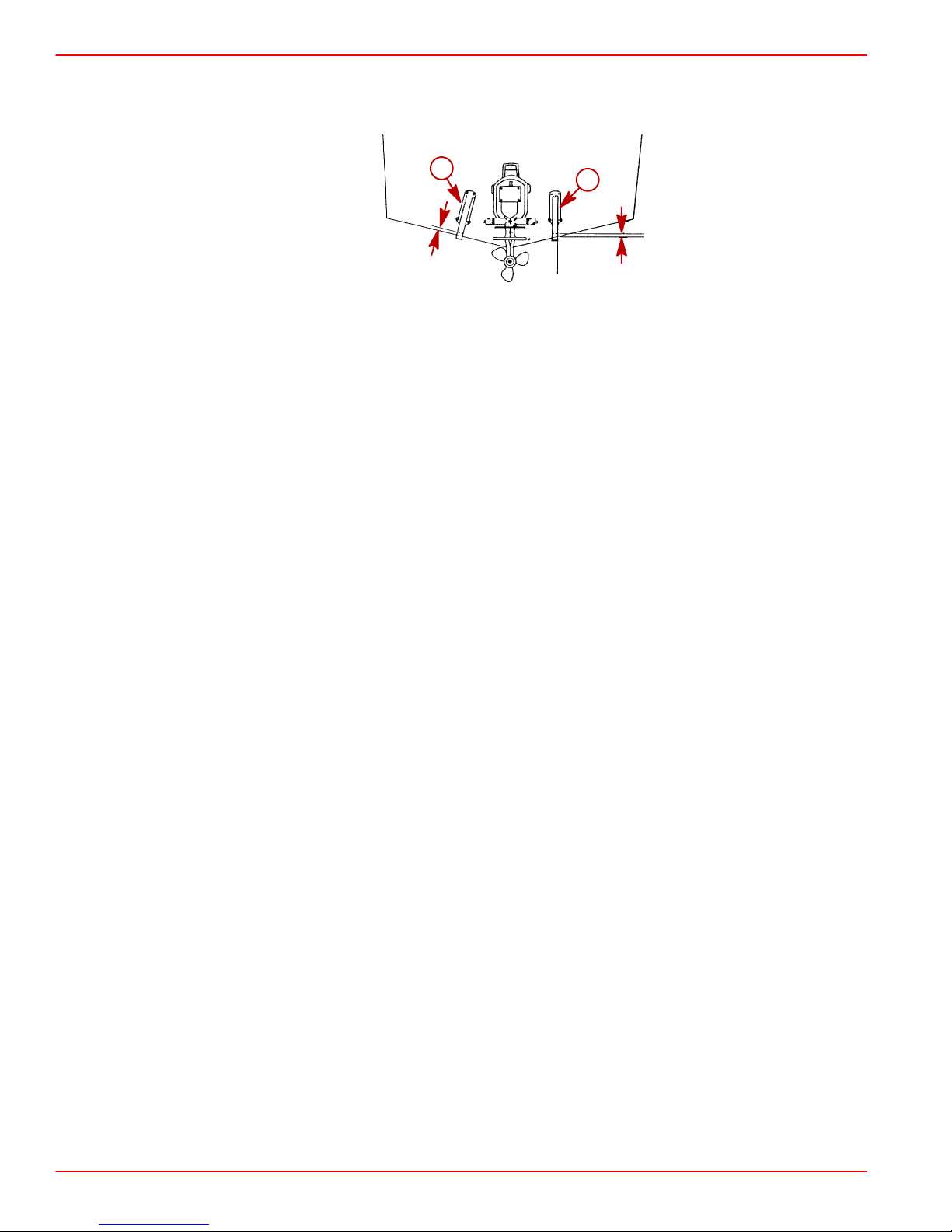

2. For Dual Engines: Locate and mark crankshaft vertical centerlines “a” on transom.

b

a a

c

c

22033

a-Crankshaft Vertical Centerline

b-Minimum Distance Between Crankshaft Vertical Centerlines

c-Crankshaft Vertical Centerlines Must Be An Equal Distance From Boat Vertical

Centerline

Minimum Distance Between Crankshaft Vertical Centerlines (Dual Side-By-Side)

Model in. (mm)

181 cid / 3.0L 28 (710)

262 cid / 4.3L

305 cid / 5.0L

350 cid / 5.7L

90-860172011 Page 11 of 137

33 (838)

Page 12

GASOLINE STERNDRIVE INSTALLATION MANUAL

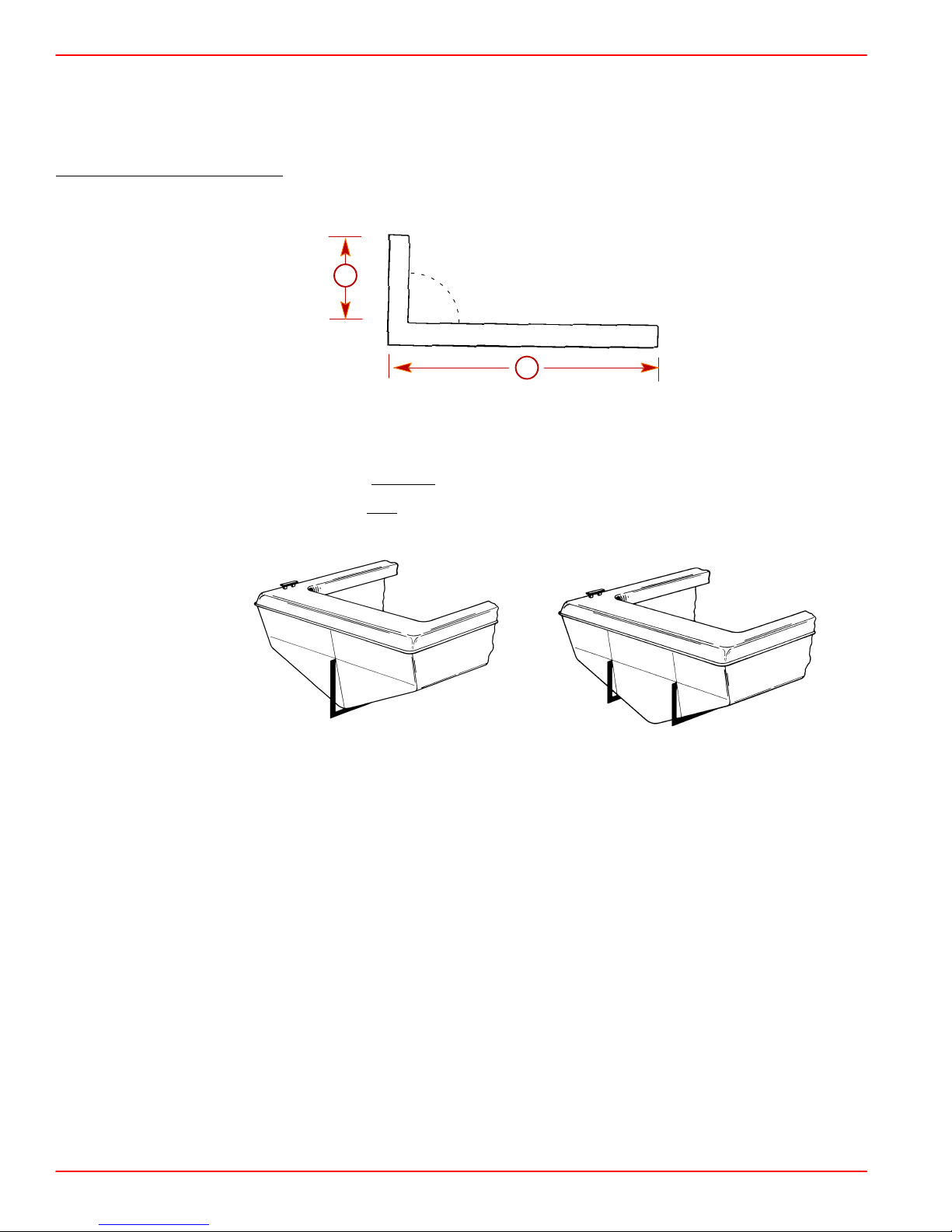

Crankshaft Horizontal Centerline (X-Dimension)

X-Dimension can be measured by the 90 degree Tool Method or by the Tape Measure

Method.

90 DEGREE TOOL METHOD

1. Construct 90 degree tool.

a

90°

b

71621

a-13-9/16 in. (345 mm)

b-Measurement: 4 ft. (1.2 m)

To Lower Drive Unit - Subtract

To Raise Drive Unit - Add

from dimension “a.”

to dimension “a.”

IMPORTANT: This dimension should only be raised or lowered after proper testing.

71622

71623

Single Engine Dual Engine

2. Place 90 degree tool along boat bottom at vertical centerline.

3. Locate the point at which top of tool contacts transom on vertical centerline. This is the

crankshaft horizontal centerline or X-Dimension.

4. Draw a line perpendicular to vertical centerline at crankshaft horizontal centerline.

Page 12 of 137 90-860172011

Page 13

TAPE MEASURE METHOD

1. Determine X-Dimension from the following chart.

GASOLINE STERNDRIVE INSTALLATION MANUAL

Transom Angle

(degrees)

This dimension should only be raised or lowered after proper

testing.

16 14-5/16 in. (364 mm)

15 14-1/4 in. (362 mm)

14 14-3/16 in. (360 mm)

13 14-1/8 in. (359 mm)

12 14-1/16 in. (357 mm)

11 14 in. (356 mm)

10 13-15/16 in. (354 mm)

2. Measure up from the boat bottom the amount shown on the chart for the appropriate

transom angle.

71622

71623

Single Engine Dual Engine

3. Draw a line perpendicular to vertical centerline at crankshaft horizontal centerline.

90-860172011 Page 13 of 137

Page 14

GASOLINE STERNDRIVE INSTALLATION MANUAL

Transom Cutout

IMPORTANT: The following instructions will provide a sterndrive unit mounting

location that is suitable for most boats. Best mounting location for a particular boat,

however, can be determined only by testing.

1. Below 25 mph (40 km/h):

2. Heavy Duty Applications:

3. Above 25 mph (40 km/h):

4. Above 50 mph (80 km/h):

Subtract 1/2 in. (13 mm) from X-Dimension.

Subtract 1 in. (25 mm) from X-Dimension.

Use X-Dimension shown.

The X-Dimension can be increased to improve performance

in some applications. However, pulling power for skiing will decrease. During testing,

X-Dimension should be increased 1/2 in. (13 mm) at a time until desired performance

is achieved but in no case should it ever be increased by more than:

Maximum Increase In X-Dimension

Alpha 2-1/2 in. (64 mm)

Bravo One and Two 3 in. (76 mm)

Bravo Three 1 in. (25 mm)

Extreme care should be taken when raising drive unit to ensure that water supply does not

become aerated. Use clear water inlet hose to monitor incoming water and monitor engine

temperature gauge to ensure engine does not overheat.

In applications where cooling water to the engine is supplied by a through the hull

or through the transom fitting, the sterndrive height will not cause cooling water aeration.

IMPORTANT: Damage to Mercury MerCruiser products caused by too high of an

installed height will not be covered by Mercury MerCruiser warranty.

Page 14 of 137 90-860172011

Page 15

GASOLINE STERNDRIVE INSTALLATION MANUAL

5. Cut out transom using the Template or the Transom Drilling Fixture Kit (purchased

separately).

90-79135--3

50017

22056

Transom Cutout Template Transom Drilling Fixture Kit

6. Follow instructions indicated on template or provided with drilling fixture.

7. Ensure that centerlines on either the template or transom drilling fixture align with lines

previously marked on transom.

8. Drill 1/4 in. (6 mm) pilot holes for hole saw guide at a 60 degree angle and cut on the

line when making transom cutout. If cutout is made incorrectly, drive unit steering lever

may contact transom, thus limiting steering travel.

9. Seal inside edge of transom cutout opening with a suitable sealant to prevent water

absorption and deterioration of transom.

10. Cut drain hole and install drain plug flange with appropriate fasteners.

90-860172011 Page 15 of 137

Page 16

GASOLINE STERNDRIVE INSTALLATION MANUAL

Seawater Connections - General Information

This section covers through the hull and through the transom water inlets only. For information on sterndrive water inlet connections, refer to the appropriate section after engine installation.

IMPORT ANT: Seal the inside edges of any hole made through the hull with a suitable

sealant to prevent water absorption and deterioration.

