Page 1

SERVICE

MANUAL

MODELS

Printed in U.S.A.

75 • 75 MARATHON • 75 SEA PRO

90 • 100 • 115 • 125 • 65/80 JET

With Serial Numbers

United States 0D283222 and Above. . .

Belgium 09793577 and Above. . . . . . . .

1997, Mercury Marine

90-830234R3 DECEMBER 1997

Page 2

Notice

Throughout this publication, “Dangers”, “Warnings”

and “Cautions” (accompanied by the International

HAZARD Symbol

to special instructions concerning a particular service

or operation that may be hazardous if performed incorrectly or carelessly.

FULLY!

These “Safety Alerts” alone cannot eliminate the hazards that they signal. Strict compliance to these special instructions when performing the service, plus

“Common Sense” operation, are major accident prevention measures.

DANGER - Immediate hazards which WILL result

in severe personal injury or death.

) are used to alert the mechanic

OBSERVE THEM CARE-

DANGER

who uses a service procedure and/or tool, which is

not recommended by the manufacturer, first must

completely satisfy himself that neither his nor the

products safety will be endangered by the service

procedure selected.

All information, illustrations and specifications contained in this manual are based on the latest product

information available at the time of publication. As required, revisions to this manual will be sent to all dealers contracted by us to sell and/or service these products.

It should be kept in mind, while working on the product, that the electrical system and ignition system are

capable of violent and damaging short circuits or severe electrical shocks. When performing any work

where electrical terminals could possibly be

grounded or touched by the mechanic, the battery

cables should be disconnected at the battery.

WARNING

WARNING - Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION

Hazards or unsafe practices which could result

in minor personal injury or product or property

damage.

Notice to Users of This

Manual

This service manual has been written and published

by the Service Department of Mercury Marine to aid

our dealers’ mechanics and company service personnel when servicing the products described herein.

It is assumed that these personnel are familiar with

the servicing procedures of these products, or like or

similar products manufactured and marketed by

Mercury Marine, that they have been trained in the

recommended servicing procedures of these products which includes the use of mechanics’ common

hand tools and the special Mercury Marine or recommended tools from other suppliers.

We could not possibly know of and advise the service

trade of all conceivable procedures by which a service might be performed and of the possible hazards

and/or results of each method. We have not undertaken any such wide evaluation. Therefore, anyone

Any time the intake or exhaust openings are exposed

during service they should be covered to protect

against accidental entrance of foreign material which

could enter the cylinders and cause extensive internal damage when the engine is started.

It is important to note, during any maintenance procedure replacement fasteners must have the same

measurements and strength as those removed.

Numbers on the heads of the metric bolts and on the

surfaces of metric nuts indicate their strength. American bolts use radial lines for this purpose, while most

American nuts do not have strength markings. Mismatched or incorrect fasteners can result in damage

or malfunction, or possibly personal injury. Therefore, fasteners removed should be saved for reuse in

the same locations whenever possible. Where the

fasteners are not satisfactory for re-use, care should

be taken to select a replacement that matches the

original.

Cleanliness and Care of

Outboard Motor

A marine power product is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten thousands of

an inch./mm. When any product component is serviced, care and cleanliness are important. Throughout

this manual, it should be understood that proper

cleaning, and protection of machined surfaces and

friction areas is a part of the repair procedure. This is

considered standard shop practice even if not specifically stated.

i90-830234R3 DECEMBER 1997

Page 3

Whenever components are removed for service,

they should be retained in order. At the time of installation, they should be installed in the same locations

and with the same mating surfaces as when removed.

Before raising or removing and outboard engine from

a boat, the following precautions should be adhered

to:

How To Use This Manual

The manual is divided into SECTIONS (shown, right)

which represents major components and systems.

Some SECTIONS are further divided into PARTS.

Each P ART has a title page. A “T able of Contents” for

the particular P ART is printed on the back page of the

title page.

1. Check that flywheel is secured to end of crankshaft with a locknut and lifting eye is threaded into

flywheel a minimum of 5 turns.

2. Connect a hoist of suitable strength to the lifting

eye.

In addition, personnel should not work on or under an

outboard which is suspended. Outboards should be

attached to work stands, or lowered to ground as

soon as possible.

We reserve the right to make changes to this manual

without prior notification.

Refer to dealer service bulletins for other pertinent information concerning the products described in this

manual.

Propeller Information

For in-depth information on marine propellers and

boat performance – see your Authorized Dealer for

the illustrated “What Y ou Should Know About Quicksilver Propellers... and Boat Performance Information” (90-86144).

SECTIONS and PARTS are listed on the “Service

Manual Outline” sheet which immediately follows the

cover of this book.

Page Numbering

Two number groups appear at the bottom of each

page. The example below is self-explanatory.

90-830234 R3 NOVEMBER 1997

Revision No. 3

Month of Printing

Year of Printing

EXAMPLE:

LOWER UNIT - 6A-7

Section Description

Section Number

Part of Section Letter

Page Number

ii 90-830234R3 DECEMBER 1997

Page 4

Service Manual Outline

Section 1 - Important Information

A - Specifications

B - Maintenance

C - General Information

D - Outboard Installation

Section 2 - Electrical

A - Ignition

B - Charging & Starting System

C - Timing, Synchronizing & Adjusting

D - Wiring Diagrams

Section 3 - Fuel System

A - Fuel Pump

B - Carburetor

C - Oil Injection

D - Emissions

Section 4 - Powerhead

Section 5 - Mid-Section

A - Clamp/Swivel Brackets & Drive Shaft Housing

B - Power Trim (S/N-USA 0G360002/BEL-9934136 and Below)

C - Power Trim (S/N-USA 0G360003/BEL-9934137 and Above)

D - Shock Absorber

E - Manual Tilt

Section 6 - Lower Unit

A - Lower Unit

B - Jet Drive

Section 7 - Attachments/Control Linkage

A - Throttle/Shift Linkage

B - Tiller Handle

Section 8 - Manual Starter

Important

Information

1

Electrical

2

Fuel System

3

Powerhead

4

Mid-Section

5

Lower Unit

6

Attachments/

Control Linkage

7

Manual Starter

8

90-830234R3 DECEMBER 1997

iii

Page 5

IMPORTANT

INFORMATION

1

A

SPECIFICATIONS

52485

Page 6

Table of Contents

Master Specifications 1A-1. . . . . . . . . . . . . . . . . . . . .

Page

1A-0 - IMPORTANT INFORMATION 90-830234R3 DECEMBER 1997

Page 7

Master Specifications

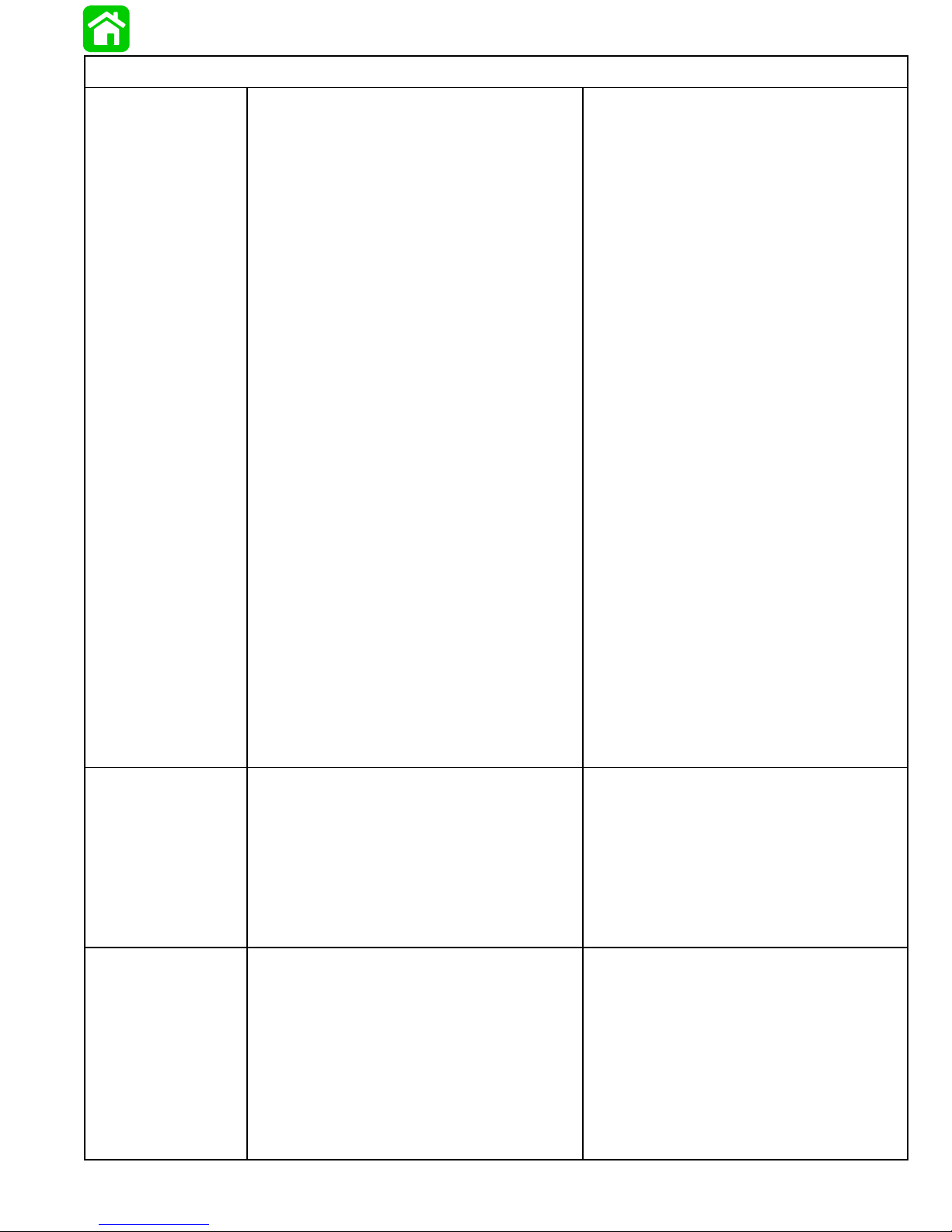

Model 65/80 Jet/75/90/100/115/125

HORSEPOWER

(KW)

OUTBOARD

WEIGHT

CYLINDER

BLOCK

STROKE Length 2.93 in. (74.42mm)

CYLINDER

BORE

PISTON Piston Type

REEDS Reed Stand Open (Max.)

TEMPERATURE

SWITCH

Model 75

Model 65 Jet/90

Model 100

Model 80 Jet/115

Model 125

Model 65 Jet

Model 75/90

Model 80 Jet

Model 100/115/125

Model 65 Jet/75/90

Type

Displacement

Model 80 Jet/100/115/125

Type

Displacement

Diameter (Standard)

Taper/Out of Round Maximum

Bore Type

Standard

0.015 in. (0.381mm) Oversize

0.030 in. (0.762mm) Oversize

Reed Stop (Max.)

T emperature Normal

190°F ± 8° (88°C ± 4°C)

170°F ± 8° (77°C ± 4°C)

75 (55.9)

90 (67.1)

100 (74.6)

115 (85.8)

125 (93.2)

315 lbs. (143kg)

305 lbs. (139kg)

357 lbs. (162kg)

348 lbs. (158kg)

In-line 3 Cylinder, 2 Cycle, Loop Charged

84.6 cu. in. (1387cc)

In-Line 4 Cylinder, 2 Cycle, Loop Charged

112.8 cu. in. (1848.8cc)

3.50 in. (88.9mm)

0.003 in. (0.076mm)

Cast Iron

Aluminum

3.495 in. (88.773mm)

3.510 in. (89.154mm)

3.525 in. (89.535mm)

0.020 in. (0.50mm)

Not Adjustable

Open – No Continuity

Closed – Continuity

Open – No Continuity

GEAR

HOUSING

FUEL

SYSTEM

Model 75/90

Gear Ratio

Gearcase Capacity

Forward Gear - No. of Teeth-Type

Pinion Gear - No. of Teeth-Type

Pinion Height

Forward Gear Backlash

Water Pressure @ RPM

Model 100/115/125

Gear Ratio

Gearcase Capacity

Forward Gear - No. of Teeth-Type

Pinion Gear - No. of Teeth-Type

Pinion Height

Forward Gear Backlash

Water Pressure @ RPM

Fuel

Recommended Gasoline

Recommended Oil

Gasoline/Oil Ratio

Fuel Pressure – @ Idle

– @ WOT

2.3:1

22.5 fl. oz. (655ml)

30

13

0.025 in. (0.64mm)

0.012 in. to 0.019 in. (0.30mm to 0.48mm)

10 to 15 PSI (69 to 103 kPa) @

5250 RPM

2.07:1

22.5 fl. oz. (655ml)

29

14

0.025 in. (0.64mm)

0.015 in. – 0.022 in. (0.38mm – 0.55mm)

10 – 15 PSI @ 5250 RPM

Gasoline and Oil

Unleaded 87 Octane Minimum

Quicksilver TC-W II or TC-W3 Outboard Oil

50:1 (25:1 Break-In)

