Page 1

Number 28

Printed in U.S.A. 90-863160 MA Y 2000

2000, Mercury Marine

BRAVO STERNDRIVES

SERVICE

MANUAL

Page 2

90- i

MerCruiser #28 Bravo Sterndrives

90-863160

MerCruiser #28 Bravo Sterndrives

90-863160

Page 3

90-863160 MAY 2000 Page i

Notice

Throughout this publication, “Dangers,” “Warnings” and “Cautions” (accompanied by the International HAZARD Symbol

) are used to alert the mechanic to special instructions concerning a particular service or operation that may be hazardous if performed incorrectly or

carelessly. OBSERVE THEM CAREFULLY!

These “Safety Alerts” alone cannot eliminate the hazards that they signal. Strict compliance

to these special instructions when performing the service, plus “Common Sense” operation,

are major accident prevention measures.

DANGER

DANGER - Immediate hazards which WILL result in severe personal injury or death.

WARNING

WARNING - Hazards or unsafe practices which COULD result in severe personal i n jury or death.

CAUTION

Hazards or unsafe practices which could result in minor personal injury or product

or property damage.

Notice to Users of This Manual

This service manual has been written and published by the Service Department of Mercury

Marine to aid our dealers’ mechanics and company service personnel when servicing the

products described herein.

It is assumed that these personnel are familiar with the servicing procedures of these products, or like or similar products manufactured and marketed by Mercury Marine, that they

have been trained in the recommended servicing procedures of these products which includes the use of mechanics’ common hand tools and the special Mercury Marine or recommended tools from other suppliers.

We could not possibly know of and advise the service trade of all conceivable procedures

by which a service might be performed and of the possible hazards and/or results of each

method. We have not undertaken any such wide evaluation. Therefore, anyone who uses

a service procedure and/or tool, which is not recommended by the manufacturer, first must

completely satisf y h i m s e l f t h a t n e i t h e r h i s n o r t h e p r o d u c t s s a f e t y w i l l b e e ndangered by the

service procedure selected.

All information, illustrations and specifications contained in this manual are based on the

latest product information available at the time of publication. As required, revisions to this

manual will be sent to all dealers contracted by us to sell and/or service these products.

It should be kept in mind, while working on the product, that the electrical system and ignition

system are capable of violent and damaging short circuits or severe electrical shocks. When

performing any work where electrical terminals could possibly be grounded or touched by

the mechanic, the battery cables should be disconnected at the battery.

Any time the intake or exhaust openings are exposed during service they should be covered

to protect against accidental entrance of foreign material which could enter the cylinders and

cause extensive internal damage when the engine is started.

Page 4

Page ii 90-863160 MAY 2000

It is important to note, during any maintenance procedure replacement fasteners must have

the same measurements and strength as those removed. Numbers on the heads of the metric bolts and on the surfaces of metric nuts indicate their strength. American bolts use radial

lines for this purpose, while most American nuts do not have strength markings. Mismatched or incorrect fasteners can result in damage or malfunction, or possibly personal

injury. Therefore, fasteners removed should be saved for reuse in the same locations whenever possible. Where the fasteners are not satisfactory for re-use, care should be taken to

select a replacement that matches the original.

We reserve the right to make changes to this manual without prior notification.

Refer to dealer service bulletins for other pertinent information concerning the products

described in this manual.

Engine Mechanical Components

Many of the engine mechanical components are designed for marine applications. Unlike

automotive engines, marine engines are subjected to extended periods of heavy load

and wide-open-throttle operation and, therefore, require heavy-duty components. Special

marine engine parts have design and manufacturing specifications which are required to

provide long life and dependable performance. Marine engine parts also must be able to

resist the corrosive action of salt or brackish water that will rust or corrode standard automotive parts within a short period of time.

Failure to use recommended Quicksilver service replacement parts can result in poor engine performance and/or durability, rapid corrosion of parts subjected to salt water and

possibly complete failure of the engine.

Use of parts other than recommended service replacement parts, will void the warranty on

those parts which are damaged as a result of the use of other than recommended replacement parts.

Replacement Parts

WARNING

Electrical, ignition and fuel system components on MerCruiser Engines and Sterndrives are designed and manufactured to comply with U.S. Coast Guard Rules

and Regulations to minimize risks of fire or explosion.

Use of replacement electrical, ignition or fuel system components, which do not

comply to th e s e rules and regulations, could result in a fire or explosion hazard and

should be avoided.

When servicing the electrical, ignition and fuel systems, it is extremely important

that all components are properly installed and tightened. If not, any electrical or ignition component opening would permit sparks to ignite fuel vapors from fuel system leaks, if they existed.

Page 5

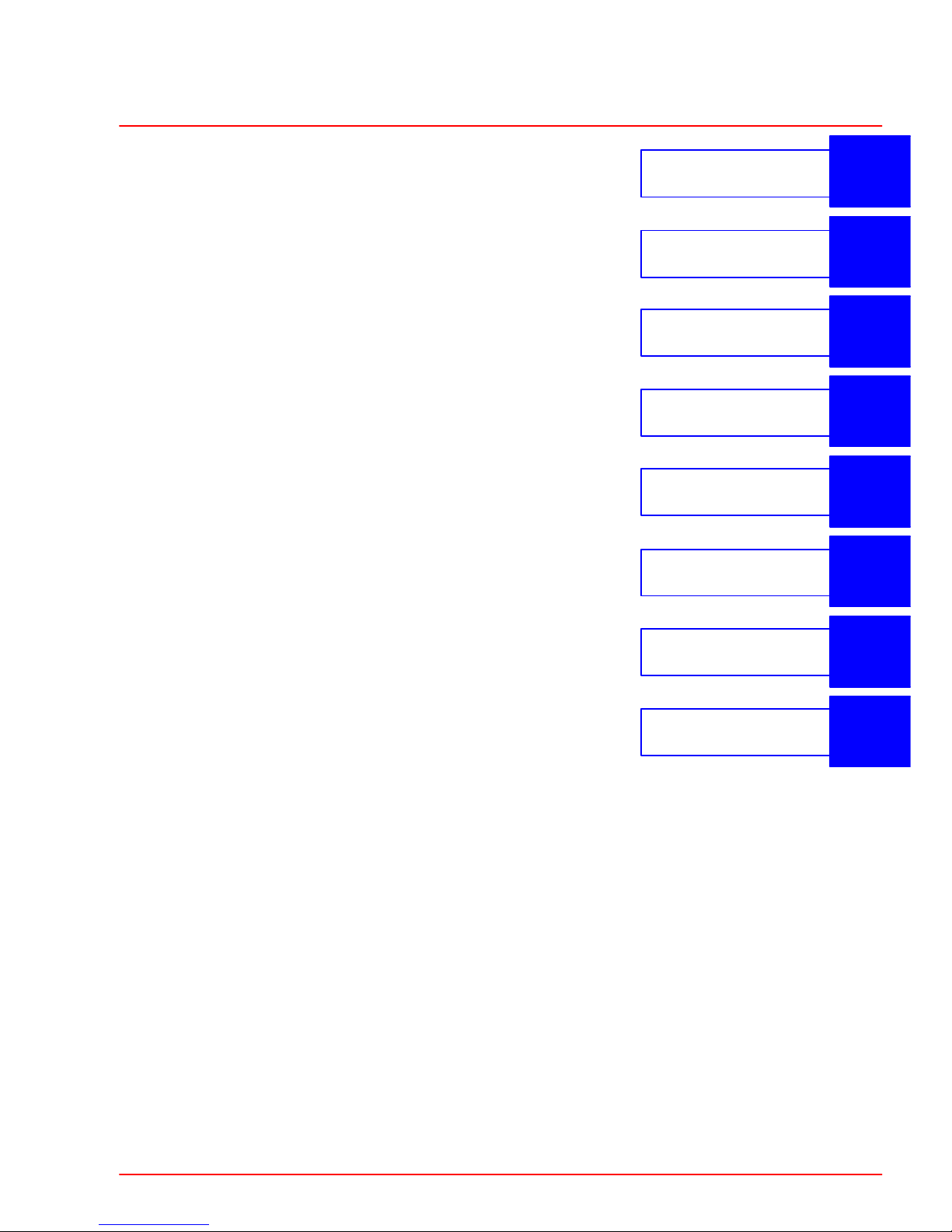

1

2

3

4

5

6

7

8

Important Information

Removal, Installation and

Adjustment

Sterndrive Unit

Transom Assembly

Power Trim

Steering Systems

Corrosion Protection

Drives

90-863160 MAY 2000 Page iii

Service Manual Outline

Section 1 - Important Information

A - General Information

B - Maintenance

C - Troubleshooting

Section 2 - Removal, Installation and Adjustment

A - All Models

Section 3 - Sterndrive Unit

A - Drive Shaft Housing

B - Gear Housing - Bravo One

C - Gear Housing - Bravo Two

D - Gear Housing - Bravo Three

Section 4 - Transom Assembly

A - Service Procedures Requiring Minor Disassembly

B - Service Procedures Requiring Major Disassembly

Section 5 - Power Trim

A - Oildyne Power Trim Pump

B - Trim Cylinders

C - Dual Power Trim Control

D - Auto Trim II

Section 6 - Steering Systems

A - Power Steering

B - Compact Hydraulic Steering

Section 7 - Corrosion Protection

A - All Models

Section 8 - Drives

A - All Models

Page 6

Page iv 90-863160 MAY 2000

Table of Contents

IMPORTANT INFORMATION

Section 1A - General Information

How To Use This Manual 1A-2. . . . . . . . . . . . . . .

Page Numbering 1A-2. . . . . . . . . . . . . . . . . . .

How to Read a Parts Manual 1A-3. . . . . . . . . . .

Introduction 1A-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Directional References 1A-4. . . . . . . . . . . . . . . . .

Propeller Rotation 1A-4. . . . . . . . . . . . . . . . . . . . .

Sterndrive Unit 10-Hour Break-In Period

(New or With Replacement Gears) 1A-5. . . . . .

Serial Number Locations and Engine

Designation Decal 1A-5. . . . . . . . . . . . . . . . . . . .

Section 1B - Maintenance

Lubricants / Sealants / Adhesives 1B-2. . . . . . .

Maintenance Schedules 1B-3. . . . . . . . . . . . . . . .

Maintenance Intervals 1B-3. . . . . . . . . . . . . . .

Gas Sterndrive 1B-3. . . . . . . . . . . . . . . . . . . . . . . .

Routine Maintenance * 1B-3. . . . . . . . . . . . . .

Gas Sterndrive(Continued) 1B-4. . . . . . . . . . . . .

Scheduled Maintenance * 1B-4. . . . . . . . . . . .

Specifications 1B-5. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specification 1B-5. . . . . . . . . . . . . . . . . . .

Fluid Capacities 1B-5. . . . . . . . . . . . . . . . . . . . . . .

Lubrication 1B-5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Cable Pivot Points 1B-5. . . . . . . . . . . . . .

Propeller Shaft 1B-6. . . . . . . . . . . . . . . . . . . . .

Steering System 1B-6. . . . . . . . . . . . . . . . . . . .

Tie Bar Pivot Points 1B-7. . . . . . . . . . . . . . . . .

Transom Gimbal Housing Assembly Swivel

Shaft and Gimbal Bearing 1B-7. . . . . . . . . . . .

Checking and Adding Sterndrive Oil 1B-8. . . . .

Inspection 1B-9. . . . . . . . . . . . . . . . . . . . . . . . .

Changing Sterndrive Oil 1B-10. . . . . . . . . . . . . . .

General Maintenance 1B-12. . . . . . . . . . . . . . . . .

Maintaining Power Package Exterior Sur-

faces 1B-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Head and Remote Control Mainte-

nance 1B-12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Quicksilver MerCathode System . .

1B-12

Maintaining Anodic Plate 1B-12. . . . . . . . . . .

Boat Bottom Care 1B-12. . . . . . . . . . . . . . . . .

Anti-fouling Paint 1B-12. . . . . . . . . . . . . . . . . .

Maintaining Ground Circuit Continuity 1B-13

Power Package Layup 1B-13. . . . . . . . . . . . . . . .

Engine 1B-13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sterndrive 1B-13. . . . . . . . . . . . . . . . . . . . . . . .

Power Package Recommissioning 1B-14. . . . . .

Engine 1B-14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sterndrive 1B-14. . . . . . . . . . . . . . . . . . . . . . . .

Section 1C - Troubleshooting

Table of Contents 1C-1. . . . . . . . . . . . . . . . . . . . .

Troubleshooting 1C-2. . . . . . . . . . . . . . . . . . . . . . .

Sterndrive Unit Troubleshooting 1C-2. . . . . . . . .

Sterndrive Unit Will Not Slide Into

Bell Housing 1C-2. . . . . . . . . . . . . . . . . . . . . . .

Drive Unit Does Not Shift Into Gear;

Remote Control Shift Handle Moves 1C-2. .

Drive Unit Does Not Shift Into Gear;

Remote Control Shift Handle Does

Not Move 1C-3. . . . . . . . . . . . . . . . . . . . . . . . .

Drive Unit Shifts Hard 1C-3. . . . . . . . . . . . . . .

Drive Unit In Gear, Will Not Shift

Out Of Gear 1C-3. . . . . . . . . . . . . . . . . . . . . . .

Gear Housing Noise 1C-4. . . . . . . . . . . . . . . .

Drive Shaft Housing Noise 1C-4. . . . . . . . . . .

Drive Shaft Housing Noise

(Continued) 1C-5. . . . . . . . . . . . . . . . . . . . . . .

Drive Shaft Housing Noise

(Continued) 1C-6. . . . . . . . . . . . . . . . . . . . . . .

Power Shift 1C-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

System Does Not React 1C-7. . . . . . . . . . . . .

System Binds 1C-7. . . . . . . . . . . . . . . . . . . . . .

Performance Troubleshooting 1C-8. . . . . . . . . . .

Low WOT Engine RPM 1C-8. . . . . . . . . . . . . .

High WOT Engine RPM 1C-8. . . . . . . . . . . . .

Propeller Ventilating/Cavitating 1C-8. . . . . . .

Poor Boat Performance And/Or Poor

Maneuverability-Bow Too Low 1C-9. . . . . . .

Poor Boat Performance And/Or Poor

Maneuverability-Bow Too High 1C-9. . . . . . .

Power Steering 1C-10. . . . . . . . . . . . . . . . . . . . . .

Hard Steering - Helm And Cable 1C-10. . . . .

Hard Steering (Engine Running)

- Power Steering System 1C-10. . . . . . . . . . .

Power Steering System External

Fluid Leaks 1C-10. . . . . . . . . . . . . . . . . . . . . . .

Compact Hydraulic Steering 1C-11. . . . . . . . . . .

Important Information 1C-11. . . . . . . . . . . . . .

Helm Becomes Jammed During Filling 1C-11

System Difficult To Fill 1C-11. . . . . . . . . . . . . .

Steering Hard To Turn 1C-11. . . . . . . . . . . . . .

Helm Unit Bumpy

- Requires Too Many Turns 1C-11. . . . . . . . .

Power Trim Electrical System 1C-12. . . . . . . . . .

Power Trim System Wiring Diagram 1C-16. . . .

Power Trim Hydraulic System 1C-17. . . . . . . . . .

Power Trim Hydraulic Schematic 1C-21. . . . . . .

Auto Trim II Electrical System 1C-22. . . . . . . . . .

Auto Trim II System Wiring Diagram 1C-28. . . .

Corrosion Protection 1C-29. . . . . . . . . . . . . . . . . .

Page 7

90-863160 MAY 2000 Page v

REMOVAL, INSTALLATION AND ADJUSTMENT

Section 2A - All Models

Torque Specifications 2A-2. . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 2A-2. . . . . . .

Tools 2A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transom Specifications 2A-3. . . . . . . . . . . . . . . .

Checking Transom Thickness 2A-3. . . . . . . .

Special Information 2A-4. . . . . . . . . . . . . . . . . . . .