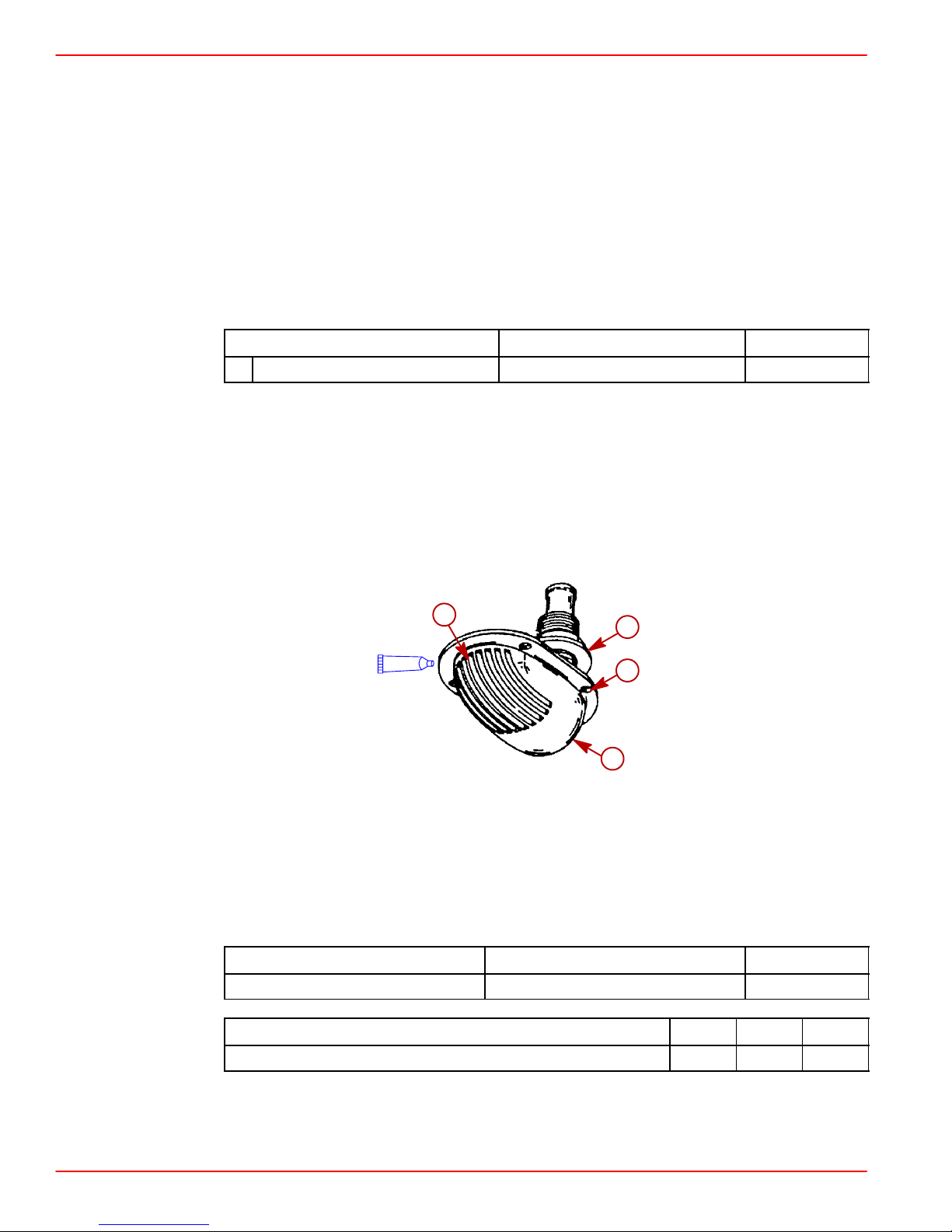

Seawater Pickup

THROUGH THE HULL MOUNTED

Description

A Marine Caulking Mounting Surfaces Obtain Locally

1. Seal inside edges of 1-3/4 in. (44 mm) hole in hull using a suitable sealer.

2. Apply marine caulking (sealer) to mounting surface on seawater pickup where hull

contact will occur when installed.

IMPORT ANT: Seawater inlet slots must face forward - parallel with the flow of water.

3. Ensure slots in seawater pickup are facing forward (toward bow of boat) and install

seawater pickup through hull.

4. Fasten pickup with four appropriate mounting screws (if so designed).

b

A

Where Used Part Number

d

c

a

72639

a-Seawater Pickup

b-Seawater Inlet Slots

c-Mounting Screw Holes (If Equipped)

d-Nut

5. Apply marine caulking as needed inside boat. Apply sealant to threads of nut and install

on pickup on inside of boat and torque nut.

Description

Loctite 271 Seawater Inlet Nut 92-809820

Description Nm lb-in. lb-ft

Nut 42 35

NOTE: If pickup being installed does not have mounting screws on underside where

mounted to hull, be certain, after nut is torqued, that slots are still facing forward.

Page 16 of 137 90-860172011

Where Used Part Number

Page 17

TRANSOM MOUNTED

1. Seal the inside edges of the 1-1/2 in. (38 mm) hole hose fitting.

2. Ensure that the hose fitting and plastic plug are in place and threads have been sealed

GASOLINE STERNDRIVE INSTALLATION MANUAL

prior to tightening each securely.

Description

Where Used Part Number

Hose Fitting Threads

A Loctite 592 PST

Plastic Plug Threads

Obtain Locally

B Silicone Sealant Or Equivalent Screw Shaft

NOTE: Use a sharp knife or wood chisel to remove excess plastic plug material so that plug

is flush with pickup casting.

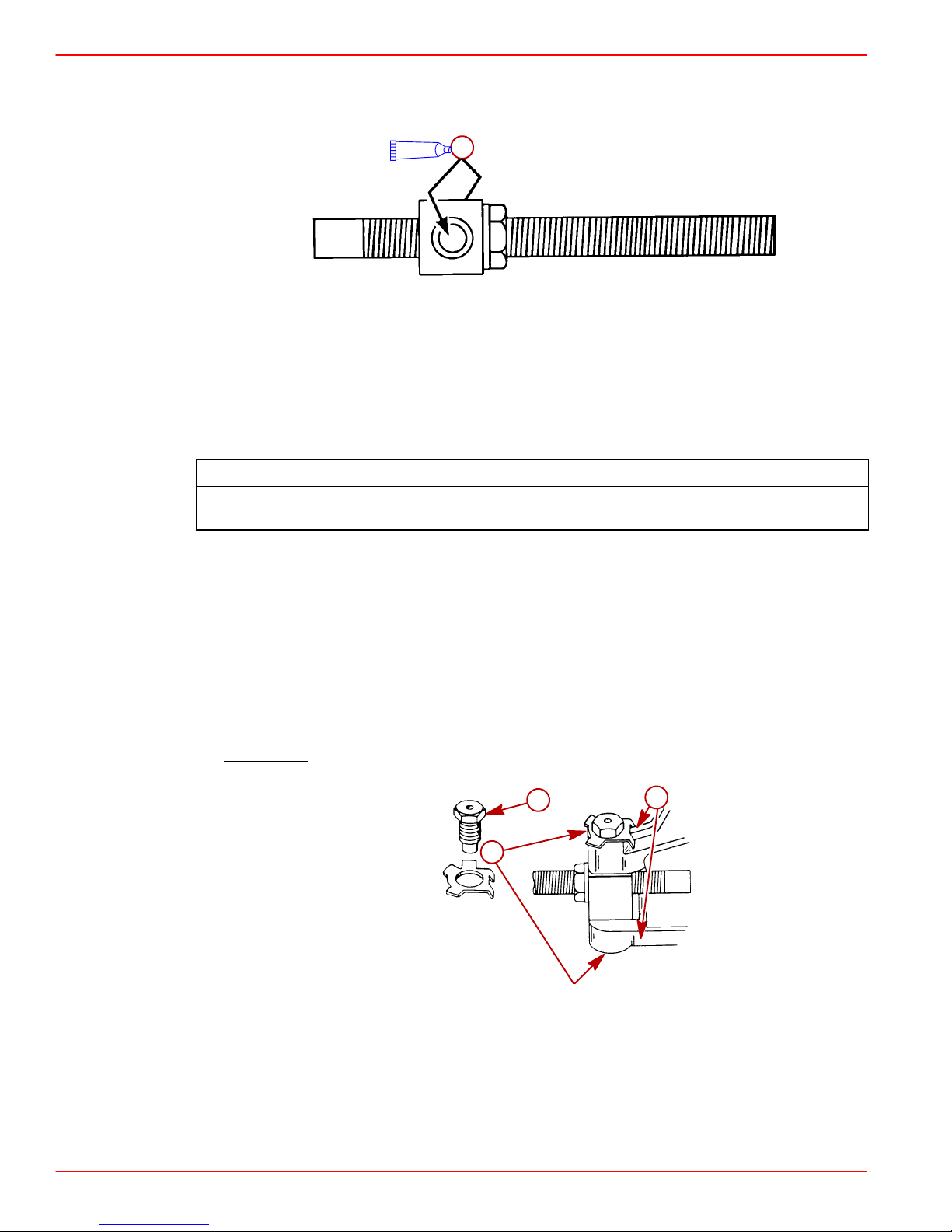

3. Position one flat washer and one rubber O-ring on each 5/16 in. x 4 in. (102 mm) long,

round head screw. Coat each screw shaft with sealant.

4. Place new gasket on pickup housing and hold pickup in place on transom. Install four

round head screws (with washers and O-rings in place) into pickup mounting holes and

through drilled 21/64 in. (8 mm) holes in transom.

b

d

A

a

e

B

f

c

g

A

h

i

j

72640

a-Hose Fitting

b-Nut (4)

c-Gasket

d-O-ring (4)

e-Washer (4)

f-Screw (4)

g-Plastic Pug

h-Pickup

i-Screen

j-Screw (2)

90-860172011 Page 17 of 137

Page 18

GASOLINE STERNDRIVE INSTALLATION MANUAL

NOTE: Some installations may have 7/32 in. (5 mm) holes drilled in transom using four 5/16

in. diameter stainless steel lag bolts in place of round head screws. In any case, flat washers

and O-rings are required as outlined.

Water Pickup Installed on Transom

a-Diagonal Mount - Leading Edge Of Pickup 1/8 in. (3.2 mm) From Boat Bottom.

b-Vertical Mount - Corner Of Leading Edge Of Pickup 1/8 in. (3.2 mm) From Boat

Bottom

5. Secure water pickup from inside with locknuts and washers (unless using lag bolts).

6. Tighten fasteners securely.

Preliminary Connections

Power Trim Pump

1. Select an appropriate mounting location for the trim pump that:

• Is within length limits of black and gray hydraulic hoses coming from gimbal housing

assembly.

a

b

72641

• Is close to the battery so that trim pump battery leads can be connected.

• Allows easy access to trim pump oil fill and vent locations.

• Is in an area where pump will not be exposed to water.

• Prevents the power steering booster cylinder from coming in contact with the trim pump

when the steering wheel is turned in either direction (right or left).

NOTE: Template 90-863152 provides mounting hole location for floor or transom mounting.

2. Remove the cap plug.

3. Mount the pump in the desired location.

Page 18 of 137 90-860172011

Page 19

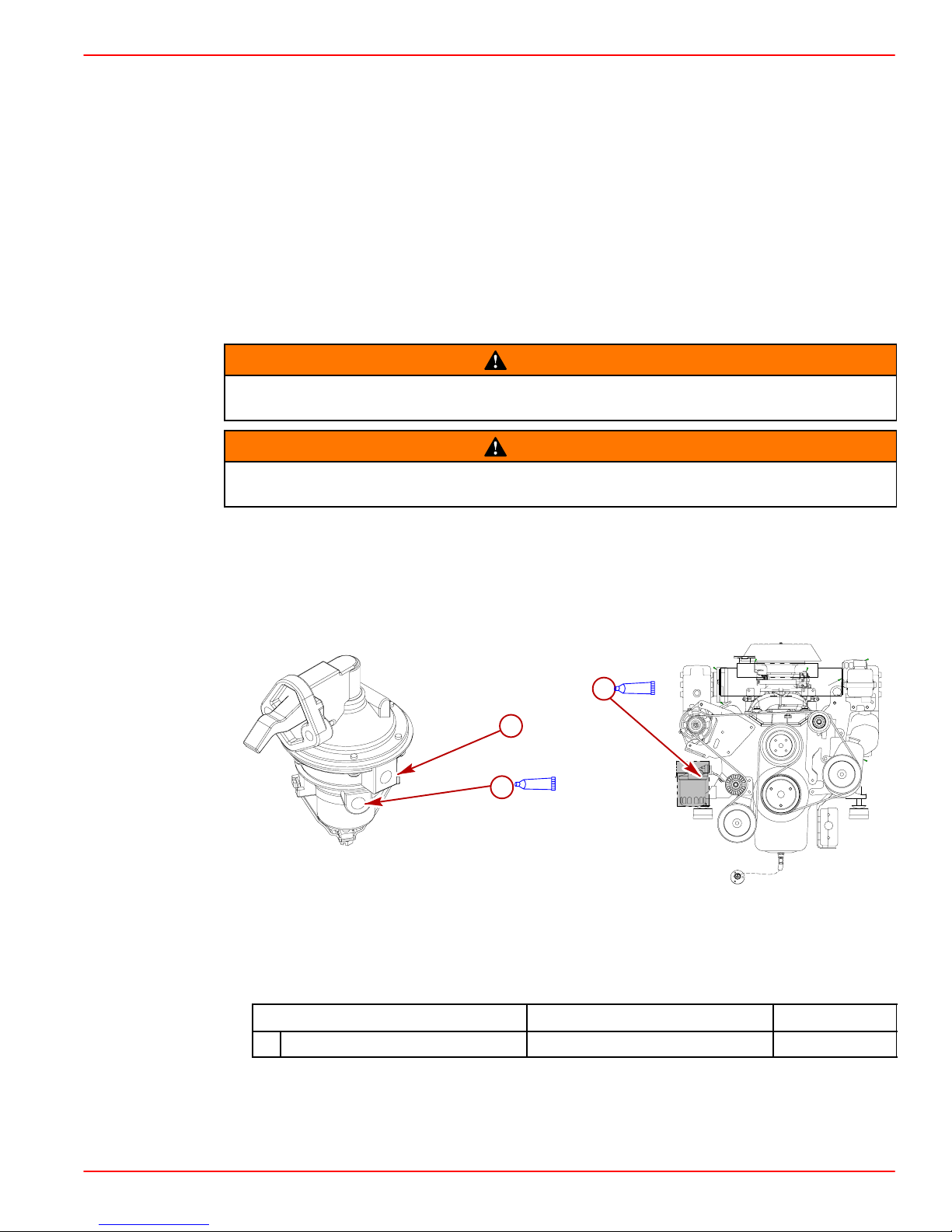

Fuel Inlet Fitting

IMPORTANT: The following information is provided to ensure proper installation of

brass fittings or plugs installed into fuel pump or fuel filter base:

• Use #592 Loctite Pipe Sealant with Teflon on threads of fuel inlet fittings or plugs.