3-1/2 PSI

6 PSI

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1A-1

Page 8

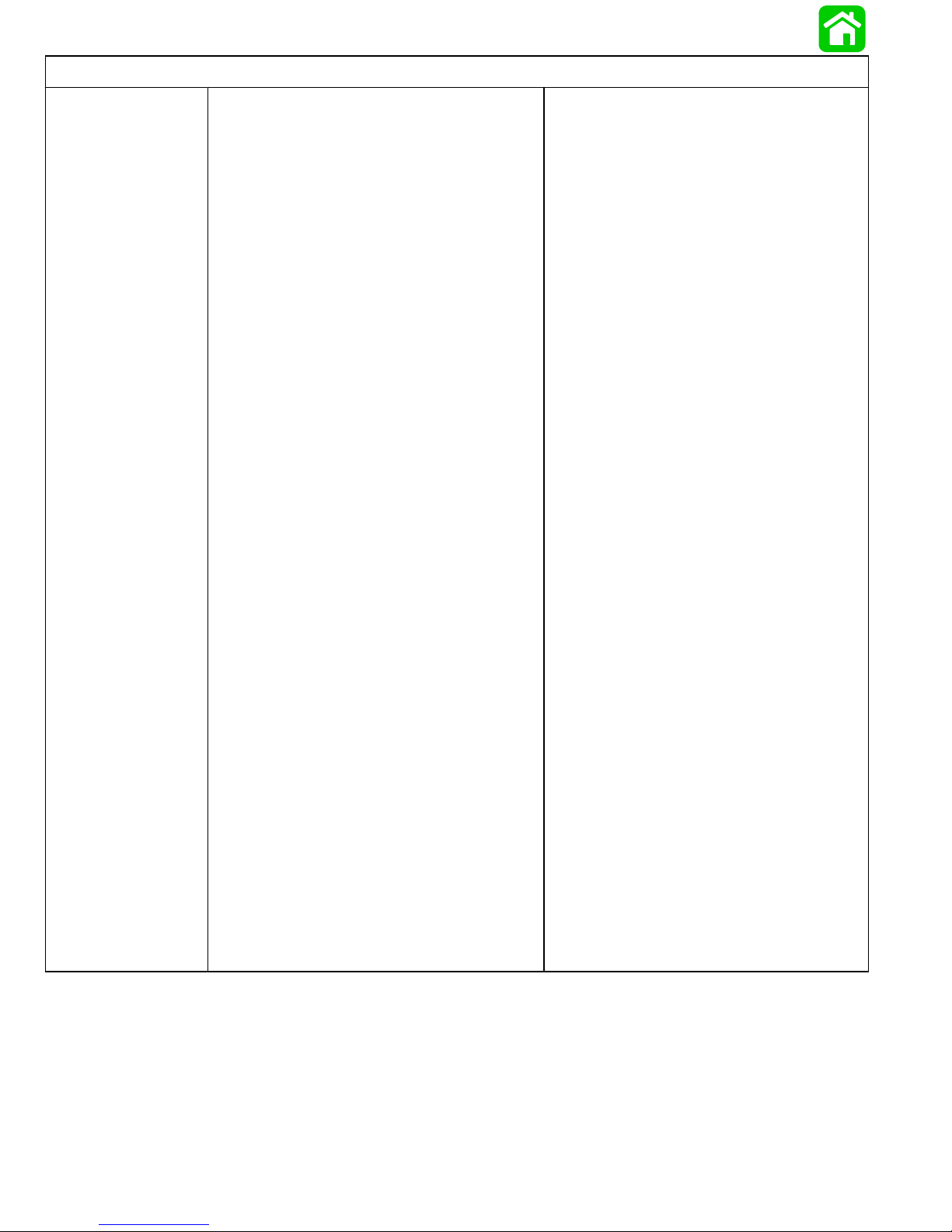

Model 65/80 Jet/75/90/100/115/125

OIL

INJECTION

STARTING

SYSTEM

Model 65 Jet/75/90

Oil Tank Capacity/Approx. Time

Max. Run Time Per Tank @ WOT

Oil Remaining When Alarm Sounds

Max. Run Time @ W.O.T. After

Alarm Sounds

Gasoline/Oil Ratio @ Idle

Gasoline/Oil Ratio @ W.O.T

Output @ 700 RPM for 15 Minutes

with Pump @ Full Open

Model 80 Jet/100/115/125

Oil Tank Capacity/Approx. Time

Max. Run Time Per Tank @ WOT

Oil Remaining When Alarm Sounds

Max. Run Time @ W.O.T. After

Alarm Sounds

Gasoline/Oil Ratio @ Idle

Gasoline/Oil Ratio @ W.O.T

Output @ 700 RPM for 15 Minutes

with Pump @ Full Open

Manual Start - Commercial 75

Manual Start - All Electric Models

Electric Start - Model 65 Jet/75/90

Starter Draw (Under Load)

Starter Draw (No Load)

1 gallon (3.78 liters)

6 Hours

1 qt. (.95 liters)

1 Hour Approx.

80:1

50:1

22cc Min.

1.4 gal. (5.3Liter)

5 hrs.

1 qt. (0.95Liter)

50 min.

80:1

50:1

29cc Minimum

Recoil Starter

Emergency Starter Rope

120 Amperes

75 Amperes

Electric Start - Model 80Jet/100/115/125

Starter Draw (Under Load)

Starter Draw (No Load)

Battery Rating

150 Amperes

75 Amperes

Min. Reserve Cap. Rating of 100 Min. and

CCA of 350 Amperes

1A-2 - IMPORTANT INFORMATION 90-830234R3 DECEMBER 1997

Page 9

Model 65/80 Jet/75/90/100/115/125

CHARGING

SYSTEM

Alternator Model

3 Cyl. Manual – Black & Red Stator

3 Cyl. Electric – Black Stator

Stamped 398-9710A3

Serial Number

USA 0D283222 – 0G280043

Belgium 09793577 – 09879064

3 Cyl. Electric – Black Stator

Stamped 398-9873A24

Serial Number

USA 0G280044 – 0G404505

Belgium 09879065 – 09916672

3 Cyl. Electric – Red Stator

Stamped 398-832075A3

Serial Number

USA 0G404506 and Above

Belgium 09916673 and Above

4 Cyl. Electric – Black Stator

Stamped 398-9710A31

Serial Number

USA 0D283222 – 0G301750

Belgium 09793577 – NA

Alternator Output @ 5250 RPM

10 Amperes

16 Amperes

14 Amperes

16 Amperes

16 Amperes

IGNITION

SYSTEM

C

A

R

B

U

R

E

T

O

R

4 Cyl. Electric – Black Stator

Stamped 398-9710A33

Serial Number

USA 0G301751 – 0G404616

Belgium NA – 09916721

4 Cyl. Electric – Red Stator

Stamped 398-832075A3

Serial Number

USA 0G404617 and Above

Belgium 09916722 and Above

Model 65 Jet/75/90

Type

Spark Plug Type (NGK)

Spark Plug Gap

Optional (Inductor Plug)

Model 80 Jet/100/115/125

Type

Spark Plug Type

Spark Plug Gap

Optional (Inductor Plug)

Idle RPM

Wide Open Throttle (WOT) RPM

– Model 75/80 Jet/100/115/125

– Model 65 Jet/90

Idle Mixture Screw Adjustment

(Preset - Turns Out)

Model 75Work/75

Model 65 Jet/90

Model 80 Jet/100/115/125

Float Setting

Float Weight

16 Amperes

16 Amperes

Capacitor Discharge

NGK BUHW-2

Surface Gap

NGK BUZHW-2

Capacitor Discharge

NGK BP8H-N-10

0.040 in. (1.0mm)

BPZ8H-N-10

675 ± 25 RPM

4750 – 5250

5000 – 5500

1-1/8 ± 1/4 TURN

1-1/4 ± 1/4 TURN

1 – 1-1/2 TURNS

9/16 in. (± 0.015 in.)

12.29mm (± 0.38 mm)

7 Grams (± 0.4 Grams)

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1A-3

Page 10

Main Jet

– Model 75

WME-29 – Carb #1

Model 65/80 Jet/75/90/100/115/125

– Carb #2

– Carb #3

.050

.052

.050

WME-41/46– Carb #1

– Carb #2

– Carb #3

WME-59 – Carb #1

– Carb #2

– Carb #3

WME-59 – Carb #3A

WME-75 – Carb #1

– Carb #2

– Carb #3

WME-77 – Carb #1

– Carb #2

– Carb #3

– Model 75 Work

WME-30 – Carb #1

– Carb #2

_ Carb #3

WME-47/48/76

– Carb #1

– Carb #2

– Carb #3

.052

.052

.052

.052

.054

.052

.054

.052

.054

.054

.054

.054

.054

.050

.052

.050

.054

.054

.054

WME-60/61 – Carb #1

– Carb #2

– Carb #3

– Model 65 Jet/90

WME-31 – Carb #1

– Carb #2

– Carb #3

WME-49/62 – Carb #1

– Carb #2

– Carb #3

WME-62-3A – Carb #3

WME-78 – Carb #1

– Carb #2

– Carb #3

.054

.054

.054

.062

.064

.062

.062

.064

.062

.064

.062

.064

.064

1A-4 - IMPORTANT INFORMATION 90-830234R3 DECEMBER 1997

Page 11

Model 65/80 Jet/75/90/100/115/125

C

A

R

B

U

– Model 100

WME-32 – Carb #1

– Carb #2

– Carb #3

– Carb #4

.046

.048

.052

.052

R

E

T

O

R

WME-50 – Carb #1

– Carb #2

– Carb #3

– Carb #4

WME-50-3A – Carb #3

WME-79 – Carb #1

– Carb #2

– Carb #3

– Carb #4

.048

.050

.048

.052

.050

.048

.050

.050

.052

Model 115

WME-33 – Carb #1

– Carb #2

– Carb #3

– Carb #4

.052

.056

.056

.060

Model 80Jet/115

WME-40 – Carb #1

– Carb #2

– Carb #3

– Carb #4

.066

.068

.068

.070

WME-40 – Carb #1A

– Carb #2A

– Carb #3A

– Carb #4A

WME-51 – Carb #1

– Carb #2

– Carb #3

– Carb #4

WME-51-3A – Carb #3

WME-80 – Carb #1

– Carb #2

– Carb #3

– Carb #4

.060

.070

.070

.074

.062

.062

.060

.064

.062

.060

.064

.062

.064

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1A-5

Page 12

Model 65/80 Jet/75/90/100/115/125

C

A

R

B

U

R

E

Model 125

WME-34 – Carb #1

– Carb #2

– Carb #3

– Carb #4

T

O

R

WME-52 – Carb #1

– Carb #2

– Carb #3

– Carb #4

WME-52-3A – Carb #3

.

.066

.068

.070

.072

.070

.080

.078

.082

.080

M

WME-81 – Carb #1

– Carb #2

– Carb #3

– Carb #4

.070

.080

.080

.082

Vent Jet

WME-46/47/48/49

.094

WME-32/33/34/40/50/51/52/59/60/61/62/

75/76/77/78/79/80/81

T

I

I

N

G

Idle (All Models 1994/1995/1996/1997)

Model 65 Jet/75/90

Model 80 Jet/100/115/125

Maximum BTDC (1994/1995)

@ Cranking Speed

– Model 75

2° ATDC – 6° BTDC

4° ATDC – 2° BTDC

– Model 65/80 Jet/90/100/115/125

None

20° BTDC

22° BTDC

@ 3000 RPM

– Model 75

– Model 65/80 Jet/90/100/115/125

18° BTDC

20° BTDC

Maximum BTDC (1996/1997)

@ Cranking Speed

– Model 75

– Model 65/Jet/90

– Model 80 Jet/100/115/125

20° BTDC

22° BTDC

25° BTDC

@ 3000 RPM

– Model 75

– Model 65/Jet/90

– Model 80 Jet/100/115/125

18° BTDC

20° BTDC

23° BTDC

Firing Order

1994/1995

Model 65 Jet/75/90

Model 80 Jet/100/115/125

1-3-2

1-3-2-4

1996/1997/1998

Model 65 Jet/75/90

Model 80 Jet/100/115/125

1A-6 - IMPORTANT INFORMATION 90-830234R3 DECEMBER 1997

1-2-3

1-3-2-4

Page 13

IMPORTANT

INFORMATION

1

C

GENERAL INFORMATION

Page 14

B

Table of Contents

Table of Contents 1C-0. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number Location 1C-1. . . . . . . . . . . . . . . . . . . . . . .

Conditions Affecting Performance 1C-1. . . . . . . . . . . . . .

Weather 1C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boat 1C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 1C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Following Complete Submersion 1C-3. . . . . . . . . . . . . . .

Submerged While Running 1C-3. . . . . . . . . . . . . . . . .

Salt Water Submersion 1C-3. . . . . . . . . . . . . . . . . . . .

Fresh Water Submersion 1C-3. . . . . . . . . . . . . . . . . .

Propeller Selection 1C-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Installation 1C-4. . . . . . . . . . . . . . . . . . . . . . . . . .

Power Trim System 1C-5. . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 1C-5. . . . . . . . . . . . . . . . . . . . . . .

Power Trim Operation 1C-5. . . . . . . . . . . . . . . . . . . . . .

Trim “In” Angle Adjustment 1C-6. . . . . . . . . . . . . . . . .

Compression Check 1C-6. . . . . . . . . . . . . . . . . . . . . . . . . .

Painting Procedures 1C-7. . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning & Painting Aluminum Propellers & Gear

Housings 1C-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decal Application 1C-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decal Removal 1C-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instructions for “Wet” Application 1C-8. . . . . . . . . . . .