Bravo Three Notice:

Trim-In Limit Insert 2A-4. . . . . . . . . . . . . . . . .

Sterndrive Unit Removal 2A-6. . . . . . . . . . . . . . .

Transom Assembly Removal 2A-8. . . . . . . . . . . .

Transom Assembly Installation 2A-12. . . . . . . . .

Sterndrive Unit Installation 2A-22. . . . . . . . . . . . .

Shift Cable Installation

and Adjustment 2A-29. . . . . . . . . . . . . . . . . . .

Troubleshooting Shift Problems 2A-33. . . . . .

STERNDRIVE UNIT

Section 3A - Drive Shaft Housing

Specifications 3A-2. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 3A-2. . . . . . . . . . . . . . .

Tools 3A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearing Preloads 3A-3. . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 3A-3. . . . .

Drive Shaft Housing Exploded View 3A-4. . . . . .

Complete Housing 3A-4. . . . . . . . . . . . . . . . . .

Exploded Parts View (Clutch) 3A-6. . . . . . . . . . .

Exploded Parts View (Shifter) 3A-7. . . . . . . . . . .

Standard Bravo U-joint Assembly 3A-8. . . . .

Bravo X, XZ, XR and Diesel

Bravo U–joint Assembly 3A-9. . . . . . . . . . . . .

Drive Shaft Housing and Gear

Case Separation 3A-10. . . . . . . . . . . . . . . . . . . . .

Drive Unit Gear Ratio Identification 3A-10. . .

Bravo One 3A-10. . . . . . . . . . . . . . . . . . . . . . . .

Bravo Two 3A-10. . . . . . . . . . . . . . . . . . . . . . . .

Bravo Three 3A-11. . . . . . . . . . . . . . . . . . . . . .

Bravo XZ 3A-11. . . . . . . . . . . . . . . . . . . . . . . . .

Bravo XR 3A-12. . . . . . . . . . . . . . . . . . . . . . . . .

Diesel Bravo One X 3A-12. . . . . . . . . . . . . . . .

Diesel Bravo Two X 3A-12. . . . . . . . . . . . . . . .

Diesel Bravo Three X 3A-13. . . . . . . . . . . . . .

Separate Housings 3A-14. . . . . . . . . . . . . . . .

Drive Shaft Housing Disassembly 3A-17. . . . . .

Shifter Repair 3A-22. . . . . . . . . . . . . . . . . . . . . . . .

Shifter Inspection 3A-25. . . . . . . . . . . . . . . . . . . . .

Shifter Reassembly 3A-26. . . . . . . . . . . . . . . . . . .

U-Joint and Pinion Gear 3A-30. . . . . . . . . . . . . . .

Inspection 3A-30. . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 3A-30. . . . . . . . . . . . . . . . . . . . . .

Reassembly 3A-34. . . . . . . . . . . . . . . . . . . . . .

Gear Disassembly,

Inspection and Reassembly 3A-42. . . . . . . . . . .

Disassembly 3A-42. . . . . . . . . . . . . . . . . . . . . .

Inspection 3A-44. . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 3A-44. . . . . . . . . . . . . . . . . . . . . .

Drive Shaft Housing and Top Cover -

Bearings and Bearing Sleeves 3A-47. . . . . . . . .

Inspection 3A-47. . . . . . . . . . . . . . . . . . . . . . . .

Bearing Sleeve Removal (Top Cover) 3A-47

Bearing Sleeve Removal

(Drive Shaft Housing) 3A-48. . . . . . . . . . . . . .

Roller Bearing Removal 3A-49. . . . . . . . . . . .

Steel Bearing Adaptor Removal 3A-51. . . . .

Steel Bearing Adaptor Installation 3A-52. . . .

Bearing Sleeve Installation 3A-53. . . . . . . . . .

Roller Bearing Installation 3A-54. . . . . . . . . . .

Drive Shaft Housing Reassembly 3A-55. . . . . . .

Install Gear Housing To Drive

Shaft Housing 3A-66. . . . . . . . . . . . . . . . . . . . .

Page 8

Page vi 90-863160 MAY 2000

Section 3B - Gear Housing - Bravo One

Specifications 3B-2. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 3B-2. . . . . . . . . . . . . . .

Bearing Preloads 3B-2. . . . . . . . . . . . . . . . . . .

Gear Ratio - Teeth Per Gear

(Gear Housing) 3B-2. . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 3B-2. . . . . . .

Tools 3B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bravo One Gear Housing Exploded View 3B-4.

Drive Shaft Components 3B-4. . . . . . . . . . . . .

Bravo One and Diesel Bravo One X

Propeller Shaft Components 3B-6. . . . . . . . .

Bravo XZ and Bravo XR Propeller

Shaft Components 3B-8. . . . . . . . . . . . . . . . .

Pre-Disassembly Inspection 3B-10. . . . . . . . . . .

Drive Shaft Housing and Gear Housing

Separation 3B-11. . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Housing Disassembly 3B-13. . . . . . . . . . . .

Drive Shaft And Pinion Bearing 3B-19. . . . . . . .

Inspection and Cleaning 3B-19. . . . . . . . . . . .

Drive Shaft Disassembly 3B-19. . . . . . . . . . . .

Pinion Bearing Removal 3B-20. . . . . . . . . . . .

Pinion Bearing Installation 3B-21. . . . . . . . . .

Drive Shaft Reassembly 3B-22. . . . . . . . . . . .

Bearing Carrier Inspection 3B-23. . . . . . . . . .

Bearing Carrier Disassembly 3B-23. . . . . . . .

Bearing Carrier Reassembly 3B-24. . . . . . . .

Propeller Shaft 3B-25. . . . . . . . . . . . . . . . . . . . . . .

Inspection 3B-25. . . . . . . . . . . . . . . . . . . . . . . .

Propeller Shaft Bearing Removal 3B-25. . . .

Propeller Shaft Bearing Installation 3B-26. . .

Driven Gear Bearing 3B-26. . . . . . . . . . . . . . . . . .

Inspection 3B-26. . . . . . . . . . . . . . . . . . . . . . . .

Driven Gear Bearing Removal 3B-27. . . . . . .

Driven Gear Bearing Installation 3B-27. . . . .

Driven Gear Bearing Cup

Removal and Inspection 3B-28. . . . . . . . . . .

Driven Gear Bearing Cup Installation 3B-28.

Speedometer Water Passage 3B-29. . . . . . . . . .

Pickup Inspection and Cleaning 3B-29. . . . .

Water Passage Seal Replacement 3B-30. . .

Gear Housing Reassembly And

Shimming 3B-31. . . . . . . . . . . . . . . . . . . . . . . . . . .

Bravo XZ and XR Heavy Duty

Propeller Shaft 3B-45. . . . . . . . . . . . . . . . . . . . . .

Gear Housing

Disassembly/Reassembly 3B-45. . . . . . . . . .

Installing Bearing Carrier 3B-45. . . . . . . . . . .

Installing Propeller Hub Assembly 3B-47. . . .

Section 3C - Gear Housing - Bravo Two

Specifications 3C-2. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 3C-2. . . . . . . . . . . . . . .

Bearing Preloads 3C-2. . . . . . . . . . . . . . . . . . .

Gear Ratio - Teeth per Gear

(Gear Housing) 3C-2. . . . . . . . . . . . . . . . . . . .

Lubricants/Sealants/Adhesives 3C-2. . . . . . . . . .

Tools 3C-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bravo Two Gear Housing Exploded View 3C-4.

Drive Shaft and Propeller

Shaft Components 3C-4. . . . . . . . . . . . . . . . .

Pre-Disassembly Inspection 3C-6. . . . . . . . . . . .

Drive Shaft Housing and Gear

Housing Separation 3C-7. . . . . . . . . . . . . . . . . . .

Gear Housing Disassembly 3C-8. . . . . . . . . . . . .

Drive Shaft and Pinion Bearing 3C-14. . . . . . . . .

Inspection and Cleaning 3C-14. . . . . . . . . . . .

Drive Shaft Disassembly 3C-15. . . . . . . . . . . .

Pinion Bearing Removal 3C-16. . . . . . . . . . . .

Pinion Bearing Installation 3C-17. . . . . . . . . .

Drive Shaft Reassembly 3C-18. . . . . . . . . . . .

Bearing Carrier 3C-19. . . . . . . . . . . . . . . . . . . . . .

Inspection 3C-19. . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 3C-20. . . . . . . . . . . . . . . . . . . . . .

Reassembly 3C-21. . . . . . . . . . . . . . . . . . . . . .

Propeller Shaft 3C-23. . . . . . . . . . . . . . . . . . . . . . .

Inspection 3C-23. . . . . . . . . . . . . . . . . . . . . . . .

Propeller Shaft Bearing Removal 3C-24. . . .

Propeller Shaft Bearing Installation 3C-24. . .

Driven Gear Bearing 3C-25. . . . . . . . . . . . . . . . . .

Inspection 3C-25. . . . . . . . . . . . . . . . . . . . . . . .

Driven Gear Bearing Removal 3C-25. . . . . . .

Driven Gear Bearing Installation 3C-26. . . . .

Driven Gear Bearing Cup Removal

and Inspection 3C-26. . . . . . . . . . . . . . . . . . . .

Driven Gear Bearing Cup Installation 3C-27.

Speedometer Water Passage 3C-27. . . . . . . . . .

Pickup Inspection and Cleaning 3C-27. . . . .

Water Passage Seal Replacement 3C-28. . .

Gear Housing Reassembly and

Shimming 3C-29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 9

90-863160 MAY 2000 Page vii

Section 3D - Gear Housing - Bravo Three

Table of Contents 3D-1. . . . . . . . . . . . . . . . . . . . .

Specifications 3D-2. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 3D-2. . . . . . . . . . . . . . .

Bearing Preloads 3D-2. . . . . . . . . . . . . . . . . . .

Gear Ratio - Teeth per Gear

(Gear Housing) 3D-2. . . . . . . . . . . . . . . . . . . .

Torque Conversion Chart For

Bearing Carrier 3D-3. . . . . . . . . . . . . . . . . . . .

Torque Conversion Chart For

Bearing Retainer Nut 3D-3. . . . . . . . . . . . . . .

Torquing Outer Prop Shaft Bearing

Retainer and Bearing Carrier 3D-4. . . . . . . .

Lubricants/Sealants/Adhesives 3D-4. . . . . . . . . .

Tools 3D-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bravo Three Gear Housing

Exploded View 3D-6. . . . . . . . . . . . . . . . . . . . . . .

Drive Shaft and Propeller Shaft

Components 3D-6. . . . . . . . . . . . . . . . . . . . . . .

Pre-Disassembly Inspection 3D-8. . . . . . . . . . . .

Gear Housing Disassembly 3D-9. . . . . . . . . . . . .

Driveshaft And Pinion Bearing 3D-16. . . . . . . . .

Inspection and Cleaning 3D-16. . . . . . . . . . . .

Drive Shaft Disassembly 3D-17. . . . . . . . . . . .

Drive Shaft Reassembly 3D-17. . . . . . . . . . . .

Pinion Bearing 3D-18. . . . . . . . . . . . . . . . . . . . . . .

Removal 3D-18. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3D-19. . . . . . . . . . . . . . . . . . . . . . . .

Propeller Shaft 3D-19. . . . . . . . . . . . . . . . . . . . . . .

Inspection 3D-19. . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 3D-20. . . . . . . . . . . . . . . . . . . . . .

Propeller Shaft Spline Lash Check 3D-21. . .

Outer Propeller Shaft Servicing 3D-23. . . . . .

Front Driven Gear And Bearing 3D-24. . . . . . . .

Inspection 3D-24. . . . . . . . . . . . . . . . . . . . . . . .

Bearing Removal 3D-24. . . . . . . . . . . . . . . . . .

Bearing Installation 3D-24. . . . . . . . . . . . . . . .

Bearing Cup Removal 3D-25. . . . . . . . . . . . . .

Bearing Cup Installation 3D-25. . . . . . . . . . . .

Bearing Carrier Seal And Bearing 3D-26. . . . . .

Inspection 3D-26. . . . . . . . . . . . . . . . . . . . . . . .

Removal 3D-26. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 3D-26. . . . . . . . . . . . . . . . . . . . . . . .

Speedometer Water Passage 3D-27. . . . . . . . . .

Inspection and Cleaning 3D-27. . . . . . . . . . . .

Seal Removal 3D-28. . . . . . . . . . . . . . . . . . . . .

Seal Installation 3D-28. . . . . . . . . . . . . . . . . . .

Gear Housing Reassembly and

Shimming 3D-29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Backlash 3D-36. . . . . . . . . . . . . . . .

Installing Gear Housing On Drive

Shaft Housing 3D-42. . . . . . . . . . . . . . . . . . . .

Propeller Installation 3D-43. . . . . . . . . . . . . . . . . .

TRANSOM ASSEMBLY

Section 4A - Service Procedures Requiring Minor Disassembly

Bravo Transom Assembly Specifications 4A-2.

Torque Specifications 4A-2. . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 4A-2. . . . .

Tools 4A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bravo Transom Assembly

Exploded Views 4A-4. . . . . . . . . . . . . . . . . . . . . .

Inner Transom Plate Components 4A-4. . . .

Bell Housing Components 4A-5. . . . . . . . . . .

Gimbal Ring Components 4A-6. . . . . . . . . . . .

Gimbal Housing Components 4A-8. . . . . . . .

Special Information 4A-10. . . . . . . . . . . . . . . . . . .

Trim Limit Switch 4A-10. . . . . . . . . . . . . . . . . .

Trim Position Sender 4A-10. . . . . . . . . . . . . . .

Removal 4A-10. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4A-12. . . . . . . . . . . . . . . . . . . . . . . .

Trim Position Sender Adjustment 4A-16. . . .

Trim Limit Switch Adjustment 4A-16. . . . . . . .

High Performance Transom

Assembly - Without Electrical

Trim Sender and Trim Limit Switch 4A-18. .

Gimbal Bearing 4A-19. . . . . . . . . . . . . . . . . . . . . .

Inspection 4A-19. . . . . . . . . . . . . . . . . . . . . . . .

Removal 4A-19. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4A-20. . . . . . . . . . . . . . . . . . . . . . . .

Shift Cable 4A-22. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 4A-22. . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Cable Installation 4A-23. . . . . . . . . . . . . .

Exhaust Bellows (If Equipped) 4A-27. . . . . . . . .

Removal 4A-27. . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Inspection 4A-27. . . . . . . . . . . .

Installation 4A-28. . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Tube (If Equipped) 4A-30. . . . . . . . . . . .

Removal 4A-30. . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Inspection 4A-30. . . . . . . . . . . .

Installation 4A-31. . . . . . . . . . . . . . . . . . . . . . . .

Water Hose and Water Fitting 4A-32. . . . . . . . . .

Removal 4A-32. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4A-33. . . . . . . . . . . . . . . . . . . . . . . .

Crimp Clamp Tool 4A-35. . . . . . . . . . . . . . . . . . . .

Page 10

Page viii 90-863160 MAY 2000

Section 4B - Service Procedures Requiring Major Disassembly

Bravo Transom Assembly Specifications 4B-2.

Torque Specifications 4B-2. . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 4B-2. . . . .

Special Tools 4B-2. . . . . . . . . . . . . . . . . . . . . . .

Bravo Transom Assembly

Exploded Views 4B-4. . . . . . . . . . . . . . . . . . . . . .

Inner Transom Plate Components 4B-4. . . .

Bell Housing Components 4B-5. . . . . . . . . . .

Gimbal Ring Components 4B-6. . . . . . . . . . . .

Gimbal Housing Components 4B-8. . . . . . . .

Bell Housing Removal 4B-10. . . . . . . . . . . . . . . .

Access Plug Kit Installation 4B-14. . . . . . . . . . . .

Gimbal Ring, Swivel Shaft and

Steering Lever Removal 4B-16. . . . . . . . . . .

Gimbal Ring Servicing 4B-20. . . . . . . . . . . . . .