• Fuel inlet fittings or plugs should first be threaded into fuel pump or fuel filter

• Fuel inlet fittings or plugs should then be tightened an additional 1-3/4 to 2-1/4

• To prevent over-tightening when installing a fuel line, the brass fittings should be

Boating standards (NMMA, ABYC and others) and Coast Guard regulations must

be adhered to when installing fuel delivery system.

Avoid gasoline fire or explosion. Improper installation of brass fittings or plugs into

fuel pump or fuel filter base can crack casting and/or cause a fuel leak.

GASOLINE STERNDRIVE INSTALLATION MANUAL

DO NOT USE TEFLON TAPE.

base until finger tight.

turns using a wrench. DO NOT OVERTIGHTEN.

held with a suitable wrench as fuel inlet fittings are tightened securely.

WARNING

WARNING

1. Remove plastic plug from fuel inlet hole.

2. Apply sealant to threads of fuel inlet fitting. DO NOT USE TEFLON TAPE.

3. Install fuel inlet fitting. To prevent cracking the casting or causing fuel leaks, turn fuel inlet

fitting in by hand until finger tight, then tighten connector to 1-3/4 to 2-1/4 turns with

wrench. DO NOT overtighten.

a

A

b

A

a

78165

3.0L Model Typical V6 And V8 Models

a-Fuel Inlet Hose Connects Here

b-Fuel Outlet

77108

Description

A Loctite 592 Fuel Inlet Fitting Obtain Locally

90-860172011 Page 19 of 137

Where Used Part Number

Page 20

GASOLINE STERNDRIVE INSTALLATION MANUAL

SPECIAL INFORMATION ABOUT ELECTRIC FUEL PUMPS

CAUTION

The electric fuel pump and factory installed water separating fuel filter have been

carefully designed to function properly together . Do not install additional fuel filters

and/or water separating fuel filters between fuel tank and engine.

The installation of additional filters may cause:

• Fuel Vapor Locking

• Difficult Warm-Starting

• Piston Detonation Due to Lean Fuel Mixture

• Poor Driveability

Transom Connections

Installing Gimbal Housing

1. Carefully remove transom assembly from shipping carton.

2. Remove and read all tags attached to transom assembly.

a

b

a-Dust Cover

b-Shipping Hardware

3. Remove the shipping hardware.

4. Remove the dust cover if boat will be shipped with drive installed.

5. Retain the serial number envelope.

22027

Page 20 of 137 90-860172011

Page 21

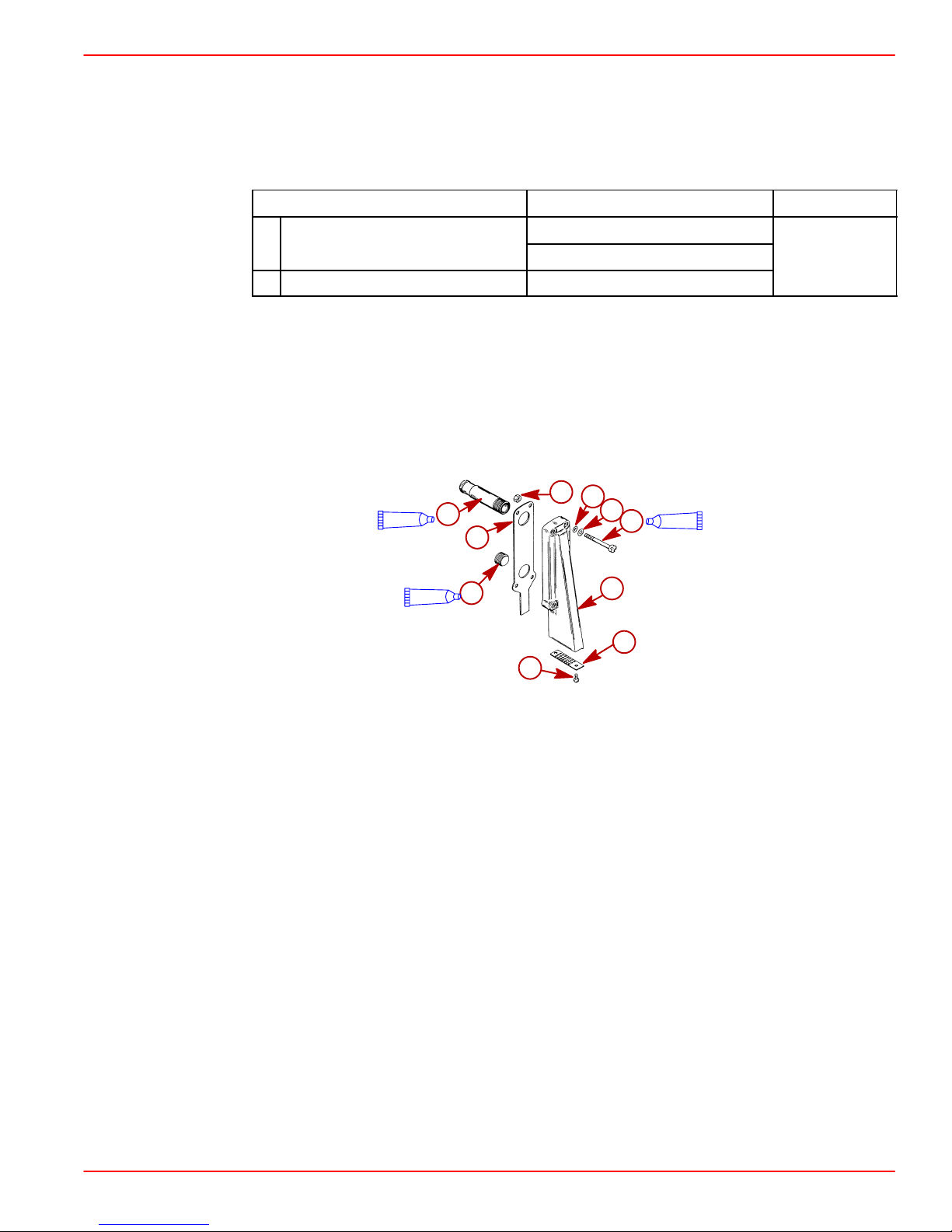

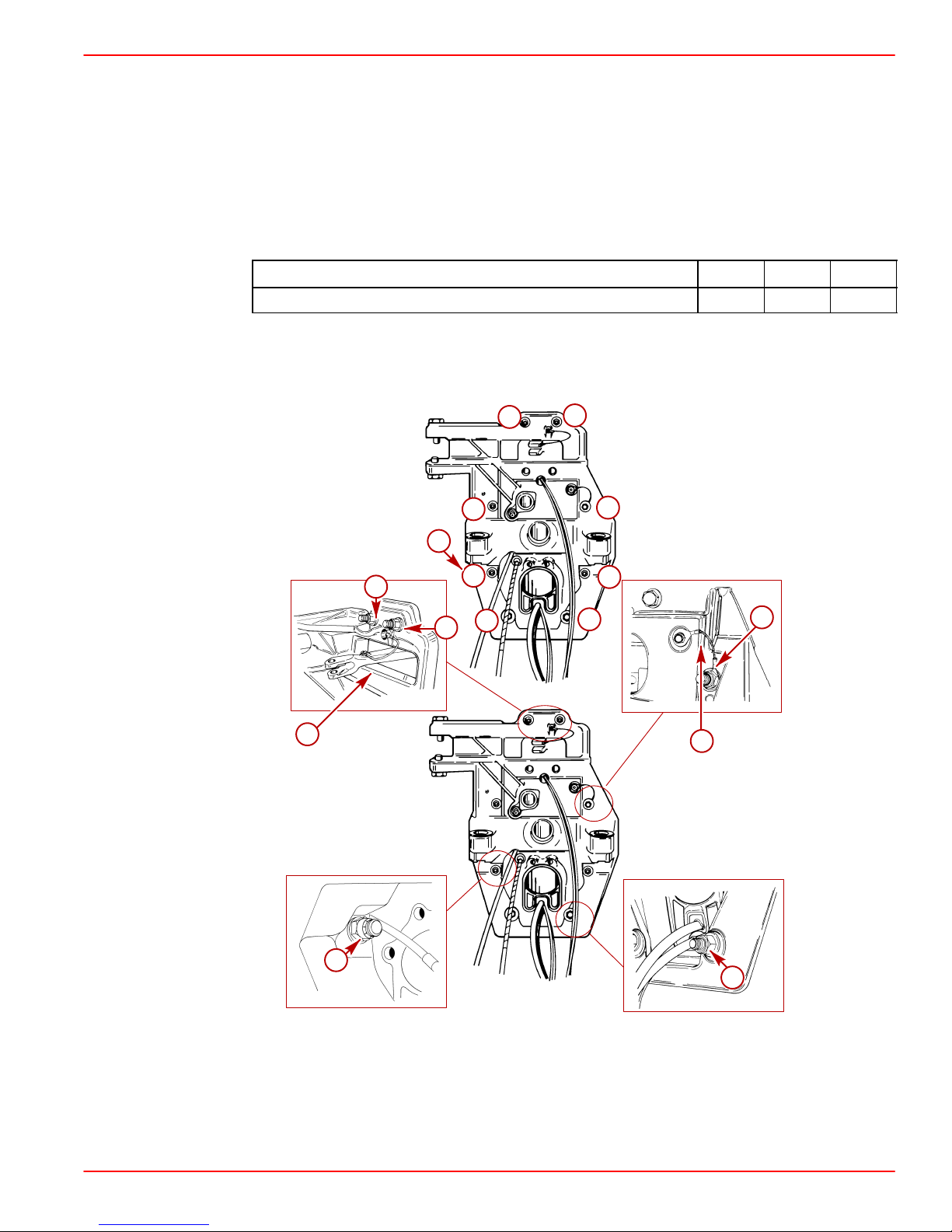

Installing Inner Transom Plate

1. Insert wires, hoses and shift cable through appropriate openings in inner transom plate.

2. Position gimbal housing on transom and hold in place.

IMPORTANT: Tighten the transom assembly fasteners using an X-pattern torque

sequence, starting from the middle fasteners. Tighten in small increments and go

around the pattern several times until the proper torque is achieved.

3. Secure transom assembly with hardware as shown. Torque the hardware.

GASOLINE STERNDRIVE INSTALLATION MANUAL

Description

Nm lb-in. lb-ft

Transom Assembly Hardware 31 23

4. Attach continuity wires.

IMPORTANT: Steering lever continuity circuit wire must be positioned as shown to

avoid stressing wire when steering lever moves.

5

3

7

2

b

a

71626

1

8

a

4

6

a

71628

c

a

70005

a-Locknuts And Flat Washers (8)

b-Torque Sequence

c-Continuity Wire

71627

c

a

71629

90-860172011 Page 21 of 137

Page 22

GASOLINE STERNDRIVE INSTALLATION MANUAL

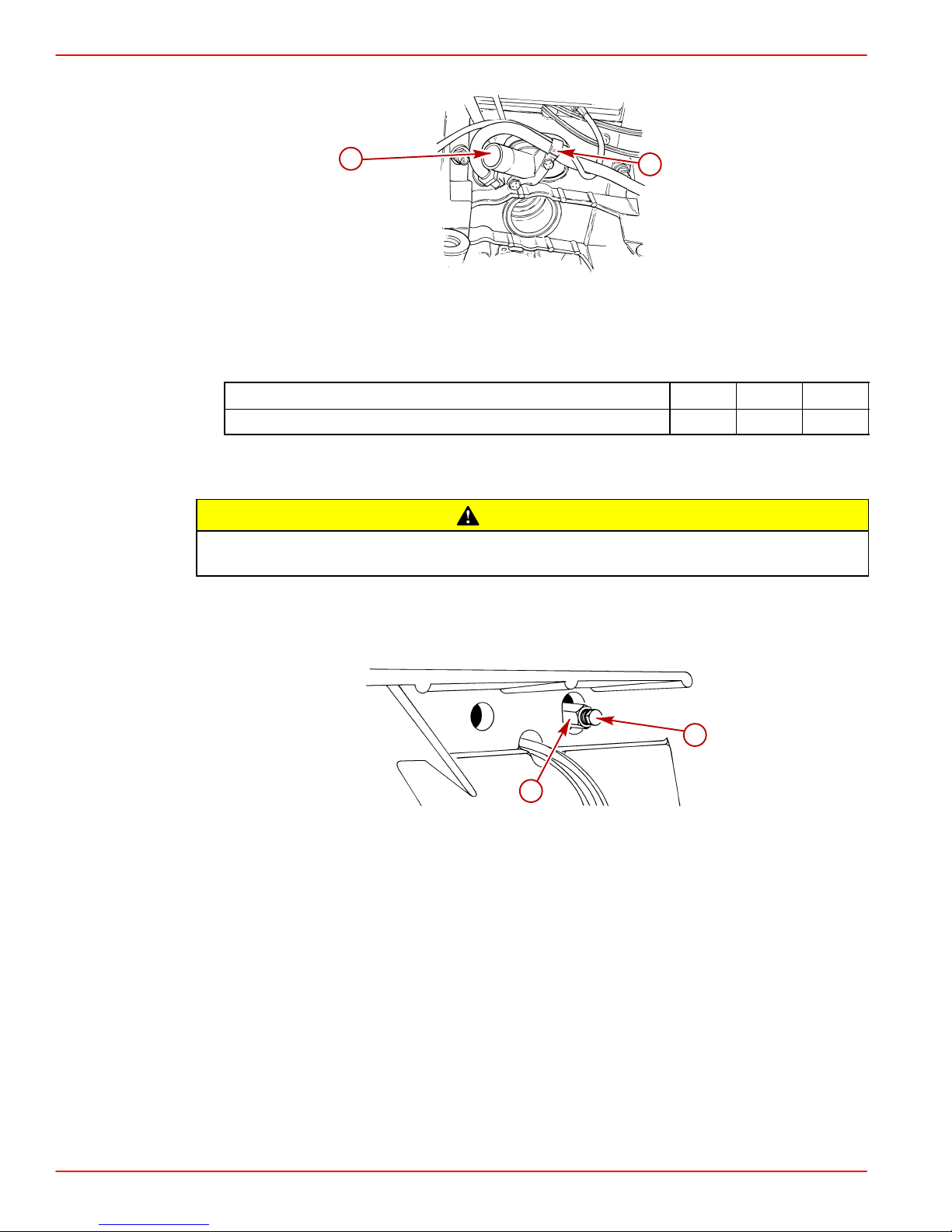

5. Install the water inlet fitting and j-clip for the gear lube and the speedometer hose.

a

a-Water Inlet Fitting

b-J-clip

6. Torque J-clip fasteners.

Description

J-Clip Fasteners 5 45

Connecting Speedometer Pickup

Excess water in bilge can damage engine or cause boat to sink. Do not remove plug

from speedometer pickup tube fitting unless connection is to be utilized.