Page

90-830234R3 DECEMBER 19971C-0 - IMPORTANT INFORMATION NOVEM

Page 15

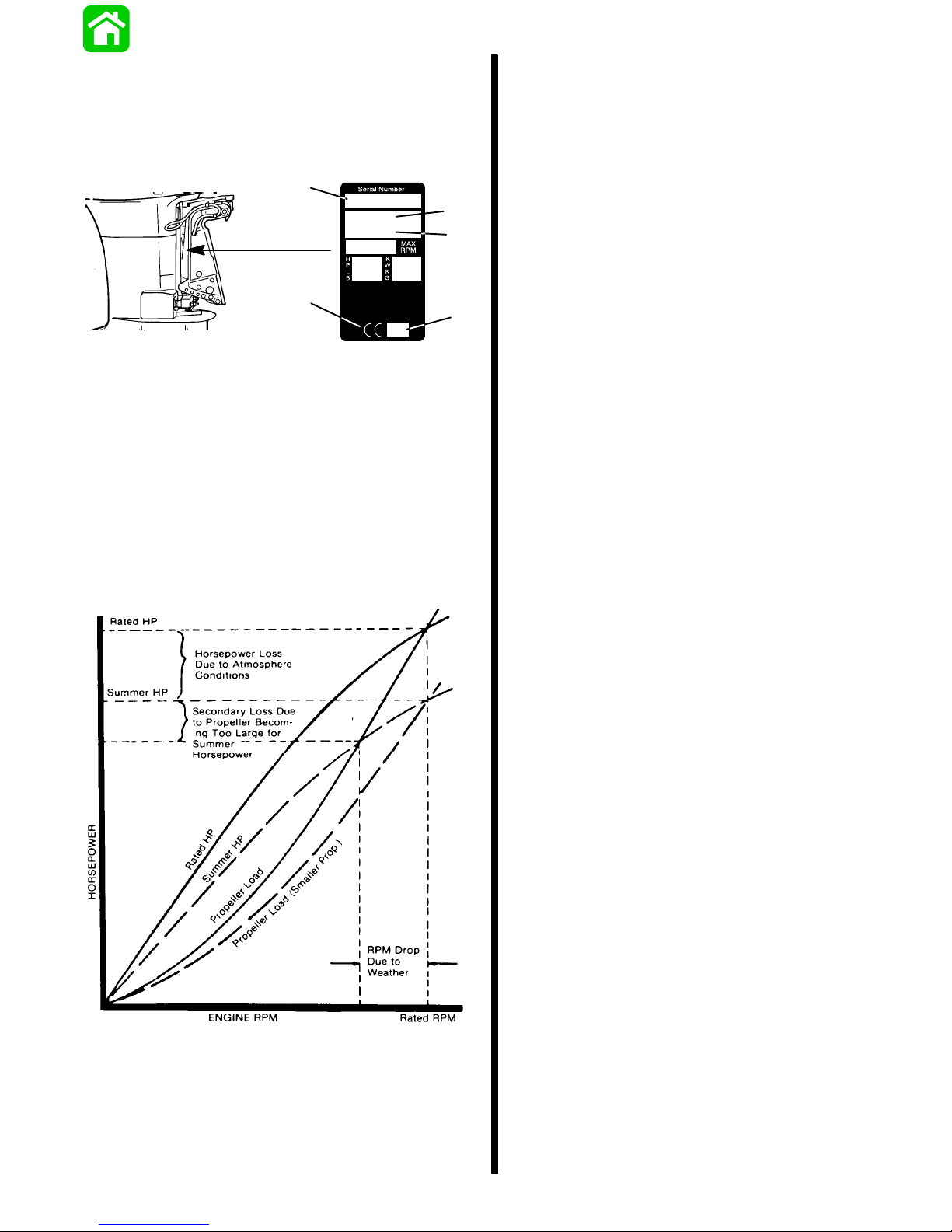

Serial Number Location

The Outboard serial number is located on the lower

starboard side of the engine block. A serial number

is also located on the starboard side of the swivel

bracket.

a

OGXXXXXX

19XX

XXXX

b

c

e

XX

a - Serial Number

b - Model Year

c - Model Description

d - Year Manufactured

e - Certified Europe Insignia

d

Conditions Affecting

Performance

Weather

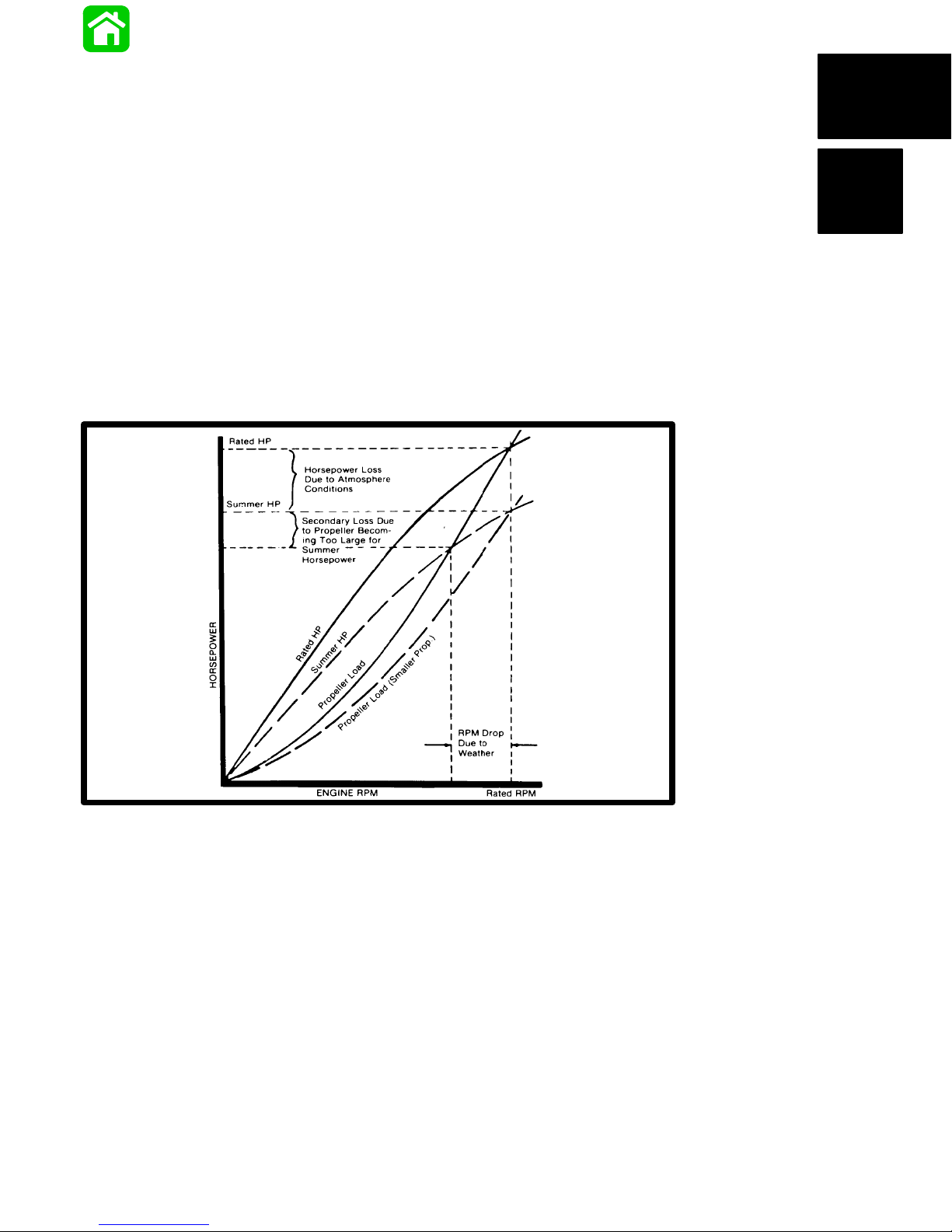

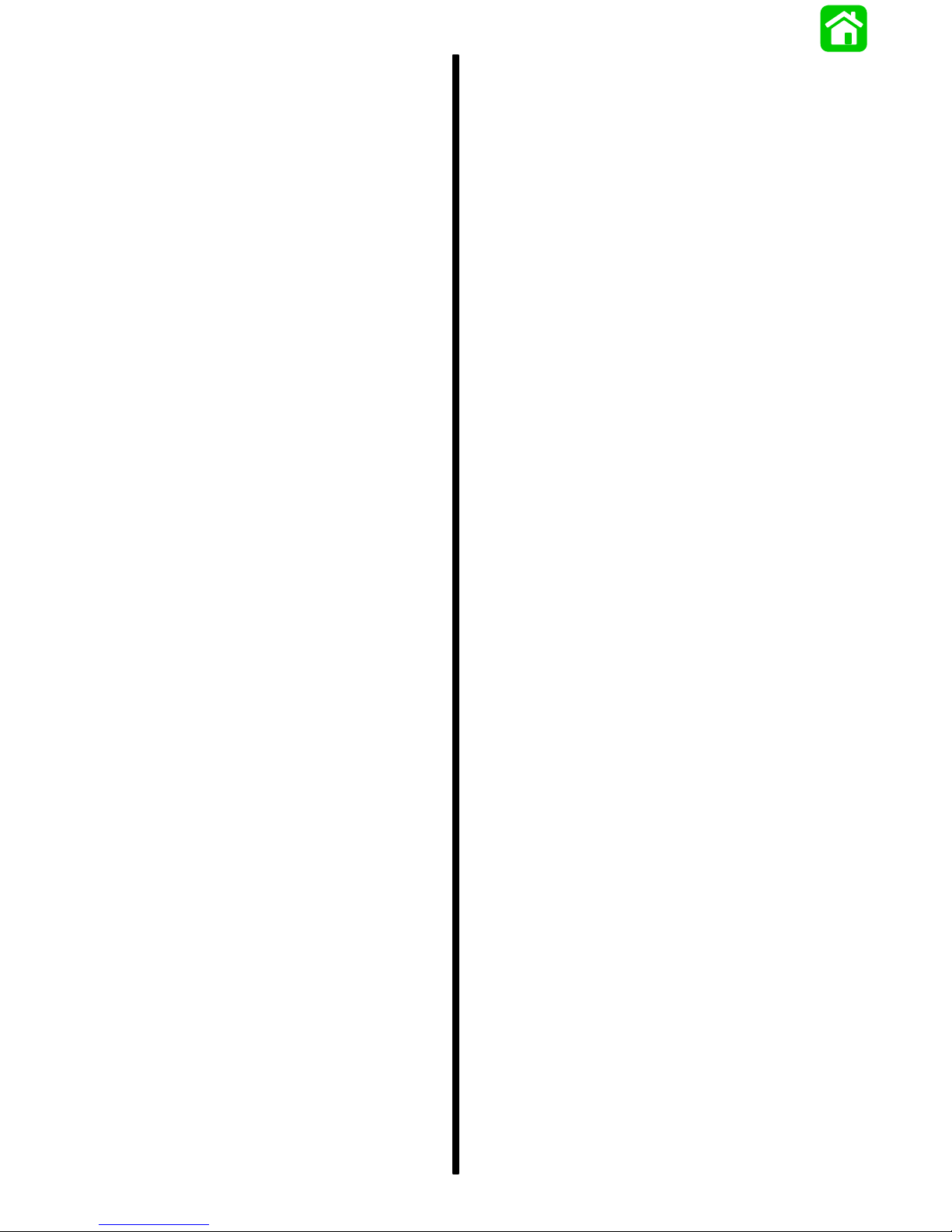

Corporations internationally have settled on adoption of I.S.O. (International Standards Organization)

engine test standards, as set forth in I.S.O. 3046

standardizing the computation of horsepower from

data obtained on the dynamometer, correcting all values to the power that the engine will produce at sea

level, at 30% relative humidity at 77° F (25° C) temperature and a barometric pressure of 29.61 inches

of mercury.

Summer Conditions of high temperature, low barometric pressure and high humidity all combine to reduce the engine power. This, in turn, is reflected in

decreased boat speeds--as much as 2 or 3 milesper-hour (3 or 5 Km per-hour) in some cases. (Refer

to previous chart.) Nothing will regain this speed for

the boater, but the coming of cool, dry weather.

In pointing out the practical consequences of weather effects, an engine--running on a hot, humid summer day--may encounter a loss of as much as 14%

of the horsepower it would produce on a dry, brisk

spring or fall day. The horsepower, that any internal

combustion engine produces, depends upon the

density of the air that it consumes and, in turn, this

density is dependent upon the temperature of the air ,

its barometric pressure and water vapor (or humidity)

content.

Accompanying this weather-inspired loss of power is

a second but more subtle loss. At rigging time in early

spring, the engine was equipped with a propeller that

allowed the engine to turn within its recommended

RPM range at full throttle. With the coming of the

summer weather and the consequent drop in available horsepower, this propeller will, in ef fect, become

too large. Consequently , the engine operates at less

than its recommended RPM.

It is a known fact that weather conditions exert a profound effect on power output of internal combustion

engines. Therefore, established horsepower ratings

refer to the power that the engine will produce at its

rated RPM under a specific combination of weather

conditions.

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1C-1

Due to the horsepower/RPM characteristics of an engine, this will result in further loss of horsepower at

the propeller with another decrease in boat speed.

This secondary loss, however, can be regained by

switching to a smaller pitch propeller that allows the

engine to again run at recommended RPM.

For boaters to realize optimum engine performance

under changing weather conditions, it is essential

that the engine have the proper propeller to allow it

to operate at or near the top end of the recommended

maximum RPM range at wide-open-throttle with a

normal boat load.

Not only does this allow the engine to develop full

power, but equally important is the fact that the engine also will be operating in an RPM range that discourages damaging detonation. This, of course, enhances overall reliability and durability of the engine.

Page 16

B

Boat

WEIGHT DISTRIBUTION

1. Proper positioning of the weight inside the boat

(persons and gear) has a significant effect on the

boat’s performance, for example:

a. Shifting weight to the rear (stern)

(1.)Generally increases top speed.

(2.) If in excess, can cause the boat to por-

poise.

(3.)Can make the bow bounce excessively in

choppy water.

(4.)Will increase the danger of the following

- wave splashing into the boat when coming off plane.

b. Shifting weight to the front (bow)

WATER ABSORPTION

It is imperative that all through hull fasteners be

coated with a quality marine sealer at time of installation. Water intrusion into the transom core and/or inner hull will result in additional boat weight (reduced

boat performance), hull decay and eventual structural failure.

CAVITATION

Cavitation is caused by water vapor bubbles forming

either from a sharp edge or angle on the gear case

or from an irregularity in the propeller blade itself.

These vapor bubbles flow back and collapse when

striking the surface of the propeller blade resulting in

the erosion of the propeller blade surface. If allowed

to continue, eventual blade failure (breakage) will

occur.

(1.)Improves ease of planing off.

(2.)Generally improves rough water ride.

(3.)If excessive, can make the boat veer left

and right (bow steer).

BOTTOM

For maximum speed, a boat bottom should be

nearly a flat plane where it contacts the water and

particularly straight and smooth in fore-and-aft direction.

1. Hook: Exists when bottom is concave in fore-

and-aft direction when viewed from the side.

When boat is planing, “hook” causes more lift on

bottom near transom and allows bow to drop,

thus greatly increasing wetted surface and reducing boat speed. “Hook” frequently is caused

by supporting boat too far ahead of transom while

hauling on a trailer or during storage.

2. Rocker: The reverse of hook and much less

common. “Rocker” exists if bottom is convex in

fore-and-aft direction when viewed from the side,

and boat has strong tendency to porpoise.

3. Surface Roughness: Moss, barnacles, etc., on

boat or corrosion of outboard’s gear housing increase skin friction and cause speed loss. Clean

surfaces when necessary.

Engine

DETONATION

Detonation in a 2-cycle engine resembles the “pinging” heard in an automobile engine. It can be otherwise described as a tin-like “rattling” or “plinking”

sound.

Detonation is an explosion of an unburned portion of

the fuel/air charge after the spark plug has fired. Detonation creates severe shock waves in the engine,

and these shock waves often find or create a weakness: The dome of a piston, cylinder head/gasket,

piston rings or piston ring lands, piston pin and roller

bearings.

A few of the most common causes of detonation in a

marine 2-cycle application are as follows:

• Over-advanced ignition timing.