Gimbal Housing Servicing 4B-26. . . . . . . . . . . . .

U-joint Bellows Replacement 4B-26. . . . . . . .

Shift Cable Bellows Replacement 4B-29. . . .

Exhaust Bellows Replacement 4B-32. . . . . .

Speedometer Hose Replacement 4B-34. . . .

Gear Lube Monitor System

Components 4B-35. . . . . . . . . . . . . . . . . . . . . .

Trim Position Sender and Trim Limit

Switch Wire Replacement 4B-38. . . . . . . . . .

Gimbal Ring / Swivel Shaft and

Steering Lever Installation 4B-39. . . . . . . . . . . .

Bell Housing Installation 4B-45. . . . . . . . . . . . . . .

Standard Transom Assembly 4B-45. . . . . . . .

High Performance Transom Assembly 4B-46

Standard And High Performance

Transom Assemblies 4B-47. . . . . . . . . . . . . .

Shift Cable Installation 4B-51. . . . . . . . . . . . . . . .

Bravo Access Plug Drilling Template 4B-55. . . .

Crimp Clamp Tool 4B-57. . . . . . . . . . . . . . . . . . . .

POWER TRIM

Section 5A - Oildyne Power Trim Pump

Trim Pump Specifications 5A-2. . . . . . . . . . . . . .

Valve Pressure Specifications 5A-2. . . . . . . .

Electrical Specification 5A-2. . . . . . . . . . . . . .

Torque Specification 5A-2. . . . . . . . . . . . . . . .

Special Tools 5A-2. . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 5A-2. . . . .

Trim Pump Exploded View 5A-3. . . . . . . . . . . . . .

Oildyne Trim Pump 5A-3. . . . . . . . . . . . . . . . .

Maintaining Power Trim Pump Oil Level 5A-4. .

Air Bleeding Power Trim System 5A-5. . . . . . . .

Bleeding OUT/UP Trim Circuit 5A-5. . . . . . . .

Bleeding IN/DOWN Trim Circuit 5A-5. . . . . .

Testing Power Trim Pump 5A-6. . . . . . . . . . . . . .

Test Gauge 5A-6. . . . . . . . . . . . . . . . . . . . . . . .

Internal Restriction Test 5A-7. . . . . . . . . . . . .

OUT/UP Pressure Test 5A-8. . . . . . . . . . . . . .

IN/DOWN Pressure Test 5A-10. . . . . . . . . . . .

Trim Pump Hydraulic System 5A-11. . . . . . . .

Trim Cylinder Internal Leak Test 5A-12. . . . . . . .

Trim Cylinder Shock Piston Test 5A-15. . . . .

Motor and Electrical Bench Tests 5A-16. . . . . . .

Trim Pump Motor Test (In Boat) 5A-16. . . . .

Trim Pump Motor Test (Out of Boat) 5A-18. .

Solenoid Test (Pump In Boat) 5A-19. . . . . . .

Solenoid Test (Pump Out of Boat) 5A-20. . . .

110 Amp Fuse Test (Pump in Boat) 5A-22. .

110 Amp Fuse Test (Pump

Out of Boat) 5A-22. . . . . . . . . . . . . . . . . . . . . .

20 Amp Fuse Test 5A-23. . . . . . . . . . . . . . . . .

Trim Pump Removal 5A-23. . . . . . . . . . . . . . . . . .

Hydraulic Repair 5A-25. . . . . . . . . . . . . . . . . . . . .

Disassembly 5A-25. . . . . . . . . . . . . . . . . . . . . .

Filter Replacement 5A-27. . . . . . . . . . . . . . . . .

UP Pressure Relief

Valve Replacement 5A-28. . . . . . . . . . . . . . . .

DOWN Pressure Relief

Valve Replacement 5A-29. . . . . . . . . . . . . . . .

Thermal Relief Valve Replacement 5A-30. . .

Pump Replacement 5A-30. . . . . . . . . . . . . . . .

Adapter Replacement 5A-31. . . . . . . . . . . . . .

Adapter Repair 5A-33. . . . . . . . . . . . . . . . . . . .

Pump Shaft Oil Seal Replacement 5A-37. . .

Motor Repair 5A-39. . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 5A-39. . . . . . . . . . . . . . . . . . . . . .

Armature Tests 5A-42. . . . . . . . . . . . . . . . . . . . . . .

Continuity Test 5A-42. . . . . . . . . . . . . . . . . . . .

Test for Shorts 5A-43. . . . . . . . . . . . . . . . . . . .

Cleaning Commutator 5A-43. . . . . . . . . . . . . .

Field Tests 5A-43. . . . . . . . . . . . . . . . . . . . . . . . . .

Test for Open Circuit 5A-43. . . . . . . . . . . . . . .

Test for Short in Field 5A-44. . . . . . . . . . . . . .

Thermal Switch Continuity Test 5A-45. . . . . .

Brush Replacement 5A-46. . . . . . . . . . . . . . . .

Reassembly 5A-49. . . . . . . . . . . . . . . . . . . . . . . . .

Trim Pump Installation 5A-55. . . . . . . . . . . . . . . .

Trim Pump Wiring Diagrams 5A-56. . . . . . . . . . .

Model With Three-Button

Trim/Trailer Panel 5A-56. . . . . . . . . . . . . . . . .

Model With Trim In Handle and

Trailer Switch Separate 5A-57. . . . . . . . . . . .

Page 11

90-863160 MAY 2000 Page ix

Section 5B - Trim Cylinders

Specifications 5B-2. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 5B-2. . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 5B-2. . . . .

Special Tools 5B-2. . . . . . . . . . . . . . . . . . . . . . . . .

Trim Cylinder Exploded Views 5B-3. . . . . . . . . . .

Bravo Trim Cylinders 5B-3. . . . . . . . . . . . . . . .

Bravo Trim System Components 5B-4. . . . . .

Power Trim Hydraulic Schematic 5B-5. . . . . . . .

Special Information 5B-6. . . . . . . . . . . . . . . . . . . .

Bravo Three Notice: Trim-In

Limit Insert 5B-6. . . . . . . . . . . . . . . . . . . . . . . .

Trim Cylinder Internal Leak Test 5B-7. . . . . . . . .

Trim Cylinder Shock Piston Test 5B-7. . . . . . . . .

Trim Cylinder Repair 5B-7. . . . . . . . . . . . . . . . . . .

Removal 5B-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 5B-9. . . . . . . . . . . . . . . . . . . . . . .

Reassembly 5B-14. . . . . . . . . . . . . . . . . . . . . .

Installation 5B-21. . . . . . . . . . . . . . . . . . . . . . . .

Section 5C - Dual Power Trim Control

Important Information 5C-2. . . . . . . . . . . . . . . . . .

Testing Dual Power Trim System 5C-2. . . . . . . .

Relay Test 5C-2. . . . . . . . . . . . . . . . . . . . . . . . .

Diode Module Test 5C-3. . . . . . . . . . . . . . . . . .

Trailer Switch Test 5C-4. . . . . . . . . . . . . . . . . .

Starboard Trim Switch Test 5C-4. . . . . . . . . .

Port Trim Switch Test 5C-4. . . . . . . . . . . . . . . .

Dual Power Trim System Component

Repair 5C-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important Information 5C-5. . . . . . . . . . . . . . .

Relay Replacement 5C-5. . . . . . . . . . . . . . . . .

Diode Module Replacement 5C-7. . . . . . . . . . . .

Removal 5C-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C-7. . . . . . . . . . . . . . . . . . . . . . . . .

Trim Control Panel Switch(es)

Replacement 5C-8. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5C-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5C-9. . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagrams 5C-10. . . . . . . . . . . . . . . . . . . . .

Dual Trim Harnesses 5C-10. . . . . . . . . . . . . . .

Electrical Box Wiring 5C-11. . . . . . . . . . . . . . .

Section 5D - Auto Trim II

Auto Trim II System 5D-2. . . . . . . . . . . . . . . . . . .

Description 5D-2. . . . . . . . . . . . . . . . . . . . . . . .

Auto Trim II Operation 5D-2. . . . . . . . . . . . . . . . .

Auto Mode Operation 5D-3. . . . . . . . . . . . . . .

“Manual” Mode Operation 5D-4. . . . . . . . . . . .

Electrical System Overload Protection 5D-6. . .

Auto Trim Limit Adjustment 5D-6. . . . . . . . . . . . .

Adjusting Sterndrive Unit Trim Angle 5D-7. .

Control Module Adjustment 5D-9. . . . . . . . . . . . .

Trim Position Indicator Adjustment 5D-10. . . . . .

Wiring Diagram 5D-11. . . . . . . . . . . . . . . . . . . . . .

STEERING SYSTEMS

Section 6A - Power Steering

Specifications 6A-2. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 6A-2. . . . . . . . . . . . . . .

Special Tools 6A-2. . . . . . . . . . . . . . . . . . . . . . .

Lubricants/Sealants/Adhesives 6A-2. . . . . . .

Description 6A-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Valve 6A-3. . . . . . . . . . . . . . . . . . . . . . .

Power Steering System 6A-4. . . . . . . . . . . . . . . .

RIGHT TURN 6A-4. . . . . . . . . . . . . . . . . . . . . . . . .

Power Steering System 6A-5. . . . . . . . . . . . . . . .

LEFT TURN 6A-5. . . . . . . . . . . . . . . . . . . . . . . . . .

Power Steering System 6A-6. . . . . . . . . . . . . . . .

NEUTRAL 6A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Helm and Cable 6A-7. . . . . . . . . . . . . . .

Steering Cable Specifications 6A-8. . . . . . . .

Filling and Air Bleeding Power

Steering System 6A-9. . . . . . . . . . . . . . . . . . . . . .

Checking Fluid Level 6A-9. . . . . . . . . . . . . . . .

Engine Cold 6A-9. . . . . . . . . . . . . . . . . . . . . . . .

Filling and Bleeding 6A-10. . . . . . . . . . . . . . . .

Power Steering Assembly 6A-11. . . . . . . . . . . . .

Removal 6A-11. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A-12. . . . . . . . . . . . . . . . . . . . . . . .

Power Steering System Pressure Test 6A-15

Pump Pressure Test 6A-17. . . . . . . . . . . . . . .

Power Steering Pump 6A-19. . . . . . . . . . . . . . . . .

Removal 6A-19. . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Control Valve Servicing 6A-20. . . . . . . .

Pump Shaft Oil Seal Replacement 6A-21. . .

Disassembly 6A-23. . . . . . . . . . . . . . . . . . . . . .

Cleaning And Inspection 6A-26. . . . . . . . . . . .

Reassembly 6A-26. . . . . . . . . . . . . . . . . . . . . .

Installation 6A-32. . . . . . . . . . . . . . . . . . . . . . . .

Multiple Sterndrive Steering

Tie Bar Arrangements 6A-33. . . . . . . . . . . . .

Determining Tie Bar Length 6A-34. . . . . . . . .

Selection 6A-35. . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A-35. . . . . . . . . . . . . . . . . . . . . . . .

Page 12

Page x 90-863160 MAY 2000

Section 6B - Compact Hydraulic Steering

Important Information About

Thru-Transom Exhaust 6B-2. . . . . . . . . . . . . . . .

Torque Specifications 6B-2. . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 6B-2. . . . . . .

Removal 6B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing The Steering Cylinder 6B-4. . . . . . . . .

Filling And Purging The System 6B-6. . . . . . . . .

Twin Station and/or Twin Cylinder 6B-6. . . . .

Single Station With Single Cylinder 6B-7. . . .

Purging 6B-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting The Clevis 6B-10. . . . . . . . . . . . . . . .

Hydraulic Fluid Level 6B-11. . . . . . . . . . . . . . . . . .

Setting Fluid Level 6B-11. . . . . . . . . . . . . . . . .

Maintaining Fluid Level 6B-11. . . . . . . . . . . . .

System Check 6B-11. . . . . . . . . . . . . . . . . . . . .

CORROSION PROTECTION

Section 7A - All Models

Specifications 7A-2. . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 7A-2. . . . . . . . . . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 7A-2. . . . .

Continuity Circuit 7A-2. . . . . . . . . . . . . . . . . . . . . .

Trim Cylinder Anodes 7A-5. . . . . . . . . . . . . . . . . .

Anodic Plate 7A-6. . . . . . . . . . . . . . . . . . . . . . . . . .

Bravo One Sterndrive Units 7A-6. . . . . . . . . .

Bravo Two Sterndrive Units 7A-8. . . . . . . . . .

Bravo Three Sterndrive Units 7A-8. . . . . . . . .

Integral MerCathode System 7A-9. . . . . . . . . . . .

Removing Electrode Assembly 7A-9. . . . . . .

Installing Electrode Assembly 7A-10. . . . . . . . . .

Connect Electrical Leads to

Controller Assembly 7A-12. . . . . . . . . . . . . . .

Wiring Diagrams 7A-13. . . . . . . . . . . . . . . . . . . . .

MerCathode Monitor 7A-13. . . . . . . . . . . . . . .

MerCathode Controller 7A-14. . . . . . . . . . . . .

Quicksilver Isolator 7A-15. . . . . . . . . . . . . . . . . . .

Corrosion Protection Testing

and Troubleshooting 7A-15. . . . . . . . . . . . . . . . .

Test Equipment Set-Up 7A-18. . . . . . . . . . . . .

Low Readings 7A-19. . . . . . . . . . . . . . . . . . . . .

Low Readings (continued) 7A-20. . . . . . . . . .

High Reading 7A-21. . . . . . . . . . . . . . . . . . . . .

Normal Reading But Corrosion

is Evident 7A-21. . . . . . . . . . . . . . . . . . . . . . . .

ACCESSORIES

Section 8A - All Models

Specifications 8A-2. . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 8A-2. . . . . . . . . . . . . . .

Lubricants / Sealants / Adhesives 8A-2. . . . .

Power Shift (P/N 38638A4) 8A-2. . . . . . . . . . . . .

Description 8A-2. . . . . . . . . . . . . . . . . . . . . . . .

General Information 8A-3. . . . . . . . . . . . . . . . .

Checking Vacuum Drop-Off 8A-5. . . . . . . . . .

Power Shift Cylinder Repair 8A-6. . . . . . . . . . . .

Removal 8A-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 8A-6. . . . . . . . . . . . . . . . . . . . . . .

Reassembly 8A-9. . . . . . . . . . . . . . . . . . . . . . .

Shift Cable Replacement and Adjustment 8A-14

Installation Preparation 8A-14. . . . . . . . . . . . .

Shift Cable Barrel Adjustment 8A-14. . . . . . .

Installing Input Cable 8A-15. . . . . . . . . . . . . . .

Installing Output Cable 8A-16. . . . . . . . . . . . .

Attach Dust Cover 8A-16. . . . . . . . . . . . . . . . .

Mounting Power Shift Cylinder 8A-17. . . . . . .

Connecting Vacuum Hose to Engine 8A-17.

Page 13

1

A

GENERAL INFORMATION

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1A-1

IMPORTANT INFORMATION

Section 1A - General Information

Table of Contents

How To Use This Manual 1A-2. . . . . . . . . . . . . . .

Page Numbering 1A-2. . . . . . . . . . . . . . . . . . .

How to Read a Parts Manual 1A-3. . . . . . . . . . .

Introduction 1A-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Directional References 1A-4. . . . . . . . . . . . . . . . .

Propeller Rotation 1A-4. . . . . . . . . . . . . . . . . . . . .

Sterndrive Unit 10-Hour Break-In Period

(New or With Replacement Gears) 1A-5. . . . . .

Serial Number Locations and Engine

Designation Decal 1A-5. . . . . . . . . . . . . . . . . . . .

Page 14

IMPORTANT INFORMATION SERVICE MANUAL NUMBER 28

Page 1A-2 90-863160 MAY 2000

How To Use This Manual

This manual is divided into sections that represent major components and systems. Some

sections are further divided into parts that more fully describe the component. Sections and

parts are listed at front of this manual.