The connection for the speedometer pickup can be accessed through a hole and fitting in

the inner transom plate.

b

77916

Nm lb-in. lb-ft

CAUTION

1. Remove plug from speedometer pickup tube fitting.

b

a-Plug

b-Inner Transom Plate Fitting

a

70037

Page 22 of 137 90-860172011

Page 23

GASOLINE STERNDRIVE INSTALLATION MANUAL

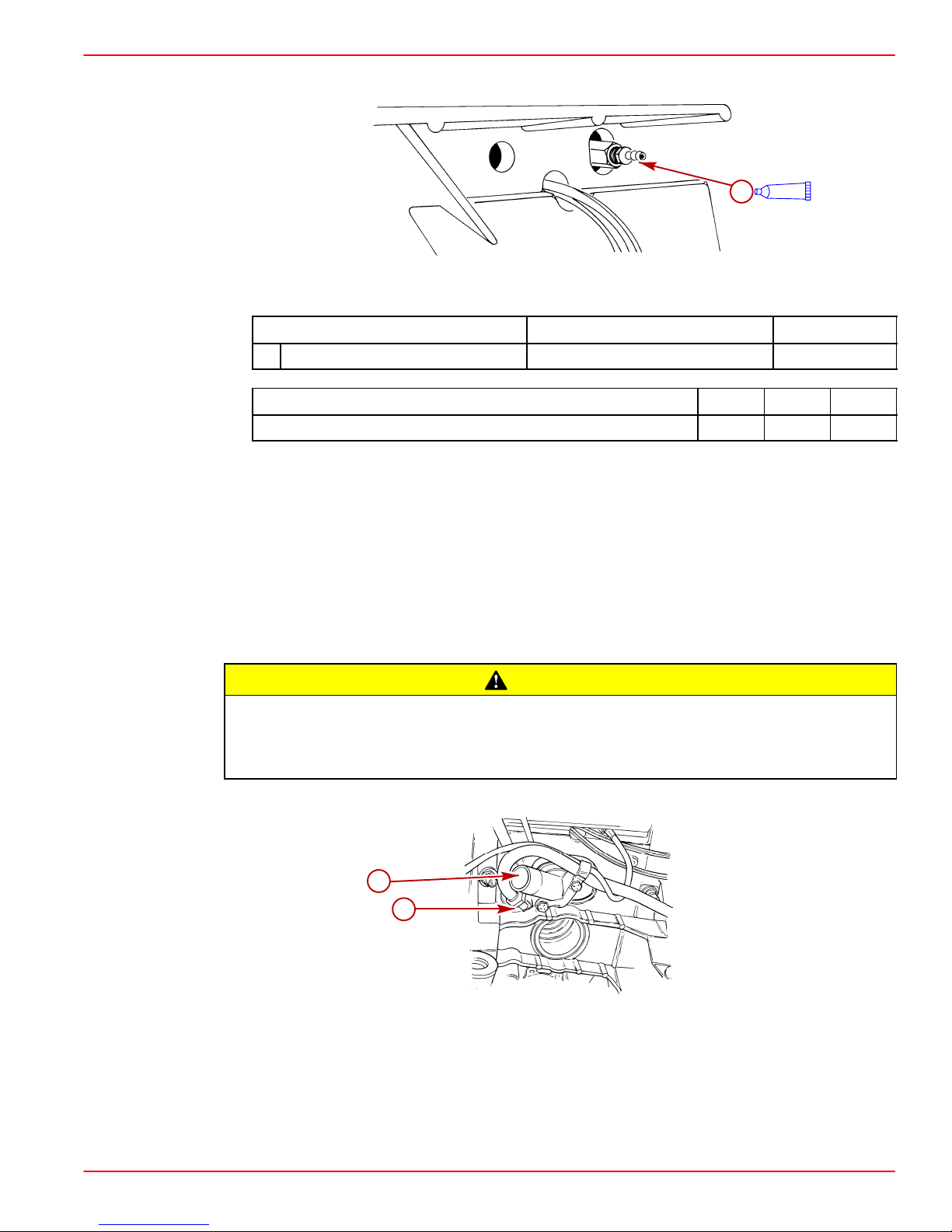

2. Apply sealant to threads of barb fitting. Install and torque the barb fitting.

Description

A Loctite 592 Speedometer Barb Fitting Obtain Locally

Description Nm lb-in. lb-ft

Barb Fitting 1.5 13

3. Connect a 5/32 in. (4 mm) speedometer hose (not provided) hose from speedometer

to barb fitting. Secure hose with cable tie.

4. Secure the hose to the transom with the hose clip and screw that are provided in the

parts bag.

NOTE: The hose must not come into contact with the steering system components or the

engine coupler and drive shaft.

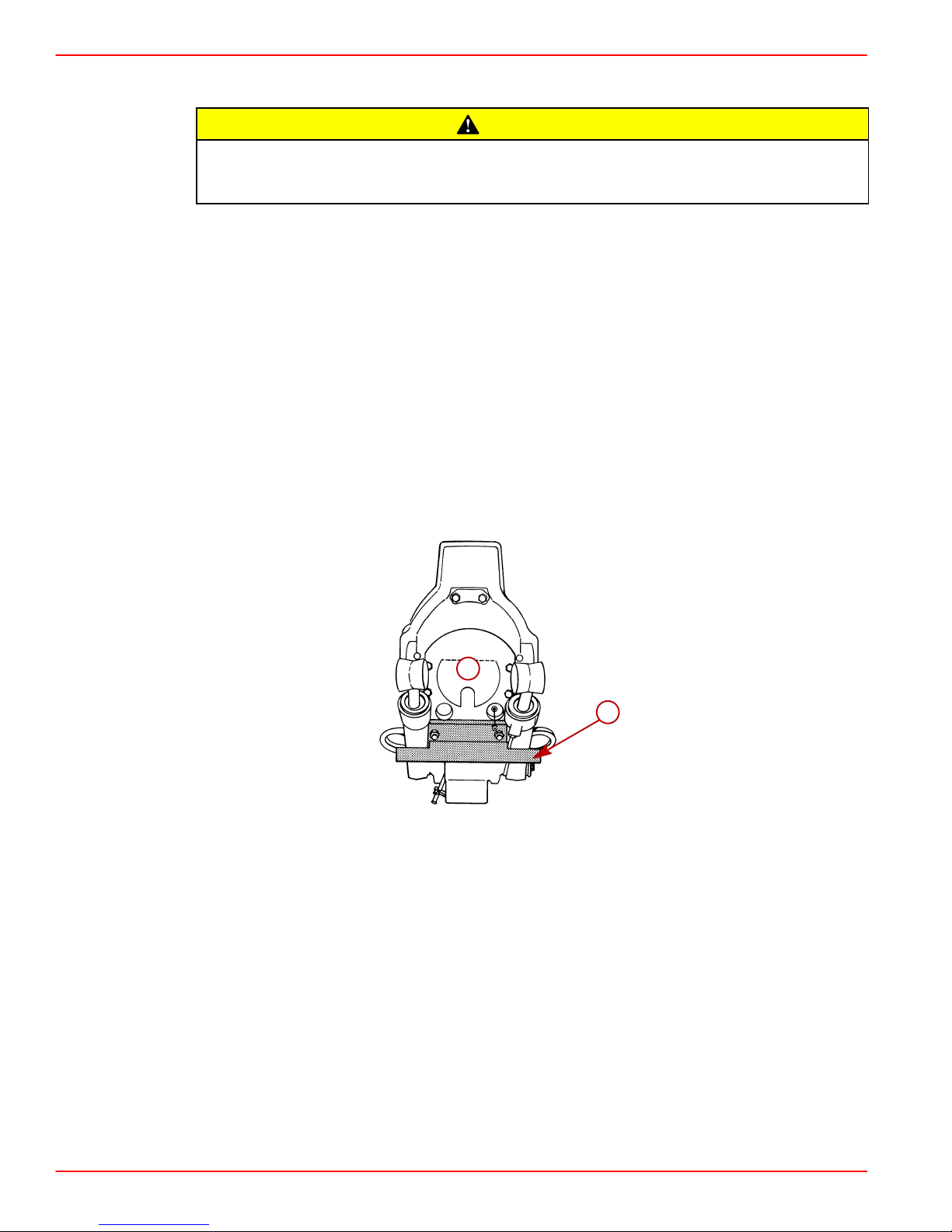

Fluid Connections

1. Connect the gear lube monitor hose to the quick release 90 degree fitting.

a-Barb Fitting

a

A

70015

Where Used Part Number

CAUTION

Avoid sterndrive unit damage. Quick release button on gear lube monitor 90 degree

hose fitting may not lock on gimbal housing if touching or depressed by water inlet

fitting or block-off plate, if equipped. Failure to do so could result in a loose 90

degree fitting causing a loss of gear lube and damage to drive unit.

2. Connect 90 degree fitting to the gimbal housing.

a

b

77916

a-Water Inlet Fitting

b-90 Degree Fitting

90-860172011 Page 23 of 137

Page 24

GASOLINE STERNDRIVE INSTALLATION MANUAL

NOTE: The quick release button on hose fitting must be positioned away from water inlet

fitting, or block-off plate if equipped. Release button must not contact water fitting or

block-off plate, if equipped.

NOTE: The hose must not come into contact with the steering system components or the

engine coupler and drive shaft.

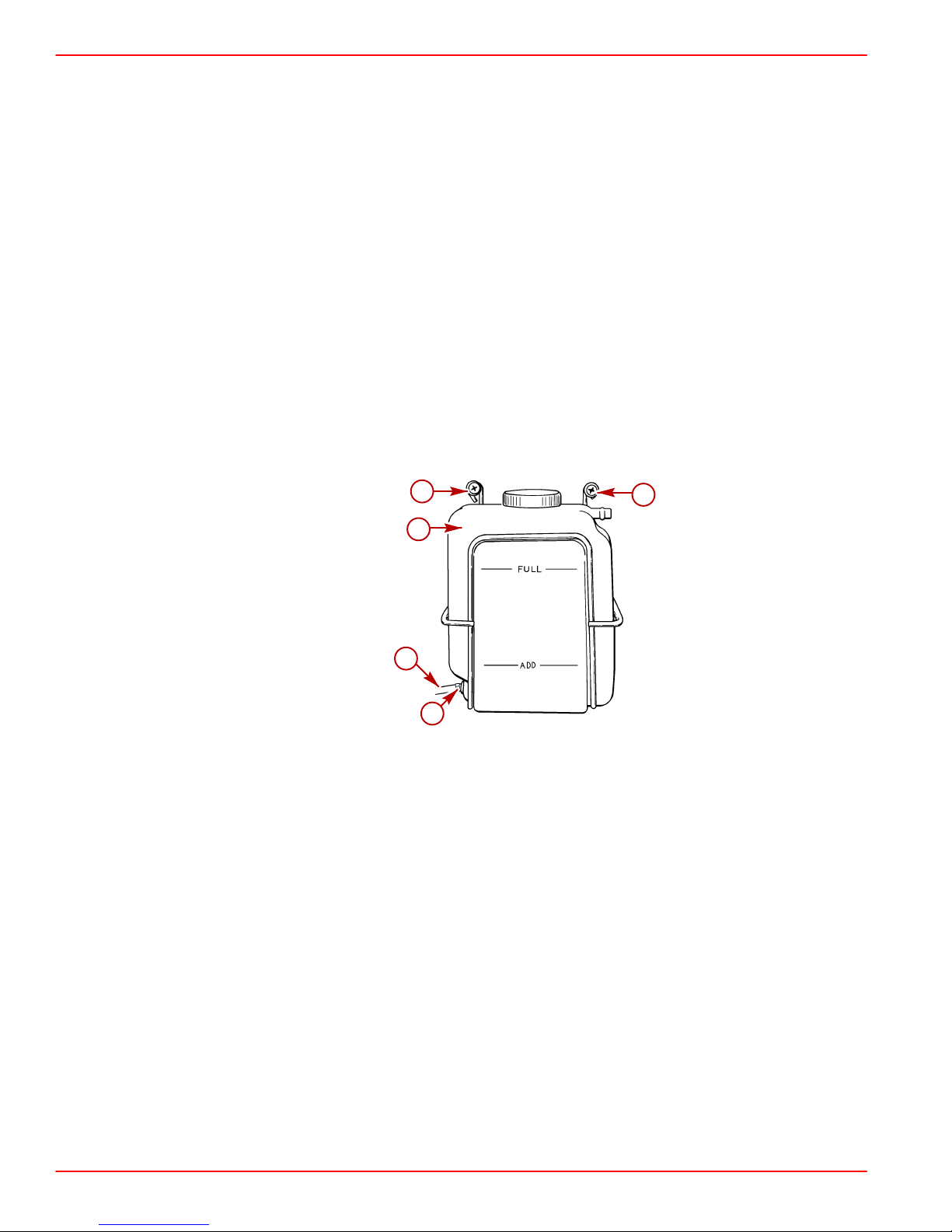

3. Select a mounting location for coolant recovery bottle and mounting bracket that meets

all of the following:

• Within limits of clear plastic tubing.