• Use of low octane gasoline.

• Propeller pitch too high (engine RPM below rec-

ommended maximum range).

• Lean fuel mixture at or near wide-open-throttle.

• Spark plugs (heat range too hot - incorrect reach

- cross-firing).

• Inadequate engine cooling (deteriorated cooling

system).

• Combustion chamber/piston deposits (result in

higher compression ratio).

90-830234R3 DECEMBER 19971C-2 - IMPORTANT INFORMATION NOVEM

Page 17

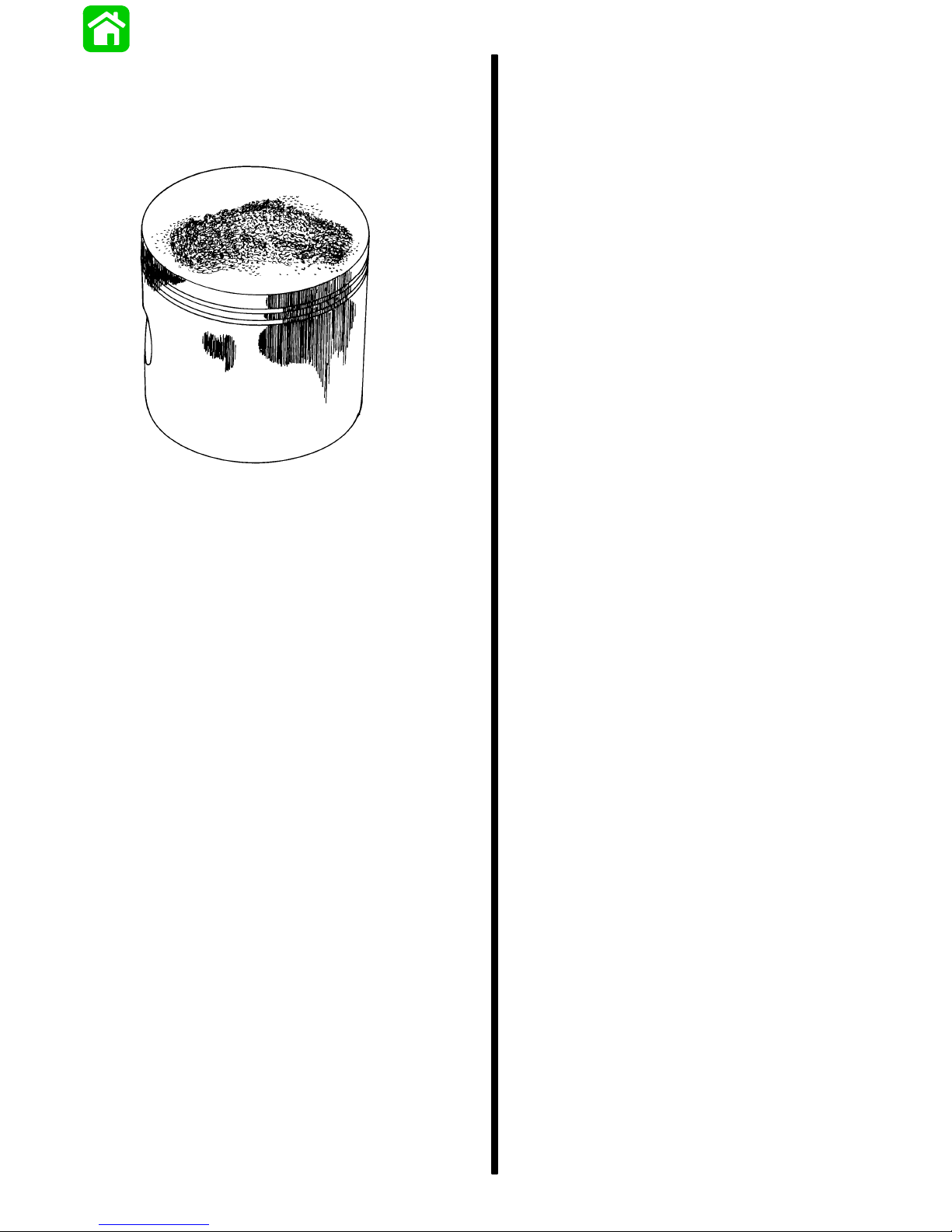

Detonation usually can be prevented if:

1. The engine is correctly set up.

Fresh Water Submersion (Special

Instructions)

2. Diligent maintenance is applied to combat the

detonation causes.

51115

Damaged Piston Resulting from Detonation

Following Complete

Submersion

Submerged While Running (Special

Instructions)

1. Recover engine as quickly as possible.

2. Remove cowling.

3. Flush exterior of outboard with fresh water to remove mud, weeds, etc. DO NOT attempt to start

engine if sand has entered powerhead, as powerhead will be severely damaged. Disassemble

powerhead if necessary to clean components.

4. Remove spark plugs and get as much water as

possible out of powerhead. Most water can be

eliminated by placing engine in a horizontal position (with spark plug holes down) and rotating flywheel.

5. Pour alcohol into carburetor throats (alcohol will

absorbed water). Again rotate flywheel.

6. Turn engine over and pour alcohol into spark plug

openings and rotate flywheel.

7. Turn engine over (place spark plug openings

down) and pour engine oil into throat of carburetors while rotating flywheel to distribute oil

throughout crankcase.

8. Again turn engine over and pour approximately

one teaspoon of engine oil into each spark plug

opening. Again rotate flywheel to distribute oil in

cylinders.

9. Remove and clean carburetors and fuel pump

assembly.

When an engine is submerged while running, the

possibility of internal engine damage is greatly increased. If, after engine is recovered and with spark

plugs removed, engine fails to turn over freely when

turning flywheel, the possibility of internal damage

(bent connecting rod and/or bent crankshaft) exists.

If this is the case, the powerhead must be disassembled.

Salt Water Submersion (Special

Instructions)

Due to the corrosive effect of salt water on internal

engine components, complete disassembly is necessary before any attempt is made to start the engine.

10. Dry all wiring and electrical components using

compressed air.

1 1. Disassemble the engine starter motor and dry the

brush contacts, armature and other corrodible

parts.

12. Reinstall spark plugs, carburetors and fuel pump.

13. Attempt to start engine, using a fresh fuel source.

If engine starts, it should be run for at least one

hour to eliminate any water in engine.

14. If engine fails to start, determine cause (fuel,

electrical or mechanical). Engine should be run

within 2 hours after recovery of outboard from

water, or serious internal damage may occur. If

unable to start engine in this period, disassemble

engine and clean all parts. Apply oil as soon as

possible.

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1C-3

Page 18

B

Propeller Selection

For in-depth information on marine propellers and

boat performance - written by marine engineers - see

your Authorized Dealer for the illustrated “What Y ou

Should Know About Quicksilver Propellers... and

Boat Performance Information” (Part No.

90-86144).

For best all around performance from your outboard/

boat combination, select a propeller that allows the

engine to operate in the upper half of the recommended full throttle RPM range with the boat normally loaded (refer to Specifications). This RPM range

allows for better acceleration while maintaining maximum boat speed.

3. After initial propeller installation, the following

common conditions may require that the propeller be changed to a lower pitch:

a. Warmer weather and great humidity will

cause an RPM loss.

b. Operating in a higher elevation causes an

RPM loss.

c. Operating with a damaged propeller or a dirty

boat bottom or gear housing will cause an

RPM loss.

d. Operation with an increased load (additional

passengers, equipment, pulling skiers, etc.).

If changing conditions cause the RPM to drop below

the recommended range (such as warmer, more humid weather, operation at higher elevations, increased boat load or a dirty boat bottom/gear case)

a propeller change or cleaning may be required to

maintain performance and ensure the outboard’s durability .

Check full-throttle RPM using an accurate tachometer with the engine trimmed out to a balanced-steering condition (steering effort equal in both directions)

without causing the propeller to “break loose”.

Refer to “Quicksilver Accessory Guide” for a complete list of available propellers.

1. Select a propeller that will allow the engine to operate at or near the top of the recommended full

throttle RPM range (listed in “Specifications,”

preceding) with a normal load. Maximum engine

speed (RPM) for propeller selection exists when

boat speed is maximum and trim is minimum for

that speed. (High RPM, caused by an excessive

trim angle, should not be used in determining correct propeller.) Normally , there is a 150-350 RPM

change between propeller pitches.

2. If full throttle operation is below the recommended range, the propeller MUST BE changed

to one with a lower pitch to prevent loss of performance and possible engine damage.

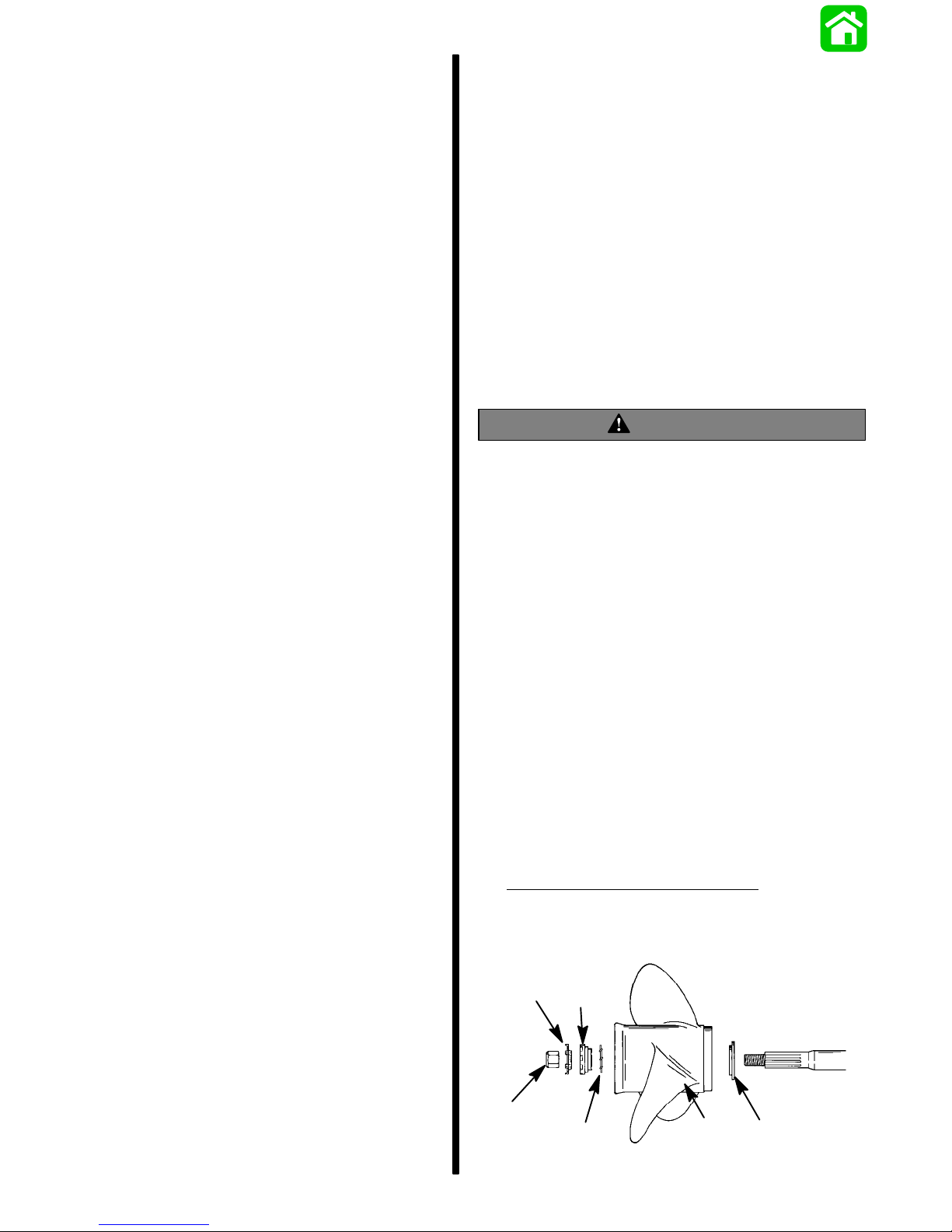

Propeller Installation

WARNING

If the propeller shaft is rotated while the engine

is in gear, there is the possibility that the engine

will crank over and start. To prevent this type of

accidental engine starting and possible serious

injury caused from being struck by a rotating propeller, always shift outboard to neutral position

and remove spark plug leads when you are servicing the propeller.

1. Shift outboard to neutral (N) position.

2. Remove leads from spark plugs to prevent engine from starting.

3. Coat the propeller shaft with Quicksilver Anti–

Corrosion Grease.

IMPORTANT: To prevent the propeller hub from

corroding and seizing to the propeller shaft, especially in salt water, always apply a coat of

Quicksilver Anti-Corrosion Grease to the entire

shaft at the recommended maintenance intervals

and also each time the propeller is removed.

4. Flo-Torque I Drive Hub Propellers

washer (a), propeller (b), continuity washer (c),

thrust hub (d), propeller nut retainer (e), and propeller nut (f) onto the shaft.