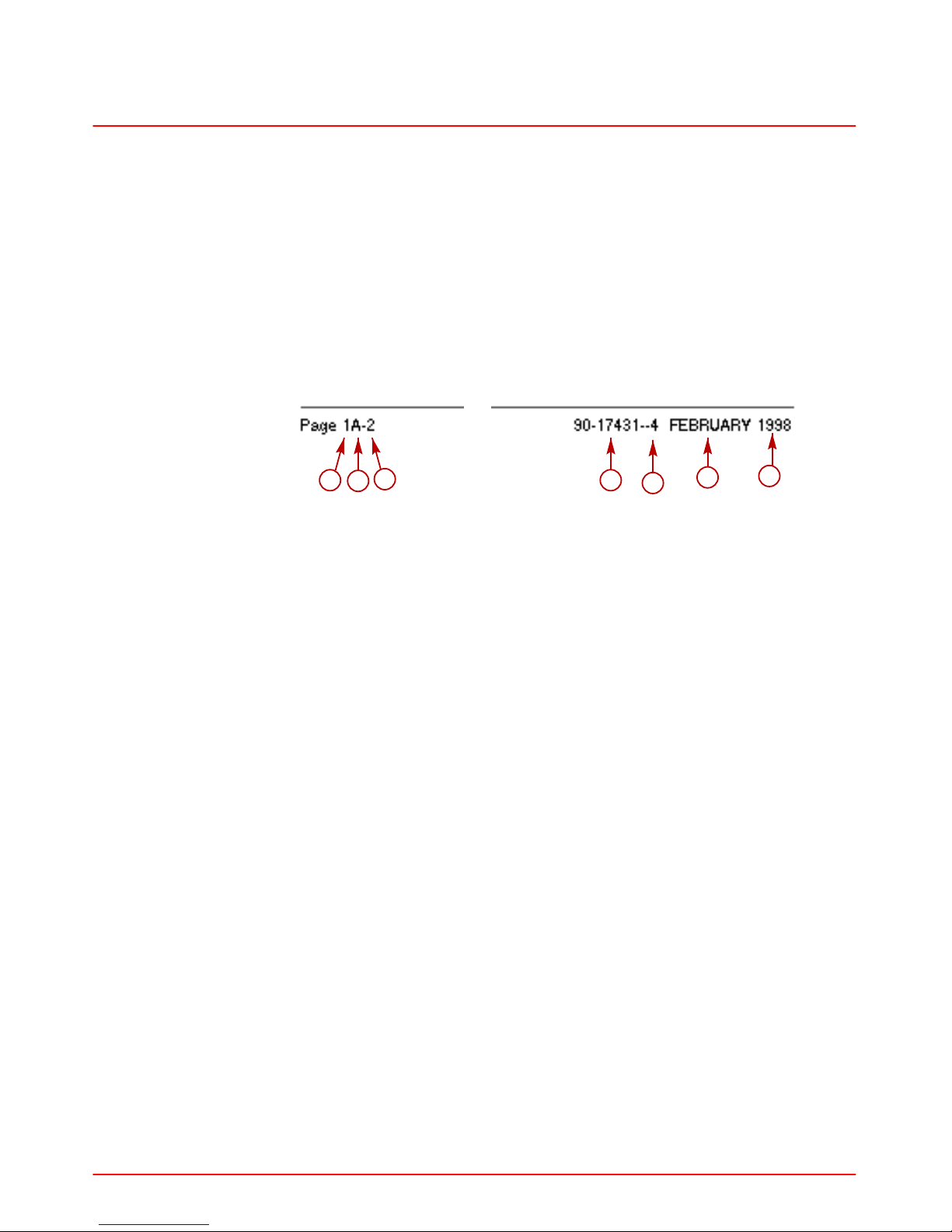

Page Numbering

Two number groups appear at the bottom of each page. Following is an example and

description.

a

b

c

d

e

f

g

a-Section Number

b-Section Part

c-Page Number

d-Manual Part Number

e-Revision Number

f-Month Printed

g-Year Printed

Page 15

GENERAL INFORMATION

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1A-3

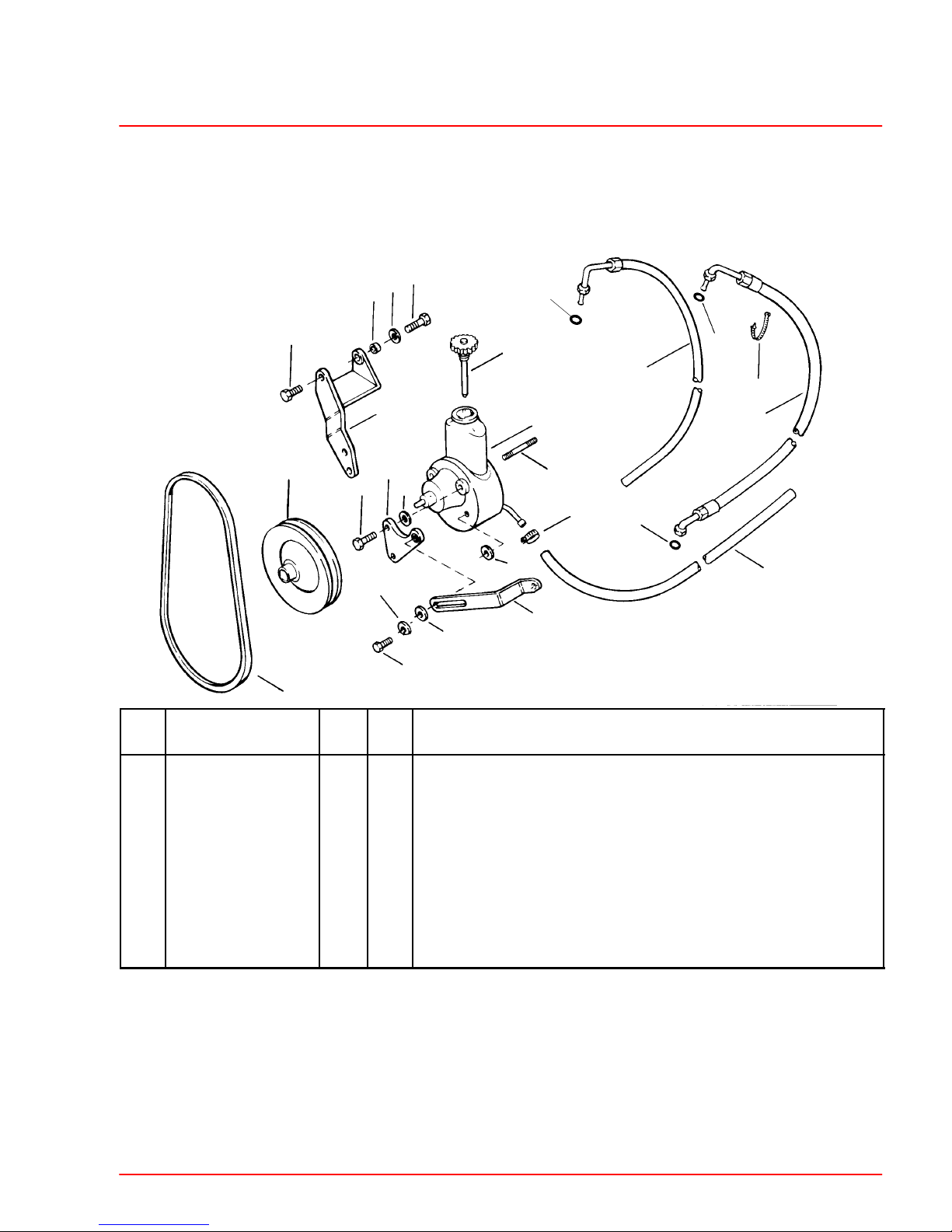

How to Read a Parts Manual

Power Steering Pump Assembly

1

2

3

4

5

6

7

8

9

10

REF.

NO.

PART NO. SYM. QTY. DESCRIPTION

1

90507A12 1 PUMP ASSEMBLY-Power Steering

2

36-95805 1 CAP

3

73873A1 1 PULLEY

4

16-41877 1 STUD

5

57-65607T 1 V-BELT

6

32-806684 1 HOSE-Pressure (FITTINGS ON BOTH ENDS)

7

25-89879 1 O-RING

8

25-806232 1 O-RING

9

13-35048 1 LOCKWASHER (3/8 in.)

10

61990 1 CABLE TIE

REF. NO. : Number shown next to part on exploded view

PART NO. : Mercury Part Number for ordering. If NSS (not sold separately) sometimes GM

part number will be given in description column.

QTY. : The quantity that must be ordered.

DESCRIPTION : Description of part, what parts are included with a part (all indented items

come with the main item above the indented parts), serial number information, and special

information.

Page 16

IMPORTANT INFORMATION SERVICE MANUAL NUMBER 28

Page 1A-4 90-863160 MAY 2000

Introduction

This comprehensive overhaul and repair manual is designed as a service guide for the

MerCruiser models previously listed. It provides specific information, including procedures

for disassembly, inspection, assembly and adjustment, to enable dealers and service

mechanics to repair these products.

Before attempting repairs, that procedure should first be read through to help understand

the methods and tools used and the cautions and warnings required for safety.

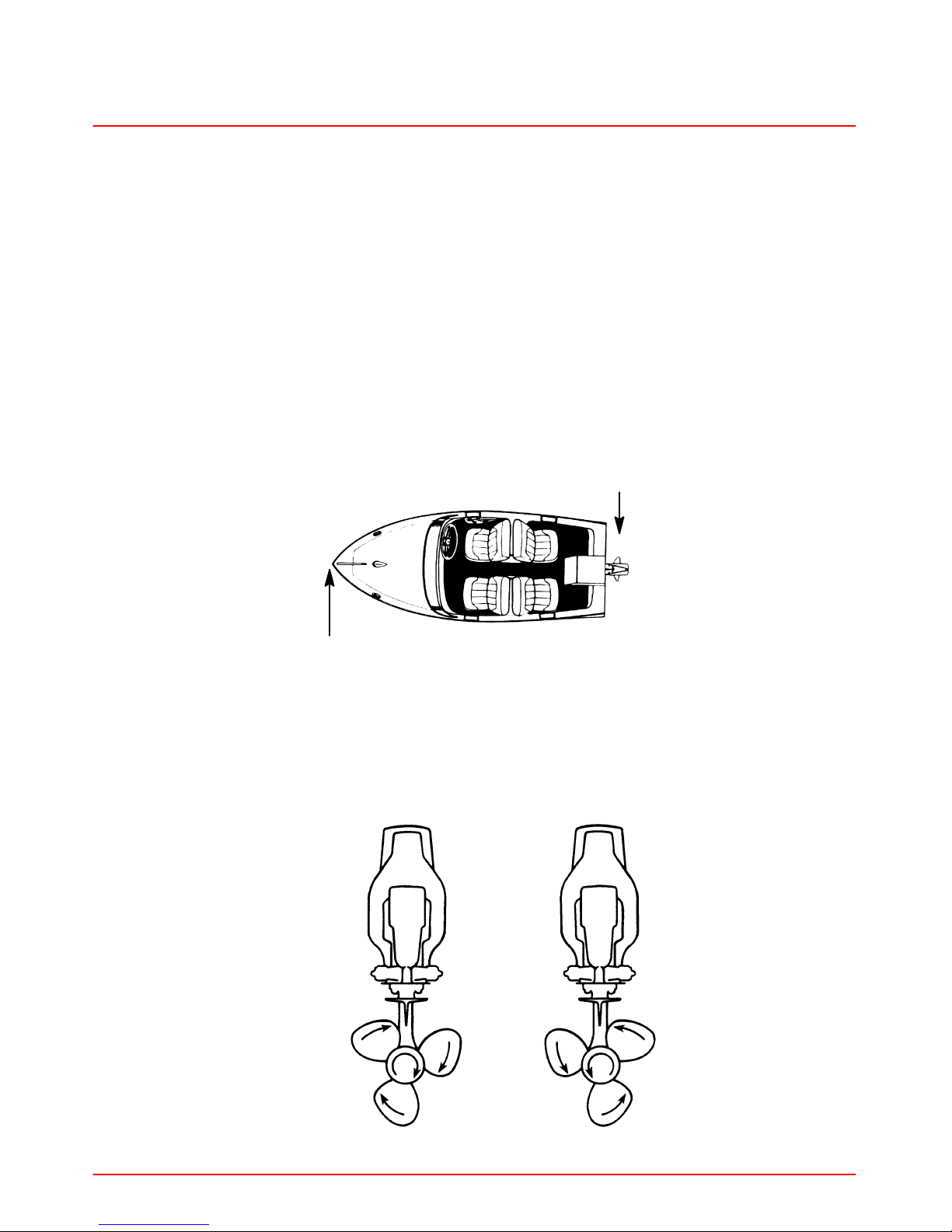

Directional References

Front of boat is bow; rear is stern. Starboard side is right side; port side is left side. In this

service manual, all directional references are given as they appear when viewing boat from

stern, looking toward bow.

72000

STARBOARD

(RIGHT)

PORT

(LEFT)

FORE or BOW

(FRONT)

AFT or STERN

(REAR)

Propeller Rotation

Propeller rotation for sterndrive can be right hand or left hand rotation as viewed from the

aft end of the propeller.

Right Hand Rotation Left Hand Rotation

Page 17

GENERAL INFORMATION

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1A-5

Sterndrive Unit 10-Hour Break-In Period (New or With

Replacement Gears)

1. Avoid full throttle starts.

2. DO NOT operate at any one constant speed for extended periods of time.

3. DO NOT exceed 75% of full throttle during the first 5 hours. During the next 5 hours,

operate at intermittent full throttle.

4. Drive unit should be shifted into forward gear a minimum of 10 times during break-in,

with run-in time at moderate rpm after each shift.