• Level with or above the heat exchanger fill neck.

• Accessible for observing coolant level and filling.

4. Mount coolant recovery bottle and mounting bracket in desired location using two

3/4 in. (19 mm) long screws and flat washers.

5. Route plastic tubing to recovery bottle. Ensure that tubing is positioned away from any

moving parts. Cut plastic tubing as required and connect to bottom connection on

recovery bottle and secure with tubing clamp provided.

6. Fasten plastic tubing to boat, as necessary , with 2 hose clips and 1/2 in. (13 mm) long

screws (provided).

b

a

c

d

a-Recovery Bottle And Mounting Bracket

b-Screws And Flat Washers

c-Plastic Tubing

d-Tubing Clamp

b

71712

Page 24 of 137 90-860172011

Page 25

Installing Steering System

HYDRAULIC (HELM) STEERING

If your power package is equipped with Compact Hydraulic Steering, refer to the Compact

Hydraulic Steering Installation Instructions in the box with the compact hydraulic steering

components. Complete the installation of the hydraulic steering system before proceeding

to Transom Preparation.

POWER STEERING

NOTE: For dual installations, power steering unit can be mounted on port or starboard

transom assembly . Measure exact distance between power package centerlines. Select a

tie bar from Mercury Precision Parts / Quicksilver Accessory Guide. Refer to tie bar

installation instructions before proceeding.

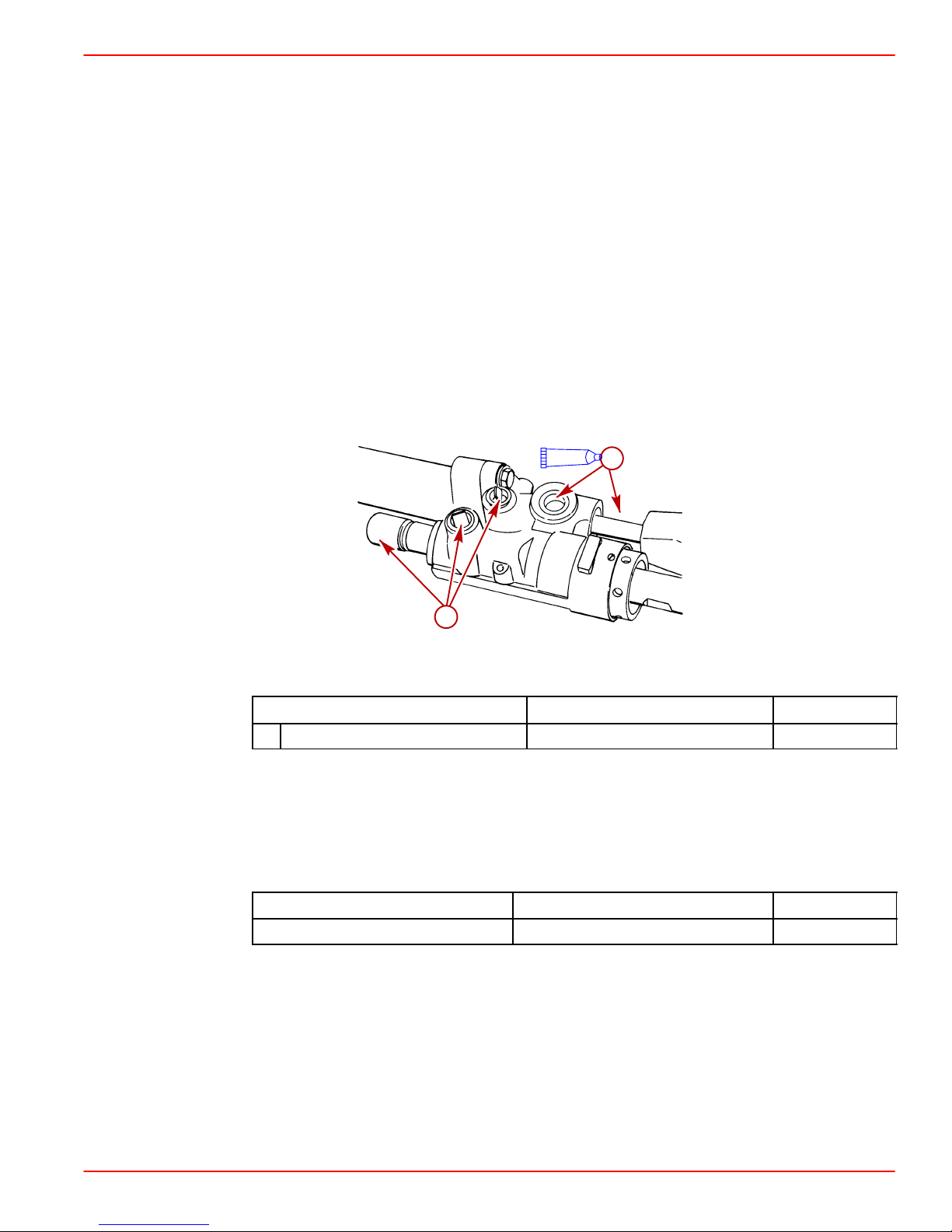

1. Inspect the bushings for debris. Lubricate the bushings.

GASOLINE STERNDRIVE INSTALLATION MANUAL

a

A

b

73898

a-Bushings

b-Shipping Hardware

Description

Where Used Part Number

A Special Lubricant 101 Bushings 92-13872A1

2. Remove shipping hardware.

3. Remove the cotter pins.

4. Loosen the upper and lower pivot bolts and ensure that the threads are well lubricated..

Add lubricant as necessary.

Description Where Used Part Number

Special Lubricant 101 Pivot Bolts 92-13872A1

90-860172011 Page 25 of 137

Page 26

GASOLINE STERNDRIVE INSTALLATION MANUAL

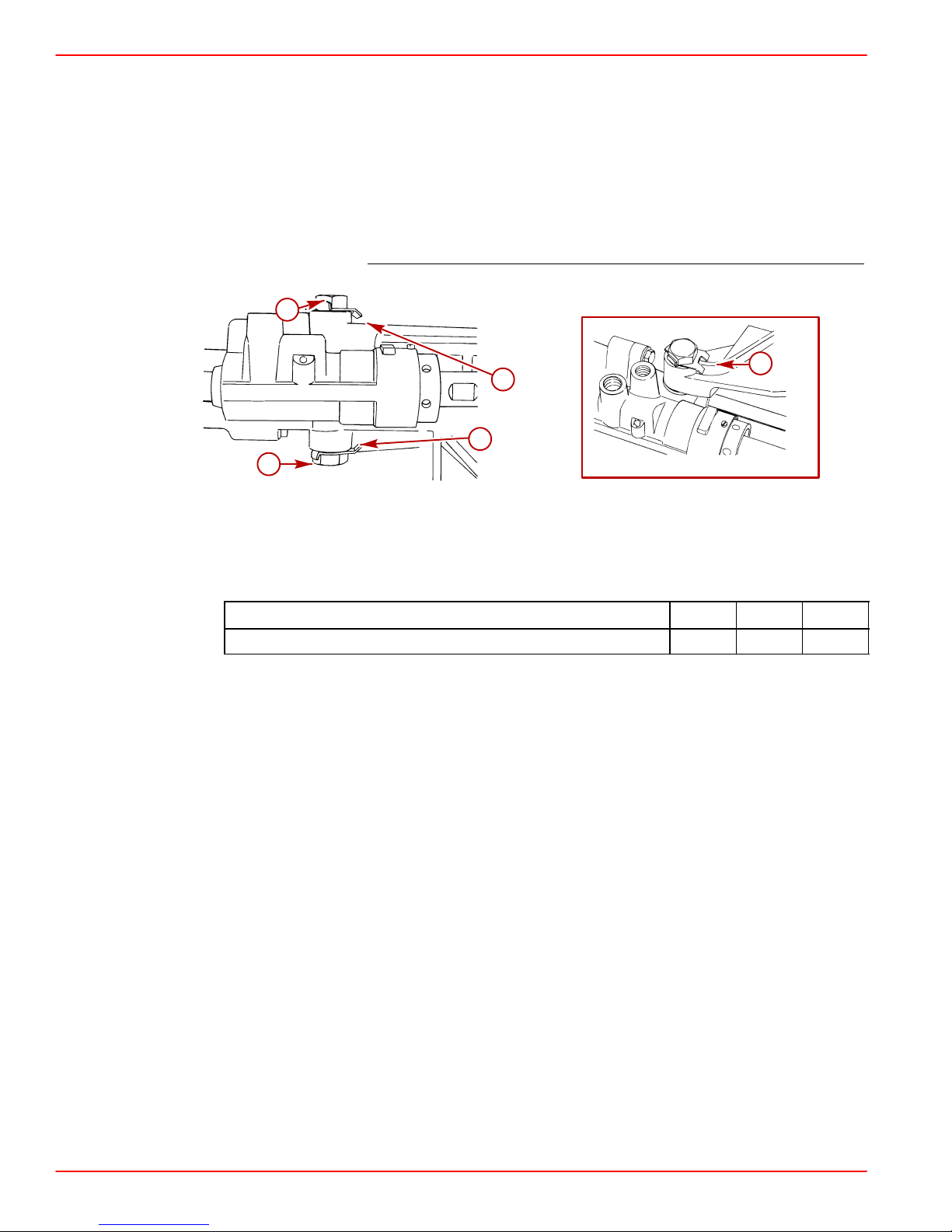

5. Install steering assembly as follows:

a. Position steering assembly so that pivot bolts will enter bushings in pivot block or

power steering control valve.

b. Install upper and lower pivot bolts along with tab washers. Ensure that tab washer

tangs straddle the ridge on inner transom plate.

c. Turn pivot bolts all the way in by hand to ensure proper alignment.

d. Ensure steering assembly pivots freely.

6. Torque pivot bolts. Bend tab washer tangs against corresponding flats on bolt heads.

c

a

b

a

c

73900

a-Tab Washers

b-Ridge

c-Pivot Bolts

Description

Pivot Bolts 34 25

NOTE: It may be necessary to tighten further to align flats on pivot bolt with tangs on tab

washer.

Nm lb-in. lb-ft

73899

Page 26 of 137 90-860172011

Page 27

GASOLINE STERNDRIVE INSTALLATION MANUAL

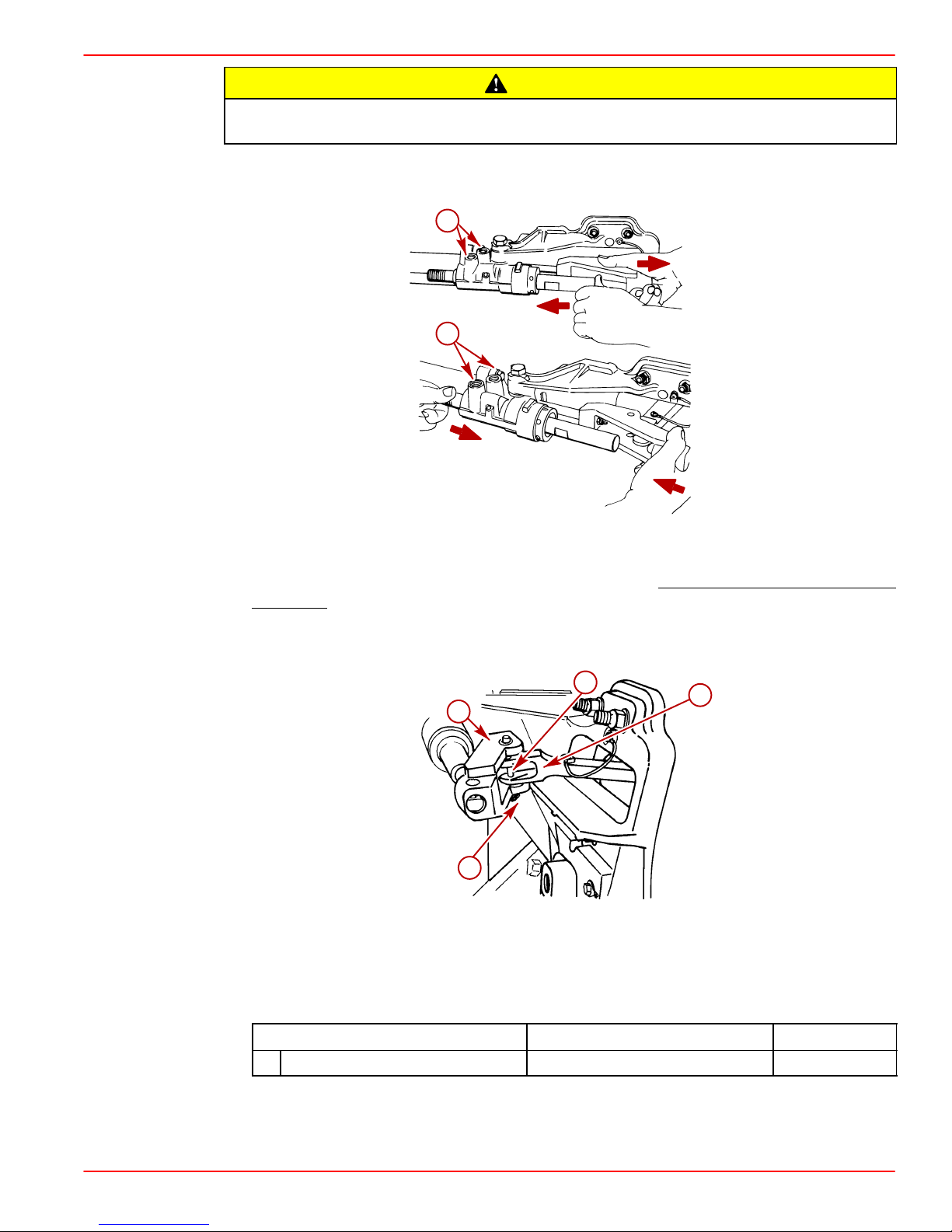

CAUTION

MOVING THE CONTROL VALVE RAM with the hoses disconnected will expel fluid

from the control valve ports. Wear eye protection.