– Install thrust

e

d

f

c

90-830234R3 DECEMBER 19971C-4 - IMPORTANT INFORMATION NOVEM

b

a

Page 19

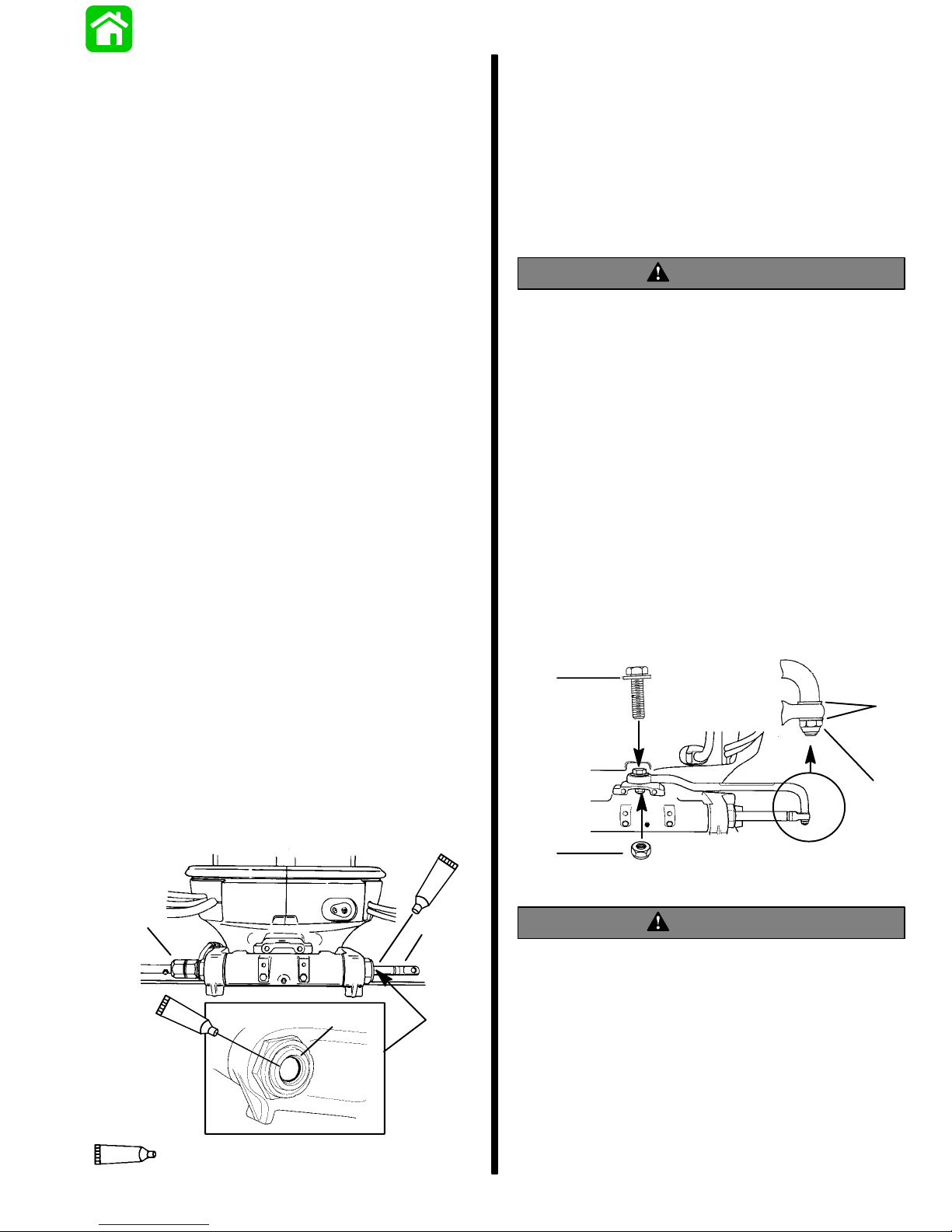

5. Flo-Torque II Drive Hub Propellers – Install forward thrust hub (a), replaceable drive sleeve (b),

propeller (c), thrust hub (d), propeller nut retainer

(e) and propeller nut (f) onto the shaft.

can result in loss of boat control as the outboard

can turn freely . The boat can now “spin out” or go

into a very tight maximum turn which, if unexpected, can result in occupants being thrown

within the boat or out of the boat.

e

f

d

6. Place a block of wood between gear case and

propeller and torque propeller nut to 55 lb. ft. (75

N·m).

7. Secure propeller nut by bending three of the tabs

into the thrust hub grooves.

b

c

a

Power Trim System

General Information

The power trim system is filled at the manufacturer

and is ready for use.

Trim outboard through entire trim and tilt range several times to remove any air from the system.

The trim system is pressurized and is not externally

vented.

Consider the following lists carefully:

TRIMMING IN OR DOWN CAN:

1. Lower the bow.

2. Result in quicker planing off, especially with a

heavy load or a stern heavy boat.

3. Generally improve the ride in choppy water.

4. Increase steering torque or pull to the right (with

the normal right hand rotation propeller).

5. In excess, lower the bow of some boats to a point

where they begin to plow with their bow in the water while on plane. This can result in an unexpected turn in either direction called “bow steering” or “over steering” if any turn is attempted or if

a significant wave is encountered.

WARNING

Avoid possible serious injury or death. Adjust

outboard to an intermediate trim position as

soon as boat is on plane to avoid possible ejection due to boat spin-out. Do not attempt to turn

boat when on plane if outboard is trimmed extremely in or down and there is a pull on the steering wheel or tiller handle.

Power Trim Operation

With most boats, operating around the middle of the

“trim” range will give satisfactory results. However, to

take full advantage of the trimming capability there

may be times when you choose to trim your outboard

all the way in or out. Along with an improvement in

some performance aspects comes a greater responsibility for the operator, and this is being aware of

some potential control hazards. The most significant

control hazard is a pull or “torque” that can be felt on

the steering wheel or tiller handle. This steering

torque results from the outboard being trimmed so

that the propeller shaft is not parallel to the water surface.

W ARNING

Avoid possible serious injury or death. When the

outboard is trimmed in or out beyond a neutral

steering condition, a pull on the steering wheel or

tiller handle in either direction may result. Failure

to keep a continuous firm grip on the steering

wheel or tiller handle when this condition exists

TRIMMING OUT OR UP CAN:

1. Lift the bow higher out of the water.

2. Generally increase top speed.

3. Increase clearance over submerged objects or a

shallow bottom.

4. Increase steering torque or pull to the left at a normal installation height (with the normal right hand

rotation propeller).

5. In excess, cause boat “porpoising” (bouncing) or

propeller ventilation.

6. Cause engine overheating if any water intake

holes are above the water line.

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1C-5

Page 20

B

Trim “In” Angle Adjustment

Compression Check

Some outboard boats, particularly some bass boats,

are built with a greater than normal transom angle

which will allow the outboard to be trimmed further

“in” or “under”. This greater trim “under” capability is

desirable to improve acceleration, reduce the angle

and time spent in a bow high boat, altitude during

planing off, and in some cases, may be necessary to

plane off a boat with aft live wells, given the variety of

available propellers and height range of engine installations.

However, once on plane, the engine should be

trimmed to a more intermediate position to a avoid a

bow-down planing condition called “plowing”. Plowing can cause “bow steering” or “over steering” and

inefficiently consumes horsepower . In this condition,

if attempting a turn or encountering a diagonal, moderate wake, a more abrupt turn than intended may result.

In rare circumstances, the owner may decide to limit

the trim in. This can be accomplished by repositioning the tilt stop pins into whatever adjustment holes

in the transom brackets is desired.

WARNING

1. Remove spark plugs.

2. Install compression gauge in spark plug hole.

3. Hold throttle plate at W.O.T.

4. Crank the engine over until the compression

reading peaks on the gauge. Record the reading.

5. Check and record compression of each cylinder.

The highest and lowest reading recorded should

not differ by more than 15% (see example chart

below). A reading below 120 psi might indicate a

total engine wear problem.

Example of compression test differences

Maximum (psi)

180 162

150 127.5

6. Compression check is important because an

engine with low or uneven compression cannot

be tuned successfully to give peak performance.

It is essential, therefore, that improper compression be corrected before proceeding with an

engine tuneup.

Minimum (psi)

Avoid possible serious injury or death. Adjust

outboard to an intermediate trim position as

soon as boat is on plane to avoid possible ejection due to boat spin-out. Do not attempt to turn

boat when on plane if outboard is trimmed extremely in or down and there is a pull on the steering wheel or tiller handle.

a

7. Cylinder scoring: If powerhead shows any indication of overheating, such as discolored or

scorched paint, visually inspect cylinders for

scoring or other damage as outlined in Section 4

“Powerhead.”

a - Stainless Steel T ilt Pin (P/N 17-49930A1)

90-830234R3 DECEMBER 19971C-6 - IMPORTANT INFORMATION NOVEM

Page 21

Painting Procedures

3. Sand blistered area with 3M 180 grit sandpaper

or P180 Gold Film Disc to remove paint blisters

only. Feather edge all broken paint edges.

Cleaning & Painting Aluminum

Propellers & Gear Housings

WARNING

Avoid serious injury from flying debris. A void serious injury from airborne particles. Use eye and

breathing protection with proper ventilation.

PROPELLERS

1. Sand the entire area to be painted with 3M 120

Regalite Polycut or coarse Scotch-Brite, disc or

belts.

2. Feather edges of all broken paint edges. Try not

to sand through the primer.

3. Clean the surface to be painted using PPG

Industries DX330 Wax and Grease Remover or

equivalent (Xylene or M.E.K.).

4. If bare metal has been exposed, use Quicksilver’s Light Gray Primer.

5. Allow a minimum of 1 hour dry time and no more

than 1 week before applying the finish coat.

6. Apply the finish coat using Quicksilver’s EDP

Propeller Black.

GEAR HOUSINGS

The following procedures should be used in refinishing gear housings. This procedure will provide the

most durable paint system available in the field. The

materials recommended are of high quality and

approximate marine requirements. The following

procedure will provide a repaint job that compares

with a properly applied factory paint finish. It is recommended that the listed materials be purchased

from a local Ditzler Automotive Finish Supply Outlet.

The minimum package quantity of each material

shown following is sufficient to refinish several gear

housings.

Procedure:

4. Clean gear housing thoroughly with (DX-330)

wax and grease remover.

5. Spot repair surfaces where bare metal is exposed with (DX-503) alodine treatment.

IMPORTANT: Do not use any type of aerosol

spray paints as the paint will not properly adhere

to the surface nor will the coating be sufficiently

thick to resist future paint blistering.

6. Mix epoxy chromate primer (DP-40) with equal

part catalyst (DP-401) per manufacturers

instructions, allowing proper induction period for

permeation of the epoxy primer and catalyst.

7. Allow a minimum of one hour drying time and no

more than one week before top coating assemblies.

8. Use Ditzler Urethane DU9000 for Mercury Black,

DU34334 for Mariner Grey, and DU35466 for

Force Charcoal, and DU33414M for Sea Ray

White. Catalyze all three colors with Ditzler DU5

catalyst mixed 1:1 ratio. Reduce with solvents

per Ditzler label.

CAUTION

Be sure to comply with instructions on the label

for ventilation and respirators. Using a spray

gun, apply one half to one mil even film thickness. Let dry , flash off for five minutes and apply

another even coat of one half to one mil film thickness. This urethane paint will dry to the touch in

a matter of hours, but will remain sensitive to

scratches and abrasions for a few days.

9. The type of spray gun used will determine the

proper reduction ratio of the paint.

IMPORT ANT : Do not paint sacrificial zinc trim tab

or zinc anode.

10. Cut out a cardboard “plug” for trim tab pocket to

keep paint off of mating surface to maintain good

continuity circuitry between trim tab and gear

housing.

1. Wash gear housing with a muriatic acid base

cleaner to remove any type of marine growth,

and rinse with water, if necessary.

2. Wash gear housing with soap and water, then

rinse.

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1C-7

Page 22

B

Decal Application

Decal Removal

DECAL APPLICATION

1

1. Mix

/2 ounce (16 ml) of dish washing liquid in one

gallon (4 l) of cool water to use as wetting solution.

1. Mark decal location before removal to assure

proper alignment of new decal.

2. Carefully soften decal and decal adhesive with a

heat gun or heat blower while removing old decal.

3. Clean decal contact area with a 1:1 mixture of isopropyl alcohol and water.

4. Thoroughly dry decal contact area and check for

a completely cleaned surface.

Instructions for “Wet” Application

NOTE: The following decal installation instructions

are provided for a “Wet” installation. All decals

should be applied wet.

TOOLS REQUIRED

1. Plastic Squeegee*

2. Stick Pin

3. Dish Washing Liquid/Detergent without am-

monia** “Joy” and “Drift” are known to be compatible for this process.

** Automotive Body Filler Squeegee

** Do not use a soap that contains petroleum based

solvents.

SERVICE TIP: Placement of decals using the

“Wet” application will allow time to position decal. Read entire installation instructions on this

technique before proceeding.

NOTE: Leave protective masking, if present, on the

face of decal until final steps of decal installation. This

will ensure that the vinyl decal keeps it’s shape during

installation.

2. Place the decal face down on a clean work surface and remove the paper backing from “adhesive side” of decal.

3. Using a spray bottle, flood the entire “adhesive

side” of the decal with the pre-mixed wetting solution.

4. Flood area where the decal will be positioned

with wetting solution.

5. Position pre-wetted decal on wetted surface and

slide into position.

6. Starting at the center of the decal, “lightly”

squeegee out the air bubbles and wetting solution with overlapping strokes to the outer edge of

the decal. Continue going over the decal surface

until all wrinkles are gone and adhesive bonds to

the cowl surface.

7. Wipe decal surface with soft paper towel or cloth.

8. Wait 10 - 15 minutes.

9. Starting at one corner, “carefully and slowly” pull

the masking off the decal surface at a 180° angle.

NOTE: T o remove any remaining bubbles, pierce the

decal at one end of the bubble with stick pin and

press out the entrapped air or wetting solution with

your thumb (moving toward the puncture).

TEMPERATURE

IMPORTANT: Installation of vinyl decals should

not be attempted while in direct sunlight. Air and

surface temperature should be between 60°F

(15°C) and 100°F (38°C) for best application.

SURFACE PREPARATION

IMPORT ANT : Do not use a soap or any petroleum

based solvents to clean application surface.

Clean entire application surface with mild dish washing liquid and water. Rinse surface thoroughly with

clean water.

90-830234R3 DECEMBER 19971C-8 - IMPORTANT INFORMATION NOVEM

Page 23

IMPORTANT

INFORMATION

1

D

OUTBOARD INSTALLATION

Page 24

Table of Contents

Page

Determining Recommended Outboard

Mounting Height 1D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notice to Installer and Owner 1D-2. . . . . . . . . . . . . . . . . .

Boat Horsepower Capacity 1D-2. . . . . . . . . . . . . . . . .

Outboard Remote Control 1D-2. . . . . . . . . . . . . . . . . .

Selecting Accessories For The Outboard 1D-2. . . . .

Selecting Steering Cables and Remote Control

Cables 1D-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locate Center line Of The Outboard 1D-3. . . . . . . . .

Drilling Outboard Mounting Holes 1D-3. . . . . . . . . . . .

Lifting Outboard 1D-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastening Outboard To The Transom 1D-4. . . . . . . .

Single Steering Cable and Steering Link

Rod Installation 1D-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Ride Guide Steering Cable to the

Outboard 1D-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Link Rod Installation 1D-5. . . . . . . . . . . . . . .

Co-Pilot Installation (Tiller Handle models) 1D-6. . . . . . .