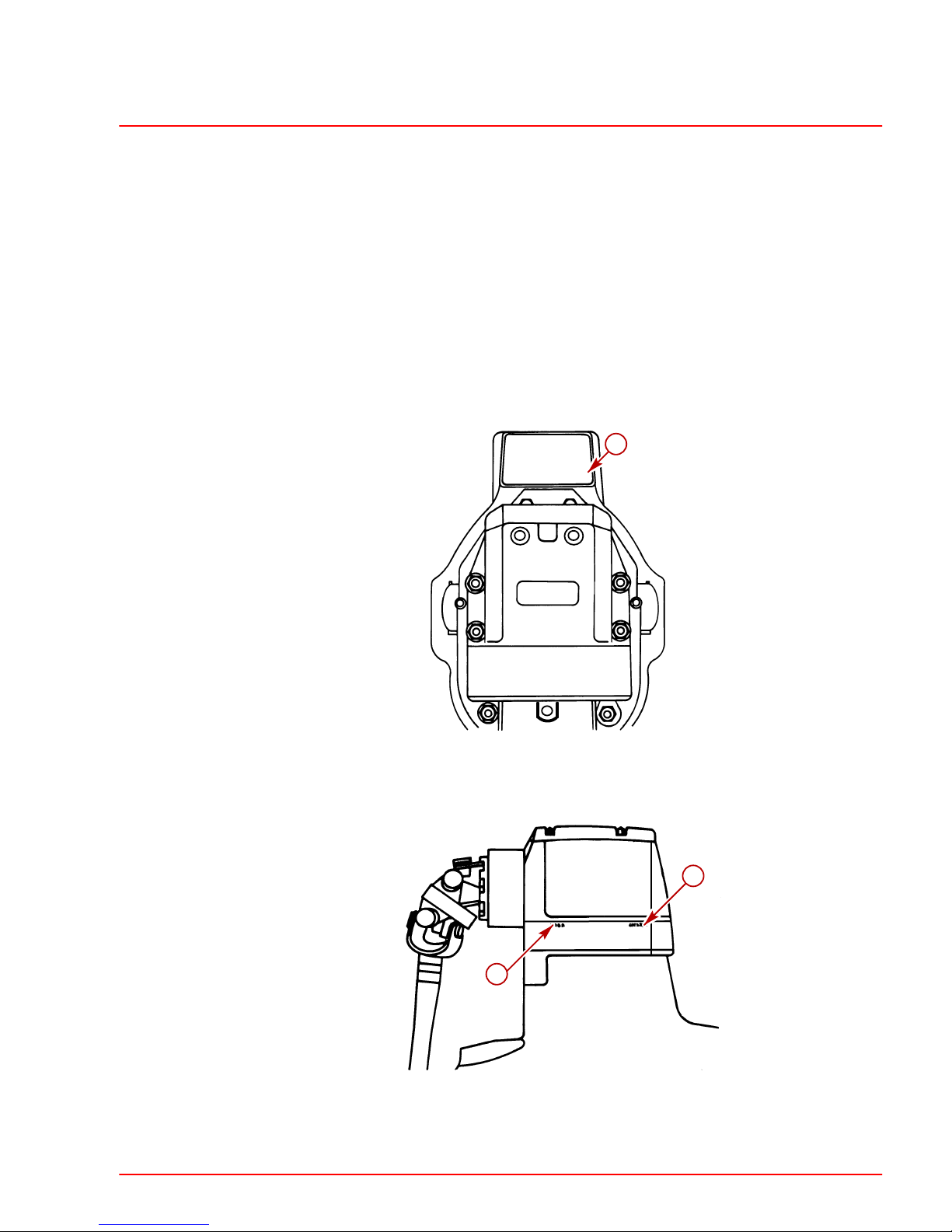

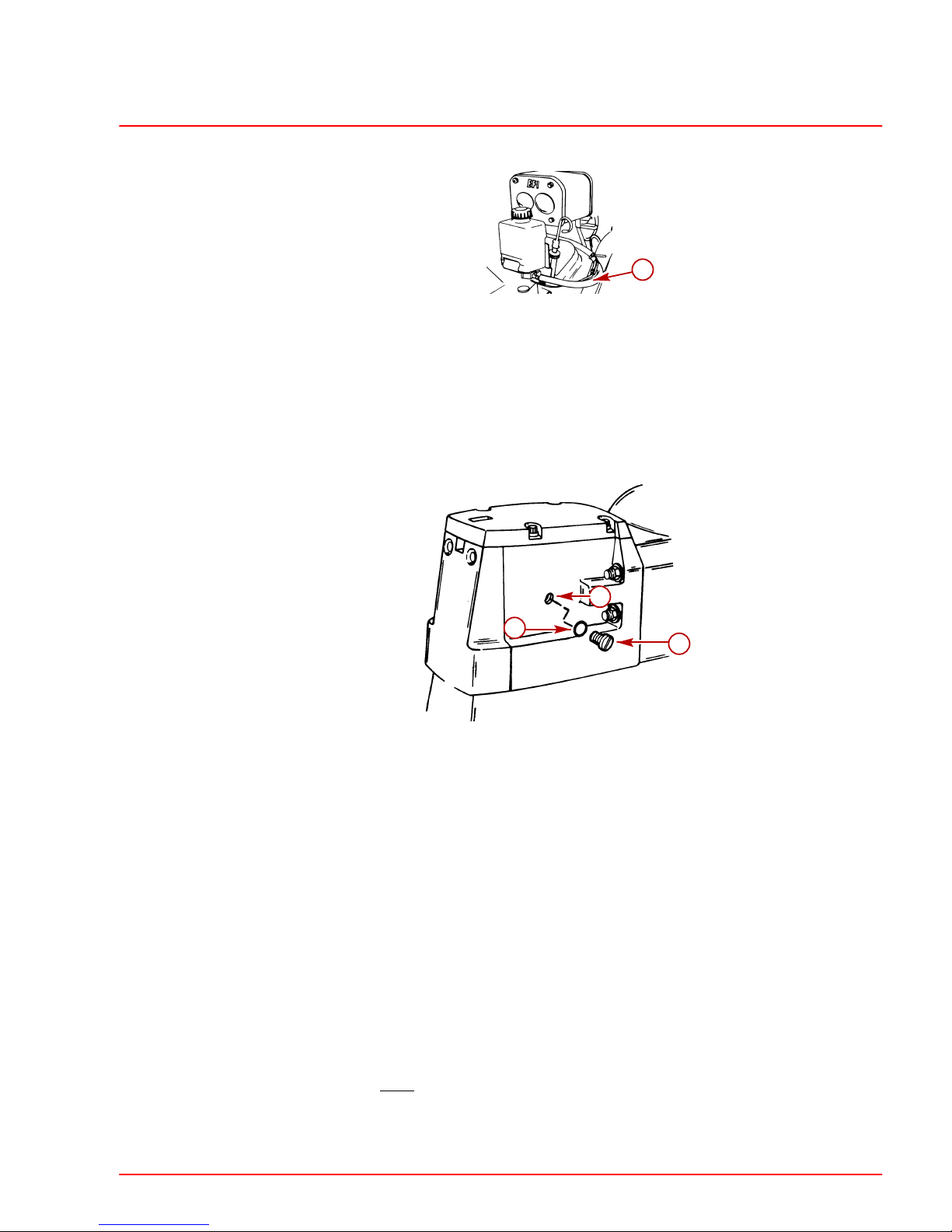

Serial Number Locations and Engine Designation Decal

a

Transom Assembly Serial Number Location

a-Transom Assembly Serial Number

b

a

Sterndrive Unit Serial Number Location - Port Side Decal

a-Sterndrive Unit Serial Number

b-Sterndrive Unit Gear Ratio

Page 18

IMPORTANT INFORMATION SERVICE MANUAL NUMBER 28

Page 1A-6 90-863160 MAY 2000

THIS PAGE IS INTENTIONALLY BLANK

Page 19

1

B

MAINTENANCE

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1B-1

IMPORTANT INFORMATION

Section 1B - Maintenance

Table of Contents

Lubricants / Sealants / Adhesives 1B-2. . . . .

Maintenance Schedules 1B-3. . . . . . . . . . . . .

Maintenance Intervals 1B-3. . . . . . . . . . . . .

Gas Sterndrive 1B-3. . . . . . . . . . . . . . . . . . . . . .

Routine Maintenance * 1B-3. . . . . . . . . . . .

Gas Sterndrive(Continued) 1B-4. . . . . . . . . . .

Scheduled Maintenance * 1B-4. . . . . . . . .

Specifications 1B-5. . . . . . . . . . . . . . . . . . . . . . .

Torque Specification 1B-5. . . . . . . . . . . . . . . . .

Fluid Capacities 1B-5. . . . . . . . . . . . . . . . . . . . .

Lubrication 1B-5. . . . . . . . . . . . . . . . . . . . . . . . .

Shift Cable Pivot Points 1B-5. . . . . . . . . . .

Propeller Shaft 1B-6. . . . . . . . . . . . . . . . . . .

Steering System 1B-6. . . . . . . . . . . . . . . . . .

Tie Bar Pivot Points 1B-7. . . . . . . . . . . . . . .

Transom Gimbal Housing Assembly Swivel

Shaft and Gimbal Bearing 1B-7. . . . . . . . .

Checking and Adding Sterndrive Oil 1B-8. . .

Inspection 1B-9. . . . . . . . . . . . . . . . . . . . . . .

Changing Sterndrive Oil 1B-10. . . . . . . . . . . . . .

General Maintenance 1B-12. . . . . . . . . . . . . . . .

Maintaining Power Package Exterior Sur-

faces 1B-12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Head and Remote Control Mainte-

nance 1B-12. . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Quicksilver MerCathode System . .

1B-12

Maintaining Anodic Plate 1B-12. . . . . . . . . .

Boat Bottom Care 1B-12. . . . . . . . . . . . . . . .

Anti-fouling Paint 1B-12. . . . . . . . . . . . . . . . .

Maintaining Ground Circuit Continuity 1B-13

Power Package Layup 1B-13. . . . . . . . . . . . . . .

Engine 1B-13. . . . . . . . . . . . . . . . . . . . . . . . . .

Sterndrive 1B-13. . . . . . . . . . . . . . . . . . . . . . .

Power Package Recommissioning 1B-14. . . .

Engine 1B-14. . . . . . . . . . . . . . . . . . . . . . . . . .

Sterndrive 1B-14. . . . . . . . . . . . . . . . . . . . . . .

Page 20

MAINTENANCE SERVICE MANUAL NUMBER 28

Page 1B-2 90-863160 MAY 2000

Lubricants / Sealants / Adhesives

Description Part Number

Quicksilver 4-Cycle 25W-40 Marine Engine Oil 92-802837A1

SAE 20W, 30W Or 40W Engine Oil Obtain Locally

Quicksilver High Performance Gear Lube 92-802854A1

Extended Life Ethylene Glycol Antifreeze Obtain Locally

Quicksilver Special Lubricant 101 92-13872A1

Quicksilver Engine Coupler Spline Grease 92-802869A1

Quicksilver Corrosion Guard Spray 92-802878 55

Quicksilver 2-4-C Marine Lubricant With Teflon 92-825407A3

Quicksilver U-Joint and Gimbal Bearing Grease 92-828052A2

Quicksilver Power Trim And Steering Fluid 92-802880A1

Exxon Unirex EP 2 Grease Obtain Locally

Quicksilver Hydraulic Fluid 64-826485A1

Texaco H015 92-862014A1

SeaStar Hydraulic Fluid HA5430

Approved Hydraulic

Chevron Aviation Fluid A

Steering Fluids

Mobil Aero HFA

Obtain Locally

Shell Aero 4

Fluid meeting MIL Specification H5606C

Page 21

MAINTENANCE

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1B-3

Maintenance Schedules

Maintenance Intervals

Maintenance intervals and tasks, as shown in this schedule, or as found in previously

printed schedules, are based on an average boating application and environment.

However, individual operating habits and personal maintenance preferences can have an

impact on the suggested intervals. In consideration of these factors, Mercury MerCruiser

has adjusted some maintenance intervals and corresponding tasks to be performed. In

some cases, this may allow for more tasks to be performed in a single visit to the servicing

dealer, rather than multiple visits. Therefore, the boat owner and servicing dealer must

discuss the current Maintenance Schedule and develop appropriate maintenance intervals

to coincide with the individual operating habits, environment and maintenance

requirements.

CAUTION

Always disconnect battery cables from battery BEFORE working around electrical

systems components to prevent injury to yourself and damage to electrical system

should a wire be accidentally shorted.

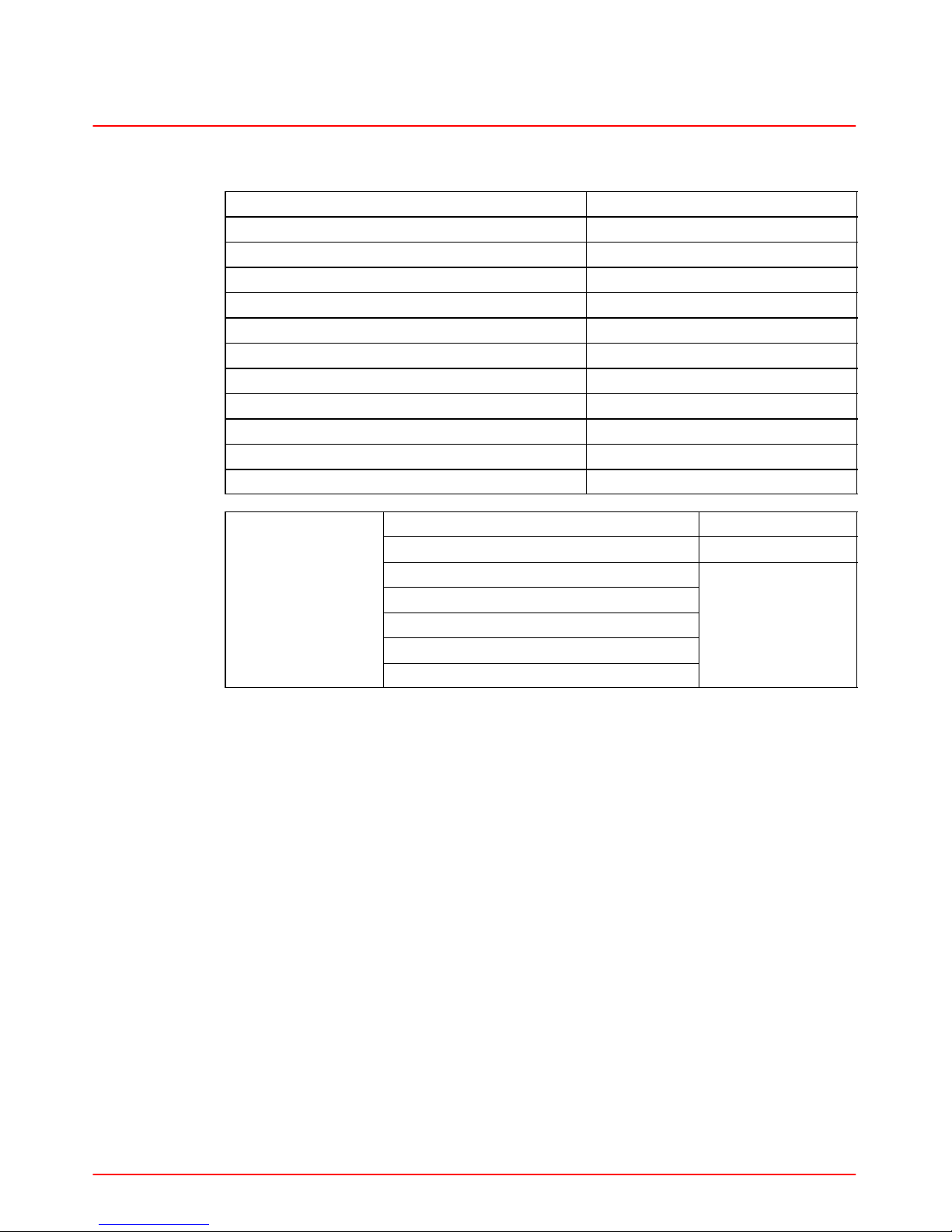

Gas Sterndrive

Routine Maintenance *

Each

Day

Start

Each

Day

End

Weekly

Every

Two

Months

Check crankcase oil (interval can be extended based on experience).

If operating in salt, brackish or polluted waters, flush cooling system after each use.

Check sterndrive unit oil level, trim pump oil level and steering fluid

level.

Check water pickups for debris or marine growth. Check water

strainer and clean. Check coolant level.

Inspect sterndrive unit anodes and replace if 50 percent eroded.

Inspect fuel pump sight tube (if equipped) and have pump replaced

if fuel is present.

Check battery connections and fluid level.

Lubricate propeller shaft and the retorque nut (if operating in only

freshwater, this maintenance may be extended to every four

months).

Operating in saltwater only: treat engine surface with corrosion

guard.