7. The control valve ram may be stiff and difficult to move when you attempt to pull it out

or push it in for installation. Move the assembly in the directions shown below.

a

a

74145

74144

a-Control Valve Ports

8. Connect clevis to steering lever. Lubricate clevis pin. Be sure to spread both ends of

cotter pin.

NOTE: Make sure to insert clevis pin from the top to ensure that cotter pin hole is as shown

in the diagram.

c

b

a

a-Clevis

b-Steering Lever

c-Clevis Pin

d-Cotter Pin

Description

A Special Lubricant 101 Clevis Pin 92-13872A1

90-860172011 Page 27 of 137

d

71904

Where Used Part Number

Page 28

GASOLINE STERNDRIVE INSTALLATION MANUAL

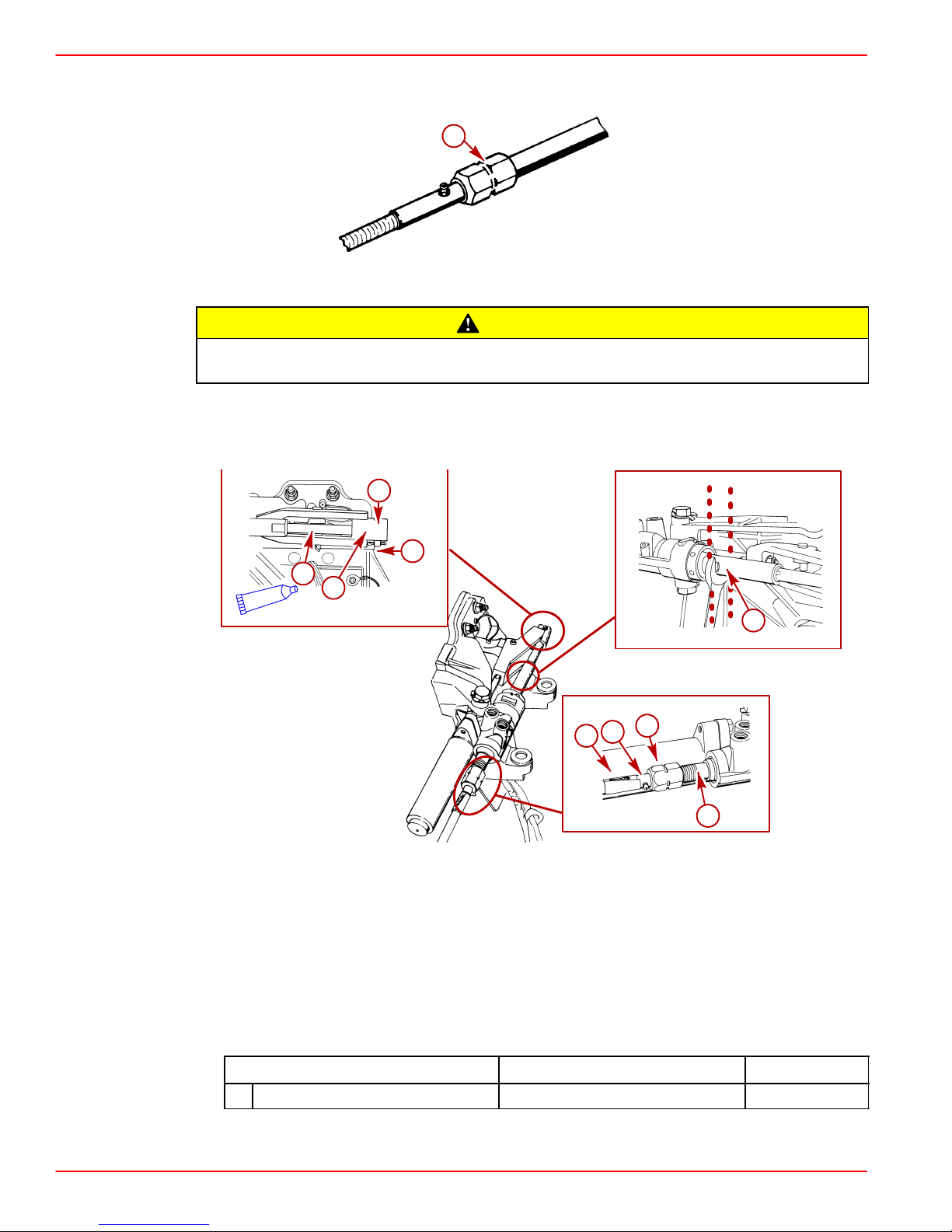

IMPORTANT: Quicksilver Ride Guide steering cable has a self-locking coupler nut

and does not require an external locking sleeve or locking plate.

a-Self-Locking Coupler Nut

Steering cable outer casing must be free to move back and forth for steering system

to function properly. Do not fasten any items to steering cable.

9. Coat steering cable end with a liberal amount of lubricant.

10. Install steering cable and secure with hardware.

a

22060

CAUTION

g

e

A

a-Steering Cable

b-Grease Fitting

c-Cable Coupler Nut

d-Cable Guide Tube

e-Steering Cable End

f-Clevis

g-Clevis Pin

h-Cotter Pin

f

h

71906

71901

d

73901

c

b

a

d

71903

Description

A Special Lubricant 101 Steering Cable End 92-13872A1

Page 28 of 137 90-860172011

Where Used Part Number

Page 29

GASOLINE STERNDRIVE INSTALLATION MANUAL

IMPORTANT: Slight feedback in the steering system could be encountered if the

cable guide tube flat surfaces are not positioned vertically.

1 1. Using a suitable wrench hold the flat surfaces on the cable guide tube in the vertical posi-

tion. Torque coupler nut. Be certain the flat surfaces are still aligned vertically after

torque is applied to coupler nut.

Description

Nm lb-in. lb-ft

Coupler Nut 47 35

CAUTION

Steering cable outer casing must be free to move back and forth for steering system

to function properly. Do not fasten any items to steering cable.

90-860172011 Page 29 of 137

Page 30

GASOLINE STERNDRIVE INSTALLATION MANUAL

MANUAL STEERING

1. Inspect bushings for debris. Lubricate bushings with Special Lubricant 101.

a

Manual Steering

a-Bushings

b-Special Lubricant 101

2. Remove shipping hardware.

3. Remove upper and lower pivot bolts and ensure threads are well lubricated with Special

Lubricant 101.

a

B

NOTICE to INSTALLER

22946

Refer to “Installation Requirements - Steering Helm and Cable” for steering cable

selection and coupler nut locking requirements.

4. Install steering assembly as follows:

a. Position steering assembly so that pivot bolts will enter bushings in pivot block or

power steering control valve.

b. Install upper and lower pivot bolts along with tab washers. Ensure that tab washer

tangs straddle the ridge on inner transom plate.

c. Turn pivot bolts all the way in by hand to ensure proper alignment.

d. Ensure steering assembly pivots freely.

5. Torque pivot bolts to 25 lb-ft (34 Nm). Bend washer tabs against corresponding flats on

bolt heads.

bc

a

Manual Steering

a-Tab Washers

b-Ridge

c-Pivot Bolts

NOTE: It may be necessary to tighten further to align flats on pivot bolt with tabs on tab

washer.

Page 30 of 137 90-860172011

22033

Page 31

GASOLINE STERNDRIVE INSTALLATION MANUAL

CAUTION

MOVING THE CONTROL VALVE RAM with the hoses disconnected will expel fluid

from the ports. Wear eye protection.

6. The cylinder ram may be stiff and difficult to move when you attempt to pull it out or push

it in for installation. First move the spool assembly in the direction(s) shown below.

a

a

74145

74144

a-Control Valve Ports

IMPORTANT: Newer style Quicksilver Ride Guide steering cable has a self-locking

coupler nut and does not require an external locking sleeve or locking plate.

a

a-Self-Locking Coupler Nut

90-860172011 Page 31 of 137

22060

Page 32

GASOLINE STERNDRIVE INSTALLATION MANUAL

Steering cable outer casing must be free to move back and forth for steering system

to function properly. Do not fasten any items to steering cable.

7. Connect steering cable as follows:

a. Remove shipping cap from both ends of steering cable guide tube or control valve

spool.

b. Coat steering cable end with a liberal amount of Special Lubricant 101.

c. Install steering cable and secure with hardware as shown on following pages.

Refer to “Installation Requirements - Steering Helm and Cable” for steering cable

selection and coupler nut locking requirements.

IMPORTANT: Slight feedback in the steering system could be encountered if the

cable guide tube flat surfaces are not positioned vertically.

CAUTION

NOTICE to INSTALLER

c

a

e

b

d

a-Steering Cable

b-Grease Fitting

c-Cotter Pin

d-Locking Sleeve (If Required - Must Be Ordered Separately)

e-Cable Coupler Nut

f-Cable Guide Tube

g-Steering Cable End

h-Cotter Pin

i-Clevis Pin

j-Steering Lever

f

50627

g

h

i

j

70018

50926

Page 32 of 137 90-860172011

Page 33

STEERING HELM AND CABLE

Transom assembly is shipped with the steering cable guide tube preset for cables with end

dimensions that comply with ABYC standards as outlined in the NMMA certification

handbook. The steering cable coupler nut must also have a means of locking it to the guide

tube, as specified in ABYC requirements.

Failure to use a steering cable locking device could cause loss of steering, which

could cause damage to the boat and/or injury.

NOTE: All current production Quicksilver RideGuide steering cables have a self-locking

coupler nut and do not require an external locking device. (Other cable manufacturers also

make cables with self-locking coupler nut.)

GASOLINE STERNDRIVE INSTALLATION MANUAL

WARNING

a

22060

a-Quicksilver RideGuide Steering Cable Self-Locking Coupler Nut (Identified By

Groove)

IMPORTANT: If using a steering cable that does not have a self-locking coupler nut,

an external locking device such as a locking sleeve must be used.

a

b

Example Of External Locking Device

a-Steering Cable

b-Locking Sleeve

CAUTION

If steering cable with improper dimensions is installed, severe damage to transom

assembly and/or steering system may result.

1. Steering cable must be the correct length, particularly when installed in larger boats.

2. Avoid sharp bends, kinks or loops in cable.

3. Fully extended steering cable end dimension must be as shown.

STEERING CABLE SPECIFICATIONS

IMPORTANT: Power steering pump lugging (squealing) in a hard right turn (against

lock) may mean a steering cable has been installed that does not have the correct

dimensions.

90-860172011 Page 33 of 137

Page 34

GASOLINE STERNDRIVE INSTALLATION MANUAL

a

c

b

e

f

k

j

l

a-Coupler Nut - 7/8 - 14 UNF - 28 Thread

b-11-3/4 in. (298 mm) Minimum

c-Interface Point

d-1/2 in. (12.7 mm) Maximum

e-27/64 in. (10.7 mm) Minimum Flat

f-7/64 in. (3.1 mm) Minimum Radius

g-5/8 in. (15.9 mm) Maximum Diameter End Fitting

h-3/8 in. (9.5 mm)

i-3/8 in. (9.8 mm) Diameter Through Hole (Chamfered Each Side)

j-1-3/8 in. (34.9 mm) Max

k-5/8 in. (15.9 mm) Diameter Tube

l-Cable Travel: Mid-Travel Position - 16-7/8 in. (429 mm)

Total Travel To Be 8 in. (203 mm) Minimum to 9 in. (228 mm) Maximum

Travel Each Side of Mid-Travel Position - 4 in. (102 mm) Minimum to

4-1/2 in. (114 mm) Maximum

d

g

C

L

h

i

21435

Page 34 of 137 90-860172011

Page 35

Transom Preparation

IMPORTANT: Exhaust pipe and gimbal housing mating surfaces must be clean and

free of nicks and scratches and O-ring must be properly seated in groove or water

and exhaust may leak into boat.

a-Gimbal Housing Mating Surface

b-O-ring

GASOLINE STERNDRIVE INSTALLATION MANUAL

a

b

22059

1. Ensure mating surfaces are clean and o-ring is properly seated.

2. Loosen hose clamps and remove exhaust pipe and bellows from engine.

c

c

b

b

a

3.0L Model V6 and V8 Models

a-Exhaust Pipe

b-Bellows

c-Clamps

d-Shipping Plug

75819

d

d

c

b

a

74768

90-860172011 Page 35 of 137

Page 36

GASOLINE STERNDRIVE INSTALLATION MANUAL

3. Through the Prop Exhaust Models: Install exhaust pipe assembly as shown, using

four bolts and lockwashers. Torque bolts.

b

a

50684

a-Exhaust Pipe

b-Bolts And Lockwashers (4)

Description

Bolts 31 23

4. Through the Transom Exhaust Models: Install block-off plate as shown, using four

bolts and lockwashers. Torque bolts.

Nm lb-in. lb-ft

a-Bolts And Lockwashers (4)

b-Block-Off Plate

Description

Bolts 31 23

NOTE: Through the Transom exhaust fittings can be installed at this time.