Remote Control Installation 1D-7. . . . . . . . . . . . . . . . . . . .

Required Side Mount Remote Control or Ignition

Key Switch Assembly 1D-7. . . . . . . . . . . . . . . . . . . . . . . . .

Boats Equipped with Side Mount

Remote Control 1D-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Boats Equipped with Panel Or Console Mount

Remote Control 1D-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Remote Wiring Harness to the Engine 1D-7

Shift and Throttle Cable Installation to the Outboard1D-8

Shift Cable Installation 1D-8. . . . . . . . . . . . . . . . . . . . .

Throttle Cable Installation 1D-9. . . . . . . . . . . . . . . . . .

Battery Connections 1D-10. . . . . . . . . . . . . . . . . . . . . . . . .

Set Up Instructions For Oil Injection System 1D-10. . . .

Filling The Oil Injection System 1D-10. . . . . . . . . . . . .

Bleeding Air From The Oil Injection System 1D-11. .

Adjusting The Oil Injection Pump 1D-11. . . . . . . . . . .

Trim Tab Adjustment 1D-12. . . . . . . . . . . . . . . . . . . . . . . . .

90-830234R3 DECEMBER 19971D-0 - IMPORTANT INFORMATION

Page 25

Notice to Installer and Owner

Outboard Remote Control

This manual as well as safety labels posted on the

outboard use the following safety alerts to draw your

attention to special safety instructions that should be

followed.

W ARNING

WARNING – Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION

CAUTION – Hazards or unsafe practices which could

result in minor injury or product or property damage.

Boat Horsepower Capacity

U.S. COAST GUARD CAPACITY

MAXIMUM HORSEPOWER XXX

MAXIMUM PERSON

CAPACITY (POUNDS) XXX

MAXIMUM WEIGHT

CAPACITY XXX

Do not overpower or overload your boat. Most boats

will carry a required capacity plate indicating the

maximum acceptable power and load as determined

by the manufacturer following certain federal guidelines. If in doubt, contact your dealer or the boat manufacturer.

W ARNING

Using an outboard that exceeds the maximum

horsepower limit of a boat can: 1. cause loss of

boat control 2. place too much weight at the transom altering the designed flotation characteristics of the boat or 3. cause the boat to break apart

particularly around the transom area. Overpowering a boat can result in serious injury , death, or

boat damage.

The remote control connected to your outboard must

be equipped with a start-in-gear protection device.

This prevents the engine from starting when the outboard is in gear.

WARNING

Avoid serious injury or death from a sudden unexpected acceleration when starting your engine. The design of this outboard requires that

the remote control used with it must have a built

in start-in-gear protection device.

Selecting Accessories For

The Outboard

Genuine Mercury Marine Quicksilver Accessories

have been specifically designed and tested for your

outboard.

Mercury Marine Quicksilver accessories are available from Mercury Marine dealers.

Some accessories not manufactured or sold by Mercury Marine are not designed to be safely used with

your outboard or outboard operating system. Acquire

and read the installation, operation, and maintenance manuals for all your selected accessories.

WARNING

Check with your dealer before installation of accessories. The misuse of acceptable accessories or the use of unacceptable accessories can

result in serious injury , death, or product failure.

Selecting Steering Cables

and Remote Control Cables

Refer to “Quicksilver Accessories Guide” to determine correct length of steering cables and remote

control cables.

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-1

IMPORT ANT : Steering cables and remote control

cables must be the correct length. Sharp bends

on too-short cables result in “kinks”; too-long

cables require unnecessary bends and/or loops.

Both conditions place extra stress on the cables.

Page 26

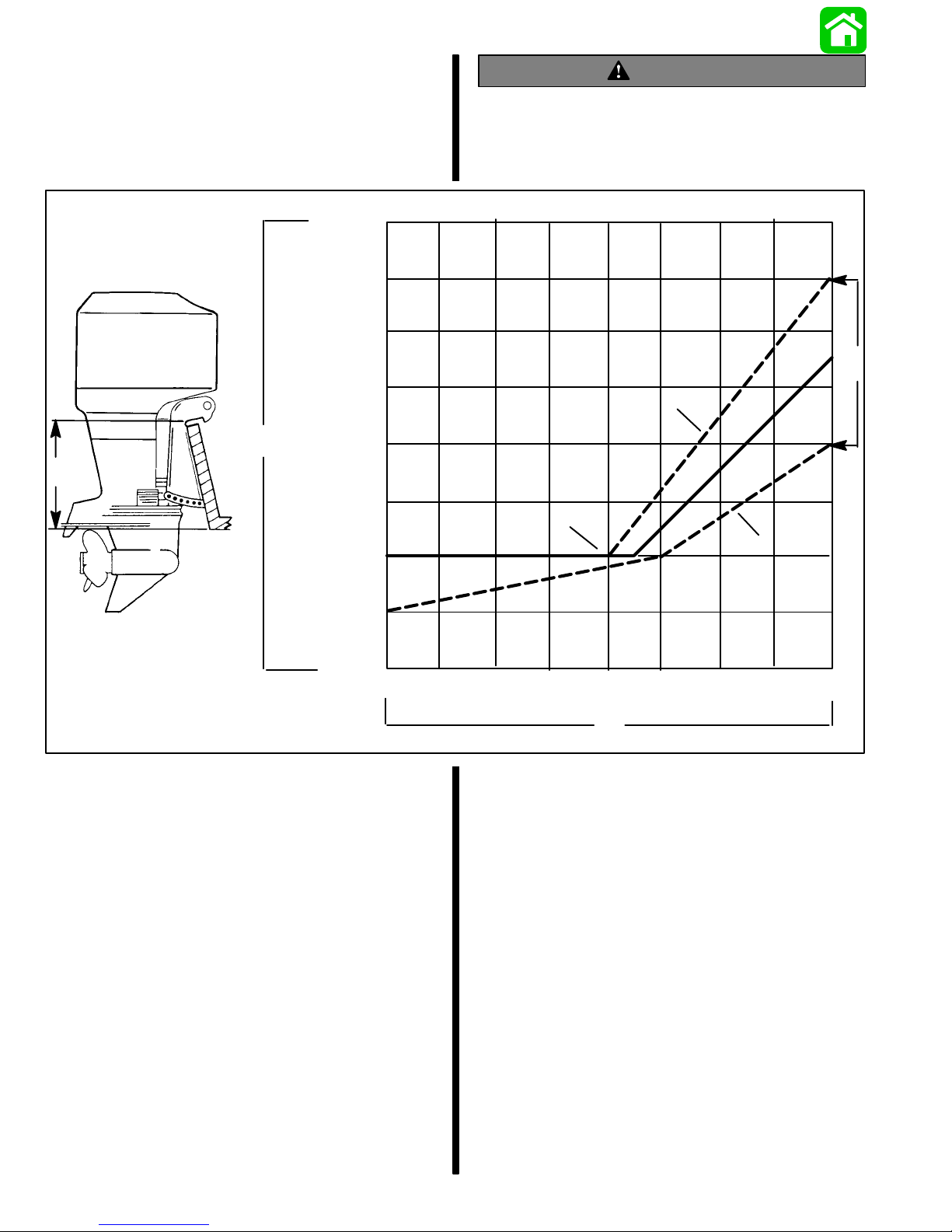

Determining Recommended

WARNING

Outboard Mounting Height

26 in.

(660m

m)

25 in.

(635m

m)

24 in.

(609m

m)

23 in.

(584m

m)

e

e

22 in.

(560m

m)

21 in.

(533m

m)

20 in.

(508m

m)

19 in.

(482m

m)

Boat instability can occur at high speeds by

installing engine at the wrong transom height.

Contact the boat manufacturer for their recommendations for a specific engine installation.

b

c

a

d

10

NOTE: Add 5 in. (127mm) for XL models and 10 in.

(254mm) for XXL models to listed outboard mounting

height.

a. This solid line is recommended to determine

the outboard mounting height.

IMPORTANT: Increasing the height of outboard

generally will provide the following: 1) Less

steering torque, 2) more top speed, 3) greater

boat stability , but, 4) will cause more prop “break

loose” which may be particularly noticeable

when planing off or with heavy load.

b. These broken lines represent the extremes of

known successful outboard mounting height

dimensions.

c. This line may be preferred to determine out-

board mounting height dimension, if maximum speed is the only objective.

20 30 40 50 60 70 80

f

d. This line may be preferred to determine out-

board mounting height dimension for dual

outboard installation.

e. Outboard mounting height (height of out-

board transom brackets from bottom of boat

transom). For heights over 22 in. (560mm), a

propeller, that is specifically designed for surfacing operation, such as the “Laser” and “Mirage” series, usually are preferred.

f. Maximum boat speed anticipated.

90-830234R3 DECEMBER 19971D-2 - IMPORTANT INFORMATION

Page 27

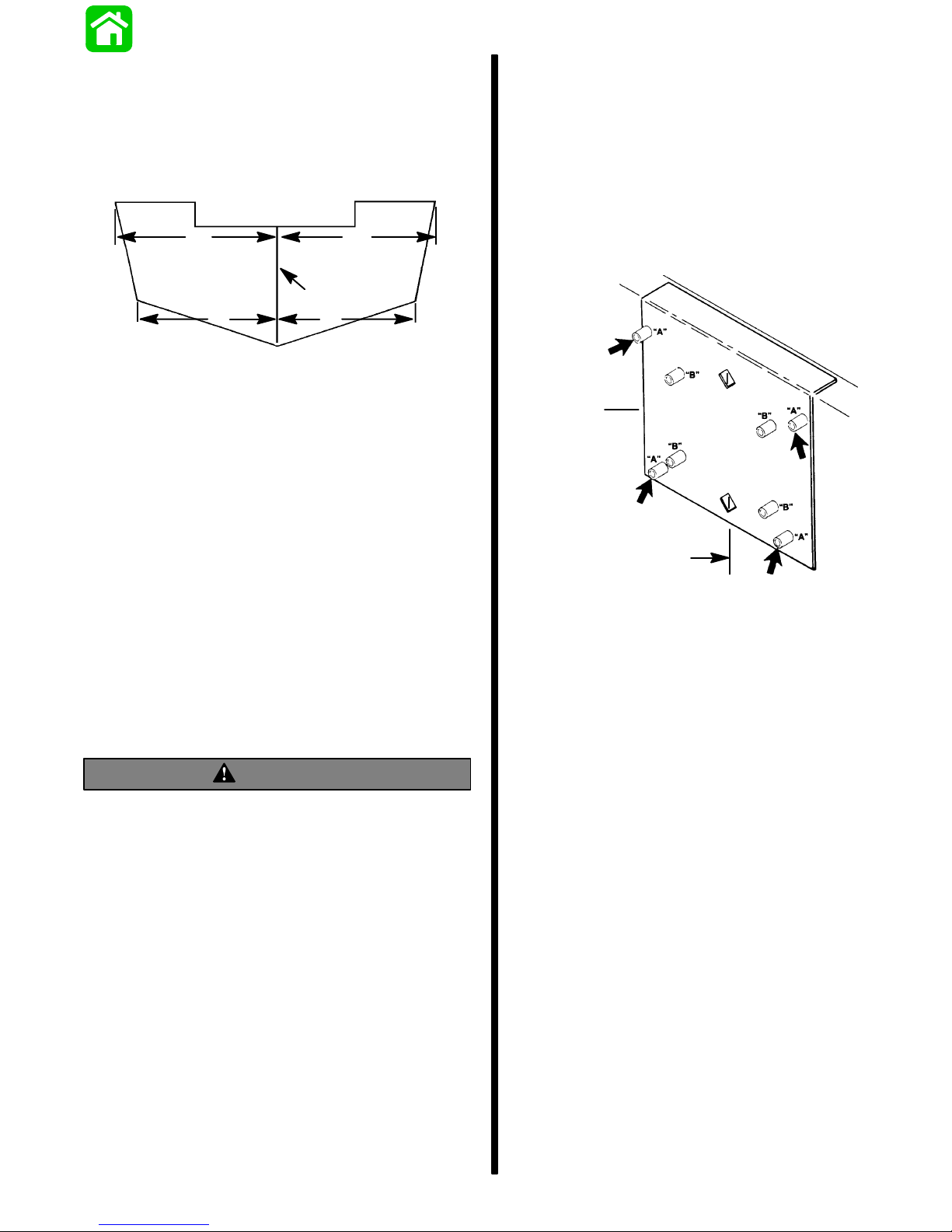

Locating Center Line Of The

Outboard

Locate (and mark with pencil) the vertical centerline

(a) of boat transom.

BA

a

DC

a - Centerline of Transom

NOTE: When drilling into a fiberglass boat, place

masking tape directly onto boat where mounting

holes will be drilled to help prevent fiberglass from

chipping.

Use a 17/32 inch (13.5mm) diameter drill bit and drill

4 mounting holes perpendicular to and thru transom.

IMPORTANT: If using “Transom Drilling Fixture”

(part number 91–98234A2), use drill guide holes

marked “A” when drilling outboard mounting

holes.

NOTE: Dimensions “A” & “B” and “C” & “D” are equal

length.

IMPORT ANT : During installation of dual outboards,

the following is recommended. A minimum of 221/2

inches (570mm) centerline to centerline width is recommended. This is required to alleviate cowling interference during lock to lock turns if one outboard

would be in the full tilt position, while the other outboard(s) are in the vertical running position.