* Only perform maintenance that applies to your particular power package

Standard Models

Horizon Models

Page 22

MAINTENANCE SERVICE MANUAL NUMBER 28

Page 1B-4 90-863160 MAY 2000

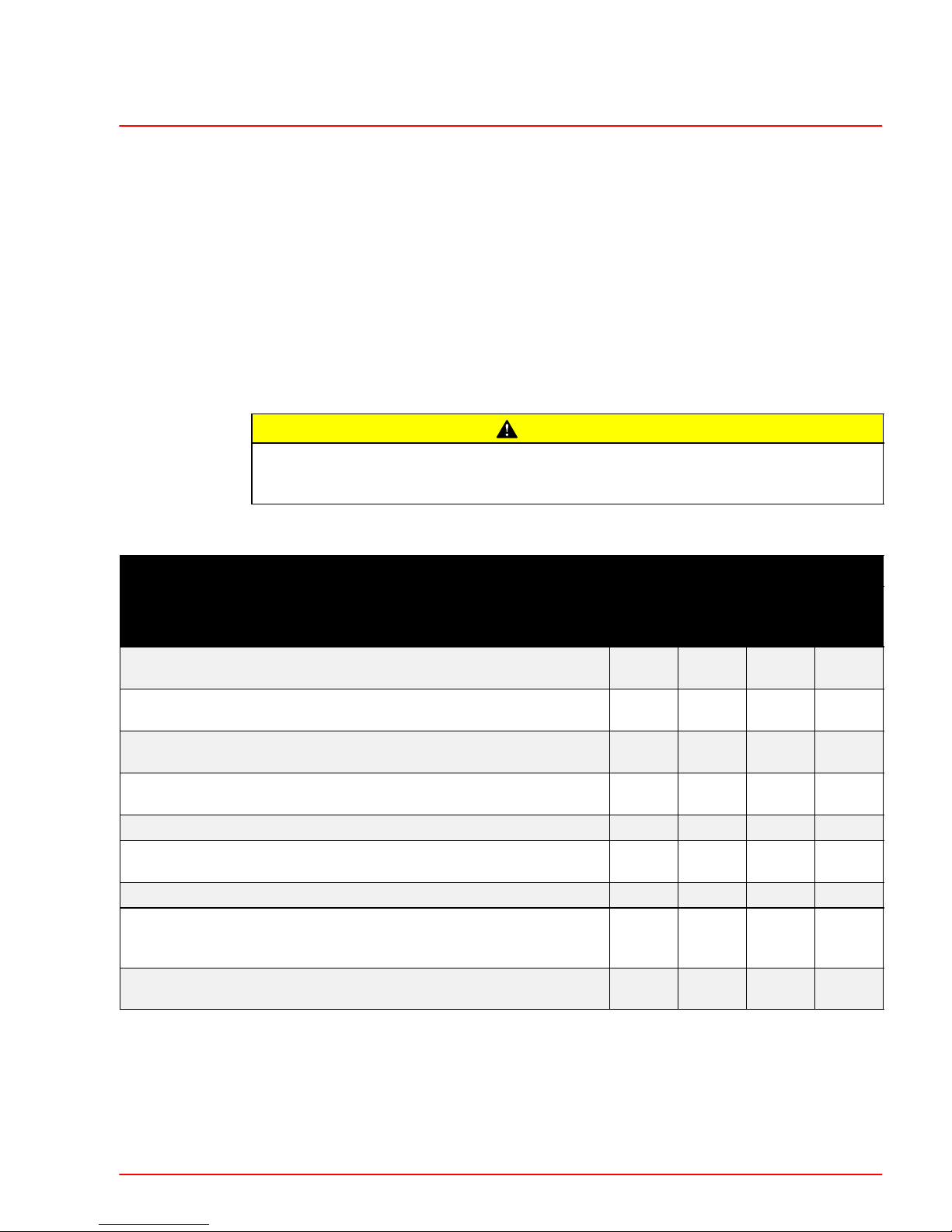

Gas Sterndrive(Continued)

Scheduled Maintenance *

Annu-

ally

Every

100

hours or

Annually

Every

200

hours

or 3

years

Every

300

hours

or 3

years

Every

2

years

Every

5

years

Touch-up power package paint and spray with Corrosion Guard.

Change crankcase oil and filter.

Change sterndrive unit oil and retorque connection of

gimbal ring to steering shaft.

Replace fuel filter(s).

Check steering system and remote control for loose,

missing or damaged parts. Lubricate cables and linkages.

Inspect U-joints, splines and bellows. Check clamps.

Check engine alignment. Lubricate U-joints splines.

Lubricate gimbal bearing and engine coupler.

Check continuity circuit for loose or damaged connec-

tions. Test MerCathode unit output on Bravo Models.

Retorque engine mounts.

Check spark plugs, wires, distributor cap and ignition

timing. Check and adjust idle speed.

Clean flame arrestor and crankcase ventilation hoses.

Replace PCV valve.

Check electrical system for loose, damaged or corroded

fasteners.

Inspect condition and tension of belts.

Check cooling system and exhaust system hose clamps

for tightness. Inspect both systems for damage or leaks.

Disassemble and inspect seawater pump and replace

worn components.

Clean seawater section of closed cooling system.

Clean, inspect and test pressure cap.

Replace coolant.

* Only perform maintenance that applies to your particular power package

Standard Models

Horizon Models

Whichever Occurs First

Interval will be reduced if not using extended life coolant.

Lubricate engine coupler every 50 hours if operated at idle for prolonged periods of time.

Page 23

MAINTENANCE

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1B-5

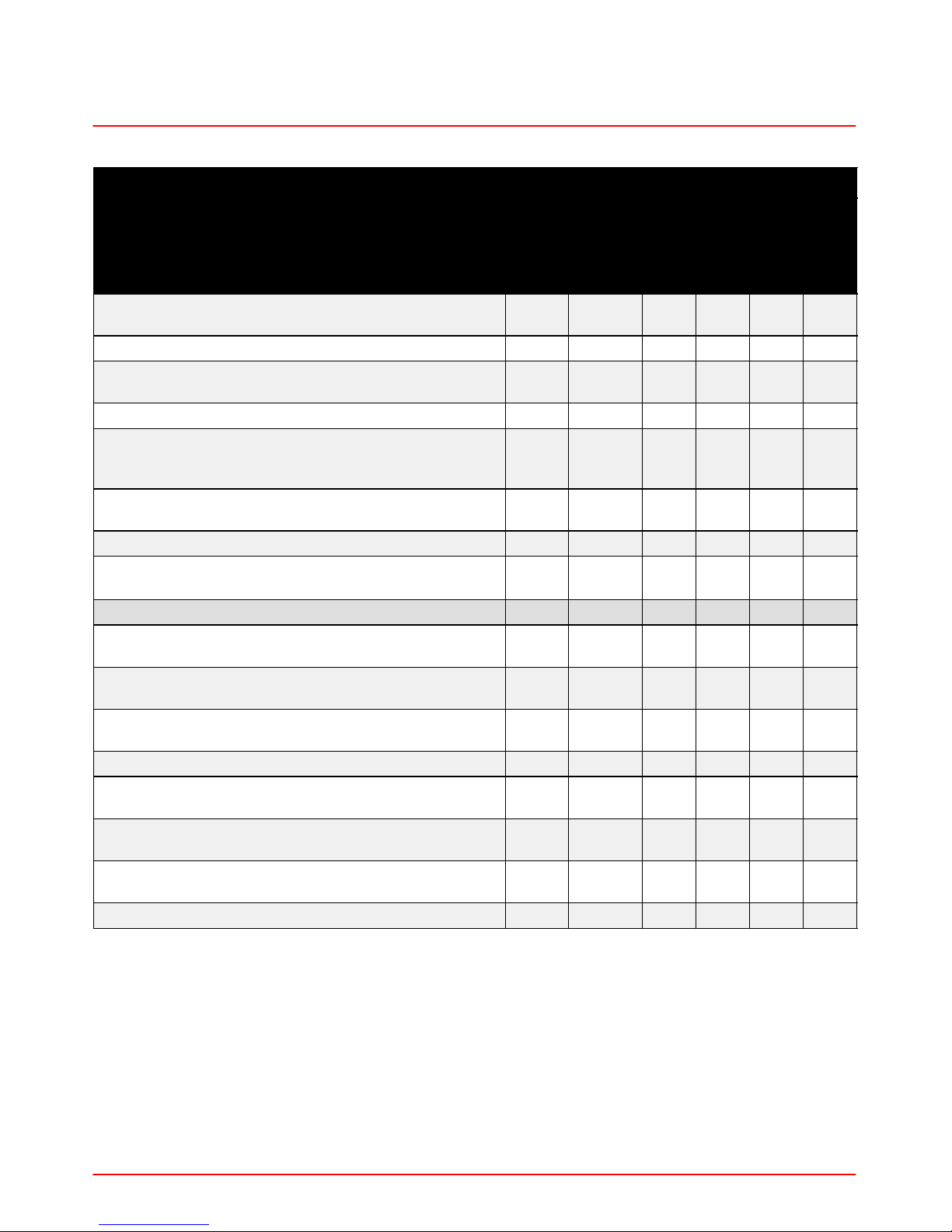

Specifications

Torque Specification

Fastener Location lb-in. lb-ft Nm

Sterndrive Unit Fill/Drain Plug 40 4.5

Sterndrive Unit Vent Plug 40 4.5

We recommend the use of Quicksilver Maintenance Products where specified.

Fluid Capacities

NOTICE

Unit Of Measurement: U.S. Quarts (Liters)

All capacities are approximate fluid measures.

Model Bravo One Bravo Two Bravo Three

Sterndrive Unit Oil Capacity 88 (2603) 104 (3076) 96 (2839)

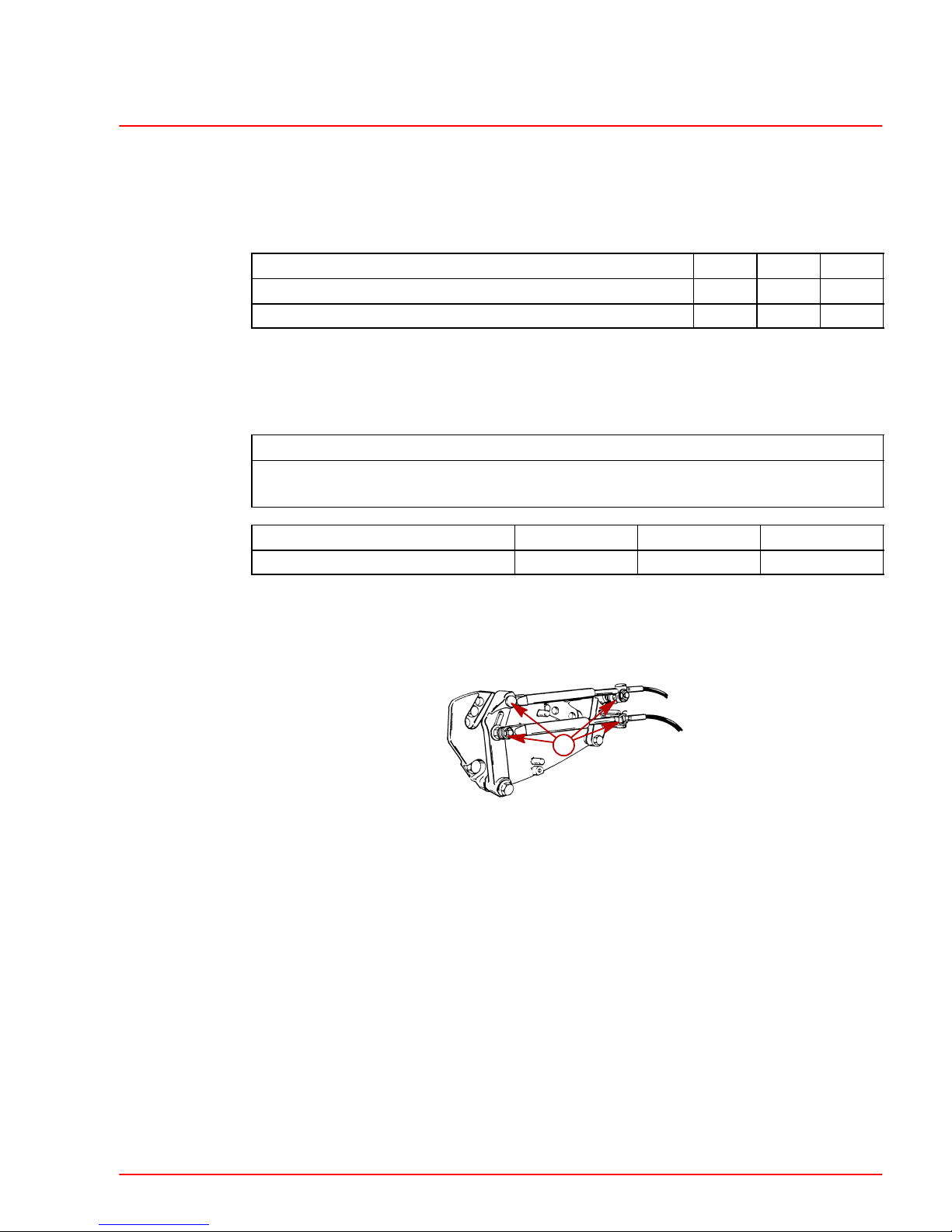

Lubrication

Shift Cable Pivot Points

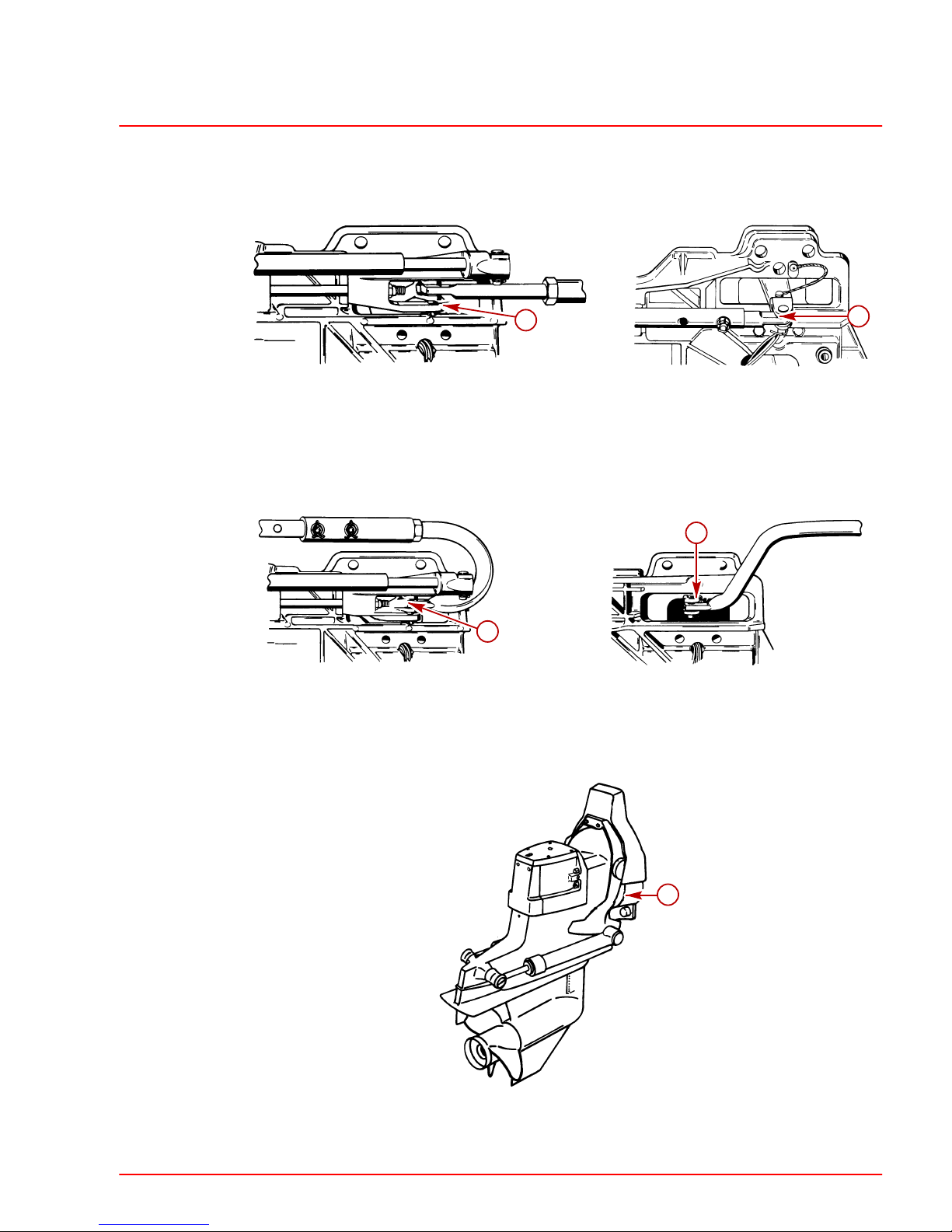

22245

a

a-Pivot Points

Page 24

MAINTENANCE SERVICE MANUAL NUMBER 28

Page 1B-6 90-863160 MAY 2000

Propeller Shaft

77047

72239

a

a

a

77046

76910

Bravo One / Bravo Two Sterndrives Bravo Three Sterndrive/ Bravo XZ & XR

a-Propeller Shaft

Steering System

WARNING

Transom end of steering cable MUST BE fully retracted into cable housing when

lubricating cable. If cable is lubricated while extended, hydraulic lock of cable could

occur.