Page 36 of 137 90-860172011

a

b

22057

Nm lb-in. lb-ft

Page 37

GASOLINE STERNDRIVE INSTALLATION MANUAL

5. Position rear engine mount attaching hardware on inner transom plate mounts as

shown.

a

a

b

50634

22054

3.0L Models

a-Exhaust Pipe

b-Bolts and Lockwashers (4)

b

c

a-Fiber Washers

b-Double-Wound Lockwashers

c-Locknuts

a

50628

90-860172011 Page 37 of 137

Page 38

GASOLINE STERNDRIVE INSTALLATION MANUAL

BRAVO MODELS

IMPORTANT: When installing through the transom exhaust

, it is recommended that

the exhaust bellows on the transom assembly be removed. This is necessary to avoid

creating a vacuum at the exhaust outlet in the propeller at higher boat speeds. This

vacuum could degrade propeller performance on some boats.

1. If required, remove and discard clamps and bellows from gimbal housing.

IMPORTANT: When installing through the propeller exhaust

:

• With Bravo One and Bravo Two Sterndrives an exhaust tube MAY BE INSTALLED

for a slight increase in performance.

• With most Bravo Three Sterndrive Models an exhaust tube MAY BE INSTALLED

for a slight increase in performance.

• With a Silent Choice Exhaust System the exhaust bellows must be removed and

an exhaust tube MUST BE INSTALLED.

• With any application, installation of an exhaust tube will increase exhaust noise.

NOTE: Exhaust tube parts are provided with a Bravo Three Sterndrive. They are located

in the sterndrive unit box.

2. If required, install exhaust tube on gimbal housing as follows:

a. Remove and discard clamps and exhaust bellows.

CAUTION

Exhaust tube clamp may corrode if grounding clip is not installed.

b. Install grounding clip on tube.

NOTE: Bellows adhesive is not used when installing an exhaust tube.

c. Position tube so that “SIDE” markings on tube are facing toward the right and left

sides.

d. Install and torque the clamp.

e

d

c

b

a

a-Exhaust Tube

b-Clamp

c-SIDE Marking

d-Exhaust Tube

e-Grounding Clip

22184

Description

Clamp 4 35

Page 38 of 137 90-860172011

Nm lb-in. lb-ft

Page 39

Driveshaft Extension Models

If your power package is equipped with a driveshaft extension, refer to the Driveshaft

Extension Installation Instructions included with your engine package.

Engine Preparation

1. Remove and read all tags attached to engine.

2. Remove the plug from the engine coupler.

3. Remove all hardware that secures engine to shipping container.

4. Connect battery cables to engine. Be sure to observe the following:

a. Make sure that grounding stud and starter solenoid terminal are free of paint or any

other material that could cause a poor electrical connection.

b. After battery cables are connected, apply a thin coat of sealant to the terminals.

GASOLINE STERNDRIVE INSTALLATION MANUAL

Description

A Liquid Neoprene Battery Terminals 92-25711-2

c. Be sure to slide rubber boot over positive (+) terminal after making connection.

5. Drape battery cables over top of engine to prevent interference during installation.

IMPORTANT: There is a fuse located at the starter solenoid. DO NOT remove this fuse.

The positive battery cable must be connected to the same stud as the fuse.

Where Used Part Number

a

b

c

d

a-Positive (+) Battery Cable

b-Starter Solenoid

c-90 Amp Fuse - DO

d-Rubber Boot Location

NOT Remove

74907

6. Remove shipping plug from coupler and lubricate splines.

Description

A Engine Coupler Spline Grease Coupler Splines 92-816391A4

7. Install quick oil drain hose plug in oil drain hose.

8. Install the fuel inlet fitting.

90-860172011 Page 39 of 137

Where Used Part Number

Page 40

GASOLINE STERNDRIVE INSTALLATION MANUAL

Engine Installation

NOTE: An engine mount drilling fixture (91-806794A1) can be used to align and adjust

engine mounts. Refer to instructions with fixture for proper use.

1. Remove the engine cover.

2. Attach a suitable sling to lifting eyes on engine and adjust so that engine is level when

suspended.

Center lifting eye on top of thermostat housing is used for engine alignment only.

Do not use to lift entire engine.

CAUTION

a

CAUTION

!

3.0L Models

a-Center Lifting Eye

b-Engine Lifting Eyes

50636

b

b

50626

50632

b

a

b

!

CAUTION

V6 and V8 Models

a-Center Lifting Eye

b-Engine Lifting Eyes

3. Loosen the engine mount adjustment nut.

4. Lift engine into position in boat using an overhead hoist.

Page 40 of 137 90-860172011

74498

74760

74754

Page 41

GASOLINE STERNDRIVE INSTALLATION MANUAL

5. Line up the intermediate elbows with the exhaust tubes.

6. Spray lubricant into the exhaust tubes to assist with intermediate elbow installation into

exhaust tubes.

b

b

a

c

50635

3.0L Models Typical V6 And V8 Models

a-Bullhorn

b-Intermediate Elbow

c-Exhaust Tube

Description

Where Used Part Number

A Power Tune Exhaust Tubes 92-802878-57

7. If equipped with quick drain oil:

a. Push end of oil drain hose out of boat hull through flange.

b. Pull oil drain hose out until it is 6 in. (152 mm) from the propeller.

50682

c

A

c. Move alignment clip on the oil drain hose and squeeze to position it on the hose just

inside of the boat hull against the flange.

d. Connect bilge drain plug to oil drain hose plug using clip.

b

d

c

a

78002

a-Oil Drain Hose

b-Alignment Clip

c-Clip

d-Bilge Drain Plug

90-860172011 Page 41 of 137

Page 42

GASOLINE STERNDRIVE INSTALLATION MANUAL

e. Push oil drain hose through flange into boat hull.

f. Install bilge drain plug in hull.

8. Align rear engine mounts with inner transom plate mounts while simultaneously aligning

exhaust tube with intermediate elbows.

9. Install both rear engine mounting bolts and hardware and torque. Do not relieve hoist

tension.

c

d

e

a

g

f

b

a-Rear Engine Mount

b-Inner Transom Plate Mount

c-Bolt

d-Washer

e-Spacer

f-Fiber Washer

g-Double-Wound Lockwasher

Description Nm lb-in. lb-ft

Rear Engine Mounting Bolts 51 38

72535

IMPORTANT: If quick drain oil fitting is within 1/2 in. (6 mm) of boat bottom, remove

fitting and install drain plug from parts bag directly into oil pan.

10. Ensure quick drain oil fitting is more than 1/2 in. (6 mm) above the boat bottom.

Page 42 of 137 90-860172011

Page 43

Exhaust System

It is the responsibility of the boat manufacturer or installing dealer to properly locate the engine and install the exhaust system. Improper installation may allow water to enter the exhaust manifolds and combustion chambers and severely damage

the engine. Damaged caused by the water in the engine will not be covered by Mercury MerCruiser Warranty, unless this damage is the result of defective parts.

MEASURING PROCEDURE

1. Fill all fuel, water, gray water and heater tanks to maximum capacity.

NOTE: Weight can be added in these locations to simulate full loaded condition.

2. Add maximum allowable cargo weight to boat in areas where it will be stowed, including

refrigerator and lockers.

3. Add 190 lb (86 kg) of weight in all locations where each passenger will sit during normal

operation.

4. Measure exhaust elbow height. Also, measure exhaust system slope on applications

with through the hull or through the transom exhaust.

GASOLINE STERNDRIVE INSTALLATION MANUAL

CAUTION

a

b

Using A Universal Protractor (Inclinometer) To Measure Slope

a-Protractor

b-Exhaust Hose Or Tube

77981

90-860172011 Page 43 of 137

Page 44

GASOLINE STERNDRIVE INSTALLATION MANUAL

5. On applications with through the propeller exhaust: Proceed to Step 7.

6. On applications with through the hull or through the transom exhaust:

a. Move load weight to bow to simulate greatest bow-down attitude the boat will

encounter in normal operation.

b. Recheck exhaust system slope.

7. Move load weight and cargo weight to stern of boat to stimulate greatest stern-down

attitude the boat will encounter such as when loading.

IMPORTANT: Be sure to consider swim platform loading and personal watercraft.

8. Recheck exhaust system measurements.

Minimum Exhaust Elbow Height from Top of Elbow to Waterline

Model Measurement

All V6 and V8 13 in. (330 mm)

a

b

13 [330]

c

d

a-Top Of Transom

b-Highest Point On Exhaust Elbow

c-Measurement

d-Waterline

Additional requirements for through the hull or transom exhaust system applications:

Minimum Continuous Downward Slope (Exhaust Hoses, Collector, Etc.)

Model Measurement (degrees)

All Sterndrive 6

70082

77956

Page 44 of 137 90-860172011

Page 45

GASOLINE STERNDRIVE INSTALLATION MANUAL

9. If measurements are less than specified, exhaust elbow risers must be installed to

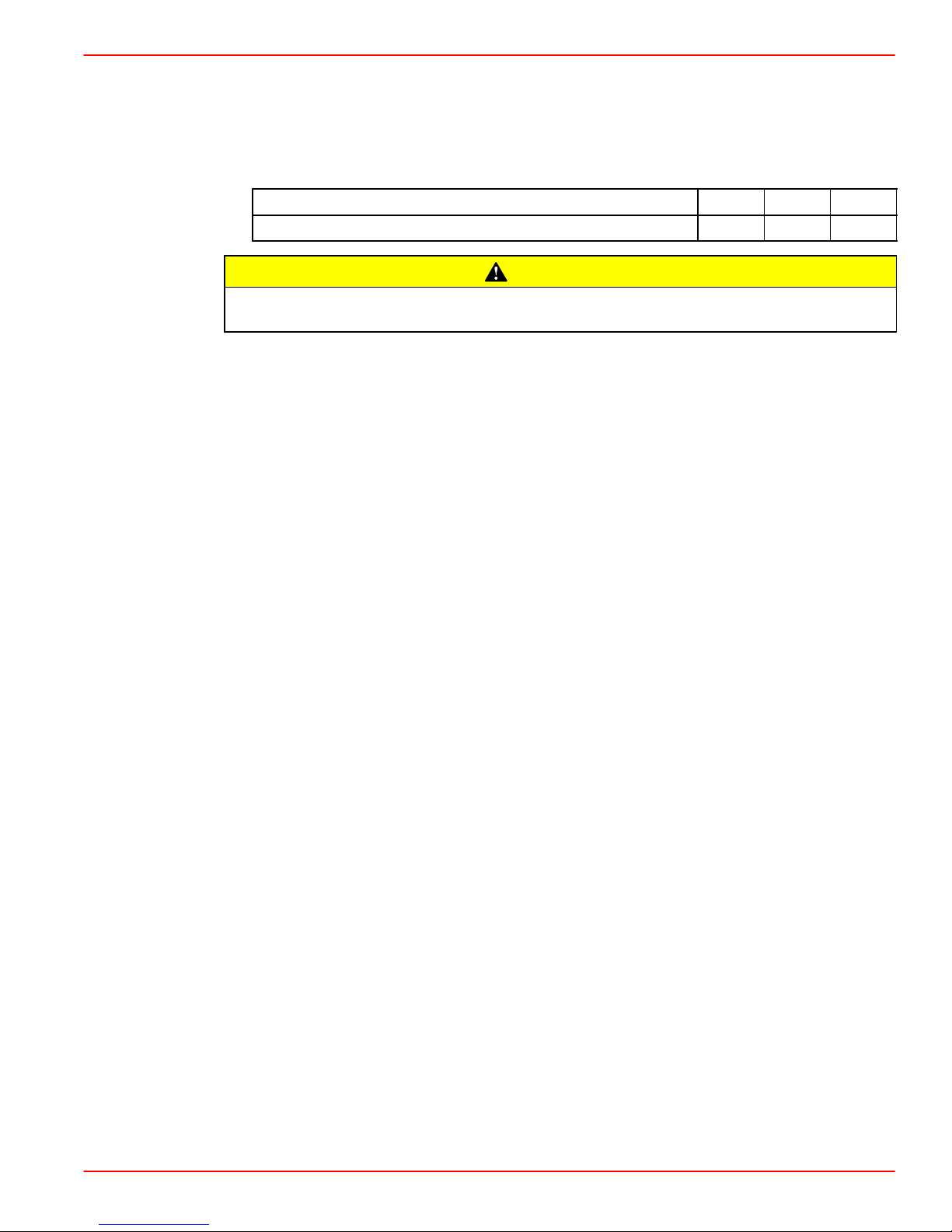

achieve proper dimension.

a

b

c

d

e

77991

Typical Riser Installation

a-Exhaust Elbow

b-Restrictor Gasket

c-Riser

d-Open Gasket (4 Slots)

e-Exhaust Manifold

NOTE: Up to a maximum of 9 in. (229 mm) of riser height can be added.

90-860172011 Page 45 of 137

Page 46

GASOLINE STERNDRIVE INSTALLATION MANUAL

Methods for Measuring Exhaust Elbow Height

STRAIGHT EDGE METHOD

1. Place a straight edge across boat.

2. With the straight edge above the engine as shown, measure the distance between the

straight edge and the top of the exhaust elbow.

3. Make sure that the boat is level from side-to-side, using a level or inclinometer. Then,

measure the distance between the straight edge and the outside waterline.

4. The dif ference between these two measurements is the exhaust elbow height above the

water line. Refer to Measuring Procedures and compare measurement to

specifications.

c

b

d

a

a-Waterline

b-Top Of Exhaust Elbow

c-Straight Edge

d-Measurement Between Straight Edge And Top Of Exhaust Elbow

e-Measurement Between Straight Edge And Water Line

e

76859

72700

Page 46 of 137 90-860172011

Page 47

CLEAR HOSE METHOD

1. Obtain a 5/16 - 3/8 in. (8-10 mm) long hose approximately 15 ft. (4.5 m) long. Put a metal

fitting or a weight on one end of the hose to keep that end of the hose below the water

line.