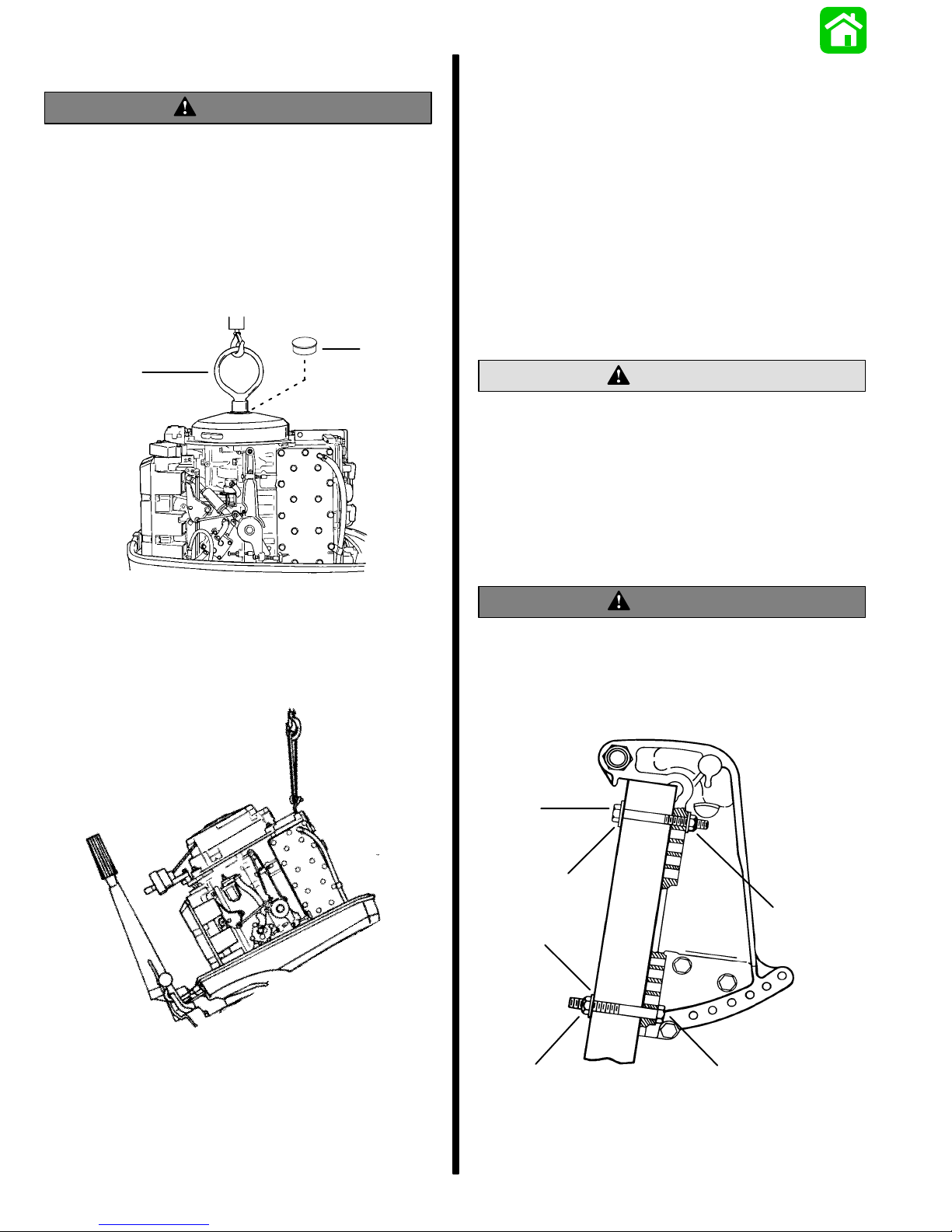

Drilling Outboard Mounting Holes

IMPORT ANT : Before drilling any mounting holes,

carefully read “Determining Recommended Outboard Mounting Height,” preceding. There is a

3/4 inch (19mm) difference between outboard

mounting holes in transom brackets.

WARNING

DO NOT, under any circumstances, allow upper

outboard mounting bolts to be closer than 1 inch

(25.4mm) from top of boat transom. Upper

mounting bolts must never be installed thru

shims.

b

a

a – Centerline of Transom

b – Transom Drilling Fixture (91–98234A2)

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-3

Page 28

Lifting Outboard

Installing Outboard To Boat

WARNING

Verify that the lifting ring is threaded into the flywheel a minimum of 5 turns and that hoist has a

maximum lift capacity over 500 lbs. (227 kg) BEFORE lifting outboard.

1. Electric Start Models – Remove plastic cap from

center of flywheel. Thread lifting ring into flywheel

hub a minimum of 5 turns. Replace plastic cap after installation.

b

a

Transom

IMPORT ANT : If boat is equipped with thru tilt tube

steering, steering cable end must be installed

into tilt tube of outboard (port outboard only for

dual outboard installations) before securing outboard to transom. Refer to ”Steering Cable and

Steering Link Rod Installation” following.

Refer to “Determining Recommended Outboard Motor Mounting Height”, preceding and position outboard on boat transom, to align mounting holes in

transom bracket that will place the outboard nearest

to the recommended mounting height.

CAUTION

Marine sealer must be used on shanks bolts to

make a water-tight installation.

IMPORT ANT: DO NOT use an impact driver when

tightening transom bolts.

Apply marine sealer to shanks of mounting bolts (not

threads) and secure outboard to transom with 4 bolts,

flat washers and locknuts, as shown. Be sure that installation is water-tight.

a - Lifting Ring

b - Plastic Cap – Replace After Installation

2. Manual Start Models – Use lifting eye on engine

and lift outboard on boat transom.

WARNING

Before operation, the outboard must be correctly

installed with four mounting bolts shown. Failure

to correctly fasten outboard could result in outboard ejecting off boat transom causing serious

injury, death, or property damage.

a

b

c

b

c

a - 1/2 Inch Diameter Bolts

b - Flat W ashers

c - Locknuts

a

90-830234R3 DECEMBER 19971D-4 - IMPORTANT INFORMATION

Page 29

Single Steering Cable and

Steering Link Rod Installation

Steering Link Rod

Installation

NOTE: These instructions are for single cable–single

outboard installations. Instructions for mounting dual

engines are included with the applicable dual engine

attaching kit. Refer to “Quicksilver Accessories

Guide” to determine correct kit.

Refer to “Quicksilver Accessories Guide” to determine correct length of steering cable.

IMPORTANT: Steering cable must be correct

length. Sharp bends on too-short of a cable result in “kinks;” too-long of a cable require unnecessary bends and/or loops. Both conditions

place extra stress on the cable.

Install steering mount and steering wheel in accordance with installation instructions that accompany

each.

Installing Ride Guide Steering Cable

To The Outboard

IMPORTANT: Before installing steering cable in

tilt tube, lubricate entire cable end with Quicksilver 2-4-C Marine Lubricant.

IMPORT ANT: The steering link rod that connects

the steering cable to the engine must be fastened

using special washer head bolt (“a” – Part Number 10-14000) and self locking nuts (“b”& “c”–

Part Number 11-34863). These locknuts must

never be replaced with common nuts (non locking) as they will work loose and vibrate off freeing the link rod to disengage.

WARNING

Disengagement of a steering link rod can result

in the boat taking a full, sudden, sharp turn. This

potentially violent action can cause occupants to

be thrown overboard exposing them to serious

injury or death.

3. Assemble steering link rod to steering cable with

two flat washers (d) and nylon insert locknut (“b”

– Part Number 1 1-34863). Tighten locknut (b) until it seats, then back nut off 1/4 turn.

4. Assemble steering link rod to engine with special

washer head bolt (“a” – Part Number 10-14000)

and nylon insert locknut (“c”– Part Number

11-34863). First torque bolt (a) to 20 lb. ft. (27.0

N·m), then torque locknut (c) to 20 lb. ft. (27.0

N·m).

NOTE: Ride Guide steering cable is lubricated at the

factory and requires no additional lubrication at initial

installation.

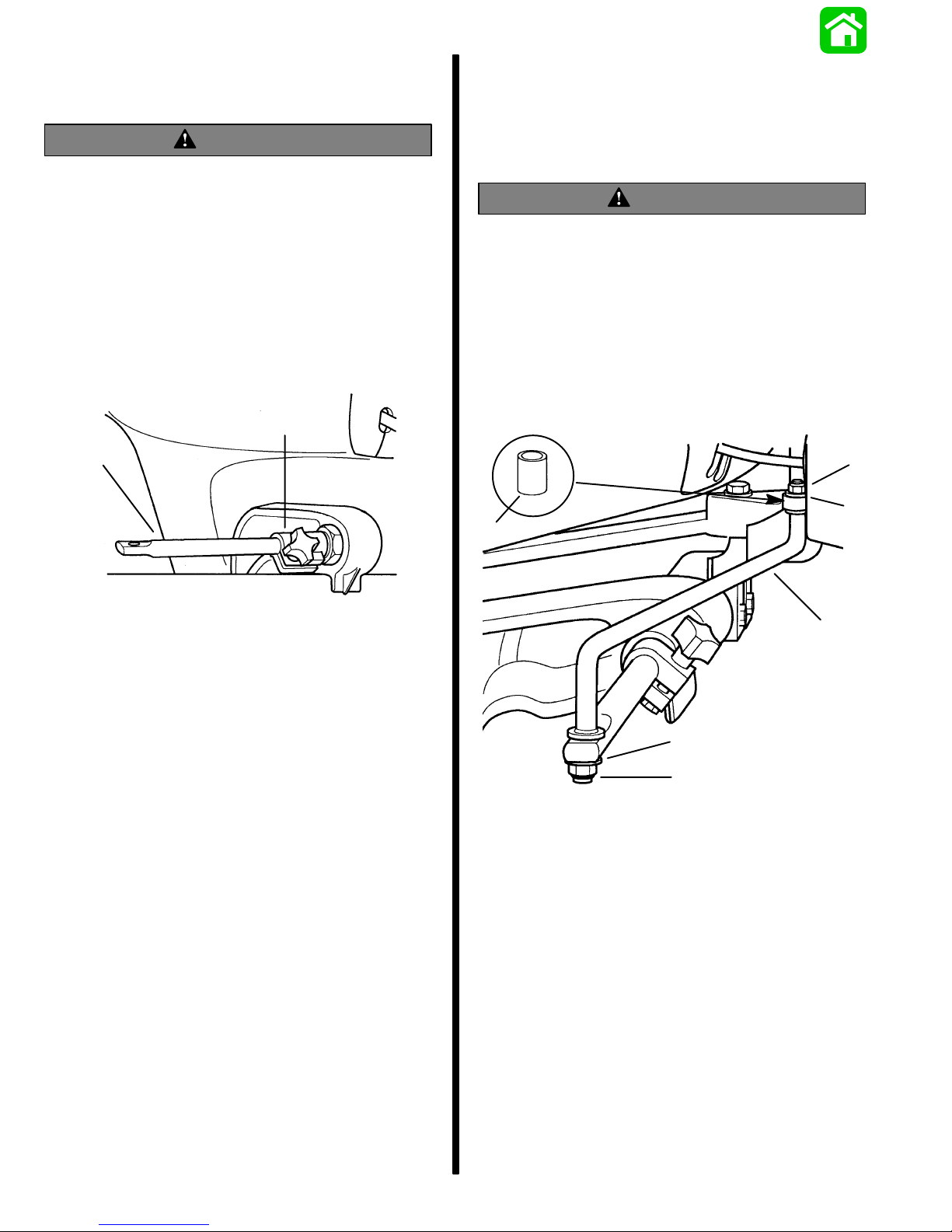

1. Lubricate seal (a) inside of outboard tilt tube and

entire cable end (b) with Quicksilver 2-4-C Marine Lubricant.

2. Insert steering cable end thru outboard tilt tube

and secure steering cable to tilt tube with steering

cable attaching nut (c), as shown. Torque nut to

35 lb. ft. (47.5 N·m).

95

c

95

a

b

a

d

b

c

WARNING

After installation is complete (and before operating outboard), check that boat will turn right

when steering wheel is turned right and that boat

will turn left when steering wheel is turned left.

Check steering thru full range (left and right) and

at all tilt angles to assure interference-free movement.

95

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-5

2-4-C With Teflon (92-825407A12)

Page 30

Co-Pilot Installation (Tiller

Handle models)

WARNING

Avoid possible serious injury or death from loss

of boat control. The Co-pilot assembly must be

installed and adjusted to maintain sufficient

steering friction to prevent the outboard from

steering into a full turn if the tiller handle is released.

1. Thread the friction collar (a) onto the starboard

side of the tilt tube. Tighten securely and position

the adjustment knob toward front of outboard.

2. Insert pilot rod (b) into the friction collar.

a

IMPORT ANT : The co-pilot link rod (c) must be fastened using self locking nylon insert locknuts

(“f”& “g”– Part Number 11-45592).These locknuts must never be replaced with common nuts

(non locking) as they will work loose and vibrate

off freeing the link rod to disengage.

WARNING

Disengagement of the co-pilot link rod can result

in the boat taking a full, sudden, sharp turn. This

potentially violent action can cause occupants to

be thrown overboard exposing them to serious

injury or death.

3. Lubricate both ends of the link rod with Quicksilver 2-4-C w/Teflon Marine Lubricant. Install link

rod between the tiller handle mount and pilot rod

as shown.

b

f

e

d

c

e

g

c - Co-Pilot Link Rod

d - Spacer (Hidden) - Place in the Upper Mounting Hole

For The Link Rod.

e - Flat W asher

f - Locknut - Torque to 120 lb. in. (13.6 N·m)

g - Locknut - T ighten Until it Seats; DO NOT exceed 120 lb.

in. (13.6 N·m), Then Back Off The Locknut 1/4 Turn.

90-830234R3 DECEMBER 19971D-6 - IMPORTANT INFORMATION

Page 31

Remote Control Installation

Shift and Throttle Cable

Refer to “Quicksilver Accessories Guide” to determine correct length of remote control cables.

IMPORT ANT : Remote control cables must be correct length. Sharp bends on too-short cables result in “kinks;” too-long cables require unnecessary bends and/or loops. Both conditions place

extra stress on the cables.

IMPORTANT: Install control cables to remote

control and mount remote control BEFORE attaching control cables to engine. Refer to installation instructions included with remote control.

Required Side Mount

Remote Control or Ignition

Key Switch Assembly

Boats Equipped with Side Mount

Remote Control

A Quicksilver Commander 2000 series Side Mount

Remote Control equipped with a warning horn must

be used with this outboard. This warning horn is necessary for the engine warning system.

Installation To The Outboard

Install the shift cable and throttle cable into the remote control and mount the remote control following

instructions which are provided the remote control.

NOTE: Install the shift cable before the throttle cable.

The shift cable is the first cable to move when the remote control handle is moved into gear.

Shift Cable Installation

1. Pull up the cowl seal and remove the port side

rubber grommet (a).

a

2. Position the remote control and outboard into

neutral.

3. Slide shift actuator (b) toward the rear of engine

(reverse gear) until resistance is felt. Measure

distance (c) between mounting stud and barrel

retainer.

a

a -Warning Horn

Boats Equipped with Panel Or

Console Mount Remote Control

A Quicksilver Ignition Key/Choke Assembly

equipped with a warning horn must be used with this

engine. This warning horn is necessary for the engine warning system.

a

4. Push the cable end (d) in (towards cable barrel)

until resistance is felt. Adjust the cable barrel (e)

to attain distance (c).

e

d

c

b

a - Warning Horn

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-7

Page 32

5. Place cable barrel into retainer and fasten the

cable end to mounting stud with nylon washer (f)

and locknut (g). Tighten locknut against the nylon

washer, then back-off the locknut 1/4 turn.