71901

b

76860

a

b

c

c

Control Valve

a-Steering Cable End

b-Pivot Point

c-Pivot Bolts

d-Adjusting Slots

Page 25

MAINTENANCE

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1B-7

Tie Bar Pivot Points

MODELS WITH CONTROL VALVE MOUNTED ON STARBOARD TRANSOM ASSEMBLY

22079

22079

a

a

Starboard Engine Port Engine

a-Pivot Point

MODELS WITH CONTROL VALVE MOUNTED ON PORT TRANSOM ASSEMBLY

22079

22079

a

a

Starboard Engine Port Engine

a-Pivot Point

Transom Gimbal Housing Assembly Swivel Shaft and Gimbal Bearing

50072

b

a-Gimbal Bearing Grease Fitting

Page 26

MAINTENANCE SERVICE MANUAL NUMBER 28

Page 1B-8 90-863160 MAY 2000

Checking and Adding Sterndrive Oil

IMPORTANT: Position sterndrive unit in DOWN/IN position so that anti-ventilation

plate is level.

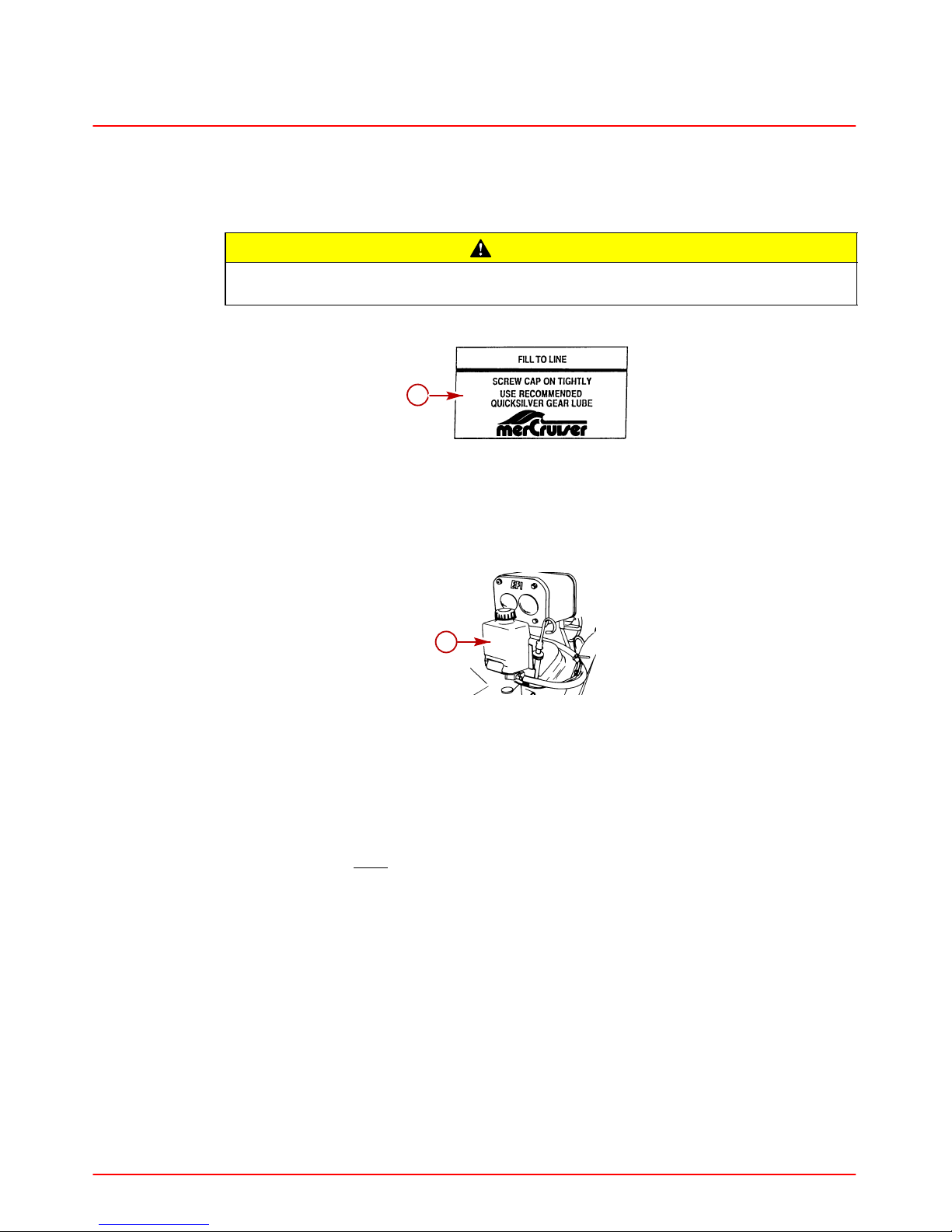

CAUTION

If more than 2 fl. oz. (59 ml) of oil is required to fill sterndrive unit, an oil leak may

exist. Find and correct cause of leak before unit is placed in operation.

NOTE: Sterndrive unit oil level is checked at gear lube monitor.

50323

a

a-Gear Lube Monitor Decal

IMPORTANT: Oil level in gear lube monitor will rise and fall during sterndrive

operation; always check oil level when sterndrive is cool and engine is shut down.

NOTE: Drive oil will purge from gear lube monitor if rubber seal is not in cap.

71990

a

a-Gear Lube Monitor

1. Fill gear lube monitor to FULL line on decal.

2. Ensure rubber seal is in place on square gear lube monitor cap.

3. Install gear lube monitor cap. Tighten cap 1/4 turn after cap contacts seal.

IMPORTANT: Do NOT overtighten cap.

4. Check oil level in gear lube monitor.

Page 27

MAINTENANCE

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1B-9

Inspection

Periodically inspect lubricant for water to ensure that sterndrive unit seals are not leaking.

Check for water at bottom of gear lube monitor. If a water leak is indicated the sterndrive

unit must be resealed.

CAUTION

If more than 2 fl. oz. (59ml) of Quicksilver High Performance Gear Lube is required

to fill gear lube monitor, a seal may be leaking. Find and correct cause of leak before

unit is placed in operation.

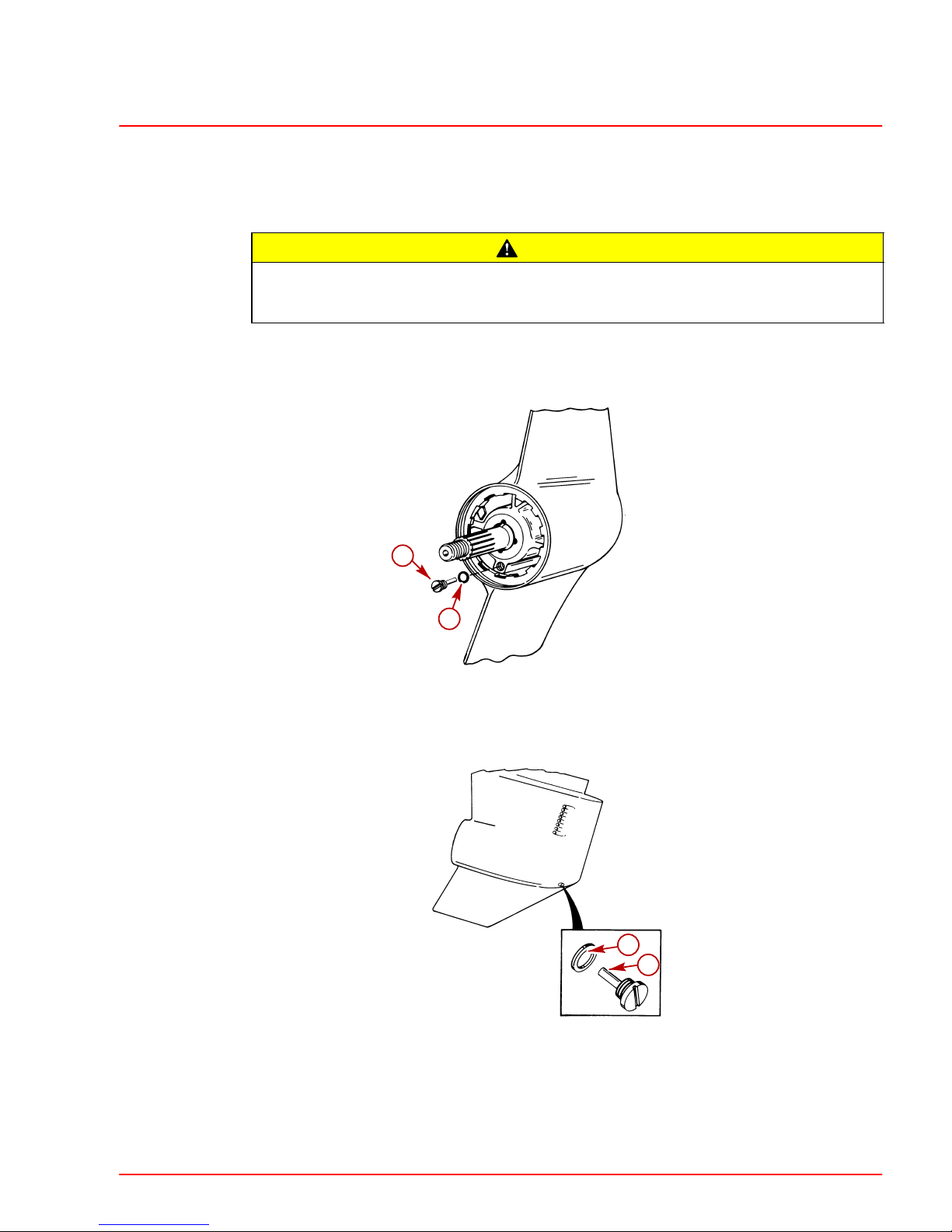

IMPORTANT: If sterndrive unit has set overnight or longer, check for water in sterndrive unit, as follows:

1. Bravo I: Trim sterndrive unit to full DOWN/IN position.

70023

a

b

a-Oil Fill/Drain Plug

b-Sealing Washer

2. Bravo II and III: Trim sterndrive unit to full UP/OUT position.

22101

22103

a

b

a-Oil Fill/Drain Plug

b-Sealing Washer

3. Remove fill/drain plug to sample lubricant. If water runs out sterndrive unit is leaking and

must be resealed.

4. Reinstall fill/drain plug. Torque to 40 lb-in. (4.5 Nm).

Page 28

MAINTENANCE SERVICE MANUAL NUMBER 28

Page 1B-10 90-863160 MAY 2000

Changing Sterndrive Oil

CAUTION

If any water drains from fill/drain hole a leak in sterndrive unit may exist. Find and

correct cause of leak before placing unit back in operatIon.

CAUTION

DO NOT attempt to fill sterndrive unit through oil vent holes, as air will be trapped

in sterndrive unit and unit will be damaged from lack of lubrication.

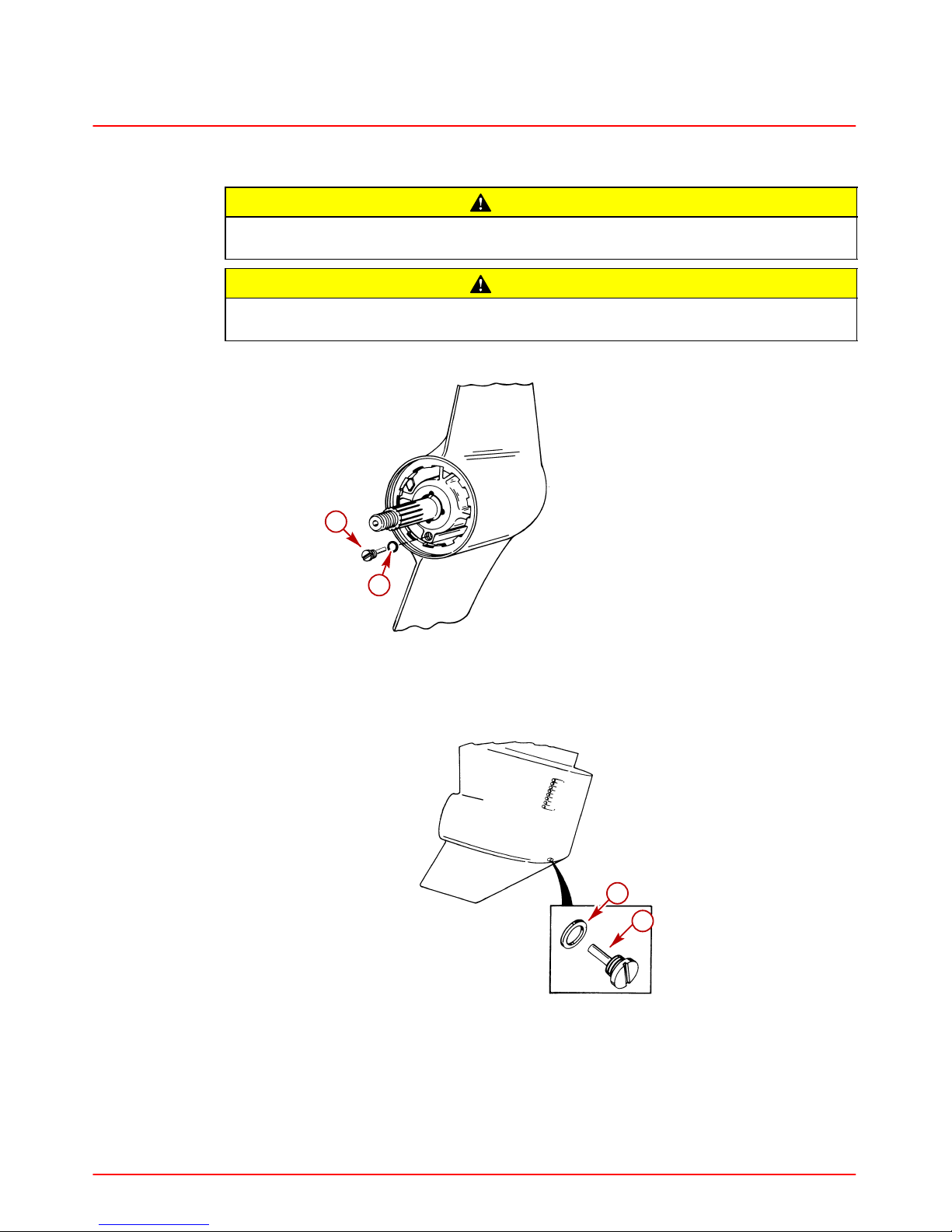

1. Bravo I: Trim sterndrive unit to full DOWN/IN position.

70023

a

b

a-Oil Fill/Drain Plug

b-Sealing Washer

2. Bravo II and III: Trim sterndrive unit to full UP/OUT position.

22101

22103

a

b

a-Oil Fill/Drain Plug

b-Sealing Washer

3. Remove sterndrive unit gear lube monitor from bracket.

4. Remove cap, empty contents of gear lube monitor into suitable container and discard.

5. Clean gear lube monitor thoroughly.

6. Return gear lube monitor to bracket. Do not refill at this time.

Page 29

MAINTENANCE

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1B-11

7. Check condition of hose and hose connections. Replace as necessary.

71990

a

a-Gear Lube Monitor

8. Remove sterndrive unit vent plug and fill/drain plug. Allow lubricant to drain completely.

9. If sterndrive unit is draining in full DOWN/IN position, trim to full UP/OUT position after

draining drain any remaining oil from internal driveshaft housing ledges.