2. Put the weighted end of the hose over the port or starboard side of the boat, keeping

it in line with the engine’s exhaust elbow.

3. Route the remainder of the hose toward the engine’s exhaust manifold and elbow.

Ensure that this open end section of the hose is as vertical as possible from the boat’s

bilge to the top of the exhaust elbow

4. Coil excess hose in bilge of boat, keeping it below the water line.

5. Lower open end of hose and siphon water until it starts to come out of the hose. Put a

finger over the hose and lift open end until it is at the top of the exhaust elbow.

6. Slowly take finger off end of hose to let the water level stabilize. The water will seek the

level of the water outside the boat. Keep hose close to exhaust elbow and as vertical

as possible.

7. Make sure that the boat is level (side-to-side) using a level or inclinometer.

8. The measurement between water in hose and top of exhaust elbow is the exhaust elbow

height.

GASOLINE STERNDRIVE INSTALLATION MANUAL

b

a

a

a-Waterline

b-Top Of Exhaust Elbow

c-Clear Plastic Hose

d-Weight

e-Measurement - Waterline To Top Of Exhaust Elbow

c

e

76859

d

72700

90-860172011 Page 47 of 137

Page 48

GASOLINE STERNDRIVE INSTALLATION MANUAL

Exhaust System Hose / Tube Connections

Avoid exhaust hose failure. Discharge water from exhaust elbow must flow around

entire inside diameter of hose to avoid causing hot spots which could eventually

result in burned-through exhaust hoses. Exhaust hoses and/or tubes must be correctly connected to exhaust elbows so that they do not restrict the flow of discharge

water from exhaust elbow.

Correct Connection Incorrect Connection

IMPORTANT: Exhaust hoses/tubes should be secured at each connection with at

least 2 hose clamps.

1. Tighten all exhaust hose and/or exhaust tube clamps securely.

CAUTION

71653

a-Hose Clamps

a

73961

Page 48 of 137 90-860172011

Page 49

Engine Alignment

1. Ensure that the dust cover is removed or folded back out of the way.

GASOLINE STERNDRIVE INSTALLATION MANUAL

a

22027

a-Dust Cover

CAUTION

DO NOT use an alignment tool from another manufacturer. Alignment tools other

than Quicksilver Alignment Tool may cause improper alignment and damage to

gimbal bearing and/or engine coupler.

2. Attempt to insert the solid end of the alignment tool through the gimbal bearing and into

the engine coupler splines.

3. If the tool does not fit, remove it and carefully raise or lower the front end of the engine

using the center alignment eye and attempt to insert the alignment tool.

90-860172011 Page 49 of 137

Page 50

GASOLINE STERNDRIVE INSTALLATION MANUAL

4. Repeat step 3. until the alignment tool installs easily (SLIDES FREELY WITH TWO

FINGERS) all the way into and out of engine coupler splines. Do not check by turning

the alignment tool.

a-Alignment Tool (Use Only Recommended Alignment Tool)

b-Insert This End Of Alignment Tool Through Gimbal Housing Assembly

b

a

22029

a-Alignment Tool

b-Gimbal Bearing

c-Engine Coupler

c

b

a

27647

Page 50 of 137 90-860172011

Page 51

GASOLINE STERNDRIVE INSTALLATION MANUAL

IMPORT ANT: Finished boat stringer must position engine so that a minimum mount

adjustment exists after front mount is adjusted down to stringer. This allows for

future adjustments.

5. 3.0L Center Mount Model:

a. Set the engine on the stringer.

b. Relieve the hoist tension.

c. Attach the hoist to the center alignment eye.

d. Fasten front mount to the stringer.

e. Recheck alignment.

f. Tighten locknut and jam nut securely.

c

a

b

3.0L Center Mount Model

a-Front Mount

b-Attaching Bolts and Flat Washers

c-Adjusting Nut

d-Locknut

e-Jam Nut

e

d

b

22054

90-860172011 Page 51 of 137

Page 52

GASOLINE STERNDRIVE INSTALLATION MANUAL

IMPORTANT: Turn both front engine mount adjustment nuts an equal amount in

direction required to align engine.

6. All Other Models:

a. Adjust front engine mounts until they rest on boat stringers.

b. Relieve hoist tension entirely and fasten both front mounts to boat stringer using ap-

propriate hardware.

c. Tighten the bottom nut to hold the engine in place. Then release the tension.

b

c

d

a

a

3.0L Side Mount Model

a-Engine Mount

b-Bolt

c-Lockwasher

d-Tab Washer

V6 and V8 Models

a-Engine Mount

b-Bottom Nut - Not Visible

c-Tab

77968

77970

a

b

c

77913

Page 52 of 137 90-860172011

Page 53

7. Recheck alignment with alignment tool. Tool must enter coupling splines freely. If not,

readjust front mounts.

8. When alignment is correct, tighten locknut securely. Recheck alignment.

9. Bend tab down on adjusting nut.

10. Remove alignment tool. If not installing drive, fold bell housing dust cover flap back into

place and tape shut for boat shipment. Dust cover flap will have to be removed before

operating engine.

11. Hook up the ground stud.

12. Connect the trim pump sender wires.

13. Install the water inlet hose onto the transom.

Hot Water Heater Installation

IMPORTANT: When connecting a cabin heater or hot water heater:

• Supply hose (from engine to heater) and return hose (from heater to engine)

MUST NOT EXCEED 5/8 in. (16 mm) inside diameter (ID).

• Make heater connections ONLY at locations shown.

• Refer to manufacturers’ instructions for complete installation information and

procedures.

GASOLINE STERNDRIVE INSTALLATION MANUAL

• Do not reposition engine temperature switch.

Avoid a performance loss and/or possible engine damage. Engine coolant must

flow continuously from the engine intake manifold to the engine water circulating

pump. NEVER close-off or block the coolant flow to or from a heater.

Avoid engine overheating which could result in engine damage. On models

equipped with Closed Cooling, an air pocket may form in the closed cooling system

if some coolant is lost from the system and the cabin heater or hot water is mounted

higher than the fill cap on the heat exchanger. Heater must be mounted lower

the fill cap of the heat exchanger on models so equipped.

SUPPLY HOSE CONNECTION

CAUTION

CAUTION

than

3.0L

a-Location For Hot Water Supply (Install Bayonet Fitting Here)

90-860172011 Page 53 of 137

a

76095

Page 54

GASOLINE STERNDRIVE INSTALLATION MANUAL

a

75473

Seawater Cooling - If Location Is Available

a-Location For Hot Water Supply

a

Seawater Cooling - Alternate Location

a-Location For Hot Water Supply

a

74973

71758

b

a

b

74639

Closed Cooling Models - If Location Is Available

a-Location for Hot Water Supply (Bayonet Fitting Replaces Brass Plug)

b-Thermostat Housing

a

Page 54 of 137 90-860172011

Page 55

RETURN HOSE CONNECTION

Typical 3.0L

a-Location For Hot Water Return (T-Fitting Installed in Water Circulating Pump

Hose)

GASOLINE STERNDRIVE INSTALLATION MANUAL

a

73572

a

Seawater or Closed Cooling System

a-Location For Hot Water Return

Electrical Connections

IMPORTANT: When routing all wire harnesses and hoses, be sure they are routed and

secured to avoid coming in contact with hot spots on engine and to avoid contact

with moving parts.

Installing Continuity Wire

1. Connect continuity circuit wire from engine to transom assembly.

IMPORT ANT: Do not attach any accessory ground (–) wires to transom plate ground

point. Accessory ground wires can only be attached to ground stud on engine.

75480

a-Continuity Wire

90-860172011 Page 55 of 137

a

71651

Page 56

GASOLINE STERNDRIVE INSTALLATION MANUAL

Instrumentation Connections

We recommend the use of Quicksilver Instrumentation and Wiring Harnesses. On dual station applications, oil pressure and water temperature senders (on engine) must be changed.

Refer to Mercury Precision Parts / Quicksilver Accessories Guide for selection.

The 4 basic gauges that must be used with the engine are:

• Tachometer

• Oil Pressure

• Water Temperature

• Voltmeter

IMPORT ANT: Connect fused accessory panel (40-amp current draw maximum) must

be connected as shown in the wiring diagrams.

1. Route instrumentation wiring harness back to engine, making sure that harness does

not rub or get pinched. If an extension harness is required, be sure to secure connection

properly.

2. Fasten harnesses to boat at least every 18 in. (460 mm), using appropriate fasteners.

3. Place hose clamp over instrumentation wiring harness.

4. Connect the instrumentation wiring harness to engine harness plug at location shown.

a

Typical

a-Wiring Harness Connector

5. Tighten hose clamp to secure wiring harness to engine harness plug.

74754

Page 56 of 137 90-860172011

Page 57

Trim Position Sender Connections

1. Connect trim position sender wires (from transom assembly) to engine harness.

GASOLINE STERNDRIVE INSTALLATION MANUAL

a

b

a

ORG/WHT

BLK

a-Engine Harness Bullet Connector

b-Transom Assembly Bullet Connector

MerCathode Connections (If Equipped)

1. Connect wires to MerCathode controller assembly as shown. Apply a thin coat of Liquid

Neoprene to all connections.

IMPORTANT: Opposite end of RED/PURPLE wire must be connected directly to

battery positive (+) terminal. DO NOT connect it to a switched positive (+) circuit.

MerCathode system must function continuously for proper corrosion protection.

BLK

BLK

b

74029

a-ORANGE Lead - From Electrode On Transom Assembly

b-RED/PURPLE Wire - To Positive (+) Battery Terminal

c-BLACK Wire - From Engine Harness

d-BROWN Wire - From Electrode On Transom Assembly

Description Where Used Part Number

A Liquid Neoprene MerCathode Connections 92-25711-2

90-860172011 Page 57 of 137

a

c

b

d

22232

Page 58

GASOLINE STERNDRIVE INSTALLATION MANUAL

Audio Warning System Connections

Alarm is not external ignition-proof, therefore, DO NOT mount alarm in engine or

fuel tank compartments.

1. Select a location for audio warning alarm which meets all of the following:

• alarm can be easily heard, yet is out of sight

• alarm can be easily accessed for installation and maintenance

• alarm will remain dry

• alarm is within length limits of the 18 in. purple alarm wire that connects to the “I” terminal

or 12 volt source on switched side of ignition switch.

NOTE: The terminal to which wire is attached must have no voltage when ignition switch

is in the OFF position.

2. Place alarm in desired location and secure to wire bundle with tie-strap provided.

3. Connect PURPLE wire from alarm to any PURPLE wire terminal on instrument gauge

or ignition switch. Tighten connection securely.

4. Connect TAN/BLUE wire from alarm to TAN/ BLUE wire from instrument harness.

WARNING

5. Place the small (transparent) decals on the bottom of the water temperature and the oil

pressure gauges.

6. Place the large decal on the instrument panel or other appropriate location in easily

viewed by the operator.

ALARM INDICATES LOW

OIL OR OVERHEATING

a

APPLY THE PROPER DECAL TO THE DASHBOARD

OR OTHER APPROPRIATE LOCATION:

AUDIO WARNING HORN WILL SOUND WHEN:

1. ENGINE OIL PRESSURE IS TOO LOW

2. ENGINE TEMP. IS TOO HIGH, OR

3. DRIVE OIL LEVEL IS TOO LOW

TO TEST AUDIO WARNING HORN:

TURN KEY TO “ON” POSITION (ENGINE OFF)

b

75430

a-Small Decal (Transparent)

b-Larger Decal

7. Test audio warning system during Predelivery Preparation section.

Page 58 of 137 90-860172011

Page 59

Power Trim Pump Connections

IMPORT ANT: Make hydraulic connections as quickly as possible to prevent oil from

leaking out of system. Be careful not to cross-thread or overtighten hose fittings.

1. Connect hydraulic hoses to trim pump. Torque fittings.

GASOLINE STERNDRIVE INSTALLATION MANUAL

Description

Nm lb-in. lb-ft

Fittings 14 125

2. Connect power trim pump control harness to trim pump.

3. Connect trim limit switch wires and secure with wire retainer and tie-strap.

d

c

75126

75127

b

f

g

a

50630

e

a-Black Hose Fitting (UP Circuit)

b-Gray Hose Fitting (DOWN Circuit)

c-Control Harness

d-Tie-Strap

e-Trim Limit Switch Wire (With Blue Sleeve) To BLUE/WHITE Harness Wire

f-Trim Limit Switch Wire (With Purple Sleeve) To PURPLE/WHITE Harness Wire

g-Wire Retainer And Tie Strap

50632

90-860172011 Page 59 of 137

Page 60

GASOLINE STERNDRIVE INSTALLATION MANUAL

4. Unscrew fill cap and remove cap plug from fill neck and discard. Install fill cap.

a-Caplug

b-Fill Cap

5. Connect power trim pump wires to battery.

a

a

b

50630

b

a-Positive Battery Lead

b-Negative Battery Lead

76631

Page 60 of 137 90-860172011

Page 61

Fluid Connections

Gear Lube Monitor Hose

IMPORT ANT: A void using excessive hose when routing it to gear lube monitor. Hose

should be routed directly to oil reservoir in as straight a line as possible to avoid low

spots (traps) in the system.

Ensure hose is not kinked when connecting in the following step. If hose is kinked,

gear lube monitor will not function properly and damage to drive unit could occur.

1. Route hose to gear lube monitor and cut off excess hose. Hose can be routed on outside

of remote oil filter or the hole in the front lifting eye bracket.

2. Connect hose and secure with hose clamp.