6. Check shift cable adjustments as follows:

a. With remote control in forward the propshaft

should lock solidly in gear. If it does not, adjust the cable barrel closer to the cable end

guide.

3. Adjust throttle cable barrel (b) so the barrel will be

able to slip into the retainer when the cable end

is on the mounting stud and there is a slight preload against the stop.

4. Check preload on throttle cable by placing a thin

piece of paper between adjustment screw and

stop. Preload is correct when the paper can be removed without tearing, but has some drag in it.

Readjust cable barrel if necessary.

5. Place the throttle cable barrel into the top retainer

hole and the cable end on the cable mounting

stud. Fasten throttle cable to the mounting stud

with nylon washer (c) and locknut (d). Tighten

locknut against the nylon washer, then back-off

the locknut 1/4 turn.

6. Lock the cable barrels in-place with cable latch

(e).

b. Shift remote control into neutral. The prop-

shaft should turn freely without drag. If not,

adjust the barrel away from the cable end

guide. Repeat steps a and b.

c. Shift remote control into reverse while turning

propeller. The propshaft should lock solidly in

gear. If not, adjust the barrel away from the

cable end guide. Repeat steps a thru c.

d. Return remote control handle to neutral. The

propeller should turn freely without drag. If

not, adjust the barrel closer to the cable end

guide. Repeat steps a thru d.

Throttle Cable Installation

NOTE: Attach Shift cable to engine prior to attaching

throttle cable.

1. Position the remote control handle into neutral

detent.

2. Position adjustment screw (a) against the stop.

a

b

d

c

e

7. Lubricate the port side rubber grommet and reinstall into cowl. Slip the grommet over the control

cables. Push the cowl seal back into place.

90-830234R3 DECEMBER 19971D-8 - IMPORTANT INFORMATION

Page 33

NOTE: The rubber grommet has to be lubricated to

ease installation.

f

f

f – Lubricant

Connecting Remote Wiring

Harness To The Engine

1. Pull up the cowl seal (a) and remove the starboard side rubber grommet (b).

b

a

2. Take hold of the engine connector (c) and install

the remote wiring harness plug (d). Connect

additional wire leads (if equipped) as shown.

NOTE: The rubber grommet can to be lubricated to

ease installation.

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-9

c

d

Page 34

3. Push the connector and plug into the holder (e).

e

Battery Connections

CAUTION

For dual outboard installations, the black (–) battery cable of each engines starter motor ground

circuit, MUST BE connected to each other by a

common circuit (cable) capable of carrying the

starting current of each engine’s starter motor.

[i.e. A locally obtained battery cable connected

between the negative (–) terminal of each outboards cranking battery].

CAUTION

Failure to observe correct polarity when connecting battery cables to battery, will result in

damage to the charging system.

4. Insert the battery cables and remote wiring harness into the rubber grommet. Reinstall the starboard side rubber grommet into the cowl. Push

the cowl seal back in place.

1. Connect battery cables (from engine) to battery.

Connect red battery cable to positive terminal

and black battery cable to negative (–) battery

terminal.

Set Up Instructions For Oil

Injection System

CAUTION

Oil injected engines additionally , must be run on

a 50:1 gasoline/oil mixture during the engine

break-in period. Refer to engine break-in procedure in the Operation & Maintenance Manual.

CAUTION

If an electric fuel pump is to be used on engines

with oil injection, the fuel pressure at the engine

must not exceed 4 psig. If necessary, install a

pressure regulator between electrical fuel pump

and engine and set at 4 psig maximum.

90-830234R3 DECEMBER 19971D-10 - IMPORTANT INFORMATION

Page 35

Filling The Oil Injection System

1. Open the cowl cap (a). Turn the oil fill cap (b) to

the left and remove.

a

Bleeding Air From The Oil Injection

System

IMPORT ANT : If air exists in either the oil pump inlet hose (a) or oil pump outlet hose (b), the air

MUST BE bled from the hose(s) or engine damage may occur.

BLEEDING AIR FROM THE OIL PUMP INLET

HOSE

b

2. Use the dipstick (c) to check oil level.

3. Hook the dipstick (d) on the tank during filling.

c

d

4. Slowly fill the oil tank with the specified oil. Do Not

overfill – add only enough oil to bring the oil level

up to the bottom of the fill neck (e).

Note:The oil tank capacity for three cylinder models

is 3.2 qt. (3.0 liters) and four cylinder models is 5.13

qt. (4.9 liters).

5. Install oil filler cap (b) and re-tighten. Reinstall the

cowl cap.

1. With the engine not running, place a shop towel

below the oil pump.

2. Loosen bleed screw (c) four turns and allow oil to

flow out of the bleed hole until no air bubbles exist

in the inlet hose (a).

BLEEDING AIR FROM THE OIL PUMP OUTLET

HOSE

3. If any air bubbles are present in the outlet hose

(b), they can be purged from the hose by removing link rod (d) from the oil pump and rotating the

pump arm (e) full clockwise while operating engine at 1000 to 1500 RPM.

b

c

e

b

FULL

90-830234R3 DECEMBER 1997 IMPORTANT INFORMATION - 1D-11

a

d

e

Page 36

Adjusting The Oil Injection Pump

Trim Tab Adjustment

When carburetor linkage is at idle position, alignment

mark (a) on oil injection arm should be in-line with

mark (b) on pump as shown. If necessary , adjust link

rod (c).

b

Propeller steering torque will cause your boat to pull

in one direction. This steering torque is a normal thing

that results from your outboard not being trimmed so

the propeller shaft is parallel to the water surface.

The trim tab can help to compensate for this steering

torque in many cases and can be adjusted within limits to reduce any unequal steering effort.

NOTE: Trim tab adjustment will have little effect reducing steering torque if the outboard is installed with

the anti-ventilation plate approximately 2 inches

(50mm) or more above the boat bottom.

Operate your boat at normal cruising speed, trimmed

to desired position. Turn your boat left and right and

note the direction the boat turns more easily.

If adjustment is necessary, loosen trim tab bolt and

make small adjustments at a time. If the boat turns

more easily to the left, move the trailing edge of trim

tab to the left. If the boat turns more easily to the right

move the trailing edge of trim tab to the right. Retighten bolt and retest.

c

a

90-830234R3 DECEMBER 19971D-12 - IMPORTANT INFORMATION

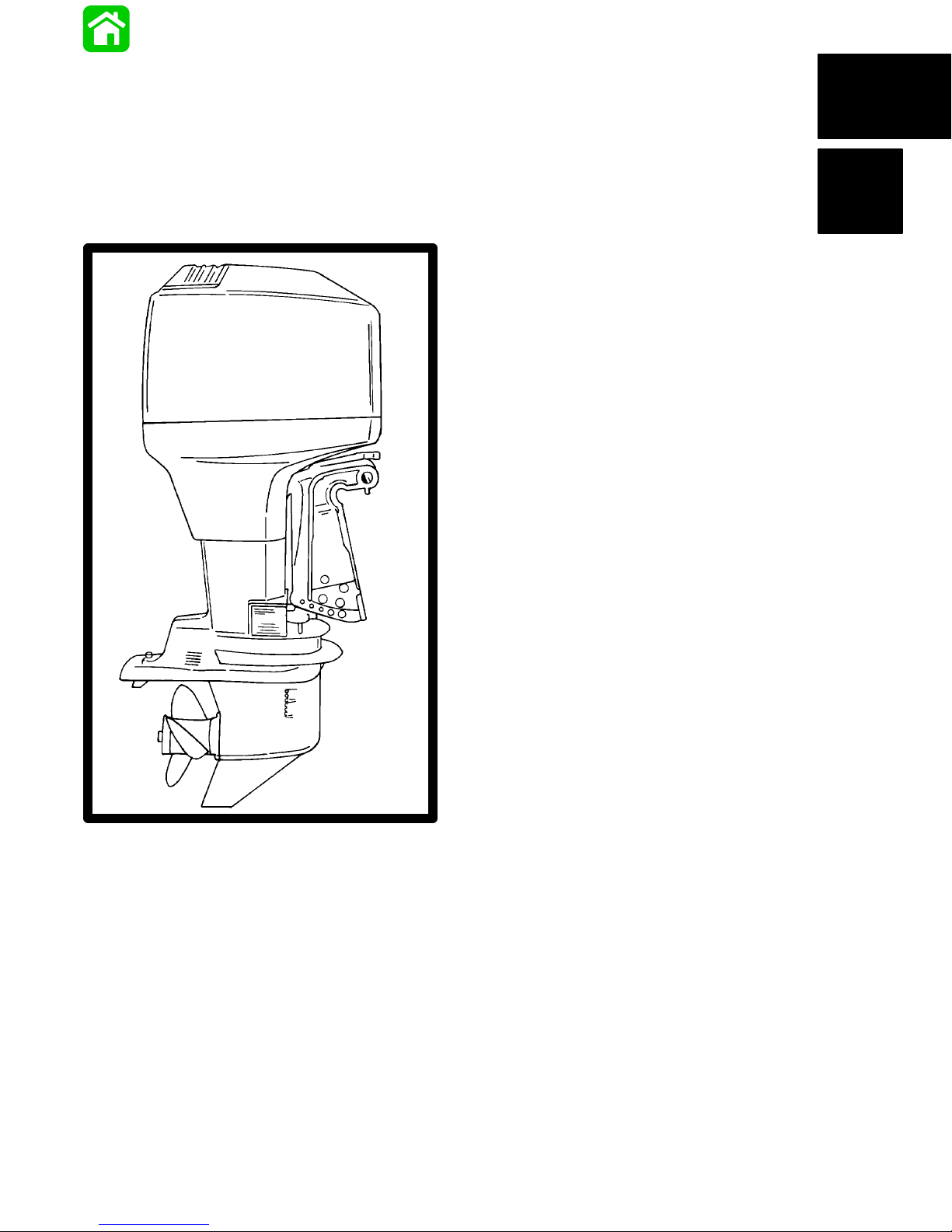

Page 37

ELECTRICAL

2

A

IGNITION

53970

Page 38

Table of Contents

Page

Special Tools 2A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Cylinder Electrical Components

(USA-0G127499/BEL-9836632 & BELOW) 2A-2. . . . . .

Electrical Components

(USA-0G127500 thru 0G437999)(BEL-9836633 thru

9926999) 2A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Cylinder Electrical Components

(USA-S/N-0G438000/BEL-9937000 & UP) 2A-6. . . . . . .

4 Cylinder Electrical Components

(S/N-USA-437999/BEL-9926999 & BELOW) 2A-8. . . . .

4 Cylinder Electrical Components

(USA-S/N-0G438000/BEL-9937000 & UP) 2A-10. . . . . .

Description 2A-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Procedures 2A-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Direct Voltage Adapter (DVA) Tests 2A-12. . . . . . . . .

Test Sequence 2A-13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition System DVA Specifications Test Chart 2A-14. .

3 Cylinder Stators

75 Manual with 9 Ampere Stator 398-9873A20,

USA-0D283222 thru 0G227199

75/90 Electric with 16 Ampere Stator

398-9710A3, USA-0D283222 thru 0G280043

Belgium-09793577 thru 09879064 2A-14. . . . . . . . . .

4 Cylinder with 16 Ampere Stator 398-9710A31

USA-0D283222 thru 0G301750

Belgium-09793577 thru 09885527 2A-14. . . . . . . . . .

3 Cylinder Stators

75 Manual with 9 Ampere Stator 398-9873A21,

USA-0D227200 and Above

75/90 Electric with 14 Ampere Stator

398-9873A24, USA-0G280044 thru 0G404505

Belgium-09879065 thru 09916672 2A-15. . . . . . . . . .

Page

4 Cylinder with 16 Ampere Stator 398-9710A33

USA-0G301751 and Above

Belgium - 09885528 thru 09916721 2A-15. . . . . . . . .

ADI Ignition using a RED Stator with an

Adapter Module 2A-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RED Stator with Adaptor and Ignition Coils 2A-18. . . . .

RED Stator DVA Test 2A-18. . . . . . . . . . . . . . . . . . . . .

Electric Start Engines 2A-18. . . . . . . . . . . . . . . . . . . . .

Manual Start Engines 2A-18. . . . . . . . . . . . . . . . . . . . .

Troubleshooting Procedures 2A-18. . . . . . . . . . . . . . .

Theory of Operation 2A-19. . . . . . . . . . . . . . . . . . . . . . . . .

Capacitor Charging #1 CDM 2A-20. . . . . . . . . . . . . . .

Capacitor Charging #2 & #3 CDM 2A-21. . . . . . . . . .

#1 Cylinder Trigger Circuit 2A-22. . . . . . . . . . . . . . . . .

Ignition Coil Circuit 2A-23. . . . . . . . . . . . . . . . . . . . . . .

Stop Circuit 2A-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rev Limiter Circuit 2A-25. . . . . . . . . . . . . . . . . . . . . . . .

RED Stator with CDM 2A-26. . . . . . . . . . . . . . . . . . . . . . . .

Ignition Component Description 2A-26. . . . . . . . . . . .

CDM (P/N 827509) 2A-27. . . . . . . . . . . . . . . . . . . . . . .

Spark Gap Tester P/N 91-850439 2A-27. . . . . . . . . .

CDM Test Harness 84-825207A2 2A-27. . . . . . . . . . .

Direct Voltage Adaptor (DVA) Test 2A-32. . . . . . . . . .

Resistance Tests 2A-34. . . . . . . . . . . . . . . . . . . . . . . . .

Ignition (Key) Switch Test 2A-35. . . . . . . . . . . . . . . . . .

Flywheel Removal and Installation 2A-35. . . . . . . . . . . . .

Stator Removal and Installation 2A-36. . . . . . . . . . . . . . .

Trigger Removal and Installation 2A-39. . . . . . . . . . . . . .

Ignition Coil Removal and Installation 2A-41. . . . . . . . . .

Switch Box Removal and Installation 2A-42. . . . . . . . . . .

2A-0 - ELECTRICAL 90-830234R3 DECEMBER 1997