10. Trim sterndrive unit to full DOWN/IN position (with anti-ventilation plate level) to

complete draining process.

c

a

b

a-Oil Vent Plug

b-Sealing Washer

c-Vent Hole

11. Using lubricant pump, fill sterndrive unit through fill/drain hole with lubricant until oil is

even with bottom edge of vent hole.

12. Without removing lubricant pump fitting from fill/drain hole, reinstall oil vent plug and

sealing washer. Torque to 40 lb-in. (4.5 Nm).

13. Continue filling drive until there is one inch of oil in the gear lube monitor.

14. Remove lubricant pump fitting and quickly reinstall fill/drain plug and sealing washer.

Torque to 40 lb-in. (4.5 Nm).

NOTE: Drive oil will purge from square gear lube monitor if rubber seal is not in cap.

15. Fill gear lube monitor to FULL line on decal.

16. Ensure rubber seal is in place on gear lube monitor cap.

17. Install gear lube monitor cap.

IMPORTANT: Do NOT

overtighten cap.

18. Check oil level in gear lube monitor.

19. Recheck oil level after first use.

Page 30

MAINTENANCE SERVICE MANUAL NUMBER 28

Page 1B-12 90-863160 MAY 2000

General Maintenance

Maintaining Power Package Exterior Surfaces

Entire power package should be sprayed at recommended intervals with Quicksilver

Corrosion Guard. Follow instructions on can for proper application.

Entire power package should be cleaned and external surfaces that have become bare

should be repainted with Quicksilver Primer and Spray Paint at recommended intervals.

Steering Head and Remote Control Maintenance

Lubricate steering head and remote control with 2-4-C Marine Lubricant with T eflon. Inspect

steering head and remote control for ease of operation.

Checking Quicksilver MerCathode System

If boat is equipped with a Quicksilver MerCathode System, system should be tested to

ensure that it is providing adequate output to protect underwater metal parts on boat. Test

should be made where boat is moored, using Quicksilver Reference Electrode and Test

Meter. Refer to SECTION 7.

Maintaining Anodic Plate

Each sterndrive unit is equipped with a sacrificial anodic plate to help protect underwater

metal parts from galvanic corrosion. Because of its self-sacrificing nature, anodic plate

MUST BE replaced if eroded 50% or more. Refer to SECTION 7.

Boat Bottom Care

To achieve maximum performance and fuel economy, boat bottom MUST BE kept clean.

Accumulation of marine growth or other foreign matter can greatly reduce boat speed and

increase fuel consumption. To ensure best performance and efficiency, periodically clean

boat bottom in accordance with manufacturer ’s recommendations.

In some areas, it may be advisable to paint the bottom to help prevent marine growth. Refer

to the following information for special notes about the use of anti-fouling paints.

Anti-fouling Paint

IMPORTANT: Corrosion damage that results from the improper application of antifouling paint will not be covered by the limited warranty.

Painting Boat Hull or Boat Transom: Anti-fouling paint may be applied to boat hull and

boat transom but you must observe the following precautions:

IMPORTANT: DO NOT paint anodes or MerCathode System reference electrode and

anode, as this will render them ineffective as galvanic corrosion inhibitors.

Page 31

MAINTENANCE

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1B-13

IMPORTANT: If anti-fouling protection is required for boat hull or boat transom, copper or tin base paints, if not prohibited by law, can be used. If using copper or tin

based anti-fouling paints, observe the following:

• Avoid an electrical interconnection between the Mercury MerCruiser Product,

Anodic Blocks, or MerCathode System and the paint by allowing a minimum of

1-1/2 in. (40 mm) UNPAINTED area on transom of the boat around these items.

71176

a

b

a-Painted Boat Transom

b-Minimum 1-1/2 in (40 mm) UNPAINTED Area Around Transom Assembly

NOTE: Sterndrive unit and transom assembly can be painted with a good quality marine

paint or an anti-fouling paint that DOES NOT

contain copper, tin, or any other material that

could conduct electrical current. Do not paint drain holes, anodes, MerCathode system and

items specified by boat manufacturer.

Maintaining Ground Circuit Continuity

The transom assembly and sterndrive unit are equipped with a ground wire circuit to ensure

good electrical continuity between engine, transom assembly and sterndrive components.

Good continuity is essential for the MerCathode System to function effectively. Refer to

SECTION 7.

Power Package Layup

Engine

Refer to appropriate Engine Service Manual.

Sterndrive

1. Lubricate steering system. Refer to SECTION 6.

2. Lubricate transom gimbal bearing and propeller shaft. Refer to SECTION 4 and

SECTION 1B.

3. Lubricate sterndrive unit U-joint shaft splines and cross bearings. Refer to SECTION 3A.

4. Inspect U-joint bellows for cracks or other signs of deterioration. Check bellows clamps

for tightness. Refer to SECTION 4.

5. Check engine alignment. Refer to Engine Service Manual.

6. Change sterndrive unit oil. Refer to SECTION 1B.

7. Inspect sterndrive for damage. Repair or replace damaged components.

8. Clean sterndrive exterior surfaces and repaint any bare metal surfaces with Quicksilver

Primer and Spray Paint. Refer to SECTION 1B.

Page 32

MAINTENANCE SERVICE MANUAL NUMBER 28

Page 1B-14 90-863160 MAY 2000

9. After paint has dried, spray entire sterndrive with Quicksi l ver Corrosion G uar d. R efer to

SECTION 1B.

CAUTION

Store sterndrive unit in the full trim DOWN/IN position. U-joint bellows may develop

a “set” if unit is stored in raised position and may fail when unit is returned to service.

10. If not already done, place sterndrive unit in the full trim DOWN/IN position.

11. Store battery. Refer to battery manufacturer’s instructions.

Power Package Recommissioning

Engine

Refer to appropriate Engine Service Manual.

Sterndrive

1. Perform ALL maintenance specified for completion “Annually” in “Maintenance Chart”

except items which were performed at the time of sterndrive layup.

2. Install fully-charged battery.

3. Clean battery cable clamps and terminals.

4. Reconnect battery cables. Be sure to tighten clamps securely.

5. Apply a thin coat of petroleum based grease to clamps and terminals to help retard

corrosion.

6. After recommissioning and starting engine, check steering system and shift control for

proper operation.

Page 33

1

C

TROUBLESHOOTING

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1C-1

IMPORTANT INFORMATION

Section 1C - Troubleshooting

Table of Contents

Table of Contents 1C-1. . . . . . . . . . . . . . . . . . . . .

Troubleshooting 1C-2. . . . . . . . . . . . . . . . . . . . . . .

Sterndrive Unit Troubleshooting 1C-2. . . . . . . . .

Sterndrive Unit Will Not Slide Into

Bell Housing 1C-2. . . . . . . . . . . . . . . . . . . . . . .

Drive Unit Does Not Shift Into Gear;

Remote Control Shift Handle Moves 1C-2. .

Drive Unit Does Not Shift Into Gear;

Remote Control Shift Handle Does

Not Move 1C-3. . . . . . . . . . . . . . . . . . . . . . . . .

Drive Unit Shifts Hard 1C-3. . . . . . . . . . . . . . .

Drive Unit In Gear, Will Not Shift

Out Of Gear 1C-3. . . . . . . . . . . . . . . . . . . . . . .

Gear Housing Noise 1C-4. . . . . . . . . . . . . . . .

Drive Shaft Housing Noise 1C-4. . . . . . . . . . .

Drive Shaft Housing Noise

(Continued) 1C-5. . . . . . . . . . . . . . . . . . . . . . .

Drive Shaft Housing Noise

(Continued) 1C-6. . . . . . . . . . . . . . . . . . . . . . .

Power Shift 1C-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

System Does Not React 1C-7. . . . . . . . . . . . .

System Binds 1C-7. . . . . . . . . . . . . . . . . . . . . .

Performance Troubleshooting 1C-8. . . . . . . . . . .

Low WOT Engine RPM 1C-8. . . . . . . . . . . . . .

High WOT Engine RPM 1C-8. . . . . . . . . . . . .

Propeller Ventilating/Cavitating 1C-8. . . . . . .

Poor Boat Performance And/Or Poor

Maneuverability-Bow Too Low 1C-9. . . . . . .

Poor Boat Performance And/Or Poor

Maneuverability-Bow Too High 1C-9. . . . . . .

Power Steering 1C-10. . . . . . . . . . . . . . . . . . . . . .

Hard Steering - Helm And Cable 1C-10. . . . .

Hard Steering (Engine Running)

- Power Steering System 1C-10. . . . . . . . . . .

Power Steering System External

Fluid Leaks 1C-10. . . . . . . . . . . . . . . . . . . . . . .

Compact Hydraulic Steering 1C-11. . . . . . . . . . .

Important Information 1C-11. . . . . . . . . . . . . .

Helm Beco me s Ja mme d Du rin g Fillin g 1C-11

System Difficult To Fill 1C-11. . . . . . . . . . . . . .

Steering Hard To Turn 1C-11. . . . . . . . . . . . . .

Helm Unit Bumpy

- Requires Too Many Turns 1C-11. . . . . . . . .

Power Trim Electrical System 1C-12. . . . . . . . . .

Power Trim System Wiring Diagram 1C-16. . . .

Power Trim Hydraulic System 1C-17. . . . . . . . . .

Power Trim Hydraulic Schematic 1C-21. . . . . . .

Auto Trim II Electrical System 1C-22. . . . . . . . . .

Auto Trim II System Wiring Diagram 1C-28. . . .

Corrosion Protection 1C-29. . . . . . . . . . . . . . . . . .

Page 34

TROUBLESHOOTING SERVICE MANUAL NUMBER 28

Page 1C-2 90-863160 MAY 2000

Troubleshooting

This section is a guide for performance and product troubleshooting. Referrals to specific

sections of this manual are made where special tests or repair procedure are to be

performed.

Because of the relationship between Power Package components (engine and sterndrive),

it will be necessary in some cases to simultaneously refer to the appropriate Engine Service

Manual for further troubleshooting information.

Effective troubleshooting is best enhanced by:

• Personal product knowledge and experience of the trained mechanic/technician.

• Allowing adequate time for testing and analysis.

• Utilizing these charts as a “guide” - a starting point.

Sterndrive Unit Troubleshooting

Sterndrive Unit Will Not Slide Into Bell Housing

Cause Special Instructions

U-joint shaft splines not aligned with

engine coupler splines.

Rotate propeller shaft

COUNTERCLOCKWISE to align

splines.

Engine not aligned. Check engine alignment.

Gimbal bearing not properly installed.

Check engine alignment to determine

if gimbal bearing is cocked or

improperly installed in gimbal housing.

Damaged U-joint shaft splines and/or

engine coupler splines.

Inspect and replace if necessary.

Drive Unit Does Not Shift Into Gear; Remote Control Shift Handle Moves

NOTE:For additional information on troubleshooting, refer to SECTION 2A and see

“Troubleshooting Shift Problems.”

Cause Special Instructions

Shift cables improperly adjusted. Adjust shift cables.

Shift cables not connected. Install and adjust shift cables.

Inner core wire broken or loose. Reconnect or replace inner core wire.

Page 35

TROUBLESHOOTING

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1C-3

Drive Unit Does Not Shift Into Gear; Remote Control Shift Handle Does Not

Move

NOTE:For additional information on troubleshooting, refer to SECTION 2A and see

“Troubleshooting Shift Problems.”

Cause Special Instructions

Control box not properly assembled. Properly reassemble control box.

Broken or damaged linkage in control

box.

Repair linkage.

Controls improperly adjusted-cable

end guide hitting brass barrel.

Adjust shift cables.

Drive Unit Shifts Hard

NOTE:For additional information on troubleshooting, refer to SECTION 2A and see

“Troubleshooting Shift Problems.”

Cause

Special Instructions

Shift cables improperly adjusted. Adjust shift cables.

Damaged remote control or drive unit

shift cable.

Replace cable(s) and adjust.

Shift cable too short (sharp bends) or

too long (loops and long bends).

Select and install proper length cable.

Corroded shift cables.

Replace, adjust and check for water

leakage.

Internal wear in remote control box. Repair as needed.

Shift cable attaching nuts too tight (end

cannot pivot).

Properly install nuts.

Shift cable pivot ends are corroded or

not lubricated.

Clean and lubricate.

Drive Unit In Gear, Will Not Shift Out Of Gear

NOTE:For additional information on troubleshooting, refer to SECTION 2A and see

“Troubleshooting Shift Problems.”

Cause Special Instructions

Shift cable broken. Replace cable and adjust.

Cable end not connected in drive unit. Remove and reinstall drive unit.

Remote control damaged. Repair or replace remote control.

Internal shift mechanism damage. Repair or replace as necessary.

Page 36

TROUBLESHOOTING SERVICE MANUAL NUMBER 28

Page 1C-4 90-863160 MAY 2000

Gear Housing Noise

Cause Special Instructions

Metal particles in drive unit lubricant.

Disassemble, clean and inspect and

replace necessary components. (Refer

to SECTION 3B, 3C or 3D)

Propeller incorrectly installed.

Inspect mounting hardware. Install

propeller correctly.

Propeller shaft bent.

Inspect and replace if necessary.

(Refer to SECTION 3B, 3C or 3D)

Incorrect gear shimming.

Check gear housing backlash and

pinion gear height. (Refer to SECTION 3B,

3C or 3D)

Worn or damaged gears and/or

bearings caused by impact,

overheating or improper shimming.

Disassemble, inspect and replace. (Refer

to SECTION 3B, 3C or 3D)

Drive Shaft Housing Noise

Cause Special Instructions

Engine flywheel housing contacting

inner transom plate or exhaust pipe.

Determine cause for interference

(loose engine mounts, transom too

thin, etc.) and correct as necessary.

Propeller with untrue or out-of-balance

blades.

Repair or replace, as required.

Abnormal sterndrive operation.

Instruct operator on proper operating

technique.

U-joint cross and bearing assembly

retaining rings improperly installed or

of incorrect size.

Make sure that proper thickness

retaining rings are used and that rings

are fully seated in u-joint bearing cap

grooves. (Refer to SECTION 3A)

Excessive side-to-side play in U-joint

cross and bearing assemblies.

Replace cross and bearing assembly.

U-joint bearing caps contacting U-joint

bellows retention sleeve.

Make sure proper cross and bearing

assemblies are used. If interference is

severe, replace cross and bearing

assembly and / or sleeve assembly.

U-joint cross and bearings rough.

Replace assemblies. Signs of scoring,

galling or roughness are the result of lack

of lubricant. (Refer to SECTION 3A)

O-rings missing or flattened out on

U-joint shaft causing shaft to rattle

against ID of gimbal bearing.

Install new o-rings. (Refer to SECTION

3A)

Page 37

TROUBLESHOOTING

SERVICE MANUAL NUMBER 28

90-863160 MAY 2000 Page 1C-5

Drive Shaft Housing Noise (Continued)

Cause Special Instructions

Worn U-joint shaft splines and/or

engine coupler splines.

Remove U-joint coupling end yoke and

insert into gimbal bearing and engine

coupling. Rotate shaft back and forth.

If play is excessive, replace U-joint

coupling end yoke and/or engine

coupler, as necessary.

Engine alignment incorrect or engine

coupler crooked.

Adjust alignment. Ensure that

alignment tool moves in and out of

coupler freely. After proper alignment

has been obtained, check for a crooked

coupler by rotating engine coupler 1/2 turn

and rechecking alignment. If

proper alignment is no longer

observed, coupler is crooked and must

be replaced. (Refer to SECTION 2)

Gimbal bearing rough.

Replace gimbal bearing. (Refer to

SECTION 4)

IMPORTANT: Gimbal bearing and carrier

MUST BE replaced as an assembly be-

cause they are a matched set. Failure to

do this may result in a loose bearing fit in

carrier.

Loose gimbal bearing.

Reinstall bearing assembly using a new

tolerance ring if carrier is loose in

gimbal housing. If bearing is loose in